DAF CF65, CF75, CF85 Service manual

4 |

STRUCTURE |

ΧΦ65/75/85 series

TECHNICAL DATA

DIAGNOSTICS

CE ENGINE FUEL SYSTEM

CE ENGINE INLET/EXHAUST SYSTEM

CE ENGINE, ENGINE BRAKE

PE ENGINE FUEL SYSTEM

PE ENGINE INLET/EXHAUST SYSTEM

ENGINE BRAKE, PE ENGINE

XE ENGINE FUEL SYSTEM

XE ENGINE INLET/EXHAUST SYSTEM

ENGINE BRAKE, XE ENGINE

0

1

2

3

4

5

6

7

8

9

10

© 200416 |

DW23241402 |

https://www.truck-manuals.net/

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

|

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

Contents |

|

|

CONTENTS |

|

|

|

|

Page |

Date |

|

0 |

|

|

|

|||

|

|

|

|

|

1. ENGINE, GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200416 1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200416 1.2 CE engine, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 . . . . . 200416 1.3 PE engine, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200416 1.4 XE engine, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200416

2. CE ENGINE FUEL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200416

3. CE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200416

4. PE ENGINE FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . . 200416

5. PE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200416

6. XE ENGINE FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200416 6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200416 6.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . . 200416

7. XE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200416 7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200416 7.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3 . . . . . 200416

8. ENGINE BRAKE, XE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200416 8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200416 8.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2 . . . . . 200416

