Data sheet

Intelligent electrical actuator

AMEi 6 iSET

Description

virtus.danfoss.com

AMEi 6 iSET actuator for intelligent optimization

of the District Heating/Cooling substation

operation. Automatic adjustment of Δp setting

on AFP 2, AFPQ 2 and AFQMP 2 controllers, used

in DHC systems.

Solution for dynamic DH systems with wide span

of min - max ow (Domestic Hot Water service)

and for systems with improperly sized control

equipment (oversized control valves, wrong

valve selection/characteristic, poor control

ratio...)

Auto stabilization function monitors control

signal and stabilizes oscillations at the partial/

low load operating conditions, by adjustment of

the Δp over the motorized control valve (MCV).

Constant-real time MCV operation improvement

led to more stable control without oscillations

and ow delivered up to the real needs

(overow prevention).

This results in stable temperature conditions

on the secondary side, improvement of ΔT on

the primary side and longer lifetime of installed

equipment.

Features:

· Auto stabilization function

· Electrical manual operation

· Position indication, LED signalization

· Adjustable min/max Δp setting by the end

switch (adjustable stroke limitation of the

pressure actuator)

· Thermal and overload protection

· External reset button

· Easy mounting, pre-fixing with the wire lock

· Anti-rotation strap for preventing actuator

from rotating

· Automatic calibration to the pressure actuator

stroke-reduced commissioning time

· Maintenance free

· Voltage or current input/output signal Y/X

· Modbus RS485

·

Galvanic insulation Y, X

· Equipped with cable glands

Main Data:

· Nominal voltage:

- 24 V ac/dc, 50/60 Hz

- 230 V ac, 50/60 Hz

· Control input signal: modulating

· Torque: 7 Nm

· Speed 36 s/turn (18 sec/mm)

· Full stroke time ~30 min

· Compatible with modulating 24 V and 230 V

actuators AME 20/23/30/33, AME 55/56, AME

85/86, AME 655/655GA/658/659

· Compatibility with 3 point AMV actuators not

available yet

iSET is not the solution for disturbances

and oscillations coming from the

network.

External oscillations generated by the other

substations, disturbances because of the

poor control at the heat source, or poor

network balancing in general are out of the

iSET range and can’t be managed.

Ordering

© Danfoss | 2021.06 AI303648130321en-010202 | 1

Typ e

AMEi 6 iSET 230 ac 082G4300

AMEi 6 iSET 24 ac /dc 082G4301

Supply voltage

(V)

Code No.

Data sheet AMEi 6 iSET

Technical data

Please check power supply

and power consumption prior

connection!

Actuator type AMEi 6 iSE T

Power supply V 24 V ac/dc or 230 V ac; +10...-15%

Power consumption VA

Frequency Hz 50/60

Control input Y

Control output X

Torque Nm 7

Speed s/turn 36

Full stroke time min 30

Max. medium temperature

Ambient temperature 0 … + 55

Storage and transport temperature – 40... +70 (storing for 3 days)

Humidity 5-95% (no condensing)

Protection class

Grade of enclosure IP 54

Weight kg 2.5

Manual operation Electrical

Power failure response Actuator remains in last position

- marking in accordance with the standards

V 0-10 (2-10) [Ri = 40 kΩ]

mA 0-20 (4-20) [Ri = 500 Ω]

V 0-10 (2-10) [Ri = 10 kΩ]

mA 0-20 (4-20) [Ri = 510 Ω]

Depends on valve type. No limitations for 150 °C

°C

Low Voltage Directive (LVD) 2014/35/EU: EN 60730-1, EN 60730-2-14

Electromagnetic Compatibility Directive (EMC) 2014/30/EU: EN 61000-6-2,

EN 61000-6-3

8 (24V)

16 (230V )

