Page 1

DATA SHEET

DATA SHEET

BIPOLAR ANALOG INTEGRATED CI RCUIT

PC1679G

µµµµ

5 V-BIAS, +15.5 dBm OUTPUT, 1.8 GHz WIDEBAND

Si MMIC AMPLIFIER

DESCRIPTION

The µPC1679G is a silicon monolithic integrated circuit designed as medium output power amplifier for high

frequency system applications. Due to +13 dBm TYP. output at 1 GHz, this IC is recommendable for transmitter

stage amplifier of L Band wireless communication systems. This IC is packaged in 8-pin plastic SOP.

This IC is manufactured using NEC’s 20 GHz fT NESATTMIV silicon bipolar process. This process uses silicon

nitride passivation film and gold electrodes. These materials can protect chip surface from external pollution and

prevent corrosion/migration. Thus, this IC has excellent performance, uniformity and reliability.

FEATURES

• Supply voltage : VCC = 4.5 to 5.5 V

• Saturated output power : P

• Wideband response : fu = 1.8 GHz TYP. @ 3 dB bandwidth

• Isolation : ISL = 34 dB TYP. @ f = 500 MHz

• Power Gain : GP = 21.5 dB TYP. @ f = 500 MHz

ORDERING INFORMATION

Part Number Package Marking Supplying Form

µ

PC1679G-E1 Embossed tape 12 mm wide.

µ

PC1679G-E2

Remark

To order evaluation samples, please contact your local NEC sales office.

(Part number for sample order:

8-pin plastic SOP (225 mi l ) 1679

O(sat)

= +15.5 dBm TYP. @ f = 500 MHz with external inductor

1 pin is tape pull-out directi on.

Qty 2.5 kp/reel.

Embossed tape 12 mm wide.

1 pin is tape roll-in directi on.

Qty 2.5 kp/reel.

PC1679G)

µ

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. P12434EJ4V0DS00 (4th edition)

Date Published September 1999 N CP(K)

Printed in Japan

Caution Electro-static sensitive devices.

The mark shows major revision points.

