Page 1

SERVICE MANUAL

SERVICE MANUAL

SM37-0211-01E

HEAD OFFICE (FACTORY)

#58, SUNG SAN-DONG, CHANGWON, KYUNGNAM, KOREA

TEL : (82-55) 239-7000 / FAX : (82-55) 239-7524

OVERSEAS SALES OFFICE

#13-5, SUNG SOO 1DONG 1GA, SUNG DONG GU, SEOUL, KOREA

TEL : (82-2) 498-6465 / FAX : (82-2) 467-9997

Page 2

Page 3

Page 4

How to use this manual

This manual describes effective maintenance

procedure for the NS125Ⅲ manufactured by

DAELIM Motor Co., Ltd.

To ensure safety and optimal operating conditions

of the vehicle, carry out regular inspections

according to the maintenance schedule(Section 3).

Sections 1 through 3 provide information on

overall vehicle; section 4, assembly and

disassembly procedures for external components,

and section 5 describes maintenance procedure for

the engine, frame and electrical systems.

To facilitate use of this manual, each page starts

with disassembly and system diagrams, service

information, and troubleshooting guide. If you

cannot find the cause of trouble, refer to Section 20:

Troubleshooting.

●●

Contents of this manual and specifications are subject

to change without prior notice for improvement of

vehicle quality.

●●

No part of this publication may be reproduced without

written permission of DAELIM Motor Co., Ltd..

Service Information

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Lubrication

Inspections/Adjustments

External Parts

Fuel System

Engine Removal/Installation

L. Crank Case Cover / Kick Starter /

Continuously Variable Transmission

Generator/Starter Clutch

Cylinder Head/Valve

Cylinder/Piston

Transmission/Crankshaft/Crank Case

Front Wheel/Front Fork/Steering

Rear Wheel/Brake/Suspension

Brake System

Charging System/Battery

Ignition System

Starter System

Light/Switch/Horn

Wiring Diagram

Troubleshooting

Contents

Engine

General

Frame

Electrical System

Page 5

Page 6

Service Information

1-1

General Safety 1-1

Service Rules 1-1

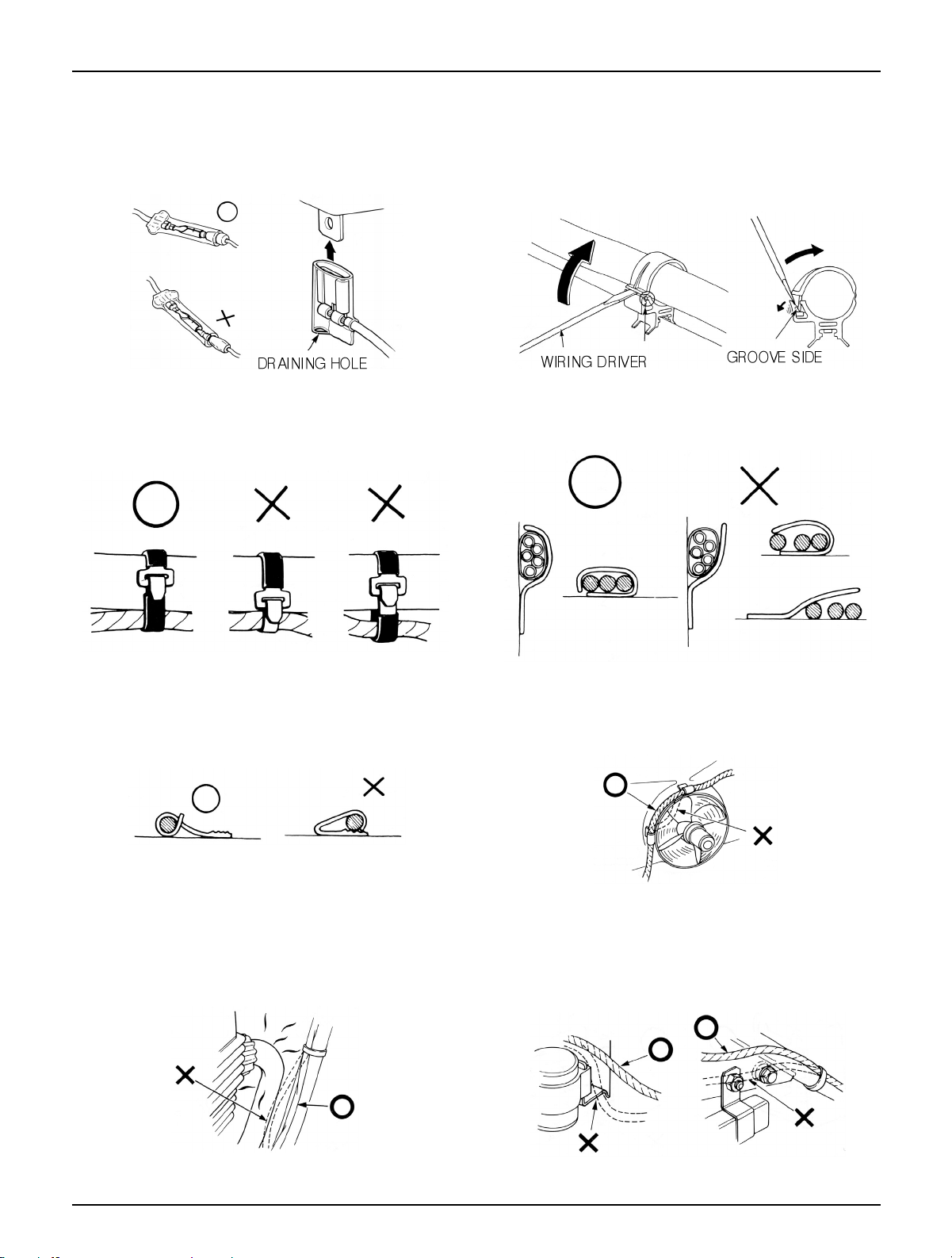

Caution when Wiring 1-5

Identification Numbers 1-9

Specifications 1-10

Torque Values 1-12

Symbols/Abbreviations 1-14

Wiring Diagram 1-15

1. Service Information

1

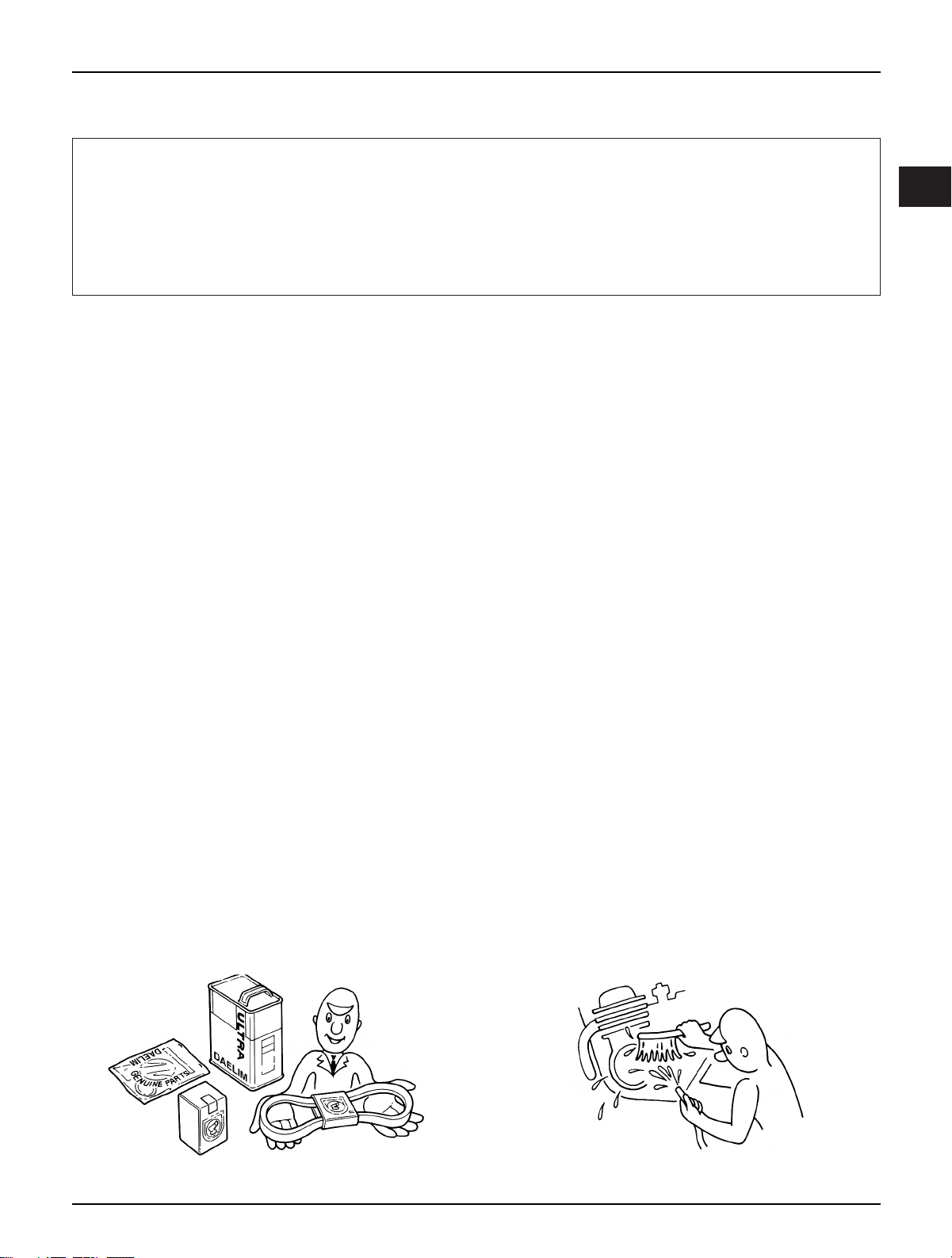

General Safety

WARNING

1. Do not run the engine for a long time in closed or not well-ventilated area because the exhaust gas contains toxic

substances such as carbon monoxide, hydrocarbon, nitric oxide.

2. The battery fluid(lean sulfuric acid) is extremely toxic. It is dangerous if skin is exposed to it or if it enters into the eye.

Be careful in handling. When exposed to the battery fluid, wash it with water and get a medical check up.(store the

battery fluid in a safe place to avoid touching by the children)

3. Pay attention not to be burned and always put on the protection gears because the engine or the muffler is hot right after

engine stops.

4. Gasoline is extremely flammable. Maintenance must performed in the place free of the open fire or electric spark.

5. When more than two person are working, always pay attention to other worker’s action and alway have safety in mind.

6. The skin exposed to used engine oil can be a major reason of the skin cancer. Pay attention not to exposed and wash

carefully with soap and water after handling.

7. If compressed air is used to clean the brake, dust scattered in the air can be breathed in by workers. Please take action not

to scatter dust in the brake cleaner, etc.

8. Flammable nitrogen gas is generated during charging the battery so charging must be performed in well-ventilated area

and free of the open fire and spark.

Service Rules

1. Parts and lubrication oil must be DAELIM genuine or

recommended parts.

2. Before maintenance, remove deposit or dust from the

chasis.

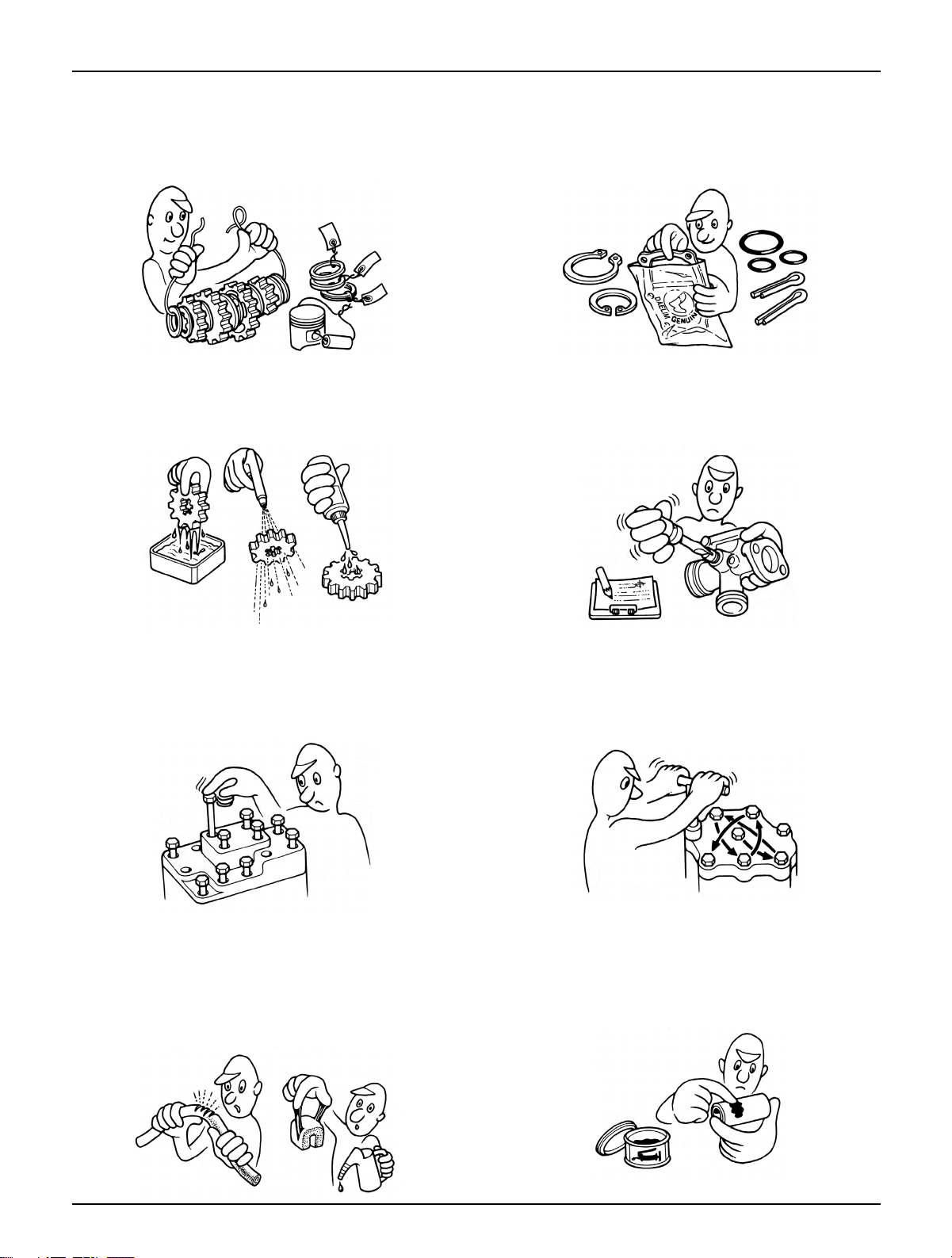

Page 7

1-2

Service Information

9. Check to see if the rubber part is worn out when

removing it and replace it if necessary. Some rubber part

is weak to gasoline and kerosene, so pay attention not to

soak with gasoline or oils.

10. Recommended grease must be applied to or filled in

the specified place.

7. Align the bolts to uniform the tightening points before

tightening them when you don’t know the bolt length.

8. Bolts, nuts and pieces must be tightened from the bigger

diameter to the smaller one, from inside to outside and

diagonally with the specified torque.

5. Clean the parts after the overhaul and before the test and

remove the cleaning oil with compressed air. Apply oil

to seal face during installation.

6. Check necessary place and measure necessary data

during installation. When installing, return to the state

before removing.

3. Store the parts of each system discriminatively to install

each part in the right place.

4. After removing gasket, O-ring, piston pin clip and cotter

pin, always replace them with the new one. When

removing the snap ring, it can be easily missed after

transformation or installation.

Page 8

1-3

Service Information

11. Maintenance needed to use the specialized tools must

performed with the right tool.

