Page 1

!

!

!

!

Installation, Operation, Maintenance and Parts Manual

Please read and save these instructions. This heater must be installed and serviced by trained gas installation and service

personnel only! Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury

and/or property damage! Retain these instructions for future reference.

7D837A thru 7D849A, 7D851A,

7AR79 thru 7AR88

®

Dayton Tube Heaters

Description

Dayton tube heaters are gas-fired infrared heaters designed to provide comfort heat.

They consist of three (3) main components: a burner control box, radiant tube, and

reflector assembly. The heaters are typically suspended from the ceiling by chains

and controlled by a thermostat. They can be installed either vented or unvented,

and may use outside air for combustion if necessary. The radiant tube may be

installed in different configurations depending on the heating requirements.

These heaters use infrared energy to heat spaces. When heat is required, the

burner control box ignites a gas/air mixture and pushes the hot gases into the

radiant tube. As the gases pass through the assembly, the tubing is heated

and emits infrared, which is then directed toward the floor by reflectors. This is

known as primary infrared and is absorbed by the floor, objects and people in

the space, raising their temperatures. They in turn re-radiate this heat, known

as secondary infrared, to create a comfort zone at the floor level. This is how

Dayton tube heaters can heat large spaces without having to provide primary

infrared for every square foot of area. However, if the goal is to spot heat a

small area within a large space, only the primary infrared makes this possible.

Dayton tube heaters are design certified for use in industrial and commercial

buildings, such as warehouses, manufacturing plants, aircraft hangars and

vehicle maintenance shops. They are not certified for residential use or where

flammable gases or vapors are generally present, such as spray booths.

damage, injury or death. Read and

understand the installation,

operating and maintenance

instructions thoroughly before

installing or servicing this

equipment.

This heater must be installed and

serviced by trained gas installation

and service personnel only. Failure

to comply could result in personal

injury, asphyxiation, death, fire and/

or property damage.

WARNING

Improper installation,

adjustment,

alteration, service or

maintenance can

cause property

For Your Safety - If you smell gas:

WARNING

In locations used for the storage of combustible materials,

signs must be posted to specify the maximum permissible

stacking height to maintain the required clearances from the

heater to the combustibles. Signs must either be posted

adjacent to the heater thermostats or in the absence of such thermostats, in a

conspicuous location.

Form 5S6496 Printed in U.S.A.

03460

1109/224/VCPVP

• Do not try to light any appliance.

• Immediately call your gas supplier

from a neighbor’s phone.

• Do not touch any electrical switch.

• Follow the gas supplier’s

instructions.

• Do not use any phone in your

building.

• If you cannot reach your gas

supplier, call the fire department.

Keep these instructions for future reference.

Page 2

Dayton Installation, Operation, Maintenance and Parts Manual

®

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Dayton Tube Heaters

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................................... 3

Overview ........................................................................................................................................................................ 3

SAFETY .............................................................................................................................................................................. 4

Warning Symbols ............................................................................................................................................................ 4

Specific Applications ....................................................................................................................................................... 4

Standards, Certifications and Governmental Regulations ................................................................................................ 5

Clearance to Combustibles ............................................................................................................................................ 6

INSTALLATION ..................................................................................................................................................................... 8

Design Considerations and Prechecks .............................................................................................................................. 8

Recommended Mounting Heights ................................................................................................................................... 10

Hanger Placement and Suspension ..................................................................................................................................11

Optional U-Bend or Elbow Accessory Configuration ........................................................................................................ 14

Radiant Tube Assembly ................................................................................................................................................... 15

Burner Control Box Suspension ...................................................................................................................................... 18

Reflector Assembly ..........................................................................................................................................................19

Baffle Assembly and Placement ....................................................................................................................................... 21

Final Heater Assembly ..................................................................................................................................................... 22

Venting ...........................................................................................................................................................................23

Combustion Air Requirements ........................................................................................................................................28

Gas Supply .....................................................................................................................................................................30

Electrical Requirements ................................................................................................................................................... 33

OPERATION ..........................................................................................................................................................................35

MAINTENANCE ...................................................................................................................................................................36

Troubleshooting Guide ....................................................................................................................................................37

PARTS ..............................................................................................................................................................................38

Repair Parts Illustration ....................................................................................................................................................38

Repair Parts List ...............................................................................................................................................................39

LIMITED WARRANTY .......................................................................................................................................................... 40

