Daikin RXYQQ8U7Y1B*, RXYQQ10U7Y1B*, RXYQQ12U7Y1B*, RXYQQ14U7Y1B*, RXYQQ16U7Y1B* Installer reference guide

...

Installer and user reference guide

VRV IV Q+ series heat pump

RXYQQ8U7Y1B*

RXYQQ10U7Y1B*

RXYQQ12U7Y1B*

RXYQQ14U7Y1B*

RXYQQ16U7Y1B*

RXYQQ18U7Y1B*

RXYQQ20U7Y1B*

Table of contents

Table of contents

1 About the documentation 6

1.1 About this document ...................................................................................................................................................... 6

1.2 Meaning of warnings and symbols................................................................................................................................. 7

2 General safety precautions 9

2.1 For the installer............................................................................................................................................................... 9

2.1.1 General ........................................................................................................................................................... 9

2.1.2 Installation site ............................................................................................................................................... 10

2.1.3 Refrigerant — in case of R410A or R32.......................................................................................................... 10

2.1.4 Electrical ......................................................................................................................................................... 12

3 Specific installer safety instructions 15

For the user 18

4 User safety instructions 19

4.1 General............................................................................................................................................................................ 19

4.2 Instructions for safe operation ....................................................................................................................................... 20

5 About the system 23

5.1 System layout.................................................................................................................................................................. 23

6 User interface 24

7 Before operation 25

8 Operation 27

8.1 Operation range.............................................................................................................................................................. 27

8.2 Operating the system ..................................................................................................................................................... 27

8.2.1 About operating the system........................................................................................................................... 27

8.2.2 About cooling, heating, fan only, and automatic operation ......................................................................... 28

8.2.3 About the heating operation.......................................................................................................................... 28

8.2.4 To operate the system (WITHOUT cool/heat changeover remote control switch)...................................... 29

8.2.5 To operate the system (WITH cool/heat changeover remote control switch) ............................................. 29

8.3 Using the dry program.................................................................................................................................................... 30

8.3.1 About the dry program................................................................................................................................... 30

8.3.2 To use the dry program (WITHOUT cool/heat changeover remote control switch) .................................... 30

8.3.3 To use the dry program (WITH cool/heat changeover remote control switch) ........................................... 30

8.4 Adjusting the air flow direction ...................................................................................................................................... 31

8.4.1 About the air flow flap.................................................................................................................................... 31

8.5 Setting the master user interface................................................................................................................................... 32

8.5.1 About setting the master user interface........................................................................................................ 32

8.5.2 To designate the master user interface (VRV DX and Hydrobox) ................................................................. 33

8.6 About control systems .................................................................................................................................................... 33

9 Energy saving and optimum operation 34

9.1 Available main operation methods ................................................................................................................................ 34

9.2 Available comfort settings .............................................................................................................................................. 35

10 Maintenance and service 36

10.1 Maintenance after a long stop period............................................................................................................................ 36

10.2 Maintenance before a long stop period......................................................................................................................... 37

10.3 About the refrigerant...................................................................................................................................................... 37

10.4 After-sales service and warranty .................................................................................................................................... 37

10.4.1 Warranty period............................................................................................................................................. 37

10.4.2 Recommended maintenance and inspection................................................................................................ 38

10.4.3 Recommended maintenance and inspection cycles ..................................................................................... 38

10.4.4 Shortened maintenance and replacement cycles......................................................................................... 39

Installer and user reference guide

2

11 Troubleshooting 40

11.1 Error codes: Overview .................................................................................................................................................... 41

11.2 Symptoms that are NOT system malfunctions............................................................................................................... 44

11.2.1 Symptom: The system does not operate....................................................................................................... 44

11.2.2 Symptom: Cool/Heat cannot be changed over ............................................................................................. 44

11.2.3 Symptom: Fan operation is possible, but cooling and heating do not work ................................................ 44

11.2.4 Symptom: The fan speed does not correspond to the setting...................................................................... 44

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Table of contents

11.2.5 Symptom: The fan direction does not correspond to the setting................................................................. 44

11.2.6 Symptom: White mist comes out of a unit (Indoor unit) .............................................................................. 45

11.2.7 Symptom: White mist comes out of a unit (Indoor unit, outdoor unit)........................................................ 45

11.2.8 Symptom: The user interface reads "U4" or "U5" and stops, but then restarts after a few minutes.......... 45

11.2.9 Symptom: Noise of air conditioners (Indoor unit)......................................................................................... 45

11.2.10 Symptom: Noise of air conditioners (Indoor unit, outdoor unit) .................................................................. 45

11.2.11 Symptom: Noise of air conditioners (Outdoor unit)...................................................................................... 45

11.2.12 Symptom: Dust comes out of the unit........................................................................................................... 46

11.2.13 Symptom: The units can give off odours ....................................................................................................... 46

11.2.14 Symptom: The outdoor unit fan does not spin.............................................................................................. 46

11.2.15 Symptom: The display shows "88"................................................................................................................. 46

11.2.16 Symptom: The compressor in the outdoor unit does not stop after a short heating operation ................. 46

11.2.17 Symptom: The inside of an outdoor unit is warm even when the unit has stopped.................................... 46

11.2.18 Symptom: Hot air can be felt when the indoor unit is stopped.................................................................... 46

12 Relocation 47

13 Disposal 48

14 Technical data 49

14.1 Information requirements for Eco Design...................................................................................................................... 49

For the installer 50

15 About the box 51

15.1 About LOOP BY DAIKIN ................................................................................................................................................... 51

15.2 Overview: About the box ................................................................................................................................................ 51

15.3 To unpack the outdoor unit ............................................................................................................................................ 52

15.4 To remove the accessories from the outdoor unit ........................................................................................................ 53

15.5 Accessory pipes: Diameters ............................................................................................................................................ 53

15.6 To remove the transportation stay ................................................................................................................................ 54

16 About the units and options 55

16.1 Overview: About the units and options.......................................................................................................................... 55

16.2 Identification label: Outdoor unit ................................................................................................................................... 55

16.3 About the outdoor unit................................................................................................................................................... 56

16.4 System layout .................................................................................................................................................................. 56

16.5 Combining units and options .......................................................................................................................................... 57

16.5.1 About combining units and options............................................................................................................... 57

16.5.2 Possible combinations of indoor units........................................................................................................... 57

16.5.3 Possible combinations of outdoor units ........................................................................................................ 58

16.5.4 Possible options for the outdoor unit............................................................................................................ 59

17 Unit installation 61

17.1 Preparing the installation site......................................................................................................................................... 61

17.1.1 Installation site requirements of the outdoor unit........................................................................................ 61

17.1.2 Additional installation site requirements of the outdoor unit in cold climates............................................ 63

17.1.3 Securing safety against refrigerant leaks....................................................................................................... 64

17.2 Opening the unit ............................................................................................................................................................. 66

17.2.1 About opening the units................................................................................................................................. 66

17.2.2 To open the outdoor unit............................................................................................................................... 66

17.2.3 To open the electrical component box of the outdoor unit ......................................................................... 67

17.3 Mounting the outdoor unit............................................................................................................................................. 68

17.3.1 To provide the installation structure ............................................................................................................. 68

18 Piping installation 70

18.1 Preparing refrigerant piping ........................................................................................................................................... 70

18.1.1 Refrigerant piping requirements.................................................................................................................... 70

18.1.2 Refrigerant piping insulation.......................................................................................................................... 71

18.1.3 To select the piping size ................................................................................................................................. 72

18.1.4 To select refrigerant branch kits.................................................................................................................... 74

18.1.5 About the piping length.................................................................................................................................. 75

18.1.6 Piping length: VRV DX only............................................................................................................................. 76

18.1.7 Multiple outdoor units: Possible layouts....................................................................................................... 79

18.2 Connecting the refrigerant piping .................................................................................................................................. 80

18.2.1 About connecting the refrigerant piping....................................................................................................... 80

18.2.2 Precautions when connecting the refrigerant piping.................................................................................... 81

