Page 1

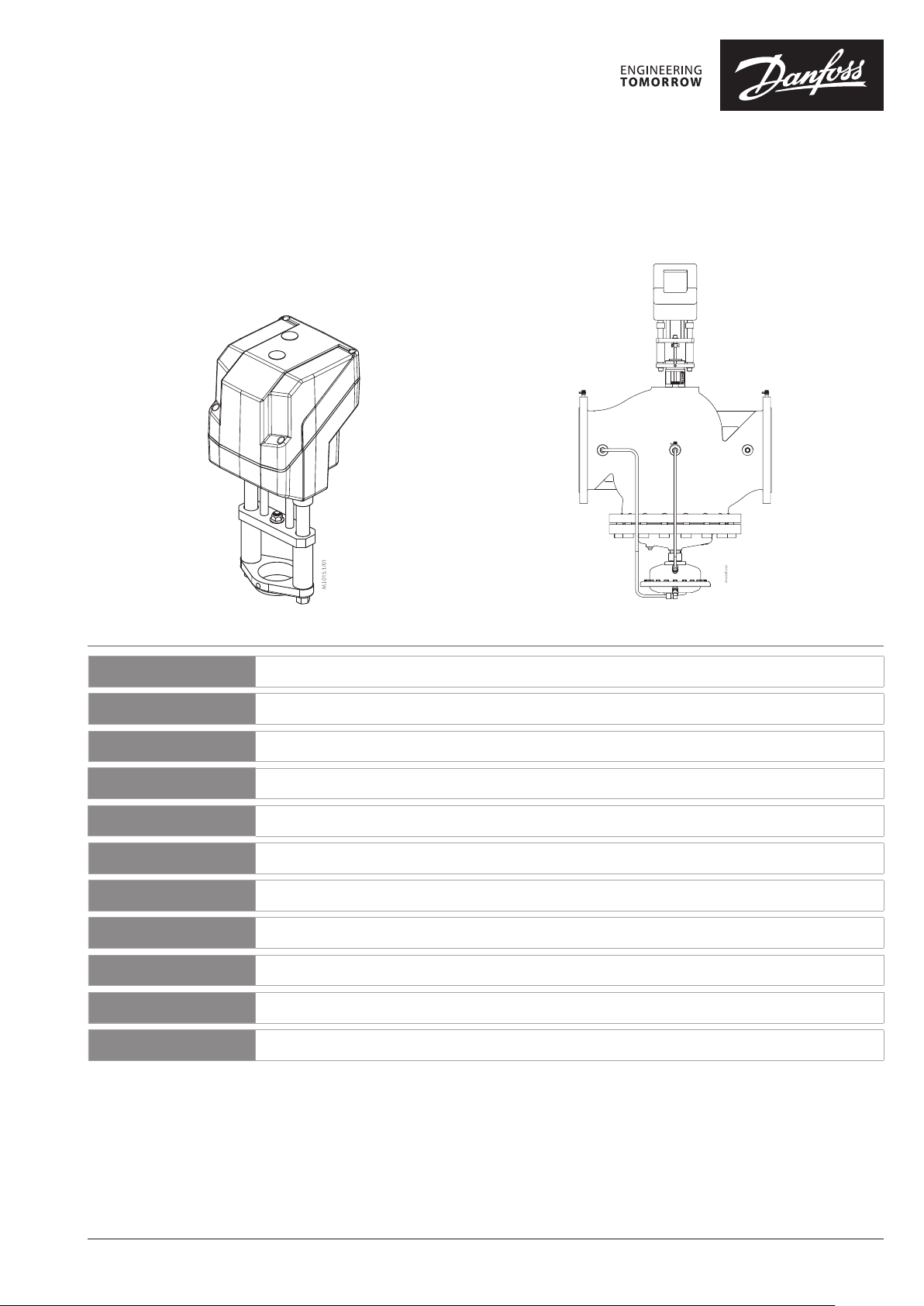

Operating Guide

AME 85 QM

AME 85 QM / 73691330

ENGLISH

DEUTSCH

FRANÇAIS

NEDERLANDS

ESPAÑOL

ITALIANO

POLSKI

ČESKY

MAGYAR

中文

РУССКИЙ

AME 85 QM +AB- QM (DN 200, 250)

AME 85 QM www.danfoss.com Page 5

AME 85 QM www.waerme.danfoss.de Seite 6

AME 85 QM www.danfoss.fr Page 7

AME 85 QM www.danfoss.nl Bladzijde 8

AME 85 QM www.danfoss.es Página 9

AME 85 QM www.danfoss.it Pagina 10

AME 85 QM www.heating.danfoss.pl Strona 11

AME 85 QM www.cz.danfoss.com Strana 12

AME 85 QM www.danfoss.com 13. oldal

AME 85 QM www.danfoss.com

AME 85 QM www.danfoss.ru Стр. 15

第 14 页

© Danfoss | 2021.08 AQ00128646944803-010301 | 1

Page 2

AME 85 QM

=

AUTO

❶

❷

MAINTENANCE

FREE

①

5-95 % RH

no condensing

8 mm

=

4 – 6 mm × 1 mm 8 mm HN 10

②

③

②

④

❸

①

①

②

AC 24 V

Connect via safety isolating

transformer.

Proportional 3 point/RL

SN 0 V Neutral

SP 24 VAC Power supply

Y

1

0 V Input

3

0(2)-10 V

0(4) -20 mA

Input

X 0(2) -10 V Output

AQ00128646944803-010301 2 | © Danfoss | 2021.08

Page 3

AME 85 QM

➍

① ②

③ ④ ⑤

⑥

Proportional 3 point/RL

SN

SP

1

24 VAC Input

3

X 0(2 )-10 V DC Output

⑦ ⑧ ⑨

0 V

24 VAC

⑩

Neutral

Power supply

⑬

⑫

© Danfoss | 2021.08 | 3AQ00128646944803-010301

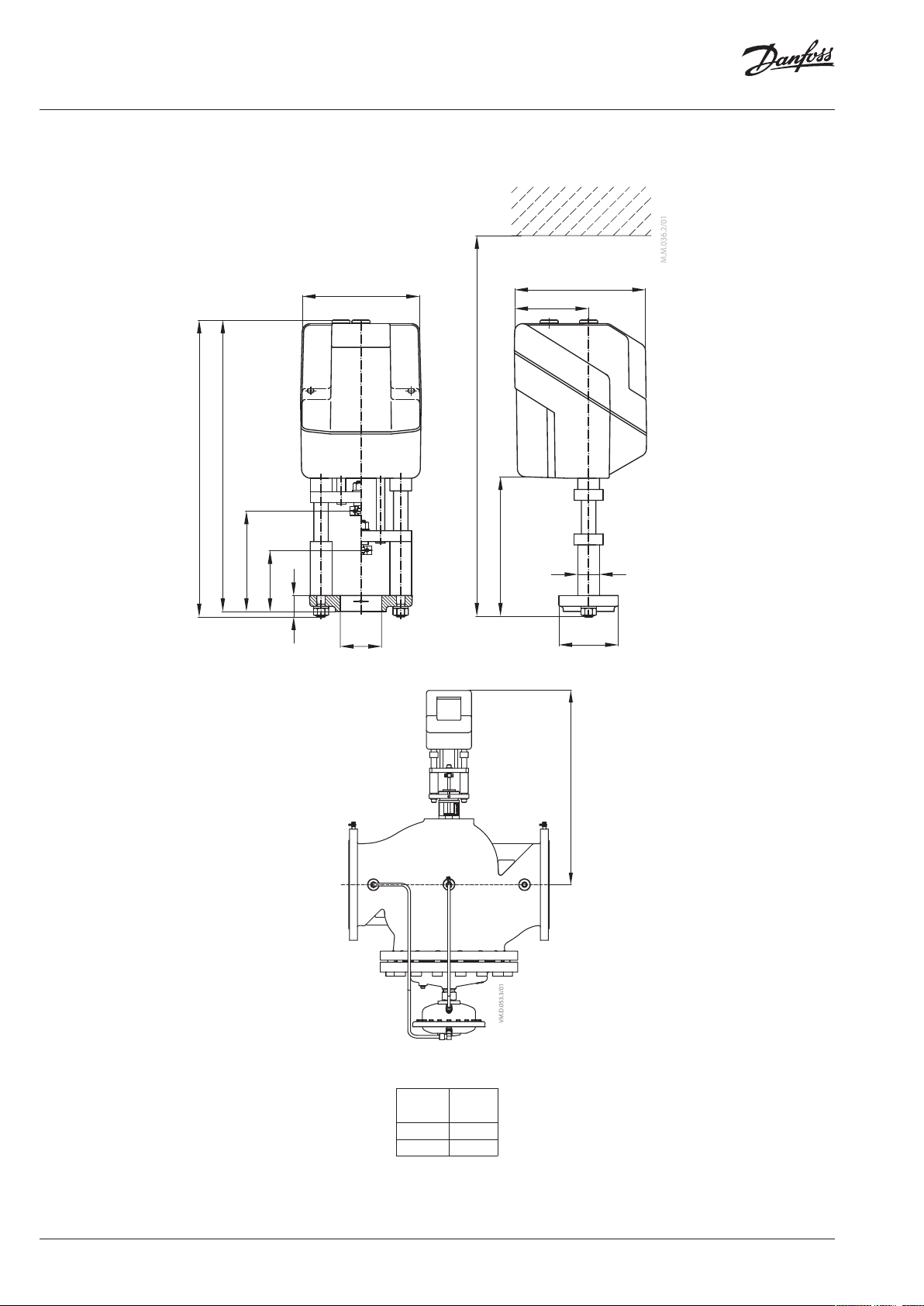

Page 4

AME 85 QM

H

(mm)

DN 200

618

DN 250

708

❺

167

412

403

mi n 137

max 85

22

Ø 57

min 530

191,5

183

103

30

82

AME 85 QM +

AB‑QM DN 200, 250

Typ e

H

AQ00128646944803-010301 4 | © Danfoss | 2021.08

Page 5

AME 85 QM

ENGLISH

Safety Note

To avoid injury of persons and

damages to the device, it is absolutely

necessary to read and observe these

instructions carefully.

Necessary assembly, start-up, and maintenance

work must be performed by qualified and

authorized personnel only.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover befo re the

power supply is fu lly switched off.

Mounting ❶

Fix the AME 85, AME 86 on the valve ①.

Admissible Installation Positions ②.

Manual override ➋

The manual override is applied by rotating the

8 mm Allen key (not supplied) to the required

position. Observe the direction of rotation

symbol.

Wiring ❸

Do not touch anythi ng on the PCB!

Switch off the power li ne before wire

the actuator! Lethal vo ltage!

Wire the actuator accordin g to the wiring

diagram.

Control signal

Control signal from the controller must be

connected to terminals Y (input signal) and SN

(common) on the AME printed board.

Output signal

Output signal from the terminal X can be used

for indication of the current position. Range

depends on the DIP switch settings.

