Page 1

Data sheet

Actuator for three point control

AMV 435

Description

AMV 435 actuator is used with two and three-way

valves type VRB, VRG, VF and VL up to DN 80

diameter and for AHQM DN 40-100. It is also

used with pressure independent balancing and

control valve type AB-QM from DN 40 to DN 100.

Ordering Actuator

Typ e Supply voltage Code No.

AMV 435

Accessories - Stem heater

Typ e DN

Stem heater 15- 80 24 V 065Z0315

24 VAC /DC 082H0162

230 VAC 082H0163

Power

supply

Code No.

The advanced design incorporates load related

‘switch-o’ to ensure that actuators and valves

are not exposed to overload.

Combinations with other valves could be seen

under Accessories.

Main data:

• Nominal voltage:

- 24 VAC/DC, 50 Hz/60 Hz

- 230 VAC, 50 Hz/60 Hz

• Control input signal:

3 point

• Force: 400 N

• Stroke: 20 mm

• Speed (selectable):

- 7.5 s/mm

- 15 s/mm

• Max. medium temperature: 130 °C

• LED signalling

• End-position signals

• Manual operation

Accessories - Adapter

Valves DN

For old VRB, VRG,

VF, VL valves

For AB-QM 1st gen. 40 - 100 -

max Δp

(bar)

15 9

20 4

25 2

32 1

40 0.8

50 0.5

Code No.

065Z0313

Technical data

DEN-SMT/SI

Power supply V 24 AC/DC, 230 AC; +10 to –15%

Power consumption VA 3 (24 V); 7,6 (230 V)

Frequency Hz 50 or 60 (for VAC power supply)

