DAF 95XF, 95XE Repair Manual

2 |

CONTENTS |

95XF series

TECHNICAL DATA

DIAGNOSTICS

XF ENGINE

XF ENGINE COOLING SYSTEM

XF ENGINE LUBRICATION SYSTEM

XE ENGINE

XE ENGINE COOLING SYSTEM

XE ENGINE LUBRICATION SYSTEM

0

1

2

3

4

5

6

7

200335

2 |

TECHNICAL DATA |

|

|

|

|

95XF series |

Contents |

|

CONTENTS

Page Date |

0 |

|

1. ENGINE GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . 200335

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . 200335

2. XF ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . 200335 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . 200335 2.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 . . . . 200335

3. XF ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . 200335 3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . 200335 3.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . 200335 3.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . 200335

4. XF ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . 200335 4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . 200335 4.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . 200335 4.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 . . . . 200335

5. XE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . 200335 5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . 200335 5.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 . . . . 200335

6. XE ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . 200335 6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . 200335 6.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . 200335 6.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . 200335

7. XE ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . 200335 7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . 200335 7.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 . . . . 200335 7.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 . . . . 200335

200335 |

1 |

TECHNICAL DATA |

2 |

|

|

Contents |

95XF series |

0

2 |

200335 |

2 |

TECHNICAL DATA |

||

|

|

|

|

95XF series |

Engine general |

||

1. ENGINE GENERAL |

|

|

|

1.1 GENERAL |

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

The terms “COLD ENGINE” and “WARM

ENGINE” are defined as follows:

COLD ENGINE

A cold engine is an engine which, having reached operating temperature, has been allowed to cool down for at least six hours.

WARM ENGINE

A warm engine is an engine which, having reached operating temperature, has not been at a standstill for more than thirty minutes.

Direction of rotation of the engine

The direction of rotation of the engine is clockwise, as seen from the timing gear end.

First cylinder of the engine

The first cylinder of the engine is the cylinder at the timing gear end.

Left-hand and right-hand side of the engine

The left-hand side of the engine is the side where the fuel pump is mounted.

The right-hand side of the engine is the side where the air compressor is mounted.

200335 |

1-1 |

TECHNICAL DATA |

2 |

|

|

Engine general |

95XF series |

0

1-2 |

200335 |

2 |

|

|

TECHNICAL DATA |

|||

|

|

|

|

|

|

|

95XF series |

|

|

XF engine |

|||

2. XF ENGINE |

|

|

|

|

|

|

2.1 GENERAL |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

Types |

XF 280 M |

|

|

|

|

|

|

|

|

|

|||

|

XF 315 M |

|

|

|

|

|

|

XF 355 M |

|

|

|

|

|

Version |

Euro 2 (M), water-cooled, four-stroke diesel |

|||||

|

engine with direct fuel injection, 4 valves per |

|||||

|

cylinder and turbo-intercooling. |

|||||

Number of cylinders |

6 |

|

|

|

|

|

Bore x stroke |

130 x 158 mm |

|

|

|

|

|

Swept volume |

12.58 l |

|

|

|

|

|

Compression ratio |

16.0 : 1 |

|

|

|

|

|

Firing order |

1-5-3-6-2-4 |

|

|

|

|

|

Weight |

approx. 1,049 kg |

|

|

|

|

|

|

|

|

|

|

|

|

ENGINE TYPE |

P (kW) at rpm |

|

M (Nm) at rpm |

|

||

|

|

|

|

|

||

XF 280 M |

280 at 2000 |

|

1750 at 1100 - 1500 |

|

|

|

|

|

|

|

|

||

XF 315 M |

315 at 2000 |

|

1900 at 1050 - 1500 |

|

|

|

|

|

|

|

|

||

XF 355 M |

355 at 2000 |

|

2050 at 1000 - 1500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

ENGINE TYPE |

IDLING SPEED |

|

MAX. NO LOAD SPEED |

|

||

|

rpm |

|

rpm |

|

||

|

|

|

|

|

||

XF 280 M |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

||

XF 315 M |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

||

XF 355 M |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

|

|

200335 |

2-1 |

|

|

TECHNICAL DATA |

2 |

|

|||

|

|

|

|

|

|

|

|

|

|

XF engine |

|

|

|

95XF series |

|

|

|

V-BELT TENSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

Belt tension, “AVX” raw-edge1 V-belts in Newtons (N) |

|

|||

|

|

|

Multiple-V-belt |

|

Single-V-belt |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

New V-belt2 |

|

|

|

|

Setting tension |

|

1200 |

|

600 |

|

|

|

|

|

|

|

|

|

|

|

Test tension |

|

≥800 |

|

≥400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Worn V-belt3 |

|

|

|

|

Minimum tension |

|

500 |

|

250 |

|

|

|

|

|

|

|

|

|

|

|

Adjusting tension |

|

700 |

|

350 |

|

|

|

|

|

|

|

|

|

(1)Raw-edge V-belts can be recognised by the absence

of textile fabric in the rubber, with the exception of the top of the belt edge, on the edges and the insides of the belt (polished belt edges). Version: either toothed or non-toothed.

(2)After fitting the new V-belt, set the pre-tension to the “setting tension” and after a trial run check whether the

pre-tension complies with the “test tension”. If the tension reading is lower than the “test tension” specified in the table, set the V-belt to the minimum “test tension”.

(3)If the V-belt tension is lower than the “minimum tension”, set the belt to the “adjusting tension”.

