Page 1

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

FEATURES

The DSIC2 realizes the following servo functions:

• Diode signal preprocessing

• Focus servo loop

• Radial servo loop

• Sledge motor servo loop

• Three-line serial interface via the microcontroller

The other features include:

• Full digital signal processing

• Low power consumption, down to 30 mW

• Low voltage supply 3 to 5.5 V

• Integrated analog-to-digital converters and digital servo

loop filters

• Double speed possible

• Easy application

– Single supply voltage

– Small number of external components; only

6 decoupling capacitors

– Flexible system oscillator circuitry

– Usable for single/double Foucault and astigmatic

focus

– Full automatic radial error signal initialization offset

control and level initialization for track position

indicator

– No external adjustments required; no component

ageing

– Wide range of adjustable servo characteristics

– Simple 3-line serial command interface

– 28-pin SO package

– Great flexibility towards different CD mechanisms

– Full and transparent application information

• High robustness/shock insensitivity

– Sophisticated track-loss (TL) detection mechanism

– Fast focus restart procedure

– Extended radial error signal

– Adjustable radial shock detector

– Defect drop-out detector

• Fully automatic jump procedure for radial servo

• Automatic focus start-up procedure and built-in FOK

(Focus OK)

• Fast radial jump or access procedure

• Self-operational servo-control without continuous

communication via the microcontroller

• Direct communication to photodiode optics; no external

preprocessing.

GENERAL DESCRIPTION

The TDA1301T is a fully digital servo processor which has

been designed to provide all servo functions, except the

spindle motor control, in two-stage three-spot compact

disc systems. The device offers a high degree of

integration, combined with the low additional cost of

external components. The servo characteristics have a

wide range of adjustment via a three-line serial interface.

This offers an enormous flexibility with respect to

applications for different CD mechanisms. The circuit is

optimized for low-power low-voltage applications.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DDD

V

DDA

I

DDD

I

DDA

I

DDD(q)

I

i(cd)

I

i(sd)

P

tot

T

amb

digital supply voltage 3.0 − 5.5 V

analog supply voltage 3.0 − 5.5 V

digital supply current − 5 − mA

analog supply current − 5 − mA

digital quiescent supply current − − 10 µA

central diode input currents (D1 to D4) note 1 − − 15.8 µA

satellite diode input currents (R1 and R2) note 1 − − 7.9 µA

total power dissipation − 50 − mW

operating ambient temperature −40 − +85 °C

Note

1. f

= 4.2336 MHz; VRL = 0 V; VRH = 2.5 V (externally applied).