Control input 3 point

Close of force N 400

Max. stroke mm 20

Speed s/mm 7,5 or 15

Max. medium temperature

Ambient temperature 0 … 55

Storage and transport temperature –40 … +70

Protection class II

Degree of protection IP 54

Weight kg 0,45

- marking in accordance with

standards

VD.LE.N5.02 © Danfoss 11/2014

o

C

Low Voltage Directive (LVD) 2006/95/EC: EN 60730-1, EN 60730-2-14

EMC Directive 2004/108/EC: EN 61000-6-2, EN 61000-6-3

130

1

Page 2

Data sheet Actuator for three point control AMV 435

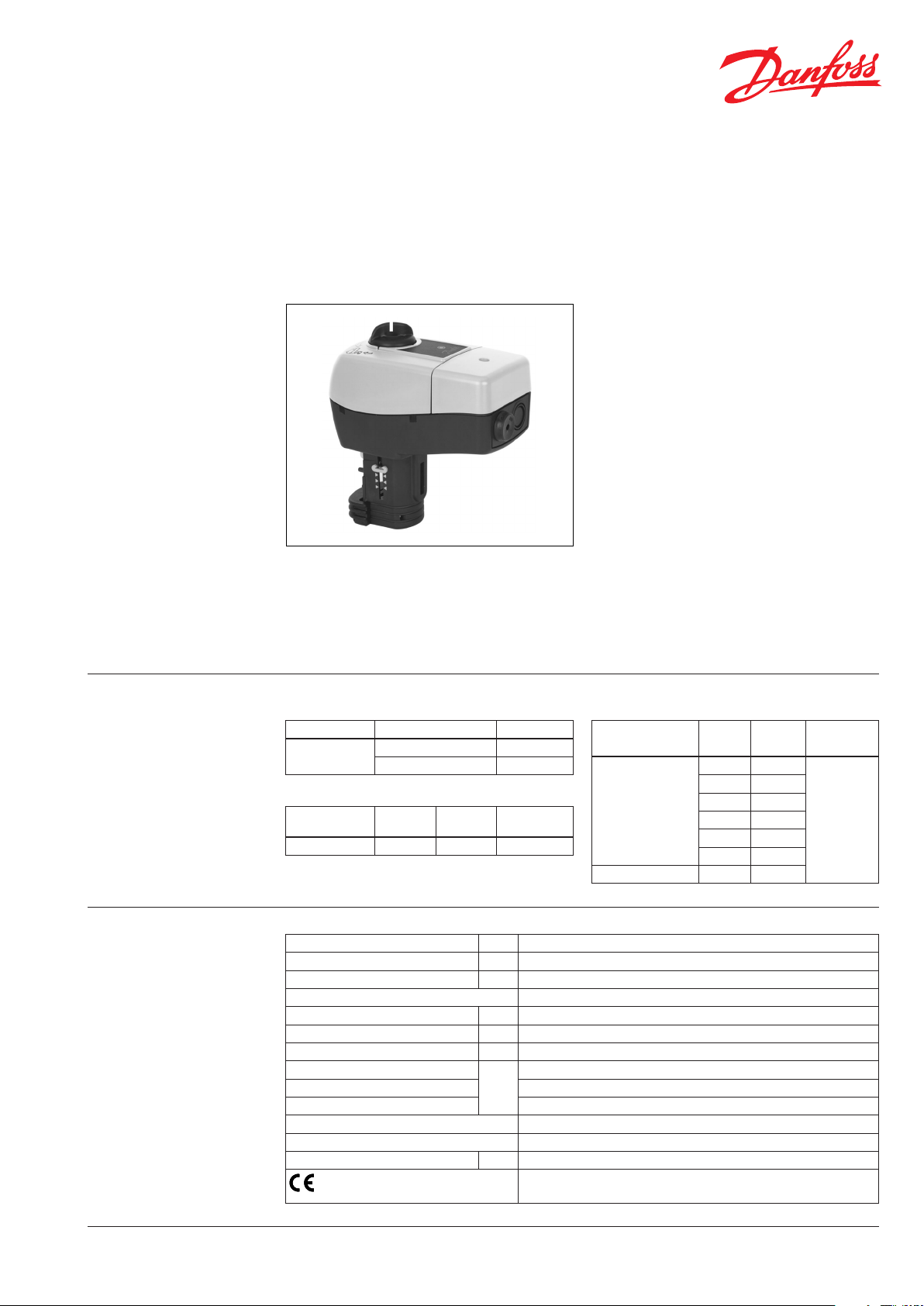

Installation Mechanical

No tool is required to mount actuator on the

valve. Installation of the valve with the actuator

is allowed in horizontal position or upwards.

Installation downwards is not allowed.

The actuator must not be installed in an

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature higher

than 55 °C. It must not be subject to steam jets,

water jets or dripping liquid as well.

Note:

The actuator may be rotated up to 360° with respect

to the valve stem by loosening the retaining xture.

Once the actuator is placed, retighten the xture.

Electrical

Electrical connections can be accessed by

removing the actuator cover. Two cable gland

entries without thread (Ø16 and combined Ø16/

Ø20) are prepared for cable glands. From factory

one entry is provided by rubber cable gland and

the other entry is prepared for opening.

Note:

Cable and cable gland used must not compromise

the actuator’s IP rating, and must ensure the

connectors are fully strain relieved.

Rubber cable gland delivered from factory does not

compromise IP rating but it does not provide fully

strain relieve according to LVD directive.

Please observe local rules and regulations as well.

③

①

②

⑤

④

Commissioning

LED signalling/

Actuator operating mode

Complete the mechanical and electrical

installation and perform the necessary checks

and tests:

• Apply power

• Apply the appropriate control signal and

check that the valve stem direction is correct

for the application.

The unit is now fully commissioned.

