Page 1

查询TEA1566供应商

INTEGRATED CIRCUITS

DATA SH EET

TEA1566

GreenChip; SMPS module

Preliminary specification

File under Integrated Circuits, IC11

1999 Apr 20

Page 2

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

FEATURES

Distinctive features

• High level of integration results in 20 to 50 fewer

components compared to a power supply with discrete

components

• On-chip 600 V MOSFET

• On/off function replaces expensive mains switch with

functional switch

• Direct off-line operation (90 to 276 VAC)

• On-chip 5% accurate oscillator.

Green features

• Low power consumption in off-mode (<100 mW)

• On-chip efficient start-up current source giving fast

start-up

• Burst mode stand-by (<2 W) for overall improved

system efficiency

• Low power operation mode with lower frequency to

reduce switching losses.

Protection features

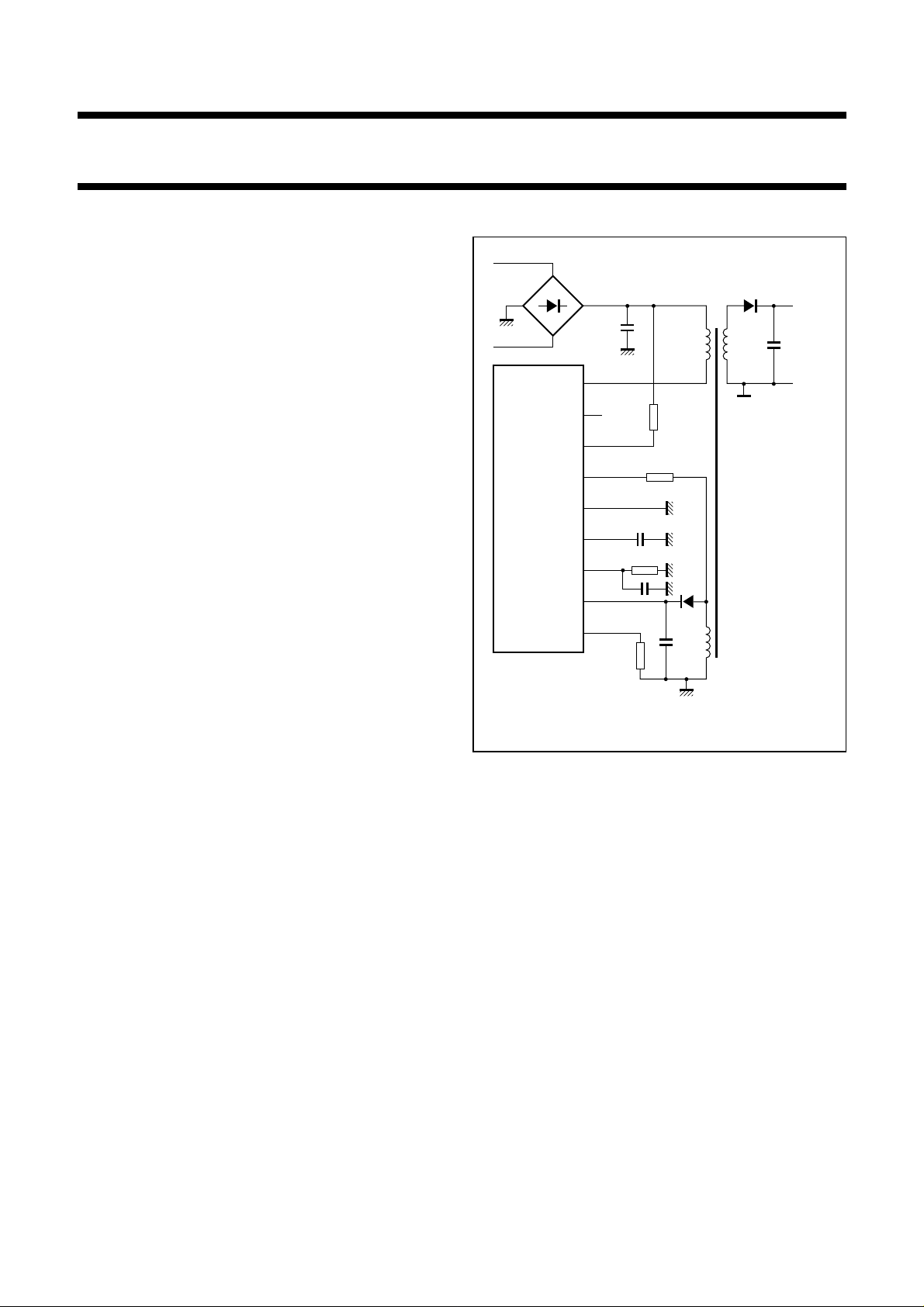

APPLICATIONS

mains

TEA1566

9

8

7

6

5

4

3

2

1

output

Vin

NC

OOB

Dem

Gnd

Vctrl

Iref

Vaux

Isense

• Demagnetization protection

• Cycle by cycle current limitation with programmable

current trip level

• Over voltage protection

• Over temperature protection

• Safe-restart mode with reduced power for system fault

conditions.

Highly versatile

• Usable in Buck and flyback topology

• Interfaces both primary and secondary side feedback.

MGR691

Fig.1 Typical flyback application.

GENERAL DESCRIPTION

The GreenChip, intended for off-line 90 to 276 VAC

power supply applications, is a monolithic high voltage

family of ICs that combines analog and digital circuits to

implement all necessary control functions for a switched

mode power supply. The functions include integrated high

voltage start-up current source, voltage mode PWM

control, 5% accurate trimmed oscillator, band gap derived

reference voltages, comprehensive fault protection, and

leading edge blanking. High level of integration leads to

cost effective power supplies that are compact, weigh less,

and at the same time give higher efficiency, are more

reliable and simple to design. Efficient green features lead

to very low power operation modes and a novel on/off

function helps replace the expensive mains switch with a

low cost functional switch.

