Page 1

INTEGRATED CIRCUITS

DATA SH EET

TEA1205AT

High efficiency DC/DC converter

Preliminary specification

File under Integrated Circuits, IC03

1998 Mar 24

Page 2

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

FEATURES

• Fully integrated DC/DC converter circuit

• Up conversion in 2 different modes

• High efficiency over wide load range

• Synchronizes to external high frequency clock

• Output power up to 3.6 W (typ.) continuous, 8 W in GSM

burst mode

• Low quiescent power consumption

• True current limit for Li-ion battery compatibility

• Shut-down function

• 8-pin SO package.

APPLICATIONS

• Cellular and cordless phones PDAs and others

• Supply voltage source for low-voltage chip sets

• Portable computers

• Battery backup supplies

• Cameras.

GENERAL DESCRIPTION

The TEA1205AT (see Fig.1) is a fully integrated DC/DC

converter circuit using the minimum amount of external

components. It is intended to be used to supply electronic

circuits with supply voltages of 3.3 or 5.5 V from

2, 3 or 4 NiCd cell batteries or one Li-ion battery at an

output power level up to 3.6 W (typ.) continuously, or 8 W

in GSM TDMA (1 : 8) burst mode. The switching frequency

of the converter can be synchronized to an external

high-frequency clock. Efficient, compact and dynamic

power conversion is achieved using a novel, digitally

controlled Pulse Width and Frequency Modulation

(PWFM) like control concept, integrated low R

power switches with low parasitic capacitances and

synchronous rectification.

dsON

CMOS

ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

TEA1205AT SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

PACKAGE

1998 Mar 24 2

Page 3

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

O

V

start

Efficiency; see Figs 6 and 7

η efficiency

Current levels

I

q

I

SHDWN

I

limN

I

lx

Power MOSFETS

R

dsON(N)

R

dsON(P)

Timing

f

sw

t

res

f

sync

output voltage VSEL = LOW 5.23 5.55 5.85 V

VSEL = HIGH 3.13 3.34 3.54 V

start-up voltage 1.6 2.0 2.2 V

up from 2.4 to 3.3 V 1 mA < I

up from 3.6 to 5.5 V 1 mA < I

<1.0A 809095%

L

<1.0A 839094%

L

quiescent current at pin 3 50 60 70 µA

shut-down current − 210µA

NFET current limit note 1 0.9 I

limIlim

1.1 I

lim

A

max. continuous current at pin 5 −−1.0 A

pin-to-pin resistance NFET 0.08 0.12 0.20 Ω

pin-to-pin resistance PFET 0.10 0.16 0.25 Ω

switching frequency 150 200 240 kHz

response time from standby to P

max

− 25 −µs

synchronisation input frequency − 13 − MHz

Note

1. The NFET current limit is set by an external 1% accurate resistor R

The typical maximum instantaneous current is defined as: I

lim

connected between pin 7 and pin 6 (ground).

lim

= 890 V/ R

so the use of R

lim

= 315 Ω will lead to a

lim

typical maximum current value of 2.83 A. The average inductor current during current limit also depends on

inductance value and resistive losses in all components in the power path. In normal application and when using

R

= 315 Ω, the average inductor current will be limited to 2.3 A typical.

lim

1998 Mar 24 3

Page 4

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

1998 Mar 24 4

handbook, full pagewidth

BLOCK DIAGRAM

High efficiency DC/DC converter TEA1205AT

Philips Semiconductors Preliminary specification

5

LX

I/V

CONVERTER

N-type

POWER

FET

GND

sense

FET

ILIM

P-type POWER FET

CONTROL LOGIC

I

IimN

TEMPERATURE

PROTECTION

20 MHz

OSCILLATOR

16278

VSEL SYNC

MODE GEARBOX

START-UP

CIRCUIT

AND

ROM

DIGITAL CONTROLLER

SHDWN

TIME

COUNTER

TEA1205AT

BANDGAP

REFERENCE

3

OUT

4

SENSE

MGM696

Fig.1 Block diagram.

