Page 1

查询TEA1622P供应商查询TEA1622P供应商

TEA1622P

STARplug

Rev. 01 — 17 March 2004 Product data sheet

1. General description

The TEA1622P is a Switched Mode Power Supply (SMPS) controller IC that operates

directly from the rectified universal mains. It is implemented in the high voltage EZ-HV™

SOI process, combined with a low voltage BICMOS process.

The device includes a high voltagepower switch and a circuit forstart-up directly from the

rectified mains voltage. A dedicated circuit for valley switching is built in, which makes a

very efficient slim-line electronic power-plug concept possible.

In its most basic version of application, the TEA1622P acts as a voltage source. Here, no

additional secondary electronicsarerequired. A combined voltageand current source can

be realized with minimum costs for external components. Implementation of the

TEA1622P renders an efficient and low cost power supply system.

2. Features

■ Designed for general purpose supplies

■ Integrated power switch: 12 Ω and 650 V

■ Operates from universal AC mains supplies: 80 V to 276 V

■ Adjustable frequency for flexible design

■ RC oscillator for load insensitive regulation loop constant

■ Valley switching for minimum switch-on loss

■ Frequency reduction at low power output for low standby power: <100 mW

■ Adjustable overcurrent protection

■ Undervoltage protection

■ Temperature protection

■ Short winding protection

■ Safe restart mode for system fault conditions

■ Simple application with both primary and secondary (opto) feedback

■ Available in 8-pin DIP package.

TM

3. Applications

■ Adapters ■ VCD

■ Set-Top Box (STB) ■ CD(R)

■ DVD ■ PC Silverbox standby SMPS.

Page 2

Philips Semiconductors

4. Quick reference data

Table 1: Quick reference data

Symbol Parameter Conditions Min Typ Max Unit

V

CC(max)

V

DRAIN(max)