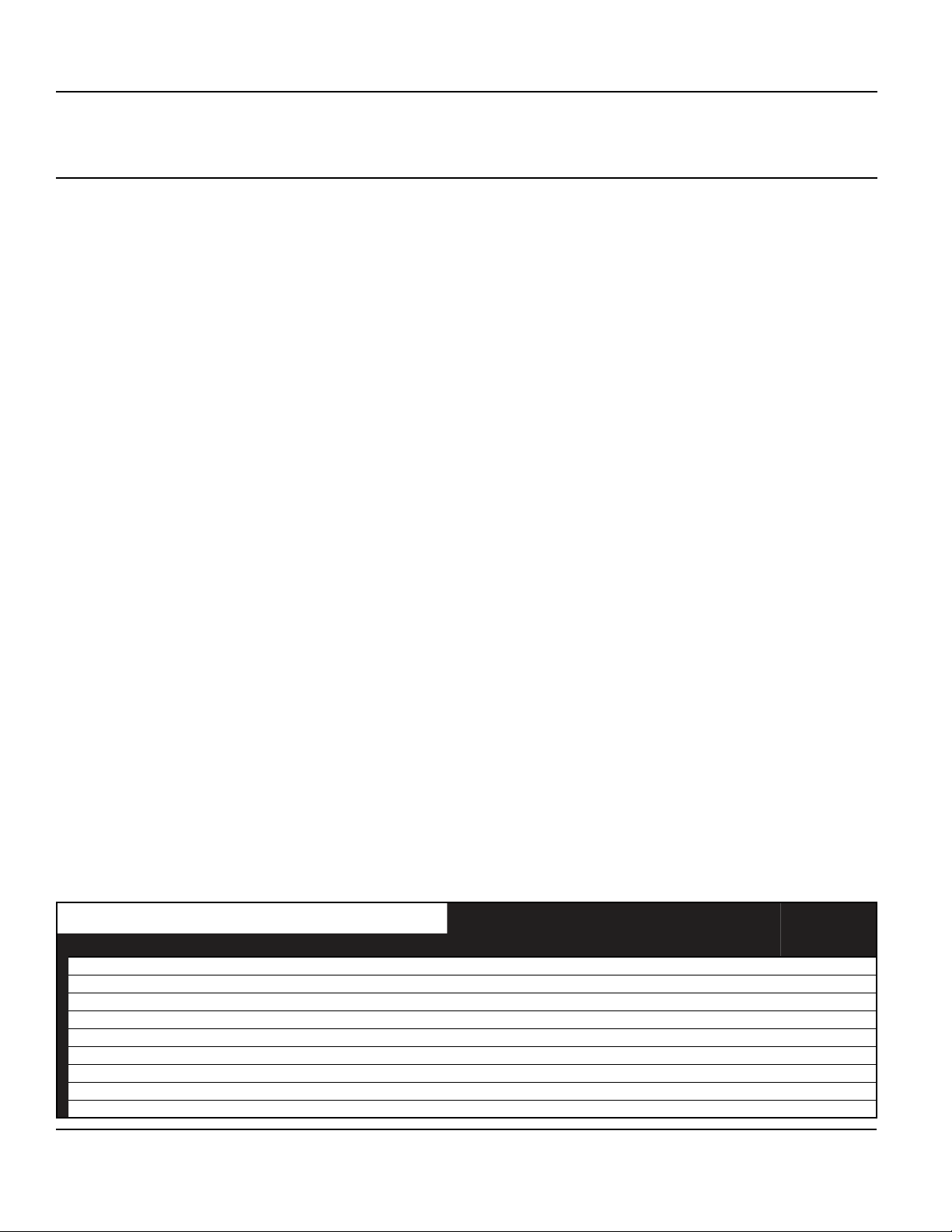

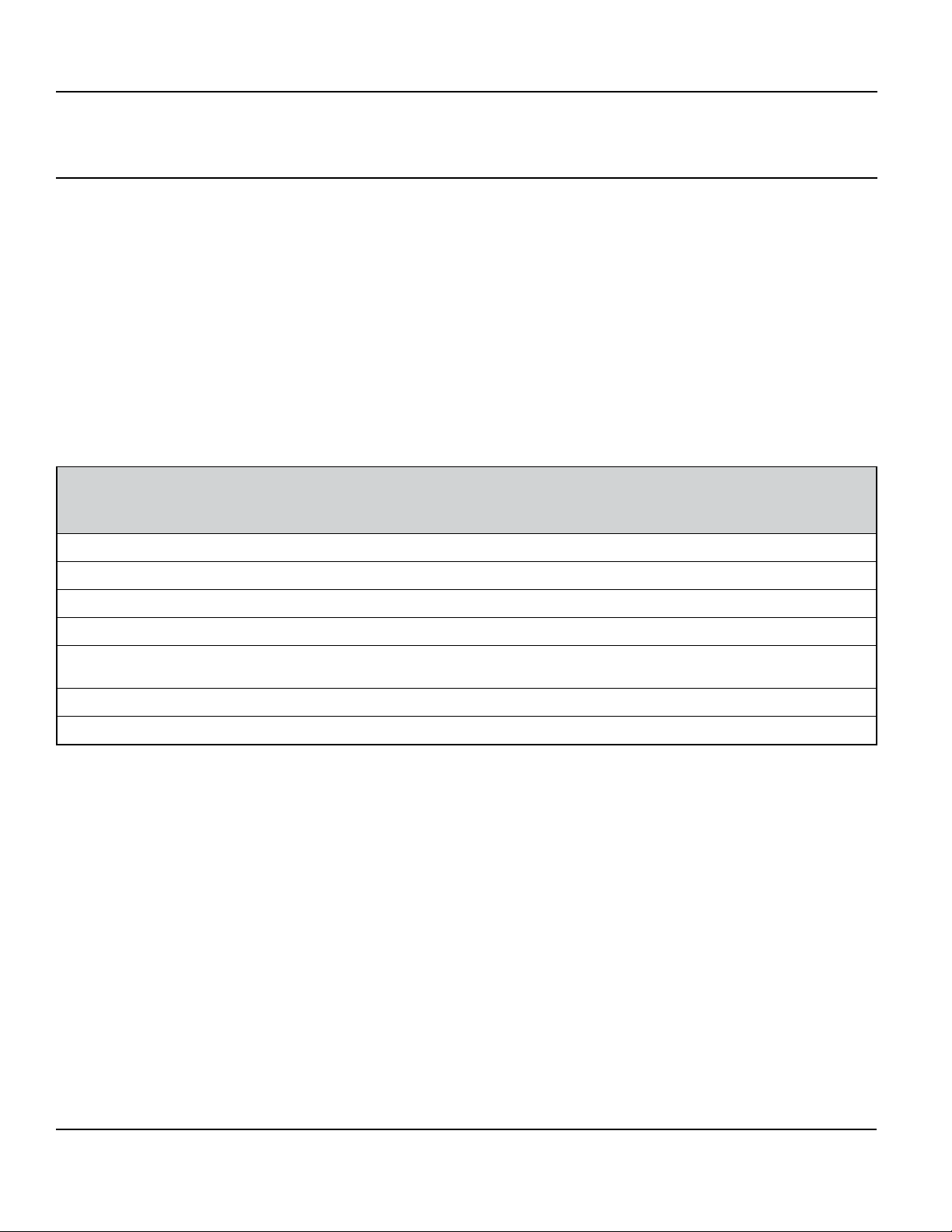

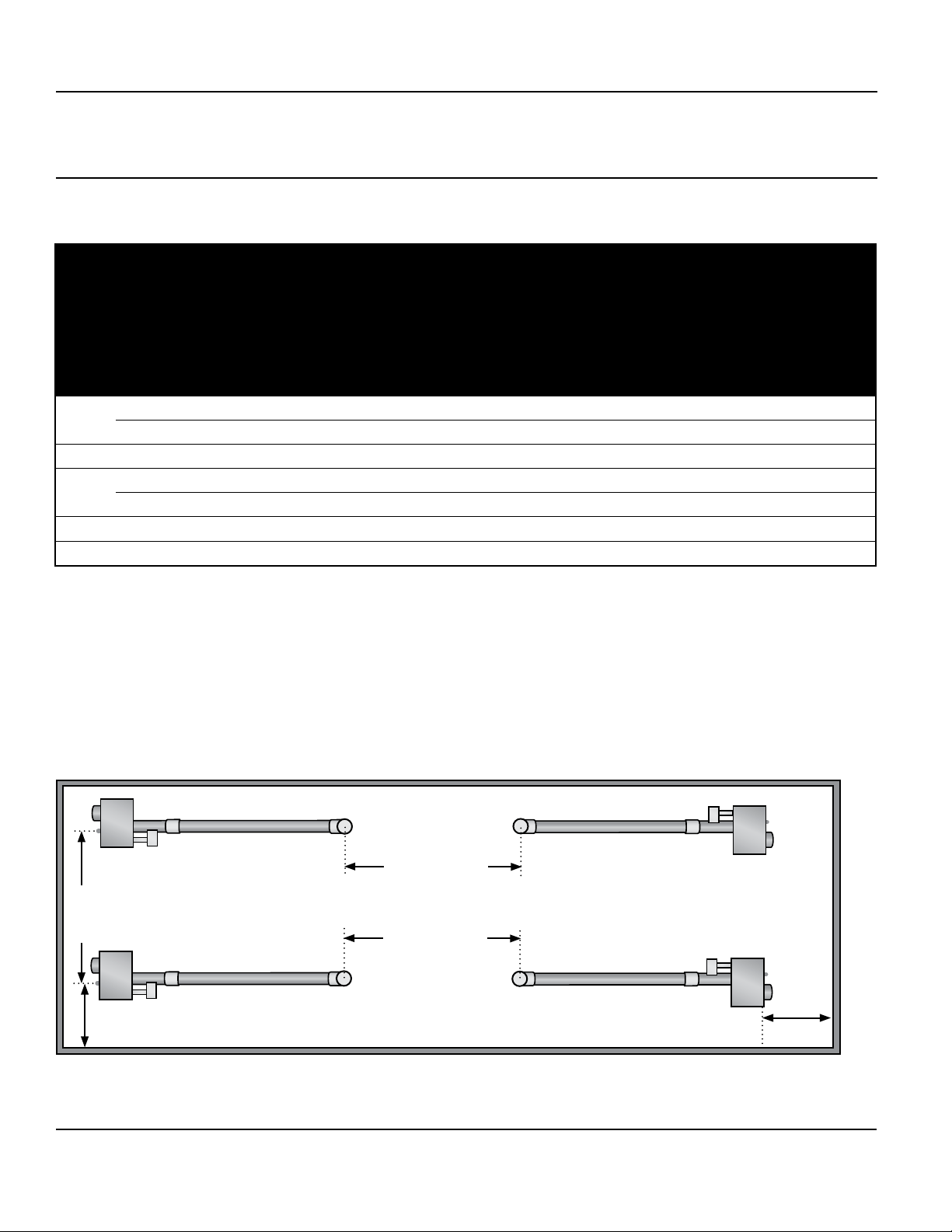

Kit Contents

Prior to installation, verify that you have received all heater components included with your tube heater. Refer to the chart

below for a list of the kit contents for your model heater. Materials not included in the kit (e.g. sheet metal screws, vent

material, terminals, etc.) are the responsibility of the installer.

Filled By:

5VD67A-

5VD70A

5VD71A-

5VD72A

5VD73A-

5VD78A

5EAJ0-J2,

5EAH3-H5

5VD79A-80A,

5EAH6-H8

Part # Description 20 ft. 30 ft. 40ft. 50ft. 60ft.

TP-19B 4” Tube Hanger with Tension Spring 3 4 5 6 7

TP-21B 4” Tube Clamp 2 3 4 5 6

TP-33B 1/2” Shut-off Ball Valve/Inlet Tap 1 1 1 1 1

TP-82 4” Reflector Center Support 2 3 4 5 6

TP-83 24” Stainless Steel Flexible Gas Connector 1 1 1 1 1

TP-105 Reflector End Cap 2 2 2 2 2

TP-106 Reflector End Cap Clips 8 8 8 8 8

THCS Tube Heater Chain Sets 5 6 7 8 9

IOM Installation, Operation & Maintenance Manual 1 1 1 1 1

2

Page 3

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

INTRODUCTION

Overview

The intent of this manual is to provide information regarding general safety, installation, operation and maintenance of

this tube heater. You must read and understand all instructions and safety warnings before installing or servicing the tube

heater.

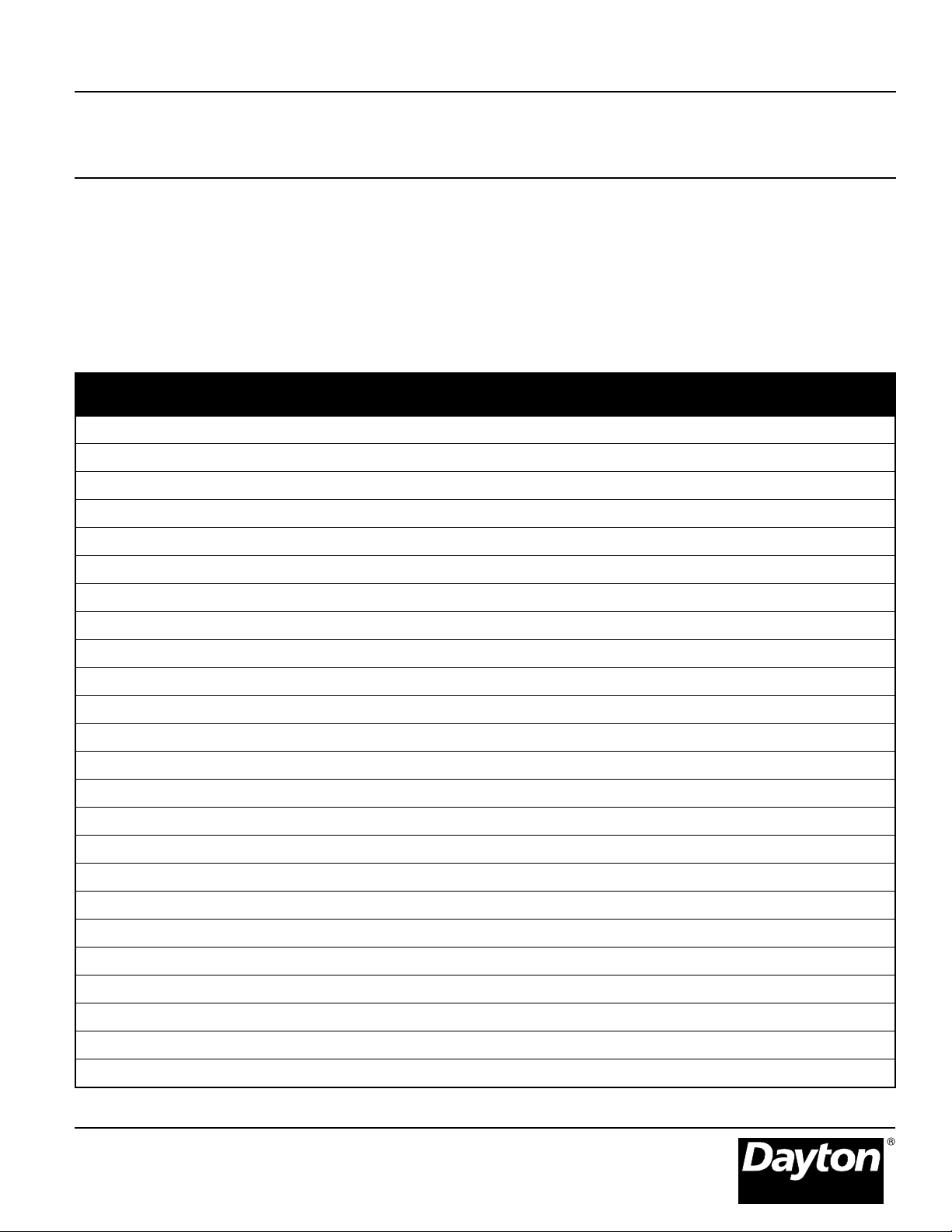

Available Models - Tube Heater Burner Box and Tube Reflector Combinations

Burner

Combo #

7D837A 5VD67A 5VD88 20-4”-ALUM 20 50,000 NAT

7D838A 5VD68A 5VD88 20-4”-ALUM 20 50,000 LP

7D839A 5VD69A 5VD88 20-4”-ALUM 20 75,000 NAT

7D840A 5VD70A 5VD88 20-4”-ALUM 20 75,000 LP

7D841A 5VD71A 5VD89 30-4”-ALUM 30 100,000 NAT

7D842A 5VD72A 5VD89 30-4”-ALUM 30 100,000 LP

7D843A 5VD73A 5VD91 40-4”-ALUM 40 100,000 NAT

7D844A 5VD74A 5VD91 40-4”-ALUM 40 100,000 LP

7D845A 5VD75A 5VD91 40-4”-ALUM 40 125,000 NAT

7D846A 5VD76A 5VD91 40-4”-ALUM 40 125,000 LP

7D847A 5VD77A 5VD90 40-4”-TITAN 40 150,000 NAT

7D848A 5VD78A 5VD90 40-4”-TITAN 40 150,000 LP

7AR80 5EAJ0 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 150,000 NAT

7AR79 5EAJ1 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 150,000 LP

7AR83 5EAJ2 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 175,000 NAT

Box #

Tube &

Reflector Pkg # Tube Type Length BTU/H Gas Type

7AR81 5EAH3 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 175,000 LP

7AR87 5EAH4 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 200,000 NAT

7AR85 5EAH5 5VD90 & 5EAH2 40-4”-TITAN & 10-4”-ALUM 50 200,000 LP

7D849A 5VD79A 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 150,000 NAT

7D851A 5VD80A 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 150,000 LP

7AR84 5EAH6 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 175,000 NAT

7AR82 5EAH7 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 175,000 LP

7AR88 5EAH8 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 200,000 NAT

7AR86 5EAH9 5VD90 & 5VD88 40-4”-TITAN & 20-4”-ALUM 60 200,000 LP

3

Page 4

!

!

!

!

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

SAFETY

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

!

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, serious injury or

death. Read and understand, the installation, operating and

maintenance instructions thoroughly before installing or

servicing this equipment. Only trained, qualified gas installation

and service personnel may install or service this equipment.

