Page 1

2-157

Features

• Fully programmable line impedance,network

balance impedance and gains

• Programmable loop current with long loop

capability

• 2-4 Wire conversion

• Power down and wake up

• Battery feed to line with wide operating range

• Off-hook and dial pulse detection

• Over-current protection

• Integral ringing amplifier with auto ring trip

• Tip/Ring reversal

• Meter pulse injection

• On-hook transmission to the line capability

• Relay driver

• Short loop ringing capability with low voltage

DC supply

Applications

Line interface for:

• PABX/Key Telephone System

• Analog Terminal Adaptors

• Pair Gain System

• Fibre in the Loop/Wireless Local Loop

Description

The Mitel MH88617 is a highly featured, low cost

Subscriber Line Interface Circuit (SLIC). It provides a

total analog transmission and signalling link between

a CODEC and a subscriber line. All functions are

integrated into a single thick film hybrid module,

which provides high reliability and optimum circuit

design needing a minimum of external components.

The line impedance, network balance impedance,

gain and loop current are all externally

programmable, making the device suitable for a wide

range of applications worldwide.

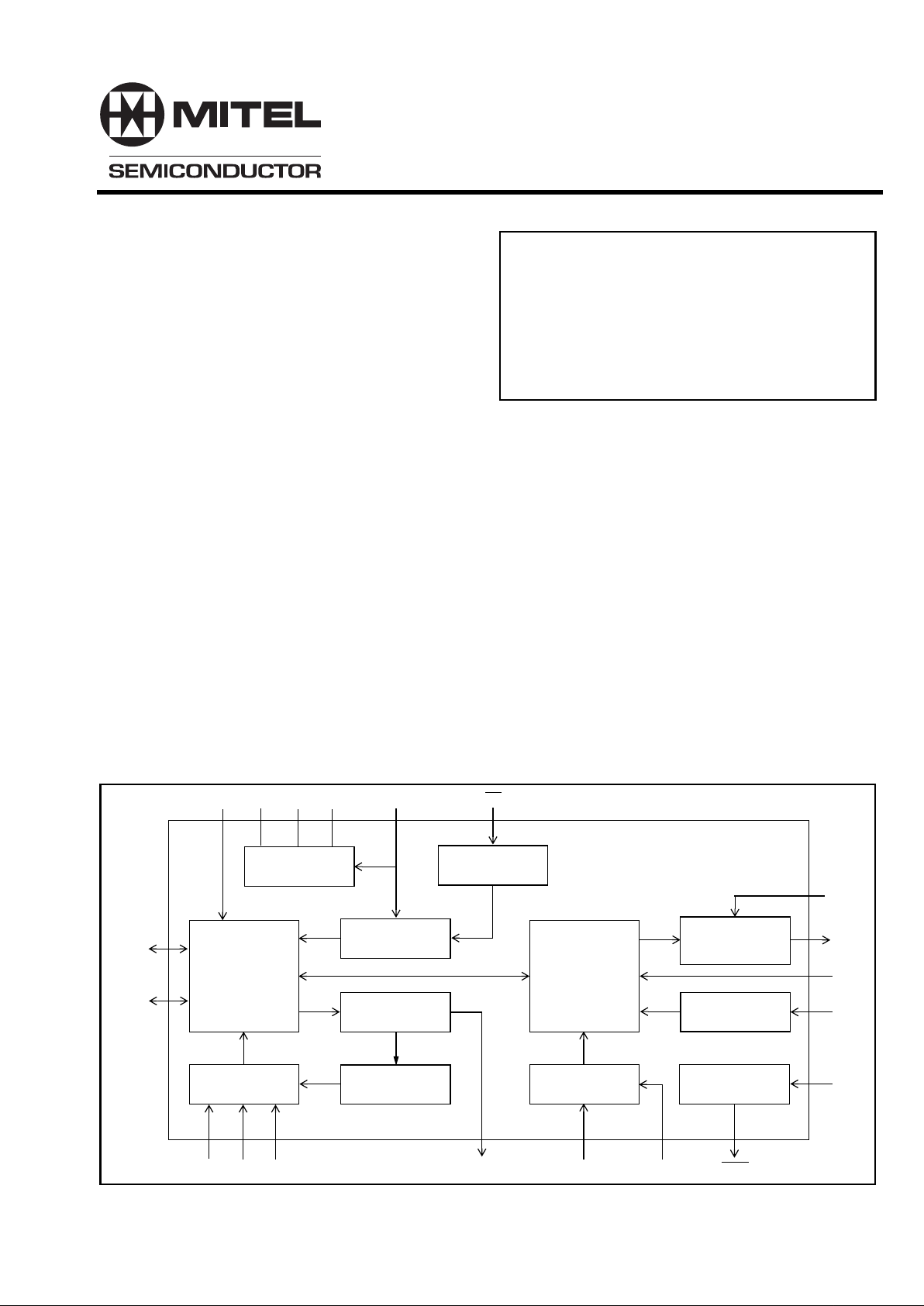

Figure 1 - Functional Block Diagram

TIP

RING

GVX

VBAT VCC VEE GND LCA

Ringing Control

and

Amplifier

LR

Power

Management

Constant

Current Control

Reversal

Supervision

Auto Ring Trip

TIP / RING

Drive and

Sense

VX

VR

ZA

RDI

RDOESEESISHKDCRI

RV

RC

2 - 4 Wire

Conversion

Gain Adjust

Programmable

Impedance

Metering

Injection

Relay Driver

& Programmable

Network Balance

DS5037 ISSUE 4 May 1999

Ordering Information

MH88617AV-PI 21PIN SIL Package

MH88617AD-PI 28PIN DIL Package

MH88617AS-PI 28PIN SM Package

MH88617AT-PI 21PIN 90° L/F Package

-40°C to 85°C

MH88617

Programmable SLIC with Ringing Amplification

Advance Information

Page 2

MH88617 Advance Information

2-158

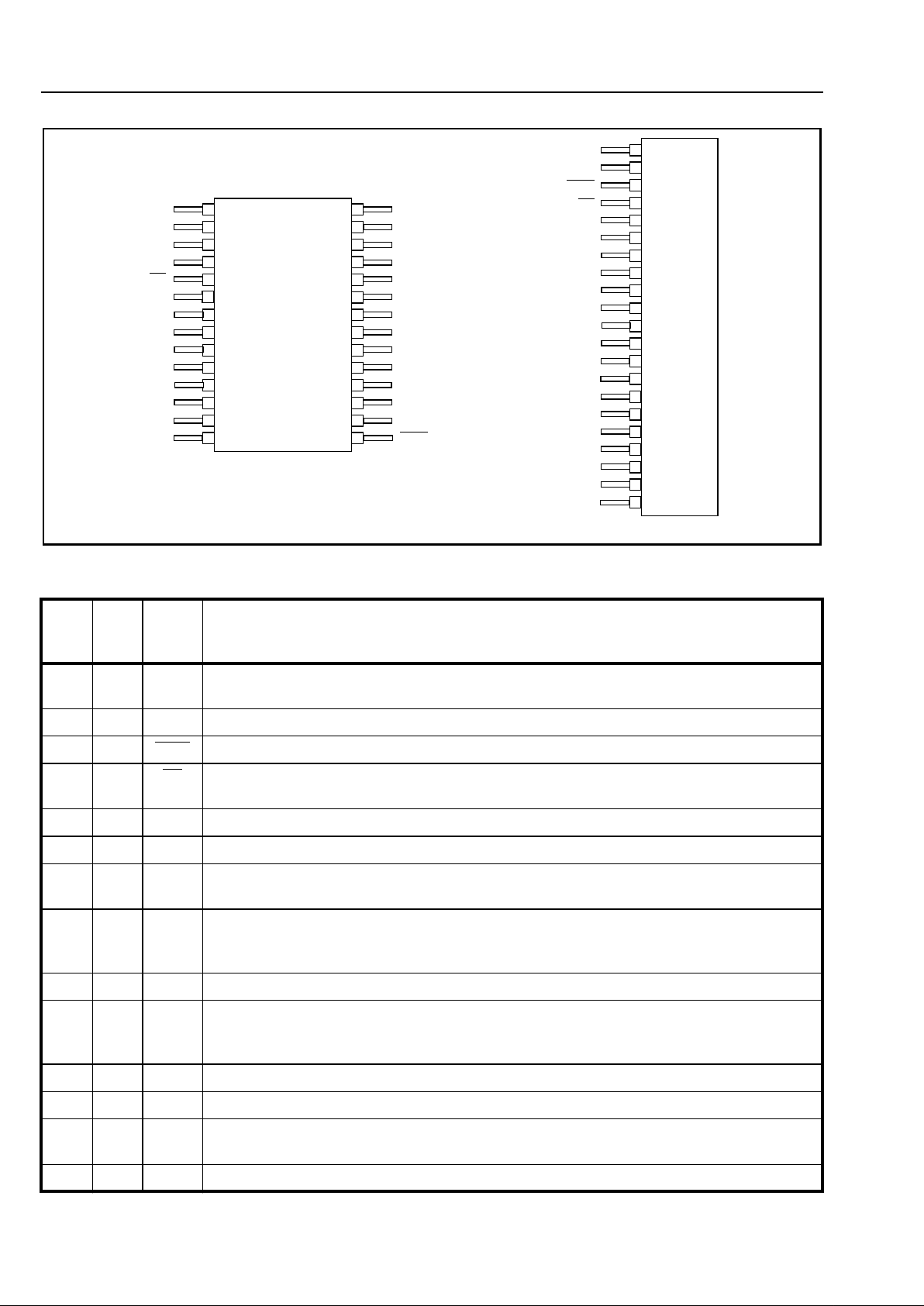

Figure 2 - Pin Connections

Pin Description

28

Pin

DIL

21

Pin

SIL

Name Description