I

DRAIN

R

DSon

f

osc

T

amb

5. Ordering information

TEA1622P

STARplug

maximum supply voltage - - 40 V

maximum voltage at pin

DRAIN

supply current drawn from

pin DRAIN

drain-source on-state

resistance

oscillator frequency range 10 - 200 kHz

ambient temperature −20 - +85 °C

Tj>0°C - - 650 V

no auxiliary supply - 0.5 - mA

I

SOURCE

= −0.25 A

=25°C - 12 13.8 Ω

T

j

= 100 °C - 17 19.6 Ω

T

j

TM

Table 2: Ordering information

Type number Package

Name Description Version

TEA1622P DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 2 of 16

Page 3

Philips Semiconductors

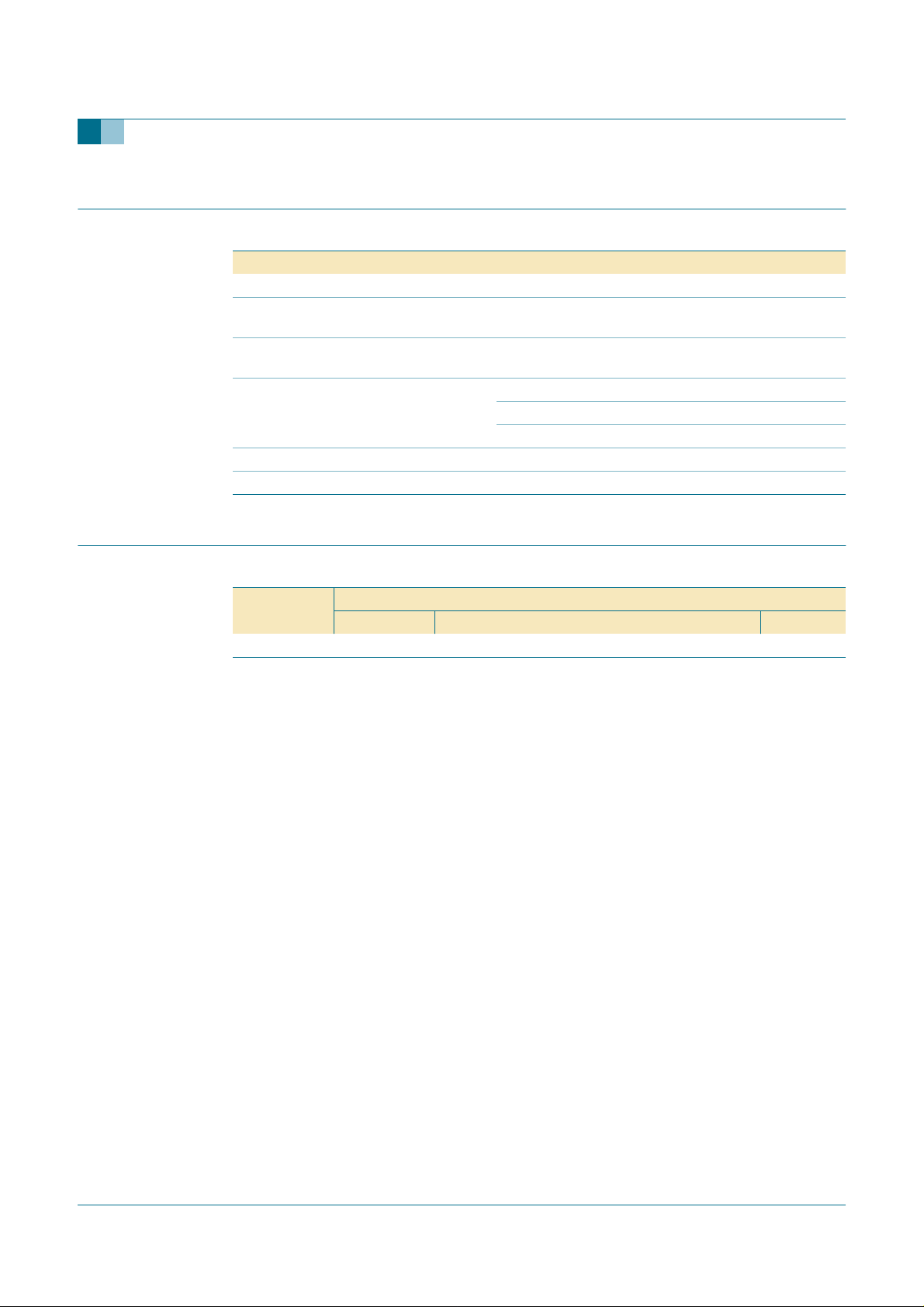

6. Block diagram

TEA1622P

STARplug

TM

V

CC

GND

RC

REG

1

2

stop

3

OSCILLATOR

low frequency

f

2.5 V

4

1.8 U

10x

TEA1622P

PWM

THERMAL

SHUTDOWN

POWER-UP

RESET

SUPPLY

LOGIC

PROTECTION

LOGIC

overcurrent

short winding

VALLEY

blank

100 mV

0.5 V

8

7

6

5

DRAIN

n.c.

SOURCE

AUX

0.75 V

col009

Fig 1. Block diagram.

7. Pinning information

7.1 Pinning

V

1

CC

GND n.c.

2

3

4

TEA1622P

001aaa309

RC SOURCE

REG AUX

Fig 2. Pin configuration.

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 3 of 16

8

7

6

5

DRAIN

Page 4

Philips Semiconductors

7.2 Pin description

Table 3: Pin description

Symbol Pin Description

V

CC

GND 2 ground

RC 3 frequency setting

REG 4 regulation input

AUX 5 input for voltage from auxiliary winding for timing (demagnetization)

SOURCE 6 source of internal MOS switch

n.c. 7 not connected

DRAIN 8 drain of internal MOS switch; input for start-up current and valley sensing

1 supply voltage

8. Functional description

The TEA1622P is the heart of a compact flyback converter, with the IC placed at the

primary side. The auxiliary winding of the transformer can be used for indirect feedback to

control the isolated output. This additional winding also powers the IC. A more accurate

control of the output voltage and/or current can be implemented with an additional

secondary sensing circuit and optocoupler feedback.