18.2.3 Multiple outdoor units: Knockout holes........................................................................................................ 81

18.2.4 To route the refrigerant piping...................................................................................................................... 82

18.2.5 To connect the refrigerant piping to the outdoor unit ................................................................................. 82

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

3

Table of contents

18.2.6 To connect the multi connection piping kit................................................................................................... 83

18.2.7 To connect the refrigerant branching kit....................................................................................................... 83

18.2.8 To protect against contamination.................................................................................................................. 84

18.2.9 To braze the pipe end..................................................................................................................................... 85

18.2.10 Using the stop valve and service port ............................................................................................................ 85

18.2.11 To remove the spun pipes.............................................................................................................................. 88

18.3 Checking the refrigerant piping ...................................................................................................................................... 89

18.3.1 About checking the refrigerant piping........................................................................................................... 89

18.3.2 Checking refrigerant piping: General guidelines ........................................................................................... 90

18.3.3 Checking refrigerant piping: Setup ................................................................................................................ 91

18.3.4 To perform a leak test.................................................................................................................................... 91

18.3.5 To perform vacuum drying............................................................................................................................. 92

18.3.6 To insulate the refrigerant piping .................................................................................................................. 93

18.4 Charging refrigerant........................................................................................................................................................ 93

18.4.1 Precautions when charging refrigerant ......................................................................................................... 93

18.4.2 About charging refrigerant............................................................................................................................. 94

18.4.3 To determine the additional refrigerant amount.......................................................................................... 95

18.4.4 To charge refrigerant: Flow chart .................................................................................................................. 98

18.4.5 To charge refrigerant...................................................................................................................................... 99

18.4.6 Step 6a: To automatically charge refrigerant................................................................................................ 101

18.4.7 Step 6b: To manually charge refrigerant....................................................................................................... 103

18.4.8 Error codes when charging refrigerant.......................................................................................................... 104

18.4.9 Checks after charging refrigerant .................................................................................................................. 104

18.4.10 To fix the fluorinated greenhouse gases label............................................................................................... 104

19 Electrical installation 106

19.1 About connecting the electrical wiring .......................................................................................................................... 106

19.1.1 Precautions when connecting the electrical wiring....................................................................................... 106

19.1.2 Field wiring: Overview.................................................................................................................................... 108

19.1.3 About the electrical wiring............................................................................................................................. 108

19.1.4 Guidelines when knocking out knockout holes............................................................................................. 110

19.1.5 About electrical compliance........................................................................................................................... 110

19.1.6 Safety device requirements ........................................................................................................................... 111

19.2 To route and fix the transmission wiring........................................................................................................................ 112

19.3 To connect the transmission wiring ............................................................................................................................... 114

19.4 To finish the transmission wiring.................................................................................................................................... 115

19.5 To route and fix the power supply ................................................................................................................................. 116

19.6 To connect the power supply ......................................................................................................................................... 116

19.7 To check the insulation resistance of the compressor .................................................................................................. 118

20 Configuration 119

20.1 Overview: Configuration ................................................................................................................................................. 119

20.2 Making field settings ....................................................................................................................................................... 119

20.2.1 About making field settings............................................................................................................................ 119

20.2.2 Field setting components............................................................................................................................... 121

20.2.3 To access the field setting components......................................................................................................... 121

20.2.4 To access mode 1 or 2.................................................................................................................................... 122

20.2.5 To use mode 1................................................................................................................................................ 123

20.2.6 To use mode 2................................................................................................................................................ 123

20.2.7 Mode 1: Monitoring settings ......................................................................................................................... 124

20.2.8 Mode 2: Field settings.................................................................................................................................... 126

20.2.9 To connect the PC configurator to the outdoor unit..................................................................................... 131

20.3 Energy saving and optimum operation .......................................................................................................................... 131

20.3.1 Available main operation methods................................................................................................................ 132

20.3.2 Available comfort settings.............................................................................................................................. 133

20.3.3 Example: Automatic mode during cooling..................................................................................................... 135

20.3.4 Example: Automatic mode during heating.................................................................................................... 136

21 Commissioning 138

21.1 Overview: Commissioning .............................................................................................................................................. 138

21.2 Precautions when commissioning .................................................................................................................................. 138

21.3 Checklist before commissioning ..................................................................................................................................... 139

21.4 About the test run........................................................................................................................................................... 140

21.5 To perform a test run...................................................................................................................................................... 141

21.6 Correcting after abnormal completion of the test run .................................................................................................. 142

21.7 Operating the unit........................................................................................................................................................... 142

22 Hand-over to the user 143

Installer and user reference guide

4

23 Maintenance and service 144

23.1 Maintenance safety precautions .................................................................................................................................... 144

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Table of contents

23.1.1 To prevent electrical hazards......................................................................................................................... 144

23.2 About service mode operation ....................................................................................................................................... 145

23.2.1 To use vacuum mode ..................................................................................................................................... 145

23.2.2 To recover refrigerant.................................................................................................................................... 145

24 Troubleshooting 147

24.1 Solving problems based on error codes ......................................................................................................................... 147

24.2 Error codes: Overview .................................................................................................................................................... 147

25 Disposal 153

26 Technical data 154

26.1 Service space: Outdoor unit ........................................................................................................................................... 154

26.2 Piping diagram: Outdoor unit ......................................................................................................................................... 156

26.3 Wiring diagram: Outdoor unit ........................................................................................................................................ 157

27 Glossary 162

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

5

1 | About the documentation

1 About the documentation

In this chapter

1.1 About this document.............................................................................................................................................................. 6

1.2 Meaning of warnings and symbols......................................................................................................................................... 7

1.1 About this document

Target audience

Authorised installers + end users

Documentation set

This document is part of a documentation set. The complete set consists of:

INFORMATION

This appliance is intended to be used by expert or trained users in shops, in light

industry and on farms, or for commercial use by lay persons.

▪ General safety precautions:

- Safety instructions that you must read before installing

- Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation and operation manual:

- Installation and operation instructions

- Format: Paper (in the box of the outdoor unit)

▪ Installer and user reference guide:

- Preparation of the installation, reference data,…

- Detailed step-by-step instructions and background information for basic and

advanced usage

- Format: Digital files on http://www.daikineurope.com/support-and-manuals/

product-information/

Latest revisions of the supplied documentation may be available on the regional

Daikin website or via your dealer.

The original documentation is written in English. All other languages are

translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional Daikin website

(publicly accessible).

Installer and user reference guide

6

▪ The full set of latest technical data is available on the Daikin Business Portal

(authentication required).

Scope of the manual

This manual describes the procedures for handling, installing and connecting the

VRV IV replacement heat pump outdoor units. This manual has been prepared to

ensure adequate maintenance of the unit, and it will provide help in case problems