26 1 DCRI DC Ringing V olta ge Input. A continuous DC voltage is applied to this pin. This voltage

is the positive supply rail for the internal ringing amplifier.

16 2 RDI Relay Driver Input. Relay driver control pin.

15 3 RDO Relay Driver Output. Open collector relay driver output.

54LR Line Reversal. Setting this pin to a logic 0 will perform a line reversal. This pin must be

connected to logic 1 for normal operation.

1 5 TIP Tip Lead. Connects to the "Tip" lead of the subscriber line.

3 6 RING Ring Lead. Connects to the "Ring" lead of the subscriber line.

12 7 VBAT Battery Voltage. Battery supply for the subscriber line. Typically -48V DC is applied to

this pin.

9 8 LCA Loop Current Adjust. The loop current is programmed by connecting a resistor between

this pin and the VCC or AGND pins. Leaving this pin open circuit def aults the loop current

to 24mA. Setting this pin to 0V will apply power down.

28 9 VX Transmit Signal (Output). 4-wire analog signal from the SLIC.

27 10 GVX Transmit Gain Adjust. The transmit gain can be programmed by connecting a resistor

between this pin and VX. The Network Balance Impedance can also be programmed by

connecting external matching components from this pin to VR.

17 11 VR Receive Signal (Input). 4-wire analog signal to the SLIC.

22 12 VCC Positive Supply Voltage. +5V.

21 13 AGND Analog Ground. Ground path for the subscriber line and all DC power supplies,

normally connected to system ground.

20 14 VEE Negative Supply Voltage. -5V.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

DCRI

RDI

RDO

LR

TIP

RING

VBAT

LCA

VX

GVX

VR

VCC

AGND

VEE

RV

ESE

ESI

IC

SHK

RC

ZA

21 Pin SIL

28 Pin DIL

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

TIP

IC

RING

IC

LR

RC

ESE

ESI

LCA

IC

IC

VBAT

IC

SHK

VX

GVX

DCRI

IC

IC

IC

VCC

AGND

VEE

RDO

RDI

VR

RV

ZA

Page 3

Advance Information MH88617

2-159

18 15 RV Ringing Voltage. A low level AC sinusoid is applied to this pin. This signal is amplified

and output from TIP/RING to the line as the ringing signal, when RC is at logic 1. This pin

should be driven with a low impedance AGND centred source.