Safety Symbols

Safety is the most important consideration during installation, operation and

maintenance of the tube heater. You will see the following symbols and signal

words when there is a hazard related to safety or property damage.

Applications

WARNING

Warning indicates a potentially

hazardous situation which, if not

avoided, could result in death or injury.

This is not an explosion-proof heater.

No heater may be used in a Class 1

or Class 2 Explosive Environment.

Consult the local Fire Marshall, fire

insurance carrier and other authorities

for approval if the proposed installation

is in question.

!

WARNING

Not for residential use!

Do not use this heater

in the home, sleeping

quarters, attached

garages, etc.

Commercial and Industrial

This tube heater is designed

and certified for use in industrial

and commercial buildings such

as, warehouses, manufacturing

plants, aircraft hangars and vehicle

maintenance shops.

!

CAUTION

Caution indicates a potentially

hazardous situation which, if not

avoided, could result in minor or

moderate injury.

NOTICE

Notice indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

4

Page 5

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Standards, Certifications and Governmental Regulations

The installation of this tube heater must comply with all applicable local, state

and national specifications, regulations and building codes (contact the local

building inspector and/or fire marshall for guidance) before installing the heater

system.

In the absence of local codes, the installation must conform to the latest edition

of the National Fuel Code ANSI Z223.1 (NFPA 54).

Refer to the following Standards and codes for application specific guidelines:

Public Garages:

The installation of this heater in public

garages must conform with the

Standard for Parking Structures, ANSI/

NFPA 88A (latest edition), or the Code

for Motor Fuel Dispensing Facilities

and Repair Garages NFPA 30A (latest

edition) and must be at least 8 ft.

above the floor.

Aircraft Hangars:

The installation of this heater in aircraft

hangars must conform with the

Standard for Aircraft Hangars, ANSI/

NFPA 409 (latest edition). The heater

must be installed at least 10 ft. above

the upper wing surfaces and engine

enclosures of the highest aircraft which

might be stored in the hangar. In areas

adjoining the aircraft storage area, the

heaters must be installed at least 8 ft.

above the floor. The heaters must be

located in areas where they will not be

subject to damage by aircraft, cranes,

moveable scaffolding or other objects.

High Altitude:

The installation of this tube heater is

approved, without modifications, for

elevations up to 6,000 ft. MSL (sea

level). Contact Dayton for installations

above these elevations.

Electrical:

The heater, when installed, must be

electrically grounded in accordance

with the National Electrical Code

ANSI/NFPA 70 (latest edition). Under

no circumstances is either the electrical

supply line or gas supply line to provide

any assistance in the suspension of the

heater.

Venting:

Venting must be installed in

accordance with the requirements set

forth in this manual and with the

NFPA 54/ANSI Z223.1 National Fuel

Gas Code (latest edition).

This unit complies with or is Certified

by one or more of the following

organizations or Standards:

• CSA International (CSA).

• American National Standards (ANSI

Z83.20b).

• National Fuel Gas Code (NFPA 54/

ANSI Z223.1).

• Occupational Safety and Health Act

(OSHA).

5

Page 6

Dayton Installation, Operation, Maintenance and Parts Manual

!

!

!

®

Dayton Tube Heaters

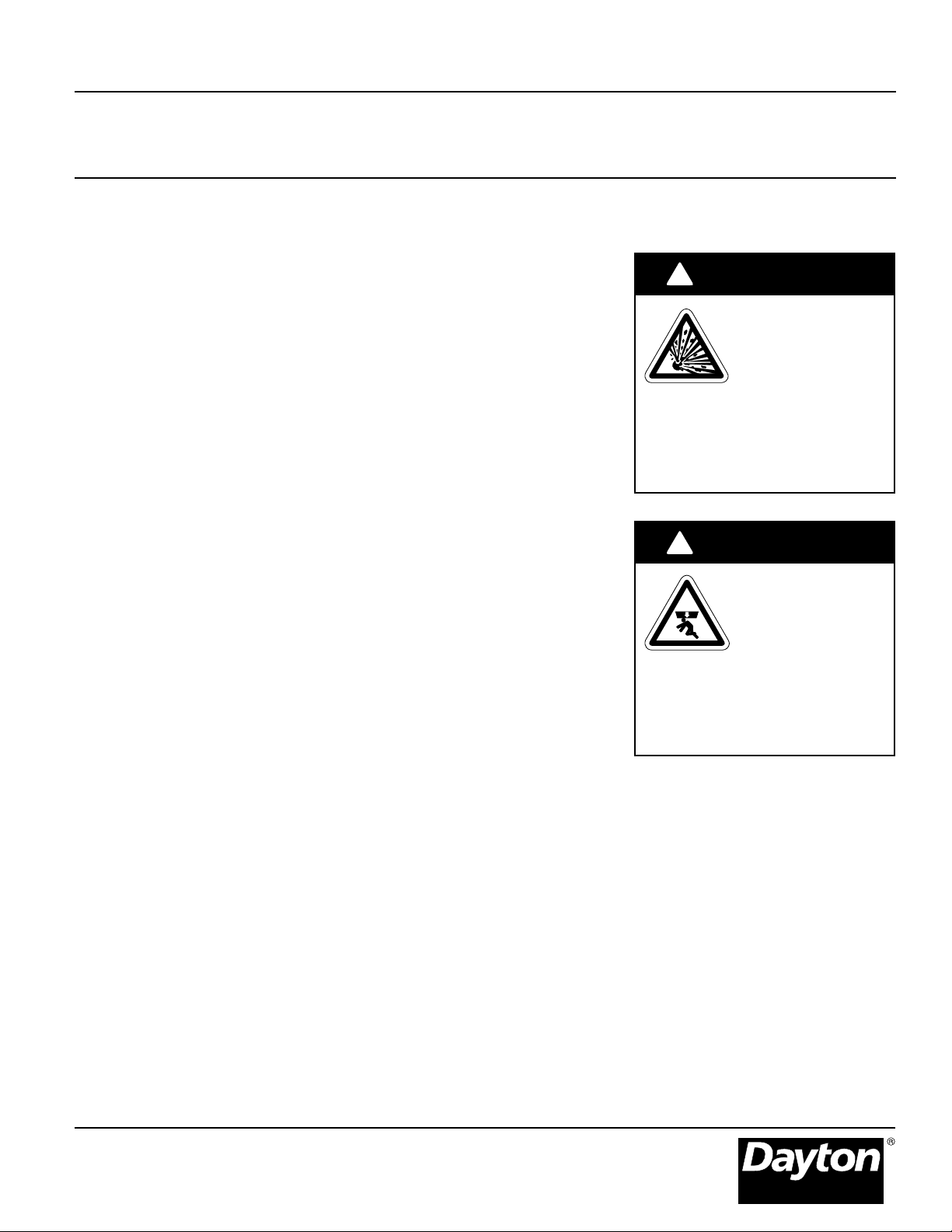

Clearance to Combustibles

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

WARNING

This is not an

explosion-proof

heater. Do not

store or use

flammable objects,

liquids or vapor in the vicinity of

the heater. Where there is the

possibility of exposure to flammable

vapors or highly combustible

materials, consult the local fire

marshall, fire insurance carrier and

other authorities for approval of the

proposed installation.

Hazards

For maximum safety, the building

must be evaluated for hazards before

installing this heating system. A critical

safety factor before installation is the

clearance to combustibles.

Clearances to combustibles is defined

as the minimum distance that must be

maintained between the tube surface

or reflector and combustible materials.

It also pertains to the distance that

must be maintained from moving

objects (e.g. overhead doors, cranes,

vehicle lifts, etc.) around the tube

heater.

WARNING

This heater should be

installed so that the

minimum clearances

to combustibles,

as marked on the

heater, will be maintained from

vehicles parked below. If vehicle

lifts are present, ensure that these

clearances will be maintained from

vehicles parked below. If vehicle

lifts are present, ensure that these

clearances will be maintained from

the highest raised vehicle.

The following is a partial list of items to

maintain clearances from:

• Gas and electrical lines

• Combustible and explosive materials

• Chemical storage areas

• Areas of high chemical fume

concentrations

• Vehicle parking areas

• Vehicle lifts

• Hoists or cranes

• Storage areas with stacked materials

• Lighting

• Sprinkler heads

• Overhead doors and tracks

• Dirty, contaminated areas

WARNING

Fire Hazard. Always

maintain published

clearance to

combustibles. Failure

to comply with the

stated clearances to combustibles

could result in personal injury, death

and/or property damage.

If you are unsure about the proposed

installation, consult your local fire

Marshall, fire insurance carrier or other

qualified authorities for the approval of

the proposed installation.

Safety Signs and Labels

It is important to provide warnings to

alert individuals to potential hazards

and safety actions. ANSI Z83.20b and

CSA 2.34, require you to post a sign

“specifying the maximum permissible

stacking height to maintain the

required published clearances from

the heater to combustibles” near the

heater’s thermostat or, in the absence

of such thermostats, in a conspicuous

location.

All safety labels must be maintained

on this appliance. Contact Grainger if

replacement labels are needed.

6

Page 7

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Clearance to Combustibles

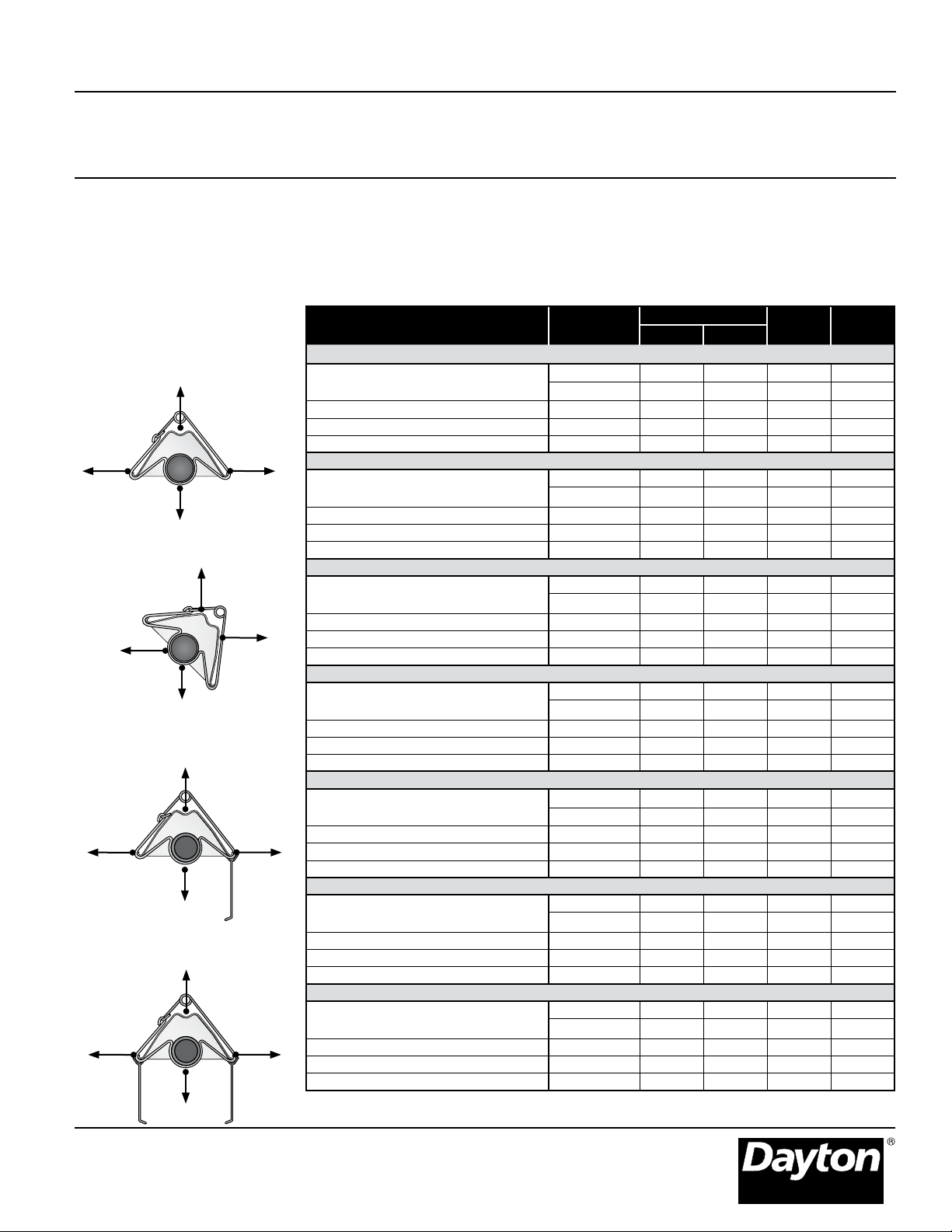

For the safe installation of this unit, the clearance to combustibles data below (Figure 1.1) contains clearances that must be

