DAF CF85 Maintenance Manual

Maintenance manual

CF85

https://www.truck-manuals.net/

https://www.truck-manuals.net/

©200423 DAF Trucks N.V., Eindhoven,

The Netherlands.

In the interest of continuing product development,

DAF reserves the right to change specifications

or products at any time without prior notice.

No part of this publication may be reproduced

and/or published by printing, by photocopying, on

microfilm or in any way whatsoever without the

prior consent in writing of DAF Trucks N.V.

©

200423 DW13278604

https://www.truck-manuals.net/

https://www.truck-manuals.net/

ΧΦ85 series

STRUCTURE

Structure

TECHNICAL DATA

0

1

THREADED CONNECTIONS

2

FLUIDS, OIL AND LUBRICANTS

3

MAINTENANCE SCHEDULE

4

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

5

©

200423

https://www.truck-manuals.net/

https://www.truck-manuals.net/

TECHNICAL DATA

ΧΦ85 series

0 Technical data

CONTENTS

Page Date

1. XE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200423

1.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200423

2. GEARBOX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200423

2.1 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200423

2.2 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200423

3. REAR AXLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200423

3.1 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200423

3.2 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200423

4. BRAKES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200423

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200423

5. STEERING GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200423

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200423

5.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200423

Contents

0

6. FRONT AXLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200423

6.1 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200423

7. LEADING REAR AXLE 09N044 (FTP-TYPE VEHICLES) . . . . . . . . . . . . . . . . . 7-1 . . . . . 200423

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200423

7.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 . . . . . 200423

©

200423 1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Contents

ΧΦ85 series

2

©

200423

https://www.truck-manuals.net/

TECHNICAL DATA

ΧΦ85 series

1. XE ENGINE

1.1 GENERAL

XE engine

Valve clearance

Valve clearance (cold/hot)