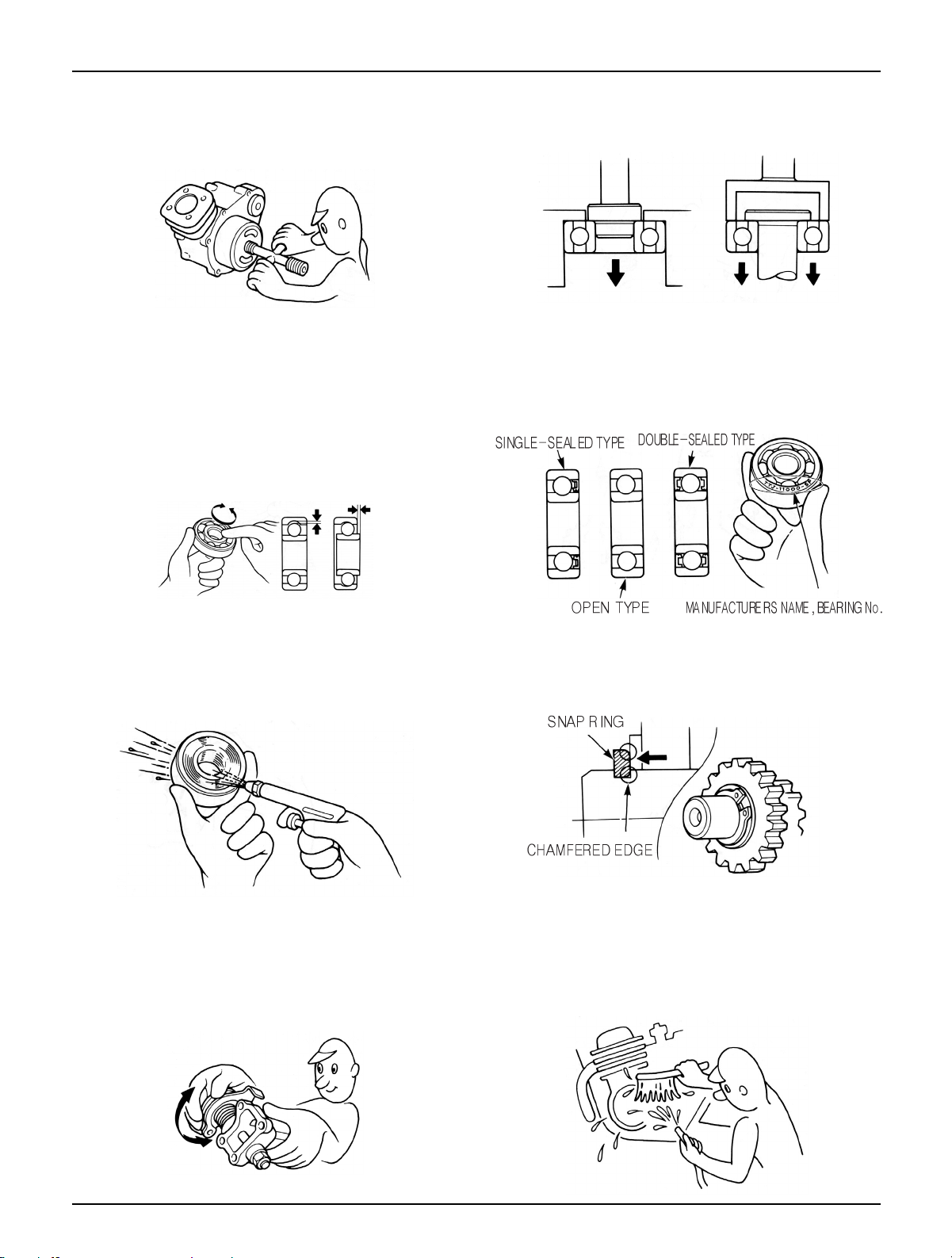

12. Never reuse the ball bearing removed with the ball

applied pressure when removing press-fitted the

bearing.

13. Check the smooth rotation of inner or outer race of the

ball bearing by rotating it manually.

Replace the ball bearing having excessive axial/

longitudinal hanging.

Wipe the ball bearing likely to have hanging with

cleaning oil.(except double-sided sealed type ball

bearing)

Replace the ball bearing of which press-fitted part is

slacked at the case or shaft.

14. Pay attention to installation direction in case of the

single-sided sealed ball bearing. Install the opendirection or double-sided sealed bearing in the way

that the face marked with manufacturer and size

should direct to the outer axle.

15. When blowing the ball bearing with compressed air

after cleaning, keep the race from rotating. High speed

rotation of the race may damage the bearing. Prior to

installation, apply oil or grease to the bearing.

16. Install the snap ring so that chamfered side directs to

the load-applied side. After installation, check the

proper installation by rotating the snap ring.

17. Check each part for proper tightening and operation

after installation.

18. The brake fluid and coolant can damage the painted

plastic or rubber parts. Keep these parts from

contacting with them and wash these parts with water

in case of contact.

’

Page 9

1-4

Service Information

21. Keep the pneumatic system interior or the engine

interior from the infiltration of dust.

22. Install the gasket mounted in the contact surface of

each case of the engine while removing gasket

material completely. Remove damaged contact surface

by wiping with the oil stone equally.

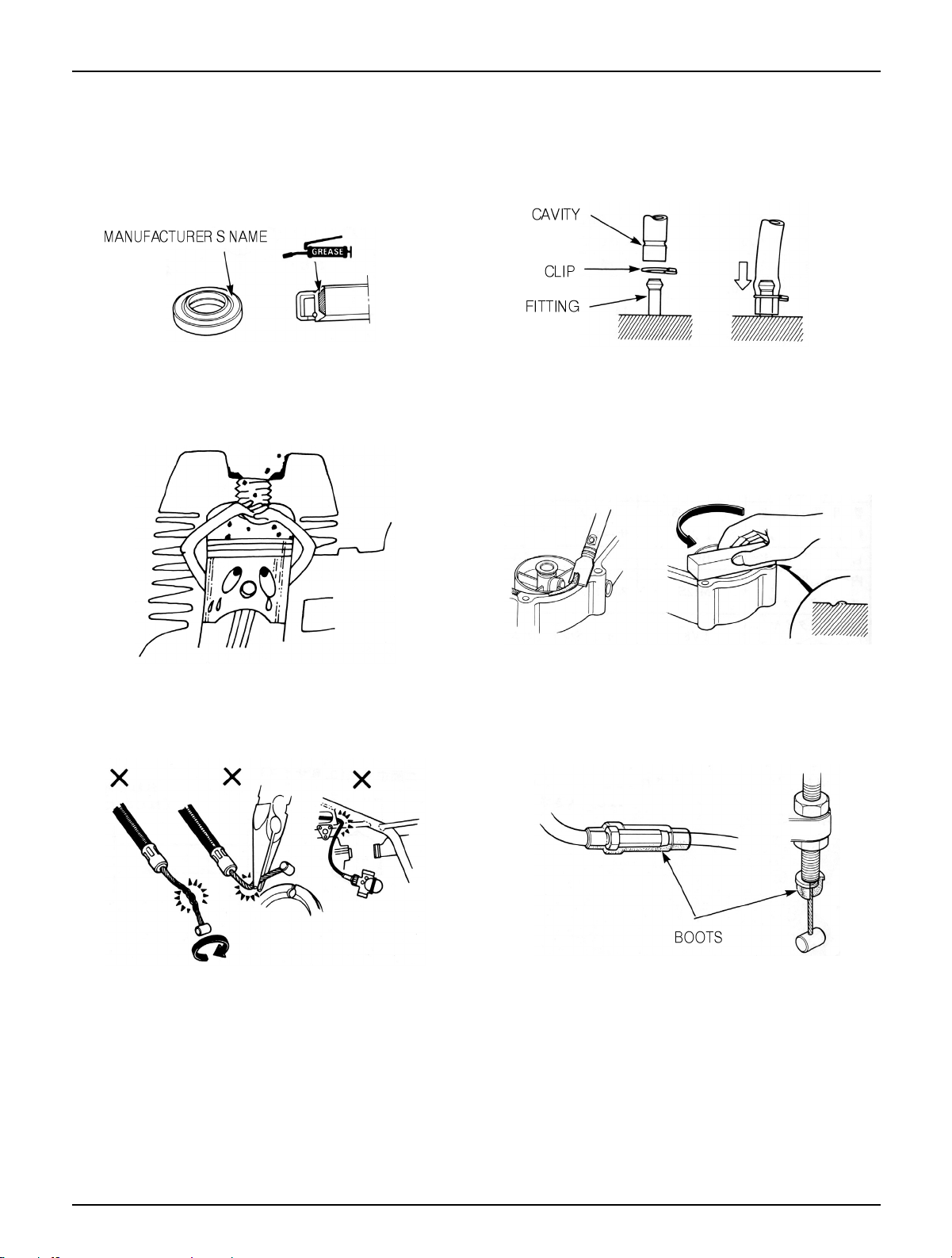

19. Install the oil seal so that the manufacturer marked

surface directs outer surface.(direction not covered

with oil)

Pay attention not to bend or damage the lip

Apply the grease to the lip

20. Connect the tube until the tube fully inserted in the

joint. Install the clip if it is supplied. Replace the tube

having slacked end.

23. Pay attention not to bend the cable excessively.

Transformed or damaged cable may cause malfunction

or damage.

24. Install the boots with the installing groove by inserting

the boots into the groove.

’

Page 10

1-5

Service Information

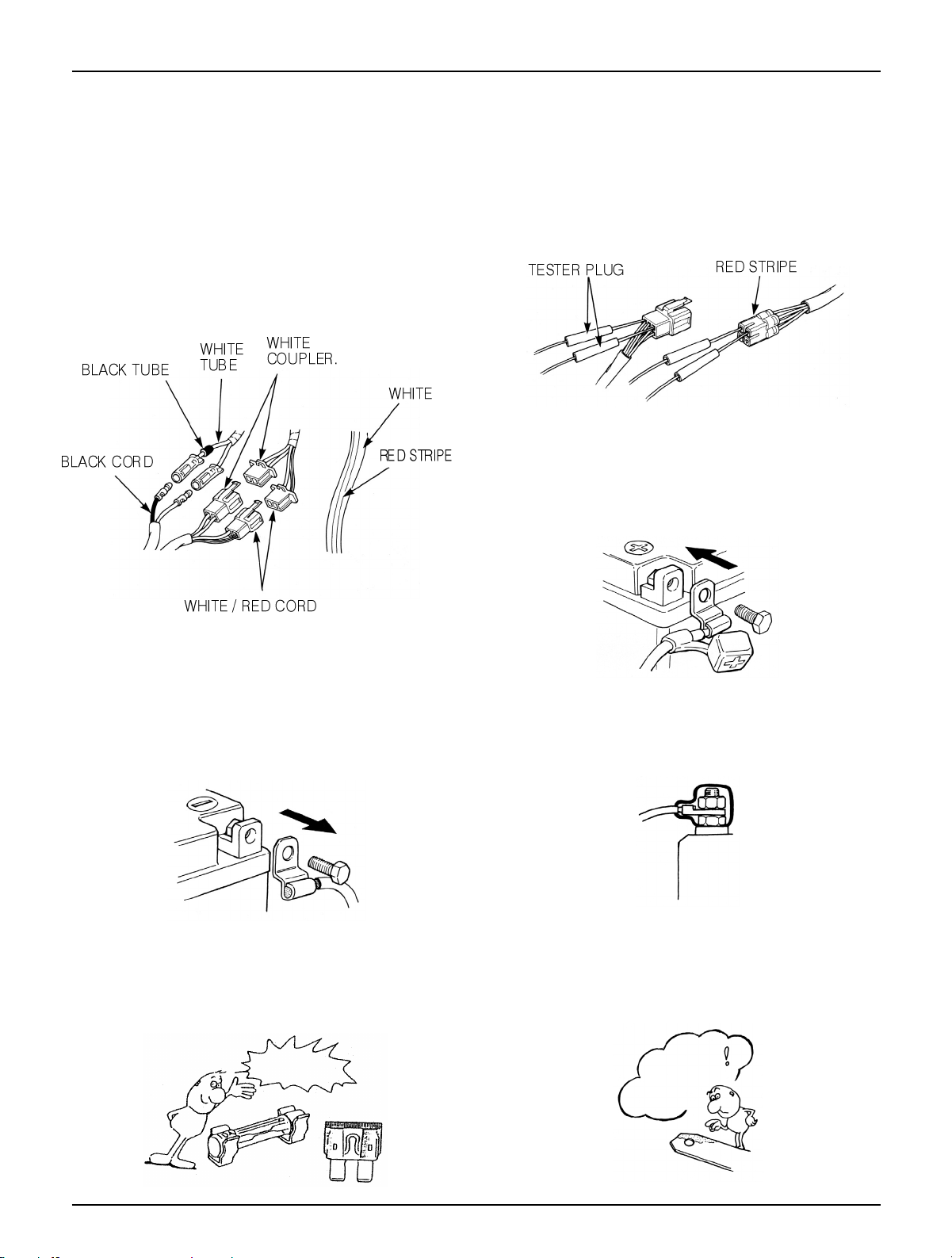

Each cord must be connected depending on its color.

When connecting different cord, attach color tube

around the connector. Connect the coupler to the

connector with same color and same pin number.

Identify the two-colored cord by main color first and

then spriped color .

When measuring voltage or resistance of the cord

terminal using tester, contact the tester plug behind of

the coupler. Pay attention not to open the cord terminal

and contact the tester plug from the front of the coupler

in case of water-proof coupler.

Recheck the condition of contact, securing and

continuity of each part after maintenance.

When connecting the battery, the plus terminal must be

connected first.

After connecting the terminal, apply the grease to the

terminal.

When disconnecting the battery, the minus terminal

must be disconnected first.

Make sure that the tool such as spanner do not contact

with the frame.

Connect covers to the terminal after maintenance.

If the fuse is short-circuited, find out the cause and

repair. Replace with the fuse having the specified

capacity.

If there is rust in the terminal, remove the rust with sand

paper prior to connecting.

Caution when Wiring

VALIDATION

OF CAPACITY!

REMOVE

THE

RUST!

Page 11

1-6

Service Information

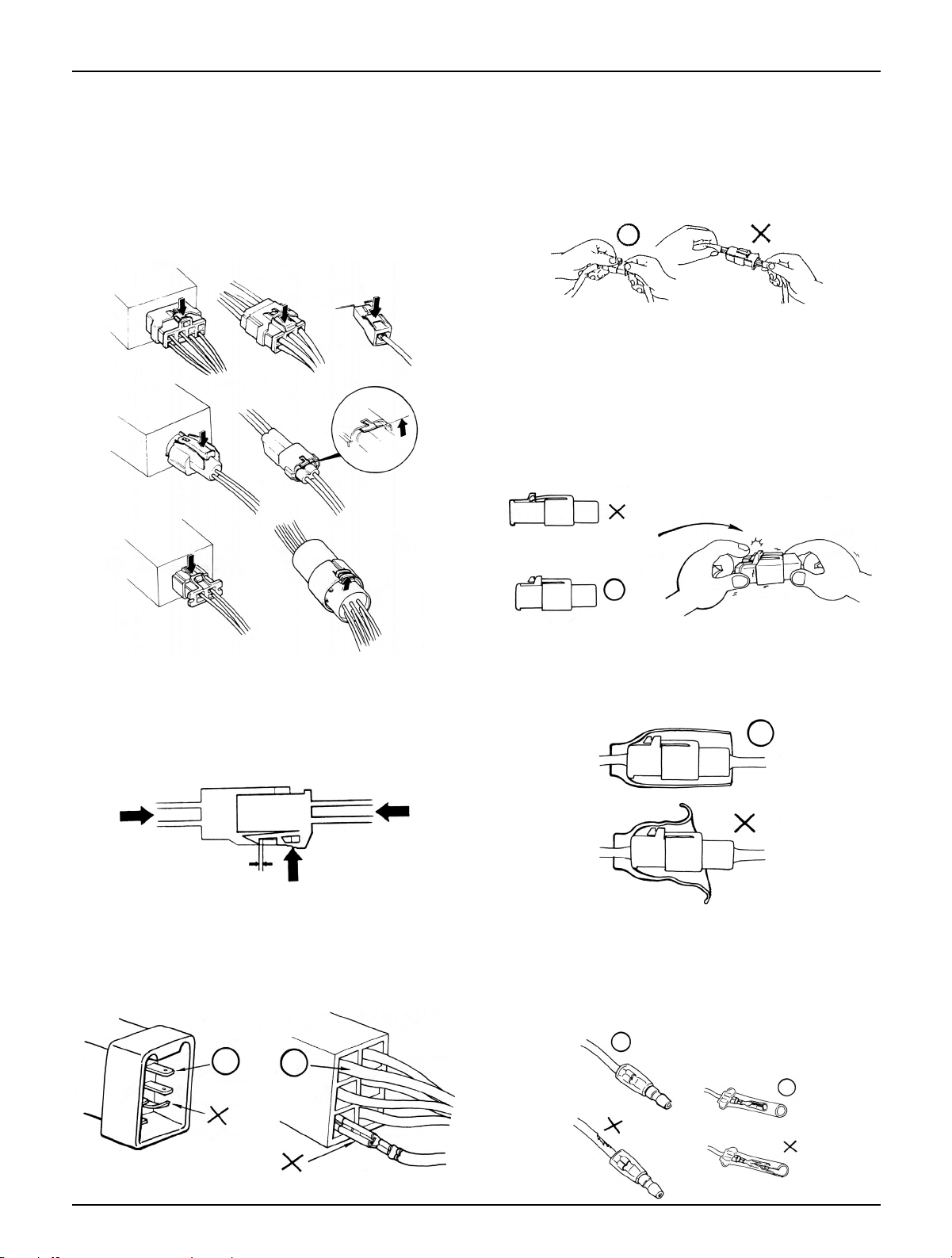

Insert the lock of the coupler until the lock is fully

secured.

Turn off the main switch before connecting/dis-

connecting.

Release the lock to disconnect the lock of the coupler.

The lock of the coupler has two types according to

releasing method(press type and pull type) so release it

properly according to the shape.

- Typical releasing method of the coupler is illustrated in

the following.