Supply voltage

Supply voltage (24V~ -15 to +10 %, 50 Hz) must

be connected to the terminals SN and SP.

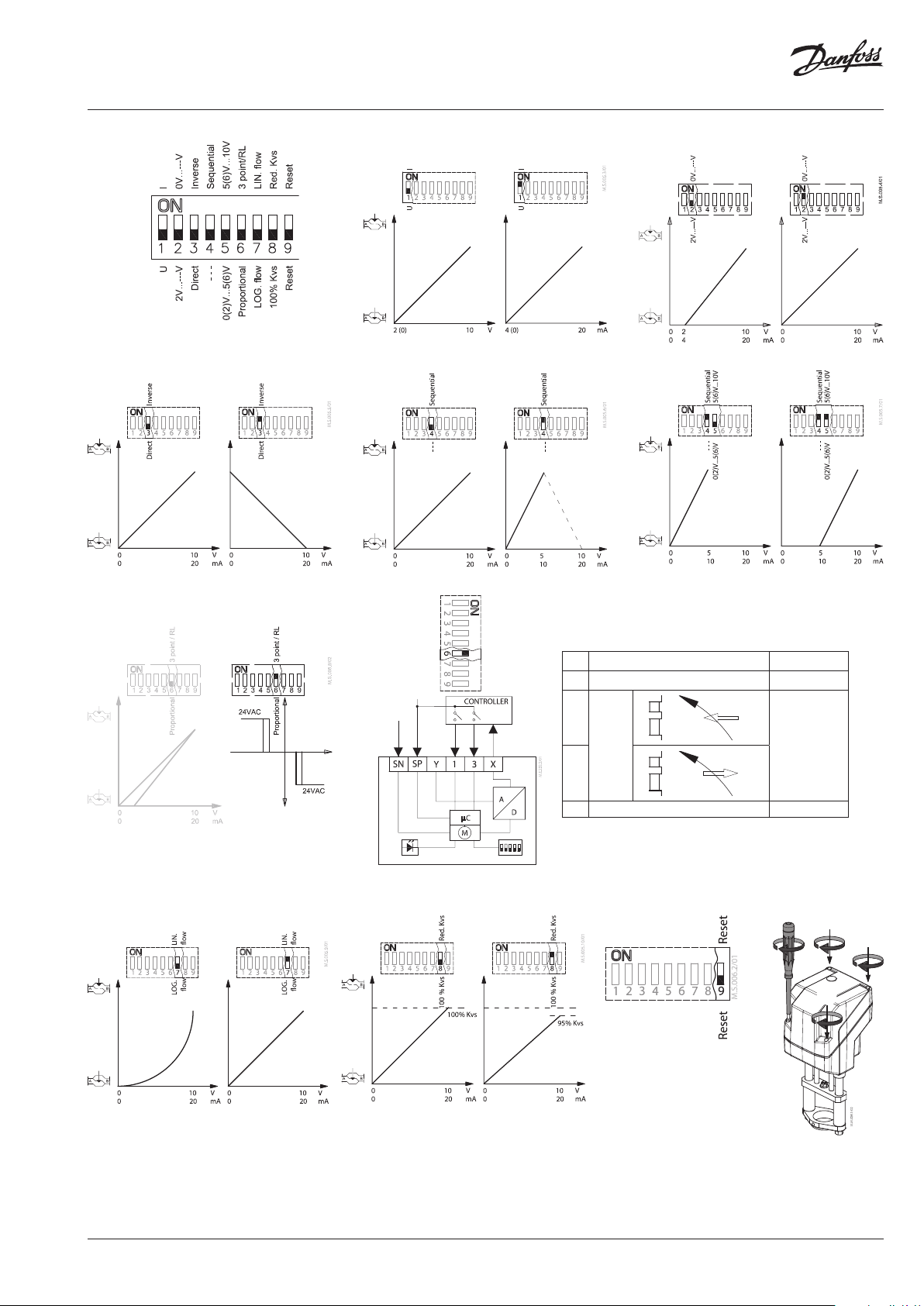

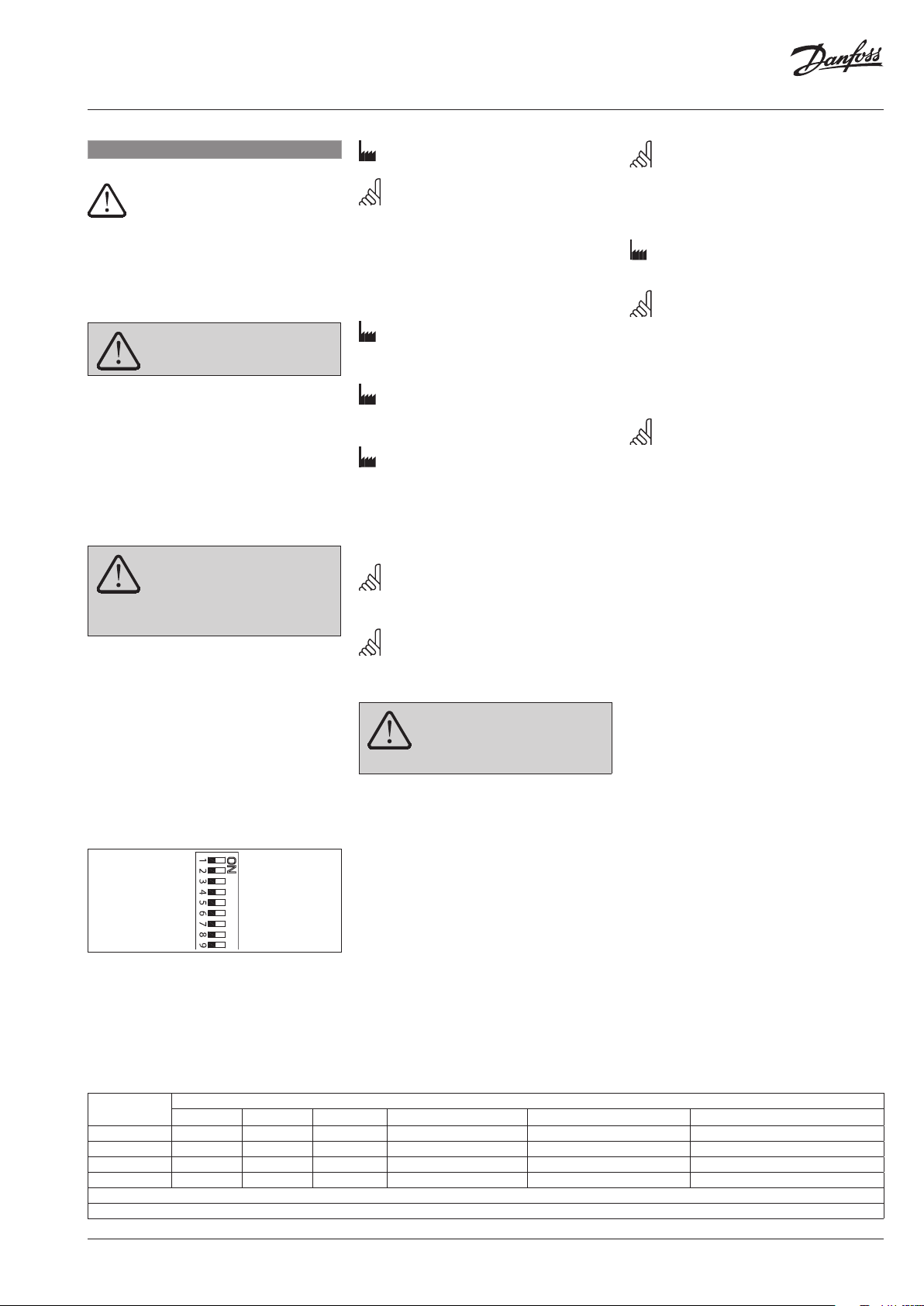

DIP switch settings ➍

U I

2 V_--- V 0 V_- -- V

Direct Inverse

--- Sequential

0(2)_5(6) V 5(6)_10 V

Proportional 3 point/RL

LOG. fl ow LIN. flow

100 % k

VS

Reset Reset

RED. k

VS

Factory settings:

ALL switches are on OFF position! ①

Note: All combinations of DIP switches are

allowed. All func tions that are selected are

added consecutively. There is only one logic

override of functionality i.e. the switch No.6

Proportional/3 point, which sets actuator to

ignore control signal and works as a “simple”

3‑point actuator

SW1: U/I ②

Factor y setting:

Voltage control signal (0‑10 V).

SW2: 2-10 V/0-10 V ③

Factory setting is:

2‑10 V.

SW3: Direct/Inverse ④

Factory setting is:

DIRECT

SW4: ---/Sequential ⑤

Two actuators can be set to work parallel with

one control signal. If the SEQUENTIAL is set than

an actuator responds to split control signal (see

0(2)-5(6) V/5(6)-10 V).

Note: This combination works in combination

with switch No.5: 0(2)‑5(6)V/5(6)‑10 V

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Note: This function is available if switch No.4:

‑‑‑/Sequential is set.

SW6: Proportional/3 point ⑦

When DIP 6 i s OFF:

actuator needs to p erform self

stroking prior cha nging DIP 6 to ON.

Output signal de pends on DIP 2, 3&5 setting.

Actuator can operate in modulating (DIP 6 to

OFF) or in “simple” 3-point mode, if the 3-point

function is selected (DIP 6 to ON).

Connect power supply on terminals SN and SP

terminals.

DIP 6 factory setting is OFF for modulating

operation.

Actuator’s stem will run to its totally extended

or retracted position by bridging SN signal to

terminals 1 or 3 and will remain in this position

as long as potential is present.

Set DIP 6 to ON for operating actuator in 3 point

mode.

Look carefully wiring diagram as wiring is

different for controllers with triac output (ECL)

in comparison to controllers with relay output.

Note: If 3 point function is selected actuator

does not respond to any control signal on

port Y. It only rises and lowers spindle if power

is supplied on por t 1 or 3

SW7: LOG. flow/LIN. flow ⑧

Factory setting is:

LOG. Flow (characteristic of valve is

unchanged)

Note: If this function is used in combination

with non‑logarithmic valves the characteristic

of motorised valve will be anti‑logarithm of

valve’s characteristic (e.g. valve with linear

characteristic will be transformed to quick

open characteristic).

SW8: 100 % KVS/RED. KVS ⑨

Note: This function works proper only with

logarithmic (equal percentage) valves.

SW9: Reset ⑩

After the actuator has been connected to

power supply, the actuator will start the

self-adjustment procedure. The indicator LED

flashes until self adjustment is finished. The

duration depends on the spindle travel and will

normally last a few minutes. The stroke length

of the valve is stored in the memory after self

adjustment has been completed. To restart

self adjustment, change the position of RESET

switch (switch No.9). If the supply voltage is

switched off or falls below 80 % in more than

0,1 s, the current valve position will be stored

in the memory and all data remain saved in the

memory also after a power supply cut-out.

Function test

The indicator light shows whether the

positioner is in operation or not. Moreover, the

indicator shows the control status and faults.

