Daelim ET-250 SERVICE MANUAL

ET-250

1

Contents

1. INFORMATION..........................................................................................................................................5

1.1 SAFETY ............................................................................................................................................5

1.2 NOTES ..............................................................................................................................................5

1.3 SPECIFICATION ENGINE ..............................................................................................................6

1.4 SERIAL NUMBER ...........................................................................................................................7

1.5 TORQUE VALUES ...........................................................................................................................8

1.6 Special Tools ......................................................................................................................................9

2. MAINTENANCE......................................................................................................................................10

2.1 MAINTENANCE DATA .................................................................................................................10

2.2 MAINTENANCE SCHEDULE......................................................................................................11

2.3 FUEL TUBE....................................................................................................................................11

2.4 THROTTLE OPERATION..............................................................................................................12

2.5 THROTTLE CABLE ADJUSTMENT............................................................................................12

2.6 AIR CLEANER...............................................................................................................................12

2.7 SPARK PLUG .................................................................................................................................12

2.8 IDLE SPEED ...................................................................................................................................13

2.9 DRIVE CHAIN ...............................................................................................................................13

2.10 BRAKE SYSTEM .........................................................................................................................14

2.11 WHEELS AND TIRES ..................................................................................................................16

2.13 TOE-IN ..........................................................................................................................................16

3. ENGINE REMOVE AND INSTALLATION............................................................................................18

3.1 General Information.........................................................................................................................18

3.2 ENGINE REMOVAL......................................................................................................................18

3.3 ENGINE INSTALLATION.............................................................................................................19

4-1 Mechanism Diagram.......................................................................................................................20

4-2 Precautions in Operation.................................................................................................................21

4-3 Troubleshooting...............................................................................................................................21

4-4 Engine Oil........................................................................................................................................22

4-5 Engine Oil Strainer Clean................................................................................................................22

4-6 Oil Pump..........................................................................................................................................23

4-7 Gear Oil ...........................................................................................................................................23

5. FUEL SYSTEM.........................................................................................................................................24

5-1 Mechanism Diagram.......................................................................................................................24

5-2 Precautions in Operation.................................................................................................................25

5-3 Trouble Diagnosis............................................................................................................................26

5-4 Carburetor Remove / Install ............................................................................................................27

5-5 Air Cut-Off Valve ............................................................................................................................28

5-6 Throttle Valve ..................................................................................................................................29

5-7 Float Chamber .................................................................................................................................30

5-8 Adjustment of Idle Speed ................................................................................................................32

5-9 Fuel Tank .........................................................................................................................................33

5-10 Air Cleaner ....................................................................................................................................34

6. CYLINDER HEAD/VALVE.....................................................................................................................35

6-1 Mechanism Diagram.......................................................................................................................35

6-2 Precautions in Operation.................................................................................................................36

2

6-3 Troubleshooting...............................................................................................................................37

6-4 Cylinder Head Removal..................................................................................................................38

6-5 Cylinder Head Inspection................................................................................................................41

6-6 Valve Stem Replacement.................................................................................................................44

6-7 Valve Seat Inspection and Service...................................................................................................45

6-8 Cylinder Head Reassembly .............................................................................................................48

6-9 Cylinder Head Installation...............................................................................................................50

6-10 Valve Clearance Adjustment..........................................................................................................52

7. CYLINDER/PISTON................................................................................................................................54

7-1 Mechanism Diagram.......................................................................................................................54

7-2 Precautions in Operation.................................................................................................................55

7-3 Trouble Diagnosis............................................................................................................................55

7-4 Cylinder and Piston Removal..........................................................................................................56

7-5 Piston Ring Installation ...................................................................................................................59

7-6 Piston Installation ............................................................................................................................60

7-7 Cylinder Installation ........................................................................................................................61

8. V-BELT DRIVING SYSTEM ...................................................................................................................63

8-1 Mechanism Diagram.......................................................................................................................63

8-2 Maintenance Description.................................................................................................................64

8-3 Trouble Diagnosis............................................................................................................................64

8-4 Left Crankcase Cover ......................................................................................................................65

8-5 Drive Belt ........................................................................................................................................67

8-6 Drive Face .......................................................................................................................................69

8-7 Clutch Outer/Driven Pulley.............................................................................................................72

9. FINAL DRIVING MECHANISM ............................................................................................................77

9-1 Mechanism Diagram - transmission cover......................................................................................77

9-2 Precautions in operation ..................................................................................................................78

9-3 Trouble Diagnosis............................................................................................................................78

9-4 Disassembly of Transmission..........................................................................................................79

9-5 Inspection of Mission Mechanism ..................................................................................................82

9-6 Bearing Replacement ......................................................................................................................84

9-7 Re-assembly of Final Driving Mechanism......................................................................................87

10. ALTERNATOR/STARTING CLUTCH..................................................................................................89

10-1 Mechanism Diagram.....................................................................................................................89

10-2 Precautions in Operation...............................................................................................................90

10-3 Right Crankcase Cover Removal..................................................................................................91

10-4 A.C.G. Set Removal.......................................................................................................................91

10-5 Right Cover Bearing ......................................................................................................................91

10-6 Flywheel Removal.........................................................................................................................92

10-7 Starting Clutch...............................................................................................................................93

10-8 Flywheel Installation.....................................................................................................................95

10-9 A.C.G. Set Installation...................................................................................................................96

10-10 Right Crankcase Cover Installation.............................................................................................96

11. CRANKCASE / CRANK........................................................................................................................98

11-1 Mechanism Diagram......................................................................................................................98

11-2 General information.......................................................................................................................99

11-3 Trouble diagnosis...........................................................................................................................99

11-4 Disassembly of crankcase............................................................................................................100

3

11-5 Crankshaft Inspection..................................................................................................................102

11-6 Assembly of crankcase ................................................................................................................103

12. COOLING SYSTEM.............................................................................................................................106

12-1 Mechanism Diagram...................................................................................................................106

12-2 General Information....................................................................................................................107

12-3 Trouble Diagnosis........................................................................................................................107

12-4 Trouble Diagnosis for Cooling System.......................................................................................108

12-5 System Test..................................................................................................................................110

12-6 Radiator .......................................................................................................................................111

12-7 Water Pump .................................................................................................................................113

12-8 Thermostat...................................................................................................................................117

13. STEERING AND SUSPENSION .........................................................................................................118

13.1 PARTS DRAWING......................................................................................................................118

13.2 TROUBLESHOOTING...............................................................................................................119

13.3 HANDLEBAR.............................................................................................................................119

13.4 THROTTLE HOUSING ..............................................................................................................122

13.5 STEERING SYSTEM .................................................................................................................122

14. FRONT WHEEL AND BRAKE SYSTEM ...........................................................................................125

14.1 PARTS DRAWING......................................................................................................................125

14.2 TROUBLESHOOTING...............................................................................................................126

14.3 FRONT WHEELS .......................................................................................................................126

14.4 HYDRAULIC BRAKE...............................................................................................................127

15. REAR WHEEL AND BRAKE SYSTEM .............................................................................................131

15.1 PARTS DRAWING......................................................................................................................131

15.2 TROUBLESHOOTING ...........................................................................................................132

15.2 TROUBLESHOOTING ...........................................................................................................133

15.3 REMOVE REAR WHEEL AND REAR BRAKE ......................................................................133

15.4 SWINGARM & REAR AXLE HOLDER...................................................................................136

15.5 Suspension Adjustment................................................................................................................138

16. FENDERS AND EXHAUST PIPE .......................................................................................................139

16.1 FENDERS DRAWING................................................................................................................139

16.2 REAR FENDERS REMOVAL....................................................................................................140

16.3 FRONT FENDER REMOVAL ...................................................................................................142

16.4EXHAUST PIPE REMOVAL ......................................................................................................143

17. ELECTRICAL SYSTEM ......................................................................................................................144

17.1 TROUBLESHOOTING...............................................................................................................144

17.2 IGNITION COIL.........................................................................................................................145

17.3 IGNITION TIMING....................................................................................................................145

17.4 BATTERY INFORMATION.......................................................................................................145

17.5 ELECTRIC STARTER ................................................................................................................146

17.6 LIGHT BULBS REPLACEMENT.............................................................................................146

18.TROUBLESHOOTING .........................................................................................................................152

18.1 ENGINE CAN NOT WORK.......................................................................................................152

18.2 POOR PERFORMANCE AT LOW AND IDLE SPEEDS .........................................................153

18.3 POOR PERFORMANCE AT HIGH SPEED ..............................................................................153

18.4 LOSS POWER.............................................................................................................................154

18.5 POOR HANDLING.....................................................................................................................155

4

1. INFORMATION

1.1 SAFTY

1.2 NOTES

1.3 SPECIFICATION

1.4 SERIAL NUMBER

1.5 TORQUE VALUE

1.6 SPECIAL TOOLS

1.1 SAFETY

GASOLINE

Gasoline is extremely flammable and is explosive under certain condition.

Do not smoke or allow sparks or flames in your work area.

● CARBON MONOXIDE

Never run the engine in a closed area. The exhaust contains poisonous carbon

monoxide gas that may cause loss of consciousness and lead to death.

● BATTERY ELECTROLYTE

The battery electrolyte contains sulfuric acid. Protect yo ur eyes, skin and

clothing. If you contact it, flush thoroughly with water and call a doctor if electrolyte

gets in your eyes.

● HOT PARTS

Engine and exhaust pipe become very hot and remain hot for one hour after the

engine is run. Wear insulated gloves before handling these parts.

● USED ENGINE/GEAR OIL

Used engine oil and gear oil may cause skin disease if repeatedly contact with

the skin for long periods.

Keep out of reach of children.

1.2 NOTES

All information, illustrations, directions and specifications included in this publication are base on the latest

product information available at the time of approval for printing.

JI-EE Dynamic Technology Industry Co., Ltd. reserves the right to make changes at any time without notice and

without incurring any obligation whatever.

No part of this publication may be reproduced without written permission.

5

1.3 SPECIFICATION ENGINE

CHASSIS

SUSPENSION

BRAKES

TIRES

Type

Displacement 249c.c.

Bore and Stroke 71 mm x 63 mm

Compression 10.6:1

Maximum Hp 19ps / 5600

Maximum Torque (Nm/rpm) 22.3 Nm / 5500

Carburetor

Ignition DC-CDI

Starting Electric

Lubrication Auto oil injection

Transmission Automatic (C.V.T. V-belt + Reverse)

Overall Length 1815mm

Overall Width 1062mm

Overall Height 1130mm

Wheel base 1193mm

Ground Clearance 150mm

Dry Weight 225Kg

Fuel Tank Capacity 12L

Front Double A-Arm & Adjustable

Rear Swing Arm & Adjustable Shock

4 Stroke,Single Cylinder, Water cooled

Front Front Hydraulic Disc*2

Rear Rear Hydraulic Disc*1

Front 21x7-10

Rear 22x10-10

PRESSURE【 psi ( kgf/cm2) 】

Front 12(0.8)

Rear 12(0.8)

COLORING

Specifications subject to change without notice.

