Page 1

Page 2

Page 3

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

TABLE OF CONTENTS

1 ROCKER COVER

1.1 DESCRIPTION AND OPERATIONOFROCKER COVER AND RELATED

PARTS ...................................................................................................... 1-3

1.2 REMOVAL OF THE ROCKER COVER .................................................... 1-4

1.3 CLEANING AND INSPECTION OF THE ROCKER COVER ................... 1-6

1.4 INSTALLATION OF THE ROCKER COVER ............................................ 1-7

2 CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND ROCKER

SHAFT/ENGINE BRAKE ASSEMBLY AND RELATED PARTS ............... 2-3

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE B

ASSEMBLY .............................................................................................. 2-7

2.3 INSPECTION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE

BRAKE ASSEMBLY ................................................................................. 2-15

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE

BRAKE ASSEMBLY ................................................................................. 2-16

2.5 DD13 EGR COOLER CLEANING PROCEDUR

ETOREMOVEEXCESS

FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE 2-26

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS

FUEL FROM COOLER AFTER ENGIN

E BRAKE SOLENOID FAILURE

RAKE

2-31

3 CAMSHAFT HOUSING

3.1 REMOVAL OF THE CAMSHAFT HOUSING ........................................... 3-3

3.2 INSPECTION OF CAMSHAF

T HOUSING ...............................................

3-8

3.3 INSTALLATION OF THE CAMSHAFT HOUSING ................................... 3-9

4 CAMSHAFT TIMING

4.1 CAMSHAFT TIMING VER

IFICATION ......................................................

4-3

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN INSTALLED ........ 4-6

5 GEARTRAINANDENGINETIMING

5.1 DESCRIPTION AN

D OPERATION OF GEAR TRAIN AND RELATED

PARTS ...................................................................................................... 5-3

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING ............................ 5-8

5.3 CHECKING AND

ADJUSTING GEAR LASH W ITH CAMSHAFT

HOUSING REMOVED ............................................................................. 5-16

6 WATER MANIFOLD

6.1 DESCRIPT

IONANDOPERATIONOFDD15&DD16WATER

MANIFOLD AND RELATED COMPONENTS .......................................... 6-3

6.2 REMOVAL OF THE DD15 & DD16 WATER M AN IFOLD ......................... 6-5

6.3 CLEAN

ING AND INSPECTION OF THE DD15 & DD16 WATER

MANIFOLD ............................................................................................... 6-7

6.4 INSTALLATION OF THE DD15 & DD16 WATER

MANIFOLD ................. 6

-8

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION i

Page 4

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

6.5 DD13 EXHAUST GAS RECIRCULATION COOLER WATER MANIFOLD

ASSEMBLY .............................................................................................. 6-10

7 COLD BOOST PIPE (C HA RGE AIR PIPE)

7.1 DESCRIPTION AND OPERATION OF COLD BOOST PIPE (CHARGE

AIR PIPE) AND RELATED COMPONENTS ............................................ 7-3

7.2 REMOVAL OF THE COLD BOOST PIPE (CHARGE AIR PIPE) ............. 7-4

7.3 INSPECTION OF COLD BOOST PIPE (CHARGE AIR PIPE) ................ 7-5

7.4 INSTALLATION OF THE COLD BOOST PIPE (CHARGE AIR PIPE) .... 7-6

8 AIR INTAKE MANIFOLD

8.1 DESCRIPTION AND OPERATION OF AIR INTAKE MANIFOLD AND

RELATED PARTS .................................................................................... 8-3

8.2 REMOVAL OF AIR INTAKE MANIFOLD .................................................. 8-6

8.3 CLEANING OF THE AIR INTAKE MANIFOLD ........................................ 8-7

8.4 INSPECTION OF THE AIR INTAKE MANIFOLD ..................................... 8-8

8.5 INSTALLATION OF AIR INTAKE MANIFOLD .......................................... 8-9

9 DD13 TURBOCHARGER

9.1 DESCRIPTION AND OPERATION OF THE DD13 TU

RBOCHARGER

AND RELATED PARTS ............................................................................ 9-3

9.2 REMOVAL OF THE DD13 TURBOCHARGER ........................................ 9-5

9.3 INSPECTION O F THE DD13 TURBOCHARGER

...................................

9.4 INSTALLATION OF THE DD13 TURBOCHARGER ................................ 9-10

9.5 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL

FROM COOLER AFTER DD13 TURBOCH

ARGER FAILURE ................

9-9

9-12

10 DD13 WASTEGATE SOLENOID

10.1 DESCRIPTION AND OPERATION OF THE DD13 WASTEGATE

SOLENOID ............................................................................................... 10-3

10.2 REMOVAL OF THE DD13 WASTEGATE SOLENOID ............................. 10-4

10.3 INSTALLATION OF THE DD13 WASTEGATE SOLENOID ..................... 10-6

11 DD15 TURBOCHARGER

11.1 DESCRIPTION AND OPERATION OF TURBOCHARGER AND

RELATED PARTS .................................................................................... 11-3

11.2 REMOVAL OF DD15 TU

RBOCHARGER ................................................

11-5

11.3 INSPECTION OF DD15 TURBOCHARGER ........................................... 11-7

11.4 INSTALLATION OF DD15 TURBOCHARGER ........................................ 11-8

11.5 EGR COOLER CLEA

NING PROCEDURE TO REMOVE EXCESS OIL

FROM EGR COOLER AFTER DD15 TURBOCHARGER FAILURE ....... 11-10

12 DD15 AXIAL POWER TURBINE

12.1 DESCRIPTI

AND OPERATION O

ON

F DD15 AXIAL POWER TURBINE

AND RELATED PARTS ............................................................................ 12-3

12.2 REMOVAL OF DD15 AXIAL POWER TURBINE ..................................... 12-5

12.3 INSPECT

ION OF THE DD15 AXIAL POWER TURBINE ........................

12-6

12.4 INSTALLATION OF DD15 AXIAL POWER TURBINE ............................. 12-7

ii DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 5

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

13 DD15 AXIAL POWER TURBINE GEAR BOX

13.1 DESCRIPTION AND OPERATION OF DD15 AXIAL POWER TURBINE

GEAR BOX AND RELATED PARTS ........................................................ 13-3

13.2 REMOVAL OF THE DD15 AXIAL POWER TURBINE GEAR BOX ......... 13-5

13.3 INSPECTION OF DD15 AXIAL POWER TURBINE GEAR BOX ............. 13-6

13.4 INSTALLATION OF THE AXIAL POWER TURBINE GEAR BOX ............ 13-7

14 CYLINDER HEAD

14.1 DESCRIPTION AND OPERATIONOF CYLINDER HEAD AND RELATED

PARTS ...................................................................................................... 14-3

14.2 REMOVAL OF THE DD13 CYLINDER HEAD ......................................... 14-10

14.3 INSTALLATION OF THE DD13 CYLINDER HEAD .................................. 14-12

14.4 REMOVAL OF THE DD15 CYLINDER HEAD ......................................... 14-15

14.5 CLEANING OF THE CYLINDER HEAD .................................................. 14-17

14.6 ASSEMBLY OF CYLINDER HEAD .......................................................... 14-18

14.7 INSTALLATION OF THE DD15 CYLINDER HEAD .................................. 14-19

14.8 REMOVAL OF VALVE SPRING (CYLINDER HEAD IN

STALLED) ..........

14-22

14.9 REMOVAL OF THE VALVE SPRING (CYLINDER HEAD REMOVED) ... 14-24

14.10 REMOVAL OF INTAKE AND EXHAUST VALVES ................................... 14-25

14.11 CLEANING OF VALVES AND RELATED PARTS .................................... 14-26

14.12 INSPECTION OF VALVE SPRINGS ........................................................ 14-27

14.13 INSPECTION OF VALVE ......................................................................... 14-28

14.14 INSTALLATION OF VALVE, SPRING,

SEAL AND VALVE CAP ..............

14-29

14.15 VALVE LASH ADJUSTMENTS ................................................................ 14-31

14.16 SETTING THE ENGINE BRAKE LASH ................................................... 14-33

15 PISTON AND CONNECTING ROD ASSEMBLY

15.1 DESCRIPTION AND OPERATION OF PISTON AND CONNECTING

ROD AND RELATED PARTS ................................................................... 15-3

15.2 REMOVAL OF PISTON AND CO

NNECTING ROD ASSEMBLY .............

15-5

15.3 DISASSEMBLY OF PISTON AND CONNECTING ROD ASSEMBLY ..... 15-7

15.4 INSPECTION OF PISTON AND CONNECTING ROD ASSEMBLY ........ 15-8

15.5 ASSEMBLY OF PISTON AN

D CONNECTING ROD ASSEMBLY ...........

15-9

15.6 INSTALLATION OF PISTON AND CONNECTING ROD ASSEMBLY ..... 15-11

16 CYLINDER LINER

16.1 DESCRIPTION AND

OPERATION OF CYLINDER LINER AND

RELATED PARTS .................................................................................... 16-3

16.2 REMOVAL OF CYLINDER LINER ........................................................... 16-4

16.3 INSPECTION OF

CYLINDER LINER ......................................................

16-5

16.4 CLEANING OF THE CYLINDER LINER .................................................. 16-7

16.5 INSTALLATION OF THE CYLINDER LINER ........................................... 16-8

17 CRANKSHAFT

17.1 DESCRIPTION AND OPERATION OF CRANKSHAFT AND RELATED

PARTS ..................................

17.2 REMOVA

......................

L OF CRANKSHAFT .................................................................

.............................................. 17-3

17-6

17.3 INSPECTION OF THE CRANKSHAFT AND RELATED PARTS ............. 17-9

17.4 INSTALLATION OF CRANKSHAFT ......................................................... 17-10

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION iii

Page 6

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

17.5 REMOVAL OF CRANKSHAFT REAR OIL SEAL ..................................... 17-14

17.6 INSTALLATION OF THE REAR OIL SEAL .............................................. 17-15

17.7 REMOVAL OF THE CRANKSHAFT FRONT OIL SEAL .......................... 17-17

17.8 INSTALLATION OF THE CRANKSHAFT FRONT OIL SEAL .................. 17-18

18 LUBRICATION SYSTEM

18.1 DESCRIPTIONANDOPERATIONOFTHELUBRICATIONSYSTEM

AND RELATED COMPONENTS .............................................................. 18-3

19 OIL PAN

19.1 DESCRIPTIONANDOPERATIONOFOILPANANDRELATED

COMPONENTS ....................................................................................... 19-3

19.2 REMOVAL OF OIL PAN ........................................................................... 19-4

19.3 CLEANING OF OIL PAN .......................................................................... 19-5

19.4 INSPECTION OF OIL PAN ...................................................................... 19-6

19.5 REMOVAL OF THREADED INSERT — PLASTIC OIL PAN ONLY

.........

19.6 INSTALLATION OF THREADED INSERT — PLASTIC OIL PAN ONLY . 1 9-8

19.7 INSTALLATION OF OIL PAN ................................................................... 19-9

20 OIL DIPSTICK TUBE

20.1 DESCRIPTION AND OPERATION OF OIL DIPSTICK TUBE AND

RELATED COMPONENTS ...................................................................... 20-3

20.2 REMOVAL OF THE OIL DIPSTICK TUBE ............................................... 20-4

20.3 INSTALLATION OF THE OIL DIPSTICK TUBE ....................................... 20-5

19-7

21 OIL PUMP

21.1 DESCRIPTION AND OPERATION OF

OIL PUMP AND RELATED

COMPONENTS ....................................................................................... 21-3

21.2 REMOVAL OF THE OIL PUMP, OIL SUCTION MANIFOLD, AND OIL

LINES ....................................................................................................... 21-4

21.3 INSPECTION OF THE OIL PUMP, OIL SUCTION MANIFOLD, AND OIL

LINES ....................................................................................................... 21-5

21.4 INSTALLATION OF THE OI

L PUMP, OIL SUCTION MANIFOLD, AND

OIL L INES ................................................................................................ 21-6

22 CRANKCASE BREATHER

22.1 DESCRIPTION AND O

PERATION OF CRANKCASE BREATHER ........

22-3

22.2 REMOVAL O F THE CRANKCASE BREATHER ...................................... 22-5

22.3 INSPECTION OF THE CRANKCASE BREATHER

22.4 INST

ALLATION O

F THE CRANKCASE BREATHER ..............................