Page 5

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

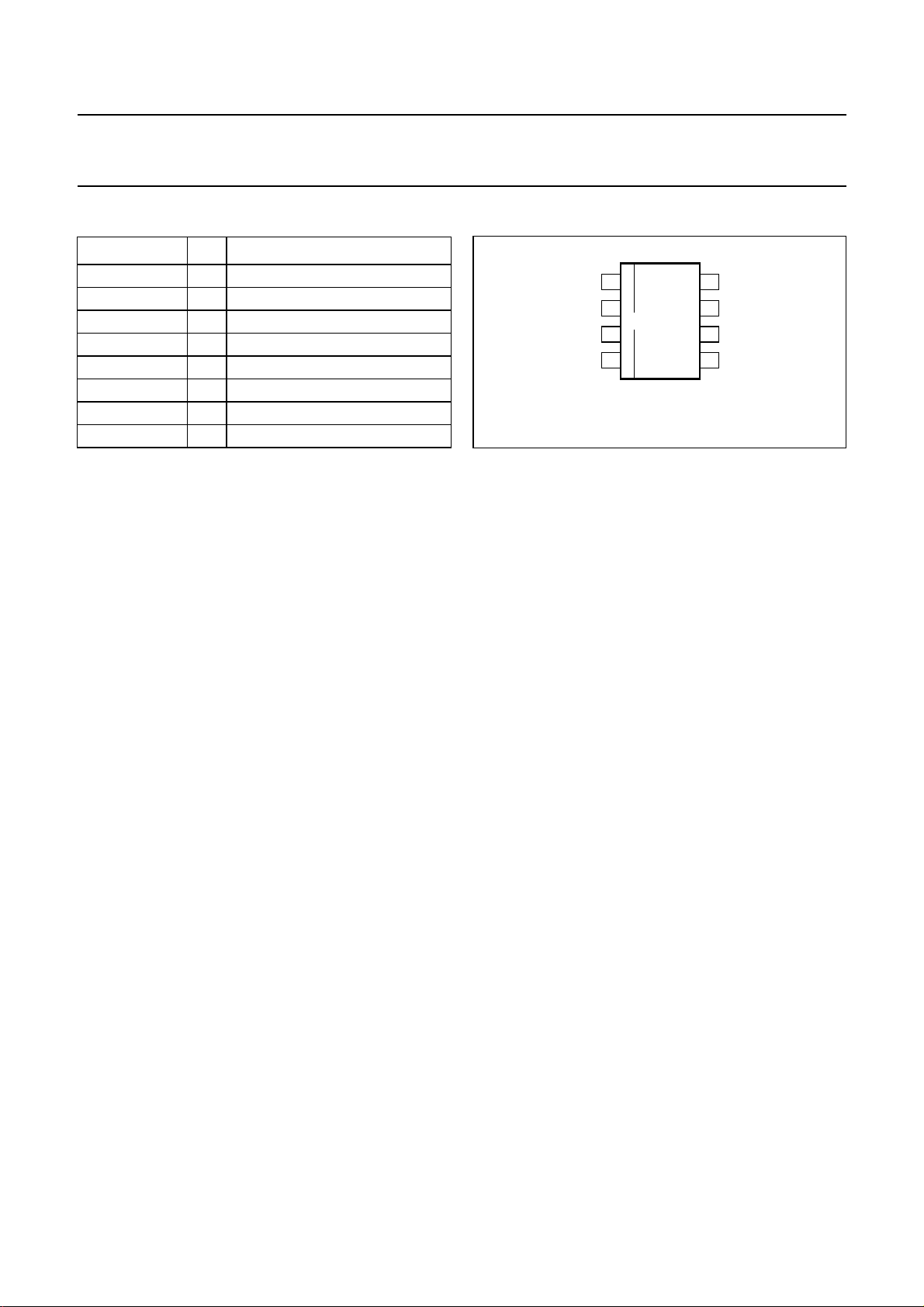

PINNING

SYMBOL PIN DESCRIPTION

VSEL 1 output voltage selection input

SYNC 2 synchronisation clock input

OUT 3 output voltage output

SENSE 4 output voltage sense input

LX 5 inductor connection

GND 6 ground

ILIM 7 current limit resistor connection

SHDWN 8 shut-down input

handbook, halfpage

1

VSEL SHDWN

2

SYNC ILIM

OUT GND

SENSE LX

TEA1205AT

3

4

8

7

6

5

MGM697

Fig.2 Pin configuration.

FUNCTIONAL DESCRIPTION

Control mechanism

The TEA1205AT DC/DC converter is able to operate in

discontinuous or continuous conduction operation.