TEA1622P

STARplug

TM

The TEA1622P uses voltage mode control. The frequency is determined by the maximum

transformer demagnetizing time and the time of the oscillator. In the first case, the

converter operates in the Self Oscillating PowerSupply (SOPS) mode. In the latter case, it

operates at a constant frequency, which can be adjusted with external components R

and CRC. This mode is called Pulse Width Modulation (PWM). Furthermore, a primary

stroke is started only in a valley of the secondary ringing. This valley switching principle

minimizes capacitive switch-on losses.

8.1 Start-up and undervoltage lock-out

Initially, the IC is self supplying from the rectified mains voltage. The IC starts switching as

soon as the voltage on pin VCCpasses the V

CC(start)

level. The supply is taken over by the

auxiliary winding of the transformer as soon as VCC is high enough and the supply from

the line is stopped for high efficiency operation.

As soon as the voltage on pin VCC drops below the V

CC(stop)

level, the IC stops switching

and restarts from the rectified mains voltage.

8.2 Oscillator

The frequency of the oscillator is set by the external resistor and capacitor on pin RC. The

external capacitor is charged rapidly to the V

stroke, it discharges to the V

level. Because the discharge is exponential, the

RC(min)

RC(max)

relative sensitivity of the duty factor to the regulation voltage at low duty factor is almost

equal to the sensitivity at high duty factors. This results in a more constant gain over the

duty factor range compared to PWM systems with a linear sawtooth oscillator. Stable

operation at low duty factors is easily realized. For high efficiency, the frequency is

reduced as soon as the duty factor drops below a certain value. This is accomplished by

increasing the oscillator charge time.

leveland, starting from a new primary

RC

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 4 of 16

Page 5

Philips Semiconductors

To ensure that the capacitor can be charged within the charge time, the value of the

oscillator capacitor should be limited to approximately 1 nF.

8.3 Duty factor control

The duty factor is controlled by the internal regulation voltage and the oscillator signal on

pin RC. The internal regulation voltage is equal to the external regulation voltage (minus

2.5 V) multiplied by the gain of the error amplifier (typical 20 dB or 10 ×).

The minimum duty factor of the switched mode power supply is 0 %. The maximum duty

factor is set to 75 % (typical value at 100 kHz oscillation frequency).