1994, 1999©

Page 2

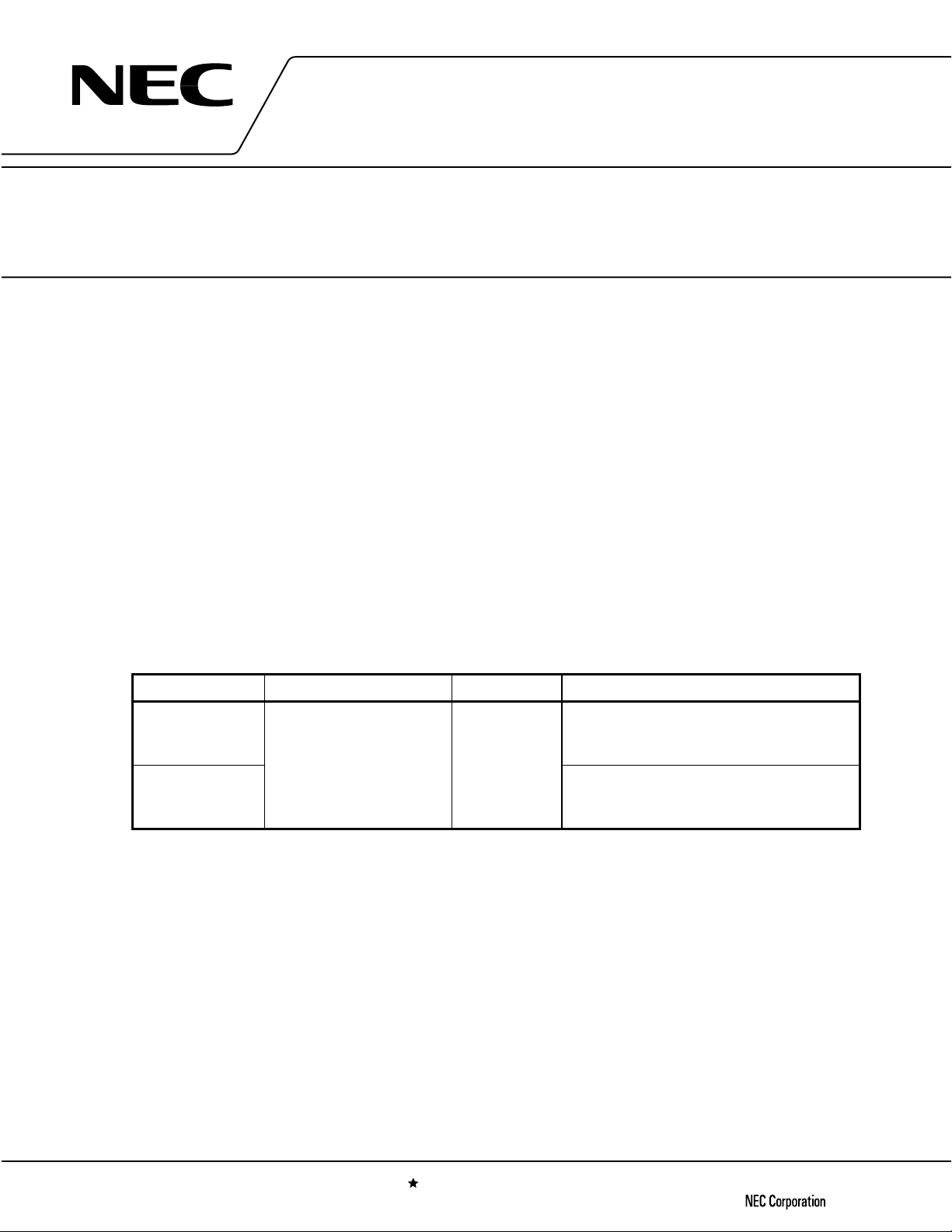

EQUIVALENT CIRCUIT PIN CONNECTIONS

µµµµ

PC1679G

IN 1

67 342

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Conditions Rating Unit

Supply Voltage V

Input Power P

Power Dissipation P

Operating Ambient Temperature T

Storage Temperature T

8 V

CC

5 OUT

INPUT

1

(Top View)

2GND

3GND

4GND

CC

TA = +25 °C, pin 5, pin 8 6 V

in

TA = +25 °C +10 dBm

D

Mounted on double copper clad 50 × 50 × 1.6 mm

A

epoxy glass PWB (T

A

stg

= +85 °C)

360 mW

45 to +85 °C

−

55 to +150 °C

−

8V

CC

7 GND

6 GND

5 OUTPUT

RECOMMENDED OPERATING RANGE

Parameter Symbol MIN. TYP. MAX. Unit Notice

Supply Voltage V

Operating Ambient Temperature T

ELECTRICAL CHARACTERISTICS (TA = +25 °C, VCC = V

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Circuit Current I

Power Gain G

Noise Figure NF f = 500 MHz

Upper Limit Operating Frequency f

Isolation ISL f = 500 M Hz 29 34

Input Return Loss RL

Output Return Loss RL

Saturated Output Power P

CC

A

CC

P

u

out

O(sat)

4.5 5.0 5.5 V The same voltage should be applied

to pin 5 and 8

45 +25 +85 °C

−

out

= 5.0 V, ZS = ZL = 50

No signal 32 40 49 mA

f = 500 MHz 19.5 21.5 23.5 dB

−

3 dB down below the gain at 0.1 GHz

in

f = 500 MHz 9 12

1.5 1.8

f = 500 MHz 1 3

f = 500 MHz, Pin = +3 dBm +13.5 +15.5

)