M2121

2-2 |

200335 |

2 |

TECHNICAL DATA |

|||

|

|

|

||

95XF series |

XF engine |

|||

Cylinder liner |

|

|

|

|

Height above cylinder block |

0.02 - 0.10 mm |

|

||

0 |

||||

Cylinder head |

|

|

||

|

|

|

||

Minimum height after overhaul |

119.50 mm |

|||

Test pressure using air (max. pressure) |

1.5 bar |

|||

Valve clearance |

|

|

|

|

Valve clearance (cold/hot) |

|

|

|

|

inlet |

0.50 mm |

|||

exhaust |

0.50 mm |

|||

Valve opening |

|

|

|

|

Valve opening at 1 mm valve clearance |

0.3 - 0.7 mm |

|||

Axial play |

|

|

|

|

Crankshaft axial play |

0.06 - 0.32 mm |

|||

Camshaft axial play |

0.10 - 0.55 mm |

|||

Idler gear axial play |

0.05 - 0.25 mm |

|||

Gear backlash |

|

|

|

|

Idler gear - crankshaft gear |

0.02 - 0.21 mm |

|||

Idler gear - fuel-pump gear |

0.02 - 0.22 mm |

|||

Idler gear - camshaft gear |

0.02 - 0.21 mm |

|||

Camshaft gear - compressor gear |

0.02 - 0.22 mm |

|||

Fuel pump gear - steering pump gear |

0.02 - 0.19 mm |

|||

Oil pump idler gear - oil pump gear |

0.02 - 0.20 mm |

|||

Crankshaft gear - oil pump idler gear |

0.02 - 0.20 mm |

|||

Number of teeth, timing gears |

|

|

|

|

Crankshaft gear |

35 |

|

|

|

Idler gear |

54 |

|

|

|

Fuel pump gear |

70 |

|

|

|

Camshaft gear |

70 |

|

|

|

Air compressor gear |

27 |

|

|

|

Fan drive housing gear |

29 |

|

|

|

Steering pump gear |

18 |

|

|

|

Lubricating oil pump idler gear |

34 |

|

|

|

Fan drive |

|

|

|

|

Heat gear wheel for max. 30 min. |

245_C |

|||

Compression pressure |

|

|

|

|

Differences in compression pressure |

15% |

|

|

|

Flywheel/starter ring gear |

|

|

|

|

Axial variation, measured at a radial distance |

|

|

|

|

of 210 mm |

0.10 mm |

|||

Starter ring gear warm up |

max. 185_C |

|||

200335 |

2-3 |

|

|

TECHNICAL DATA |

|

2 |

|

|

|

|

|

|

|

XF engine |

|

95XF series |

|

|

2.2 TIGHTENING TORQUES |

|

|

|

|

|

|

|

0 |

|

The tightening torques stated in this section are |

|

|

|

|

different from the standard tightening torques |

|

|

|

|

stated in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections which |

|

|

|

|

are not stated must therefore be tightened to the |

|

|

|

|

tightening torque stated in the overview of |

|

|

|

|

standard tightening torques. |

|

|

|

|

When attachment bolts and nuts are to be |

|

|

|

|

replaced, it is important that they are of exactly |

|

|

|

|

the same length and property class as the ones |

|

|

|

|

removed unless stated otherwise. |

|

|

|

|

Starter motor |

|

|

|

|

Attachment nuts |

73 |

Nm(1) |

|

|

Alternator |

|

|

|

|

Alternator bracket attachment bolts |