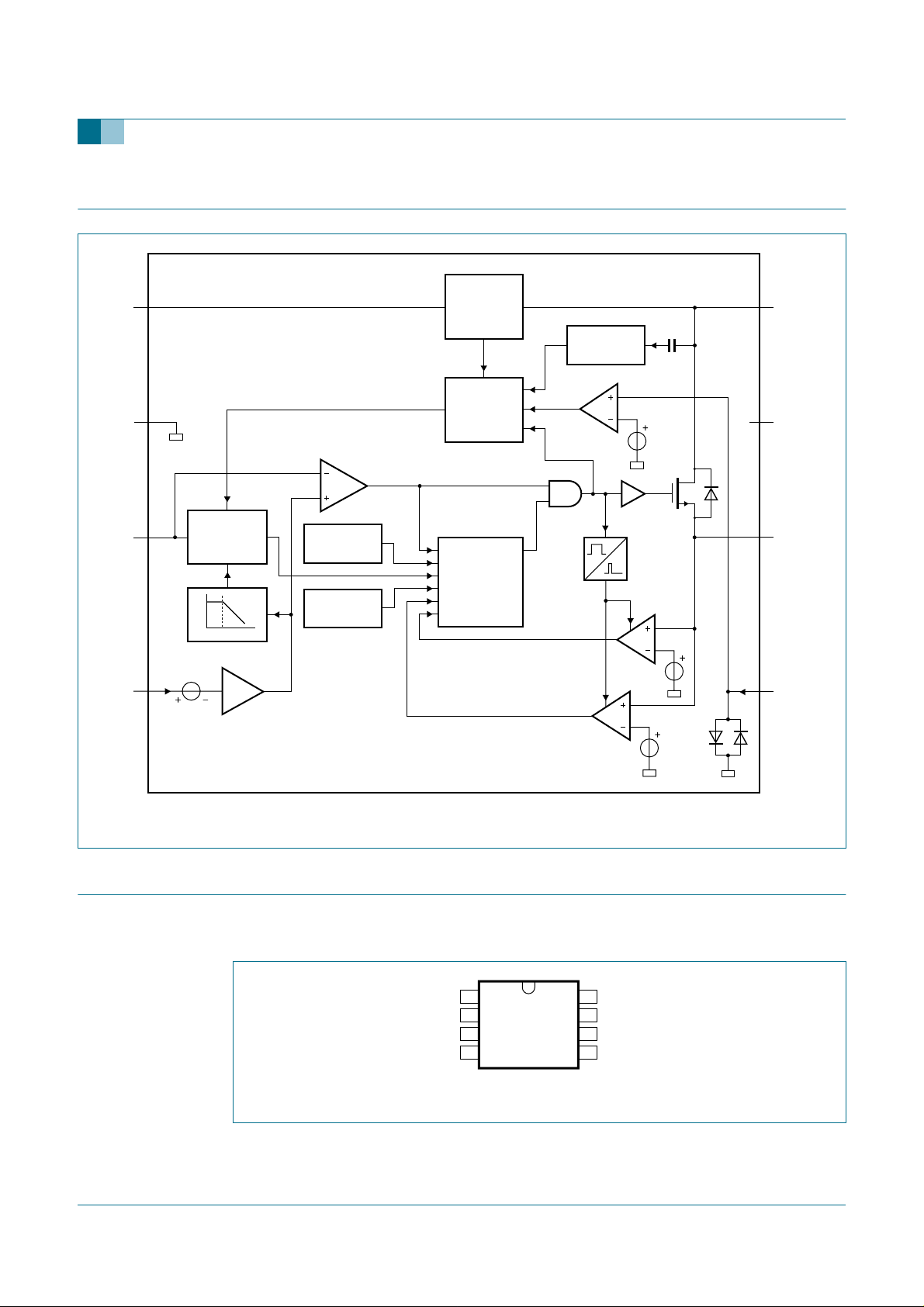

8.4 Valley switching

A new cycle is started at the primary stroke when the switch is switched on (see Figure 3).

After a certain time (determined by the RC oscillator voltage and the internal regulation

level), the switch is turned off and the secondary stroke starts. The internal regulation

level is determined by the voltage on pin REG. After the secondary stroke, the drain

voltage shows an oscillation with a frequency of approximately

Where:

TEA1622P

STARplug

1

------------------------------

2π LpC

×

p

TM

Lp is the primary self inductance on the drain node

Cp is the parasitic capacitance on the drain node.

As soon as the oscillator voltage is high again and the secondary stroke has ended, the

circuit waits for a low drain voltage before starting a new primary stroke.

The primary stroke starts some time before the actual valley at low ringing frequencies,

and some time after the actual valley at high ringing frequencies. Figure 4 shows a typical

curve for a reflected voltage N × Vo of 80 V. This voltage is the output voltage Vo (see

Figure 5) transferred to the primary side of the transformer with the factor N (determined

by the turns ratio of the transformer). Figure 4 shows that the system switches exactly at

minimum drain voltage for ringing frequencies of 480 kHz, thus reducing the switch-on

losses to a minimum. At 200 kHz, the next primary stroke is started at 33° before the

valley. The switch-on losses are still reduced significantly.

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 5 of 16

Page 6

Philips Semiconductors

TEA1622P

STARplug

TM

primary

stroke

drain

valley

secondary

stroke

RC

oscillator

regulation level

A: Start of new cycle with valley switching.

B: Start of new cycle in a classical PWM system.

Fig 3. Signals for valley switching.

secondary

stroke

secondary

ringing

A

B

col007

40

phase

(°)

20

0

−20

−40

0 800600200 400

Reflected voltage at N × Vo=80V.

