Page 1

INTEGRATED CIRCUITS

DATA SH EET

TEA6300

TEA6300T

Sound fader control circuit

Product specification

File under Integrated Circuits, IC01

May 1990

Page 2

Philips Semiconductors Product specification

Sound fader control circuit

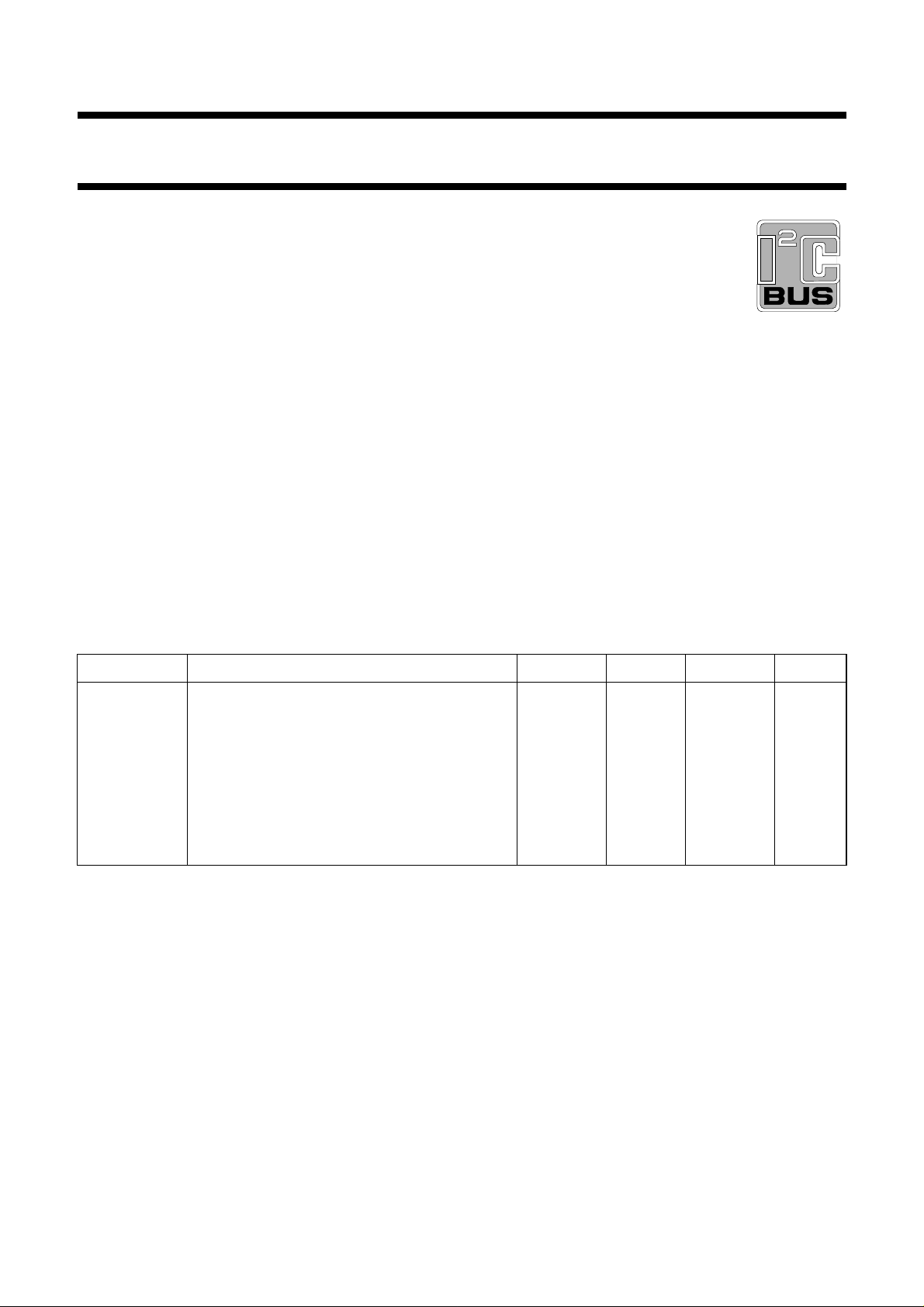

GENERAL DESCRIPTION

The Sound Fader Control circuit (SOFAC) is an I2C-bus

controlled preamplifier for car radios.