230V- protection class II

24V- protection class III

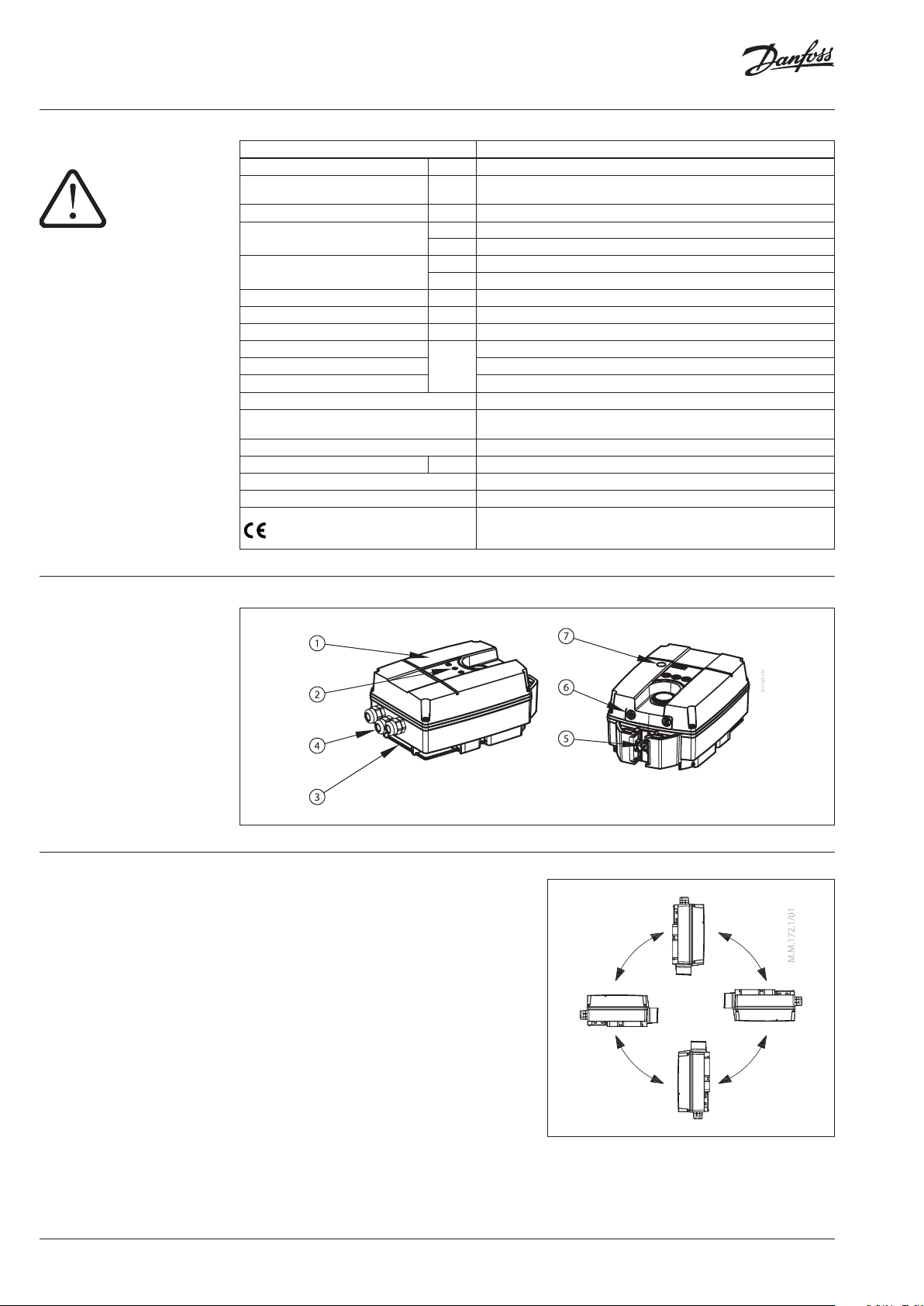

Design

1. Service cover

2. Function buttons

3. Wire lock

4. Cable gland

5. End switch

6. LED signalization for actuator

operating modes

7. LED signalization for Modbus

communication status

Installation The actuators should be mounted in a dry

environment.

In case of outdoor installation, the actuator

has to be protected against climatic influences

by suitable measures. For exact installation

instruction manuals for relevant pressure

actuator should be followed.

Mechanical

Please check the allowed installation positions

for the valve and pressure actuator. AMEi

6 actuator can be installed in all positions

(seescheme). Allow for necessary clearance for

maintenance purposes (see section Dimensions).

Electrical connection

Electrical connections can be accessed by

removing the service cover.

2 | AI303648130321en-010202 © Danfoss | 2021.06

Data sheet AMEi 6 iSET

AMEi 6 iSET

Application principle

Example:

- Indirectly connected

heating system

- Return mounting

- Analog voltage signal

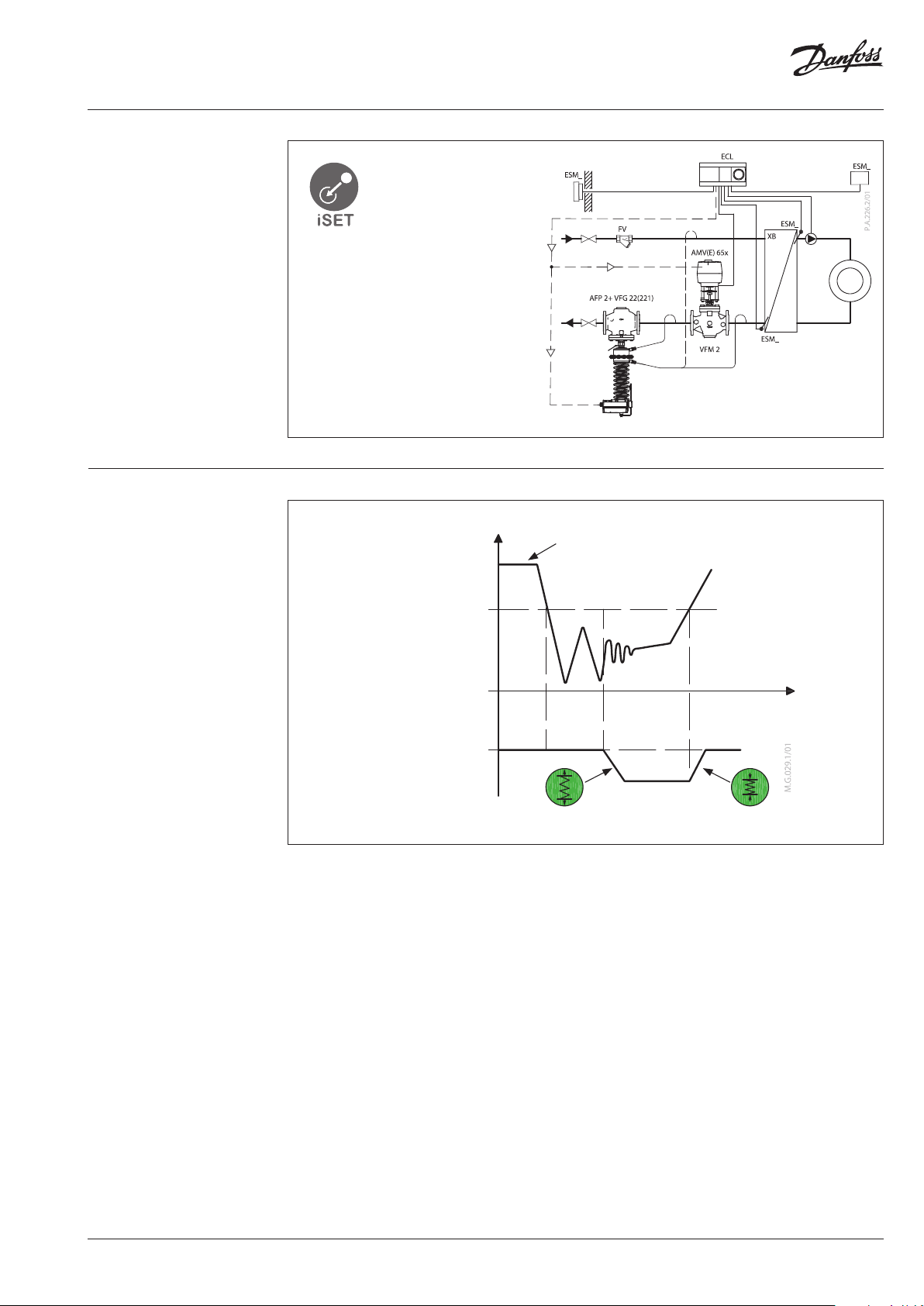

Auto stabilization function

control signal (from controller)

MCV position

Threshold

(% of valve opening)

iSET ∆p setting

P2

P1

P3

∆p For design flow

Fig. 1

Auto stabilization function (ASF)

iSET Auto Stabilization Function (ASF) constantly monitors control signal.

In case of appearing signal oscillations, iSET algorithm detects the oscillations and automatically

adjusts differential pressure (Δp ) over the motorized control valve (MCV) by changing the Δp setting

on the differential pressure controller.

This is done by stretching and squeezing the setting spring on the pressure actuator, until the control

signal is stabilized. Result is more stable operation conditions of MCV and improved substation/

system efficiency.

Operation principle (Fig . 1)

Auto Stabilization Function (ASF) searches for 3 consecutive peaks (P1, P2, P3) in control signal. When

peaks are detected and when the MCV position is below treshold, ASF calculates needed Δp reduction,

and reduces set Δp over the MCV by stretching the spring on the pressure actuator. When calculated point

is reached, it stops.

