Page 1

MICROWAVE CORPORATION

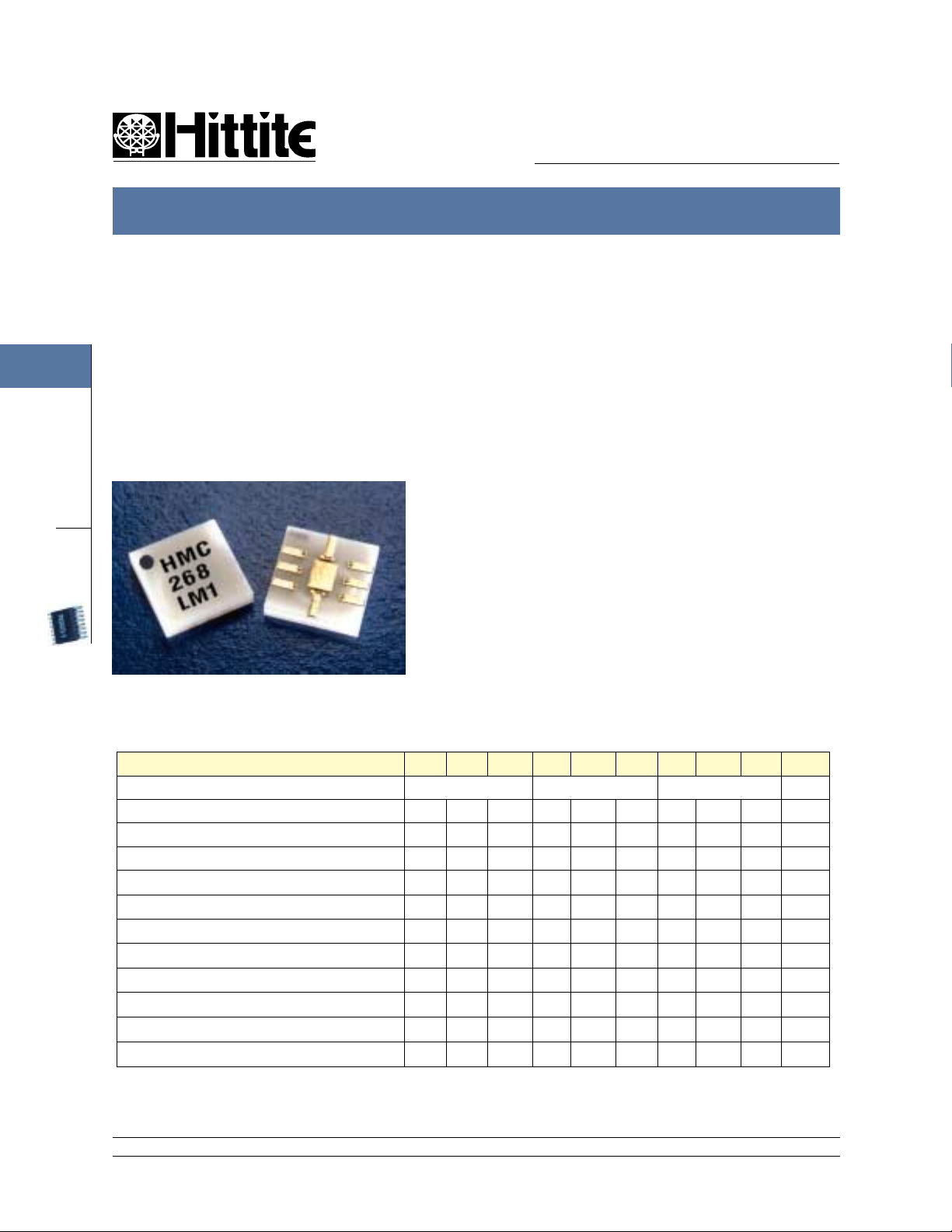

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

FEBRUARY 2001

Features

SMT mmWAVE PACKAGE

1

EXCELLENT NOISE FIGURE : 2.6 dB

15 dB GAIN

P1 dB OUTPUT POWER: +13 dBm

AMPLIFIERS

SMT

V01.0900

General Description

The HMC268LM1 is a two stage GaAs MMIC Low

Noise Amplifier (LNA) in a SMT leadless chip

carrier package covering 20 to 32 GHz. The LM1

is a true surface mount broadband millimeterwave

package offering low loss & excellent I/O match,

preserving MMIC chip performance. Utilizing a

GaAs PHEMT process the device offers 2.6 dB

noise figure, 15 dB gain and +13 dBm output

power from a bias supply of +4V @ 45 mA. The

packaged LNA enables economical PCB SMT

assembly for millimeterwave point-to-point radios, LMDS, and SATCOM applications. As an

alternative to chip-and-wire hybrid assemblies