7 16 ESE External Signal Enable. Meter pulse input enable.

8 17 ESI External Signal Input. Meter pulse input.

2,

4,10

11,13

,23

25,24

18 IC Internal Connection. No connection should be made to this pin.

14 19 SHK Switch Hook Detect (Output). A logic 1 at this pin indicates when the subscriber has

gone Off-Hook.

620RCRinging Control (Input). A logic 1 will cause the ringing voltage to be applied to the line.

19 21 ZA Line Impedance. Connect passive components from ZA to ground to match input and

line impedance.

Pin Description (continued)

28

Pin

DIL

21

Pin

SIL

Name Description

Functional Description

The MH88617 is a Subscriber Line Interface Circuit

(SLIC) used to provide an analog interface between

the 4-wire connection and the 2-wire subscriber line

of a communications system.

It provides powering of the subscriber line along with

signalling, control and status circuits. This combines

to provide a comprehensive line and interface

solution in applications such as PABX, Key Systems,

Analog Terminal Adapters, Pair Gain Systems, Fibre

in the Loop and Wireless Local Loop.

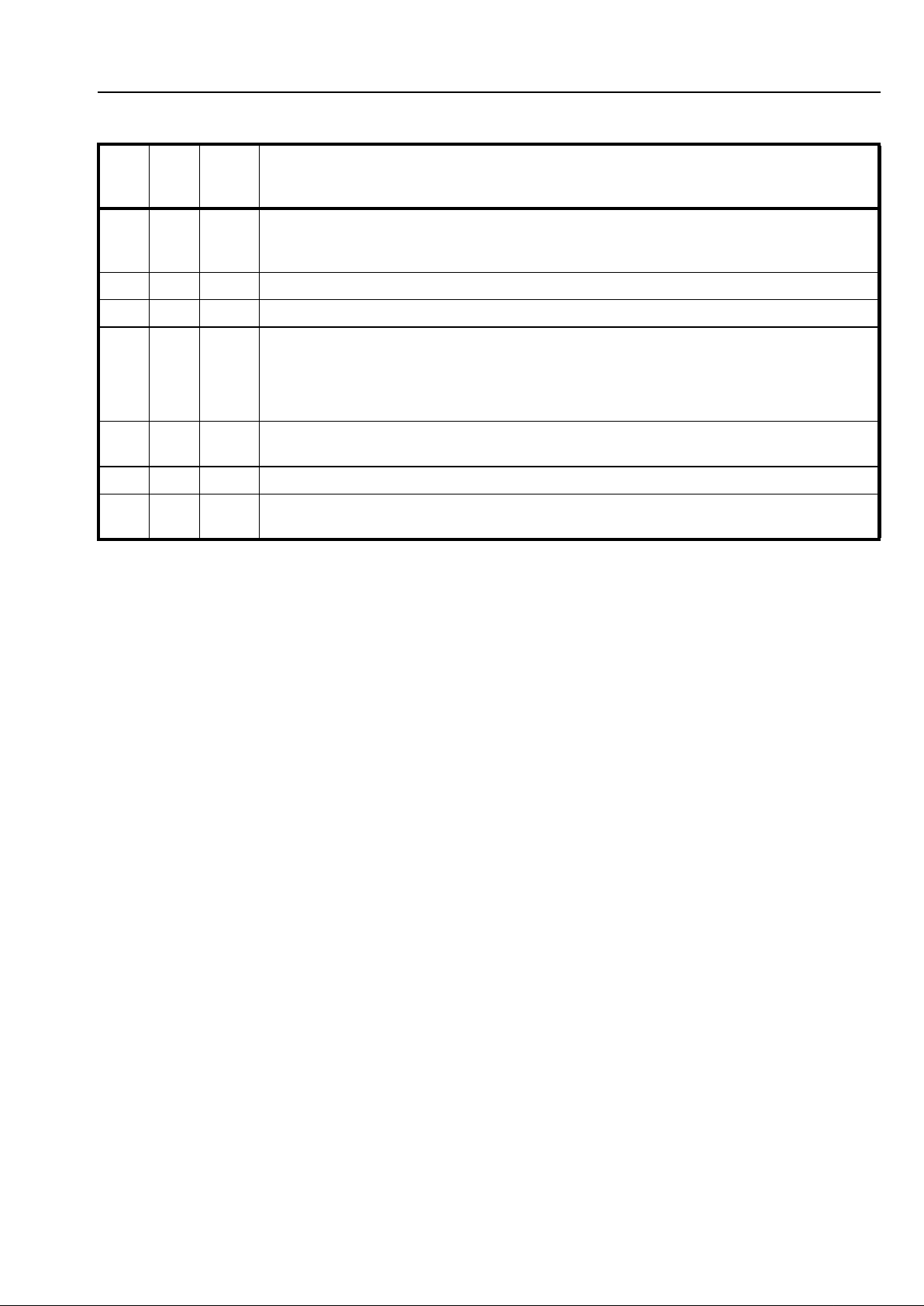

External Protection Circuit

An External Protection Circuit assists in preventing

damage to the device and the subscriber equipment,

due to over-voltage conditions (see Figure 3). Also

reference MSAN-156.

2-4 Wire Conversion

The SLIC converts the balanced 2-Wire input at Tip

and Ring to a ground referenced signal at VX. The

device converts the ground referenced signal input at

VR to a balanced 2-Wire signal across Tip and Ring.

Normally the VX and VR pins connect to a Codec

that interfaces the analog signal to a digital

network.During full duplex transmission, the signal at

Tip and Ring consists of both the signal from the

device to the line and the signal from the line to the

device. The signal input at VR being sent to the line,

must not appear at the output VX. In order to prevent

this, the device has an internal cancellation circuit,

the measure of this attenuation is Transhybrid Loss

(THL).

The MH88617 has the ability to transmit analog

signals from VR through to Tip and Ring when onhook. This can be used when sending caller line

identification information.

Battery Feed and Loop Current Adjust

The MH88617 has an active feedback circuit to

regulate the DC current to the subscriber line. This

current is programmable over a wide range via the

LCA pin. With LCA open circuit the current will be set

to 24mA. This can be increased up to 55mA by

connecting a resistor between LCA and VCC or

reduced down to 14mA by connecting a resistor

between LCA and AGND. MSAN-156 shows a table

of resistor values and loop current.