Features

• Source selector for three stereo inputs

• Inputs and outputs for noise reduction circuits

• Volume and balance control; control range of 86 dB in

steps of 2 dB

• Bass and treble control from + 15 dB (treble 12 dB)

to −12 dB in steps of 3 dB

• Fader control from 0 dB to −30 dB in steps of 2 dB

• Fast muting

• Low noise suitable for DOLBY* B and C NR (noise

reduction)

• Signal handling suitable for compact disc

2

• I

C-bus control for all functions

• ESD protected

TEA6300

TEA6300T

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

V

V

f

r

α

CC

i(rms)

i(rms)

CS

Supply voltage 7,0 8,5 13,2 V

Input sensitivity for full power at the output stage − 50 − mV

Input signal handling − 1,65 − V

Frequency response 35 − 20 000 Hz

Channel separation; f = 250 Hz to 10 kHz 70 92 − dB

THD Total harmonic distortion − 0,05 − %

(S+N)/N Signal plus noise-to-noise ratio − 80 − dB

T

amb

Operating ambient temperature range −40 −+ 85 °C

* Dolby is a registered trademark of Dolby Laboratories Licensing Corporation, San Francisco, California (U.S.A.).

PACKAGE OUTLINES

28-lead dual in-line; plastic (SOT117); SOT117-1; 1996 August 15.

28-lead mini-pack; plastic (SO28; SOT136A); SOT136-1; 1996 August 15.

May 1990 2

Page 3

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

May 1990 3

Philips Semiconductors Product specification

Sound fader control circuit

Fig.1 Block diagram.

