Detroit Diesel Engine MBE4000 Service Manual

EPA07 MBE 4000 SERVICE MANUAL

ABSTRACT

This manual provides instruction for servicing the MBE 4000 Diesel Engine. Specifically, a basic

overview of each major component and the system, along with the recommendations for removal,

cleaning, inspection, criteria for replacement, repair, installation, and mechanical troubleshooting

are contained in this manual.

TRADEMARK INFORMATION

Loctite® is a registered trademark of Loctite Corporation. Wabco® is a registered trademark of

American Standard, Inc. Hengst® is a registered trademark of Walter Hengst GMBH & Co.

Perma-Lok® is a registered trademark of National Starch and Chemical Investment Holding

Corporation. Henkel® is a registered trademark of Henkel Corporation. Diagnostic Link® is a

registered trademark of Detroit Diesel Corporation. POWER COOL® is a registered trademark of

Detroit Diesel Corporation.

ENGINE EXHAUST

Consider the following before servicing engines:

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

□ Always start and operate an engine in a well ventilated

area.

□ If operating an engine in an enclosed area, vent the

exhaust to the outside.

□ Do not modify or tamper with the exhaust system or

emission control system.

REVISION NOTIFICATION

Modifications to this manual are announced in the form of Service Information Bulletins. The

bulletins are posted on the World Wide Web (www.detroitdiesel.com/public/sibs/sibnav.asp).

