Page 1

TABLE OF CONTENTS

Parking Brake Adjustmemt

YOUR RESPONSIBILITIES

CONTROL FEATURES

MANUAL CHOKE LEVER

THROTTLE LEVER

BRAKE CONTROLS

FUEL SYSTEM

Fuel Tank

Fuel Valve

Inline Fuel Filter

TIRES AND WHEELS

Tire & Wheel inspection

Tire Pressu re

FUEL INDICATOR METER

REVERSE INDICATOR LAMP

SPEEDOMETER & ODOMETER

SPECIFICATIONS

BREAK-IN YOUR NEW DAELIM ATV

1

2

2

2

3

3

3

3

3

5

6

7

7

7

8

9

10

10

10

10

10

11

11

11

11

11

12

12

Page 2

TABLE OF CONTENTS

THROTTLE LEVER

Adjusting The Throttle Cable

SPARK PLUG

BRAKING SYSTEMS

The Brake Cables Inspection

The Brake Cables Adjustment

The Brake Hoses Inspection

To Fill The Reservoir

Purging Brake Lines

DRIVE CHAIN

Chain Slack Adjustment

AIR FILTER

Air Filter Maintenance

To Clean The Filter

ENGINE WARTER COOLER

Checking C Leveroolant

Replenishment Of Coolant

Replenishment Of Anti-freeze

Check Cooling System For Leaks

ENGIEE OIL

Checking Engine Oil Level

Changing Engine Oil

TRANSMISSION OIL

Changing Transmission Oil

ELECTRICAL BATTERY

12

12

12

12

12

13

13

13

14

16

16

17

18

18

19

20

21

MEMO

22

Page 3

DAELIM

ET250

DAELIM

DAELIM

YOUR RESPONSIBILITIES

DAELIM

Page 4

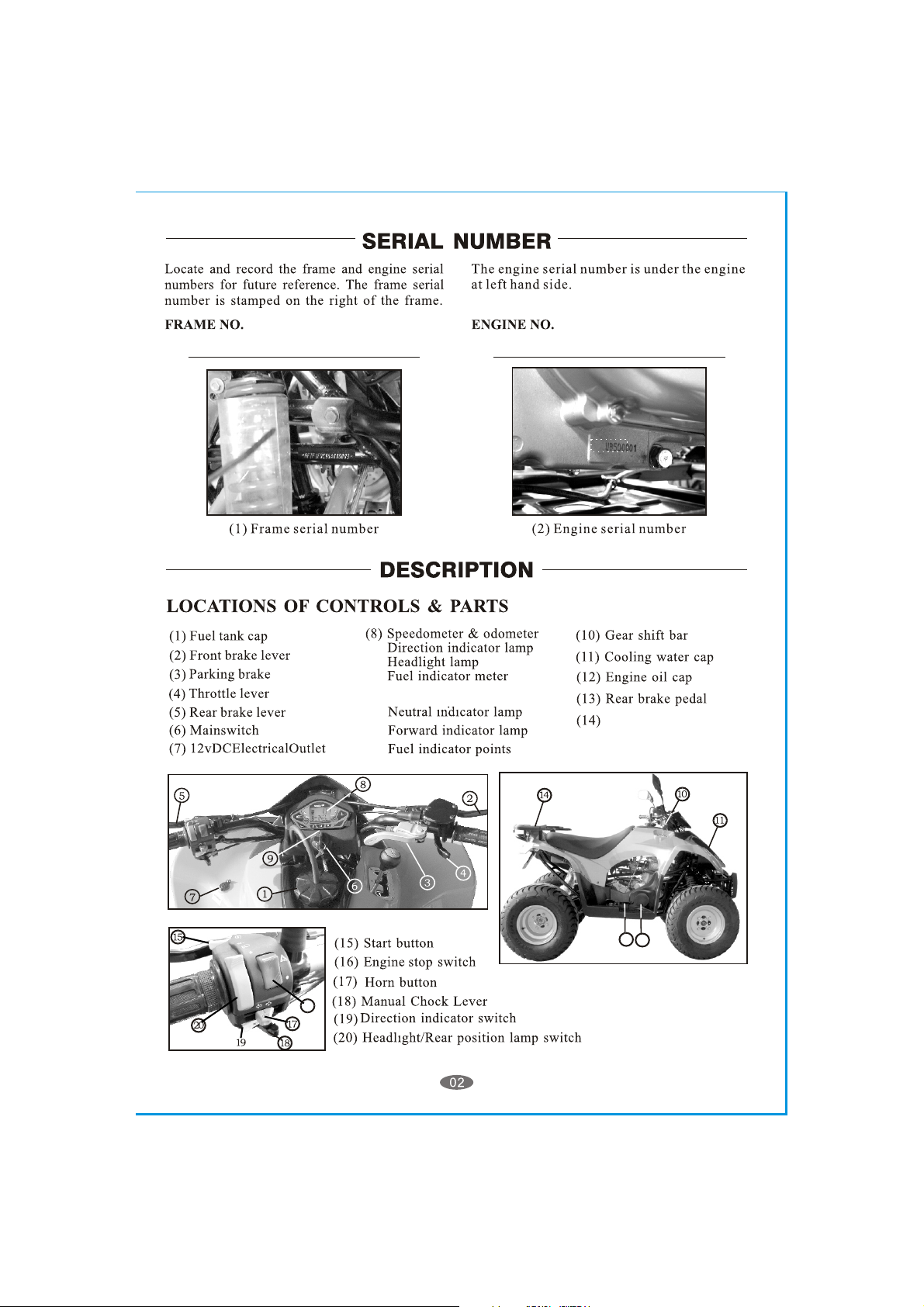

(9) Reverse indicator lamp

12

}

Rear cargo rack

13

16

Page 5

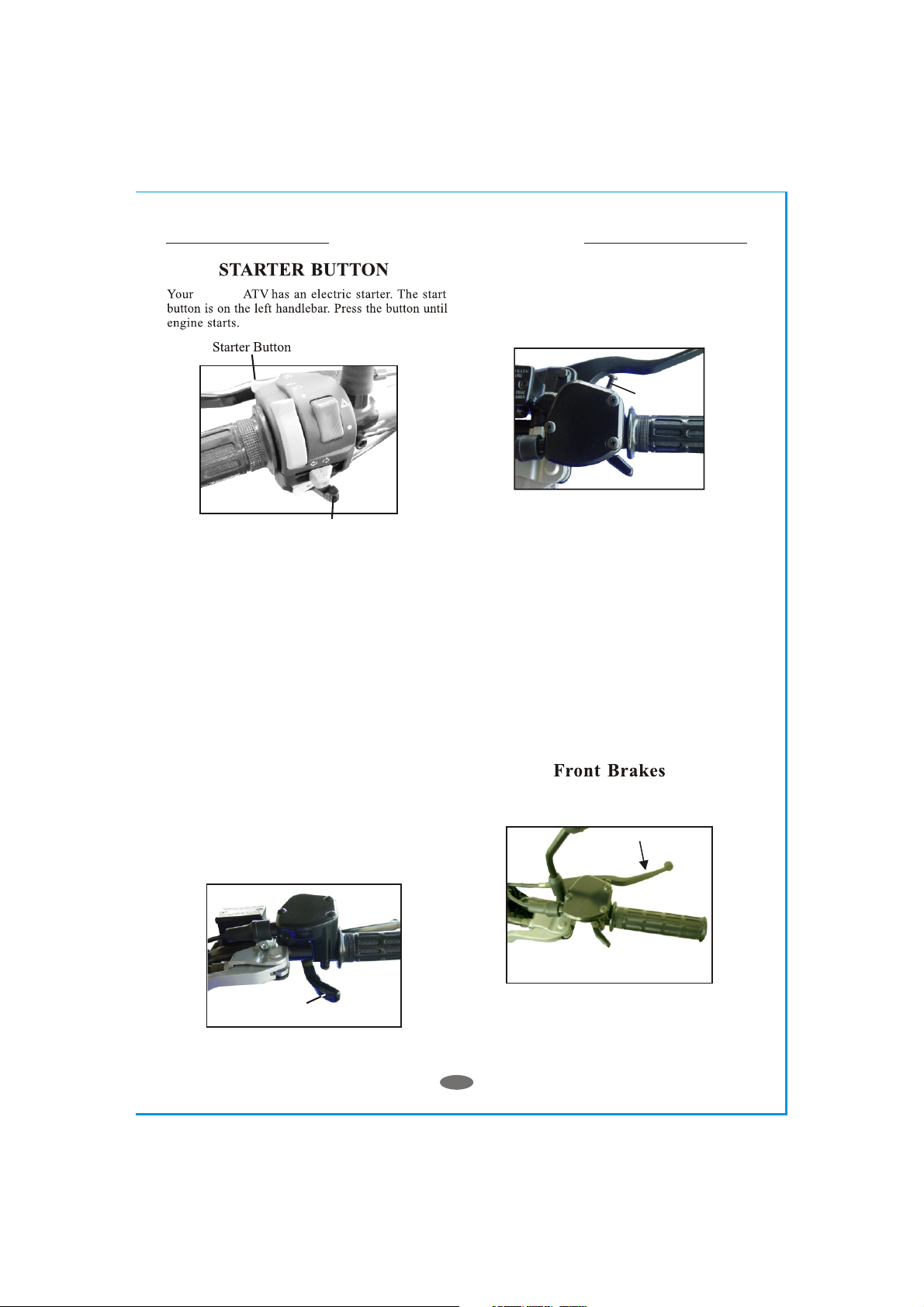

CONTROL FEATURES

DAELIM

Manual Choke Lever

MANUAL CHOKE LEVER

The ET250 are equipped with a manually

operated carburetor choke system.

This choke is operated by the lever at the bottom

of the left hand control switch.

When first starting the engine,(cold start), place

the lever in the full left position, (Choke closed

or on) As the engine warms return the lever to

the full right position. (Choke open or off).

The travel of the throttle lever is controlled by

the throttle stop bolt.

As your operator gains more experience, you

can increase the throttle travel to allow for

additional speed to be obtained.

Throttle Stop

Adjustment Boit

To increase the throttle's travel, thus

increasing the maximum speed, turn the

throttle stop bolt counter clockwise. To

decrease the throttle's travel, thus decreasing

the maximum speed, turn the throttle stop bolt

clockwise.

The throttle cable should be adjusted so there

is 2mm, (1/8") free travel at the lever before

the throttle starts to open.

BRAKE CONTROLS

This vehicle is equipped with dual front

hydraulic disc brakes and a rear hydraulic

disc brake.

THROTTLE LEVER

The throttle lever is located on the right-hand

handle bar below the grip. To operate the

throttle lever, place your right thumb on the

lever and press forward to increase your speed.

To decrease your speed, reduce your pressure

on the lever and the spring tension will

automatically reduce your speed.

Throttle

The front brakes are controlled by the long

brake lever on the right-handle bar.