ΩΩΩΩ

6.0 8.0 dB

−

−

−

−

−

GHz

dB

dB

dB

dBm

2

Data Sheet P12434EJ4V0DS00

Page 3

µµµµ

PC1679G

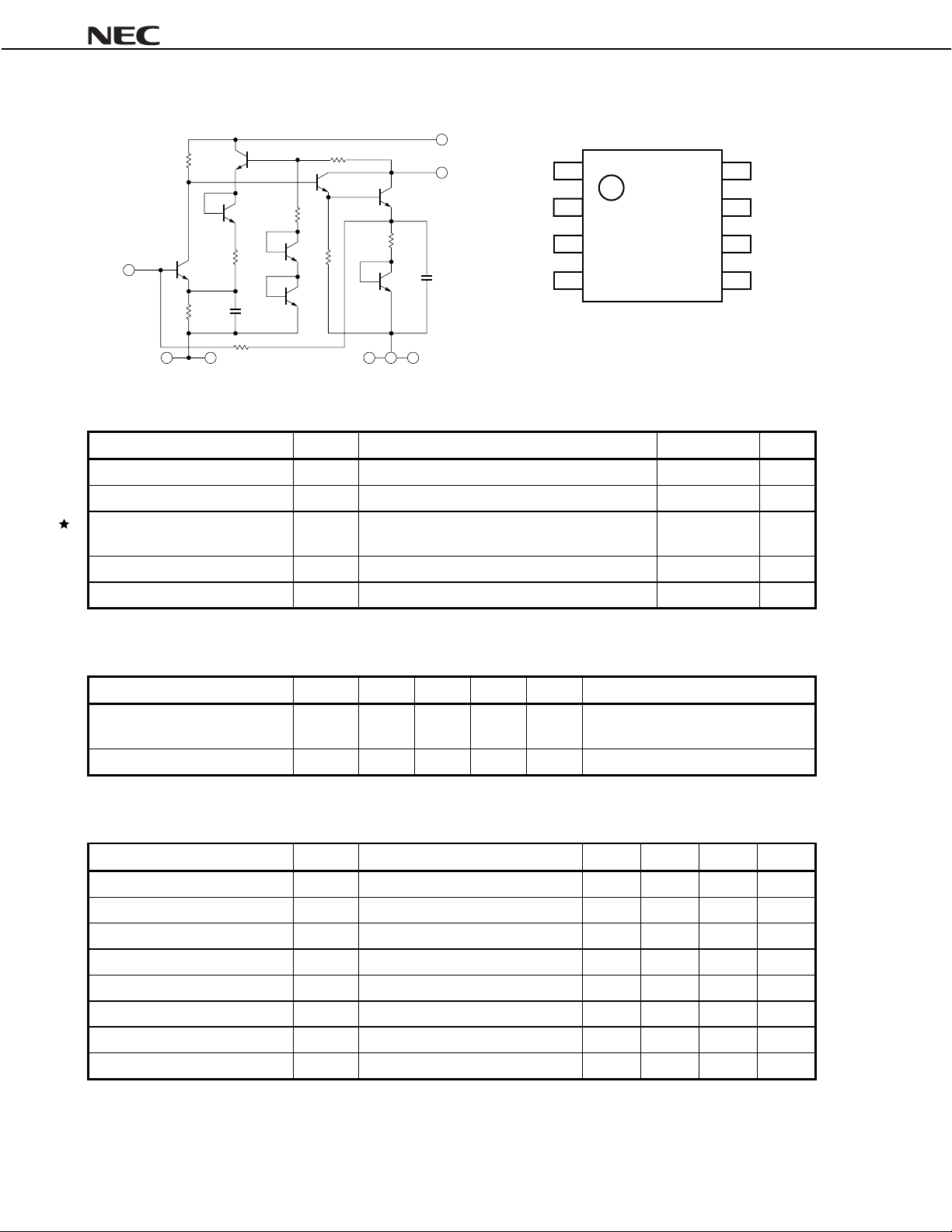

TEST CIRCUIT

V

CC

1 800 pF

C

3

L: 20.5 T, 2 mm I.D., 0.25 UEW

L

(about 300 nH)

C

2

50 Ω

OUT

IN

50 Ω

1

C

1 800 pF

8

1

5

1 800 pF

2, 3, 4, 6, 7

INDUCTOR FOR THE OUTPUT PIN

The internal output transistor of this IC consumes 30 mA, to output medium power. To supply current for output

CC

transistor, connect an inductor between the V

pin (pin 8) and output pin (pin 5). Select large value inductance, as

listed above.