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION i

EPA07 MBE 4000 SERVICE MANUAL

ii DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

TABLE OF CONTENTS

GENERAL INFORMATION ...................................................................... 1

SCOPE AND USE OF THIS MANUAL .................................................... 3

GENERAL DESCRIPTION ...................................................................... 3

AFTERTREATMENT SYSTEM ................................................................ 4

ELECTRONIC ENGINE CONTROL SYSTEM ......................................... 4

ENVIRONMENTAL CONDITIONS ........................................................... 7

SAFETY INSTRUCTIONS AND PRECAUTIONS .................................... 8

CPC VEHICLE INTERFACE HARNESS .................................................. 18

ENGINE BRAKING POWER .................................................................... 19

1ENGINE

1.1 ENGINETRIMCOVERSANDFRAMES ................................................. 1-3

1.2 CYLINDER HEAD COVER ...................................................................... 1-6

1.3 CYLINDER HEAD .................................................................................... 1-8

1.4 CYLINDER BLOCK .................................................................................. 1-21

1.5 FRONT AND REAR ENGINE LIFTING BRACKETS ............................... 1-42

1.6 ENGINE BRAKE ...................................................................................... 1-44

1.7 FRONT RADIAL SEAL ............................................................................. 1-51

1.8 REAR RADIAL SEAL ............................................................................... 1-54

1.9 CRANKSHAFT WEAR SLEEVE .............................................................. 1-57

1.10 CRANKSHAFT ASSEMBLY ..................................................................... 1-63

1.11 FRONT COVER HOUSING ..................................................................... 1-86

1.12 CRANKSHAFT POSITION SENSOR ...................................................... 1-88

1.13 CRANKSHAFT VIBRATION DAMPER AND PULLEY ............................. 1-89

1.14 FLYWHEEL .............................................................................................. 1-91

1.15 RING GEAR ............................................................................................. 1-100

1.16 PILOT BEARING ...................................................................................... 1-104

1.17 ENGINE BARRING TOOL ....................................................................... 1-108

1.18 FLYWHEEL HOUSING ............................................................................ 1-110

1.19 PISTON, PISTON RING, AND CONNECTING ROD ............................... 1-112

1.20 VALVES .................................................................................................... 1-138

1.21 ROCKER ARM ......................................................................................... 1-154

1.22 CAMSHAFTANDGEARASSEMBLY...................................................... 1-158

1.A ADDITIONAL INFORMATION .................................................................. 1-169

2FUELSYSTEM

2.1 ELECTRONIC UNIT PUMP ..................................................................... 2-3

2.2 FUEL RETURN AND NOZZLE SPILL LINE ............................................ 2-17

2.3 FUEL OVERFLOW VALVE ...................................................................... 2-19

2.4 HIGH PRESSURE FUEL LINE AND TRANSFER TUBE ......................... 2-20

2.5 FUEL INJECTOR HARNESS ADAPTOR FRAME ................................... 2-30

2.6 FUEL INJECTOR ..................................................................................... 2-32

2.7 PROTECTIVE SLEEVE ........................................................................... 2-41

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION iii

EPA07 MBE 4000 SERVICE MANUAL

2.8 MOTOR CONTROL M ODUL E ................................................................. 2-44

2.9 FUEL FILTER ........................................................................................... 2-47

2.10 FUEL FILTER HOUSING ......................................................................... 2-50

2.11 FUEL FILTER BRACKET ......................................................................... 2-53

2.12 FUEL HAND PRIMER PUMP .................................................................. 2-55

2.13 FUEL PUMP ............................................................................................. 2-57

2.14 FUEL PUMP DRIVE ................................................................................. 2 -60

2.15 FUEL DOSER VALVE (FDV) .................................................................... 2-63

2.16 DOSER BLOCK ASSEMBLY ................................................................... 2-68

2.17 FUEL DOSER VALVE COOLANT LINES ................................................ 2-71

2.A ADDITIONAL INFORMATION .................................................................. 2-73

3 LUBRICATION SYSTEM

3.1 LUBRICATION SYSTEM DESCRIPTION ................................................ 3-3

3.2 OIL PAN ................................................................................................... 3-5

3.3 PISTON OIL SPRAY NOZZLE ................................................................. 3-8

3.4 CAMSHAFT LUBRICATION NOZZLE ..................................................... 3-12

3.5 OIL PUMP AND SUCTION PIPE ............................................................. 3-15

3.6 OIL FILTER .............................................................................................. 3-22

3.7 OIL COOLER/FILTER HOUSING ............................................................ 3-24

3.8 ENGINE OIL PRESSURE/TEMPERATURE SENSOR ............................ 3-31

3.9 OIL FILL-TUBE AND OIL DIPSTICK ....................................................... 3-33

3.A ADDITIONAL INFORMATION .................................................................. 3-37

4 COOLING SYSTEM

4.1 COOLING SYSTEM ................................................................................. 4-3

4.2 COOLANT PUMP .................................................................................... 4-8

4.3 FRONT IDLER AND TENSIONER SUPPORT ........................................ 4-18

4.4 THERMOSTAT ......................................................................................... 4-19

4.5 ENGINE COOLANT TEMPERATURE SENSOR ..................................... 4-23

4.6 CYLINDER HEAD COOLANT VENT LINE ............................................. 4-25

4.A ADDITIONAL INFORMATION .................................................................. 4-35

5 FUEL, LUBRICATING OIL, AND COOLANT

5.1 FUEL ........................................................................................................ 5-3

5.2 LUBRICATING OIL .................................................................................. 5-5

5.3 COOLANT ................................................................................................ 5-7

5.A ADDITIONAL INFORMATION .................................................................. 5-13

6 AIR INTAKE SYSTEM

6.1 AIR INTAKE ELBOW AND GRID HEATER .............................................. 6-3

6.2 INTAKE THROTTLE VALVE AND ADAPTOR .......................................... 6-8

6.3 GAS MIXER HOUSING ........................................................................... 6-10

6.4 AIR INTAKE MANIFOLD .......................................................................... 6-13

6.5 ELECTROSTATIC OIL SEPARATOR, CRANKCASE SEPARATOR, AND

OIL SEPARATOR DRAIN LINE ................................................................ 6-16

6.6 INTAKE AIR TEMPERATURE/PRESSURE SENSOR ............................. 6-23

6.7 TURBOCHARGER ................................................................................... 6-25

6.8 WASTEGATE ACTUATOR....................................................................... 6-35

iv DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

6.A ADDITIONAL INFORMATION .................................................................. 6-41

7 EXHAUST SYSTEM

7.1 EXHAUST MANIFOLD ASSEMBLY ......................................................... 7-3

7.2 BRAKE GATE .......................................................................................... 7-11

7.3 ELECTRONIC PROPORTIONAL VALVE ................................................ 7-26

7.A ADDITIONAL INFORMATION .................................................................. 7-29

8 EXHAUST GAS RECIRCULATION COMPONENTS

8.1 EGR GAS INLET PIPE ............................................................................ 8-3

8.2 EGR COOLER GAS OUTLET PIPE ........................................................ 8-7

8.3 EGR COOLER AND SUPPORT BRACKET ............................................ 8-9

8.4 EGR COOLER HEAT SHIELD AND MOUNTING BRACKET .................. 8-18

8.5 EGR COOLER COOLANT INLET TUBE ................................................. 8-19

8.6 EGR COOLER COOLANT RETURN TUBE ............................................ 8-21

8.7 EGR CONTROL VALVE ........................................................................... 8-23

8.A ADDITIONAL INFORMATION .................................................................. 8-25

9 ELECTRICAL EQUIPMENT

9.1 DRIVE BELTS .......................................................................................... 9-3

9.2 ALTERNATOR/AIR CONDITIONING COMPRESSOR BRACKET .......... 9-12

9.A ADDITIONAL INFORMATION .................................................................. 9-15

10 POWER TAKE-OFF

10.1 FRONT POWER TAKE-OFF .................................................................... 10-3

10.2 REAR ENGINE POWER TAKE-OFF ....................................................... 10-7

11 SPECIAL EQUIPMENT

11.1 AIR COMPRESSOR FLANGE ................................................................. 11-3

11.2 AIR COMPRESSOR ................................................................................ 11-5

11.A ADDITIONAL INFORMATION .................................................................. 11-11

12 OPERATION AND VERIFICATION

12.1 PREPARATION FOR A FIRST TIME START........................................... 12-3

12.2 STARTING THE ENGINE ........................................................................ 12-8

12.3 RUNNING THE ENGINE ......................................................................... 12-11

12.4 STOPPING THE ENGINE ........................................................................ 12-13

12.A ADDITIONAL INFORMATION .................................................................. 12-15

13 ENGINE TUNE-UP

13.1 CHECKING THE VALVE LASH ................................................................ 13-3

13.2 ADJUSTING THE VALVE LASH .............................................................. 13-9

13.A ADDITIONAL INFORMATION .................................................................. 13-11

14 PREVENTIVE MAINTENANCE

14.1 SCHEDULED INTERVALS ...................................................................... 14-3

15 ENGINE STORAGE

15.1 PREPARING ENGINE FOR STORAGE .................................................. 15-3

INDEX ................................................................................................. Index-1

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION v

EPA07 MBE 4000 SERVICE MANUAL

vi DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

GENERAL INFORMATION

Section Page

SCOPE AND USE OF THIS MANUAL ....................................................... 3

GENERAL DESCRIPTION ......................................................................... 3

AFTERTREATMENT SYSTEM ................................................................... 4

ELECTRONIC ENGINE CONTROL SYSTEM ............................................ 4

ENVIRONMENTAL CONDITIONS .............................................................. 7

SAFETY INSTRUCTIONS AND PRECAUTIONS ...................................... 8

CPC VEHICLE INTERFACE HARNESS .................................................... 18

ENGINE BRAKING POWER ...................................................................... 19

EPA07 MBE 4000 SERVICE MANUAL

2 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

SCOPE AND USE OF THIS MANUAL

EPA07 MBE 4000 SERVICE MANUAL

This manual contains complete instructions on operation, adjustment (tune-up), p

reventive

maintenance, and repair (including complete overhaul) for the MBE 4000 engine. This manual

was written primarily for persons servicing and overhauling the engine. In addition, this manual

contains all of the instructions essential to the operators and u sers

. Basic maintenance and

overhaul procedures are common to all MBE 4000 engines, and apply to all engine models.