When disconnecting the coupler, disconnect it while

holding the coupler body. Pull while holding the wire

harness cord and do not remove the coupler connection.

Release the lock by inserting the coupler slightly and

then narrowing connection to remove the coupler.

Pay attention not to damage the vinyl cover of the

coupler.

Check to see if there is bended terminal and secure it to

avoid disconnecting.

If the wire harness coating is damaged, repair by

winding vinyl tape or replace it.

Prior to connecting the connector, make sure that the

cover is not damaged and the mess terminal is not

opened.

Page 12

1-7

Service Information

Wire band must be secured firmly in the specified

location of the frame. In case of aluminium band, secure

the wire harness to the coated part.

Secure the wire harness firmly using the clamp.

Insert the connector until the vinyl cover is fully inserted

into the terminal.

The opening of the vinyl cover must face at the ground

direction but in case of the plain connector, the draining

opening must face at the sky direction.

When removing T-start, broaden the groove of T-start

using the wiring driver and release the torque.

Connect the harness and the hose to T-start and then

insert until the groove is locked.

When removing T-start from the frame, replace it with

the new one.

In case of the weld clamp, do not clamp in the welded

part.

When clamping the wire harness, make sure that the

harness is not contacted with the shaft or rotating part.

When clamping the wire, pay attention not to contact

with hot part.

The wire harness must be routed without contacting

with the end of the lamp or any sharp edge.

The wire harness must be routed without contacting

with the end of the bolt or the piece.

Page 13

1-8

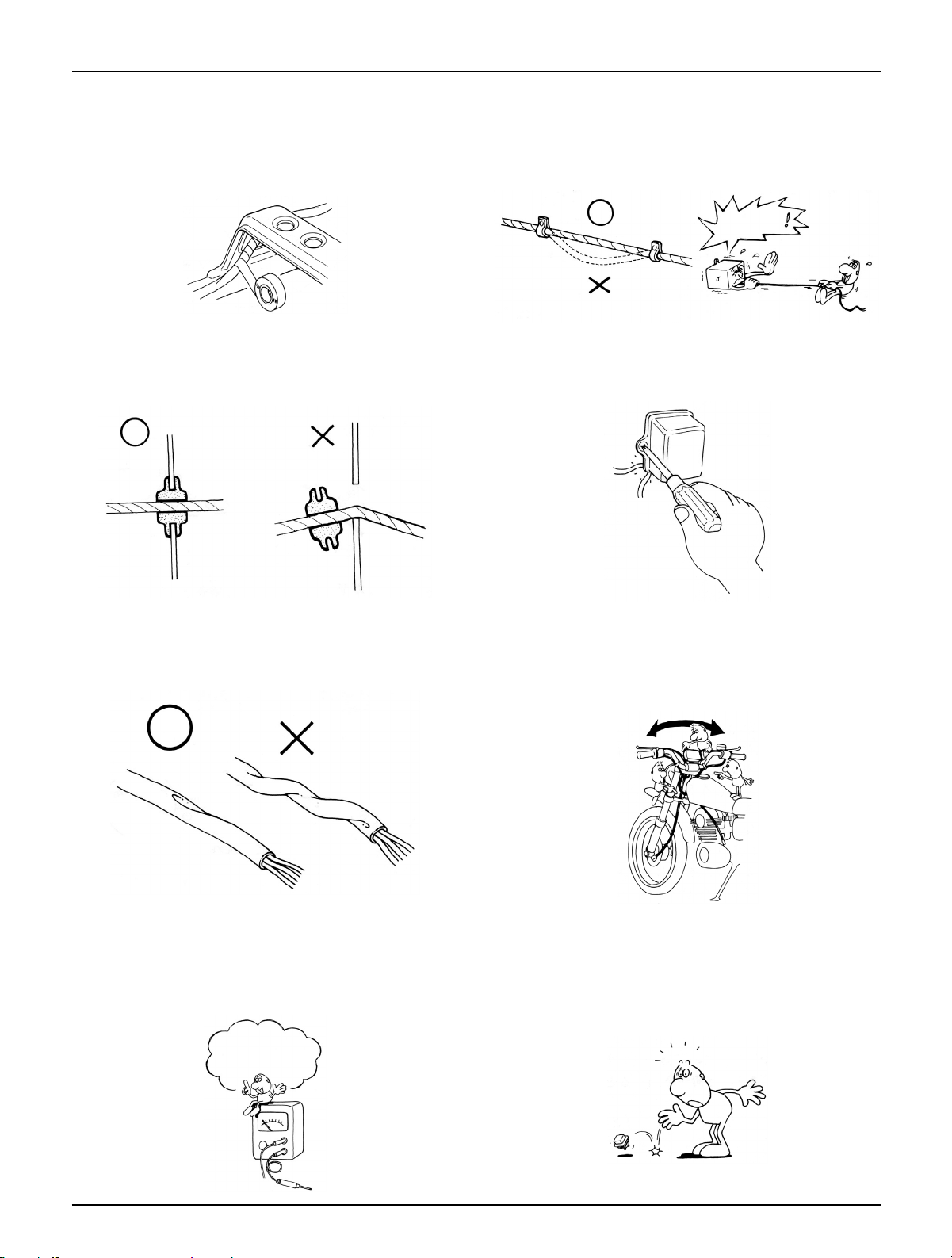

Service Information

If necessary, lock the wire harness properly. When mounting parts, make sure that the wire harness

is not pressed by the parts.

In case that the wire harness is contacted with the end or

the sharp edge, protect both parts with tube or tape.

The wire must not hang down or be pulled excessively.

Do not twist the wire harness. Wire the wire harness not to be pulled or expanded

when the handle is turned to the right or the left

completely. Avoid excessive bending or chewing and

interference with the engine.

Prior to using the tester, please read the manual care-

fully and understand the contents.

When testing the resistance of the tester, the zero

adjustment must be performed before testing.

Do not drop or throw the parts especially semiconductor

contained parts because these parts may be damaged by

the impact of the drop.

NOT TO

PULL!

Is this

measurement range or

configuration in accord

with the manual?

Page 14

Service Information

1-9

Identification Numbers

Frame serial number

Engine serial number

FARME SERIAL NUMBER LOCATION

The frame serial number is stamped on the front

central part of the frame.

ENGINE SERIAL NUMBER LOCATION

The engine serial number is stamped on the central

part of the left crankcase.

Page 15

Service Information

1-10

Item Specifications

Overall length 1,970mm

Overall width 700mm

Overall height 1,110mm

Dimensions Wheel base 1,350mm

Seat height 765mm

Ground clearance 130mm

Dry weight 110kg

Curb weight 240kg

Type Underbone

Front suspension/stroke Telescopic/97mm

Rear suspension/stroke Swing arm/74mm

Front tire size/type 120/70-13/Tubeless

Rear tire size/type 130/60-13/Tubeless

Tire Pressure 1 person Front 1.75kg/㎠(175kPa)

Rear 2.00kg/㎠(200kPa)

Frame 2 person Front 2.25kg/㎠ (225kPa)

Rear 2.25kg/㎠ (225kPa)

Front brake Hydraulic disk

Rear brake Drum brake

Fuel tank capacity Full capacity 7.5ℓ

Reserve capacity 1.2ℓ

Caster angle 25

○

Trail 84.7㎜

Front fork oil capacity 80㎤

Type Oil cooled/air cooled 4 cycle SOHC engine

Cylinders/Arrangement 1(Single cylinder), front angle 80

○

Bore and stroke 56 ×50.7 mm

Displacement 124.9㎤

Compression ratio 10.8 : 1

Valve train SOHC chain drive

Oil capacity 1.1ℓ After disassembly

0.75ℓ After Oil filter change

Engine 0.8ℓ After Oil change

0.9ℓ

After Oil change with Oil in the Oil hose removed

Lubrication system Forced pressure splash type

Air cleaner type Wet sump

Cylinder compression 13.8kg/㎠

Intake valve: Open 5

○

BTDC

Closed 14

○

ABDC

Exhaust valve: Closed 18

○

BBDC

Closed 1

○

ATDC

Valve clearance(cooling-off period)

intake 0.12 ± 0.02 ㎜

Exhaust 0.12 ± 0.02 ㎜

Specifications

Page 16

Service Information

1-11

Item Specifications

Type/Venturi bore CV type(vacuum)24.2mm

Model mark BDS 26 -112

Choke type Autoby-starter

Carburetor Main jet #95

Pilot screw initial setting 1 and 1/2 trust out

Float level 13 mm

Idle speed 1,800±100(rpm)

Clutch type Automatic Transmission

Drive Train Primary reduction 3.231(42/14)

Secondary reduction 2.786(39/14)

Ignition system C.D.I. lgnition

Ignition timing F mark 15

○

BTDC/1,800(rpm)

Full advance 19

○

AC generator capacity 125W/5,000(rpm)

Battery type/capacity Closed type (MF)12V 8AH

Spark plug CR8EH-9

Spark plug gap 0.8-0.9mm(0.031-0.035in)

Electrical Fuse capacity 15A

Systems starting system Kick/starter motor

Headlight(high/low) 12V 35/35W

Position light 12V 3.4W

Turn signal light(Fr/Rr) 12V 10W×4

Tail/stop light 12V 21 / 5W

High-beam indicator 12V 3.4W

Turn signal indicator 12V 3.4W×2

Speedometer lamp 1.7W×2

Trunk lamp 1.4W×1

Page 17

Service Information

1-12

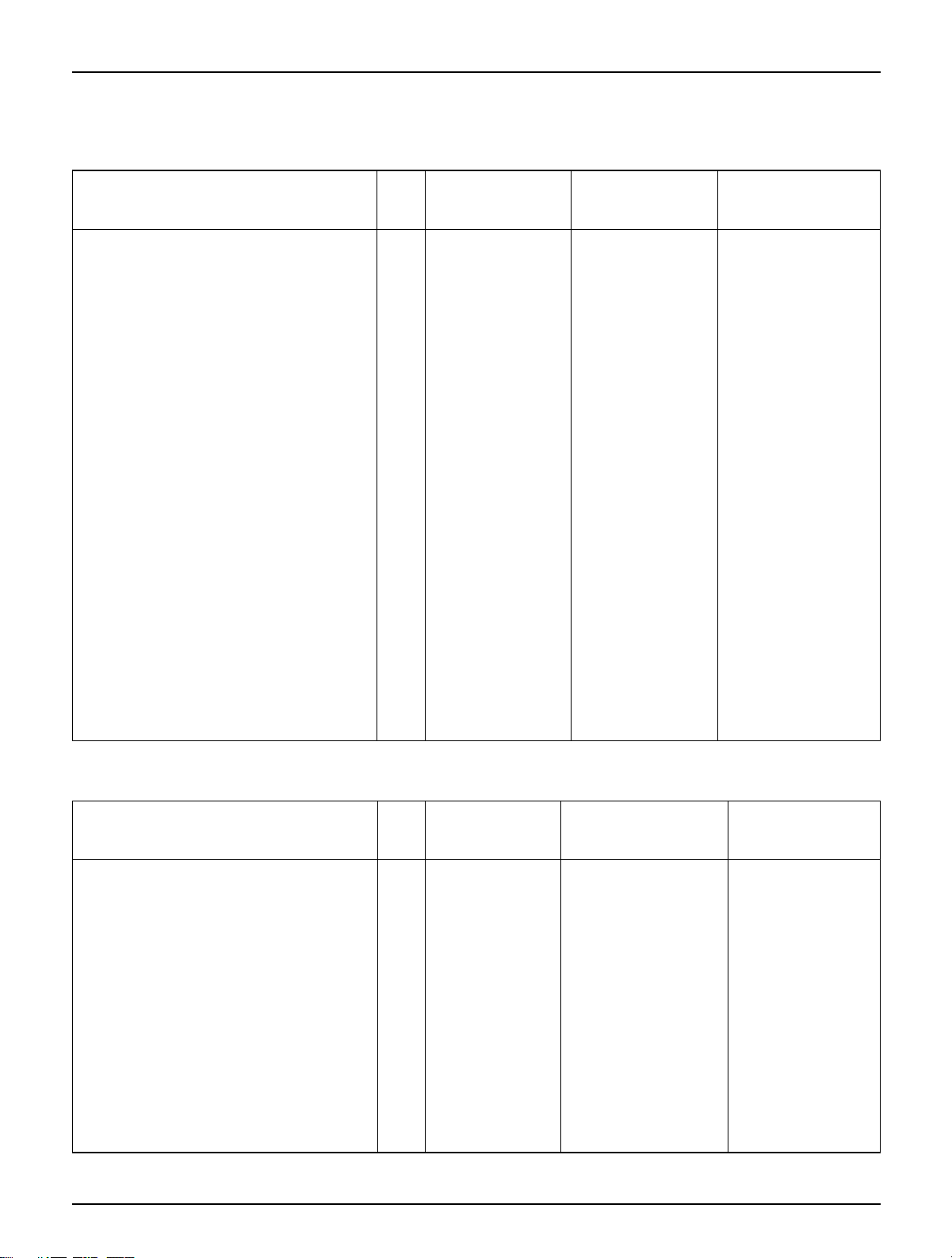

Item Q’ty Thread dia(mm)

Torque value

Remarks

kg.m(N.m,ft-lb)

Oil filter cap 1 20 1.5(15, 11)

Valve adjust screw lock nut 4 5 1.1(11, 8)

Kick starter pedal bolt 1 6 1.2(12, 8)

Flywheel bolt 1 12 5.5(55, 40) Apply engine oil

Drive face bolt 1 12 5.5(55, 40)

Clutch outer bolt 1 12 5.5(55, 40)

Cam chain tensioner pivot bolt 1 8 1.0(10, 7)

Spark plug 1 12 1.2(12, 9)

Cam sprocket bolt 2 6 1.2(12, 9) Apply engine oil

Camshaft holder nut 4 8 2.0(20, 14) Apply engine oil

Cam chain tensioner mounting bolt 2 6 1.2(12, 9)

Cam chain tensioner sealing screw 1 6 0.4(4, 2.9)

Cylinder head cover bolt 4 6 1.0(10, 7)

Transmission cover bolt 8 6 1.2(12, 8)

Transmission cover drain bolt 1 8 1.0(10, 7)

Transmission cover check bolt 1 8 0.9(9, 6)

Cooling fan bolt 3 6 1.0(10, 7)

Starting clutch nut 1 22 9.5(95, 67)

Starter motor terminal nut 2 6 0.9(9, 6)

Radiator hose eye joint bolt 4 12 3.2(32, 23)

Radiator hose nut 2 14 3.2(32, 23)

Torque Values

Engine

Item Q’ty Thread dia(mm)

Torque value

Remarks

kg.m(N.m,ft-lb)

Steering stem lock nut 1 26 7.5(75, 55)

Steering top thread nut 1 26 0.3(3, 2) Initial torque

Handle post nut 1 10 6.0(60, 44)

Front fork bottom bridge bolt 4 10 7.5(75, 55)

Front fork socket bolt 2 8 2.0(20, 14)

Apply locking agent

Front axle nut 1 12 5.5~6.5(55~65, 40~47)

Front brake disk bolt 3 8 3.9(39, 28)

Apply locking agent

Ignition coil bolt 1 5 0.5(5, 4)

Rear axle nut 1 14 6.0-8.0(60-80, 43-58)

Engine hanger nut 2 10 7.3(73, 53)

Engine hanger plate bolt 6 10 2.7(27, 20)

Frame

Page 18

Service Information

1-13

Item Q’ty Thread dia(mm)

Torque value

Remarks

kg.m(N.m,ft-lb)

Brake caliper bracket bolt 2 8 2.7(27, 20)

Brake caliper bleeder valve 1 8 0.6(6, 4.3)

Brake caliper slide pin (socket bolt)

1 8 2.3(23, 17)

Brake caliper pin bolt 1 8 1.8(18, 13)

Apply locking agent

Brake pad pin bolt 2 8 1.8(18, 13)

Master cylinder reservoir cap 4 4 0.13(1.3, 0.94)

Brake hose bolt 2 10 3.5(35, 25)

Brake lever pivot bolt 1 6 1.0(10, 7)

Brake lever pivot lock nut 1 6 1.0(10, 7)

Rear shock-absorber upper bolt 1 10 2.7(27, 20)

Rear shock-absorber lower bolt 1 10 4.0(40, 29)

Rear shock-absorber damper rod lock nut

2 10 3.8(38, 27)

Apply locking agent

Torque values listed above are for specific tightening points. Torque values for other items are listed in the

following table.

SH(Small Head): Indicates 6mm bolt of 8mm flange head.