03

Page 6

CONTROL FEATURES

Parking Brake Adjustmemt

Parking Off

the adjustable nut

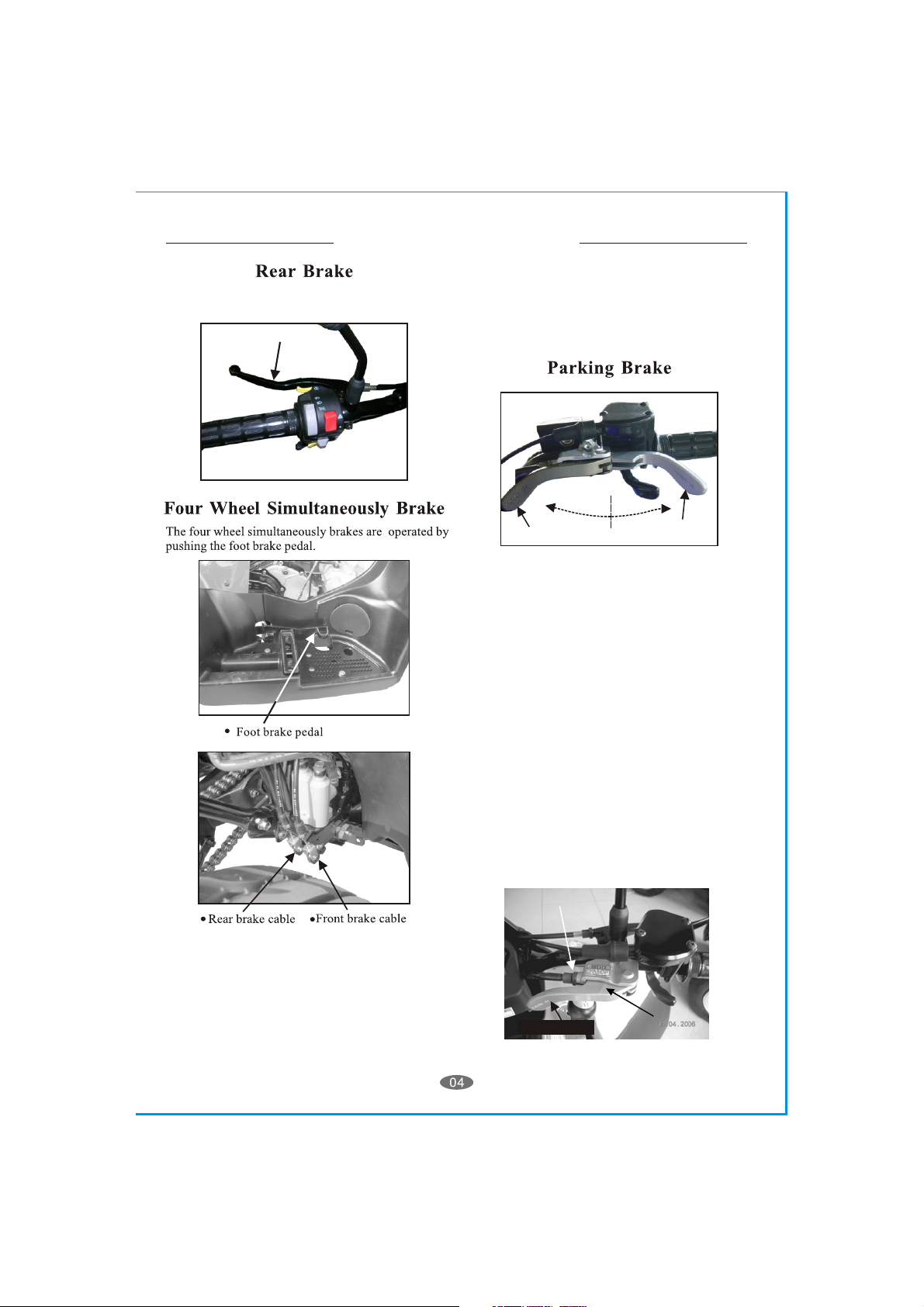

The rear brake is controlled by the long brake

lever on the left-handle bar.

pressure to your front brakes so that the

wheels lock up, stop turning, and causing a

loss of steering control. if the front wheels lock

up, and stop turning, lightly reduce the

pressure on the front brake lever until they

unlock and start to turn.

The rear brake is the primary stopping brake

on your vehicle. Using the rear brake to stop

your vehicle will prevent steering control loss.

Use your front and rear brakes in combination

(or use the four wheel simultaneously barke)

to control your speed while descending a

grade. Use caution not to apply too much

Parking Off

The parking brake is shown on the picture.

The position of parking Off is on the left

side. Turn parking brake to right side is

parking On.

This should be engaged as a parking brake

whenever the vehicle is not in operation.

Parking On

Parking Brake Adjustmemt

As you found out the parking brake which

has been decreased its brake ability.

You must adjus the parking brake.

1. Turn the parking brake to"Parking Off"

position. then screw the adjustable nut

to original position.

2. Lossen"Parking Brake Adjustable Nut"

near the rear brake caliper.Use your hand

to screw "Parking Brake Adjustable Bolt"

by clockwise to the end. Then back to a

quarter turn, tighen the nut to complete

the parking brake adjustable.

the adjustable nut

Parking Off

the parking brake

Page 7

3. Also,as you found out the parking brake

Parking Brake Adjustable Bolt

Parking Brake Adjustable Nut

ability which is a bit insufficient, you can

screw the adjustable nut of parking brake.