This manual is divided into numbered sections. Section one covers the engine (less major

assemblies). The remaining sections cover a complete system such a

s the fuel system, lubrication

system, or air system. Each section is divided into subsections which contain complete

maintenance and operating instructions for a specific engine subassembly. Each section begins

with a table of contents. Pages and illustrations are nu

mbered consecutively within each section.

Information can be located by using the table of contents at the front of the manual or the table of

contents at the beginning of each section. Information on specific subassemblies or accessories

within the major section is listed immediately follow

ing the section title.

GENERAL DESCRIPTION

The MBE 4000 Engine described in this manual is a water-cooled, four-stroke, direct injection

diesel engine. The cylinders are arranged in li

(unit pump) with a short injection line to the injection nozzle, which is located in the center of

the combustion chamber. The unit pumps are attached to the crankcase and are driven from the

camshaft. Each cylinder has two intake v

ne. Each cylinder has a separate fuel injection pump

alves and two exhaust valves.

Charge-air cooling and an exhaust gas turbocharger are standard equipment on all MBE 4000

engines.

The engine is equipped with a fully elec

tronic control system. Besides the engine and its related

sensors, this system is composed of the Motor Control Module (MCM), and the Common

Powertrain Controller (CPC). The two units are connected by a proprietary datalink through

which all necessary data and info

rmation can be exchanged.

Engine braking is controlled by a pneumatically-operated exhaust brake and by a hydraulically

operated constant throttle system. For greater braking power, an optional engine brake is available.

The cylinder block has integra

ted oil and water channels. The six individual cylinder heads are

made of cast iron. The cylinder head gasket is an adjustment-free seal with elastomer sealing

elements.

Thepistonsaremadeofalumin

um alloy with ring carriers and a shallow combustion chamber

recess. The pistons are cooled by oil spray nozzles.

The crankshaft is precision-forged with seven main bearings and eight custom-forged counter

weights, and a vibration d

amper at the front end.

The camshaft is made of induction-hardened steel and has seven main bearings. Each cylinder has

cams for intake and exhaust valves and a unit pump.

The valves are controll

ed by mushroom tappets, pushrods, and rocker arms. The intake and

exhaust valves are opened and closed by a valve-guided bridge.

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 3

EPA07 MBE 4000 SERVICE MANUAL

There is a force-feed lubricating oil circuit supplied by a gear-type oil pump. This pump is

positioned at the rear of the oil pan a nd driven by gears from the crankshaft. The oil

heat

exchanger is located near the front of the crankcase on the right-hand side near the turbocharger.

The gear-type fuel pump is located near the front of the crankcase on the left hand side. The pump

is driven from the forward end of the camshaft.

The air compressor, with a power-steering pump attached, is driven by a gear on the camshaft.

The engine is cooled by a closed system using recirculated coolant; temperature is regulated

automatically by a thermostat.

There are two drive belts, each with its own automatic belt tensioner. The fan is driven by one

belt. The alternator, coolant pump (and any other accessories) are driven by a main drive belt.

AFTERTREATMENT SYSTEM

In order to meet current emissions regulations, the traditional muffler has been replaced by a new

aftertreatment device. This device consists of a diesel oxidation catalyst and a diesel particulate

filter and together these two components burn off col

“Regeneration.” The key to successful regeneration is high exhaust temperature for an extended

period of time. Without adequate temperatures for regeneration, the filter will continue to trap

particulates and eventually plug. In order to av

actively regenerated aftertreatment system. For additional information refer to the Aftertreatment

System Technician's Guide 7SE63.

lected particulate matter in a process called

oid plugging, Detroit Diesel has designed an

ELECTRONIC ENGINE CONTROL SYSTEM

The engine is equipped with a fully electronic control system, Detroit Diesel Electronic Controls

(DDEC®) VI. Besides the engine and its related sensors, this system is composed of the Motor

Control Module (MCM), and the Common

connected by a proprietary datalink through which all necessary data and information can be

exchanged.

The MCM monitors both the engine and

detected, the system selects an appropriate response; for example, the emergency running mode

may be activated.

Powertrain Controller (CPC). The two units are

the datalink. When a malfunction or other problem is

4 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Motor Control Module

EPA07 MBE 4000 SERVICE MANUAL

The engine mounted MCM includes c ontrol logic to provide overall engine management

.