maintained. Check the heater’s rating plate to verify the minimum clearance to combustibles and gas type for your model

heater.

Figure 1.1 • Clearances to

Combustibles Data

0° Mounting

Angle

Side

45° Mounting

Angle

Front

0° w/ 1

Side Shield

Front

0° W/ 2 Side

Shields

Side

Top

Side

Below

Top

Behind

Below

Top

Behind

Below

Top

Side

Below

Mounting

Model No.

Dayton - 5VD67A, 5VD68A (20’ min. to 40’ max.)

50,000 BTU/H [N, P]

7D - 837A,838A

0° w/ 1 side shield 0° 29 8 6 47

0° w/ 2 side shields 0° 9 9 6 47

20 ft. from burner 0° 7 7 6 30

Dayton - 5VD69A, 5VD70A (20’ min. to 40’ max.)

75,000 BTU/H [N, P]

7D - 839A,840A

0° w/ 1 side shield 0° 29 8 6 60

0° w/ 2 side shields 0° 9 9 6 60

20 ft. from burner 0° 7 7 6 30

Dayton - 5VD71A, 5VD72A, 5VD73A, 5VD74A (30’ min. to 40’ max.)

100,000 BTU/H [N, P]

7D - 841A,842A,843A,844A

0° w/ 1 side shield 0° 29 8 6 66

0° w/ 2 side shields 0° 16 16 6 66

20 ft. from burner 0° 7 7 6 30

Dayton - 5VD75A, 5VD76A (40’ min. to 60’ max.)

125,000 BTU/H [N, P]

7D - 845A,846A

0° w/ 1 side shield 0° 42 8 6 76

0° w/ 2 side shields 0° 20 20 6 76

20 ft. from burner 0° 7 11 6 30

Dayton - 5VD77A, 5VD78A, 5VD79A, 5VD80A, 5EAJ0, 5EAJ1 (40’ min. to 60’ max.)

150,000 BTU/H [N, P]

7D-847A,848A,849A,851A, 7AR-79,80

0° w/ 1 side shield 0° 42 8 6 81

0° w/ 2 side shields 0° 23 23 6 81

20 ft. from burner 0° 11 11 6 44

Dayton - 5EAJ2, 5EAH3, 5EAH6, 5EAH7 (50’ min. to 60’ max.)

175,000 BTU/H [N, P]

7AR - 81, 82, 83, 84

0° w/ 1 side shield 0° 50 8 6 92

0° w/ 2 side shields 0° 30 30 6 92

20 ft. from burner 0° 11 11 6 44

Dayton - 5EAH4, 5EAH5, 5EAH8, 5EAH9 (50’ min. to 60’ max.)

200,000 BTU/H [N, P]

7AR - 85, 86, 87, 88

0° w/ 1 side shield 0° 54 8 6 94

0° w/ 2 side shields 0° 30 30 6 94

20 ft. from burner 0° 11 11 6 44

Minimum end clearance for all models is 12 inches. *Heaters mounted on an angle between 0°

to 45° must maintain clearances posted for both 0° and 45° mounting angles; whichever is greater.

Angle *

0° 9 9 6 47

45° 39 8 10 47

0° 9 9 6 60

45° 39 8 10 60

0° 14 14 6 66

45° 39 8 10 66

0° 20 20 6 76

45° 58 8 10 76

0° 24 24 6 81

45° 58 8 10 81

0° 34 34 6 92

45° 63 8 10 92

0° 41 41 6 94

45° 63 8 10 94

Side

Top BelowFront Behind

7

Page 8

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Installation

Design Considerations and Prechecks

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Placement of infrared tube heaters

is influenced by many factors. Aside

from safety factors, considerations

such as the number of elbows that

are allowed, maximum vent lengths,

ducting of combustion air and

combining vents are a few examples.

This manual, along with national, state

and local codes, addresses these issues.

It is critical that all guidelines and

instructions are followed.

To ensure a properly designed heating

system, a heating layout should be

developed for the correct placement

of the burner control box, radiant

tubing, venting and combustion air

intake ducts. Inspect and evaluate the

mounting conditions, vent locations,

gas supply and electrical wiring.

Refer to the chart below for the

recommended distances for the model

being installed.

Heater Installation Chart

Distance

Recommended

Model # BTU/H

7D837A-7D838A 50,000 9’ to 14’ 10’ to 20’ 20’ to 40’ 16’

7D839A-7D840A 75,000 11’ to 18’ 20’ to 30’ 30’ to 50’ 20’

7D841A-7D844A 100,000 13’ to 23’ 20’ to 30’ 30’ to 50’ 20’

7D845A-7D846A 125,000 14’ to 25’ 20’ to 30’ 30’ to 50’ 25’

7D847A-7D851A,

7AR79-7AR80

7AR81-7AR84 175,000 17’ to 35’ 30’ to 40’ 40’ to 60’ 30’

7AR85-7AR88 200,000 18’ to 40’ 30’ to 40’ 40’ to 60’ 30’

150,000 15’ to 35’ 30’ to 40’ 40’ to 60’ 25’

Mounting Heights

Between

Heaters

Distance

Between

Heater Rows

Maximum

Distance Between

Heater and Wall

When designing an infrared radiant heating system, consider the following:

• Has the building’s heat loss been

evaluated?

• Does the design meet the needs of

the space?

• Have all clearance to combustible

situations been observed?

• Have recommended mounting

heights been observed?

• Is the supply (burner) end of the

heater located where more heat is

required?

• Is it best to offset the heaters and/

or rotate the reflectors towards the

heat zone?

• Are protective guards, side shields,

‘U’ or ‘L’ reflector covers needed?

• Does the heater require outside fresh

air for combustion?

• Is the environment harsh or

contaminated (requiring outside air

for combustion)?

• Are chemicals or vapor a

concern (requiring outside air for

combustion)?

NOTE: The effective infrared surface

temperature of a person or object may

be diminished with wind above 5 mph.

The use of adequate wind barrier(s)

may be required.

8

NOTE: When heated, materials high in

hydrocarbons (solvents, paint thinner,

mineral spirits, formaldehydes, etc.)

can evaporate. This may result in

odors or fumes being emitted into the

environment. To correct this problem,

clean the area and/or introduce

additional ventilation.

Heaters installed and serviced in

accordance with the installation

manual do not emit odors into the

environment. See notice on page 28

additional information.

Page 9

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Design Scenario

A tube heater system is being installed in 70’ (L) x 40’ (W) space with 12’ ceilings. Two overhead doors are located at one

end and an equipment storage area exists on one side. The calculated heat load is 300,000 BTU/H.

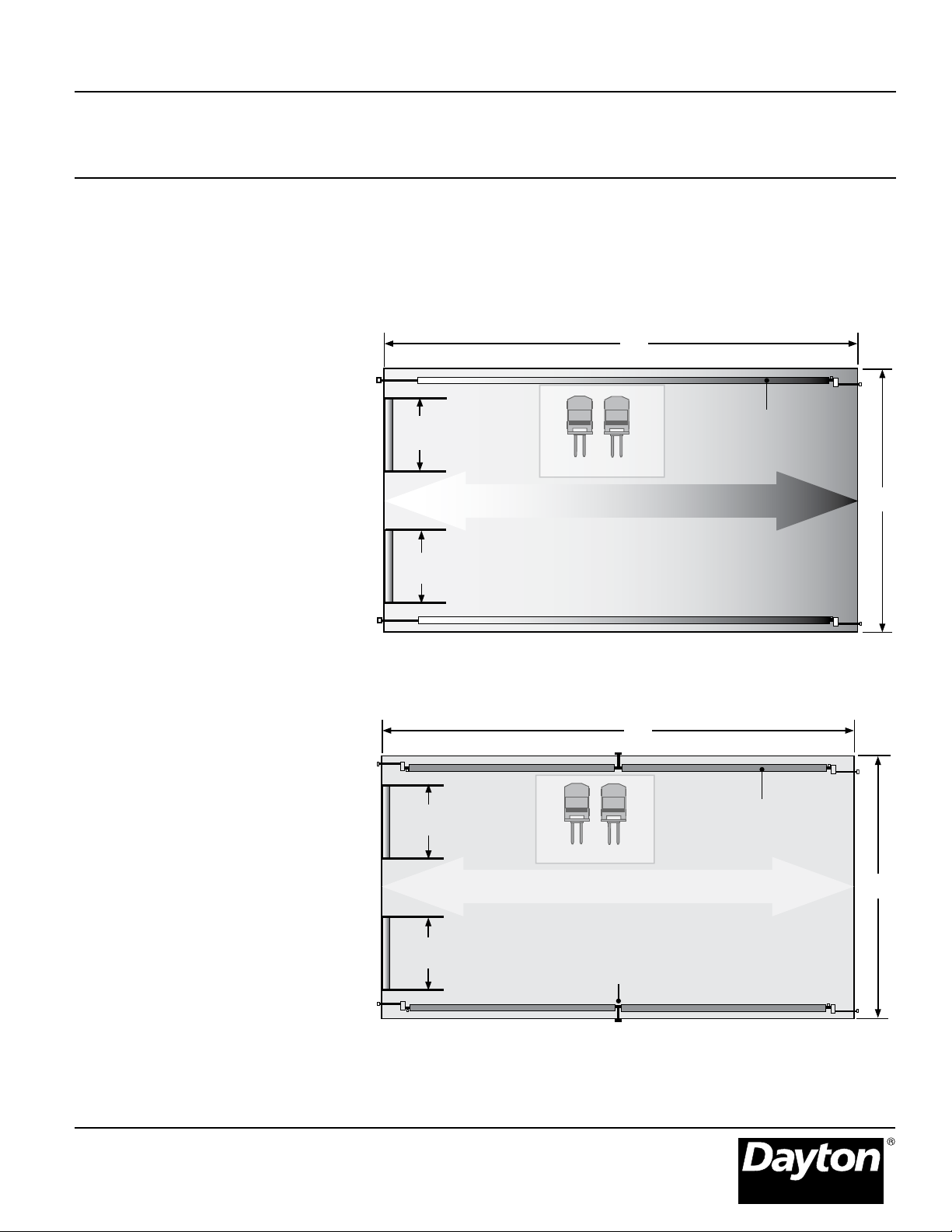

Figure 2.1 • Poor Design

• Two burners (150,000 BTU/H each)

are placed at one end, opposite the

area of highest demand (overhead

doors).