TEA6300T

TEA6300

Page 4

Philips Semiconductors Product specification

Sound fader control circuit

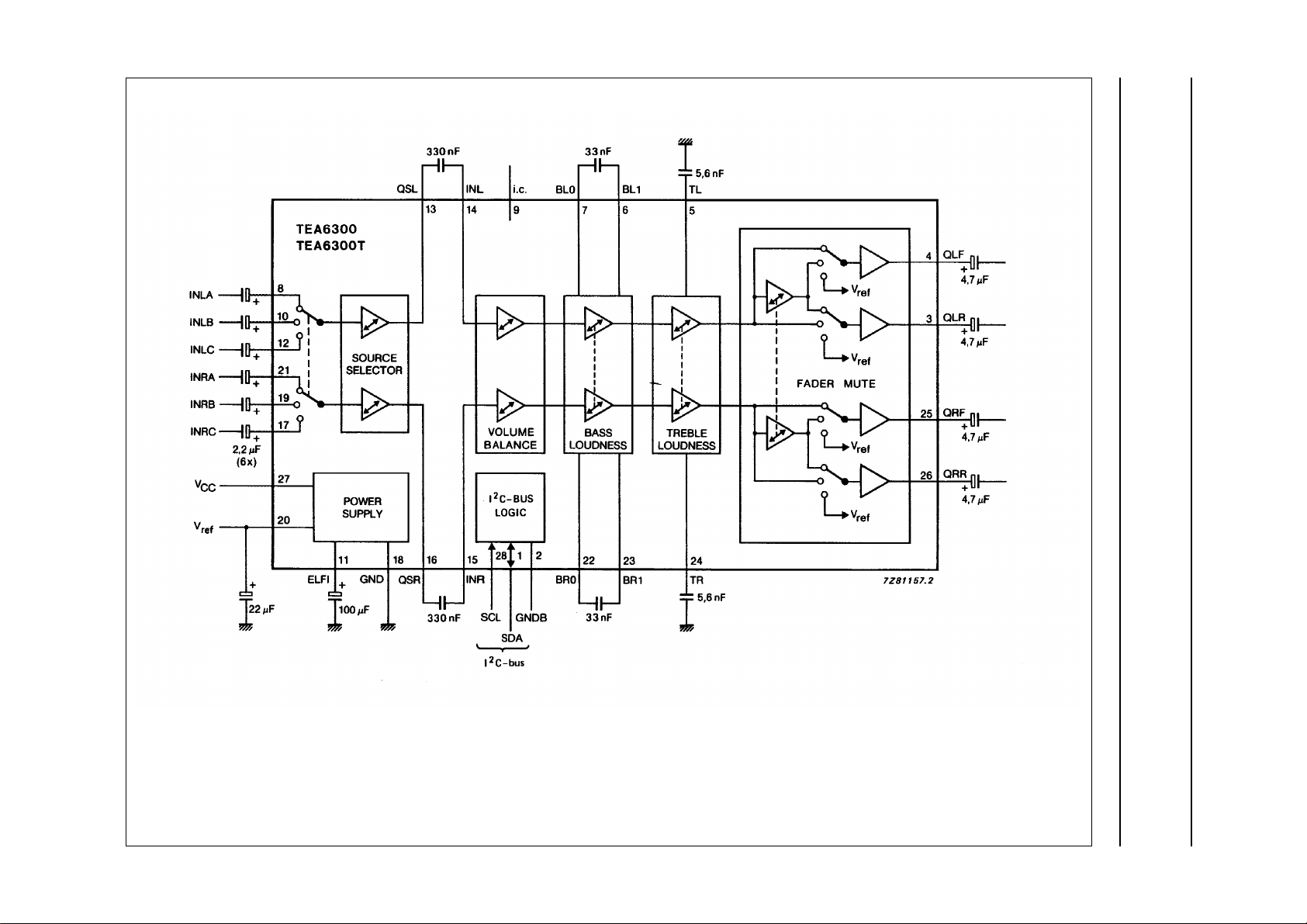

PINNING

2

2

C-bus)

C-bus)

1 SDA serial data input/output (I

2

2 GNDB ground for I

3 QLR output left rear

4 QLF output left front

5 TL treble control capacitor; left channel

6 BL1 bass control capacitor; left channel

7 BL0 bass control capacitor; left channel

8 INLA input left source A

9 i.c. internally connected

10 INLB input left source B

11 ELFI electronic filtering for supply

12 INLC input left source C

13 QSL output source selector left

14 INL input left control part

15 INR input right control part

16 QSR output source selector right

17 INRC input right source C

18 GND ground

19 INRB input right source B

20 V

21 INRA input right source A

22 BRO bass control capacitor; right channel

23 BR1 bass control capacitor; right channel

24 TR treble control capacitor; right channel

25 QRF output right front

26 QRR output right rear

27 V

28 SCL serial clock input (I

reference voltage (1/2 VCC)

ref

supply voltage

CC

C-bus terminals

TEA6300

TEA6300T

Fig.2 Pinning diagram.

May 1990 4

Page 5

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

FUNCTIONAL DESCRIPTION

The source selector selects three stereo channels −RF part (AM/FM), recorder and compact disc. As the outputs of the

source selector and the inputs of the main control part are available, additional circuits such as compander and equalizer

systems may be inserted into the signal path. The AC signal setting is performed by resistor chains in combination with

multi-input operational amplifiers. The advantage of this principle is the combination of low noise, low distortion and a

high dynamic range for the circuit.

The separate volume controls of the left and the right channel facilitate correct balance control. The range and balance

control is software programmable.

Because the TEA6300 has four outputs a low-level fader is included. The fader control is independent of the volume

control and an extra mute position is built in for the front, the rear or for all channels. The last function may be used for

muting during preset selection. An extra pop suppression circuit is built in for pop-free switching on and off. As all

switching and control functions are controllable via the two-wire I

microcomputer and the TEA6300 is required.

The on-chip power-on-reset sets the TEA6300 to the general mute mode.

RATINGS

Limiting values in accordance with the Absolute Maximum System (IEC 134)

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

P

tot

T

stg

T

amb

Supply voltage (pin 27-18) − 16 V

Maximum power dissipation − 1W

Storage temperature range −55 +150 °C

Operating ambient temperature range −40 + 85 °C

2

C-bus, no external interface between the

May 1990 5

Page 6

Philips Semiconductors Product specification

Sound fader control circuit

CHARACTERISTICS

V

= 8,5 V; RS = 600 Ω; RL = 10 kΩ; f = 1 kHz; T

CC

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

CC

I

CC

I

CC

I

CC

V

DC

V

REF

G

v

V

o(rms)

V

o(rms)

V

i(rms)

f

r

α

CS

THD V

THD V

THD V

RR

100

RR

range

Supply voltage 7,0 8,5 13,2 V

Supply current − 26 − mA

Supply current at 8,5 V −−33 mA

Supply current at 13,2 V −−44 mA

DC voltage

inputs, outputs and reference 0,45 0,5 0,55 V

Internal reference voltage (pin 20)