All switching actions are completely determined by a

digital control circuit which uses the output voltage level as

its control input. This novel digital approach enables the

use of a new pulse width and frequency modulation

scheme, which ensures optimum power efficiency over the

complete range of operation of the converter. The scheme

works as follows. At low output power, a very small current

pulse is generated in the inductor, and the pulse rate

varies with a varying load. When the output voltage drops

below a specific limit, which indicates that the converter’s

current capability is not sufficient, the digital controller

switches to the next state of operation. The peak current in

the inductor is made higher, and the pulse rate can again

vary with a varying load. A third operation state is available

for again higher currents.

When high output power is requested, the device starts

operating in continuous conduction mode. This results in

minimum AC currents in the circuit components and hence

optimum efficiency, cost, and EMC. In this mode, the

output voltage is allowed to vary between two predefined

voltage levels. As long as the output voltage stays within

this so-called window, switching continues in a fixed

pattern. When the output voltage reaches one of the

window borders, the digital controller immediately reacts

by adjusting the pulse width and inserting a current step in

such a way that the output voltage stays within the window

with higher or lower current capability. This approach

enables very fast reaction to load variations. Figure 3

shows the various coil current waveforms for low and high

current capability in each power conversion mode.

Figure 4 shows the converter’s response to a sudden load

increase. The upper trace shows the output voltage.

The ripple on top of the DC level is a result of the current

in the output capacitor, which changes in sign twice per

cycle, times the capacitor’s internal Equivalent Series

Resistance (ESR). After each ramp-down of the inductor

current, i.e. when the ESR effect increases the output

voltage, the converter determines what to do in the next

cycle. As soon as more load current is taken from the

output the output voltage starts to decay. When the output

voltage becomes lower than the low limit of the window,

a corrective action is taken by a ramp-up of the inductor

current during a much longer time. As a result, the DC

current level is increased and normal continuous

conduction mode can continue. The output voltage

(including ESR effect) is again within the predefined

window.

Figure 5 depicts the spread of the output voltage window.

The absolute value is most dependent on spread, while the

actual window size is not affected. For one specific device,

the output voltage will not vary more than 4%.

Start-up

A possible deadlock situation in boost configuration can

occur after a sequence of disconnecting and reconnecting

the input voltage source. If, after disconnection of the input

source, the output voltage falls below 2.0 V, the device

may not restart properly after reconnection of the input

source, and may take continuous current from the input.

An external circuit to prevent the deadlock situation is

shown in Chapter “Application information”.

Shut-down

When the shut-down pin is made HIGH, the converter

disables both switches and power consumption is reduced

to a few µA.

1998 Mar 24 5

Page 6

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

Synchronisation function

In continuous conduction mode, the converter

switching frequency is synchronized to the signal at the

SYNC input, provided that this signal is present and its

frequency is 13 MHz. The switching frequency will than

be 26 times smaller than the applied input frequency at

the sync pin. If no sync signal is applied (Sync pin H

or L), the converter’s switching frequency will be

around 203 kHz, equally to behaviour at 13 MHz sync

input frequency, but with a larger tolerance. When this

function is not used, the SYNC pin must be tied to pin 3

or pin 6.

Power switches

The power switches in the IC are one N-type and one

P-type MOSFET, having a typical pin-to-pin resistance of

0.12 Ω and 0.16 Ω respectively. The maximum average

current in the switches is 1.0 A.

Temperature protection

At too high device temperature (typical 165 °C), the

converter stops operating. It resumes operation when the

device temperature falls below 165 °C again. As a result,

low-frequent cycling between on and off state will occur.

It should be noted that in the event of device temperatures

around the cut-off limit, the application differs strongly from

maximum specifications.

Behaviour at input voltage exceeding the specified

range

In general, an input voltage exceeding the specified range

is not recommended since instability may occur. However,

at an input voltage equal to or higher than the target output

voltage plus the diode voltage drop, but lower than 6 V, the

converter will stop switching and the external schottky

diode will take over, resulting in V

equalling Vi minus the

o

diode voltage drop (see Fig.8).

handbook, halfpage

low power

mode

medium power

mode 1

medium power

mode 2

low DC current

increasing

load

Current limit

If the current in the N-type power switch exceeds the limit

which is set by the value of the external resistor, current

ramping is stopped immediately, and the next switching

phase is entered. Current limitation is required to enable

optimal use of energy in Li-ion batteries, and to keep

power conversion efficient during temporary high loads.

Furthermore, current limitation protects the IC against

overload conditions, inductor saturation, etc.