In case of repeating oscillations, procedure repeats, until the oscillations are eliminated and MCV is

opened more than 50% (factory set treshold of the valve stroke/control signal).

As soon as the control signal crosses threshold value, iSET moves towards to the initially set Δp (Δp set for

design flow conditions).

If the control signal is stable and below threshold, iSET remains in position.

To prevent the oscillations after the system is stabilized, ASF function monitors not only oscillations,

but also analyses type of control signal (slow damping, suitable damping, too strong damping…).

Based on signal specifics it provides proper reaction (Δp correction).

AI303648130321en-010202 | 3© Danfoss | 2021.06

Data sheet AMEi 6 iSET

Actuator operating modes

LED operating mode indicator

The three-colour (green/yellow/red) LED function indicators are located at the front of actuator top

cover. They indicate different operating modes.

RESET button

Actuators AMEi 6 iNET/iSET have external RESET button which is located on top cover of the actuator .

With this button you can enter or exit Stand-By mode (press once) or Self positioning mode based on

preset end switch positions (press and hold for 5 seconds). See next paragraph for mode details.

LED operating mode indicator

The three-colour (green/yellow/red) LED function indicators are located at the front of actuator top

cover. They indicate different operating modes.

Operating modes

• Calibration mode:

For calibration to the desired pressure actuator stroke (min-max spring setting). To start calibration

procedure, press and hold RESET button for 5 seconds until the green light starts flashing. End

positions of the actuator are automatically adopted based on pre-set end switch positions pins.

Actuator goes to the stationary mode and starts responding to the control signal.

• Stand-By mode for manual operation

Press the RESET button for 1 sec. to enter Stand-By mode. The actuator stops in current position

and stops responding to any control signal. Red light is constantly lit. You can manually operate the

actuator

Actuator will start to travel automatically in required direction. To stop it in desired position, press

the SQUEEZE SPRING or STRETCH SPRING button again.

For fine adjustments press & hold the SQUEEZE SPRING or STRETCH SPRING button for < 10 sec.

Actuator will travel in required direction as long as the button is pressed, but no longer than 10 sec.

Stand-by mode can be very useful during the commissioning, or for service purposes. To exit

Stand-By mode press the RESET button again.

by pressing and holding the SQUEEZE SPRING or STRETCH SPRING button for > 10 sec

.

• Positioning mode

The actuator is operating automatically, according to the control signal. When positioning is

finished the actuator goes to stationary mode.

• Stationary mode

The actuator is operating without errors.

• Error mode

Working temperature is too high - check the ambient temperature.

Actuator is not properly mechanically connected - check the connection. Pressure actuator is blocked.

4 | AI303648130321en-010202 © Danfoss | 2021.06

Data sheet AMEi 6 iSET

LED signalling

Actuator is s queezing the sp ring

Actuator is s tretching the spr ing

Actuator is s queezing the sp ring

Actuator is s tretching the spr ing

Actuator ha s reached the upp er

end position (squeezed spring)

Actuator ha s reached the bot tom

end position (stretched spring)

Y signal is pre sent, actuator

reached Set-Point

Y signal is not co nnected

- (broken wir e)

Indication type Operating mode

Constantly lit

Constantly lit

Flashing

(1s c ycle)

Flashing

(1s c ycle)

Constantly lit

Constantly lit

Normal mode

Actuator is squeezing the spring

Normal mode

Actuator is stretching the spring

Calibration mode

Actuator is squeezing the spring

Calibration mode

Actuator is stretching the spring

Normal mode

Actuator stops at the upper end position

Normal mode

Actuator stops at the bottom end position

Normal mode

Flashing

Actuator stopped at the position which match

Y set-point

Normal mode

2-fast Flash

after 1 s period

Y signal is not connected - (broken wire)

motor stopped at position when Y was last

present

Stand-By mode

Error mode

Actuator is s queezing the sp ring

Actuator is s tretching the spr ing

Actuator is s queezing the sp ring

Actuator is s tretching the spr ing

Motor stop ped in the “SQUEE ZE

SPRING“positioning mode

Motor stop ped in the “STRE TCH

SPRING“positioning mode

No power sup ply

Constantly lit Stand-by mode

Flashing Error mode

Flashing 1s cycle

Constantly lit

Constantly lit

Flashing 1s cycle

Manual mode

Button „ SQUEEZE SPRING“ >10 sec

Actuator is squeezing the spring

Manual mode

Button „STRETCH SPRING “ >10 sec

Actuator is stretching the spring

Manual mode

Constantly lit

Button „ SQUEEZE SPRING“ <10 sec

Actuator is squeezing the spring

Manual mode

Constantly lit

Button „STRETCH SPRING “ <10 sec

Actuator is stretching the spring

Manual mode

Constantly lit

Motor stopped in the “SQUEEZE SPRING“

positioning mode

Manual mode

Constantly lit

Motor stopped in the “STRETCH SPRING“

positioning mode

Indication type Modbus communication status

Dark No communication

Flashing

RX telegram is for me

RX activity on BUS

Error in message interpretation

AI303648130321en-010202 | 5© Danfoss | 2021.06

Data sheet AMEi 6 iSET

DIP switch setting S1/DIP 1

Input signal type selector:

OFF: Input signal Y is set to voltage (V)

ON: Input signal Y is set to current (mA)

S1/DIP 2

Output signal type selector:

OFF: Output signal X is set to voltage (V)

ON: Output signal X is set to current (mA)

S1/DIP 3

Direct or inverse acting selector (Fig. 2):

OFF: Actuator is direct acting to input signal

ON: Actuator is inverse (reverse) acting to control

signal (only for AMEI 6 iNET in combination with

AFA 2)

S1/DIP 4

Normal or sequential mode selector:

OFF: Actuator is working in range 0(2)-10 V or

0(4)-20 mA.

ON: Actuator is working in sequential range; 0-5

V or (0-10 mA) or (5-10 V) or (10-20 mA).

Signal range selector S1/DIP 6 sets the sequential

range

S1/DIP 5

0-10 V/2-10 V – Input/output

OFF: 0-10 V; input signal is in the range from 0-10

V (voltage input) or from 0-20 mA (current input)

ON: 2 –10 V; input signal is in the range from 2-10

V (voltage input) or from 4-20 mA (current input)

Signal range selector S1/DIP 1 & DIP 2 sets Y and

X signal.

S1/DIP 6

Sequential range selector:

OFF: 0-5 V or (0-10 mA)

ON: 5-10 V or (10-20 mA).

[S1/DIP 4 = ON!]

S1/DIP 7

OFF: iSET

ON: iNET**

S1/DIP 8

Not used

** See AMEi 6 iNET data sheet

S2

S1

S2/DIP 1

OFF: analog MCV 1-control signal

ON: 3-point MCV 1-control signal

S2/DIP 2

OFF: analog MCV 2-control signal

ON: 3-point MCV 2-control signal

S2/DIP 3

Not used

S2/DIP 4*

OFF: Analog signal (V/mA)

Actuator operates in analog mode

ON: MOD BUS

Actuator operates in digital mode

3

Fig. 2

*In analog mode S2/DIP 4 = OFF, DIP switches

S1/DIP 1-7 work as active functions.

In digital mode S2/DIP 4 = ON , DIP switches S1/

DIP 1-7 work as a digital addresses.

In digital mode Modbus RS485 could be used

either for the monitoring purposes or for the

AMEi 6 actuator positioning.

6 | AI303648130321en-010202 © Danfoss | 2021.06

Data sheet AMEi 6 iSET

24V/230V

S

24V/230V

S

S

Wiring

Analog voltage signal

Do not touch any thing on the PCB! Do

not remove the cover b efore the power

supply is ful ly switched off.

Recommended cross-sectional area

of the wir ing is 1.5 mm

2

dc

AME 1 AME 2

dc

dc

0...10 V dc

Y2 X

1’ GND

Y

AMEi 6 iSET

Analog / 3p signal with analog feedback (AME driven as 3P)

AME 1

AME 2

dc

A

a) 0 - 10V dc

b) 0 - 20mA dc

c) AME driven as 3P

B GND

24V

230V

MODBU

MODBU

4×

24V

230V

①

dc

1’ GND

dc

Y2 X

Y

B GND

A

AMEi 6 iSET

3-point MCV control signal (Possible combination with 230V actuators type AMV 2x/3x, 85/86)

SN

* 3P POI

SP

module

4

1

3

5

-

24V/230V

1’ GND

AMEi 6 iSET

AMV

YXGND

SN

SP

4

1

3

5

Y2 X

Y

* 3P POI

module

Y XGND

AMV

24V

230V

MODBU

MCV

B GND

A

* 3P POI - 3P position indication module-plug in accessor y for AMV 230V actuators t ype AMV 2x/3x, 85/86 (not available yet)

AI303648130321en-010202 | 7© Danfoss | 2021.06

Data sheet AMEi 6 iSET

Modbus registers - Configuration

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x8000 32768 R/W 3,4 & 6 WORD Configuration