V

= 0,5 V

ref

CC

Maximum voltage gain

bass and treble linear, fader off 19 20 21 dB

Output voltage level

for P

at the output stage − 500 − mV

max

for start of clipping − 1000 − mV

Input sensitivity

at Vo = 500 mV − 50 − mV

Frequency response

bass and treble linear; roll-off

frequency −1 dB 35 − 20 000 Hz

Channel separation

G

= 0 dB; bass and treble linear;

v

frequency range 250 Hz to 10 kHz 70 92 − dB

Total harmonic distortion

frequency range 20 Hz to 12,5 kHz

= 50 mV; Gv= 20 dB − 0,1 0,3 %

i

= 500 mV; Gv = 0 dB − 0,05 0,2 %

i

= 1,6 V; Gv= −10 dB − 0,2 0,5 %

i

Ripple rejection

V

< 200 mV; Gv = 0 dB;

r(rms)

bass and treble linear;

at f = 100 Hz − 70 − dB

at f = 40 Hz to 12,5 kHz − 60 − dB

= 25 °C; test circuit Fig.10; unless otherwise specified

amb

− 4,25 − V

TEA6300

TEA6300T

CC

May 1990 6

Page 7

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Signal plus noise-to-noise ratio

bass and treble linear; notes 1 and 2

CCIR 468-2 weighted; quasi peak

(S + N)/N V

(S + N)/N V

(S + N)/N V

(S + N)/N V

(S + N)/N V

(S + N)/N V

P

no

α

B

Source selector

Z

i

Z

o

R

L

C

L

α

S

G

v

V

b int/Vref

V

i(rms)

V

i(rms)

THD Vi= 500 mV; RL= 10 kΩ−−0,1 %

V

no

V

o

= 50 mV; Vo= 46 mV; Po= 50 mW − 65 − dB

i

= 500 mV; Vo= 45 mV; Po= 50 mW − 67 − dB

i

= 50 mV; Vo= 200 mV; Po= 1 W 65 70 − dB

i

= 500 mV; Vo= 200 mV; Po= 1 W 65 78 − dB

i

= 50 mV; Vo= 500 mV; Po= 6 W − 70 − dB

i

= 500 mV; Vo= 500 mV; Po= 6 W − 85 − dB

i

Noise output power

mute position, only contribution of

TEA6300; power amplifier for 25 W −−10 nW

Crosstalk (20 log V

bus(p-p)/Vo(rms)

)

between bus inputs and signal outputs

GV= 0 dB; bass and treble linear − 110 − dB

Input impedance 20 30 40 kΩ

Output impedance −−100 Ω

Output load resistance 10 −−kΩ

Output load capacity 0 − 200 pF

Input isolation

not selected source; frequency range

40 Hz to 12,5 kHz − 80 − dB

Voltage gain

RL≥ 10 kΩ−0−dB

Internal bias voltage ratio − 1 −

Maximum input voltage level (RMS value)

THD < 0,5% − 1,65 − V

THD < 0,5%; VCC= 7,5 V − 1,5 − V

Total harmonic distortion

Noise output voltage

weighted CCIR 468-2, quasi peak − 920µV

DC offset voltage

between any inputs −−10 mV

May 1990 7

Page 8

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300T

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Control part

Source selector disconnected,

source resistance 600 Ω

Z

i

Z

o

R

L

C

L

V

i(rms)

V

no

V

no

V

no

V

no

Volume control

G

c

∆G

a

∆G

a

∆G

t

α

m

DC step offset

Input impedance 35 50 65 kΩ

Output impedance − 100 150 Ω

Output load resistance 5 −−kΩ

Output load capacity 0 − 2500 pF

Maximum input voltage

THD < 0,5%; G

= −10 dB;