The line driver stage is biased between +5V and

-48V DC. Therefore it should be noted that loop

current will flow in the +5V supply, this must be taken

into consideration when choosing the +5V supply.

The device will operate over a very wide VBAT

supply range but care must be taken when

programming the constant current that the maximum

power dissipation is not exceeded. For the major ity

Page 4

MH88617 Advance Information

2-160

of applications this will not be a problem, however

the device could be damaged if used to drive a very

short line with the maximum battery voltage and

maximum programmable loop current.

For very long loops the constant current drive reverts

to a constant voltage source. A graph of loop current

versus line resistance is shown in Figure 4.

Under fault conditions, Tip or Ring are protected

from short circuits to ground when the current

exceeds the protection trip threshold. Under these

circumstances, the SLIC will go into a power down

mode and periodically check the line status until the

fault has been removed. Thereby minimizing power

dissipation. The SLIC will revert to an operational

state once the fault is removed.

Ringing Amplification

The MH88617 incorporates an internal ringing

amplifier circuit. A balanced ringing signal is applied

across Tip and Ring, when a DC voltage is

connected to the DCRI pin, a low level sinusoidal

signal is applied to RV and RC is set to logic 1. The

ringing voltage is approximately 50 times the signal

at RV. The gain depends on the ringer load and

impedance at ZA. If an absolute gain is required, a

transistor can be fitted across ZA to give 42.

The SLIC also has the ability to provide ringing on

short loops without the need for a high voltage DCRI

supply. This is achieved by connecting the DCRI pin

to a low voltage supply such as +5V or +12V

providing the subscriber equipment ringing detector

has a low enough sensitivity threshold. In this

application the input at RV needs to be a square

wave (refer MSAN-156).

The SLIC has an automatic ring-trip circuit that

ensures the ringing is removed when the subscriber

goes off-hook. However the user must still insure RC

is taken to logic 0 when SHK signals the subscriber

has gone off-hook.

Programmable Input Impedance

By connecting external passive components

between ZA and ground (AGND) the device’s input

impedance can be set to match the line impedance.

As shown in Figure 3 and Table 1. A more

comprehensive list is given in MSAN-156.

Programmable Network Balance

The network balance of the device can be

programmed by connecting external passive

components between GVX and VR, as shown in

Figure 3 and Table 1.

Figure 3 - Typical Application Circuit

TIP

RING

VX

VR

AGND

VCC

TIP

RING

+5V

MH88617

Protection

Circuit

Notes:

ZA

Z1

VEE VBAT DCRI

-5V

-48V

RV

LR

GVX

SD3

SD2

SD1

SD0

RDI

ESE

RC

VX

VR

MT896x

ESI

SHK

RDO

SHK

Relay Drive

Output

LCA

Loop Current

Adjust Input

1.0Vrms

Sinewave

(16-68Hz)

1.0Vrms

Sinewave

(12/16kHz)

1) For Resistor and Impedance values

0-100V

DSTo

DSTi

CLK

F1i

CA

+5V

10k

C1 C2

2) C1 and C2 are 100nF decoupling capacitors

R2

Z2

R1

see Table 1

T

E.G Teccor

P2353AB

F1

F2

3) F1 and F2 Slow Blow Fuses

Page 5

Advance Information MH88617

2-161

Table 1 gives table of values for some common

applications. A more comprehensive list is given in

MSAN-156.

Programmable Transmit and Receive

Gain

The transmit gain from Tip and Ring to VX can be

programmed by connecting a resistor between GVX

and VX. Similarly the Receive Gain from VR to Tip

and Ring can be programmed by connecting an

impedance in series with VR as shown in Figure 3

and Table 1. Refer to MSAN-156 for additional

impedances.

Off-Hook and Dial Pulse Detection

The switch hook detect output (SHK) goes to a logic

1, when loop current is above the detect threshold

(see DC Electrical Characteristics). This occurs

when the subscriber’s equipment seizes the line to

initiate a call or answer a call. When loop disconnect

dialling is being used, SHK pulses to logic 0 to

indicate the digits being dialled. This output should

be debounced by the system software.

During On-hook transmission SHK remains at logic

0.

Reversal

During normal operation i.e. LR connected to logic 1,

the DC voltage on Tip is positive with respect to

Ring. This can be reversed by applying a logic 0 to

the Line Reversal pin (LR). This feature is used for

signalling. The SLIC is functional during reversal but

for optimum performance forward operation is

recommended.

Meter-Pulse Injection

If the External Signal Enable (ESE) is taken to logic

1 and a 12kHz or 16kHz Meter Pulse signal is

applied to the ESI pin then this signal will be

amplified and output across Tip and Ring. This is

used for calculating the cost of a telephone call.

The gain of the meter pulse signal varies with

programmed input impedance e.g. with the input

impedance programmed for 600Ω and a 200Ω AC

load applied across Tip and Ring the ESI signal will

be amplified by a factor of 2.

Some applications require the 12/16 kHz meter

pulse signal to be ramped before being input at ESI.

Power Down

If AGND is applied to LCA pin the MH88617 will

enter a power down mode where the internal circuitry

is turned off and the power consumption is reduced.

This can be used to conserve power when the line is

inactive.

If the system wants to initiate a call the AGND must

be removed from the LCA before the ringing signal is

transmitted.

If the subscriber initiates a call by seizing the line, SHK

will go to logic 1. The system should monitor this and

respond by removing the AGND from LCA causing the

device to wake up.