the HMC268LM1 eliminates the need for

wirebonding, thereby providing a consistent connection interface for the customer. All data is with

the non-hermetic, epoxy sealed LM1 packaged

LNA device mounted in a 50 ohm test fixture.

Guaranteed Performance, Vdd = +4V*, -55 to +85 deg C

retemaraP .niM .pyT .xaM .niM .pyT .xaM .niM .pyT .xaM stinU

**egnaRycneuqerF62-0203-6223-03zHG

niaG114171315181215181Bd

erugiFesioN5.22.36.24.38.28.3Bd

ssoLnruteRtupnI877Bd

ssoLnruteRtuptuO2187Bd

noitalosIesreveR623332823282Bd

)Bd1P(noisserpmoCBd1rofrewoPtuptuO711931931mBd

)tasP(rewoPtuptuOdetarutaS316141715181mBd

)3PI(tpecretnIredrOdrihTtuptuO312271225112mBd

)ddV(egatloVylppuS57.30.452.457.30.452.457.30.452.4cdV

)2ggV&1ggV(egatloVylppuS0.2-51.0-0.00.2-51.0-0.00.2-51.0-0.0cdV

)ddI(tnerruCylppuS540554055405Am

* Vdd = +4V, adjust Vgg1 & Vgg2 between -2.0 to 0.0 Vdc to achieve Idd = 45 mA.