occur.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

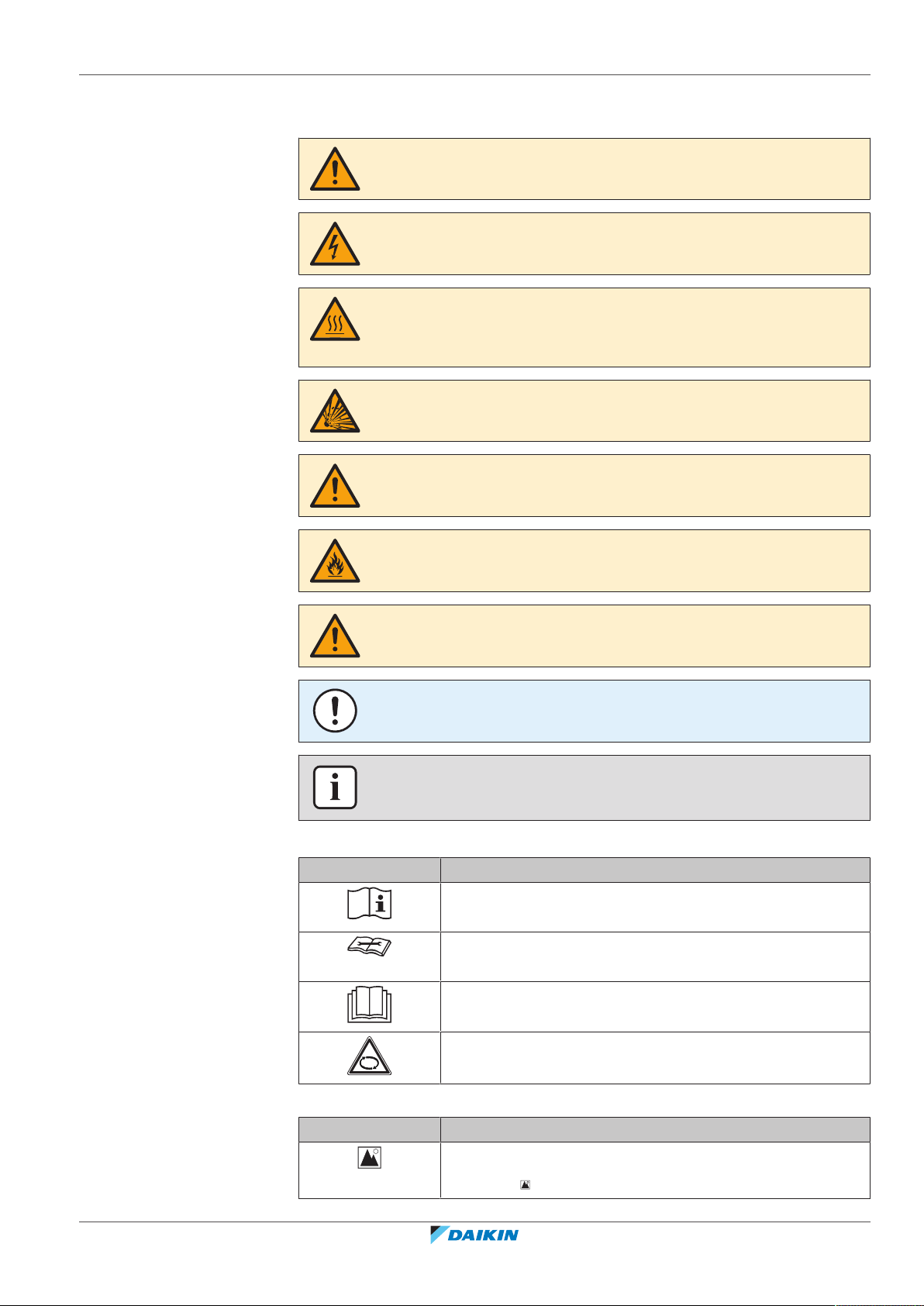

1.2 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING/SCALDING

Indicates a situation that could result in burning/scalding because of extreme hot or

cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious injury.

1 | About the documentation

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate injury.

NOTICE

Indicates a situation that could result in equipment or property damage.

INFORMATION

Indicates useful tips or additional information.

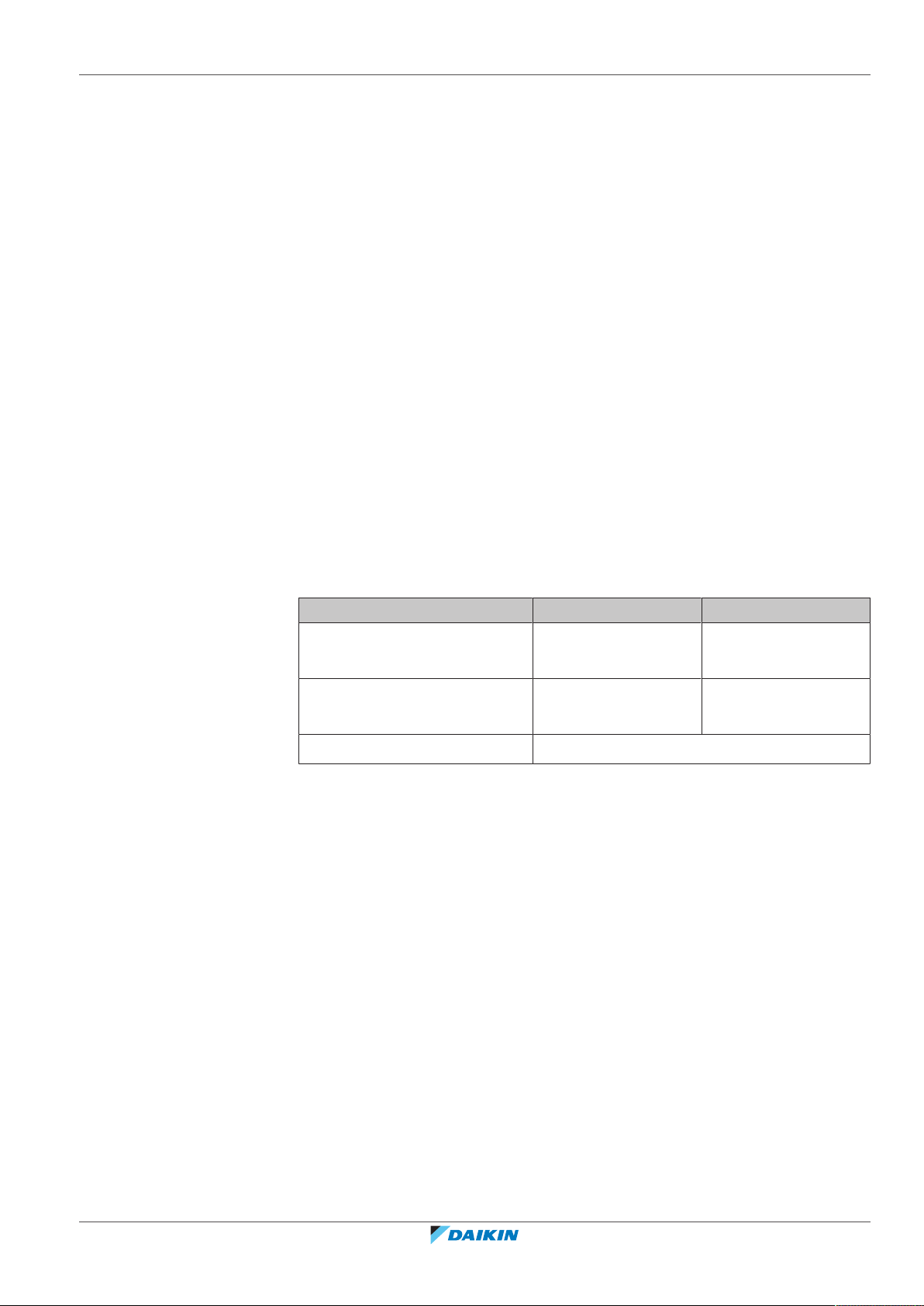

Symbols used on the unit:

Symbol Explanation

Before installation, read the installation and operation

manual, and the wiring instruction sheet.

Before performing maintenance and service tasks, read the

service manual.

For more information, see the installer and user reference

guide.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

The unit contains rotating parts. Be careful when servicing or

inspecting the unit.

Symbols used in the documentation:

Symbol Explanation

Indicates a figure title or a reference to it.

Example: " 1–3 Figure title" means "Figure 3 in chapter 1".

Installer and user reference guide

7

1 | About the documentation

Symbol Explanation

Indicates a table title or a reference to it.

Example: " 1–3 Table title" means "Table 3 in chapter 1".

Installer and user reference guide

8

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

2 General safety precautions

In this chapter

2.1 For the installer....................................................................................................................................................................... 9

2.1.1 General ................................................................................................................................................................... 9

2.1.2 Installation site ....................................................................................................................................................... 10

2.1.3 Refrigerant — in case of R410A or R32 ................................................................................................................. 10

2.1.4 Electrical ................................................................................................................................................................. 12

2.1 For the installer

2.1.1 General

If you are NOT sure how to install or operate the unit, contact your dealer.