Item

Torque Value

Item

Torque Value

N.m Kg-m ft-lb N-.m Kg-m ft-lb

5mm bolt, nut 5 0.5 4 5mm screw 4 0.4 3

6mm bolt, nut 10 1.0 7 6mm screw 9 0.9 7

8mm bolt, nut 22 2.2 16 6mm flange bolt, nut 9 0.9 7

10mm bolt, nut 35 3.5 25 6mm flange bolt, nut 12 1.2 9

12mm bolt, nut 55 5.5 40 8mm flange bolt, nut 27 2.7 20

10mm flange bolt, nut 40 4.0 29

Page 19

Service Information

1-14

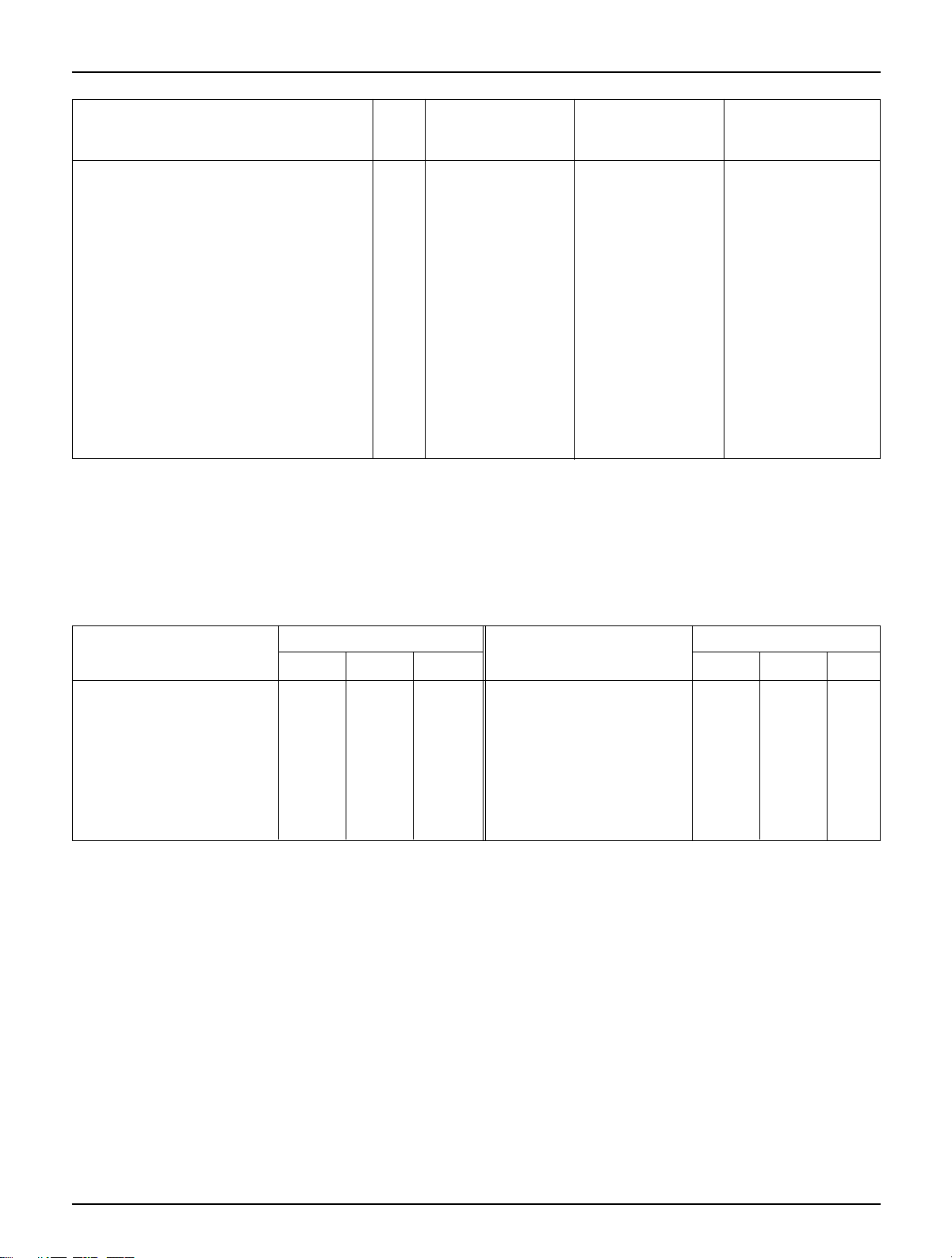

Symbols/Abbreviations

The following symbols are used in this manual to represent job-related warnings or cautions.

The following symbols indicate oil adding, oil change, or parts.

The following abbreviations are used in this manual.

ASS’Y Assembly

L. Left

R. Right

Symbol Meaning

Add oil. If there is no specific oil indicated, use the designated or recommended engine oil.

Apply grease

(⇨ 3-1) Indicates reference page.(example: Refer to page 3-1)

Symbol Meaning Symbol Meaning

OIL

GREASE

WARNING

NOTE

Indicates dangerous area. Serious

accident may result if instructions

are not followed.

Indicates important work. Minor

injury or vehicle part damage may

result if instruction are not followed.

Indicates general safety matters.

Provides safety and appropriate

handling procedures.

CAUTION

Page 20

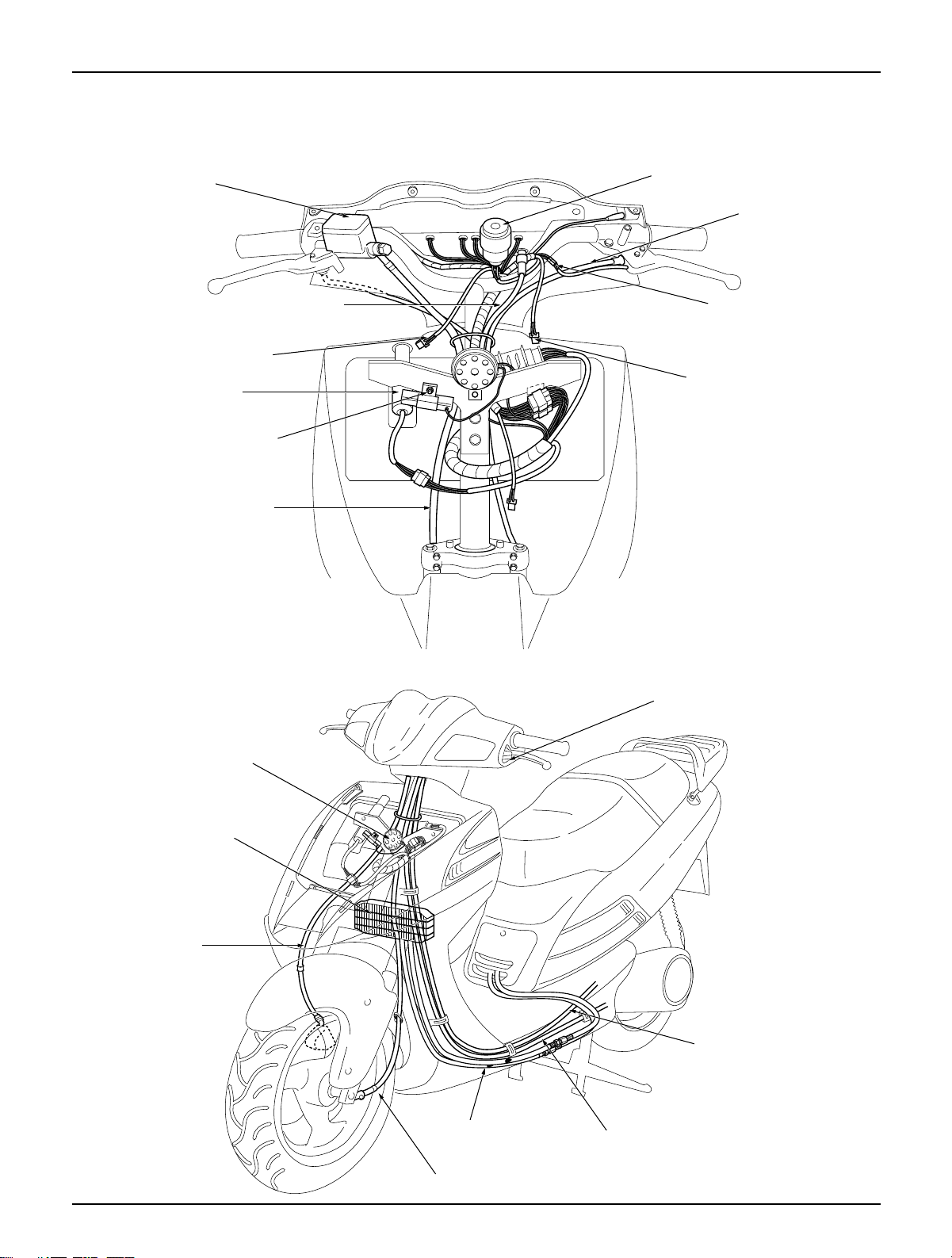

Wiring Diagram

Service Information

1-15

Rear brake cable

Winker relay

Stop switch connector

Front winker connector

Front brake hose

Horn

Radiator

Packing lever

Front brake hose

Speedometer cable

Rear brake cable

Radiator hose

Throttle cable

Main switch

Resister(excepted

some countries)

Front winker connector

Speedometer Cable

Front brake master

cylinder

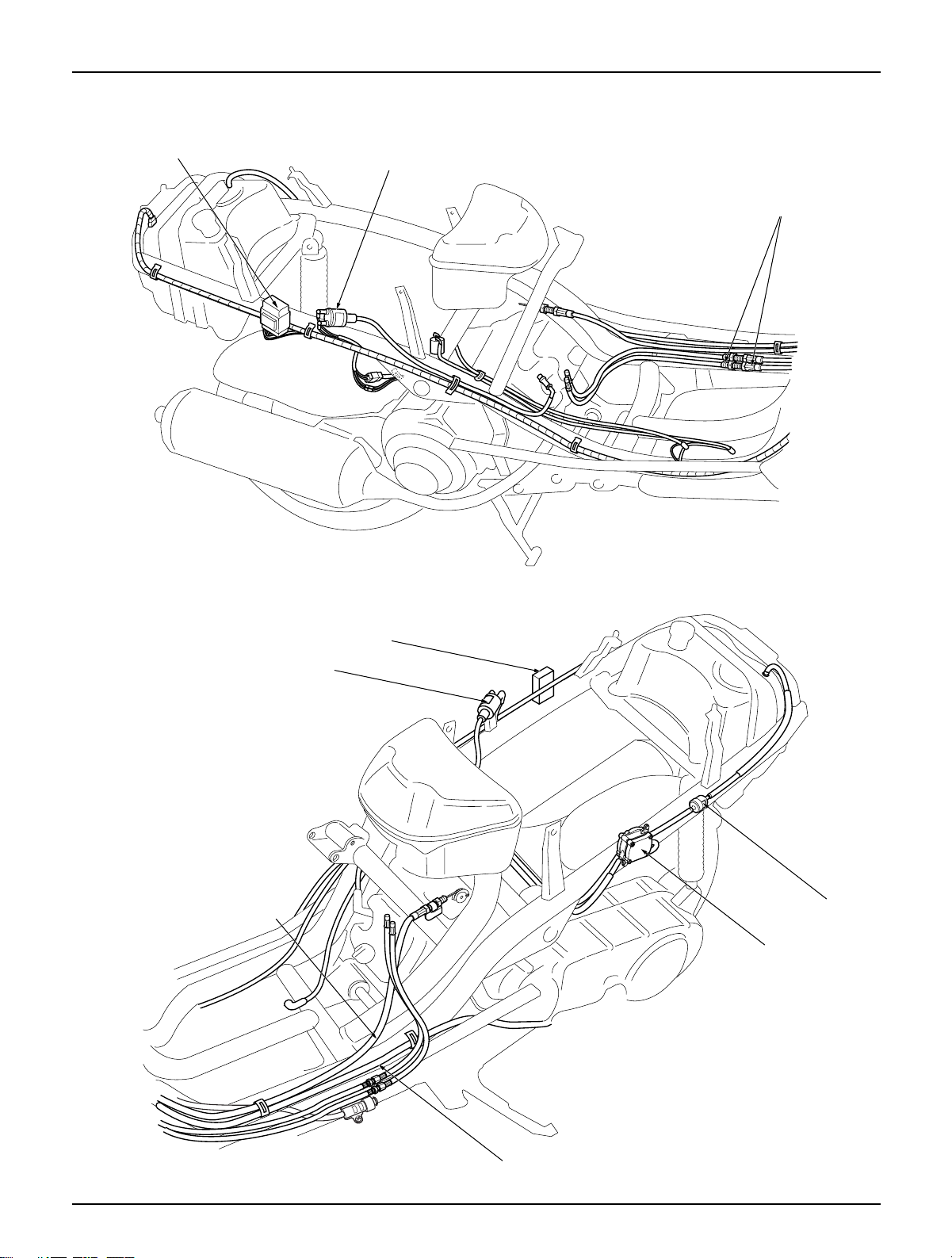

Page 21

Service Information

1-16

CDI unit

Ignition coil

Radiator hose

CDI unit

Ignition coil

Throttle cable

Rear brake cable

Fuel pump

Fuel filter

Page 22

Lubrication

2-1

2. Lubrication

Service Information

General Safety

WARNING

1. The exhaust gas contains poisonous substance. Do not keep engine idling in a closed or poorly ventilated

place for a long period of time.

2. Used engine oil may cause skin cancer if repeatedly left in contact with the skin for prolonged periods. It is

desirable not to handle used oil frequently; however, wash your hands thoroughly with soap and water

immediately after handling the used oil.

3. The oil pump can be serviced without removing the engine from the frame.

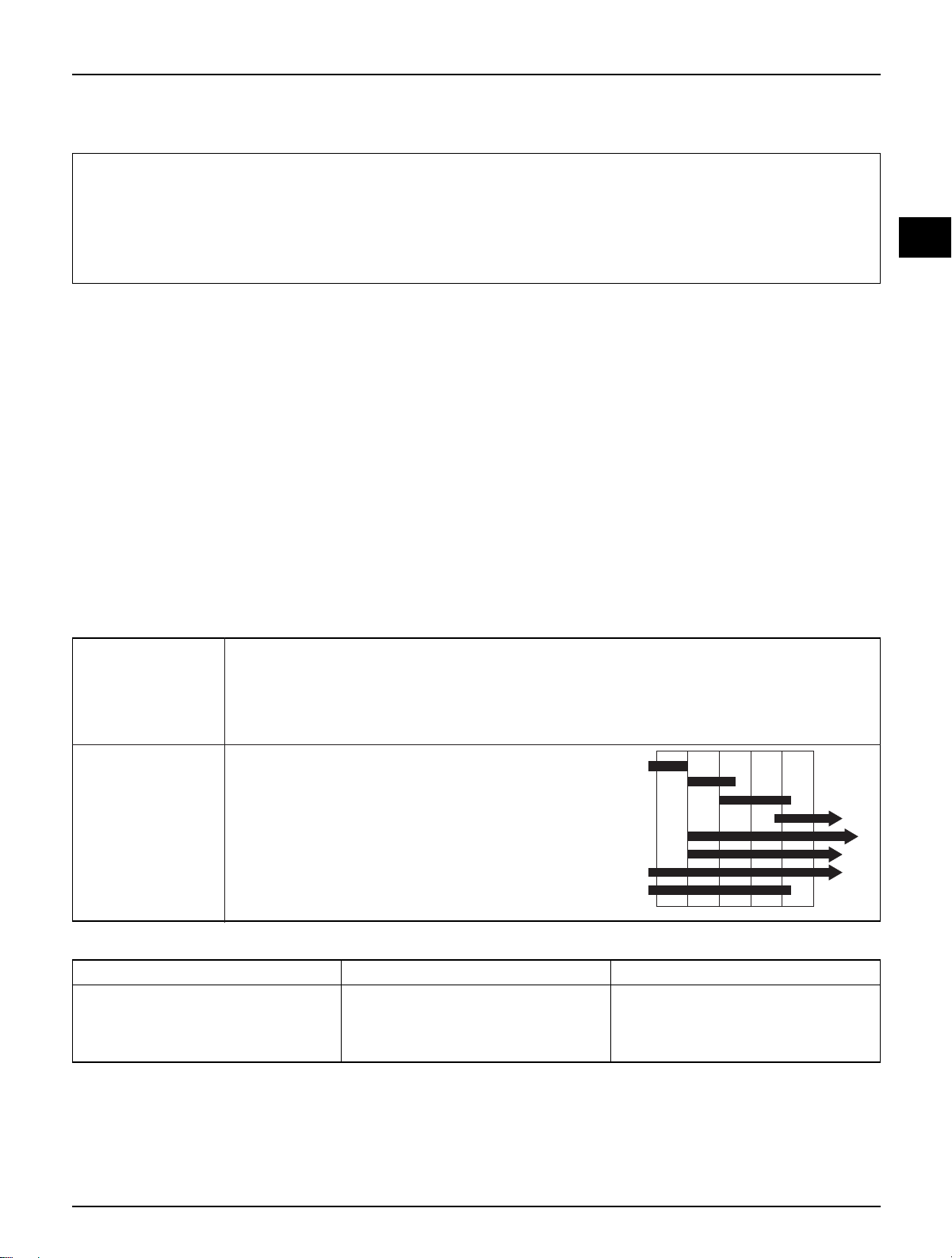

Engine Oil

API service classification: SE, SF, SH grade

Oil

Viscosity: SAE10W-30

Recommendation

(Use appropriate type of oil with viscosity

satisfying the atmospheric temperature

In your riding area based on the table shown

on the right side.)