Constant light

- normal operation

No light

- no operation or no power supply

Intermittent light (1 Hz)

- self adjusting-mode

Intermittent light (3 Hz):

- power supply too low

- insufficient valve stroke (<20 s)

- end-position cannot be reached.

Dimensions ➎

Part Name

Guides X O O O O O

Position indicators X O O O O O

Gears X O O O O O

Bushings X O O O O O

O: Indica tes that this hazar dous substance co ntained in all of the h omogeneous ma terial for this par t is below the limi t requirement in GB /T 26572;

X: Indica tes that this hazar dous substance co ntained in at leas t one of the homoge neous material fo r this part is above t he limit requirem ent in GB/T 26572;

Lead (P b) Mercur y (Hg) Cadmium (Cd) Hexavalent Chromium (Cr(VI)) Polybrominated biphenyls (PBB) Polybrominated diphenyl ethers (PBDE)

Hazardous Substances Table

© Danfoss | 2021.08 | 5AQ00128646944803-010301

Page 6

AME 85 QM

DEUTSCH

Sicherheitshinweise

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Montage ❶

AME 85, AME 86 am Ventil ansetzen ①.

Zulässige Temperatur ②.

Manuelle Hubverstellung ❷

Die Handverstellung erfolgt durch Verstellen

mit dem 8-mm-Innensechskantschlüssels

(nicht im Lieferumfang enthalten) auf die

gewünschte Position. Die Drehrichtungsanzeige

berücksichtigen.

Elektrischer Anschluß ❸

* 24 V ~ Über Schutztransformator

Steuersignal

Das Steuersignal des Reglers ist an Klemme

Y (Eingangssignal) und Klemme SN

(Sammelklemme) an der AME-Printplatte

anzuschließen.

Ausgangssignal

Das Ausgangssignal von Klemme X kann zur

Anzeige der aktuellen Position benutzt werden.

Der Bereich hängt von der Brücke ab.

Spannungsversorgun3ung (24V~ –15

bis +10 %, 50 Hz) ist an Klemme SN und SP

anzuschließen.

Einstellung der DIP Brücke ❹

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung unbedingt zu

beachten.

Entfernen Sie die Abdeckung nicht,

bevor die Stromversorgung komplett

ausgeschaltet ist.

anschließen (AC 24 V Connect via

safety isolating transformer)

Bitte die Platine nicht direkt berühren!

Trennen Sie das Netz kabel vor der

Spannung!

Schließen Sie den Stellantrieb gemäß dem

Verdrahtungsplan an.

Verdrahtung des Stellantriebs! Tödliche

U I

2 V_---V 0 V_---V

Direkte Sekventiel

--- Proportional

0(2) V_5(6) V 5(6) V_10 V

Omvendt 3-punk t/RL

LOG. fl ow LIN. f low

100 % Kvs Re d. Kvs

Reset Nulstil

Werkseinstellung:

ALLE Schalter sind in der Position OFF! ①

BEMERKUNG: alle Kombinationen von DIP

Schalter sind erlaubt. Gewählte Funktionen

sind hintereinandergelegt. Es gibt nur eine

logische Umsteuerung der Funktionen: Brücke

Nr.6 proportional / 3‑Punkt. Dadurch wird

der Antrieb so umgeschaltet, dass das Signal

ignoriert wird und arbeitet als “üblicher”

3‑Punkt Antrieb.

SW1: U/I ②

Werkseinstellung:

Spannungsregelsignal (0‑10 V).

SW2: 2-10 V/0-10 V ③

Werkseinstellung:

2‑10 V.

SW3: Direct/Inverse ④

Werkseinstellung:

DIRECT

SW4: ---/Sequentiell ⑤

Zwei Antriebe können parallel mit einem

Steuersignal arbeiten. Bei der Einstellung

SEQUENTIAL Antrieb reagiert auf geteilten

Steuersignal (sehe 0(2)-5(6) V/5(6)-10 V).

BEMERKUNG: Diese Kombination

funktioniert mit dem Schalter No.5: 0(2)‑5(6)

V/5( 6)‑10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

BEMERKUNG: diese Funktion ist wirksam,

wenn der Schalter No.4: ‑ ‑‑ / Sequentiell

eingestellt ist.

SW6: Proportionäl/3-Punkt ⑦

Wenn der DIP‑ 6 ist auf Stellmotor

muss Ventilhub vor dem Ändern de r

DIP 6 auf ON.

Ausgangssignal ist abhän gig von DIP‑2, 3 &5

Einstellung.

Stellmotor kann bei jeglichen arbeiten

modulierend (DIP-6, um AUS) oder in “einfacher”

3-Punkt, wenn die 3-Punkt Funktion ausgewählt

ist (DIP-6, um auf).

Anschließen Spannungsversorgung an den

Klemmen SN und SP Klemmen.

Werkseitig eingestellte DIP 6 auf OFF für den

Betrieb in Stellmotor modulierend Modus.

Stellmotor Antriebsstange ausgeführt

werden soll, der vollkommen erweitert oder

eingefahrener Stellung Audio-Bestandskunden

SN Signal an den Klemmen 1 oder 3 und bleibt

in diesem Position -so lange wie Potenzial

vorhanden ist.

Stellen Sie DIP-Schalter 6 auf EIN für den

Stellmotor in 3 Punkt.

Bitte schauen Sie Schaltplan als Verdrahtung

ist anders für Regler mit Triacausgang (ECL) in

Prachtdecke durch Controller mit Relaisausgang.

BEMERKUNG: Wenn die 3‑Punkt Funktion

gewählt wird, reagiert der Antrieb nicht auf

irgendwelche der Steuersignale Y Klemme.

Der Antrieb bewegt die Motorenspindel nach

oben oder nach unten bei dem Steuersignal

auf Klemme 1 oder 3.

SW7: LOG. flow/LIN. flow ⑧

Werkseinstellung:

LOG. Flow (Ventilcharakteristik bleibt

unverändert).

BEMERKUNG: falls diese Funktion mit dem

nicht logarithmischen Ventil ver wendet wird,

übernimmt der Antrieb die Anti‑Logarithem

der Ventilcharakteristik. (Ventil mit linearer

Kennlinie wird in die Kennlinie umgewandelt).

SW8: 100 % KVS/RED. KVS ⑨

BEMERKUNG: diese Funktion arbeitet richtig

nur mit logarithmischen (gleichprozentigen)

Ventilen.

SW9: Reset ⑩

Nach Einschalten der Stromversorgung startet

der Regelantrieb den Selbstanpassungsvorgang.

Die Leuchtdiode blinkt, bis die Anpassung

abgeschlossen ist. Dies dauert normalerweise

einige Minuten, abhängig von der Distanz

der Spindelbewegung. Die Hublänge

des Ventils wird nach abgeschlossener

Selbstanpassung im Speicher registriert. Der

Selbstanpassungsvorgang kann durch Drücken

der RESET-Taste wiederholt werden (Schalter

No.9). Bei Ausfall der Versorgungsspannung oder beim Absinken auf einen Wert kleiner 80 %

- länger als 0,1 s, wird die aktuelle Ventilposition

im Speicher gespeichert. Alle Daten sind also

auch im Falle einer Stromunterbrechung

gesichert.

Funktionstest

Die Leuchtdiode zeigt den Motorbetrieb, den

Betriebszustand und eventuelle Fehler an.

Dauerlicht

- normaler Betrieb

Kein Licht

- nicht in Betrieb oder keine

Stromversorgung

Blinklicht (1 Hz)

- Selbstanpassungsmodus

Blinklicht (3 Hz)

- Versorgungsspannung zu niedrig

- Ventilhublänge ungenügend (<20 s)

- Endposition nicht erreichbar.

Abmessungen ❺

AQ00128646944803-010301 6 | © Danfoss | 2021.08

Page 7

AME 85 QM

FRANÇAIS

Sécurité

attentivement et de respecter ces instructions.

Le montage, la mise en marche et toute

opération de maintenance doivent être

effectués par un service ou une personne de

qualification.

Suivre les instructions du fabricant du système

ou de son service.

Montage ❶

Fixer l’AME 85, AME 86 sur la vanne ①.

Orientations de montage ②.

Débrayage manuel ➋

Le débrayage manuel est appliqué en faisant

pivoter la clé Allen de 8 mm (non fournie)

dans la position requise. Observez le sens du

symbole de rotation.

Branchement électrique ❸

* 24 V c.a. - Brancher via un transformateur

Signal de commande

Le signal du régulateur doit être branché sur

la borne Y (signal d’entrée) et la borne SN

(commun) sur la carte imprimée de l’AME.

Signal de sortie

Le signal de sortie de la borne X peut servir pour

indiquer la position actuelle. La zone dépend

des réglages du sélecteur de fonction DIP.

Tension d’alimentation

La tension d’alimentation (24V~-15/+10 %, 50

Hz) doit être branchée aux bornes SN et SP.

Réglages du sélecteur de fonction

DIP ❹

Pour éviter des blessures des

personnes et des dégâts au dispositif,

il est absolument nécessaire de lire

Ne pas retirer le capot a vant d’avoir

totalement coupé l’alimentation.

d’isolement de sécurité (AC 24 V Connec t

via safety isolating transformer)

Ne pas toucher la car te de circuit

imprimé !

Couper l’alimentation avant de

raccorder l’actionneur ! Danger de mort !

Raccorder l’actionneur conformément au

schéma de branchement électrique.

U I

2 V_---V 0 V_---V

Direct Inverse

--- Séquentiel

0(2) V_5(6) V 5(6) V_10 V

Proportionnel

Débit LO G. Débit LI N.

100 % Kvs Red . Kvs

Reset Reset

3 points/RL

Réglage d’usine:

TOUTES les commandes sont en position

ARRÊT! ①

REMARQUE: Toutes les combinaisons des

commandes DIP sont possibles.

Toutes les fonctions sélectionnées sont ajoutées

l’une à l’autre. Il y a seulement un pontage logique

des fonctions: commande 6 Proportionnel/ 3

points qui fait le moteur ignorer le signal de

commande et fonctionne comme un »simple«

3‑points moteur.

SW1: U/I ②

Réglage de l’usine:

le signal de commande de tension (0‑10 V).

SW2: 2-10 V/0-10 V ③

Réglage de l’usine:

2‑10 V.

SW3: Direct/Inverse ④

Réglage de l’usine:

DIRECT

SW4: ---/Séquentiel ⑤

Deux moteurs peuvent être réglés de telle

manière qu’ils fonctionnent parallèlement

avec un signal de commande. Si la fonction

SÉQUENTIEL est réglée, le moteur répond au

signal de commande »split« (voir

0(2)-5(6) V/5(6)-10 V).

REMARQUE: Cette combinaison fonctionne

en combinaison avec la commande 5:

0(2)‑5(6)V/5(6)‑10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

REMARQUE: Cette fonction est disponible, si

la commande 4: ‑‑‑/Séquentiel est réglée.