................................. 22-6

22-7

23 OIL FILTER

23.1 REPLACEMENT OF THE OIL FILTER .................................................... 23-3

24 OIL SAMPLE VALVE

24.1 REPLACING OIL PLUG WITH OIL SAMPLE VALVE .............................. 24-3

24.2 REMOVAL OF OIL SAMPLE VALVE ....................................................... 24-4

24.3 INSTALL

ATION OF OIL SAMPLE VALVE ................................................

24-5

25 OIL FIL

LER NECK

25.1 REMOVAL OF THE OIL FILLER NECK ................................................... 25-3

iv DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 7

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

25.2 INSTALLATION OF THE OIL FILLER NECK ........................................... 25-4

26 OIL COOLANT MODULE

26.1 DESCRIPTION AND OPERATION OF THE OIL COOLANT MODULE .. 26-3

26.2 REMOVAL OF THE OIL COOLANT M OD ULE ........................................ 26-5

26.3 INSTALLATION OF THE OIL COOLANT MODULE ................................ 26-7

26.4 REMOVAL OF THE OIL THERMOSTAT .................................................. 26-9

26.5 INSTALLATION OF THE OIL THERMOSTAT .......................................... 26-11

27 PRIMING THE LUBRICATION SYSTEM

27.1 PRIMING THE ENGINE LUBRICATION SYSTEM .................................. 27-3

28 COOLING SYSTEM

28.1 DESCRIPTION AND OPERATION OF COOLING SYSTEM AND

RELATED COMPONENTS ...................................................................... 28-3

29 ENGINE WATER PUMP

29.1 DESCRIPTION AND OPERATION OF ENGINE WATER PUMP

............

29-3

29.2 REMOVAL OF THE WATER PUMP ......................................................... 29-4

29.3 INSPECTION OF THE WATER PUMP .................................................... 29-5

29.4 INSTALLATION OF THE WATER PUMP ................................................. 29-6

30 COOLANT THERMOSTAT

30.1 DESCRIPTION AND OPERATION OF COOLANT THERMOSTAT ........ 30-3

30.2 REMOVAL OF COOLANT THERMOSTAT AN

D SEAL ...........................

30-5

30.3 INSPECTION OF COOLANT THERMOSTAT AND SEAL ....................... 30-6

30.4 INSTALLATION OF COOLANT THERMOSTAT AND SEAL .................... 30-7

31 COOLANT FILTER

31.1 DESCRIPTION AND OPERATION OF COOLANT FILTER ..................... 31-3

31.2 REMOVAL OF THE COOLANT FILTER .................................................. 31-4

31.3 INSTALLATION OF THE COO

32 COOLANT FILTER SERVIC

LANT FILTER ..........................................

EMODULE

31-5

32.1 REMOVAL OF COOLANT FILTER SERVICE MODULE ......................... 32-3

32.2 INSTALLATION OF COOL

33 COOLANT INLET ELB

ANT FILTER SERVICE MODULE ..................

OW

32-4

33.1 REMOVAL OF THE COOLANT INLET ELBOW ...................................... 33-3

33.2 INSTALLATION OF

34 FLYWHEEL AND FL

THE COOLANT INLET ELBOW ..............................

YWHEEL HOUSING

33-4

34.1 DESCRIPTION AND OPER ATION OF FLYWHEEL, FLYWHEEL

HOUSING AND R

ELATED PARTS ..........................................................

34-3

34.2 REMOVAL OF FLYWHEEL HOUSING .................................................... 34-6

34.3 INSTALLATION OF FLYWHEEL HOUSING ............................................ 34-7

34.4 REMOVAL OF

34.5

INSPECTION OF FL

THE FLYWHEEL ..............................................................

YWHEEL ................................................................. 34-10

34-9

34.6 INSTALLATION OF FLYWHEEL .............................................................. 34-11

34.7 INSPEC

TION OF FLYWHEEL HOUSING AND REAR OIL SEAL AREA

OF CRANKSHAFT ................................................................................... 34-12

34.8 REMOVAL OF RING GEAR ..................................................................... 34-13

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION v

Page 8

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

34.9 INSTALLATION OF RING GEAR ............................................................. 34-14

35 FRONT ENGINE MOUNT/RADIATOR SUPPORT

35.1 DESCRIPTION AND OPERATION OF FRONT ENGINE

MOUNT/RADIATOR SUPPORT AND RELATED PARTS ........................ 35-3

35.2 REMOVAL OF THE FRONT ENGINE MOUNT/RADIATOR SUPPORT .. 35-4

35.3 INSPECTION OF THE FRONT ENGINE MOUNT/RADIATOR

SUPPORT ................................................................................................ 35-5

35.4 INSTALLATION OF THE FRONT ENGINE MOUNT/RADIATOR

SUPPORT ................................................................................................ 35-6

36 VIBRATION DAMPER

36.1 REMOVAL OF THE VIBRATION DAMPER ............................................. 36-3

36.2 INSTALLATION OF THE VIBRATION DAMPER ..................................... 36-4

37 FRONT ENGINE COVER

37.1 DESCRIPTION AND OPERATION OF THE FRONT ENGINE CO

VER ..

37.2 REMOVAL OF THE FRONT ENGINE COVER ........................................ 37-4

37.3 INSPECTION OF THE FRONT ENGINE COVER ................................... 37-5

37.4 INSTALLATION OF THE FRONT ENGINE COVER ................................ 37-6

37-3

38 ENGINE LIFTER BRACKETS

38.1 DESCRIPTION AND OPERATION OF ENGINE LIFTER BRACKETS

AND RELATED PARTS ............................................................................ 38-3

38.2 REMOVAL OF THE FRONT ENGINE LIFTER BRACKET WITHOUT

FRONT ENGINE POWER TAKE-OFF ..................................................... 38-8

38.3 REMOVAL OF THE FRONT ENGINE LI

FTER BRACKET WITH FRONT

ENGINE POWER TAKE-OFF .................................................................. 38-9

38.4 REMOVAL OF THE REAR ENGINE LIFTER BRACKETS ...................... 38-10

38.5 INSPECTION OF THE ENGINE

LIFTER BRACKETS ............................

38-11

38.6 INSTALLATION OF THE REAR ENGINE LIFTER BRACKETS .............. 38-12

38.7 INSTALLATION OF THE FRONT ENGINE LIFTER BRACKET WITHOUT

FRONT ENGINE POWER TAK

E-OFF .....................................................

38-13

38.8 INSTALLATION OF THE FRONT ENGINE LIFTER BRACKET WITH

FRONT ENGINE POWER TAKE-OFF ..................................................... 38-14

39 BELT DRIVE TENSIONER SYSTEM

39.1 DESCRIPTION AND OPERATIONOFBELTDRIVETENSIONERAND

RELATED PARTS .................................................................................... 39-3

39.2 REMOVAL OF THE B

39.3 INSTALLATION OF THE B ELT TENSIONER ...........

4 REMOVAL OF THE IDLER PULLEY AND IDLER PULLEY BRACKET .. 39-7

39.

39.5 INSTALLATI

ON OF THE IDLER PULLEY AND IDLER PULLEY

ELT TENSIONER ..................................................

............................... 39-6

39-5

BRACKET ................................................................................................ 39-8

39.6 REMOVAL OF NON-BRACKETED IDLER PULLEY .............................. 39-9

39.7 INSTALLA

TION OF NON-BRACKETED IDLER PULLEY ........................

39-10

39.8 REMOVAL OF THE ACCESSORY MOUNTING BRACKET .................... 39-11

39.9 INSTALLATION OF THE ACCESSORY MOUNTING BRACKET ............ 39-12

vi DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT D IESEL CORPORATION

All information subject to change without notice.

Page 9

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

40 POLY-V-BELTS

40.1 REMOVAL OF THE POLY-V-BELTS ....................................................... 40-3

40.2 INSPECTION OF THE POLY-V-BELTS ................................................... 40-6

40.3 INSTALLATION OF THE POLY-V-BELTS ................................................ 40-9

41 AIR COMPRESSOR

41.1 DESCRIPTION AND OPERATION OF THE AIR COMPRESSOR .......... 41-3

41.2 REMOVAL OF THE AIR COMPRESSOR ................................................ 41-5

41.3 INSPECTION OF THE AIR COMPRESSOR ........................................... 41-6

41.4 INSTALLATION OF THE AIR COMPRESSOR ........................................ 41-8

42 CYLINDER BLOCK

42.1 DESCRIPTION AND OPER ATION OF CYLINDER BLOCK AND

RELATED PARTS .................................................................................... 42-3

42.2 REMOVAL AND DISASSEMBLY OF ENGINE FROM THE VEHICL

E....

42-9

42.3 CLEANING THE CYLINDER BLOCK ...................................................... 42-12

42.4 REASSEMBLY AND INSTALLATION OF CYLINDER BLOCK ................ 42-16

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION vii

Page 10

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

viii DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 11

1 ROCKER COVER

Section Page

1.1 DESCRIPTION AND OPERATIONOF ROCKER COVERAND RELATED

PARTS ...................................................................................................... 1-3

1.2 REMOVAL OF THE ROCKER COVER .................................................... 1-4

1.3 CLEANING AND INSPECTION OF THE ROCKER COVER ................... 1-6

1.4 INSTALLATION OF THE ROCKER COVER ............................................ 1-7

Page 12

1-2 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 13

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

1.1 DESCRIPTION AND OPERATION OF ROCKER COVER AND RELATED

PART S

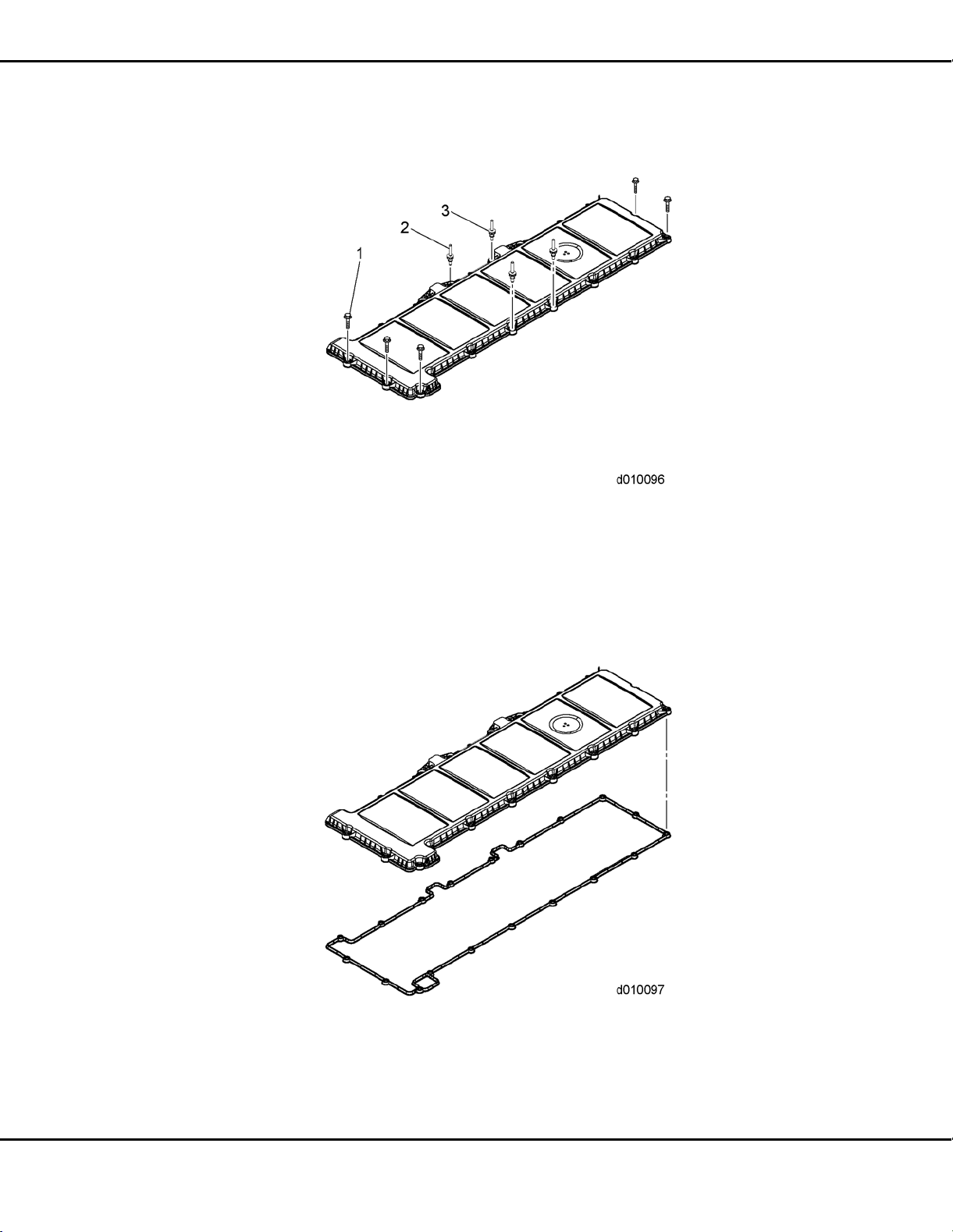

The rocker cover (2) is made of an aluminum or plastic material and uses an elastome

r seal (1)

which completely encloses the valve operating mechanism including the overhead camshafts,

brake assemblies and the injector harness.