Inlet 0.50 mm

Exhaust 0.50 mm

DEB

DEB setting 1.40 mm

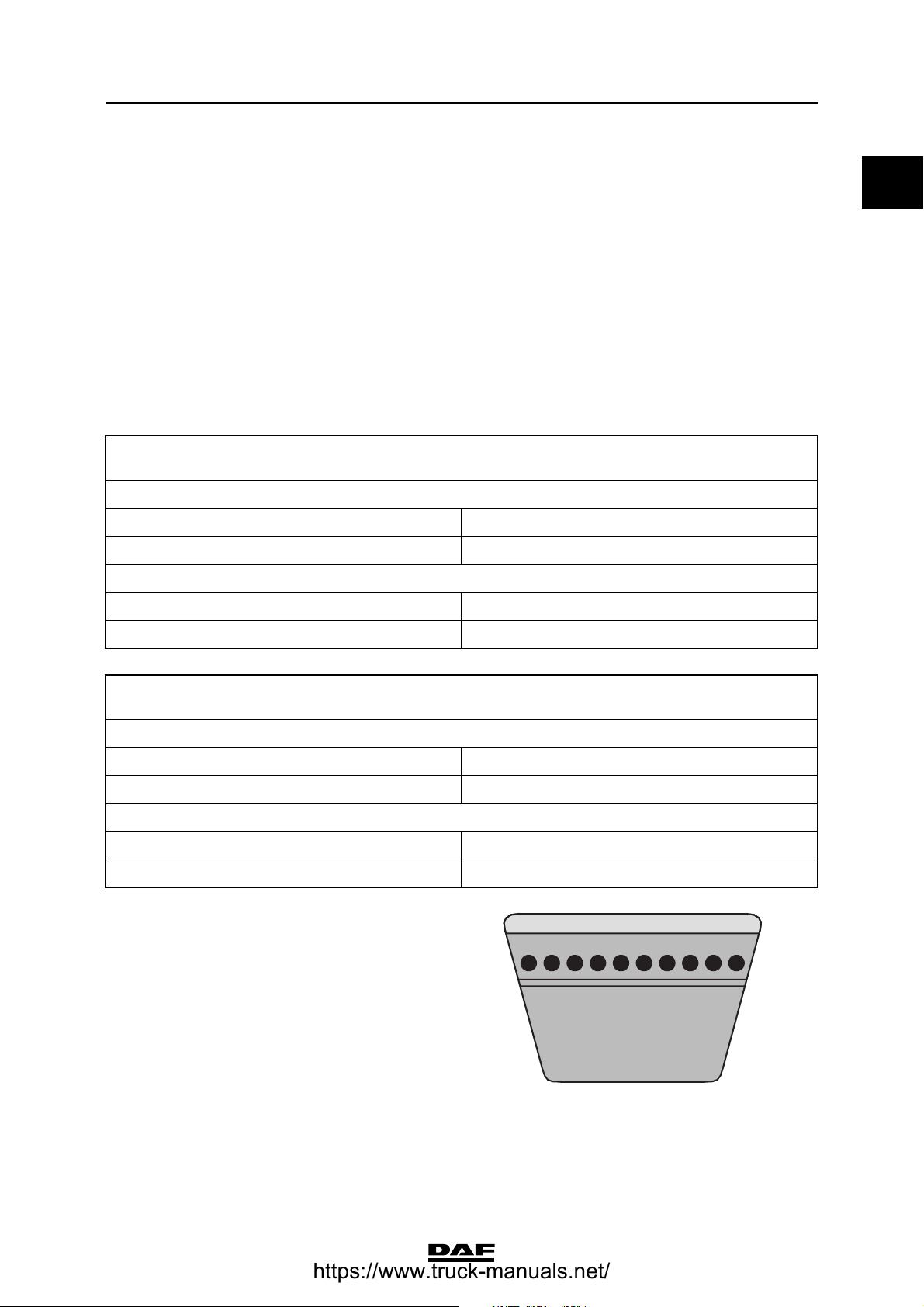

V-belt tension

V-belt tension, "AVX" raw edge

Application example: air-conditioning compressor drive

New V-belt

Setting tension 600

Test tension 400

Run-in V-belt

(2)

(3)

(1)

XE engine

0

(N)

Minimum tension 250

Adjusting tension 350

V-belt tension, "XPB" raw edge

Application example: steering pump drive on FAX vehicle

New V-belt

(2)

Setting tension 1250

Test tension 950

Run-in V-belt

(3)

Minimum tension 750

Adjusting tension 950

(1) Raw-edge V-belts can be recognised by the absence of

textile fabric in the rubber, with the exception of the top of

the belt edge, on the edges and the insides of the belt

(polished belt edges). Version: either a toothed or a nontoothed belt.

(2) After fitting the new V-belt, set the pre-tension to the

"setting tension" and after a trial run check whether the

pre-tension complies with the "test tension". If the test

tension reading is lower than the value specified in the

table, set the V-belt to the minimum "test tension".

(3) If the V-belt tension is lower than the "minimum tension",

set the belt to the "adjusting tension".

(1)

(N)