SW6: Proportionnel/ 3 points ⑦

Lorsque le DIP 6 est SUR Ac tuateur

doit exécuter autoré gulation avant

le DIP en perpétuelle évolution 6 sur

ON.

Signal de sortie d épend du commutateur DIP 2,

3 et 5 Réglage.

Actuateur permet de fonctionner en modulant

(DIP 6 sur OFF) ou dans “simple” 3-points mode,

si la fonction 3 points est sélectionnée (DIP 6

sur ON).

Alimentation pour alimenter les bornes SN et SP

les bornes.

Réglage d’usine DIP 6 sur OFF pour la mise en

œuvre d’Actuateur en mode modulant.

Actuateur tige continue de fonctionner à sa

position rétractée en établissant totalement

étendue ou signal de SN à la borne 1 ou 3

et resteront dans cette positon tant que le

potentiel est présent.

Régler le DIP 6 sur ON pour l’exploitation

Actuateur en mode 3 points.

Schéma de raccordement en tant que regarder

attentivement câblage est différente pour

les régulateurs avec sortie triac (ECL) en

comparaison avec les régulateurs avec sortie

de relais.

REMARQUE: Si la fonction 3 points est

sélectionnée, le moteur ne répond à aucun signal

de commande sur la borne Y. Cette fonction

seulement déplace la broche vers le haut et vers

le bas, s’il y a de l’alimentation en courant sur les

bornes 1 et 3.

SW7: Débit LOG./ débit LIN. ⑧

Réglage de l’usine:

débit LOG. (caractéristique de la vanne ne change

pas).

REMARQUE: Si cette fonction est utilisée

en combinaison avec les vannes non‑

logarithmiques, la caractéristique de la

vanne motorisée sera l’anti‑logarithme

de la caractéristique de la vanne (p.e. une

vanne avec la caractéristique linéaire sera

transformée en caractéristique »rapidement

ouverte«).

SW8: 100 % KVS/RED. KVS ⑨

REMARQUE: Cela ne fonctionne proprement

qu’avec les vannes logarithmiques (même

pourcentage).

SW9: Exploitation ⑩

Une fois alimenté, le moteur commence un

procédé d’auto-réglage. La diode lumineuse

clignote jusqu’à ce que l’auto-réglage soit

términé. Cela dure normalement env. 2 minutes,

suivant le déplacement de la broche. La course

de la vanne est conservée en mémoire à la fin

de l’auto-réglage. Le changement de position

de la commande R. À Z. (commande 9) fera

redémarrer l’auto-réglage. Si l’alimentation est

interrompue – ou chute à une valeur inférieure

à 80 % - pendant plus de 0,1 sec., la position

actuelle de la vanne est mémorisée. Toutes les

données seront donc mémorisées, même en cas

de coupure de courant.

Test de fonction

La diode lumineuse indique que le moteur est

en fonction. Elle indique aussi l’état de marche

et les erreurs éventuelles.

Lumière permanente

- marche normale

Pas de lumière

- fonction arrêtée, pas d’alimentation

Clignotements par intervalles (1Hz)

- mode d’auto-réglage

Clignotement par intervalles (3Hz)

- alimentation en courant trop faible

- course de vanne insuffisante (<20s)

- la fin de course ne peut pas être atteinte.

Dimensions ❺

© Danfoss | 2021.08 | 7AQ00128646944803-010301

Page 8

AME 85 QM

NEDERLANDS

Veiligheid

Om verwondingen van personen en

schade aan het apparaat te voorkomen

dient men deze instructies met

aandacht te lezen.

Montage, inbedrijfstelling en

onderhoudswerkzaamheden mogen alleen

door deskundig en erkend personeel uitgevoerd

worden.

Neem alle instructies betreffende

installatiecomponenten van andere fabrikanten

in acht.

Verwijder de afdek kap niet voordat de

voedingsspanning volledig is

uitgeschakeld.

Montage ❶

Bevestig de servomotor op de afsluiter ①.

Toegestane montage posities ②.

Handbediening ❷

De handbediening gebeurt door de (niet

meegeleverde) inbussleutel van 8 mm in de

juiste positie te draaien.

Bekijk de richting van het rotatiesymbool.

Aansluiting ❸

Gevaarlijke spanning, raak niets aan

op de printplaat. Sch akel de stroom uit

voordat de bedrading van d e

servomotor wordt aangebracht!

Dodelijke spanning!

Sluit de servomoto r aan volgens het

aansluitschema.

* AC 24 V (AC 24 V)

** Verbind via een transformator met

veiligheidsisolatie (Connect via

safety isolating transformer.)

Stuursignaal

Het stuursignaal van de regelaar wordt

aangesloten op klem Y (ingangssignaal) en op

klem SN (gemeenschappelijke nul) van de AME

printplaat.

Uitgangssignaal

Het uitgangssignaal van klem X (t.o.v. klem SN)

kan gebruikt worden als indicatie van de

klepstand. Het bereik hangt af van de instelling

van de DIP schakelaars.

Voedingsspanning

De voedingsspanning (24 V~ -15 tot +10%,

50 Hz) wordt aangesloten op de klemmen SN (nul)

en SP (24Vac).

Dip-schakelaarinstellingen ➍

U I

2 V_---V 0 V_---V

Direct . Inver se

--- Sequential (volgorde)

0(2)_5(6) V 5(6)_10 V

Proportional 3 point/RL

LOG. fl ow LIN. flow

100 % k

VS

Reset Reset

RED. k

VS

Fabrieksinstellingen:

alle schakelaars staan in de OFF (uit)‑

positie.①

NB: Alle combinaties van DIP‑instellingen zijn

toegestaan. Alle gekozen functies worden bij

elkaar opgeteld. Er is echter één uitzondering

Schakelaar 6 Propor tional / 3 point, welke de

motor instelt als “simpele” 3‑punts servomotor.

SW1: U/I ②

Fabrieksinstelling:

0‑10 V stuursignaal

SW2: 2V … 10 / 0V … 10 ③

De fabrieksinstelling is:

2 … 10V.

SW3: Direct/Omgekeerd ④

De fabrieksinstelling is:

Direct

SW4: ---/Sequential ⑤

Twee servomotoren kunnen naar hetzelfde

signaal “luisteren”. Als Sequential is ingesteld

reageert de motor op een gedeeld signaal.

NB: Deze instelling werkt samen met

schakelaar 5: 0(2) V … 5(6 V) / 6(6) V … 10 V

SW5: 0(2) V … 5(6 V)/6(6) V … 10 V ⑥

NB: Deze functie is geldig als schakelaar 4 op

Sequential staat.

SW6: Proportioneel/3-punts ⑦

De servomotor werkt als een simpele 3-punts

motor als de 3punts functie is ingesteld.

Voedingsspanning wordt aangesloten op de

klemmen SN en SP. Op

24 Vac voor “omlaag”

de klemmen 1 en 3 wordt

en “omhoog” aangesloten.

Uitgangssignaal X geeft de werkelijke stand aan.

NB: in de 3-puntsfunctie reageert de

servo motor niet op signalen via klem Y. De

spindel beweegt alleen bij spanning op klem

1 of klem 3.

SW7: LOG flow/LIN flow ⑧

Fabrieksinstelling:

LOG. Flow (afsluiter‑karakteristiek

ongewijzigd)

NB: De grote AB‑QM‑afsluiter heeft een

lineaire karakteristiek.. In de stand LIN

flow blijft de karakteristiek lineair. In de

stand LOG flow wordt de karakteristiek

van de servomotor dusdanig aangepast

dat de servomotor en de afsluiter

tezamen als afsluiter werken met een

LOG‑karakteristiek.

SW8: 100% KVS/RED. KVS ⑨

In te stellen in de stand OFF.

SW9: Reset ⑩

Nadat de servomotor is aangesloten op de

voedingsspanning begint de automatische

afstelprocedure. De indicatie LED knippert tot

de afstelling is beëindigd. De tijdsduur is

afhankelijk van de kleplift en bedraagt

gewoonlijk enkele minuten. De slag van de

klep wordt in het geheugen opgeslagen. Om

de afstelprocedure opnieuw te starten dient

de stand van RESET veranderd te worden.

Wanneer de voedings-spanning wordt

uitgeschakeld of langer dan 0,1s onder 80%

daalt, wordt de momentele klepstand in het

geheugen opgeslagen en blijven alle

gegevens bewaard, ook na het uitschakelen

van de voeding.

Functietest

De LED indicator toont het motorbedrijf,

bedrijfstoestand en eventuele fouten.

De LED indicator toont het motorbedrijf,

bedrijfstoestand en eventuele fouten.

Continue aan

- normaal bedrijf

Continu uit

- geen bedrijf of geen voedingsspanning

Knipperend (1 Hz)

- automatische afstelprocedure

Knipperend (3 Hz):

- voedingsspanning te laag

- onvoldoende klepslag (,20 s)

- eindpositie onbereikbaar.

Afmetingen ❺

AQ00128646944803-010301 8 | © Danfoss | 2021.08

Page 9

AME 85 QM

ESPAÑOL

Nota de seguridad

instrucciones.

Las operaciones de montaje, puesta en marcha

y mantenimiento deben ser realizadas

únicamente por personal cualificado y

autorizado.

Por favor, respete las instrucciones del

fabricante u operador del sistema.

Montaje ❶

Montaje del AME 85, 86 en la válvula ①.

Posiciones permitidas de instalación ②.

Cancelación manual ❷

La cancelación manual se lleva a cabo girando

la llave Allen de 8 mm (no suministrada) hasta la

posición precisa. Preste atención a los símbolos;

proporcionan información acerca del sentido

de giro.

Cableado ❸

* AC 24 V conexión a través de un transformador

Seńal de control

La seńal de control proveniente del regulador

deberá ser conectada al terminal Y (seńal de

entrada) y al terminal SN (común) en el circuito

impreso del AME.

Seńal de salida

La seńal de salida del terminal X puede usarse

para indicar la posición actual. El rango

dependerá de la configuración del interruptor

DI P.

Tensión de alimentación

La tensión de alimentación (24V~-15/+10 %, 50

Hz) tiene que ser conectada a los terminales SN

y SP.

Las configuarciones del interruptor

DIP ❹

A fin de evitar lesiones personales o

daños en el dispositivo, es

absolutamente necesario leer y

respetar estrictamente estas

No retire la cubier ta antes de haber

desconectado el suministro eléctrico

por completo.

aislante de seguridad (AC 24 V Connect

via safety isolating transformer)

¡

No toque nada en la pl aca de circuito

impreso!

¡Desacti ve la línea de suministro eléc trico

¡Tensión letal!

Conecte el ac tuador de acuerdo con el esq uema de

cableado.

antes de conectar el actuador!

U I

2 V_---V 0 V_---V

Directo Secuencial

--- Proporcional

0(2) V_5(6) V 5(6) V_10 V

Inverso 3 punt os R / L

Flujo LOG . Flujo LIN.