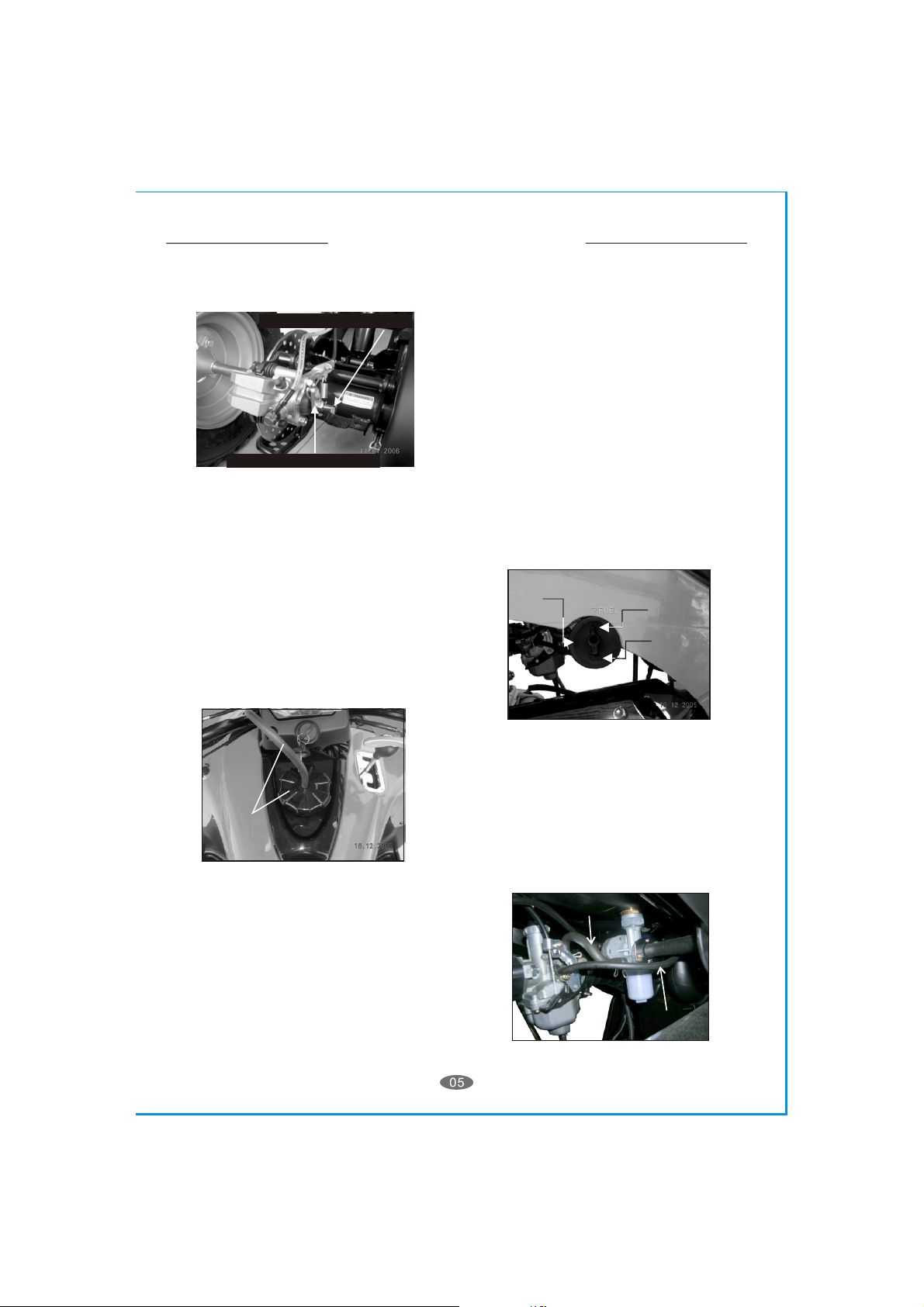

The fuel tank fill cap is located on top of the

unit just ahead of the seat. The cap contains a

vent to prevent a vacuum from forming in the

tank as fuel is used. The vent tube must be

attached to the cap and inserted in the vent

tube holder hole while operating the unit. The

fuel cap vent and vent tube must be clean and

clear of obstructions for the unit to operate

normally. You can check the vent and vent

tube by blowing air through the tube. If you can

not blow through the vent tube and cap you

must clean the vent and tube or replace them.

CONTROL FEATURES

Parking Brake Adjustable Bolt

Parking Brake Adjustable Nut

FUEL SYSTEM

Fuel Tank

cause damage to the cap or seal.

The fuel tank capacity is 12 liters, 3.17 gal,

including a reserve of 2.5 liters, 0.66 gal.

Use unleaded automobile gasoline with an

octane level of 91 or higher.

YourATV is equipped with a fuel gage located

in the instrument cluster between the handlebars.

NEVER REFUEL YOUR ATV when the

engine is HOT. Wait 30 minutes after turning

off the unit before refueling. Spilling fuel on a

HOT engine could cause a fire. Wipe up any

fuel spills before re-starting.

Fuel Valve

The unit is equipped with a three way fuel

valve located on the left side of the unit just

below the seat.

The valve has three settings; "ON", "RES"

and "PRI".

PRI

ON

RES

Fuel Tank Cap

& Vent Line

Every time you refuel your unit, check the

rubber seal inside the cap for cuts, tears and

dirt. Clean or replace the seal if it becomes

worn or torn. The seal must be in good

condition to insure a proper seal of the cap to

the tank to prevent fuel spills. DO NOT allow

dirt or other debris to enter the tank when

refueling.

Replace the cap if damaged or if it will not seal

to the tank.

Tighten the cap snugly, being careful not to

over tighten. Over tightening the cap can

Place the valve in the "ON" for normal operation

of the unit.This allows fuel to flow to the

carburetor for normal operating. The "RES"

position allows fuel to flow from the small

reserve in the tank to allow the unit to be

taken to a refueling location. When you have

to switch to the "RES" position you must refuel

the unit as soon as possible.

