Page 1

Installation Guide

AME (-H) 610, 613, 633

ENGLISH

DEUTSCH

FRANCAIS

MAG YAR

POLSKI

中文

VFG 2

VFG 21

VFG 25

Electrical Actuator AME (-H) 610, 613, 633 www.danfoss.com Page 7

Elektrischer Stellantrieb AME (-H) 610, 613, 633 www.danfoss.de Seite 9

Servo-moteurAME (-H) 610, 613, 633 www.danfoss.fr Page 12

Elektromos szelepmozgató AME (-H) 610, 613, 633 www.danfoss.hu Oldal 15

Siłownik elektryczny AME (-H) 610, 613, 633 www.danfoss.pl Strona 18

电动调节阀驱动器 AME(-H) 610,613,633 www.danfoss.com 第 21 页

VFU 2 VFGS 2 AFQM

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1

Page 2

2

L

B

L

B

1

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

❶

B

VFG, VFGS DN 15-125 VFG DN 150-250

VFG, VFGS DN 150-250

with body extension

Valves DN 15 20 25 32 40 50 65 80 10 0 125 150 200 250

L mm 130 250 260 280 200 230 290 310 350 400 480 600 730

VFG(S)

VFG(S)

T

300

max

VFU 2

B mm 212 212 238 238 240 240 275 275 380 380 326 354 404

Weight kg 7 9 10 13 17 22 33 41 60 79 85 145 228

B1 mm - - - - - - - - - - 630 855 1205

Weight kg - - - - - - - - - - 140 210 300

B mm 95 95 106 106 123 123 13 5 135 165 165 - - -

C mm 3 11 3 11 337 337 339 339 374 374 47 9 479 - - -

Weight kg 7 9 10 13 17 22 33 41 60 79 - - -

A

C

L

VFU DN 15-125

DN 65 80 100 125

L

A 600 610 - B 425 425 530 530

B

AFQM + AMV(E) 6xx

290 310 350 400

(mm)

Page 3

Installation Guide AME (-H) 610, 613, 633

❷

Valve type

DN 15- 125 150-250 15- 125 15- 125 150-250 65 -125

PN 16, 25, 40 25

Medium Hot water Steam Hot water

T

max Medium

VFG 2

VFG 21

VFG 25

VFG 2: 200

VFG 21: 150

VFG 25: 200

VFG 2

VFG 21

140 200

VFU 2 VFGS 2 AFQM

❸

① ① ①

AFQM

AFQM

②

②

VFU 2

VFU 2

300 (PN 16)

350 (PN 25, 40)

300 150

VFG 2 (21, 25)

VFG 2 (21, 25)

②

③

VFGS 2

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

33

Page 4

4

PE

L

N

0(4) - 20 mA

0(2) - 10 V

GND

0(4) - 20 mA

0(2) - 10 V

Valve Open

End switches

Valve Close

Power supply

Output stroke

Input controller

①

①

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

❹

❻

①

②

❺

❼

OPEN

STOP

AUTO

STOP

CLOSE

③

①

②

④

DN 150-250

②

②

①

❽ ❾

①

②

③

Page 5

Installation Guide AME (-H) 610, 613, 633

❿

①

⓫

VFG.., AFQ

①

②

S1

S2

S2

②

CLOSE

OPEN

STOP

AUTO

STOP

③

21

21

0/2-10 V

0/4-20 mA

0-20 mA

4

S2

3

3

0-20 mA

0-10 V

4-20 mA

2-10 V

0.74 mA

0.72 V

VFG..

AFQ

VFU

0-10 V

20 mA

10 V

4

4-20 mA

2-10 V

④

⑥

1

⑤

⑧

OPEN

STOP

AUTO

STOP

CLOSE

S2

⑨

1

VFG.., AFQ

⑩

⑪

S2

CLOSE

OPEN

STOP

AUTO

STOP

③

1

⑦

⑮

⑬

S2

1

⑯

⑫

OPEN

STOP

AUTO

STOP

CLOSE

⑭

OPEN

STOP

AUTO

STOP

CLOSE

⑰

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

55

Page 6

Installation Guide AME (-H) 610, 613, 633

⓬

VFU

⑩

①

S2

⑪

②

OPEN

STOP

AUTO

STOP

CLOSE

S2

1

⑥

⑧

④

OPEN

⑤

STOP

AUTO

STOP

CLOSE

③

1

⑭

⑦

⑬

⑯

S2

⑨

⑰

1

S2

1

⓭

VFU

OPEN

STOP

AUTO

STOP

CLOSE

OPEN

STOP

AUTO

STOP

CLOSE

①

③

OPEN

STOP

AUTO

STOP

CLOSE

VFG.., AFQ

②

④

⑫

VFU

VFUVFG.., AFQ

OPEN

STOP

AUTO

STOP

CLOSE

⓮

OPEN

STOP

AUTO

STOP

CLOSE

⑤

③

⑮

OPEN

STOP

AUTO

STOP

CLOSE

⑱

②

①

④

VFUVFG.., AFQ

OPEN

STOP

AUTO

STOP

CLOSE

⑦

⑤

6

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

⑥

VFUVFG.., AFQ

Page 7

Installation Guide AME (-H) 610, 613, 633

ENGLISH

Safety Notes

Prior to assembly and commissioning

to avoid injury of persons and damages

of the devices, it is absolutely necessary

to carefully read and observe these

instructions.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorized

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Mounting

Permissible Installation Positions ❸

① - DN 15-50 (T

valve type AFQM -

- DN 15-80 (T

valve types VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

all allowed valve types

- DN 65-125 (T

valve type AFQM -

- DN 100-250 (T

valve types VFG 2, VFG 21, VFU 2

③ DN 15-250:

valve type VFGS 2 (steam).

Valve Installation ❹

1. Install strainer in front of valve.

2. Rinse system before installing valve.

3. Observe flow direction ① on the valve

body

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Disassembly of Valve,

Actuator ❼

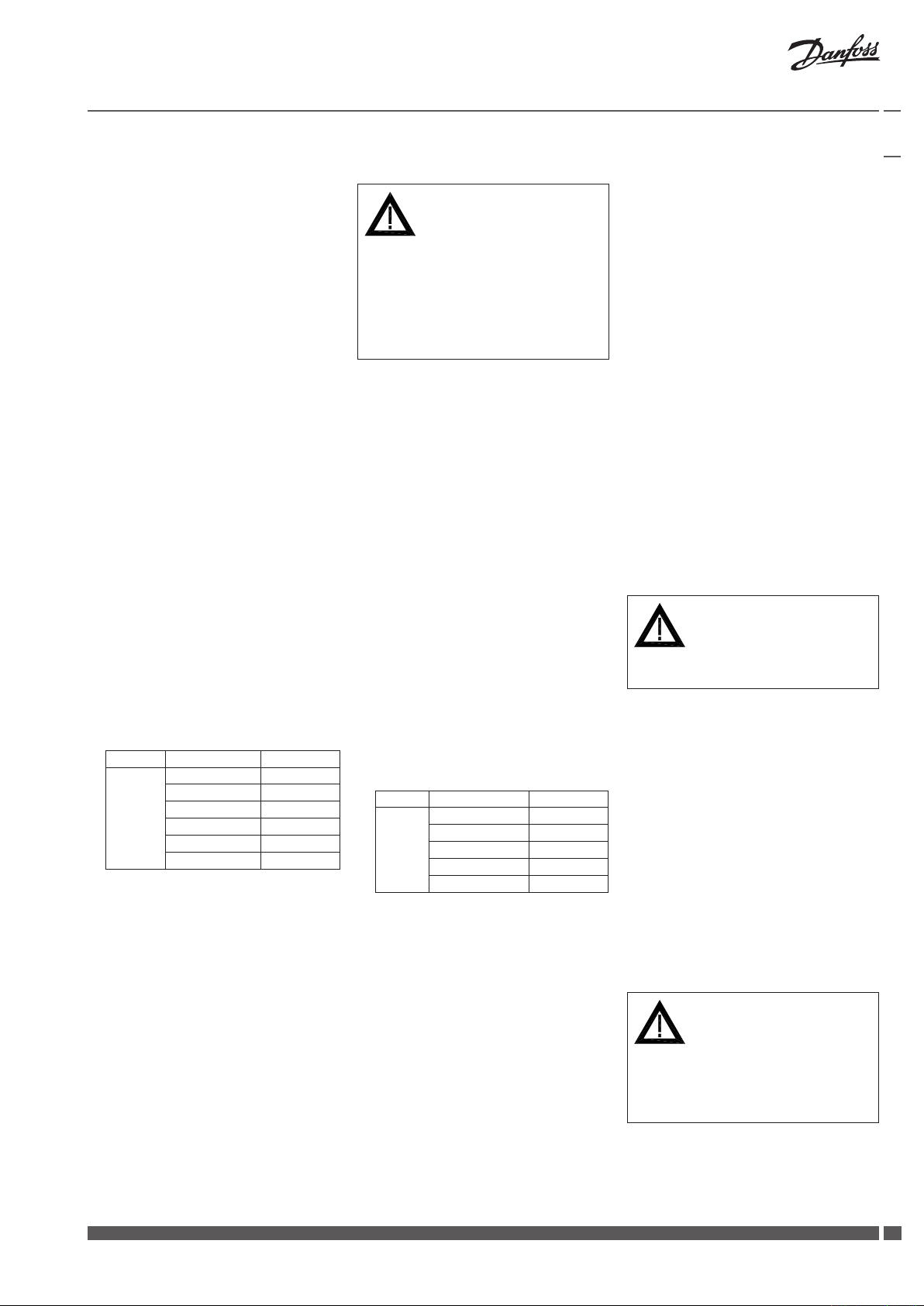

Danger

Danger of injury by steam or hot water! ①

Valve without actuator is open ①,

sealing ② is in the actuator.