DANGER: RISK OF BURNING/SCALDING

▪ Do NOT touch the refrigerant piping, water piping or internal parts during and

immediately after operation. It could be too hot or too cold. Give it time to return

to normal temperature. If you must touch it, wear protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

2 | General safety precautions

WARNING

Improper installation or attachment of equipment or accessories could result in

electrical shock, short-circuit, leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or approved by Daikin.

WARNING

Make sure installation, testing and applied materials comply with applicable

legislation (on top of the instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective gloves, safety glasses,…)

when installing, maintaining or servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that nobody, especially

children, can play with them. Possible risk: suffocation.

WARNING

Provide adequate measures to prevent that the unit can be used as a shelter by small

animals. Small animals that make contact with electrical parts can cause

malfunctions, smoke or fire.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

Installer and user reference guide

9

2 | General safety precautions

In accordance with the applicable legislation, it might be necessary to provide a

logbook with the product containing at least: information on maintenance, repair

work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an accessible place at the

product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

CAUTION

▪ Do NOT place any objects or equipment on top of the unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under dry weather conditions to

avoid water ingress.

2.1.2 Installation site

▪ Provide sufficient space around the unit for servicing and air circulation.

▪ Make sure the installation site withstands the weight and vibration of the unit.

▪ Make sure the area is well ventilated. Do NOT block any ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic waves.

Electromagnetic waves may disturb the control system, and cause malfunction of

the equipment.

▪ In places where there is a risk of fire due to the leakage of flammable gases

(example: thinner or gasoline), carbon fibre, ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is produced.

Corrosion of copper pipes or soldered parts may cause the refrigerant to leak.

2.1.3 Refrigerant — in case of R410A or R32

If applicable. See the installation manual or installer reference guide of your

application for more information.

Installer and user reference guide

10

NOTICE

Make sure refrigerant piping installation complies with applicable legislation. In

Europe, EN378 is the applicable standard.

NOTICE

Make sure the field piping and connections are NOT subjected to stress.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

2 | General safety precautions

WARNING

During tests, NEVER pressurize the product with a pressure higher than the

maximum allowable pressure (as indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks,

ventilate the area immediately. Possible risks:

▪ Excessive refrigerant concentrations in a closed room can lead to oxygen

deficiency.

▪ Toxic gas might be produced if refrigerant gas comes into contact with fire.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump down the system, and there

is a leak in the refrigerant circuit:

▪ Do NOT use the unit's automatic pump down function, with which you can collect

all refrigerant from the system into the outdoor unit. Possible consequence: Selfcombustion and explosion of the compressor because of air going into the

operating compressor.

▪ Use a separate recovery system so that the unit's compressor does NOT have to

operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them directly into the environment.

Use a vacuum pump to evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is no gas leak. Use nitrogen

to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more than the specified amount

of refrigerant.

▪ When the refrigerant system is to be opened, refrigerant MUST be treated

according to the applicable legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant may only be charged after

performing the leak test and the vacuum drying.

Possible consequence: Self-combustion and explosion of the compressor because of

oxygen going into the operating compressor.

▪ In case recharge is required, see the nameplate of the unit. It states the type of

refrigerant and necessary amount.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

▪ The unit is factory charged with refrigerant and depending on pipe sizes and pipe

lengths some systems require additional charging of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the system, this to

ensure pressure resistance and prevent foreign materials from entering into the

system.

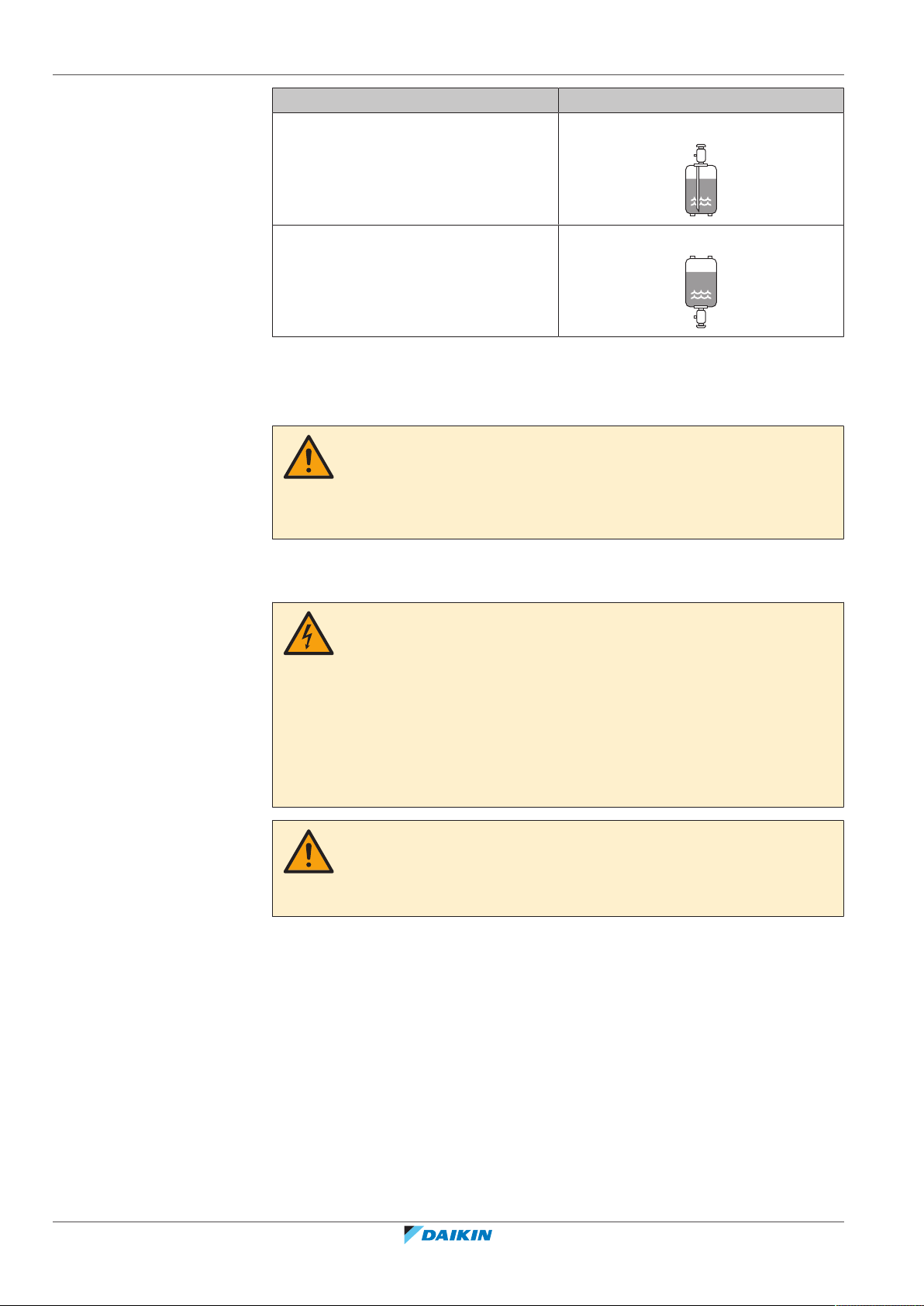

▪ Charge the liquid refrigerant as follows:

Installer and user reference guide

11

2 | General safety precautions

If Then

A siphon tube is present

Charge with the cylinder upright.

(i.e., the cylinder is marked with "Liquid

filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside down.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may prevent normal

operation.

CAUTION

When the refrigerant charging procedure is done or when pausing, close the valve of

the refrigerant tank immediately. If the valve is NOT closed immediately, remaining

pressure might charge additional refrigerant. Possible consequence: Incorrect

refrigerant amount.

2.1.4 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the switch box cover, connecting

electrical wiring or touching electrical parts.