The inductor has both DC and AC effects. In terms of DC, the inductor biases the output transistor with minimum

voltage drop to output enable high level. In terms of AC, the inductor make output-port impedance higher to get

enough gain. In this case, large inductance and Q is suitable.

φ

CAPACITORS FOR THE V

Capacitors of 1 800 pF are recommendable as the bypass capacitor for the V

CC

, INPUT AND OUTPUT PINS

CC

pin and the coupling capacitors

for the input and output pins.

The bypass capacitor connected to the VCC pin is used to minimize ground impedance of VCC pin. So, stable bias

can be supplied against VCC fluctuation.

The coupling capacitors, connected to the input and output pins, are used to cut the DC and minimize RF serial

impedance. Their capacitance are therefore selected as lower impedance against a 50 Ω load. The capacitors thus

perform as high pass filters, suppressing low frequencies to DC.

To obtain a flat gain from 100 MHz upwards, 1 800 pF capacitors are used in the test circuit. In the case of under

10 MHz operation, increase the value of coupling capacitor such as 10 000 pF. Because the coupling capacitors are

determined by equation, C = 1/(2 πRfc).

Data Sheet P12434EJ4V0DS00

3

Page 4

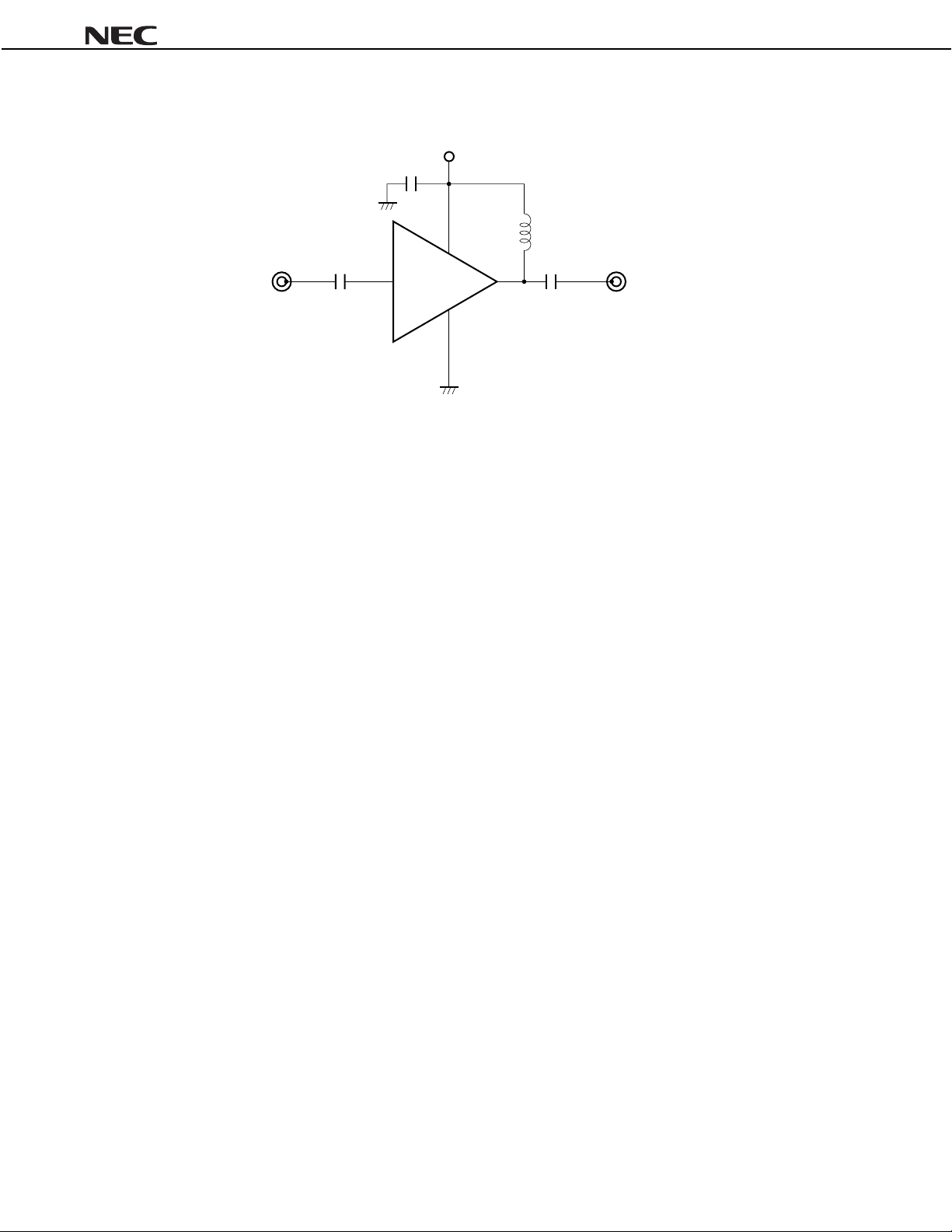