sys

March 1994 2

Page 2

Philips Semiconductors Product specification

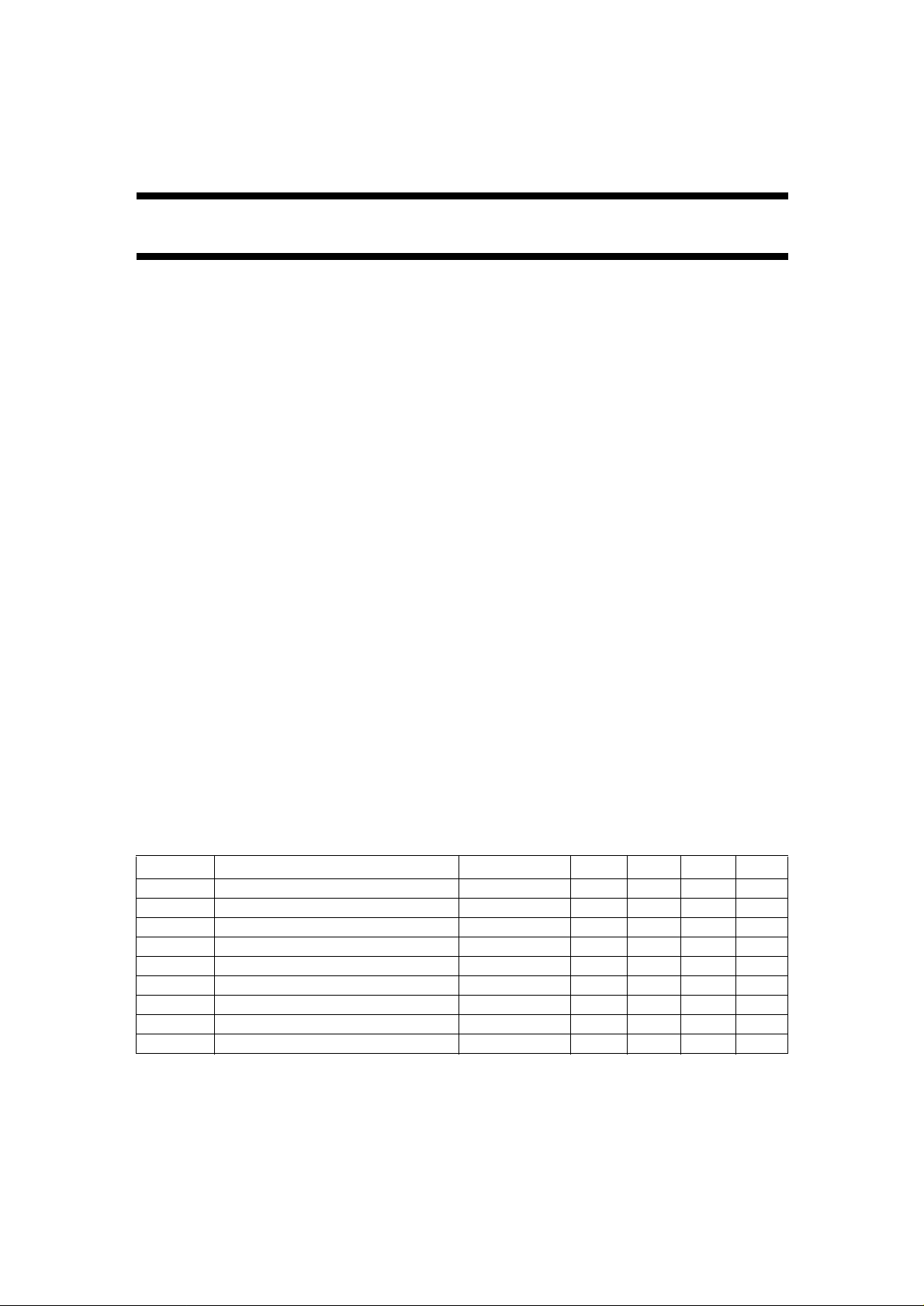

Fig.1 Block diagram.

Digital servo processor (DSIC2) TDA1301T

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

TDA1301T 28 SO28L plastic SOT136A

BLOCK DIAGRAM

PINS PIN POSITION MATERIAL CODE

PACKAGE

March 1994 3

Page 3

Philips Semiconductors Product specification

Fig.2 Pin configuration.

Digital servo processor (DSIC2) TDA1301T

PINNING

SYMBOL PIN DESCRIPTION

RST 1 reset input (active LOW)

LDON 2 laser drive on output

V

SSA

V

RH

D1 5 unipolar current input

D2 6 unipolar current input

D3 7 unipolar current input

V

RL

D4 9 unipolar current input

R1 10 unipolar current input

R2 11 unipolar current input

V

DDA

XTAL

TEST1 14 test input 1

TEST2 15 test input 2

OTD 16 off-track detector output

CLKO 17 clock output

XTALO 18 oscillator output

XTALI 19 oscillator input

V

DDD1

V

SSD

RA 22 radial actuator output

FO 23 focus actuator output

SL 24 sledge output

SILD 25 serial interface load input

SICL 26 serial interface clock input

SIDA 27 serial interface data input/output

V

DDD2

3 analog ground

4 reference input for reference voltage

generator

(central diode signal input)

(central diode signal input)

(central diode signal input)

8 reference input for ADC

(central diode signal input)

(satellite diode signal input)

(satellite diode signal input)

12 analog supply voltage

13 oscillator reference input

ref

20 digital power supply 1

21 digital ground

28 digital power supply 2

March 1994 4

Page 4

Philips Semiconductors Product specification

–

]

]