** Acceptable gain and NF peformance is achievable down to 17 GHz.

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 28

Page 2

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

V01.0900

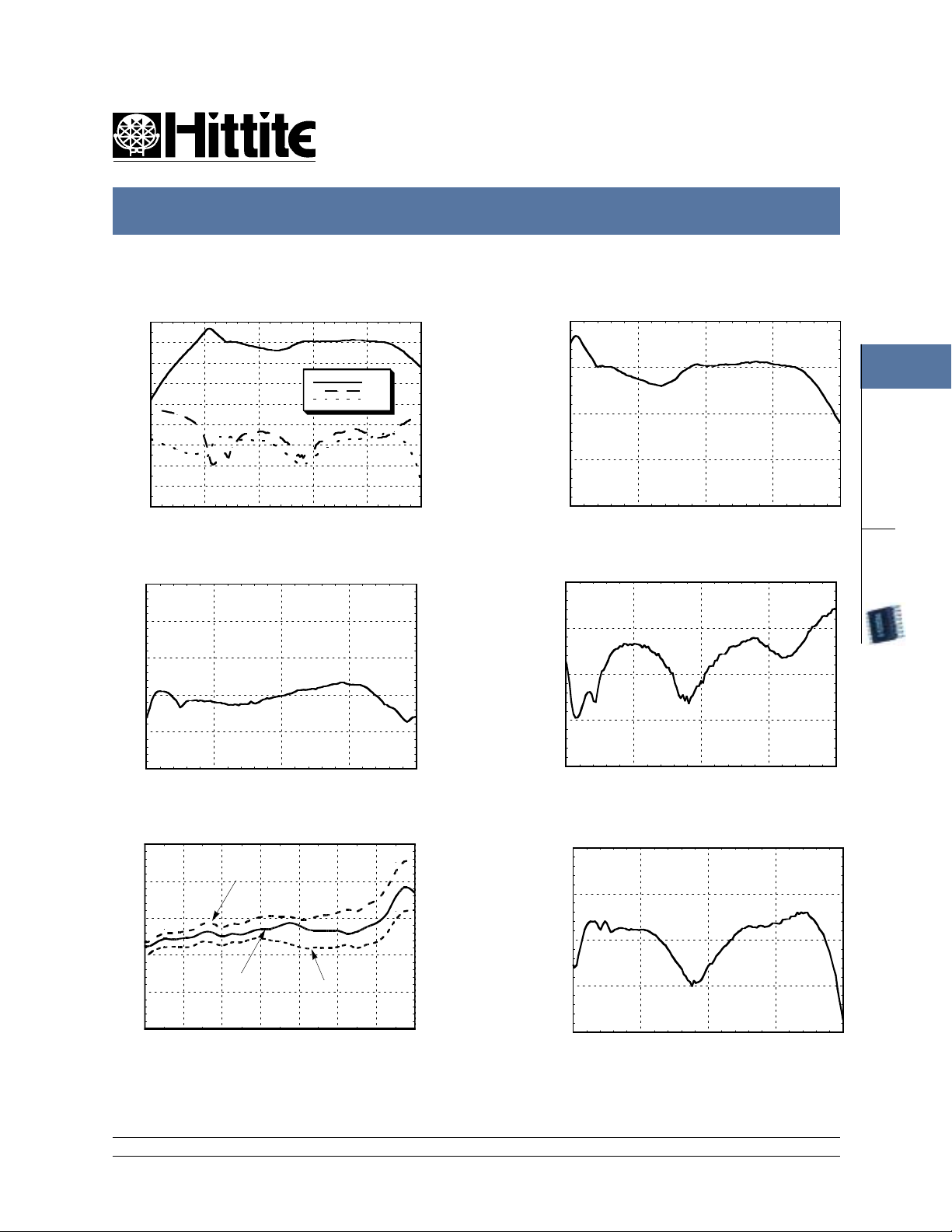

Broadband Gain and Return Loss

20

15

10

5

0

-5

-10

RESPONSE (dB)

-15

-20

-25

10 15 20 25 30 35

FREQUENCY (GHz)

S21

S11

S22

Isolation

0

-10

-20

-30

-40

REVERSE ISOLATION (dB)

FEBRUARY 2001

Gain

20

15

10

GAIN (dB)

5

0

15 20 25 30 35

FREQUENCY (GHz)

Input Return Loss

0

-5

-10

-15

INPUT R ETUR N L OSS (dB )

1

AMPLIFIERS

SMT

-50

15 20 25 30 35

FREQUENCY (GHz)

Noise Figure

5

4

3

2

NOISE FIGURE (dB)

1

0

20 22 24 26 28 30 32 34

+85 C

+25 C

FREQUENCY (GHz)

-40 C

-20

15 20 25 30 35

FREQUENCY (GHz)

Output Return Loss

0

-5

-10

-15

OUTPUT RETURN LOSS (dB)

-20

15 20 25 30 35

FREQUENCY (GHz)