100 % Kvs Red. Kvs

Restablecimiento Restablecimiento

Ajuste de fábrica:

Todos los interruptores tienen que estar en la

posición OFF! ①

IMPORTANTE: Todas las combinaciones de

los interruptores están permitidas. Todas las

funciones seleccionadas serán añadidas una

a la otra. Solamente hay una sobreposición de

las funciones: el interruptor No.6 Proporcional

/ 3 vías que hace que el actuador ignore la

señal y funcione como un “sencillo” actuador

de 3 vías.

SW1: U/I ②

Ajuste de fábrica:

señal de control de tensión (0 ‑10 V).

SW2: 2-10 V/0-10 V ③

Ajuste de fábrica:

2‑10 V.

SW3: Directo/Inverso ④

Ajuste de fábrica:

DIRECT

SW4: ---/Secuencial ⑤

Se pueden ajustar dos acuadores

simultaneamenete que respondan a la misma

señal de control a la vez.

Al elegir SEQUENTIAL el actuador responderá

a la señal de control dividida (vease 0(2)-5(6)

V/5(6)-10 V).

Nota: Esta combinación funciona en

combinación con el interruptor No.5:

0(2)‑ 5(6) V/5(6)‑10 V).

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Nota: Esta función es posible al elegir el

interruptor No.4:‑‑‑/ Secuencial.

SW6: Proporcional/3 vías ⑦

Cuando los interruptores DI P 6 es de

actuador debe realizar ajuste

automático de la longitu d de carrera

antes del conmutador DIP 6 en l a posición ON.

Señal de salida de pende de los interruptores DI P

2, 3 &5 Ajuste.

Actuador puede funcionar en modulante (DIP

6 a OFF) o en modo “simple” 3-puntos, si la

función se selecciona 3 puntos (DIP 6 a).

Conectar la corriente de alimentación SN y SP.

terminales de los terminales.

Ajuste de fábrica los interruptores DIP 6 en la

posición OFF para el funcionamiento actuador

modulante en modo.

Actuador vástago es totalmente extendida

o se ejecutará hasta su posición retraída,

señal de transición SN a los terminales 1 o 3

y permanecerá en tal tomografía mientras

potencial está presente.

Ajuste los interruptores DIP 6 en

funcionamiento actuador de 3 puntos modo.

Observe atentamente diagrama de

conexionado como cableado es diferente

para los controladores con salida triac (ECL) en

comparación a los controladores con salida de

relé.

Importante: Al elegir la función de 3 vías,

el actuador no responerá a ninguna de las

señales de control en el puerto Y. El vástago

se moverá hacia arriba o abajo si hay

alimentación en el puerto 1 ó 3.

SW7: LOG.flow/LIN.flow ⑧

(LOG.flujo /LIN.flujo)

Ajuste de fábrica:

LOG flow (característica de la válvula no

cambiada)

Imporatante: Al usar esta función con las

válvulas no logarítmicas, la característica de

la válvula motorizada será el antilogaritmo

de la característica de la válvula (por ejemplo

la válvula con la característica linear será

transformada en al caracteristica de apertura

rápida).

SW8: 100 % KVS/RED. KVS ⑨

Nota: Esta función funciona correctamente

solamente con las válvulas logarítmicas (de

flijo igual porcentage).

SW9: Funcionamiento ⑩

Después de suministrar corriente de

alimentación al actuador, éste inicia un proceso

de auto ajuste. El diodo LED parpadea hasta

que el proceso de auto ajuste haya llegado a

término. Este proceso dura normalmente un

par de minutos dependiendo del recorrido

del vástago. El recorrido de la válvula es

almaceneado en la memoria después de

terminado el auto ajuste. Para empezar de

nuevo el auto ajuste pulsar el interruptor

RESET (interruptor No.9). Si se corta la tensión

de alimentación o en caso de que ésta caiga

por debajo de 80 % durante más de un 0,1 s, la

posición actual de la válvula será guardada en

la memoria. De esta manera, todos los datos

quedarán guardados en la memoria, incluso en

caso de corte de corriente.

Test de funcionamiento

El diodo luminoso indica si el motor está

funcionando. Además indica el estado de

funcionamiento y fallos eventuales.

Luce constantemente

- funcionamineto normal

No luce

- no está en marcha, no hay alimentación

Luce intermitentemente a intervalos (1 Hz)

- estado de auto ajuste

Luce intermitentemente a intervalos (3 Hz)

- corriente de alimentación demasioado baja

- recorrido de la válvula insuficinete

(<20 s)

- el recorrido máximo no puede ser

alcanzado.

Dimensiones ❺

© Danfoss | 2021.08 | 9AQ00128646944803-010301

Page 10

AME 85 QM

ITALIANO

Attenzione

Per evitare danni alle persone e

all’apparecchio, è assolutamente

attentamente queste istruzioni.

Montaggio, avviamento e manutenzione

devono essere eseguiti solo da personale

autorizzato e qualificato.

Seguire sempre le istruzioni del costruttore o

dell’assistenza.

Montaggio ❶

Fissare l’AME 85 QM sulla valvola ①.

Posizioni d’installazione consentite ②.

Esclusione manuale ❷

Per agire in modo manuale, ruotare la chiave

esagonale da 8 mm (non fornita) sulla posizione

richiesta. Osservare la direzione di rotazione del

simbolo.

Collegamento elettrico ❸

* 24 VAC: Collegare tramite trasformatore di

Segnale di comando

Il segnale di comando deve essere collegato

ai morsetti Y (ingresso segnale) e SN (comune)

serigrafati sulla scheda dell’AME.

Segnale di uscita

Il segnale di uscita dal morsetto X può essere

utilizzato per indicare la posizione della valvola.

Il campo dipende dalla configurazione del DIP

switch.

Alimentazione

L’alimentazione (24 V ~ -15/+10 %, 50 Hz) deve

essere collegata ai morsetti SN e SP.

Impostazioni dei DIP switch ❹

necessario leggere e osservare

Non rimuovere il cope rchio prima di

aver completamente scollegato

l’alimentazione elettrica.

isolamento di sicurezza.

(Connect via safety isolating transformer.)

Non toccare i componenti del PCB!

Scollegare dalla rete di alimentazione

prima di effettuare i collegamenti

elettrici sull’attuatore! Tensione mortale!

Collegare l’attuatore secondo lo schema

elettrico.

U I

2 V_--- V 0 V_- -- V

Diretto Invers o

---

0(2)_5(6) V 5(6)_10 V

Proporzionale 3 punti/RL

Portata LOG. Portata LIN.

100 % k

VS

Resettaggio Resettaggio

Sequenziale

RED. k

VS

Impostazioni di fabbrica:

Tutti gli switch sono in posizione OFF! ①

Nota: Tutte le combinazioni dei DIP switch

sono consentite. Tutte le funzioni selezionate

sono aggiunte in sequenza. C’è soltanto una

sovrapposizione logica delle funzioni, ad es.

lo switch N°6 Proporzionale/3 punti, che fa

ignorare all’attuatore il segnale di comando

e lo fa funzionare come un “semplice” motore

a 3 punti.

SW1: U/I ②

Impostazione di fabbrica:

Segnale di comando di tensione (0‑10 V).

SW2: 2-10 V/0-10 V ③

Impostazione di fabbrica:

2‑10 V.

SW3: Diretto/Inverso ④

Impostazione di fabbrica:

DIRETTO

SW4: ---/Sequenziale ⑤

Due attuatori possono essere configurati per

far sì che funzionino in parallelo con lo stesso

segnale di comando. Se è settata la funzione

SEQUENZIALE, allora l’attuatore risponde al

segnale di comando “split” (vedi 0(2)-5(6) V/5(6)10 V).

NOTA: Questa combinazione va associata allo

switch No 5: 0(2)‑5(6)V/5(6)‑10 V

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

NOTA: Questa funzione è disponibile

se lo switch No 4: ‑‑‑ /Sequenziale viene

selezionato.

SW6: Proporzionale/3 punti ⑦

Se viene selezionata la funzione 3punti, allora

l’attuatore può funzionarecome “semplice”

attuatore a 3 punti. L’alimentazione elettrica

deve essere collegata ai morsetti SN e SP. Il

segnale di comando 24 V CA è collegato per

l’apertura e la chiusura dell’attuatore ai morsetti

1 o3. Il segnale di ritorno X corrisponde alla

posizione corretta.

Nota: Se la funzione a 3 punti è selezionata,

l’attuatore non risponde al segnale di

comando sul morset toY. Alza e abbassa

l’alberino solo quando l’alimentazione è

presente sui morsetti 1 o 3.

SW7: Portata LOG./Portata LIN. ⑧

Impostazioni di fabbrica:

Portata LOG. (le caratteristiche della valvola

rimangono immutate)

NOTA: La maggior parte delle valvole

Danfoss dotate di attuatore hanno una curva

caratteristica portata/posizione logaritmica

(equi-percentuale). Impostando lo switch su

portata LIN. la caratteristica della valvola può

essere modificata. Questa combinazione di

attuatore e valvola corrisponde ad una valvola

con curva caratteristica LINEARE.

SW8: 100 % KVS/RED. KVS ⑨

NOTA: Questa funzione può essere

correttamente utilizzata solo con valvole

logaritmiche (equi‑percentuali).

SW9: Ripristino ⑩

Dopo essere stato alimentato, l’attuatore inizia

una procedura di auto-determinazione della

corsa. Il LED lampeggia fino a quando l’autoregolazione è terminata. Questa operazione

dura normalmente pochi minuti a seconda della

corsa. La corsa della valvola viene memorizzata

alla fine di questa processo. Per ripetere la

procedura di auto-determinazione occorre

modificare la posizione del RIPRISTINO (switch

N° 9). Se la tensione viene a mancare o si

abbassa ad un valore inferiore all’80 % per più

di 0,1 s, la posizione attuale della valvola viene

memorizzata. Anche tutti i dati verranno salvati

in caso di interruzione della corrente.

Test di funzionamento

L’indicatore luminoso indica se l’attuatore è

in funzione o meno. Indica inoltre lo stato di

funzionamento o di avaria.

Luce costante

- funzionalità normale

Nessuna luce

- nessun funzionamento né alimentazione

Luce intermittente (1 Hz):

- modalità di autoregolazione

Luce intermittente (3 Hz):

- alimentazione troppo bassa

- corsa insufficiente della valvola (<20 s)

- il fine corsa non può essere raggiunto.

Dimensioni ❺

AQ00128646944803-010301 10 | © Danfoss | 2021.08

Page 11

AME 85 QM

POLSKI

Warunki bezpieczeństwa

Aby uniknąć obrażeń u ludzi oraz

uszkodzenia

zapoznać się

z tymi informacjami i przestrzegać ich.

Niezbędne prace związane z montażem,

uruchomieniem i konserwacją mogą być

wykonywane wyłącznie przez autoryzowany

wykwalifikowany personel.

Prosimy stosować się do instrukcji producenta

lub operatora układu.

Nie zdejmować pok rywy p rzed

całkowitym

Montaż ❶

Zamontować siłownik AME 85, AME 86 na

zaworze ①.

