Page 1

Portable Model P-1000

H2S Process Analyzer

Operator’s Installation and Instruction Manual

The Woodlands, Texas 77387

Ph.281.367.4100 / Fax 281.298.2868

August 24, 2007 • Document #3343 • Revision 1.0

DETCON, Inc.

3200 Research Forest Dr.,

www.detcon.com

Page 2

P-1000

This page Intentionally left blank

Portable Model 1000 H2S Analyzer ii

Page 3

P-1000

Table of Contents

1.0

Introduction .............................................................................................................................................1

1.1 UniTox™ Model 200 Description........................................................................................................ 1

1.2 Principle of Operation .......................................................................................................................... 3

1.3 Specifications ....................................................................................................................................... 4

2.0 Installation and Start Up ........................................................................................................................5

2.1 HOBOware™ Installation and setup.................................................................................................... 5

2.2 Connecting a logger directly to a USB cable ....................................................................................... 6

2.3 Analyzer Initial Operational Tests........................................................................................................ 8

2.4 HOBOware™ Operational Test ........................................................................................................... 8

3.0 Analyzer Operating Software...............................................................................................................10

3.1 Normal Operation............................................................................................................................... 10

3.2 Calibration Mode................................................................................................................................ 10

3.3 Program Mode.................................................................................................................................... 10

3.4 Programming Magnet Operating Instructions .................................................................................... 11

3.5 Software Flow Chart .......................................................................................................................... 13

4.0 Calibration .............................................................................................................................................14

4.1 Calibration Procedure – Zero ............................................................................................................. 14

4.2 Calibration Procedure - Span ............................................................................................................. 14

4.3 Calibration Frequency ........................................................................................................................ 17

5.0 Status of Programming and ISM Parameters ....................................................................................17

5.1 View Program Status.......................................................................................................................... 17

5.2 Set Span Level.................................................................................................................................... 18

5.3 Set Date .............................................................................................................................................. 18

5.4 Program Features (UniTox DM-200 Sensor) ..................................................................................... 19

6.0 Exchanging ISM Modules ....................................................................................................................20

6.1 Physical Exchange.............................................................................................................................. 20

6.2 Establishing Communication.............................................................................................................. 20

7.0 Trouble Shooting Guide........................................................................................................................20

7.1 UniTox™ Error Messages.................................................................................................................. 20

7.2 Display Contrast Adjust ..................................................................................................................... 22

8.0 Spare Parts List .....................................................................................................................................22

9.0 Warranty................................................................................................................................................23

9.1 Service Policy..................................................................................................................................... 23

10.0 Diagrams ................................................................................................................................................23

10.1 Flow Diagram..................................................................................................................................... 23

10.2 Wiring Diagram.................................................................................................................................. 24

Table of Figures

Figure 1 Construction of Electrochemical Cell.................................................................................................... 1

Figure 2 Intelligent Sensor Module...................................................................................................................... 2

Figure 3 Overview................................................................................................................................................ 2

Figure 4 Gas Ports ................................................................................................................................................ 3

Portable Model 1000 H2S Analyzer iii

Page 4

P-1000

Figure 5 HOBO Opening Screen.......................................................................................................................... 6

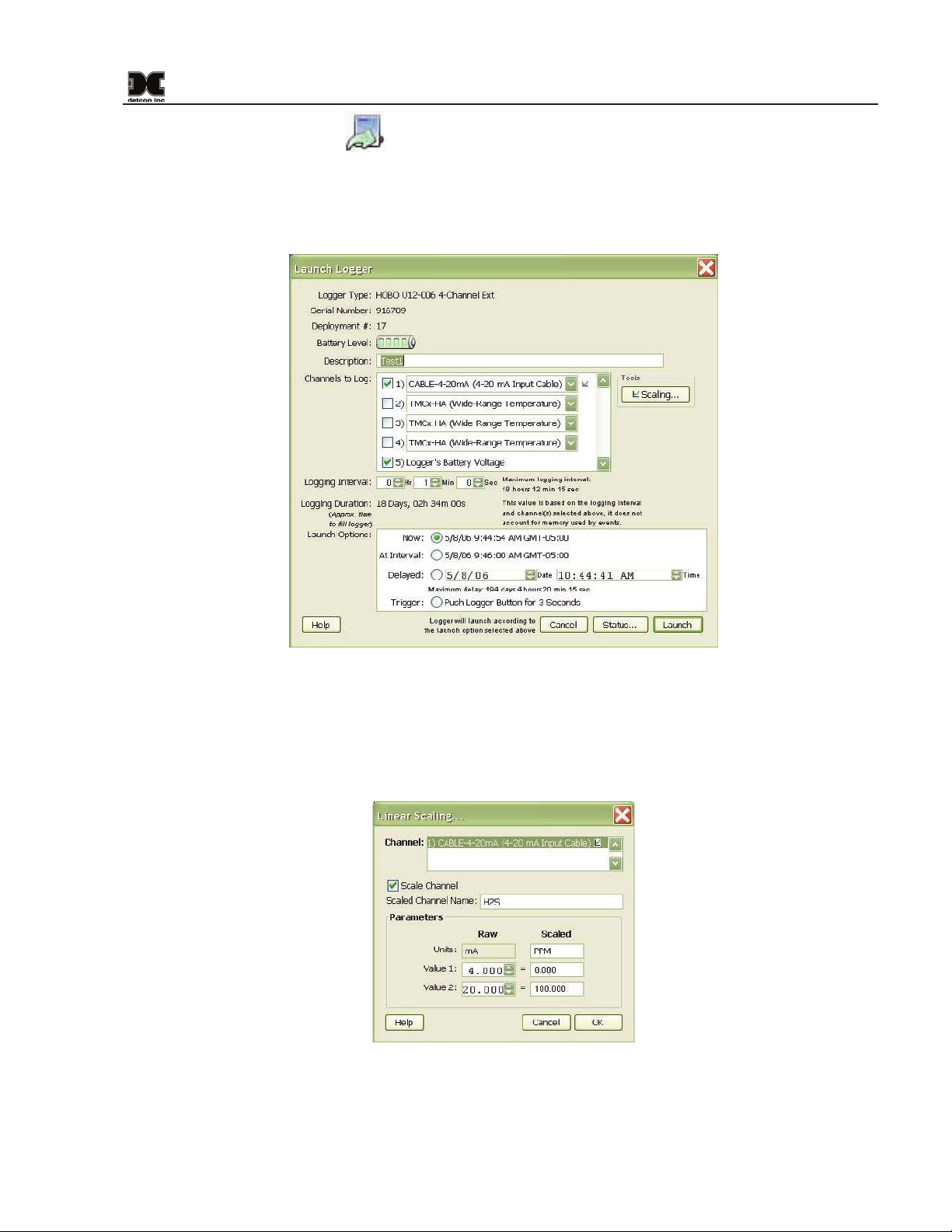

Figure 6 HOBO Launch Window......................................................................................................................... 7