4–

D3 D4+

----------------------

–=

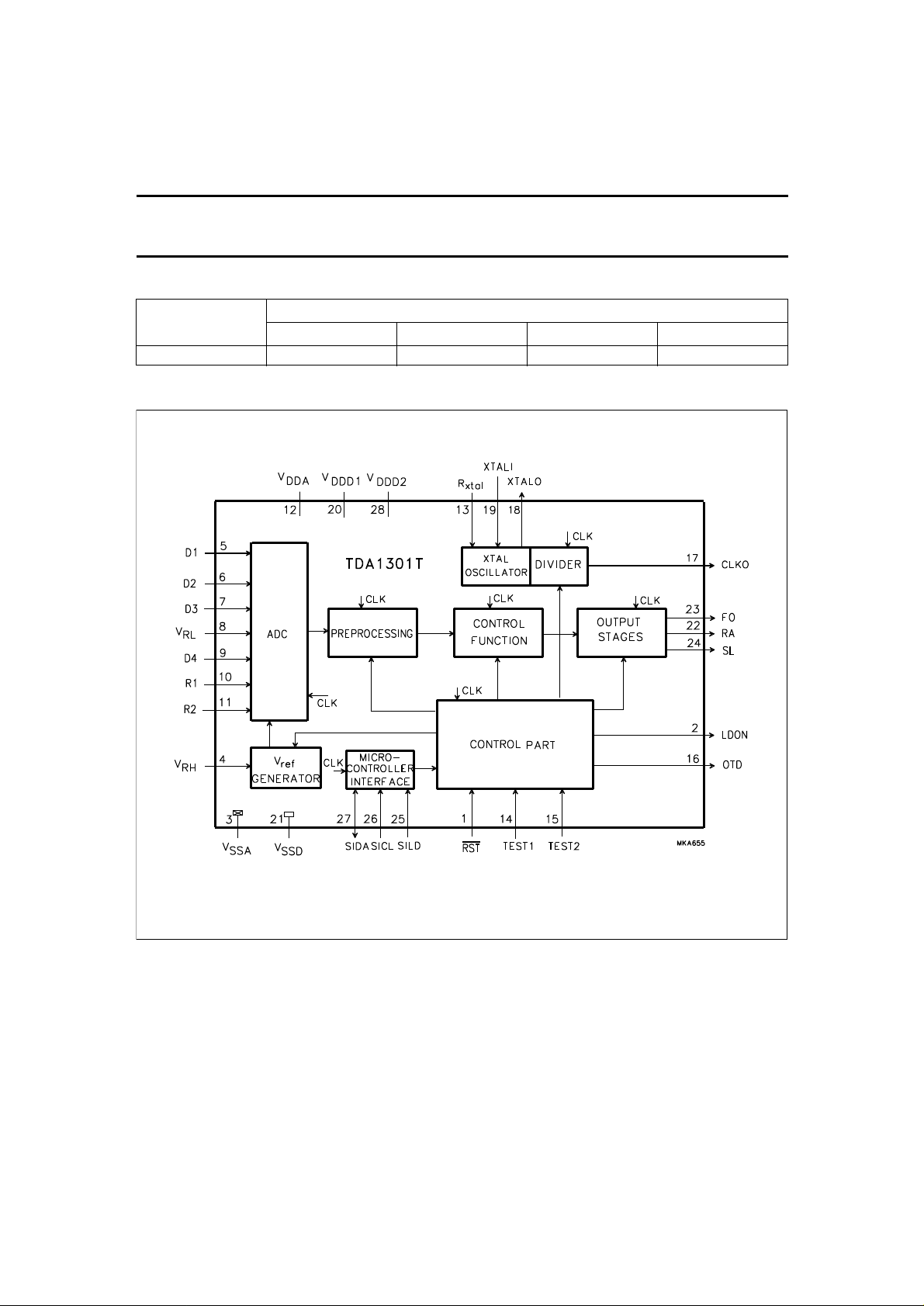

Fig.3 Diode configuration.

Digital servo processor (DSIC2) TDA1301T

FUNCTIONAL DESCRIPTION

Three spots front-end

The photo detector in a two-stage three-spots compact

disc system normally contains six discrete elements. Four

of these elements (in the event of single Foucault: three

elements) carry the central aperture (CA) signal while the

other two elements (satellite signals) carry the radial

tracking information. Besides the HF signal, which is finally

applied to both of the audio channels, the central aperture

also contains information for the focus servo loop. To

enable the HF signal to be processed, the frequency

contents of the central aperture signal must be divided into

an HF data part and an LF servo part. The HF signal is

processed outside the DSIC2 by the TDA1302 or a

discrete amplifier-equalizer. The necessary crossover

point, to extract the LF servo part, is compensated for in

the amplifier.