55 |

Nm |

|

|

Alternator attachment bolts |

50 |

Nm |

|

|

Pulley attachment nut, version 55A |

70 |

Nm |

|

|

Pulley attachment nut, version 95A |

70 |

Nm |

|

|

Air compressor |

|

|

|

|

M12 attachment bolts for compressor |

110 Nm |

|

|

|

M8 attachment bolts for bracket |

30 |

Nm |

|

|

M10 attachment bolts for bracket |

60 |

Nm |

|

|

Compressor gear flange bolt |

120 Nm |

|

|

|

M14 cylinder head threaded coupling |

40 |

Nm |

|

|

M26 cylinder head threaded coupling |

90 |

Nm |

|

|

Delivery pipe reducer valve |

75 |

Nm |

|

|

Suction and pressure line unions |

90 |

Nm |

|

|

Air-conditioning compressor |

|

|

|

|

M12 attachment bolts for compressor bracket |

110 Nm |

|

|

|

M10 attachment bolts for compressor |

60 |

Nm(1) |

|

|

Exhaust manifold |

|

|

|

|

Fit gasket with steel side towards manifold |

|

|

|

|

Sleeved attachment bolts |

65 |

Nm |

|

|

Heat shield attachment bolts |

30 |

Nm(1) |

2-4 |

200335 |

2 |

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

95XF series |

|

|

XF engine |

||

Inlet manifold |

|

|

|

|

|

Attachment bolts |

60 |

Nm |

|

|

|

|

|

0 |

|||

Glow plug attachment nut |

55 |

Nm |

|

|

|

Air inlet hose clamps |

12 |

Nm |

|

|

|

Turbocharger |

|

|

|

|

|

Heat shield attachment bolts |

30 |

Nm(1) |

|

|

|

Turbine housing clamp plate attachment nut |

15 |

Nm |

|

|

|

Attachment nuts, exhaust manifold |

|

Nm(2) |

|

|

|

flange/turbocharger |

60 |

|

|

|

|

Elbow on turbocharger |

40 |

Nm |

|

|

|

Oil supply pipe banjo bolt |

90 |

Nm |

|

|

|

(1) Secure with Loctite 243

(2) Apply Copaslip to secure

200335 |

2-5 |

TECHNICAL DATA |

2 |

|

|

XF engine |

95XF series |

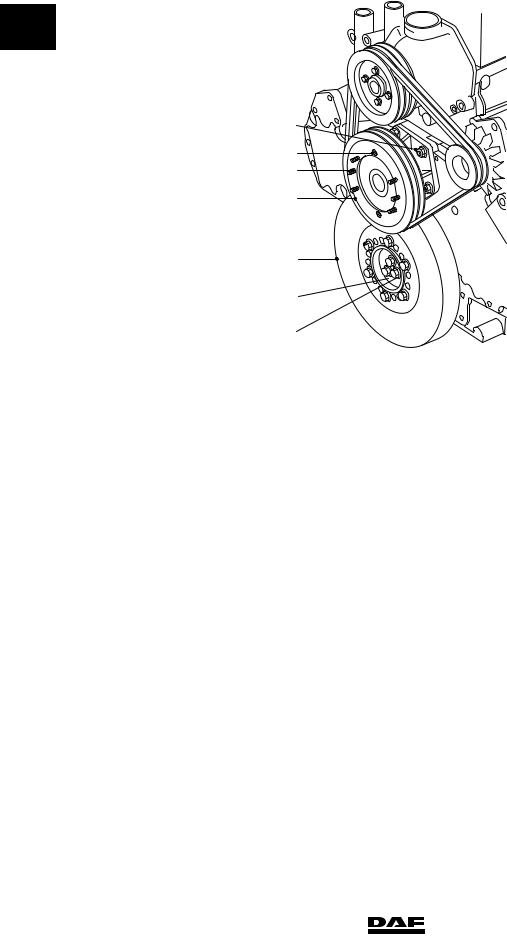

Vibration damper and fan drive |

|

0

8

9

7

6

5

4

3

2

1

|

|

M200945 |

Vibration damper hub attachment bolts (1) in 4 |

|

|

phases: |

|

|

1st phase, all attachment bolts |

100 Nm(1) |

|

2nd phase, all attachment bolts |

100 Nm(1) |

|

3rd phase, all attachment bolts |

100 Nm(1) |

|

4th phase, all attachment bolts |

100 Nm(1) |

|

Attachment bolts, vibration damper (5) |

110 Nm |

|

Attachment nuts, fan drive (8) |

60 |

Nm |

Attachment bolts, fan pulley (9) |

30 |

Nm(2) |

Attachment nuts, fan clutch (7) |

25 |

Nm(2) |

(1) Tighten the attachment bolts evenly

(2) Secure with Loctite 243

2-6 |

200335 |

2

95XF series

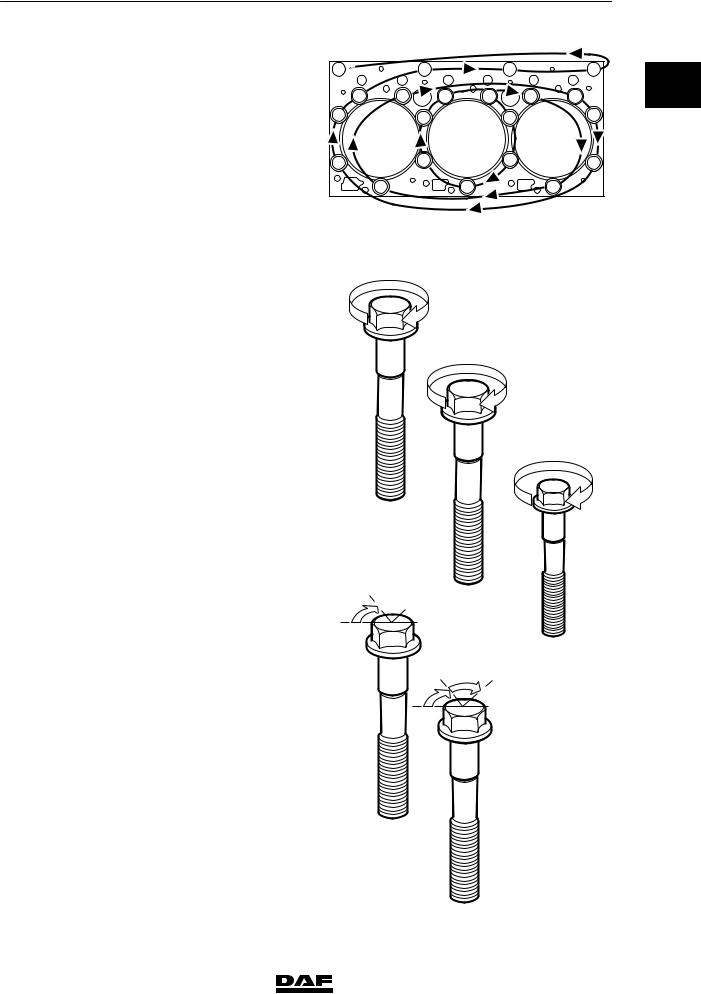

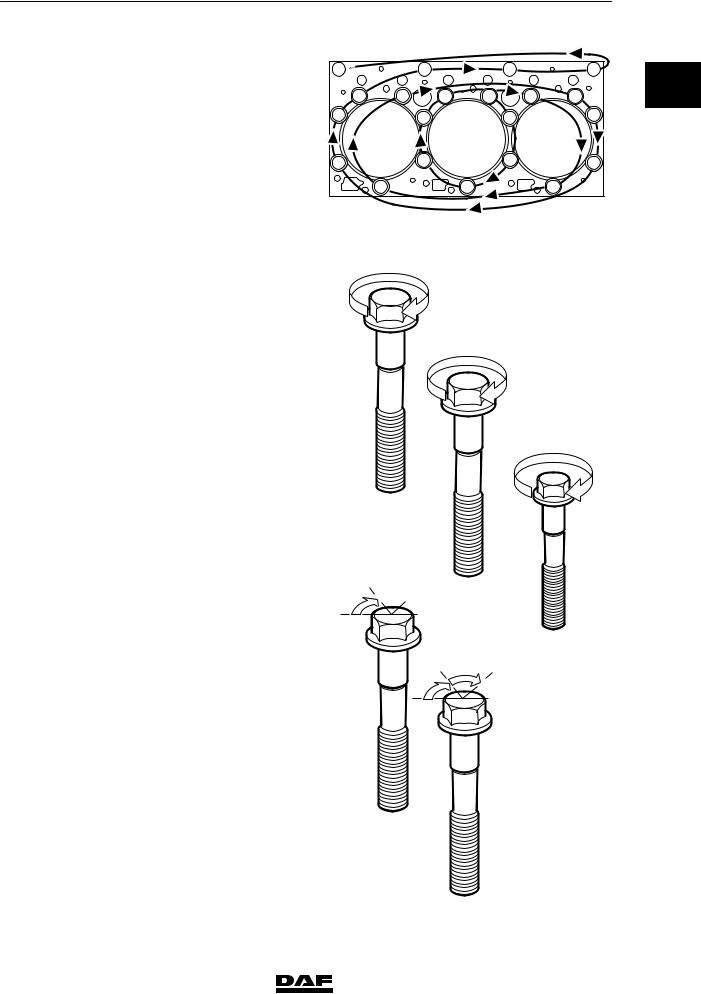

Cylinder head attachment bolts

Cylinder head bolts must only be used once . So the cylinder head bolts should always be replaced. The new cylinder head bolts have a red/brown sealant on the thread.