6

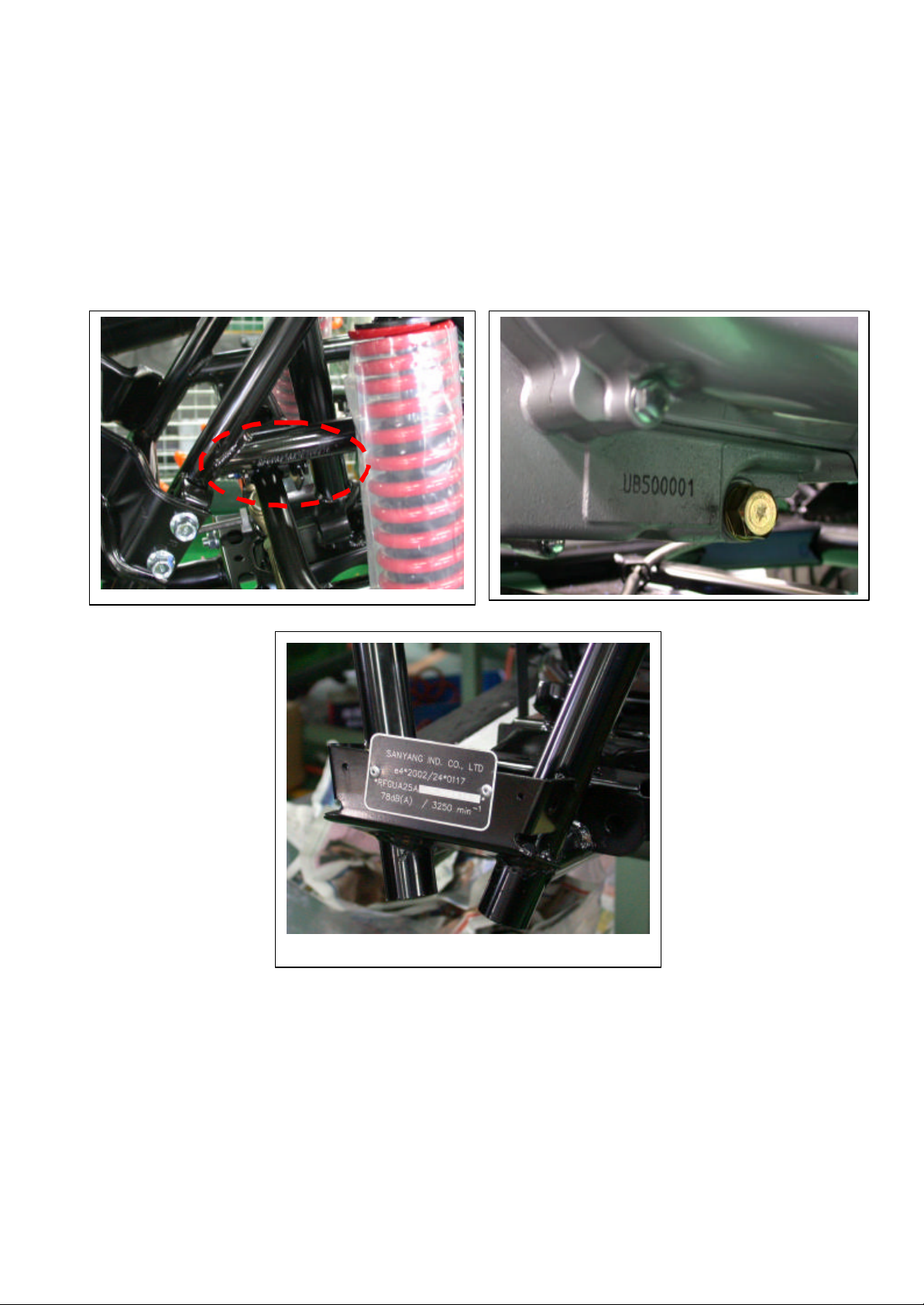

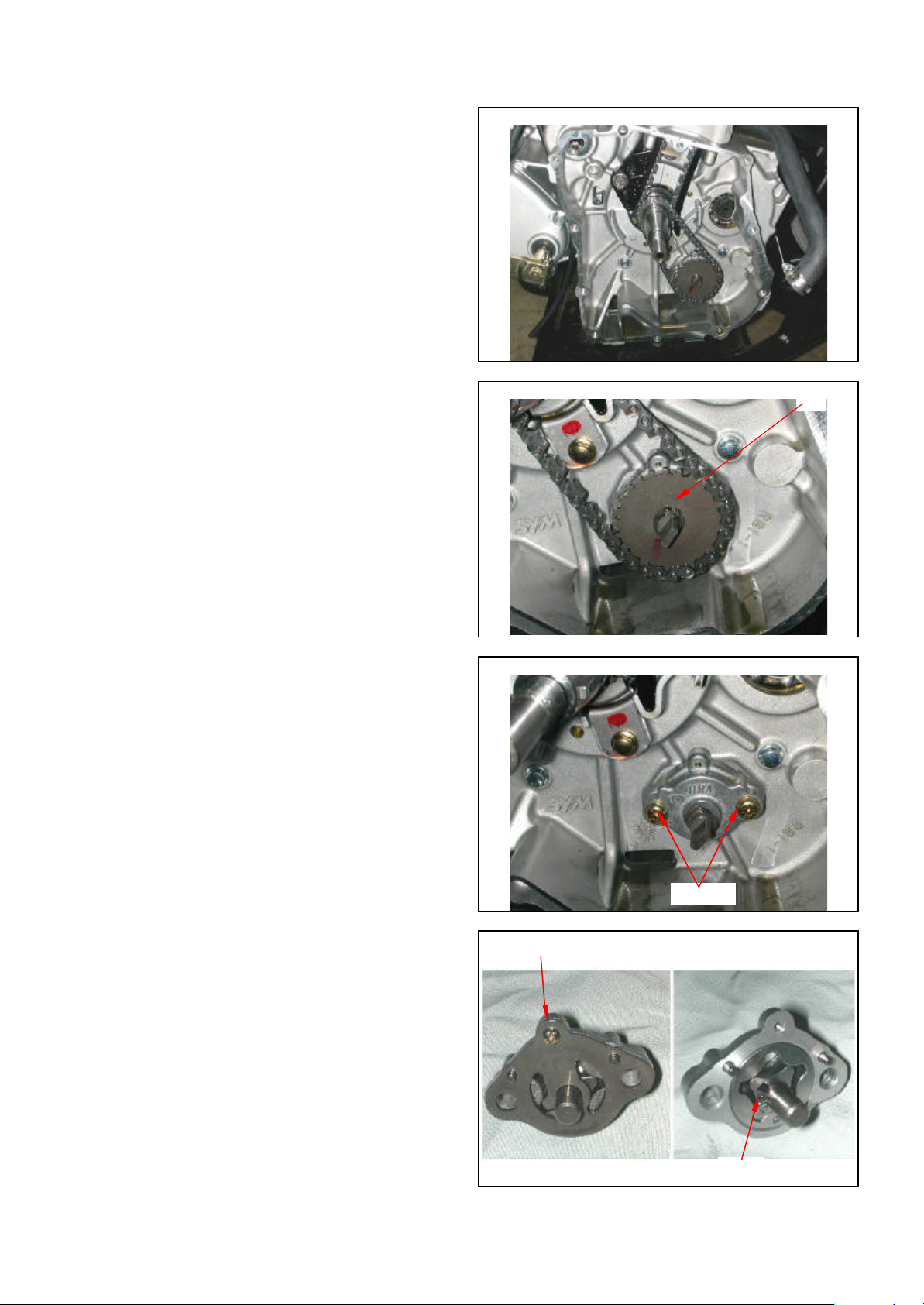

1.4 SERIAL NUMBER

The frame serial number is stamped on the front of the frame.

The engine serial number is stamped on the left side of the crankcase.