• Recommended mounting heights

are not observed.

• Produces an uneven heat

distribution.

Figure 2.2 • Good Design

• Four burners (75,000 BTU/H each)

are placed in each corner. Burner

(hotter) ends direct heat to areas of

highest head demand.

• Recommended mounting heights

observed.

Doors and

tracks

Too Cold

Doors and

tracks

Doors and

tracks

70’

60’ - 150,000 BTU

Equipment storage

Poor Design

70’

20’ - 75,000 BTU

Equipment storage

Better Heat Distribution

Gas Supply

(2 total)

Too Hot

Gas Supply

(4 total)

40’

40’

• Distributes heat more evenly.

Good Design

Doors and

tracks

Sidewall Vent (2 total)

9

Page 10

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Recommended Mounting Heights

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Model

20 ft. 50 MBH 10’ - 16’ 20’ x 12’ 12’ x 12’ 10’ - 20’ 20’ - 40’ 16’

30 ft. 100 MBH 13’ - 20’ 33’ x 18’ N/A 20’ - 30’ 30’ - 50’ 20’

40 ft. 100-125 MBH 13’ - 25’ 44’ x 21’ 23’ x 17’ 20’ - 30’ 30’ - 50’ 20’

50 ft.

60 ft.

NOTE: Factory recommended

mounting heights are listed as a

guideline. If infrared heaters are

mounted to low or to high, they may

result in heat discomfort or lack of

heat. It is generally recommended to

Figure 2.3 • Recommended Mounting Heights and Distances - see chart above for dimensions.

150-200 MBH 16’ - 30’ 56’ x 30’ N/A 30’ - 40’ 40’ - 60’ 25’

150-200 MBH 17’ - 40’ 67’ x 34’ 34’ x 26’ 30’ - 40’ 40’ - 60’ 25’

BTU Range

75 MBH 12’ - 20’ 22’ x 15’ 12’ x 12’ 20’ - 30’ 30’ - 50’ 18’

150 MBH 16’ - 30’ 45’ x 26’ 24’ x 20’ 30’ - 40’ 40’ - 60’ 25’

Recommended

Mounting Heights

observe the recommended mounting

heights to optimize comfort conditions.

However, certain applications such

as spot heating, freeze protection,

outdoor patio heating or very high

ceilings may result in the heaters

Coverage Straight

Config. (LxW)

Coverage U-Tube

Config. (LxW)

Distance Between

Heater Rows (Ft.)

Dim. A

being mounted outside of the factory

recommended mounting heights.

Clearances to combustibles must

always be maintained.

Distance Between

Heater Rows (Ft.)

Dim. B

Max. Distance Be-

tween Heaters and

Wall (Ft.)

Dim C

Dimension B

Distance between

heater rows

Dimension C

Maximum distance between heater and wall

Dimension A

Dimension A

10

Dimension C

Maximum

distance

between

heater

and wall

Page 11

Dayton Installation, Operation, Maintenance and Parts Manual

!

!

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Hanger Placement and Suspension

Suspension of the heater must

conform to applicable codes

referenced in the Safety section and

these instructions.

1. Lay radiant tubing out in the

following order. Position tubes in

their approximate locations. Figure

2.4.

• 10 ft. primary combustion

chamber.

• Radiant emitter tubes.

IMPORTANT! 150 MBH models must

use the 10 ft. titanium alloy treated

combustion chamber as the first tube

connected to the burner control box.

The combustion chamber has an

orange identification sticker located on

the swaged end of the tube.

2. Mark locations for hanging points.

Figure 2.4 Chart.

NOTE: If the available hanging points

do not allow for the recommended

spacing (or if an alternative hanging

method is utilized) then additional

hangers may be necessary.

• The spacing between the burner

control box mounting brackets

and the first hanger should be

approximately 2’-4”.

• The space between the first two

hangers placed on the first tube

should be approximately 8’-10”.

• The space between hangers

thereafter, one per tube, should be

approximately 9’-8”.

WARNING

Failure to maintain

the published

clearance to

combustibles may

result in fire and/or explosion,

property damage, serious injury or

death. Always maintain clearances

and post signs where needed.

WARNING

Improper suspension

of the heater may

result in collapse

and being crushed.

Always suspend the appliance from

a permanent part of the building

structure that can support the total

weight and force of the heater.

11

Page 12

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Hanger Placement and Suspension

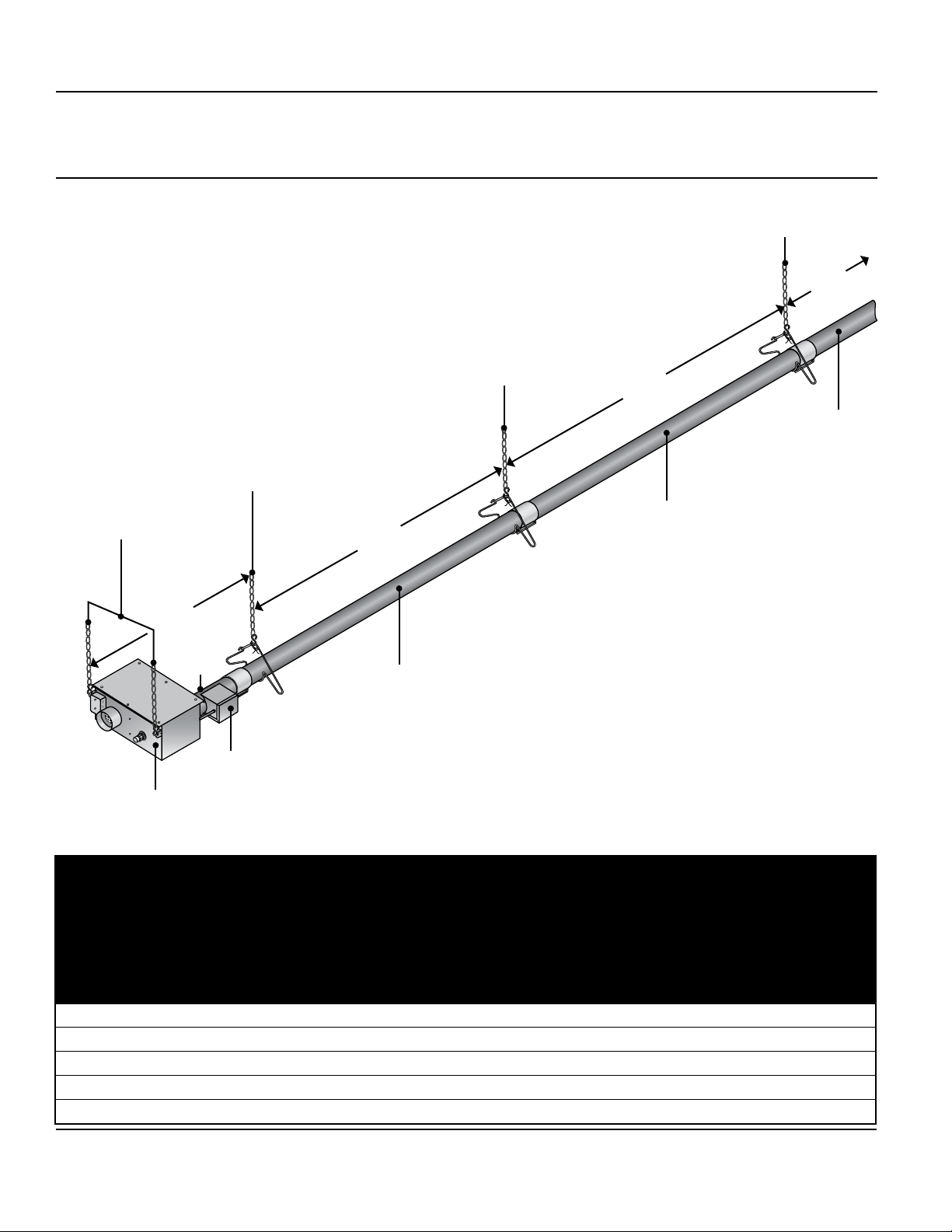

Figure 2.4 • Heater Suspension Layout

NOTE: A sticker identifying the

combustion chamber(s) is located on

the swaged end of the tube(s).

Hanging

Point

Burner Control Box

Hanging Points

8’-10”

2’-4”

16” Burner

Tube

10 ft. Primary Combustion Chamber

Hanging Point

9’-8”

Hanging

Point

9’-8”

Radiant Emitter

Tube(s)

Radiant Emitter Tube

Igniter/Sensor Box

Burner Control Box

Heater Mounting Requirements and Weights

Model

20 ft. 21’-8” 3 2 120 lbs. 5 6 3 2

30 ft. 31’-4” 4 2 160 lbs. 6 N/A 4 N/A

40 ft. 41’-0” 5 2 190 lbs. 7 8 5 3

50 ft. 50’-8” 6 2 235 lbs. 8 N/A 6 N/A

60 ft. 60’-4” 7 2 265 lbs. 9 10 7 4

Dimension

Straight Config.

Hanging Points

Control Box

Hanging Points

Shipping Weight

Chain Set Qty.

Straight Config.

Chain Set Qty.

U-Tube Config.

Optional Brass

Knuckles (P/N:

5VD54)

12

Optional Single

Mount Bracket

(P/N: 5VD85)

U Config. Only.

Page 13

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Heater Placement and Suspension

Suspension of the heater must

conform to applicable codes

referenced in the Safety section and

these instructions.

3. Prepare the mounting surface. If

necessary, weld blocks, drill holes,

etc. Figure 2.5.

NOTE: The burner control box

and radiant tubes should be in

straight alignment and level.

Figure 2.5 • Mounting the Hangers

3. I-Beam

4. Beam Clamp

6. Threaded Rod

5. Threaded Rod

and Turnbuckle

4. Fasten beam clamp, screw hook or

other type of suspension anchor to

hanging point.

5. Attach and close S-hook and #1

double-loop chain to anchor.

Check that it is securely attached.

NOTE: Threaded rod and

turnbuckles may be used.

3. I-Beam

4. Beam Clamp

5. S-hook and

#1 double-loop

chain

6. Chain

6. Attach hangers to chains. Adjust

chain lengths until radiant

tubing is level and equal weight

distribution is achieved.

NOTE: Chains must be straight up

and down. Do not install chains at

an angle as this can result in tube

warpage or separation.

3. Concrete

Beam

4. Screw Hook

6. Chain

4.

Screw

hook

with

locknut

and

washer

3. Wood

Beam

6. Chain

13

Page 14

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Optional U-Bend or Elbow Accessory Configuration

Figure 2.6 • U-Tube Hanger Mounting Options

Single Mounting

Bracket

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Brass Knuckle

Exhaust

End

U-Tubes can be mounted from a single suspension

point using a Single Mounting Bracket (P/N: 5VD85)

with five S-hooks and #1 double-loop chains.