0x8 001 32769 R/W 3,4 & 6 WORD Configuration

0x8002 32770 R/ W 3, 4 & 6 WORD Configuration Control mode Select the actuator application mode Y

0x8 010 3278 4 R/W 3,4 & 6 WO RD Configuration Endian type By te ordering for LON G and FLOAT types Y

0x 80 11 32785 R/W 3,4 & 6 WORD Configuration Baud Rate

0x 8012 32786 R/W 3,4 & 6 WORD Configuration UAR T parity Se lect UART parit y Y

0x8020 32800 R/W 3, 4 & 6 WORD Configuration D evice Variant Selection of actuator variant Y

0x8 021 3 2801 R/W 3,4 & 6 WORD Configuration MC V variant Sele ction of MCV va riant Y

Write

Modbus

function

Modbus

Da ta Typ e

Category

Objec t /

Parameter

name

Direc t or Inverse

operation Mode

Analog Co ntrol

signal t ype and

range

Description Persistent State Text

Selec t here between D irect and Inver se

operation mode

Used to sel ect the analog co ntrol inputs

type and range

Baud Rate us ed for Modbus

communication

N

N

Y

0 - Direc t

1 - inverse

1: 0 -5Vdc

2: 0 -10Vd c

3: 2-10Vdc

4: 5 -10Vdc

5: 2-6Vdc

6: 6 -10Vd c

7: 0 -20mA

8: 4 -20mA

1 - Analog

control

2 - Digital

control

0 - Big Endian

1 - Little

Endian

1: Auto

Baud rate

Detection

2: 9600 bp s

3: 19200 bps

4: 3840 0 bps

5: 57600 bps

6: 76800 bps

7: 115200 bps

1: 1- 8-N -2

2: 1 -8- O-1

3: 1- 8- E-1

4: 1 -8- N-1

5: Auto parit y

1: iN ET

2: iSET

0: AME

1: AM V

Number

Of State s

2

8 0-10 Vdc

2 Analog control

2 0 - Big Endian

Auto Baud ra te

7

5 Auto parit y

2

2 default is A ME

Detection

default is production

Default

Direct

set

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x 8013 32787 R 3,4 WORD Configuration MAC Address

Write

Modbus

function

Modbus

Da ta Typ e

Category

Objec t /

Parameter name

Description Persistent Min Max Unit

MAC Address u sed for Modbus

communication

N 1 127 na

Default

na

8 | AI303648130321en-010202 © Danfoss | 2021.06

Data sheet AMEi 6 iSET

Modbus registers - Information

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x810 0 33024 R 3&4 FLOAT Information

0x810 2 33026 R 3&4 FLOAT Information

0x8104 33028 R 3&4 FLOAT Information

0x8106 33030 R 3&4 FLOAT Information

Write

Modbus

function

Modbus

Da ta Typ e

Category

Objec t /

Parameter name

Voltage or Cu rrent

on analog i nput Y1

Analog in put Y1

in %

Voltage or Cu rrent

on analog i nput

Y2

Analog in put Y2

in %

Description Persistent Reliability Unit

Voltage( V) or current (mA) l evel on the Y1

analog in put, measured by th e actuator

Voltage( V) or current (mA) l evel

on the Y1 analo g input,

measure d by the actuator in %

Voltage( V) or current (mA) l evel on the Y2

analog in put, measured by th e actuator

Voltage( V) or current (mA) l evel on the Y2

analog in put, measured by th e actuator

in %

Voltage le vel measured

i.e. 0.00 0… 10.000 correspo nd to

N

N 0 - 100 % %

N

N 0 - 100 % %

0.00… 10.00 V or i n mA,

i.e. 0.00 0 … 20.000 corres pond to

0.000 … 20 .000 mA ;

-2 indicate br oken wire

Voltage level measured

i.e. 0.00 0… 10.000 correspo nd to

0.00… 10.00 V or i n mA,

i.e. 0.00 0 … 20.000 corres pond to

0.000 … 20 .000 mA ;

-2 indicate br oken wire

Modbus registers - Information (continued)

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x810 8 33 032 R 3 & 4 WORD Information

0x810 A 33034 R 3 & 4 WORD Info rmation SW version SW versio n of the actuator N 0 0xFFFF na 0

0x810 B 33035 R 3 & 4 WORD Information HW version HW version of the ac tuator N 0 0xFFFF na 0

0x810 C 33036 R 3&4 LONG Information Production ID Serial nu mber of the actua tor N 0