Frame serial number

7

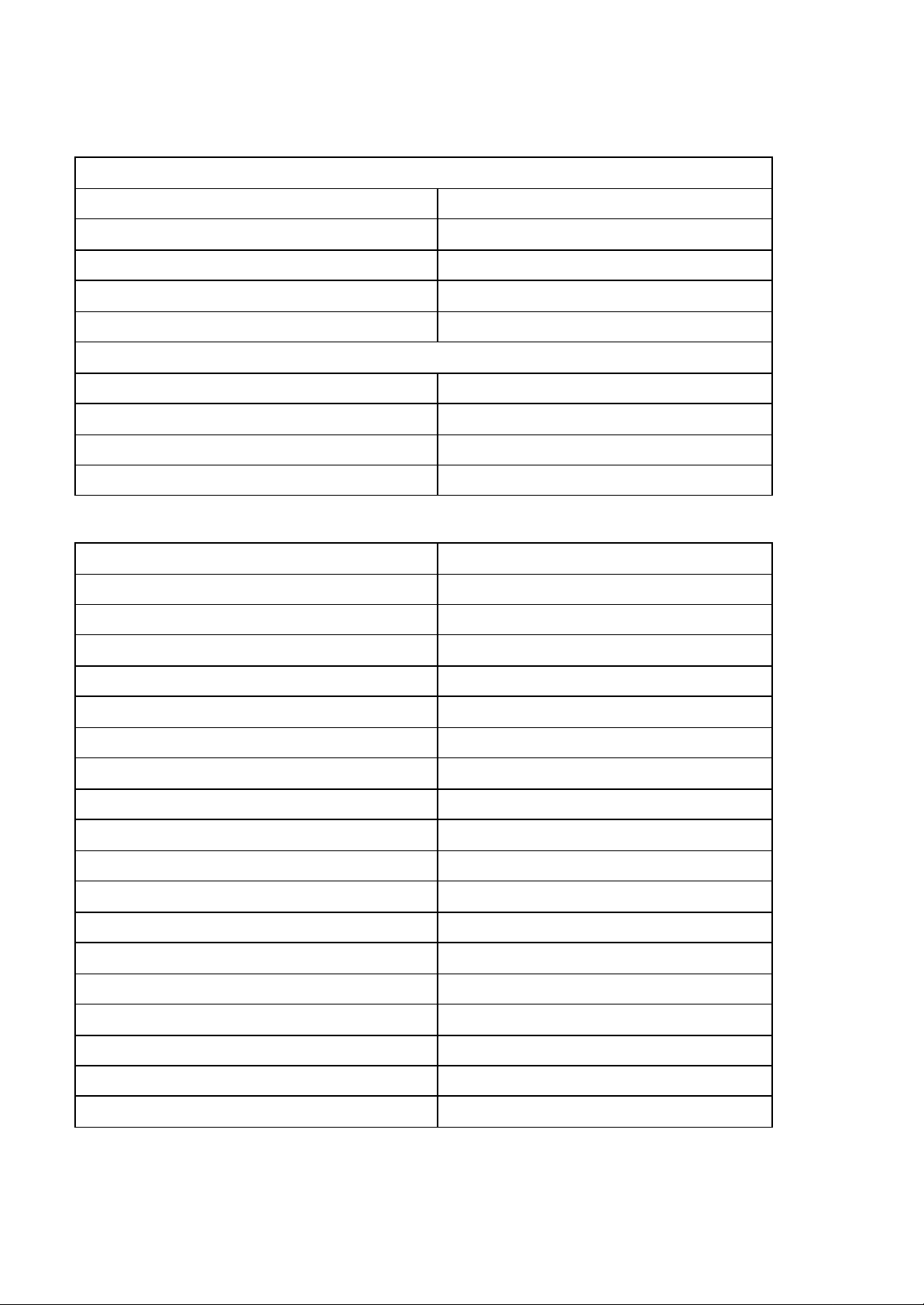

1.5 TORQUE VALUES

STANDARD

5 mm bolt and nut

● 6 mm bolt and nut

● 8 mm bolt and nut

●10 mm bolt and nut

●12 mm bolt and nut

ENGINE

Cylinder head nut

● Spark plug

● Cylinder head bolt

● Alternator bolt

●

●

FRAME

● Handlebar upper holder bolt

● Throttle housing cover screw

● Steering shaft nut

5 N.m (3.5 lbf.ft)

10 N.m (7.2 lbf.ft)

22 N.m (16 lbf.ft)

35 N.m (25 lbf.ft)

55 N.m (40 lbf.ft)

28 N.m (20.7 lbf.ft)

12 N.m (8.9 lbf.ft)

20 N.m (14.8 lbf.ft)

8 N.m (5.9 lbf.ft)

24 N.m (17.7 lbf.ft)

4 N.m (2.9 lbf.ft)

50 N.m (36.9 lbf.ft)

● Steering shaft holder bolt

● Wheel rim bolt

● Tie rod lock nut

● King pin nut

● Handlebar lower holder nut

● Front wheel bolt

● Front axle castle nut

● Front brake arm nut

● Rear brake arm nut

● Rear axle castle nut

● Rear wheel bolt

● Exhaust muffler mounting bolt

● Engine hanger bolt

● Rear axle holder bolt

● Swing a rm pivot nut

33 N.m (24 lbf.ft)

18 N.m (13.3 lbf.ft)

35 N.m (25.8 lbf.ft)

40 N.m (29 lbf.ft)

40 N.m (29.5 lbf.ft)

24 N.m (17.7 lbf.ft)

40-60 N.m (30-45 lbf.ft)

4 N.m (3.0 lbf.ft)

7 N.m (5.2 lbf.ft)

40-60 N.m (30-45 lbf.ft)

24 N.m (17.7 lbf.ft)

30 N.m (22.1 lbf.ft)

30 N.m ( 22 lbf.ft)

90 N.m (65 lbf.ft)

90 N.m (65 lbf.ft)

● Rear shock absorber mounting nut

45 N.m (33 lbf.ft)

8

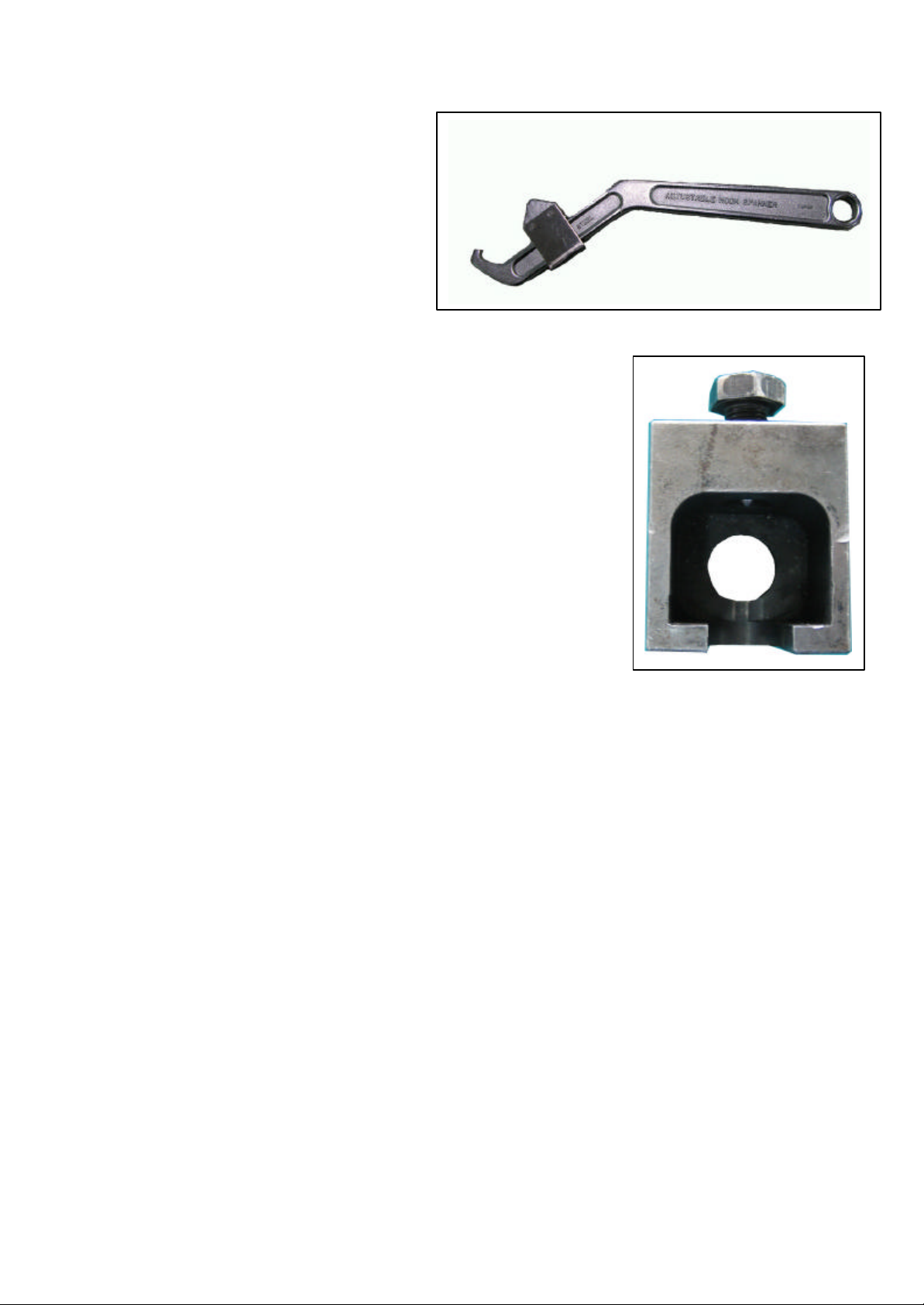

1.6 Special Tools

1. Adjustable Hook Spencer

(E1105-LRA0-FT1)

Purpose: Adjusting of suspension

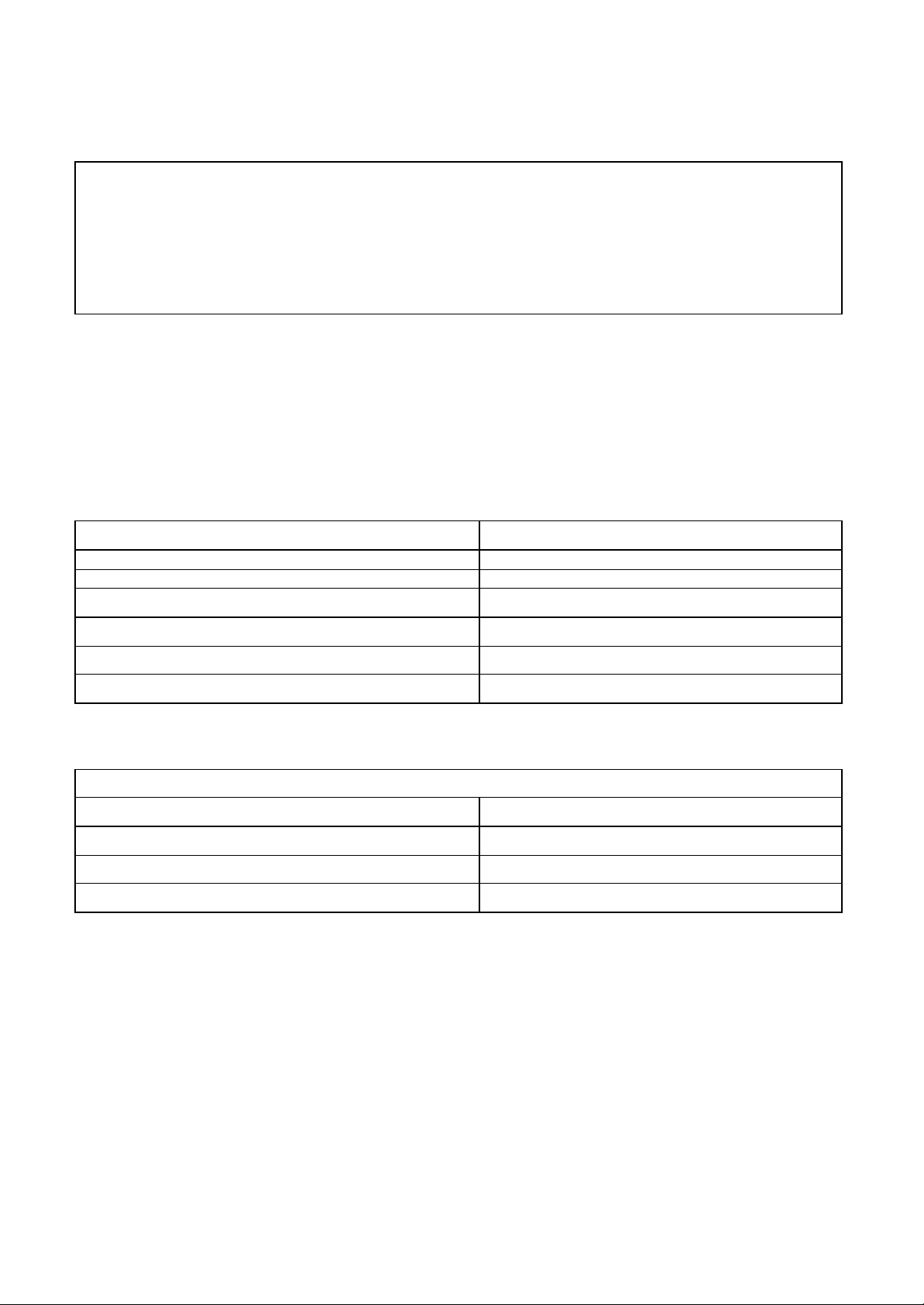

2. Ball Joint Puller(E0205-LRA0-FT1)

Purpose: Taking out the ball joint from front knuckle as repairing.