© 200416 |

1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

|

Contents |

ΧΦ65/75/85 series |

0

2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Engine, general |

||

1. ENGINE, GENERAL |

|

|

|

|

|

0 |

|

1.1 GENERAL |

|

||

|

|

|

|

CE engine |

|

|

|

|

|

|

|

Cold engine |

A cold engine is an engine which, having reached |

||

|

operating temperature, has been allowed to cool |

||

|

down for at least six hours. |

||

Warm engine |

A warm engine is an engine which, having reached |

||

|

operating temperature, has not been at a standstill |

||

|

for more than thirty minutes. |

||

Direction of rotation of the engine |

The direction of rotation of the engine is clockwise, |

||

|

as seen from the vibration damper end. |

||

First cylinder of the engine |

The first cylinder of the engine is the cylinder at the |

||

|

vibration damper end of the engine. |

||

Left-hand and right-hand side of the engine |

The left-hand side of the engine is the side where the |

||

|

air compressor and electronic unit are mounted. The |

||

|

right-hand side of the engine is the side where the |

||

|

turbocharger and oil filter are mounted. |

||

PE/XE engine |

|

|

|

Cold engine |

A cold engine is an engine which, having reached |

||

|

operating temperature, has been allowed to cool |

||

|

down for at least six hours. |

||

Warm engine |

A warm engine is an engine which, having reached |

||

|

operating temperature, has not been at a standstill |

||

|

for more than thirty minutes. |

||

Direction of rotation of the engine |

The direction of rotation of the engine is clockwise, |

||

|

as seen from the timing gear end. |

||

First cylinder of the engine |

The first cylinder of the engine is the cylinder at the |

||

|

timing gear end. |

||

Left-hand and right-hand side of the engine |

The left-hand side of the engine is the side where the |

||

|

fuel pump is mounted. The right-hand side of the |

||

|

engine is the side where the air compressor is |

||

|

mounted. |

||

© 200416 |

1-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

4 |

|

|

|

|

|

|

|

Engine, general |

|

ΧΦ65/75/85 series |

|

|

Engine identification |

|

|

0 |

|

|

|

|

|

Engine number |

|

|

|

|

The engine number is located in two places on |

|

|

|

|

|

|

|

|

|

|

the engine: |

|

|

|

|

stamped into the engine block |

|

|

|

|

- CE: top of the oil cooler |

|

|

|

|

- PE: above the compressor |

|

|

|

|

- XE: above the UPEC unit |

|

|

|

|

on the type plate |

|

|

|

|

- CE: on the timing gear case or the flywheel |

|

|

|

|

housing (depending on the production date) |

|

|

|

|

- PE: on the inlet manifold |

|

|

|

|

- XE: on the inlet manifold |

|

|

|

|

Engine type |

|

|

|

|

The type number XE315C1 indicates: |

|

|

|

|

X engine family |

X = |

12.6 ltr. |

|

|

|

P = |

9.2 ltr. |

|

|

|

C = |

5.88 ltr. |

|

|

E engine version |

E = |

electronic timing |

|

|

|

S = |

turbocharger intercooler |

|

|

315 engine output in kilowatt (kW) |

|

|

|

|

C Euro emissions |

C = |

Euro 3 |

|

|

|

M = |

Euro 2 |

|

|

|

L = |

Euro 1 |

|

|

1 Engine version number |

1 = |

first update |

1-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

Engine, general |

|||

1.2 CE ENGINE, GENERAL |

|

|

|

|

|

|

|

|

|

|

0 |

||

|

|

|

|

|

|

|

Engine types |

|

|

|

|

|

|

|

|

|

|

|

||

Coding |

CE 136 C |

|

|

|

||

|

|