Fig 4. Typical phase of drain ringing at switch-on.

001aaa311

f (kHz)

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 6 of 16

Page 7

Philips Semiconductors

8.5 Demagnetization

The system operates in discontinuous conduction mode all the time. As long as the

secondary stroke has not ended, the oscillator will not start a new primary stroke. During

the suppression time t

may be necessary in applications where the transformer has a large leakage inductance

and at low output voltages.

8.6 Protections

8.6.1 Overcurrent protection

The cycle-by-cycle peak drain current limit circuit uses the external source resistor RI(see

Figure 5) to measure the current. The circuit is activated after the leading edge blanking

time t

leb

primary peak current.

8.6.2 Short winding protection

The short winding protection circuit is also activated after the leading edge blanking time.

If the source voltage exceeds the short winding protection voltage V

stops switching. Only a power-on reset will restart normal operation. The short winding

protection also protects in case of a secondary diode short circuit.

, demagnetization recognition is suppressed. This suppression

suppr

. The protection circuit limits the source voltage to V

source(max)

TEA1622P

STARplug

, and thus limits the

, the TEA1622P

swp

TM

8.6.3 Overtemperature protection

An accurate temperature protection is provided in the TEA1622P. When the junction

temperature exceeds the thermal shutdown temperature, the IC stops switching. During

thermal protection, the IC current is lowered to the start-up current. The IC continues

normal operation as soon as the overtemperature situation has disappeared.

8.6.4 Overvoltage protection

Overvoltage protection can be achieved in the application by pulling pin REG above its

normal operation level, or by keeping the level of pin AUX above V

primary stroke is terminated immediately, and no new primary stroke is started until the

voltage on pin REG drops to its normal operation level. Pin REG has an internal clamp.

The current feed into pin REG must be limited.

8.7 Characteristics of the complete power-plug

8.7.1 Input

The input voltage range comprises the universal AC mains from 80 V to 276 V.

8.7.2 Accuracy

The accuracy of the complete converter, functioning as a voltage source with primary

sensing, is approximately 8 % (mainly dependent on the transformer coupling). The

accuracy with secondary sensing is defined by the accuracy of the external components.

For safety requirements in case of optocoupler feedback loss, the primary sensing

remains active when an overvoltage circuit is connected.

. The current

demag

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 7 of 16

Page 8

Philips Semiconductors

8.7.3 Efficiency

An efficiency of 75 % at maximum output power can be achieved for a complete converter

designed for universal mains.

8.7.4 Ripple

A minimum ripple is obtained in a system designed for a maximum duty factor of 50 %

under normal operating conditions, and a minimized dead time. The magnitude of the

ripple in the output voltage is determined by the frequency and duty factor of the

converter, the output current level, and the value and ESR of the output capacitor.

9. Limiting values

Table 4: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

Voltages

V

CC

V

RC

V

SOURCE

V

DRAIN

Currents

I

REG

I

AUX

I

RC

I

SOURCE

I

DRAIN

General

P

tot

T

stg

T

amb

T

j

V

esd

TEA1622P

STARplug

supply voltage continuous

oscillator input voltage

DMOS power transistor source

voltage

DMOS power transistor drain

voltage

regulation input current

auxiliary winding input current

oscillator capacitor charge

current

source current −1+1A

drain current −1+1A

total power dissipation T

<45°C - 1.0 W

amb

storage temperature −55 +150 °C

ambient temperature −20 +85 °C

junction temperature −20 +145 °C

electrostatic discharge voltage human body model

pin DRAIN −1000 +1000 V

all other pins −2000 +2000 V

machine model

all pins −200 +200 V

[1]

−0.4 +40 V

[1]

−0.4 +3 V

−0.4 +5 V

−0.4 +650 V

[2]

-6mA

[2]

−10 +5 mA

−3- mA

[3]

[4]

TM

[1] Pins VCC and RC are not allowed to be current driven.

[2] Pins REG and AUX are not allowed to be voltage driven.