9

2. MAINTENANCE

rpm

2.1 MAINTENANCE DATA 2.8 IDLE SPEED

2.2 MAINTENANCE SCHEDULE 2.9 DRIVE CHAIN

2.3 FUEL TUBLE 2.10 BRAKE SYSTEM

2.4 THROTTLE OPERATION 2.11 WHEELS AND TIRES

2.5 THROTTLE CABLE AJUSTMENT 2.12 STEERING SYSTEM

2.6 AIR CLEANER 2.13 TOE -IN

2.7 SPARK PLUG

2.1 MAINTENANCE DATA

SPECIFICATION

SPARK PLUG

SPARK PLUG GAP 0.8 mm

RECOMMENDED SPARK PLUGS NGK CR8E

THROTTLE LEVER FREE PLAY 5-10 mm

IDLE SPEED 1700±100

BRAKE LEVER FREE PLAY 15-25 mm

DRIVE CHAIN SLACK 10-25 mm

TOE-IN 5±10 mm

TORQUE VALUES

SPARK PLUG 12-19 N.m

TIE-ROD LOCK NUT 35-43 N.m

ENGINE OIL 1.4 Liter (1.2Liter for change)

GEAR LUBRICATION OIL 750cc (650cc for change)

10

2.2 MAINTENANCE SCHEDULE

The internal maintenance in the following table is based on average riding, normal conditions.

Riding in unusually dusty areas, require more frequent servicing.

300KM

1 Month 3 Months 6 Months 1 Year 2 Years

Fuel Lines I I R

Throttle Operation I I

Air Filter I C R

Fuel Filter R

Spark Plug I I R

Drive Chain I, L Lubricate for every 1 month

Brake Shoes I

Brake System I I

Brake Fluid I R

Nuts, Bolts & Fasteners I

WHEEL/TIRES I I

Wheels I I

Steering System I I

Suspension System I I

C.V.T Drive belt I R

Transmission Oil R Replace for every 3,000km or 6 Months

Engine Oil R Replace for every 3,000km or 6 Months

Battery I I,C I,C

Oil Filter (Screen) C C

Valve Clearance I I

Coolant I I R

Cooling Fan I I

Carburetor (Idle Speed) I I

Choke I

Note – I: Inspect and Clean, Adjust, Lubricate or Replace, if necessary

C: Clean L: Lubricate R: Replace

Every Every Every Every Notes

2.3 FUEL TUBE

Inspect the fuel lines for deterioration, damaging or

leakage and replace if necessary.

11

2.4 THROTTLE OPERATION

Inspect for smooth throttle lever full opening and automatic

full closing in all steering positions.

Inspect if there is no deterioration, damage or kink in the

throttle cable, replace it if necessary.

Check the throttle lever, free play is 5-10 mm at the tip of the

throttle lever.

Disconnect the throttle cable at the upper end.

Lubricate the cable with commercially lubricant to prevent

premature wear.

2.5 THROTTLE CABLE ADJUSTMENT

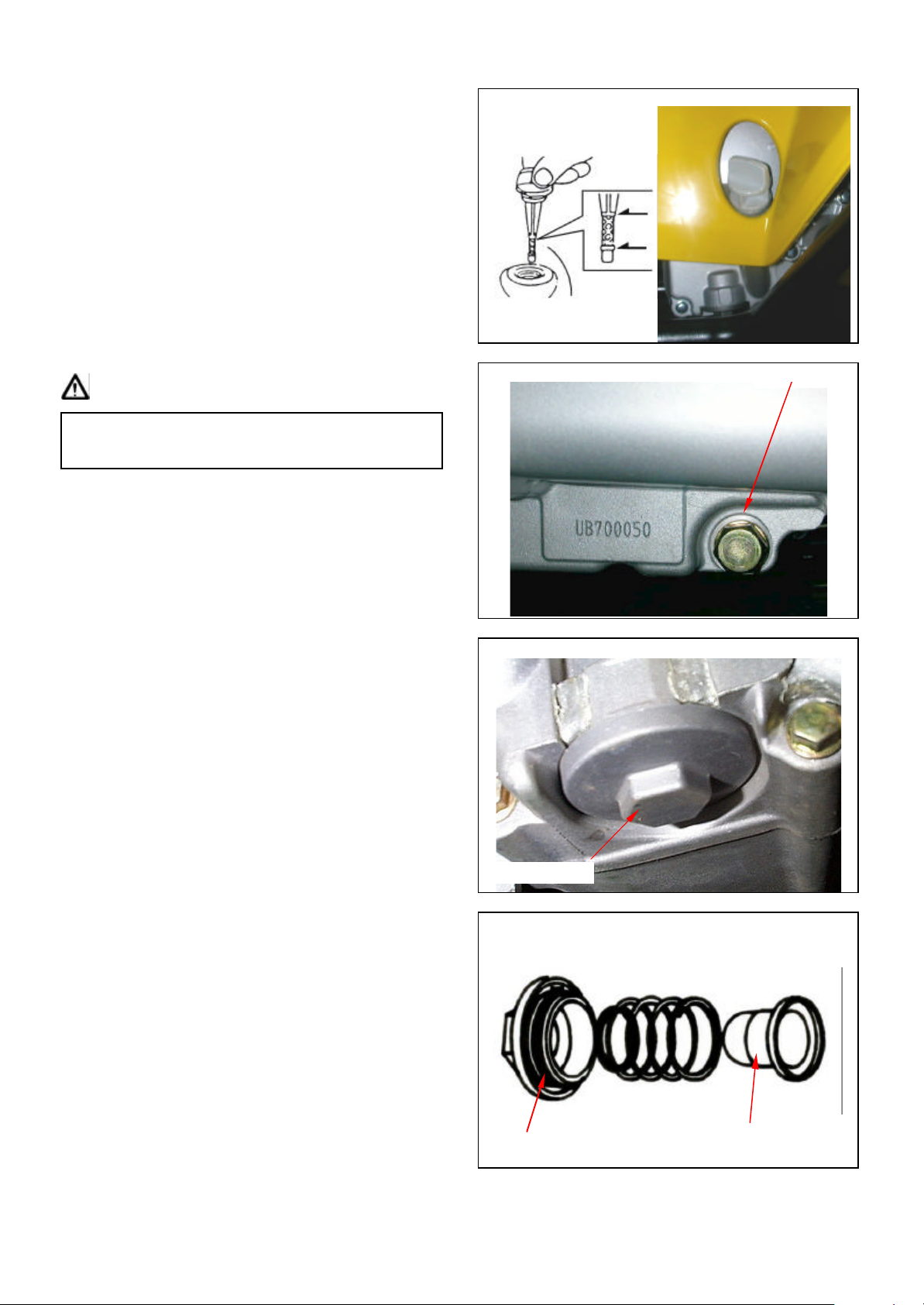

Slide the rubber cap of the adjuster off the throttle

Housing, loosen the lock nut and adjust the free play

of the throttle lever by turning the adjuster on the throttle housing.

Inspect the free play of the throttle lever.

Throttle

2.6 AIR CLEANER

Please remove the four hooks, and then disassemble

two screws inside the air cleaner case.

Pull out the air filter element from the air cleaner case.

Washing the element in non-flammable solvent, squeeze

out the solvent thoroughly.

Let it dry.

Soak the filter element in gear oil and then squeeze

out the excess oil.

Install the every component into air cleaner in the reverse order of

removal.

Note: for more detail please check chapter 5-10

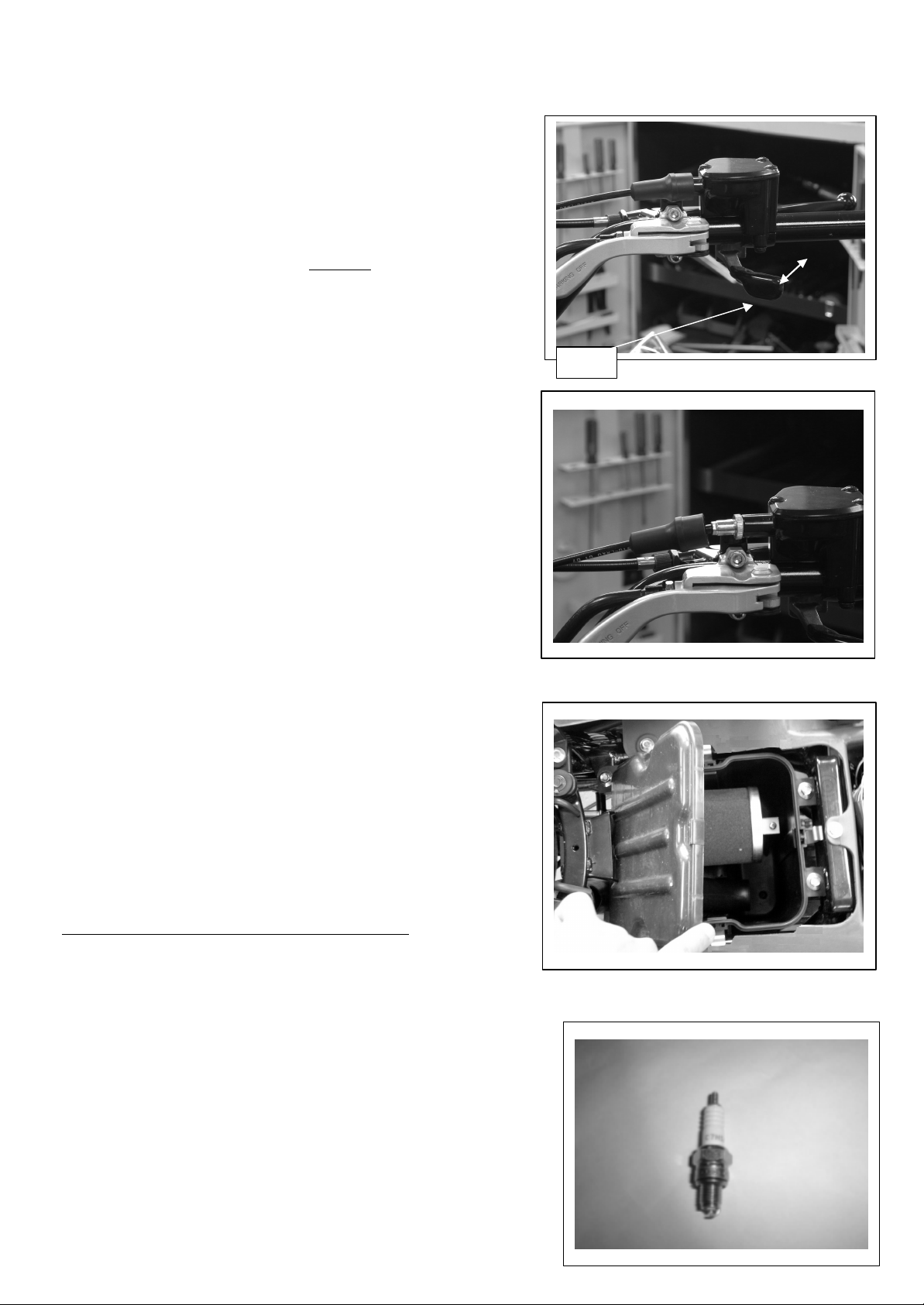

2.7 SPARK PLUG

This spark plug is located at the front of the engine.

