Page 1

PROPANE GAS-FIRED RADIANT CONSTRUCTION HEATER

OWNER’S MANUAL

MODEL 35-R

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide

poisoning and/or electrical shock.

Only persons who can understand and follow the instructions should use or service this heater.

If you need assistance or heater information such as an instructions manual, labels, etc. contact the manufacturer.

Save this manual for future reference.

For more information, visit www.desatech.com

Page 2

Safety Information ............................................... 2

TABLE OF CONTENTS

Product Identification ........................................... 3

Unpacking ........................................................... 3

Theory of Operation ............................................ 3

Propane Gas Supply ........................................... 4

Ventilation ............................................................

Installation Instructions ........................................ 4

Locating Heater ................................................... 4

Operating Instructions ......................................... 5

Cleaning and Maintenance .................................. 6

Troubleshooting ................................................... 7

Illustrated Parts Breakdown and Parts List ......... 8

Specifications ....................................................

4

Replacement Parts ............................................ 10

Warranty and Repair Service ............................ 12

10

SAFETY INFORMATION

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproduc

tive harm.

WARNING: Fire, burn, inhalation and explosion hazard.

Keep solid combustibles, such

as building materials, paper or

cardboard, a safe distance away

from the heater as recommended

by the instructions. Never use

the heater in spaces which do or

may contain volatile or airborne

combustibles or products such

as gasoline, solvents, paint thinner, dust particles or unknown

chemicals.

WARNING: Not for home or

recreational vehicle use.

The heater is designed for use as a construction heater in accordance with ANSI Z83.7/CGA 2.14. Other

standards govern the use of fuel gases and heating

products for specific uses. Your local authority

can advise you about these. The primary purpose

of construction heaters is to provide temporary

heating of buildings under construction, alteration

or repair. Properly used, the heater provides safe

economical heating. Products of combustion are

vented into the area being heated.

We cannot foresee every use which may be made of

our heaters. Check with your local fire safety au

thority if you have questions about heater use.

-

Other standards govern the use of fuel gases and

heat producing products for specific uses. Your

local authorities can advise you about these.

Carbon Monoxide Poisoning: Some people are

more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning re

semble the flu, with headaches, dizziness and/or

nausea. If you have these signs, the heater may not

be working properly. Get fresh air at once! Check

for proper ventilation and have heater serviced.

Propane Gas: Propane gas is odorless. An odor-

making agent is added to propane gas. The odor

helps you detect a propane gas leak. However, the

odor added to propane gas may fade. Propane gas

may be present even though no odor exists.

Make certain you read and understand all warn

ings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

1. Install and use heater with care. Follow all

local ordinances and codes. In the absence

of local ordinances and codes, refer to the

Standard for Storage and Handling of Liq

uefied Petroleum Gas, ANSI/NFPA 58 and

the Propane Installation Code, CAN/CGA

B149.2. This instructs on the safe storage and

handling of propane gases.

2. Use only the hose and factory preset regulator

provided with the heater.

3. Use only propane gas set up for vapor with

drawal.

4. Provide adequate ventilation. Before using

heater, provide at least a 3 ft

ing of fresh, outside air for each 100,000

Btu/hr of rating.

5. Do not use heater in occupied dwellings or in

living or sleeping quarters.

6. Do not use heater in basement or below ground

level.

7. Keep appliance area clear and free from com

bustible materials, gasoline, paint thinner and

other flammable vapors and liquids. Dust is

-

combustible. Do not use heater in areas with

high dust content.

2

(0.28 m2) open-

-

-

-

-

-

2

www.desatech.com

117296-01A

Page 3

SAFETY INFORMATION

Continued

8. Minimum heater clearances from combustibles: Sides 20" (50.8 cm), Top 40" (101.6 cm),

Front 54" (137.2 cm).

9. Keep heater at least 6 m (20 ft) from propane

tank(s).

10. Keep propane tank(s) below 38° C (100° F).

11. Check heater for damage before each use. Do

not use a damaged heater.

12. Check hose before each use of heater. If highly

worn or cut, replace with hose specified by the

manufacturer before using heater.

13. Locate heater on stable and level surface if

heater is hot or operating.

14. Not intended for use on finished floors.

15. Never block any air inlet or air outlet openings

of heater.

16. Keep heater away from strong drafts, wind,

water spray, rain or dripping water.

17. Do not leave heater unattended.

18. Keep children and animals away from

heater.

19. Never move, handle or service a hot or operat

ing heater. Severe burns may result. Wait 15

minutes after turning heater off.

20. To prevent injury, wear gloves when handling

heater.

21. Never attach duct work to heater.

22. Do not alter heater. Keep heater in its original

state.

23. Do not use heater if altered.

24. Turn off gas supply to heater when not in

use.

25. Use only original replacement parts. This

heater must use design-specific parts. Do

not substitute or use generic parts. Improper

replacement parts could cause serious or fatal

injuries.

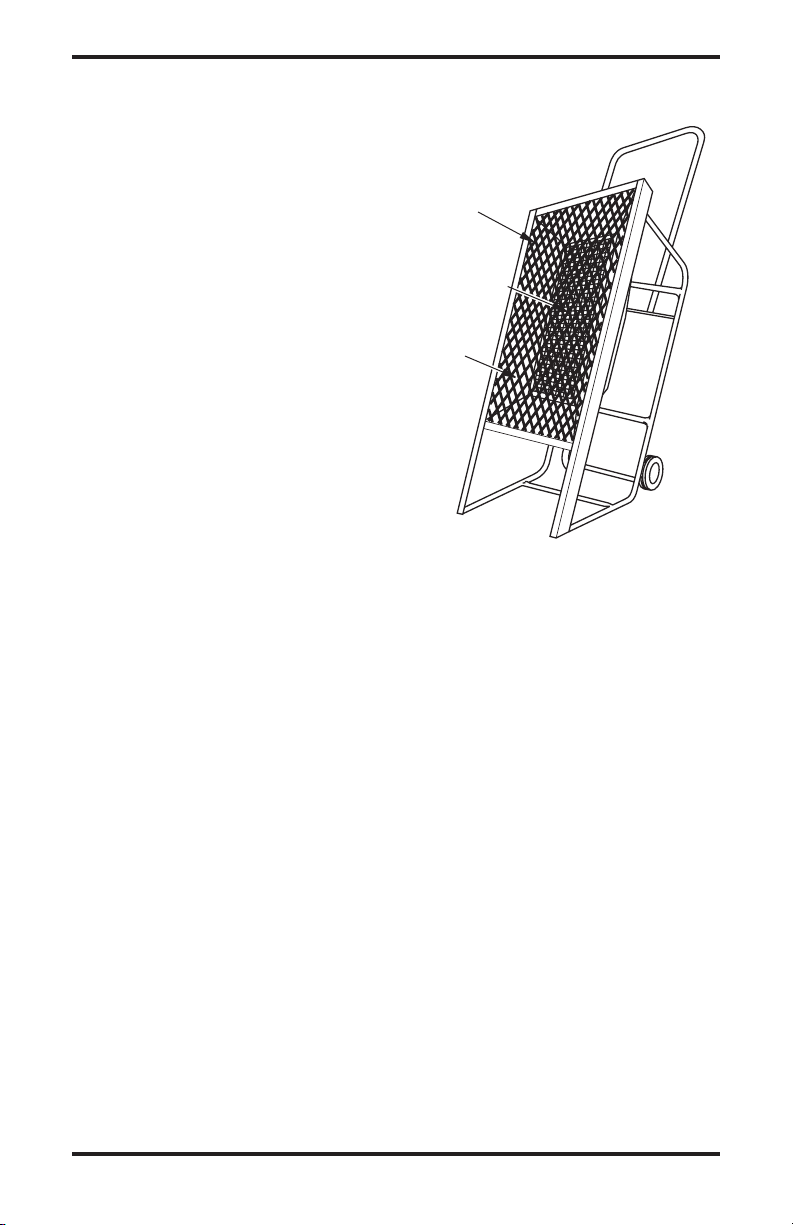

PRODUCT

IDENTIFICATION

Expanded

Metal

Screen

Burner

Face

Reflector

-

Figure 1 - Product Identification

UNPACKING

1. Remove all packing items applied to heater for

shipment. Keep plastic cover caps (attached to

valve inlet and hose/regulator assembly) for

storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater

is damaged, promptly inform dealer where you

bought heater.

THEORY OF OPERATION

The Fuel System: For propane units, the hose/

regulator assembly attaches to the propane gas

supply. For natural gas units, the gas supply at

taches to the heater through user supplied hose or

pipe. This provides fuel to the heater.

The Ignition System: The piezo ignitor lights the

burner fuel supply.