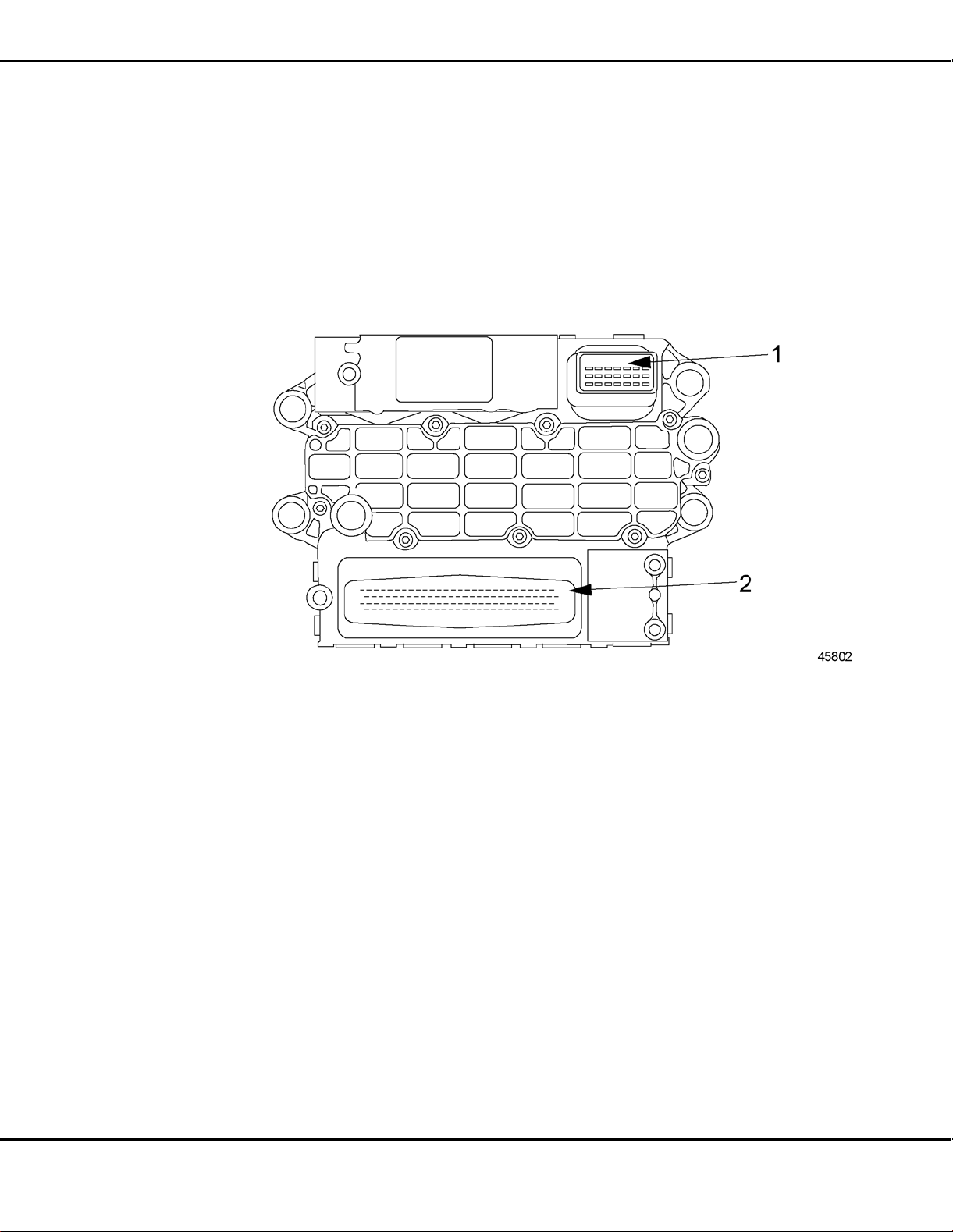

See Figure 1. The MCM processes the data received from the CPC, for example the position of

the accelerator pedal, engine brake, etc. These data are evaluated together with the data from the

sensors on the engine, such as, charge and oil pressure and coolant and

fuel temperature. The

data is then compared to the characteristic maps or lines stored in the MCM. From these data,

quantity and timing of injection are calculated and the unit pumps are actuated accordingly

through the solenoid valves.

1. 21–Pin Connector 2. 120–Pin Connector

Figure 1 Motor Control Module

NOTE:

Do NOT ground the MCM. This can result in false codes being logged.

Engine Harness

The MCM has a 120–pin connector Engine Harness which is factory installed. It also has a

21–pin connector and 31–pin connector which are the responsibility of the OEM.