Diode signal processing

The analog signals from the photo detectors are converted

into a digital representation using analog-to-digital

converters. The ADCs are designed to convert unipolar

currents into a digital code. The dynamic range of the input

currents is adjustable within a given range and is

dependent on the ADC input reference voltages V

and

RL

VRH. The maximum current for the central diodes signals

is given in equation (1).

I

i max( )fsysVRHVRL

( ) 1.5 106–×××= µA[

(1)

The maximum current for the satellite signals is given in

equation (2).

I

i max( )fsysVRHVRL

V

is generated internally. There are four different levels

RH

–( ) 0.75 106–×××= µA[

(2)

(1.0, 1.5, 2.0 and 2.5 V) which can be selected under

software control. In the application VRL is connected to

V

. It is also possible to drive VRH with an external

SSA

voltage source but in this situation the internal voltage

source has to be switched off (software controlled).

Signal conditioning

The digital codes retrieved from the ADCs are applied to

logic circuitry to obtain the various control signals. The

signals from the central aperture detectors are processed

so that the normalized focus error signal (FE) given in

equation (3) is realized:

FE

n

D1 D2–

---------------------D1 D2+

D3 D

(3)

Where the detector set-up is assumed to be as illustrated

in Fig.3.

March 1994 5

Page 5

Philips Semiconductors Product specification

( )

R1 R2+( ) Sum_gain×–

[]sin=

Digital servo processor (DSIC2) TDA1301T

In the event of single Foucault focusing method, the DSIC2

signal conditioning can be switched under software control

so that the signal processing conforms to that given in

equation (4).

FEn2

×=

---------------------D1 D2+

(4)

D1 D2–

The FEn thus obtained is further processed by a

proportional integral and differential filter section (PID).

A focus OK flag (FOK) is generated by means of the

central aperture signal and an adjustable reference level.

This signal is used to provide extra protection for the

Track-Loss (TL) generation, the focus start-up procedure

and the drop-out detection. The radial or tracking error

signal is generated by the satellite detector signals R1 and

R2. The radial error signal (RE) can be formulated as per

equation (5).

RE

=

s

R1 R2–( ) RE_gain×

R1 R2+( ) RE_offset×

+

(5)

Where the index ‘s’ indicates the automatic scaling

operation which is performed on the radial error signal.

This scaling is necessary to avoid non-optimum dynamic

range usage in the digital representation and, also, to

reduce radial bandwidth spread. The radial error signal will

also be released from offset during disc start-up. The four

signals from the central aperture detectors, together with

the satellite detector signals, generate a track position

signal (TPI) which can be formulated as per equation (6).

TPI D1 D2 D3 D4+ + +

(6)

Where the weighting factor Sum_gain is generated

internally in the DSIC2 during initialization.

Focus control

The following focus servo functions are incorporated in the

DSIC2 digital controller.

OCUS START-UP

F

Five initially loaded coefficients influence the start-up

behaviour of the focus controller. The automatically

generated triangular voltage can be influenced by

3 parameters, for the height (ramp_heigth) and DC-offset

(ramp_offset) of the triangle and its steepness (ramp_inc).

To protect against false focus point detections two

parameters are available. One is an absolute level on the

CA signal (CA_start) and the other is an absolute level on

the FEn signal (FE_start). When the CA_start level is

reached, the FOK signal becomes true. If the FOK signal

is true when the level on the FEn signal is reached the

focus PID is enabled and switches on when the next zero

crossing is detected in the FEn signal.

FOCUS POSITION CONTROL LOOP

The focus control loop contains a digital PID controller

which has 5 parameters available to the user. These

coefficients influence the integrating (foc_int), proportional

(foc_prop) and differentiating (foc_pole_lead) action of this

PID and the digital low-pass filter (foc_pole_noise) which

follows the PID. The fifth coefficient (foc_gain) influences

the loop gain.

D

ROP-OUT DETECTION

This detector can be influenced by one parameter

(CA_drop). The FOK signal will become false and the

integrator of the PID will hold if the CA signal drops below

the programmed absolute CA level. When the FOK signal

becomes false it is assumed, initially, to be caused by a

black dot.