CE 162 C |

|

|

|

|

|

|

CE 184 C |

|

|

|

|

General specifications |

|

|

|

|

|

|

Environmental standard |

Euro 3 (C) |

|

|

|

||

Number of cylinders |

6 cylinders in line |

|

|

|

||

Valves |

4 valves per cylinder |

|||||

Bore x stroke |

102 x 120 mm |

|

|

|

||

Cubic capacity |

5.9 litres |

|

|

|

||

Compression ratio |

17,3 : 1 |

|

|

|

|

|

Fuel injection |

direct injection |

|

|

|

||

Injection sequence |

1-5-3-6-2-4 |

|

|

|

|

|

Air inlet system |

Turbocharger intercooling |

|||||

Engine management system |

ECS-DC3 |

|

|

|

||

Cooling |

fluid |

|

|

|

||

Weight |

approx. 500 kg |

|

|

|

||

Engine speeds, CE engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Idling |

|

Maximum no-load rpm |

|

|

|

|

rpm |

|

|

|

|

|

|

|

|

|

|

|

CE 136 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

CE 162 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

CE 184 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

© 200416 |

1-3 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

|

4 |

|

|

|

|

|

|

|

|

|

|

Engine, general |

|

|

ΧΦ65/75/85 series |

|

|

|

1.3 PE ENGINE, GENERAL |

|

|

|

|

0 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Engine types |

|

|

|

|

|

|

|

|

|

||

|

|

Coding |

PE 183 C 1 |

|

||

|

|

|

|

PE 228 C |

|

|

|

|

|

|

PE 265 C |

|

|

|

|

General specifications |

|

|

|

|

|

|

Environmental standard |

Euro 3 (C) |

|

||

|

|

Number of cylinders |

6 cylinders in line |

|||

|

|

Valves |

4 valves per cylinder |

|||

|

|

Bore x stroke |

118 x 140 mm |

|

||

|

|

Cubic capacity |

9.2 litres |

|

||

|

|

Compression ratio |

17,5 : 1 |

|

|

|

|

|

Fuel injection |

direct injection |

|

||

|

|

Injection sequence |

1-5-3-6-2-4 |

|

|

|

|

|

Air inlet system |

Turbocharger intercooling |

|||

|

|

Engine management system |

UPEC |

|

||

|

|

Cooling |

fluid |

|

||

|

|

Weight |

approx. 860 kg |

|

||

|

|

Engine speeds, PE engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Idling |

|

Maximum free-running rpm |

|

|

|

|

rpm |

|

|

|

|

|

|

|

|

|

|

|

PE 183 C1 |

|

575 - 625 |

|

Approx. 2580 |

|

|

|

|

|

|

|

|

|

PE 228 C |

|

575 - 625 |

|

Approx. 2580 |

|

|

|

|

|

|

|

|

|

PE 265 C |

|

575 - 625 |

|

Approx. 2580 |

|

|

|

|

|

|

|

1-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

Engine, general |

|||

1.4 XE ENGINE, GENERAL |

|

|

|

|

|

|

|

|

|

|

0 |

||

|

|

|

|

|

|

|

Engine types |

|

|

|

|

|

|

|

|

|

|

|

||

Coding |

XE 250 C 1 |

|

|

|

||

|

|

XE 280 C 1 |

|

|

|

|

|

|

XE 280 C 3 (4 öko) |

||||

|

|

XE 315 C 1 |

|

|

|

|

|

|

XE 315 C 3 (4 öko) |

||||

|

|

XE 355 C 1 |

|

|

|

|

General specifications |

|

|

|

|

|

|

Environmental standard |

Euro 3 (C) |

|

|

|

||

Number of cylinders |

6 cylinders in line |

|||||

Valves |

4 valves per cylinder |

|||||

Bore x stroke |

130 x 158 mm |

|

|

|

||

Cubic capacity |

12.6 litres |

|

|

|

||

Compression ratio |

17,4 : 1 |

|

|

|

|

|

Fuel injection |

direct injection |

|

|

|

||

Injection sequence |

1-5-3-6-2-4 |

|

|

|

|

|

Air inlet system |

Turbocharger intercooling |

|||||

Engine management system |

UPEC |

|

|

|

||

Cooling |

fluid |

|

|

|

||

Weight |

approx. 1,080 kg |

|||||

Engine speeds, XE engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Idling rpm |