1999 Apr 20 2

Page 3

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

ORDERING INFORMATION

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TEA1566S SIL9P plastic single in-line power package; 9 leads SOT131-2

TEA1566J DBS9P plastic DIL-bent-SIL power package; 9 leads (lead length12 mm) SOT157-2

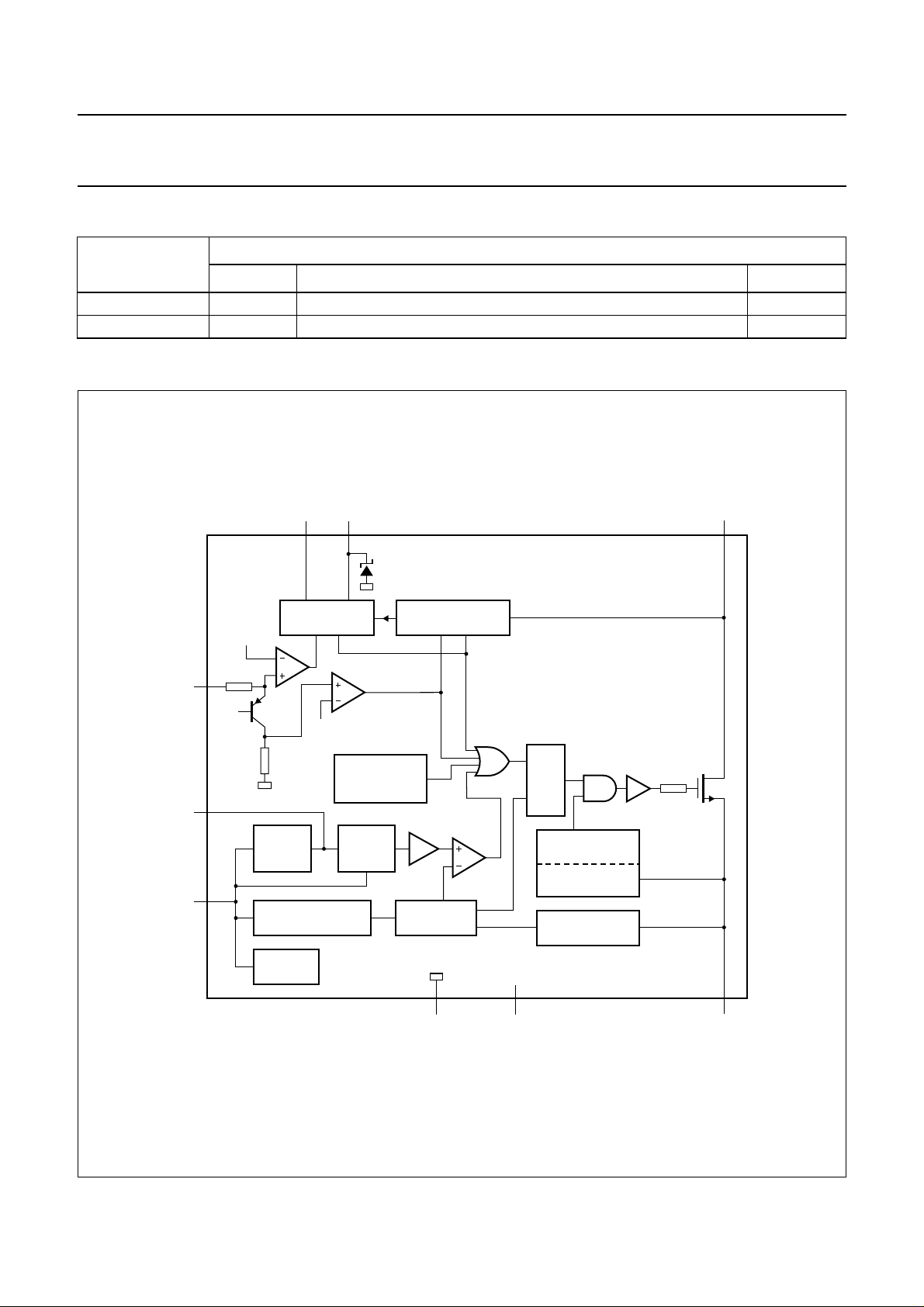

BLOCK DIAGRAM

handbook, full pagewidth

OOB

Vaux

VAUX

ON/OFF

1 kΩ

7

MANAGEMENT

CURRENT SOURCE

START-UP

TEA1566

VinIref

923

Vctrl

Dem

4

6

5.5 V

SAMPLE

AND

HOLD1

DEMAGNETIZATION

NEGATIVE

CLAMP

burst mode

stand-by

TEMPERATURE

MANAGEMENT

OVER

PROTECTION

SAMPLE

AND

HOLD2

amplifier

OSCILLATOR

Fig.2 Block diagram.