▪ Disconnect the power supply for more than 10minutes, and measure the voltage

at the terminals of main circuit capacitors or electrical components before

servicing. The voltage MUST be less than 50VDC before you can touch electrical

components. For the location of the terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service cover is removed.

WARNING

If NOT factory installed, a main switch or other means for disconnection, having a

contact separation in all poles providing full disconnection under overvoltage

categoryIII condition, MUST be installed in the fixed wiring.

Installer and user reference guide

12

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

2 | General safety precautions

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable legislation.

▪ All field wiring MUST be performed in accordance with the wiring diagram

supplied with the product.

▪ NEVER squeeze bundled cables and make sure they do NOT come in contact with

the piping and sharp edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit to a utility pipe, surge

absorber, or telephone earth. Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER use a power supply shared by

another appliance.

▪ Make sure to install the required fuses or circuit breakers.

▪ Make sure to install an earth leakage protector. Failure to do so may cause

electrical shock or fire.

▪ When installing the earth leakage protector, make sure it is compatible with the

inverter (resistant to high frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

▪ When connecting the power supply: connect the earth cable first, before making

the current-carrying connections.

▪ When disconnecting the power supply: disconnect the current-carrying cables

first, before separating the earth connection.

▪ The length of the conductors between the power supply stress relief and the

terminal block itself must be as such that the current-carrying wires are tautened

before the earth wire is in case the power supply is pulled loose from the stress

relief.

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the power terminal block (slack

in the power wiring may cause abnormal heat).

▪ When connecting wiring which is the same thickness, do as shown in the figure

above.

▪ For wiring, use the designated power wire and connect firmly, then secure to

prevent outside pressure being exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the terminal screws. A screwdriver

with a small head will damage the head and make proper tightening impossible.

▪ Over-tightening the terminal screws may break them.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Install power cables at least 1 m away from televisions or radios to prevent

interference. Depending on the radio waves, a distance of 1 m may not be

sufficient.

Installer and user reference guide

13

2 | General safety precautions

WARNING

▪ After finishing the electrical work, confirm that each electrical component and

terminal inside the electrical components box is connected securely.

▪ Make sure all covers are closed before starting up the unit.

NOTICE

Only applicable if the power supply is three‑phase, and the compressor has an ON/

OFF starting method.

If there exists the possibility of reversed phase after a momentary black out and the

power goes on and off while the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed phase can break the

compressor and other parts.

Installer and user reference guide

14

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

3 | Specific installer safety instructions

3 Specific installer safety instructions

Always observe the following safety instructions and regulations.

WARNING

Tear apart and throw away plastic packaging bags so that nobody, especially

children, can play with them. Possible risk: suffocation.

CAUTION

Appliance not accessible to the general public, install it in a secured area, protected

from easy access.

This unit, both indoor and outdoor, is suitable for installation in a commercial and

light industrial environment.

CAUTION

Excessive refrigerant concentrations in a closed room can lead to oxygen deficiency.

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover is removed.

DANGER: RISK OF BURNING/SCALDING

DANGER: RISK OF ELECTROCUTION

WARNING

Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks,

ventilate the area immediately. Possible risks:

▪ Excessive refrigerant concentrations in a closed room can lead to oxygen

deficiency.

▪ Toxic gas might be produced if refrigerant gas comes into contact with fire.

WARNING

ALWAYS recover the refrigerant. Do NOT release them directly into the environment.

Use a vacuum pump to evacuate the installation.

WARNING

During tests, NEVER pressurize the product with a pressure higher than the

maximum allowable pressure (as indicated on the nameplate of the unit).

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

CAUTION

Do not vent gases into the atmosphere.

WARNING

Any gas or oil remaining inside the stop valve may blow off the spun piping.

If these instructions are NOT followed correctly it may result in property damage or

personal injury, which may be serious depending on the circumstances.

Installer and user reference guide

15

3 | Specific installer safety instructions

WARNING

NEVER remove the spun piping by brazing.

Any gas or oil remaining inside the stop valve may blow off the spun piping.

WARNING

▪ ONLY use R410A as refrigerant. Other substances may cause explosions and

accidents.

▪ R410A contains fluorinated greenhouse gases. Its global warming potential (GWP)

value is 2087.5. Do NOT vent these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective gloves and safety glasses.

CAUTION

Do NOT push or place redundant cable length in the unit.

WARNING

▪ If the power supply has a missing or wrong N-phase, equipment might break

down.

▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber,

or telephone earth. Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the cables do NOT come in

contact with sharp edges or piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires, extension cords, or

connections from a star system. They can cause overheating, electrical shock or

fire.

▪ Do NOT install a phase advancing capacitor, because this unit is equipped with an

inverter. A phase advancing capacitor will reduce performance and may cause

accidents.

WARNING

▪ All wiring MUST be performed by an authorised electrician and MUST comply

with the applicable legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical construction MUST comply

with the applicable legislation.

Installer and user reference guide

16

WARNING

For the existing power supply and transmission wiring, check that the specifications

match the requirements described in this chapter and that other parts (especially

terminals) do not appear to have deteriorated. Take the appropriate steps (e.g.

replacement) if necessary.

WARNING

ALWAYS use multicore cable for power supply cables.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

3 | Specific installer safety instructions

CAUTION

▪ When connecting the power supply: connect the earth cable first, before making

the current-carrying connections.

▪ When disconnecting the power supply: disconnect the current-carrying cables

first, before separating the earth connection.

▪ The length of the conductors between the power supply stress relief and the

terminal block itself must be as such that the current-carrying wires are tautened

before the earth wire is in case the power supply is pulled loose from the stress

relief.

CAUTION

Do NOT perform the test operation while working on the indoor units.

When performing the test operation, NOT only the outdoor unit, but the connected

indoor unit will operate as well. Working on an indoor unit while performing a test

operation is dangerous.

CAUTION

Do NOT insert fingers, rods or other objects into the air inlet or outlet. Do NOT

remove the fan guard. When the fan is rotating at high speed, it will cause injury.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

17

For the user

For the user

Installer and user reference guide

18

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

4 User safety instructions

Always observe the following safety instructions and regulations.

In this chapter

4.1 General.................................................................................................................................................................................... 19

4.2 Instructions for safe operation............................................................................................................................................... 20

4.1 General

WARNING

If you are NOT sure how to operate the unit, contact your

installer.

WARNING

Children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of

experience and knowledge can only use this appliance if

they have been given supervision or instruction concerning

the use of the appliance by a person responsible for their

safety.

4 | User safety instructions

Children MUST NOT play with the appliance.

Cleaning and user maintenance MUST NOT be carried out

by children without supervision.

WARNING

To prevent electrical shocks or fire:

▪ Do NOT rinse the unit.

▪ Do NOT operate the unit with wet hands.

▪ Do NOT place any objects containing water on the unit.

CAUTION

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

19

4 | User safety instructions

▪ Units are marked with the following symbol:

▪ Batteries are marked with the following symbol:

This means that electrical and electronic products may NOT be mixed with

unsorted household waste. Do NOT try to dismantle the system yourself: the

dismantling of the system, treatment of the refrigerant, of oil and of other parts

must be done by an authorized installer and must comply with applicable

legislation.

Units must be treated at a specialized treatment facility for reuse, recycling and

recovery. By ensuring this product is disposed of correctly, you will help to

prevent potential negative consequences for the environment and human

health. For more information, contact your installer or local authority.

This means that the batteries may NOT be mixed with unsorted household

waste. If a chemical symbol is printed beneath the symbol, this chemical symbol

means that the battery contains a heavy metal above a certain concentration.

Possible chemical symbols are: Pb: lead (>0.004%).

Waste batteries must be treated at a specialized treatment facility for reuse. By

ensuring waste batteries are disposed of correctly, you will help to prevent

potential negative consequences for the environment and human health.

4.2 Instructions for safe operation

CAUTION

▪ NEVER touch the internal parts of the controller.

▪ Do NOT remove the front panel. Some parts inside are

dangerous to touch and appliance problems may

happen. For checking and adjusting the internal parts,

contact your dealer.