v

bass and treble linear − 2,0 − V

Noise output voltage

weighted acc CCIR 468-2, quasi-peak,

bass and treble linear, fader off

Gv= 20 dB − 110 220 µV

Gv= 0 dB − 25 50 µV

Gv= −66 dB − 19 38 µV

mute position − 11 22 µV

Continuous control range − 86 − dB

Step resolution − 2 − dB

Attenuator set error

(Gv= + 20 to −50 dB) −−2dB

Attenuator set error

(Gv= + 20 to −66 dB) −−3dB

Gain tracking error

balance in mid position,

bass and treble linear −−2dB

Mute attenuation 72 90 − dB

Between any adjoining step

and any step to mute

Gv= 0 to −66 dB − 0,2 10 mV

G

= 20 to 0 dB − 215mV

v

In any treble and fader position

G

= 0 to −66 dB −−10 mV

v

In any bass position

Gv= 0 to −66 dB −−20 mV

TEA6300

May 1990 8

Page 9

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300T

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Bass control

Bass control range

G

b

G

b

Treble control

G

t

G

t

G

t

Fader control

G

f

α

m

Digital part

f = 40 Hz; maximum boost 14 15 16 dB

f = 40 Hz; maximum attenuation 11 12 13 dB

Step resolution − 3 − dB

Step error −−0,5 dB

Treble control range

f = 15 kHz; maximum boost 11 12 13 dB

f = 15 kHz; maximum attenuation 11 12 13 dB

f > 15 kHz; maximum boost −−15 dB

Step resolution − 3 − dB

Step error −−0,5 dB

Continuous attenuation

fader control range − 30 − dB

Step resolution − 2 − dB

Attenuator set error −−1,5 dB

Mute attenuation 74 84 − dB

TEA6300

Bus terminals

Input voltage

V

IH

V

IL

HIGH 3 − 12 V

LOW −0,3 −+1,5 V

Input current

I

IH

I

IL

V

OL

AC characteristics

HIGH −10 −+10 µA

LOW −10 −+10 µA

Output voltage LOW; IL= 3 mA −−0,4 V

In accordance with the I2C-bus specification

Power-on-Reset

When RESET is active the GMU (general mute)

bit is set and the I2C-bus receiver is in RESET

position

Increasing supply voltage

V

CC

V

CC

V

CC

start of reset −−2,5 V

end of reset 5,2 6,0 6,8 V

Decreasing supply voltage; start of reset 4,2 5,0 5,8 V

Notes to the characteristics

1. The indicated values for output power assume a 6 W power amplifier with 20 dB gain, connected to the output of the

May 1990 9

Page 10

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

circuit. Signal-to-noise ratios exclude noise contribution of the power amplifier.

2. Signal-to-noise ratios on a CCIR 468-2 average meter reading are 4,5 dB better than on CCIR 468-2 quasi peak.

2

C-BUS FORMAT

I

S SLAVE ADDRESS A SUBADDRESS A DATA A P

S = start condition SUBADDRESS = see Table 1

SLAVE ADDRESS = 1000 0000 DATA = see Table 1

A = acknowledge, generated by the slave P = STOP condition

If more than 1 byte of DATA is transmitted, then auto-increment of the subaddress is performed.

2

Table 1 I

FUNCTION SUBADDRESS

volume left 0 0 0 0 0 0 0 0 X X VL5 VL4 VL3 VL2 VL1 VL0

volume right 0 0 0 0 0 0 0 1 X X VR5 VR4 VR3 VR2 VR1 VR0

bass 0 0 0 0 0 0 1 0 X X X X BA3 BA2 BA1 BA0

treble 0 0 0 0 0 0 1 1 X X X X TR3 TR2 TR1 TR0

fader 0 0 0 0 0 1 0 0 X X MFN FCH FA3 FA2 FA1 FA0

switch 0 0 0 0 0 1 0 1 GMU XXXXSCCSCBSCA

C-bus; subaddress/data

DATA

D7 D6 D5 D4 D3 D2 D1 D0

Function of the bits:

VL0 to VL5 volume control left

VR0 to VR5 volume control right

BA0 to BA3 bass control

TR0 to TR3 treble control

FA0 to FA3 fader control

FCH select fader channel (front or rear)

MFN mute control of the selected fader channel (front or rear)

SCA to SCC source selector control

GMU mute control (general mute)

for the outputs QLF, QLR, QRF and QRR

X don't care bits (logic 1 during testing)