It is absolutely necessary to depressurize

system prior to any work.

Carry out disassembly in reverse order as

assembly.

Electrical Connection

HIGH VOLTAGE !

Danger of injury and life in case of

improper handling!

Do not remove the cover before the power

supply is fully switched off.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal regulations.

Definition of Application

The electrical actuator is used in

connection with the following valves:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

Fields of application are the temperature

control of water, water-glycol mixtures

and steam for heating, district heating and

cooling systems.

Flanges ② in the pipeline system

must be in parallel direction, the

sealing surfaces must be clean and

undamaged.

4. Install valve.

5. Tighten screws crosswise in 3 steps up

to the maximum torque.

Actuator and Valve Installation ❺

Before mounting:

1. Carry out the electrical connection

procedure acc. to the next paragraph

2. turn the rotary switch to the postion

“OPEN” ① to run the actuator stem ②

completely back

Valves DN 150-250

For valves DN 150 - 250 the stem of the

actuator must be screwed into the valve

stem.

Switch off power supply prior to

connecting lines.

The electrical connection must only be

performed by an expert electrician.

To access electrical panel remove the cover

first.

Removing the cover ❽

1. Loosen slotted screw at the rotary

switch ①, remove rotary switch.

2. Unscrew screw ② and remove cover ③.

Connections

When cover is removed connect lines in

accordance with connection diagram, see ❾:

① Connection for:

STB - Safety Temperature Limiter

STW - Safety Temperature Monitor

SDB - Safety Pressure Limiter

Prior to remounting the cover, carry out

settings at the actuator, see next section.

Overview Actuators AME 6..

610/3 0 613/3 3 (-H )613/33

Safety

function

Mechanical

adjustment

- + +

- - +

Dimensions, Weights ❶

Flanges: Connection dimensions acc. to

EN 1092-2

Observe the Installation Instructions ③

attached to valves DN 150-250.

Valves DN 15-125

1. Place actuator on the valve and align.

2. Tighten union nut ④ torque 100 Nm

Insulation ❻

Prior to connection it is absolutely

necessry to remove the jumper ① -

only types AME (-H) 613, 633 with safety

return function.

Actuator Settings ❿

Prior to carrying out any settings,

dismount cover like described in previous

section.

Valve Types for AME(-H) 6..

The electical actuator AME(-H) 6.. can be

mounted on the following valves, see ❷.

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

77

Page 8

8

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

Switch designations ❿ ①

Output Signal Settings ❿ ②

Input settings ❿ ③

The selection of voltage or current input

is carried out via the connection on the

terminal strip, terminal 15 or 16, see

“Electrical diagram” ❾.

Final Position Settings

After having mounted the valves and the

actuator, the final positions “Valve OPEN”

and “Valve CLOSED” must be set.

Pre-conditions for the settings:

• theactuatorismountedonthevalve

•

the electrical connection is completed.

Valves VFG .., AFQM ⓫

Setting the final position

“Valve CLOSED” ①

Procedure:

1. Set switch S2 ②

2. Set rotary switch to position “CLOSE” ③.

3. The stroke indicator ④ must move in

the direction of the arrow up to its stop.

Valve is completely closed.

4. Align stroke indicator:

• Loosenscrews⑤.

• Aligndisplayto0⑥.

• Tightenscrews.

5. Turn rotary switch by one position to

STOP ⑦

6. Press key S4 once ⑧

7. Set switch S2 ⑨

The final position “Valve CLOSED” is set.

Setting the final position

“Valve OPEN” ⑩

Procedure:

1. Find the stroke in the table below:

Typ e

VFG 2

VFG 21

VFG 25

AFGM

2. Set switch S2 ⑪

3. Set rotary to position “OPEN” ⑫

Valve opens

Example:

DN 100, Stroke 20 mm

As soon as the stroke ⑬ has been

reached , set rotary switch to position

“STOP” ⑭

4. Press key S4 once ⑮

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

Valve stroke

6 mm

8 mm

12 mm

18 mm

20 mm

24 mm

5. Set switch S2 ⑯

The final position “Valve OPEN” is set.

After you completed setting final position

re-mount the cover and rotary switch and

turn rotary switch to position "AUTO" ⑰.

If you would like to reset the final

positions repeat the procedure ⓫ again.

Valves VFU 2 ⓬

Remarks to VFU 2:

In contrary to the valves VFG .., AFQM ,

the valve VFU 2 has a reversed closing

direction.

The valve VFU 2 is opened by the safety

return function.

Setting the final position

“Valve OPEN” ①

Procedure:

1. Set switch S2 ②

2. Set rotary switch to position “CLOSE” ③.

3. The stroke indicator ④ must move in

the direction of the arrow up to its stop.

Valve is completely open ①

4. Align stroke indicator:

• Loosenscrews⑤.

• Aligndisplayto0⑥.

• Tightenscrews.

5. Turn rotary switch by one position to

“STOP” ⑦

6. Press key S4 once ⑧

7. Set switch S2 ⑨

The final position “Valve OPEN” is set.

Setting the final position

“Valve CLOSED” ⑩

Procedure:

1. Take stroke from the following table:

Typ e

VFU

2. Set switch S2 ⑪

3. Set rotary switch to position “OPEN” ⑫

Valve closes, as soon as the stroke ⑬

has ben reached, set rotary switch to

position “STOP” .

4. Stroke indicator moves up to its stop,

the valve is shown on the scale ⑭

Example:

DN 100, stroke 20 mm

5. Turn rotary switch by one position to

“STOP” ⑮

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Valve stroke

6 mm

8 mm

12 mm

18 mm

20 mm

6. Pres key S4 once ⑯

7. Set switch S2 ⑰

The final position “Valve CLOSED” is set.

After you completed setting final position

re-mount the cover and rotary switch and

turn rotary switch to position "AUTO" ⑱.

If you would like to reset the final

positions repeat the procedure ⓬ again.

Operation

Electrical Manual Adjustment ⓭

• Rotaryswitchsetto“CLOSE“①

Actuator stem is extended ②:

After repositioning, turn to “STOP”

• Rotaryswitchsetto“OPEN“③

Actuator stem is retracted ④:

After repositioning, turn to “STOP”

• Rotaryswitchsetto“STOP“

Actuator stem stays in its last position.

• Rotaryswitchsetto“AUTO“⑤

Actuator is controlled via the external

controller.

Standard setting

Strictly observe for normal operation.

Mechanical Manual Adjustments ⓮

(only for the actuators AME-H 613)

In case of a power supply failure or a

operating fault, the valve may be opened

or closed

1. Turn rotary switch to position

“CLOSE” ①.

2. Loosen security screw ②.

3. With hook wrench (accessory) retract

actuator stem ③:

VFG .., AFQM opens ④

VFU 2 closes ④

4. With hook wrench (accessory) extend

actuator stem ⑤:

VFG .., AFQM closes ⑥

VFU 2 opens ⑥

Prior to switching to automatic operation

(AUTO), it is absolutely necessary to

completely turn the adjustment nut ⑤ to

its stop.

Tighten security screw ⑦.

If this is not observed, the valve cannot be

closed. (VFU ... not be opened).

Page 9

Installation Guide AME (-H) 610, 613, 633

DEUTSCH

Sicherheitshinweise

Vor dem Einbau und der Inbetriebnahme

ist zur Vermeidung von Personenschäden

und Schäden an den Geräten die

vorliegende Betriebsanleitung sorgfältig

durchzulesen und unbedingt zu beachten.

Einbau-, Inbetriebnahme- und

Wartungsarbeiten dürfen nur durch

geschultes und autorisiertes Fachpersonal

durchgeführt werden.

Vor dem Einbau des Ventils und der

anschließenden Montage des Stellantriebs

und vor Wartungsarbeiten an der

Ventileinheit muss die Anlage:

- drucklos gemacht werden

- abkühlen

- entleert werden

- gereinigt werden.

Die Vorgaben des Anlagenherstellers oder

des Anlagenbetreibers sind zu beachten.

Entfernen Sie die Abdeckung

nicht, bevor die Stromversorgung

komplett ausgeschaltet ist.

Entsorgungshinweise

Vor der Entsorgung ist der

Stellantrieb zu zerlegen. Die

einzelnen Komponenten sind

dann, nach Werkstoffen

getrennt, zu entsorgen.

Entsorgungsbestimmungen sind zu

beachten.

Bestimmungsgemäße Verwendung

Der elektrische Stellantrieb wird in

Verbindung mit den folgenden Stellventilen

eingesetzt: VFG 2 (21), VFG 2, VFGS2, AFQM.

Einsatzgebiete sind die Temperaturregelung

von Wasser, Wasser-Glycolgemischen und

Dampf für Heizungs-, Fernheizungs- und

Kühlungsanlagen.

Übersicht Stellantriebe AME ...

AME 610 /30

Sicherheitsfunktion

Mechanische

Handverstellung

Abmessungen, Gewichte ❶

Flansch: Anschlussmaße EN 1092-2

613/3 3

(-H )613/33

- + +

- - +

Ventiltypen für AME(-H) 6..

Der elektrische Stellantrieb AME (-H) 6..

kann auf folgende Ventile montiert werden,

siehe ❷.