Note:

-Because of the sealant used on the cylinder head bolts, their untightening torque may be very high!

-All M16 and M12 threaded holes must be carefully cleaned with a screw tap before the bolts are fitted.

-Once the bolts have been tightened to the specified torque, the angular displacement of the M16 bolts must immediately be started.

-The sealant cannot be applied later.

Tightening cylinder head attachment bolts

Note:

Apply a drop of oil underneath the bolt heads (on their abutting surface). Sealant also reduces the frictional resistance, which means that no oil must be applied to the thread.

1st phase |

|

Tighten M16 in the order |

50 Nm(1) |

indicated |

|

2nd phase |

|

Tighten M16 in the order |

|

indicated |

150 Nm |

Tighten M12 in the order |

94 Nm(1) |

indicated |

|

3rd phase |

|

M16 in the order |

|

indicated |

|

in two steps of |

60_ angular |

|

displacement |

(1)Apply a drop of oil to bolts M16 and M12 on the abutting surface of the bolt heads.

|

|

|

TECHNICAL DATA |

|

|||

|

|

|

|

|

XF engine |

|

|

21 |

|

18 |

|

19 |

20 |

0 |

|

17 |

11 |

7 |

1 |

8 |

12 |

||

|

|||||||

16 |

|

6 |

|

2 |

13 |

|

|

15 |

|

5 |

|

3 |

14 |

|

|

|

10 |

|

4 |

|

9 |

|

|

|

|

|

|

|

M200562 |

|

|

50 Nm

M16 |

150 Nm |

|

I

M16 |

94 Nm |

II

M12

II

60

M16 |

60 |

|

III

M16

III

M200563

200335 |

2-7 |

|

|

TECHNICAL DATA |

|

|

2 |

|

|

|

|

|

|

|

|

XF engine |

|

|

95XF series |

|

|

Timing gear |

|

|

|

|

|

Camshaft locking plate attachment bolts |

30 |

Nm(1) |

|

0 |

|

||||

|

Attachment bolts, fuel pump drive shaft locking |

30 |

Nm(1) |

||

|

|

plate |

|||

|

|

Timing case attachment bolts |

30 |

Nm(1) |

|

|

|

Timing cover attachment bolts: |

|

|

|

|

|

M10 attachment bolts |

60 |

Nm |

|

|

|

M8 attachment bolts |

25 |

Nm |

|

|

|

Timing cover protection plate attachment bolt |

15 |

Nm |

|

|

|

Camshaft gear attachment bolt |

425 |

Nm(1) |

|

|

|

Idler gear attachment bolt |

170 |

Nm |

|

|

|

Attachment bolt, fuel pump gear wheel |

260 |

Nm(1) |

|

|

|

Attachment bolt, silencer |

30 |

Nm |

|

|

|

Steering pump gear attachment nut |

80 |

Nm(1) |

|

|

|

Steering pump intake pipe banjo bolt |

90 |

Nm |

|

|

|

Steering pump delivery pipe banjo bolt |

40 |

Nm |

|

|

|

Compressor gear attachment nut |

120 |

Nm |

|

(1)Secure with Loctite 243

2-8 |

200335 |

2 |

|

|

TECHNICAL DATA |

||

95XF series |

|

|

XF engine |

||

Flywheel housing |

|

|

|

|

|

Attachment bolts |

110 Nm(1) |

|

|

|

0 |

Sealant to be used when fitting flywheel |

Loctite 510 |

|

|

|

|

housing |

|

|

|

|

|

Flywheel |

|

|

|

|

|

Attachment bolts |

|

|

|

|

|

Without PTO |

260 Nm(1) + 90_ angular displacement |

|

|||

Without PTO spanner size 21 mm |

260 Nm + 90_ angular displacement |

|

|

||

With PTO |

260 Nm + 150_ angular displacement |

|

|||

Engine mountings on timing gear end |

|

|

|

|

|

Cylinder block bracket attachment bolts |

92 Nm |

|

|

|

|

Chassis engine bracket attachment bolts |

73 Nm |

|

|

|

|

Vibration damper engine bracket attachment |

|

|

|

|

|

bolts |

225 Nm + 60_ angular displacement |

|

|

||

Engine mountings on flywheel end |

|

|

|

|

|

Flywheel housing engine bracket attachment |

|

|

|

|

|

bolts |

260 Nm |

|

|

|

|

Chassis engine bracket attachment bolts |

73 Nm |

|

|

|

|

Vibration damper engine bracket attachment |

|

|

|

|

|

bolts |

225 Nm + 60_ angular displacement |

|

|

||

Engine hanger brackets |

|

|

|

|

|

Attachment bolts |

110 Nm |

|

|

|

|

Valve gear |

|

|

|

|

|

Valve cover attachment bolts |

25 Nm |

|

|

|

|

Rocker setting bolt lock nut |

40 Nm |

|

|

|

|

Bridge piece setting bolt lock nut |

40 Nm |

|

|

|

|

Lubricating oil strip/rocker seat attachment |

|

|

|

|

|

bolts |

110 Nm |

|

|

|

|

DEB set screw nut |

25 Nm |

|

|

|

|

Solenoid valve |

20 Nm |

|

|

|

|

Wiring harness attachment bolt |

9 Nm |

|

|

|

|

Valve sleeve attachment bolts |

30 Nm |

|

|

|

|

Tighten the valve sleeve bolts in the |

|

|

|

|

|

sequence shown. |

7 |

|

15 |

9 |

2 |

|

3 |

11 |

13 |

|

|

|

|

|

|||

|

5 |

|

|

|

6 |

|

1 |

14 |

8 |

|

|

|

|

|

|

|

|

|

|

10 |

12 |

|

4 |

|

|

|

|

|

M200942 |

(1)Secure with Loctite 243

200335 |

2-9 |

TECHNICAL DATA |

2 |

|

|

XF engine |

95XF series |

0

2-10 |

200335 |

2 |

|

TECHNICAL DATA |

||

|

|

|

||

95XF series |

XF engine cooling system |

|||

3. XF ENGINE COOLING SYSTEM |

|

|

|

|

3.1 |

GENERAL |

|

|

|

|

|

0 |

||

|

|

|

|

|

Thermostat |

|

|

|

|

|

|

|

||

Thermostat opening temperatures: |

|

|

|

|

- |

thermostat opens at |

83_C |

||

- thermostat opened at least 12 mm at |

95_C |

|||

Thermostat seat |

Loctite 638 |

|||

Water pump |

|

|

|

|

Maximum radial play |

0.16 - 0.20 mm |

|||

Expansion tank pressure cap |

|

|

|

|

Pressure relief valve opening pressure |

0.75 bar |

|||

Underpressure valve opening pressure |

0.1 bar |

|||

Pressure testing the cooling system |

|

|

|

|

Test pressure |

0.5 - 0.7 bar |

|||

200335 |

3-1 |