FOCUS LOSS DETECTION AND FAST RESTART

Whenever FOK is false for longer than approximately

3 ms, it is assumed that the focus point is lost. A fast

restart procedure is initiated which is capable of restarting

the focus loop within 200 to 300 ms depending on the

programmed coefficients set by the microcontroller.

FOCUS LOOP GAIN SWITCHING

The gain of the focus control loop (foc_gain) can be

multiplied by a factor of 2 or divided by a factor of 2 during

normal operation. The integrator value of the PID is

corrected accordingly. The differentiating (foc_pole_lead)

action of the PID can be switched at the same time as the

gain switching is performed.

Radial control

The following radial servo functions are incorporated in

the DSIC2 digital controller.

LEVEL INITIALIZATION

During start-up an automatic adjustment procedure is

activated to set the values of the radial error gain

(RE_gain), offset (RE_offset) and satellite sum signal gain

(Sum_gain) for TPI level generation. The initialization

procedure runs in a radial open-loop situation and is

≤300 ms. This start-up time period may coincide with the

last part of the turn table motor start-up time period.

March 1994 6

Page 6

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

Automatic gain adjustment: as a result of this initialization

the amplitude of the RE signal is adjusted within 10%

around the nominal RE amplitude.

Offset adjustment: the additional offset in RE due to

the limited accuracy of the start-up procedure is less

than 50 nm.

TPI level generation: the accuracy of the initialization

procedure is such that the duty cycle range of TPI

becomes 0.4 < δ < 0.6 {δ = TPI(HIGH)/TPI(period)}.

SLEDGE HOME

Sledge moves to reference position (end_stop_switch) at

the inner side of the disc with user defined voltage.

T

RACKING CONTROL

The actuator is controlled using a PID loop-filter with user

defined coefficients and gain. For stable operation

between the tracks, the S-curve is extended over3⁄4 track.

Upon request from the microcontroller S-curve extension

over 2 tracks is used, automatically changing to access

control when these two tracks are exceeded.

Both modes of S-curve extension make use of a

track-count mechanism as described in Section “Off-track

counting” . In this mode track counting results in automatic

‘return-to-zero track’, to avoid major music rhythm

disturbances in the audio output to provide improved

shock resistance. The sledge is continuously controlled

using the filtered value of the integrator contents of the

actuator, or upon request by the microcontroller. The

microcontroller can read out this integrator value and

provides the sledge with step pulses to reduce power

consumption. Filter coefficients of the continuous sledge

control can be preset by the user.

ACCESS

The access procedure is divided into 2 different modes,

depending on the requested jump size.

The access procedure makes use of a track counting

mechanism (see Section “Off-track counting” ), a velocity

signal based upon the number of tracks passed within a

fixed time interval, a velocity setpoint calculated from the

number of tracks to go and a user programmable

parameter indicating the maximum sledge performance.

If the number of tracks to go is greater than break_dist the

sledge jump mode will be activated (otherwise the actuator

jump will be performed). The requested jump size together

with the required sledge braking distance at maximum

access speed defines the value break_dist.

During the actuator jump mode, velocity control with a PI

controller is used for the actuator.

The sledge is then continuously controlled using the

filtered value of the integrator contents of the actuator.

All filter parameters (for actuator and sledge) are user

programmable.

In the sledge jump mode, maximum power (user

programmable) is applied to the sledge in the correct

direction, while the actuator becomes Idle (the contents of

the actuator integrator leaks to zero just after the sledge

jump mode is initiated).

Table 1 Access procedure.

ACCESS

TYPE

Actuator

JUMP SIZE ACCESS SPEED

1 − break distance

(1)

decreasing velocity

jump

Sledge

jump

break

(1)

− 32768 minimum power to

sledge

(1)

Note

1. Can be preset by the microcontroller.

Defect detector

A built-in defect detector prevents the light spot from going

out-of-focus and going off-track due to disc drop-out

excitations. The defect detector can be switched ON or

OFF under software control and can be applied to the

focus control only, or to both the focus and radial control.

The detected defect signal holds the focus and radial loop

filter outputs. The hold signal is generated whenever the

reflected light intensity drops rapidly (<1.5 ms) down to

75% of the actual intensity level.

Shock detector

The shock detector can be switched ON during normal

track following. The shock detector detects, within an

adjustable frequency band, whether the disturbances in

the radial spot position relative to the track exceeds an

adjustable level. Every time the radial tracking error (RE)

exceeds this level the radial control bandwidth is switched

directly to twice the original bandwidth.