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 29

Page 3

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

FEBRUARY 2001

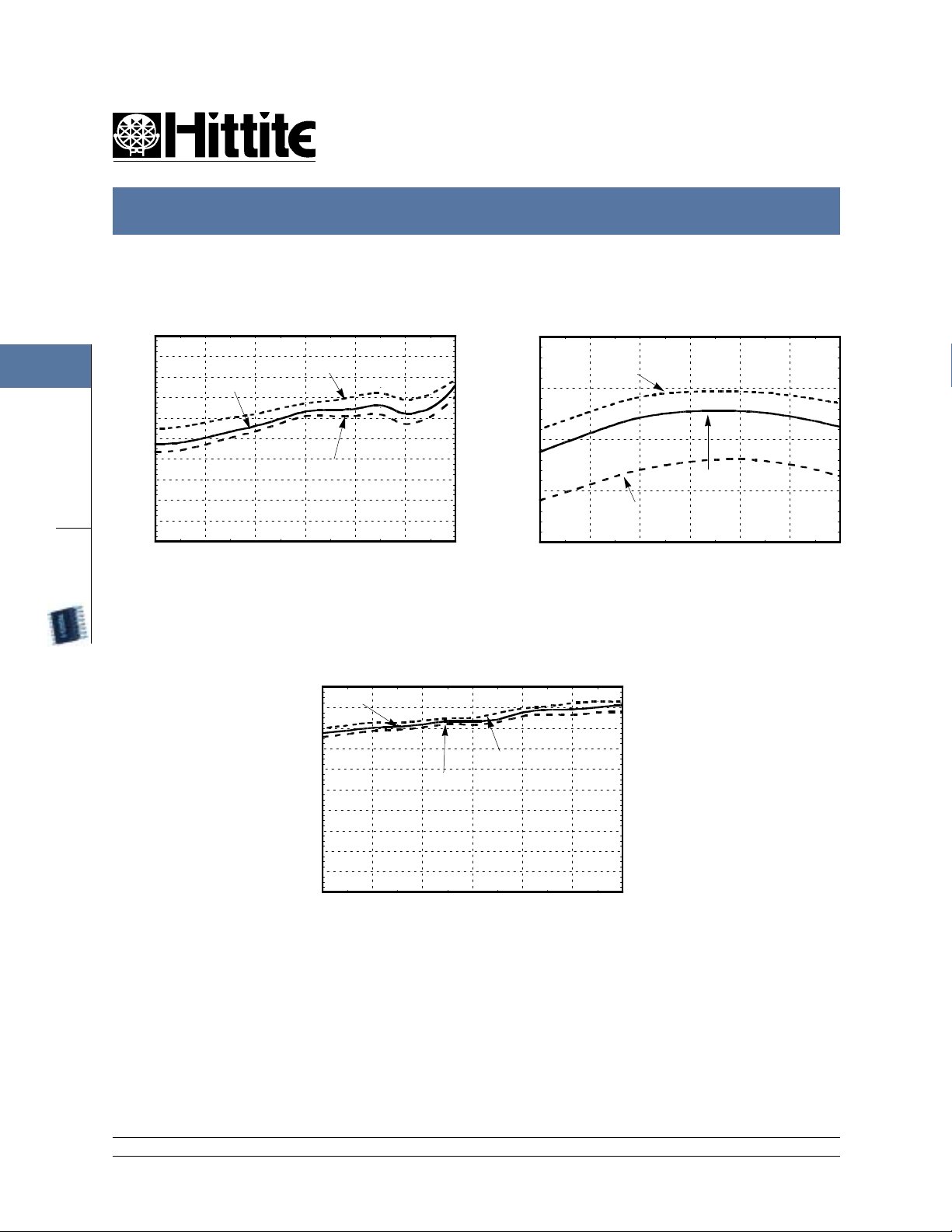

Output P1dB vs. Temperature

1

P1dB OUTPUT (dBm)

AMPLIFIERS

SMT

20

18

16

14

12

10

8

6

4

2

0

20 22 24 26 28 30 32

+25C

FREQUENCY (GHz)

-40C

+85C

Psat vs. Temperature

20

+25C

18

16

14

12

10

8

Psat (dBm)

6

4

2

0

20 22 24 26 28 30 32

Output IP3 vs. Temperature

THIRD ORDER INTERCEPT (dBm)

-40C

+85C

FREQUENCY (GHz)

V01.0900

30

-40C

25

20

+25C

15

+85C

10

20 22 24 26 28 30 32

FREQUENCY (GHz)