1.1ℓ(After disassembly)

Oil capacity

0.75ℓ(After Oil filter change)

0.8ℓ(After Oil change)

0.9ℓ(After Oil change with Oil in the Oil hose removed)

20·20W

10W

30

40

20W 50

20W 40

10W 40

10W - 30

–10 0 10 20 30 40℃

Pump body clearance 0.08–0.17(0.003-0.007) 0.23(0.009)

Rotor tip clearance 0.03–0.13(0.001-0.005) 0.18(0.007)

Pump side clearance 0.04–0.09(0.002-0.004) 0.12(0.005)

Oil filter screen cap 1.5kg–m, (15N.m, 11ft–Ib)

Oil filter cover bolt 1.1kg–m, (11N.m, 8ft–Ib)

Oil pump mounting bolt 1.1kg–m, (11N.m, 8ft–Ib)

Oil drain plug bolt 2.5kg–m, (25N.m, 18ft–Ib)

Item Standard value Tolerance

Oil Pump

Torque Values

Unit: mm(in)

2

Service information 2-1

Troubleshooting 2-2

Engine Oil Level Check 2-3

Engine Oil Change 2-3

Oil Filter Element Change 2-4

Oil Pump 2-4

Radiator 2-7

Lubrication Points 2-9

Page 23

Lubrication

2-2

Troubleshooting

Oil level too low - high oil consumption

● External oil leaks

● Worn piston rings

● Worn valve guide or seal

Oil contamination

● Oil or filter not changed often enough

● Head gasket faulty

● Worn piston rings

Low oil pressure

● Oil level now

● Pressure relief valve stuck open

● Plugged oil pick-up screen

● Oil pump worn

● External oil leaks

High oil pressure

● Pressure relief valve stuck closed

● Plugged oil filter, gallery, or metering orifice

● Incorrect oil being used

No oil pressure

● Oil level low

● Oil Pump drive gear broken

● Oil pump faulty

● Internal oil leakage

Page 24

Lubrication

2-3

Engine Oil Level Check

● Erect the motorcycle on the main stand.

● Warm up the engine to heat the engine oil to an

appropriate level.

● Stop the engine, and check the oil level line on the

sight-glass installed on the L. crank case cover.

● If the oil level is between the lower and higher

sight-glass oil level line, oil level is satisfactory. If

the oil level is below or near the lower level mark,

add the recommended engine oil.

Engine Oil Change

NOTE

●

Loosen the oil drain plug bolt and drain engine oil.

● Operate the kick starter arm several times to

remove the remaining oil from the engine.

● Tighten the oil drain plug bolt.

Torque value: 2.0-3.0kgf··m

CAUTION

It is extremely important to replace oil filter or

clean the oil filter screen at the first maintenance

interval (after 1,000Km).

Clean the oil filter screen every 4,000Km.

Clean the filter screen with fresh cleaning oil.

Check the hole cap O-ring for satisfactory condition.

Tighten the hole cap with specified tightening

torque.

Torque value: 1.5kgf··m

● Loosen the special screw, remove the plug

maintenance cover.

● Fill the recommended oil after opening oil filter

cap of cylinder head cover.

Oil Capacity: 1.1ℓℓ(After disassembly)

0.75ℓℓ(After Oil change)

0.8ℓℓ(After Oil filter change)

0.9ℓℓ(

After Oil change with Oil in

the Oil hose removed

)

● API service classification: SE, SF, SH grade

● Start the engine and keep it idle for a few minutes.

● Stop the engine and check the oil level. If the oil

level is low, add the recommended engine oil.

● Check on oil leaks.

To completely and rapidly drain engine oil, warm

up engine and erect the motorcycle on its side stand.

Filter screen

Sight-glass

Drain plug bolt

Tappet adjusting hole cap

Page 25

Lubrication

2-4

Oil Filter Element Change

● Drain engine oil. ( 2-3)

● Remove the oil filter cover bolts, filter cover, filter

element and spring.

● Change the oil filter element with a new one.

● Check the relief valve inside the oil filter cover for

satisfactory operation.

● Check if the oil filter seal is in good condition.

● Assemble the filter element spring and filter cover,

and tighten bolts.

Torque value: Oil filter cover 1.1kg-m(11N.m.8ft-lb)

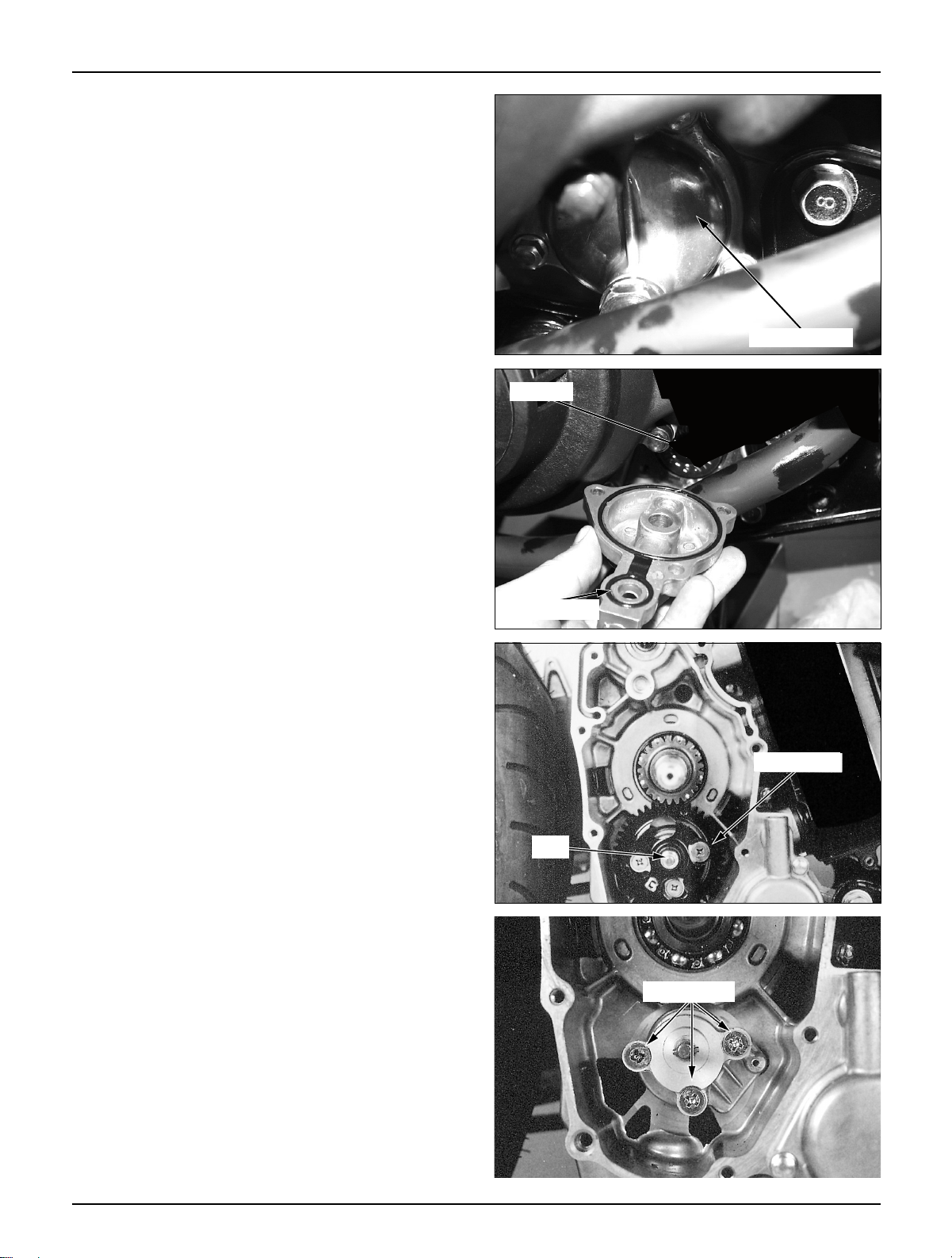

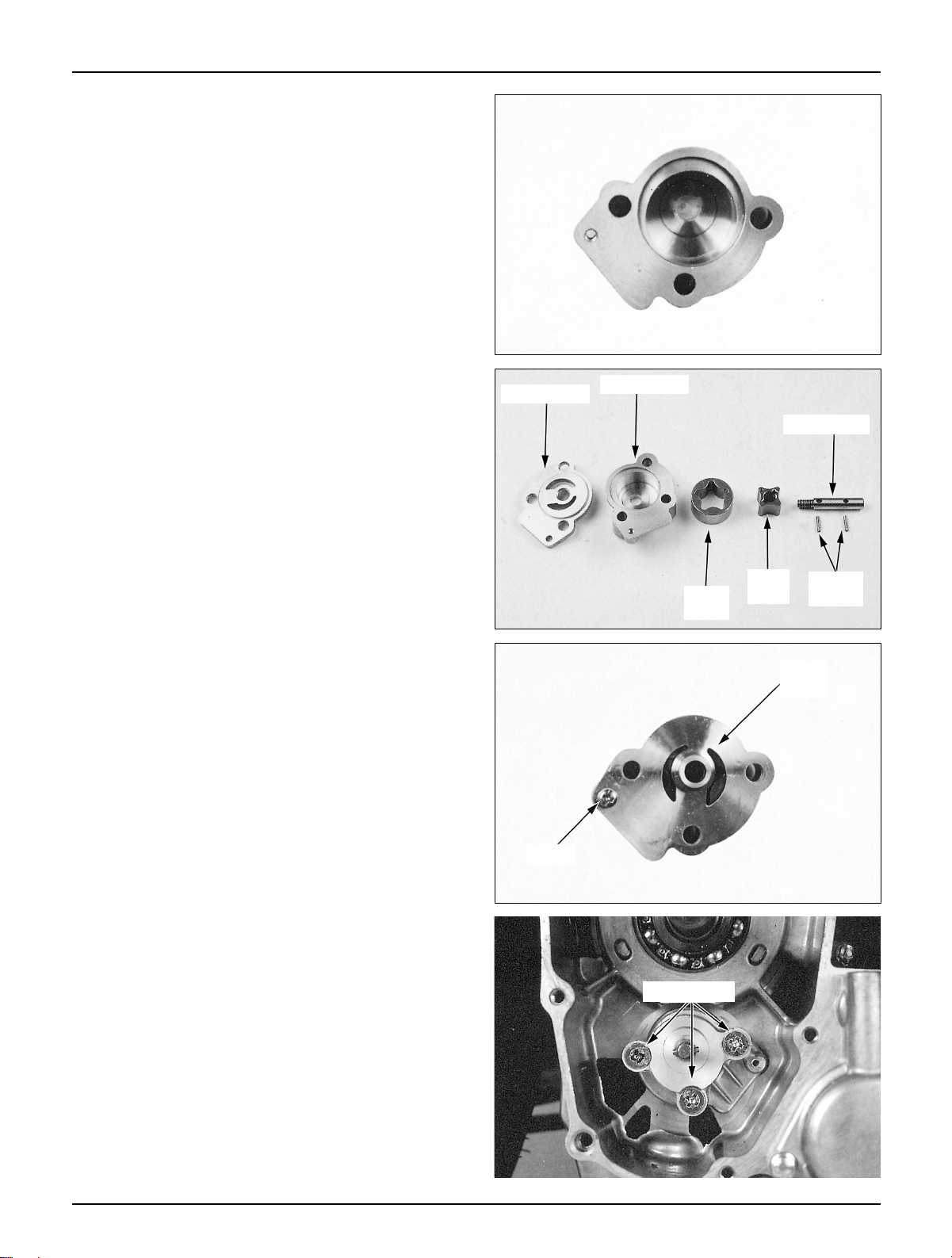

Oil Pump

● Remove the following parts:

- Luggage box (⇨ 4-5)

- Rear cushion bolt(⇨ 6-2)

- RH. floor side cover(⇨ 4-5)

- Exhaust muffler(⇨ 4-9)

- Center cover (⇨ 4-4)

- Shroud (⇨ 8-2)

- Cooling fan(⇨ 8-2)

- R. Crank cover (⇨ 8-4)

- A.C. generator (⇨ 8-2)

- Starter driven gear and reduction gear (⇨ 8-5)

- Starter clutch (⇨ 8-6)

● Loosen the oil pump drive gear setting nuts.

● Remove the oil pump drive gear.

● Remove the oil pump driven gear.

Oil filter cover

Element

Drive gear

Nut

Setting bolts

Oil filter seal

Page 26

Lubrication

● Remove the oil pump.

● Clean the oil pump body, inner and outer rotors

with fresh cleaning oil.

● Measure the rotor tip clearance.

Service limit: 0.18mm (0.007in)

Inspection

● Assemble the inner and outer rotors to the oil

pump

● Measure the pump body clearance.

Service limit: 0.23mm (0.009in)

● Measure the pump side clearance.

Service limit: 0.12mm (0.005in)

2-5

Outer

rotor

Inner

rotor

Setting

pin

Pump shaft

Pump body

Pump plate

Outer

rotor

Inner

rotor

Page 27

Lubrication

2-6

Removal/Installation

● Remove the inner and outer rotors from the

pump body.

● Clean all parts with fresh cleaning oil.

● Attach the oil pump plate to the pump body.

● Tighten screws.

Installation

● Assemble the oil pump to the R. crank case cover.

● Install the following parts.

- Oil pump drive gear and driven gear

- Starter clutch

- Starter driven gear and reduction gear

- A.C. generator

- R. crank case cover

- Shroud and cooling fan

- Center cover

- Body cover

- Luggage box

● Install the inner and outer rotors.

● Assemble the pump shaft with setting pins.

Screw

Pump

Plate

Outer

rotor

Inner

rotor

Setting

pin

Pump shaft

Pump body

Pump plate

Setting bolts

Page 28

Lubrication

2-7

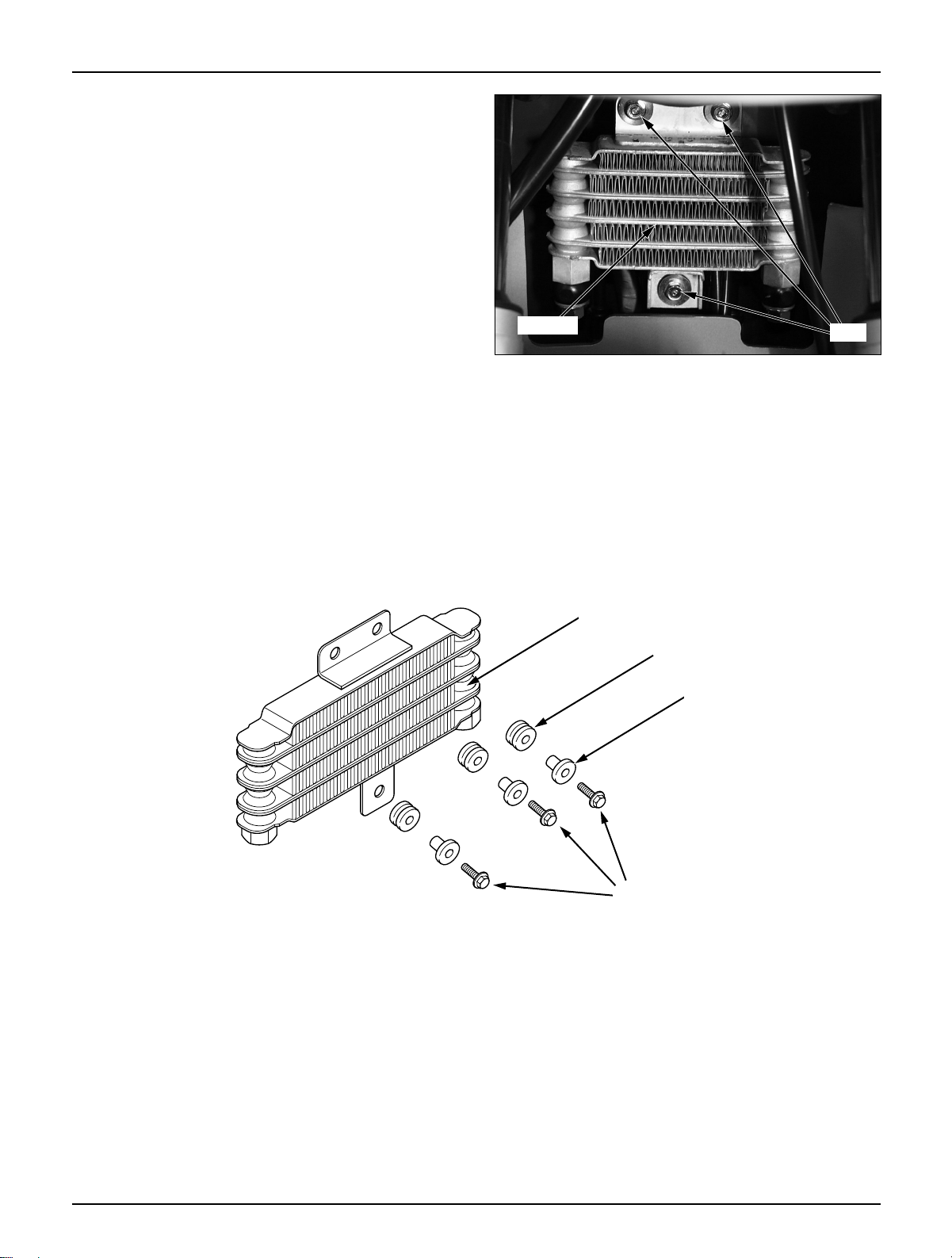

Radiator

Removal/Installation

● Remove the front wheel.