M2121

©

200423 1-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

XE engine

1.2 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

XE engine

Lubrication system

Oil drain plug 60 Nm

Oil filter screw cap 40 Nm

Centrifugal filter central bolt 20 Nm

Fuel system

Fuel filter screw cap 25 Nm

ΧΦ85 series

Cylinder head cover

Cylinder head cover attachment bolts 25 Nm

DEB

DEB attachment bolts 110 Nm

DEB set screw nut 25 Nm

V-belt tensioner

Central bolt, tensioning gear 110 Nm

1.3 FILLING CAPACITIES

XE engine

Lubrication system

Total capacity (including oil cooler and oil filter) approx. 34 litres

Capacity of oil sump, maximum level approx. 30 litres

Capacity of oil sump, minimum level approx. 22 litres

Cooling system

Cooling system approx. 47 litres

With integrated retarder approx. 57 litres

1-2

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

2. GEARBOX

2.1 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

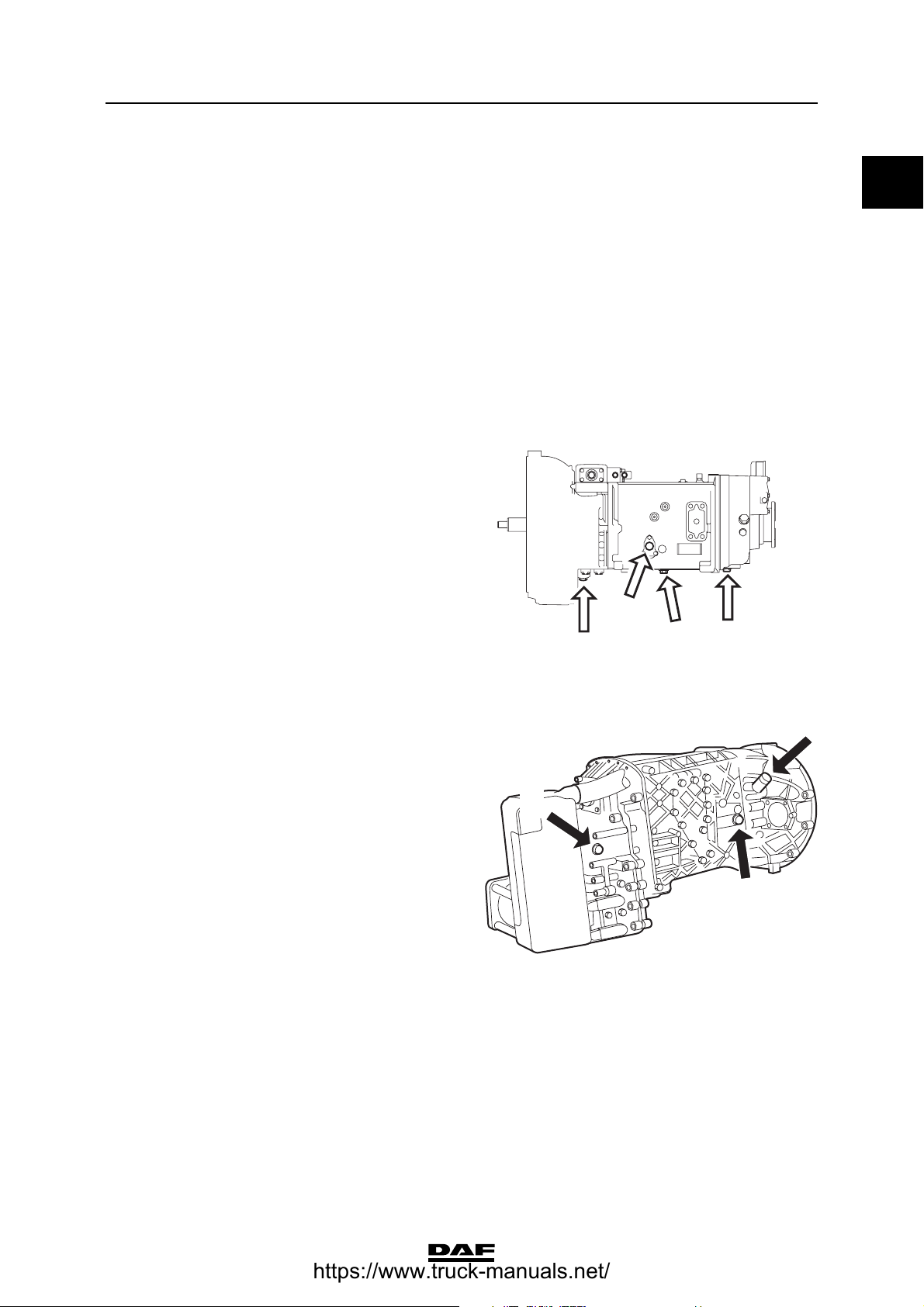

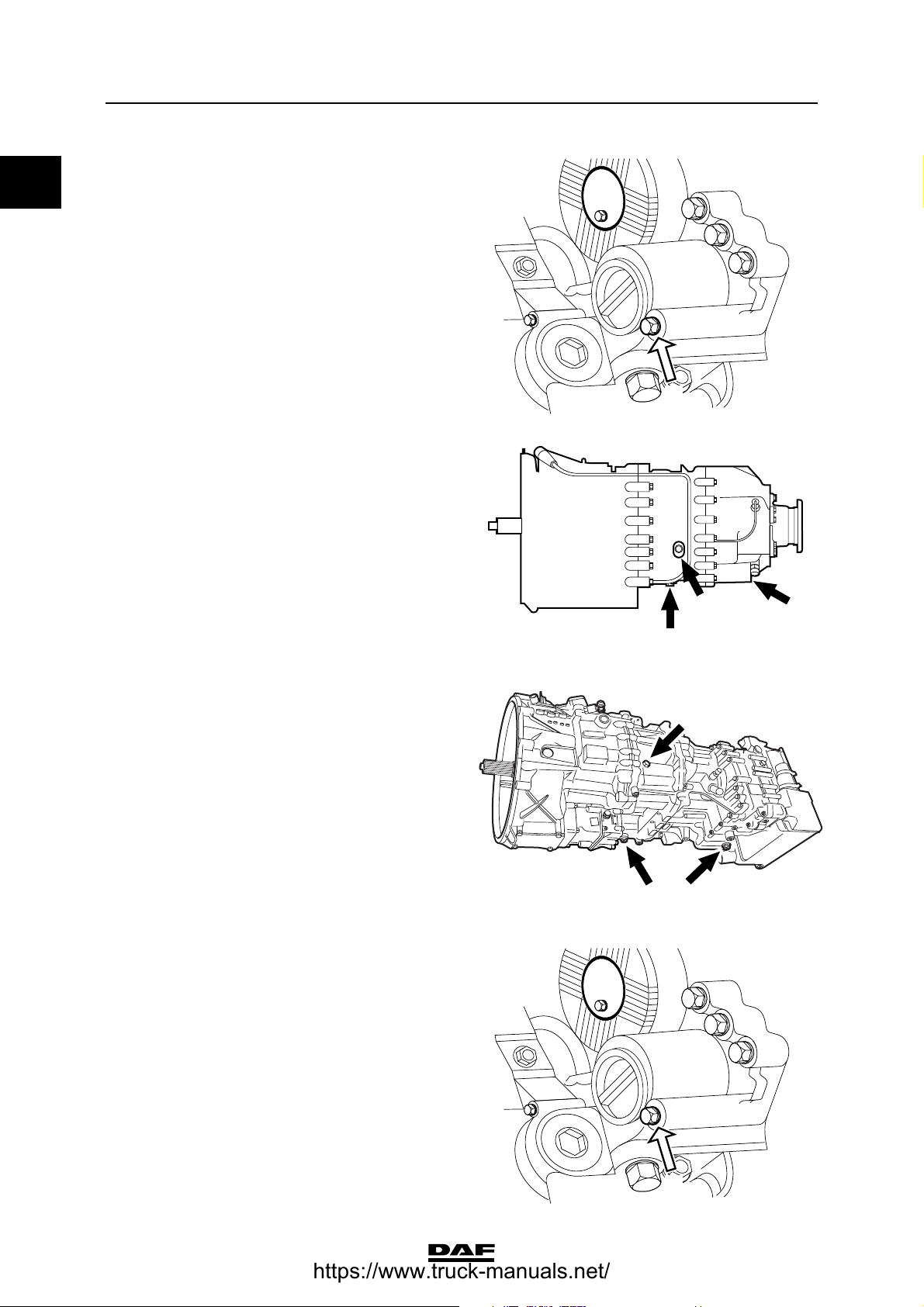

ZF 8S -151/181 and 16S-151/181/221

gearboxes

Level check/filler plug (A) 60 Nm

M24 drain plug (B) 60 Nm

M38 drain plug (B) 120 Nm

Drain plug (C/D) 60 Nm

Gearbox

0

ZF 8S-151/181 and 16S-151/181/221 with

integrated retarder

Drain plug (D) 60 Nm

D

B

A

C

D

M3023

B

C

V300186

©

200423 2-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Gearbox

Oil filter attachment bolt (1) 23 Nm

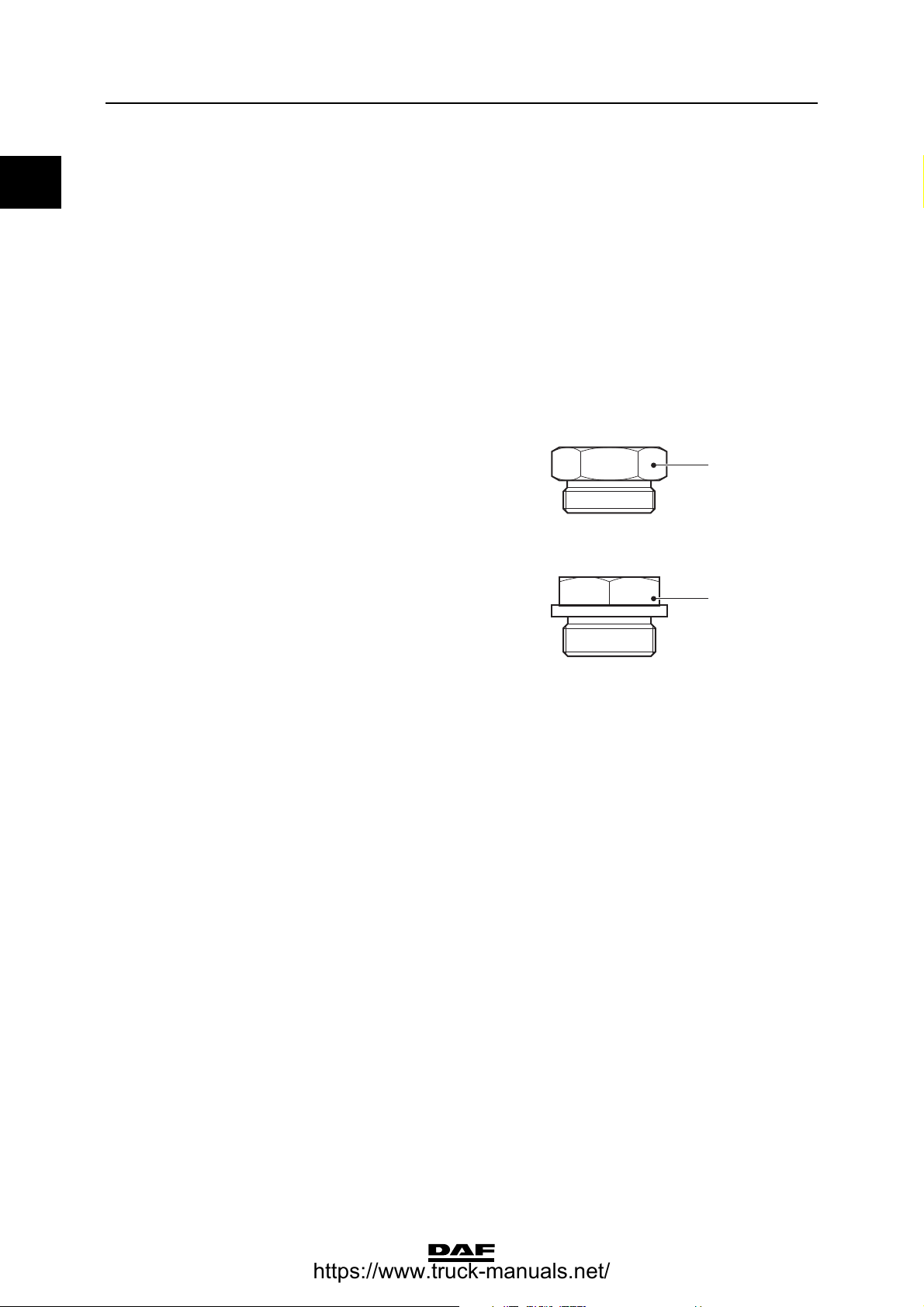

ZF AS Tronic

Level check/filler plug (A) 60 Nm

Drain plug (B/C) 60 Nm

1

ΧΦ85 series

M3052

ZF AS Tronic with integrated retarder

Level check/filler plug (A) 60 Nm

Drain plug (B/C) 60 Nm

Oil filter attachment bolt (1) 23 Nm