1. Gasket 4. Air Cleaner Bracket

2. Rocker Cover 5. Stud (Bolt)

3. Bolt

Figure 1-1 Rocker Cover

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 1-3

Page 14

1.2 REMOVAL OF THE ROCKER COVER

1.2 REMOVAL OF THE ROCKER COVER

Remove as follows:

1. Steam clean the engine.

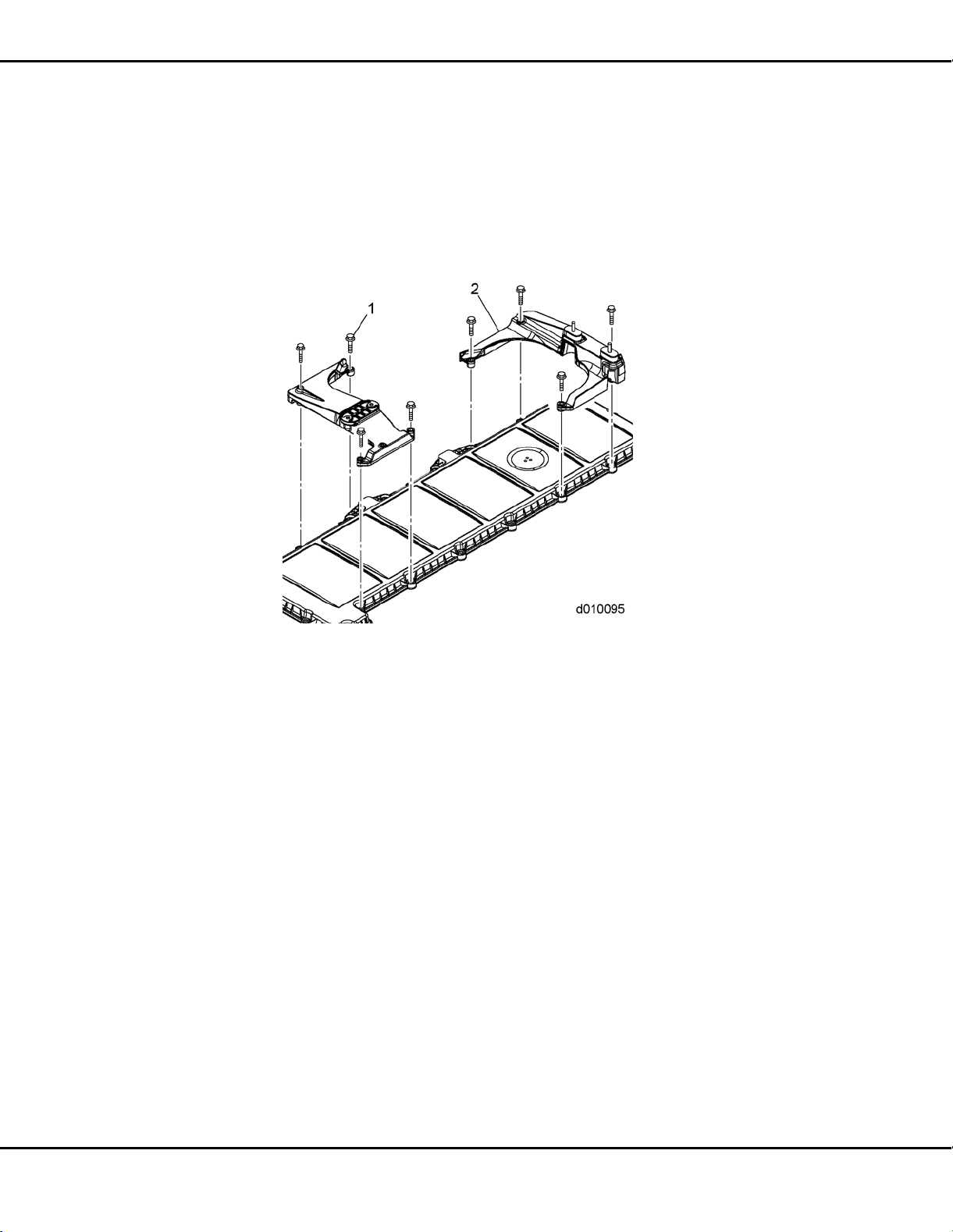

2. Remove bolts (1) or nuts (if equipped) from the two air filter housing brackets (2) and

remove housings from the rocker cover.

1-4 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 15

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

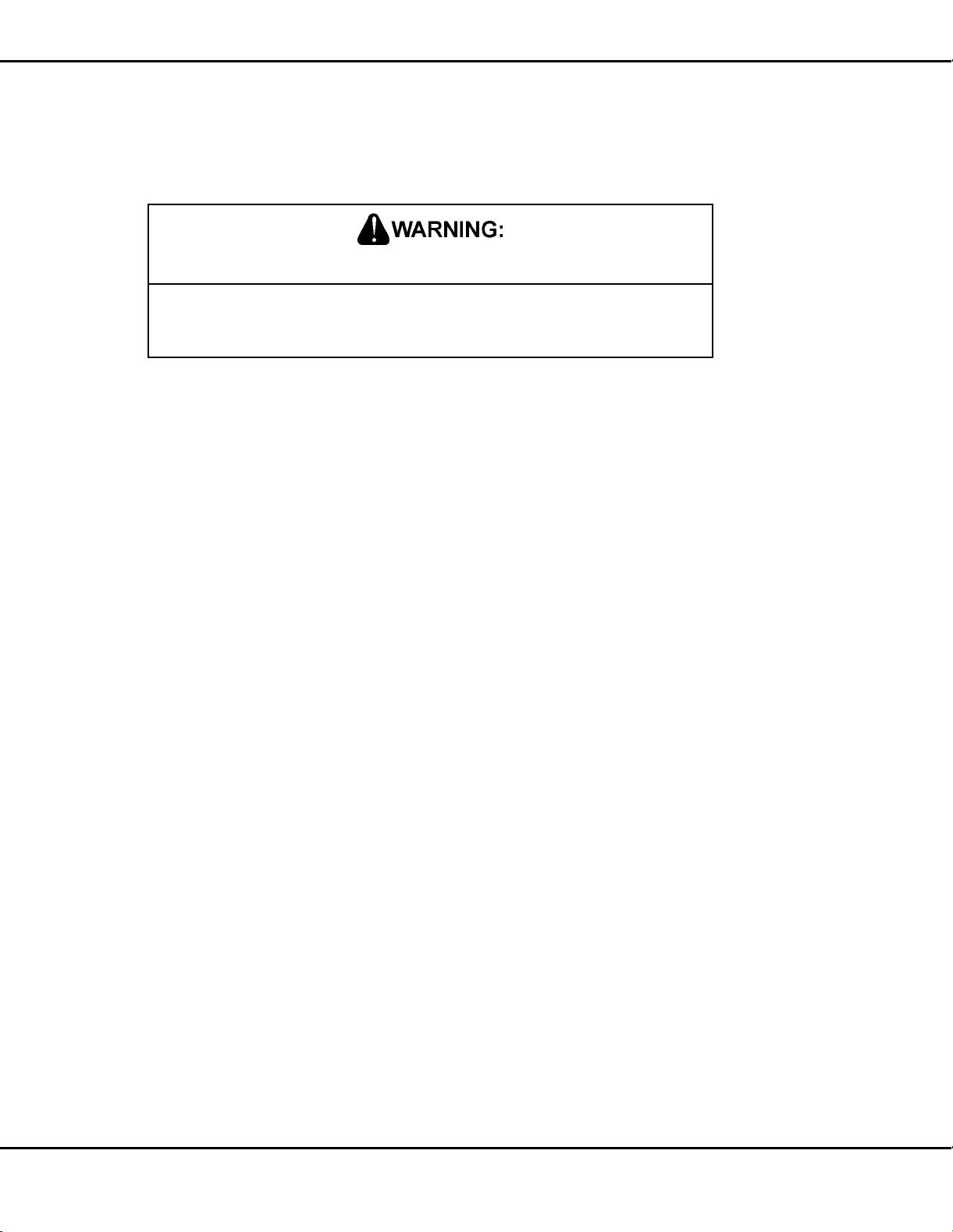

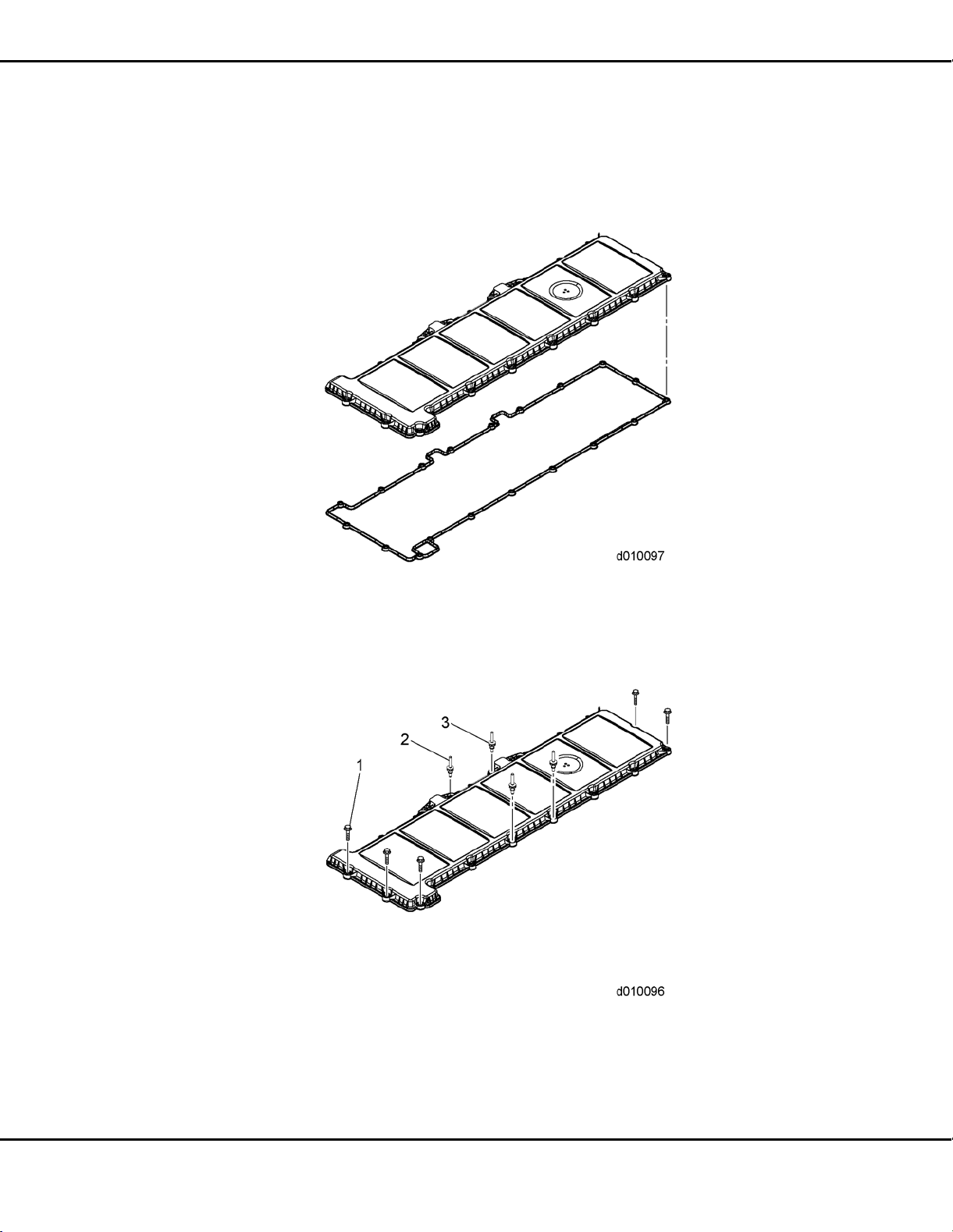

3. Loosen the bolts (1) or stud bolts (2) (if equipped) and isolators (3); remove rocker cover.

NOTE:

Mark the location of the stud bolts. The stud bolts must be replaced in their original

location during installation.