Figure 7 Set Scaling ............................................................................................................................................. 7

Figure 8 Stop Logger............................................................................................................................................ 8

Figure 9 Plot Setup Screen ................................................................................................................................... 9

Figure 10 H2S graphic display............................................................................................................................. 9

Figure 11 Programming Magnet ........................................................................................................................ 11

Figure 12 Front Panel......................................................................................................................................... 12

Figure 13 Software Flowchart............................................................................................................................ 13

Figure 14 Auto Span Sequence .......................................................................................................................... 16

Figure 15 UTM PCB .......................................................................................................................................... 22

Figure 16 Flow Diagram .................................................................................................................................... 23

Figure 17 Wiring Diagram ................................................................................................................................. 24

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.2860 •

Portable Model 1000 H2S Analyzer iv

www.detcon.com • sales@detcon.com

Page 5

P-1000

1.0 Introduction

The Detcon Model P-1000 H

measurement of Hydrogen Sulfide gas concentrations. The portable battery powered instrument utilizes

advanced electrochemical sensor technology and microprocessor based electronic control circuitry that

includes a built in data logger. Stored data can be downloaded to a spreadsheet and used to create trend

graphs. A universal signal conditioning circuit with an LCD display and the intelligent sensor module allow

several ranges of analysis that include 0-20ppm, 0-100ppm, and 0-1,000ppm. The analyzer sensor and control

circuitry are mounted in a weatherproof enclosure with a built in battery supply and sample conditioning

components. The Model P-1000-H

before battery recharge is required. A 12VDC Battery Charger/Power Source is supplied as part of the

standard equipment.

The analyzer requires a liquid-free, 5-10psig sample pressure, provided by the customer. The on-board gas

sample conditioning system includes a stainless steel pressure gauge (0-30psig), a Rotameter with flow valve,

and a Polycarbonate Coalescing Filter to provide the analyzer with condensing liquid protection. A 500cc/min

sample flow rate should be delivered to the Model 200 UniTox™ H

flow is maintained by a control valve Rotameter. An Activated Carbon Scrubber is used to remove H

to venting. A 3-way valve provides for switching between sample monitoring and zero/span calibration.

1.1 UniTox™ Model 200 Description

The Detcon Model P-1000 H2S Process Analyzer is built around the UniTox™ Model 200 Series universal

toxic sensor. The Detcon UniTox™ Model 200 Series Sensors are non-intrusive “Smart” sensors designed to

detect and monitor for toxic gases in the parts per million (ppm) range. UniTox™ sensors operate as standard

two-wire 4-20mA loop-powered devices. Their intrinsically safe electronics design, when used with specified

intrinsically safe field wire barriers, conforms to a Class 1, Division 1, Group A, B, C, and D area

classifications.

The UniTox™ gas sensor consists of two major components: 1) the Universal Transmitter Module (UTM) and

2) the gas/range specific Intelligent Sensor Module (ISM). The universality of the design allows any ISM type

to be plugged into any UTM with seamless operation resulting. The ISM consists of an electrochemical toxic

gas sensor and associated PCB providing pre-amplifier, microprocessor, and memory storage functions.

Typical ranges of detection used in the P-1000 Analyzer are 0-20ppm, 0-100ppm and 0-1,000ppm. Other

ranges are available. All ranges are covered by this manual.

1.1.1 Sensor Technology

S Process Analyzer is a portable gas analyzer designed to provide accurate

2

S is capable of continuous operation for a period of approximately 30 days

2

S Sensor for analysis. The H2S sample

2

S prior

2

The sensors are electrolytic chemical cells. Each cell consists of three electrodes embedded in an electrolyte

solution all housed beneath a diffusion membrane. Sensitivity to specific target gases is achieved by varying

composition of any combination of the sensor components. The cells are diffusion limited via small capillary

barriers resulting in long service life of up to 3 or more years.

Figure 1 Construction of Electrochemical Cell

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 1 of 24

Page 6

P-1000

1.1.2 Universal Transmitter Module (UTM)

The UTM is microprocessor based, and is packaged as a field replaceable module, which is built into the P1000 enclosure. Circuit functions include a PIC microprocessor, 2-line alphanumeric display, magnetic

programming switches, and a linear 4-20mA DC output. Field wiring is terminated on the bottom side of the

UTM cover. The UTM also provides an LCD contrast adjust pot and a protective input fuse.

1.1.3 Intelligent Sensor Module (ISM)

The ISM is microprocessor-based and is packaged as a plug-in replaceable module to facilitate easy

replacement and minimum downtime. Circuit functions include an electrochemical sensor, pre-amplifier, PIC

microprocessor, and memory data storage.

Connector Base

ISM (Inteligent Sensor

Module) with intregal cell

Flow-Through Sample Chamber

Figure 2 Intelligent Sensor Module

The ISM housing is constructed of 316 stainless steel. The ISM plugs into the analyzer via 5 rigid gold plated

pins and is then secured via a threaded machined collar that provides mechanical stability.

UTM

ISM

HOBO Data Logger

Coalescing Filter

USB Port

30 PSI Guage

Adjustable Rotameter

3-Way Valve

Battery

Carbon Scrubber

Figure 3 Overview

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 2 of 24

Page 7

t

P-1000

1.2 Principle of Operation

Sample gas is fed into the unit via the Process Sample Inlet port on the side of the unit. The flow of the gas is

regulated by the Rotameter, and passed through the coalescing filter to remove moisture and condensation.

The nominal flow rate should be 500cc/min. with a minimum flow rate of 200cc/min. and a maximum of

1000cc/min. The gas enters the ISM via the Flow-through Chamber where it is read by the sensor, and vented

to the atmosphere via an Activated Carbon Scrubber to the Vent Port. H

diffusion barrier of the cell where detection is made by an electrochemical reaction at the surface of an

electrode called the sensing electrode. The controlling circuit maintains a small external operating voltage

between the sensing and counter electrodes of the proper bias and magnitude so that no current flows to or

from the reference electrode while its potential is maintained at the correct fixed voltage — usually ground.

The electrochemical reaction creates a change in current flow from the counter electrode to the sensing

electrode. This change in current is proportional to the gas concentration and is reversible. The quick

response of the sensor results in continuous and reliable monitoring of H

Process Sample Inlet

Port

S gas diffuses through the capillary

2

S Concentration.

2

Span/Zero Gas Inlet

Port

Vent Por

Battery Charger Port

12VDC

Figure 4 Gas Ports

Data from the sensor is exported by a HOBO Data Logger via a USB Port. The incorporation of the

HOBOware™ Software and a PC or Laptop complete the unit and allow the user to record the data in graphic

format that can be viewed via the HOBOware™ software. For more information, refer to the HOBOware™

Users Guide.

During Calibration the 3-way valve is placed in the CALIBRATE position and Cal Gas is fed to the sensor via

the Sample Gas Inlet Port.

1.2.1 Interference Data

UniTox™ Model 200 series electrochemical H2S sensors are subject to interference from some gases. This

interaction is shown in Table 1 as the relation between the amount of the interfering gas applied to the sensor,

and the corresponding reading that will occur. All measurements are in ppm unless otherwise noted.

Table 1 Gas Interference

Gas Name Symbol Cross Gas Name Symbol Cross

Acetyldehyde C2H3O n/d Hydrocarbons C-H’s n/d

Acetylene C2H2 n/d Hydrocarbons (unsat.) C-H’s (u) n/d

Acrylonitrile C3H3N n/d Hydrogen H2 1%=<5

Alcohols Alcohols n/d Hydrogen Bromide HBr n/d

Amines Amines n/d Hydrogen Chloride HCL 5=0

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 3 of 24

Page 8

P-1000

Gas Name Symbol Cross Gas Name Symbol Cross

Ammonia NH3 n/d Hydrogen Cyanide HCN 10=0

Arsenic Triflouride AsF3 n/d Hydrogen Flouride HF n/d

Arsenic Pentaflouride AsF5 n/d Hydrogen Selenide HSe n/d

Arsine AsH3 n/d Iodine I2 n/d

Boron Triflouride BF3 n/d Isopropanol C3H8O n/d

Bromine Br2 n/d Methane CH4 n/d

Butadiene C4H6 n/d Methanol CH3OH n/d

Buten-1 Buten-1 n/d Methyl-ethyl-ketone C4H8O n/d

Carbon Dioxide CO2 n/d Methyl Mercaptan CH3SH 2:1

Carbon Disulfide CS2 n/d Nitric Oxide NO 35=<2

Carbon Oxide Sulfide COS n/d Nitrogen N2 n/d

Carbon Monoxide CO 300-1.5 Nitrogen Dioxide NO2 5=-0.5

Carbonyl Sulfide COS n/d Oxygen O2 n/d

Chlorine CL2 1§0.2 Ozone O3 n/d

Chlorine Dioxide CLO2 n/d Phosgene COCL2 n/d

Chlorine Triflouride CLF3 n/d Phosphine PH3 n/d

Diborane B2H6 n/d Phosphorous Triflouride PF3 n/d

Dimethyl Sulfide C2H6S n/d Silane SiH4 n/d

Disilane Si2H6 n/d Silicon Si n/d

Epichlorohydrin C3H5OCL n/d Silicon Tetra Flouride SiF4 n/d

Ethanol C2H5OH n/d Sulfur Dioxide SO2 5=<1

Ethyl Mercaptan C2H5SH 3=1 Tetrahydrothiophene C4H8S n/d

Ethylene C2H4 100=0 Thiophane C4H4S n/d

Ethylene Oxide C2H4O n/d Toluene C6H5CH3 n/d

Fluorine F2 n/d Tungsten Hexaflouride WF6 n/d

Formaldehyde CH2O n/d Vinyl Acetate C4H6O2 n/d

Germane GeH4 n/d Vinyl Chloride C2H3CL n/d

Hydrazine N2H4 n/d

Mercaptan compounds are the most commonly found cross interference gases found in natural gas samples.

High alcohol concentrations should not effect readings except as transients during rapid concentration changes.

1.3 Specifications

Method of Detection

Electrochemical Cell

Accuracy/Repeatability

± 2% FS

Output

Linear 4-20mA DC

Operating Temperature

-40 to 75°C

Operating Pressure

Inlet 5-10psig; Outlet Vent: Ambient ±1psig

Power Consumption

Normal operation = 4mA (0.1 watts @ 12VDC); Maximum = 20mA (0.5 watts @ 12VDC)

Electrical Classification

General Purpose NEMA4X

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 4 of 24

Page 9

P-1000

2.0 Installation and Start Up

Before the unit can be operated on the battery, the battery should be charged completely. The battery charger

should be connected to the cannon plug labeled “Charger Power In 12VDC”, on the side of the unit, and

plugged into a 120VAC receptacle. The unit power switch should be in the “OFF” position during charging.

The charger indicator will signal when the battery is fully charged by illuminating the Green LED on the

charger. Although it should be possible to operate the unit with the battery charger ‘plugged in’, it is advised

to charge the battery only when the unit is not operating. When the battery is fully charged remove the battery

charger from the unit.

Connect the gas sample to the “Process Sample Inlet Port” located on the side of the unit (Figure 4). Make

sure that the 3-way valve is set to “Sample”. Set the input gas sample to 5-10psig on the pressure gauge, and

set the flow rate to 500cc/min. using the flow valve on the Rotameter. If applicable connect tubing to the Vent

Port and vent the sample to a safe location.

NOTE: Maximum input pressure is 10pisg.

NOTE: The sample should be vented to a safe place at pressures of atmosphere ±1Psig.

NOTE: The unit must be placed in an upright position for the Rotameter to provide an

accurate reading. Laying the unit down, or leaning the unit back will cause an inaccurate

reading of gas flow and can cause the unit to operate inefficiently.

Upon completion of all gas connections apply system power and observe the following normal condition:

A temporary upscale reading will occur as the sensor powers up. This upscale reading should clear to the

sample level with-in approximately 5 minutes of turn-on.

NOTE: If the display contrast needs adjustment, refer to section 7.2 Display Contrast Adjust.

2.1 HOBOware™ Installation and setup

A PC or Laptop can be used to log data from the Analyzer. The HOBOware™ Software package is provided

to integrate the PC/Laptop with the analyzer. HOBOware™ is software for launching, reading, and plotting

data from the HOBO® U-Series loggers.

System Requirements:

Windows 2000 Pro, Windows XP, or Windows Vista

Sun Java Runtime Environment (JRE) 1.4.2 (included on CD), or later

One of the following Internet browsers: Firefox 1.0, Netscape 7.2, Opera 7.54u2, Microsoft Internet Explorer

6.0 or later

Minimum screen resolution of 800x600

An available USB port, an Onset Certified USB Cable, and a U-Series HOBO data logger

Minimum 256 MB memory

256+ colors

Insert the CD in the computer’s CD-ROM drive. The installation program should start automatically. If it

does not, navigate to the CD drive in My Computer or Windows Explorer and double-click HOBOware™

Setup.exe to launch the HOBOware™ installer.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 5 of 24

Page 10

P-1000

If the latest version of Java (1.4.2) is not installed, the installer will install it. HOBOware™ will inform you if

your Java version is not up to date.

Follow the screen prompts to install the HOBOware™ software.

HOBOware™ should open automatically when the installation is complete (unless the Launch HOBOware™

box is un-checked on the Completing the HOBOware Setup Wizard dialog before clicking Finish). If it

doesn’t, double-click the HOBOware™ icon

on the desktop or Quick Launch menu. Or, from the Start

menu, select Programs, Onset Applications, and HOBOware™.

Figure 5 HOBO Opening Screen

2.2 Connecting a logger directly to a USB cable

1. Open the HOBOware™ software application.

2. Plug the large end of the USB interface cable into a USB port on the computer.

3. Plug the small end of the USB interface cable into the port on the logger. (Refer to the diagram and

instructions that came with the logger if help is required in help finding the port.)

4. If the logger has never been connected to this computer before, it may take some time for the computer

to detect the new hardware and report that it has connected successfully. One or more messages will

appear, indicating that new hardware has been found, and there may be an audible chime.

NOTE: The computer may prompt to reboot before you can use the logger. It is not necessary

to reboot.

5. When the logger is recognized by HOBOware™, the right side of the status bar at the bottom of the

HOBOware window will update to reflect the number of loggers connected. When the logger is

recognized, it is ready for use.

6. Wait for the status bar to update the number of loggers before continuing.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 6 of 24

Page 11

P-1000

7. Click the Launch icon on the toolbar. This displays the logger’s Launch window. Launch

windows vary for each type of logger, but most should look similar to Figure 6.

8. Review the default Launch settings. Enter an appropriate name in the Description field, (Test1 in this

example) and select Channel 1in the Channels to Log select box.

Figure 6 HOBO Launch Window

9. Select Scaling to open the Linear Scaling Window (Figure 7). The scale channel check box should be

checked. Give the channel an appropriate name, (H2S in this example) and set the scaling units to ppm

with 4mA set for 0.0 and 20mA set for full scale. I.e. for 0-20ppm full scale would be 20ppm, or

20mA=20ppm. Select OK to return to the Launch Logger Screen.

Figure 7 Set Scaling

10. Almost any logging Interval can be set from 1 second to over 18 hours, it is suggested to set a 1 to 5

minute Logging Interval. Choose the Now launch option to immediately start-logging data, other options

may be selected and are discussed in detail in the HOBOware™ User’s Guide. Click Launch to begin

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 7 of 24

Page 12

P-1000

logging. HOBOware™ displays the progress of the launch and warns the user not to unplug the logger

while it is being configured.

NOTE: Launch settings are discussed in depth in “Chapter 2: Working with loggers.” in the

HOBOware™ Users Guide.

11. To disconnect a logger, simply unplug it from the USB cable or the computer.

2.3 Analyzer Initial Operational Tests

After a warm-up period has been allowed for, the sensor should be checked to verify sensitivity to its target

gas.

Material Requirements

Span gas containing the target gas in air or nitrogen. It is recommended that the target gas concentration

be 50% of scale at a controlled flow rate of 500 ml/min. For example, a Model DM-200-H

sensor in the range 0-100ppm would require a test gas of 50ppm H

S. For a sensor with a range of 0-

2

S UniTox™

2

20ppm a test gas of 10ppm is recommended, etc.

a) Connect span gas to the “Span/Zero Inlet Port” and place the 3-way Valve in the “Calibrate” position.

b) Apply the span gas at a controlled flow rate of 500cc/min. Observe that the LCD display increases to a

level of 10% of the span level. I.e. if the sensor range is 0-100ppm and the span gas is 50ppm the reading

should rise to within 10% of 50ppm (45-55ppm).

c) Remove the span gas, place the 3-way valve if the “Sample” position, and observe that the LCD display

increases/decreases to the expected process level.

Detcon H

S gas sensors are calibrated prior to shipment, and should not require significant adjustment on start

2

up. However, it is recommended that a complete calibration test and adjustment be performed within 24 hours

of installation. Refer to calibration instructions in section 4.0.

2.4 HOBOware™ Operational Test

1. After initial test of Analyzer, if the data logger is not attached to the PC and the HOBOware software is

not running, invoke the HOBO Software and connect the data logger to the PC/Laptop via the USB Cable.

2. When the logger is recognized by HOBOware, the right side of the status bar at the bottom of the

HOBOware window will update to reflect the number of loggers connected. When the logger is

recognized, it is ready for use.

3. Click the Readout icon

on the toolbar. Click Stop when HOBOware asks if you want to stop the

logger before reading out.

Figure 8 Stop Logger

4. HOBOware™ will down load the information from the logger and prompt for a filename to save the file.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 8 of 24

Page 13

P-1000

5. Save the file with an appropriate name for later recall. The Software will then prompt for a Plot Setup.

Figure 9 Plot Setup Screen

6. HOBOware™ will then display a graph of the data logged during the Initial Operational Tests of the

Analyzer.

Figure 10 H2S graphic display

NOTE: the sample rate of Figure 10 was set to 1-second intervals for the purpose of clarity.

The display acquired from your unit may look different from Figure 10, but should show the

application of gas, the highest reading, and the removal of gas as shown here.

For more information on the HOBOware™ Software, refer to the HOBOware™ User’s Guide.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 9 of 24

Page 14

P-1000

3.0 Analyzer Operating Software

Operating software is menu driven with operator interface via the use of two magnetic program switches

located under the front panel. The two switches are labeled “PGM 1” and “PGM 2”. The menu consists of 3

items which include sub-menus as indicated below. (Note: see section 3.5 for a complete software flow chart.)

01. Normal Operation

a) Current Status

02. Calibration Mode

a) Zero Cal

b) Span Cal

03. Program Mode

a) View Program Status

b) Set Span Level

c) Set Date

3.1 Normal Operation

In normal operation, the display tracks the current status of the sensor and gas concentration and appears as:

“0 PPM xxx” (where “xxx” is the abbreviated gas type, i.e., “0 PPM H2S”). The current output corresponds to

the monitoring level of 0-100% of range (I.E. a reading of 0ppm = 4mA and full scale = 20mA). If applicable,

the second line of the display will show current “Fault” conditions.

3.2 Calibration Mode

Calibration mode allows for sensor zero and span adjustments. “1-Zero Cal, 2-Span Cal”

3.2.1 Zero Adjustment

Zero is set in ambient air with no target gas present or with zero Air or N2 gas applied to the sensor. (Refer to

Section 4.1 for details.)

3.2.2 Span Adjustment

Span adjustment is performed with a target gas concentration of 50% of range in air or nitrogen. Span gas

concentrations other than 50% of range may be used as long as they are between 10 to 90% of range. (Refer to

section 4.2 for details.)

3.3 Program Mode

The program mode provides a program status menu (View Program Status) to check all operational

parameters. It also allows for the adjustment of the auto span gas level setting and the current calendar date.

3.3.1 View Program Status

The view program status scrolls through a menu that displays the following (the slash means the data is on line

two of the display):

Sensor type. The menu item appears as: “Sensor Type / H2S”

Sensor range of detection. The menu item appears as: “Sensor Range / 0-XXX PPM”

ISM software version number. The menu item appears as: “ISM Code Ver. / X.XX Mth Year”

UTM software version number. The menu item appears as: “UTM Code Ver. / X.XX Mth Year”

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 10 of 24

Page 15

P-1000

The time weighted average and peak data (last 8 hours). Menu item appears as: “TWA: xx PPM / PK: xx

PPM@ –xx Min”

Estimated remaining sensor life. The menu item appears as: “Sensor Life / XX%”

Calibration span gas level setting. The menu item appears as: “Auto Span Level / XX PPM”

Date. The menu item appears as: “Present Date/ mm/dd/yy”

Last successful span date. The menu item appears as: “Last Span Date / mm/dd/yy”

Temperature. The menu item appears as: “Present Temp / XX°C”

3.3.2 Set Span Level Adjustment

The Span level is adjustable from 10% to 90% of range. The menu item appears as: “Span Gas Value / xx

PPM”

3.3.3 Set Date Adjustment

Set the present date. The menu item appears as: “Date / mm/dd/yy” (where mm=Month, dd=Day, and

yy=year).

3.4 Programming Magnet Operating Instructions

Operator interface to UniTox™ gas detection products is via magnetic switches located behind the UTM

faceplate. Two switches labeled “PGM 1” and “PGM 2” allow for complete calibration and programming.

Figure 11 Programming Magnet

A magnetic programming tool is used to operate the magnetic switches. Switch action is defined as

momentary contact, 3-second hold, and 15-second hold. In momentary contact use, the programming magnet

is waved over a switch location. In 3-second hold, the programming magnet is held in place over a switch

location for 3 or more seconds. In 15-second hold, the programming magnet is held in place over a switch

location for 15 seconds. Three (3) and fifteen (15) second holds are used to enter or exit calibration and

program menus while momentary contact is used to make set-point adjustments. The location of “PGM 1” and

“PGM 2” is shown in Figure 12.

NOTE: If, after entering the calibration or program menus, there is no interaction with the

menu items for more than 30 seconds, the sensor will return to its normal operating condition.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 11 of 24

Page 16

P-1000

Programming

Switches

3-Way

Calibrate/

Sample

Valve

Figure 12 Front Panel

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 12 of 24

Page 17

P-1000

3.5 Software Flow Chart

Figure 13 Software Flowchart

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 13 of 24

Page 18

P-1000

4.0 Calibration

4.1 Calibration Procedure – Zero

Material Requirements

Zero Air or N

a) Connect zero air or N

position. Apply zero air or N

b) Enter the calibration menu by holding the programming magnet stationary over “PGM 1” for 3 seconds

until the display reads “1-Zero Cal 2-Span Cal”, withdraw the magnet.

c) Enter the Zero Cal menu by holding the magnet stationary over “PGM 1” for 3 seconds until the display

reads: “Auto Zero”, and withdraw the magnet. The sensor will enter the Auto Zero mode, which lasts for

7 seconds. When complete, the display will read “Zero Complete” for 2 seconds and will report the date

of the last span as a reminder. The display will read; “Return to Normal Operation” for 3 seconds.

d) Turn off and remove the zero air or N

NOTE1: If the circuitry is unable to adjust the zero to the proper setting the sensor will enter a

calibration fault mode which will cause the display to alternate between the sensor’s current

status reading and the calibration fault screen which appears as: “Zero Cal Fault”.

NOTE2: Upon entering the calibration menu, the 4-20mA signal drops to 3.5 mA until the

unit returns to normal operation.

NOTE3: When a “Zero Cal Fault” occurs, the sensor microprocessor retains its previous zero

calibration reference.

4.2 Calibration Procedure - Span

It is advised that a Zero Calibration is performed prior to a Span Calibration.

Material Requirements

Detcon PN 943-003270-000 Programming Magnet

Span gas containing H

range (which is the factory default) at a controlled flow rate of 500cc/min. Example: for a Model DM200-H

of 0-20ppm a test gas of 10ppm is recommended, etc. Other concentrations can be used as long as they

fall within 10% to 90% of range. See below for details.

Calibration consists of entering the calibration function and following the menu-displayed instructions. The

display will ask for the application of span gas in a specific concentration. This concentration is equal to the

span gas level setting. The factory setting for span gas concentration is typically 50% of range, but may be

different depending on gas availability. For optional calibration, a span gas containing a concentration equal

to 50% of range is required. If a span gas containing 50% of range is not available, other concentrations may

be used as long as they fall within 10% to 90% of range. However, any alternate span gas concentration value

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 14 of 24

S sensor with a range of 0-100ppm, a test gas of 50ppm is recommended. For a sensor with a range

2

CAUTION: Verification of the correct calibration gas level setting and calibration span gas

concentration is required before “span” calibration. These two numbers must be equal before

proceeding.

gas cylinder

2

gas to the “Span/Zero Gas Inlet Port” and switch the 3-way valve to the “Calibrate”

2

S gas in air or nitrogen. The target gas concentration is recommended at 50% of

2

gas at a rate of 500cc/min for 5 minutes prior to continuing.

2

gas, and remove the gas from the unit. Auto zero is complete.

2

Page 19

P-1000

must be programmed via the calibration gas level menu before proceeding with span calibration. Follow the

instructions below for span calibration.

1) Verify the current calibration gas level setting as indicated by the programming status menu. To do this,

follow the instructions in Section 5.1 and make note of the setting found in the calibration span gas level

setting. The item appears as “Auto Span Level / XX PPM”.

2) If the calibration gas level setting is equal to the calibration span gas concentration, proceed step 3). If

not, adjust the calibration gas level setting so that it is equal to your calibration span gas concentration:

a) Enter the programming menu by holding the programming magnet stationary over “PGM 2” for 15

seconds until the display reads “View Program Status”, and withdraw the magnet.

b) Scroll through the programming menu by momentarily waving the programming magnet over “PGM

1” or “PGM 2”. The menu options are: View Program Status, Set Span Level, and Set Date.

c) From the programming menu scroll to the calibration level listing. The menu item appears as: “Set

Span Level”.

d) Enter the menu by holding the programming magnet stationary over “PGM 1” for 3 seconds until the

display reads “Auto Span Level / ##PPM”, and withdraw the magnet.

e) Use the programming magnet to make an adjustment using “PGM 1” to increase or “PGM 2” to

decrease the display reading until the reading is equal to the desired calibration span gas concentration.

To accept/retain the newly entered value, hold the programming magnet over “PGM1” for 3 seconds.

NOTE: The newly entered span gas valve is not saved to permanent memory until a span

calibration is successfully executed with it. New span gas values that are not saved to

permanent memory will be lost when power is lost.

f) Exit back to normal operation by holding the programming magnet over “PGM 2” for 3 seconds, or

automatically return to normal operation in 30 seconds.

3) Connect the span gas to the “Span/Zero Gs Inlet Port” and switch the 3-way valve to the “Calibrate”

position.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 15 of 24

Page 20

P-1000

Figure 14 Auto Span Sequence

4) From the calibration menu “1-Zero Cal 2-Span Cal” proceed into the span adjust function by holding the

programming magnet stationary over “PGM 2” for 3 seconds. The display will ask for the application of

the target gas and concentration. The display reads “Apply XXPPM Span Gas” (The ‘X’s indicate the

concentration requested).

5) Apply the calibration span gas at a flow rate of 500cc/min.. When the sensor response exceeds 10% of the

applied test gas, the display will change to “Auto Span Test” for a period of 2 minutes.

If sensor response does not exceed 10% of applied gas after 1 minute, the menu “1-Abort Span / 2-Continue

Span” appears. This gives the user an opportunity to verify proper span gas delivery and concentration before

continuing forward. If it is desirable to “Abort Span” and try again, then that choice may be exercised.

6) After two minutes, the message will change to “Auto Span Adjust” for an additional 30 seconds. During

this period, the sensor will analyze the signal for stability. The criterion for stability is signal drift within

±2% of full scale in 30 seconds. If met, the message changes to “Auto Span Complete”.

7) If not met, up to 4 additional 30 second stability check periods are administered. If all 5 stability checks

fail then the unit returns to Normal Operations with the original Auto Span parameter intact. An

alternating message of “Span Calibration Fault” is displayed to remind the user that a re-calibration is still

necessary.

8) With “Auto Span Complete” achieved, the display reports the remaining “Sensor Life xx%”, and the “New

Span Date”, and then “Remove Span Gas / XX PPM” which prompts the user to remove the span gas from

the sensor. During “Remove Span Gas / XX PPM” disconnect the span gas and re-apply the zero air or N

2

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 16 of 24

Page 21

P-1000

gas so that the sensor recovers toward zero. When the signal level falls below 10% of full scale the

display changes to “Return to Normal Operation”.

9) Turn off and remove the zero air or N2 gas, and remove the gas from the unit. Turn the 3-way

“Calibrate/Sample” valve to the “Sample position”. Adjust the flow Rotameter for a flow rate of

500cc/min. Span Calibration is complete.

4.2.1 Additional Notes

a) Upon entering the calibration menu, the 4-20mA signal drops to 3.5mA and is held at this level until the

sensor returns to normal operation.

b) If during calibration the sensor circuitry is unable to attain the proper adjustment for span, the sensor will

enter into “Span Calibration Fault” mode, which will cause the display to alternate between the sensor’s

current status reading and the calibration fault screen which appears as: “Span Cal Fault”. If this occurs,

recalibrate the sensor by entering the calibration menu as described in section 4.2. If the sensor fails again,

refer to technical troubleshooting, Section 7.0.

NOTE: The newly entered span gas valve is not saved to permanent memory until a span

calibration is successfully executed with it. New span gas values that are not saved to

permanent memory will be lost when power is lost.

4.3 Calibration Frequency

In most applications, monthly to quarterly calibration intervals will assure reliable detection. However,

sample streams differ. Upon initial installation or when connecting to a new sampling location, calibration

should be performed to assure reliable operation.

5.0 Status of Programming and ISM Parameters

The programming menu includes a “View Program Status” listing that allows the operator to view the sensor

type, range, software version numbers, time weighted average (TWA) and peak reading in last 8 hours,

remaining sensor life, auto span level, present date, last span date, and present temperature. The programming

menu also allows the changing of the span gas level setting (see Section 4.2), and calendar date.

5.1 View Program Status

a. Enter the programming menu by holding the programming magnet stationary over “PGM 2” for 15

seconds until the display reads “VIEW PROG STATUS”, and withdraw the magnet. Scroll through the

programming menu by momentarily waving the programming magnet over “PGM 1” or “PGM 2”. The

menu options are: View Program Status, Set Span Level, and Set Date.

b. Scroll to the “VIEW PROG STATUS” listing and hold the programming magnet over “PGM 1” for 3

seconds. The menu will automatically scroll (at 3-second intervals) through the following information

before returning to the “VIEW PROG STATUS” listing.

¾ Ssensor type. The item appears as: “Sensor Type / H

¾ Sensor range of detection. The item appears as: “Sensor Range / 0-XXX PPM”

¾ ISM software version number. The item appears as: “ISM Code Ver. / X.XX Mth Year”

¾ UTM software version number. The item appears as: “UTM Code Ver. / X.XX Mth Year”

¾ Time weighted average and peak. The item appears as: “TWA: XX PPM / PK: XX PPM@ –XX Min”

¾ Estimated remaining sensor life. The item appears as: “Sensor Life / XX%”

¾ Calibration span gas level setting. The menu item appears as: “Auto Span Level / XX PPM”

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 17 of 24

2

S”

Page 22

P-1000

¾ Date. The item appears as: “Present Date/ 5/1/01”

¾ Last successful span date. The item appears as: “Last Span Date / dd/mm/yy”

¾ Temperature. The item appears as: “Present Temp / XX°C”

c. Exit to normal operations by holding the programming magnet over “PGM 2” for 3 seconds, or the sensor

will automatically return to normal operation in 30 seconds.

5.2 Set Span Level

a) Enter the programming menu by holding the programming magnet stationary over “PGM 2” for 15

seconds until the display reads “View Program Status”, and withdraw the magnet.

b) Scroll through the programming menu by momentarily waving the programming magnet over “PGM

1” or “PGM 2”. The menu options are: View Program Status, Set Span Level, and Set Date.

c) From the programming menu scroll to the calibration level listing. The menu item appears as: “Set

Span Level”.

d) Enter the menu by holding the programming magnet stationary over “PGM 1” for 3 seconds until the

display reads “Auto Span Level / ##PPM”, and withdraw the magnet.

e) Use the programming magnet to make an adjustment using “PGM 1” to increase or “PGM 2” to

decrease the display reading until the reading is equal to the desired calibration span gas concentration.

To accept/retain the newly entered value, hold the programming magnet over “PGM1” for 3 seconds.

NOTE: The newly entered span gas value is not saved to permanent memory until a span

calibration is successfully executed with it. New span gas values that are not saved to

permanent memory will be lost when power is lost.

f) Exit back to normal operation by holding the programming magnet over “PGM 2” for 3 seconds, or

automatically return to normal operation in 30 seconds.

5.3 Set Date

The following procedure is used to set the present calendar date:

a) Enter the programming menu by holding the programming magnet stationary over “PGM 2” for 15

seconds. The display will read “View Program Status”, withdraw the magnet. Scroll through the

programming menu by momentarily waving the programming magnet over “PGM 1” or “PGM 2”.

The menu options are: View Program Status, Set Span Level, and Set Date.

b) From the programming menu scroll to the “Set Date” listing. Enter the menu by holding the

programming magnet stationary over “PGM 1” for 3 seconds until the display reads “Set Date /

xx/xx/xx”, withdraw the magnet. The first set of numbers (month) will flash on and off indicating

they are ready for adjustment. Use the programming magnet to adjust “PGM 1” to increase or “PGM

2” to decrease the display reading until the reading is equal to the desired month.

c) Next, advance to the second set of numbers (the day) by holding the programming magnet stationary

over “PGM 1” for 3 seconds until the month set flashes on and off indicating they are ready for

adjustment. Use the programming magnet to adjust “PGM 1” to increase or “PGM 2” to decrease the

display reading until the reading is equal to the desired day.

d) Next, advance to the third set of numbers (the year) by holding the programming magnet stationary

over “PGM 1” for 3 seconds until the year set flashes on and off indicating they are ready for

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 18 of 24

Page 23

P-1000

adjustment. Use the programming magnet to adjust “PGM 1” to increase or “PGM 2” to decrease the

display reading until the reading is equal to the desired year.

e) To retain the newly entered value, hold the programming magnet over “PGM1” for 3 seconds.

f) Exit to normal operation by holding the programming magnet over “PGM 2” for 3 seconds, or the

sensor will automatically return to normal operation in 30 seconds.

5.4 Program Features (UniTox DM-200 Sensor)

Detcon UniTox™ toxic gas sensors incorporate a comprehensive program to accommodate easy operator

interface and fail-safe operation. Program features are detailed in this section. Each sensor is factory tested,

programmed, and calibrated prior to shipment.

Sensor Life

The sensor life feature is a reference based on signal output from the sensor cell. When a sensor life of 25% or

less remains, the sensor cell should be replaced within a reasonable maintenance schedule.

Data Logging

The data logging feature records the most recent 8 hours of data for time-weighted average (TWA) and peak

(PK) reading. The menu item appears as “TWA: xx PPM / PK: xx PPM@ xx Min”. TWA is a rolling 8 hour

average updated at 30 minute intervals. The peak (PK) reading is the instantaneous peak reading recorded in

the last 8 hours and the “@ –xx Min” represents the “number of minutes ago” that the peak reading took place.

For example: “PK: 33PPM@ –360 Min” explains that a peak reading of 33ppm took place 6 hours (360

minutes) ago.

Over Range

When the sensor detects gas greater than 100% of range, it will display the highest reading of its range and an

output of 20mA.

Under Range Fault

If the sensor should drift below a zero baseline of –10% of range, the display will indicate a fault: “Sensor

Fault” and report an output of 3.5mA. This is typically fixed by performing another zero cal.

Span Calibration Fault

If during calibration the sensor circuitry is unable to attain the proper adjustment for span, the sensor will enter

into the span calibration fault mode and cause the display to alternate between the sensor’s normal operation

reading and the calibration fault screen which appears as: “Span Cal Fault”. The previous calibration settings

will remain saved in memory.

Zero Calibration Fault.

If during calibration the sensor circuitry is unable to attain the proper adjustment for zero, the sensor will enter

into the zero calibration mode and cause the display to alternate between the sensor’s normal operation reading

and the calibration fault screen which appears as: “Zero Cal Fault”. The previous calibration settings will

remain saved in memory.

Missing Sensor

If the ISM is missing or not connected properly, the UTM will report, “Missing Sensor” and an output of

1.0mA will be set.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 19 of 24

Page 24

P-1000

Memory Fault

If new data points cannot successfully be retrieved from memory, the display will indicate: “Memory Fault”.

Comm Error

If the ISM and UTM are not communicating properly, then the UTM will report “Comm Error”.

6.0 Exchanging ISM Modules

A key feature of the UniTox™ product is its complete universality (exchangeability) between any combination

of ISM and UTM. The ISM carries all necessary identification and parameter data stored in permanent

memory, which allows any ISM to instantly begin seamless operation with any UTM.

6.1 Physical Exchange

To remove an ISM, disconnect the swag lock tube fittings at the flow adapter and unthread the flow through

chamber. Twist the retaining collar on the ISM in a counter clockwise direction until the threads are cleared.

The ISM should be pulled straight down and out. To reinstall the ISM, align the gold pins with the receptacle

and press the ISM in until completely seated. Move the retaining collar up and thread clockwise until snug.

Reconnect the flow through chamber, and re-attach the swag lock tube fittings.

NOTE: Remember to twist the retaining collar tight after successful ISM/UTM communication is established.

The collar should tighten snugly up to the mating surface in order to create a watertight seal. Never grab the

ISM main housing and attempt to twist. This may damage the gold pin connections.

6.2 Establishing Communication

The UTM will display "Missing Sensor" during time when the ISM is not connected. When an ISM is

disconnected from a UTM, the user must wait approximately 7 seconds before another ISM can be plugged

into the UTM. This 7-second period is the time required by the UTM to reach the "ready-to-receive" state.

After plugging an ISM into the UTM, within 1-3 seconds, the ISM identification/parameter information will

be displayed and at the conclusion of the data string, a "Returning to Normal Operation" message will be

shown. If for some reason the ISM identification/parameter information does not come up after 10 seconds,

then unplug the ISM and repeat the process again after 10 seconds.

7.0 Trouble Shooting Guide

7.1 UniTox™ Error Messages

Error messages from the UniTox™ Sensor are displayed on the LCD in the P-1000 Analyzer and are not

forwarded to the Data Logger or a connected PC/Laptop.

7.1.1 "Missing Sensor" Message

Probable Cause: ISM not being registered by UTM.

1. Reinstall ISM after waiting 10 seconds.

2. Re-power UniTox sensor.

7.1.2 "Comm Error" Message

Probable Causes: Faulty wiring/connection, UTM or ISM microprocessor failure.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 20 of 24

Page 25

P-1000

1. Re-Install ISM.

2. Swap ISM and UTM with another functional pair to determine if ISM or UTM is the problem.

7.1.3 No LCD or 4-20mA signal activity with power applied

Probable Causes: Blown input fuse, Insufficient Operating Voltage, Miss-wired connection.

1. Check/Replace Fuse.

2. Check for correct polarity and verify Operating voltage at the UTM input terminals.

3. Check status of external field wire I.S. Barrier.

4. Replace UTM with functional UTM.

7.1.4 Erratic Sensor Behavior – False/Fault Alarms

Probable Causes: Wet/Intermittent terminals, RFI Interference, Bad Electrochemical Sensor, Target or Crossinterfering Gases being Detected.

1. Check that ISM collar and rain cover are firmly connected and terminals are not wet.

2. RFI- Use shielded cabling.

3. Re-calibrate sensor and make sure it calibrates successfully and Sensor Life is acceptable.

4. Make sure alarms are not being caused by real gas clouds or cross-interfering gases.

7.1.5 "Span Cal Fault" Message

Probable Causes: Incorrect cal gas delivery, Bad calibration gas, Failing Electrochemical sensor, Inadequate

wait time, Incorrect Cal gas value.

1. Verify that existing Sensor Life% value is not < 25%.

2. Verify that the correct span gas value is entered in the program.

3. Determine if failing Auto Span is due to inadequate signal or inadequate stability .

4. Check cal gas flow, type, concentration, and expiration date (validate cal gas with pull tube).

5. If failing AutoSpan stability test, apply cal gas for 3-5 minutes before executing AutoSpan.

6. If failing AutoSpan signal test, change-out electrochemical sensor and retry AutoSpan .

7.1.6 Clearing "Span Cal" Fault Message

1. This message can be cleared by performing either a successful AutoSpan or AutoZero.

7.1.7 "Zero Cal Fault" Message

Probable Cause: Zero cal before sensor stabilization

1. Use “Zero Air” or N

for 5-10 minutes before performing Zero Calibration (Section 4.1)

2

7.1.8 "Sensor Fault" Message

Probable Cause: Zero baseline has drifted negative, Excessive temperature drift.

1. Re-Calibrate Zero.

2. If "Sensor Fault" is intermittent and correlates with temperature – Contact Detcon.

7.1.9 4-20mA not matching LCD display

Probable Causes: Various

1. Verify adequate operating voltage (> 11.5 VDC).

2. Reads 1.1mA with "Missing Sensor" - unplug and re-install the ISM, and/or cycle power to the unit.

3. Reads 3.5mA – Unit out of Normal Operation, user must clear out of user interface software.

4. Reads > 0.2mA in accurately – 4-20mA should be recalibrated, Contact Detcon for procedure.

7.1.10 "Memory Error" Message

Probable Cause: Faulty memory chip.

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 21 of 24

Page 26

P-1000

7.1.11 LCD Not Easily Read

1. Adjust contrast potentiometer (Section 7.2).

7.2 Display Contrast Adjust

Detcon UniTox™ sensors feature a 2-line, 16-character liquid crystal display. Like most LCD’s, character

contrast can be affected by viewing angle and temperature. Temperature compensation circuitry included in

the UniTox™ design will compensate for this characteristic, however temperature or operating voltage

extremes may still cause a shift in the contrast.

Display contrast can be adjusted by the user if necessary. To adjust the display contrast, remove the front

panel (see Figure 12) and use a small screwdriver to turn the blue contrast potentiometer adjust screw located

on the back side of the UTM circuit board (see Figure 15). Adjust per preference. The adjustment location is

marked “CONTRAST”.

Figure 15 UTM PCB

8.0 Spare/Replacement Parts

327-000000-000 Programming Magnet

922-9900P1-000 Universal Transmitter Module (UTM)

975-P10110-240 Battery Charger

344-400000-000 12V 7Ah Battery

392-32240S-01K 0-1000ppm ISM

392-32240S-100 0-100ppm ISM

392-32240S-020 0-20ppm ISM

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 22 of 24

Page 27

P-1000

9.0 Warranty

Detcon, Inc., as manufacturer, warrants each new electrochemical toxic gas plug-in sensor cell, for a specified

period one-year beginning on the date of shipment to the original purchaser. The sensor cell is warranted free

from defects in material and workmanship. Should any sensor cell fail to perform in accordance with

published specifications within the warranty period, return the defective part to Detcon, Inc., 3200 A-1

Research Forest Dr., The Woodlands, Texas 77381, for necessary repairs or replacement.

9.1 Service Policy

Detcon, Inc., as manufacturer, warrants under intended normal use each new UniTox™ UTM control circuit

and ISM control circuit to be free from defects in material and workmanship for a period of one year from the

date of shipment to the original purchaser. Detcon, Inc., further provides for a five year fixed fee service policy

wherein any failed UTM or ISM shall be repaired or replaced as is deemed necessary by Detcon, Inc., for a

fixed fee of $75.00. The fixed fee service policy shall affect any factory repair for the period following the

one year warranty and shall end five years after the date of shipment to the original purchaser. All warranties

and service policies are FOB the Detcon facility.

10.0 Diagrams

10.1 Flow Diagram

Sample

Span Gas

Vent

ISM

Carbon Scrubber

Coalescing

3-Way Valve

Calibrate

Filter

Pressure Guage

Flow

Meter

Sample

In-line Humidifying Tube

Figure 16 Flow Diagram

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 23 of 24

Page 28

P-1000

10.2 Wiring Diagram

Connector Base

Red

12VDC Battery Charger

Black

2Pin Male Connector

ISM

392-xxxx0S-yyy

xxxx = Gas type

yyy = Range

(will vary)

CONTRAST

J2

YELBLKWHT BLU

Blue

Black

White

Yellow

UTM

922-9900P1-000

Blue

Yellow

Red

Black

Black

Red

Red

Red

Black

Black

TB1

Terminal Block

J3

+

P/N 995-741470-420

Power Switch

NO

COM

NC

SW1

Hobo Cable

Red

Red

Black

Hobo Datalogger

P/N 992-012006-000

+ -

(Blk) PSJ1-4 / B2-(-)

B1

Battery

P/N 344-400000-000

(Blu) B1-(-) / B2-(+)

Figure 17 Wiring Diagram

Portable Model 1000 H2S Analyzer Rev. 1.0 Page 24 of 24

Loading...

Loading...