|

Maximum free-running rpm |

|

|

|

|

|

|

|

|

|

XE 250 C1 |

|

525 - 575 |

|

approx. 2200 |

|

|

|

|

|

|

|

|

|

XE 280 C1/C3 |

|

525 - 575 |

|

approx. 2200 |

|

|

|

|

|

|

|

|

|

XE 315 C1/C3 |

|

525 - 575 |

|

approx. 2200 |

|

|

|

|

|

|

|

|

|

XE 355 C1 |

|

525 - 575 |

|

approx. 2260 |

|

|

|

|

|

|

|

|

|

© 200416 |

1-5 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

|

Engine, general |

ΧΦ65/75/85 series |

0

1-6 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

CE engine fuel system |

||

2. CE ENGINE FUEL SYSTEM |

|

|

|

|

|

0 |

|

2.1 GENERAL |

|

||

|

|

|

|

Fuel level element |

|

|

|

|

|

|

|

Angular displacement |

86 |

||

Resistance value |

|

|

|

- Full |

approx. 500 |

||

- • |

approx. 355 |

||

- ∂ |

approx. 234 |

||

- |

approx. 137 |

||

- Not used |

approx. 33 |

||

Vacuum relief valve opening pressure |

10 - 20 mbar |

||

Pressure relief valve opening pressure |

200 - 300 mbar |

||

Fuel fine filter |

|

|

|

Maximum pressure drop across fuel fine filter |

2.0 bar |

||

Fuel lift pump |

|

|

|

Fuel lift pump pressure in front of fine filter (with |

|

|

|

engine at idling speed) |

5 - 13 bar |

||

Fuel lift pump pressure behind fine filter (with |

|

|

|

engine at idling speed) |

3 - 11 bar |

||

Pressure relief valve opening pressure |

11 bar |

||

Maximum underpressure on suction side of fuel |

|

|

|

lift pump |

0.5 bar |

||

High-pressure pump |

|

|

|

Pump pressure (dependent on the operating |

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

||

Fuel rail |

|

|

|

Fuel rail pressure (dependent on the operating |

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

||

Fuel rail pressure-limiting valve |

|

|

|

Opening pressure |

1650 bar |

||

Injector |

|

|

|

Number of holes in injector |

8 |

|

|

Resistance of magnet coil |

0.15 - 0.5 |

||

© 200416 |

2-1 |

https://www.truck-manuals.net/

|

TECHNICAL DATA |

4 |

|

|

CE engine fuel system |

ΧΦ65/75/85 series |

|

0 |

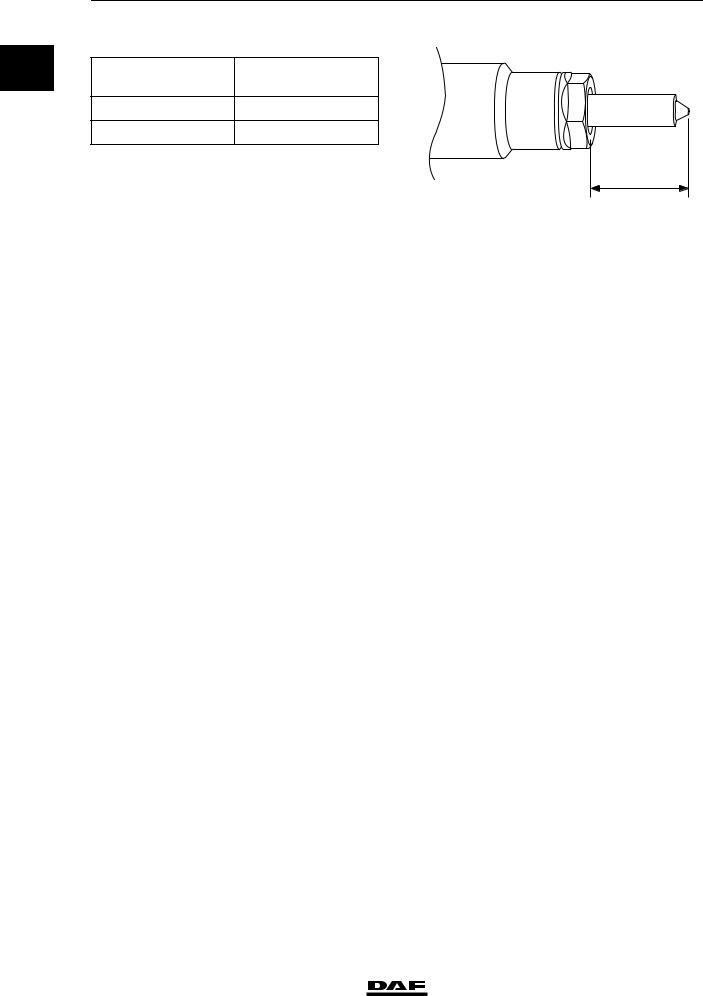

Injector washer |

|

|

Nozzle length |

Washer thickness |

|

|

|

(distance A) |

|

|

|

21.5 ≥ 0.2 mm |

1.5 mm |

|

|

23.0 ≥ 0.2 mm |

3.0 mm |

|

A

i400693

Fuel return overflow valve |

|

Fuel return overflow valve opening pressure |

1.2 - 2.0 bar |

Fuel return pipe |

|

Maximum return pipe pressure build-up |

0.2 bar |

Return fuel measurement |

|

Maximum quantity of return fuel at idling speed |

180 ml/min. |

Permitted minimum time for filling a measuring |

|

beaker to a volume of 360 ml |

2 min. |

2-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

CE engine fuel system |

||

2.2 TIGHTENING TORQUES |

|

|

|

|

|

0 |

|

|

|

||

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Electronic unit cooling plate |

|

|

|

Attachment bolts holding the electronic unit to the |

|

|

|

cooling plate |

10 Nm |

||

Attachment bolts holding the cooling plate to the |

|

|

|

engine block |

24 Nm |

||

VOSS quick-release coupling fittings |

18 Nm |

||

Low-pressure fuel pipes |

|

|

|

Banjo bolts |

24 Nm |

||

VOSS quick-release coupling fittings |

24 Nm |

||

Fuel return overflow valve in cylinder head |

24 Nm |

||

High-pressure pump |

|

|

|

Attachment nuts holding the high-pressure pump |

|

|

|

to the timing gear case |

25 Nm |

||

High-pressure fuel pipe |

|

|

|

High-pressure pipe union nut |

22 Nm |

||

Fuel rail |

|

|

|

Attachment bolts |

24 Nm |

||

Pressure-limiting valve |

100 Nm |

||

Injector pipes |

|

|

|

Injector pipe union nuts |

22 Nm |

||

Fuel supply pipe |

|

|

|

Fuel supply pipe nut |

50 Nm |

||

Injectors |

|

|

|

Injector clamping bracket attachment bolts |

10 Nm |

||

Injector electrical connection |

1.5 Nm |

||

© 200416 |

2-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

|

CE engine fuel system |

ΧΦ65/75/85 series |

0

2-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

CE engine inlet/exhaust system |

||

3. CE ENGINE INLET/EXHAUST SYSTEM |

|

|

|

|

|

0 |

|

3.1 GENERAL |

|

||

|

|

|

|

|

|

|

|

Turbocharger |

|

CE 136 C |

Holset HY 35 W |

CE 162 C |

Holset HY 35 W |

CE 184 C |

Holset HX 35 W |

Minimum actuating pressure of wastegate cap- |

|

sule under which the control rod will move |

2.0 bar |

Axial bearing play of compressor shaft |

0.038 - 0.093 mm |

Radial bearing play of compressor shaft |

0.329 - 0.501 mm |

Rejection standards for cracking

1.Cracks in the connector flange must not reach as far as the attachment holes.

2.Cracks in the connector flange must not

reach from the channels as far as the exterior.

3.Cracks in the connector flange may not be

longer than 15 mm.