When the fuel valve set on the "ON" or "RES"

position, the unit is equipped with a vacuum

controlled fuel valve. The fuel supply is autom

Fuel Line

Vacumn Control

Line

Page 8

CONTROL FEATURES

atically shut off when the engine is stopped.

The fuel will automatically begin to flow when

the engine is turned over.

To test the fuel valve remove the fuel line from

the carburetor and place the end in a container

to catch the fuel. Insure that your tank has fuel

and press the starter button. Fuel should flow

Into the container from the fuel line.

When the fuel valve set on the "PRI" Position,

the unit is not equipped with a vacuum

controlled fuel valve. The fuel will flow to the

carburetor directly.

The purposes of "PRI" include two functions.

One is let fuel flow out when repairing ATV,

another reason is if all above operations fail,

the user can turn the fuel valve to "PRI" position

in order to let fuel flow into the carburetor

favorably.

ALWAYS CHECK YOUR Fuel level before

you start riding your ATV. Remember:

You can drive further in one hour on your ATV

than you can walk in one day.

Inline Fuel Filter

Your ATV is equipped with an inline fuel filter

to prevent dirt and debris from entering the

carburetor and engine.

Check the filter for dirt or damage before each

ride and at each refueling. Replace the filter if

dirty or damaged.

DO NOT operate the unit with out a fuel filter.

Doing so can cause damage to the carburetor

and engine.

Inline Fuel Filter

Remove the filter from the fuel line by holding

the line and pulling the filter. Install the new

filter by inserting the filter into the fuel line and

returning the clamps to the original position.

Turn the fuel valve to the "PRI" position and

check for leaks. Inspect the fuel lines for cuts,

abrasions and deterioration. Replace fuel lines

as needed. Return the fuel valve to the "ON"

position for normal operations.

DO NOT start or operate the engine if the fuel

filter or lines are leaking. Leaking fuel can

cause a fire.

TIRES AND WHEELS

Tire & Wheel inspection

It is important to inspect your tires and wheels

for damage and wear before each riding

session. Inspect each tire for cuts, tears and

punctures. Inspect the wheel rim for dents and

separation of the wheel from the tire bead.

Replace any tire or wheel found to be

damaged.

Operating your ATV with damaged tires or

wheels is dangerous. Damaged tires or wheels

can result in a sudden loss of tire pressure and

control which could result in injuries.

Check your tire pressure before each riding

session and at each refueling operation.

Always check the pressure when the tires are

cool. Use the tire pressure gauge that came

with your ATV to check the tire pressure.

Wheel Nuts torque 24-30 N/m (18-22 1b/ft)

The filter should be replaced every 600 hours

of operation and at the start of each season.

To replace the filter, first turn the fuel valve to

the "ON" or "RES" position. Then carefully

compress the wire clamp rings until the clamp

is free of the fuel line. Slide each clamp away

from the filter about 3/4".

Tire Pressure

Page 9

FUEL INDICATOR METER

2

5

3

4

6

7

5

3

9

8

1

REVERSE INDICATOR LAMP

Your ATV is equipped with a fully automatic

C.V.T. transmission and has forward and

reverse gearing. A transmission shifting shaft

is located on the right hand side of your vehicle.

The shifter has three positions "F" Forward, "N"

Neutral and "R" Reverse.

The instrument panel has three lights that

correspond to the transmission shifter shaft

position.

The transmission must be placed in the "N"

(neutral - Green indicator Lamp) to start the

engine.

Slowly move the shifting lever to the desired

gear pausing slightly at the neutral position.

Once you have the gear selected increase the

throttle slowly until the transmission becomes

fully engaged and the vehicle starts moving in

the desired direction.

When shifting gears it is important that you

bring the vehicle to a complete stop with the

rear brake fully engaged and the enqine at idle.

If you attempt to shift the transmission with the

engine running above the idle speed the

engine will automatically shut down to protect

the transmission.

If this should happen you will need to turn off

the ignition switch to reset the safety lock out

before attempting to restart the enqine.

Page 10

SPEEDOMETER & ODOMETER

1

2

Page 11

SPECIFICATIONS

Engine

Typ e

Displacement

Bo re / Stro ke

Compression

Power

Transmission

Typ e

Chassis

Overall Length

Overall Width

Overall High

Wheel Base

Dry Weight

Suspension

Front

Rear

Brakes

Front

Rear

Tires

Front

Rear

Tire Pressure

Wheels

Bolt Pattern

Carburetor

Make/Size

Main Jat

Pilot Jet

Air Mixture Adjustment

Idle Speed

Sprockets

Frnot

Rear

Chain

Battery

Fluids

Fuel

Engine Oil

Transmission

Spark Plug

NGK

Carrying Capacity

Rack Capacity

Tow in g Ca pa ci ty

Maximum Rider Weight

Minimum Rider Age

Typ e

Volume

Typ e

Volume

Typ e

Volume

Electrode Gap

Front

Rear

Trailer Weight

Tongue Weight

4 Stroke Single Cylinder Liquid cooled

249 cc

71mm * 63mm

10.8:1

19ps @ 6500rpm

Automatic (CVT V-belt + Reverse)

1830mm / 72.0"

1040mm / 40.9"

1150mm / 45.3"

1190mm / 46.9"

215kg / 474 lbs

Dual A-arm/ Adjustable Shocks @ 2.95" travel

Swing Arm/ Adjustable Shock @ 4.72" travel

Hydraulic Disc*2

Hydraulic Disc

21*7-10

22*10-10

3.8psi / 0.265kg/cm

4 x 110mm

Kei-Hin with Manual choke

1.1mm

0.35mm

Back out 1 - 2 turns

Idle 1600 - 1800rpm

15 teeth

38 teeth

#520*90 O-Ring

12V-10AH-GTX12-BS

Unleaded Gasoline 89 octane

12 li te rs / 3. 17 g a l

SAE 10W-30

1.4 liters / 1.4gt (1.2 liters / 1.2gt for change)