Common Powertrain Con

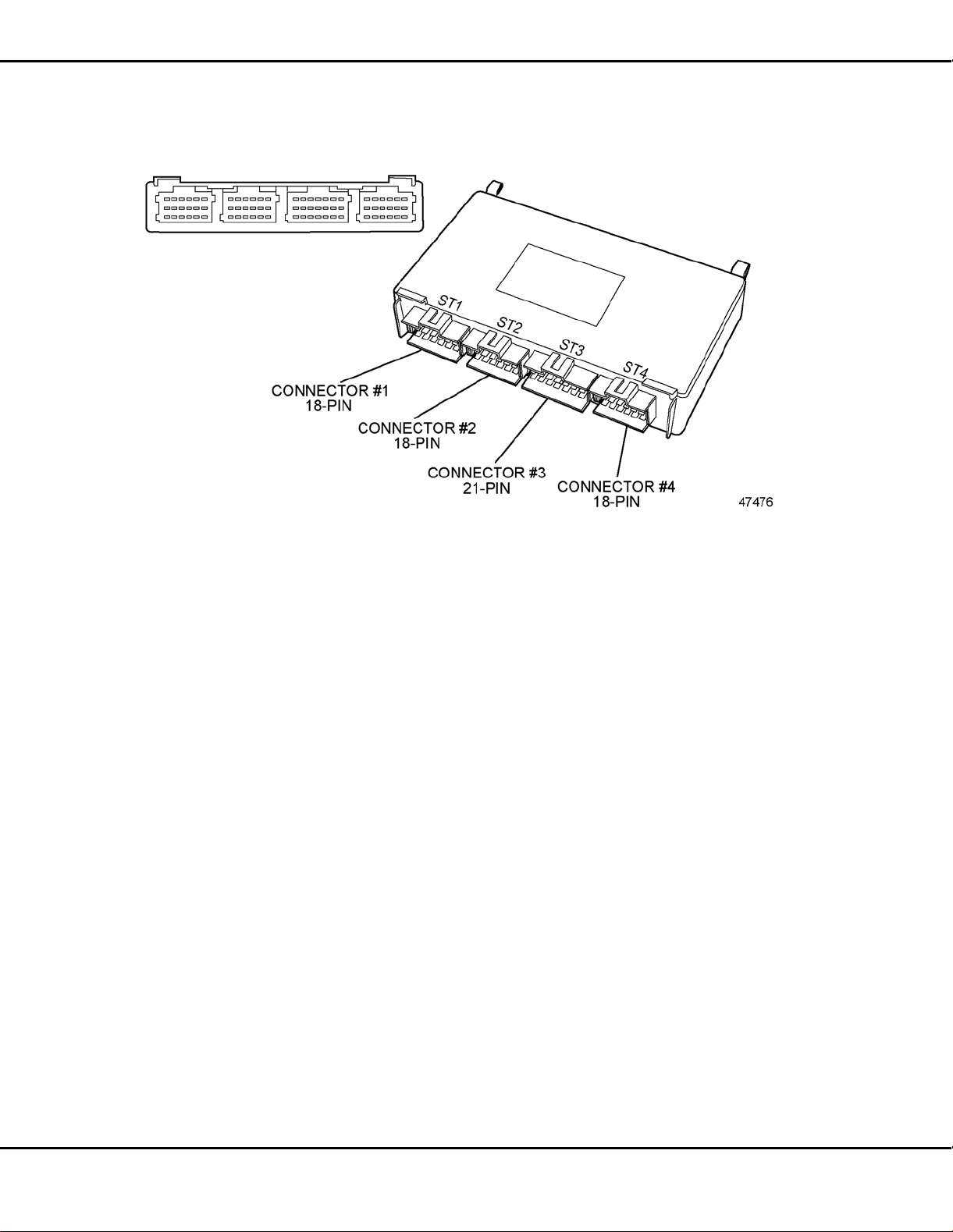

The CPC has three 18–pin connectors and one 21–pin connector. The following sections contain

the connector pin-outs for truck, vocational, transit bus, fire truck, and crane applications.

troller

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 5

EPA07 MBE 4000 SERVICE MANUAL

The CPC is the interface between the MCM and the vehicle/equipment for engine control and

manages other vehicle/equipment functions. See Figure 2.

Figure 2 Common Powertrain Controller

6 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

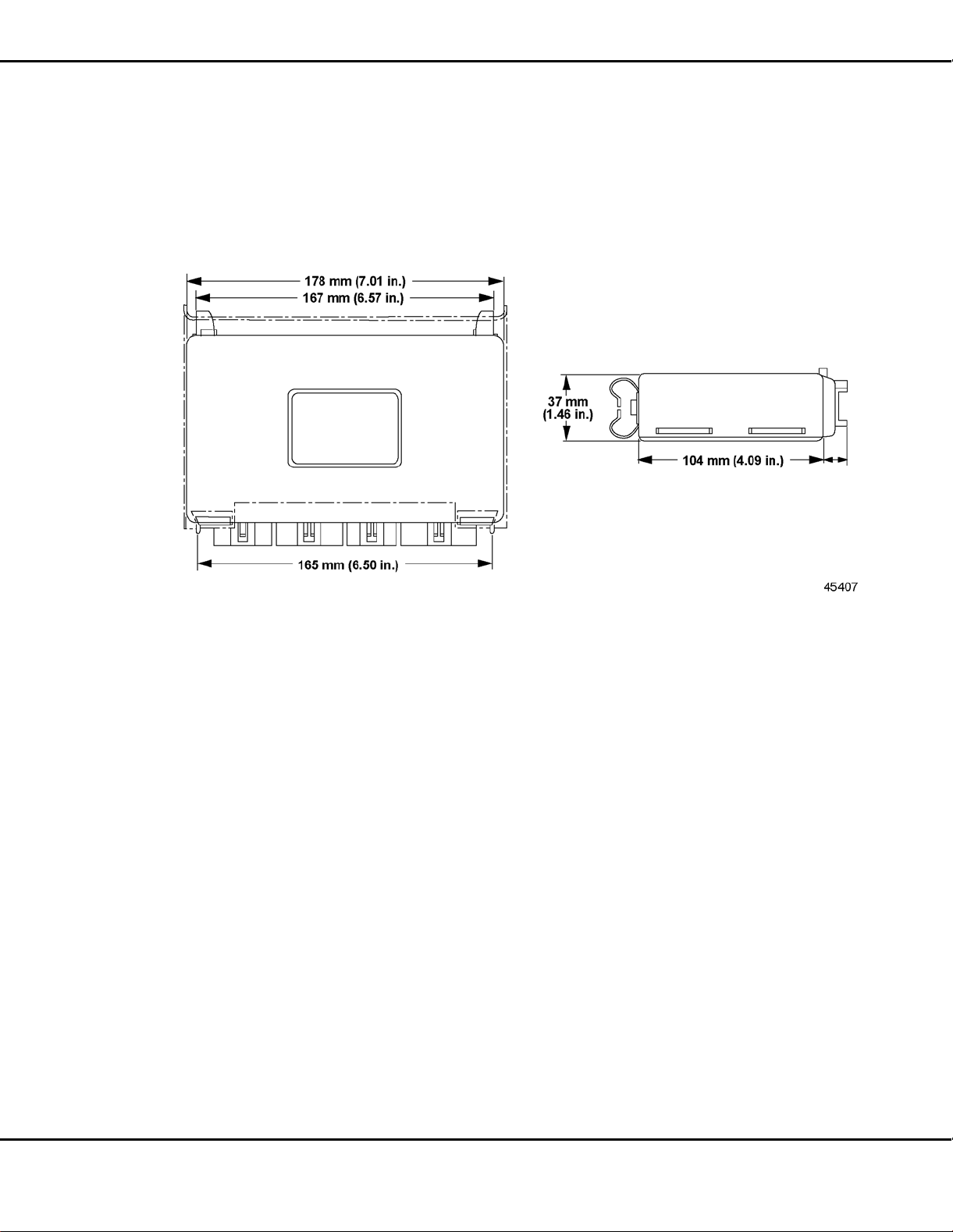

The OEM is responsible for mounting this part in an enclosed, protected environment. The

mounting bracket is the responsibility of the OEM. There must be maximum physical s

eparation

of the Vehicle Interface Harness (VIH) from other vehicle/equipment electrical systems. Other

electrical system wires should ideally be at least three feet away from the VIH and should not

be parallel to the VIH. This will eliminate coupling electromagnetic energy f

rom other systems

into the VIH. See Figure 3.

Figure 3 CPC Dimensions

The CPC receives data from the op

erator (accelerator pedal position, switches, various sensors)

and other electronic control units (for example, synchronization controllers for more than one

genset, air compressor controls).

NOTE:

The CPC should be mounted with the connectors pointing down.

ENVIRONMENTAL CONDITIONS

Temperature, vibration

, and water intrusion must be considered.

Temperature

The ambient operating temperature range is –40°F to 185°F (-40°C to 85°C).