[3] Human body model: equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

[4] Machine model: equivalent to discharging a 200 pF capacitor through a 0.75 µH coil and a 10 Ω series

resistor.

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 8 of 16

Page 9

Philips Semiconductors

10. Thermal characteristics

Table 5: Thermal characteristics

Symbol Parameter Conditions Typ Unit

R

th(j-a)

thermal resistance from junction

to ambient

in free air

TEA1622P

STARplug

[1]

100 K/W

TM

[1] Thermal resistance R

printed-circuit board. See the TEA152x application notes for details.

can be lower when pin GND is connected to sufficient copper area on the

th(j-a)

11. Characteristics

Table 6: Characteristics

T

=25°C; no overtemperature; all voltages are measured with respect to ground; currents are positive when flowing into

amb

the IC; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Supplies

Supply on pin V

V

CC(start)

V

CC(stop)

I

CC(operate)

I

CC(startup)

I

CC(ch)

Supply on pin DRAIN

I

DRAIN

Pulse width modulator mode

δ

min

δ

max

Self oscillating power supply mode

V

demag

t

suppr

Oscillator: pin RC

V

RC(min)

V

RC(max)

t

RC(ch)

f

osc

Duty factor regulator: pin REG

V

REG

CC

start voltage 9 9.5 10 V

stop voltage undervoltage lock-out 7.0 7.5 8.0 V

operating supply current normal operation - 1.3 1.9 mA

start-up supply current start-up - 180 400 µA

charging current V

>60V

DRAIN

=0V −650 −520 −390 µA

V

CC

= 8.5 V −375 −275 −175 µA

V

CC

supply current drawn from pin DRAIN no auxiliary supply - 0.5 - mA

with auxiliary supply;

>60V

V

DRAIN

- 30 125 µA

minimum duty factor - 0 - %

maximum duty factor f

demagnetization recognition voltage

= 100 kHz - 75 - %

osc

50 100 150 mV

level

time of suppression of transformer

1.0 1.5 2.0 µs

ringing at start of secondary stroke

minimum voltage of RC oscillator

60 75 90 mV

setting

maximum voltage of RC oscillator

2.4 2.5 2.6 V

setting

RC charging time - 1 - µs

oscillator frequency range 10 - 200 kHz

input voltage on pin REG 2.4 2.5 2.6 V

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 9 of 16

Page 10

Philips Semiconductors

TEA1622P

STARplug

TM

Table 6: Characteristics

T

=25°C; no overtemperature; all voltages are measured with respect to ground; currents are positive when flowing into

amb

…continued

the IC; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

G

V(erroramp)

V

REG(clamp)

voltage gain of error amplifier - 20 - dB

clamping voltage on pin REG I

= 6 mA - - 7.5 V

REG

Valley switching recognition

dV/dt

valley

f

valley

t

d(valley-on)

valley recognition −102 - +102 V/µs

ringing frequency for valley switching N × Vo= 100 V 200 550 800 kHz

delay from valley recognition to

- 150 - ns

switch-on

Output stage (FET)

I

L(drain)

V

BR(drain)

R

DSon

t

drain(f)

drain leakage current V

drain breakdown voltage Tj>0°C 650 - - V

drain-source on-state resistance I

drain fall time V

= 650 V - - 125 µA

DRAIN

SOURCE

= −0.06 A

=25°C - 12 13.8 Ω

T

j

= 100 °C - 17 19.6 Ω

T

j

DRAIN(switch_on)

= 300 V;

-75-ns

no external capacitor at pin

DRAIN

Temperature protection

T

prot(max)

T

prot(hys)

maximum threshold temperature 150 160 170 °C

threshold temperature hysteresis - 2 - °C

Overcurrent and short winding protection: pin SOURCE

V

source(max)

V

swp

t

d(propagation)

overcurrent protection voltage dV/dt = 0.1 V/µs 0.47 0.50 0.53 V

short winding protection voltage dV/dt = 0.5 V/µs 0.7 0.75 0.8 V

delay from detecting V

source(max)

to

dV/dt = 0.5 V/µs - 160 185 ns

switch-off

t

leb

leading edge blanking time both overcurrent and short

250 350 450 ns

winding protection

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 10 of 16

Page 11

Philips Semiconductors

12. Application information

TEA1622P

STARplug

TM

CF1

mains

R1

R4

R3

Further application information can be found in the TEA152x application notes.