The shock detection level is adjustable in 64 steps from

0 to 100% of the nominal radial amplitude. The bandpass

filter (BPF) lower frequency (−3 dB) can be fixed at 0 or

20 Hz. Independently, the BPF upper frequency (−3 dB)

can be fixed at 750 or 1850 Hz.

Off-track counting

TPI is a flag which is used to indicate whether the spot is

positioned on the track (with a margin of 1⁄4 of the

track-pitch).

March 1994 7

Page 7

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

In combination with the radial polarity flag (RP) the relative

spot-position over the tracks can be determined. These

signals are, however, affected with some uncertainties

caused by:

• Disc defects such as scratches and fingerprints.

• The HF information on the disc, which is considered as

noise by the detector signals.

In order to determine the spot position with sufficient

accuracy, extra conditions are necessary to generate a TL

signal as well as an off-track counter value. These extra

conditions influence the maximum speed and this implies

that, internally, one of the three following counting states is

selected. These states are:

1. Protected state: used in normal play situations.

A good detection caused by disc defects is important

in this state.

2. Slow counting state: used in low velocity track jump

situations.

In this state a fast response is important rather than

the protection against disc defects (if the phase

relationship between TL and RP of a1⁄2π rad is affected

too much, the direction cannot be determined

accurately any more).

3. Fast counting state: used in high velocity track jump

situations.

Highest obtainable velocity is the most important

feature in this state.

Off-track detection

During active radial tracking, off-track detection is realized

by continuously monitoring the off-track counter value. The

off-track flag (OTD) becomes valid whenever the off-track

counter value is not equal to zero. Depending on the type

of extended S-curve the off-track counter will be reset after

3

⁄4 extend or at the original track in the 21⁄4 track extend

mode.

Output stages

The control signals for the different actuators are 1-bit

noise shaped digital outputs at 1.0584 MHz. An analog

representation of the output signals can be achieved by

connecting a first-order low-pass filter to the outputs.

When the

sledge output stages are 3-state.

Serial interface

To control the DSIC2 operation, a serial interface is

implemented which allows communication with a

microcontroller via a 3-line serial bus consisting of:

RST pin is held LOW, the focus, radial and

• Serial clock line (SICL

• Serial data line (SIDA)

• Serial control line (SILD).

The SICL line is controlled by a microcontroller and can be

completely asynchronous from the oscillator frequency of

the DSIC2. The SILD line is used for read/write control and

end-of-byte signalling.

The communication is bi-directional and processes 8-bit

words (1 byte, MSB first). The data present on the SIDA

line is clocked on the positive edge of SICL. One

information exchange consists of one command byte and

up to 7 data bytes.

The first byte defines the command, and is always input to

the DSIC2. This byte defines if data has to be written to or

read from the DSIC2. If data has to be written to the DSIC2

this byte also specifies the number of data bytes. The

number of bytes read from the DSIC2 can vary from 0 up

to 5 and only depends on how many the microprocessor

requires to read. Further information concerning the serial

protocol is available upon request.

Clock generation

The DSIC2 operates with an internal clock frequency of

approximately 4 MHz. The circuit that generates the clock

has three modes: the oscillator frequency divided by 2, 3

or 4 (software controlled). It is therefore possible to

connect a crystal or a resonator with a frequency of

8.4672, 11.2896 or 16.9344 MHz. These frequencies are

derived from today’s frequently used decoder IC

frequencies. It is also possible to drive the clock circuit with

an external clock signal. The clock buffer output (CLKO)

can supply the system clock or twice the system clock

(also switchable under software control via the serial bus)

to be used as a clock generator for other ICs. The oscillator

circuit is optimized for low power dissipation. To guarantee

optimum performance with a quartz crystal or a resonator

the gain of the oscillator can be adjusted by an external

resistor connected to the XTAL

Reset

The reset is controlled by means of the

LOW). This circuit ensures proper initialization of the

digital circuit and the output stages.

Laser drive on

The LDON pin is used to switch the laser drive OFF and

ON. It is an open-drain output. When the laser is ON, the

output has a high impedance.

ref

input.