error

5

Gnd

PWM

comparator

R

Q

S

OVER CURRENT

PROTECTION

LEADING EDGE

BLANKING

FREQUENCY

CONTROL

81

NC

driver

stage

power

MOSFET

6 Ω

MGR692

Isense

1999 Apr 20 3

Page 4

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

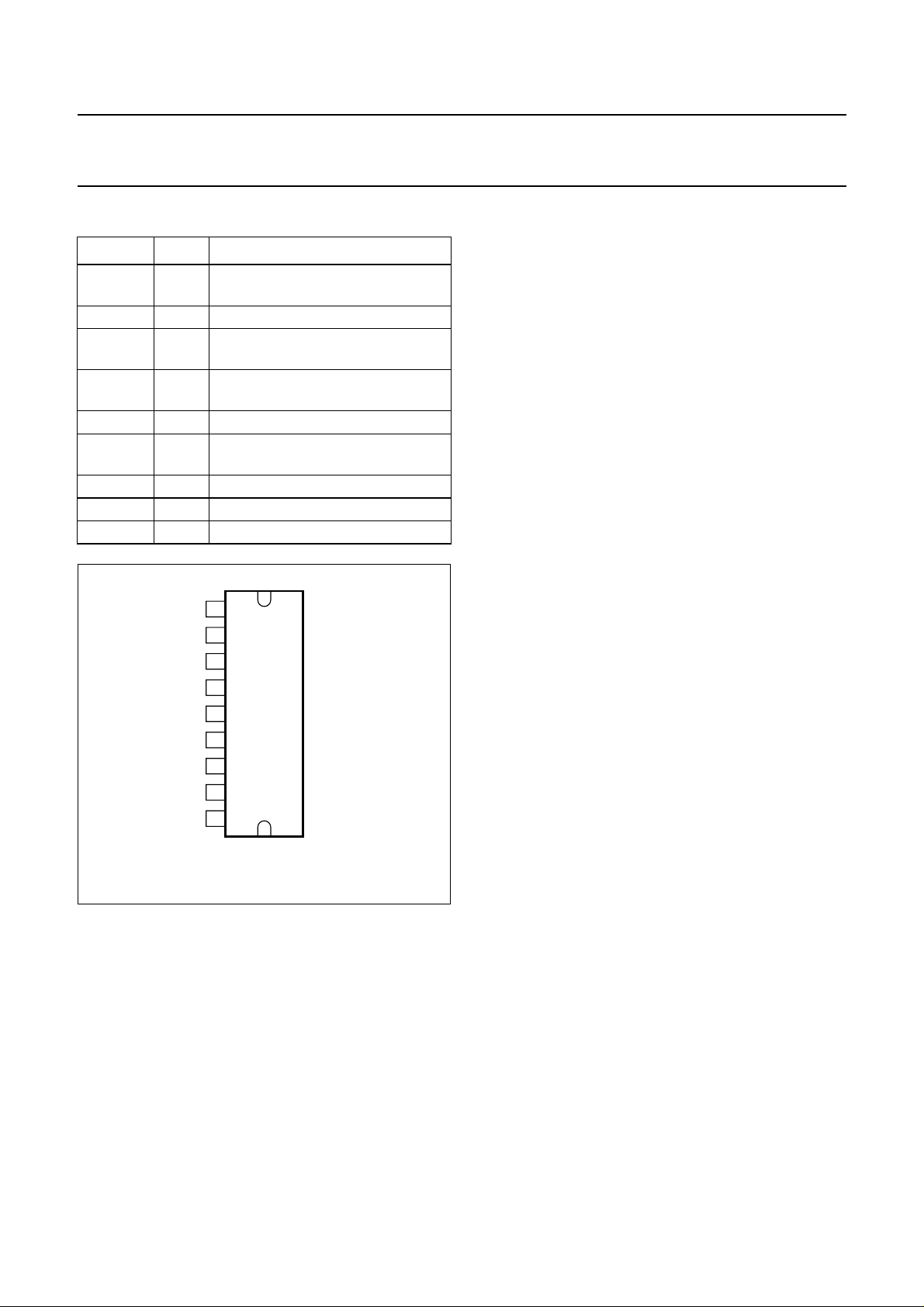

PINNING

SYMBOL PIN DESCRIPTION

Isense 1 programmable current sense

resistor

Vaux 2 IC supply capacitor

Iref 3 reference resistor for setting

internal reference currents

Vctrl 4 feedback voltage for duty cycle

control

Gnd 5 ground

Dem 6 demagnetization input signal from

primary side auxiliary winding

OOB 7 on/off/burst mode input signal

NC 8 not connected

Vin 9 MOSFET drain connection

handbook, halfpage

Isense

Vaux

Iref

Vctrl

Gnd

Dem

OOB

NC

Vin

1

2

3

4

5

6

7

8

9

TEA1566

MGR693

Fig.3 Pin configuration.

FUNCTIONAL DESCRIPTION

The GreenChip family of ICs are highly integrated, with

most common PWM functions like error amplifier,

oscillator, bias current generator, and band gap based

reference voltage circuits fully integrated in the ICs.

High level of integration leads to easy and cost effective

design of power supplies.The ICs have been fabricated in

a Philips proprietary high voltage BCDMOS process that

enables devices of up to 720 V to be fabricated on the

same chip with low voltage circuitry.

An efficient on-chip start-up circuit enables fast start-up

and dissipates negligible power after start up. On-chip

accurate oscillator generates a saw tooth waveform which

is used by the voltage mode feedback control circuitry to

generate a pulse width modulated signal for driving the

gate of the power MOSFET. A novel regulation scheme is

used to implement both primary and secondary side

regulation to minimize external component count.

Protection features like over voltage, over current, over

temperature, and demagnetization protection, give

comprehensive safety against system fault conditions.

The GreenChip offers some advanced features that

greatly enhance the efficiency of the overall system.

Off-mode reduces the power consumption of the IC below

100 mW. Burst mode stand-by reduces the power

consumption of the system to below 2 W. Low power

operation mode reduces the operating frequency of the

system, when the system is working under low load

conditions, to reduce the switching losses.

Start-up current source and Vaux management

A versatile on-chip start-up current source makes an

external, highly dissipating, trickle-charge circuit

unnecessary. See Fig.2 for the block diagram of the IC.

The start-up current source derives power from the mains

via pin Vin (drain). It supplies current (see symbols

‘Istart-low’ and ‘Istart-high’ of Chapter “Characteristics”) to

charge the Vaux (IC supply) capacitor and at the same

time provides current to the control circuitry of the IC. Once

the Vaux capacitor is charged to its start-up voltage level

(11 V), the on-chip oscillator starts oscillating and the IC

starts switching the power MOSFET. Power is then

supplied to the load capacitor via the secondary winding.

Figure 1 shows a typical flyback application diagram.

The Vaux capacitor is also supplied by an auxiliary

winding on the primary side. This winding is coupled to the

secondary side winding supplying the output capacitor.

As the output capacitor voltage increases and approaches

its nominal value, the re-supply of the Vaux capacitor is

done by the auxiliary winding. Figure 4 shows relevant

waveforms at start-up. For successful take over of supply

of Vaux capacitor by the auxiliary winding, it is important

that the re-supply of Vaux capacitor starts before its

voltage drops to its Under Voltage Lockout (UVLO) level of

8.05 V of the system and stops delivering power to the

output.

1999 Apr 20 4

Page 5

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

In case of output short circuit, the Vaux capacitor is no

longer supplied by the auxiliary winding and its voltage

drops till it reaches the UVLO level. If the output is an open

circuit, the output voltage will rise till it reaches the Over

Voltage Protection (OVP) level. The IC will detect this state

and stop switching.

In absence of switching of the power device, the Vaux

capacitor will not be re-supplied and its voltage will drop till

it reaches UVLO level. Once the Vaux voltage drops to

UVLO level, the start-up current source is re-activated and

it charges the Vaux capacitor to its start level and the

system goes through a cycle similar to the start-up cycle.

Figure 5 shows the relevant waveforms during safe-restart

mode. The charging current (see symbol ‘Irestart-prot’ in

Chapter “Characteristics”) from the start-up circuit during

the safe-restart mode is lower than the normal start-up

current (see symbol ‘Istart-high’ in

Chapter “Characteristics”) in order to implement a low

“hiccup” duty cycle. This helps insure devices on the

output secondary winding do not get destroyed during

output short circuit, violating safety conditions.

The start-up current source also plays a key role in

implementation of burst mode stand-by (see symbol

‘Irestart-stby’ in Chapter “Characteristics”), which will be

explained later.