The Automatic Control System: This system causes

the heater to shut down if the flame goes out.

-

117296-01A

www.desatech.com

3

Page 4

PROPANE GAS SUPPLY

Propane gas and propane tank(s) are to be furnished by the user.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5 of the

Standard for Storage and Handling of Liquefied

Petroleum Gas, ANSI/NFPA 58 and/or CAN/CGA

B149.2. Your local library or fire department will

have this booklet.

The amount of propane gas ready for use from

propane tanks varies. Two factors decide this

amount.

1. The amount of liquid propane gas in tank(s)

2. The temperature of tank(s)

This heater is designed to operate with a minimum

20 pound (9 kg) propane tank. You may need two

or more tanks or one larger tank in colder weather.

Use a 100 pound (45 kg) tank for longer operation

or in very cold weather. Less gas is vaporized at

lower temperatures. Your local propane gas dealer

will help you select the proper supply system. The

minimum surrounding air temperature rating for

each heater is -20° F (-29° C).

Average Temperature Number Of Tanks

At Tank Location 100 lb (45 kg)

above 0° F (-18° C) 1

below 0° F (-18° C) 2

Smaller tanks can be used for limited run times

but it is recommended to use larger tanks for

optimum performance.

VENTILATION

WARNING: Provide at least

a 3 ft2 (0.28 m2) opening of

fresh, outside air while running

heater. If proper fresh, outside

air ventilation is not provided,

carbon monoxide poisoning

can occur. Provide proper

fresh, outside air ventilation

before running heater.

INSTALLATION

INSTRUCTIONS

Read these instructions carefully. Read and adhere to these

instructions. Do not allow anyone who has not read these

instructions to assemble, light,

adjust or operate this heater.

Do not attempt to operate the

heater with any gas other than

that indicated on the heater

nameplate.

For the U.S. and/or Canada, the installation of this

appliance must comply with local and/or Provin

cial codes or, in the absence of these codes, with

the (U.S.) National Fuel Gas Code, ANSI Z223.1

– Latest Edition (for natural and propane/LP gas

operation) and with the (U.S) Standard for the

Storage and Handling of Liquefied Petroleum

Gases, ANSI/NFPA 58 (for propane/LP gas opera-

tion) or with the current (Canadian) CAN/CGA

B149.1 and B149.2 installation codes.

This heater (including hose and regulator assembly

if applicable) must be inspected before each use

and at least annually by a qualified service person.

If the hose shows evidence of excessive abrasion

or wear or if the hose is cut, it must be replaced

prior to the heater being put into operation. The

replacement hose assembly shall be that specified

by the manufacturer.

Tip Over Switch

This heater incorporates a tip over switch which

automatically shuts off the burner in the event of

tipping. Ensure that this switch is in the vertical position and is secured with the screws provided.

LOCATING HEATER

Although this heater incorporates a tip over switch,

the heater and propane/LP gas supply cylinder must

be located on a hard, flat, level surface to minimize

the risk of accidental tipping. The propane/LP gas

supply cylinder should be adequately restrained to

prevent accidental tipping. DO NOT operate this

heater with the supply cylinder in any other than

the upright position.

This appliance must be installed only in locations

where the potential for physical damage to the

appliance (i.e., due to physical contact) is reduced

to a minimum.

-

4

www.desatech.com

117296-01A

Page 5

LOCATING HEATER

Continued

The installer must inform the owner/operator of

this appliance that precautions must be taken to

protect the appliance from physical damage.

This appliance produces radiant heat. Therefore,

it must be located at least 6 feet away from

any propane/LP gas container and must not be

directed toward any propane/LP gas container

within 20 feet.

The heater must be installed in a location such that

it will not be exposed directly to water spray, rain

and/or dripping water.

Use of this heater in a draft/windy area decreases

its efficiency. If possible, operate the unit in a

draft free area.

CONNECTING TO GAS SUPPLY

This model may be connected to a self-contained

propane/LP gas supply system using the hose and

regulator assembly supplied with the appliance

OR, it may be connected to a permanently installed

propane/LP gas supply system.

If connected to a self-contained propane/LP

gas supply system, the hose assembly must be

inspected prior to each use of the heater. If it is

evident that there is excessive abrasion or wear or

if the hose is cut, it must be replaced prior to the

heater being put into operation.

WARNING: Never use a fork

lift truck type cylinder.

The connection to a propane/LP cylinder must be

made in a well ventilated area using the regulator

and hose assembly supplied with the appliance.

DO NOT attempt to adjust this regulator. It has

been preset at the factory to provide safe and

proper operation of the appliance. Use a 7/8" open

end wrench to connect the POL fitting (supplied

with the propane/LP regulator) to the propane/LP

cylinder. Turn the POL nut in a counterclockwise

direction (left hand thread) until tight. DO NOT

use pipe compound on POL threads.

The heater must be located at least 6 feet away

from any propane/LP cylinder and must not be

directed toward any propane/LP cylinder within

20 feet. If more than one heater is used, they

and the supply cylinders must be separated by at

least 20 feet.

The gas supply must be turned off at the propane/

LP supply cylinder when the heater is not in use.

When the heater is to be stored indoors, the con

nection between the propane/LP supply cylinder

and the heater must be disconnected and the

cylinder removed from the heater and stored in

accordance with Chapter 5 of the Standard for

the Storage and Handling of Liquefied Petroleum

Gases ANSI/NFPA 58

If connected to a permanently installed propane/

LP supply system, the system requires the use

of a two-stage gas regulator assembly which is

normally provided by your propane/LP dealer as

part of the propane/LP supply system. Consult with

your local propane/LP dealer for details concern

ing proper equipment and installation.

Piping must be clean and free from scale or

burrs.

.

WARNING: Never use a flame

for gas leak testing.

OPERATING

INSTRUCTIONS

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, per

sonal injury or loss of life.

CAUTION: This appliance

is hot during normal operation,

avoid physical contact.

CAUTION: Do not place

clothing or other combustible

materials on this appliance.

DO NOT operate this heater if any part has been

under water. Call a qualified service technician to

inspect the appliance and to replace any part of

the control system or gas control valve which has

been under water.

-

-

-

117296-01A

www.desatech.com

5

Page 6

OPERATING

INSTRUCTIONS

Continued

LIGHTING HEATER

1. Before attempting to light the heater check

for gas leaks. Turn on the gas supply to the

appliance and check all fittings and connections for gas leaks using a mild soap and water

solution. NEVER use a match to check for gas

leaks. Should a gas leak occur, shut off the gas

supply to the appliance immediately. Correct

all leaks at once.

2. Use only the fuel intended for this appliance.

Check the appliance rating plate for the correct

fuel information.

3. Turn on the main gas supply.

4. Press and hold button on control valve.

5. Press button on piezo ignitor 6 to 8 times.

Burner should light.

Thermocouple

Figure 2 - Heater Parts

To Match Light the Pilot

Hold a lit match to the burner face while pressing

and holding the control valve button. After the

burner ignites, keep button pressed for one (1)

minute or until the burner stays lit after releasing

button. DO NOT light gas at the burner orifice. DO

NOT face heater when attempting to light. Always

stand to the side of the unit when lighting.

CAUTION: When lighting

burner with a match or taper,

light at bottom of screen. Not

at orifice.

Burner

Ignitor

Electrode

Piezo

Ignitor

Button

Control

Valve Button

Note: In cases where long runs of gas supply lines

have been installed ahead of the appliance, it may

be necessary to bleed trapped air out of supply lines

before lighting pilot. New installations generally

require bleed of supply lines. Wait a minimum of

five minutes after bleeding supply lines before

attempting to light heater.

IMPORTANT: DO NOT attempt to adjust the

main burner input using the main gas supply valve.

This may cause the pilot and thermocouple to shut

down the burner.

SHUTTING OFF HEATER

1. Close propane gas supply cylinder valve.

2. Observe the burner until flame is extin

guished.

3. Listen for closure of the safety valve.

IMPORTANT: DO NOT reopen the propane gas

supply cylinder valve before the safety valve

closes.

CLEANING AND

MAINTENANCE

WARNING: Never attempt

to service heater while it is

connected to propane supply,

operating or hot. Severe burns

can occur.

1. Turn heater off and let cool at least 20 minutes

before cleaning.

2. Keep heater clean. Clean heater annually or as

needed to remove dust and debris. If heater is

dirty or dusty, clean heater with a damp cloth.

Use household cleaners on difficult spots.

3. Inspect heater before each use. Check connec

tions for leaks. Apply mixture of liquid soap

and water to connections. Bubbles forming

show a leak. Correct all leaks at once.