B

AC

B

G000243

A

C

G000250

2-2

https://www.truck-manuals.net/

1

M3052

©

200423

TECHNICAL DATA

ΧΦ85 series

2.2 FILLING CAPACITIES

ZF gearboxes

ZF 8S/16S-151

Filling capacity approx. 11 litres

ZF 8S/16S-181

Filling capacity approx. 13 litres

ZF 16S-221

Filling capacity approx. 13 litres

ZF 16S-151 with integrated retarder

Filling capacity approx. 11 litres

ZF 16S-181 with integrated retarder

Filling capacity approx. 12 litres

ZF 16S-221 with integrated retarder

Filling capacity approx. 12 litres

Gearbox

0

ZF AS Tronic gearboxes

ZF 12 AS 1930/2330

Filling capacity approx. 11 litres

ZF 12 AS 2540

Filling capacity approx. 12 litres

ZF 12 AS 1931/2331 with integrated retarder

Filling capacity approx. 12 litres

ZF 12 AS 2541 with integrated retarder

Filling capacity approx. 13 litres

©

200423 2-3

https://www.truck-manuals.net/

TECHNICAL DATA

0

Gearbox

ΧΦ85 series

2-4

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

3. REAR AXLE

3.1 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

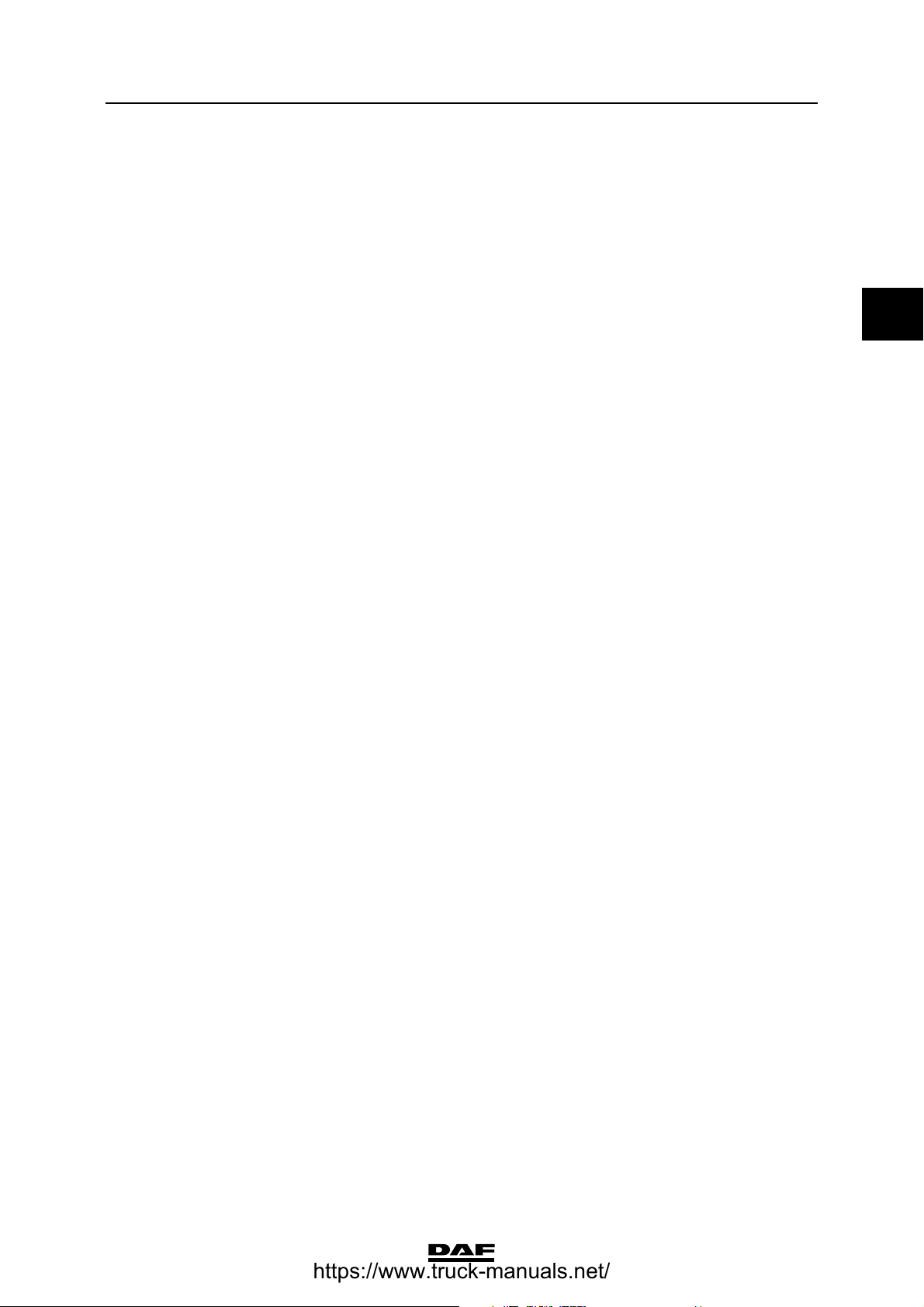

Filler and drain plugs/hub plugs (Torx wrench) 85 Nm

M24 U-bolt nut, property class 8

If flanged nut 740 Nm ≥ 55 Nm

If yellow zinc plated hexagonal nut 615 Nm ≥ 50 Nm

Rear axle

0

(1)

(1)

(1) Evenly tighten the two U-bolt nuts alternately.

M24 U-bolt nut, property class 10

If flanged nut 880 Nm ≥ 60 Nm

If yellow zinc plated hexagonal nut 615 Nm ≥ 50 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

M22 U-bolt nut, property class 10

(leading rear axle)

If flanged nut 700 Nm ≥ 50 Nm

If yellow zinc plated hexagonal nut 530 Nm ≥ 40 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

(1)

(1)

(1)

(1)