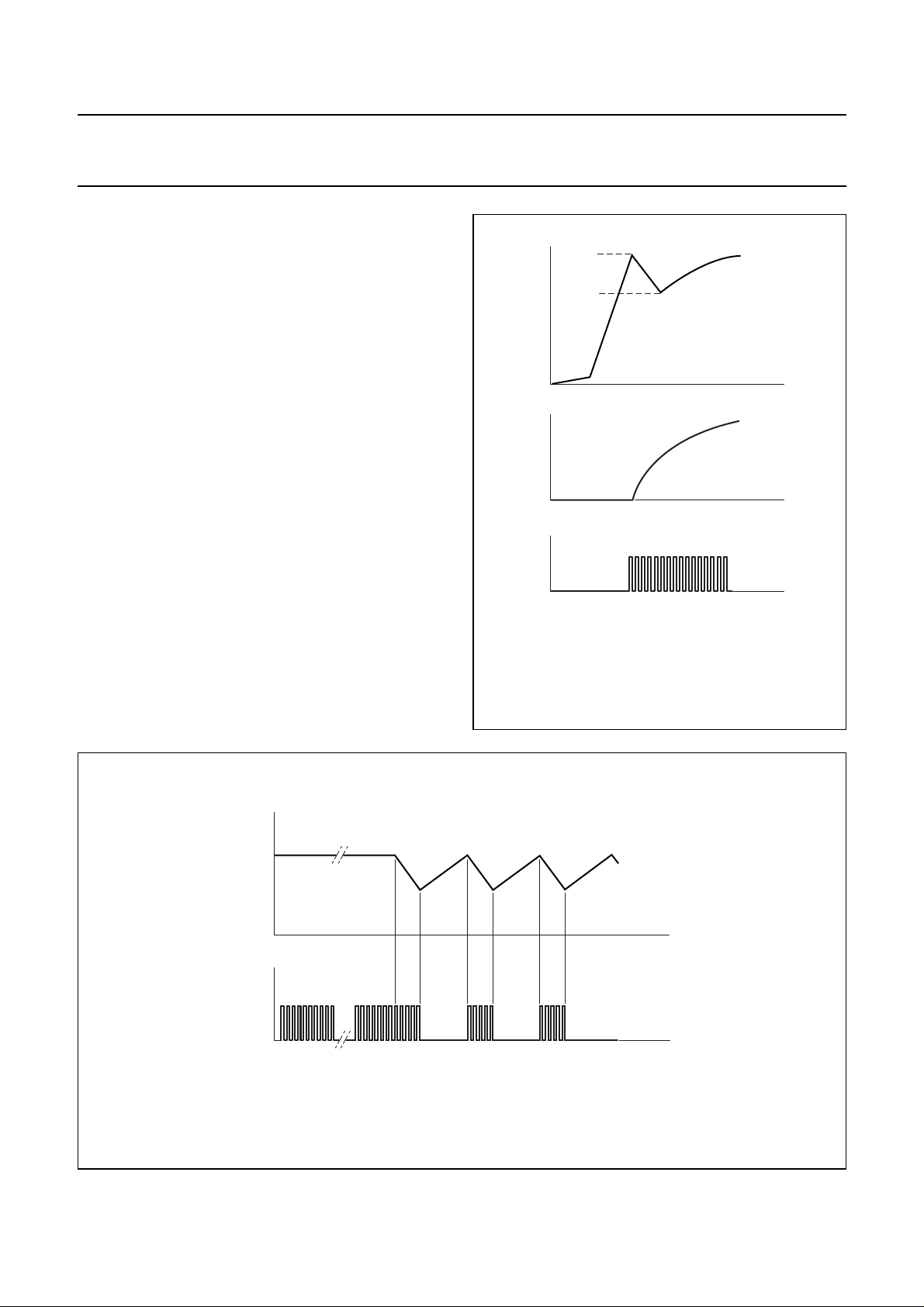

Vaux

Vout

Vgate

(1) Start-up current charges capacitor V

(2) Charging of capacitor V

11 V

(2)

8.05 V

(1)

switchingoff

.

is taken-over by the auxiliary winding.

aux

aux

Fig.4 Normal start-up waveforms.

t

t

t

MGR694

handbook, full pagewidth

(1) Start-up current source charges capacitor V

Vaux

Vgate

normal operation

.

aux

fault condition

(1)

switching off

Fig.5 Safe-start mode waveforms.

1999 Apr 20 5

MGR695

t

t

Page 6

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

Reference

All reference voltages are derived from a temperature

compensated, on-chip, band gap. The band gap reference

voltage is also used, together with an external resistor

connected at pin Iref, to generate accurate, temperature

independent, bias currents in the chip:

V

REF

I

REF

=

------------- R

REF

[A]

The frequency of the controller is also set by the reference

resistor Rref (also see Section “Oscillator”).

Sample and hold

GreenChip ICs employ voltage mode feedback for

regulating the output voltage. In primary feedback mode, a

novel sample and hold circuit is used. The sample and

hold circuit works by sampling the current into pin Dem,

which is related to the output voltage via Rdem, during the

time that the secondary current is flowing:

a × V

V

dem+

out=Iref

× R

dem+Vdem+

where:

is specified in chapter “Characteristics”

a = a constant determined by turn ratio of the

transformer.

This sampled current information is stored on the external

capacitor connected to pin Vctrl. The pulse width

modulator uses this voltage information to set the duty

cycle of operation for the power MOSFET. In secondary

feedback, the feedback voltage is provided by an

opto-coupler.