4. Clean inside of heater using compressed

air. Blow air back and forth along the entire

burner face until all dust has been dislodged

from surface of reverberator and screen. Blow

air through venturi from the control end of

heater.

5. Inspect hose/regulator assembly before each

use. If hose is highly worn or cut, replace.

6. Have heater inspected yearly by a qualified

service agency.

-

-

6

www.desatech.com

117296-01A

Page 7

TROUBLESHOOTING

WARNING: Never attempt to service heater while it is connected

to propane supply, operating or hot. Severe burns can occur.

SYMPTOM

Burner fails to light

Pilot lights but goes out when

automatic control valve button

is released

Burn rate is low

Burner lights but goes out when

button is released

POSSIBLE CAUSE

1. Gas supply valve closed

2. Exce ss-flo w ch eck valve

closed

3. Blockage in burner orifice

4. Piezo ignition system not

sparking

1. Not enough warm-up time

2. Low gas pressure

3. Thermocouple loose or needs

to be replaced

4. Automatic control valve needs

to be replaced

1. Plugged gas orifices

2. Low gas pressure

3. Low fuel supply

1. Loose wi res on ti p over

switch

2. Loose or broken lead wire

3. Loose or mislocated thermocouple wire

4. Defective thermocouple

5. Defective control

6. Defective tip over switch

REMEDY

1. Open gas supply valve slowly

2. Close propane supply valve

on propane tank and reopen

slowly

3. Replace burner orifice

4. Assure ignitor electrode gap is

5.0 mm (0.195 in). Check wire

lead for damage Replace piezo

ignitor and/or ignitor electrode

as necessary. Do not bend elec

trode, this may cause breakage

1. Relight, hold automatic control

valve button in 45 seconds

2. Check for proper gas supply

3. Tighten connection or replace

thermocouple

4. Replace automatic control

valve

1. Replace gas orifice

2. Check gas supply; check

regulator output

3. Consult gas supplier to determine adequate supply. Tank

could be empty

1. Tighten wires on tip over

switch

2. Tighten or repair wire

3. Tighten thermocouple. Make

sure thermocouple is located

correctly between reverberator and grid

4. Replace thermocouple

5. Replace control

6. Replace tip over switch

-

117296-01A

www.desatech.com

7

Page 8

MODEL 35-R

1

17

12

13

15

14

16

2

3

4

5

10

9

7

8

11

6

ILLUSTRATED PARTS BREAKDOWN

8

www.desatech.com

117296-01A

Page 9

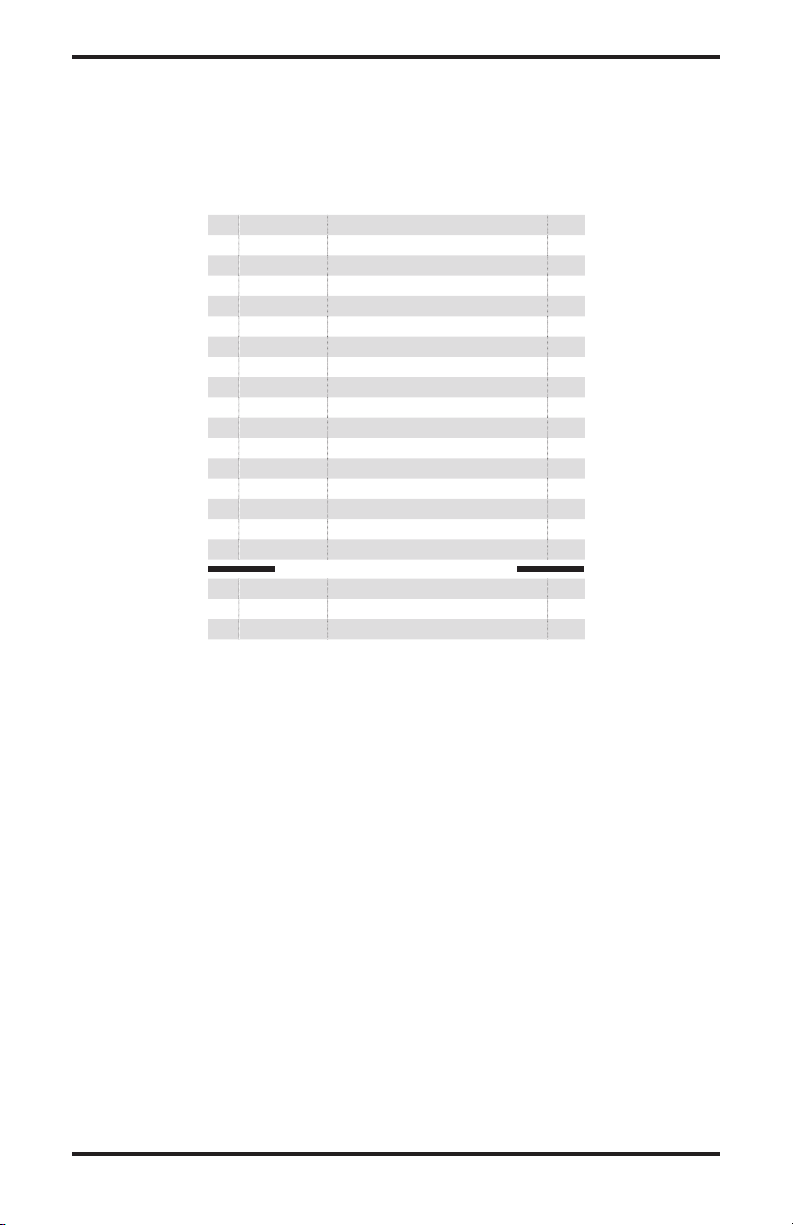

PARTS LIST

MODEL 35-R

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 10 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 115286-01 Burner 1

2 114121-01 Thermocouple 1

3 117384-01 Thermocouple Bracket 1

4 115291-01 Ignitor Electrode 1

5 117385-01 Ignitor Bracket 1

6 102445-01 Piezo Ignitor Kit 1

7 115287-01 Orifice 1

8 115285-01 Valve 1

9 115289-01 Junction Block 1

10 115288-01 Tip Switch 1

11 111090-02

12 115290-01 Hose/Regulator Assembly 1

13 115292-01 Wheel 2

14 114156-02 Axle Bracket 2

15 115294-01 Wheel Lock 2

16 117297-01 Main Frame Lower Assembly 1

17 117310-01 Reflector 1

114245-06 General Information Decal 1

115297-01 Warning Tag

114246-03

Brass Elbow 1

PARTS AVAILABLE - NOT SHOWN

1

Caution Decal 1

117296-01A

www.desatech.com

9

Page 10

SPECIFICATIONS

• Rating: 35,000 Btu/Hr

• Fuel: Propane Vapor Only

• Fuel Consumption per Hour:

0.38 gallon (1.5 liters), 1.6 lbs (1.74 kg)

• Supply Pressure To Regulator (for input adjust

ment): Maximum - 200 lbs or tank pressure

Minimum - 10 psi

• Manifold Pressure: 9.5" W.C. (2.3 kPa)

• Minimum Surrounding Air Temperature:

-20° F (-29° C)

REPLACEMENT PARTS

WARNING: Use only original

replacement parts. This heater

must use design-specific parts.

Do not substitute or use generic

-

parts. Improper replacement

parts could cause serious or fatal injuries. This will also protect

your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), either call

DESA Heating Productsʼ at 1-866-672-6040 or

DESA Industries at 1-905-826-8010.

When calling DESA, have ready:

• your name and address

• model and serial numbers of your heater

• how heater was malfunctioning

• purchase date

In most cases, we will ask you to return the part

to the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), call DESA

Heating Productsʼ at 1-866-672-6040 or DESA

Industries at 1-905-826-8010.

When calling DESA, have ready:

• model and serial numbers of your heater

• the replacement part number

10

www.desatech.com

117296-01A

Page 11

NOTES

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

117296-01A 11

www.desatech.com

Page 12

WARRANTY AND REPAIR SERVICE

KEEP THIS WARRANTY

Model

Serial No.

Date of Purchase

LIMITED WARRANTIES FOR NEW AND FACTORY

RECONDITIONED PRODUCTS

New Products: DESA Heating Products warrants this heater and any parts thereof, to be free of defects in materials

and workmanship for one (1) year from the date of first purchase, when operated and maintained in accordance

with the manufacturer's instructions. These warranties are extended only to the original retail purchaser, when

proof of purchase is provided.

Factory Reconditioned Heaters: DESA Heating Products warrants this factory reconditioned heater and any parts

thereof, to be free of defects in materials and workmanship for thirty (30) days from the date of first purchase,

when operated and maintained in accordance with the manufacturer's instructions. These warranties are extended

only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of proper main

tenance, normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts or

repair by anyone other than an authorized dealer or service center. Routine maintenance is the responsibility of

the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DESA assumes no responsibility for indirect, incidental or consequential damages. Some states do not allow the

exclusion or limitation of incidental or consequential damages or limitations or exclusions may not apply to you. This

Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our

standard written warranty. We make no other warranty, expressed or implied.