4.Cracks in the connector flange must not be

less than 6 mm apart. |

|

5. There must be no cracks in the housing. |

5 |

|

1

2

3

4

i400784

Exhaust gas back pressure |

|

At full-load engine speed |

100 mbar |

Maximum back pressure during engine brake ap- |

|

plication |

4.3 bar |

Inlet underpressure |

|

At full-load engine speed (clean air filter) |

25 mbar |

At full-load engine speed (clogged air filter) |

62 mbar |

Glow element |

|

Resistance value |

180 - 220 m |

© 200416 |

3-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

|

|

|

CE engine inlet/exhaust system |

ΧΦ65/75/85 series |

|

|

3.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Turbocharger |

|

|

|

Attachment nuts, exhaust manifold flange/turbo- |

43 Nm (1) |

|

|

charger |

|

|

|

Oil discharge pipe attachment bolts |

23 Nm |

|

|

Oil supply pipe union |

28 Nm |

|

|

Turbocharger V-clamp |

10 Nm |

|

|

(1) Fasten with Copaslip |

|

|

|

Glow element |

|

|

|

Attachment bolts |

14 Nm |

|

|

Air cooler |

|

|

|

Hose clamps |

7 Nm |

3-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

|

|

|

|

TECHNICAL DATA |

|||

|

|

|

|

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

|

PE engine fuel system |

||||||

4. PE ENGINE FUEL SYSTEM |

|

|

|

|

|

|

||||

|

|

|

|

|

0 |

|||||

4.1 GENERAL |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

Gallery pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

At starting speed |

|

|

|

approx. 0.5 - 1.0 bar |

|

|

|

|||

At idling speed |

|

|

|

approx. 2.5 - 3.0 bar |

|

|

|

|||

At maximum no-load engine speed |

|

approx. 6.5 - 7.0 bar |

|

|

|

|||||

Fuel level element |

|

|

|

|

|

|

|

|

|

|

Angular displacement |

|

86 |

|

|

|

|

||||

Resistance rating |

|

|

|

|

|

|

|

|

|

|

- Full |

|

|

|

approx. 500 |

|

|

|

|

||

- • |

|

|

|

approx. 355 |

|

|

|

|

||

- ∂ |

|

|

|

approx. 234 |

|

|

|

|

||

- |

|

|

|

approx. 137 |

|

|

|

|

||

- Not used |

|

|

|

approx. 33 |

|

|

|

|

||

Underpressure valve opening pressure |

10 - 20 mbar |

|

|

|

|

|||||

Overpressure valve opening pressure |

|

200 - 300 mbar |

|

|

|

|

||||

Overview of injectors |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Number of |

