DAF LF45, LF55 Service manual

0

8

LF45/55 series

STRUCTURE

TECHNICAL DATA

DIAGNOSTICS

SINGLE REAR AXLE 5.10

SINGLE REAR AXLE 5.12

SINGLE REAR AXLE 5.14

SINGLE REAR AXLE 8.20

SINGLE REAR AXLE 10.20

SINGLE REAR AXLE 10.26

SINGLE REAR AXLE 11.26

ᓻ 200313

1

2

3

4

5

6

7

8

https://www.truck-manuals.net/

https://www.truck-manuals.net/

0

8

LF45/55 series Contents

TECHNICAL DATA

1

CONTENTS

Page Date

1. SINGLE REAR AXLE 5.10 1-1 200313.............................................. ....

1.1 General 1-1 200313......................................................... ....

1.2 Tightening torques 1-1 200313................................................ ....

1.3 Filling capacities 1-2 200313.................................................. ....

2. SINGLE REAR AXLE 5.12 2-1 200313.............................................. ....

2.1 General 2-1 200313......................................................... ....

2.2 Tightening torques 2-1 200313................................................ ....

2.3 Filling capacities 2-2 200313.................................................. ....

3. SINGLE REAR AXLE 5.14 3-1 200313.............................................. ....

3.1 General 3-1 200313......................................................... ....

3.2 Tightening torques 3-1 200313................................................ ....

3.3 Filling capacities 3-2 200313.................................................. ....

4. SINGLE REAR AXLE 8.20 4-1 200313.............................................. ....

4.1 General 4-1 200313......................................................... ....

4.2 Tightening torques 4-1 200313................................................ ....

4.3 Filling capacities 4-2 200313.................................................. ....

5. SINGLE REAR AXLE 10.20 5-1 200313............................................. ....

5.1 General 5-1 200313......................................................... ....

5.2 Tightening torques 5-1 200313................................................ ....

5.3 Filling capacities 5-2 200313.................................................. ....

6. SINGLE REAR AXLE 10.26 6-1 200313............................................. ....

6.1 General 6-1 200313......................................................... ....

6.2 Tightening torques 6-1 200313................................................ ....

6.3 Filling capacities 6-2 200313.................................................. ....

7. SINGLE REAR AXLE 11.26 7-1 200313............................................. ....

7.1 General 7-1 200313......................................................... ....

7.2 Tightening torques 7-1 200313................................................ ....

7.3 Filling capacities 7-2 200313.................................................. ....

ᓻ 200313

https://www.truck-manuals.net/

8TECHNICAL DATA

Contents LF45/55 series

2

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 5.10

TECHNICAL DATA

1-1