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase must be

presented with the heater. The heater will be inspected. A defect may be caused by faulty materials or workmanship.

If so, DESA will repair or replace the heater without charge.

REPAIR SERVICE

Return your heater to your nearest authorized service center. Repairs not covered by the warranty will be billed at

standard prices. Each Service Center is independently owned and operated. We reserve the right to amend these

specifications at any time without notice.

When writing for information regarding your heater, be sure to include the model number and serial number as shown

on the model plate. For more information about this warranty, write:

-

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

ATTN: Customer Service Department

2220 Argentia Road, Unit #4

Mississauga, Ontario

L5N2K7

Page 13

CALENTADOR PARA CONSTRUCCIÓN DE RADIACIÓN A GAS

PROPANO

MANUAL DEL PROPIETARIO

MODELO 35-R

IMPORTANTE: lea y comprenda este manual antes de

ensamblar, encender o dar servicio al calentador. El uso

inadecuado del calentador puede causar lesiones graves.

Conserve este manual para referencias futuras.

ADVERTENCIA GENERAL DE PELIGRO:

El incumplimiento de las precauciones e instrucciones pro

porcionadas con este calentador puede causar la muerte,

lesiones físicas graves y pérdidas o daños a la propiedad ocasionados por incendios, explosiones, quemaduras, asfixia,

intoxicación con monóxido de carbono y/o electrocución.

Únicamente las personas que puedan entender y seguir las

instrucciones deberán usar o dar servicio a este calentador.

Si necesita ayuda o información sobre el calentador, por

ejemplo, un manual de instrucciones, etiquetas, etc., comuníquese con el fabricante.

Guarde este manual para referencias futuras.

Para obtener más información visite www.desatech.com

Page 14

Información de seguridad .................................... 2

TABLA DE CONTENIDO

Identificación del producto ...................................

Desempaque ....................................................... 3

Teoría de funcionamiento .................................... 3

Suministro de gas propano ................................. 4

Ventilación ...........................................................

Instrucciones de instalación ................................ 4

Ubicación del calentador ..................................... 4

Instrucciones de funcionamiento ......................... 5

3

Limpieza y mantenimiento ................................... 6

Solución de Problemas ....................................... 7

Clasificación ilustrada de piezas y lista de piezas

Especificaciones ................................................

4

Piezas de repuesto ............................................ 10

Garantía y servicio de reparación ..................... 12

.. 8

10

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA: este producto contiene y/o genera químicos

reconocidos por el estado de Cali

fornia como causantes de cáncer

o de defectos de nacimiento, u

otros daños reproductivos.

ADVERTENCIA: peligro de

incendio, quemaduras, inhalación

y explosión Mantenga los combustibles sólidos, como materiales de

construcción, papel o cartón, a una

distancia segura del calentador

según se recomienda en las instrucciones. Nunca use el calentador

en áreas en las que haya, o pueda

haber, combustibles volátiles o que

se acumulen en el aire, o bien, productos como gasolina, solventes,

diluyente de pintura, partículas de

polvo o químicos desconocidos.

ADVERTENCIA: no usar en

residencias ni en vehículos recreativos.

El calentador está diseñado para usarse como

calentador para construcción conforme a la norma

ANSI Z83.7/CGA 2.14. Otras normas rigen el uso

de gases combustibles y productos de calefacción

para usos específicos. La autoridad local puede

informarle acerca de éstas. El propósito principal de

los calentadores para construcción es proporcionar

calefacción temporal en edificios en construcción,

modificación o reparación. Cuando se usa correc

tamente, el calentador proporciona calefacción

económica y segura. Los productos de combustión

se ventilan al área que se está calentando.

2

-

www.desatech.com

No podemos prever todos los usos que se les pueden

dar a nuestros calentadores. Consulte a la autori

dad local de seguridad contra incendios en caso

que tenga alguna pregunta acerca del uso de

calentadores.

Otras normas rigen el uso de gases combustibles y

productos que producen calor para usos específicos. Las

autoridades locales pueden informarle acerca de éstas.

Intoxicación con monóxido de carbono:

personas sufren mayores efectos del monóxido de

carbono que otras. Los primeros signos de intoxicación

con monóxido de carbono son semejantes a los de la

gripe, con dolor de cabeza, mareo o náusea. Si usted

presenta estos síntomas, es posible que el calentador no

esté funcionando correctamente. ¡Respire aire fresco

inmediatamente! Compruebe que haya ventilación

adecuada y haga que reparen el calentador.

Gas propano:

propano se le agrega un agente con olor. El olor

le ayuda a detectar las fugas de gas propano. Sin

embargo, el olor que se añade al gas propano puede

desvanecerse. Es posible que haya gas propano a

pesar de que no huela a gas.

Asegúrese de leer y comprender todas las advertencias.

Conserve este manual como referencia. Es su guía para

la operación segura y correcta de este calentador.

1. Instale y use el calentador con cuidado. Siga

las ordenanzas y los códigos locales. A falta

de reglamentos y códigos locales, consulte la

Norma de almacenamiento y manejo de gas

licuado de petróleo, ANSI/NFPA 58 y el Código

de instalación de gas propano, CAN/CGA B149.

Estos proporcionan instrucciones acerca del

almacenamiento y manejo seguro del propano.

2. Use sólo la manguera y el regulador preins

talado en la fábrica que se incluyen con el

calentador.

3. Use solamente el montaje de gas propano para

la extracción de vapores.

4. Proporcione ventilación adecuada. Antes de

-

usar el calentador, asegúrese de que exista una

abertura para aire fresco del exterior de por

lo menos 0.28 m

BTU/h de clasificación.

5. No use el calentador en viviendas ocupadas,

en estancias ni en dormitorios.

el gas propano es inodoro. Al gas

2

(3 pies2) por cada 100,000

117296-01A

-

algunas

-

Page 15

INFORMACIÓN DE

SEGURIDAD

Continuación

6. No use el calentador en un sótano ni debajo del

nivel del suelo.

7. Mantenga el área en dónde se localiza el aparato

despejada y libre de materiales combustibles,

gasolina, diluyentes para pintura y otros vapores

y líquidos inflamables. El polvo es combustible.

No use el calentador en áreas con alto contenido

de polvo.

8. Distancias mínimas entre el calentador y combustibles: Laterales 50.8 cm (20"), Parte superior

101.6 cm (40"), Parte anterior 137.2 cm (54").

9. Mantenga el calentador a una distancia mínima

de 6 m (20 pies) de los tanques de propano.

10. Mantenga los tanques de propano a menos de

38° C (100° F).

11.

Antes de cada uso, verifique si el calentador ha sufrido algún daño. No use un calentador dañado.

12. Revise la manguera antes de cada uso del calentador. Si la manguera está muy desgastada

o con roturas, reemplácela con una manguera

especificada por el fabricante antes de usar el

calentador.

13. Cuando el calentador esté caliente o funcionando póngalo en una superficie estable y

nivelada.

14.

No está diseñado para su uso en pisos terminados.

15. Nunca bloquee ninguna de las aberturas de

entrada y de salida de aire del calentador.

16. Mantenga el calentador alejado de corrientes

fuertes de aire, viento, rocío, lluvia y goteras

de agua.

17. No deje el calentador desatendido.

18. Evite que los niños y los animales se acerquen

al calentador.

19. Nunca mueva, maneje o dé servicio a un ca

lentador caliente o en funcionamiento. Pueden

producirse quemaduras graves. Espere 15

minutos después de apagar el calentador.

20. Para evitar lesiones, use guantes cuando mani

pule el calentador.

21. Nunca fije tubería al calentador.

22. No altere el calentador. Mantenga el calentador

en su estado original.

23. No use el calentador si éste ha sido alterado.

24. Cierre el suministro de gas al calentador cuando

no se esté usando.

25. Use sólo piezas de repuesto originales. Este ca

lentador debe usar piezas diseñadas específica

mente. No las sustituya ni use piezas genéricas.

El uso de piezas de repuesto inadecuadas puede

ocasionar lesiones graves o fatales.

IDENTIFICACIÓN DEL

PRODUCTO

Rejilla

metálica

expandida

Parte

delantera del

quemador

Reflector

Figura 1 - Identificación del producto

DESEMPAQUE

1. Retire todos los materiales en los que se empacó el calentador para el envío. Conserve los

tapones de plástico (colocados en la válvula de

entrada y en el conjunto de manguera y regulador) para propósitos de almacenamiento.