May 1990 10

Page 11

Philips Semiconductors Product specification

Sound fader control circuit

Table 2 Bass setting

G

V

DB BA3 BA2 BA1 BA0

+15 1 1 1 1

+15 1 1 1 0

+15 1 1 0 1

+15 1 1 0 0

+12 1 0 1 1

+ 91010

+61001

+31000

00111

− 30110

− 60101

− 90100

−12 0 0 1 1

DATA

TEA6300

TEA6300T

Table 3 Treble setting

G

V

DB TR3 TR2 TR1 TR0

+12 1 1 1 1

+12 1 1 1 0

+12 1 1 0 1

+12 1 1 0 0

+12 1 0 1 1

+ 91010

+61001

+31000

00111

− 30110

− 60101

− 90100

−12 0 0 1 1

DATA

−12 0 0 1 0

−12 0 0 0 1

−12 0 0 0 0

−12 0 0 1 0

−12 0 0 0 1

−12 0 0 0 0

May 1990 11

Page 12

Philips Semiconductors Product specification

Sound fader control circuit

Table 4 Volume setting LEFT

G

V

DB VL5 VL4 VL3 VL2 VL1 VL0

20 111111

18 111110

16 111101

14 111100

12 111011

10 111010

8 111001

6 111000

4 110111

2 110110

0 110101

− 2 110100

− 4 110011

− 6 110010

−8 110001

−10 110000

−12 101111

−14 101110

−16 101101

−18 101100

−20 101011

−22 101010

−24 101001

−26 101000

−28 100111

DATA

TEA6300

TEA6300T

G

V

DB VL5 VL4 VL3 VL2 VL1 VL0

−30 100110

−32 100101

−34 100100

−36 100011

−38 100010

−40 100001

−42 100000

−44 011111

−46 011110

−48 011101

−50 011100

−52 011011

−54 011010

−56 011001

−58 011000

−60 010111

−62 010110

−64 010101

−66 010100

mute left 010011

mute left 010010

..

..

..

mute left 000000

DATA

May 1990 12

Page 13

Philips Semiconductors Product specification

Sound fader control circuit

Table 5 Volume setting RIGHT

G

V

DB VR5 VR4 VR3 VR2 VR1 VR0

20 111111

18 111110

16 111101

14 111100

12 111011

10 111010

8 111001

6 111000

4 110111

2 110110

0 110101

− 2 110100

− 4 110011

− 6 110010

− 8 110001

−10 110000

−12 101111

−14 101110

−16 101101

−18 101100

−20 101011

−22 101010

−24 101001

−26 101000

−28 100111

DATA

TEA6300

TEA6300T

G

V

DB VR5 VR4 VR3 VR2 VR1 VR0

−30 100110

−32 100101

−34 100100

−36 100011

−38 100010

−40 100001

−42 100000

−44 011111

−46 011110

−48 011101

−50 011100

−52 011011

−54 011010

−56 011001

−58 011000

−60 010111

−62 010110

−64 010101

−66 010100

mute right 010011

mute right 010010

..

..

..

mute right 000000

DATA

May 1990 13

Page 14

Philips Semiconductors Product specification

Sound fader control circuit

Table 6 Fader function

SETTING DATA

FRONT REAR

DB DB MFN FCH FA3 FA2 FA1 FA0

fader off

0 0 1 11111

0 0 0 11111

fader front

− 2 0 1 11110

−4 0 1 11101

−6 0 1 11100

−8 0 1 11011

−10 0 1 11010

−12 0 1 11001

−14 0 1 11000

−16 0 1 10111

−18 0 1 10110

−20 0 1 10101

−22 0 1 10100

−24 0 1 10011

−26 0 1 10010

−28 0 1 10001

−30 0 1 10000

mute front

−80 0 0 11110

.. .

.. .

.. .

−80 0 0 10000

TEA6300

TEA6300T

SETTING DATA

FRONT REAR

DB DB MFN FCH FA3 FA2 FA1 FA0

fader off

0 01 01111

0 00 01111

fader rear

0 − 21 01110

0 − 41 01101

0 − 61 01100

0 − 81 01011

0 −101 01010

0 −121 01001

0 −141 01000

0 −161 00111

0 −181 00110

0 −201 00101

0 −221 00100

0 −241 00011

0 −261 00010

0 −281 00001

0 −301 00000

mute rear

0 −800 01110

.. .

.. .

.. .