|

Nozzle no. |

Hole diameter |

|

Bar filter |

Opening |

|

|

|

|

holes in |

|

|

|

|

|

pressure |

|

|

|

|

injector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PE 183 C1 |

|

8 |

|

1080 |

0,175 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

PE 228 C |

|

8 |

|

1080 |

0,175 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

PE 265 C |

|

8 |

|

1080 |

0,175 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel lift pump |

|

|

|

|

|

|

|

|

|

|

Fuel lift pump pressure |

|

7.0 - 8.0 bar |

|

|

|

|

||||

Pressure relief valve opening pressure |

approx. 8.5 bar |

|

|

|

|

|||||

Pump housing |

|

|

|

|

|

|

|

|

|

|

Weight, including camshaft and pump units |

approx. 70 kg |

|

|

|

|

|||||

Pressure relief valve opening pressure |

approx. 5.5 - 6 bar |

|

|

|

||||||

© 200416 |

4-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

|

|

|

PE engine fuel system |

ΧΦ65/75/85 series |

|

|

4.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

|

Injector pipes |

|

|

Injector pipe union nuts |

30 |

Nm |

Fuel filter housing |

|

|

Fuel leak-off pipe union |

20 |

Nm |

Fuel filter cap |

25 |

Nm |

Injectors |

|

|

Clamping piece attachment bolt |

30 |

Nm + 60 angular displacement (1) |

Leak-off pipe banjo bolt |

20 |

Nm |

(1) Use bolts once only. |

|

|

Pump housing |

|

|

Pressure relief valve |

20 |

Nm |

Attachment bolts to connect pump housing to |

|

|

engine block |

60 |

Nm |

Pump housing rear cover attachment bolts |

30 |

Nm |

Attachment bolts for pump camshaft locking plate |

30 |

Nm |

Attachment bolts for pump housing sealing plates |

30 |

Nm |

Attachment bolts for pulse disk on camshaft |

30 |

Nm (1) |

Attachment bolt, camshaft sensor |

8 Nm |

|

Non-return valve |

45 |

Nm |

Fuel temperature sensor |

20 |

Nm |

(1) Use Loctite 243 |

|

|

Pump units |

|

|

Bolts for attaching pump units to pump housing |

46 |

Nm |

Pump unit electrical connection |

1 Nm |

|

Fuel lift pump |

|

|

Attachment bolts to connect fuel lift pump to |

30 Nm (1) |

|

pump housing |

||

(1) Use Loctite 243

4-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

TECHNICAL DATA |

||

|

|

|

|

|

ΧΦ65/75/85 series |

PE engine inlet/exhaust system |

|||

5. PE ENGINE INLET/EXHAUST SYSTEM |

|

|

|

|

|

|

0 |

||

5.1 |

GENERAL |

|

||

|

|

|

||

Explanation of turbocharger type designation |

|

|

|

|

|

|

|

||

Example of type designation: |

|

|

|

|

GT40-88S/54NPS/0.95-84 |

|

|

|

|

GT40 |

Turbine type designation |

|

|

|

88 |

Maximum compressor rotor diameter |

|

|

|

S |

Wastegate model |

|

|

|

54 |

Compressor rotor trim |

|

|

|

NPS |

Version with intake side without compressor housing bypass |

|||

PS |

Version with intake side with compressor housing bypass |

|||

0.95 |

Turbine housing size |

|

|

|

84 |

Turbine rotor trim |

|

|

|

Exhaust back pressure |

|

At full-load engine speed |

80 - 90 mbar |

Inlet underpressure |

|

At full-load engine speed (clean air filter) |

25 - 35 mbar |

At full-load engine speed (clogged air filter) |

54 - 64 mbar |

Turbocharger |

|

Control rod movement of control bypass |

|

at 1.8 bar |

1 mm |

Stud bolts for fastening |

Copaslip |

© 200416 |

5-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

|

|

|

PE engine inlet/exhaust system |

ΧΦ65/75/85 series |

|

|

5.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

|

|

Turbocharger |

|

|

|

Heat shield attachment bolts |

30 |

Nm (1) |

|

Turbine housing clamp plate attachment nut |

15 |

Nm |

|

Exhaust manifold flange/turbocharger attach- |

|

Nm (2) |

|

ment nuts |

60 |

||

Elbow attachment with exhaust brake on turbo- |

|

|

|

charger |

40 |

Nm |

|

Oil supply pipe banjo bolt |

90 |

Nm |

|

(1) |

Use Loctite 243 to secure |

|

|

(2) |

Fasten with Copaslip |

|

|

Glow element |

|

|

|

Attachment bolts |

30 |

Nm |

|

Air cooler |

|

|

|

Air cooler hose clamps |

10 |

Nm |

|

5-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

|

|

|

|

TECHNICAL DATA |

|||

|

|

|

|

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

|

XE engine fuel system |

||||||

6. XE ENGINE FUEL SYSTEM |

|

|

|

|

|

|

||||

|

|

|

|

|

0 |

|||||

6.1 GENERAL |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

Gallery pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

At starting speed |

|

|

|

approx. 0.5 - 1.0 bar |

|

|

|

|||

At idling speed |

|

|

|

approx. 2.5 - 3.0 bar |

|

|

|

|||

At maximum no-load engine speed |

|

approx. 6.5 - 7.0 bar |

|

|

|

|||||

Fuel level element |

|

|

|

|

|

|

|

|

|

|

Angular displacement |

|

86 |

|

|

|

|

||||

Resistance value |

|

|

|

|

|

|

|

|

|

|

- Full |

|

|

|

approx. 500 |

|

|

|

|

||

- • |

|

|

|

approx. 355 |

|

|

|

|

||

- ∂ |

|

|

|

approx. 234 |

|

|

|

|

||

- |

|

|

|

approx. 137 |

|

|

|

|

||

- Not used |

|

|

|

approx. 33 |

|

|

|

|

||

Vacuum relief valve opening pressure |

10 - 20 mbar |

|

|

|

|

|||||

Pressure relief valve opening pressure |

200 - 300 mbar |

|

|

|

|

|||||

Overview of injectors |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Number of |