Dopuszczalne pozycje montażu ②.

Sterowanie ręczne ❷

Ręczne sterowanie jest realizowane przez

obrót 8 mm klucza imbusowego (nie jest na

wyposażeniu) do odpowiedniego położenia.

Należy zwrócić uwagę na symbole opisujące

kierunek obrotu.

Okablowanie ❸

* 24 V AC Podłączać za pośrednictwem

separującego transformatora

bezpieczeńst wa (AC 24 V Connect

via safety isolating transformer)

Wersja na 230 V~

Nie wolno nic zego dotykać na pł ytce

jest pod napięciem! Zagrożenie życia!

Podłącze nia przewodów wykon ać zgodnie ze

schematem podłączeń elektrycznych.

Sygnał sterujący

Sygnał sterujący ze sterownika musi być

podłączony do wyprowadzeń Y (sygnał

wejściowy) oraz SN (masa) na płytce drukowanej

siłownika AME.

Sygnał wyjściowy

Sygnał wyjściowy z wyprowadzenia X może być

użyty do wskazania bieżącej pozycji. Zakres

zależy od ustawień przełącznika DIP.

Napięcie zasilania

Napięcie zasilania (24V~ -15 do +10 %, 50Hz)

musi być podłączone do wyprowadzeń SN i SP.

Ustawienia przełącznika DIP ❹

obwodu drukowanego, gdy urządzenie

0(2) V_5(6) V 5(6) V_10 V

Proporcjonalny 3-punktowy/RL

sprzętu, należy koniecznie

odłączeniem zasilania.

U I

2 V_---V 0 V_---V

Zgodnie Odwrotnie

--- Sequential

LOG. fl ow LIN . flow

100 % Kvs Red. Kv s

Reset Reset

i

Wszystkie wybierane funkcje są sumowane.

Istnieje tylko jedno logiczne ominięcie

funkcjonalności: przełącznik nr 6 Proportional

/3 point (Proporcjonalny/3‑punktowy),

który powoduje, że siłownik ignoruje sygnał

sterujący i działa jako prosty 3‑punktow y

siłownik.

SW1: U/I ②

Ustawienie fabryczne:

sterowanie sygnałem napięciowym (0..10 V).

SW2: 2-10 V/0-10 V ③

Ustawienie fabryczne:

2‑10 V.

SW3: Direct/Inverse ④

Ustawienie fabryczne:

DIRECT

SW4:---/Sequential ⑤

Dwa siłowniki mogą być sterowane równolegle

jednym sygnałem sterującym. Jeśli wybrana jest

opcja SEQUENTIAL, siłownik reaguje na dzielony

sygnał sterujący (patrz 0(2)-5(6) V/5(6)-10 V).

UWAGA: To ustawienie działa w połączeniu z

przełącznikiem nr 5: 0(2)‑5(6) V/5(6)‑10 V

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

UWAGA: Ta funkcja jest dostępna, gdy

ustawiony jest przełącznik nr 4: ‑‑ ‑ /

Sequential.

SW6: Proportional/3 point ⑦

Gdy przełąc znik DIP 6 jest NA

Siłownik musi w ykonywać

samodostrajania przed zmianą

ustawień przełąc znika DIP 6 na ON (WŁ. ).

Sygnał wyjściow y zależy od DIP 2, 3 &5 nas tawa.

Siłownik może pracować w modulujący (DIP 6

do WYŁĄCZONY) lub w “proste” 3-punktowego,

po wybraniu opcji 3-point (DIP 6 ON).

Podłączyć napięcie zasilania na zaciskach SN i

SP zacisków.

Fabrycznie ustawione na OFF DIP 6 do obsługi

Siłownik w trybie modulujący.

Siłownik jest całkowicie wysunięty trzpień

będzie pracować w jego trakcie wsuwania

trzpienia lub przez możliwość przemierzania

SN sygnał do zacisków 1 i 3 i pozostanie w

tym pozytronowa tak długo, jak jest obecny

potencjał.

Ustawić Siłownik DIP 6 do pracy w trybie

3-punktowy.

Przyjrzyj się uważnie jak połączenia elektryczne

schemat połączeń elektrycznych jest różne w

zależności od regulatorów z wyjścia triakowe

(ECL) w porównanie do regulatorów z wyjście

przekaźnika.

UWAGA: Jeśli wybrano opcję 3‑point,

siłownik nie reaguje na jakikolwiek sygnał

sterujący na w yprowadzeniuY. Siłownik

będzie podnosił i opuszczał wrzeciono, jeśli

na wyprowadzenia 1 i 3 zostanie podane

napięcie.

SW7: LOG. flow/LIN. flow ⑧

Ustawienie fabryczne:

LOG. Flow (niezmieniona charakterystyka

zaworu)

UWAGA: Jeśli ta funkcja jest uż ywana w

połączeniu z zaworami nielogarytmicznymi,

charakterystyka zaworu napędzanego będzie

antylogarytmem charakterystyki zaworu

(np. zawór liniowy przekształci się w zawór

szybkiego otwarcia).

SW8: 100 % KVS/RED. KVS ⑨

UWAGA: Ta funkcja działa prawidłowo

wyłącznie z zaworami logar ytmicznymi

(stałoprocentowymi).

SW9: Reset ⑩

Po podłączeniu siłownika do zasilania

rozpoczyna się procedura samoregulacji.

Dioda LED błyska do momentu zakończenia

tego procedury. Trwa to zazwyczaj parę

minut w zależności od skoku wrzeciona. Po

zakończonym procesie samoregulacji wartość

skoku zaworu jest zachowana w pamięci.

Zmiana pozycji przełącznika RESET (przełącznik

nr 6) ponownie wyzwala proces samoregulacji.

Jeżeli napięcie zasilające zostanie odcięte lub

przez okres ponad 0,1 sekundy spadnie poniżej

80 %, to aktualna pozycja zaworu jest chowana

w pamięci; zapewnia to, zachowana zachowanie

wszystkich danych - również w przypadku

przerw w zasilaniu.

Test działania

Dioda świetlna wskazuje, czy silnik jest aktywny

czy też nie. Co więcej, dioda LED wskazuje

też status sterowania i błędy.Dioda świetlna

wskazuje, czy silnik jest aktywny czy też nie.

Co więcej, dioda LED wskazuje też status

sterowania i błędy.

Stałe świecenie

- normalna pracaBrak świecenia

- brak działania lub zasilania

Miganie z częstotliwością 1Hz

- tryb samoregulacji

Miganie z częstotliwością 3Hz

- zbyt niskie napięcie zasilania

- niedostateczny skok zaworu (<20 s)

- nie można osiągnąć położenia

krańcowego.

Wymiary ❺

Ustawienia fabryczne:

wszystkie przełączniki są w położeniu OFF! ①

UWAGA: Dozwolone są wszystkie

kombinacje przełąc zników DIP.

© Danfoss | 2021.08 | 11AQ00128646944803-010301

Page 12

AME 85 QM

ČESKY

Bezpečnostní pokyny

Abyste předešli zranění osob a

poškození zařízení, před montáží a

přečíst tyto pokyny a bezpečnostní instrukce.

Nedemontujte servopohony s funkcí

bezpečnostní pružiny! Při nesprávné manipulaci

hrozí nebezpečí zranění nebo usmrcení!

Servopohon je těžký. Manipulujte s ním opatrně,

abyste předešli zranění osob nebo poškození

produktu.

Montáž ❶

Upevněte AME 85 QM na ventil ①.

Přípustná instalační poloha ②.

Ruční ovládání ❷

Ruční ovládání se provádí otočením

imbusového klíče 8 mm (není přiložen) do

požadované polohy. Všímejte si směru značky

otáčení.

Zapojení ❸

* Připojte 24 V AC prostřednictvím

Řídicí signál

Řídicí signál z řídicí jednotky musí být připojen

ke svorkám Y (vstupní signál) a SN (společný

vodič) na desce tištěných spojů AME.

Výstupní signál

Výstupní signál ze svorky X lze použít pro

indikaci aktuální polohy. Rozsah závisí na

nastavení přepínačů DIP.

Napájecí napětí

Napájecí napětí (24 V~ -15 až +10 %, 50 Hz) musí

být připojeno ke svorkám SN a SP.

Nastavení DIP spínače ❹

uváděním zařízení do provozu si musíte

Nesundávejte kryt, dokud není

napájen í zcela vypnuto.

bezpečnostního izolačního transformátoru

(AC 24 V Connect via safety

isolating transformer)

Nedotýkejte se ni čeho na elektronice

pohonu!

Před zapojováním ser vopohonu

vypněte elektrické vedení! Přítomnost napětí

nebezpečného životu!

Servopohon zapojte podle schématu zapojení.

U I

2 V_--- V 0 V_- -- V

Přímý Inverzní

--- Sekvenční

0(2)_5(6) V 5(6)_10 V

Proporcionální

Průtok LO G Pr ůtok LIN

100 % k

VS

Resetování Resetování

3bodový/RL

RED. k

VS

Tovární nastavení:

VŠECHNY spínače jsou nastaveny do V YPNUTÉ

polohy! ①

Poznámka: Všechny kombinace přepínačů

DIP jsou povoleny. Všechny funkce, k teré jsou

vybrány, jsou přidány po sobě. Existuje pouze

jedno logické potlačení funkcí, tj. spínač č.6 Volba

modulačního nebo třípolohového režimu, který

nastavuje servopohon tak, aby ignoroval řídicí

signál a plnil funkci „jednoduchého“ 3bodového

servopohonu.

SW1: U/I ②

Tovární nastavení:

Napěťový reg ulační signál (0‑10 V).

SW2: 2-10 V/0-10 V ③

Tovární nastavení:

2‑10 V.

SW3: Přímý/Inverzní ④

Tovární nastavení:

PŘÍMÝ

SW4: ---/Sekvenční ⑤

Dva servopohony lze nastavit tak, aby

pracovaly paralelně s jedním řídicím signálem.

Pokud je nastaven do polohy ON, pracuje

servopohon v sekvenčním rozsahu:0(2)...5(6)

V nebo 0(4)...10(12)mA nebo 6(6)...10V nebo 10

(12)....20mA.

Poznámka: Tato kombinace pracuje spolu se

spínačem č.5: 0(2)‑5(6) V/5(6)‑10 V

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Poznámka: Tato funkce je použitelná pouze s

nastaveným spínačem č. 4: ‑‑‑/Sekvenční.

SW6: Modulační nebo třípolohový režim ⑦

Servopohon může pracovat jako „jednoduchý“

3bodový servopohon, pokud je navolená

3bodová funkce. Napájení by mělo být

připojeno k portům SN a SP. Na portu 1 nebo

3 je připojen signál 24 V AC pro zvedání nebo

spouštění servopohonu. Zpětný signál X

signalizuje správnou polohu.

Poznámka: Pokud navolíte 3bodovu funkci,

servopohon nereaguje na žádný řídicí signál

na portu Y. Pouze zvedne a spustí vřeteno,

pokud je napájení přivedeno na port 1 nebo 3.