2. Saque todas las piezas de la caja.

3. Revise todas las piezas en busca de daños

durante el transporte. Si el calentador está

dañado, informe de inmediato al distribuidor

a quien se lo compró.

-

TEORÍA DE

FUNCIONAMIENTO

El sistema de combustible: en las unidades de

gas propano, el conjunto de manguera y regulador

se fija al suministro de gas propano. En las unidades de gas natural, el suministro de gas se fija

al calentador mediante una manguera o tubería

que el usuario debe suministrar. Esto proporciona

combustible al calentador.

El sistema de encendido: el encendido piezo-

eléctrico enciende suministro de combustible del

-

quemador.

-

El sistema de control automático: este sistema

ocasiona que el calentador se apague si se extin

gue la llama.

-

117296-01A

www.desatech.com

3

Page 16

SUMINISTRO DE GAS

PROPANO

El gas propano y el o los tanques de propano los

debe proveer el usuario.

Use el calentador solamente con un sistema de

suministro con extracción de vapores de propano.

Consulte el capítulo 5 de la Norma de almace

namiento y manejo de gas licuado de petróleo,

ANSI/NFPA 58 y/o la Norma CAN/CGA B149.2.

La biblioteca local o el departamento de bomberos

deben tener este folleto.

El volumen de gas listo para usarse a partir de

tanques de propano varía. Dos factores determinan

este volumen:

1. La cantidad de gas propano líquido en los

tanques

2. La temperatura del o los tanques

Este calentador está diseñado para funcionar con

un tanque de por lo menos 9 kg (20 libras). Es posi

ble que en climas fríos necesite dos o más tanques,

o un tanque de mayor capacidad. Use un tanque de

45 kg (100 lb) para operar el calentador durante un

periodo de tiempo más prolongado o en clima muy

frío. A temperaturas más bajas se vaporiza menos

gas. Su proveedor local de gas propano le ayudará

a seleccionar el sistema de suministro adecuado.

La temperatura mínima del aire circundante para

cada calentador es de -29 °C (-20 °F).

Temperatura promedio en Número de tanques

la ubicación de los tanques 45 kg (100 lb)

superior a -18 °C (0 °F) 1

inferior a -18 °C (0 °F) 2

Es posible usar tanques más pequeños para

tiempos de funcionamiento limitados, pero se

recomienda usar tanques más grandes para

obtener un rendimiento óptimo.

VENTILACIÓN

ADVERTENCIA: debe haber

una abertura para aire fresco

del exterior de por lo menos

0.28 m

lentador está encendido. Si no

proporciona ventilación de aire

fresco del exterior podría haber

intoxicación con monóxido de

carbono. Proporcione una ventilación adecuada de aire fresco

del exterior antes de encender

el calentador.

2

(3 pies2) cuando el ca-

INSTRUCCIONES DE

INSTALACIÓN

Lea estas instrucciones cuidadosamente. Lea y siga estas instrucciones. No permita que nadie que

no haya leído estas instrucciones

-

ensamble, encienda, ajuste o haga

funcionar este calentador.

No intente hacer funcionar el

calentador con ningún otro gas

que no sea el indicado en la placa

del calentador.

Para EE.UU. y/o Canadá, la instalación de este aparato

debe cumplir los códigos locales y/o provinciales o,

en ausencia de estos códigos, debe cumplir el Código

-

nacional de gas combustible, ANSI Z223.1, última

edición, (de EE.UU.) (para el funcionamiento con gas

natural o con propano o gas LP) y la Norma para el al-

macenamiento y manejo de gases licuados de petróleo,

ANSI/NFPA 58 (de EE.UU.) (para el funcionamiento

con propano o gas LP) o con los códigos de instalación

CAN/CGA B149.1 y B149.2 vigentes (Canadienses).

Una técnico de servicio capacitado debe inspeccionar

este calentador (incluyendo el conjunto de manguera

y regulador, si es aplicable) antes de cada uso y por

lo menos una vez al año. Si la manguera muestra

abrasión o desgaste excesivo, o si tiene roturas, se

debe reemplazar antes de poner el calentador en funcionamiento. El conjunto de la manguera de repuesto

debe ser el especificado por el fabricante.

Interruptor de seguridad en caso de vuelcos

Este calentador cuenta con un interruptor de seguridad incorporado que apaga el quemador automática

mente si el calentador se vuelca o se cae. Asegúrese

de que este interruptor esté en posición vertical y

sujeto con los tornillos que se incluyen.

UBICACIÓN DEL CALENTADOR

Aunque este calentador cuenta con un interruptor de

seguridad en caso de vuelcos, tanto el calentador como

el cilindro de suministro de propano o gas LP se deben

colocar en una superficie dura, plana y nivelada para

minimizar el riesgo de una volcadura accidental. El

cilindro de suministro de propano o gas LP debe estar

adecuadamente sujetado para evitar que se vuelque accidentalmente. NO haga funcionar este calentador si el

cilindro de suministro no está en posición vertical.

Este aparato se debe instalar solamente en ubicaciones en las que el daño físico potencial al

aparato (por ejemplo, debido a contacto físico) se

reduzca al mínimo.

-

4

www.desatech.com

117296-01A

Page 17

UBICACIÓN DEL

CALENTADOR Continuación

El instalador debe informar al propietario o al operador de este aparato que se deben tomar precauciones

para proteger al mismo de daños físicos.

Este aparato produce radiación de calor. Por lo tanto,

se debe situar a por lo menos 1.83 m (6 pies) de

cualquier contenedor de propano o gas LP y no se

debe dirigir hacia ningún contenedor de propano o

gas que esté a 6.1 m (20 pies) o menos.

El calentador se debe instalar en una ubicación tal

que no se exponga directamente al rocío de agua, a

la lluvia ni a goteras.

El uso de este calentador en áreas con corrientes de

aire o viento disminuye su eficacia. Si es posible, haga

funcionar la unidad en un área sin corrientes de aire.

CONEXIÓN AL SUMINISTRO DE GAS

Este modelo se puede conectar a un sistema de

suministro de propano o gas LP gas autónomo

utilizando el conjunto de manguera y regulador que

se incluyen con el aparato O se puede conectar a un

sistema de suministro de propano o gas LP instalado

permanentemente.

Si se conecta a un sistema de suministro de propano

o gas LP autónomo, el conjunto de la manguera se

debe inspeccionar antes de cada uso del calentador.

Si es obvio que hay abrasión o desgaste excesivo,

o si la manguera tiene roturas, se debe reemplazar

antes de poner el calentador en funcionamiento.

ADVERTENCIA: nunca use

un cilindro del tipo que se utiliza

en montacargas.

La conexión al cilindro de propano o gas LP se debe

hacer en un área bien ventilada utilizando el conjunto

de manguera y regulador que se incluye con el aparato.

NO intente ajustar este regulador. Se ha configurado

previamente en la fábrica para que el aparato funcione

de forma segura y correcta. Use una llave española de

7/8" para instalar la conexión de rosca invertida (inclui

da con el regulador de propano o gas LP) al cilindro de

propano o gas LP. Gire la tuerca de rosca invertida en

sentido contrario al de las manecillas del reloj (rosca a la

izquierda) hasta que esté apretada. NO use compuesto

para tuberías en las roscas invertidas.

El calentador se debe situar a por lo menos 1.83

m (6 pies) de cualquier cilindro de propano o gas

LP y no se debe dirigir hacia ningún cilindro de

propano o gas que esté a 6.1 m (20 pies) o menos.

Si se usa más de un calentador, éstos y los cilindros

de suministro deben estar separados por lo menos

6.1 m (20 pies).

Cuando el calentador no esté en servicio debe

cerrar el suministro de gas del cilindro de propano

o gas LP.

Cuando el calentador se vaya a guardar en interiores,

se debe desinstalar la conexión entre el cilindro de

suministro de propano o gas LP y el calentador y

el cilindro se debe extraer del calentador y guardar

de acuerdo con el capítulo 5 de la Norma para el

almacenamiento y manejo de gases licuados de

petróleo ANSI/NFPA 58

Si está conectado a un sistema de suministro de pro

pano o gas LP instalado permanentemente, el sistema

requiere el uso de un conjunto de regulador de gas

de dos etapas que generalmente le proporcionará su

distribuidor de propano o gas LP como parte del sis

tema de suministro. Consulte a su distribuidor local

de propano o gas LP para obtener detalles acerca de

la instalación y el equipo adecuados.

Las tuberías deben estar limpias y libres de impu

rezas o rebabas.

.

ADVERTENCIA: nunca use

una llama para probar si hay

fugas de gas.