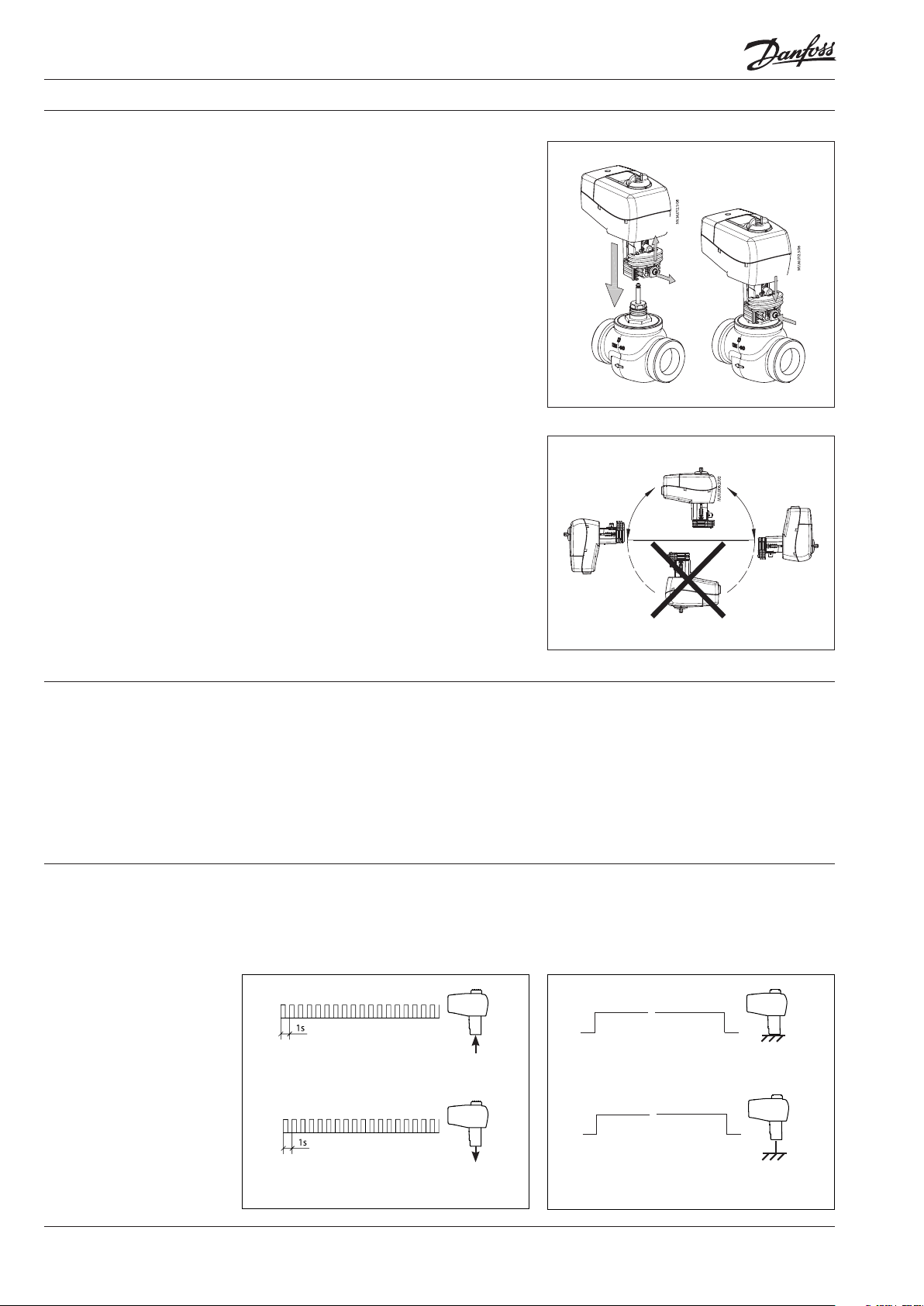

LED function indicator

The bi-colour (green/red) LED function indicator

is located on the actuator cover. It indicates the

operating modes.

Flashing red LED:

moving to retracted position

≈

Constant red LED:

retracted position reached

≈

Flashing green LED:

moving to extrac ted position

2

VD.LE.N5.02 © Danfoss 11/2014

Constant green LED:

extracted position reached

DEN-SMT/SI

Page 3

Data sheet Actuator for three point control AMV 435

Manual override Manual override is done by means of control

knob on actuator housing:

• Disconnect control signal

• Adjust valve position using the control knob

(observe the rotation direction)

After manual override is not needed:

• Restore control signal

Wiring

Do not touch anything on the PCB!

Do not remove the cover before the

power supply is fully switched o.

Max. power allowed on ports

4 and 5 is 7 VA.

down

power

supply

down

Terminals 1, 3:

Control voltage input from the controller.

Power supply 24 VAC/DC, 230 VAC (dependent

on type)

Note:

AB-QM valve closes if moved to extracted position

(terminal 1) and opens if moved to retracted

position (terminal 3).

up

Terminals 4, 5:

Output used for position indication or

monitoring

N

Neutral/Common (0 V)

Wiring length

0-50 m 0.75 mm

> 50 m 1.5 mm

up

Recommended crosssectional area of the wiring

2

2

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

DEN-SMT/SI

VD.LE.N5.02 © Danfoss 11/2014

3

Page 4

Data sheet Actuator for three point control AMV 435

Dimensions

147

82,5

Actuator - valve combinations

159, 5

min. 180

AMV 435 + AMV 435 + AMV 435 + AMV 435 + AMV 435 + AMV 435 +

VRB 2, VRG 2 VRB 3, VRG 3 VF 2, VL 2 VF 3, VL 3 AB-QM (DN 40-100) AHQM (DN 40-100)

4

VD.LE.N5.02

Produce d by Danfoss A/S © 11/2014

Loading...

Loading...