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 30

Page 4

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

V01.0900

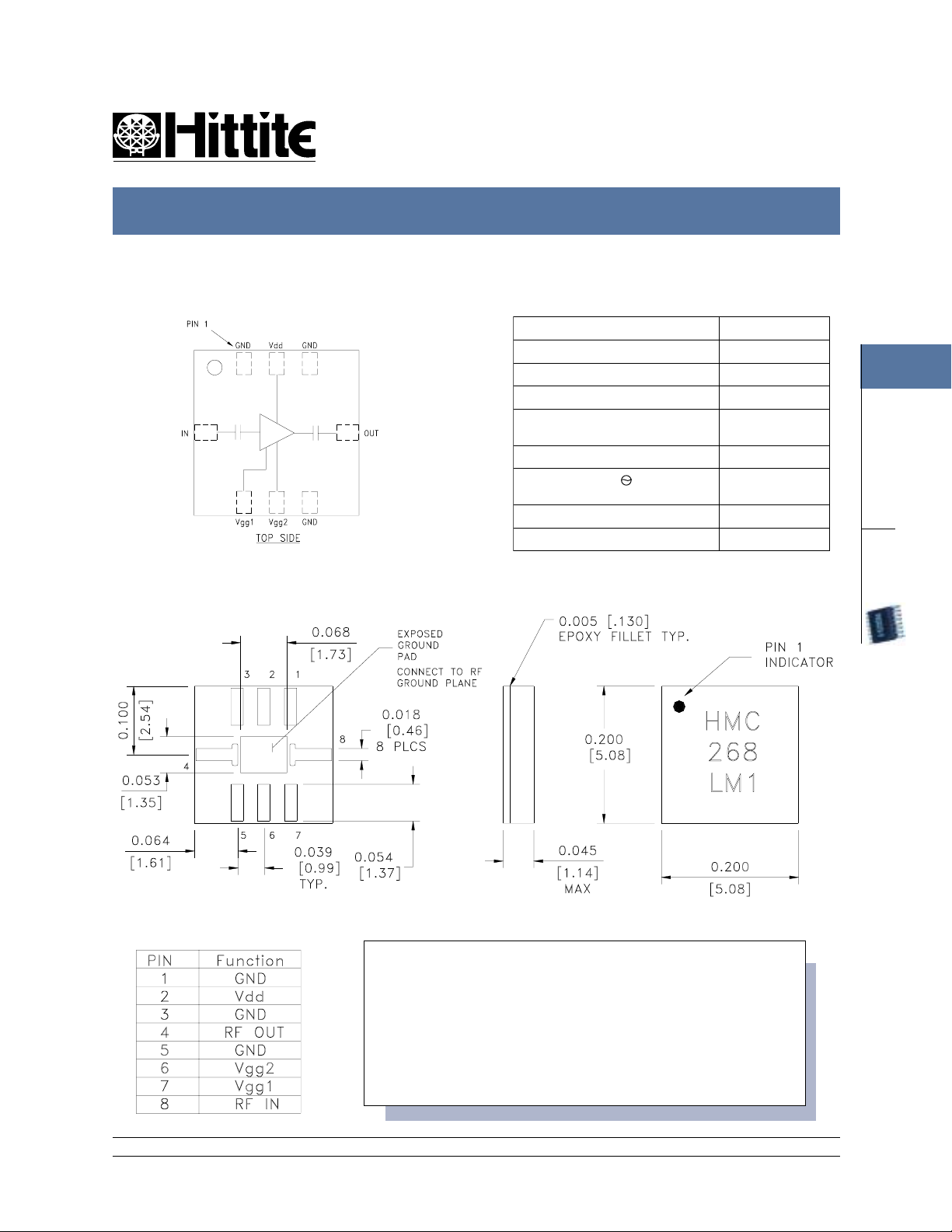

Functional Diagram

See HMC268LM1 Biasing Note Page 1 - 58

Outline

FEBRUARY 2001

Absolute Maximum Ratings

)ddV(egatloVylppuS

)ddI(tnerruCylppuSAm05

)2&1ggV(egatloVsaiBetaGcdV0.0ot0.2-

)2&1ggI(tnerruCetaGCDAm4

)niFR(rewoPtupnI

)ces1<deilpparewopFR,V4+=ddV(

)cT(erutarepmeTlennahC

)cj(ecnatsiseRlamrehT

)ediskcaBlennahC(

erutarepmeTegarotS051+ot56-

erutarepmeTgnitarepO58+ot55-

571oC

982oW/C

cdV5.4+

mBd51+

o

C

o

C

1

AMPLIFIERS

SMT

1. MATERIAL:

A) PACKAGE BODY & LID: PLASTIC.