4. Remove rocker cover gasket from the

rocker cover.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 1-5

Page 16

1.3 CLEANING AND INSPECTION OF THE ROCKER COVER

1.3 CLEANING AND INSPECTION OF THE ROCKER COVER

Clean as follows:

1. Clean cover in clean solvent or fuel.

EYE INJURY

To avoid injury from flying debris when using compressed

air, wear adequate eye protection (face shield or safety

goggles) and do not exceed 276 kPa (40 psi) air pressure.

2. Blow dry with compressed air.

3. Check the rocker cover, breather passage and seal for damage. Replace as necessary.

4. Inspect the bolts. Replace if damaged.

1-6 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 17

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

1.4 INSTALLATION OF THE ROCKER COVER

Install as follow s:

1. Install rocker cover gasket into groove in rocker cover.

2. Install bolts (1) or stud bolts (2) (if removed) and isolators (3) into rocker cover.

3. Install roc

ker c over onto camshaft housing.

4. Finger tighten all bolts (1) and stud bolts; then torque to 20 N·m (14 lb·ft).

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 1-7

Page 18

1.4 INSTALLATION OF THE ROCKER COVER

5. Install the two air filter brackets (2) (if equipped), onto the rocker cover and torque the

eight nuts to 20 N·m (14 lb·ft).

ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always

operate the engine in a well-venti

exhaust is toxic.

6. Start the engine and check f

lated area. Engine

or leaks.

1-8 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 19

2 CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE

ASSEMBLY

Section Page

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND

SHAFT/ENGINE BRAKE ASSEMBLY AND RELATED PARTS ............... 2-3

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE

ASSEMBLY .............................................................................................. 2-7

2.3 INSPECTION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE

BRAKE ASSEMBLY ................................................................................. 2-15

2.4 INSTALLATION OF THE CAMSHAFT

BRAKE ASSEMBLY ................................................................................. 2-16

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS

FUEL FROM COOLER AFTER E

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS

FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE 2-31

ANDROCKERSHAFT/ENGINE

NGINE BRAKE SOLENOID FAILURE

ROCKER

2-26

Page 20

2-2 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 21

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

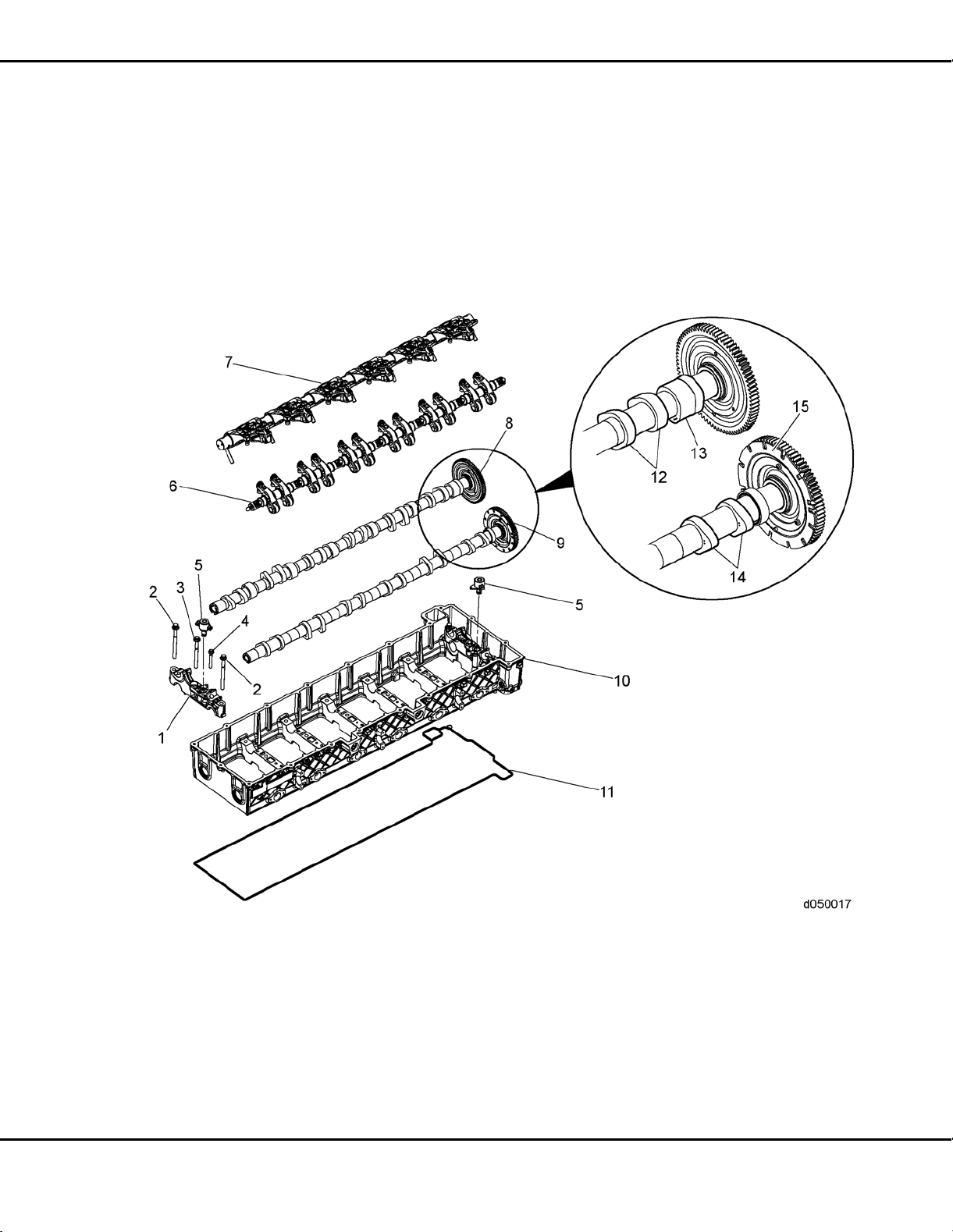

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND ROCKER

SHAFT/ENGINE BRAKE ASSEMBLY AND RELATED PARTS

The engine uses a dual overhead camshaft and rocker shaft design. The intake and ex

haust

camshafts are timed to each other, through a geartrain, to the crankshaft. The camshaft housing

houses the camshafts and valve train. It has internal oil passages to supply oil from the block to the

camshaft and rocker bearings along with pressurized oil to the engi

ne brake rockers via the engine

brake solenoids through the exhaust shaft. T he camshaft housing is made of aluminium material.

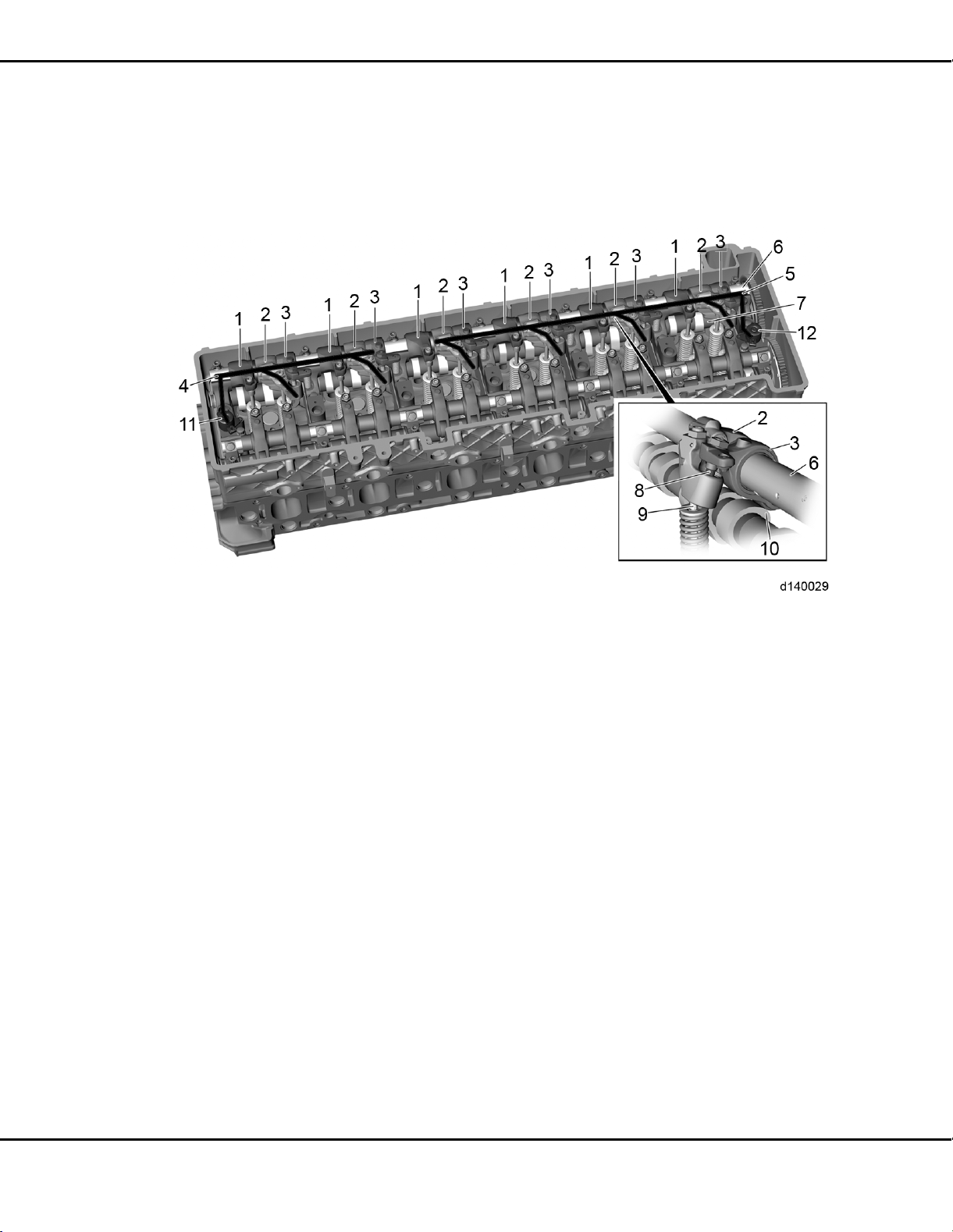

1. Camshaft Bearing Cap 6. Intake Rocker Arm

2. Bolt 120 mm 7. Exhaust Rocker Arm

3. Bolt 108 mm 8. Exhaust Camshaft and Gear

4. Bolt 63 mm 9. Intake Camshaft and Gear

5. Engine Brake Solenoid

10. Camshaft Housing 15. Intake Camshaft Tone Wheel

11. Gasket

12. Exhaust Camshaft Lobes

13. Exhaust Camshaft Brake Cam

Lobe

14. Intake Camshaft Lobes

Figure 2-1 Camshaft Housing and Related Parts

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-3

Page 22

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

AND RELATED PARTS

2.1.1 Engine Braking

The engine uses an integral engine brake. Engine braking is controlled electronica

llybythe

engine control system with an electric solenoid. When activated, the solenoid allows oil pressure

to activate a piston on the exhaust rocker arm. Engine braking is accomplished with a single

exhaust valve in each cylinder. The exhaust camshaft uses a separate

engine brake-only lobe that

allows for double valve activation for high efficiency braking. The exhaust valve is first operated

toward the completion of the intake stroke, closed during the compression stroke and opened a

second time when the compression stroke is completed. The engine

brake system is enabled using

the following components:

For EPA07 engines:

□ Engine brake solenoid valve in front of engine applies l

ow engine braking.