CAUTION

Do NOT operate the system when using a room

fumigation-type insecticide. Chemicals could collect in the

unit, and endanger the health of people who are

hypersensitive to chemicals.

Installer and user reference guide

20

CAUTION

It is unhealthy to expose your body to the air flow for a

long time.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

4 | User safety instructions

CAUTION

To avoid oxygen deficiency, ventilate the room sufficiently

if equipment with burner is used together with the system.

WARNING

This unit contains electrical and hot parts.

WARNING

Before operating the unit, be sure the installation has been

carried out correctly by an installer.

WARNING

Never touch the air outlet or the horizontal blades while

the swing flap is in operation. Fingers may become caught

or the unit may break down.

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet or outlet. Do NOT remove the fan guard. When the

fan is rotating at high speed, it will cause injury.

CAUTION: Pay attention to the fan!

It is dangerous to inspect the unit while the fan is running.

Be sure to turn off the main switch before executing any

maintenance task.

CAUTION

After a long use, check the unit stand and fitting for

damage. If damaged, the unit may fall and result in injury.

WARNING

NEVER replace a fuse with a fuse of a wrong ampere

ratings or other wires when a fuse blows out. Use of wire

or copper wire may cause the unit to break down or cause

a fire.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

21

4 | User safety instructions

WARNING

▪ Do NOT modify, disassemble, remove, reinstall or repair

the unit yourself as incorrect dismantling or installation

may cause an electric shock or fire. Contact your dealer.

▪ In case of accidental refrigerant leaks, make sure there

are no naked flames. The refrigerant itself is entirely

safe, non-toxic and non-combustible, but it will generate

toxic gas when it accidentally leaks into a room where

combustible air from fan heaters, gas cookers, etc. is

present. Always have qualified service personnel

confirm that the point of leakage has been repaired or

corrected before resuming operation.

WARNING

Stop operation and shut off the power if anything

unusual occurs (burning smells etc.).

Leaving the unit running under such circumstances may

cause breakage, electric shock or fire. Contact your dealer.

WARNING

The refrigerant in the system is safe and normally does not

leak. If the refrigerant leaks in the room, contact with a fire

of a burner, a heater or a cooker may result in a harmful

gas.

Turn off any combustible heating devices, ventilate the

room and contact the dealer where you purchased the

unit.

Do not use the system until a service person confirms that

the portion where the refrigerant leaks is repaired.

CAUTION

NEVER expose little children, plants or animals directly to

the airflow.

Installer and user reference guide

22

CAUTION

Do NOT touch the heat exchanger fins. These fins are

sharp and could result in cutting injuries.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

5 About the system

a

e

c

d d

c

b

The indoor unit part of VRV IV replacement heat pump system can be used for

heating/cooling applications. The type of indoor unit which can be used depends

on the outdoor units series.

NOTICE

Do NOT use the system for other purposes. In order to avoid any quality

deterioration, do NOT use the unit for cooling precision instruments, food, plants,

animals, or works of art.

NOTICE

For future modifications or expansions of your system:

A full overview of allowable combinations (for future system extensions) is available

in technical engineering data and should be consulted. Contact your installer to

receive more information and professional advice.

In general following type of indoor units can be connected to a VRV IV replacement

heat pump system (not exhaustive list, depending on outdoor unit model and

indoor unit model combinations):

5 | About the system

▪ VRV direct expansion (DX) indoor units for R410A (air to air applications).

▪ AHU (air to air applications): EKEXV-kit+EKEQ-box are required, depending on the

application.

▪ VRV direct expansion (DX) indoor units for non-R410A (air to air applications).

See "Possible combinations of indoor units"[457].

Airhandling unit connection in pair to VRV IV replacement heat pump outdoor unit

is supported.

Airhandling unit connection in multi to VRV IV replacement heat pump outdoor

unit is supported, even combined with VRV direct expansion indoor unit(s).

For more specifications, see technical engineering data.

In this chapter

5.1 System layout.......................................................................................................................................................................... 23

5.1 System layout

a VRV IV replacement heat pump outdoor unit

b Refrigerant piping

c VRV direct expansion (DX) indoor unit

d User interface (dedicated depending on indoor unit type)

e Cool/Heat changeover remote control switch

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

23

6 | User interface

6 User interface

CAUTION

▪ NEVER touch the internal parts of the controller.

▪ Do NOT remove the front panel. Some parts inside are dangerous to touch and

appliance problems may happen. For checking and adjusting the internal parts,

contact your dealer.

This operation manual offers a non-exhaustive overview of the main functions of

the system.

Detailed information on required actions to achieve certain functions can be found

in the dedicated installation and operation manual of the indoor unit.

Refer to the operation manual of the installed user interface.

Installer and user reference guide

24

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

7 Before operation

WARNING

Ask your dealer for improvement, repair, and maintenance. Incomplete

improvement, repair, and maintenance may result in water leakage, electric shock

and fire.

WARNING

Ask your dealer to move and reinstall the air conditioner. Incomplete installation may

result in a water leakage, electric shock, and fire.

WARNING

NEVER let the indoor unit or the user interface get wet. It may cause an electric

shock or a fire.

WARNING

Do NOT place objects in direct proximity of the outdoor unit and do NOT let leaves

and other debris accumulate around the unit. Leaves are a hotbed for small animals

which can enter the unit. Once in the unit, such animals can cause malfunctions,

smoke or fire when making contact with electrical parts.

7 | Before operation

WARNING

Avoid placing the user interface in a place where it can be splashed with water.

Water entering the machine may cause an electric leak or may damage the internal

electronic parts.

WARNING

This unit contains electrical and hot parts.

WARNING

Before operating the unit, be sure the installation has been carried out correctly by

an installer.

NOTICE

NEVER inspect or service the unit by yourself. Ask a qualified service person to

perform this work.

CAUTION

Do NOT touch the heat exchanger fins. These fins are sharp and could result in

cutting injuries.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

WARNING

Do NOT place a flammable spray bottle near the air conditioner and do NOT use

sprays near the unit. Doing so may result in a fire.

CAUTION

It is unhealthy to expose your body to the air flow for a long time.

Installer and user reference guide

25

7 | Before operation

CAUTION

To avoid oxygen deficiency, ventilate the room sufficiently if equipment with burner

is used together with the system.

CAUTION

Do NOT operate the system when using a room fumigation-type insecticide.

Chemicals could collect in the unit, and endanger the health of people who are

hypersensitive to chemicals.

CAUTION

NEVER expose little children, plants or animals directly to the airflow.

NOTICE

NEVER press the button of the user interface with a hard, pointed object. The user

interface may be damaged.

NOTICE

NEVER pull or twist the electric wire of the user interface. It may cause the unit to

malfunction.

NOTICE

Do NOT place the user interface in a place exposed to direct sunlight. The LCD display

may get discoloured or fail to display the data.

NOTICE

Do NOT place items which might be damaged by moisture under the indoor unit.

Condensation may form if the humidity is above 80%, if the drain outlet is blocked or

the filter is polluted.

NOTICE

Arrange the drain hose to ensure smooth drainage. Incomplete drainage may cause

the building, furniture, etc. to get wet.

NOTICE

Be sure to turn ON the power 6 hours before operation in order to have power

running to the crankcase heater and to protect the compressor.

This operation manual is for the following systems with standard control. Before

initiating operation, contact your dealer for the operation that corresponds to your

system type and mark. If your installation has a customised control system, ask

your dealer for the operation that corresponds to your system.

Installer and user reference guide

26

Operation modes (depending on indoor unit type):

▪ Heating and cooling (air to air).

▪ Fan only operation (air to air).