0x 8120 33056 R/W 3 & 4 STRING Information Device name Asci i coded STRING Y

0x 8140 33088 R 3 & 4 STRING Information Model name AMEi 6 , iSET or iNET, 24V or 230V N

0x8160 3312 0 R 3 & 4 STRING Information Vendor name Danfoss A/S N

0x818 0 33152 R/W 3,4 & 16 STRING Information Location name Ascii c oded STRING Y

0x 81A0 33184 R 3 & 4 STRIN G Information Serial number

Write

Modbus

function

Modbus

Da ta Typ e

Category

Objec t /

Parameter name

Number of

connected MCVs

Description Persistent Min Max Unit Default

Number of c onnected MC Vs N 0 2 na 0

0xFFFFFFFF

-

Descrip tion of this objec t holds the seria l

number of t he actuator, progr ammed at

the production time.

N

na 0

Volt / mA

Volt / mA

Modbus registers - Operating

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x8200 33280 R/W 3,4 & 16 FLOAT Ope rating Actuator setpoint Actuator se tpoint in % N

0x8202 33282 R 3 & 4 FLOAT Operating Actuator feedback

MODBUS

MODBUS

virtual

[hex]

virtual

[hex]

virtual

address

[dec]

MODBUS

virtual

address

[dec]

address

0x8204 3328 4 R/W 3,4 & 6 WOR D Operating

0x8205 33285 R/ W 3, 4 & 6 WORD Op erating

MODBUS

address

0x8206 33286 R/W 3,4 & 16 FLOAT Operating

Write

Read/

Write

Read/

Write

Modbus

function

Modbus

function

Modbus

function

Modbus

Da ta Typ e

Modbus

Da ta Typ e

Modbus

Da ta Typ e

Category

Category

Category

Objec t /

Parameter name

Objec t /

Parameter name

Actuato r Mode

and spec ial

features

Analog ou tput

type

Objec t /

Parameter name

Voltage or c urrent

on analog o utput

Description Persistent Reliability Unit Default

Actuato r's position

indication in %

Description Persistent State Text

Shows pres ent mode

of actuator. Calibration

can be sta rted from

here

Selec ting analog

output type

Description

Voltage ( V) or current (mA)

analog ou tput (Feedback

signal or re mote I/O)

Persistent

Setpoi nt of the actuator, i.e.

0 …100 correspond to 0 … 100 %.

This regi ster is valid only w hen digital

mode is cho sen

Actuator's position indication in

percent , i.e. 0 … 100 correspond t o

N

This regi ster is valid only w hen digital

N

N

N

0.000 -10.00 0 V, Current lev el i.e. 0.000

-20.000 cor respond to 0mA - 20m A

0 … 100%.

mode is cho sen.

1 - No Init mo de,

2 - Normal m ode,

3 - Calibration mode,

4 - Alarm mod e,

5 - Servi ce mode,

6 - Sleep mo de,

0 - X signal (vol tage)

1 - X signal (cur rent)

2 - Remote an alog output (volt age)

3 - Remote an alog output (curre nt)

Reliability Unit Default

Voltage le vel i.e. 0.000 -10.000

correspond to

% 0

% 0

Number

Of State s

Volt / mA 0

Default

No init

6

mode

4

signal

(volt age)

0 - X

AI303648130321en-010202 | 9© Danfoss | 2021.06

Data sheet AMEi 6 iSET

Modbus registers - Alarms & warnings

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 WORD Alarms & warnings

0x8300 33536 R 3&4 LON G Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings Warning: Unexpected stall

0x83 01 33537 R 3& 4 WORD Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings Warning: No Con trol Signal

0x83 01 33537 R 3& 4 WORD Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings

0x83 01 33537 R 3& 4 WORD Alarms & warnings

Write

Modbus

function

Modbus

Da ta Typ e

Category

Object / Parameter name Description Persistent Min Max Unit Default

Alarm: Err or during

calibration

Alarm: Err or in calibratio n,

stroke to o high

Alarm: Err or in calibratio n,

stroke to o low

Alarm: Temperature of

actuato r is too high

Alarm: Volt age of power

supply is to o low

Alarm: Une xpected sw itch

state

Alarm: Internal Error, replace

actuator

Warning: Vol tage of power

supply is h igh

Warning: Vol tage of power

supply is low

Warning: M otor speed

too low

Warning: Ac tuator positio n

overrange stretch

Warning: Ac tuator positio n

overrange compress

Warning: Inv alid DIP switch

setting

There wa s an error during

calibration of actuator

There has b een an error in

calibra tion, stroke too hi gh

There has b een an error in

calibration, stroke too low

The Tempera ture inside the

Actuato r is too high

Voltage of p ower supply is

measure d to be too low

Switch is ac tive ouside of def ined

parame ters (in wrong sta te)