Figure 2.7 • Angled Hanger Mounting Options

U-Tubes can be mounted at a

15°, 30° or 45° angle with two

suspension points, using two Brass Knuckle

(P/N: 5VD54) fittings, #1 double-loop chains and S-hooks.

45°

30°

15°

For 45° hanging angle use two

S-hooks and two #1 double-loop chains.

For variety of hanging angles, use the Brass

Knuckle (P/N: 5VD54) fitting with a #1

double-loop chain and S-hook.

14

Page 15

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Radiant Tube Assembly

To install the radiant tubes:

1. Place tubes in hangers with the welded seam facing downward and the

swaged end of the tube towards the exhaust end of the heater system.

Figure 2.8.

Refer to Figure 2.20 on page 22 for tube installation sequence.

Figure 2.8 • Attach Hangers

Radiant tube

Hanger

2. Slide tube clamps onto radiant tubes. Figure 2.9.

Figure 2.9 • Attach Tube Clamps

Swaged end

Welded seam

faces down

Concave surface

Tube clamp

NOTE: If the tube clamp comes apart, the spacer

must be reassembled with the spacer’s concave

surface facing against the radiant tube surface.

15

Page 16

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Radiant Tube Assembly

3. Slip-fit the radiant tube sections

together until tightly connected

(install swaged end of each tube

towards exhaust end). NOTE: If it

is difficult to mate the tubes, they

may be installed incorrectly.

4. Center tube clamps over the seams

where two radiant tube sections

connect. If necessary, rotate tube

clamps so they will not interfere

with the reflector end caps during

expansion and contraction of the

heater while operating.

5. Tighten tube clamp bolts to secure.

When proper compression is

obtained (40-60 ft-lbs. torque), the

tube seam will create a visible mark

on the tube clamp.

NOTE: Excessive torque may

damage the tube clamp.

The tube clamp is tight when proper

torque is achieved (normally when seam

becomes visible).

Tubes are not fit snuggly together and

the tube clamp is not centered over the

seam.

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

• A maximum of one 180° U-bend or

two 90° elbows can be installed on a

heater.

• Omit one 36” section of turbulator

baffle. Refer to Baffle Assembly

section.

Optional U-Bend or Elbow

Accessory Configurations

Figure 2.11 • Optional Tube

Connections

90 Degree

Elbow Bend

(P/N: 3TZ71)

6. Determine the location of the

burner control box and note the

placement of the mounting chains.

Figure 2.10 • Tube Connections

Tubes fit snuggly together and the tube

clamp is centered over the seam.

Correct Tube Connection

Incorrect Tube Connection

A 180 degree U-bend or 90 degree

accessory fitting may be installed in the

radiant tube heater system.

Refer to chart on page 17 for minimum

distance requirements from the burner

control box.

When installing a U-bend or Elbow

Accessory Fitting:

•

The top clearance of an uncovered

(no reflector) U-bend or elbow

accessory fitting to combustibles is

18”.

• If operating the heater un-vented,

separate the intake air to the heater

from its exhaust products a minimum

of 4’; further separation may be

necessary. Combustion air may also

be supplied.

180 Degree

U-Bend

(P/N: 3F835)

16

Page 17

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Radiant Tube Assembly

Figure 2.12 • Elbow and U-Bend Clearances

Dimension A

Elbow can be set

in both directions

Tube Clamp

Tube Clamp

8”

Figure 2.13 • U-Bend and Elbow Dimensions

16”

6”

16”

Dimension A

12”

Dimension B

20”

Tube Clamp

U-Bend can be set in both directions

Tube Clamp

12.5”

12.5”

10”

20”

P/N: 3F835

Minimum Distance from Burner Control Box to

U-Bend or Elbow Accessory

Models Dimension A

50-100 MBH 10 ft.

125 MBH 15 ft.

150-175 MBH 20 ft.

200 MBH 25 ft.

P/N: 3TZ71

Overall Dimensions for Heaters Configured

with U-Bend (P/N: 3F835)

Model Dimesion B

20 ft. 13’-0”

30 ft. N/A

40 ft. 22’-8”

50 ft. N/A

60 ft. 32’-4”

17

Page 18

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Burner Control Box Suspension

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Suspending the burner control box

must be done in accordance with

applicable codes listed in the Safety

section and these instructions.

The burner control box must be in

straight alignment with the radiant

tubes and level.

1. Determine the mounting chain

locations for hanging the burner

control box.

2. Fasten beam clamp, screw hook or

other type of suspension anchor to

hanging point.

3. Attach and close S-hook and #1

double-loop chain to anchor.

Check that is securely connected.

4. Attach chain assemblies and

S-hooks to mounting brackets on

the burner control box. Adjust

chain lengths until level and in

straight alignment with the radiant

tubes. The burner sight glass will

be visible from the floor.

Figure 2.14 • Burner Control Box Assembly • Side View

1

2

3

Burner Control Box tube is in

straight alignment with 10’

4

Primary Combustion Chamber

8.1”

Burner Sight Glass

12”

Figure 2.15 • Burner Control Box with U-Bend • End View

(bottom side of the tube)

16”

29.6”

16”

3.5”

18

5.5”

8.1”

3”

5”

18”

Page 19

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Reflector Assembly

To install the reflectors:

1. Attach reflector center supports

onto radiant tubes.

2. Slide each reflector section through

the hangers and adjust the reflector

tension spring into the V-groove

on the top of the reflector.

The reflectors should overlap

approximately 4”.

3. To prevent the reflectors from

shifting, secure the reflector

sections together using sheet metal

screws except at the expansion

joint. Figure 2.18. NOTE: Installer

to provide sheet metal screws.

4. Attach reflector end caps, with

polished side inward, to each end

of the reflector run.

Reflectors, and reflector accessories,

direct infrared energy to the floor

level. The reflector assembly depends

on the heater configuration, proximity

to combustibles and the space

surrounding the heater.

Before you begin assembly, determine

if the use of reflector accessories are

necessary. Figure 2.17.

Figure 2.16 • Reflector Assembly

Hanger

and Chain

Radiant

Tube

Reflector

Reflector Center

Support

Place at the

mid-point

of the tube

Reflector

Tension

Spring

19

4” Overlap

Reflector

End Cap

Clips

Page 20

Dayton Installation, Operation, Maintenance and Parts Manual

®

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Dayton Tube Heaters

Reflector Assembly

Common Optional Accessories

Reflector Accessories Description Part #

Elbow Reflector* 90° bend, highly polished aluminum reflector elbow. Designed to fit atop one

elbow accessory fitting.

U-Reflector* 180° bend, highly polished aluminum reflector U-bend. Designed to fit atop

one U-bend accessory fitting.

Side Shield Reflector *^

Protective Guard Used to prevent debris or objects from becoming lodged between the radiant

* Reflectors cannot be rotated when used with this accessory.

^ Refer to the Clearance to Combustibles chart on page 7 for minimum distances to combustibles when side shield

extension(s) are used.

Highly polished side shield extension used to direct infrared rays downward,

away from side walls and combustibles.

tube and reflector. Required when mounting heaters below 8 ft.

5VD83

5VD84

5VD86

5VD81

Additional accessory options are available in the W.W. Grainger catalog.

Figure 2.17 • Reflector Shield Accessories

Elbow reflector (P/N: 5VD83)

Used over a 90-degree elbow

radiant tube.

U-shaped reflector (P/N: 5VD84)

Used over a ‘U-shaped

radiant tube.

20

Side shield extension (P/N: 5VD86)

Directs infrared rays downward, away

from sidewalls and combustibles.

Page 21

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Baffle Assembly and Placement

To assemble the baffles:

NOTE: Baffles may be inserted into the

tube while being assembled.

1. Determine the number of baffles

needed for your model number.

Remove one 36” baffle section if

heater is installed with an elbow or

U-bend accessory.

Figure 2.18 • Assembling the Baffles

Baffle keyhole

Baffle tabs

2. Install the baffle tabs at a 90° angle

to the baffle keyhole.

Figure 2.18.

3. Insert one baffle tab into keyhole

and slide completely to one side

until both baffle tabs appear in the

keyhole.

2

3

4. Adjust the tabs to the center of the

keyhole and rotate the baffle 90° to

lock the baffle sections together.

5. Repeat this process with remaining

baffle sections to complete

assembly.

4

To insert the baffles:

1. Insert baffles with the keyhole end

first.

2. Rotate baffle assembly so that it is in

the vertical position.

Figure 2.19 • Inserting the Baffles

Completed connection

3. Slide baffle assembly into the last

radiant tube section, furthest from

burner control box.

21

3

NOTE: Baffle assemblies longer than

10’ will continue to be fed into next

tube section.

IMPORTANT: Baffle assembly must be

flush with the end of the last tube

section and in the vertical position.

21

Page 22

Dayton Installation, Operation, Maintenance and Parts Manual

®

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Dayton Tube Heaters

Final Heater Assembly

NOTICE

Different inputs and models utilize different baffle lengths. Remove all enclosed baffle sections from box and retain with

applicable heater. Reference shipping label for proper baffle size.

Each 36” baffle section must be assembled with other baffles and placed in the radiant tube section furthest from the

burner. Important: Omit one section of baffle if heater is configured with a U-bend or Elbow accessory fitting.

Figure 2.20 • Secured Reflector Joints and Baffle Location

20 Foot

30 Foot

40 Foot

Key

Burner Control Box

with 16” Burner Tube

Expansion Joint on

Reflectors

Secured Joint on

Reflectors

Primary Combustion

Chamber Tube with

Clamp

Radiant Tube with

Clamp

Baffle Location

50 Foot

60 Foot

22

Page 23

Dayton Installation, Operation, Maintenance and Parts Manual

!

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Venting

!

WARNING

Insufficient

ventilation and/or

improperly sealed

vents may release

gas into the building

which could result in health

problems, carbon monoxide

poisoning or death.

Improper venting may result in fire,

explosion, injury or death.

Seal vent pipes with high temperature

sealant and three (3) #8 sheet metal

screws. Vent enclosed spaces and

buildings according to the guidelines

in this manual and applicable

national, state, provincial and local

codes.

The heating system may operate either

vented or un-vented (see page 27).

Venting can terminate through the

sidewall (horizontal) or the roof (vertical)

and be individually or commonly vented.

Follow these guidelines and all

applicable codes for all models, prior to

installing vent material. Local codes may

vary. In the absence of local codes, refer

to the National Fuel Code ANSI Z223.1

(NFPA 54) latest edition or the National

Standards of Canada.

Venting Requirements

• 4” single wall galvanized steel vent

pipe or Dura/Connect single wall

flexible exhaust vent must be used.

• Seal single wall vent with high

temperature sealant and three (3) #8

sheet metal screws.

• Single wall galvanized vent pipe must

be insulated in cold environments.

• Do not use more than two 90°

elbows in the exhaust vent.

• To maintain clearances to

combustibles, the use of an approved

wall or roof thimble and double-wall

Type B-vent is required for the

portion of vent pipe that runs

through combustible material in the

building wall or roof (see figures 2.21

& 2.22).

• The maximum vent length is 20’.

23

Page 24

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Vent Assembly

Figure 2.21 • General Vent Requirements:

Vent Cap

24 in.