Montage

Zulässige Einbaulagen ❸

① - DN 15-50 (T

Ventiltyp AFQM -

- DN 15-80 (T

Ventiltypen VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

alle zulässigen Ventiltypen

- DN 65-125 (T

Ventiltyp AFQM -

- DN 100-250 (T

Ventiltypen VFG 2, VFG 21, VFU 2

③ DN 15-250:

Ventiltyp VFGS 2 (Dampf)

Einbau Ventil ❹

1. Schmutzfänger vor dem Ventil einbauen.

2. Anlage vor dem Einbau des Ventils spülen.

3. Durchflussrichtung ① uf dem

Ventilgehäuse beachten.

4. Ventil einbauen.

5. Schrauben über Kreuz in 3 Stufen bis

zum max. Drehmoment anziehen.

Montage Stellantrieb und Ventil ❺

Vor der Montage:

1. “Elektrischen Anschluss durchführen,

siehe nächsten Abschnitt

2. Drehschalter auf Stellung “OPEN” ①

drehen, dadurch Antriebsstange ②

ganz einfahren

Ventile DN 150 - 250

Bei den Ventilen DN 150 - 250 muss die

Antriebstange in die Ventilstange

eingeschraubt werden.

Ventile DN 15 - 125

1. Stellantrieb am Ventil ansetzen und

ausrichten

2. Überwurfmutter ④ anziehen

Anzugsmoment 100 Nm

Isolierung ❻

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Flansche ② in der Rohr-leitung

müssen parallel, Dichtflächen sauber

und ohne Beschädigung sein.

Den Ventilen DN 150 - 250

beigefügte Montageanlei-tung

beachten.

Demontage von Stellventil und

Stellantrieb ❼

Ventil ist ohne Antrieb offen ①,

Gefahr

Verletzungsgefahr durch

Heißwasser ①

Abdichtung ② befindet sich im Antrieb.

Vor Demontage Anlage unbedingt

drucklos machen.

Demontage in umgekehr-ter Reihenfolge

wie die Montage durchführen.

Gefahr durch

Stromschlag!

Bei unsachgemäßer Handhabing besteht

Lebens- und Verletzungsgefahr!

Elektrischer Anschluss

Vor dem Anschluss der Leitungen unbedingt

Spannungsversorgung abschalten.

Durchführung des elektrischen Anschlusses

nur durch Elektrofachkraft.

Um den elektrischen Anschluss vornehmen zu

können, muss erst der Deckel entfernt werden.

Vorgehensweise ❽

1. Schlitzschraube am Drehschalter ①

lösen, Drehschalter abziehen

2. Schraube ② herausschrauben und

Deckel ③ abnehmen

Elektrischer Anschluss

Nach dem Entfernen des Deckels kann die

Verdrahtung gemäß Anschlussplan erfolgen ❾.

① Anschluss für:

STB -Schutz-Temperaturbegrenzer

STW -Schutz-Temperaturwächter

SDB - Sicherheitsdruckbegrenzer

Vor der Montage des Deckels alle

Einstellungen vornehmen.

Bei Anschluss unbed ingt Brücke

entfernen ① - nur Typen AME (-H)

613, 633 mit Sicherheitsfunktion.

Einstellung Stellantrieb ❿

Bevor die Einstellungen vorgenommen

werden können, Deckel wie beschrieben

entfernen ③❽.

Schalterbezeichnungen ❿ ①

Einstellung Ausgangssignal ❿ ②

Einstellung Eingangssignal ❿ ③

Auswahl Spannungs- oder Stromeingang

erfolgt über den Anschluss an der

Klemmleiste, Klemme 15 oder 16, siehe

“Elektrischer Anschlussplan” ❾

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

99

Page 10

10

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

Einstellung der Endlagen

Nach der Montage Ventil und Stellantreib

müssen die Endlagen “Ventil AUF” und

“Ventil ZU” eingestellt werden.

Voraussetzung für die Einstellung:

• derStellantriebistaufdasVentil

montiert

• der elektrische Anschluss ist erfolgt

Ventile VFG .., AFQM ⓫

Endlage “Ventil ZU” ① einstellen

Vorgehensweise

1. Schalter S2 einstellen ②

2. Drehschalter auf Stellung “CLOSE” ③

stellen

3. Hubanzeige ④ muss sich in Pfeilrichtung

bis zum Anschlag bewegen

Ventil ist ganz geschlossen

4. Hubanzeige ausrichten:

• Schrauben ⑤ lösen

• Anzeige auf 0 ausrichten ⑥

• Schrauben anziehen

5. Drehschalter um eine Stellung, auf

STOP, weiterdrehen ⑦

6. Schalter S2 einstellen ⑧

7. Taste S4 einmal drücken ⑨

Endlage “Ventil ZU” ist eingestellt.

Endlage “Ventil AUF” einstellen ⑩

Vorgehensweise

1. Ventilhub aus der folgenden Tabelle

ablesen

Typ

VFG 2

VFG 21

VFG 25

AFGM

1. Schalter S2 einstellen ⑪

2. Drehschalter auf Stellung “CLOSE”

drehen ⑫

Ventil öffnet

Beispiel: DN 100, Ventilhub 20 mm

sobald der Ventilhub ⑬ erreicht

ist, Drehschalter um eine Stellung

weiterdrehen auf “STOP”⑭

3. Taste S4 einmal drücken ⑮

4. Schalter S2 ⑯ einstellen

Einstellung der Endlagen ist

abgeschlossen.

Nach Beendigung der Einstellungen,

Deckel und Drehschalter montieren und

Drehschalter auf Position "AUTO" drehen ⑰.

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

Ventilhub

6

8

12

18

20

24

Ventile VFU 2 ⓬

Anmerkungen zu VFU 2:

Das Ventil VFU 2 hat gegenüber den Ventilen

VFG .., AFQM eine umgekehrte Schließrichtung.

Das Ventil VFU 2 wird durch die

Sicherheits-funktion geöffnet.

Endlage “Ventil AUF” ① einstellen

Vorgehensweise

1. Schalter S2 einstellen ②

2. Drehschalter auf Stellung “CLOSE” ③

stellen.

3. die Hubanzeige ④ muss sich in

Pfeilrichtung bis zum Anschlag bewegen

Ventil ist ganz geöffnet ①

4. Hubanzeige ausrichten:

• Schrauben⑤ lösen

• Anzeigeauf0⑥ ausrichten

• Schraubenanziehen

5. Drehschalter um eine Stellung auf STOP

weiterdrehen ⑦

6. Schalter S2 einstellen ⑧

7. Taste S4 einmal drücken ⑨

Endlage “Ventil AUF” für Ventil VFU 2 ist

eingestellt.

Endlage “Ventil ZU” einstellen ⑩

Vorgehensweise

1. Ventilhub aus der folgenden Tabelle

ablesen

Typ

VFU

1. Schalter S2 einstellen ⑪

2. Drehschalter auf Stellung “CLOSE”

drehen ⑫

Ventil schließt (VFU 2), die Hubanzeige ⑬

bewegt sich in Pfeilrichtung

3. die Hubanzeige bis zum Anschlag

fahren lassen, auf der Skala ⑭ wird der

Ventilhub angezeigt

Beispiel: DN 100, Ventilhub 20 mm

4. Drehschalter um eine Stellung

weiterdrehen auf “STOP” ⑮

5. Taste S4 einmal drücken ⑯

6. Schalter S2 ⑭ einstellen ⑰

Einstellung der Endlagen ist

abgeschlossen

Nach Beendigung der Einstellungen,

Deckel und Drehschalter montieren und

Drehschalter auf Position "AUTO" drehen ⑱.

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Ventilhub

6

8

12

18

20

Bedienung

Drehschalterstellungen, elektrische

Handverstellung ⓭

• Drehschalter auf “CLOSE” ①

Antriebsstange fährt aus ② nach der

Verstellung auf “STOP” drehen

• Drehschalterauf“OPEN”③

Antriebsstange fährt ein ④ nach der

Verstellung auf “STOP” drehen

• Drehschalterauf“STOP”

Antriebsstange bleibt in der letzten

Position stehen

• Drehschalterauf“AUTO”⑤

Stellantrieb wird über den externen

Regler angesteuert.

Standardeinstellung

für normalen Regelbetrieb unbedingt

einstellen

Mechanische Handverstellungen ⓮

(nur bei den Stellantrieben AMV-H 613)

Bei Ausfall der Spannungsversorgung oder

bei einer Störung kann das Ventil geöffnet

oder geschlossen werden

1. Drehschalter auf Stellung “OPEN”

drehen ①

2. Sicherungsschraube ② lösen

3. Mittels Hakenschlüssel (Zubehör)

Antriebsstange ③ einfahren

VFG .., AFQ öffnet

VFU 2 schließt

4. Mittels Hakenschlüssel Antriebsstange

ausfahren ⑤

VFG .., AFQ schließt

VFU 2 öffnet

Vor Umschaltung in den Automatikbetrieb

(AUTO) unbedingt die Einstellmutter ⑤ bis

zum Anschlag eindrehen.

Sicherungsschraube ⑦ festschrauben

Wird das nicht beachtet, dann kann

das Ventil nicht geschlossen werden

(VFU geöffnet werden).