|

Nozzle no. |

Hole diameter |

|

Bar filter |

Opening |

|

|

|

|

holes in |

|

|

|

|

|

pressure |

|

|

|

|

injector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XE 250 C1 |

|

8 |

|

1081 |

0.182 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

XE 280 C1/C3 |

|

8 |

|

1081 |

0.182 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

XE 315 C1/C3 |

|

8 |

|

1081 |

0.182 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

XE 355 C1 |

|

8 |

|

1286 |

0.182 |

|

Yes |

300 + 10 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel lift pump |

|

|

|

|

|

|

|

|

|

|

Fuel lift pump pressure |

|

7.0 - 8.0 bar |

|

|

|

|

||||

Pressure relief valve opening pressure |

approx. 8.5 bar |

|

|

|

|

|||||

Pump housing |

|

|

|

|

|

|

|

|

|

|

Weight, including camshaft and pump units |

approx. 70 kg |

|

|

|

|

|||||

Pressure relief valve opening pressure |

circa 5.5 - 6 bar |

|

|

|

|

|||||

© 200416 |

6-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

|

|

|

XE engine fuel system |

ΧΦ65/75/85 series |

|

|

6.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

|

Injector pipes |

|

|

Injector pipe union nuts |

30 |

Nm |

Fuel filter housing |

|

|

Fuel leak-off pipe union |

20 |

Nm |

Fuel filter cap |

25 |

Nm |

Injectors |

|

|

Clamping piece attachment bolt |

30 |

Nm + 60 angular displacement (1) |

Leak-off pipe banjo bolt |

20 |

Nm |

(1) Use bolts once only. |

|

|

Pump housing |

|

|

Pressure relief valve |

20 |

Nm |

Attachment bolts to connect pump housing to |

|

|

engine block |

60 |

Nm |

Pump housing rear cover attachment bolts |

30 |

Nm |

Attachment bolts for pump camshaft locking plate |

30 |

Nm |

Attachment bolts for pump housing sealing plates |

30 |

Nm |

Attachment bolts for pulse disk on camshaft |

30 |

Nm (1) |

Attachment bolt, camshaft sensor |

8 Nm |

|

Non-return valve |

45 |

Nm |

Fuel temperature sensor |

20 |

Nm |

(1) Use Loctite 243 |

|

|

Pump units |

|

|

Bolts for attaching pump units to pump housing |

46 |

Nm |

Pump unit electrical connection |

1 Nm |

|

Fuel lift pump |

|

|

Attachment bolts to connect fuel lift pump to |

30 Nm (1) |

|

pump housing |

||

(1) Use Loctite 243

6-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

TECHNICAL DATA |

|

||

|

|

|

|

||

ΧΦ65/75/85 series |

XE engine inlet/exhaust system |

|

|||

7. XE ENGINE INLET/EXHAUST SYSTEM |

|

||||

0 |

|||||

7.1 |

GENERAL |

|

|

||

|

|

|

|||

Explanation of K.K.K. turbocharger type |

|

|

|

||

|

|

|

|||

designation |

|

|

|

||

Example of type designation: |

K31-39 71 Q Y B KB |

|

|||

|

|

22.9 1 D C A Y D |

|

||

K31 |

Turbine build series |

|

|

|

|

39 |

diameter of compressor rotor 3.9 inch |

|

|||

71 |

diameter ratio of compressor rotor d/d |

|

|||

Q |

Compressor rotor development letter |

|

|||

Y |

Compressor housing development letter |

|

|||

B |

Compressor housing variant |

|

|

|

|

Kk = compressor housing with recirculation (= ported shroud)

a = compressor housing with no recirculation (= non-ported shroud)

b |

b = recirculation variant |

|

|

a = no recirculation |

|

22 |

surface of turbine housing throat (cm2) |

|

9 |

turbine housing version number |

|

|

9 |

= with control bypass |

|

2 |

= without control bypass |

1Turbine trim figure:

=d/d = 89.5 (trim 80)

=d/d = 87 (trim 76)

=d/d = 84 (trim 70)

=d/d = 79 (trim 62)