Disconnect the spark plug cap and unscrew the spark plug.

Check the condition of spark plug electrodes wear.

12

Change a new spark plug if the electrodes and insulator tip appear unusually fouled or burned.

Discard the spark plug if there is apparent wear or if the insulator is cracked or chipped.

The spark plug gap shall keep in 0.6-0.7mm

With the sealing washer attached, thread the spark plug in by hand to prevent crosses threading.

Tighten the spark plug with 12-19 N.m

2.8 IDLE SPEED

Connect an engine speed meter.

Warm up the engine, 10 minutes are enough.

Turn the idle-speed adjust screw on the carburetor to obtain the idle speed. “Turn in” (clockwise) will

get higher speed. “Turn out” (counter clockwise) will get lower speed.

IDLE SPEED: 1700±100 rpm

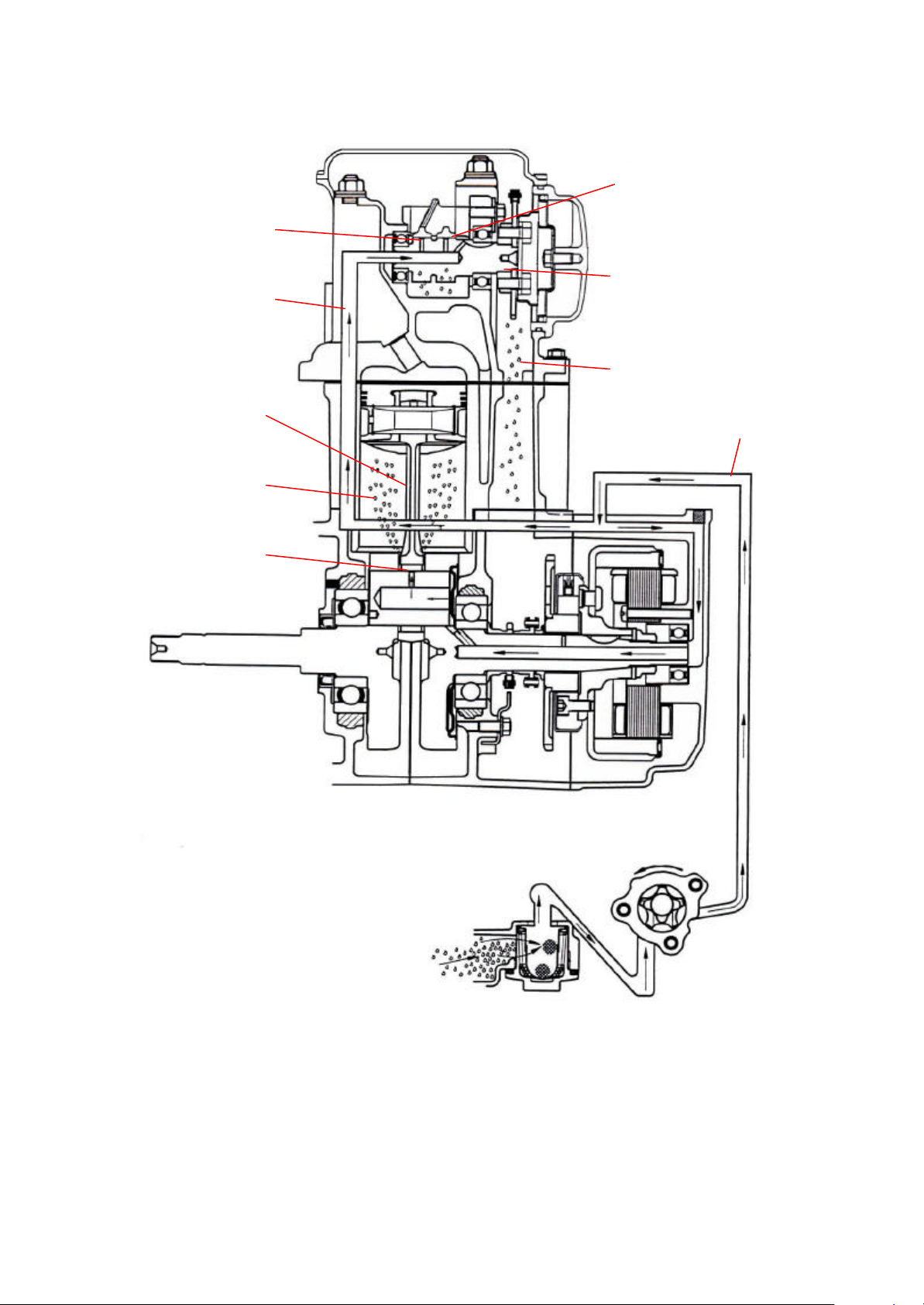

2.9 DRIVE CHAIN

Stopping the ATV and shift the transmission into neutral(N) .

Measure the drive chain slack midway between the

sprockets.

Chain slack =15~25mm (5/8~1 inch)

Adjust the chain slack.

Loosen the lock nuts and turn drive chain adjusting nuts

until get the correct slack.

Tighten the axle holder bolts.

Torque = 90N.m (65 lbf.ft)

When the drive chain becomes very dirty, it should be removed, cleaned and lubricated by specify lubricator.

Please use special chain oil to lubricate the drive chain.

Clean the drive chain with kerosene and wipe it dry.

Inspect the drive chain for any possible wearing or damaging.

Replace the ch ain, if it is worn excessively or damaged.

Inspect the sprocket teeth, if it is excessive wearing or damaging,

please replace it.

13

2.10 BRAKE SYSTEM

Inspect the front brake lever and cable for excessive play or other

damage.

Replace or repair if necessary.

Measure the brake lever free play at the end of the brake lever trip.

Front Brake lever free play is 15 -25 mm.

Turn the parking brake to the left side is “parking off”, while

turn to right side is “parking on”.

Inspect the rear brake lever and cable for excessive

play or other damage.

Replace or repair if necessary.

Measure the rear brake lever free play at the

end of the lever trip .

Rear Brake lever free play is 15-25 mm.

14

Brake le ver

Adjustable nut

Parking Brake

Parking Off

Parking On

Adjustment

Brake level

Rear Brake

NOTE:

Ÿ The second method to adjust brake level is under the driver

seat and rear brake component.

Ÿ In order to avoid a pre-load occurred between brake disk and

lining. After all adjusting of brake system are completed,

please check the small clearance between brake disk and

lining.

Adjustable nut

Parking Brake Adjustable nut

15

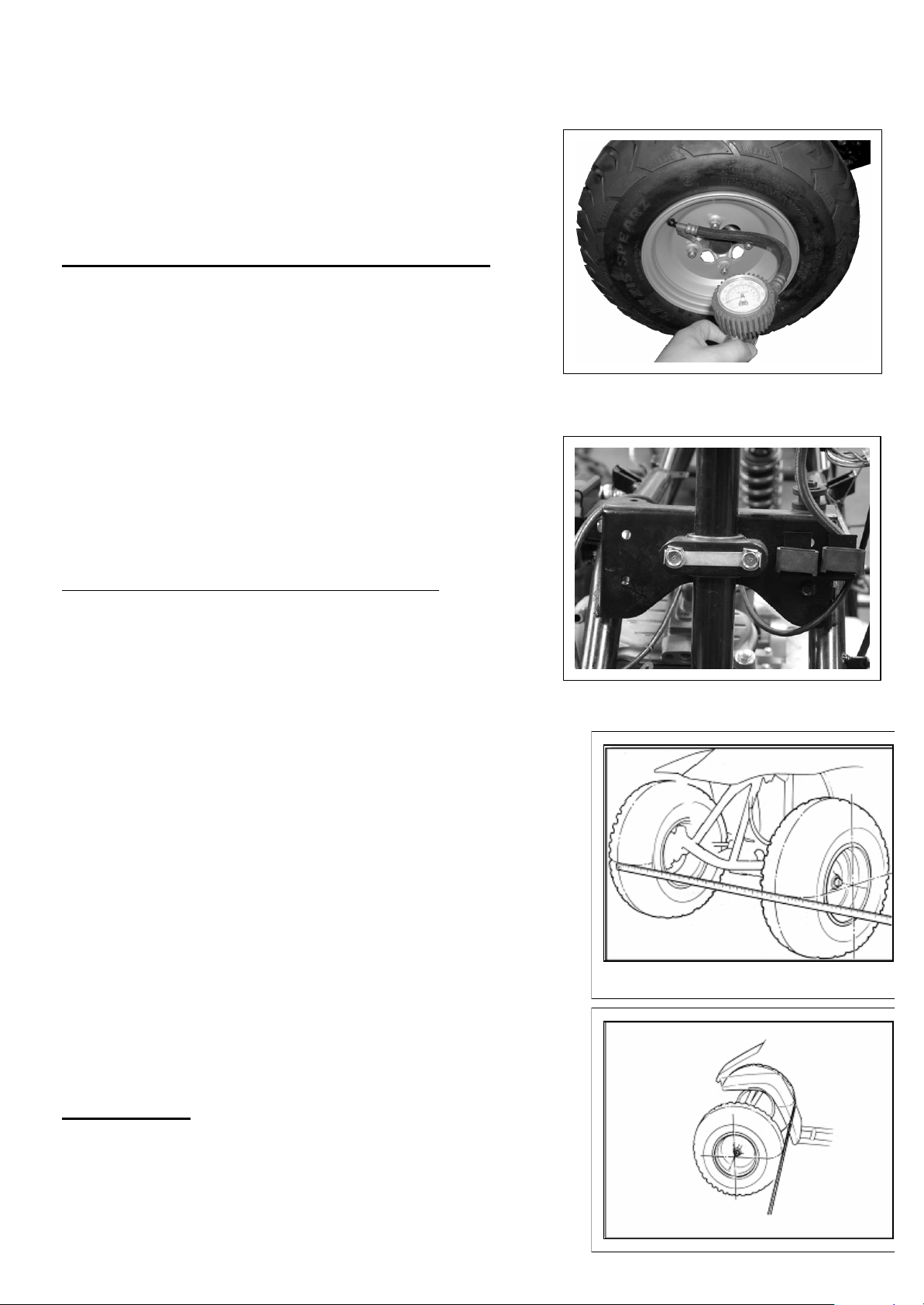

2.11 WHEELS AND TIRES

Inspect the tire surfaces for cuts, nails or other sharp ob jects.

Check the each tire surface at cold tire condition.