Page 11

Installation Guide AME (-H) 610, 613, 633

Übersetzung

❶

VFG, VFGS DN 150-250

mit Gehäuseverlängerung

(

with body extension)

Ventile (Va lves)

Gewicht (Weight)

❷

Ventil Typ (Valve type)

OK (Medium)

T

(T

max OK

Heißwasser (Hot water)

Dampf (Stea m)

❺ ⓫ ⓬ ⓭ ⓮

ÖFFNEN (OPEN)

STOP (STO P)

AUTO (AUTO)

STOP (STO P)

SCHLIESSEN (CLOSE)

max medium

)

❾

Ausgang Hub (Output stroke)

Eingang Regler (Input controller)

Ventil geöffnet (Valve Open)

Endschalter (End switches)

Ventil geschlossen (Valve Close)

Spannungsver sorgung (Power supply)

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1111

Page 12

12

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

FRANCAIS

Sécurité

Montage

Dimensions, poids ❼

Pour éviter des dommages physiques et matériels, il est absolument nécessaire de lire

attentivement et de respecter ces instructions avant le montage et la mise en service.

Le travail d’assemblage, de démarrage et de

maintenance nécessaire doit être effectué

uniquement par un personnel qualifié,

formé et autorisé.

Avant le travail d'assemblage et de maintenance du contrôleur, le système doit être:

- dépressurisé

- refroidi

- vidé

- nettoyé

Suivre les instructions du fabricant du

système ou de son service.

Ne pas retirer le couvercle avant

d'avoir coupé l'alimentation.

Indications de mise au rebus

Ce produit peut être démonté

et tous ses composants classés

si possible en différentes

catégories en vue de leur

recyclage ou destruction

Dans tous les cas , suivre la législation locale

de mise au rebus.

Conditions d’utilisation

Le servomoteur électrique est utilisé en

combinaison avec les vannes suivantes

VFG 2(21), VFG 25, VFU 2, VFGS2, AFQM.

Domaines d’application : régulation de la

température de l’eau, de la température

de l’eau, de l’eau glycolée et de la vapeur

pour chauffage, chauffage urbain et

installations de réfrigération.

Vue d’ensemble moteurs AME....

AME 610 /30

Fonction de secours

Commande manuelle

Méchanique

613/3 3

(-H )613/33

- + +

- - +

Dimensions, Poids ❶

Brides : Raccordement selon EN 1092-2

Types de vannes pour AME (-H) 6..

Le moteur électrique AME (-H) 6.. peut ętre

monté sur les vannes suivantes, voir ❷.

Orientations de montage autorisées ❸

① - DN 15-50 (T

vannes AFQM -

- DN 15-80 (T

vannes VFG 2, VFG 21, VFG 25, VFU 2

② - DN 15-250 (T

tous types de vannes

- DN 65-125 (T

vannes AFQM -

- DN 100-250 (T

vannes VFG 2, VFG 21, VFU 2

③ - DN 15-250:

vannes VFGS 2 (vapeur).

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

max

< 120oC):

Montage vanne ❹

1. Monter le filtre devant la vanne.

2. Rincer l’installation avant le montage

de la vanne.

3. Respecter le sens d’écoulement ①

indiqué sur le corps de la vanne.

4. Monter la vanne.

Les brides ② dans la tuyauterie

doivent être parallèles, les surfaces

d’étanchéité propres et sans

dommages.

5. Serrer les vis en 3 étapes en croix,

jusqu’au couple de rotation max.

Montage moteur et vanne ❺

Avant le montage:

1. Procéder au branchement électrique,

voir prochain paragraphe

2. Tourner le bouton rotatif sur position

“OPEN” ① , ainsi rétracter totalement la

tige du moteur ②

Vannes DN150 - 250

Pour les vannes DN150-250 la tige du moteur

doit être vissée dans la tige de la vanne.

Respecter la notice de

montage ③ jointe aux vannes

DN 150-250

Vannes DN15 - 125

1. Positionner le moteur sur la vanne et

procéder ŕ l’alignement

2. Serrer l’écrou prisonnier ④, facteur de

serrage 100 Nm

Isolation ❻

Danger

Risques de brűlures par l’eau

chaude ①

La vanne n’est pas étanche sans moteur ①,

le cône d’étanchéité ② se trouve dans

l’écrou de fixation du moteur.

Impérativement mettre l’installation hors

pression avant tout démontage.

Pour le démontage suivre la procédure de

montage dans le sens inverse.

Danger d’électrocution!

Lors d’une manipulation non

appropriée, danger de mort ou

risques de blessures.

Raccordement électrique

Avant le branchement des câbles,

impérativement couper l’alimentation.

Le branchement doit être effectué

uniquement par du personnel qualifié.

Pour accéder au bornier électrique,

retirer le couvercle.

Procédure ❽

1. Desserrer la vis au niveau du bouton

rotatif ①, retirer le bouton

2. Dévisser la vis ② et retirer le capot ③

Schéma de branchement électrique

Lorsque le couvercle est ouvert, raccorder

selon le schéma, voir ❾:

① Branchement pour :

STB – Limiteur de température de sécurité

STW – Contrôleur de température de sécurité

SDB – Limiteur de pression de sécurité

Avant de remettre le couvercle , effectuer

la configuration du moteur , voir section

suivante.

Lors du branchement,

impérativement retirer le pont ①

Uniquement types AME (-H)

613, 633 avec fonction de secours

Réglage moteur ❿

Avant les réglages, démonter le capot ③❽.

Désignation des commutateurs ❿ ①

Réglage du signal de sortie ❿ ②

Réglage du signal d’entrée ❿ ③

Le choix de l’entrée courant ou tension

se fait par le branchement sur le bornier,

borne 15 ou 16, voir «schéma de

branchement électrique» ❾.

Page 13

Installation Guide AME (-H) 610, 613, 633

Réglage des positions fins de course

Après le montage de la vanne et du moteur,

les positions fins de course «vanne ouverte»

et «vanne fermée» doivent être réglées.

Conditions pour le réglage:

• le moteur est monté sur la vanne

• le branchement électrique est effectué

Vannes VFG..., AFQM ⓫

Régler la position fin de course

«vanne fermée» ①

Procédure:

1. Régler le switch S2 ②

2. Tourner le bouton rotatif sur position

«CLOSE» ③

3. L’indication de course ④ doit se déplacer

dans le sens de la flèche jusqu’en butée

La vanne est totalement fermée

4. Aligner l’indication de course :

• Desserrer les vis ⑤

• Aligner l’affichage sur 0 ⑥

• Serrer les vis

5. Avancer le bouton rotatif d’une position

sur “STOP” ⑦

6. Régler le commutateur S2 ⑧

7. Presser 1 fois la touche S4 ⑨

La position fin de course «vanne fermée»

est réglée

Régler la position fin de course

«vanne ouverte» ⑩

1. Relever la course de la vanne dans le

tableau suivant

Typ e

VFG 2

VFG 21

VFG 25

AFGM

2. Régler le switch S2 ⑪

3. Tourner le bouton rotatif sur position

“OPEN” ⑫

La vanne ouvre

Exemple : DN100, course de la vanne

20 mm Dčs que la course de la vanne

est atteinte, avancer le bouton rotatif

d’une position sur «STOP» ⑭

4. Presser une fois la touche S4 ⑮

5. Régler le commutateur S2 ⑯

Le réglage des positions fins de course

est terminé.

Une fois le paramétrage réalisé , remonter

le couvercle et le bouton tournant en le

mettant sur "AUTO" ⑰.

Si vous souhaitez remettre à zéro le réglage

de course , répéter la procédure ⓫.

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

Course vanne

6

8

12

18

20

24

Vannes VFU2 ⓬

Remarques concernant VFU2 :

La vanne VFU2 a un sens de fermeture

contraire par rapport aux vannes

VFG..., AFQM

La vanne VFU2 est ouverte par la fonction

de secours.

Régler la position fin de course

«vanne ouverte» ①

Procédure:

1. Régler le switch S2 ②

2. Tourner le bouton rotatif sur position

«CLOSE» ③

3. L’indication de course ③ doit se déplacer

dans le sens de la flèche jusqu’en butée

La vanne est totalement ouverte ①

4. Aligner l’indication de course :

• Desserrerlesvis⑤

• Alignerl’achagesur0⑥

• Serrerlesvis

5. Avancer le bouton rotatif d’une position

sur “STOP” ⑦

6. Régler le commutateur S2 ⑧

7. Presser 1 fois la touche S4 ⑨

La position fin de course «vanne ouverte»

pour vanne VFU2 est réglée.

Régler la position fin de course

«vanne fermée» ⑩

1. Relever la course de la vanne dans le

tableau suivant

Typ e

VFU

2. Régler le switch S2 ⑪

3. Tourner le bouton rotatif sur position

“CLOSE” ⑫

La vanne ferme (VFU2), l’indication de

course ⑬ se déplace dans le sens de la

flèche

4. Laisser aller l’indication de course

jusqu’en butée. La course de la vanne

est indiquée sur l’échelle ⑭

Exemple : DN100, course de la vanne

20 mm

5. Avancer le bouton rotatif d’une position

sur «STOP» ⑮

6. Presser 1 fois la touche S4 ⑯

7. Régler le commutateur S2 ⑰

Le réglage des positions fins de course

est terminé

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Course vanne

6

8

12

18

20

Une fois le paramétrage réalisé , remonter

le couvercle et le bouton tournant en le

mettant sur "AUTO" ⑱.

Si vous souhaitez remettre à zéro le réglage

de course , répéter la procédure ⓬.