1998 Mar 24 6

high DC current

time

MGK924

Fig.3 Coil current waveforms in the various power

modes.

Page 7

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

handbook, full pagewidth

load increase

V

o

I

L

start corrective action

time

time

high window limit

low window limit

MGK925

Fig.4 Response to load increase.

handbook, full pagewidth

5.85

V

o

(V)

5.66

5.44

5.23

V

4%

h

V

l

maximum positive spread

V

h

+3%

4%

V

l

+3%

maximum negative spreadtypical situation

Fig.5 Output voltage window position at typical, maximum and minimum specification.

1998 Mar 24 7

−3%

−3%

4%

upper specification limit

V

h

V

l

lower specification limit

MGM698

Page 8

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

n

T

j

T

amb

T

stg

V

es

Note

1. Human body model: equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

voltage on any pin shut-down mode −0.2 +6.5 V

operational mode −0.2 +5.9 V

junction temperature −25 +150 °C

operating ambient temperature −40 +80 °C

storage temperature −65 +125 °C

electrostatic handling note 1 −3000 +3000 V

thermal resistance from junction to ambient in free air 150 K/W

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part E”

Reference Handbook”

. The handbook can be ordered using the code 9397 750 00192.

. The numbers of the quality specification can be found in the

“Quality

CHARACTERISTICS

= −20 to +80 °C; all voltages with respect to ground; positive currents flow into the IC; unless otherwise specified.

T

j

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

O

output voltage VSEL = LOW 5.23 5.55 5.85 V

VSEL = HIGH 3.13 3.34 3.54 V

V

start

start-up voltage 1.6 2.0 2.2 V

Efficiency

η efficiency

up from 2.4 to 3.3 V 1 mA < I

up from 3.6 to 5.5 V 1 mA < I

<1.0A 809095%

L

<1.0A 839094%

L

Current levels

I

q

I

SHDWN

I

limN

I

lx

quiescent current at pin 3 50 60 70 µA

shut-down current − 210µA

NFET current limit note 1 0.9 I

limIlim

1.1 I

lim

A

max. continuous current at pin 5 −−1.0 A

Power MOSFETS

R

dsON(N)

R

dsON(P)

pin-to-pin resistance NFET 0.08 0.12 0.20 Ω

pin-to-pin resistance PFET 0.10 0.16 0.25 Ω

1998 Mar 24 8

Page 9

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Timing

f

sw

t

res

f

sync

Temperature

T

amb

T

max

Digital levels

V

lL

V

IH

V

IH

V

IH

Sense pin resistance

R

SENSE

switching frequency 150 200 240 kHz

response time from standby to

P

max

− 25 −µs

synchronisation input frequency − 13 − MHz

operating ambient temperature −20 +25 +80 °C

internal cut-off temperature 150 165 180 °C

LOW-level input voltage pins

0 − 0.4 V

1, 2, 7 and 8

HIGH-level input voltage pin 1 note 2 V3− 0.4 − V3+ 0.3 V

HIGH-level input voltage pin 2 notes 2 and 3 2.0 − V3+ 0.3 V

HIGH-level input voltage pin 8 notes 2 and 3 2.9 − V3+ 0.3 V

SENSE pin resistance to GND up to 3.3 V mode 437.2 546.5 655.8 kΩ

up to 5.0 V mode 662.2 827.8 993.4 kΩ

Notes

1. The NFET current limit is set by an external 1% accurate resistor R

The typical maximum instantaneous current is defined as: I

lim

connected between pin 7 and pin 6 (ground).

lim

= 890 V/ R

so the use of R

lim

= 315 Ω will lead to a

lim

typical maximum current value of 2.83 A. The average inductor current during current limit also depends on

inductance value and resistive losses in all components in the power path. In normal application and when using

R

= 315 Ω, the average inductor current will be limited to 2.3 A typical.

lim

2. V3 is the voltage at pin 3 (OUT).

3. If the applied high level is less than V3− 1 V, the quiescent current level of the device will increase. The maximum

increase is 300 µA in the event that pin 2 is at 2.0 V.

1998 Mar 24 9

Page 10

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

100

handbook, full pagewidth

efficiency

(%)

90

80

70

60

50

40

−1

10

Using a Coilcraft DO3308P 10 µH inductor and a Sprague 595D 330 µF capacitor.

The dotted line represents the Pulse Frequency Modulation (PFM) and the solid line the Pulse Width Modulation (PWM).