RST pin (active

March 1994 8

Page 8

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

DDD

V

DDA

∆V

SS

P

max

T

stg

T

amb

HANDLING

Classification A: human body model; C = 100 pF; R = 1500 Ω; V ≥ 2000 V.

Charge device model: C = 200 pF; R = 0 Ω; V ≥ 250 V.

Pulse widths in accordance with

pocket-book”

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

digital supply voltage 0 6.5 V

analog supply voltage 0 6.5 V

difference in ground supply voltage between V

SSA

and V

−5.0 +5.0 mV

SSD

maximum power dissipation − 100 mW

storage temperature −65 +150 °C

operating ambient temperature −40 +85 °C

“UZW-BO/FQ-A302 and B302”

are applicable and can be found in the

“Quality reference

(ordering number 9398 510 34011).

from junction to ambient in free air 80 K/W

March 1994 9

Page 9

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

CHARACTERISTICS

V

= V

DDA

= 5 V; V

DDD

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

DDD

V

DDA

I

DDD

I

DDA

I

DDD(q)

P

tot

digital supply voltage 3.0 − 5.5 V

analog supply voltage 3.0 − 5.5 V

digital supply current − 5 − mA

analog supply current − 5 − mA

quiescent current − − 60 µA

total power dissipation −40 − +85 °C

Analog part

I

i(cd)max

maximum input current for

central diode input signal

I

i(sd)max

maximum input current for

satellite diode input signal

V

RH

HIGH level reference voltage note 2

output stage 1 0.9 1.0 1.1 V

output stage 2 1.35 1.5 1.65 V

output stage 3 1.8 2.0 2.2 V

output stage 4 2.25 2.5 2.75 V

PSRR power supply ripple rejection

at pin 4

V

RH

V

RL

HIGH level reference voltage input state; note 4 0.5 − V

LOW level reference voltage 0 V

(THD+N)/S total harmonic distortion plus

signal-to-noise ratio

S/N signal-to-noise ratio − 55 − dB

PSRR power supply ripple rejection

at pin 12

G

tol

gain tolerance note 6 −10 − +15 %

∆G variation of gain between

channels

α

cs

channel separation − 60 − dB

Digital part

I

NPUTS: TEST1, TEST2, SICL AND SILD

V

IL

V

IH

I

LI

LOW level input voltage T

HIGH level input voltage T

input leakage current − − 10 µA

INPUT: NRST

V

IL

V

IH

I

LI

LOW level input voltage T

HIGH level input voltage T

input leakage current − − 10 µA

SSA

= V

SSD

= 0 V; T

= 25 °C; unless otherwise specified.

amb

note 1 − 15.8 − µA

note 1 − 7.9 − µA

note 3 45 55 − dB

DDA

− 1.5 − V

DDA

at 0 dB; note 5 − −50 −45 dB

note 3 − 45 − dB

− − 2 %

= −40 to +85 °C − − 0.3V

amb

= −40 to +85 °C 0.75V

amb

= −40 to +85 °C − − 0.2V

amb

= −40 to +85 °C 0.8V

amb

− − V

DDD

− − V

DDD

− 0.5 V

DDD

DDD

V

V

March 1994 10

Page 10

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

OUTPUTS: CLKO AND OTD

I

OL

I

OH

t

r

t

f

OUTPUT: LDON

I

OL

I

OZ

t

r

t

f

OUTPUTS; RA, FO AND SL

I

OL

I

OH

I

OZ

t

r

t

f

INPUT/OUTPUT: SIDA

V

IL

V

IH

I

OL

I

OH

I

OZ

t

r

t

f

OSCILLATOR

f

osc

C

i

C

o

C

fb

R

xtal

R

ext

V

19(p-p)

LOW level output current VOL = 0.4 V 1.6 − − mA

HIGH level output current VOH = V

− 0.4 V 1.3 − − mA

DDD

rise time note 7 − − 44 ns

fall time note 7 − − 40 ns

LOW level output current VOL = 0.4 V 3.3 − − mA

3-state output leakage current T

= −40 to +85 °C;

amb

VO = V

SSD/VDDD

− − 1.5 µA

rise time, LOW to 3-state CL = 50 pF − − 37 ns

fall time, 3-state to LOW CL = 50 pF − − 20 ns

LOW level output current VOL = 0.4 V 3.3 − − mA

HIGH level output current VOH = V

3-state output leakage current T

amb

VO = V

− 0.4 V 1.8 − − mA

DDD

= −40 to +85 °C;