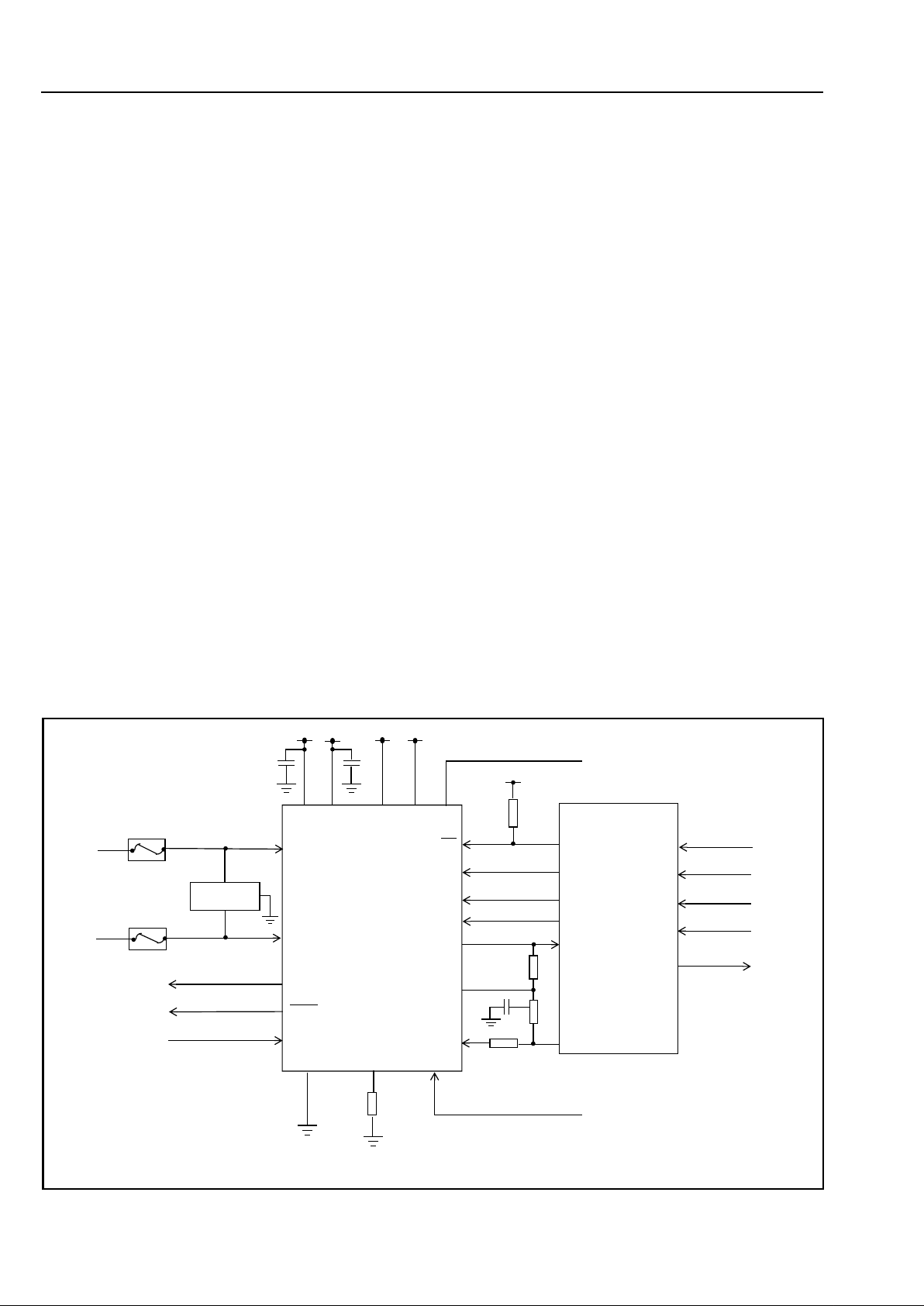

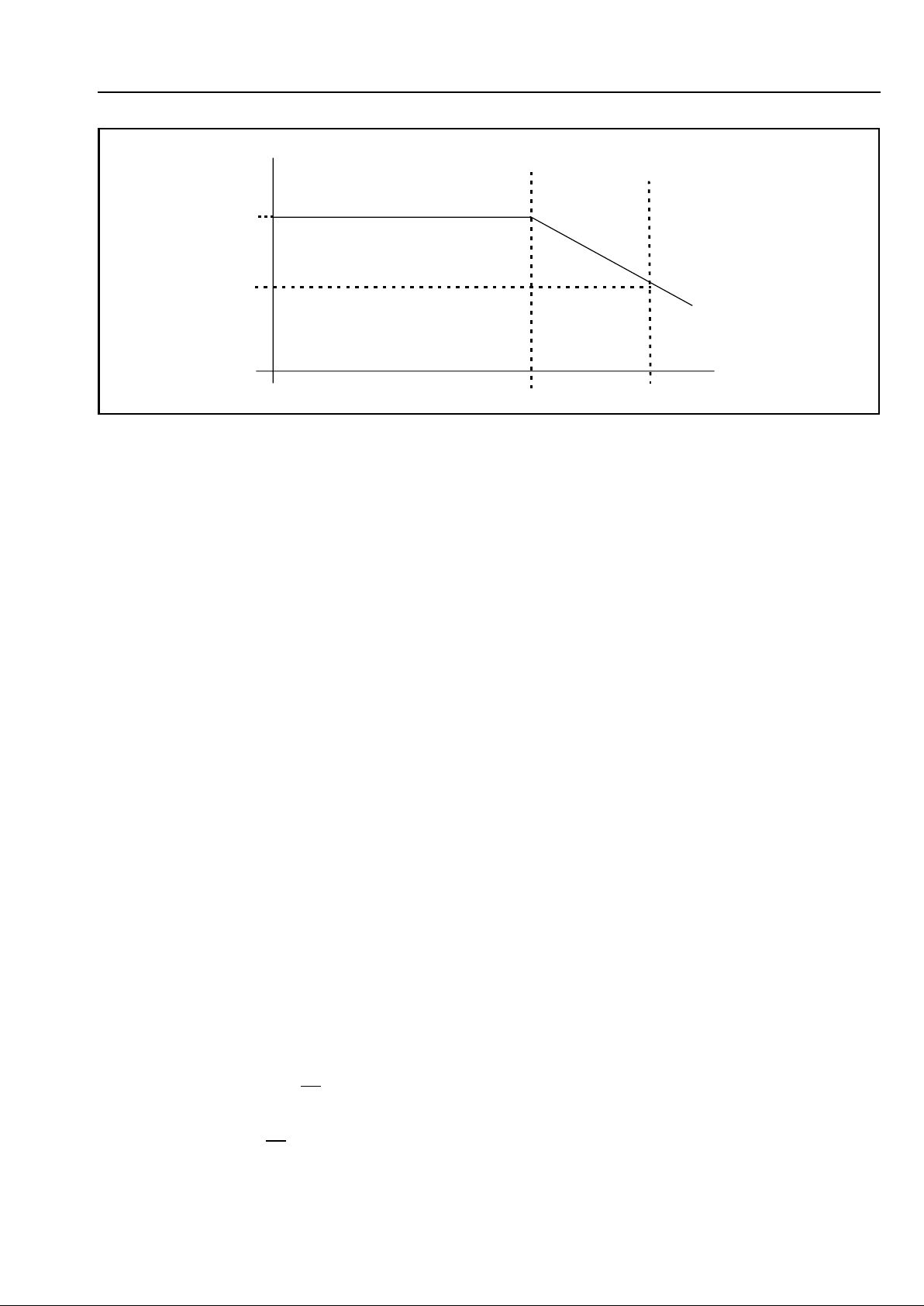

Figure 4 - Loop Current vs. Line Resistance

24mA

0Ω

≈1800Ω

R

LOOP

I

LOOP

VBAT @ -48V

LCA O/C

Constant

Current

Constant

Voltage

≈2800Ω

14mA

Page 6

MH88617 Advance Information

2-162

Relay Driver

An open collector output is provided as a driver for

an external relay. Applying 5V to the RDI pin will

cause the RDO pin to sink current to ground. A

flyback diode must be connected across the relay

coil to protect this output.

The DC resistance of the relay coil must exceed

230Ω

Mechanical Data

See Figure 11, 12, 13, and 14 for details of the

mechanical specification.

Table 1 - External Programming Components

Note: The programming component values shown, give the optimum performance in terms of gain accuracy, return loss and THL. A

compromise is these values can be made if a reduction in performance is acceptable.

Line Conditions Programming Components

Line

Impedance

Balance

ImpedanceVXGainVRGain

Z1 Z2 R1 R2

600Ω 600Ω 0dB 0dB 30k 18k + 18k T

470pF

36k 110k

600Ω 600Ω 4dB -4dB 30k 28k5 + 28k5 T

330pF

57k 180k

600Ω 350Ω+1KΩ

//210nF

0dB 0dB 60k//30k 18k + 18k T

(10k3+5.3nF)

36k 110k

370Ω+620Ω/

/310nF

370Ω+620Ω

//310nF

0dB 0dB 40k//(1.2nF+ 32k5) 18k + 18k T

100pF

36k (124k//1.5nF)

+ 64k

220Ω+820Ω/

/115nF

220Ω+820Ω

//115nF

0dB 0dB 41k//(630pF+3k) 36k 36k (164k//550pF)

+ 34k

900Ω 900Ω 0dB 0dB 38k9 18k+18k T

330pF

36k 174k

270Ω+750Ω/

/150nF

270Ω+750Ω

//150nF

0dB 0dB 40k3//(11k5+730pF) 18k+18k T

100pF

36k (150k//760pF)

+ 48k5

Page 7

Advance Information MH88617