Oscillator

The oscillator is used to set the switching duty cycle by

comparing the oscillator ramp to the output of the error

amplifier in the pulse width modulator circuit.The oscillator

is fully integrated and works by charging and discharging

an internal capacitor between two voltage levels to create

a sawtooth waveform with a rising edge which is 80% of

the oscillator cycle. This ratio is used to set a maximum

switching duty cycle of 80% for the IC. The oscillator is

internally trimmed to 5% accuracy. The oscillator

frequency can be adjusted between 50 to 100 kHz

(see symbol f

osc-h-range

in Chapter “Characteristics”) by

changing the external reference resistor (see symbol Rref

in Chapter “Characteristics”) that sets the chip bias

currents. This gives additional flexibility to the power

supply designer in the choice of his system

components.The frequency is correlated with the value of

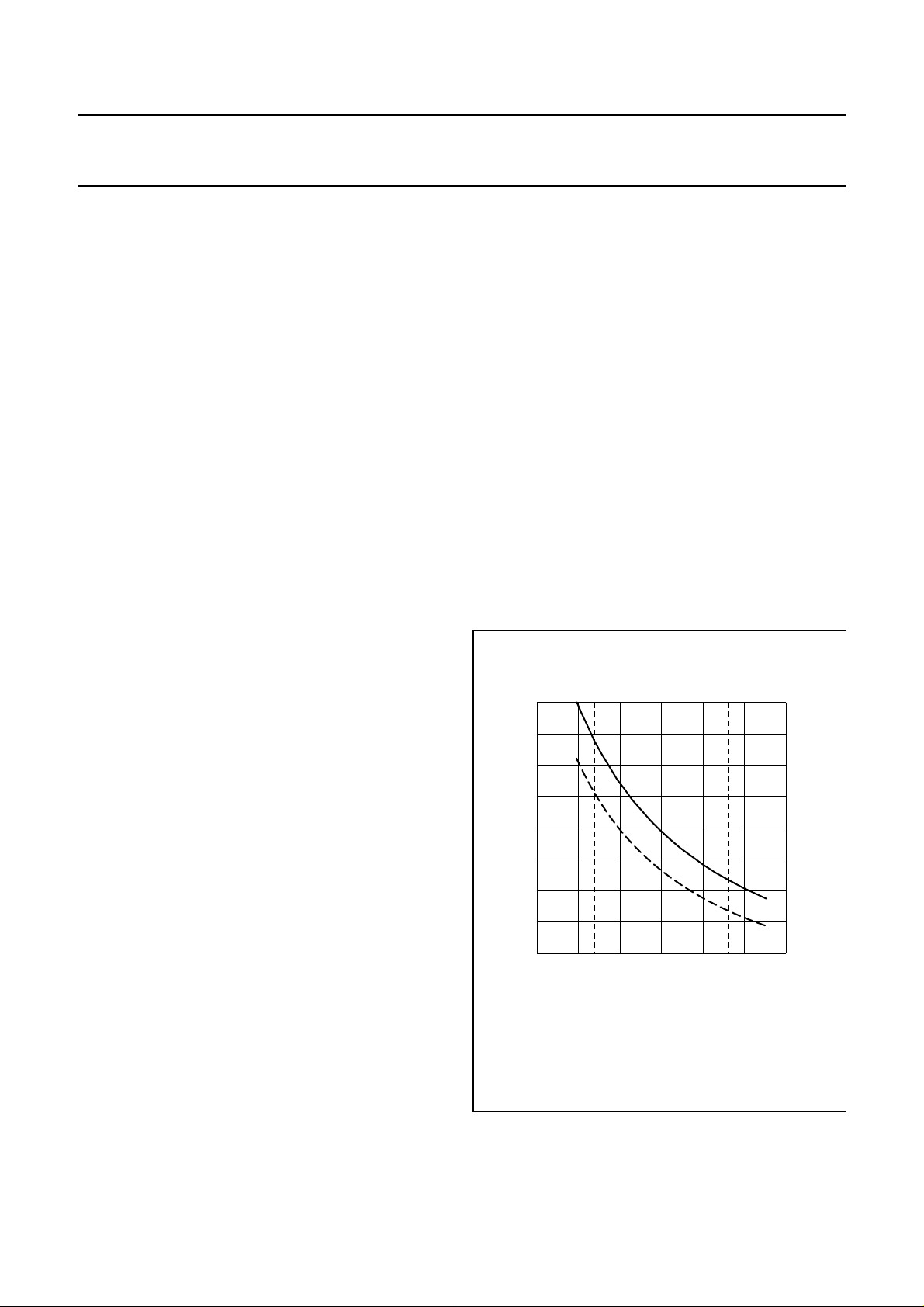

the reference resistor Rref (see Fig.6).

In Chapter “Characteristics” f

osc-typical

osc-l

and f

osc-h

and

, f

the Rref operating resistor range are specified.

MGR936

110

handbook, halfpage

high

frequency

(kHz)

90

55

low

frequency

(kHz)

45

Pulse width modulator

The pulse width modulator, which is made up of an

inverting error amplifier and a comparator (see Fig.2),

drives the power MOSFET with a duty cycle which is

inversely proportional to the voltage on pin Vctrl.

In primary feedback mode, this is the voltage on the

sample and hold capacitor and in secondary feedback

mode, this voltage is provided by an opto-coupler. A signal

from the oscillator sets a latch that turns on the power

MOSFET. The latch is reset by the signal from the pulse

width modulator or by the duty cycle limiting circuit.

The latching PWM mode of operation prevents multiple

switching of the power switch. The maximum duty cycle is

set internally at 80%.

Figure 7 shows the normal switching operation of the IC.

1999 Apr 20 6

70

50

30

10 20 30 40

(1) High frequency mode.

(2) Low frequency mode.

(1)

(2)

Fig.6 Frequency as function of the R

R

REF

(kΩ)

REF

35

25

15

value.

Page 7

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

Multi frequency control

The oscillator is also capable of working at a lower

frequency (see f

in Chapter “Characteristics”). A ratio

osc-l

of 1 : 2.5 is maintained between high and low frequency of

the oscillator. Low frequency operation is invoked if the

power supply is working at or below one ninth of its peak

power. By working at a lower frequency, the switching

losses in the power supply are reduced. A novel scheme

is used to ensure that the transfer of high to low frequency

and vice versa has no effect on the regulation of the output

voltage.

Gate driver

The gate driver has a totem-pole output stage that has

current sourcing capability of 120 mA and a current sink

capability of 550 mA. This is to enable fast turn on and turn

off of the power device for efficient operation.

A lower driver source current has been chosen in order to

limit the ∆V/∆t at switch-on. This is advantageous for EMI

(ElectroMagnetic Interference) and reduces the current

spike across Rsense.

Demagnetization protection

This feature guarantees discontinuous conduction mode

operation for the power supply which simplifies the design

of feedback control and gives faster transient response.

Demagnetization protection is an additional protection

feature that protects against saturation of the

transformer/inductor. Demagnetization protection also

protects the power supply components against excessive

stresses at start-up, when all energy storage components

are completely discharged. The converter is cycle by cycle

protected during shorted output system fault condition due

to the demagnetization protection. The value of the

demagnetization resistor (R

) can be calculated with the

dem

formula given in Section “Sample and hold”.

Negative clamp

The negative clamp circuit does not let the voltage on

pin Dem go below −0.4 V, when the auxiliary winding

voltage goes negative during the time that the power

device is turned on, to ensure correct operation of the IC.

Over voltage protection

An Over Voltage Protection (OVP) mode has been

implemented in the GreenChip series. This circuit works

by sensing the Vaux voltage. If the output voltage exceeds

the preset voltage limit, the OVP circuit turns off the power

MOSFET. With no switching of the power device, the Vaux

capacitor is not re-supplied and discharges to UVLO level

and the system goes into the low dissipation safe-restart

mode described earlier. The system recovers from the

safe-restart mode only if the OVP condition is removed.