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

|

|

XF engine cooling system |

95XF series |

|

|

|

3.2 |

TIGHTENING TORQUES |

|

|

|

|

|

|

0 |

|

The tightening torques stated in this section are |

|

|

|

|

different from the standard tightening torques |

|

|

|

|

stated in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections which |

|

|

|

|

are not stated must therefore be tightened to the |

|

|

|

|

tightening torque stated in the overview of |

|

|

|

|

standard tightening torques. |

|

|

|

|

When attachment bolts and nuts are to be |

|

|

|

|

replaced, it is important that they are of exactly |

|

|

|

|

the same length and property class as the ones |

|

|

|

|

removed unless stated otherwise. |

|

|

|

|

Water pump |

|

|

|

|

M8 attachment bolts |

30 Nm |

|

|

|

Threaded coupling |

35 Nm |

|

|

|

Coolant pipe |

|

|

|

|

Attachment bolts |

54 Nm |

|

|

|

Coolant pipe threaded coupling |

90 Nm |

|

|

|

Coolant pipe plug |

30 Nm |

|

|

|

Thermostat housing |

|

|

|

|

Attachment bolts |

30 Nm |

|

|

|

Plug |

|

35 Nm |

|

|

Radiator |

|

|

|

|

Attachment nuts |

70 Nm |

|

|

|

3.3 |

FILLING CAPACITIES |

|

|

|

Cooling system capacity |

approx. 50 litres |

|

|

|

Cooling system capacity with ZF-intarder |

approx. 60 litres |

|

3-2 |

200335 |

2 |

TECHNICAL DATA |

||

|

|

|

|

95XF series |

XF engine lubrication system |

||

4. XF ENGINE LUBRICATION SYSTEM |

|||

4.1 GENERAL |

|

|

|

|

|

0 |

|

|

|

|

|

Oil pressure |

|

|

|

|

|

|

|

Oil pressure at engine idling speed |

1 bar (warm engine) |

||

Oil pressure at full-load engine speed |

3,5 - 4.5 bar |

||

Oil filter |

|

|

|

Type |

disposable filter |

||

Quantity |

1 |

|

|

Installation in the oil circuit |

full flow |

||

Opening pressure of bypass valve at a |

|

|

|

pressure difference of |

2,5 0.3 bar |

||

Oil cooler |

|

|

|

Opening pressure of bypass valve at a |

|

|

|

pressure difference of |

2 bar |

||

Oil section test pressure |

6 bar |

||

200335 |

4-1 |

|

|

TECHNICAL DATA |

|

2 |

|

|

|

|

|

|

|

XF engine lubrication system |

|

95XF series |

|

|

4.2 TIGHTENING TORQUES |

|

|

|

|

|

|

|

0 |

|

The tightening torques stated in this section are |

|

|

|

|

different from the standard tightening torques |

|

|

|

|

stated in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections which |

|

|

|

|

are not stated must therefore be tightened to the |

|

|

|

|

tightening torque stated in the overview of |

|

|

|

|

standard tightening torques. |

|

|

|

|

When attachment bolts and nuts are to be |

|

|

|

|

replaced, it is important that they are of exactly |

|

|

|

|

the same length and property class as the ones |

|

|

|

|

removed unless stated otherwise. |

|

|

|

|

Fuel filter |

|

|

|

|

Attachment bolts, fuel filter/water pipe |

|

|

|

|

connection |

40 |

Nm |

|

|

Fuel pump filter head banjo bolt |

40 |

Nm |

|

|

Lubricating oil strip/rocker seats |

|

|

|

|

Attachment bolts |

110 Nm |

|

|

|

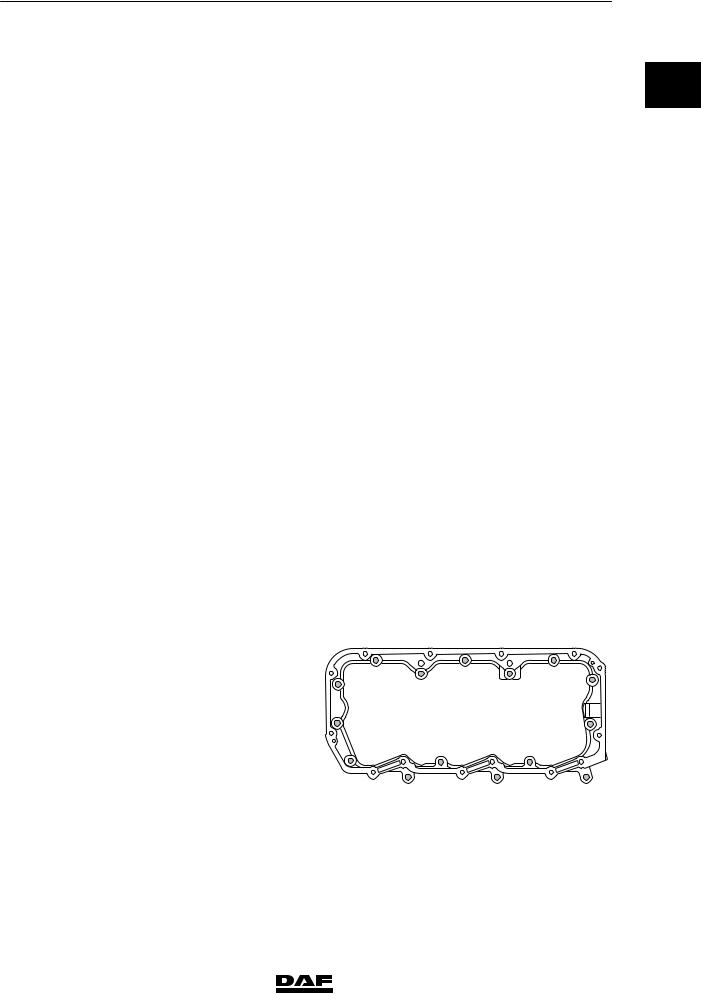

Oil sump |

|

|

|

|

Clamp attachment bolts |

25 |

Nm |

|

|

Oil drain plug |

60 |

Nm |

|

|

Oil pump |

|

|

|

|

Attachment bolts for oil pump housing sections |

30 |

Nm |

|

|

Attachment bolts connecting oil pump to main |

|

Nm(1) |

|

|

bearing cap |

60 |

|

|

|

Delivery pipe attachment bolts |

30 |

Nm(1) |

|

|

Idler gear central bolt |

60 |

Nm(1) |

|

|

Strainer |

|

|

|

|

Bracket attachment bolts |

30 |

Nm(1) |

|

|

Lubricating oil filter |

|

|

|

|

Lubricating oil filter housing attachment bolts |

50 |

Nm(2) |

|

|

Oil filter |

45 |

Nm |

|

|

Coupling in lubricating oil filter head |

60 |

Nm(3) |

|

|

Bypass pressure regulator |

|

|

|

|

Plug |

80 Nm |

|

4-2 |

200335 |

2 |

|

TECHNICAL DATA |

||

|

|

|

|

|

95XF series |

|

XF engine lubrication system |

||

Oil cooler |

|

|

|

|

Attachment bolts connecting oil cooler to |

|

|

|

|

50 Nm |

|

|

0 |

|

cylinder block |

|

|

||

Coolant supply pipe union |

90 Nm |

|

|

|

Plug, adjustable banjo connection |

90 Nm |

|

|

|

Banjo bolt, adjustable banjo connection |

90 Nm |

|

|

|

Centrifugal oil filter |

|

|

|

|

Central bolt |

20 Nm |

|

|

|

Oil discharge pipe union |

50 Nm |

|

|

|

Dip stick |

|

|

|

|

Threaded coupling |

60 Nm |

|

|

|

(1)Secure with Loctite 243

(2)Secure with Loctite 572

(3)Secure with Loctite 2701

Oil sprayer

Banjo bolt M14 for oil sprayer with locking plate

M10 banjo bolt for oil sprayer

Main bearing caps

Main bearing cap attachment bolts

Big-end bearing caps

Attachment bolts, big-end bearing caps

1st phase, |

35 Nm |

sequence 1-2-3-4 |

|

2nd phase, |

45 Nm |

sequence 4-3-2-1 |

|

3rd phase, |

60_ angular |

sequence 1-2-3-4 |

displacement(2) |

30 Nm

30 Nm

150 Nm + 120_ angular displacement(1)

1 |

4 |

3 |

2 |

|

M200661 |

(1)Apply a drop of oil to thread and contact surface.

(2)Connecting rod bolts are to be used once and tightened as instructed.

When fitting the connecting rod in the engine, apply a drop of oil to the threads and contact surfaces of the connecting rod bolts.