□ Engine brake solenoid valve in rear of engine applies medium engine braking.

□ For high, both front and rear solenoids are activated.

□ Six exhaust rocker arms with actuator pistons.

□ Six brake rocker arms which are actuated by the brake cam lobes.

□ Exhaust camshaft has one brake cam lobe per cylinder.

2-4 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 23

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

For EPA07 engines, the exhaust rocker arm shaft lubricating oil passages direct pressurized oil to

the rocker arms. The exhaust rocker arm has two additional oil passages to operate t

he engine

brakes. Oil for cylinders 1 and 2 is supplied by the Front Engine Brake Solenoid Valve. Oil for

cylinders3to6aresuppliedbytheRear Engine Brake Solenoid Valve.

1. Exhaust Rocker Arm 7. Exhaust Camshaft

2. Exhaust Rocker Arm with Actuator Piston 8. Actuator Piston

3. Brake Rocker Arm 9. Exhaust Valve

4. Oil Passage for Cylinders 1 and 2

5. Oil Passage for Cylinders 3, 4, 5 and 6

6. Exhaust Rocker Arm Sh aft

10. Brake Cam Lobe

11. Engine Brake Solenoid Valve, Front

12. Engine Brake Solenoid Valve, Rear

Figure 2-2 EPA07 Engine Brake

For EPA10 engines:

□ Engine brake solenoid valve in front of engine applies low engine braking.

□ For medium engine braking, both front and rear solenoids are activated.

□ For high, both front and rear solenoids are activated, along with EGR.

□ Six exhaust rocker arms with actuator pistons.

□ Six brake rocker arms which are actuated by the brake cam lobes.

□ Exhaust camshaft has one brake cam lobe per cylinder.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-5

Page 24

2.1 DESCRIPTION AND OPERATION OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

AND RELATED PARTS

For EPA10 engines, the exhaust rocker arm shaft lubricating oil passages direct pressurized oil to

the rocker arms. The exhaust rocker arm has two additional oil passages to operate t

he engine

brakes. Oil for cylinders 1 through 3 is supplied by the Front Engine Brake Solenoid Valve. Oil

for cylinders 4 through 6 are supplied by the Rear Engine Brake Solenoid Valve.

1. Exhaust Rocker Arm 7. Exhaust Camshaft

2. Exhaust Rocker Arm with Actuator Piston 8. Actuator Piston

3. Brake Rocker Arm 9. Exhaust Valve

4. Oil Passage for Cylinders 1, 2 and 3

5. Oil Passage for Cylinders 4, 5 and 6

6. Exhaust Rocker Arm Shaft

10. Brake Cam Lobe

11. Engine Brake Solenoid Val

12. Engine Brake Solenoid Valve, Rear

Figure 2-3 EPA 10 Engine Brake

ve, Front

2-6 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 25

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE

ASSEMBLY

Remove as follows:

1. Turn engine OFF, (key OFF, engine OFF).

2. Steam clean the engine.

3. Disconnect the battery power to the engine. Refer to OEM procedure

s.

4. Remove the air cleaner and the turbocharger inlet pipe and hose. Refer to OEM procedures.

5. Remove air cleaner housing. Refer to OEM procedures.

6. Remove the rocker cover. Refer to section 1.2.

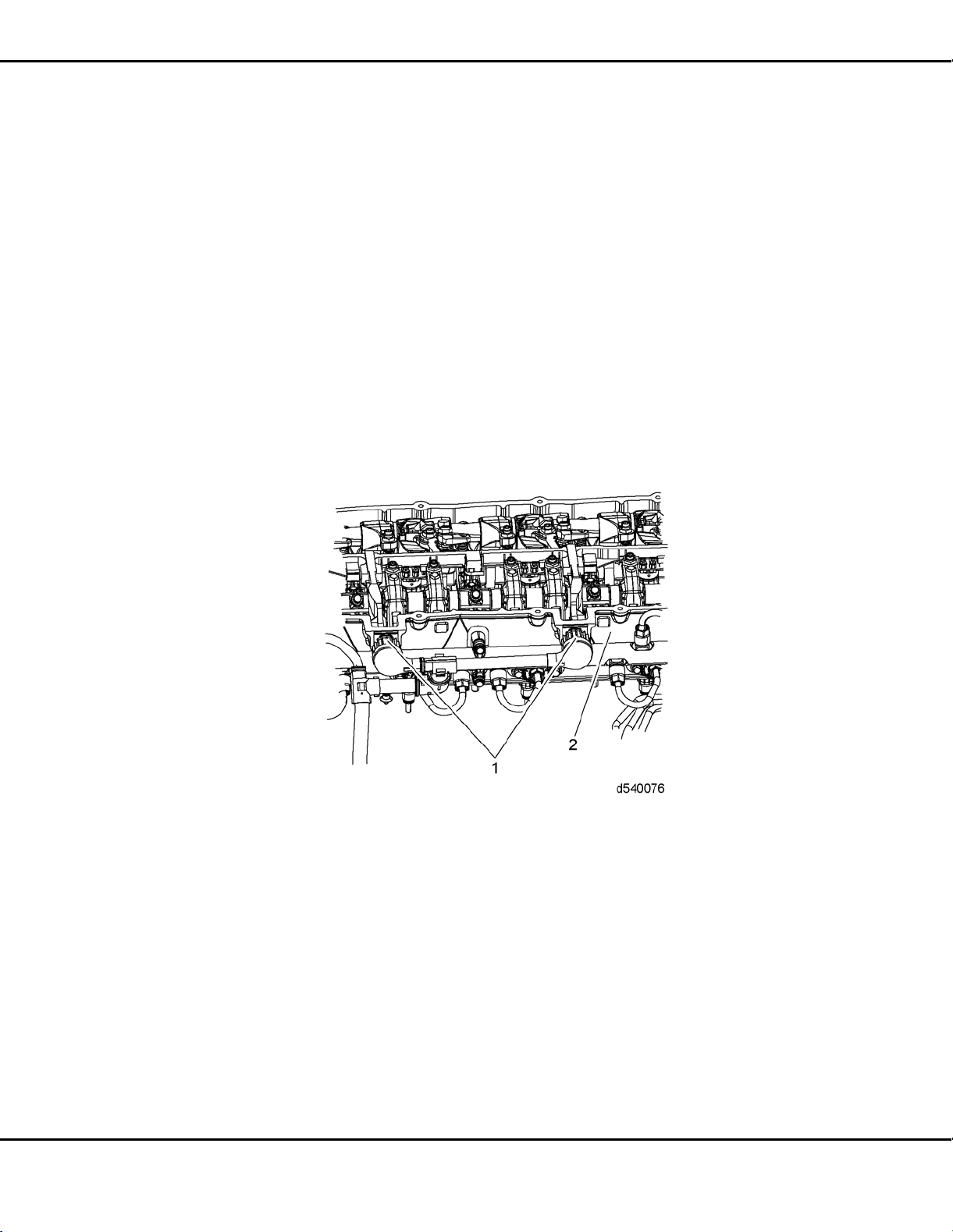

7. Remove the two 14-pin fuel injector harness connectors (1) from the camshaft housing

housing (2).

NOTE:

Top Dead Center (TDC) can be confirmed by installing camshaft timing tool. For

the DD13 use Camshaft Timing Tool (W470589034000). For the EPA07 DD15 use

Camshaft Timing Tool

(W470589054000). For the EPA10 DD15 use Camshaft Timing

Tool (W470589104000).

8. Using Engine Barring tool (J-46392), rotate the crankshaft to TDC on cylinder No. 1.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-7

Page 26

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

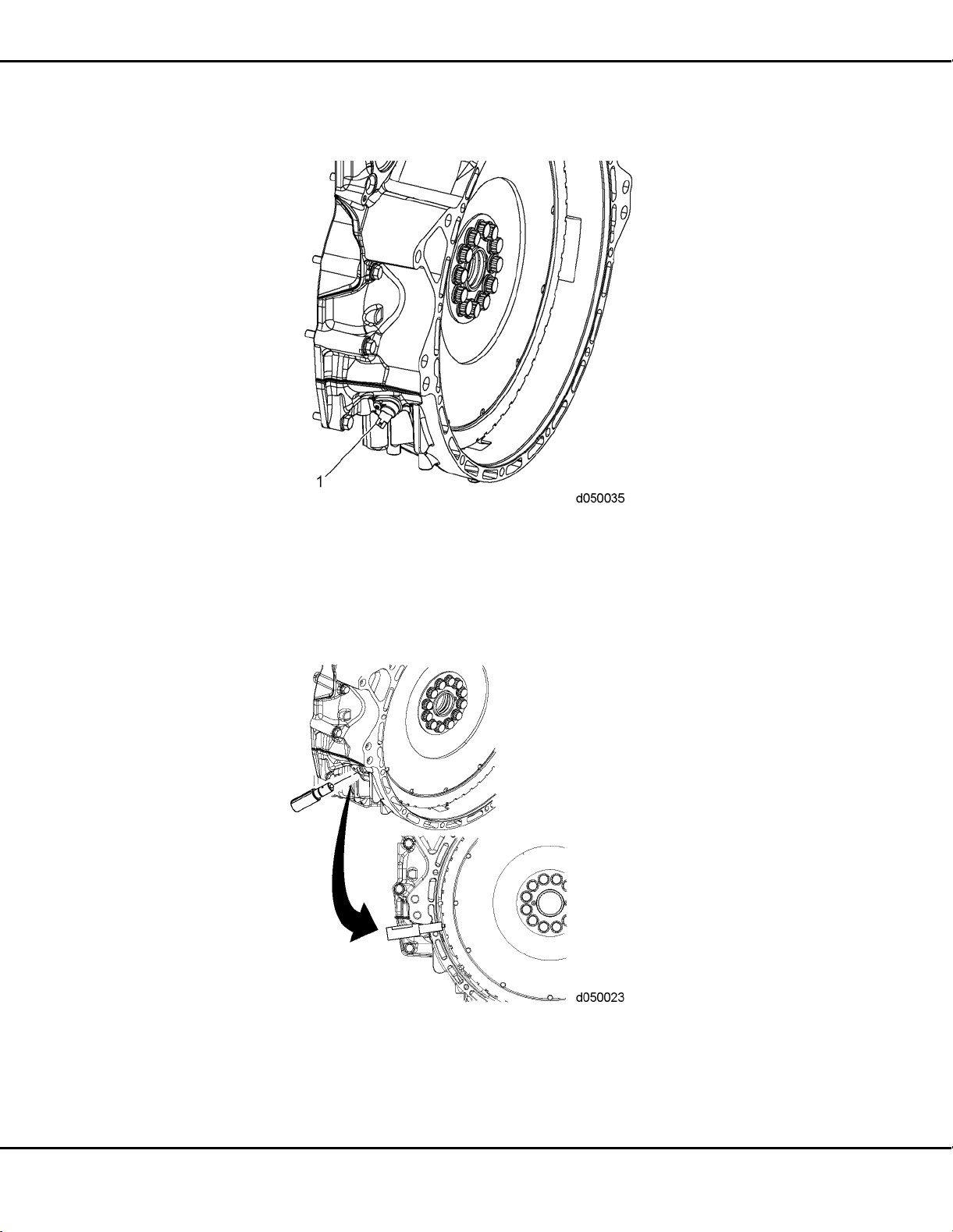

9. Remove the Crankshaft Position Sensor (CKP) (1) from t he rear of the flywheel housing.

Refertosection.

10. To accurately locate TDC, install the flywheel housing crankshaft TDC Locating Pin

(W470589001500) into the CKP sensor hole located in the rear of the flywheel housing.

The plastic tip will protrude int

o the cutout in the tone wheel. TDC can be verified by the

proper installation of the camshaft timing tool.

2-8 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 27

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

11. When the TDC dot (3) between two teeth on the flywheel aligns with the edge of pointer

(2), the engine is at TDC firing stroke.

12. For EPA07 DD13:

[a] Disconnect both 14-pin injector harness connectors (8).

[b] Disconnect the 24 electrical te

rminals at the fuel injectors (7).