Over current protection

Cycle by cycle Over Current Protection (OCP) is provided

by sensing the voltage on an external resistor which is

connected to the source of the power MOSFET.

The voltage on the current sense resistor, which reflects

the amplitude of the primary current, is compared

internally with a reference voltage using a high speed

comparator. This threshold voltage is specified as V

th(Imax)

in the chapter “Characteristics”. The maximum primary

V

(protection) current is therefore: [A]

I

prot

th Imax()

=

-----------------------R

sense

If the power device current exceeds the current limit, the

comparator trips and turns off the power device.

The power device is typically turned off in 210 ns

(see tDin Chapter “Characteristics”).

The availability of the current sense resistor off-chip for

programming the OCP trip level increases design flexibility

for the power supply designer. An off-chip current sense

resistor also reduces the risk of an OCP condition being

sensed incorrectly. At power MOSFET turn-on the

∆V/∆t limiters capacitance discharge current does not

have to flow through the sense resistor, because this

capacitor can be connected between drain and source of

the power MOSFET directly.

The Leading Edge Blanking (LEB) circuit works together

with the OCP circuit and inhibits the operation of the OCP

comparator for a short duration (see t

LEB

in

Chapter “Characteristics”) when the power device is

turned on. This ensures that the power device is not turned

off prematurely due to false sensing of an OCP condition

because of current spikes caused by discharge of

primary-side snubber and parasitic capacitances.

LEB time is not fixed and it tracks the oscillator frequency.

1999 Apr 20 7

Page 8

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

Over temperature protection

Protection against excessive temperature is provided by

an analog temperature sensing circuit that turns off the

power device when the temperature exceeds typically

140 °C.

On/off mode

The expensive mains switch can be replaced by an

in-expensive functional switch by using the on/off mode.

Figure 13 shows a flyback converter configured to use the

on/off mode. Depending upon the position of switch S1,

either voltage close to ground or a voltage of greater than

typical 2.5 V exists on pin OOB.

The difference between these voltages is detected

internally by the IC. The IC goes into the off-mode if the

voltage is low, where it consumes a current of typical

350 µA (see Iin-off in Chapter “Characteristics”). If the

voltage on pin OOB is typically 2.5 V (see Von/off in

Chapter “Characteristics”), the IC goes through the

start-up sequence and commences normal operation.

In Fig.14 a Mains Under Voltage Lock Out (MUVLO)

function has been created using 3 resistors. Assuming that

R3 is chosen very high ohmic, the GreenChip™ starts

operating if:

V

MAINS

R1

------- R2

V

OOB

R1 R2»()×≈

Burst mode stand-by

Pin OOB is also used to implement the burst mode

stand-by. In burst mode stand-by, the power supply goes

into a special low dissipation state where it typically

consumes less than 2 W of power. Figure 14 shows a

flyback converter using the burst mode stand-by feature.

The system enters burst mode when the microcontroller

closes switches S2 and S3 on the secondary side.

Switch S2 shorts the output capacitor to the voltage level

of the microcontroller capacitor. The output secondary

winding now supplies the microcontroller capacitor. When

the voltage on the microcontroller capacitor exceeds the

zener voltage (V

) the opto-coupler is activated which

z

sends a signal to pin OOB. In response to this signal, the

IC stops switching and goes into a “hiccup” mode.

Figure 7 shows the burst-mode operation graphically.

The hiccup mode during burst mode operation differs from

the hiccup in safe-restart mode during system fault. For

safe restart mode, the power has to be reduced. For burst

mode, sufficient power to supply the microcontroller has to

be delivered. To prevent transformer rattle, the

transformer peak current is reduced by a factor of 3.

Burst mode stand-by operation continues till the

microcontroller opens switches S2 and S3. The system

then goes through the start-up sequence and commences

normal switching behaviour.

In this way it is assured that the power supply only starts

working above a Vmains of e.g. 80 V. The bleeder current

through R1 should be low (e.g. 30 µA at 300 V).

1999 Apr 20 8

Page 9

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

handbook, full pagewidth

Vin

Vin

Vdrain

Vout

Vaux

Vgate

Iaux

burst mode

VµP

0

(1)

start up

sequence

normal

operation

over voltage

protection

output short

circuit

burst mode stand-by

normal

operation

MGR696

(1) All negative currents are currents out the chip.

Fig.7 Typical waveforms.

1999 Apr 20 9

Page 10

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134); unless noted all voltages are measured with

respect to pin GND.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

I(max)

I

D

V

OOB

I

OOB

I

demag

V

ctrl

V

lsense

I

ref

V

aux

T

j

T

stg

V

es

maximum DC input voltage − 600 V

during inductive turn-off;

− 720 V

note 1

supply current − 7A

mode detect input voltage −0.3 +14 V

mode detect input current −+2mA

demagnetization input current −±1mA

feedback input voltage −0.3 +5 V

current sense input voltage −0.3 +5 V

reference input current −−1mA

auxiliary supply voltage −0.3 +18 V

operating junction temperature −10 +140 °C

storage temperature −40 +150 °C

electrostatic handling voltage class 2

human body model; note 3 − 2500 V

machine model; note 4 − 250 V

Notes

1. Repetitive clamped inductive turn-off energy <15 mJ.

2. Single pulse avalanche energy at T

<25°C: 570 mJ.

j

3. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ resistor.

4. Equivalent to discharging a 200 pF capacitor through a 0.75 mH coil.

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

IC controller

R

R

th(j-a)

th(j-c)

thermal resistance from junction to ambient 70 K/W

thermal resistance from junction to case 31 K/W

Power FET

R

R

th(j-a)

th(j-c)

thermal resistance from junction to ambient 37 K/W

thermal resistance from junction to case 0.85 K/W

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part E”

.