D |

Turbine rotor development letter |

C |

Turbine housing development number |

A |

Turbine housing variant |

YTurbine inlet flange size

y = dimension for a 12.6 litre engine w = size for a 9.2 litre engine

t = size for a 6.2 litre engine

DTurbine housing material: b = GG 40

d = Simo

f = Nirisist d2 h = Nirisist d3 k = Nirisist d5

© 200416 |

7-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

|

|

|

|

|

XE engine inlet/exhaust system |

ΧΦ65/75/85 series |

|

|

|

Explanation of GARRETT turbocharger type |

|

|

0 |

|

|

||

|

designation |

|

|

|

|

|

|

|

|

|

|

Example of type designation: GT40-88S/54NPS/ |

|

|

|

|

0.95-84 |

|

|

|

|

GT40 |

Turbine type designation |

|

|

|

88 |

Maximum compressor rotor diameter |

|

|

|

S |

Wastegate model |

|

|

|

54 |

Compressor rotor trim |

|

|

|

NPS |

Version with intake side without compressor housing bypass |

|

|

|

PS |

Version with intake side with compressor housing bypass |

|

0.95Turbine housing size

84 |

Turbine rotor trim |

|

Turbocharger |

|

|

Stud bolts for fastening |

Copaslip |

|

GARRETT wastegate |

|

|

Movement of control rod at 1.60 ≥ 0.05 bar |

1.0 mm |

|

K.K.K. wastegate |

|

|

Movement of control rod at 1.95 ≥ 0.05 bar |

3.5 ≥ 0.05 mm |

|

Exhaust back pressure |

|

|

At full-load engine speed |

90 mbar |

|

Inlet underpressure |

|

|

At full-load engine speed (clean air filter) |

50 mbar |

|

At full-load engine speed (clogged air filter) |

75 mbar |

|

7-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

XE engine inlet/exhaust system |

||

7.2 TIGHTENING TORQUES |

|

|

|

|

|

0 |

|

|

|

||

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Turbocharger |

|

|

|

Heat shield attachment bolts |

30 |

Nm (1) |

|

Turbine housing clamp plate attachment nut |

15 |

Nm |

|

Exhaust manifold flange/turbocharger |

|

Nm (2) |

|

attachment nuts |

60 |

||

Elbow attachment with exhaust brake on |

|

|

|

turbocharger |

40 |

Nm |

|

Oil supply pipe banjo bolt |

90 |

Nm |

|

(1) |

Use Loctite 243 to secure |

|

|

(2) |

Fasten with Copaslip |

|

|

Glow element |

|

|

|

Attachment bolts |

30 |

Nm |

|

Air cooler |

|

|

|

Air cooler hose clamps |

10 |

Nm |

|

© 200416 |

7-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

|

XE engine inlet/exhaust system |

ΧΦ65/75/85 series |

0

7-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Engine brake, XE engine |

||

8. ENGINE BRAKE, XE ENGINE |

|

|

|

|

|

0 |

|

8.1 GENERAL |

|

||

|

|

|

|

DEB solenoid valve |

|

|

|

|

|

|

|

Resistance rating |

|

|

|

Cold (20 C) |

32,6 - 36,8 |

||

Hot (80 C - 100 C) |

41,8 - 46,1 |

||

DEB oil pressures |

|

|

|

Minimum cut-in pressure |

1.5 bar |

||

Maximum service pressure |

4.5 bar |

||

Maximum pressure of DEB control valve |

8.0 bar |

||

DEB settings |

|

|

|

DEB clearance |

1.40 mm |

||

Exhaust brake |

|

|

|

Calibration of butterfly valve opening: |

|

|

|

- with DEB |

14 mm |

||

- without DEB |

10.5 mm |

||

© 200416 |

8-1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

|

Engine brake, XE engine |

ΧΦ65/75/85 series |

8.2 TIGHTENING TORQUES

0

The tightening torques specified in this paragraph are different from the standard tightening torques cited in the overview of the standard tightening torques. The other threaded connections not specified must therefore be tightened to the torque cited in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important - unless stated otherwise - that these bolts and nuts are of exactly the same length and property class as those removed.

DEB |

|

|

|

|

|

|

|

|

Valve cover attachment bolts |

25 |

Nm |

7 |

|

15 |

9 |

2 |

|

Rocker setting bolt lock nut |

40 |

Nm |

3 |

11 |

13 |

|

||

|

|

|||||||

Bridge piece setting bolt |

|

|

|

|

|

|

|

|

lock nut |

40 |

Nm |

5 |

|

|

|

6 |

|

DEB attachment bolts |

110 Nm |

|

|

|

||||

|

|

|

|

|

||||

DEB set screw nut |

25 |

Nm |

1 |

|

14 |

8 |

|

|

Solenoid valve |

20 |

Nm |

|

|

|

|

||

|

|

|

|

|

||||

Wiring harness attachment bolt |

5 Nm |

|

10 |

12 |

|

4 |

||

Spring plate attachment bolt |

12.5 Nm |

|

|

|||||

|

|

|

|

|

||||

Valve sleeve attachment bolts |

30 |

Nm (1) |

|

|

|

|

M200942 |

|

(1) |

Tighten the attachment bolts in the order indicated |

|

|

|

|

|

||

Exhaust brake |

|

|

|

|

|

|

|

|

Exhaust brake elbow attachment nuts on turbo- |

40 Nm (1) |

|

|

|

|

|||

charger |

|

|

|

|

|

|

||

Heat shield attachment bolts |

|

|

30 Nm (2) |

|

|

|

|

|

(1) |

Fasten with Copaslip |

|

|

|

|

|

|

|

(2) |

Use Loctite 243 to secure |

|

|

|

|

|

|

|

8-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

DIAGNOSTICS |

|

||

|

|

|

|

|

ΧΦ65/75/85 series |

|

Contents |

|

|

CONTENTS |

|

|

|

|

|

Page |

Date |

|

|

1. TRACTIVE PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1-1 . . . |

. . 200416 |

1 |

|

1.1 Tractive problems |

1-1 |

200416 |

||

|

||||

2. CE ENGINE FUEL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200416

3. CE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200416

4. ENGINE BRAKE, CE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . . 200416

5. FUEL SYSTEM, XE/PE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200416

6. XE/PE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200416 6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200416 6.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . . 200416

7. ENGINE BRAKE, XE/PE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200416 7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200416 7.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 . . . . . 200416

© 200416 |

1 |

https://www.truck-manuals.net/

DIAGNOSTICS |

4 |

|

|

Contents |

ΧΦ65/75/85 series |

1

2 |

© 200416 |

https://www.truck-manuals.net/

Loading...

Loading...