SA E 85W-1 40 e ight g ear Oi l

750cc / 25.4oz (650cc / 22oz for change)

NGK-CR8E

0.6-0.7mm / 0.023"-0.027"

--/--

16kg / 301b

150kg / 3001bs

50kg / 110lbs

150kg / 330lb

16 years

2

/ 0.26bar

2

/

4

NO

OPTION

ET300ET250

4 Stroke Single Cylinder Liquid cooled

287.2 cc

75mm * 65mm

10.0:1

20ps @ 6500rpm

Automatic (CVT V-belt + Reverse)

1830mm / 72.0"

1040mm / 40.9"

1150mm / 45.3"

1190mm / 46.9"

217kg / 478 lbs

Dual A-arm/ Adjustable Shocks @ 2.95" travel

Swing Arm/ Adjustable Shock @ 4.72" travel

Hydraulic Disc*2

Hydraulic Disc

21*7-10

22*10-10

3.8psi / 0.265kg/cm

4 x 110mm

Kei-Hin with Manual choke

1.08mm

0.35mm

Back out 1 - 2 turns

Idle 1600

15 teeth

38 teeth

#520*90 O-Ring

12V-10AH-GTX12-BS

Unleaded Gasoline 89 octane

12 li te rs / 3. 17 g a l

SAE 10W-30

1.4 liters / 1.4gt (1.2 liters / 1.2gt for change)

SAE 85W-140 eight gear Oil

750cc / 25.4oz (650cc / 22oz for change)

NGK-CR8E

0.6-0.7mm / 0.023"-0.027"

--/--

16kg / 301b

150kg / 3001bs

50kg / 110lbs

150kg / 330lb

16 years

2

/

4

100rpm

NO

OPTION

2

/ 0.26bar

Page 12

[The are equipped with a

ET250

This choke is operated by the lever at the bottom

When first starting the engine,(cold start), place

As the engine warms return the lever to

manually operated carburetor choke system.

of the left hand control switch.

the lever in the full left position, (Choke closed or on)

the full right position. (Choke open or off).]

BREAK-IN YOUR NEW DAELIM ATV

DAELIM

Page 13

Page 14

DAELIM

12

Page 15

THROTTLE LEVER

Throttle

The throttle lever is located beside the righthandlebar grip and is operated by using the righthand thumb. The lever is spring loaded and will

return to the idle position when you remove your

thumb from the lever. To accelerate the unit,

simply press the lever forward to open the throttle

slide in the carburetor. To slow the unit, reduce the

pressure on the lever or remove your thumb and

the throttle will return to the idle position

automatically.

Adjusting the throttle cable

Adjuster Nut

The cable should be adjusted to allow for " free

travel before the throttle engages the carburetor

throttle slide. Slide the adjuster cover down the

cable to uncover the adjuster assembly. To adjust

the cable's free travel, loosen the locking nut of

the cable adjuster, and turn the adjuster nut until

there is " free travel in the lever. Tighten the

locking nut to secure the adjusting nut. Slide the

1

/

8

cover back over the adjuster assembly.

The speed of the unit can be adjusted by

adjusting the throttle stop screw to limit throttle

travel. Loosen the throttle stop screw locking nut

Locking Nut

1

/

8

Throttle Stop

Adjustment Boit

and turn the throttle stop screw clockwise to

reduce the throttle travel thus reducing the

maximum speed of the unit. Turning the stop

screw counter clockwise will increase the throttle

travel thus increasing the maximum speed of the

unit. Tighten the stop screw locking nut when the

desired throttle travel has been established.

SPARK PLUG

Replace spark plug at the beginning of each

season with a replacement plug NGK-CR8E.

Disconnect spark plug wire.

Clean dirt from around spark plug base with

brush or compressed air.

Remove spark plug with spark plug wrench.

Set the spark plug gap on the new plug to

0.023"

Install the new plug screwing it in finger tight

and then use the plug wrench to screw the

plug in another turn.

Inspect the spark plug wire for cuts, nicks or

other damage. Replace as needed.

1

/

2

Page 16

BRAKING SYSTEMS

Your ATV unit is equipped with dual front

hydraulic disc brakes and a rear hydraulic

disc brake. The front brakes (right) and rear

brake (left) are applied by squeezing the brake

lever on the right & left handle-bar , while the

four wheel simultaneous brakes are applied

by pressing the brake pedal on the right-footrest.

Proper maintenance of the brake system is a

necessary part of safe operation of your unit. The

brake systems should be inspected and tested

before each riding session.

The Brake Cables Inspection

Visually inspect the brake cables for any signs of

wear. Inspect the cables for frays and kinks that

Inhibit the free movement of the cable. Replace

frayed or kinked cable before operating your unit.

inspect the cables for rust or corrosion. Replace

any brake cable that show signs of corrosion as

this could cause a reduction in cable strength that

can lead to the cable breaking.

Test the brakes by applying pressure to the

brake lever and trying to push the unit forward. If

the wheel rotates while the brakes are applied,

adjust the brake cable until the wheels no longer

rotate.