[c] Disconnect two wiring terminals at each engine brake solenoid (6).

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-9

Page 28

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

[d] Loosen the Allen screws holding the intermediate frame (5) to the camshaft housing

(1). Remove the intermediate frame .

13. For EPA10 engines:

[a] Remove the fuel injector electrical harness clips (2) from the 14-pin electrical

connectors.

2-10 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 29

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

[b] Remove the bolts securing the two-piece fuel injector electrical harness (1 and 3) and

remove the harness from the camshaft housing housing.

14. Remove the engine brake solenoids from the camshaft housing.

NOTICE:

Ensure when loosening the rocker shaft bolts that the bolts are

loosened fro m the inside bolts outward in 1/2 turn increments.

The increment procedure need

stobefollowedtopreventthe

rocker shaft from breaking.

15. Completely loosen all

of the adjusting screws on all of the rocker arms.

16. Loosen the seven bolts securing the intake rocker shaft to the camshaft bearing caps.

NOTICE:

Make sure that the camshaft housing housing is not damaged

during removal of the intake/exhaust rocker shaft assemblies.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-11

Page 30

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

17. Using Rocker Arm Lifter / Spacer tool (W470589044000) for the DD13, or Rocker Arm

Lifter / Spacer Intake tool (W470589004000) for the DD15, remove the intake rocker

shaft assembly.

NOTICE:

Ensure when loosening the rocker shaft bolts that the bolts are

loosened from the inside bolts outward in 1/2 turn increments.

The increment procedure needs to be followed to prevent the

rocker shaft from breaking.

18. Loosen the seven bolts securing the exhaust rocker

shaft to the camshaft caps.

19. Using Rocker Arm Lifter / Spacer Exhaust (W470589074000) for the DD13 or Rocker

Arm Lifter / Spacer Exhaust (W470589004000) for the DD15, remove the exhaust rocker

shaft assembly. When removing the EPA10 exhau

st rocker shaft, ensure the rockers are

in the up position.

NOTE:

The engine brake s

olenoids do not have to be removed unless damaged.

NOTE:

Mark cap position for proper reassembly.

2-12 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 31

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

20. Remove the remaining bolts (1) from t he camshaft bearing caps (2).

21. Using tool Cam Bearing Cap Puller (J-488

83) and Injector Unit Pump Puller (J-46375),

remove the camshaft bearing caps (1) from the camshaft housing.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-13

Page 32

2.2 REMOVAL OF CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

22. Remove the intake and exhaust camshaft assemblies (1 & 2) from the camshaft housing

(3). Use care not to damage intake cam tone wheel when handling.

2-14 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 33

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

2.3 INSPECTION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE

BRAKE ASSEMBLY

Inspect the camshaft and rocker shaft assemblies as follows:

1. Inspect the camshafts for lobe damage; replace if necessary.

2. Inspect the camshaft gears for damage; replace if necessary.

3. Inspect the rocker shaft for scoring or scuffing; replace if necess

ary.

4. Inspect rocker arms for roller and bushing damage; replace if necessary.

5. Inspect adjusting screws and buttons; replace if necessary.

6. Inspect cam caps and cam journals in camshaft housing

for damage; replace if necessary.

7. Inspect the tone wheel on the intake camshaft for cracks, bending or any damage. If

damage is found, replace the intake camshaft.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-15

Page 34

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE

BRAKE ASSEMBLY

Install as follows:

1. Verify that the crankshaft is at top dead center (TDC) on cylinder number one using

TDC Locating Pin (W470589001500) installed in crankshaft position sensor (CKP) hole

located in the flywheel housing.

2. Install Camshaft Timing Tool (W470589054000) (1) for EPA07 DD15, (W470589104000)

for EPA10 DD15, and (W470589034000) for EPA10 DD13 to the rear of the camshaft

housing. Tighten the two bo

lts.

2-16 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 35

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

3. Locate the etched triangle on the camshaft gear teeth and mark the teeth with a paint pen.

4. Lubricate the lower camshaft bearing surfaces and camshaft journals before inst

camshafts. Install the exhaust and intake camshaft gear assemblies into the camshaft

housing.

5. Align the marked gear teeth with the marks on the timing tool.

alling the

6. Install Camshaft Timing Tool (W470589054000) (1) for EPA07 DD15, (W470589104000)

for EPA10 DD15, and (W470589034000) for EPA10 DD13 to the front of the camshaft

housing and into the groove

s cut into the camshafts. Secure timing tool to the camshaft

with a bolt.

[a] At this point the front timing tool should slide into the camshaft grooves easily with

no drag.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-17

Page 36

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

[b] If there is excessive drag when installing the tool, the camshafts are out of time. If so,

repeat this procedure at Step 3.

7. Verify that the marks on the gear teeth match the marks on the timing tool.

NOTICE

The camshaft caps are numbered and need to be installed

correctly.

8. Install the seven camshaft caps onto intake and exhaust camshafts.

9. The first and seventh camshaft caps hold the engine brake solenoid to camshaft cap.

Replace the O-rings o

n the solenoid prior to reinstallation. Install the engine brake

solenoid.

NOTE:

There are 30 bolts r

etaining the DD13 camshaft assemblies (shown); 14 120 mm (M10)

bolts, seven 108 mm (M10) bolts and nine 63 mm (M8) bolts. The DD15 uses 28 bolts,

with two external bolts at the rear of the camshaft housing.

2-18 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 37

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

10. Install the 30 bolts to camshaft caps; finger tighten the bolts. Refer to figure for proper

bolt placement.

11. Using the torque sequence shown below torque the M10 camshaft cap bolts to the

following:

□ 20 N·m (15 lb·ft)

□ Then torque to 50-55 N·m (37-40 lb·ft).

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-19

Page 38

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

12. Using the torque sequence shown below, torque the nine 63 mm M8 bolts to 30 N·m

(22 lb·ft).

13. Remove TDC Locating Pin (W470589001500) from CKP sensor hole in the flywheel

housing.

14. Install crankshaft position se

nsor. Refer to section .

15. Install a dial indicator onto gear case and zero out the dial indicator.

16. Position the stem of dial indicator to rest between the teeth on the camshaft gear.

17. Hold the number five idler

gear with a screwdriver. Check the lash between the camshaft

gear and idler gear number five.

2-20 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 39

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

18. The dial indicator should read 0.051 - 0.257 mm (0.002 - 0.010 in). If the gear lash is

excessive between either camshaft gear and the number five idler gear, inspect the n

umber

five idler gear spindle, camshaft gear and camshaft housing. Repair as necessary.

NOTICE:

The camshaft journal area is lubrica ted by oil that has to travel

throughthe rockershaft. Iftherocker shaftis installed incorrectly,

oil passages do not lineup. This results in insufficient lubrica

tion

and damage to the camshaft journals. Incorrect shaft installation

may also result in the engine brakes not functioning and cause

damage to the rocker arm bushings.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-21

Page 40

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

NOTICE:

The markings on the front of the rockers shafts must face the

front of the engine for proper rocker arm lubrication and engine

brake operation.

NOTICE:

Ensure when tightening the rocker shaft bolts t hat the bolts are

drawn down from the inside bolts outward in 1/2 turn increments,

before final torque. If the rocker shaft bolt isfully torqued without

using the increment procedure the rocker shaft can br

eak.

NOTE:

On EPA10 engines the intake and exhaust rocker shaf

ts are marked "TOP FRONT" and

“TOP REAR.” Top front must face towards the front of the engine.

19. Remove timing tools.

2-22 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 41

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

20. Using Rocker Arm Lifter / Spacer Intake (W470589044000) (1) for the DD13 or Rocker

Arm Lifter / Spacer Intake (W470589004000) for the DD15, install the intake rocker

shaft

assembly to the camshaft cap and secure with seven clamping blocks and bolts.

21. Using the torque sequence shown below, torque the bolts to 50-55 N·m (36-41 lb·ft) +90°.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-23

Page 42

2.4 INSTALLATION OF THE CAMSHAFT AND ROCKER SHAFT/ENGINE BRAKE ASSEMBLY

22. Using Rocker Arm Lifter / Spacer (W4705589074000) for the DD13 or Rocker Arm Lifter

/ Spacer Intake (W470589004000) for the DD15, install the exhaust rocker shaft ass

embly

to the camshaft cap and secure with seven clamping blocks and bolts.

23. Using the torque sequence shown below, torque the bolts to 50-55 N·m (36-41 lb·ft) +90°.

24. Remove timing tools.

25. Install the fuel injectors, if removed. Refer to section .

26. Lash the valves and engine brakes. Refer to section 14.15.

27. Install the fuel injector wiring harness. Refer to section .

28. Install the rocker cover. Refer to section 1.4.

29. Reconnect the battery power to the engine. Refer to OEM procedures.

2-24 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 43

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

30. Install air cleaner housing. Refer to OEM procedures.

31. Install the turbocharger inlet pipe and hose, and air cleaner. Refer to OEM proced

32. Prime lubrication system. Refer to section 27.1.

ures.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-25

Page 44

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER

ENGINE BRAKE SOLENOID FAILURE

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS

FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE

Inspect as follows:

1. Clamp

2. Hose

3. Coolant C rossover Pipe

4. Bolt

5. Support

6. Coolant Connecting Tube

7. Exhaust Gas Connecting Tube

8. Gasket

9. Seal Ring

10. Banjo Union 19. Exhaust Gas Crossover Tube

11. Banjo Bolt 20. Gasket

12. Bolt 21. Bolt

13. Bolt 22. Venturi

14. Outlet Nipple 23. Mixer Pipe

15. Seal 24. Seal Ring

16. Exhaust Gas Recirculation

Cooler Water Manifold Assembly

17. Clamps 26. Lifting Bracket Mounting Bolt

18. H ot Pipe 27. Front Lifting Bracket

25. Bolt

Figure 2-4 EPA10 DD13 EGR Cooler Water Manifold and Related Parts

2-26 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 45

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

1. Clamp

10. Banjo Union 19. Exhaust Gas Crossover Tube /

Lifting Eye

2. Hose

3. Coolant Crossover Pipe

4. Bolt

5. Support

6. Coolant Connecting Tube

7. Exhaust Gas Connecting Tube

11. Banjo Bolt 20. Gasket

12. Bolt 21. Bolt

13. Bolt 22. Venturi

14. Outlet Nipple 23. Mixer Pipe

15. Seal 24. Seal Ring

16. Exhaust Gas Recirculation

25. Bolt

Cooler Water Manifold Assembly

8. Gasket

9. Seal Ring

17. Clamps 26. Bolt

18. Hot Pipe

Figure 2-5 EPA10 DD13 EGR Cooler Water Manifold and Related Parts

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-27

Page 46

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER

ENGINE BRAKE SOLENOID FAILURE

Check as follows:

NOTICE:

This procedure must be followed after replacing an engine

brake solenoid due to any failure that could cause high DOC

temperature codes, excessive fuel, oil, or coolant to enter the

exhaust system. Failure to perform this procedure could cause

severe engine damage.

1. Remove the marmon clamps (2) and EGR hot pipe (3) and inspect for any signs of liquid

or moisture. The EGR hot pipe (exhaust pipe) and EGR

cooler inlet (1) should have

a black dry soot residue inside.

[a] If liquid or moisture is present in the pipe, go to the next step.

[b] If there is no sign of liquid or moisture in the p

hot pipe. No further action is required.

ipe or EGR cooler (1), install the

2-28 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 47

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

2. Remove the mixer pipe (1) from the cold boost pipe (2).

3. Remove the exhaust gas crossover tube /

lifting eye (2) and venturi (6).

4. Place a towel over the outlet of the EGR cooler and retain it with a zip tie.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-29

Page 48

2.5 DD13 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER

ENGINE BRAKE SOLENOID FAILURE

To avoid injury from flying debris when using compressed

air, wear adequate eye protection (face shield or safety

goggles) and do not exceed 40 psi (276 kPa) air pressure.

5. Using a rubber tipped blow gun, blow compressed shop air into th

e individual tubes in

the EGR cooler to clear any excess fuel, soot, and carbon.

6. After performing the cleaning procedure, refer to section to install the:

[a] mixer pipe.

[b] exhaust gas crossover tube/lifting eye (EPA07 engines) and exhaust gas crossover

tube (EPA10 engines).