SSD/VDDD

− − 1.5 µA

rise time note 7 − − 37 ns

fall time note 7 − − 20 ns

LOW level input voltage T

HIGH level input voltage T

= −40 to +85 °C − − 0.3V

amb

= −40 to +85 °C 0.75V

amb

− − V

DDD

DDD

V

LOW level output sink current VOL = 0.4 V 3.3 − − mA

HIGH level output source

VOH = V

− 0.4 V 1.8 − − mA

DDD

current

3-state output leakage current T

= −40 to +85 °C;

amb

VO = V

SSD

or V

− − 1.5 µA

DDD

rise time note 7 − − 37 ns

fall time note 7 − − 20 ns

oscillator frequency 8 − 17 MHz

input capacitance − − 4 pF

output capacitance − − 4 pF

feedback capacitance − − 3 pF

external oscillator reference

note 8 25 − 100 kΩ

resistor

external reference resistor note 9 − 10 − kΩ

minimum input clock voltage

level from external oscillator

(peak-to-peak value)

AC-coupled;

R

= 10 kΩ;

ext

R

= 1 MΩ connected

bias

− 500 − mV

between pins 18 and 19

March 1994 11

Page 11

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Slave clock mode: XTALI

V

IL

V

IH

t

H

Notes

1. f

sys

2. Internal reference source with 4 different output voltages. Selection is achieved via the serial interface. The given

values are for an unloaded reference voltage.

3. f

ripple

4. Internal reference is switched OFF by serial interface. VRH is the reference input.

5. Externally applied VRH = 2.5 V and VRL = 0 V, measuring bandwidth: 200 Hz to 20 kHz, f

6. The gain of the ADC is defined as: G

output is the number of pulses at the digital output in counts per second and II is the DC input current in mA.

The maximum input current depends on the system frequency (f

For D1 to D4: I

For R1 and R2: I

The gain tolerance is the deviation from the calculated gain regarding note 1.

7. At 10 to 90% levels with CL = 50 pF.

8. A resistor must be connected to set the gain of the oscillator circuit. The value of the resistor depends on the crystal

or resonator connected to the oscillator circuit (see also Chapter “Application information” ).

9. When the TDA1301T is supplied by an external oscillator frequency, no crystal or resonator is required while the

external reference resistor has different limits.

LOW level input voltage − − 0.5 V

HIGH level input voltage 2.0 − − V

HIGH level input time relative to the clock

45 − 55 %

period

= 4.2336 MHz; VRL = 0 V; VRH = 2.5 V (externally applied).

= 1 kHz; V

= 0.5 V (p-p).

ripple

= 1.5 × f

i(max)

i(max)

sys

= 0.75 × f

× V

sys

ref

× V

= f

ADC

sys/Imax

× 10−6/Ri× f

× 10−6/Ri× f

ref

i(ADC)

(counts/mA). Thus the digital output is II× G

sys

[µA].

sys

[µA].

) and on V

sys

= VRH− V

ref

RL

= 1 kHz.

where: digital

ADC

March 1994 12

Page 12

Philips Semiconductors Product specification

Fig.4 Application diagram.

(1)

1

⁄

2

V

DDD

= OFF.

Digital servo processor (DSIC2) TDA1301T

APPLICATION INFORMATION

March 1994 13

Page 13

Philips Semiconductors Product specification

Fig.5 28-lead small-outline; plastic (SO28L, SOT136A).

handbook, full pagewidth

7.6

7.4

10.65

10.00

A

MBC236 - 1

0.3

0.1

2.45

2.25

1.1

0.5

0.32

0.23

1.1

1.0

0 to 8

o

2.65

2.35

detail A

S

18.1

17.7

0.1 S

1 14

1528

pin 1

index

0.9

0.4

(4x)

0.25 M

(28x)

0.49

0.36

1.27

Dimensions in mm.

Digital servo processor (DSIC2) TDA1301T

PACKAGE OUTLINE

March 1994 14

Page 14

Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

SOLDERING

Plastic small-outline packages

B

Y WAVE

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

BY SOLDER PASTE REFLOW

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

DEFINITIONS

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between

270 and 320 °C. (Pulse-heated soldering is not

recommended for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

March 1994 15

Loading...

Loading...