● Remove the front cover, front side cover and

inner box.

● Loosen the flange bolt(3EA), oil bolt and remove

the radiator from the main pipe bracket.

Radiator

Radiator bracket

Radiator collar

Flange bolt

bolts

Radiator

Page 29

Lubrication

2-8

Inspection

● Check the damage or oil leaks from the radiator.

Radiator Installation

● Assemble the radiator to the main pipe bracket.

● Tighten the oil bolt.

● Install the inner box.

● Install the front side cover.

bolts

Radiator

Page 30

Lubrication

2-9

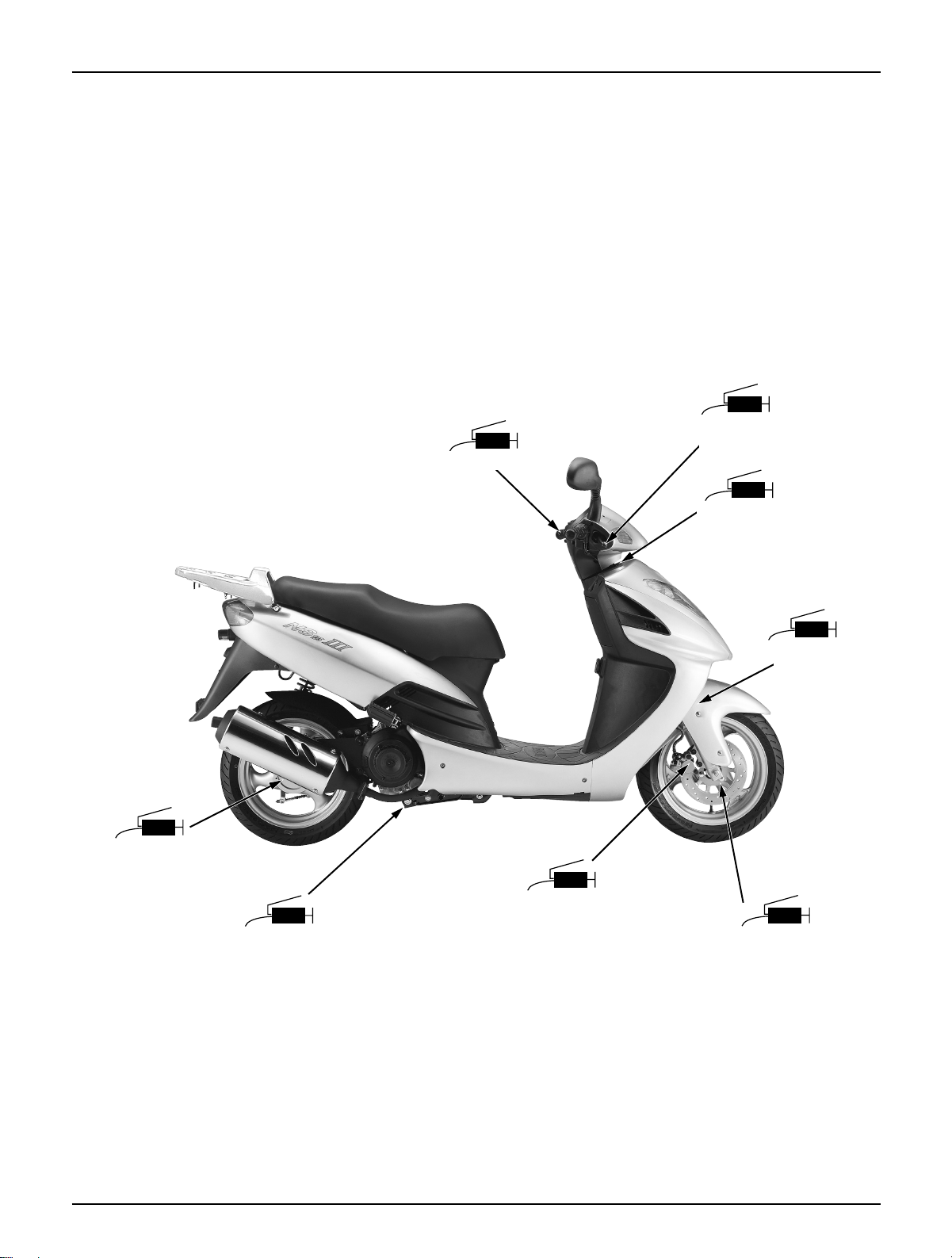

Lubrication Points

Unless specifically designated, use general grease to

lubricate the lubrication points. For sliding parts

not shown here, add oil or grease.

Control Cable Lubrication

Remove and clean the upper assembly of the throttle

cable, and apply oil. If the cable has expanded,

replace it.

Wheel

bearing

Side/main stand pivot

Brake caliper

bracket

Wheel bearing

/speedometer gear

Front fork

dust seal

grease

grease

grease

grease

grease

grease

grease

grease

Front brake

lever pivot

Setting head

bearing

Throttle grip

Page 31

MEMO

Page 32

Inspections/Adjustments

3-1

3. Inspections/Adjustments

Service Information 3-1

Regular Inspection Schedule 3-3

Fuel Line 3-4

Throttle Grip Operation 3-4

Air Cleaner 3-4

Spark Plug 3-5

Valve Tappet Clearance 3-5

Cylinder Compression Pressure

3-6

Carburetor Idling 3-6

Brake Fluid 3-7

Brake Pad/Shoe 3-7

Brake System 3-7

Brake Lever Free Play 3-8

Headlight Adjustment 3-8

Side Stand 3-8

Suspension 3-9

Bolts and Nuts 3-9

Wheels/Tires 3-10

Steering Head Bearing 3-10

Service Information

WARNING

● The exhaust gas contains poisonous substance. Do not keep engine idling in a closed or poorly ventilated

place for a long period of time.

NOTES

Driver only

Front tire 175kPa (1.75kg/㎠)

Rear tire 200kPa (2.00kg/㎠)

Cold tire pressure

Driver and

Front tire 225kPa (2.25kg/㎠)

a passenger

Rear tire 280kPa (2.80kg/㎠)

Tire size

Front tire 120/70-13(Tubeless)

Rear tire 130/60-13(Tubeless)

Min,tread depth

Front tire 4mm (0.16 in)

Rear tire 7.5mm (0.3 in)

For information on engine oil and oil filter, refer to sections 2-3 and 2-4

Stand the main stand prior to beginning work.

Throttle grip play 2–6mm(1/8-1/4 in)

Spark plug CR8EH-9

Spark plug gap 0.8–0.9mm(0.031-0.035in)

Valve clearance

IN 0.12± 0.02mm(0.005±0.001 in)

EX 0.12±0.02mm(0.005±0.001 in)

Carburetor idle speed 1,800±100rpm

Cylinder pressure 13.8kg/㎠

Specifications

Tires

3

Page 33

3-2

Inspections/Adjustments

Torque Values

Spark plug 1.1kg–m, (11N.m, 8ft–lb)

Cylinder head cover bolts 1.0kg–m, (10N.m, 7ft–lb)

Valve adjusting nuts 1.1kg–m, (11N.m, 8ft–lb)

Timing hole cap 0.6kg–m, (6N.m, 4.3ft–lb)

Tools

Wrench, 8×9mm

Adjusting wrench

Compression gauge

Page 34

Fuel line(Fuel tube) I I I I

Fuel filter R R R R

Throttle grip operation I I I I

Air cleaner C for each 1,000km Note 2

Spark plug I R I

Valve clearance I I I I

Transmission oil R

Engine oil R R R R

Engine oil filter element R R R R

Carburetor idle speed I I I I

Brake fluid I I R Note 3

Brake shoe/pad I I I

Brake system I I I I

Brake stop switch I I I

Headlight beam distance

III

Side stand I I I

Suspension I I I

Bolt and nut tightness I I

wheels/tires I I I

Steering head bearing I I

3-3

Inspections/Adjustments

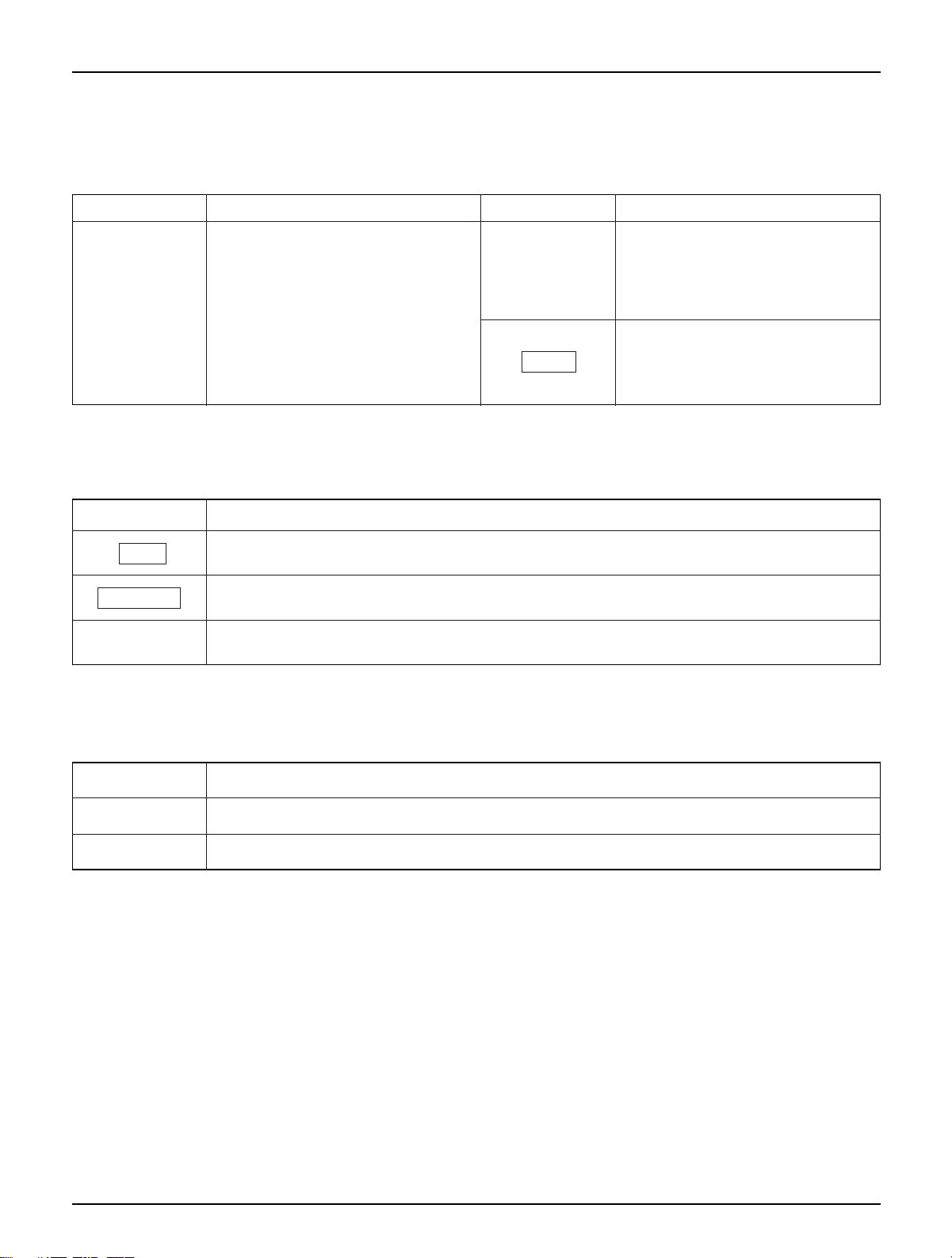

Regular Inspection Schedule

Carry out pre-operation check at each scheduled maintenance period based on the information described in

the owner’s manual.

I: Inspect, and clean, adjust, lubricate or replace, if necessary.

R: Replace L: Lubricate C: Clean

Frequency

Odometer reading(Note 1)

Item

1000km 4000km 8000km 12000km

Remark

61218

Should be received by an authorized DAELIM dealer, unless the owner has proper tools and service data

and not mechanically qualified.

In the interest of safety, we recommended these items be served only by an authorized DAELIM dealer.

NOTE

1. After the odometer reading exceeds 12,000km, repeat maintenance service at intervals indicated in the table.

2. After riding in areas with high humidity or pollution, carry out maintenance service more frequently.

3. Replace every 2 years. Proper technology is required for this job.

Page 35

Inspecitions/Adjustments

3-4

Fuel Line (Fuel Tube)

● Remove the luggage box (⇨ 4-5)

● Check the fuel tube of the fuel pump connected

to the fuel tank and carburetor. If the fuel tube is

cracked, damaged or leaks, replace it.

Throttle Grip Operation

● Check if the throttle grip operates smoothly in any

steering position.

● If the throttle grip does not operate properly,

lubricate the throttle cable.

● If the throttle grip does not operate properly,

check the throttle cable for aging, damage or

kinking.

● Check the throttle grip free play.

Free play: 2~6mm(1/8~1/4in)

Air Cleaner

● Unlock the system with main key, and open the

seat.

● Loosen the 6 setting screw assembled to the air

cleaner case cover.

● Loosen the 2 setting screw assembled to the air

cleaner element.

● Remove the air cleaner element.

Fuel pump

Fuel tube

Screw

Screw

Air cleaner element

Page 36

3-5

Inspecitions/Adjustments

● Soak the element in solvent, and dry completely.

● Soak in gear oil (SAE #80-90), and squeeze firmly

to remove excessive oil.

● If the element is excessively contaminated or

damaged, replace it.

● Assemble in the reverse order of the disassembling.

Spark Plug

● Remove the plug maintenance cover.

● Remove the spark plug cap and disassemble the plug.

● Check the plug for damage, contamination or

deposits.

● If the spark plugs are severely contaminated or

damaged, replace with new ones. If the plugs can be

reused after removing only the carbon, use plug

cleaner and wire brush to clean the plugs.

● Always use a feeler gauge to check the clearance.

Genuine plug: CREH-9

Spark plug clearance: 0.8-0.9mm

Torque value: 1.1kg-m(11N.m, 8ft-lb)

NOTE

Valve Tappet Clearance

● Remove the following parts.

-- Center cover. (⇨ 4-4)

● Loosen the 4 cylinder head bolts.

NOTE

● Measure valve clearance with a feeler gauge.

Valve tappet clearance:

Intake: 0.12±±0.02mm(0.05±±0.001in)

Exhaust: 0.12±±0.02mm(0.05±±0.001in)

Carry out inspection/adjustment when the

engine is cold. (35℃/95F)

Remove the cylinder head cover.

Turn the flywheel counterclockwise, and match

the “T” mark on the flywheel with the index

mark on the R crank case cover.

The piston at this time must be at the top dead

center of the compression stroke.

First, manually tighten the plugs, and use a spark

plug wrench to tighten completely.

Cylinder

head cover

“T” mark

Wash

Squeeze

Dry

Gear oil

(#80-90)

Check

washer

for damage

Check for

cracks.

Check

gap

Squeeze

out oil

Oil

0.8~0.9mm

Page 37

Inspections/Adjustments

3-6

● Loosen the lock nut with a valve wrench, and set

valve clearance to a prescribed level by turning the

adjusting screw with a valve adjusting wrench.

● After setting clearance to the prescribed level, hold

the adjuster screw with a valve adjusting wrench,

and tighten the lock nut.

Torque values: 1.1kg-m(11N.m,8ft-lb)

Tools: Wrench 8××9mm

Adjusting wrench B

● Measure the valve clearance again.

● Install the cylinder head cover and tighten the bolts.

Torque values: 1.0kg-m(10N.m. 7ft-lb)

Cylinder Compression Pressure

● Start and warm up the engine.

● Remove the plug maintenance cover.

● Stop engine, and remove the spark plug cap and

spark plug.

● Install a compression gauge.

● Open the throttle completely, and crank the engine

with the starter motor until the gauge reading

rising.

Tool: Compression gauge

NOTE

Compression pressure: 13.8kg/cm

2

● If the pressure is low, check the following:

- Inadequate valve clearance adjustment

- Valve leakage

- Leakage from the cylinder had gasket

- Piston / cylinder worn

● If pressure is high, check the following:

- Carbon deposits on the piston head, and cylinder

head.

Carburetor Idling

NOTE

The maximum reading is usually reached within

4~7 seconds.