0−800 00000

Table 7 Selected inputs

DATA

SELECTED INPUTS

SCC SCB SCA

data not allowed 1 1 1

data not allowed 1 1 0

data not allowed 1 0 1

INLC, INRC 1 0 0

data not allowed 0 1 1

INLB, INRB 0 1 0

INLA, INRA 0 0 1

data not allowed 0 0 0

May 1990 14

Table 8 Mute control

MUTE DATA

REMARKS

CONTROL GMU

active 1 outputs QLF, QLR

QRF and QRR are

muted

passive 0 no general mute

Page 15

Philips Semiconductors Product specification

Sound fader control circuit

Fig.3 Bass control without T-pass filter.

TEA6300

TEA6300T

Fig.4 Bass control with T-pass filter.

Pin numbers in parentheses refer to the bass control, right channel.

Fig.5 T-pass filter.

May 1990 15

Page 16

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

Fig.6 Treble control.

Fig.7 Output noise voltage (CCIR 468-2 weighted: quasi peak).

May 1990 16

Page 17

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

Fig.8 Signal-to-noise ratio (CCIT 468-2 weighted; quasi peak) with a 6 W power amplifier (gain 20 dB) without

noise contribution of the power amplifier (see Fig.9).

Fig.9 Recommended level diagram; V

May 1990 17

= 50 mV, Vo = 500 mV for P

i min

max

.

Page 18

Philips Semiconductors Product specification

Sound fader control circuit

APPLICATION INFORMATION

TEA6300

TEA6300T

Fig.10 Test and application circuit.

May 1990 18

Page 19

Philips Semiconductors Product specification

Sound fader control circuit

PACKAGE OUTLINES

handbook, full pagewidth

DIP28: plastic dual in-line package; 28 leads (600 mil)

D

seating plane

L

Z

28

e

b

TEA6300

TEA6300T

SOT117-1

M

E

A

2

A

A

1

w M

b

1

15

c

(e )

1

M

H

pin 1 index

1

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

max.

mm

1 2

min.

max.

b

1.7

1.3

0.066

0.051

b

0.53

0.38

0.020

0.014

cD E weM

1

0.32

0.23

0.013

0.009

(1) (1)

36.0

35.0

1.41

1.34

14.1

13.7

0.56

0.54

E

14

(1)

L

3.9

3.4

M

15.80

15.24

0.62

0.60

H

E

17.15

15.90

0.68

0.63

0.252.54 15.24

0.010.10 0.60

e

1

0.15

0.13

Z

max.

1.75.1 0.51 4.0

0.0670.20 0.020 0.16

OUTLINE

VERSION

SOT117-1

IEC JEDEC EIAJ

051G05 MO-015AH

REFERENCES

May 1990 19

EUROPEAN

PROJECTION

ISSUE DATE

92-11-17

95-01-14

Page 20

Philips Semiconductors Product specification

Sound fader control circuit

SO28: plastic small outline package; 28 leads; body width 7.5 mm

D

c

y

Z

28

15

TEA6300

TEA6300T

SOT136-1

E

H

E

A

X

v M

A

pin 1 index

1

e

0 5 10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

A

max.

2.65

0.10

A

1

0.30

0.10

0.012

0.004

A2A

2.45

2.25

0.096

0.089

0.25

0.01

b

3

p

0.49

0.32

0.36

0.23

0.019

0.013

0.014

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1) (1)

cD

18.1

7.6

17.7

7.4

0.71

0.30

0.69

0.29

14

w M

b

p

scale

eHELLpQ

1.27

0.050

10.65

10.00

0.419

0.394

1.4

0.055

A

2

0.043

0.016

A

1.1

0.4

Q

A

3

θ

ywv θ

Z

0.9

0.4

0.035

0.004

0.016

o

8

o

0

L

p

L

0.25 0.1

0.01

(A )

1

detail X

1.1

0.25

1.0

0.043

0.01

0.039

OUTLINE

VERSION

SOT136-1

IEC JEDEC EIAJ

075E06 MS-013AE

REFERENCES

May 1990 20

EUROPEAN

PROJECTION

ISSUE DATE

95-01-24

97-05-22

Page 21

Philips Semiconductors Product specification

Sound fader control circuit

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

DIP

SOLDERING BY DIPPING OR BY WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO

packages.

(order code 9398 652 90011).

). If the

stg max

TEA6300

TEA6300T

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

AVE SOLDERING

W

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

R

EPAIRING SOLDERED JOINTS

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

May 1990 21

Page 22

Philips Semiconductors Product specification

Sound fader control circuit

TEA6300

TEA6300T

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

May 1990 22

Loading...

Loading...