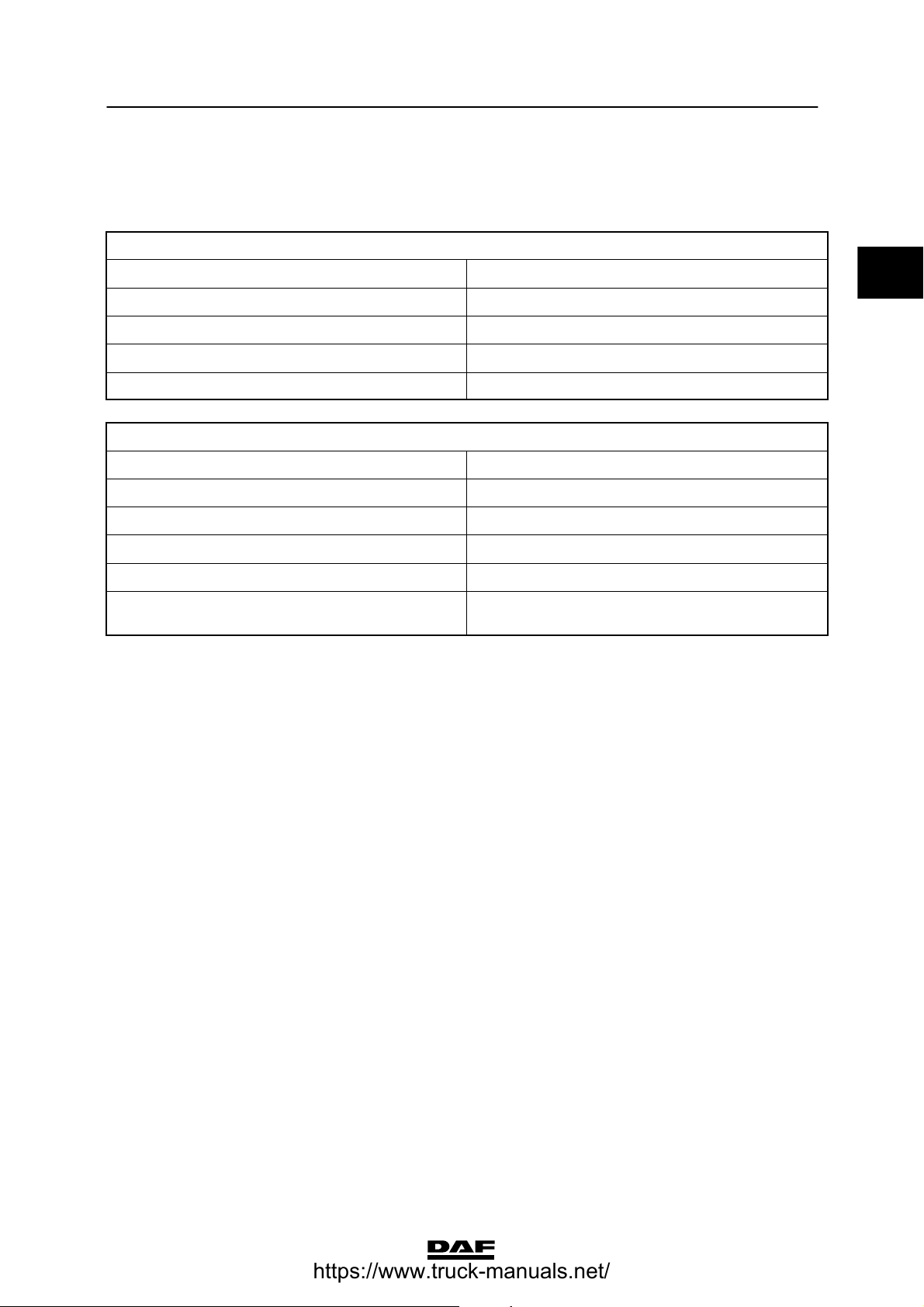

1. SINGLE REAR AXLE 5.10

1.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Pinion gear splines

Sealant Loctite 572

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

1.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 5.10 LF45/55 series

1-2

Differential

Attachment bolts/nuts 90 Nm

(1)

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Only use a new nut

1.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 5.12

TECHNICAL DATA

2-1

2. SINGLE REAR AXLE 5.12

2.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Crown wheel guide bolt

Sealant Loctite 572

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

2.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 5.12 LF45/55 series

2-2

Differential

Attachment bolts/nuts 80 Nm

(1)

Drive flange attachment nut (self-locking) 675 Nm

(2)

Lock nut for crown wheel guide bolt 120 Nm

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Bolts to be treated with Loctite 572

2. Only use a new nut

2.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 5.14

TECHNICAL DATA

3-1

3. SINGLE REAR AXLE 5.14

3.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Loctite 2701

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

3.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 5.14 LF45/55 series

3-2

Differential

Differential lock cover attachment bolts 20 Nm

(1)

Attachment bolts and nuts 90 Nm

(1)

Drive flange attachment nut (self-locking) 675 Nm

(2)

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Bolts to be treated with Loctite 572

2. Only use a new nut

3.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 8.20

TECHNICAL DATA

4-1

4. SINGLE REAR AXLE 8.20

4.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Loctite 2701

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

4.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 8.20 LF45/55 series

4-2

Differential

Drive flange attachment nut (self-locking) 675 Nm

(1)

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

(2)

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

4.3 FILLING CAPACITIES

Differential

Filling capacity approx. 8.0 litres

Hub

Filling capacity 0.25 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 10.20

TECHNICAL DATA

5-1

5. SINGLE REAR AXLE 10.20

5.1 GENERAL

Wheel hub

Before installing the wheel hub, axle journal

to be treated with Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Loctite 2701

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

5.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 10.20 LF45/55 series

5-2

Differential

Drive flange attachment nut (self-locking) 675 Nm

(1)

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

(2)

Drainplug 54Nm

Wheel hub

-1

st

phase 300 Nm

(1)

-2

nd

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-3

rd

phase 350 Nm

-4

th

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-5

th

phase 1100 Nm

Stub axle attachment bolts 260 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