Verify all engine adjustments satisfy

specifications. Make adjustments, if necessary.

Heat the engine to make accurate idling inspection

and adjustment. Stand the vehicle on the main stand.

Turn the throttle stop screw and make adjustments

to prescribed idling speed.

Feeler gauge

Adjusting

wrench

Spark plug cap

Compression gauge

Throttle Stop Screw

Page 38

3-7

Inspecitions/Adjustments

Brake Fluid

● Remove the brake fluid cover.

● Check the oil level inside the front brake reservoir.

If the oil level is near the lower limit line, remove

the reservoir diaphragm and fill DOT 3 and DOT

4 brake fluid to the top limit line.

● If the brake fluid reaches the lower limit line,

check the entire brake system for leaks.

Brake Pad/Shoe

Brake pad replacement

● Check the brake pads for wear.

● If the red mark on the pad reaches the brake disc,

replace the pads.

NOTE

Brake Shoe Replacement

● If the arrow mark of the wear limit aligns with the

‘△’mark when the rear brake lever is fully

pressed, it indicates the brake lining has reached

the service limit. Replace the brake shoes.

Brake System

● Check the front brake hose for cracks or damage.

If any leaks are found, replace immediately.

● Check the brake rod for looseness or damage,

and replace it if necessary.

Brake hose

Brake caliper

Brake hose bolt

Master cylinder

‘△’ mark

Red Mark

Replace the brake pads in sets.

Page 39

Inspections/Adjustments

3-8

Brake Lever Free Play

● Check the free play after pulling the lever.

Front:10-20mm

Rear:10-20mm

Rear Brake Free Play Adjustment

● Turn the adjuster nut to adjust the free play.

● After initial adjustment, check the operation of

the rear brake light switch. Make additional

adjustments, if necessary.

Adjuster

Headlight Adjustment

● Adjust the headlight beam level by operating the

adjusting screw located on the upper side of the

front fender.

NOTE

Side Stand

● Erect the main stand.

● Pull the lower end of the side stand, and see if it

moves freely.

● If the side stand does not move smoothly, apply

grease to the pivot area.

● If the side stand moves too freely, check the side

stand spring.

● Check the axial movement of the side stand.

Adjust the beam level according to local laws

and regulations.

Improper beam level adjustment may blind on

coming drivers, or may incorrectly light the road

ahead.

Side stand

spring

Adjuster

Page 40

3-9

Suspension

NOTE

Front wheel

● Hold the brake lever, and compress the front

cushion up and down several times to check the

operating conditions.

● Check the front fork for oil leakage, parts damage

or looseness.

Rear wheel

● Compress the near cushion up and down several

times to check the operating conditions.

● Check the rear fork for oil leakage, parts damage

or looseness.

Bolts and Nuts Tightening

●Check all nuts and bolts of the frame during the

regular maintenance ( 3-3) to check if they meet

the prescribed torque value.

● Check all pins, clips, hose clamps and cable stays.

Inspections/Adjustments

Do not ride motor cycle with an unsatisfactory

suspension. Loose or worn suspension parts will

lead to deterioration in the vehicle’s safety and

operation efficiency.

F

F

● Check the side stand ignition cut-off switch ;

-Put the side stand up.

-Start the engine.

-Lower the side stand. The engine should stop as

you put the side stand down.

● If there is a problem with the system, check the

side stand swich.

Side stand

switch

Page 41

Inspections/Adjustments

3-10

● Check the tread depth at the tire center.

● If the tread depth has reached the service limit,

replace the tire.

Service limit: 4mm (0.16in)

7.5mm (0.3in)

Steering Head Bearing

NOTE

● Lift the front wheel and check if the handle moves

right and left smoothly. If the handles move

heavily, check if the cable or electric cord

interferes with the handle. If the handle moves

satisfactorily, adjust the steering head bearing.

Check the cable if it interferes with the handle

operation.

Wear indicator position mark

Wheels/Tires

NOTE

Item Front wheel Rear wheel

Driver only 1.75(175) 2.00(200)

Driver and a passenger 2.25(225) 2.25(225)

Standard Pressure kg/

㎠㎠

(kPa)

Check the tire pressure when the tires have been

cooled off. Check the tread (the part making

contact with the road surface) and side for wear,

cracks or damage. Replace damaged tires.

Tire pressure gauge

Page 42

External Parts

4-1

4. External Parts

Service Information

NOTE

● This section describes external parts removal/installation.

● Do not apply unreasonable force when disassembling covers, to prevent possible damage.

● A muffler is hot. Do not service it immediately after the engine is stopped.

Service Information 4-1

Maintenance Procedure 4-2

External Parts Removal/Installation

4-3

Muffler 4-9

Front Fender 4-10

4

Page 43

External Parts

4-2

● This chart shows arrows connected in the order of disassembling covers.

① Front cover

② Inner box

③ Front side cover

④ Floor side cover

⑧

Maintenance cover

⑦ Center cover

⑨ Rear under cover

⑮

Rear handle cover

⑩ Body cover

⑫ Floor panel

⑭

Front handle cover

⑤ Luggage box

⑥ Rear carrier

⑬ Tail combination-light

⑪

Rear upper cover

Maintenance Procedure

Names of frame covers

①

⑭

③

④

②

⑮

⑦

⑧

⑫

⑤

⑥

⑪

⑨

⑬

⑩

Page 44

External Parts

4-3

Front Cover removal/Installation

● Loosen the 2 upper screws.

● Loosen the 2 lower screws.

● Pull upward and remove the front cover.

● Install in the reverse order of removal.

Front Side Cover Removal/Installation

● Remove the front fender. (⇨ 4-10)

● Remove the front wheel. (⇨ 12-5)

● Remove the 2 front lower flange bolts and the 2 upper screws.

● Remove the 2 inner box setting screws.

● Remove the front side cover.

● Install in the reverse order of removal.

Screw

Front cover

Screw

Inner box

Front side cover

Bolt

Screw

Screw

Page 45

External Parts

4-4

Inner Box

● Loosen the 2 bolts installed on the bag holder.

● Remove the bag holder.

● Open the inner box lid.

● Remove the 1 cap nut.

● Remove the 2 flange bolt installed on the floor

panel.

● Remove the 6 front side cover screws.

● Remove turn the main key cover slightly to

unlock, and remove the main key cover.

● Remove the inner box

● Install in the reverse order of removal.

Center Cover

● Loosen the 4 setting screws assembled to the

body cover.

● Remove each of the setting screws assembled to

the floor panel.

● Band inwards, and remove the center cover.

● Install in the reverse order of removal.

Screw

Front inner box

Nut

Bolt

Bag holder

Radiator

Screw

Center cover

Screw

Flug maintenance cover

Page 46

4-5

External Parts

Side Cover

● Remove the floor mat.

● Loosen the 2 screws on the side of the

R/L side covers.

● Loosen 1 each of the R/L screws

assembled to the floor panel.

● Loosen 3 each of the R/L body cover

clips assembled to the floor panel.

● Remove R/L side covers.

● Install in the reverse order of removal.

Luggage Box

● Unlock the system with the main key, and open

the seat.

● Loosen the 4 cap nuts.

● Remove the fuel tank cap.

NOTE

● Remove the luggage box.

● Install in the reverse order of removal.

● Remove the wiring of trunk lamp.

Side cover

Side stand

switch

Seat

Fuel tank cap

Luggage

box

Nut

Screw

Trunk lamp

Hinge

pin

Bolt

Bolt

Assemble the fuel tank cap after removing the

luggage box.

Page 47

External Parts

4-6

Rear Carrier

● Loosen 1 each of the R/L flange bolt set on the

body cover side.

● Loosen the 2 flange bolts set on top of the body

cover.

● Remove the rear carrier.

● Install in the reverse order of removal.

Body Cover/Rear Cover

● Remove the rear carrier. (⇨ 4-6)

● Remove the luggage box. (⇨ 4-5)

● Remove the center cover. (⇨ 4-4)

● Loosen 2 each of the R/L body cover

grill screws set with the floor panel.

● Loosen 1 each of the R/L body cover

clips assembled to the rear fender.

● Loosen 1 each of the R/L flange bolts set

on the frame body.

● Loosen 2 rear under cover setting screws,

and remove the rear under cover.

● Remove the R/L frame body cover.

● Loosen the 2 rear upper cover setting

screws.

● Install in the reverse order of removal.

Screw

Body cover clip

Rear upper cover

Frame body

cover

fuel fiter

puel pump

Rear carrier

Screw

Page 48

Tail Combination-Light

●Remove the following parts.

- Luggage box. (⇨ 4-5)

- Luggage carrier. (⇨ 4-6)

- Body cover. (⇨ 4-6)

- Rear under cover. (⇨ 4-6)

● Loosen the 2 bolts assembled

to the frame rear part.

● Loosen the 2 R/L side setting

bolts.

● Remove the tail combination-

light wiring.

● Remove the tail combination-

light

● Install in the reverse order of

removal.

4-7

External Parts

Floor Panel/Battery Cover

● Remove the center cover. (⇨ 4-4)

● Loosen 2 each of the R/L pillion step

cover setting screws of the floor mat, and

remove the floor mat.

● Loosen the 2 battery cover setting

screws, and remove the battery cover.

● Withdraw the battery wiring, and

remove the battery.

● Remove the air cleaner duct.

● Loosen the 4 setting bolts.

● Remove the side cover. (⇨ 4-5)

● Remove the 4 center cover setting

screws.

● Remove the floor panel.

● Install in the reverse order of removal.

Floor

mat

Screw

Floor panel

Bolt

Bolt

Bolt

Rear under

cover

Screw

Bolt

Battery cover

cover

Page 49

External Parts

4-8

Handle Cover

Front Handle Cover

● Loosen the 4 rear handle cover setting screws.

(1 each on R/L side, and 2 each on meter side)

● Loosen 1 front handle cover setting screw.

● Remove 1 R/L handle side cover lower screw,

and 1 each of the special upper side screws.

● Pull the front handle cover forward, and remove

the wiring.

● Remove the front handle cover.

● Install in the reverse order of removal.

Rear Handle Cover

● Loosen the 3 screws assembled to the handle bar.

● Loosen the 3 screws assembled to the meter.

● Remove the R/L side switch wiring.

● Remove the rear handle cover.

● Install in the reverse order of removal.

Rear view mirror

Bolt

Screw

Screw

Front handle cover

Handle side

cover

Meter

Rear handle

cover

Speedometer cable

Screw

Page 50

4-9

External Parts

Muffler

Removal

● Loosen the 3 flange nuts securing the EX. pipe

comp.

● Loosen the flange bolt securing the rear wheel

mud guard.

● Loosen the 2 flange bolts securing the R. crank-

case.

● Remove the EX. muffler comp.

WARNING

EX. Pipe removal

● Remove the plug maintenance cover.

● Loosen the 2 flange bolts securing the cylinder

comp.

● Remove the EX. pipe by drawing it to the ground

direction.

Installation

● Install the 2 flange bolts after securing the EX.

pipe with the stud bolt of the cylinder comp.

● Install the gasket on the EX. muffler, connect the

EX. pipe and install the 2 flange nuts temporarily.

● Install the 2 flange bolts on the R.crankcase

temporarily.

● Tighten the 3 flange nuts to install the EX. muffler

and EX. pipe.

● Install the flange bolt on the rear wheel mud

guard.

● Tighten the muffler securing 2 flange bolts to

install the R. crankcase.

● Tighten torque of the R. crankcase.

Torque: 5.5kg-m(55N.m, 40ft-lb)

WARNING

Never perform the maintenance of the muffler

right after stopping the vehicle because the

muffler is extremely hot.

When installing the gasket, replace it with the

new one.

Check to see if there is any evacuation after

installing the muffler.

Flange bolts

Flange nuts

EX.pipe

EX.pipe

Setting Bolt

Page 51

External Parts

4-10

Front Fender

● Loosen the flange bolt connecting the front

fender A and B.

● Loosen the 2 setting screws of the front fender A,

and remove the front fender A.

● Loosen 1 setting screw of the front fender B.

● Remove the speedometer cable guide.

● Remove the front fender B.

● Install in the reverse order of removal.

Fender B

Screw

Screw

Fender A

Bolt

Page 52

MEMO

Page 53

Fuel System

5-0

Fuel tank

Fuel strainer

Fuel pump

Carburetor

Page 54

Fuel System

5-1

5. Fuel System

Service Information 5-1

Troubleshooting 5-2

Fuel Tank 5-3

Air Cleaner Removal 5-4

Carburetor 5-4

Pilot Screw Adjustment 5-9

Fuel Pump Inspection 5-9

Service Information

General Safety

WARNING

● Gasoline is extremely flammable. Avoid fire in the work place, also paying particular attention to sparks.

Furthermore, the evaporated (gasified) gasoline is highly explosive. Work in a well-ventilated areas.

● Exhaust gas contains poisonous substance. Do not keep engine running for a long period of time in a

closed, or poorly ventilated area.

CAUTION

● Do not excessively bend or twist cable. Distorted or damaged cable may lead to mechanical malfunctions.

● Pay particular attention to the position of O-ring. Replace with new ones when disassembled.

● If it is desired to store a vehicle for a period longer than 1 month, drain gasoline out of the carburetor float

chamber. Gasoline left in the float chamber will be deteriorated causing the slow jet to be clogged with

deposits, and idling may become unstable.

Specifications

Fuel tank capacity: 7.5ℓ

Reserve fuel capacity: 1.2ℓ

Item Standard

Type/Throttle bore CV type (vacuum) 24.2mm

Model mark BDS 26 -112

Main jet No. #95

Pilot screw opening 1 and 1/2 returns

Pilot jet 13 mm

Idling speed 1800±100(rpm)

Throttle grip free play 2-6mm

Tool

Float level gauge

Carburetor

5

Page 55

Fuel System

5-2

Troubleshooting

Unable to start the engine

● No fuel in the tank.

● Fuel cannot be supplied.

● Fuel excessively absorbed into the cylinder.

● Air cleaner clogged.

● No spark from plugs.

Unstable idling, unsatisfactory rotation

● Unsatisfactory idling adjustment.

● Mixture too lean or rich

● Air cleaner clogged.

● Secondary air absorbed into the intake system.

● Fuel system clogged.

Mixture too lean

● Carburetor jets clogged.

● Fuel tank cap air hole clogged.

● Fuel strainer screen clogged.

● Fuel tube kinked, pressed or clogged.

● Float valve malfunction.

● Oil level too low.

Mixture too rich

● Float valve malfunction.

● Oil level too high.

● Air jets clogged.

Page 56

Fuel System

Fuel Tank

Remove

WARNING

● Remove the following parts.

- Luggage box (⇨ 4-5)

- Rear carrier (⇨ 4-6)

- Body cover (⇨ 4-6)

- Center cover (⇨ 4-4)

- Rear cover (⇨ 4-6)

- Tail combination-light (⇨ 4-7)

● Remove the fuel tube from the fuel pump.

● Remove the fuel unit wire coupler.

● Loosen the 2 top fuel tank bolts.

● Loosen the 2 bottom fuel tank bracket bolts.

● Remove the fuel tank bracket.

● Remove the fuel tank.

Installation

Install in the reverse order of removal.

NOTES

5-3

Check for gasoline leakage.

“Gasoline” mark is on the fuel tank cap.

Check this mark when filling gasoline.

Gasoline is extremely flammable. Avoid fire during

work, and pay particular attention to electric sparks.

Furthermore, the evaporated (gasified) gasoline is

highly explosive. Work in a well-ventilated areas.

Fuel Pump

Fuel Pump

Bracket

Bolt

Fuel Tank

Page 57

Fuel System

5-4

Air Cleaner Removal

● Remove the luggage box. (⇨ 4-5)

● Loosen the 2 R/L bolts attached to the frame body.

●

Loosen the band attached to the lower part(carburetor)

of the intake coupling and remove the air cleaner.

● Install in the reverse order of removal.

Carburetor

Remove

● Remove the air cleaner. (⇨ 5-4)

● Loosen the throttle cable lock nut, and remove

the throttle cable from the carburetor.

● Remove the auto cock cord.

● Loosen the set plate setting screw.

● Loosen the chamber connecting band and the

carburetor insulator band.

● Remove the carburetor.

Vacuum Chamber Removal

● Remove the fuel tube and drain tube.

Air cleaner

Band

Intake

coupling

Band

Lock nut

Setting screw

Throttle cable

Page 58

Fuel System

5-5

● Remove the compression spring, vacuum piston,

and diaphragm.

● Remove the 4 vacuum chamber screws.

● Turn the jet needle holder with a screwdriver,

and remove the jet needle holder, spring, and jet

needle.

Inspection

● Check the vacuum piston for wear, cracks,

scratches or other damage.

● Check the jet needle edge for extensive wear,

twist or damage.

● Check if the diaphragm has become thin or

cracked, and check the spring for wear or

damage.

Spring

Screw

Jet needle

holder

Spring

Diaphragm

Vacuum piston

Jet needle

Jet needle

holder

Page 59

Fuel System

Float Chamber/Float/Jet Removal

● Lossen the 4 float chamber screws.