200335 |

4-3 |

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

XF engine lubrication system |

95XF series |

|

|

4.3 FILLING CAPACITIES |

|

|

|

|

|

0 |

|

Lubrication system |

|

|

|

Total capacity, including oil cooler and oil filter |

approx. 32 litres |

|

|

||

|

|

Oil sump capacity, maximum level |

approx. 25 litres |

|

|

Oil sump capacity, minimum level |

approx. 17 litres |

4-4 |

200335 |

2 |

|

|

TECHNICAL DATA |

|||

|

|

|

|

|

|

|

95XF series |

|

|

XE engine |

|||

5. XE ENGINE |

|

|

|

|

|

|

5.1 GENERAL |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

Types |

XE 280 C |

|

|

|

|

|

|

|

|

|

|||

|

XE 315 C/C2 |

|

|

|

|

|

|

XE 355 C |

|

|

|

|

|

|

XE 390 C |

|

|

|

|

|

Version |

Euro 3 (C), (C2 = 4 öko), water-cooled, |

|||||

|

four-stroke diesel engine with direct fuel |

|||||

|

injection, 4-valves per cylinder and |

|||||

|

turbo-intercooling. |

|||||

Number of cylinders |

6 |

|

|

|

|

|

Bore x stroke |

130 x 158 mm |

|

|

|

|

|

Swept volume |

12.58 l |

|

|

|

|

|

Compression ratio |

16.0 : 1 |

|

|

|

|

|

Firing order |

1-5-3-6-2-4 |

|

|

|

|

|

Weight |

approx. 1,080 kg |

|

|

|

|

|

|

|

|

|

|

|

|

ENGINE TYPE |

P (kW) at rpm |

|

M (Nm) at rpm |

|

||

|

|

|

|

|

||

XE 280 C |

280 at 2000 |

|

1750 at 1000 - 1500 |

|

|

|

|

|

|

|

|

||

XE 315 C/C2 |

315 at 2000 |

|

1900 at 1100 - 1500 |

|

|

|

|

|

|

|

|

||

XE 355 C |

355 at 2000 |

|

2100 at 1100 - 1500 |

|

|

|

|

|

|

|

|

||

XE 390 C |

390 at 1900 |

|

2350 at 1100 - 1500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

ENGINE TYPE |

IDLING SPEED |

|

MAX. NO LOAD SPEED |

|

||

|

|

|

|

|

||

XE 280 C |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

||

XE 315 C/C2 |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

||

XE 355 C |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

||

XE 390 C |

525 - 575 |

|

approx. 2300 |

|

|

|

|

|

|

|

|

|

|

200335 |

5-1 |

|

|

TECHNICAL DATA |

2 |

|

|||

|

|

|

|

|

|

|

|

|

|

XE engine |

|

|

|

95XF series |

|

|

|

V-BELT TENSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

Belt tension, “AVX” raw-edge1 V-belts in Newtons (N) |

|

|||

|

|

|

Multiple-V-belt |

|

Single-V-belt |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

New V-belt2 |

|

|

|

|

Setting tension |

|

1200 |

|

600 |

|

|

|

|

|

|

|

|

|

|

|

Test tension |

|

≥800 |

|

≥400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Worn V-belt3 |

|

|

|

|

Minimum tension |

|

500 |

|

250 |

|

|

|

|

|

|

|

|

|

|

|

Adjusting tension |

|

700 |

|

350 |

|

|

|

|

|

|

|

|

|

(1)Raw-edge V-belts can be recognised by the absence

of textile fabric in the rubber, with the exception of the top of the belt edge, on the edges and the insides of the belt (polished belt edges). Version: either toothed or non-toothed.

(2)After fitting the new V-belt, set the pre-tension to the “setting tension” and after a trial run check whether the

pre-tension complies with the “test tension”. If the tension reading is lower than the “test tension” specified in the table, set the V-belt to the minimum test tension.

(3) If the V-belt tension is lower than the “minimum tension”, set the belt to the “adjusting tension”.