[c] venturi.

7. If the cooler has an excessive amount of buildup that cannot be removed, replace the

EGR cooler. R efer to section .

2-30 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 49

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS

FUEL FROM COOLER AFTER ENGINE BRAKE SOLENOID FAILURE

Inspect as follows:

1. Venturi 9. Connecting Tube

2. Bolt

3. Gasket

4. Bolt

5. Exhaust Gas Crossover Tube

6. Bolt

7. Lifting Bracket

8. Connecting Tube

10.Seal Ring 18. Hot Pipe

11. Banjo Union 19. Water Manifold

12. Banjo Bolt 20. Support

13. Exhaust Gas Cooler 21. Clamp

14. Strap 22. Hose

15. Shim 23. Mixer Pipe

16. Clamp 24. Coolant Del

17. Metal Seal

ivery Pipe

25. Seal Ring

Figure 2-6 EPA10 DD15 EGR Cooler and Related Parts

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-31

Page 50

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER

ENGINE BRAKE SOLENOID FAILURE

1. Venturi 9. Banjo Union

2. Bolt

3. Gasket

4. Bolt

5. Exhaust Gas CrossoverTube/Lifting

Eye

6. Connecting Tube

7. Connecting Tube

8. Seal Ring

10. Banjo Bolt 18. Support

11. Exhaust Gas Cooler 19. Clamp

12. Strap 20. Hose

13. Shim 21. Mixer Pipe

14. Clamp 22. Coolant Delivery Pipe

15. Metal Seal 23. Seal Ring

16. Hot Pipe

17. Water Manifold

Figure 2-7 EPA07 DD15 EGR Cooler and Re lated Parts

2-32 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 51

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

Check as follows:

NOTICE:

This procedure must be followed after replacing an engine

brake solenoid due to any failure that could cause high DOC

temperature codes, excessive fuel, oil, or coolant to enter the

exhaust system. Failure to perform this procedure could cause

severe engine damage.

1. Remove the clamps (2), exhaust pipe (4) and gaskets (3) from the EGR cooler (1) and

inspect and inspect for any signs of liquid or moist

ure. The EGR hot pipe and EGR cooler

inlet should have a black dry soot residue inside.

[a] If liquid or moisture is present in the pipe, go to the next step.

[b] If there is no sign of liquid or moisture in the p

No further action is required. Refer to section .

ipe, install the EGR cooler hot pipe.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 2-33

Page 52

2.6 DD15 EGR COOLER CLEANING PROCEDURE TO REMOVE EXCESS FUEL FROM COOLER AFTER

ENGINE BRAKE SOLENOID FAILURE

2. Remove the mixer pipe (4) from the cold boost pipe (1). Refer to section .

3. Remove the exhaust gas crossover tube/

lifting eye (2) and venturi (3).

4. Place a towel over the outlet of the EGR cooler and retain it with a zip tie.

To avoid injury from flying debr

is when using compressed

air, wear adequate eye protection (face shield or safety

goggles) and do not exceed 40 psi (276 kPa) air pressure.

5. Using a rubber tipped blow gun blow compressed shop air into the individual tubes in

the EGR cooler to clear any excess fuel, soot, and carbon.

6. After performing t

he cleaning procedure, refer to section to install the:

[a] mixer pipe.

[b] exhaust gas crossover tube/lifting eye (EPA07 engines) and exhaust gas crossover

tube (EPA10 eng

ines).

[c] venturi.

7. If the cooler has an excessive amount of buildup that cannot be removed, replace the

EGR cooler

. Refer to section .

2-34 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 53

3 CAMSHAFT HOUSING

Section Page

3.1 REMOVAL OF THE CAMSHAFT HOUSING ........................................... 3-3

3.2 INSPECTION OF CAMSHAFT HOUSING ............................................... 3-8

3.3 INSTALLATION OF THE CAMSHAFT HOUSING ................................... 3-9

Page 54

3-2 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 55

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

3.1 REMOVAL OF THE CAMSHAFT HOUSING

The camshaft housing houses the camshafts and valve train. It has internal oil passa

ges to supply

oil from the block to the camshaft and rocker bearings along with pressurized oil to the engine

brake rockers via the engine brake solenoids through the exhaust shaft. The camshaft housing is

made of aluminium material.

Remove as follows:

1. Steam clean the engine.

2. Remove the rocker cover. Refer to section 1.2.

3. Disconnect the fuel injector harness (1) from the camshaft housing (2).

4. Remove the following high pressure fuel line components:

PERSONAL INJURY

To prevent the escape of high pressure fuel t hat can

penetrate skin, ensure the engine has been shut down for

a minimum of 10 minu

tes before servicing any component

within the high pressure circuit. Residual high fuel

pressure may be present within the circuit.

[a] High pressure fuel line bracket (1) and high pressure fuel lines from the fuel rail to

the h igh pressure fuel pump (2). Refer to section .

[b] High pressu

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 3-3

re fuel lines from the fuel rail to the fuel injectors (3). Refer to section .

Page 56

3.1 REMOVAL OF THE CAMSHAFT HOUSING

[c] Pressure Limiting Valve (PLV) return line from the fuel rail to the fuel filter module

(4). Refer to section .

5. Remove the rocker shaft/engine brake and camshaft assemblies. Refer to section 2.2.

6. Disconnect the intake manifold temperature sensor (2).

3-4 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 57

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

7. Disconnect the fuel rail pressure sensor (1).

8. Disconnect the camshaft position sens

or (1) from the camshaft housing (2).

9. Unclip all of the electrical wiring harness attaching points from the camshaft housing.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 3-5

Page 58

3.1 REMOVAL OF THE CAMSHAFT HOUSING

10. Remove the bolt (2) securing the doser coolant line (1) and the P-clip to the camshaft

housing (3).

11. Remove the remaining two bolts (29 and 30) securing the camshaft housing t o the cylinder

head.

12. Attach a lift

ing device to the camshaft housing and lift the camshaft housing off of the

cylinder head.

3-6 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 59

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

PERSONAL INJURY

To avoid injury when removing or installing a heavy engine

component, ensure the component is properly supported

and securely attached to an adequate lifting device to

prevent the component from falling.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 3-7

Page 60

3.2 INSPECTION OF CAMSHAFT HOUSING

3.2 INSPECTION OF CAMSHAFT HOUSING

Inspect the camshaft housing as follows:

1. Inspect the camshaft journals for scoring or scratches, replace if damaged.

2. Inspect the camshaft caps for cracks, replace if damaged.

3. Inspect the camshaft housing for cracks and damage to the bolt hole t

hreads in the

housing, replace if damaged.

4. Inspect the camshaft housing sealing surfaces for damage. Inspect the following sealing

surfaces for damage:

[a] The camshaft housing to rocker cover.

[b] The camshaft housing to cylinder head.

[c] The O-ring seal on the injector harness.

[d] The O-ring seal on the engine brake solenoids.

5. Inspect the rocker shaft installation surface located inside the camshaft housing for

scoring or scratches.

3-8 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 61

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

3.3 INSTALLATION OF THE CAMSHAFT HOUSING

Install as follow s:

1. Install a new seal into the camshaft housing.

2. Using an appropriate lifting device install camshaft housing onto the cylinder head.

PERSONAL INJURY

To avoid injury when removing or installing a heavy engine

component, ensure the component is properly supported

and securely attached to an adequate lifting device to

prevent the component from falling.

3. Ensuring that no oil gets into the bearing cap

dowel pin hole, lubricate the camshaft

housing camshaft journals.

4. Install the camshaft assemblies into the camshaft housing. Refer to section 2.4.

5. Install the following high pressure fuel

line components:

[a] High pressure fuel line bracket (1), and high pressure fuel lines from fuel rail to high

pressure fuel pump (2); refer to section .

[b] High pressure fuel lines from fue

l rail to fuel injectors (3); refer to section .

[c] Fuel line from fuel rail to fuel filter module (4); refer to section .

6. Install the rocker cover. Refer to section 1.4.

7. Prime th

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 3-9

e fuel system. Refer to section .

Page 62

3.3 INSTALLATION OF THE CAMSHAFT HOUSING

3-10 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION

All information subject to change without notice.

Page 63

4 CAMSHAFT TIMING

Section Page

4.1 CAMSHAFT TIMING VERIFICATION ...................................................... 4-3

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN IN

STALLED ........

4-6

Page 64

4-2 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 65

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

4.1 CAMSHAFT TIMING VERIFICATION

Verify the camshaft timing as follows:

1. Remove the rocker cover. Refer to section 1.2.

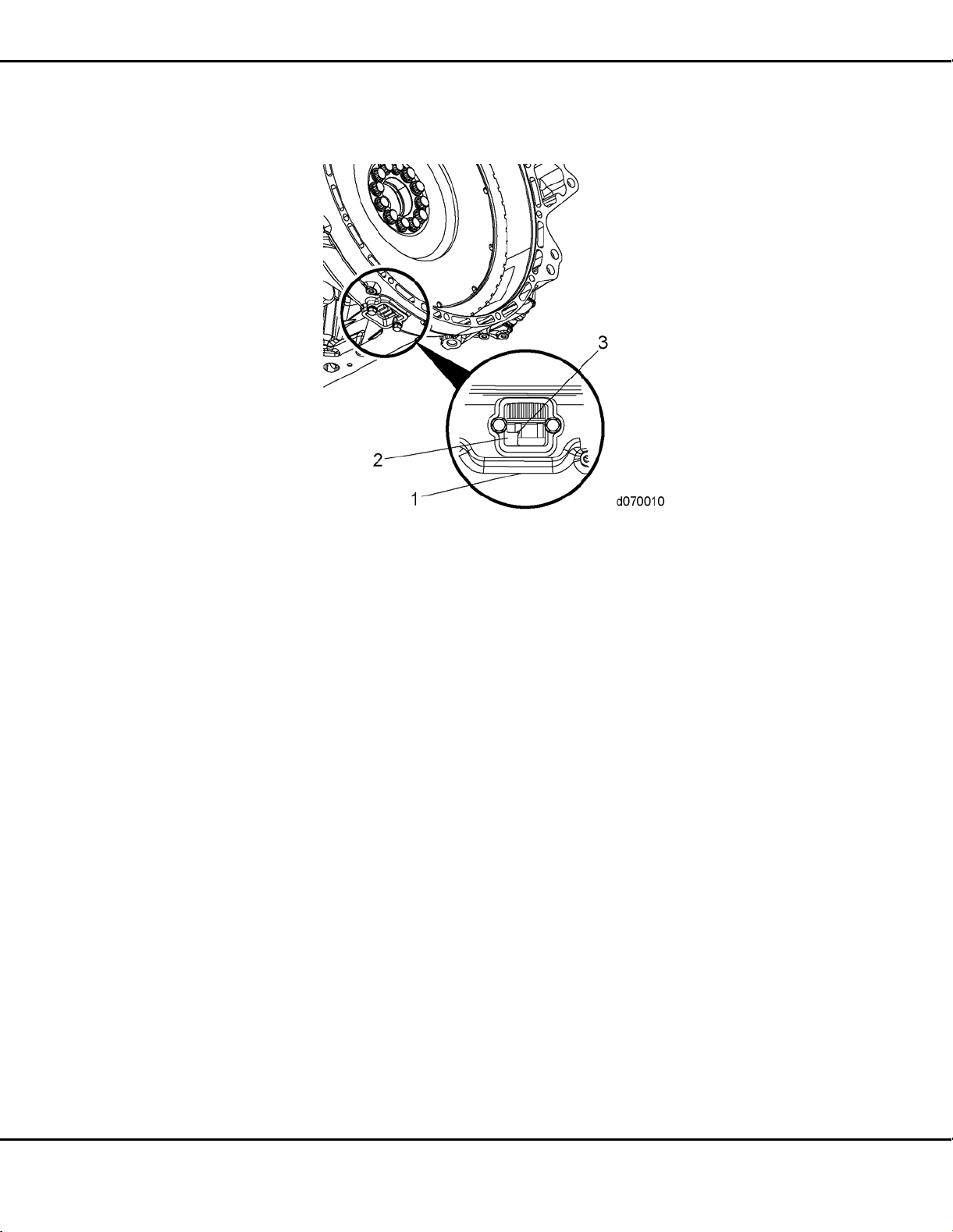

2. Bar the engine to top dead center (TDC) with Engine Barring Tool (J-46392) (3) on

cylinder No.1 with the No. 6 valve in overlap. The dot (2) that is loca

flywheel tone ring is aligned with the edge of the pointer (1).

ted inside the

3. Locate the mark on the camshaft and mark the top of the corresponding gear tooth with a

light colored paint pen.