B) PIN CONTACT : COPPER, 0.5 OUNCE.

2. PLATING : ELECTROLYTIC GOLD (20 TO 50 MICROINCHES TYPICAL) OVER

ELECTROLYTIC NICKEL (50 MICROINCHES MINIMUM).

3. DIMENSIONS ARE IN INCHES (MILLIMETERS).UNLESS OTHERWISE SPECIFIED

ALL TOLERANCES ARE ± 0.005 (± 0.13).

4. ALL GROUNDS MUST BE SOLDERED TO THE PCB RF GROUND.

5. SEE APPLICATION NOTE FOR RECOMMENDED ATTACHMENT TECHNIQUE TO PCB.

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 31

Page 5

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

FEBRUARY 2001

HMC268LM1 Evaluation PCB

1

AMPLIFIERS

SMT

C2

C1

C1

C1

C2C2

LM1 Evaluation PCB

0.018

[0.46]

0.057

[1.45]

0.039

[0.99]

0.078

[1.98]

0.150

[3.81]

0.018

[0.46]

Suggested LM1 PCB Land Pattern

Tolerance: ±0.003" (±0.08 mm)

V01.0900

-B-

Suggested Ground Via Size:

Ø0.010" (0.25) and Qty: 8 to 12

-A-

0.053

[1.35]

ALL FEATURES

0.086

[2.18]

.003 A B

The grounded Co-Planar Wave Guide (G-CPW) PCB input/output transitions allow use of Ground-SignalGround (GSG) probes for testing. Suggested probe pitch is 400µm (16 mils). Alternatively, the board can

be mounted in a metal housing with 2.4 mm coaxial connectors.

Evaluation Circuit Board Layout Design Details

euqinhceTtuoyaLWPC-GotpirtSorciM

lairetaMuC,zo2/1htiw3004sregoR

ssenkcihTcirtceleiD)mm02.0("800.0

htdiWeniLpirtsorciM)mm64.0("810.0

htdiWeniLWPC-G)mm14.0("610.0

paGDNGoteniLWPC-G)mm31.0("500.0

remaiDeloHaiVdnuorG)mm31.0("800.0

1C.gkP2040,roticapaCFp001

2C

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 32

01

.gkP6021,roticapaCFp000,

LM1 Package Mounted to Evaluation PCB

Page 6

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

V01.0900

FEBRUARY 2001

HMC268LM1 Recommended SMT Attachment Technique

Preparation & Handling of the LM1 Millimeterwave Package for Surface Mounting

The HMC LM1 package was designed to be compatible with

high volume surface mount PCB assembly processes. The

LM1 package requires a specific mounting pattern to allow

proper mechanical attachment and to optimize electrical

performance at millimeterwave frequencies. This PCB layout

pattern can be found on each LM1 product data sheet. It can

also be provided as an electronic drawing upon request from

Hittite Sales & Application Engineering.

Follow these precautions to avoid permanent damage:

Cleanliness: Observe proper handling procedures to ensure

clean devices and PCBs. LM1 devices should remain in their

original packaging until component placement to ensure no

contamination or damage to RF, DC & ground contact areas.

Static Sensitivity: Follow ESD precautions to protect against

ESD strikes ( see catalog page 8 - 2 ).

General Handling: Handle the LM1 package on the top with a

vacuum collet or along the edges with a sharp pair of bent

tweezers. Avoiding damaging the RF, DC, & ground contacts on the package bottom. Do not apply excess pressure

to the top of the lid.

Solder Materials & Temperature Profile: Follow the information contained in the application note. Hand soldering is

not recommended. Conductive epoxy attachment is not recommended.

Solder Paste

Solder paste should be selected based on the user’s experience and be compatible with the metallization systems

used. See the LM1 data sheet Outline drawing for pin & ground contact metallization schemes.