INSTRUCCIONES DE

FUNCIONAMIENTO

ADVERTENCIA: no seguir

estas instrucciones al pie de la

letra puede resultar en incendio

o explosión que produzcan da

ños a bienes, lesiones físicas o

la muerte.

PRECAUCIÓN: este aparato

se calienta durante la operación normal, evite el contacto

físico.

-

PRECAUCIÓN: no coloque

ropa ni otros materiales combustibles sobre este aparato.

NO haga funcionar este calentador si alguna de

sus partes ha estado sumergida en agua. Llame a

un técnico de servicio capacitado para que inspeccione el aparato y reemplace las piezas del sistema

de control o de la válvula de controle de gas que

hayan estado sumergidas en agua.

-

-

-

-

117296-01A

www.desatech.com

5

Page 18

INSTRUCCIONES DE

FUNCIONAMIENTO

Continuación

ENCENDIDO DEL CALENTADOR

1. Antes de intentar encender el calentador,

verifique que no haya fugas de gas. Abra el

suministro de gas al aparato y revise todos los

conectores y las conexiones en busca de fugas

utilizando una solución jabonosa suave. NUNCA use un fósforo para revisar si hay fugas de

gas. Si se produce una fuga de gas, cierre el

suministro de gas al aparato inmediatamente.

Repare todas las fugas inmediatamente.

2. Use sólo el combustible indicado para este

aparato. Revise la placa de clasificación del

aparato para ver la información acerca del

combustible correcto.

3. Abra el suministro de gas principal.

4. Oprima y mantenga oprimido el botón de la

válvula de control.

5. Oprima el botón del encendedor piezoeléctrico

de 6 a 8 veces. El quemador deberá encender.

Termopar

Figura 2 - Piezas del calentador

Para encender el piloto con un fósforo

Sujete un fósforo encendido en la parte delantera del

quemador mientras oprime y mantiene el botón de la

válvula de control oprimido. Una vez que el quemador

se encienda, mantenga el botón oprimido durante

un (1) minuto o hasta que el quemador permanezca

encendido después de soltar el botón. NO encienda el

gas en el orificio del quemador. NO se coloque frente

al calentador cuando intente encenderlo. Siempre colóquese a un lado de la unidad cuando lo encienda.

PRECAUCIÓN: cuando encienda el quemador con un fós

foro o una antorcha, enciéndalo

por la parte inferior de la rejilla.

No lo encienda por el orificio.

6

Quemador

Electrodo del

encendedor

Botón del

encendedor

piezoeléctrico

Botón de la

válvula de

control

-

www.desatech.com

Nota: en los casos en que haya tuberías de suministro gas largas instaIadas antes que el aparato, es

posible que sea necesario purgar el aire atrapado en

las tuberías antes de encender el piloto. Las insta

laciones nuevas generalmente requieren la purga

de las tuberías de suministro. Espere un mínimo de

cinco minutos después de purgar las tuberías antes

de intentar encender el calentador.

IMPORTANTE: NO intente ajustar la alimentación

al quemador principal utilizando la válvula de sumi

nistro de gas principal. Esto podría ocasionar que el

piloto y el termopar apaguen el quemador.

CÓMO APAGAR EL CALENTADOR

1. Cierre la válvula del cilindro de suministro de

gas propano.

2. Observe el quemador hasta que la llama se

extinga.

3. Escuche el cierre de la válvula de seguridad.

IMPORTANTE: NO vuelva a abrir la válvula del

cilindro de suministro de gas propano antes de que

la válvula de seguridad se cierre.

LIMPIEZA Y

MANTENIMIENTO

ADVERTENCIA: nunca intente

dar servicio a un calentador mientras esté conectado al suministro

de propano, esté funcionando o

esté caliente. Pueden producirse

quemaduras graves.

1. Apague el calentador y déjelo enfriar por lo

menos 20 minutos antes de limpiarlo.

2. Mantenga limpio el calentador. Limpie el ca

lentador anualmente o según sea necesario para

retirar el polvo y los residuos. Si el calentador

está sucio o tiene polvo, límpielo con un paño

húmedo. Utilice limpiadores domésticos en las

manchas difíciles.

3. Inspeccione al calentador antes de cada uso.

Revise las conexiones en busca de fugas. Aplique

una mezcla de jabón líquido y agua en todas las

conexiones. La formación de burbujas indicará una

fuga. Repare todas las fugas inmediatamente.

4. Limpie el interior del calentador utilizando aire

comprimido. Haga soplar el aire hacia adelante

y hacia atrás a lo largo de toda la parte delantera

del quemador hasta que se haya eliminado todo

el polvo de la superficie del reverberador y la

rejilla. Haga pasar aire a través del venturi desde

el extremo del control del calentador.

5. Inspeccione el conjunto de manguera y regula

dor antes de cada uso. Si la manguera está muy

desgastada o rota, reemplácela.

6. Haga que una agencia de servicio calificada

inspeccione el calentador anualmente.

117296-01A

-

-

-

-

Page 19

SOLUCIÓN DE PROBLEMAS

ADVERTENCIA: nunca intente dar servicio a un calentador mientras esté conectado al suministro de propano, esté funcionando o

esté caliente. Pueden producirse quemaduras graves.

SÍNTOMA

El quemador no se enciende

El piloto se enciende, pero se apa

ga cuando se suelta el botón de la

válvula de control automático

La tasa de consumo es baja

CAUSA POSIBLE

1. La válvula de suministro de

gas está cerrada

2. La válvula de exceso de flujo

está cerrada

3. Bloqueo en el orificio del

quemador

4.

El sistema de encendido piezoeléctrico no produce chispa

-

1. El tiempo de calentamiento no

fue suficiente

2. La presión de gas está baja

3. El termopar está flojo o se

debe reemplazar

4. La válvula de control automático se debe reemplazar

1.

Los orificios de gas están tapados

2. La presión de gas está baja

3. El suministro de combustible

está bajo

REMEDIO

1. Abra la válvula del suministro

de gas lentamente

2.

Cierre la válvula del suministro

de propano en el tanque de propa

no y vuelva abrirla lentamente

3. Reemplace el orificio del

quemador

4.

Asegúrese de que la abertura del

electrodo del encendedor sea de

5.0 mm (0.195"). Verifique la

terminal del cable en busca de

daños. Reemplace el encendedor

piezoeléctrico y/o el electrodo

del encendedor según sea nece

sario. No doble el electrodo; esto

podría ocasionar rupturas

1.

Vuelva encender, mantenga el

botón de la válvula de control au

tomático oprimido 45 segundos

2. Verifique que el suministro de

gas sea adecuado

3. Apriete la conexión o reem

place el termopar

4. Reemplace la válvula de control automático

1. Reemplace el orificio de gas

2.

Verifique el suministro de gas;

verifique la salida del regulador

3. Consulte con el proveedor de

gas para determinar el sumi

nistro adecuado. El tanque

podría estar vacío

-

-

-

-

-

El quemador se enciende, pero se

apaga cuando se suelta el botón

117296-01A

1. Los cables del interruptor de

seguridad en caso de vuelcos

están flojos

2. La terminal del cable está floja

o rota

3. El cable del termopar está flojo

o mal colocado

4. Termopar defectuoso

5. Control defectuoso

6. Interruptor de seguridad en

caso de vuelcos defectuoso

www.desatech.com

1. Apriete los cables del inte

rruptor de seguridad en caso

de vuelcos

2. Apriete o repare el cable

3. Apriete el termopar. Asegú

rese de que el termopar esté

ubicado correctamente entre

el reverberador y la parrilla

4. Reemplace el termopar

5. Reemplace el control

6. Reemplace el interruptor de

seguridad en caso de vuelcos

-

-

7

Page 20

CLASIFICACIÓN ILUSTRADA DE PIEZAS

1

17

12

13

15

14

16

2

3

4

5

10

9

7

8

11

6

MODELO 35-R

8

www.desatech.com

117296-01A

Page 21

LISTA DE PIEZAS

MODELO 35-R

Esta lista contiene piezas reemplazables utilizadas en el calentador. Al hacer un pedido de piezas, siga

las instrucciones enumeradas en Piezas de repuesto en la página 10 de este manual.

N° DE

N°

PARTE DESCRIPCIÓN CANT.