2-163

*Exceeding these values may cause permanent damage. Functional operation under these conditions is not implied.

.

‡ Typical figures are at 25˚C with nominal supply voltages and are for design aid only

Note 1: Applies to a sinusoidal input. RV can also be driven with a TTL signal (AC coupled) see MSAN-156.

Absolute Maximum Ratings* - All voltages are with respect to AGND unless otherwise specified.

Parameter Sym Min Max Units

1 DC Supply Voltage V

CC

V

EE

-0.3

-6

6

0.3

V

V

2 DC Battery Voltage V

BAT

-75 0.3 V

3 DC Ringing Voltage V

DCRI

-0.7 150 V

4 DC Reference Voltage LCA -0.3 6 V

5 Relay Driver Voltage RDO -0.3 15 V

6 Relay Driver Coil Resistance 230 Ω

7 Ringing Input Voltage RV 0 3 Vrms

Note 1

8 Maximum Power Handling Capacity

(Off-hook) @ 25˚C

@ 70˚C

@ 85˚C

PD 2250

1530

1290

mW

mW

mW

9 Storage Temperature T

S

-55 +125 ˚C

Recommended Operating Conditions

Parameter Sym Min Typ‡Max Units Test Conditions

1 DC Supply Voltages V

CC

V

EE

4.75

-5.25

5.0

-5.0

5.25

-4.75

V

V

2 DC Battery Voltage V

BAT

-72 -48 -20 V

3 DC Ringing Voltage V

DCRI

5 110 V

4 Ringing Input Voltage RV 2.5 Vrms Note 1

5 Ringing Output Power PR 2250 mW @ 25˚C

6 Operating Temperatures T

OP

-40 25 85 ˚C

Page 8

MH88617 Advance Information

2-164

† Electrical Characteristics are over Recommended Operating Conditions unless otherwise stated.

‡Typical figures are at 25°C with nominal supply voltages and are for design aid only.

Note: Figure quoted is the +5V supply current plus loop current which flows between -48V (battery supply) and the +5V supply