©

200423 3-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Rear axle

ΧΦ85 series

3.2 FILLING CAPACITIES

Differential Filling quantity with

minimum caster

1339 axle approx. 18.0 litres approx. 20.0 litres

1347 axle approx. 21.5 litres approx. 23.5 litres

1354 axle approx. 16.5 litres approx. 16.5 litres

1355(T) axle (1

1355(T) axle (2

1132(T) axle (1

1132(T) axle (2

Wheel hub Filling capacity per hub

1354 axle approx. 2 litres

1355(T) axle approx. 2 litres

1132(T) axle approx. 0.8 litres

st

axle) approx. 13.0 litres approx. 18.0 litres

nd

axle) approx. 11.5 litres approx. 13.0 litres

st

axle) approx. 17.0 litres approx. 25.5 litres

nd

axle) approx. 15.0 litres approx. 17.5 litres

Filling quantity with

maximum caster

3-2

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

4. BRAKES

4.1 GENERAL

Brake travel of automatic brake adjuster (Haldex) 35 - 40 mm

Brake travel of automatic brake adjuster

(FTP axle) 25 - 35 mm

Reverse torque of adjusting bolt > 18 Nm

Brakes

0

©

200423 4-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Brakes

ΧΦ85 series

4-2

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

5. STEERING GEAR

5.1 GENERAL

Maximum steering ball joint axial clearance 1.5 mm

Steering gear

0

©

200423 5-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Steering gear

5.2 TIGHTENING TORQUES

Steering gear

The tightening torques stated in this paragraph

are different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

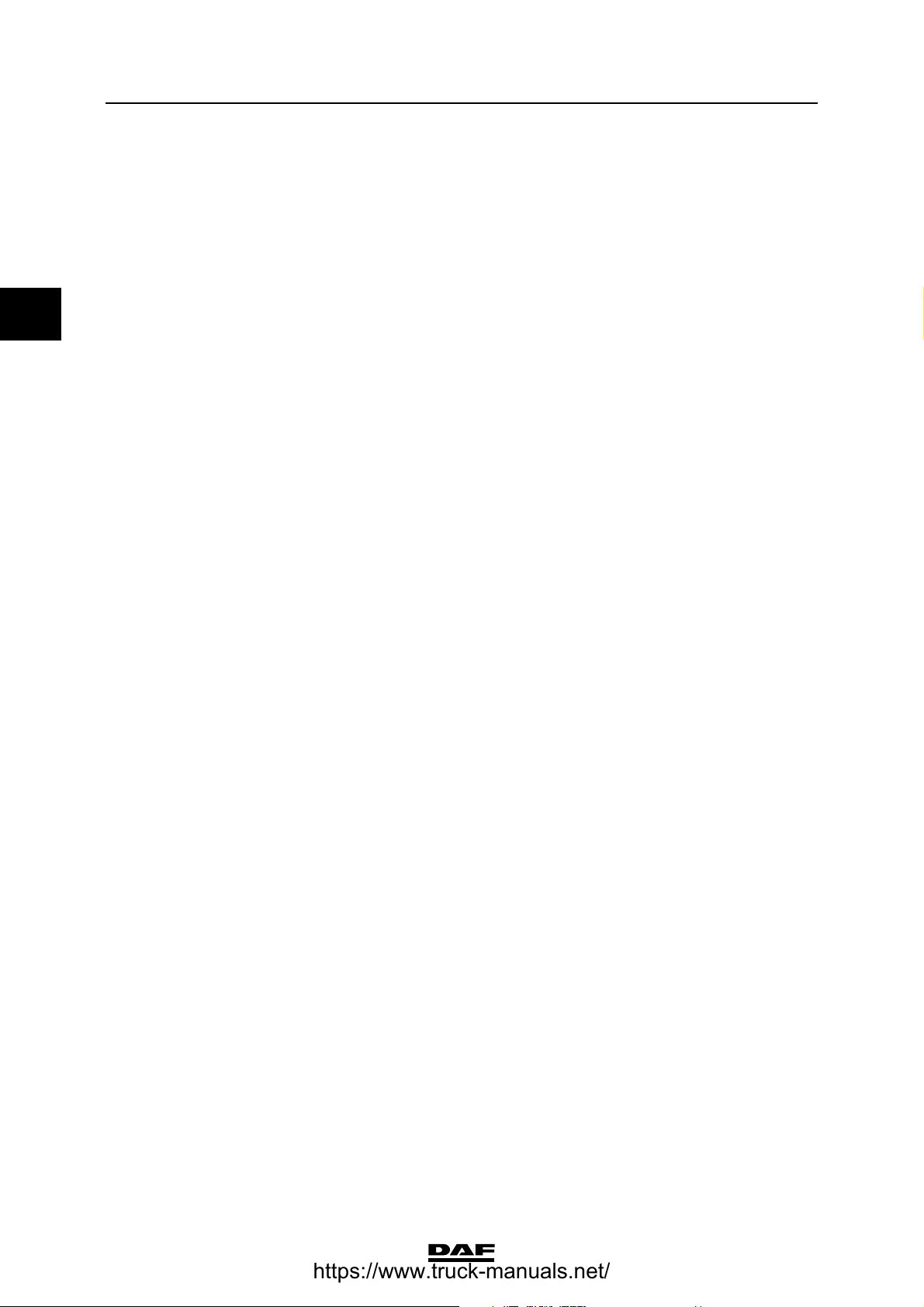

Filter plug without flange (A),

fluid flow control valve block

of EMAS system 125 Nm ≥ 5 Nm

ΧΦ85 series

A

S7 00 906

Filter plug with flange (B),

fluid flow control valve block

of EMAS system 270 Nm ≥ 20 Nm

Note:

- The two plugs are interchangeable.