Water Intrusion

The CPC is not water tight and cannot be subject to water spray. It must be mounted in an

enclosed, protected environment.

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 7

EPA07 MBE 4000 SERVICE MANUAL

SAFETY INSTRUCTIONS AND PRECAUTIONS

The following safety measures are essential when working on the MBE 4000 engine.

To reduce the chance of personal injury and/or property damage, the following instructions

must be carefully observed:

□ Proper service and repair are important to the service technician and th

e safe, reliable

operation of the engine. If part replacement is necessary, the part must be replaced with

one of the same part number or with an equivalent part number. Do not use a replacement

part of lesser quality.

□ The service procedures recommended and described in this manual are effective methods

of performing repair. Some of these procedures require the use of specially designed tools.

Accordingly, anyone who intends to use a replacement part, pr

ocedure or tool that is not

recommended, must first determine that neither personal safety nor the safe operation of the

engine will be jeopardized by the replacement part, procedure or tool selected.

□ It is important to note that this manual contains var

ious “Cautions” and “Notices” that must

be carefully observed in order to reduce the risk of personal injury during repair or the

possibility that improper repair may damage the engine or render it unsafe. It is also

important to understand that these “Cautions” an

d “Notices” are not exhaustive, because it

is impossible to warn personnel of the possible hazardous consequences that might result

from failure to follow these instructions.

8 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

Exhaust (Start/Run Engine)

Before starting and running an engine, adhere to the following safety precautions:

PERSONAL INJURY

To avoid injury before starting and running the engine,

ensure the vehicle is parked on a level surface, parking

brake is set, and the wheels are blocke d.

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

□ Always start and operate an engine in a well ventilated

area.

□ If operating an engine in an enclosed area, vent t

exhaust to the outside.

□ Do not modify or tamper with the exhaust system or

emission control system.

he

Stands

Safety stands are required in conjunc

jack or the hoist to carry the load. When lifting an engine, ensure the lifting device is fastened

securely. Ensure the item to be lifted does not exceed the capacity of the lifting device.

To avoid injury when removing or installing a heavy engine

component, ensure the component is properly supported

and securely attached to an ad

prevent the component from falling.

tion with hydraulic jacks or hoists. Do not rely on either the

PERSONAL INJURY

equate lifting device to

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 9

EPA07 MBE 4000 SERVICE MANUAL

Glasses

Select appropriate safety glasses for the job. It is especially important to wear sa

fety glasses when

using tools such as hammers, chisels, pullers or punches.

PERSONAL INJURY

To avoid injury when working on or near an operating

engine, wear protective clothing, eye pro tection, and

hearing protection.

Work Place

Organize your work area and keep it clean. A fall could result in a serious injury. E liminate

the possibility of a fall by:

□ Wiping up oil spills

□ Keeping tools and parts off the floor

After servicing or adjusting the engine:

□ Reinstall all safety devices, guards or shields

□ Ensure that all tools and servicing equipment are removed from the engine

10 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

Welding

Wear welding goggles and gloves when welding or using an acetylene torch.

PERSONAL INJURY

To avoid injury from arc welding, gas welding, or

cutting, wear required safety equipment such as an arc

welder’s face plate or gas welder’s goggles, welding

gloves, protective apron, long sleeve shirt, head

protection, and safety shoes. Always perform welding

or cutting operations in a well ventilated area. The gas

in oxygen/acetylene cylinders used in gas w elding and

cutting is under high pressure. If a cylinder should fa

due to careless handling, the gage end could strike an

obstruction and fracture, resulting in a gas leak leading

to fire or an explosion. If a cylinder should fa

in the gage end breaking off, the sudden release of

cylinder pressure will turn the cylinder into a dangerous

projectile. Observe the following precau

tions when using

oxygen/acetylene gas cylinders:

□ Always wear required safety shoes.

□ Do not handle tanks in a careless manne

gloves or slippery hands.

□ Use a chain, bracket, or other restraining device at all

times to prevent gas cylinders fro

m falling.

□ Do not place gas cylinders on their sides, but stand

them upright when in use.

□ Do not drop, drag, roll, or strike

a cylinder forcefully.

□ Always close valv es completely when finished welding

or cutting.

ll resulting

rorwithgreasy

ll

FIRE

To avoid injury from fire, check for fuel or oil leaks before

weldingorcarryinganopen

flame near the engine.

NOTICE:

Use proper shielding around hydraulic lines when welding to

prevent hydraulic line dam age.

Ensure that a metal shield separates the acetylene and oxygen that must be chained to a cart.

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 11

EPA07 MBE 4000 SERVICE MANUAL

Clothing

Safe work clothing fits and is in good repair. Work shoes are sturdy and rough-soled. B

are feet,

sandals or sneakers are not acceptable foot wear when adjusting and/or servicing an engine. Do

not wear the following when working on an engine:

PERSONAL INJURY

To avoid injury when working near or on an operating

engine, remove loose items of clothing and jewelry. Tie

back o r contain long hair that could be caught in any

moving part causing injury.

PERSONAL INJURY

To avoid injury when working on or near an operating

engine, wear protective clothing, eye pro tection, and

hearing protection.

□ Rings

□ Wrist watches

□ Loose fitting clothing

Any of these items could catch on moving parts causing serious injury.

Power Tools

Do not use defective portable power tools.

ELECTRICAL SHOCK

To avoid injury from electrical s

operating instructions prior to usage.

Check for frayed cords prior

to using the tool. Be sure all electric tools are grounded. Defective

electrical equipment can cause severe injury. Improper use of electrical equipment can cause

severe injury.

hock, follow OEM furnished

12 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Air

EPA07 MBE 4000 SERVICE MANUAL

Recommendations regarding the use of compressed air are indicated throughout the m

anual.

EYE INJURY

To avoid injury from flying debris when using compressed

air, wear adequate eye protection (face shield o r safety

goggles) and do not exceed 276 kPa (40 psi) air pressure.