1 115286-01 Quemador 1

2 114121-01 Termopar 1

3 117384-01 Soporte del termopar 1

4 115291-01 Electrodo del encendedor 1

5 117385-01 Soporte del encendedor 1

6 102445-01 Encendedor piezoeléctrico 1

7 115287-01 Orificio 1

8 115285-01 Válvula 1

9 115289-01 Bloque de conexiones 1

10 115288-01 Interruptor de seguridad en caso de vuelcos 1

11 111090-02

12 115290-01 Conjunto de manguera y regulador 1

13 115292-01 Rueda 2

14 114156-02 Soporte del eje 2

15 115294-01 Seguro de la rueda 2

16 117297-01 Ensamble inferior del bastidor principal 1

17 117310-01 Reflector 1

114245-06 Etiqueta adhesiva de información general 1

115297-01

114246-03

Codo de latón 1

PIEZAS DISPONIBLES (NO SE MUESTRAN)

Etiqueta de advertencia 1

Etiqueta de precaución 1

117296-01A

www.desatech.com

9

Page 22

ESPECIFICACIONES

• Clasificación: 35,000 BTU/h

• Combustible: vapor de propano solamente

• Consumo de combustible por hora:

1.5 litros (0.38 galones), 1.74 kg (1.6 lb)

• Presión del suministro al regulador (para ajuste

de entrada): máximo de 200 lb o a presión del

tanque, mínima de 10 PSI

• Presión del múltiple: 2.3 kPa (9.5" C.A.)

• Temperatura mínima del aire circundante:

-29° C (-20° F)

PIEZAS DE REPUESTO

ADVERTENCIA: use sólo

piezas de repuesto originales.

Este calentador debe usar piezas

diseñadas específicamente. No

las sustituya ni use piezas genéricas. El uso de piezas de repuesto

inadecuadas puede ocasionar

lesiones graves o fatales. Esto

también protegerá la cobertura

de su garantía de piezas reemplazadas con garantía.

PIEZAS CON GARANTÍA

Póngase en contacto con los distribuidores autorizados de este producto. Si no le pueden proveer las

piezas repuesto originales, llame a DESA Heating

Products al 1-866-672-6040 o bien a DESA Indus

tries al 1-905-826-8010.

Cuando llame a DESA tenga listo:

• su nombre y dirección

•

los números de modelo y de serie de su calentador

• la falla del calentador

• la fecha de compra

En la mayoría de los casos, le pediremos que

devuelva la pieza a la fábrica.

PIEZAS NO CUBIERTAS POR LA

GARANTÍA

Póngase en contacto con los distribuidores autorizados de este producto. Si no le pueden proveer las

piezas repuesto originales, llame a DESA Heating

Products al 1-866-672-6040 o bien a DESA Industries al 1-905-826-8010.

Cuando llame a DESA tenga listo:

•

los números de modelo y de serie de su calentador

• el número de la pieza de repuesto

-

10

www.desatech.com

117296-01A

Page 23

NOTAS

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

117296-01A 11

www.desatech.com

Page 24

GARANTÍA Y SERVICIO DE REPARACIÓN

GUARDE ESTA GARANTÍA

Modelo

N° de serie

Fecha de compra

GARANTÍA LIMITADA PARA PRODUCTOS NUEVOS

Y REACONDICIONADOS DE FÁBRICA

Productos nuevos:DESA Heating Products garantiza este calentador y cualquiera de sus partes contra cualquier

defecto en los materiales y mano de obra por un (1) año a partir del día de la compra, siempre y cuando se haya

operado y dado mantenimiento de acuerdo con la instrucciones del fabricante. Estas garantías se extienden sola

mente al comprador minorista original, cuando se proporciona un comprobante de compra.

Calentadores reacondicionados de fábrica: DESA Heating Products garantiza este calentador y cualquiera de sus

partes contra cualquier defecto en los materiales y mano de obra por treinta (30) días a partir del día de la compra,

siempre y cuando se haya operado y dado mantenimiento de acuerdo con la instrucciones del fabricante. Estas garantías

se extienden solamente al comprador minorista original, cuando se proporciona un comprobante de compra.

Esta garantía sólo cubre el costo de las piezas y la mano de obra requeridas para restaurar el producto a una

condición de operación correcta. Los costos de transporte e incidentales asociados con reparaciones bajo garantía

no son reembolsables mediante la misma.

El servicio de garantía está disponible sólo a través de distribuidores y centros de servicio autorizados.

Esta garantía no cubre defectos ocasionados por mal uso, abuso, negligencia, accidentes, falta de mantenimiento

adecuado, desgaste normal, alteración, modificación, manipulación, combustibles contaminados, reparación

usando piezas inadecuadas o reparación realizada por cualquiera que no sea un distribuidor o centro de servicio

autorizado. El mantenimiento de rutina es responsabilidad del propietario.

ESTA GARANTÍA EXPRESA SE OTORGA EN LUGAR DE CUALQUIER OTRA GARANTÍA, YA SEA EXPRESA

O IMPLÍCITA, INCLUYENDO GARANTÍAS DE APROVECHAMIENTO Y APTITUD PARA UN PROPÓSITO EN

PARTICULAR.

DESA no asume ninguna responsabilidad por daños indirectos, incidentales o consecuentes. Algunos estados no

permiten la exclusión o limitación de daños incidentales o perjuicios, o es posible que las exclusiones no sean

aplicables a usted. Esta garantía limitada le otorga derechos legales específicos y posiblemente tenga otros derechos

que varían de un estado a otro.

Nos reservamos el derecho de modificar estas especificaciones en cualquier momento sin previo aviso. La única garantía aplicable es nuestra garantía estándar por escrito. No otorgamos ninguna otra garantía, expresa o implícita.

-

SERVICIO DE GARANTÍA

Si su calentador requiere servicio, regréselo al centro de servicio autorizado más cercano. Se debe presentar la prueba

de compra junto con el calentador. El calentador será inspeccionado. Un defecto puede ser ocasionado por materiales

o mano de obra defectuosos. Si es así, DESA reparará o reemplazará el calentador sin ningún cargo.

SERVICIO DE REPARACIÓN

Devuelva su calentador al centro de servicio autorizado más cercano. Las reparaciones no cubiertas por la garantía

se cobrarán a precio regular. Cada centro de servicio tiene propietario y operación independientes. Nos reservamos

el derecho de modificar estas especificaciones en cualquier momento sin previo aviso.

Cuando escriba solicitando información sobre su calentador, asegúrese de incluir el número de modelo y el número de

serie como se muestran en la placa del modelo. Para obtener más información sobre esta garantía escriba a:

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004, EE.UU.

2220 Argentia Road, Unit #4

Mississauga, Ontario, Canadá

L5N2K7

Dirigido a: Customer Service Department

Page 25

APPAREIL DE CHAUFFAGE DE CHANTIER À GAZ PROPANE

RAYONNANT

MANUEL D'UTILISATION

MODÈLE 35-R

IMPORTANT : lisez et comprenez ce manuel avant d'assembler,

d'allumer ou de réparer l'appareil de chauffage. Une mauvaise

utilisation de l'appareil de chauffage peut causer des blessures

graves. Conservez ce manuel pour référence future.

AVERTISSEMENT DE RISQUE GÉNÉRAL :

Tout manquement aux précautions et aux instructions four

nies avec cet appareil de chauffage peut causer la mort, des

blessures corporelles graves ainsi que la perte de biens et

des dommages causés par les risques associés au feu, à une

explosion, aux brûlures, à l'asphyxie, à l'empoisonnement

au monoxyde de carbone et par les chocs électriques.

Seuls les individus qui comprennent et qui respectent ces instructions peuvent utiliser ou réparer cet appareil de chauffage.

Si vous avez besoin d'aide ou de renseignements concernant l'appareil de chauffage tels que le manuel d'instructions, les étiquettes, etc., communiquez avec le fabricant.

Conservez ce manuel pour consultation future.

Pour plus de détails, visitez le site www.desatech.com

-

Page 26

Information relative à la sécurité ......................... 2

TABLE DES MATIÈRES

Identification du produit ....................................... 3

Déballage ............................................................ 3

Théorie de fonctionnement .................................. 3

Approvisionnement en gaz propane .................... 4

Ventilation ............................................................

Instructions d'installation ..................................... 4

Placement de l'appareil de chauffage ................. 4

Notice d'utilisation ................................................ 5

Nettoyage et entretien ......................................... 6

Dépannage .......................................................... 7

Vue détaillée et liste des pièces .......................... 8

Spécifications ....................................................

4

Pièces de rechange ........................................... 10

Service de garantie et de réparation ................. 12

10

INFORMATION RELATIVE

À LA SÉCURITÉ

AVERTISSEMENT : cet appareil

contient ou produit des produits

chimiques déterminés par l'État de

Californie comme cancérigènes et

pouvant causer des malformations

congénitales et d'autres troubles

liés à la reproduction.