M2121

Cylinder liner |

|

Height above cylinder block |

0.02 - 0.10 mm |

Cylinder head |

|

Minimum height after overhaul |

119.50 mm |

Test pressure using air (hot) |

1.5 bar |

Valve clearance |

|

Valve clearance (cold/hot) |

|

inlet |

0.50 mm |

exhaust |

0.50 mm |

Valve opening |

|

Valve opening at 1 mm valve clearance |

0.3 - 0.7 mm |

5-2 |

200335 |

2 |

|

TECHNICAL DATA |

||

|

|

|

|

|

95XF series |

|

XE engine |

||

Axial play |

|

|

|

|

Crankshaft axial play |

0.06 - 0.32 mm |

|

|

|

|

|

0 |

||

Camshaft axial play |

0.10 - 0.55 mm |

|

|

|

Idler gear axial play |

0.05 - 0.25 mm |

|

|

|

Gear backlash |

|

|

|

|

Idler gear - crankshaft gear |

0.02 - 0.21 mm |

|

|

|

Idler gear pump housing camshaft gear |

0.02 - 0.22 mm |

|

|

|

Idler gear - camshaft gear |

0.02 - 0.21 mm |

|

|

|

Camshaft gear - compressor gear |

0.02 - 0.22 mm |

|

|

|

Pump housing camshaft gear - steering pump |

|

|

|

|

gear |

0.02 - 0.19 mm |

|

|

|

Oil pump idler gear - oil pump gear |

0.02 - 0.20 mm |

|

|

|

Crankshaft gear - oil pump idler gear |

0.02 - 0.20 mm |

|

|

|

Number of teeth, timing gears |

|

|

|

|

Crankshaft gear |

35 |

|

|

|

Idler gear |

54 |

|

|

|

Pump housing camshaft gear |

70 |

|

|

|

Camshaft gear |

70 |

|

|

|

Air compressor gear |

27 |

|

|

|

Fan drive housing gear |

29 |

|

|

|

Steering pump gear |

18 |

|

|

|

Lubricating oil pump idler gear |

34 |

|

|

|

Fan drive |

|

|

|

|

Heat gear wheel for max. 30 min. |

245_C |

|

|

|

Compression pressure |

|

|

|

|

Differences in compression pressure |

max. 15% |

|

|

|

Flywheel/starter ring gear |

|

|

|

|

Axial variation, measured at a radial distance |

|

|

|

|

of 210 mm |

0.10 mm |

|

|

|

Starter ring gear warm up |

max. 185_C |

|

|

|

200335 |

5-3 |

|

|

TECHNICAL DATA |

|

2 |

|

|

|

|

|

|

|

XE engine |

|

95XF series |

|

|

5.2 TIGHTENING TORQUES |

|

|

|

|

|

|

|

0 |

|

The tightening torques stated in this section are |

|

|

|

|

different from the standard tightening torques |

|

|

|

|

stated in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections which |

|

|

|

|

are not stated must therefore be tightened to the |

|

|

|

|

tightening torque stated in the overview of |

|

|

|

|

standard tightening torques. |

|

|

|

|

When attachment bolts and nuts are to be |

|

|

|

|

replaced, it is important that they are of exactly |

|

|

|

|

the same length and property class as the ones |

|

|

|

|

removed unless stated otherwise. |

|

|

|

|

Starter motor |

|

|

|

|

Attachment nuts |

73 |

Nm(1) |

|

|

Alternator |

|

|

|

|

Alternator bracket attachment bolts |

55 |

Nm |

|

|

Alternator attachment bolts |

50 |

Nm |

|

|

Pulley attachment nut, version 55A |

70 |

Nm |

|

|

Pulley attachment nut, version 95A |

70 |

Nm |

|

|

Air compressor |

|

|

|

|

M12 attachment bolts |

110 Nm |

|

|

|

M8 attachment bolts for bracket |

30 |

Nm |

|

|

M10 attachment bolts for bracket |

60 |

Nm |

|

|

Compressor gear flanged nut |

120 Nm |

|

|

|

M14 cylinder head threaded coupling |

40 |

Nm |

|

|

M26 cylinder head threaded coupling |

90 |

Nm |

|

|

Delivery pipe reducer valve |

75 |

Nm |

|

|

Suction and pressure line unions |

90 |

Nm |

|

|

Air-conditioning compressor |

|

|

|

|

M12 attachment bolts for compressor bracket |

110 Nm |

|

|

|

M10 attachment bolts for compressor |

60 |

Nm(1) |

|

|

Exhaust manifold |

|

|

|

|

Fit gasket with steel side towards manifold |

|

|

|

|

Sleeved attachment bolts |

65 |

Nm |

|

|

Heat shield attachment bolts |

30 Nm(1) |

|

5-4 |

200335 |

2 |

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

95XF series |

|

|

XE engine |

||

Inlet manifold |

|

|

|

|

|

Attachment bolts |