Dedicated functions exist depending on the type of indoor unit, refer to dedicated

installation/operation manual for more information.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

8 Operation

In this chapter

8.1 Operation range...................................................................................................................................................................... 27

8.2 Operating the system ............................................................................................................................................................. 27

8.3 Using the dry program............................................................................................................................................................ 30

8.4 Adjusting the air flow direction.............................................................................................................................................. 31

8.5 Setting the master user interface .......................................................................................................................................... 32

8.6 About control systems............................................................................................................................................................ 33

8 | Operation

8.2.1 About operating the system .................................................................................................................................. 27

8.2.2 About cooling, heating, fan only, and automatic operation ................................................................................. 28

8.2.3 About the heating operation ................................................................................................................................. 28

8.2.4 To operate the system (WITHOUT cool/heat changeover remote control switch) ............................................. 29

8.2.5 To operate the system (WITH cool/heat changeover remote control switch)..................................................... 29

8.3.1 About the dry program .......................................................................................................................................... 30

8.3.2 To use the dry program (WITHOUT cool/heat changeover remote control switch)............................................ 30

8.3.3 To use the dry program (WITH cool/heat changeover remote control switch) ................................................... 30

8.4.1 About the air flow flap ........................................................................................................................................... 31

8.5.1 About setting the master user interface ............................................................................................................... 32

8.5.2 To designate the master user interface (VRV DX and Hydrobox) ......................................................................... 33

8.1 Operation range

Use the system in the following temperature and humidity ranges for safe and

effective operation.

Outdoor temperature –5~43°CDB –20~21°CDB

Indoor temperature 21~32°CDB

Indoor humidity ≤80%

(a)

To avoid condensation and water dripping out of the unit. If the temperature or the

humidity is beyond these conditions, safety devices may be put in action and the air

conditioner may not operate.

Above operation range is only valid in case direct expansion indoor units are

connected to the VRV IV system.

8.2 Operating the system

Cooling Heating

–20~15.5°C WB

15~27°CDB

14~25°C WB

(a)

8.2.1 About operating the system

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

▪ Operation procedure varies according to the combination of outdoor unit and

user interface.

▪ To protect the unit, turn on the main power switch 6 hours before operation.

▪ If the main power supply is turned off during operation, operation will restart

automatically after the power turns back on again.

Installer and user reference guide

27

8 | Operation

8.2.2 About cooling, heating, fan only, and automatic operation

8.2.3 About the heating operation

▪ Changeover cannot be made with a user interface whose display shows

"change-over under centralised control" (refer to installation and operation

manual of the user interface).

▪ When the display "change-over under centralised control" flashes, refer to

"About setting the master user interface"[432].

▪ The fan may keep on running for about 1 minute after the heating operation

stops.

▪ The air flow rate may adjust itself depending on the room temperature or the fan

may stop immediately. This is not a malfunction.

It may take longer to reach the set temperature for general heating operation than

for cooling operation.

The following operation is performed in order to prevent the heating capacity from

dropping or cold air from blowing.

Defrost operation

In heating operation, freezing of the outdoor unit's air cooled coil increases over

time, restricting the energy transfer to the outdoor unit's coil. Heating capability

decreases and the system needs to go into defrost operation to be able to remove

frost from the outdoor unit’s coil. During defrost operation the heating capacity on

the indoor unit side will temporarily drop until defrosting is completed. After

defrosting, the unit will regain its full heating capacity.

If Then

RXYQQ outdoor unit is

installed

The indoor unit will stop fan operation, the

refrigerant cycle will reverse and energy from inside

the building will be used to defrost the outdoor unit

coil.

The indoor unit will indicate defrost operation on the display .

Hot start

In order to prevent cold air from blowing out of an indoor unit at the start of

heating operation, the indoor fan is automatically stopped. The display of the user

interface shows . It may take some time before the fan starts. This is not a

malfunction.

INFORMATION

▪ The heating capacity drops when the outside temperature falls. If this happens,

use another heating device together with the unit. (When using together with

appliances that produce open fire, ventilate the room constantly). Do not place

appliances that produce open fire in places exposed to the air flow from the unit

or under the unit.

▪ It takes some time to heat up the room from the time the unit is started since the

unit uses a hot-air circulating system to heat the entire room.

▪ If the hot air rises to the ceiling, leaving the area above the floor cold, we

recommend that you use the circulator (the indoor fan for circulating air).

Contact your dealer for details.

Installer and user reference guide

28

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

8 | Operation

a

b

1

1

1

1

1

8.2.4 To operate the system (WITHOUT cool/heat changeover remote control switch)

1 Press the operation mode selector button on the user interface several times

and select the operation mode of your choice.

Cooling operation

Heating operation

Fan only operation

2 Press the ON/OFF button on the user interface.

Result: The operation lamp lights up and the system starts operating.

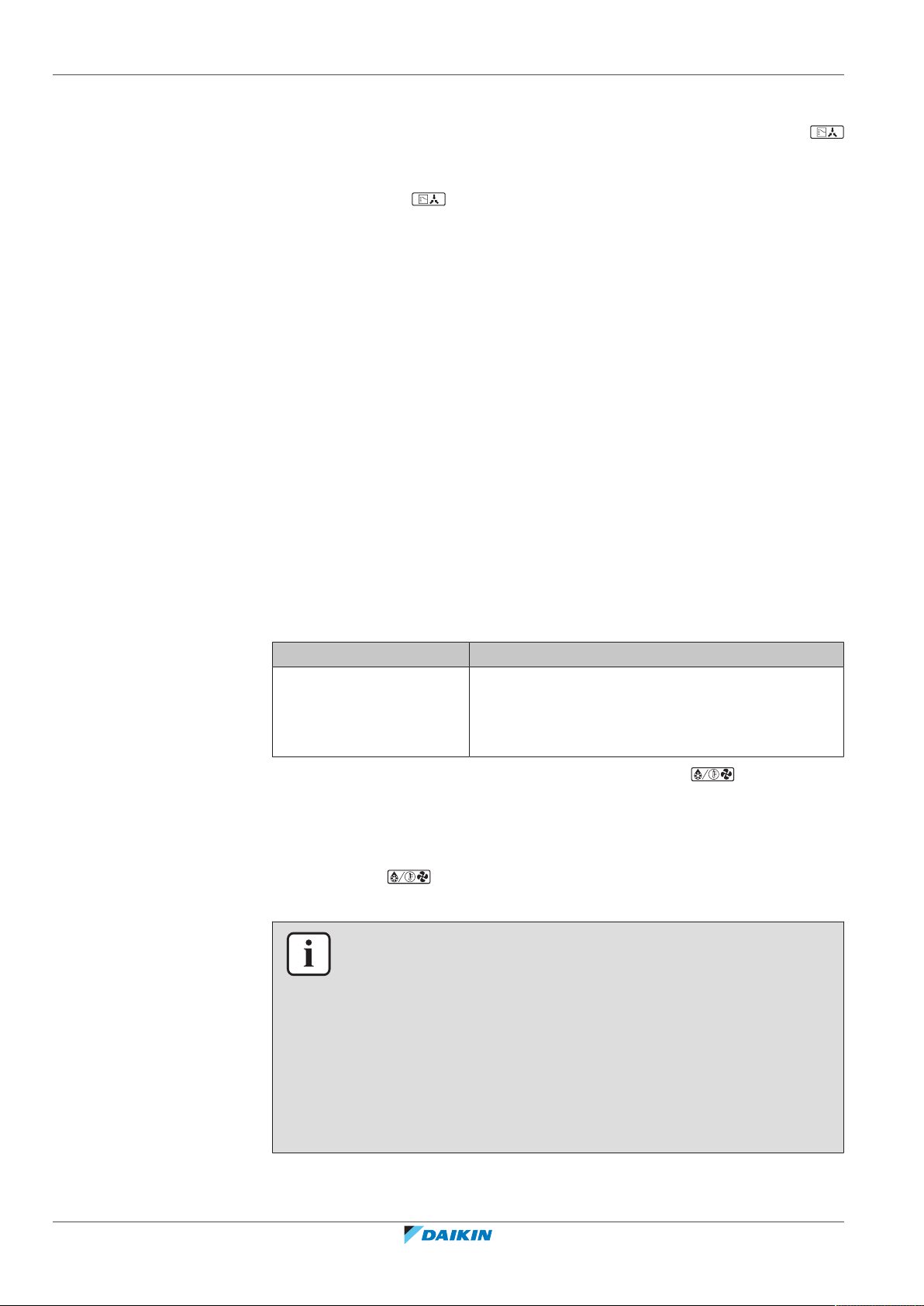

8.2.5 To operate the system (WITH cool/heat changeover remote control switch)

Overview of the changeover remote control switch

a FAN ONLY/AIR CONDITIONING SELECTOR

SWITCH

Set the switch to for fan only operation or to

for heating or cooling operation.

b COOL/HEAT CHANGEOVER SWITCH

Set the switch to for cooling or to for

heating

Note: In case a cool/heat changeover remote control switch is used, the position of

DIP switch 1 (DS1-1) on the main PCB needs to be switched to the ON position.