(See Brake Adjustment)

The Brake Cables Adjustment

Adjust the brake cable so that the lever has zero

free play and a minimum clearance of "

between the lever and the handle grip when the

brake is fully applied. Adjust the cable by using

the adjustment wheel where the cable attaches

Adjusting Ring

The front

brakes

1

/

to the lever assembly. After obtaining the correct

adjustment, insure that the locking nut is

tightened securely against the adjusting wheel to

prevent the adjustment wheel from turning due

to vibration. Keep your brake cables lubricated

with a high quality cable lubricant to prevent rust

and corrosion. The cables should be lubricated

every 60 days or more often if operated in a

dusty or wet environment.

Replacement of the brake cables should ONLY

be preformed by a qualified mechanic.

The Brake Hoses Inspection

Visually inspect the brake hose for any signs of

wear or leaks. Check the fluid level in the fluid

reservoir by checking the position of cup behind

the right-footrest.

The fluid level should fill at least of the cup

when the unit is setting on a level surface.

Test the brakes by applying pressure to the brake

2

lever and trying to push the unit forward. If the

wheel rotates while the brakes are applied, check

The front

brakes

3

4

/

Locking Nut

Adjusting Ring

The rear

brake

Hose

The rear

brake

Page 17

Bleecler Valve

your fluid level and brake pads. If the brake lever

Bleecler Valve

Bleecler Valve

Cover

feels spongy or does not stop when squeezed,

you may have air in the lines. All air must be

purged from the brake lines for the disc brake to

operate properly. (See purging brake lines).

After riding your unit, be sure to clean any build up

of mud, sand and dirt from the brake rotor skid

plate. This will protect the rotor disc from rust and

corrosion.

Purging Brake Lines

To Fill The Reservoir

Remove the reservoir cover.

Fill the reservoir to 1/8" from top with Dot-3

SAE-J 1703 grade brake fluid.

Caution: DO NOT

Allow dirt to fall into the

reservoir

Refold the cover gasket as shown in picture and

replace cover.

Fill to 1/8"

from top

Bleecler Valve

Bleecler Valve

THE FRONT CALIPER

THE REAR CALIPER

For the hydraulic brake system to operate safely,

the brake system must be purged of air in the lines

and reservoir.

To bleed the air will require two people to perform

the following procedure.

1. Place a drain pan under the brake caliper

to catch the fluid.

2. Open the bleeder valve turn counter

clockwise.

3. Squeeze the brake lever to expel air from

1

/

2

the system.

4. While holding the brake lever, close the

bleeder valve.

5. Repeat steps 2 through 4 until the brake

fluid coming from the bleeder valve is a

solid stream without any air, then close the

valve and replace rubber protection cap.

6. Test the brake system by squeezing the

lever, the lever should feel firm and stop

without fading.

Page 18

DRIVE CHAIN

Air Filter Box

10-20mm

0.39"-0.79"

The drive chain will stretch with use and will

require periodic adjustments. To check the chain

tension, remove the chain guard and measure the

slack.

The amount of slack in the chain should not

exceed 10-20mm or 0.39"-0.79".

Inspect the drive and axle sprockets for worn,

damaged or broken teeth. Replace as needed.

Inspect the chain links for damaged, worn or loose

rivets. Repair or replace as needed.

Chain Slack Adjustment

Axle Locking Bolts

Loosen the axle position lock bolt slightly and turn

the chain adjuster nut to take up the excess slack

in the chain. Once the chain has been adjusted to

the proper tension retighten the axle position

locking bolt.

AIR FILTER

Air Filter Maintenance

To maintain the highest performance from your

engine and to reduce excessive wear that could

cause engine failure the engine requires a

continuous flow of clean air. Air is taken into the

engine through an air filter to clean the air prior

to mixing it with fuel in the carburetor.

During normal operation the filter accumulates

dirt from the air and will need to be cleaned to

maintain the proper air flow. The filter should

be cleaned every 30 days, more often if you

ride in a dusty or dirty environment and the

element should be replaced every year.

The air filter box is located under the seat toward

the front of the unit.

To Clean The Filter

Remove the cover of the air filter box.

Remove the filter element from the air box.

Chain Adjustment

The chain should be kept well lubricated to

prevent excess wear and premature failure. We

recommend that you lubricate the chain every 15

hours of operation, or more frequently if needed,

with a high quality chain lubricant.

Wash the element in a non-flammable solvent

such as air-filter cleaner from your local auto

parts dealer.

1. Dry the element completely before continuing.

2. Soak the element in clean engine oil until

completely saturated.

3. Squeeze out the excess oil until the element

does not drip any oil.

4. Allow the element to dry then reinstall the

element and cover.

Page 19

ENGINE WARTER COOLER

The engine coolant is cooled by an external

radiator located at the front of the unit. It is

important that the radiator fins be kept free of

dirt build up to prevent the engine from over

heating which can cause sever damage to the

engine. Remove any build up of dirt or mud from

the radiator fins with a pressurized spray of water.

Maintaining the coolant will allow the cooling

system to work properly and prevent freezing,

overheating,and corrosion.

PLEASE PAY SPECIAL ATTENTION that using

poor quality coolant may shorten the service life

of the radiator.

Concentration:50%.(Use distilled water when

mixing coolant)

Radiator capacity: Main radiator:800c.c.

Coolant should be changed once a year normally.

Reserved tank:350c.c.

Removing the radiator cap while the engine is

hot can cause the coolant to spray out,seriously

scalding you.Always let the engine and radiator

cool down before removing the radiator cap.

Checking LeverCoolant

Main radiator cap

Reserved tank

1.Stops ATV in the level place.

2.Remove the front cover.

3.Check reserved tank from viewing window

to see if coolant level is between the upper

limit and lower limit mark.

4.Add coolant up to upper mark if coolant is

close to the lower mark.

WARNING: The radiator coolant is under pressure

when hot. NEVER REMOVE the radiator cap until

the unit has cooled for at least 1 hour or server

injury or burns may result!