DC Electrical Characteristics

†

Characteristics Sym Min Typ

‡

Max Units Test Conditions

1 Supply Current

I

CC

I

CC

I

EE

I

BAT

I

DCRI

I

DCRI

12

I

Loop

+ 12

-12

-3

100

100

mA

mA

mA

mA

µA

mA

Test circuit as Fig 7

On-Hook

Off-Hook Note

On-Hook

On-Hook

RC at logic 0

RC at logic 1

2 Power Consumption PC 40

270

80 mWmWPower down,

On-hook = -48V

Idle

3 Constant current feed to line I

Loop

24 mA LCA O/C, V

bat

= -48V

R

Loop

= 300Ω, VCC= 5V

4 Adjustable loop current range I

Loop

14 55 mA

5 Maximum operating loop

resistance

R

Loop

2000 Ω I

Loop

= 18mA,

V

bat

= -48V

includes telephone set

6 Tip or Ring to Gnd, Over-

Current Protection

100 mA V

bat

= -48V

7 Low Level Output Voltage

High Level Output Voltage

V

OL

V

OH

2.4

0.4 V

V

IOL= 4mA

IOH= 0.4mA

8 Relay driver current sink

capability

20 mA RDI = 5V

9 Low Level Input Voltage

High Level Input Voltage

Low Level Input Current

High Level Input Current

V

IL

V

IH

I

IL

I

IH

5.0

0.1

0.5

0.8 V

V

mA

mA

10 Switch Hook detect threshold 4 8.5 13 mA V

bat

= -48V

Page 9

Advance Information MH88617

2-165

AC Electrical Characteristics

†

Characteristics Sym Min Typ

‡

Max Units Test Conditions

1 Ringing drive capability 5 REN 5 REN=1400 Ω @ 20Hz

R

LOOP

= 1800Ω

V@Load=35V

rms

(@25˚C)

DCRI=100VDC

V

bat

=-48V

2 AC Ringing Amplifier

Gain (Note 5)

Output Voltage (Note 3)

Frequency Range

A

RING

V

RING

F

RING

16

50

60

68

Vrms

Hz

V

BAT

= -48V DC

V

DCRI

= 100V DC

RV = 1.2Vrms

sinewave, REN 5

3 Auto Ring Trip & SHK detect

time

Ring Trip

SHK

200

40

mS

mS

Test circuit as Fig 5

RV = 16Hz, RC = 1

RC at logic 0

4 Input Impedance at VR 10 kΩ

5 Output Impedance at VX 10 Ω

6 Receive Gain (VR to 2-Wire)

Off-Hook

Programmable Range

On-Hook

(relative to Off-Hook)

-0.2

-12

0

6

0.2

6

dB

dB

dB

Test circuit as Fig 7

Input 0.5V at 1kHz

T-R Load > 10kΩ,

Output<2.25V @ 1kHz

7 Frequency Response Gain

(relative to Gain @ 1kHz)

-0.25 0 0.25 dB Test circuit as Fig 7

300 - 3400Hz

8 Transmit Gain (2-Wire to VX)

Programmable Range

-0.2

-12

0 0.2

6

dB Test circuit as Fig 6

Input 0.5V @ 1kHz

9 Frequency Response Gain

(relative to Gain @ 1kHz)

-0.25 0 0.25 dB Test circuit as Fig 6

300 - 3400Hz

10 Total Harmonic Distortion at

VX and 2-Wire.

THD 1 % Test circuits as Fig 6&7

Output 0dBm @ 1kHz

11 Overload at VX and 2-Wire. 5 % Test circuits as Fig 6&7

Output +3dBm @ 1kHz

12 Common Mode Rejection

Ratio

CMRR 48 dB Test circuit as Fig. 9

200 - 3400Hz

13 Idle Channel Noise at VX Nc 12 dBrnC Test circuit as Fig. 7

Input 0V

14 Idle Channel Noise at 2-Wire Nc 12 dBrnC Test circuit as Fig. 7

Input 0V

15 Power Supply Rejection Ratio

at VX and 2-Wire VX

2-Wire

PSRR

25

25

dB

dB

Test circuit as Fig. 7 Ripple

0.1Vrms 1kHz @ VCC/ V

EE

/ V

BAT

/ V

DCRI

16 Transhybrid Loss THL

18

21

dB

Test circuit as Fig 7

300 - 3400Hz

500 - 2500Hz

17 Return Loss at 2-Wire RL

18 dB

Test circuit as Fig 8

300 - 3400Hz

Page 10

MH88617 Advance Information

2-166

† Electrical Characteristics are over Recommended Operating Conditions unless otherwise stated.

‡Typical figures are at 25°C with nominal power supplies unless otherwise stated and are for design aid only.

Test conditions shown in Figures 7-12 are programmed for 600Ω.

Note 1: All of the above test conditions use a test source impedance which matches the device’s impedance.

Note 2: dBm is referenced to 600Ω unless otherwise stated.

Note 3: The typical output voltage from the ringing amplifier assumes the output is unloaded.

Note 4: The test shown is for 600R impedance for other impedance use the programming components as shown in Table 1.

Note 5: The gain will change depending on the programming components at ZA. For amplifier gain MSAN156 describes a circuit

where the gain can be guaranteed to be 42.

18 Longitudinal to Metallic

Balance

Metallic to Longitudinal

Balance

55

48

60

40

60

53

dB

dB

dB

dB

Test circuit as Fig. 9

200-1000Hz

1000-3400Hz

Test circuit as Fig. 10

200-1000Hz

1000-4000Hz

19 Meter Pulse output level

(Note 5)

ESO 1.75 2 2.25 Vrms ZA= 30K (600R config)

T-R AC Load = 200Ω, ESI =

1Vrms

20 Audio settling time after

reversal

50 mS

AC Electrical Characteristics† (continued)

Characteristics Sym Min Typ

‡

Max Units Test Conditions

Page 11

Advance Information MH88617

2-167

Figure 5 - DC Condition Test

Figure 6 - 2-4 Gain Wire Test Circuit

VBAT VCC VEE DCRI

VR

VX

SHK

TIP

RING

RVRC

LR

GNDESE

Z1

ESI

RDO

100Ω

RDI

1K

ZA

1K

+5V

+5V

-5V

+90V-48V

DUT

LCA

SW1

1

2

3

10uF

1.6k

I

Ringing

Source

1.2Vrms

Z2

GVX

Z1 = 30kΩ

Z2 = 18k + 18K T 470pF

20Hz

R1

R2

300R

R2 = 110k

R1 = 36k

Vs

I=24mA

100uF

+

100uF

+

Gain = 20 * Log (VX / Vs)