TYPICAL CHARACTERISTICS (Unless otherwise specified, TA = +25 °C)

CIRCUIT CURRENT vs. OPERATATING

CIRCUIT CURRENT vs. SUPPLY VOLTAGE

60

No Signal

50

AMBIENT TEMPERATURE

60

No Signal

CC

= 5.0 V

V

50

µµµµ

PC1679G

40

(mA)

CC

30

20

Circuit Current I

10

0

0123456 –60–40–200+20+40+60+80+100

NOISE FIGURE AND INSERTION

POWER GAIN vs. FREQUENCY

25

9

20

8

(dB)

P

15

7

10

6

Noise Figure NF (dB)

5

4

5

Insertion Power Gain G

0

40

(mA)

CC

30

20

Circuit Current I

10

0

Supply Voltage VCC (V) Operating Ambient Temperature T

INSERTION POWER GAIN vs. FREQUENCY

VCC = 5.5 V

G

P

VCC = 5.0 V

VCC = 4.5 V

25

20

(dB)

P

15

VCC = 5.0 V

TA = –45 °C

TA = +25 °C

TA = +85 °C

10

VCC = 5.5 V

5

NF

VCC = 5.0 V

Frequency f (GHz)

VCC = 4.5 V

3.01.00.30.10.030.01

Insertion Power Gain G

0

Frequency f (GHz)

A

(°C)

3.01.00.30.10.030.01

INPUT RETURN LOSS AND OUTPUT

ISOLATION vs. FREQUENCY

0

RETURN LOSS vs. FREQUENCY

+10

VCC = 5.0 VVCC = 5.0 V

–10

–20

–30

(dB)

(dB)

out

in

–10

–20

0

RL

RL

out

in

Isolation ISL (dB)

–40

–50

3.01.00.30.10.030.01

Frequency f (GHz)

4

Data Sheet P12434EJ4V0DS00

–30

Input Return Loss RL

Output Return Loss RL

–40

3.01.00.30.10.030.01

Frequency f (GHz)