To start

1 Select operation mode with the cool/heat changeover switch as follows:

Cooling operation

Heating operation

Fan only operation

2 Press the ON/OFF button on the user interface.

Result: The operation lamp lights up and the system starts operating.

To stop

3 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops operating.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

Installer and user reference guide

29

8 | Operation

8.3 Using the dry program

8.3.1 About the dry program

NOTICE

Do not turn off power immediately after the unit stops, but wait for at least 5

minutes.

To adjust

For programming temperature, fan speed and air flow direction refer to the

operation manual of the user interface.

▪ The function of this program is to decrease the humidity in your room with

minimal temperature decrease (minimal room cooling).

▪ The micro computer automatically determines temperature and fan speed

(cannot be set by the user interface).

▪ The system does not go into operation if the room temperature is low (<20°C).

8.3.2 To use the dry program (WITHOUT cool/heat changeover remote control switch)

To start

1 Press the operation mode selector button on the user interface several times

and select (program dry operation).

2 Press the ON/OFF button of the user interface.

Result: The operation lamp lights up and the system starts operating.

3 Press the air flow direction adjust button (only for double-flow, multi-flow,

corner, ceiling-suspended and wall-mounted). Refer to "8.4 Adjusting the air

flow direction"[431] for details.

To stop

4 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops operating.

NOTICE

Do not turn off power immediately after the unit stops, but wait for at least 5

minutes.

8.3.3 To use the dry program (WITH cool/heat changeover remote control switch)

Installer and user reference guide

30

To start

1 Select cooling operation mode with the cool/heat changeover remote control

switch.

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

8 | Operation

1

1

2 Press the operation mode selector button on the user interface several times

and select (program dry operation).

3 Press the ON/OFF button of the user interface.

Result: The operation lamp lights up and the system starts operating.

4 Press the air flow direction adjust button (only for double-flow, multi-flow,

corner, ceiling-suspended and wall-mounted). Refer to "8.4 Adjusting the air

flow direction"[431] for details.

To stop

5 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops operating.

NOTICE

Do not turn off power immediately after the unit stops, but wait for at least 5

minutes.

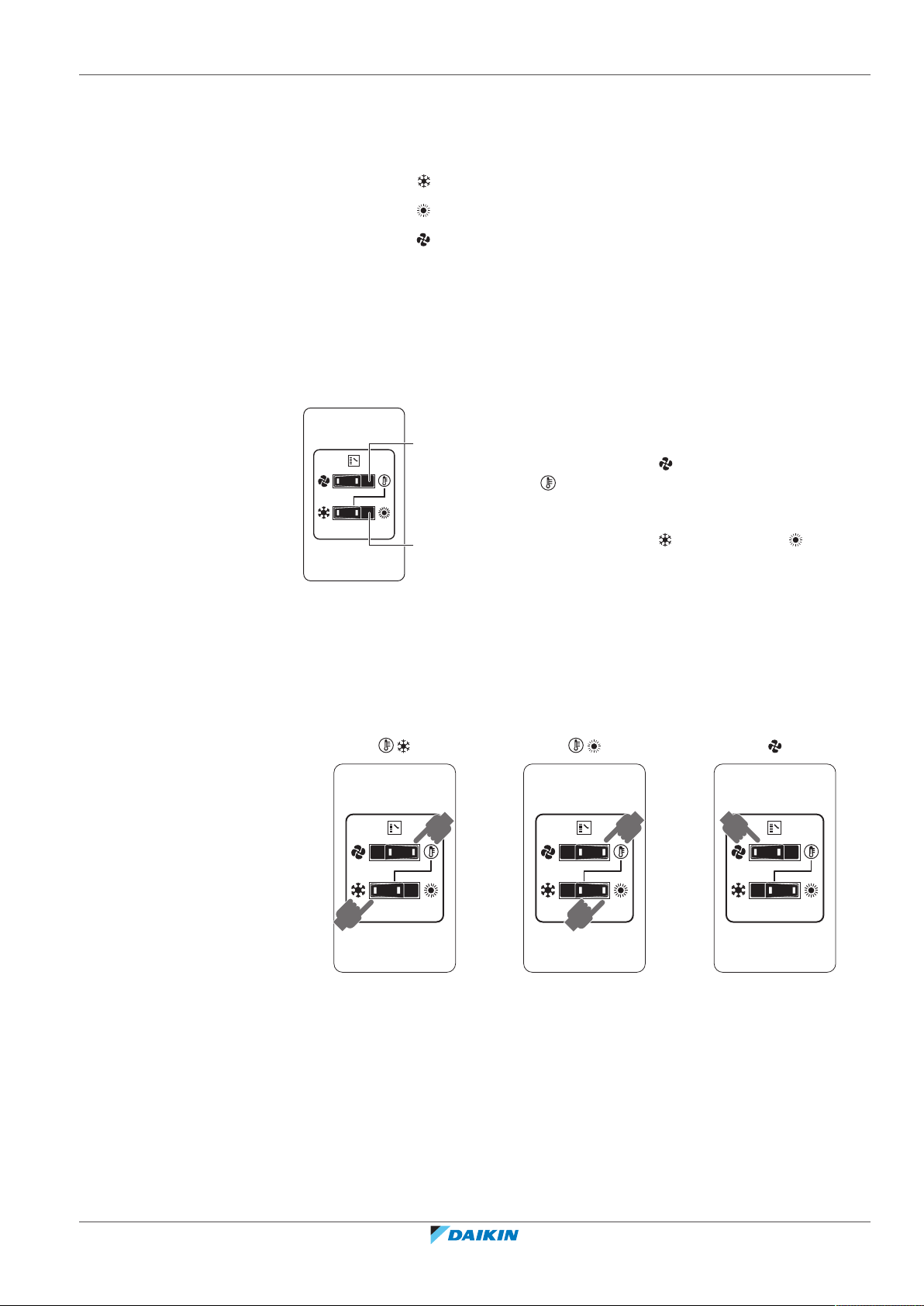

8.4 Adjusting the air flow direction

Refer to the operation manual of the user interface.

8.4.1 About the air flow flap

Double flow+multi-flow units

Corner units

Ceiling suspended units

Wall-mounted units

RXYQQ8~20U7Y1B

VRV IV Q+ series heat pump

4P546229-1A – 2020.10

For the following conditions, a micro computer controls the air flow direction

which may be different from the display.

Cooling Heating

▪ When the room temperature is lower

than the set temperature.

▪ When starting operation.

▪ When the room temperature is higher

than the set temperature.

▪ At defrost operation.

Installer and user reference guide

31

8 | Operation

c c

b

b

a

Cooling Heating

▪ When operating continuously at horizontal air flow direction.

▪ When continuous operation with downward air flow is performed at the time of

cooling with a ceiling-suspended or a wall-mounted unit, the micro computer

may control the flow direction, and then the user interface indication will also

change.

The air flow direction can be adjusted in one of the following ways:

▪ The air flow flap itself adjusts its position.

▪ The air flow direction can be fixed by the user.

▪ Automatic and desired position .

WARNING

Never touch the air outlet or the horizontal blades while the swing flap is in