Attachment bolt, steering column universal joint 54 Nm + 4 Nm

(1) Fit new original attachment bolt and nut.

B

S7 00 907

(1)

5-2

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

6. FRONT AXLE

6.1 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

U-bolt nut M20, property class 10

If flanged nut 450 Nm ≥ 40 Nm

If yellow zinc plated hexagonal nut 400 Nm ≥ 40 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

Front axle

0

(1)

(1)

M22 U-bolt nut, property class 10

(leading rear axle)

If flanged nut 700 Nm ≥ 50 Nm

If yellow zinc plated hexagonal nut 530 Nm ≥ 40 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

(1)

(1)

©

200423 6-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Front axle

ΧΦ85 series

6-2

https://www.truck-manuals.net/

©

200423

TECHNICAL DATA

ΧΦ85 series

Leading rear axle 09N044 (FTP-type vehicles)

7. LEADING REAR AXLE 09N044 (FTP-TYPE VEHICLES)

7.1 GENERAL

Wheel bearing play, 09N044 leading rear axle 0 mm

0

©

200423 7-1

https://www.truck-manuals.net/

TECHNICAL DATA

0

Leading rear axle 09N044 (FTP-type vehicles)

7.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

Hub nut 100 Nm

Hub cap 500 Nm

U-bolt nut M20, property class 10 553 Nm

(1) Turn back until split pin can be fitted.

(2) Evenly tighten the two U-bolt nuts alternately.

ΧΦ85 series

(1)

(2)

7-2

https://www.truck-manuals.net/

©

200423

THREADED CONNECTIONS

ΧΦ85 series

2 Threaded connections

CONTENTS

Page Date

1. THREADED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

Contents

2

©

200423 1

https://www.truck-manuals.net/

THREADED CONNECTIONS

2

Contents

ΧΦ85 series

2

©

200423

https://www.truck-manuals.net/

THREADED CONNECTIONS

ΧΦ85 series

1. THREADED CONNECTIONS

1.1 GENERAL

The components may have threaded connections

that have been treated with lubricant (dipped

threaded connection). Galvanised bolts and nuts

are wax dipped in the factory. Black annealed

and phosphatised bolts and nuts are oil dipped.

The advantage of using dipped nuts and bolts is

that friction during tightening is reduced, so that

the specified pre-tension force can be accurately

obtained. The tightening torque can be reduced

while the pre-tension force remains the same.

To achieve a small spread in the pre-tension

force, the dipped threaded connection must be

tightened accurately.

Therefore, always use a reliable torque wrench

that provides a high degree of accuracy.

Note:

Have torque wrenches regularly inspected and

calibrated.

Threaded connections

2

Re-use of fasteners (bolt/nut/threaded end)

1. Clean the thread (take particular care to

remove locking compound residues) and the

clamping faces

2. Check the thread for damage.

To do so, manually screw a new nut/bolt onto

the thread to be checked.

If the new nut/bolt cannot be fully handscrewed onto the entire thread of the

fastener to be checked, the fastener is not

allowed to be re-used.

3. Apply one drop of engine oil to the upper turn

of the bolt (threaded end)/lower turn of the

nut and one drop to the clamping faces

(other lubricants are not allowed).

4. If a locking compound has been specified, oil

should not be applied to the thread.

©

200423 1-1

https://www.truck-manuals.net/

THREADED CONNECTIONS

2

Threaded connections

The following applies to all threaded

connections (for both new and used

vehicles):

- in the case of standard connections, apply

the lubricant before fitting, and (re)tighten in

accordance with the standard for dipped

bolts;

- in the case of special connections, apply the

lubricant before fitting, and (re)tighten in

accordance with the values specified in the

instructions.

The instructions for using lubricants also apply to

new bolts from the warehouse. Dry threaded

connections may not be used because of their

highly variable friction coefficients.

Please consult the workshop manual

for the specified tightening torque.

}

ΧΦ85 series

1-2

https://www.truck-manuals.net/

©

200423

FLUIDS, OIL AND LUBRICANTS

ΧΦ85 series

3 Fluids, oil and lubricants

CONTENTS

Page Date

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

Contents

3

©

200423 1

https://www.truck-manuals.net/

FLUIDS, OIL AND LUBRICANTS

3

Contents

ΧΦ85 series

2

©

200423

https://www.truck-manuals.net/

Loading...

Loading...