*The standard of tire pressure is 12(0.8) psi ( kgf/cm2)

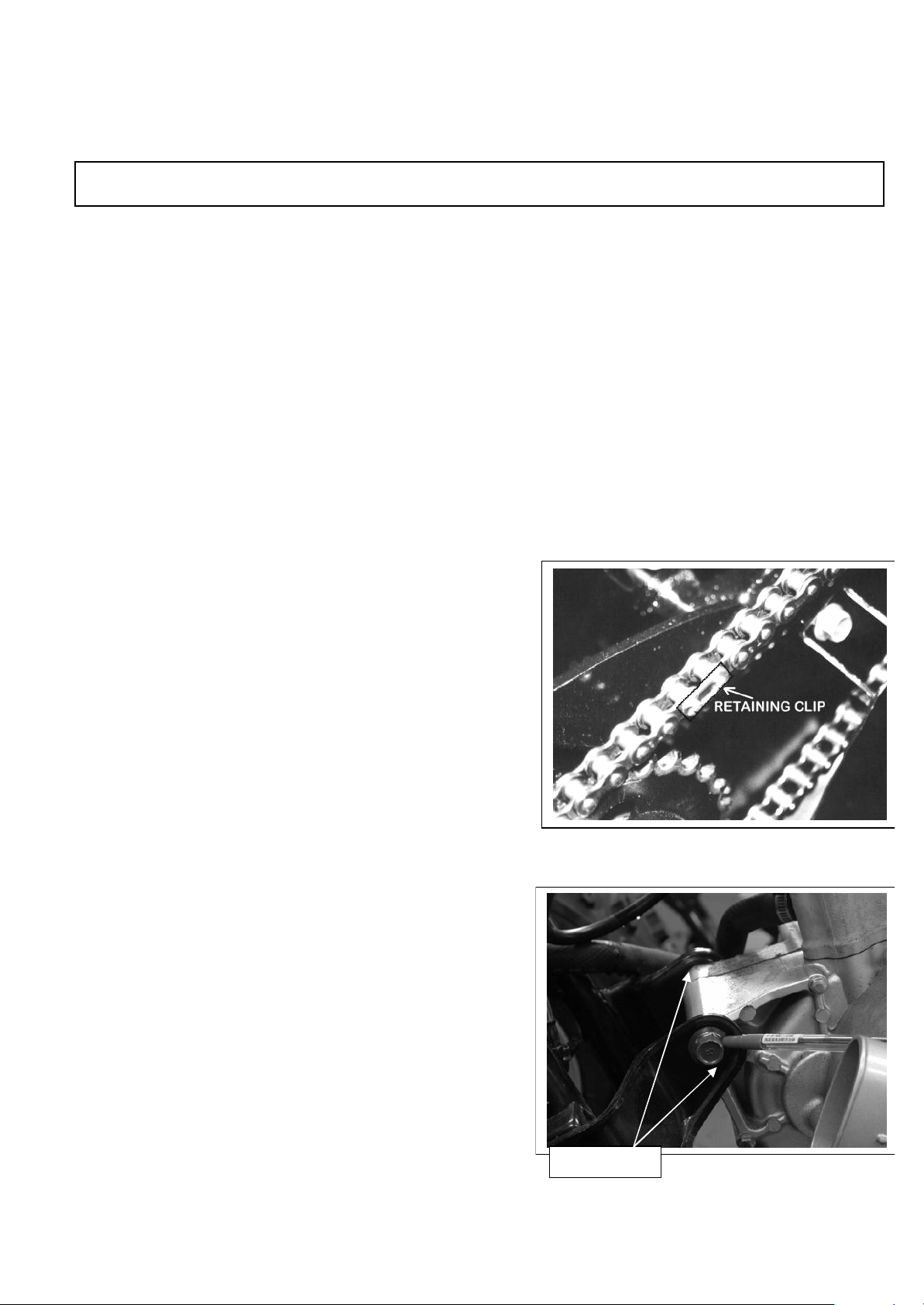

STEERING SHAFT HOLDER BUSHING

Remove the front fender first.

Remove the steering shaft holder and check the steering shaft bushing

for wears or damage.

If the bushing is worn or damaged, please change a new one.

Grease the steering shaft bushing and install the parts

in the reverse order of removal.

Torque: steering shaft holder bolt: 33 N.m (24 lbf.ft)

2.13 TOE-IN

Keep the vehicle on level ground and the front wheels facing straight

ahead.

Mark the centers of the tires to indicate the axle center height.

Measure the distance between the marks.

Carefully to move the vehicle back, let the wheels turn 180 degree,

so the marks on the tires are aligned with the axle center height.

Measure the distance between the marks.

Calculate the difference in the front and rear measurements.

Toe-in: 5±10mm

16

Lock Nuts

If the toe-in is out of standard, adjust it by changing

the length of the tie-rods equally by turning the tie -rod

while holding the ball joint.

Tighten the lock nuts.

Torque: 35-43 N.m

17

3. ENGINE REMOVE AND INSTALLATION

3.1 REPAIR CONDITION 3.3 ENGINE INSTALLATION

3.2 ENGINE REMOVAL

3.1 General Information

ENGINE SHALL BE REMOVED IN THE CONDITIONS OF NECESSARY REPAIRMENT OR

ADJUSTMENT TO THE TRANSMISSION AND COMBUSTION SYSTEM ONLY

3.2 ENGINE REMOVAL

Before removing engine, you need to remove all of components such as seat, front and back fender,

fuel tube, exhaust pipe, carburetor cable and drive chain…etc. You can then see three hanger bolts which have

screwed on engine.

Loosen these three hanger bolts. You have succeeded to remove this engine.

There are some pictures to describe main step of removing engine.

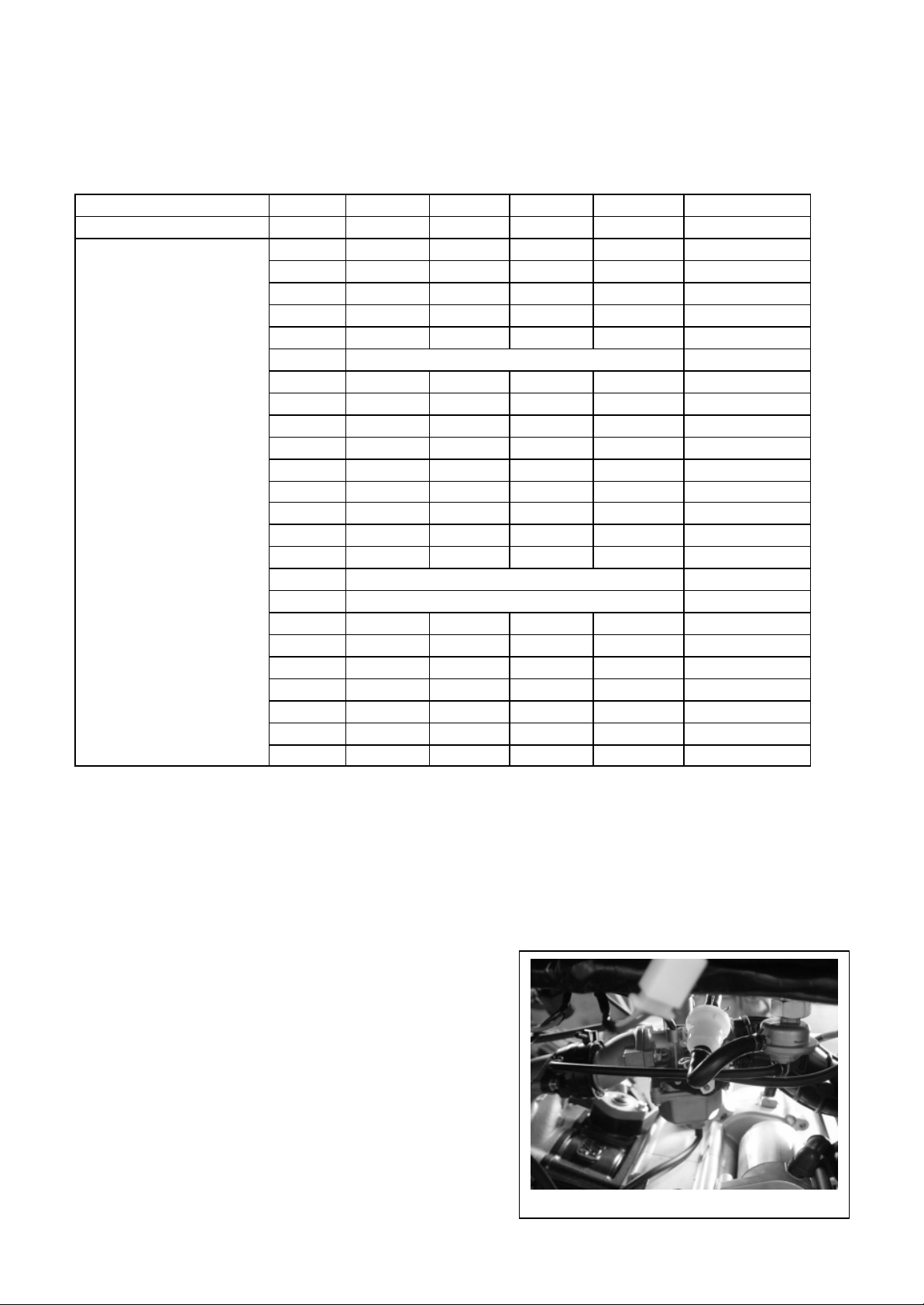

Disconnect the wire connectors. There are three connectors for

carburetor auto-choke, starter motor and generator respectively.

Remove the drive chain cover.

Remove the drive chain retaining clip and master link,

and remove the drive chain.

Hanger bolt

18

3.3 ENGINE INSTALLATION

The Engine installation is essentially in the reverse order of removal.

The torque of engine hanger bolt is 30 N.m

Route the wires and cable in reverse order properly.