Reserved tank cap

Upper

Lower

Replenishment Of Coolant

1.Park the vehicle on level ground.

2.Remove the front cover.

a.Open reserved tank cap, refill coolant

until reaches the upper limit.

b.To avoid radiator getting rusty, do not use

coolant other than those recommended.

Replenishment OfAnti-freeze

Please refer to table showing what percentage

of anti-freeze should be used under different

temperatures if the vehicle is to be operated in

the low temperature areas.(below 0 c)

o

A reference table for anti-freeze concentration

percentage under differert temperatures

1.Radiator anti-freeze specification for this ATV

is H68.

2.Proper anti-freeze percentages for different

frozen temperatures are as follows:

3.If the specified anti-freeze is unavaiable,use

an equivalent with the same high quality.

4.Increase radiator maintenance intervals

when the weather is extremely cold.

Anti-freeze percentage

20%

30%

40%

50%

Freezing temperature

-8

-15

-24

-36

50% CONCENTRATION is used for all ATV

before delivery to ensure the effectiveness

of anti-freeze.

Check Cooling System For Leaks

If low coolant levels occur often or if coolant is

seen under unit after being parked it may indicate

a leak in your coolant system.

Inspect radiator and piping for leaks and damage.

Replace or repair any leaking radiator and piping

before starting the engine.

Page 20

ENGINE OIL

•••••

Checking Engine Oil Level

Engine Oil Dip Stick

& And F ill Tube

Engine Oil Drain

Lower

Upper

Your ATV uses automotive type engine oil to

lubricate the engine. The engine oil dip stick is

located on the right hand side of your engine

below the transmission shifting lever.

To check your oil level, remove the dip stick by

turning the thumb hold counter clockwise until

the stick has been completely disengaged from

the threads. Pull the dip stick out of the

crankcase and check the level of the oil as

indicated on the dip stick. The engine oil is full

when the oil reaches the level on the stick as

indicated in the photo above.

Always check your engine oil level with the

engine off and cold. Removing the dip stick

with the engine running could cause hot oil to

splash from the crankcase causing severe

burns.

Checking your engine oil while the engine is

hot can give you a false reading; always check

the oil level with a cold engine.

Your engine requires SAE 10W-30 engine oil and

the crankcase capacity is 1.2 Liters / 1.2 quart.

The engine oil should be changed before the

start of each riding season or every 1000KM

of operation. When riding where conditions are

dusty or humidity is high the engine oil should

be change more frequently.

•••••

••••••• •••••••••••

2. Remove the crankcase drain plug located

on the bottom of the crankcase on the underside

of the unit.

3. Remove the engine oil dipstick located on the right

hand side of the engine below the shifter shaft.

4. Allow the oil to drain completely (15-30 min).

5. Reinstall the drain plug and tighten.

Torque to 7-101bf-ft

6. F ill the c rankcase with o f SAE 10W-30 e ngine o il

through the dip dipstick hole.1.2 Liters/1.2 quart.

7. Reinstall the engine oil dipstick and finger

tighten.

8. Dispose of used oil at a proper recycling

station as required by law

TRANSMISSION OIL

Your ATV uses SAE 85W-140 gear oil to

lubricate the drive and transmission gears.

Your gear oil should be checked before each

riding session. The gear oil should be changed

before each riding 1 year or every 5000KM

operation.

Changing Transmission Oil

Transmission

Oil Filler Hole

Changing Engine Oil

1. Place an oil catch pan under the unit directly

below the engine crankcase.

1. P lace a no il c atch p an u nder the u nit d irectly

below the transmission box.

Page 21

•••••

Seat Latch

Transmission

Oil Drain

••••••• •••••••••••

2.Remove the tr ansmission b ox d rain p lug

located on the bottom of the transmission

box on the underside of the unit.

3. R. emove t he t ransmission box f ill hole plug locate

on top of the transmission box on the right hand

side of the engine.

4. A llow the o il to d rain completely (15-30 min).

5. Reinstall the d rain p lug a nd tighten.

Torque to 7-101bf-ft.

6. Fill t he t ransmission box with of SAE 85W-140

gear oil 250cc engine = 650cc /22oz.

7. Reinstall t he f ill hole plug and t orque t o 2-31bf-ft.

8. Dispose of used oil at a proper recycling

station as required by law.

ELECTRICAL BATTERY

Battery GTX12-BS

When reinstalling the battery, be sure to connect

the red cable to the positive (+) terminal and the

black cable to the negative (-) terminal.

The battery should be replaced every three years

or when it no longer holds a charge.

Do not expose the battery, for extended periods of

time, to freezing temperatures. If the battery has

been frozen it will need to be replaced. There are

inline fuses on the positive lead of the battery to

protect the wiring system from over loads. If your

starter motor will not turn over and the battery is

fully charged, check the inline fuse on the unit.

The unit's battery is located under the seat and

supplies electrical power to the unit. The battery

is a 12 volt jell acid type that contains no liquid

electrolyte. The battery should be removed from

the vehicle when stored for extended periods

and charged before being replaced in the unit.

Use a trickle charger set at 12 volts to recharge

the battery to full charge before replacing it in

the unit.

Amperage

Rating

15A

10A

30A

15A

Green

Color

Blue

Red

Blue

Series Items

Head Lamp

Fan Motor

Battery

Position Lamp

Stop&Tail Lamp

License Lamp

Illumi Lamp

Winke Lamp

For anothers series items of electrical units,

please refer to the fuse as shown in list.

Page 22

I, L

I

R

Page 23

Page 24

NOTATION

Loading...

Loading...