225

200

175

C)

0

150

125

100

TEMPERATURE (

75

50

25

012345678

Recommended solder reflow profile

for HMC LM1 SMT package

TIME (min)

1

AMPLIFIERS

SMT

Solder Paste Application

Solder paste is generally applied to the PCB using either a stencil printer or dot placement. The volume of solder

paste will be dependent on PCB and component layout and should be controlled to ensure consistent mechanical

& electrical performance. Excess solder may create unwanted electrical parasitics at high frequencies.

Solder Reflow

The soldering process is usually accomplished in a reflow oven but may also use a vapor phase process. A solder

reflow profile is suggested above.

Prior to reflowing product, temperature profiles should be measured using the same mass as the actual assemblies.

The thermocouple should be moved to various positions on the board to account for edge and corner effects and

varying component masses. The final profile should be determined by mounting the thermocouple to the PCB at the

location of the device.

Follow solder paste and oven vendor’s recommendations when developing a solder reflow profile. A standard

profile will have a steady ramp up from room temperature to the pre-heat temperature to avoid damage due to

thermal shock. Allow enough time between reaching pre-heat temperature and reflow for the solvent in the paste to

evaporate and the flux to completely activate. Reflow must then occur prior to the flux being completely driven off.

The duration of peak reflow temperature should not exceed 15 seconds. Packages have been qualified to withstand a peak temperature of 235°C for 15 seconds. Verify that the profile will not expose device to temperatures in

excess of 235°C.

Cleaning

A water-based flux wash may be used.

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 33

Page 7

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

FEBRUARY 2001

HMC268LM1 General Biasing & Application Circuit

Optimal biasing of the HMC268LM1 SMT two stage low noise amplifier Vdd, Vgg1 & Vgg2 DC ports is

1

described below. The LNA schematic is repeated below. Note the recommended addition of the external

bypass chip capacitor. For additional general MMIC amplifier biasing guidance, please refer to the Hittite

Microwave “MMIC Amplifier Biasing Procedure” found on page 8-8 in our February 2000 catalog or on

www.hittite.com under the Application Note section.

AMPLIFIERS

SMT

RF IN

(PIN 8)

C1 C2

V 1

gg

(Pin 7)

(Pin 2)

Vdd

C1

50 W

Vds1

C1 C2

V 2

gg

(Pin 6)

Vds2

C2

25 W

RF OUT

(PIN 4)

V01.0900

seulaVtnenopmoCdednemmoceR

1CFp001

2CFp000,01

IMPORTANT DC LIMITS! When biasing the HMC268LM1 please note the following;

A) Do Not exceed 3.5 Vdc on internal circuit nodes Vds1 and Vds2 (internal Drain to Source volt-

ages). Calculate the Vds1&2 voltages from the LNA schematic above.

B) Do Not bias Vdd, Vgg1 & Vgg2 DC ports in such a way that Vgs becomes a positive voltage

(internal Gate to Source voltage).

HMC268LM1 Biasing Schemes for Performance Trade-Offs

The biasing may be adjusted slightly to achieve either low noise with lowest DC power consumption or low

noise with highest output power. Be sure to adhere to the IMPORTANT DC LIMITS! above while optimiz-

ing performance.

A) Low Noise and Low Power Consumption : Vdd = 3.5Vdc @ Idd = 30mA. Set Vgg1 = Vgg2.

B) Low Noise and High Output Power : Vdd = 4.0Vdc @ Idd = 45mA. Utilizing Vgg1 & Vgg2 nominal

bias is obtained for a typical Idd current of 30mA for the second or “output” stage and 15 mA for

the first stage. The first step to bias the amplifier is to tune the Vgg1 = -1.0Vdc and Vgg2 to drive

30mA for the full amplifier. Then Vgg1 is reduced to obtain Idd = 45 mA of current for the amplifier.

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 34

Page 8

MICROWAVE CORPORATION

SMT LOW NOISE AMPLIFIER MMIC 20 - 32 GHz

HMC268LM1

V01.0900

FEBRUARY 2001

1

AMPLIFIERS

SMT

12 Elizabeth Drive, Chelmsford, MA 01824 Phone: 978-250-3343 Fax: 978-250-3373 Web Site: www.hittite.com

1 - 35

Loading...

Loading...