Fig 5. Application with primary sensing.

13. Test information

LF

D5

Z1

CF2

R2

C

VCC

R

C

RC

RC

V

CC

GND

RC

REG

1

2

TEA1622P

3

4

D2

DRAIN

8

n.c.

7

SOURCE

6

AUX

5

D1

R

I

R

AUX

C5

C6 - Ycap

col010

V

o

13.1 Quality information

The

General Quality Specification for Integrated Circuits, SNW-FQ-611

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 11 of 16

is applicable.

Page 12

Philips Semiconductors

14. Package outline

TEA1622P

STARplug

TM

DIP8: plastic dual in-line package; 8 leads (300 mil)

D

seating plane

A

L

Z

e

b

8

pin 1 index

1

w M

b

1

b

2

5

SOT97-1

M

E

A

2

A

c

(e )

1

M

H

E

1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

12

min.

max.

050G01 MO-001 SC-504-8

b

1.73

1.14

0.068

0.021

0.045

0.015

IEC JEDEC JEITA

mm

OUTLINE

VERSION

SOT97-1

A

max.

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

b

0.53

0.38

4

0 5 10 mm

scale

1

1.07

0.89

0.042

0.035

b

2

0.36

0.23

0.014

0.009

REFERENCES

(1) (1)

cD E e M

9.8

9.2

0.39

0.36

6.48

6.20

0.26

0.24

1

3.60

3.05

0.14

0.12

E

8.25

7.80

0.32

0.31

EUROPEAN

PROJECTION

10.0

0.39

0.33

M

L

e

H

8.3

w

max.

0.2542.54 7.62

1.154.2 0.51 3.2

0.010.1 0.3

0.0450.17 0.02 0.13

ISSUE DATE

99-12-27

03-02-13

(1)

Z

Fig 6. Package outline.

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 12 of 16

Page 13

Philips Semiconductors

15. Soldering

15.1 Introduction to soldering through-hole mount packages

This text gives a brief insight to wave, dip and manual soldering. A more in-depth account

of soldering ICs can be found in our

(document order number 9398 652 90011).

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

15.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 to 4 seconds at 250 °C or 265 °C, depending on solder material applied, SnPb or

Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

TEA1622P

STARplug

Data Handbook IC26; Integrated Circuit Packages

TM

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

15.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is

less than 300 °C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

15.4 Package related soldering information

Table 7: Suitability of through-hole mount IC packages for dipping and wave soldering

methods

Package Soldering method

Dipping Wave

DBS, DIP, HDIP, RDBS, SDIP, SIL suitable suitable

[2]

PMFP

[1] For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

board.

[2] For PMFP packages hot bar soldering or manual soldering is suitable.

− not suitable

stg(max)

[1]

). If the

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 13 of 16

Page 14

Philips Semiconductors

TEA1622P

STARplug

16. Revision history

Table 8: Revision history

Document ID Release date Data sheet status Change notice Order number Supersedes

TEA1622P_1 20040317 Product data - 9397 750 12578 -

TM

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 14 of 16

Page 15

Philips Semiconductors

17. Data sheet status

TEA1622P

STARplug

TM

Level Data sheet status

I Objective data Development This data sheet contains data from the objective specification for product development. Philips

II Preliminary data Qualification This data sheetcontainsdata from the preliminary specification. Supplementary data will be published

III Product data Production This data sheet contains data from the product specification. Philips Semiconductors reserves the

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at

URL http://www.semiconductors.philips.com.

[3] For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

[1]

Product status

18. Definitions

Short-form specification — The data in a short-form specification is

extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with

the Absolute Maximum Rating System (IEC 60134). Stress above one or

more of the limiting values may cause permanent damage to the device.

