Page 1

Data sheet

Actuator for three point control

AMV 150

Description

Ordering

Actuator is primarily designed to regulate valve

in the respond to the demand of a controller

in District heating, heating, floor heating,

solar heating, zone heating, comfort cooling,

ventilating and air conditioning systems etc.

Actuator AMV 150 can be controlled by

electronic controllers with 3-point output.

Actuator

Typ e Supply voltage Speed Code No.

AM V 150

24 VAC

230 VAC 082G3090

24 s/mm

082G3089

Actuator can be used in combination with:

- Valve types VS 2 (DN 15 only) and VMV

- Self acting flow controller AVQM (DN15 only)

Features:

• Self stroking feature: automatic adaptation

of stroke to valve’s end -position - reduces

commissioning time

• Manual operation

• Position indication

• LED signalling (below the cover)

• No tool mounting

• Supplied with 1.5 m cable

• Suitable for high temperatures

Main Data:

• Nominal voltage

24 VAC, 50/60 Hz

230 VAC, 50/60 Hz

• Control input signal: 3 point

• Force: 250 N

• Stroke: 5 mm

• Speed: 24 s/mm

• Max. medium temperature: 150 °C

Accessories

Typ e Supply voltage Length Code No.

Cable

24 VAC

230 VAC 082H8053

5 m

082H8052

Technical data

© Danfoss | 2017.05

Power supply V 24 or 230 AC; +10 % to −15 %

Power consumption VA 1 (24 V), 8 (230 V)

Frequency Hz 50 /60

Control input 3-point

Closing force N 250

Max. stroke mm 5

Speed s/mm 24

Max. medium temperature

Ambient temperature 0 … 55

Storage and transport temperature −40 … +70

Ambient humidity 95 % r.h., non-condensing

Protection class II

Grade of enclosure IP 54

Weight kg 0.34

- marking in accordance with standards

°C

Low Voltage Directive (LVD) 2014/35/EU: EN 60730-1, EN 60730-2-14

Electromagnetic Compatibility Directive (EMC) 2014/30/EU:

EN 61000-6-2, EN 61000-6-3

150

VD.KH.A7.02 | 1

Page 2

Data sheet AMV 150

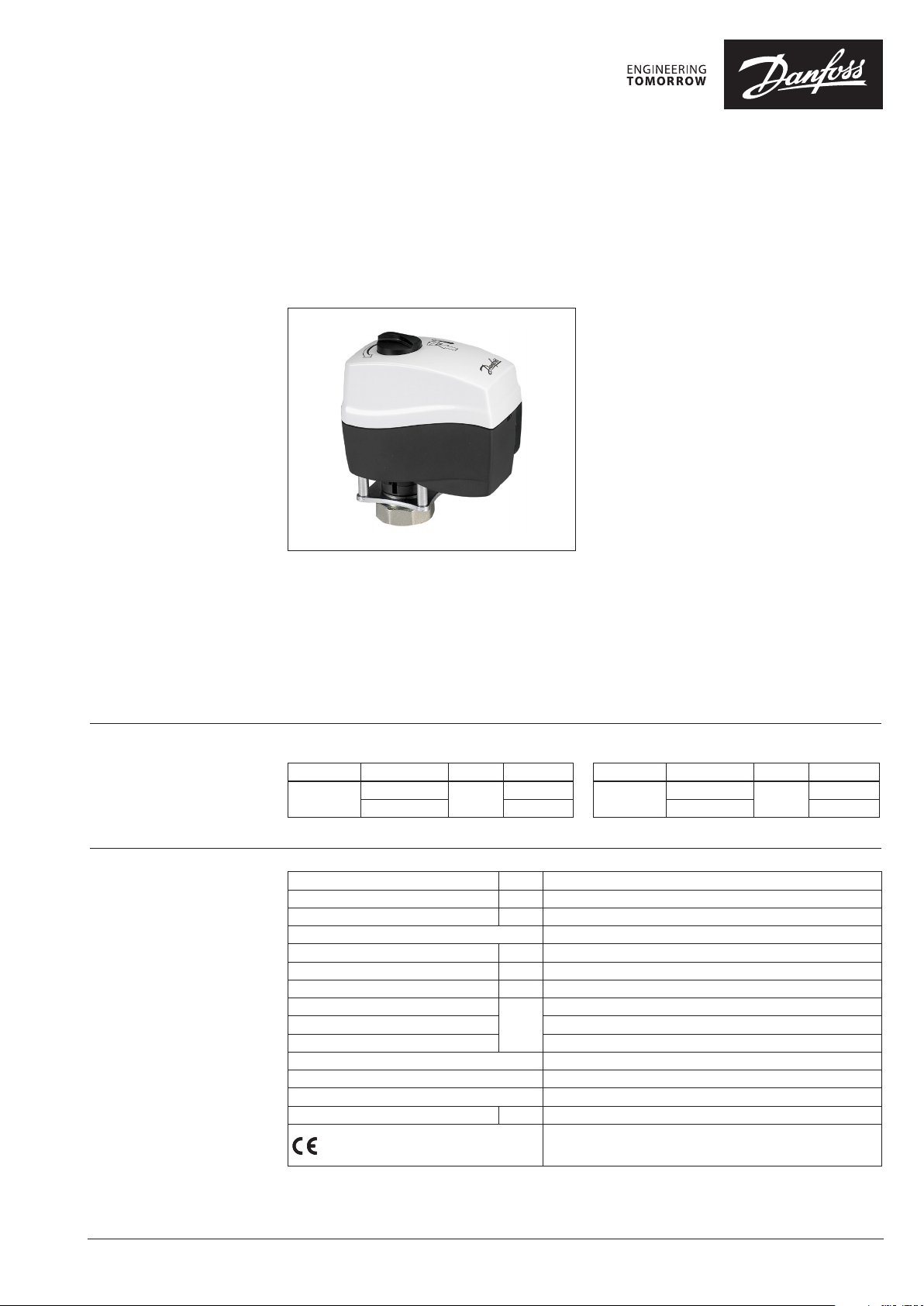

Application principles

Indirectly connected district heating system with heat

exchanger

Installation

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

Direct-connected district heating system with mixing

facility

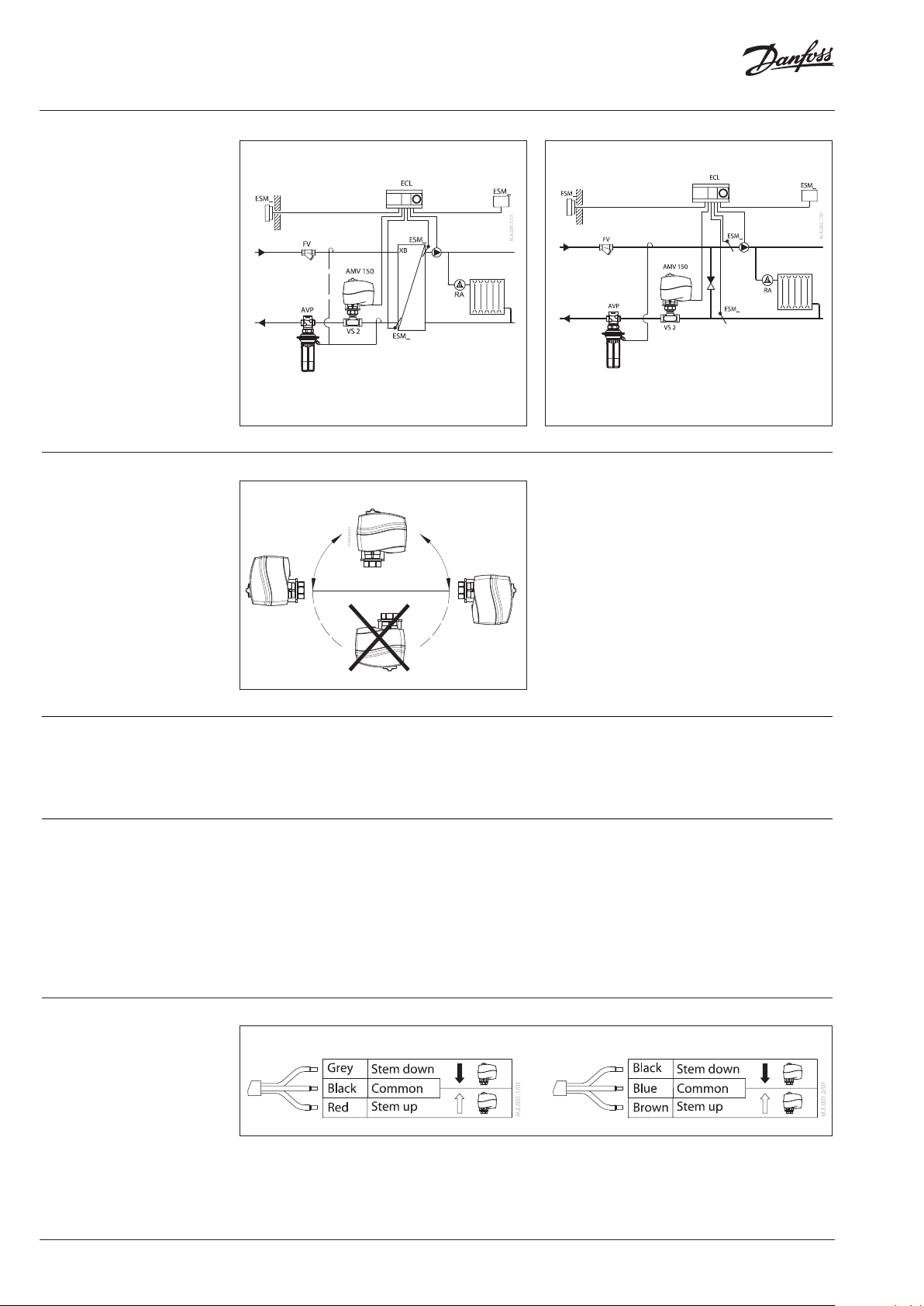

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

Electrical

Important: It is strongly recommended that the

mechanical installation is completed before the

electrical installation.

Each actuator is supplied with the connecting

cable for the controller.

Commissioning Complete the mechanical and electrical

installation (see instructions) and perform the

necessary checks and tests:

- Turn on the power

- Set the appropriate control signal and check

that the valve stem direction is correct for the

application.

The unit is now fully commissioned.

Wiring

2 | VD.KH.A7.02

230 V 24 V

© Danfoss | 2017.05

Page 3

Data sheet AMV 150

Manual operation

Actuator - valve

combinations

① Press and hold the button (on the bottom side

of the actuator) during manual operation.

Remark:

A ”click” sound after energizing the actuator means

that the gear wheel has jumped into normal

position.

Dimensions

AMV 150 +

VS 2 (DN 15)

200

108

92

AMV 150 +

VMV

AMV 150 +

AVQM (DN 15)

50

82

© Danfoss | 2017.05

VD.KH.A7.02 | 3

Page 4

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet AMV 150

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | VD.KH.A7.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2017.05

Loading...

Loading...