1999 Apr 20 10

Page 11

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

CHARACTERISTICS

= −10 to +110 °C; Vin= 300 V; V

T

j

currents out of the chip are negative; all voltages are measured with respect to ground.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Input voltage and current on pin 9

V

dlow

I

in

I

in(off)

minimum start drain voltage 100 −−V

input current normal operation 20 60 100 µA

off mode current V

Start-up current source and Vaux management on pin 2

V

start

V

uvlo

V

hys

I

start(low)

I

start(high)

l

aux

I

restart(prot)

I

restart(stdby)

V

clamp

start-up voltage 10.4 11 11.6 V

under voltage lockout 7.4 8.05 8.6 V

operation voltage hysteresis V

start-up current 0 V < V

start-up current 0.5 V < V

IC supply current in high frequency mode 7.0 7.7 8.5 mA

restart current in protection mode −600 −530 −460 µA

restart current in stand-by mode −2.5 −2.1 −1.7 mA

clamp voltage level l

Reference input on pin 3

V

ref

R

ref

reference voltage capacitor pin Iref = 50 nF 2.37 2.47 2.57 V

operating resistor range 16.9 24.9 33.2 kΩ

Oscillator

f

osc-l

f

osc-h

δ

max

f

ratio

f

osc-h-range

low frequency low power mode;

high frequency normal mode;

maximum duty cycle f = f

ratio f

osc-h/fosc-l

range of f

osc-h

Demagnetization input on pin 6

V

th(comp)

t

PD

demag comparator threshold V

propagation delay to output

buffer

I

bias

V

clamp(neg)

V

clamp(pos)

input bias current V

negative clamp level I

positive clamp level I

Sample and hold input on pin 6

I

dem

l

) sample threshold current % of Idem 78 83 88 %

th(sh

t

PD

normal control current lref = 100 µA 90 100 110 µA

propagation delay of current

comparator

= 8.6 to 13 V; R

aux

= 24.9 kΩ±0.1%; all currents into the chip are positive and all

Iref

< 1.95 V 150 350 550 µA

OOB

start-Vuvlo

< 0.5 V −270 −230 −190 µA

aux

aux<Vstart

= 5 mA (non switching) 15 − 18 V

aux

2.60 2.95 3.30 V

−5.0 −3.0 −1.0 mA

27.5 29 30.5 kHz

C

=50nF

IREF

66 70 74 kHz

C

=50nF

IREF

osc-h

78 80 82 %

2.30 2.45 2.60

with changing R

decreasing 50 65 80 mV

dem

IREF

50 70 100 kHz

300 500 700 ns

=65mV −0.50

dem

= −500 µA −0.45 −0.35 0 V

dem

= 100µA 2.3 2.6 2.9 V

dem

(1)

−−0.10

(1)

µA

δVdemag/δt positive 170 450 730 ns

δVdemag/δt negative 20 90 160 ns

1999 Apr 20 11

Page 12

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Over voltage protection on pin 2

V

OVP

t

d(OVP)

Isense and low power on pin 1

t

LEB

V

th(Imax)

t

d

V

th(lopower)

Control

dδ/dV gain f

V

CTRL(min)

V

CTRL(max)

I

CTRL(leak)

absolute maximum OVP level fixed maximum level 14.0 14.7 15.5 V

OVP delay time 350 550 800 ns

leading edge blanking time R

= 0.7 × R

ref

R

ref=Rref(nom)

= 1.3 × R

R

ref

ref(nom)

ref(nom)

180 260 340 ns

240 340 440 ns

415 470 560 ns

maximum current limit voltage 0.46 0.49 0.53 V

delay to MOSFET off time to MOSFET off at

150 210 270 ns

dV/dt = 200 mV/µs;

Cgs = 500 pF

threshold voltage for switch over to low power 155 165 175 mV

−95 −85 −75 %/V

−60 −50 −40 %/V

2.00 2.15 2.30 V

minimum control voltage on

osc-h

f

osc-l

pin 4

maximum control voltage on

2.90 3.05 3.20 V

pin 4

leakage current in/out on

note 1 −1 − +1 µA

pin 4

Over temperature protection

T

trip

temperature limit 130 140 155 °C

On/off/burst mode selection input on pin 7

V

V

on/off

burst

on/off trip level 2.3 2.5 2.8 V

burst mode trip level active 6.5 − 7.5 V

inactive −−5.5 V

I

OOB

output current on pin OOB V

> 400 mV; note 1 −5 − -0.1 µA

OOB

Power MOSFET 7N60E; note 2

V

DS(break)

R

DS(on)

drain-to-source breakdown

voltage

drain-to-source on-state

resistance

Tj=25°C;

Vgs = 0 V; Id = 0.25 mA

Tj=25°C;

Vgs=10V;Vaux=10V;

600 −−V

− 1.0 1.2 Ω

Id = 7A

Notes

1. Min. and max. values are guaranteed by design.

2. The power MOSFET outputs of these devices are similar to the Philips Semiconductor type PHP7N60. These

devices feature an excellent combination of fast switching, ruggedized device design, low on-resistance and cost

effectiveness.

1999 Apr 20 12

Page 13

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

160

handbook, halfpage

P

(W)

120

80

40

0

0 40 80 160

MGR937

120

T

case

Fig.8 Normalised power derating.

(°C)

3

10

handbook, halfpage

C

j

(pF)

2

10

10

11010

Coss

2103

VDS (V)

Fig.9 Junction capacitance.

MGR939

handbook, halfpage

3

a

2

1

0

−80

a = R

DS(on)/RDS(on)

ID= 6.2A; V

aux

at 25 °C.

>10V.

0 16080

Tj (°C)

Fig.10 Normalised drain-to-source on-state

resistance.

MGR938

1.2

handbook, halfpage

a

1.1

1

0.9

−100 0 100 200

Tj (°C)

Fig.11 Normalised drain-to-source breakdown

voltage.

MGR940

1999 Apr 20 13

Page 14

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

handbook, full pagewidth

I

VS= 50V; I

V

= 0.5 V; V

dem

IVC= 6mA; V

L =25 mH

MAX

=7A

aux

CLAMP

closed

=11V

= 720V

open

vc

Vctrl

Vaux

Vin

TEA1566

Dem Gnd

Fig.12 Clamped inductive test circuit.

APPLICATION INFORMATION

A converter using the GreenChip is usually a flyback or

a Buck converter that is made up of the EMI filter, full

bridge rectifier, filter capacitor, transformer, output

stage(s), and some snubber circuitry.

Depending upon the type of feedback used, either an

auxiliary winding (primary regulation) or an opto-coupler

(secondary regulation) is used. GreenChip, due to its

high level of integration uses very few external

components. A sense resistor converts the primary current

into a voltage on pin Isense. The IC uses this information

for setting the peak current in the converter.

A capacitor supplied by an auxiliary winding buffers the

internal supply of the IC and is connected on pin Vaux.

L

V

MGR941

S

Isense

I

MAX

CURRENT

SENSING

CIRCUIT

CLAMP

CIRCUIT

The primary side auxiliary winding is connected via a

resistor to pin Dem. Besides being used for

demagnetization protection, pin Dem is also used for

primary side regulation.