SW7: Průtok LOG/Průtok LIN; volba

rovnoprocentí nebo linearní

charakteristiky ⑧

Tovární nastavení:

LOG. Průtok (charakteristika ventilu je

nezměněna)

Poznámka: Velké ventily AB‑QM mají lineární

charakteristiku. S nastavením spínače do

polohy Průtok LIN zůstávají charak teristiky

lineární . Pokud nastavíte spínač do polohy

Průtok LOG, průtok ventilem je nastaven na

rovnoprocentí charakteristiku.

SW8: 100 % KVS/RED. KVS ⑨

Poznámka: Tato funkce funguje správně

pouze slogaritmickými (rovnoprocentními)

vent ily.

SW9: Resetování ⑩

Po zapojení ke zdroji napájecího napětí se

servopohon začne automaticky nastavovat.

LED kontrolka bude během tohoto nastavování

blikat. Doba nastavování závisí na délce dráhy

vřetena a obvykle trvá několik minut. Velikost

dráhy zdvihu je po dokončení nastavování

uložena do paměti. Chcete-li nastavování

zopakovat, tak stačí změnit polohu spínače

RESET (spínač č. 1). Jestliže dojde k výpadku

dodávky elektrické energie nebo poklesne-li

napětí pod 80 % nominální hodnoty na dobu

delší než 0,1 sec, zaznamená se do paměti

aktuální poloha kuželky ventilu. Tyto hodnoty

zůstanou v paměti uloženy i v tom případě, kdy

bude servopohon odpojen od zdroje elektrické

energie.

Funkční test

Kontrolka zobrazuje, zda je polohovač funkční,

nebo nikoliv. Kromě toho kontrolka zobrazuje

kontrolní stavy a poruchy.

Trvale svítí

- normální funkce

Nesvítí

- žádná funkce nebo bez napájení

Svítí přerušovaně (1 Hz)

- režim vlastního nastavení

Svítí přerušovaně (3 Hz):

- napájení je příliš nízké

- nedostatečný zdvih ventilu (<20 s)

- nelze dosáhnout koncové polohy.

Rozměry ❺

AQ00128646944803-010301 12 | © Danfoss | 2021.08

Page 13

AME 85 QM

MAGYAR

Biztonsági megjegyzések:

Az itt szereplő utasítások gondos

elolvasása és betartása feltétlenül

fontos a személyi sérülések és

berendezés károsodások elkerülésére.

A szükséges szerelési, beállítási és karbantartási

munkákat kizárólag szakképzett és megbízott

személyzet végezheti el.

Kérjük, tartsa be a rendszer gyártójának és

üzemeltetőjének rendelkezéseit!

Ne távolítsa el a fedele t a

tápfeszültség teljes lekapcsolása előtt.

Beépítés ❶

Szerelje fel az AME 85 QM egységet

aszelepre ①.

Lehetséges beépítési helyzetek ②.

Kézi működtetés ❷

A kézi működtetést egy 8 mm-es belső nyílású

kulcsnak (nem tartozék) a kívánt helyzetbe

történő elfordításával végezhetjük el. Ügyeljen a

forgásirány jelzésre.

Bekötés ❸

* AC 24 V Kapcsolás a biztonsági

szigetelőtranszformátoron keresztül.

(AC 24 V Connect via safety

isolating transformer)

Ne érintsen meg semm it a PCB‑n!

Kapcsolja ki a tápellátást mielőtt

beköti az állítóművet! Életveszélyes

feszültség! Csatlakoztassa az állítóművet az

elektromos bekötési rajz szerint.

Vezérlőjel

A szabályozóról érkező vezérlőjelet az Y

(bemenőjel) és az SN (közös) csatlakozókra kell

csatlakoztatni az AME nyomtatott áramköri

lapon.

Kimeneti jel

Az X csatlakozóról érkező kimeneti jel

használható az aktuális pozíció kijelzésére. A

tartomány a DIP kapcsolók beállításától függ.

Tápfeszültség

A tápfeszültséget (24 V~ -15-től +10%-ig, 50 Hz)

az SN és az SP csatlakozókhoz kell csatlakoztatni.

DIP kapcsolók beállításai ❹

U I

2 V_--- V 0 V_- -- V

Egyenes Fordított

--- Szekvenciális

0(2)_5(6) V 5(6)_10 V

Arányos 3-pontos/RL

LOG. Térfogatáram LIN. térfogatáram

100 % k

VS

Visszaállítás Visszaállítás

RED. k

VS

Gyári beállítások:

MINDEGYIK kapcsoló OFF (KI) állásban

van! ①

MEGJEGYZÉS: A DIP kapcsolók helyzeteinek

minden kombinációja megengedett.

Minden kiválasztott funkció egymás után

hozzáadódik a korábbiakhoz. Csak egy

esetben bírálja felül a funkcionalitásokat

a logika, amikor a 6‑os számú kapcsoló a

Proportional (Arányos) / 3ponton van, amely

úgy állítja be a szelepmozgatót, hogy az ne

reagáljon a vezérlőjelre, és „egyszerű” három‑

pont vezérlésű állítóműként üzemeljen.

SW1: U/I ②

Gyári beállítás:

feszültség vezérlőjel (0‑10 V).

SW2: 2-10 V/0-10 V ③

A gyári beállítás:

2‑10 V.

SW3: Egyenes/Fordított ④

A gyári beállítás:

EGYENES

SW4: ---/Szekvenciális ⑤

Két szelepmozgató párhuzamos működésre

állítható egy vezérlőjellel működtetve.

SZEKVENCIÁLISRA állított helyzetben a

szelepmozgató úgy reagál, hogy felosztja a

vezérlőjelet (lásd a 0(2)-5(6) V/5(6)-10 V).

MEGJEGYZÉS: Ez a kombináció az 5. számú

mikrokapcsolóval együtt működik:

0(2)‑5(6)V/5(6)‑10 V

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

MEGJEGYZÉS: Ez a funkció akkor áll

rendelkezésre, ha a 4 számú mikrokapcsoló:

‑‑‑/SZEKVENCIÁLIS helyzetben van.

SW6: Arányos/3-pontos ⑦

A szelepmozgató működhet „egyszerű” hárompont vezérlésű állítóműként, ha a három-pont

funkció van kiválasztva. A tápfeszültsége

az SN és az SP pontokra kell csatlakoztatni.

Az 1-es vagy a 3-as ponthoz a 24 VAC jel

csatlakozik a szelepmozgató fel, vagy le irányú

mozgatásához. A visszatérő X jel jelzi a helyes

pozíciót.

Megjegyzés: ha a három‑pont funkció

van kiválasztva, a szelepmozgató nem

reagál semmilyen, az Y porton megjelenő

vezérlőjelre. Csak akkor emeli fel, vagy engedi

le az orsót, ha feszültséget kap az 1‑es vagy a

3‑as ponton.

SW7: LOG. Térfogatáram/LIN.

térfogatáram ⑧

Gyári beállítás:

LOG. Vízátfolyás (a szelep jelleggörbéje

változatlan)

MEGJEGYZÉS: A nagy AB‑ QM szelepek

jelleggörbéje lineáris. Ha a kapcsoló LIN

pozícióban áll, a jelleggörbe lineáris

marad. Ha a kapcsoló LOG pozícióban áll, a

szelepmozgató vízátfolyási jelleggörbéje úgy

módosul, hogy a szelepmozgató és a szelep

LOG jelleggörbéjű szelepként működik együtt.

SW8: 100 % KVS/RED. KVS ⑨

MEGJEGYZÉS: Ez a funkció csak logaritmikus

(egyenszázalékos) szelepeknél működik

megfelelően.

SW9: Visszaállítás ⑩

Az egység tápfeszültségre kapcsolása után, a

szelepmozgató elkezdi az önbeállítást.

Az LED az önbeállítás befejezéséig villog. Az

időtartam az orsómozgás nagyságától függ, és

normál esetben a folyamat eltart néhány percig.

Az önbeállítás befejezésekor a szeleplöket

hossza eltárolásra kerül a memóriában. Az

önbeállítás újrakezdéséhez változtassa meg

a RESET mikrokapcsoló (1. kapcsoló) állását.

Ha a tápfeszültség lekapcsolódik, vagy 0,1

másodpercnél tovább 80 % alá esik, akkor

az aktuális szeleppozíció elmentésre kerül a

memóriában. Energiaellátás kimaradásakor az

Működés vizsgálat

A jelzőfény mutatja, hogy a pozicionáló

működik-e vagy sem. Továbbá, a kijelző mutatja

a szabályozó státuszát és hibáit.

Állandó fényjelzés

- normál működés

Nincs fényjelzés

- nem működik, vagy nincs energiaellátás

Szakaszosan világító fény (1 Hz)

- önbeállító mód

Szakaszosan világító fény (3 Hz):

- tápfeszültség túl alacsony

- elégtelen szelep löket (<20 mp)

- véghelyzet nem elérhető.

Méretek ❺

© Danfoss | 2021.08 | 13AQ00128646944803-010301

Page 14

AME 85 QM

有害物质含量表

汞

镉

六价铬

多溴联苯

多溴二苯 醚

说明书

位置指示器

齿轮

XOOOO

O

轴套管

XOOOO

O

表示该有害物质在该部件 所有均质材料中的含量 均在GB/T 2657 2规定的限量要求以下。

表示该有害物质至少在该部件的某一均质材料中的含量超出

规定的限 量要求。

不要碰触电路板上的任何元件!

请按接线图接线

当

是在驱动器需要执行行程

定。

中文

安全注意事项

行。

请遵循系统制造商或系统操作人员的说明。

安装❶

将AME85,AME86驱动器安装到阀体上 ①

允许的安装朝向 ②

手动操控 ❷

转动 8 毫米 Alley 钥匙(未提供)至指定位置,

即转为手动操控。注意观察旋转图标的方向。

接线 ❸

* 24 V 交流通过安全隔离变压器连接

控制信号

从控制器来的控制信号接到AME 的Y端(输入

信号)和SN端(公共端)。

阀位反馈

阀位反馈信号从X 端输出,SN为公共端

电源电压

电源电压(24V -15 % 到+10 % ,50Hz )连接

到端子SN和SP

DIP 拨动开关的设定 ❹

为避免发生人身和设备事故,请仔细

阅读本手册。

安装、调试、维修必须由专业人员进

切 勿 在 完 全 切 断 电 源 之 前 ,揭 开

保护盖。

(AC 24 V Connect via safety isolating

transformer)

接 线 前 请 先 断 开 电 源 !致 命 的 电

压!

U I

2 V_---V 0 V_---V

正向 反向动作

---

0(2) V_5(6) V 5(6) V_10 V

比例控制 三点控制 /RL

LOG. fl ow LIN. flow

100 % k

VS

Reset Reset

顺序动作

RED. k

VS

SW1: U/I ②

出厂设定:

电压控制信号

SW2: 2-10 V/0-10 V ③

出厂设定:

2‑ ‑10 V.