Fuel Lines

Remove fuel lines as an assembly. Do not remove fuel lines individually. Avoid getting fuel

injection lines mixed up.

Fluids and Pressure

Be extremely careful when dealing with fluids under pressure.

PERSONAL INJURY

To avoid injury from penetrating fluids, do n

ot put your

hands in front of fluid under pressure. Fluids under

pressure can penetrate skin and clothing.

Fluids under pressure can have enough force to penetrate the skin. These fluids can infect a minor

cut or opening in the skin. If injured by escaping fluid, see a doctor at once. Serious infection

or reaction can result without imm

ediate medical treatment.

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 13

EPA07 MBE 4000 SERVICE MANUAL

Fuel

Keep the hose and nozzle or the funnel and container in contact with the metal of the fu

when refueling to avoid the possibility of an electric spark igniting the fuel.

FIRE

To avoid injury from fire caused by heated diesel-fuel

vapors:

□ Keep those people who are not directly involved in

servicing away from the engine.

□ Stop the engine immediately if a fuel leak is detected.

□ Do not smoke or allow open flames when working on

an operating engine.

□ Wear adequate protective clothing (face shield,

insulated gloves and apron, etc.).

□ To prevent a buildup of potentially volatile vapors,

keep

the engine area well ventilated during operation.

el tank

GASOLINE VAPOR IGNITION

To avoid injury from possible gasoline vapor ignition when

refueling, keep the hose, nozzle, funnel, or container in

contact with the metal opening of the fuel tan

k. This will

reduce the likelihood of a dangerous spark.

14 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

The following cautions should be followed when filling a fuel tank:

PERSONAL INJURY

To avoid injury from fuel spills, do not overfill the fuel tank.

FIRE

To avoid injury from fire, keep all potential ignition sources

away from diesel fuel, including open flames, sparks, and

electrical resistance heating elements. Do not smoke when

refueling.

Batteries

Electrical storage batteries emit highly flammable hydrogen gas when charging and continue to

do so for some time after receiving a steady cha

rge.

Battery Explosion and Acid Burn

To avoid injury from battery explosion or contact with

battery acid, work in a well ventilate

d area, wear protective

clothing, and avoid sparks or flames near the battery. If

you come in contact with battery acid:

□ Flush your skin with water.

□ Apply baking soda or lime to help neutralize the acid.

□ Flush your eyes with water.

□ Get medical attention immediat

ely.

Always disconnect the battery cable before working on the electrical system.

PERSONAL INJURY

To avoid injury from accidental engine startup while

servicing the engine, disconnect/disable the starting

system.

Disconnect the batteries or disable an air starter when working on the engine to prevent accidental

starting.

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 15

EPA07 MBE 4000 SERVICE MANUAL

Fire

Keep a charged fire extinguisher within reach. Be sure you have the correct type of ext

inguisher

for the situation.

Cleaning Agent

Avoid the use of carbon tetrachloride as a cleaning agent because of the h

releases. Ensure the work area is adequately ventilated. Use protective gloves, goggles or face

shield, and apron.

PERSONAL INJURY

To avoid injury from harmful vapors or skin contact, do not

use carbon tetrachloride as a cleaning agent.

Exercise caution against burns when using oxalic acid to clean the cooling passages of the engine.

armful vapors that it

WorkingonaRunningEngine

When working on an engine that is running, acc

cause severe burns.

idental contact with the hot exhaust manifold can

PERSONAL INJURY

To avoid injury from unguarded rotating and moving engine

components, check that all protective devices have been

reinstalled after working on the en

gine.

PERSONAL INJURY

To avoid injury, use care when w

orking around moving belts

and rotating parts on the engine.

16 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

EPA07 MBE 4000 SERVICE MANUAL

Start Attempts

Avoid excessive injection of ether into the engine during start attempts.

NOTICE:

Avoid excessive injection of ether into the engine during

start attempts. Injection of excessive ether may result in an

uncontrolled internal engine explosion that could cause engine

damage. Follow the manufacturer's instructions on proper

product use.

Follow the instructions on the container or by the manu

facturer of the starting aid.

Fluoroelastomer (Viton) Use

Under normal design conditions, fluoroelastomer (VITON) parts, such as O-rings and seals,

are perfectly safe to handle.

CHEMICAL BURNS

To avoid injury from chemical burns, wear a face

shield and neoprene or PVC gloves when h

fluoroelastomer O-rings or seals that have been degraded

by excessive heat. Discard gloves after handling degraded

fluoroelastomer parts.

However, a potential hazard may occur if these components are raised to a temperature above

316°C (600°F), such as during a

cylinder failure or engine fire. At temperatures above 316°C

(600°F) fluoroelastomer will decompose (indicated by charring or the appearance of a black,

sticky mass) and produce hydrofluoric acid. This is extremely c orrosive and, if touched by bare

skin, may cause severe burns

, sometimes with symptoms delayed for several hours.