Manipulation

Positions du bouton rotatif,

commande manuelle électrique ⓭

• Bouton rotatif sur «CLOSE» ①

La tige du moteur descend ②

Après l’ajustement, tourner sur «STOP»

• Boutonrotatifsur«OPEN»③

La tige du moteur se rétracte ④

Après l’ajustement, tourner sur «STOP»

• Boutonrotatifsur«STOP»

La tige du moteur reste dans sa dernière

position

• Boutonrotatifsur«AUTO»⑤

Le moteur est commandé par un

régulateur extérieur

Réglage standard

A régler impérativement pour une

régulation normale

Commande manuelle mécanique ⓮

(Uniquement pour moteurs AME-H 613)

Lors d’une coupure de l’alimentation ou

lors d’une perturbation, la vanne peut être

ouverte ou fermée

1. Tourner le bouton rotatif sur position

«OPEN» ①

2. Desserrer la vis de sécurité ②

3. Rétracter la tige à l’aide d’une clé à

griffes (accessoire) ③

VFG..., AFQ ouvre ④

VFU2 ferme④

4. Descendre la tige à l’aide d’une clé à

griffes (accessoire) ⑤

VFG..., AFQ ferme ⑥

VFU2 ouvre ⑥

Avant de commuter dans le mode de

fonctionnement automatique (AUTO),

impérativement serrer l’écrou de

réglage jusqu’en butée ⑤.

Serrer la vis de sécurité ⑦

En cas de non-respect, la vanne ne peut

pas être fermée (VFU ouverte).

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1313

Page 14

14

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

Translation

❶

VFG, VFGS DN 150-250

avec extension de corps

(

with body extension)

Vannes (Va lves)

Poids (Weight)

❷

Type de vanne (Valve type)

Fluide (Medium)

T

(T

maxi fluid e

Eau chaude (Hot water)

Vapeur (Steam)

❺ ⓫ ⓬ ⓭ ⓮

OUVRIR (OPEN)

STOP (STO P)

AUTO (AUTO)

STOP (STO P)

FERMER (CLOSE)

max medium

)

❾

Sortie copie signal (Output stroke)

Signal d'entrée (Input controller)

Vanne ouverte (Valve Open)

Fins de course (End switches)

Vanne fermée (Valve Close)

Alimentation (Power supply)

Page 15

Installation Guide AME (-H) 610, 613, 633

MAG YAR

Biztonsági elõírások

Szerelés

Szigetelés ❻

Az itt leirt utasítások gondos elolvasása és

betartása feltétlenül szükséges a személyi

sérülések és berendezés károsodások

elkerülésére.

A szükséges szerelési, beüzemelési

és karbantartási munkákat kizárólag

szakképzett és azzal megbízott személyzet

végezheti el.

Fel- és leszerelés elõtt helyezze a rendszert

nyomásmentes állapotba.

- nyomásmentesítve,

- lehűtve,

- leürítve és,

- megtisztítva.

A rendszer gyártó vagy rendszer

üzemeltetõ elõírásait tartsuk be.

Ne távolítsa el a fedelet a tápfeszültség

teljes lekapcsolása előtt.

Hulladékelhelyezési utasítás

A hulladékban történő

elhelyezés, vagy újrahasznosítás előtt ezt a terméket, ha

van rá mód, szét kell szerelni,

alkatrészeit szét kell válogatni

és csoportosítani.

Mindig tartsa be a helyi hulladékkezelési

szabályokat.

Alkalmazások leírása

Az elektromos szelepmozgatót a következõ

szelepekhez csatlakoztatva használjuk:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

Alkalmazási területek: Víz, víz-glikol

keverékek, és gõz hõmérséklet zabályozása

fûtõ, távfûtõ és hûtõ rendszerekben.

Áttekintés szelepmozgatók AME 6..

610/3 0 613/3 3 (-H )613/33

Biztonsági

funkció

Mechanikus

beállítás

- + +

- - +

Méretek és súlyok ❶

Peremek: csatlakozási méretek a EN 1092-2

Szeleptípusok az AME(-H) 6..

mozgatóhoz

Az AME (-H) 6.. szelepmozgató a következõ

szelepekre szerelhetõ, - lásd a ❷.

Megengedett beépítési helyzetek ❸

① - DN 15-50 (T

szeleptípus AFQM -

- DN 15-80 (T

szeleptípus VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

minden megengedett szeleptípus

- DN 65-125 (T

AFQM típus -

- DN 100-250 (T

VFG2, VFG21, VFU szeleptípusok

③ DN 15-250:

VFGS 2 szeleptípus (gőz).

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Szelep beépítés ❹

1. Szerelje fel a szûrõt a szelep elé.

2. A szelep felszerelése elõtt öblítse ki a

rendszert.

3. Tartsa be a folyásirányra ① vonatkozó

kikötést (szeleptesten feltüntetve).

A csõvezeték peremeinek ②

párhuzamosnak, a tömítõ felületeknek

pedig tisztának és sértetlennek kell lenni.

4. Szerelje fel a szelepet.

5. Átlósan és három lépésben húzza meg

a csavarokat a max. nyomatékra.

Szelepmozgató felszerelése a

szelepre ❺

Felszerelés elõtt:

1. Végezze el a mozgató elektromos

bekötését a következõ bekezdés szerint.

2. Fordítsa a forgó kapcsolót “OPEN” ①

thelyzetbe, a szelepmozgató rúd ②

teljes visszahuzásához.

Szelepek DN 150 - 250

DN 150 - 250 méretû szelepeknél a

mozgató rudat a szelepszárba kell csavarni.

Tartsa be a DN 150 - 250 méretû

szelepekhez mellékelt ③ felszerelési

utasításokat.

Szelepek DN 15 - 125

1. Helyezze a szelepmozgatót a szelepre,

és központosítsa a szelephez.

2. A hollandi anyát ④ húzza meg 100 Nm

nyomatékra.

A szelep és szelepmozgató

szétszerelése ❼

Veszély

Gõz vagy forró víz okozta sérülés veszélye! ①

A mozgató nélküli szelep nyitva van ①, a

tömítés ② a szelepmozgatóban található.

Bármilyen munka elõtt feltétlenül szükség

van a rendszer nyomásmentesítésére.

A szétszerelést végezze az összerelés

fordított sorrendjében.

Elektromos csatlakozás

Veszély - Nagyfeszültség!

Nem megfelelõ kezelés esetén sérülés és

életveszélyes.

A bekötések elõtt kapcsolja le az

energiaellátást.

Az elektromos csatlakoztatást kizárólag

szakképzett villanyszerelõ végezheti el.

Az elektromos panelhez csak a fedél

eltávolítása után lehet hozzáférni.

Eljárás ❽

1. Lazítsa meg a hornyos csavart a

forgó kapcsolónál ①, és távolítsa

el a kapcsolót.

2. Csavarja ki a csavart ② és távolítsa

el a fedelet ③.

Elektromos kapcsolási rajzok

Amikor a fedelet eltávolította, csatlakoztassa

a kábeleket a ❾-es számú rajz szerint:

① Csatlakozás:

STB - Biztonsági hõmérséklet korlátozóhoz

STW - Biztonsági hõmérséklet figyelõhöz

SDB- Biztonsági nyomás korlátozóhoz

A fedél eltávolítása előtt hajtsa végre

a következő fejezetben található

beállításokat.

Csatlakozás elõtt feltétlenül távolítsa

el az áthidalót. ① Csak a AME (-H)

613, 633 típusoknál, melyek biztonság

visszatérõ funcióval vannak ellátva.

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1515

Page 16

16

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

Szelepmozgató beállításai ❿

A beállítások elvégzése elõtt szerelje le

a fedelet ① - lásd a 9. oldalt.

Kapcsolók jelölései ❿ ①

Kimeneti jel beállításai ❿ ②

Bemenet beállításai ❿ ③

A feszültség vagy áram bemenet kiválasztása

a kapocslécre való csatlakozással történik

(15 vagy 16 csatlakozó), lásd az "Elektromos

kapcsolási rajzot” ❾.

Végsõ pozíció beállítások

A szelep és a szelepmozgató felszerelése

után, a "Szelep NYITVA” és "Szelep ZÁRVA"

végpozíciókat be kell állítani.

A beállítások elõfeltételei:

• amozgatólegyenfelszerelveaszelepre

•

az elektromos csatlakoztatás legyen

elvégezve.

Szelepek .., AFQM ⓫

“Szelep ZÁRVA” ①

végpozíció beállítása

Eljárás:

1. Állítsa át az S2 kapcsolót ②.

2. Állítsa a forgó kapcsolót a “CLOSE/

ZÁRVA” ③ állásba.

3. A löketjelzõnek ④ a nyíl irányában

ütközésig el kell mozdulni.

Ekkor a szelep teljesen zárva van.

4. Állítsa be a löketjelzõt:

• Lazítsamegacsavarokat⑤.

• Mozdítsa el a skálát a 0 ⑥ állásba.

• Húzzamegacsavarokat.

5. Fordítsa el a forgó kapcsolót egy

pozícióval a STOP helyzetbe ⑦.

6. Nyomja meg az S4 gombot ⑧ egyszer.

7. Állítsa be az S2 kapcsolót ⑨.

Ezzel a “Szelep ZÁRVA” végpozíció

beállítása befejezõdött.

“Szelep NYITVA” ⑩

végpozíció beállítása

Eljárás:

1. Keresse meg a szelep löketét a lenti

táblázatban.

Típus

VFG 2

VFG 21

VFG 25

AFGM

2. Állítsa át az S2 kapcsolót ⑪.

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

Szelep löket

6

8

12

18

20

24

3. Állítsa a forgó kapcsolót “OPEN/NYITVA”

állásba ⑫.

Ekkor a szelep kinyit.