5.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 10.26

TECHNICAL DATA

6-1

6. SINGLE REAR AXLE 10.26

6.1 GENERAL

Wheel hub

Before installing the wheel hub, axle journal to

be treated with

Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Loctite 2701

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

6.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 10.26 LF45/55 series

6-2

Differential

Drive flange attachment nut (self-locking) 1250 Nm

(1) / (3)

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

(2)

Drainplug 54Nm

Wheel hub

-1

st

phase 300 Nm

(1)

-2

nd

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-3

rd

phase 350 Nm

-4

th

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-5

th

phase 1100 Nm

Stub axle attachment bolts 260 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

3. Secure with Loctite 262

6.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

0

ᓻ 200313

https://www.truck-manuals.net/

0

8

LF45/55 series Single rear axle 11.26

TECHNICAL DATA

7-1

7. SINGLE REAR AXLE 11.26

7.1 GENERAL

Wheel hub unit

Before installing the wheel hub unit, axle

journal to be treated with

Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Loctite 2701

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Loctite 2701

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

7.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise.

ᓻ 200313

https://www.truck-manuals.net/

8

TECHNICAL DATA

Single rear axle 11.26 LF45/55 series

7-2

Differential

Drive flange attachment nut 1250 Nm

(1) / (3)

Differential-gear lock attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

(2)

Drainplug 54Nm

Wheel hub unit

-1

st

phase 500 Nm

(3)

-2

nd

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-3

rd

phase 550 Nm

-4

th

phase turn the hub 10 revolutions at a speed of

approx. 40 rpm

-5

th

phase 1300 Nm

Stub axle attachment bolts 260 Nm

Notes:

1. Only fit a new nut and apply Loctite 262 to

secure

2. Bolts to be treated with Loctite 572

3. Only use a new nut

7.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

0

ᓻ 200313

https://www.truck-manuals.net/

8

LF45/55 series Contents

DIAGNOSTICS

1

CONTENTS

Page Date

1. SINGLE REAR AXLE 5.10 1-1 200313.............................................. ....

1.1 Fault-finding table 1-1 200313................................................. ....

2. SINGLE REAR AXLE 5.12 2-1 200313.............................................. ....

2.1 Fault-finding table 2-1 200313................................................. ....

3. SINGLE REAR AXLE 5.14 3-1 200313.............................................. ....

3.1 Fault-finding table 3-1 200313................................................. ....

4. SINGLE REAR AXLE 8.20 4-1 200313.............................................. ....

4.1 Fault-finding table 4-1 200313................................................. ....

5. SINGLE REAR AXLE 10.20 5-1 200313............................................. ....

5.1 Fault-finding table 5-1 200313................................................. ....

6. SINGLE REAR AXLE 10.26 6-1 200313............................................. ....

6.1 Fault-finding table 6-1 200313................................................. ....

7. SINGLE REAR AXLE 11.26 7-1 200313............................................. ....

7.1 Fault-finding table 7-1 200313................................................. ....

1

ᓻ 200313

https://www.truck-manuals.net/

8DIAGNOSTICS

Contents LF45/55 series

2

1

ᓻ 200313

https://www.truck-manuals.net/

8

LF45/55 series Single rear axle 5.10

DIAGNOSTICS

1-1

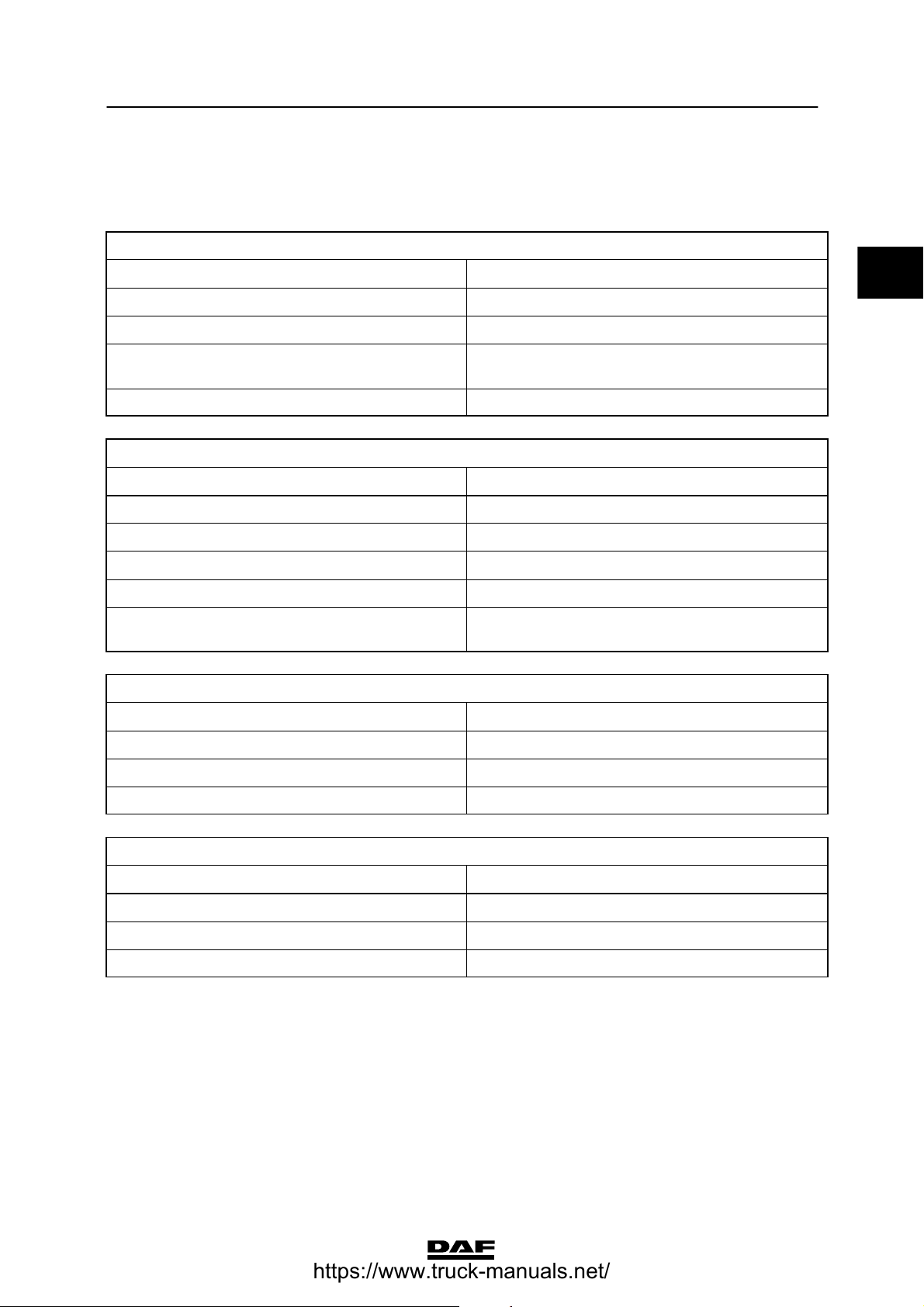

1. SINGLE REAR AXLE 5.10

1.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Attachment bolts loosened or broken off Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

ᓻ 200313

1

https://www.truck-manuals.net/

8

DIAGNOSTICS

Single rear axle 5.10 LF45/55 series

1-2

ᓻ 200313

1

https://www.truck-manuals.net/

8

LF45/55 series Single rear axle 5.12

DIAGNOSTICS

2-1

2. SINGLE REAR AXLE 5.12

2.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Attachment bolts loosened or broken off Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

ᓻ 200313

1

https://www.truck-manuals.net/

8

DIAGNOSTICS

Single rear axle 5.12 LF45/55 series

2-2

ᓻ 200313

1

https://www.truck-manuals.net/

8

LF45/55 series Single rear axle 5.14

DIAGNOSTICS

3-1

3. SINGLE REAR AXLE 5.14

3.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

1

https://www.truck-manuals.net/

8

DIAGNOSTICS

Single rear axle 5.14 LF45/55 series

3-2

ᓻ 200313

1

https://www.truck-manuals.net/

8

LF45/55 series Single rear axle 8.20

DIAGNOSTICS

4-1

4. SINGLE REAR AXLE 8.20

4.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

1

https://www.truck-manuals.net/

8

DIAGNOSTICS

Single rear axle 8.20 LF45/55 series

4-2

ᓻ 200313

1

https://www.truck-manuals.net/

8

LF45/55 series Single rear axle 10.20

DIAGNOSTICS

5-1

5. SINGLE REAR AXLE 10.20

5.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

1

https://www.truck-manuals.net/

8

DIAGNOSTICS

Single rear axle 10.20 LF45/55 series

5-2

ᓻ 200313

1

https://www.truck-manuals.net/

Loading...

Loading...