Page 5

µµµµ

PC1679G

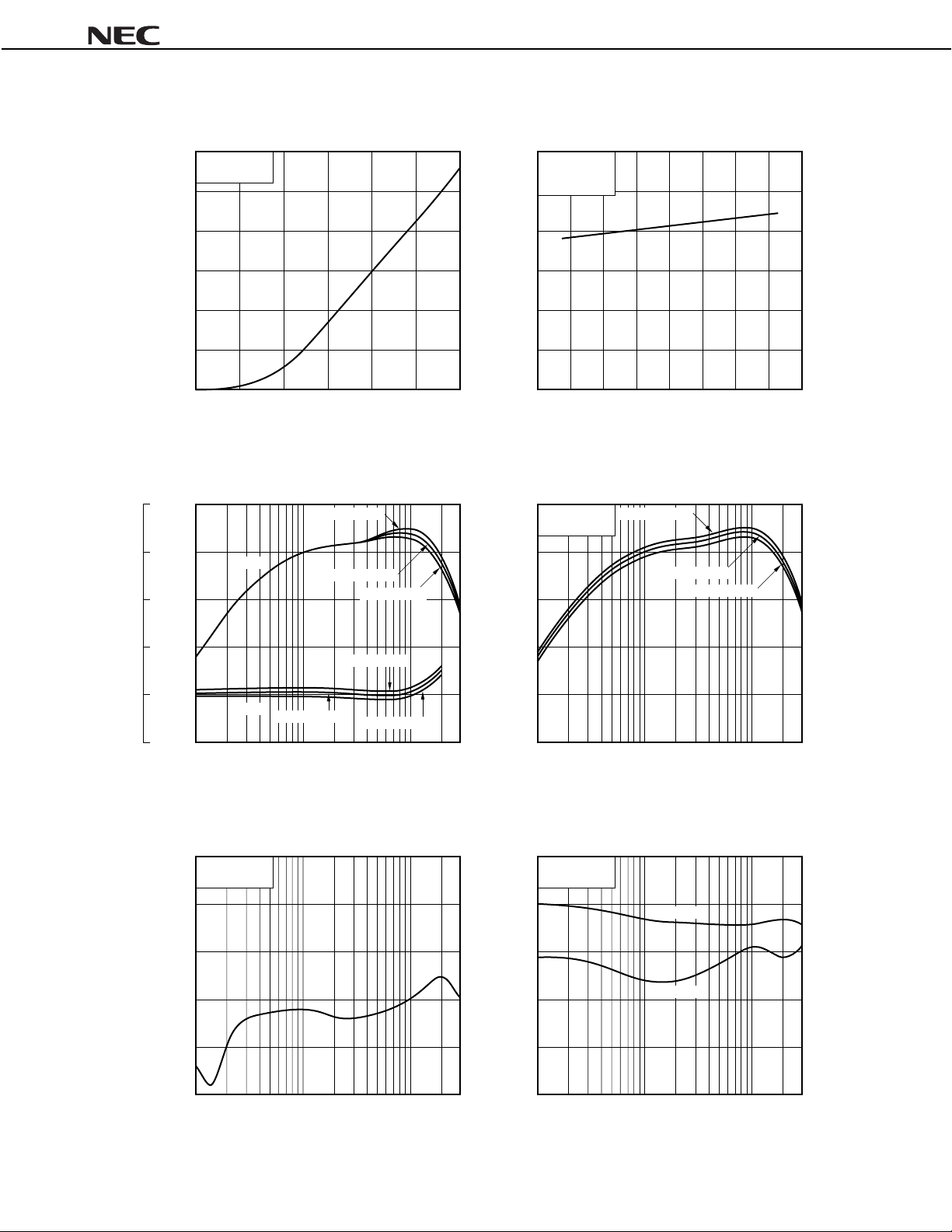

OUTPUT POWER vs. INPUT POWER

+25

f = 500 MHz

+20

(dBm)

out

+15

VCC = 5.0 V

+10

Output Power P

+5

0

–20 –15 –10 –5 0 +5 +10

VCC = 5.5 V

VCC = 4.5 V

Input Power Pin (dBm)

SATURATED OUTPUT POWER vs. FREQUENCY

+25

Pin = +3 dBm

+20

(dBm)

O(sat)

VCC = 5.5 V

+15

VCC = 5.0 V

+10

VCC = 4.5 V

OUTPUT POWER vs. INPUT POWER

+25

f = 500 MHz

CC

= 5.0 V

V

+20

(dBm)

out

+15

TA = +25 °C

TA = +85 °C

TA = –45 °C

+10

Output Power P

+5

0

–20 –15 –10 –5 0 +5 +10

Input Power Pin (dBm)