AVERTISSEMENT : danger

d'incendie, de brûlure, d'inhala

tion et d'explosion. Gardez les

produits combustibles solides

comme les matériaux de cons

truction, le papier et les cartons,

à une distance sûre de l'appareil

de chauffage tel que recommandé

dans les instructions. N'utilisez

jamais l'appareil de chauffage

dans des espaces susceptibles

de contenir des combustibles

volatils ou atmosphériques ou des

produits tels que de l'essence, des

diluants, du solvant à peinture, des

particules de poussières ou des

produits chimiques inconnus.

AVERTISSEMENT : cet appareil n'est pas conçu pour usage

domestique ou les véhicules de

camping.

Cet appareil de chauffage est conçu comme appareil de

chauffage de chantier en conformité avec les normes

ANSI Z83.7/CGA 2.14. D'autres normes régissent

l'utilisation des gaz combustibles et des produits de

chauffage pour des utilisations particulières. Vos

autorités locales peuvent vous conseiller à propos de

ces normes. La fonction principale des appareils de

2

-

-

www.desatech.com

chauffage de chantier est la production temporaire de

chaleur pour des édifices en construction ou en cours

de modification ou de réparation. Utilisés correctement,

ces appareils de chauffage représentent une source de

chaleur économique et sûre. Les produits de combustion

sont évacués dans l'espace qui est chauffé.

Nous ne pouvons pas prévoir toutes les utilisations

possibles de nos appareils de chauffage. Vérifiez

auprès de votre responsable local de la sécuritéincendie si vous avez des questions relatives à

l'utilisation de l'appareil de chauffage.

D'autres normes régissent l'utilisation des gaz com

bustibles et des produits de chauffage pour des utilisations particulières. Les autorités locales peuvent

vous conseiller à propos de ces normes.

Empoisonnement au monoxyde de carbone :

taines personnes sont plus sensibles au monoxyde de

carbone que d'autres. Les premiers symptômes d'un

empoisonnement au monoxyde de carbone ressemblent

à la grippe avec des maux de tête, du vertige ou de la

nausée. Si vous avez ces symptômes, il se pourrait que

l'appareil de chauffage ne fonctionne pas bien. Respirez

tout de suite de l'air frais ! Vérifiez si la ventilation est

suffisante et faites réviser l'appareil de chauffage.

Gaz propane :

odorant est ajouté au gaz propane. Cette odeur vous permet de détecter une fuite de gaz. Cependant, cette odeur

ajoutée au propane peut se dissiper. Du gaz propane peut

être présent même s'il n'y a pas d'odeur.

Lisez et comprenez tous les avertissements. Conser

vez ce manuel pour consultation future. Il vous permettra de faire fonctionner cet appareil de chauffage

correctement et en toute sécurité.

1. Installez et utilisez l'appareil de chauffage avec

2. N'utilisez que le tuyau et le détendeur réglé en usine

3. N'utilisez que du gaz propane composé pour le

le gaz propane n'a pas d'odeur. Un produit

précaution. Respectez tous les règlements et codes

locaux. En l'absence de codes ou de règlements

locaux, consultez la Norme pour l'emmagasinage

et la manipulation du gaz de pétrole liquéfié

(ANSI/NFPA58) et le Code d'installation du

propane (CAN/CGA B149.2). Ces documents

décrivent les précautions à prendre pour l'entre

posage et la manutention du gaz propane.

qui ont été fournis avec l'appareil de chauffage.

retrait de vapeur.

cer-

117296-01A

-

-

-

Page 27

INFORMATION RELATIVE

À LA SÉCURITÉ Suite

4. Assurez une ventilation suffisante. Avant d'utiliser

l'appareil de chauffage, aménagez une ouverture

sur l'extérieur d'au moins 0,28 m² (3 pi

chaque 100 000 BTU/h de puissance.

5.

N'utilisez pas l'appareil de chauffage dans un édifice

habité ou dans des endroits où l'on vit et dort.

6. N'utilisez pas l'appareil de chauffage dans les

sous-sols ou sous le niveau du sol.

7. Ne placez pas de matériaux combustibles, d'es

sence, de solvant à peinture ou d'autres vapeurs ou

liquides inflammables à proximité de l'appareil. La

poussière est combustible. N'utilisez pas l'appareil

de chauffage là où il y a beaucoup de poussière.

8. Distances mi nimales ent re lʼap pare il de

chauffage et les combustibles : côtés 50,8

cm ( 2 0 po), dess u s 101,6 cm (4 0 po),

devant 137,2 cm (54 po).

9. Placez l'appareil de chauffage à au moins 6 m

(20 pi) des réservoirs de propane.

10. Conservez les réservoirs de propane à moins de

38° C (100° F).

11. Vérifiez l'appareil de chauffage avant chaque

utilisation. N'utilisez pas d'appareil de chauffage

endommagé.

12. Avant chaque utilisation de l'appareil de chauf

fage, vérifiez que le tuyau n'est pas endommagé.

S'il est très usé ou fendu, remplacez le tuyau par

le type de tuyau spécifié par le fabricant avant

d'utiliser l'appareil de chauffage.

13. Placez l'appareil de chauffage sur une surface

stable et de niveau si l'appareil est chaud ou en

fonctionnement.

14. Cet appareil n'est pas conçu pour utilisation sur

des planchers finis.

15. Ne bloquez jamais une ouverture d'entrée d'air

ou de sortie d'air de l'appareil de chauffage.

16. Éloignez l'appareil de chauffage des courants

d'air, du vent, des éclaboussures, de la pluie ou

de l'eau ruisselante.

17. Ne laissez pas l'appareil de chauffage sans

surveillance.

18. Ne laissez pas les enfants et les animaux s'ap

procher de l'appareil de chauffage.

19. Ne déplacez, ne manipulez et ne révisez jamais un

appareil de chauffage brûlant ou en opération. Vous

risqueriez de vous brûler gravement. Attendez 15

minutes après avoir éteint l'appareil de chauffage.

20. Pour ne pas vous blesser, portez des gants lorsque

vous manipulez l'appareil de chauffage.

21. Ne raccordez jamais de tuyauterie de ventilation

à l'appareil de chauffage.

22. Ne modifiez pas l'appareil de chauffage. Mainte

nez l'appareil de chauffage dans son état initial.

23. N'utilisez pas l'appareil de chauffage s'il a été

modifié.

117296-01A

2

) pour

www.desatech.com

24. Fermez l'approvisionnement en gaz de l'appareil

de chauffage s'il n'est pas utilisé.

25. Utilisez seulement des pièces de rechange

d'origine. Cet appareil de chauffage utilise des

pièces conçues spécifiquement pour lui. N'uti

lisez pas de substituts ou de pièces génériques.

L'utilisation de pièces de rechange inadéquates

peut causer des blessures graves ou fatales.

IDENTIFICATION DU

PRODUIT

-

Écran métal

étendu

Face du

brûleur

Réflecteur

-

Figure 1 - Identification du produit

DÉBALLAGE

1.

Enlevez tout matériau d'emballage appliqué sur l'appareil de chauffage pour son expédition. Conservez

les bouchons en plastique (sur la vanne et sur l'assem

blage du tuyau et du détendeur) pour l'entreposage.

2. Retirez toutes les pièces de l'emballage.

3. Inspectez toutes les pièces pour voir si elles ont

été endommagées pendant le transport. Si l'appareil de chauffage est endommagé, informez-en

au plus vite le revendeur où vous l'avez acheté.

-

THÉORIE DE

FONCTIONNEMENT

Système d'approvisionnement en carburant :

les appareils à propane, l'assemblage de tuyau et de détendeur est relié à l'approvisionnement en gaz propane.

Pour les appareils au gaz naturel, l'approvisionnement

en gaz se rattache à l'appareil de chauffage par les

tuyaux ou les canalisations fournis par l'utilisateur. Il

achemine le combustible à l'appareil de chauffage.

Circuit d'allumage :

l'approvisionnement en combustible du brûleur.

-

Système de contrôle automatique :

provoque l'arrêt de l'appareil de chauffage en cas

d'extinction de la flamme.

l'allumeur piézo-électrique allume

ce système

-

-

pour

3

Page 28

APPROVISIONNEMENT

EN GAZ PROPANE

Le gaz propane et les réservoirs de propane doivent

être fournis par l'utilisateur.

N'utilisez cet appareil de chauffage qu'avec un sys

tème d'approvisionnement à élimination de vapeur

de propane. Consultez le chapitre 5 de la Norme pour

l'emmagasinage et la manipulation du gaz de pétrole

liquéfié, ANSI/NFPA 58 et/ou CAN/CGA B149.2.

Votre bibliothèque ou votre service d'incendie a

cette publication.

La quantité de gaz propane utilisable dans les réser

voirs varie. Deux facteurs influencent cette quantité :

1. La quantité du liquide propane contenue dans

les réservoirs

2. La température des réservoirs