These are stress ratings only and operation of the device at these or at any

other conditions above those given in the Characteristics sections of the

specification is not implied. Exposure to limiting values for extended periods

may affect device reliability.

Application information — Applications that are described herein for any

of these products are for illustrative purposes only. Philips Semiconductors

make no representation or warranty that such applications will be suitable for

the specified use without further testing or modification.

[2] [3]

Definition

Semiconductors reserves the right to change the specification in any manner without notice.

at a later date. Philips Semiconductors reserves the right to change the specification without notice, in

order to improve the design and supply the best possible product.

right to make changes at any time in order to improve the design, manufacturing and supply.Relevant

changes will be communicated via a Customer Product/Process Change Notification (CPCN).

customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to

make changes in the products - including circuits, standard cells, and/or

software - described or contained herein in order to improve design and/or

performance. When the product is in full production (status ‘Production’),

relevant changes will be communicated via a Customer Product/Process

Change Notification (CPCN). Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no

license or title under any patent, copyright, or mask work right to these

products, andmakes no representations orwarranties that these productsare

free from patent,copyright,or mask work right infringement, unless otherwise

specified.

20. Trademarks

19. Disclaimers

Life support — These products are not designed for use in life support

appliances, devices, or systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips Semiconductors

STARplug —is a trademark of Koninklijke Philips Electronics N.V.

EZ-HV — is a trademark of Koninklijke Philips Electronics N.V.

21. Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, send an email to: sales.addresses@www.semiconductors.philips.com

9397 750 12578 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data sheet Rev. 01 — 17 March 2004 15 of 16

Page 16

Philips Semiconductors

22. Contents

1 General description. . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Quick reference data . . . . . . . . . . . . . . . . . . . . . 2

5 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

6 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

7.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 4

8 Functional description . . . . . . . . . . . . . . . . . . . 4

8.1 Start-up and undervoltage lock-out . . . . . . . . . 4

8.2 Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8.3 Duty factor control. . . . . . . . . . . . . . . . . . . . . . . 5

8.4 Valley switching. . . . . . . . . . . . . . . . . . . . . . . . . 5

8.5 Demagnetization. . . . . . . . . . . . . . . . . . . . . . . . 7

8.6 Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8.6.1 Overcurrent protection . . . . . . . . . . . . . . . . . . . 7

8.6.2 Short winding protection. . . . . . . . . . . . . . . . . . 7

8.6.3 Overtemperature protection . . . . . . . . . . . . . . . 7

8.6.4 Overvoltage protection . . . . . . . . . . . . . . . . . . . 7

8.7 Characteristics of the complete power-plug . . . 7

8.7.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8.7.2 Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8.7.3 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8.7.4 Ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 8

10 Thermal characteristics. . . . . . . . . . . . . . . . . . . 9

11 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 9

12 Application information. . . . . . . . . . . . . . . . . . 11

13 Test information. . . . . . . . . . . . . . . . . . . . . . . . 11

13.1 Quality information . . . . . . . . . . . . . . . . . . . . . 11

14 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 12

15 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15.1 Introduction to soldering through-hole mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15.2 Soldering by dipping or by solder wave . . . . . 13

15.3 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 13

15.4 Package related soldering information . . . . . . 13

16 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 14

17 Data sheet status. . . . . . . . . . . . . . . . . . . . . . . 15

18 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

19 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

20 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

21 Contact information . . . . . . . . . . . . . . . . . . . . 15

TEA1622P

STARplug

TM

© Koninklijke Philips Electronics N.V. 2004

All rights are reserved. Reproduction in whole or in part is prohibited without the prior

written consent of the copyright owner. The information presented in this document does

not form part of any quotation or contract, is believed to be accurate and reliable and may

be changed without notice. No liability will be accepted by the publisher for any

consequence of its use. Publication thereof does not convey nor imply any license under

patent- or other industrial or intellectual property rights.

Published in The Netherlands

Date of release: 17 March 2004

Document order number: 9397 750 12578

Loading...

Loading...