Impedance = 600Ω

VR

VX

SHK

TIP

RING

RVRC

LR

GNDESE

Z1

ESI

RDO

100Ω

RDI

1K

1K

+5V

+5V

-5V

-48V

DUT

LCA

Ringing

Source

10H

1k

Ω

VBAT VCC VEE DCRI

ZA

+90V

1.2Vrms

R1

Z2

R2

GVX

Z1 = 30kΩ

Z2 = 18k + 18K T 470pF

R2 = 110k

R1 = 36k

Page 12

MH88617 Advance Information

2-168

Figure 7 - 4-2 Wire Gain Test Circuit

Figure 8 - Return Loss

Zin (600Ω)

Gain = 20 * Log (V(Zin) / Vs)

Vs

I=24mA

100uF

+

100uF

+

VR

SHK

TIP

RING

RVRC

LR

GNDESE

Z1

ESI

RDO

100

Ω

RDI

1K

1K

+5V

+5V

-5V

-48V

DUT

LCA

Ringing

Source

10H

1kΩ

VBAT VCC VEE DCRI

ZA

+90V

1.2Vrms

Z2

Z1 = 30kΩ

Z2 = 18k + 18K T 470pF

GVX

VX

20Hz

R1

R2

R2 = 110k

R1 = 36k

V1

300Ω

300Ω

Vs

Return Loss = 20 * Log (2V1/Vs)

Zin

I=24mA

100uF

+

100uF

+

VR

SHK

TIP

RING

RVRC

LR

GNDESE

Z1

ESI

RDO

100Ω

RDI

1K

1K

+5V

+5V

-5V

-48V

DUT

LCA

Ringing

Source

10H

1k

Ω

VBAT VCC VEE DCRI

ZA

+90V

1.2Vrms

Z2

R2

GVX

VX

20Hz

R1

Z1 = 30kΩ

Z2 = 18k + 18K T 470pF

R2 = 110k

R1 = 36k

Page 13

Advance Information MH88617

2-169

Figure 9 - Longitudinal to Metallic Balance & CMRR Test Circuit

Figure 10 - Metallic to Longitudinal Balance

Vs

300

Ω

300Ω

Long. to Met. Balance = 20 * Log (V1 / Vs)

V1

I=24mA

100uF

+

100uF

+

VR

SHK

TIP

RING

RVRC

LR

GND

ESE

Z1

ESIRDO

100Ω

RDI

1K

1K

+5V

+5V

-5V

-48V

DUT

LCA

Ringing

Source

10H

1kΩ

1.2Vrms

CMRR = 20 * Log (V2/Vs)

Z2

R2

Z1 = 30kΩ

Z2 = 18k + 18K T 470pF

VBAT VCC VEE DCRI

GVX

ZA

+90V

VX

20Hz

R1

V2

R2 = 110k

R1 = 36k

300Ω

300Ω

V1

Vs

Met. to Long. Balance = 20 * Log (V1 / Vs)

510

Ω

I=24mA

100uF

+

100uF

+

VR

SHK

TIP

RING

RVRC

LR

GNDESE

Z1

ESI

RDO

100Ω

RDI

1K

1K

+5V

+5V -5V-48V

DUT

LCA

Ringing

Source

10H

1kΩ

VBAT VCC VEE DCRI

GVX

ZA

+90V

1.2Vrms

Z1 = 30kΩ

Z2 = 18k + 18k T 470pF

Z2

VX

20Hz

R1

R2

R2 = 110k

R1 = 36k

Page 14

MH88617 Advance Information

2-170

Figure 11 - Mechanical Data for 21 Pin SIL Hybrid

Figure 12 - Mechanical Data for 28 Pin DIL Hybrid

1

0.75 + 0.02

0.020 + 0.005

(0.5

+ 0.13)

0.100 + 0.010

(1.3 + 0.25)

0.05 + 0.01

0.180 + 0.020

(4.57 + 0.51)

(2.54 + 0.25)

*

*

0.14 Max

(3.5 Max)

0.010 + 0.002

(0.25

+ 0.05)

0.1 Max

(2.5 Max)

2.120 Max

(53.85 Max)

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

* Dimensions to centre of pin.

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions:

wave soldering max. temp: 260˚C for

10 secs.

(19.0 +0.51)

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

1.42 Max

(36.1 Max)

0.162 Max (4.12 Max)

0.05 Typ

(1.27 Typ)

0.020 + 0.005

(0.5

+ 0.13)

0.080 Max

0.260

+0.015

(25.8 Typ)

* Dimensions to centre of pin.

1.01 Typ

0.27 Max

(6.9 Max)

0.08 Typ (2 Typ)

0.100

+0.010

(2.54

+0.25)

*

*

1

*

(2.0 Max)

(6.6+0.38)

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions:

Wave Soldering - Max temp at pins 260˚C for 10 secs.

Page 15

Advance Information MH88617

2-171

Figure 13 - Mechanical Data for 28 Pin SMT

Figure 14 - Mechanical Data for 28 Pin T Bend

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

1.42 Max

(36.1 Max)

0.162 Max (4.11 Max)

0.08 Max

* Dimensions to centre of pin.

1

(2.0 Max)

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions:

(25.40 Typ)

0.060 Typ

(1.52 Typ)

1.00 Typ

0.110+0.015

(2.80+0.38)

0.287 Max

(7.29 Max)

0.100+0.010

(2.54+0.25)

*

0.020 + 0.005

(0.5 + 0.13)

0.05 Typ

(1.27 Typ)

*

Max reflow temp: 220˚C for 10 secs.

1.15 Max

(29.2 Max)

1

2.12 Max

(53.85 Max)

0.05 + 0.01

(1.3

+ 0.25)

0.260 + 0.015

(6.60 + 0.38)

0.080

+ 0.020

(2.03

+ 0.51)

0.080 Max

(2.03 Max)

0.170 Max

(4.32 Max)

0.100 + 0.010

0.020 + 0.005

(0.51

+ 0.13)

(2.54 + 0.25)

*

*

(19.0 + 0.51)

0.75 + 0.02

Notes:

1) Not to scale

2) Dimensions in inches.

(Dimensions in millimetres)

* Dimensions to centre of pin.

3) Pin tolerances are non-accumulative.

4) Recommended soldering conditions:

Wave Soldering Max temp at pins 260˚ for 10 secs.

Page 16

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

http://www.mitelsemi.com

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form part of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

Loading...

Loading...