Min.*

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Storm Collar

Adjustable Roof Flashing

1 in. minimum clearance

1 in. minimum clearance

B to C Adapter

Single-wall Elbow or Alternate Tee Fitting

*Consult the NFPA ANSI Z223.1 Gas Vent Termination criteria if roof pitch exceeds 9:12

Figure 2.22 • Sidewall Venting Requirements

Roof*

Double-wall B Vent

Firestop Spacer

Heater

Single-wall Vent (field supplied)

Sidewall Venting

Guidelines:

Building

Overhang

Sidewall

Vent Cap

Wall

Thimble

36 in.

min.

6 in.

min.

Sidewall

B to C Adapter

Double-wall

B-Vent

1/4 in. downward

pitch per foot

Single

Wall Vent

24

Heater

• To prevent moisture from entering

the heater system, slope the vent

pipe down toward the outlet 1/4”

per foot of length. Do not pitch the

heater.

• Vent must extend beyond any

combustible overhang.

Page 25

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Vent Assembly

Vent Termination

• Vent must terminate a minimum

of 4’ (1.2m) below, 4’ (1.2m)

horizontally from or 12” (30 cm)

above any window or door that may

be opened and gravity air inlet into

the building.

•

Vent must terminate a minimum of 3’

(.9m) above any forced air inlet that is

located within 10’ (3.1m).

• The bottom of the vent terminal

must be located a minimum of 12”

(30 cm.) above grade level and must

extend beyond any combustible

overhang. Vents adjacent to

public walkways must terminate a

minimum a 7’ (2.1 m) above grade

level.

• The vent cap must be a minimum of

6’ (15.2 cm) from the sidewall of the

building.

Roof Venting

Guidelines:

• Separate air intake duct from vent

pipe a minimum of 4’ (1.2 m) by

placing vent pipes higher than

adjacent air intake duct.

Figure 2.23 • Rooftop Venting - Side View

• Venting may utilize a standard

B-vent cap.

• The vent terminal must be installed

to prevent blockage by snow and

protect building materials from

degradation by flue gases.

• Vents must extend beyond any

combustible or be a minimum of 36”

below a combustible overhang.

• The vent terminal must extend a

minimum of 2’ (.6 m) above the

roof.

Vent Cap

Roof

B to C Adapter

Single-wall Elbow or Alternate Tee Fitting

24 in. Min.*

Roof

Double-wall B Vent Pipe

Firestop Spacer

Heater

*Consult the NFPA ANSI Z223.1 Gas

Vent Termination criteria if roof pitch

exceeds 9:12.

25

Page 26

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Vent Requirements

Common Venting

• A dual exhaust assembly (P/N: 3F817)

must be used when joining two

heaters to a common vent so that byproducts of one heater do not flow

into the adjoining vent of the other

heater.

• 6” diameter double-wall B-vent and

6” vent cap must be used.

• Common vented heaters must be

controlled with the same thermostat.

Do not operate individually.

Figure 2.24 • Common Rooftop Venting - Side View

24 in.

Rooftop Vent Cap

Double-wall B Vent

Firestop Spacer

Heater

Min.*

Roof

Heater

Figure 2.25 • Common Sidewall Venting - Top View

Sidewall

6 in.

min.

Sidewall Vent Cap

Wall Thimble

Double-wall B-Vent

Single Wall Vent

B To C

Adapter

Dual Exhaust Assembly

Heater

Dual Exhaust Assembly

Heater

*Consult the NFPA ANSI Z223.1 Gas

Vent Termination criteria if roof pitch

exceeds 9:12.

26

Page 27

310mm

!

!

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Optional Unvented Operation

When installing in an un-vented

configuration:

• A factory supplied vent cap/diffuser

(P/N: 3F839) must be used.

• Ventilation of the space is required

to dilute the by-products of

combustion. Sufficient displacement

of fresh air intake and exhaust byproduct must be provided.

• The minimum clearance between

the air intake and the exhaust

terminal is 4’. NOTE: When

installing in a U-bend configuration,

use caution to separate vent gases

from heater intake.

• A minimum positive air displacement

(movement) of 4 ft3/1000 Btu/hr

input of installed heaters is required.

NOTE: Gravity or mechanical means

may be used to accomplish the air

displacement. Local codes may require

that the mechanical exhaust system be

interlocked with the electrical supply

line to the heaters, enabling both to

function simultaneously.

• The use of combustion air intake is

recommended.

Figure 2.26 • Minimum end clearance for unvented heater

WARNING

Not for

residential use.

The use of unvented

tube heaters in

residential indoor spaces may result in

property damage, serious injury or

death. Use unvented operation in

commercial and industrial installations

with proper ventilation rates only.

310mm

12”

12”

27

Page 28

Dayton Installation, Operation, Maintenance and Parts Manual

®

Dayton Tube Heaters

Combustion Air Requirements

Figure 2.27 • Vertical Outside Air Supply for Single Heater

NOTICE

This heater has a factory preset air

orifice for proper combustion air

supply. If using combustion air intake

from indoors, the required volume of

the space must be a minimum of

50 ft3/1000 Btu/hr of installed heater

input unless the building is of unusually

tight construction. If the building has

air infiltration rates of less than 0.40 air

changes per hour, outside combustion

air is typically needed unless the sheer

size of the building allows otherwise.

Non-contaminated air for

combustion must be ducted to the

heater if chlorinated or fluorinated

contaminants, high humidity and other

contaminants such as sawdust or

welding smoke are present in the area

where the heater is installed, or if the

building has a negative pressure.

Side View

4” pipe

Figure 2.28 • Horizontal Outside Air Supply for Single Heater

Side View

Air Intake

Cap

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Roof Intake Cap

18” Min.

Flexible Air Inlet Boot

Flexible Air Inlet Boot

4” pipe

Wall

Roof

Burner

Control Box

Burner

Control Box

Combustion air intake may be located

on either the sidewall or the roof.

Figures 2.27 - 2.29.

Figure 2.29

Vertical Outside Air Supply for Common Heater • Side View

Note: Common

intake heaters

must share the

same thermostat.

18” Min.

Flexible Air

Inlet Boot

4” pipe4” pipe

Roof Intake Cap

6” pipe

Roof

28

Burner

Control Box

Page 29

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Combustion Air Requirements

Guidelines:

General Requirements

• No more than two 90° elbows are

allowed.

• Allow for expansion. Use a 4” flexible

hose to connect the duct to the

burner control box.

• Do not draw air from attic space.

• In humid environments, use insulated

duct, PVC pipe or DWV (drain waste

vent) to prevent condensation on the

outer surface.

• Separate air intake duct from vent

pipe a minimum of 4’. Also, place

pipe higher than adjacent air intake

duct.

• A factory approved wall intake cap

(P/N: 3F837) must be used with

horizontal outside intake ducts. The

wall intake cap (P/N: 3F837) must be

installed to prevent blockage. Locate

the intake where dirt, steam, snow,

etc. will not contaminate or clog the

intake screen.

Limitations for length and size of combustion air intake duct

Single Heater Intake Dual Heater Intake

Air Intake Duct Size Max. Intake Length Duct Size Max. Intake Length

4 in. 20 ft. 4 in.(single)/6 in.(dual) 20 ft.

5 in. 30 ft. 4 in.(single)/8 in.(dual) 30 ft

6 in. 40 ft.

Consult factory for longer intake lengths.

Figure 2.30 • Combustion Air Intake

Air Intake Cap

Burner Control Box

29

Page 30

Dayton Installation, Operation, Maintenance and Parts Manual

!

®

Dayton Tube Heaters

Gas Supply

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

!

WARNING

Improperly connected gas lines may

result in fire, explosion, poisonous

fumes, toxic gases, asphyxiation or

death. Connect gas lines in

accordance to national, state,

provincial and local codes.

IMPORTANT! Before connecting the

gas supply to the burner control box:

• Verify that the heater’s gas type (as

listed on the rating plate) match that

of your application.

• Check that the gas piping and

service has the capacity to handle

the total gas consumption of all

heaters being installed, as well as

any other gas appliances being

connected to the supply line.

• Check that the main gas supply line

is of proper diameter to supply the

required fuel pressures.

• If utilizing used pipe, verify that its

condition is clean and comparable to

a new pipe. Test all gas supply lines

in accordance with local codes.

• Test and confirm that inlet pressures

are correct. Refer to the rating

plate on the burner control box for

required minimum and maximum

pressures (see chart below). The

gas supply pipe must be of sufficient

size to provide the required capacity

and inlet pressure to the heater

(if necessary, consult the local gas

company). Do not exceed the

maximum allowed pressure for the

heater, the space or the gas piping

system.

Manifold Pressure

Required

Type of Gas

Natural 3.5 Inches W.C. 5.0 Inches W.C. 14.0 Inches W.C.

Liquefied Petroleum 10.0 Inches W.C. 11.0 Inches W.C. 14.0 Inches W.C.

Manifold Pressure

Minimum

Inlet Pressure

Maximum

Inlet Pressure

Note: Check manifold pressure at the tap on the gas valve. Readings will be above atmospheric pressure.

Pressure Equivalents: 1 Inch W.C. = .058 oz/sq. in. = 2.49 Mbar

30

Page 31

Dayton Installation, Operation, Maintenance and Parts Manual

!

!

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Gas Connection

To connect the gas:

WARNING

Failure to install, operate

or service this appliance

in the approved manner

may result in property

damage, injury or death. Only trained,

qualified gas installation and service

personnel may install or service this

equipment.

This heater must be installed and

service by trained gas installation

and service personnel only.

The installation must conform with local

building codes or, in the absence of

such codes, the National Fuel Code

(NFPA 54) and in conjunction with ANSI

Z21.24/CSA 6.10 “Connectors for Gas

Appliances”.

IMPORTANT! The heating system will

expand and contract during operation.

Allowances for expansion must be

made between the connection to the

heater and the gas supply. Excessive

bending, kinks, twists or vibration must

be avoided. A flexible gas connection of

approved type is required. Flexible

stainless steel gas connectors installed

in one plane, and without sharp bends,

kinks or twists is recommended.

The gas pipe and connection must be

supported independently. Do not

install gas supply line in a manner that

bears the weight of the heater.

Connect the main gas supply line with

an approved flexible connector (Figures

2.31 & 2.32) or, if national or local

codes require rigid piping, a swing

joint. See the safety messages at the

beginning of this section.

The gas outlet must be in the same

room as the appliance and accessible.

It may not be concealed within or run

through any wall, floor or partition.

When installing the heater in a

corrosive environment (or near

corrosive substances), use a gas

connector suitable for the

environment. Do not use the gas

piping system to electrically ground the

heater.

1. Install a sediment trap / drip leg if

condensation may occur at any

point of the gas supply line. This will

decrease the possibly of loose scale

or dirt in the supply line entering the

heater’s control system and causing

a malfunction.

NOTE: High pressure gas above 14

Inches W.C. (water column pressure)

requires a high pressure regulator and

ball valve.

2. Form the stainless steel flexible

connector into a smooth C-shape

allowing 12 in. between the flexible

connector’s end nuts. Figure 2.31.

3. Attach the ball valve to the gas

supply pipe. Apply pipe compound

to NPT adapter threads to seal the

joint. Use only a pipe compound

resistant to LP.

NOTE: Provide a 1/8 in. NPT plugged

tapping accessible for test gauge

connection immediately upstream of

gas connection to the heater (provided

on ball valve).