4. Remove the Crankshaft Position Sensor (CKP) from the flywheel housing. Refer to section

.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 4-3

Page 66

4.1 CAMSHAFT TIMING VERIFICATION

5. Install the flywheel TDC Locating Pin (W470589001500), through the crankshaft position

sensor hole in the flywheel housing and engage into the flywheel notch.

6. Install the rear Camshaft Timing Tool (W470589054000) for EPA07 DD15,

(W470589104000) for EPA10 DD15, and (W470589034000) for DD13 (1) onto the

camshaft housing.

4-4 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 67

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

7. Install the rear Camshaft Timing Tool (W470589054000) for EPA07 DD15,

(W470589104000) for EPA10 DD15, and (W470589034000) for DD13 (1) into the

grooves cut into the cams and pin it into the camshaft housing with a bolt.

8. Verify that the marks on the gear teeth match the m arks on the timing tool. If the marks do

not match, research the root caus

e of incorrect camshaft timing.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 4-5

Page 68

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN INSTALLED

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN INSTALLED

Time as follows:

1. Bar the crankshaft over to TDC cylinder No. 1 and lock with W470589001500 through

the crankshaft position sensor hole.

2. Install the rear Camshaft Timing Tool (W470589054000) for EPA07 DD

15,

(W470589104000) for EPA10 DD15, and (W470589034000) for DD13 (1) onto the rear

of the camshaft housing.

3. Locate the mark on the camsh

afts and mark the top of the corresponding gear tooth with

a light colored paint pin.

4. Lubricate the camshafts and camshaft housing journals with clean engine oil.

NOTE:

The intake camshaft has the tone wheel and must be installed on the intake side of

the engine.

5. Install the camshaft

s into the camshaft housing in their respective locations lining up the

marked cam gear teeth with the mark on the timing plate.

6. Install the rear Camshaft Timing Tool (W470589054000) for EPA07 DD15,

(W470589104000)

for EPA10 DD15, and (W470589034000) for DD13 (1) into the

grooves cut into the camshafts to verify correct cam timing. Any resistance felt while

4-6 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 69

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

installing or removing could indicate the camshafts being out of time. Install a bolt into

the tool to hold it into place.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 4-7

Page 70

4.2 TIMING THE CAMSHAFTS WITH THE GEAR TRAIN INSTALLED

4-8 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 71

5 GEAR TRAIN AND ENGINE TIMING

Section Page

5.1 DESCRIPTION AND OPERATION OF GEAR TRAIN AND RELA

PARTS ...................................................................................................... 5-3

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING ............................ 5-8

5.3 CHECKING AND ADJUSTING GEAR LASH WITH C

HOUSING REMOVED ............................................................................. 5-16

AMSHAFT

TED

Page 72

5-2 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 73

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

5.1 DESCRIPTION AND OPERATION OF GEAR TRAIN AND RELATED

PART S

The gear train is located at the rear of the engine. The gear train consists of intak

e and exhaust

camshaft gears, idler gears No. 1, 2, 3, 4, and 5, crankshaft gear, oil pump gear, fuel pump gear,

air compressor gear, and Axial Power Turbine (APT) gear.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 5-3

Page 74

5.1 DESCRIPTION AND OPERATION OF GEAR TRAIN AND RELATED PARTS

1. Idler Gear No. 1 9. Crankshaft Gear

2. Idler Gear No. 2

3. Idler Gear No. 3

4. Idler Gear No. 4

5. Idler Gear No. 5

6. Air Compressor Gear

7. Fuel Pump Gear

8. Axial Power Turbine Gear

10. Oil Pump Gear

11. Camshaft Gear Exha

12. Camshaft Gear Intake

A. Level A

B. Level B

C. Level C

x.ToFrontofEngine

ust

Figure 5-1 DD15 Engine Gear Train

5-4 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 75

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

The gear train on the DD Platform engines is located at the rear of the engine and has three levels.

Level A consists of the outermost gears (closest to the flywheel), Level B consists o

f the middle

gears, and Level C consists of the innermost gears (closest to the block). The gears in the gear

train are both directly and indirectly driven by the crankshaft gear.

□ Level A: The outermost gears include the crankshaft gear which drive

s the outer idler gear

number one and the oil pump gear. Idler gear number four is on the crankshaft gear and

the axial power turbine drives the idler gear number four when the Axial Power Turbine

(APT) is creating power. The APT can add additional torque to the cr

ankshaft through

idler gear number four up to 260 N·m (192 lb·ft). These gears are all helical cut.

NOTE:

On the DD13, there is no Axial Power Turbine (APT) and no Idl

er gear number four. The

position of the idler gear number four is covered by a plate, and sealed with an O-ring.

□ Level B: The middle gears include idler gear number one, which drives the air compressor

gear and the idler gear number two. Idler gear number two

drives the high pressure fuel

pump and idler gear number three. These gears are all straight cut.

□ Level C: The innermost gears include inner idler gear number three which drives idler gear

number five. Idler gear number five drives both int

ake and exhaust camshafts. These

gears are all straight cut.

Gear train noise is an indication of excessive gear lash, chipped or burred gear teeth. A rattling

noise usually indicates excessive gear la

sh. A whining noise indicates too little gear lash.

Therefore, when noise develops in a gear train, the gear train needs to be inspected.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 5-5

Page 76

5.1 DESCRIPTION AND OPERATION OF GEAR TRAIN AND RELATED PARTS

1. Idler Gear No. 1 9. Crankshaft Gear

2. Idler Gear No. 2

3. Idler Gear No. 3

4. Idler Gear No. 4

5. Idler Gear No. 5

6. Air Compressor Gear

7. Fuel Pump Gear

8. Axial Power Turbine Gear

10. Oil Pump Gear

11. Camshaft Gear Exha

12. Camshaft Gear Intake

A. Level A

B. Level B

C. Level C

x.ToFrontofEngine

ust

Figure 5-2 DD15 Engine Gear Train

5-6 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 77

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

Multiply Crankshaft Speed by Effective Ratio to Attain Individual Component Speed

Component Effective Ratio Speed

Crankshaft ________ RPM

Camshafts 0.50 ________ RPM

Idler #1 0.79 ________ RPM

Idler #2 0.86 ________ RPM

Idler #3 0.75 ________ RPM

Idler #4 1.33 ________ RPM

Idler #5 0.45 ________ RPM

Water Pump 2.22 ________ RPM

Air Compressor 1.41 ________ RPM

Fuel Pump 1.50 ________ RPM

Oil Pump 1.33 ________ RPM

APT Gearbox Drive 4.00 ________ RPM

APT Turbine Shaft 26.64 ________ RPM

Table 5-1 HDEP Geartrain Ratios

The power steering pump can be mounted in two places. If the engine is equipped with a

single-cylinder air compressor, it will be mounted to the front of the air compressor. If the engine

is equipped with a two cylinder air compressor, then the power steering pump will be mounted on

the back of the gear case to the fuel pump.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 5-7

Page 78

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING

Install and time the gear train as follows:

NOTE:

Coat the inside of the gears, bushings and gear train with clean oil before installation.

1. Install the crankshaft gear on the crankshaft.

2. Rotate the crankshaft to top dead center (TDC) on cylinder number one. Install and lock

Crankshaft TDC Locating Tool (J-48630) into place with bolt.

3. Install spindle into idler ge

ar number five.

4. Install idler gear number five onto the cylinder head using Shoulder Bolt (J-47486).

5. Install two bolts into idler gear number five and hand tighten. Remove (J-47486). Torque

to 60-65 N·m (44-48 lb·f

t).

6. Install the spindle into idler gear number three.

5-8 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPO RATION

All information subject to change without notice.

Page 79

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

7. Install Installation Cantilever tool (J-47487) onto idler gear number three.

8. Install two bolts into the spindle and idler gear No. 3; snug the bolts.

NOTE:

When idler gear No. 3 and timing tool J–47487 are installed to the gear case, timing tool

J–47487 should come off of the gear with ease. If the timing tool is not easily removed,

that is a indication that the gea rs are not timed.

9. Check the gear lash between idler gear No. 3 and idler gear No. 5.

10. Install a dial indicator onto gear case and position the stem to rest between the teeth on

large gear of idler gear No. 3; zero out the dial indicator.

11. Hold idler gear No. 5 with a screw driver to check gear lash.

12. The lash reading on the dial indicator should be 0.079 - 0.305 mm (0.003-0.012 in.).

13. When correct gear lash is established, torque idler gear No. 3 to 60–65 N·m (44-48 lb·ft).

14. Install the spindle and gear plate onto the idler gear number two.

15. Install the spindle, idler gear number two, and the gear plate onto the cylinder block.

Torque to 100 N·m (73 lb·ft).

16. Remove the air compressor to the cylinder block (if installed). Refer to section 41.2.

17. Install the thrust washers and spindle onto the idler gear number one.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 5-9

Page 80

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING

NOTE:

For ease of installation on idler gear number one, roll the gear into idler gear number two.

18. Install the spindle, thrust washers, idler gear number one, and gear plate onto the cylinder

block by engaging the teeth of idler gear number one into the crankshaft gear teeth first,

then roll upward into idler gear number two. Torque to 100 N·m (73 lb·ft).

19. Install the air c ompressor. Refer to section 41.4.

NOTE:

When installing idler gear number four, verify that the part number on the gear is facing

the block.

20. On the DD15, with the cone of the idler gear number four facing outward, install the t hrust

washer onto the spindle then install the spindle onto the idler gear number four.

21. On the DD15, install the assembled thrust washer, spindle and idler gear number four onto

the c ylinder block. Torque to 100 N·m (73 lb·ft).

NOTE:

Tool J-47487 should remove with ease. If not, check gears for proper installation.

22. Remove the idler gear number three tool (J-47487).

23. Check that the idler gear number one is flush with the rear side of the c rankshaft gear and

that the idler gear number four on the DD15 is fl ush with the front side of the crankshaft

gear.

24. Install the camshaft housing. Refer to section 3.3.

25. Lubricate the camshaft journals and install the camshafts into the camshaft housing.

26. Mark the camshafts TDC indicator triangle located on the inside of the camshaft gear with

a suitable m arker.

5-10 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETRO IT DIESEL COR PORATIO N

All information subject to change without notice.

Page 81

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

27. Install Camshaft Timing Tool (1) (W470589054000) for EPA07 DD15 - shown,

(W470589104000) for EPA10 DDl5, and (W470589034000) for DD13 into the holes at

the rear of the camshaft housing and secure to the camshaft housing with two bolts.

28. Install both of the intake and exhaust camshafts into the camshaft housing. Refer to section

2.4.

29. Rotate the camshafts until the mark on the inside of the gear aligns with the mark on

Camshaft Timing Tool (W470589054000) for EPA07 DD15, (W470589104000) for

EPA10 DDl5, and (W470589034000) for DD13.

All information subject to change without notice.

DDC-SVC-MAN-0081 2010 Copyright © 2010 DETROIT DIESEL CORPORATION 5-11

Page 82

5.2 ENGINE GEAR TRAIN INSTALLATION AND TIMING

30. Install Camshaft Timing Tool (1) (W470589054000) for EPA07 DD15 - shown,

(W470589104000) for EPA10 DDl5, and (W470589034000) for DD13 into the holes at the

slot in the front of the camshaft housing and secure to the camshaft housing with one bolt.

31. Ensure timing marks on the camshaft gears are at TDC and aligned to the marks on t he tool.

32. Install the seven camshaft caps onto intake and exhaust camshafts.

NOTE:

The first and seventh camshaft caps hold the engine brake solenoid to camshaft cap.

5-12 DDC-SVC-MAN-0081 2010 Copyright © 2010 DETRO IT DIESEL COR PORATIO N

All information subject to change without notice.

Page 83

EPA07/10 DD PLATFORM WORKSHOP MANUAL - ENGINE

33. Prior to engine brake solenoid installation, replace the O-rings on the engine brake

solenoids.

NOTE: