Detcon TP-524C User Manual

detcon inc.

Detcon MicroSafe™

TP-524C Hydrogen Sulfide Sensor

This manual covers the following ranges: 0-20 PPM, 0-50 PPM, and 0-100 PPM

Operator’s Installation & Instruction Manual

May 09, 2012 • Document #2297 • Version 2.5

Table of Contents

3.0Description

3.1Principle of Operation

3.2Application

3.3Specifications

3.4Operating Software

3.5Installation

3.6Start-up

3.7Calibration

3.8Status of Programming: Software Version, Calibration Level, Heater Voltage, Range, and Sensor Life

3.9Program Features

3.10Display Contrast Adjust

3.11Trouble Shooting Guide

3.12Spare Parts List

3.13Warranty

3.14Service Policy

3.15Software Flow Chart

3.16Revision Log

Detcon Model TP-524C Hydrogen Sulfide Sensor PG.2

3.0 DESCRIPTION

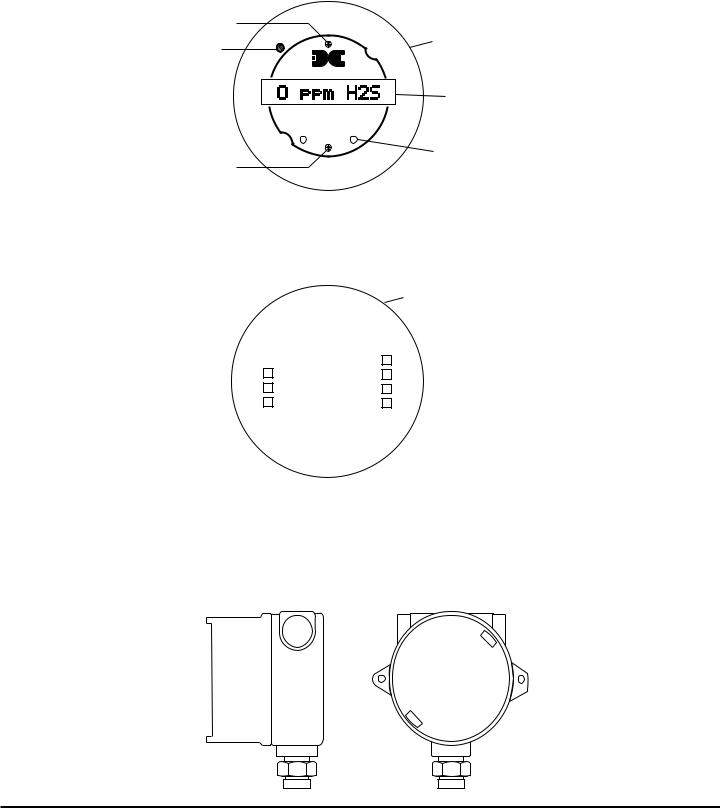

Detcon MicroSafe™ Model TP-524C, hydrogen sulfide sensors are non-intrusive “Smart” sensors designed to detect and monitor H2S in air. Ranges of detection are 0-20 ppm, 0-50 ppm, and 0-100 ppm. One of the primary features of the sensor is its method of automatic calibration which guides the user through each step via instructions displayed on the backlit LCD. The sensor features LED indicators for FAULT and CAL status and is equipped with a standard analog 4-20 mA output. The microprocessor supervised electronics are packaged as a plug-in module that mates to a standard connector board. Both are housed in an explosion proof condulet that includes a glass lens. A 16 character alpha/numeric indicator is used to display sensor readings as well as the sensor’s menu driven features via a hand-held programming magnet.

3.0.1 Sensor Technology

The sensor technology is a patented solid state metal oxide semiconductor. The sensor consists of two thin films; a temperature sensitive heater film, and an hydrogen sulfide sensitive sensor film. Both films are deposited on a silicon microchip by vacuum deposition. The heater film elevates the operating temperature of the sensor film to a level where a good sensitivity and response to hydrogen sulfide is achieved. The sensor film is a proprietary metal oxide that shows a dynamic response to hydrogen sulfide gas. Range of sensitivity is from part per billion to % by volume. The rugged sensor is capable of maintaining its operating characteristics for periods of up to 7-10 years in most industrial environments and as such, is supported by a 10-year conditional warranty.

Construction of

Semiconductor Sensor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sensor |

|

|

|

|

|||

Heater |

|

Film |

Silicon |

|||||||

|

|

|

|

|||||||

Film |

|

|

|

|

Microchip |

|||||

Detcon Model TP-524C Hydrogen Sulfide Sensor PG.3

3.0.2 Microprocessor Control Circuit

The control circuit is microprocessor based and is packaged as a plug-in field replaceable module, facilitating easy replacement and minimum down time. Circuit functions include a basic sensor pre-amplifier, sensor temperature control, on-board power supplies, microprocessor, back lit alpha numeric display, fault and calibration status LED indicators, magnetic programming switches, and a linear 4-20 mA DC output.

Program Switch #1

Display Contrast Adjust

Program Switch #2

CONTRAST |

PGM |

1 |

Plug-in Microprocessor Control Circuit |

|

|

|

|

MODEL |

detcon inc. |

TP-524C |

|

HOUSTON, TEXAS |

|||

|

|

|

Menu Driven Display |

MicroSafe™ H2S Gas Sensor |

|||

FLT |

|

|

CAL |

|

PGM |

2 |

Fault & Cal LEDs |

|

|

|

|

3.0.3 Base Connector Board

Base Connector Board

|

|

|

|

|

|

|

|

|

|

|

|

BLU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-20 mA Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mA |

|

YEL |

|

|

|

|

|

|

Sensor |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VDC Power In |

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The base connector board is mounted in the explosion proof enclosure and includes: the mating connector for the control circuit, reverse input and secondary transient suppression, input filter, and lugless terminals for field wiring.

3.0.4 Explosion Proof Enclosure

Detcon Model TP-524C Hydrogen Sulfide Sensor PG.4

The sensors are packaged in a cast metal explosion proof enclosure. The enclosure is fitted with a threaded cover that has a glass lens window. Magnetic program switches located behind the transmitter module face plate are activated through the lens window via a hand-held magnetic programming tool allowing non-intrusive operator interface with the sensor. Calibration can be accomplished without removing the cover or declassifying the area. Electrical classification is Class I; Groups B, C, D; Division 1 (explosion proof).

3.1 PRINCIPLE OF OPERATION

Functional

Block

Diagram

Pre-Amp

Temperature Micro- Sensor Compensation processor

Element

Transmitter

Power Supply

Display |

|

Cal & Fault |

Analog 4-20 mA Out |

LEDs |

I/O Circuit |

|

|

4-20mA |

Protection |

Power In |

Method of detection is by diffusion/adsorption. Air and gas diffuse through a sintered stainless steel filter and contact the heated surface of the metal oxide sensor film. As hydrogen sulfide gas molecules react with oxygen ions on the film, there is a decrease in electrical resistance proportional to the gas concentration. The heater film elevates the temperature of the sensor film creating convection and promoting a quick response to changing gas concentrations. Electronically, the heater film is used to maintain a constant temperature of the sensor film enhancing stability and repeatability. The sensor response is reversible and results in continuous monitoring of ambient air conditions.

3.2 APPLICATION

Model TP-524C MicroSafe™ sensors are designed to detect and monitor hydrogen sulfide gas in ambient air in the range of 0-100 parts per million. The sensor can also be programmed to operate in the range 0-20 ppm or 0-50 ppm. Minimum sensitivity and scale resolution is 1 ppm. Operating temperature range is --40° F. to +175° F. While the sensor is capable of operating outside these temperatures, performance specifications are verified within the limit.

3.2.1 Sensor Placement/Mounting

Sensor location should be reviewed by facility engineering and safety personnel. Area leak sources and perimeter mounting are typically used to determine number and location of sensors. Hydrogen sulfide gas is slightly heavier than air (approximately 1.18); therefore, the sensors are generally located 2 - 4 feet above grade.

3.2.2 Interference Data |

|

|

Gas |

PPM |

|

Methane |

25,000 |

= 0 |

Ethane |

5,000 |

= 0 |

Hexane |

5,000 |

= 0 |

Propane |

5,000 |

= 0 |

Butane |

5,000 |

= 0 |

Carbon Monoxide |

800 |

= 0 |

Carbon Dioxide |

5,000 |

= 0 |

Carbon Disulfide |

14 |

= 0 |

Methanol |

200 |

= 0 |

Isopropanol |

200 |

= 0 |

Ammonia |

500 |

= 0 |

Diesel Fuel |

1000 |

= 0 |

Dimethyl Sulfide |

4.4 |

= 0 |

Ethylene |

200 |

= 0 |

Freon 12 |

1000 |

= 0 |

Hydrogen |

5% |

= 0 |

Methyl Mercaptan |

16 |

= 6 |

Sulfur Dioxide |

300 |

= 0 |

Toluene |

32 |

= 0 |

Ethanol |

200 |

= 0 |

Detcon Model TP-524C Hydrogen Sulfide Sensor PG.5

3.3 SPECIFICATIONS

Method of Detection

Solid state metal oxide diffusion/adsorption

Electrical Classification

CSA-NRTL (US OSHA) approved Class I; Groups B, C, D; Div. 1.

Response Time

T50 < 30 seconds, T80 < 60 seconds

Clearing Time

T80 < 30 seconds

Repeatability

±10% of reading or ± 2 ppm (greater of)

Range

0-20 ppm, 0-50 ppm, or 0-100 ppm

Operating Temperature

-40° to +175° F (-40°C to +75°C)

Accuracy

±10% of reading or ± 2 ppm (greater of)

Sensor Warranty

10 year conditional

Power Consumption

Normal operation = 68 mA (<1.7 watt); Full alarm = 85 mA (2 watts)

Output

Linear 4-20 mA DC

Input Voltage

12-28 VDC

3.4 OPERATING SOFTWARE

Operating software is menu listed with operator interface via the two magnetic program switches located under the face plate. The two switches are referred to as “PGM 1” and “PGM 2”. The menu list consists of 3 items which include sub-menus as indicated below. (Note: see the last page of this manual for a complete software flow chart.)

01.Normal Operation

a)Current Status

02.Calibration Mode

a)Span

03.Program Menu

a)View Program Status

b)Set Calibration Level

c)Set Heater Level

d)Set Range

e)Utility Menu

3.4.1Normal Operation

In normal operation, the display reflects the current status of the sensor and gas concentration and appears as: “0 PPM H2S”. The mA current output corresponds to the monitoring level and range of detection = 4-20 mA.

3.4.2 Calibration Mode

Detcon Model TP-524C Hydrogen Sulfide Sensor PG.6

Loading...

Loading...