19

4. LUBRICATION SYSTEM

4-1 Mechanism Diagram

4-2 Precautions in Operation

4-3 Troubleshooting

4-4 Engine Oil

4-5 Engine Oil Strainer Clean

4-6 Oil Pump

20

4-1 Mechanism Diagram

Press-In Lubrication

Oil Route

Con-Rod

Spray Lu brication

Press-In Lubrication

Valve Rocker Arm

Cam Shaft

Spray Lubrication

Oil Route

Rotate Direction

Oil Pump

Oil Strainer

21

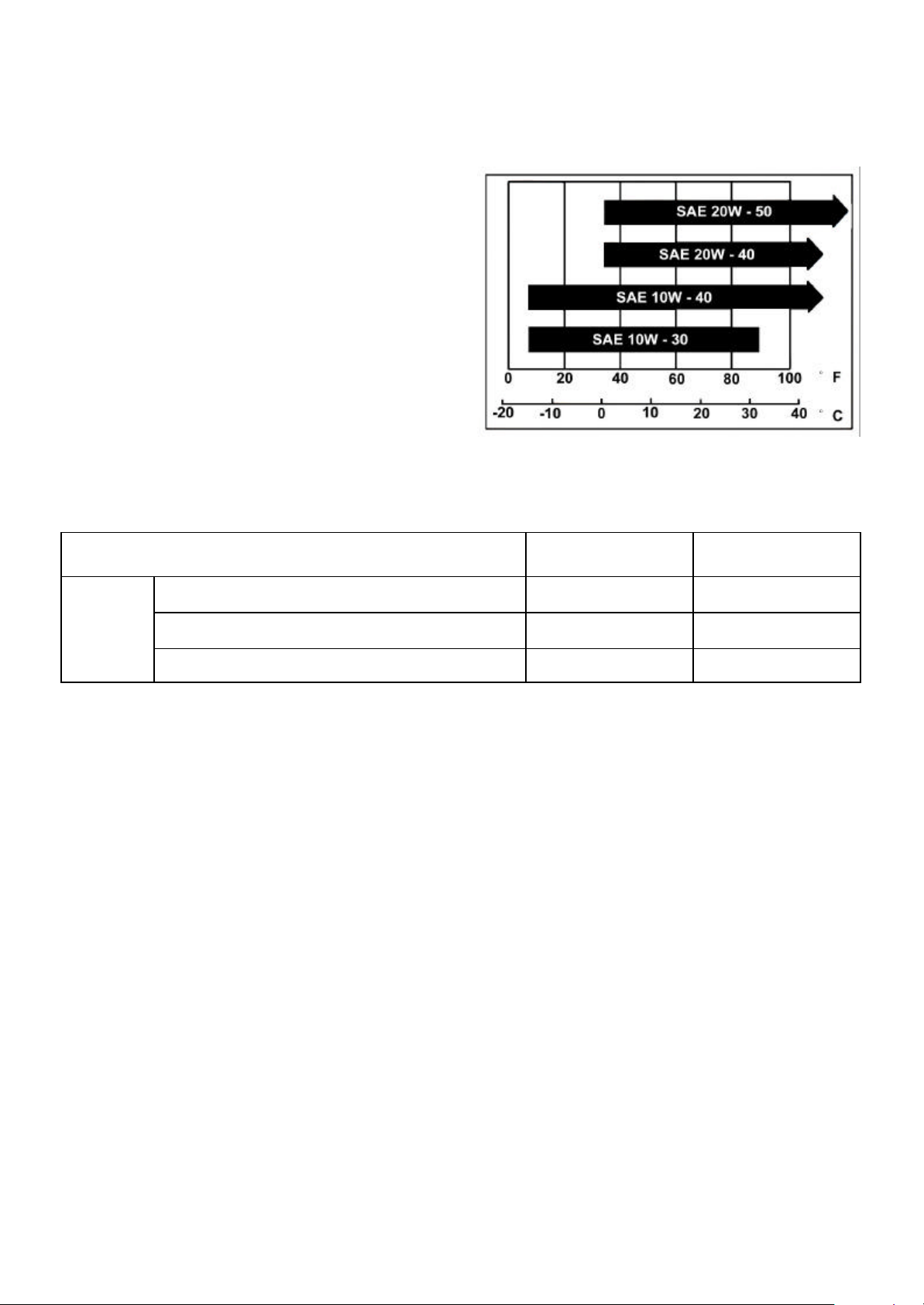

4-2 Precautions in Operation

General Information:

l This chapter contains maintenance operation

for the engine oil pump and gear oil

replacement.

Specifications

Engine oil quantity Disassembly: 1400 c.c.

Change: 1200c.c.

Oil viscosity SAE 10W-30 (Recommended

King serial oils)

Gear oil Disassembly: 750c.c.

Change: 650c.c.

Gear oil viscosity SAE 140

(Recommended SYM Hypoid gear oils)

Items Standard (mm) Limit (mm)

Inner rotor clearance 0.15 0.20

Clearance between outer rotor and body 0.15~0.20 0.25 Oil pump

Clearance between rotor side and body 0.04~0.09 0.12

Torque value

Torque value oil strainer cap 1.5~3.0kgf -m

Engine oil drain bolt 1.9~2.5kgf -m

Gear oil drain bolt 1.0~1.5kgf -m

Gear oil join bolt 1.0~1.5kgf -m

Oil pump connection bolt 0.8~1.2kgf -m

??:mm

4-3 Troubleshooting

Low engine oil level

Ÿ Oil leaking

Ÿ Valve guide or seat worn out

Ÿ Piston ring worn out

Low oil pressure

Ÿ Low engine oil level

Ÿ Clogged in oil strainer, circuits or pipes

Ÿ Oil pump damage

Dirty oil

Ÿ No oil change in periodical

Ÿ Cylinder head gasket damage

Ÿ Piston ring worn out

22

4-4 Engine Oil

Turn off engine, and park the ATV in flat surface

with main stand.

Check oil level with oil dipstick.

So not screw the dipstick into engine as checking.

If oil level is nearly low level, fill out

recommended oil to upper level.

Oil Change

Caution

Drain oil as engine warmed up so that makes sure

oil can be drained smoothly and completely.

Place an oil pan under the ATV, and remove oil

drain bolt.

After drained, make sure washer can be re-used.

Install oil drain bolt.

Drain bolt

Torque value? 1.9~2.5kgf-m

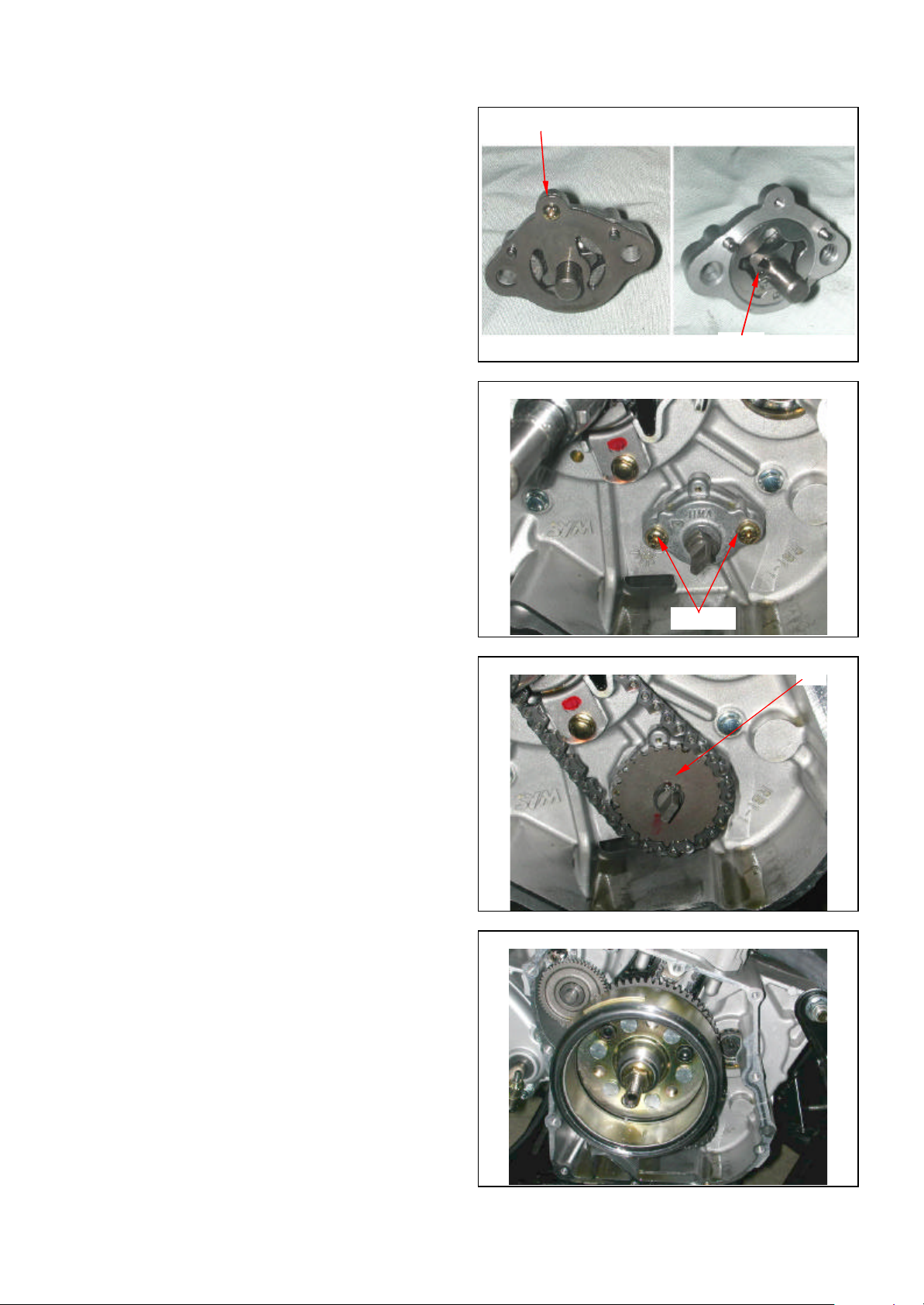

4-5 Engine Oil Strainer Clean

Drain engine oil out .

Remove oil strainer and spring.

Clean oil strainer.

Check if O-ring can be re-used.

Install oil strainer and spring.

Install oil strainer cap.

Torque value? 1.5~3.0kgf-m

Add oil to crankcase (oil viscosity SAE 10W-30)

Recommended using King serial oil.

Engine oil capacity: 1200c.c. when replacing

Install dipstick, start the engine for running

several minutes.

Turn off engine, and check oil level again.

Check if engine oil leaks.