SW3: 正向/反向动作 ④

出厂设定:

正向

SW4: -- -/顺序动作 ⑤

两个驱动器可共用一个控制

信 号 并 联 工 作 。选 择 顺 序 动

作功能后控制信号将被分割

(0(2)-5(6)V/5(6)-10 V)。

注意:此项功能与拨动开关第 5 位配合使

用。

0(2)V‑5(6V)/5(6)V‑10 V。

SW5: 0(2) V-5(6) V/5(6)-10 V ⑥

注意:此项功能当拨动开关第 4 位设为顺

序动作时有效。

SW6: 比例控制/三点控制 ⑦

DIP 6

自检之前更改 DIP 6为" ON "。

输出信号取决于 DIP 2、3和5设

驱 动 器 可 以 运 行 的 调 制( DIP 6为 ”关 闭 ”)或

在”简单的”三点”模式中,如果三点功能(

DIP 6为” ON “)。

连接电源 端子上 SP 和 SN 端子接线端连接。

原厂设置 DIP 6为 OFF 来运行驱动器在调制模

式。

驱动器阀杆它仍会运行完全扩展或缩回位置的

衔接 SN 信号端子1或3,将 一 直 保 持 这 种 正 电 子

只要潜力。

设置 DIP 6为 On 用于操作驱动器在3点模式。

仔细观察电路接线图为接线不同控制器带有

双 向 可 控 硅 输 出( ECL )在 對照 控制器与继电

器输出。

出厂设定:

对数特性

注意:如果驱动器设定为线形而阀体特性

不是对数特性,则组合后的特性可解为快

开特性。

SW8: 100 %KVS 降低/KVS ⑨

选择降低KVS功能后阀门的KVS 值可降为比

它小一号阀门的KVS值与它本身KVS值之间的

中间值。

如:阀门本身KVS值为16,比它小一号阀门的

KVS值为10,则降低以后的KVS值为13。

注意:此项功能仅对对数特性的阀门有

效。

SW9: 复位 ⑩

驱动器第一次通电后将自动进行行程自检,自

检时 LED 指示灯闪烁直到自检结束。

自检的时间根据行程大小和速度快慢各不相

同,大致需几分钟时间。自检结束后行程信息

被记录到存储器中。将拨动开关的第 9位拨到

复位位置也可启动自检进程。电源断电或电压

降低于 80 % 的时间超过 0,1 秒 ,所 有 的 当 前 数

据被保存到存储器中。

功能测试功能测试

LED 指示灯可提供当前状态和故障指示:

持续亮

-正常工作

不亮

-没有任何操作或无电源电

压

闪烁(1Hz)

-自检中

闪烁(3Hz)

-电源电压过低

-行程不对(<20s)

-不能到达末端位置

尺寸 ❺

出厂设定:

所有位都在 OFF 位 置 。①

注意:允许对 DIP 拨动开关进行任意组合。

所有选定的功能将依次添加。 只有一种功

能逻辑操控,即拨动开关第 6 位比例控制/

三点控制,它将把驱动器设为不理会控制

注 意: 注 意: 选择三点控制以后驱动器不对 Y 端

子的控制信号作出反应。

SW7: 对数流量特性/线性流量特性 ⑧

几乎所有丹佛斯阀门的流量特性都是对数特性

的。如果驱动器设定为线性,则驱动器的工作

特性与阀体配合后可得出线性的特性。

信 号 ,而 是 作 为 “简单的”三点驱动器使用。

部件名称

O:

X:

铅 (Pb)

X O O O O O

X O O O O O

(Hg)

(Cd)

GB/T 26572

(Cr( VI))

(PBB)

(PBDE)

AQ00128646944803-010301 14 | © Danfoss | 2021.08

Page 15

AME 85 QM

РУССКИЙ

Техника безопасности

Во избежание получения травм или

повреждений устройства обязательно

прочитайте настоящую инструкцию и

тщательно ее соблюдайте.

Все необходи мые работы по сборке, вводу

действие и техническому обслу живанию

оборудования должны выполняться только

квалифицированным персоналом, имеющим

соответс твующее разрешение.

Следуйте указаниям производителя системы или

оператора системы.

Не снимайте крышку до то го, как

питание будет полностью

отключено.

Установка❶

Закрепить электропривод AME 85, AME86 на

клапане ①.

Монтажные положения регулятора ②.

Ручное позиционирование ❷

Ручное позиционирование производится с

помощью 8-мм шестигранного торцевого ключа (в

комплек т поставки не входит) путем его поворота

до нужного положения. Соблюдайте указанное на

изображении направление вращения.

Схема электрических

соединений ❸

* 24 В переменного тока

Подключать через безопасный

разделительный трансформатор.

(AC 24 V Connect via safety

isolating transformer)

Не прикасаться к открытым

контактам!

монтажом проводки электропривода!

Опасное для жизни напряжение!

Смонтируйте про водку привода согласно

электрической схеме.

Управляющий сигнал

Управляющий сигнал с регулятора подается на

клеммы Y (входной сигнал) и SN (ноль) платы AME.

Выходной сигнал

Выходной сигнал с клеммы Х может быть

использован для индикации текущего положения.

Диапазон зависит от нас троек переключателя DIP.

Напряжение питания

Напряжение питания (24 В переменного тока от –15

до +10 %, 50 Гц) подается на клеммы SN и SP.

Настройки переключателя DIP ❹

Отключать линию питания перед

U I

2 V_---V 0 V_---V

Прямо обратно

---

0(2) V_5(6) V 5(6) V_10 V

Аналоговый 3 импульсный/R L

Логарифмическая Линейная харак теристика

100 % Kvs Red. Kv s

Сброс Сброс

последовательно

в

Заводские установки:

ВСЕ переключатели находятся в

положении OFF (выключено). ①

ПРИМЕЧАНИЕ: Приемлемы все

комбинации переключателей DIP. Все

выбранные функции добавляются

друг к другу. Существует только одно

логическое перерегулирование функций:

переключатель № 6 – (аналоговый/

импульсный) настраивать исполни‑

тельный механизм таким образом

аналоговый, что он игнорирует

управляющий сигнал и работает как

импульсный исполнительный механизм.

SW1: U/I (напряжение/ток) ②

Заводская установка:

управляющий сигнал напряжения

(0 ‑ 10 B).

SW2: 2-10B/0-10 B ③

Заводская установка:

2‑10 B.

SW3: Прямо/обратно ④

Заводская установка:

ПРЯМО.

SW4: ---/последовательно ⑤

Существует возможнос ть установить два

исполнительных механизма так, что они работают

параллельно, с одним управляющим сигналом.

Если настроена функция ПОС ЛЕДОВАТЕЛЬНО,

то исполнительный механизм реагирует на

управляющий сигнал «сплит»

(см. 0(2)-5(6) В/5(6) -10 В).

ПРИМЕЧАНИЕ: Данная схема работает в

комбинации с переключателем № 5: 0(2)‑

5(6) В/5(6)‑10 В.

SW5: 0(2)-5(6) В/5(6)-10 В ⑥

ПРИМЕЧАНИЕ: Данная функция

имеет место лишь в случае, если

настроен переключатель № 4: ‑‑‑/

последовательно.

SW6: Аналоговый / импульсный ⑦

Если DIP‑ 6 ‑ это на привод,

исполнительный механизм

необходимо выполнить выход ной

сигнал зависит от DIP‑2, 3 5 настройка.а

перед изменением DIP 6.

привод, исполнительный механизм могу т работать

в модулирующий (6 в положение OFF (выкл.))

или в “простой” 3-позиционное режим, если

3-позиционное функция выбирается (6).

сеть питания подключается на клеммы SN и SP.

клеммам.

Заводские настройки перек лючателя DIP 6 в

положение OFF (выкл.) для управления привод,

исполнительный механизм в модулирующий

режим.

привод, исполнительный механизм клапана

будет работать в его совершенно прод ление или

отведенное положение, связывая их SN сигнал к

клеммам 1 или 3 и будет оставаться в этом позиция

до тех пор, пока потенциал.

Установите переключатель DIP 6 на привод,

исполнительный механизм для работы в 3 режима

точки.

Внимательно посмотрите электрическая схема как

монтаж проводки для регуляторов с симисторные

выходы (ECL) в сравнение для регуляторов с

релейный выход.

ПРИМЕЧАНИЕ: В случае, если выбрана

импульсная функция, исполнительный

механизм не реагирует ни на какой

аналоговый управляющий сигнал на входе

Y. Исполнительный механизм поднимает

и опускает шток только в случае, если

электропитание подаетс я на вход 1

или 3.

SW7: Логарифмическая/Линейная

характеристика ⑧

Заводская установка:

(Логарифмическая) характеристика

регулирования клапана не меняется.

ПРИМЕЧАНИЕ: В случае применения

данной функции в комбинации с

“нелогарифмическими” клапанами,

характеристика моторного клапана

будет являться антилогарифмом

характеристики клапана (например,

клапан с линейной характеристикой

трансформируется в характеристик у

быстрого открывания).

SW8: 100 % KVS/REDKVS ⑨

ПРИМЕЧАНИЕ: Данная функция

работает корректно только в случае

применения клапанов с логарифмической

(равнопоцентной) характеристикой

регулирования.

© Danfoss | 2021.08 | 15AQ00128646944803-010301

Page 16

AME 85 QM

SW9: Reset (Сброс) ⑩

После подачи тока на исполнительный механизм

последний начинает процесс автоподстройки.

Об этом свидетельствует мигание светодиода,

которое продолжается до окончания процесса

автоподстройки. Продолжительность процесса

обычно составляет несколько минут, в

зависимости от перемещения штока. Величина

хода клапана после окончания автоподстройки

регистрируется в запоминающем устройстве.

Процесс автоподстройки возобновляется нажатием

на кнопку сброса «RESET» (перек лючатель № 9).

При сбросе напряжения питания или при его

падении более чем на 80 % в течение более 0,1

с, текущее положение клапана регис трируется

в запоминающем устройстве. Таким образом ,

вся информация сохраняется в запоминающем

устройстве, в том числе в случаях сбоя напряжения

питания.

Функциональный тест

Световой диод наряду с индикацией

задействования привода производит также

индикацию рабочего состояния и возможных

ошибок.

Постоянное свечение

- обычное рабочее состояние эксплуатации

Отсутствие свечения

- выключение, напряжение отключено.

Прерывистое свечение (1 Гц):

- режим автоподстройки

Прерывистое свечение (3 Гц):

- электропитание слишком мало

- недостаточная величина времени хода

клапана (<20 с)

- невозможность входа в исходное положение.

Габаритные ❺

ІМПОРТЕР:

UA: ТОВ з ІІ «Данфосс ТОВ», вул. Вікентія Хвойки, 15/15/6, м. Київ, 04080, Україна

73691330 / AQ00128646944803-01030116 | © Danfoss | DCS-S/SI | 2021.08

Loading...

Loading...