Példa:

DN 100, Löket 20 mm

Mihelyt a löket elmozdulás ⑬

megtörténik, állítsa a forgó kapcsolót

“STOP” állásba ⑭.

4. Nyomja meg az S4 ⑮ ongombot egyszer.

5. Állítsa be az S2 kapcsolót ⑯.

Ezzel a “Szelep NYITVA” végpozíció

beállítása befejeződött.

Miután beállította a véghelyzetet, szerelje

vissza a fedelet és a forgó kapcsolót allítsa

a forgó kapcsolót “AUTO” állásba ⑰.

Ha szeretné a véghelyzetet resetelni,

ismételje meg a ⓫-es eljárást újra.

Szelepek VFU 2 ⓬

Megjegyzések a VFU 2 szelephez:

A VFG .., AFQM szelepekkel ellentétben, a VFU

2 ellentétes zárási iránnyal rendelkezik.

A VFU 2 szelepet a biztonsági visszatérõ

funkció nyitja.

“Szelep NYITVA” ①

végpozíció beállítása

Eljárás:

1. Állítsa át az S2 kapcsolót ②.

2. Állítsa a forgó kapcsolót a “CLOSE/

ZÁRVA” ③ állásba.

3. A löketjelzõnek ④ a nyíl irányában

ütközésig el kell mozdulni.

A szelep teljesen nyitva van ①

4. Állítsa be a löketjelzõt:

• Lazítsamegacsavarokat⑤.

• Mozdítsaelaskáláta0⑥ állásba.

• Húzzamegacsavarokat.

5. Fordítsa el a forgó kapcsolót egy

pozícióval a STOP helyzetbe ⑦.

6. Nyomja meg az S4 gombot ⑧ egyszer.

7. Állítsa be az S2 kapcsolót ⑨.

Ezzel a “Szelep NYITVA” végpozíció

beállítása befejeződött.

“Szelep ZÁRVA” ⑩

végpozíció beállítása

Eljárás:

1. Keresse meg a szelep löketét a

következõ táblázatból.

Típus

VFU

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Szelep löket

6

8

12

18

20

2. Állítsa át az S2 kapcsolót ⑪.

3. Állítsa a forgó kapcsolót “OPEN/NYITVA”

állásba ⑫.

A szelep lezár (VFU 2), és mihelyt a

löketelmozdulás ⑬ hmegtörténik,

állítsa a kapcsolót "STOP" állásba.

4. A löketjelzõ ütközésig elmozdul, és a

szeleplöket kijelzésre kerül a skálán ⑭.

Példa:

DN 100, löket 20 mm

5. Fordítsa el a forgó kapcsolót egy

pozícióval a “STOP” ⑮ állásba.

6. Nyomja meg az S4 gombot ⑯ eg yszer.

7. Állítsa be az S2 kapcsolót ⑰

Ezzel a “Szelep ZÁRVA” végpozíció

beállítása befejezõdött.

Miután a szelep véghelyzet beállítást

befejezte, szerelje vissza a fedelet és a forgó

kapcsolót allítsa a forgó kapcsolót “AUTO”

állásba ⑱.

Ha szeretné a véghelyzetet resetelni,

ismételje meg újra a ⓬-es eljárást.

Mûködés

Elektromos kézi beállítások ⓭

• Aforgókapcsolóhelyzete:“CLOSE“①

A mozgatórudat kitoljuk ②:

Újra pozícionálás után, forditsa “STOP”

állásba.

• Aforgókapcsolóhelyzete“OPEN“③

A mozgatórudat visszahúzzuk ④:

Újra pozícionálás után, fordítsa “STOP”

állásba.

• Aforgókapcsolóhelyzete“STOP“

A mozgatórúd az utolsó pozíciójában

marad.

• Aforgókapcsolóhelyzete“AUTO“⑤

A szelepmozgatót a külsõ szabályozón

keresztül szabályozzuk.

Standard beállítás

Szigorún tartsa be a normál üzemhez.

Mechanikus kézi beállítások ⓮

(Csak AMV-H 613 szelepmozgatóknál)

Energiaellátási vagy üzemi hiba esetén a

szelep nyitható vagy zárható.

1. Fordítsa a forgó kapcsolót “CLOSE/

ZÁRVA” állásba ①.

2. Lazítsa meg a ② biztosító csavart.

3. Körmöskulcs (tartozék) segítségével

húzza vissza a mozgatórudat ③:

VFG .., AFQM nyit ④

VFU 2 zár ④

Page 17

Installation Guide AME (-H) 610, 613, 633

4. Körmöskulcs (tartozék) segítségével

tolja ki a mozgatórudat ⑤:

VFG .., AFQM zár ⑥

VFU 2 nyit ⑥

Automatikus üzemre (AUTO) kapcsolás

elõtt, feltétlenül szükséges a beállító anya

⑤ ütközésig fordítása.

Húzza meg a biztosító csavart ⑦.

Ha ezt az utasítást nem tartja be, akkor

a szelepet nem lehet zárni.

(VFU ... nem lehet nyitni).

Referencia megjegyzések

❶

VFG, VFGS DN 150-250

szeleptest toldattal

(

with body extension)

Szelepek ( Valve s)

Súly (Weig ht)

❷

Szeleptípus (Valve type)

Áramló közeg (Medium)

T

max Közeg

(T

max medium

)

Melegvíz (Hot water)

Gőz (Steam)

❾

kimeneti szelepemelkedés jel

(Output stroke)

Bemeneti szabályozó (Input controller)

Szelep nyitva (Valve Open)

Végálláskapcsolók (End switches)

Szelep zárva (Valve Close)

Működtető feszültség (Power supply)

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1717

Page 18

18

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

POLSKI

Warunki bezpieczeństwa

Montaż

Demontaż zaworu, napędu ❼

W celu uniknięcia zranienia osób i uszkodzenia urządzeń należy bezwzględnie przed

montażem i uruchomieniem zaworu zapoznać się dokładnie z niniejszą instrukcją.

Czynności związane z montażem, uruchomieniem i obsługą mogą być dokonywane

wyłącznie przez osoby uprawnione i odpowiednio wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ostudzić urządzenie

- opróżnić układ,

- oczyścić

Należy stosować się do instrukcji producenta

lub operatora układu.

Nie wolno zdejmować obudowy

przed całkowitym odłączeniem

napięcia zasilającego.

Instrukcja złomowania

Przed złomowaniem lub

utylizacją niniejszy produkt

należy rozebrać na części

i posortować na różne grupy

materiałowe.

Należy przestrzegać lokalnych przepisów

w zakresie złomowania.

Zakres zastosowań

Siłownik elektryczny stosowany

jest w połączeniu z zaworami:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

Znajdują zastosowanie w regulacji

temperatury wody, roztworu woda-glikol

i pary wodnej w układach cieplnych,

instalacjach grzewczych i chłodzenia.

Przegląd siłowników AME 6..

AME 610 /30 613 /33 (-H )613/33

Funkcja

bezpieczeństwa

Regulacja

mechaniczna

Wymiary, Masa ❶

Kołnierze – wymiary połączeń zgodne

z EN 1092-2, uszczelka typu C.

Typy zaworów do AME(-H)6..

Siłownik elektryczny typu AME(-H) 6...może

współpracować z zaworami regulacyjnymi,

zgodnie ❷.

- + +

- - +

Dopuszczalne pozycje montażu ❸

① - DN 15-50 (T

zawór typu AFQM -

- DN 15-80 (T

zawory typów VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

wszystkie dopuszczalne typy zaworów

- DN 65-125 (T

zawór typu AFQM -

- DN 100-250 (T

zawory typów VFG 2, VFG 21, VFU 2

③ - DN 15-250:

zawór typu VFGS 2 ( do pary)

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

max

< 120oC):

Montaż zaworu ❹

1. Zamontować filtr przed zaworem.

2. Przed zamontowaniem zaworu

przepłukać instalację.

3. Zwrócić uwagę na wskaźnik kierunku

przepływu ① na korpusie zaworu.

Kołnierze ② na rurociągu muszą

być wzajemnie równoległe, a

powierzchnie pod uszczelki czyste

i bez uszkodzeń.

4. Zamontować zawór.

5. Dokręcać przeciwległe nakrętki w 3

krokach do osiągnięcia maksymalnego

momentu.

Montaż siłownika i zaworu ❺

Przed montażem

1. Wykonaj połączenia elektryczne, patrz

dalsza część instrukcji

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” ①, to spowoduje całkowite

cofnięcie trzpienia ②.

Dla zaworów DN 150–250

Trzpień siłownika musi zostać wkręcony

w trzpień zaworu.

Szczegóły znaleźć można

w Instrukcji Użytkowania

zaworów DN 150–250 ③

Dla zaworów DN 15–125

1. Umieścić siłownik na zaworze.

2. Dokręcić nakrętkę łączącą ④.

Moment: 100 Nm

Izolacja ❻

Uwaga

Ryzyko poparzenia parą lub

gorącą wodą! ①

Zawór bez napędu jest otwarty ①,

uszczelnienie ② znajduje się w napędzie.

Przed demontażem należy bezwzględnie

zrzucić ciśnienie z układu.

Kolejność wykonywanych czynności przy

demontażu odwrotna w stosunku do

kolejności podczas montażu.

Podłączenie elektryczne

WYSOKIE NAPIĘCIE!

Ryzyko obrażeń i zagrożenie życia

w przypadku nieprawidłowej obsługi.

Przed wykonaniem podłączeń elektrycznych

należy bezwzględnie wyłączyć zasilanie.