60 |

Nm |

|

|

|

|

|

0 |

|||

Glow plug attachment nut |

55 |

Nm |

|

|

|

Air inlet hose clamps |

12 |

Nm |

|

|

|

Turbocharger |

|

|

|

|

|

Heat shield attachment bolts |

30 |

Nm(1) |

|

|

|

Turbine housing clamp plate attachment nut |

15 |

Nm |

|

|

|

Attachment nuts |

|

|

|

|

|

Exhaust manifold flange/turbocharger |

60 |

Nm(2) |

|

|

|

Elbow on turbocharger |

40 |

Nm |

|

|

|

Oil supply pipe banjo bolt |

90 |

Nm |

|

|

|

(1) Apply Loctite 243 to secure

(2) Apply Copaslip to secure

200335 |

5-5 |

TECHNICAL DATA |

2 |

|

|

XE engine |

95XF series |

Vibration damper and fan drive |

|

0

8

9

7

6

5

4

3

2

1

|

|

M200945 |

Vibration damper hub attachment bolts (1) in 4 |

|

|

phases: |

|

|

1st phase, all attachment bolts |

100 Nm(1) |

|

2nd phase, all attachment bolts |

100 Nm(1) |

|

3rd phase, all attachment bolts |

100 Nm(1) |

|

4th phase, all attachment bolts |

100 Nm(1) |

|

Attachment bolts, vibration damper (5) |

110 Nm |

|

Attachment nuts, fan drive (8) |

60 |

Nm |

Attachment bolts, fan pulley (9) |

30 |

Nm(2) |

Attachment nuts, fan clutch (7) |

25 |

Nm(2) |

(1) Tighten the attachment bolts evenly

(2) Secure with Loctite 243

5-6 |

200335 |

2

95XF series

Cylinder head attachment bolts

Cylinder head bolts must only be used once. So the cylinder head bolts should always be replaced. The new cylinder head bolts have a red/brown sealant on the thread.

Note:

-Because of the sealant used on the cylinder head bolts, their untightening torque may be very high!

-All M16 and M12 threaded holes must be carefully cleaned with a screw tap before the bolts are fitted.

-Once the bolts have been tightened to the specified torque, the angular displacement of the M16 bolts must immediately be started.

-The sealant cannot be applied later.

Tightening cylinder head attachment bolts

Note:

Apply a drop of oil underneath the bolt heads (on their abutting surface). Sealant also reduces the frictional resistance, which means that no oil must be applied to the thread.

1st phase |

|

Tighten M16 in the |

50 Nm(1) |

order indicated |

|

2nd phase |

|

Tighten M16 in the |

|

order indicated |

150 Nm |

Tighten M12 in the |

94 Nm(1) |

order indicated |

|

3rd phase |

|

M16 in the order |

|

indicated in two stages of |

60_ angular |

|

displacement |

(1)Apply a drop of oil to bolts M16 and M12 on the abutting surface of the bolt heads.

|

|

|

TECHNICAL DATA |

|

|||

|

|

|

|

|

XE engine |

|

|

21 |

|

18 |

|

19 |

20 |

0 |

|

17 |

11 |

7 |

1 |

8 |

12 |

||

|

|||||||

16 |

|

6 |

|

2 |

13 |

|

|

15 |

|

5 |

|

3 |

14 |

|

|

|

10 |

|

4 |

|

9 |

|

|

|

|

|

|

|

M200562 |

|

|

50 Nm

M16 |

150 Nm |

|

I

M16 |

94 Nm |

II

M12

II

60

M16 |

60 |

|

III

M16

III

M200563

200335 |

5-7 |

|

|

TECHNICAL DATA |

|

|

2 |

|

|

|

|

|

|

|

|

XE engine |

|

|

95XF series |

|

|

Timing gear |

|

|

|

|

|

Camshaft locking plate attachment bolts |

30 |

Nm(1) |

|

0 |

|

||||

|

Pump housing camshaft locking plate |

30 |

Nm(1) |

||

|

|

attachment bolts |

|||

|

|

Timing case attachment bolts |

25 |

Nm |

|

|

|

Timing cover attachment bolts: |

|

|

|

|

|

M10 attachment bolts |

60 |

Nm |

|

|

|

M8 attachment bolts |

25 |

Nm |

|

|

|

Timing cover protection plate attachment bolt |

15 |

Nm |

|

|

|

Camshaft gear attachment bolt |

425 |

Nm(1) |

|

|

|

Idler gear attachment bolt |

170 |

Nm |

|

|

|

Pump housing camshaft gear attachment bolt |

260 |

Nm(1) |

|

|

|

Compressor gear attachment nut |

120 |

Nm |

|

|

|

Steering pump gear attachment nut |

80 |

Nm(1) |

|

|

|

Suction pipe banjo bolt |

90 |

Nm |

|

|

|

Delivery pipe banjo bolt |

40 |

Nm |

|

(1)Apply Loctite 243 to secure

5-8 |

200335 |

Loading...

Loading...