andling

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 17

EPA07 MBE 4000 SERVICE MANUAL

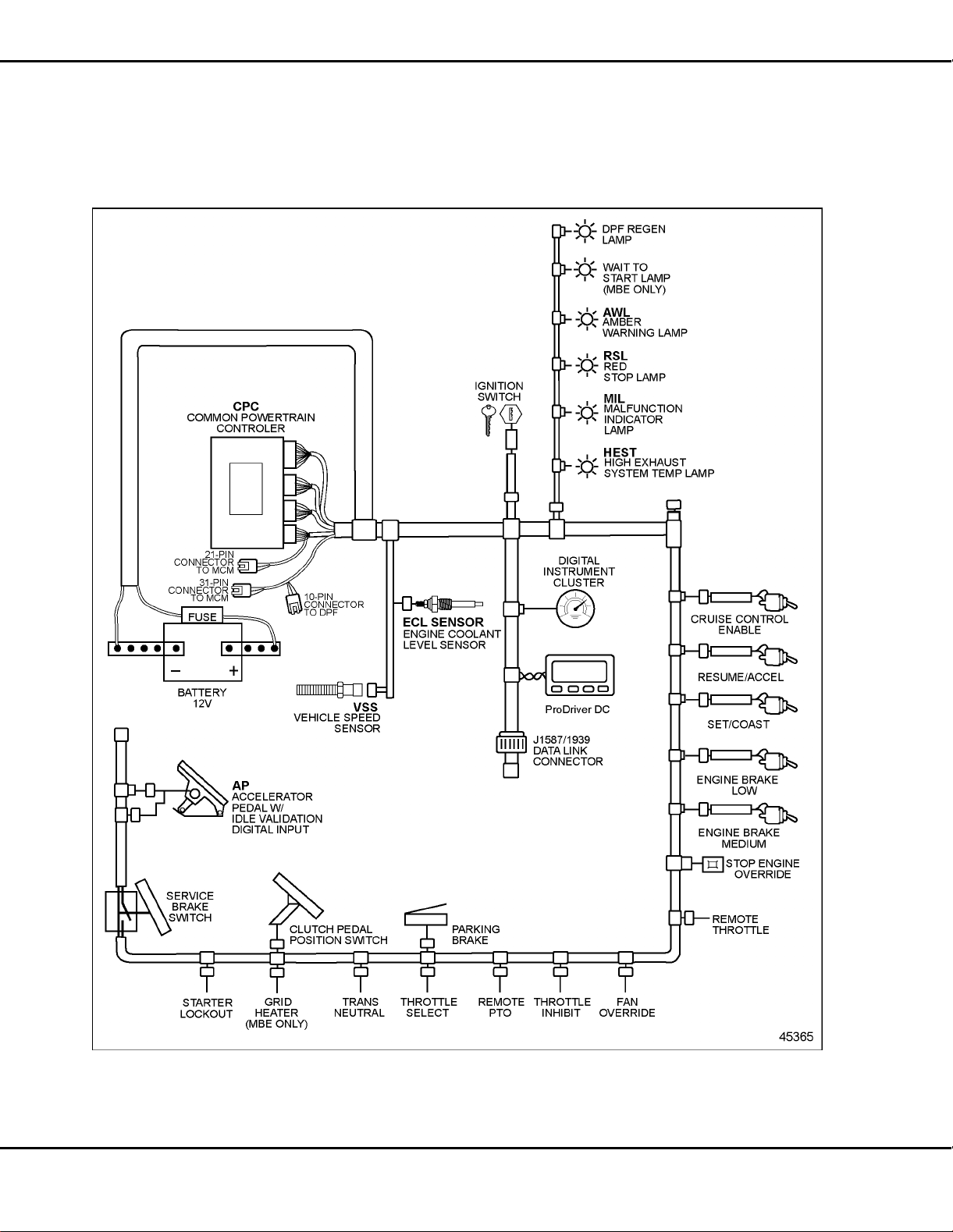

CPC VEHICLE INTERFACE HARNESS

The OEM supplied Vehicle Interface Harness (VIH) connects the CPC to the MCM and othe

vehicle systems. See Figure 4.

r

Figure 4 Vehicle Interface Harness

18 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

ENGINE BRAKING POWER

EPA07 MBE 4000 SERVICE MANUAL

To supplement vehicle braking, the M BE 4000 engine can be equipped with an engine bra

ke.

Exhaust Brake/Constant Throttle Valves

To increase braking performance, the engine is equipped with an exhaust brake on the

turbocharger in conjunction with constant throttle valves on the cylin

der head.

NOTE:

The constant throttle values are activated by engine oil pressure.

The exhaust back-pressure is used by the exhaust brake to increa

se braking performance.

Optional Engine Brake

For high braking output, the MBE 4000 engine can be equipped with an optional engine

brake. The engine brake increases the air mass flow throug

brake horsepower. The engine brake can be operated either manually, in different stages, or

automatically, through the cruise control function.

Because the charge air pressure is maintained at a high

is available immediately, if the operator desires it, without any turbo lag.

h the engine to provide up to 600

level during braking, full throttle response

All information subject to change without notice.

DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION 19

EPA07 MBE 4000 SERVICE MANUAL

20 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

1 ENGINE

Section Page

1.1 ENGINE TRIM COVERS AND FRAMES ................................................. 1-3

1.2 CYLINDER HEAD COVER ...................................................................... 1-6

1.3 CYLINDER HEAD .................................................................................... 1-8

1.4 CYLINDER BLOCK .................................................................................. 1-21

1.5 FRONT AND REAR ENGINE LIFTING BRACKET

1.6 ENGINE BRAKE ...................................................................................... 1-44

1.7 FRONT RADIAL SEAL ............................................................................. 1-51

1.8 REAR RADIAL SEAL ............................................................................... 1-54

1.9 CRANKSHAFT WEAR SLEEVE .............................................................. 1-57

1.10 CRANKSHAFT ASSEMBLY ..................................................................... 1-63

1.11 FRONT COVER HOUSING ..................................................................... 1-86

1.12 CRANKSHAFT POSITION SENSOR ...................................................... 1-88

1.13 CRANKSHAFT VIBR ATION DAMPER AND PULLEY ............................. 1-89

1.14 FLYWHEEL .............................................................................................. 1-91

1.15 RING GEAR ............................................................................................. 1-100

1.16 PILOT BEARING ...................................................................................... 1-104

1.17 ENGINE BARRIN

1.18 FLYWHEEL HOUSING ............................................................................ 1-110

1.19 PISTON, PISTON RING, AND CONNECTING ROD ............................... 1-112

G TOOL .......................................................................

S ...............................

1-42

1-108

1.20 VALVES .................................................................................................... 1-138

1.21 ROCKER ARM ......................................................................................... 1-154

1.22 CAMSHAFT AND GEAR ASSEMBLY ...................................................... 1-158

1.A ADDITIONAL INFORMATION .................................................................. 1-169

1-2 DDC-SVC-MAN-0026 Copyright © 2011 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Loading...

Loading...