THIRD ORDER INTERMODULATION DISTORTION

vs. OUTPUT POWER OF EACH TONE

–60

(dBc)

–50

3

IM

–40

VCC = 5.0 V

f1 = 500 MHz

2

= 502 MHz

f

VCC = 5.5 V

–30

–20

VCC = 4.5 V

+5

Saturated Output Power P

0

Frequency f (GHz)

–10

Third Order Intermodulation Distortion

0

Output Power of Each Tone P

O(each)

+15+10+50–53.01.00.30.10.030.01

(dBm)

Data Sheet P12434EJ4V0DS00

5

Page 6

µµµµ

PC1679G

S-PARAMETER (TA = +25°C, VCC = V

S11-FREQUENCY

out

= 5.0 V)

3.0 G

1.0 G

0.1 G

2.0 G

S22-FREQUENCY

2.0 G

3.0 G

0.1 G

0.5 G

1.0 G

6

Data Sheet P12434EJ4V0DS00

Page 7

TYPICAL S-PARAMETER VALUES

PC1679G

µ

VCC = V

out

= 5.0 V, ICC = 40 mA

µµµµ

PC1679G

FREQUENCY S

MHz MAG. ANG. MAG. ANG. MAG. ANG. MAG. ANG.

100.0000 0.133 177.2 11.167

200.0000 0.154 171.2 11.585

300.0000 0.184 159.6 12.121

400.0000 0.217 147.3 12.690

500.0000 0.247 132.4 13.210

600.0000 0.279 117.7 13.509

700.0000 0.307 102.8 13.902

800.0000 0.333 88.3 13.966

900.0000 0.342 76.4 13.895

1000.0000 0.412 60.4 14.401

1100.0000 0.419 46.1 14.244

1200.0000 0.434 31.7 14.249

1300.0000 0.450 18.1 14.096

1400.0000 0.461 3.2 13.945

1500.0000 0.481

1600.0000 0.486

1700.0000 0.487

1800.0000 0.486

1900.0000 0.479

2000.0000 0.469

2100.0000 0.467

2200.0000 0.454

2300.0000 0.450

2400.0000 0.449

2500.0000 0.443 179.3 7.022 135.4 0.045

2600.0000 0.441 163.8 6.289 130.2 0.037

2700.0000 0.430 149.9 5.800 126.1 0.029

2800.0000 0.426 139.0 5.277 121.8 0.027

2900.0000 0.429 128.2 5.108 116.7 0.027 6.1 0.672 110.0 1.84

3000.0000 0.432 118.6 4.894 114.0 0.025 15.9 0.635 103.2 2.02

3100.0000 0.419 110.7 4.541 107.4 0.028 31.2 0.598 98.0 2.05

11

12.2 13.888

−

27.2 13.645

−

43.7 13.460

−

61.2 13.043

−

78.4 12.509

−

95.6 11.678 179.0 0.057 13.6 0.794

−

113.5 10.720 168.4 0.057 9.9 0.819

−

130.9 9.763 158.2 0.056 3.5 0.840 179.9 0.63

−

148.4 8.754 150.0 0.054

−

165.0 7.849 142.4 0.050

−

21

S

4.7 0.024

−

9.8 0.022

−

16.1 0.018

−

23.9 0.015 4.9 0.669

−

32.2 0.015 20.0 0.681

−

40.9 0.017 35.5 0.680

−

51.0 0.021 42.6 0.674

−

59.8 0.026 44.8 0.659

−

69.5 0.027 42.5 0.628

−

78.5 0.033 52.0 0.646

−

87.9 0.037 46.1 0.636

−

97.3 0.041 42.5 0.635

−

106.9 0.043 41.8 0.640

−

116.9 0.047 35.8 0.655

−

125.9 0.051 34.1 0.664

−

136.5 0.053 30.5 0.691

−

147.3 0.053 27.3 0.707

−

157.9 0.056 21.6 0.742

−

170.0 0.058 17.7 0.771

−

12

S

4.9 0.589

−

10.3 0.620

−

3.0 0.648

−

1.4 0.846 168.7 0.71

−

6.4 0.852 157.1 0.78

−

9.9 0.829 145.9 0.90

−

13.3 0.790 133.6 1.11

−

11.1 0.733 124.7 1.49

−

1.1 0.697 117.2 1.75

−

22

S

3.9 1.40

−

9.7 1.41

−

17.3 1.51

−

25.9 1.63

−

35.1 1.42

−

44.3 1.15

−

53.6 0.88

−

62.0 0.71

−

70.6 0.72

−

75.4 0.48

−

83.6 0.46

−

90.1 0.43

−

97.8 0.41

−