● Remove the float pins, float, and valve.

5-6

Screw

Screw

Float chamber

Pin

Float

Float valve

● Check the float valves and seats for cracks or

damage.

● Check the float valve operation.

● Remove the main jet, needle jet holder, and

needle jet, and remove the slow jet.

NOTE

Prior to unfastening the pilot screws, count the

number of turns until the screws are lightly

tightened, so that the screws can be returned to

the original condition after assembling.

Do not tighten the pilot screws too hard as it

may cause damage to the screw seat.

Main jet

Float valve

Seat

Page 60

Fuel System

● Clean all jets and holes with an air hose.

5-7

● Assemble the needle jet, needle jet holder, main

jet, and slow jets.

● Assemble and turn the pilot screw to the number

of turns memorized.

Carburetor body

Page 61

Fuel System

5-8

Float Level

● Install the float valves, and float pins.

● Check the float valve level.

Float level: 13mm

● Assemble the float chamber.

Vacuum Chamber Assembly

● Insert the jet needle and spring to the piston, and

install the holder.

NOTE

● Install the compression spring and vacuum

chamber.

Carburetor Installation

● Assemble the air vent, fuel tubes, and drain tubes

to the carburetor.

Match the diaphragm with the body notch.

● Check the insulator O-ring for wear or damage,

and install the insulator.

Insulator

O-ring

Main jet

Float level gauge

Spring

Page 62

Fuel Pump Inspection

NOTE

● Start the engine and keep in the idling state.

● Fuel pump is considered as satisfactory if

dispensing volume of more than 28cc in 10

seconds is obtained after disconnecting fuel

pump from caburetor and dispensing fuel over 5

seconds.

● If specified dispensing volume cannot be

obtained, check fuel tube, negative pressure tube

fuel strainer.

If there is no abnormality, replace fuel pump

with assy.

Fuel System

● Connect the Autoby starter cable to the terminal.

● Assemble the carburetor insulator and connecting

tube to the carburetor, and tighten the band screw.

● Connect the throttle cable to the carburetor.

● Rearrange the tube passing positions.(⇨ 1-10)

●Adjust the throttle operation.

● Adjust the carburetor idling.

● Adjust the pilot screws.

● Check on oil leakage.

Pilot Screw Adjustment

NOTE

● Gently tighten the pilot screw clockwise, and

unscrew in reverse for 2 turns.

● This is the optimal status of the pilot screw.

● Start the engine, and warm up the engine to a

normal operation level temperature.

● Adjust idling speed with the throttle stop screw.

Idling speed: 1,800

±±

100 rpm

● Slowly turn the pilot screw until the engine stops

running, and unscrew in reverse for 1 turn.

● Start the engine, and adjust the idling speed by

turning the throttle screw, if necessary.

5-9

Take due precautions during the assembly work

to prevent damage to the pilot screw seat.

Before checking dispensing volume, operate the

engine in warm state to adjust idling rpm to

specified range.

Screw

Autobystarter cable

Throttle Stop Screw

Fuel Pump

Page 63

MEMO

Page 64

Engine Removal

6-1

6. Engine Removal

Service Information 6-1

Engine Removal 6-2

Service Information

General Safety

NOTE

● The following works can be carried out without removing the engine from the vehicle body.

- Transmission (⇨ Section 11)

- A.C. generator (⇨ Section 8)

- Kick starter, continuously variable transmission(⇨ Section 7)

- Cylinder head, cylinder, and piston (⇨ Section 9 and 10)

- Carburetor (⇨ Section 5)

- Oil pump (⇨ Section 2)

●Items to be worked after removing engine

- Crankshaft, crankshaft bearing, crank case bearing

● Engine oil capacity: 1.0ℓ-when disassembled

Torque values:

Engine hanger bolt (Front): 2.7kg-m(27N.m, 20ft-1b)

(Rear) : 3.5kg-m(35N.m, 25ft-1b)

Use a jack to remove or install the engine. Support the motorcycle with a jack firmly, taking precautions

not to damage the frame, engine, cable or harness.

Attach tape to the frame to protect it during the engine removal or installation.

6

Page 65

Lower bolt

Engine Removal

Engine Removal

● Drain the engine oil.

● Remove the following parts.

- Luggage box ( 4-5)

- Frame body cover ( 4-6)

- Air cleaner ( 5-4)

● Remove A.C. generator, and starter motor cable.

● Remove the high-tension cord.

● Remove the carburetor. ( 5-6)

● Remove the rear brake rod.

● Remove the fuel tube.

● Remove the L.floor side cover.

● remove the radiator hose.

● Loosen the 3 rear mud-guard setting bolts.

● Loosen the engine hanger mounting bolt.

● Loosen the rear cushion lower bolt.

6-2

Brake rod

A.C.G connector

Hanger bolt

Page 66

Engine Removal

● Remove the engine.

(with the muffler and rear wheel attached)

● Remove the muffler. ( 4-9)

● Remove the rear wheel. ( 13-3)

Installation

● Install in the reverse order of removal.

NOTE

Toque:

Engine hanger bolt:(Front)2.7kg-m(27N.m, 20ft-lb)

(Rear)3.5kg-m(35N.m, 25ft-lb)

● Check the following after the engine is assembled.

- Engine oil

- Electric systems

- Adjust the rear brake free play.

6-3

Take precautions not to damage wiring and cable.

Take precautions not to damage the threaded part of

bolts.

Arrange the cable, tubes and wiring in the right

positions.

Page 67

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

7-0

L. crank case cover

Page 68

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

7. L. Crank Case Cover/Kick Starter/Continuously variable transmission

7-1

Service Information 7-1

Troubleshooting 7-1

L. Crank Case Cover 7-2

Kick Starter 7-4

Drive Belt 7-7

Movable Drive Face 7-9

Clutch/Disassembly 7-12

Driven Face Disassembly 7-12

Service Information

General Safety

● Take precautions not to apply grease or oil to the drive belt and pulley surface.

Take precautions not to apply the grease oil to the movable drive face or weight roller.

Specifications

Item Standard Service Limit

Movable drive face bushing inner diameter 24.000-24.013(0.9449-0.9454) 24.040(0.9465)

Drive face boss outer diameter 23.980-23.993(0.9441~0.9446) 23.960(0.9433)

Drive belt width 22(0.8661) 20.5(0.8071)

Weight roller outer diameter 10.95-20.05(0.4311-0.7893) 19.5(0.7677)

Clutch outer and inner diameter 120.0-120.5(4.7244-4.7441) 120.5(4.7441)

Driven face spring play 97.85(3.8524) 97.23(3.8279)

Driven face outer diameter 37.965-37.985(1.4946-1.4955) 37.911(1.4926)

Driven face inner diameter 38.0-38.025(1.4961-1.4970) 38.060(1.4984)

Troubleshooting

Engine starts but motorcycle does not

work.

● Drive belt worn.

● Ramp plate damaged.

● Clutch shoe worn or damaged.

● Movable driven face spring cut.

Engine stops, or the vehicle runs suddenly,

after starting.

● Clutch shoe spring cut.

Vehicle unable to run at the maximum

speed, or lack of output

● Drive belt worn.

● Defective movable driven face spring.

● Weight roller worn.

● Pulley face contaminated.

NOTE

Unit:mm(in)

7

Page 69

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Installation

● Remove the crank case gasket, and install a new

gasket and dowel pin.

L. Crank Case Cover

Removal

● Loosen the kick starter pedal bolt.

● Remove the kick starter pedal.

● Remove the cover side cooling hose.

● Loosen the L. crank case cover bolt, and remove

the cover.

● Remove the gasket and dowel pin.

7-2

Crank case cover

Kick starter pedal

Page 70

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Tighten the L. crank case cover bolt.

● Assemble the cooling hose to the cover.

● Install the kick starter pedal and tighten bolts.

Torque value: 2.2kg-m (22N.m, 16ft-Ib)

● Feed the DAELIM genuine oil to the cylinder

head cover.

7-3

Crank case cover

Kick starter pedal

Page 71

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Kick Starter

Removal

● Remove the L. crank case cover.( 7-2)

● Remove the kick starter spring from the kick

return stopper plate on the L. crank case cover.

● Remove the kick starter spindle.

● Remove the kick driven gear.

● Remove the kick starter idle shaft.

7-4

Kick driven gear

Stopper plate

Kick start idle shaft

Page 72

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Disassemble the kick starter driven gear.

● Disassemble the kick starter idle shaft.

Kick Starter Inspection

● Check the kick starter spindle for wear or

damage.

● Check the return spring for defects or damage.

● Check the kick starter spindle bushing and the

idle gearshaft assembly for damage.

7-5

Driven gear

Idle gear

OIL

Page 73

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Check the kick starter driven gear for wear and

damage. Check the friction spring for defects and

damage.

7-6

Friction

spring

Kick starter

driven gear

Page 74

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Kick Starter Assembly

● Assemble the kick starter idle gear shaft and the

kick driven gear comp to the left cover.

NOTE

● As shown in the figure, match the kick driven

gear friction spring with the L. crank case cover

groove, and assemble.

● Match the kick starter spindle with the idle gear

punch mark, and assemble.

● Hold, and turn, in reverse, the kick return spring

arm.

● Assemble the kick stopper plate.

Drive Belt

Removal

● Remove L. crank case cover. ( 7-2)

● Loosen the clutch outer setting nut with a

universal holder.

Tool: Universal holder

7-7

Setting nut

Driven gear

Idle gear

OIL

Apply grease to the spring groove, kick driven

gear, and idle gear wedge.

Page 75

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Drive Belt Inspection

● Check the drive belt for cracks, deterioratect and

abnormal wear. Replace the defective drive belt.

● Check the drive belt width.

Service limit: 20.5mm (0.8071in)

NOTE

● Remove the drive belt from the clutch / driven

pulley, as shown in the figure.

Drive Belt Assembly

● Temporarily assemble the clutch / driven pulley

to the drive shaft.

● As shown in the right side figure, turn the

movable driven face clockwise, and assemble the

drive belt to the driven pulley while widening

the driven pulley belt contact part.

● Assemble the clutch / driven pulley to the drive

shaft.

NOTE

7-8

Make sure that the movable drive face do not

return to the original position until the

clutch/driven pulley are completely assembled

to the drive shaft.

Use Daelim genuine parts.

Be careful not to apply oil to the belt pulley

contact.

Drive

shaft

Drive belt

Clutch/driven pulley

Width

Movable

driven face

Teeth type

Page 76

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Movable Drive Face

Removal

● Remove the L. crank case cover.

● Fix the drive pulley holder to the crank shaft.

● Remove the drive pulley nut, washer and drive

face.

Tool: Drive pulley holder

● Assemble the clutch outer to the drive shaft.

● Fix the clutch outer with the universal holder, and

fasten with the setting nuts.

Torque value: 5.5kg-m (55N.m,40ft-Ib)

Tool: Universal holder

● Assemble the L. crank case cover.

● Remove the movable drive face and the drive

face boss.

● Remove the ramp plate, weight roller, and O-ring

from the movable drive face.

7-9

Drive face boss

Ramp plateWeight rollerFace boss

Drive face

Nut

Drive pulley holder

Setting nut

Page 77

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Check the movable drive face boss for wear or

damage.

● Check the outer diameter of the movable drive

face boss.

Service limit: 23.96mm (0.943in)

● Check the inner diameter of the movable drive

face.

Service limit: 24. 043mm (0.946in)

Movable Drive Face Inspection

● Check the weight roller for wear or damage.

● Check the weight roller outer diameter.

Service limit: 19.5mm (0.767in)

Movable Drive Face Assembly

● Supply grease on the inner side of the movable

drive face boss part.

● Assemble oil seal in the both sides of the

movable drive face boss part.

● Assemble the weight roller.

● Assemble the ramp plate.

● Connect the movable drive face boss together.

NOTE

7-10

Do not apply the grease to the pully surface of

the movable drive face.

If grease is applied, remove the grease.

Ramp plate

Weight roller

Movable drive face

Drive face boss

Drive face boss

Page 78

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Assemble the movable drive face boss and the

movable drive face to the crank shaft.

● Assemble the assembly drive belt to the crank

shaft.

● Tighten the drive pulley nut with a drive holder.

Torque value: 5.5kg-m (55N.m,40ft-Ib)

Tool: Drive pulley holder

7-11

Drive belt

Setting nut

Page 79

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

Clutch Disassembly

● Remove the L. crank case cover. ( 7-2)

● Disassemble the movable drive face. ( 7-9)

● Disassemble the drive belt. ( 7-7)

● Use a universal holder to hold the clutch outer,

and remove the clutch outer after disassembling

the 12mm flange nut.

● Remove the movable driven face and the clutch

from the drive shaft.

Driven Face Disassembly

● Disassemble the 30mm special nut.

7-12

Movable drive

face.clutch

Drive

Drive

Drive

Clutch spring

Drive plate

Face nut

Rubber

Spring collar

Clutch spring

Clutch shoe

Setting nut

Page 80

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

7-13

● Remove the seal collar.

● Remove the guide roller and its pin.

● Remove the movable driven face.

● Remove the O-ring from the movable drive face.

● Remove the oil seal from the movable driven

face.

● Remove the inner bearing.

Seal collar

Guide roller

Inner bearing

Movable

driven face

Oil seal

Guide pin

O-ring

Movable

driven face

Page 81

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

7-14

● Disassemble the circlip and remove the outer

bearing.

Clutch/Driven Face Inspection

● Measure the free length of the driven face spring.

Service limit: 97.23mm (3.822in)

● Check the clutch outer for wear or damage.

● Measure the inner diameter of the clutch outer.

Service limit: 120.5mm(4.736in)

● Check the clutch shoe for wear or damage.

● Measure the thickness of each shoe.

Service limit: 2.0mm(0.078in)

Outer bearing

Lining

Free length

Clutch outer

Clutch shoe

Page 82

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Check the driven face assembly for wear or

damage.

● Measure the outer diameter of the driven face.

Service limit: 37.94mm(1.491in)

● Check the movable driven face for wear or

damage.

● Measure the inner diameter of movable driven

face.

Service limit: 38.06mm(1.496in)

● Check the guide globe for wear or damage.

● Check the oil seal for wear, damage or other

defects.

Driven Face Assembly

● Assemble the outer bearing to the movable

driven face.

NOTE

● Insert the circlip into the groove.

● Fill the grease into all bearing grooves.

Grease application: 9.0-9.5g

7-15

Assemble the bearing so that the sealed edge

faces outward.

● Assemble inner bearing.

NOTE

Tool: - Bearing driver attachment

- Driver pilot

Assemble the bearing so that the sealed edge

faces outward.

Outer bearing

Inner bearing

Movable face

Guide pin globe

Page 83

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Assemble the seal collar.

● Assemble the movable driven face, guide roller

and roller pin

● Assemble the driven pulley, spring and clutch in

the clutch spring compressor. Compress the

assembly by turning the tool handle until the

lock nut can be installed.

● Clamp the clutch spring compressor in a vise and

tighten the lock nut to the specified torque using

the lock nut wrench. Remove the spring

compressor.

Torque value: 5.5kg-m(55N.m, 40ft-lb)

Tool: - Lock nut wrench

- Clutch spring compressor

Clutch/Driven Pulley Assembly

● Assemble the driven pulley to the drive shaft.

7-16

Seal collar

Movable driven

face/clutch

Clutch spring compressor

Lock nut wrench

Lock nut

Guide roller

Movable

driven face

Page 84

L. Crank Case Cover/Kick Starter/Continuously Variable Transmission

● Assemble the clutch outer. Hold the clutch outer,

and tighten nuts with the prescribed torque.

Torque value: 5.5kg-m(55N.m, 40ft-lb)

Tool: Universal holder

● Assemble the drive face.

● Assemble the L. crank case cover.

7-17

Setting nut

Page 85

Generator/Starter Clutch

8-0

Page 86

8-1

8. Generator/Starter Clutch

Service Information 8-1

Shroud 8-2

A.C Generator 8-2

R.Crank Case Cover 8-4

Starter Clutch 8-6

Service Information

General Safety

● This section describes the removal and assembling of the A.C. generator.

● For information on A.C generator inspection, refer to the section 15.

● The charging system can be maintained without removing the engine.

Specifications

Item Standard value service Limit

Starter driven gear

O.D 39.622-39.635(1.5599 -1.5604) 39.53(1.556)

I.D 32.000-32.025(1.2578 -1.2588) 32.10(1.2618)

Reduction gear I.D 12.016-12.034(0.4723 -0.4730) 12.10(0.4756)

Reduction gear shaft O.D 11.966-11.984(0.4703 -0.4710) 11.97(0.4705)

Torque values

Fly wheel bolt 5.5kg.m(55N.m, 39ft-lb)

Starter clutch socket bolt 3.2kg.m(32N.m, 23ft-lb)

R. crank case cover bolt 1.1kg.m(11N.m, 8ft-lb)

Tools

Fly wheel puller

Fly wheel holder

Unit: mm(in)

8