Podłączenia elektryczne mogą być

wykonane wyłącznie przez uprawnionego

elektryka.

W celu wykonania podłączeń elektrycznych

wcześniej należy zdjąć osłonę.

Tryb postępowania ❽

1. Zluzować wkręt w przełączniku

obrotowym ①, usunąć przełącznik

obrotowy.

2. Odkręcić śrubę ② i usunąć obudowę ③

Schemat podłączeń elektrycznych

Po zdjęciu obudowy wykonać podłączenia

przewodów zgodnie ze schematem

elektrycznym, patrz ❾:

① zaciski do:

STB – Ogranic znik temp eratur y bezpie czeńst wa

STW – Strażnik temperatury bezpieczeństwa

SDB – Ogranicznik ciśnienia bezpieczeństwa

Przed założeniem osłony wykonać wszystkie

nastawy siłownika - patrz rozdział następny.

Przed połączeniem należy

koniecznie usunąć mostek ① dot. wyłącznie typów AME(-H)

613, 633 z funkcją sprężyny

powrotnej.

Nastawy siłownika ❿

Przed wykonaniem jakichkolwiek nastaw

należy zdemontować osłonę ③❽.

Oznaczenia mikroprzełączników ❿ ①

Nastawy sygnałów wyjściowych ❿ ②

Page 19

Installation Guide AME (-H) 610, 613, 633

Nastawy sygnałów wejściowych ❿ ③

Wybór rodzaju sygnału - napięciowy lub

prądowy - dokonywany jest przez odpowiednie podłączenia na listwie zaciskowej –

zacisk 15 lub 16 – patrz „Schemat podłączeń

elektrycznych” ❾.

Nastawy pozycji krańcowych

Po zamontowaniu zaworu i siłownika należy

ustawić pozycje krańcowe „Zawór otwarty”

i „Zawór zamknięty”.

Warunki wstępne wykonania nastaw to:

• siłownikzamontowanynazaworze,

• wpełniwykonanepodłączenia

elektryczne.

Zawory VFG..., AFQM ⓫

Ustawianie pozycji krańcowej

„Zawór zamknięty” ①

Tryb postępowania:

1. Ustawić przełącznik S2 ②.

2. Ustawić przełącznik obrotowy w pozycji

„CLOSE” ③.

3. Wskaźnik położenia ④ musi

przemieszczać się zgodnie z kierunkiem

strzałki aż do zatrzymania.

Zawór jest całkowicie zamknięty.

4. Wyregulować wskaźnik położenia:

• poluzowaćśruby⑤.

• ustawićpozycję0⑥.

• dokręcićśruby.

5. Przestawić przełącznik obrotowy na

pozycję „STOP” ⑦.

6. Ustawić przełącznik S2 ⑧.

7. Nacisnąć klucz S4 jeden raz ⑨.

Pozycja krańcowa „Zawór zamknięty”

została nastawiona.

Ustawianie pozycji krańcowej

„Zawór otwarty” ⑩

1. Odczytać skok zaworu z poniższej tabeli.

Typ

VFG 2

VFG 21

VFG 25

AFGM

1. Ustawić przełącznik S2 ⑪.

2. Przestawić przełącznik obrotowy na

pozycję „OPEN”. ⑫

Zawór otwiera się.

Przykład: DN 100, skok 20 mm

Kiedy tylko skok ⑬ zostanie osiągnięty,

należy przestawić przełącznik obrotowy

na pozycję „STOP” ⑭.

3. Nacisnąć klucz S4 jeden raz ⑮.

4. Ustawić przełącznik S2 ⑯.

Pozycja krańcowa „Zawór otwarty”

została nastawiona.

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

Skok zaworu

6

8

12

18

20

24

Po zakończeniu ustawień pozycji krańcowych zamontować ponownie osłonę

i przełącznik obrotowy a następnie prze-

łącznik ten ustawić w pozycji "AUTO" ⑰.

W celu zresetowania pozycji krańcowych

należy powtórzyć procedurę ⓫.

Zawory VFU 2 ⓬

Uwagi do zaworów VFU 2:

W stosunku do zaworów VFG ..., AFQM, zawór typu

VFU 2 ma odwrócony ki erunek zamykania.

Zawór VFU 2 jest otwierany przez funkcję

bezpieczeństwa sprężyny powrotnej.

Ustawianie pozycji krańcowej

„Zawór otwarty” ①

Tryb postępowania:

1. Ustawić przełącznik S2 ②.

2. Ustawić przełącznik obrotowy w pozycji

„CLOSE” ③.

3. Wskaźnik położenia ④ musi

przemieszczać się zgodnie z kierunkiem

strzałki aż do zatrzymania.

Zawór jest całkowicie otwarty ①.

4. Wyregulować wskaźnik położenia:

• poluzowaćśruby⑤.

• ustawićpozycję0⑥ .

• dokręcićśruby.

5. Przestawić przełącznik obrotowy na

pozycję „STOP” ⑦.

6. Ustawić przełącznik S2 ⑧.

7. Nacisnąć klucz S4 jeden raz ⑨.

Pozycja krańcowa „Zawór otwarty”

została nastawiona.

Ustawianie pozycji krańcowej

„Zawór zamknięty” ⑩

1. Odczytać skok zaworu z poniższej tabeli.

Typ

VFU

DN

15, 20, 25

32, 40

50, 65

80

100, 125

1. Ustawić przełącznik S2 ⑪.

2. Przestawić przełącznik obrotowy na

pozycję „CLOSE” ⑫.

Zawór zamyka się. Kiedy tylko skok ⑬

zostanie osiągnięty, należy przestawić

przełącznik obrotowy na pozycję „STOP”.

3. Wskaźnik położenia podnosi się do oporu,

skok zawór jest przedstawiony na skali ⑭.

Przykład: DN 100, skok 20 mm.

4. Przestawić przełącznik obrotowy na

pozycję „STOP” ⑮.

5. Nacisnąć klucz S4 jeden raz ⑯.

6. Ustawić przełącznik S2 ⑰.

Pozycja krańcowa „Zawór zamknięty”

została nastawiona.

Skok zaworu

6

8

12

18

20

Po zakończeniu ustawień pozycji krańcowych zamontować ponownie osłonę

i przełącznik obrotowy a następnie prze-

łącznik ten ustawić w pozycji "AUTO" ⑱.

W celu zresetowania pozycji krańcowych

należy powtórzyć procedurę ⓬.

Działanie

Regulacja ręczna - elektryczna ⓭

• Przełącznikobrotowyustawionyna

"CLOSE" ①. Trzpień siłownika jest

wysuwany ②.

Po zmianie położenia, przekręcić na

pozycję „STOP”.

• Przełącznikobrotowyustawionyna

"OPEN" ③. Trzpień siłownika jest

cofany ④.

Po zmianie położenia, przekręcić na

pozycję „STOP”.

• Przełącznikobrotowyustawionyna

„STOP”. Trzpień siłownika pozostaje w

ostatnim położeniu.

• Przełącznikobrotowyustawionyna

"AUTO" ⑤

Siłownik sterowany jest sygnałem z

regulatora.

Ustawienia standardowe

Stosowane do normalnej pracy automat ycznej.

Regulacja ręczna - mechaniczna ⓮

(tylko w siłownikach AMV-H 613)

W przypadku awarii żródła zasilania lub

błędu działania, zawór może zostać ręcznie

otworzony lub zamknięty.

1. Przestawić przełącznik obrotowy na

pozycję „CLOSE” ①.

2. Poluzować śrubę zabezpieczającą ②.

3. Przy pomocy klucza (akcesoria) cofnąć

trzpień siłownika ③.

VFG..., AFQ otwieranie ④

VFU 2 zamykanie ④

4. Przy pomocy klucza (akcesoria)

wysunąć trzpień siłownika ⑤.

VFG..., AFQ zamykanie ⑥

VFU 2 otwieranie ⑥

Przed przełączeniem w tryb pracy automatycznej (AUTO) nale ży bezwzg lędnie dokładni e

pokręcić nakrętką regulacyjną ⑤ do oporu.

Dokręcić śrubę zabezpieczającą ⑦.

Jeśli tak się nie stanie, zawór nie będzie domykany (VFU... nie będzie w pełni otwierany).