Pin OBB is a multi use pin and depending upon connection

can be used for implementation of the on/off/burst mode

functions.

Pin 8 is not connected and serves as a high voltage spacer

pin.

Pin Vin is the connection for the drain of the internal power

MOSFET and is a high voltage pin. The internal start-up

current source also uses this pin as a supply for charging

up the Vaux capacitor during start-up and safe-restart

modes.

The auxiliary winding is also used for primary mode output

voltage regulation. A resistor connected on pin Iref sets

the reference currents in the IC. A small capacitor

(0.2 to 2 nF) connected on pin Vctrl is used by the internal

sample and hold circuit for regulation in primary feedback

scheme. The same pin is also used for secondary sensing

and serves as the input for the signal from the

opto-coupler.

Pin Gnd is the ground connection pin.

1999 Apr 20 14

GreenChip is a versatile IC that can be used in flyback

and Buck converter topologies and can be configured to

work in different modes. The application diagrams on the

next pages give some examples.

For additional information also see:

•

Application note AN98011: “200 W SMPS with

TEA1504”

•

Application note AN98058: “75 W SMPS with

TEA1566”

.

Page 15

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

handbook, full pagewidth

mains

TEA1566

9

8

7

6

5

4

3

2

1

Vin

NC

OOB

Dem

Gnd

Vctrl

Iref

Vaux

Isense

R

SENSE

C

R

DEM

R

REF

REF

C

R

AUX

OOB

S1

MGR697

R

CTRL

output

Fig.13 Typical flyback configuration with secondary sensing and on/off feature.

1999 Apr 20 15

Page 16

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

handbook, full pagewidth

mains

TEA1566

9

8

7

6

5

4

3

2

1

Vin

NC

OOB

Dem

Gnd

Vctrl

Iref

Vaux

Isense

R1

R2

S1

S2

output

from

microcontroller

microcontroller

supply

V

z

R3

Fig.14 Flyback configuration using the burst mode stand-by, MUVLO and on/off features.

1999 Apr 20 16

MGR698

Page 17

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

handbook, full pagewidth

mains

output

Vin

9

NC

8

OOB

7

Dem

6

Gnd

TEA1566

5

4

3

2

1

Vctrl

Iref

Vaux

Isense

MGR699

Fig.15 Typical Buck configuration with primary sensing.

handbook, full pagewidth

mains

output

Vin

9

NC

8

OOB

7

Dem

6

Gnd

TEA1566

5

Vctrl

4

Iref

3

Vaux

2

Isense

1

MGR700

Fig.16 Typical Buck configuration with secondary sensing.

1999 Apr 20 17

Page 18

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

PACKAGE OUTLINES

SIL9P: plastic single in-line power package; 9 leads

D

d

seating plane

b

SOT131-2

non-concave

x

E

h

view B: mounting base side

A

B

j

A

1

D

h

2

E

19

Z

DIMENSIONS (mm are the original dimensions)

A

UNIT A

mm

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

1

max.

2.0

OUTLINE

VERSION

SOT131-2

4.6

4.2

e

b

b

cD

max.

1.1

p2

0.75

0.48

0.60

0.38

IEC JEDEC EIAJ

b

p

(1)

24.0

23.6

REFERENCES

w M

0 5 10 mm

scale

deD

h

20.0

10 2.54

19.6

1999 Apr 20 18

E

12.2

11.8

L

c

Q

(1)

E

h

6

3.4

3.1

Lj

Q

17.2

2.1

16.5

1.8

EUROPEAN

PROJECTION

0.25w0.03

ISSUE DATE

92-11-17

95-03-11

(1)

Z

x

2.00

1.45

Page 19

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

DBS9P: plastic DIL-bent-SIL power package; 9 leads (lead length 12 mm)

non-concave

D

d

j

x

E

h

B

D

h

view B: mounting base side

A

2

E

A

SOT157-2

19

e

Z

DIMENSIONS (mm are the original dimensions)

UNIT A A e

17.0

15.5

4.6

4.2

mm

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

SOT157-2

1

e

(1)

cD

0.75

0.48

0.60

0.38

IEC JEDEC EIAJ

deD

24.0

20.0

23.6

19.6

w M

b

p

E

h

12.2

10 5.08

11.8

REFERENCES

0 5 10 mm

scale

(1)

12bp

2.54

e

5.08

L

3

L

E

2

h

6

Q

LL3m

3.4

12.4

3.1

11.0

c

m

e

2.4

1.6

PROJECTION

2

4.3

EUROPEAN

2.1

1.8

v M

(1)

v

Qj

0.8

0.25w0.03

ISSUE DATE

95-03-11

97-12-16

Z

x

2.00

1.45

1999 Apr 20 19

Page 20

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

SOLDERING

Introduction to soldering through-hole mount

packages

This text gives a brief insight to wave, dip and manual

soldering. A more in-depth account of soldering ICs can be

found in our

Packages”

Wave soldering is the preferred method for mounting of

through-hole mount IC packages on a printed-circuit

board.

Soldering by dipping or by solder wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joints for more than 5 seconds.

Suitability of through-hole mount IC packages for dipping and wave soldering methods

DBS, DIP, HDIP, SDIP, SIL suitable suitable

“Data Handbook IC26; Integrated Circuit

(document order number 9398 652 90011).

PACKAGE

The total contact time of successive solder waves must not

exceed 5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the

package, either below the seating plane or not more than

2 mm above it. If the temperature of the soldering iron bit

is less than 300 °C it may remain in contact for up to

10 seconds. If the bit temperature is between

300 and 400 °C, contact may be up to 5 seconds.

SOLDERING METHOD

DIPPING WAVE

(1)

stg(max)

). If the

Note

1. For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit board.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1999 Apr 20 20

Page 21

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

NOTES

1999 Apr 20 21

Page 22

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

NOTES

1999 Apr 20 22

Page 23

Philips Semiconductors Preliminary specification

GreenChip; SMPS module TEA1566

NOTES

1999 Apr 20 23

Page 24

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PT Philips Development Corporation, Semiconductors Division,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku,

TOKYO 108-8507, Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381, Fax +9-5 800 943 0087

Middle East: see Italy

Netherlands: Postbus 90050, 5600PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: see Singapore

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 319762,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 93 301 6312, Fax. +34 93 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2741 Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2886, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 62 5344, Fax.+381 11 63 5777

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1999 SCA63

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 295002/50/01/pp24 Date of release: 1999 Apr 20 Document order number: 9397 750 03312

Loading...

Loading...