110 10

PFM

10

Fig.6 Efficiency as a function of load current IL (2.4 to 3.3 V).

2

PWM

IL (mA)

MGM699

3

100

handbook, full pagewidth

efficiency

(%)

90

80

70

60

50

40

−1

10

Using a Coilcraft DO3308P 10 µH inductor and a Sprague 595D 330 µF capacitor.

The dotted line represents the Pulse Frequency Modulation (PFM) and the solid line the Pulse Width Modulation (PWM).

PFM

110 10

10

Fig.7 Efficiency as a function of load current IL (3.6 to 5.5 V).

PWM

2

IL (mA)

MGM700

3

1998 Mar 24 10

Page 11

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

APPLICATION INFORMATION

handbook, full pagewidth

C1

L1

LX

ILIM

GND VSEL SYNC SHDWN

V

I

Fig.8 Complete application for upconversion.

A typical component choice for an upconverter from

3 NiCd cells or one Li-ion cell to 5.0 V in a GSM handset

(peak power 7.5 W, peak current 2.7 A) is (see Fig.8):

• L1 = 10 µH; I

> 2.3 A; low DC resistance, e.g.

sat

Coilcraft DO3308-103

• C1 = 100 µF; low ESR capacitor; necessity depends on

type of input voltage source

• C2 = 330 µF; ESR = 0.1 Ω; e.g. Sprague 595D series

• D1; medium power Schottky diode; e.g. Philips

PRLL5819.

D1

C2

MGM701

V

O

TEA1205AT

R

lim

OUT

SENSE

SHDWN pin. TR1, R1 and R2 should be omitted in that

case.

More application information can be found in the

associated application note.

For lower power applications, the I

and RDC values of

sat

the inductor can be scaled back by the scaling factor of the

output current from the values above. The same holds for

the ESR value of the output capacitor. A further

improvement is increase of inductance and decrease of

output capacitance.

An additional circuit to prevent start-up deadlock in

upconversion is shown in Fig.9. The function of TR1, R1

and R2 is to put the converter into shut-down mode when

the input source is suddenly disconnected. The circuit

operates as follows. When VI is present, TR1 conducts

and the SHDWN pin is kept LOW. As soon as VI falls below

1 V, TR1 no longer conducts and the device is put into

shut-down before VO falls below 2 V. In the event that a

signal is available which indicates the presence of the

input voltage source, this signal should be applied to the

1998 Mar 24 11

handbook, halfpage

R2

V

I

2.7 MΩ

V

O

R1

1 MΩ

TR1

Fig.9 External deadlock prevention circuit.

SHDWN

MGK930

Page 12

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

PACKAGE OUTLINE

SO8: plastic small outline package; 8 leads; body width 3.9 mm

D

c

y

Z

8

pin 1 index

1

e

5

A

2

A

4

w M

b

p

SOT96-1

E

H

E

1

L

detail X

A

X

v M

A

Q

(A )

L

p

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT96-1

A

max.

1.75

0.069

A

1

0.25

0.10

0.010

0.004

A2A

1.45

1.25

0.057

0.049

IEC JEDEC EIAJ

076E03S MS-012AA

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

UNIT

inches

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

4.0

3.8

0.16

0.15

1.27

0.050

1998 Mar 24 12

eHELLpQZywv θ

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

6.2

5.8

0.244

0.228

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

95-02-04

97-05-22

o

8

o

0

Page 13

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(order code 9398 652 90011).

Reflow soldering

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

Wave soldering

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

1998 Mar 24 13

Page 14

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1998 Mar 24 14

Page 15

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1205AT

NOTES

1998 Mar 24 15

Page 16

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213, Tel. +43 160 1010,

Fax. +43 160 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: seeSouth America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15thfloor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 689 211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. +45 32 88 2636, Fax. +45 31 57 0044

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615800, Fax. +358 9 61580920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 40 99 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 23 53 60, Fax. +49 40 23 536 300

Greece: No. 15, 25th March Street, GR 17778 TAVROS/ATHENS,

Tel. +30 1 4894 339/239, Fax. +30 1 4814 240

Hungary: seeAustria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 3 301 6312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 632 2000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2686, Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2865, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 625 344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1998 SCA57

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 415102/1200/01/pp16 Date of release: 1998 Mar 24 Document order number: 9397 750 03344

Loading...

Loading...