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

1919

Page 20

20

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

Opis rysunków

❶

VFG, VFGS DN 150-250

z przedłużonym korpusem

(

with body extension)

Zawory ( Valve s)

Masa (Weight)

❷

Typ zaworu (Valve type)

Czynnik (Medium)

T max czynnika (T max medium)

Woda (Hot water)

Para (Ste am)

❾

Sygnał wyjściowy (Ausgang Hub)

Sygnał wejściowy (Eingang Regler)

Zawór otwarty (Ventil geöffnet)

Wyłączniki krańcowe (Endschalter)

Zawór zamknięty (Ventil geschlossen)

Zasilanie (Spannungsver sorgung)

Page 21

Installation Guide AME (-H) 610, 613, 633

中文

安全注意事项

安装

驱动器的拆卸 ❼

为避免人员受伤或设备受损,在进行组装

和调试前,请务必认真阅读并遵守该说明。

所需的安装、启动和维护工作必须由训练有

素且获得授权的合格人员进行。

在对控制器进行安装和维护之前,必须将

系统:

- 减压

- 冷却

- 排空

- 清洁。

请遵循系统制造商或系统操作人员的说

明。

切勿在完全切断电源之前,揭开保护盖。

弃置说明

在 回 收 和 处 理 之 前 ,应 拆 卸

本产品,并尽可能将分拆的

组件进行分类。

务必坚持贯彻当地的回收处理

法规。

应用

本驱动器和下列阀门配合使用:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

本产品用于供热、区域供热、制冷等系统中

的温度控制,介质可以为水,水-乙二醇混合

物 ,蒸 汽 等 。

AME 6.. 系列驱动器概述

610/3 0 613/3 3 (-H )613/33

安全功能

机械手动

- + +

- - +

尺 寸 ,重 量 ❶

法兰 尺寸按 EN 1092-2

与 AME(-H) 6.. 驱动器相配

AME(-H) 6.. 系列驱动器可安装于如下阀体

上 ,参 见 ❷。

允许的安装位置 ❸

① - DN 15-50 (T

阀门型号 AFQM -

- DN 15-80 (T

阀门型号 VFG 2, VFG 21, VFG 25, VFU 2

② - DN 15-250 (T

所有允许的阀门型号

- DN 65-125 (T

阀门型号 AFQM -

- DN 100-250 (T

阀门型号 VFG 2, VFG 21, VFU 2

③ DN 15-250:

阀门型号 VFGS 2(蒸汽)

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

阀门安装 ❹

1. 在阀前应安装过滤器。

2. 安装阀门前应冲洗管道。

3. 注意阀体上标明的 ① 介质流动方向 。

法兰 ② 必须平行

法兰 ② 必 须 平 行 ,其 密 封 表 面 应 清 洁

且无损坏。

4. 安装阀体。

5. 按对角方向拧紧螺栓。

驱动器和阀体的连接 ❺

在安 装前:

1. 按下一节中的接线图接好线。

2. 将驱动器上的转换开关置于“OPEN”

① 的位置,以使驱动器内的驱动杆完全

收缩。

阀门 DN 150-250

对于 DN 150 - 250 的阀门,驱动器的驱动杆

必须拧进阀体的驱动杆中。

详细请参照 DN 150-250 的安装指南 ③。

阀门 DN 15-125

1. 将驱动器置于阀体上并对正。

2. 以 100 Nm 的力矩拧紧螺帽 ④。

保温 ❻

危险

小心蒸汽或热水!①

阀门未安装驱动器时是敞开的 ①,密 封 ②

在驱动器上。

因此在作业时必须卸去系统压力。

拆卸顺序与安装时相反。

电气连接

高 压 ,小 心

操作不当将 有 触电的 危险!

接线前先断开电源。

必须由电气专业人员进行连接。 取下保护

盖后方可接触到配电盘。

取下保护盖 ❽

1. 松开转换开关的固定螺钉 ①,取 下 转 换

开关。

2. 松开螺丝 ②,取下接线盒上的保护盖 ③。

连接

取下保护盖后,依照接线图接线,参考 ❾:

① 用作连接:

STB - 温度限制安全功能

STW - 温度监测安全功能

SDB - 压力限制安全功能

盖回盖子之前,首先要对驱动器进行设定,

详见下一章。

当需要使用 ① 端子实现安全功能控制

时 ,需 先 摘 下 ① 处跳线 - 仅当驱动器

是AME(-H) 613, 633 时有此功能。

驱动器的设定 ❿

在设定前,先依照上一节所述打开接线盖

盒。

开关及按钮排列 ❿ ①

输出信号设定 ❿ ②

输入信号设定 ❿ ③

输入信号是电压还是电流由接于哪个 端子

来 决 定 ,即 连 接 于 端 子 15 还是 16,详见

“电气接线图” ❾。

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

2121

Page 22

22

Installation Guide AME (-H) 610, 613, 633

DH-SMT/SI VI.AA.X3.6U Danfoss Heating

全开/全关位置确定

安装完阀门和驱动器后,必须设定阀门的全

开/全关 位置。

设定前需具备如下条件:

•

电气接线完毕

对于阀门 VFG .., AFQM ⓫

设定阀门

全关位置 ①

步骤:

1. 设定拨动开关 S2 ② 。

2. 将转换开关打到“CLOSE”位置 ③。

3. 阀位指示器 ④ 朝箭头指示方向运动直

至停止。

此时阀门完全关闭。

4. 对齐阀位指示器:

• 松开固定螺丝 ⑤。

• 将刻度 0 与阀位指示器对齐 ⑥。

• 拧紧螺 丝。

5. 将 转 换 开 关 转 到“STOP”位 置 ⑦。

6. 按下 S4 按钮一次 ⑧。

7. 设定拨动开关 S2 ⑨。

阀门全关位置设定完毕。

设定阀门

全开位置 ⑩

步骤:

1. 在下表中找出阀门行程:

型号

VFG 2

VFG 21

VFG 25

AFGM

2. 设定拨动开关 S2 ⑪

3. 将 转 换 开 关 置 于“ OPEN”⑫

阀门打开

如:

DN 100,行 程 20 mm

一旦达到阀门行程位置 ⑬,立 刻 将 转

换 开 关 达 到“ STOP”⑭

4. 按下 S4 按钮一次 ⑮

5. 按下 S2 按钮一次 ⑯

阀门全开位置设定完毕。

完成设定后,盖上盖子,安上转换开关柄,

将转换开关打到“AUTO”位 置 ⑰。

若想重新设定全开/全关位置,请重复步

骤 ⓫。

DN

15, 20, 25

32, 40

50, 65

80

100, 125

150, 200, 250

阀门行程

6 mm

8 mm

12 mm

18 mm

20 mm

20 mm

阀门 VFU 2 ⓬

注:

与 VFG.., AFQM 比,VFU 2 是反向作用的

阀体,即当驱动器安全复位时阀门打开。

设定阀门

全开位置 ①

步骤:

1. 设定拨动开关 S2 ②。

2. 将转换开关打到“CLOSE”位置 ③。

3. 阀位指示器 ④ 朝箭头指示方向运动直

至停止。

此时阀门全开 ①。

4. 对齐阀位指示器:

• 松开固定螺丝 ⑤。

• 将刻度 0 与阀位指示器对齐 ⑥。

• 拧紧螺 丝。

5. 将 转 换 开 关 转 到“ STOP”位 置 ⑦。

6. 按下 S4 按钮一次 ⑧。

7. 设定拨动开关 S2 ⑨。

阀门全开位置设定完毕。

设定阀门

全关位置 ⑩

步骤:

1. 在下表中找出阀门行程:

型号

VFU

2. 设定拨动开关 S2 ⑪

3. 将 转 换 开 关 置 于“ OPEN”⑫

此时阀门往关的方向走。一旦达到阀门

行程,立即将转换开关打到 "STOP" 位

置。

4. 阀位指示器达到最上端 ⑭

如:

DN 100,行 程 20 mm

5. 将 转 换 开 关 转 到“ STOP”位 置 ⑮

6. 按下 S4 按钮一次 ⑯

7. 设定拨动开关 S2 ⑰

阀门全关位置设定完毕。

完成设定后,盖上盖子,安上转换开关柄,

将 转 换 开 关 达 到“AUTO”位 置 ⑱。

若想重新设定全开/全关位置,请重复步

骤 ⓬。

DN

15, 20, 25

32, 40

50, 65

80

100, 125

阀门行程

6 mm

8 mm

12 mm

18 mm

20 mm

操作

电手动 ⓭

• 将转换开关打到“CLOSE”①

驱动器内的驱动杆向外运动 ②:

走完一个行程后打到“STOP”

• 将转换开关打到“OPEN”③

驱动杆向内收缩 ④:

走完一个行程后打到“STOP”

• 将转换开关打到“STOP”

阀门将 保 持原 来的位 置。

• 将转换开关打到“AUTO”⑤

驱动器将由外部控制器控制。

标准设定

严 格 遵 守 ,以 保 证 正 常 作 业

机械手动 ⓮

(仅对驱动 器 AME-H 613 有效)

若 发 生 停 电 或 运 行 故 障 ,阀 门 可 能 会 打 开

或关闭

1. 将转换开关打到“CLOSE”①。

2. 松开安全螺丝 ②。

3. 用扳手(附件)使驱动杆向内收缩 ③:

VFG .., AFQM 阀门打开 ④

VFU 2 阀门关闭 ④

4. 用 扳 手(附 件 )使 驱 动 杆 向 外 运 动 ⑤:

VFG .., AFQM 阀门关闭 ⑥

VFU 2 阀门打开 ⑥

在将转换开关打回到自动之前(AUTO),

必须将调整螺 帽按图中所示方向 ⑤ 拧到

不能动为止。

将安全螺丝拧紧 ⑦。

若不这样,阀门将关不上。

(VFU 则 为 打 不 开 )。

Page 23

Installation Guide AME (-H) 610, 613, 633

翻译

❶

VFG, VFGS DN 150-250

带阀体加长件

(with body extension)

阀门 ( Valve s)

重量 (Weight)

❷

阀门类型 (Valve type)

介质 (Medium)

介质最大温度 (T max medium)

热水 (Hot water)

蒸汽 (Steam)

❺ ⓫ ⓬ ⓭ ⓮

开 (OPEN)

停止 (STO P)

自动 (AU TO)

停止 (STO P)

关 (CLOSE)

❾

阀位反馈 (Output stroke)

调节器输入 (Input controller)

阀门开 (Valve Open)

限位开关 (End switches)

阀门开 (Valve Close)

电源 (Power supply)

Danfoss Heating VI.AA.X3.6U DH-SMT/SI

2323

Page 24

Installation Guide AME (-H) 610, 613, 633

73696030 / VI.AA.X3.6U

Produced by Danfoss A/S © 04/2010

Loading...

Loading...