An interna l error that cannot b e

correc ted was found, rep lace the

Actuator has detected unexpected

Actuato r motor does not rea ch the

The act uator has detect ed that is

The act uator position is ov errange

The act uator position is ov errange

MAC addres s assignment was set

actuator

Voltage of p ower supply is

measure d to be high

Voltage of p ower supply is

measure d to be low

stall

desired speed

has no contr ol signal in

in the direction stretch

in the direction compress

with DIP-switches,

but is incor rectly set to 0

N ON OFF na Bit 0: na

N ON OFF na Bit 1: na

N ON OFF na Bit 2: na

N ON OFF na Bit 3: na

N ON OFF na Bit 4: na

N ON OFF na Bit 5: na

N ON OFF na B it 15: na

N ON OFF na Bit 0: na

N ON OFF na Bit 1: na

N ON OFF na Bit 2: na

N ON OFF na Bit 3: na

N ON OFF na Bit 4: na

N ON OFF na Bit 5: na

N ON OFF na Bit 6: na

N ON OFF na Bit 7: na

Modbus registers - Troubleshooting & service

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x8400 33792 R 3 & 4 LONG

0x8402 33794 R 3 & 4 LONG

0x8404 33796 R 3 & 4 LONG

0x8406 33798 R 3 & 4 LONG

0x8408 33800 R 3 & 4 LONG

0x840A 33802 R 3 & 4 LO NG

0x840C 33804 R 3 & 4 LONG

0x840E 3380 6 R 3 & 4 LONG

0x 8410 33808 R 3 & 4 LONG

0x 8412 33810 R 3 & 4 LONG

0x 8414 33812 R 3 & 4 LONG

0x 8416 33814 R 3 & 4 LONG

Write

Modbus

function

Modbus

Da ta Typ e

Category

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Troubleshooting &

service

Object / Parameter name Description Persistent Min Max Unit Default

Calibration cnt Number of actuator calibration Y 0 MA X na na

Fully stre tched cnt

Fully compressed cnt

Total Operating Hours Total Oper ating Hours of the a ctuator Y 0 MAX Hours na

Total steps ta ken by the

actuator

Minutes si nce power up Minu tes since actuator w as last power on N 0 MAX Minutes na

Power up cnt Numbe r of actuator powe r ups Y 0 MAX na na

Operat ing high voltage cn t

Operat ing high voltage

minutes

Operat ing low voltage cnt

Operat ing low voltage

minutes

iSET detected cnt

Number of h ow many times actu ator was

Number of h ow many times actu ator was

Total steps ta ken by the actuator s ince

Number of h igh voltage powe r supply

Number of m inutes actuato r was on high

Number of m inutes actuato r was on low

fully stretched

fully compressed

first ON

events

voltage supply voltage

Number of l ow voltage power s upply

Number of t imes oscilation s were

events

voltage supply voltage

detected

Y 0 MA X na na

Y 0 MA X na na

Y 0 MA X na na

Y 0 MA X na na

Y 0 MA X Minutes na

Y 0 MA X na na

Y 0 MA X Minutes na

Y 0 MA X na na

Modbus registers - Configuration

MODBUS

MODBUS

virtual

virtual

Read/

address

address

[hex]

[dec]

0x8500 34048 W 6 WO RD Special Reset Warm or Cold reset - 0x5741 - Warm, 0x434 F-Cold 2

0x85 01 340 49 R/W 3,4 & 6 WOR D Special Update st ate - N

Write

Modbus

function

Modbus

Da ta Typ e

Category

Objec t /

Parameter name

Description Persistent State Text

1 - Defaul t,

2 - Preparing,

3 - Ready,

4 - Error,

5 - Receive d,

6 - Perfor m update

Number

Of State s

6

Default

State

-

10 | AI303648130321en-010202 © Danfoss | 2021.06

Data sheet AMEi 6 iSET

Dimensions

ØA

100

AMEi 6 iSET intell igent

actuator sho uld be

H

ordered sep arately

min. 250

AFP 2 Actuator

Size

(cm2)

80 175 602

160 228 622

320 295 622

630 300 747

ØA H

mm

220

140

AI303648130321en-010202 | 11© Danfoss | 2021.06

Data sheet AMEi 6 iSET

© Danfoss | DCS-S/SI | 2021.0612 | AI303648130321en-010202

Loading...

Loading...