105.0 0.39

−

112.7 0.39

−

120.6 0.39

−

129.2 0.42

−

138.5 0.44

−

147.7 0.48

−

158.3 0.53

−

169.0 0.59

−

K

Data Sheet P12434EJ4V0DS00

7

Page 8

PACKAGE DIMENSIONS

8 PIN PLASTIC SOP (225 mil) (Unit: mm)

85

detail of lead end

P

µµµµ

PC1679G

1

4

A

F

G

S

B

E

D

NOTE

Each lead centerline is located within 0.12 mm of

its true position (T.P.) at maximum material condition.

C

M

M

H

I

L

K

ITEM MILLIMETERS

A

B

C

D 0.42

E

F

G

H

J

K 0.17

L 0.6±0.2

M

N

P3°

I

5.2±0.2

0.85 MAX.

1.27 (T.P.)

+0.08

−0.07

0.1±0.1

1.57±0.2

1.49

6.5±0.3

4.4±0.15

1.1±0.2

+0.08

−0.07

0.12

0.10

+7°

−3°

J

NS

8

Data Sheet P12434EJ4V0DS00

Page 9

µµµµ

PC1679G

NOTE ON CORRECT USE

(1) Observe precautions for handling because of electro-static sensitive devices.

(2) Form a ground pattern as widely as possible to minimize ground impedance (to prevent undesired oscillation).

All the ground pins must be connected together with wide ground pattern to decrease impedance difference.

(3) The bypass capacitor should be attached to VCC line.

(4) The inductor must be attached between VCC and output pins. The inductance value should be determined in

accordance with desired frequency.

(5) The DC cut capacitor must be attached to input pin.

RECOMMENDED SOLDERING CONDITIONS

This product should be soldered under the following recommended conditions. For soldering methods and

conditions other than those recommended below, contact your NEC sales representative.

Soldering Method Soldering Conditions Recommended Condition Symbol

Infrared Reflow Package peak temperature: 235 °C or below

Time: 30 seconds or less (at 210 °C)

Count: 3, Exposure limi t: None

VPS Package peak temperature: 215 °C or below

Time: 40 seconds or less (at 200 °C)

Count: 3, Exposure limi t: None

Wave Soldering Soldering bath temperature: 260 °C or below

Time: 10 seconds or less

Count: 1, Exposure limi t: None

Partial Heating Pin temperature: 300 °C

Time: 3 seconds or less (per side of device)

Exposure limit: None

After opening the dry pack, keep it in a place below 25 °C and 65 % RH for the allowable storage period.

Note

Note

Note

Note

Note

IR35-00-3

VP15-00-3

WS60-00-1

–

Caution Do not use different soldering methods together (except for partial heating).

For details of recommended soldering conditions for surface mounting, refer to information document

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL (C10535E).

Data Sheet P12434EJ4V0DS00

9

Page 10

[MEMO]

µµµµ

PC1679G

10

Data Sheet P12434EJ4V0DS00

Page 11

[MEMO]

µµµµ

PC1679G

Data Sheet P12434EJ4V0DS00

11

Page 12

µµµµ

PC1679G

NESAT (NEC Silicon Advanced Technology) is a trademark of NEC Corporation.

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...