31

Page 32

Dayton Installation, Operation, Maintenance and Parts Manual

!

®

Dayton Tube Heaters

Gas Supply

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

4. Attach the flexible connector to the

adapter and burner control box

inlet. Seal the joints.

NOTE: Excessive torque on the

manifold may misalign the orifice.

Always use two wrenches to tighten

mating pipe connections.

5. Final assembly must be tested for

gas leaks according to NFPA or

local codes.

!

CAUTION

When using a stainless steel flexible

connector, do not attach the connector

nuts directly to the gas pipe supply.

Connector nuts must be installed to an

approved adapter.

Figure 2.31 • Flexible Gas Connection Side View

Ball Valve / Inlet Tap

Adapter

Drip Leg/

Sediment Trap

12”

Stainless Steel Gas Connector, formed

into smooth C-Shape

2” max displacement

Heater Movement

Adapter

Burner

Control Box

Figure 2.32 • Flexible Gas Connection End View

!

WARNING

Testing for gas leaks

with an open flame

or other sources of

ignition may lead to a

fire or explosion and cause serious

injury or death. Test in accordance

with NFPA or local codes.

Ball Valve/Inlet Tap

Stainless Steel

Gas Connector

45°

45°

Horizontal

Burner Control Box

Remove cap to clean

sediment trap

32

Page 33

120V-60 Hz.

Supply

NOTE: Up to 4 line voltage tube heaters can be

wired to most thermostats.

T

L1

Neutral

Ground

Heaters on the same vent must

share the same thermostat.

Additional heaters

Multiple Burner Box

(if applicable)Burner Box

COM

24V

Burner Control Box

w/ 24VAO

L1

N

120 Volt Power

(Observe polarity)

24V Digital

Thermostat

120 V

24V

+

Common

W

R

-

COM

24V

COM

24V

Burner Control Box

w/ 24VAO

Burner Control Box

w/ 24VAO

Common required

for thermostats

that require

constant power.

Common required

for thermostats

that require

constant power.

1/4” spade terminals

required (field supplied)

External

Transformer

(field suppied)

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Electrical Requirements

• Verify that the heater’s voltage (as

listed on the rating plate) matches

that of your application.

• The heater must be grounded

in accordance with the National

Electrical Code ANSI/NFPA70 (latest

edition).

• Heaters operate on 120 volts,

60Hz., single phase. The maximum

amperage requirement is 4.8 amps

starting current; 1.1 amps running

current per heater.

• It is recommended that the

thermostat be installed on the hot

side of a fused supply line and have

sufficient amp rating for the heater(s)

that it controls.

• Observe proper electrical polarity.

Figure 2.33 - Field Wiring 120V Connection(s)

• Clearance to combustibles must

be maintained between electrical

apparatus and wiring. See clearance

data on page 7.

• Wiring must not be run above or

below the heater or exposed to the

radiant output.

• Installations utilizing a 24 volt

thermostat require a relay

transformer. Figure 2.34.

Figure 2.34 - Field Wiring 24V Thermostat Connection

33

Page 34

Dayton Installation, Operation, Maintenance and Parts Manual

Terminal

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

®

Dayton Tube Heaters

Internal Wiring Diagrams

If any of the original wire as supplied with this appliance must be replaced, it must be replaced with wiring material having

a temperature rating of at least 105°C.

Figure 2.35 • Ladder Diagram: Mark 17DU-117 with Lights

120VACL1

BK

BK

BK

Indicator Lights

BK

BK

Gas Valve

BK

BK

Blower

N

BK

W

G

GND

NEUT

VALVE

BK

Ignitor

Pressure Switch

Flame Rod

O

R

BK

W

BR

TH

SIC1

LINE1

PROBE

NEUT

Ignition Module

Figure 2.36 • Block Diagram: Mark 17DU-117 with Lights

L1

120VAC

N

BK

Block

BK

BK

BK

BK

Pressure Switch

BK

Indicator Lights

BK

BK

BK

O

W

W

R

W

G

Burner

Probe

SIC1

Line1

TH

Neutral

Valve

Neutral

Ground

W

Ignitor

Flame

Rod

BK

BR

Ignition

Module

W

Blower

Gas Valve

34

Page 35

Dayton Installation, Operation, Maintenance and Parts Manual

!

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Operation

Sequence of Operation

!

WARNING

This heater is not

equipped with a pilot

ignition system.

Do not attempt to light the system

manually.

LIGHTING PROCEDURES:

1. Verify that service lid is secured.

2. Open (turn on) gas supply to the

heater.

3. Close (turn on) electrical circuit

(typically thermostat).

Starting Circuit

Upon a call for heat, the fan is

energized. Once operational static

pressure is achieved, the differential

switch will close initiating the ignition

sequence. After a 5-second delay, the

hot surface igniter is energized for 45

seconds and the control allows the gas

valve to open.

The trial for ignition is 8 seconds. If

flame sense is not established within

8.5 seconds, the heater will attempt

two (2) additional ignition sequences

before proceeding to soft lockout. Soft

lockout automatically retries after one

(1) hour or the control can be reset by

briefly interrupting the power source.

Running Circuit

After ignition, the flame rod monitors

the burner flame. If sense of flame is

lost, the control immediately acts to

reignite the gas-air mixture (identical to

the starting sequence). If flame sense is

not established within 8.5 seconds, the

heater will attempt two (2) additional

ignition sequences before proceeding

to soft lockout. The control can be

reset by briefly interrupting the power

source.

4. If the heater fails to light, turn off

gas, open electrical circuit (set

thermostat to lowest setting or to

off). Wait five (5) minutes before

repeating above steps.

SHUTDOWN PROCEDURES:

1. Open (turn off) electrical circuit.

2. Close (turn off) gas supply to the

heater.

3. Wait five (5) minutes before

relighting heater.

35

Page 36

Dayton Installation, Operation, Maintenance and Parts Manual

!

!

!

!

!

!

®

Dayton Tube Heaters

Routine Inspection

7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

WARNING

Personal injury or death may result if

maintenance is not performed by

properly trained gas installer or

service personnel. Contact the

installing distributor or place of

purchase for service. Do not

operate heating system if repairs

are necessary.

!

WARNING

Allow heater to cool

prior to servicing.

WARNING

Disconnect power

to heater before

servicing.

!

WARNING

Use protective

glasses when

cleaning the heater.

At least once per year, the heating

system should be inspected and

serviced by trained gas installation and

service personnel only. This inspection

should be performed at the beginning

of the heating season to insure that all

heater components are in proper

working order and that the heating

system operates at peak performance.

Particular attention should be paid to

the following items.

• Blower Motor: Annual oiling of the

blower motor with SAE 20 oil will

extend bearing life significantly.

Ensure that the squirrel cage in the

blower is kept clean. If dirt

becomes a problem, installation of

outside air intake ducts for

combustion is recommended.

• Vent pipe system: Check the

outside termination and the

connections at the heater. Inspect

the vent exhausts for leakage,

damage, fatigue, corrosion and

obstructions. If dirt becomes a

problem, installation of outside air

intake ducts for combustion is

recommended.

• Combustion air intake system

(when applicable): Check for

blockage and/or leakage. Check

the outside termination and the

connection at the heater.

• Heat exchangers: Check the

integrity of the heat exchangers.

Replace if there are signs of

structural failure. Check for

corrosion and/or buildup within the

tube exchanger passageways.

• Burner: Check for proper ignition,

burner flame and flame sense.

Flame should extend directly

outward from burner without

floating or lifting.

• Wiring: Check electrical

connections for tightness and/or

corrosion. Check wires for

damage.

• Gas Connection: Inspect the

integrity of the gas connection to

the heater. Check for leaks,

damage, fatigue or corrosion. Do

not operate if repairs are necessary

and turn off gas supply to the

heater. Contact service personnel.

• Reflectors: To maintain effective

infra-red heating, always keep both

sides of the reflector clean.

Maintenance can vary significantly

depending on the environment.

Dirt and dust can be vacuumed or

wiped with a soap and water

solution. Use metal polish if the

reflectors are severely dirty.

Contact service personnel if repairs are

necessary. Do not operate unit.

36

Page 37

Dayton Installation, Operation, Maintenance and Parts Manual

Models 7D837A thru 7D849A, 7D851A, 7AR79 thru 7AR88

Troubleshooting Guide

Symptom Possible Cause Corrective Action

Thermostat closed, fan doesn’t operate. • Blown fuse.

• Faulty thermostat.

• Loose or disconnected wire.

• Faulty fan.

Thermostat closed. Fan operates. Switch

does not close.

Note: If hot surface igniter is

energized, the indicator light is faulty.

Thermostat closed. Fan operates. Pressure

switch closes. No hot su

Thermostat closed. Fan operates.

Pressure switch closes. Hot surface

igniter energizes. Valve does not open.

Thermostat closed. Fan and hot surface

igniter operate. Ignition occurs, burner

cycles off in less than 60 seconds.

Thermostat closed. Fan and hot surface

igniter operate. After 45 seconds hot

surface igniter shuts off. No ignition.

Loss of heater efficiency. • Low gas pressure.

Radiant tube leaking burnt gases. • Loose tube connections.

Condensation. • Stack length is too long.

Tube bowing. • Insufficient combustion air.

Tube corroding. • Contaminated combustion air. • Provide fresh air inlet duct.

Visual inspection of burner operation

not possible.

Stack sooting. • Insufficient combustion air.

Odor or fumes in space

(normal during first firing and

will subside after initial burn off,

approximately 20 minutes).

rface

igniter.

• Loose or disconnected wire.

• Box lid or gasket not in place.

• Plugged pressure switch lines.

• Plugged or restricted exhaust vent.

• Baffle location incorrect.

• Faulty pressure switches.

• Faulty hot surface igniter.

• Faulty circuit board.

• Disconnect gas valve wires.

• Faulty circuit board.

• Faulty gas valve.

• Low gas pressure.

• Baffle improperly positioned.

• Faulty exhaust pressure switch.

• Restricted flue vent.

• No electrical ground.

• Reversed polarity.

• Closed gas supply.

• Dirty or restricted orifice.

• Faulty valve. Disconnected wire.

• Inlet pressure exceeds 14 Inches W.C.

• Dirty or restricted orifice.

• Foreign matter inside burner.

• Unit cycles on and off.

• Reflector is dirty or not in place.

• Clogged fan blower.

• Holes or cracks in radiant tubes.

• Light gauge flue stack used.

• Contaminated combustion air.

• Over fired.

• Contaminated combustion air.

• Heater unable to expand properly.

• Dirty or sooted sight glass.

• Unit mounted upside-down.

• Improper gas.

• Dirty fan or blockage.

• Vaporized solvents decomposing when

contacting radiant tubes.

• Evaporation of oils, solvents at floor level.

• Fork lifts.

• Loose tube / vent connections.

• Replace.

• Replace.

• Repair as required.

• Lubricate, repair or replace.

• Repair as required.

• Put in place.

• Clean as necessary.

• Remove foreign matter.

• Re-position baffles at vent end.

• Replace only. Do not adjust.

• Replace.

• Replace.

• Repair as required.

• Replace.

• Replace.

• Provide required gas pressure.

• Re-position baffle at vent end.

• Replace.

• Remove foreign matter.

• Connect electrical ground to junction box.

• Repair.

• Open all gas connections.

• Remove. Clean with a soft object.

• Replace or repair.