Oil strainer cap

O-ring

23

Oil strainer

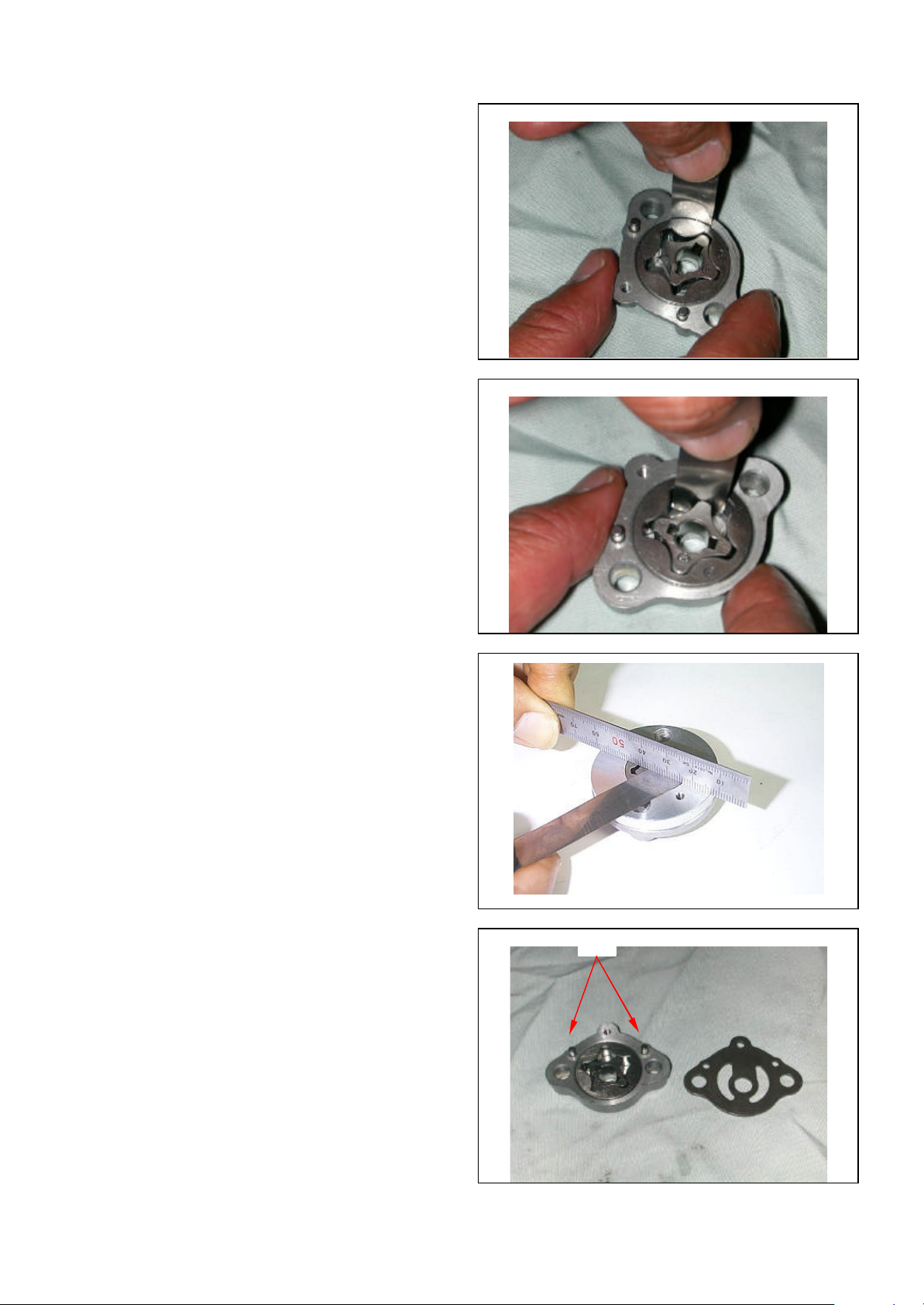

4-6 Oil Pump

Oil Pump Removal

Remove generator and starting gear. (Refer to

chapter 10) ?

Remove cir clip and take out oil pump driving

chain and sprocket.

Make sure that pump shaft can be rotated freely.

Remove 2 screws on the oil pump, and then

remove oil pump.

Oil Pump Disassembly

Remove the screws on oil pump co ver and

remove the cover.

Remove oil pump shaft roller and shaft.

Clip

2 screws

1 screw

Roller

24

Oil Pump Inspection

P

ins

Check the clearance between oil pump body and

outer rotor.

Limit: 0.25 mm

Check clearance between inner and outer rotors.

Limit: 0.20 mm

Check clearance between rotor side face and

pump body

Limit: 0.12 mm

Oil Pump Re-assembly

Install inner and outer rotors into the pump body.

Align the indent on driving shaft with that of

inner rotor.

Install the oil pump shaft and roller.

Install the oil pump cover and fixing pins

properly.

25

Tighten the oil pump screw.

Oil Pump Installation

Install the oil pump, and then tighten screws.

Torque value? 0.8~1.2kgf-m

Make sure that oil pump shaft can be rotated

freely.

Install oil pump drive chain and sprocket, and

then install cir clip onto oil pump shaft.

Install starting gear and generator.

(Refer to chapter 10)

1 screw

Roller

2 screws

Clip

26

4-7 Gear Oil

Gear Oil Change

Remove oil join bolt.

Remove drain bolt and drain gear oil out.

Install the drain bolt after drained.

Torque value: 1.0~1.5kgf-m

Make sure that the drain bolt washer can be re-used.

Add oil to specified quantity from the join hole .

Gear Oil Quantity: 650c.c. when replacing

Make sure that the join bolt washer can be re-used,

and install the bolt.

Start engine and run engine for 2-3 minutes.

Turn off engine and make sure that oil level is in

correct level.

Make sure that no oil leaking.

Gear oil join bolt

Gear oil drain bolt

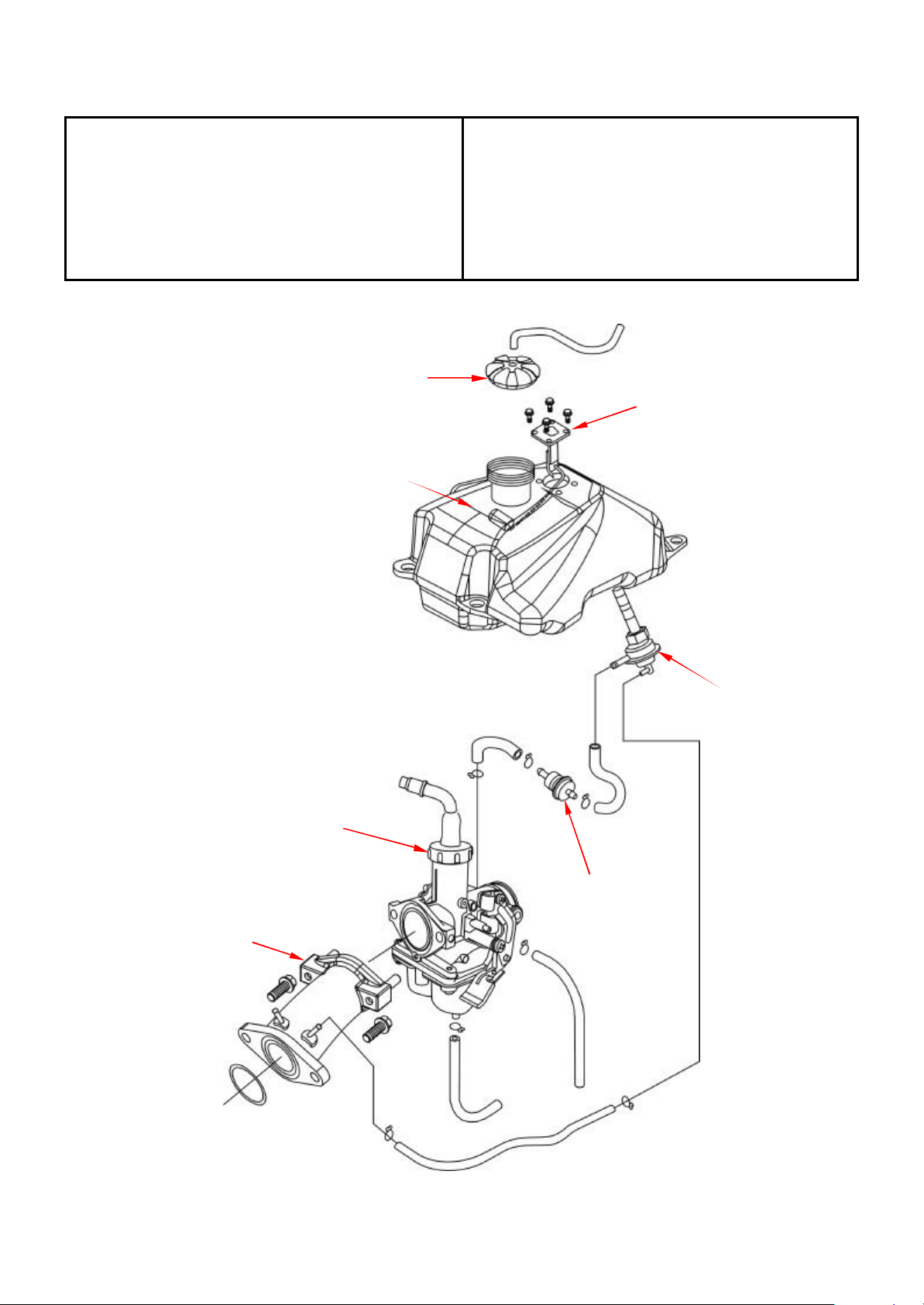

5. FUEL SYSTEM

Carburetor

Fuel

tank cap

Fuel

strainer

5-1 Mechanism Diagram

5-6 Throttle Valve

5-2 Precautions in Operation

5-3 Trouble Diagnosis

5-4 Carburetor Remove / Install

5-5 Air Cut-Off Valve

5-1 Mechanism Diagram

5-7 Float Chamber

5-8 Adjustment of Idle Speed

5-9 Fuel Tank

5-10 Air Cleaner

Fuel unit

Fuel tank

Inlet pipe

Auto fuel cock

5-2 Precautions in Operation

General Information

Warning

Gasoline is a low ignition point and explosive materials, so always work in a well-ventilated place and

strictly prohibit flame when working with gasoline.

Cautions

Ÿ Do not bend off throttle cable. Damaged throttle cable will make unstable drive-ability.

Ÿ When disassembling fuel s ystem parts, pay attention to O-ring position, replace with new one as

re-assembly

Ÿ There is a drain screw in the float chamber for draining residual gasoline.

Ÿ Do not disassemble air cut valve arbitrarily.

Tool

Special service tools

¢ Vacuum/air pressure pump

¢ Fuel level gauge

Specification of CARBURETOR

ITEM UA25A

Carburetor diameter Ø 22mm

I.D. number PTG 050

Fuel level 14.8mm

Main injector # 110

Idle injector # 35

Idle speed 1700 ± 100rpm

Throttle lever clearance 1~3 mm

Air screw 2 turns

5-3 Trouble Diagnosis

Poor engine start

Ÿ No fuel in fuel tank

Ÿ Clogged fuel tube

Ÿ Too much fuel in cylinder

Ÿ No spark from spark plug(malfunction of

ignition system )

Ÿ Clogged air cleaner

Ÿ Malfunction of carburetor chock

Ÿ Malfunction of throttle operation

Stall after started

Ÿ Malfunction of carburetor chock

Ÿ Incorrect ignition timing

Ÿ Malfunction of carburetor

Ÿ Dirty engine oil

Ÿ Air existing in intake system

Ÿ Incorrect idle speed

Rough idle

Ÿ Malfunction of ignition system

Ÿ Incorrect idle speed

Ÿ Malfunction of carburetor

Ÿ Dirty fuel

Intermittently misfire as acceleration

Ÿ Malfunction of ignition system

Late ignition timing

Ÿ Malfunction of ignition system

Ÿ Malfunction of carburetor

Power insufficiency and fuel consuming

Ÿ Fuel system clogged

Ÿ Malfunction of ignition system

Mixture too lean

Ÿ Clogged fuel injector

Ÿ Vacuum piston stick and closed

Ÿ Malfunction of float valve

Ÿ Fuel level too low in float chamber

Ÿ Clogged fuel tank cap vent

Ÿ Clogged fuel filter

Ÿ Obstructed fuel pipe

Ÿ Clogged air vent hose

Ÿ Air existing in intake system

Mixture too rich

Ÿ Clogged air injector

Ÿ Malfunction of float valve

Ÿ Fuel level too high in float chamber

Ÿ Malfunction of carburetor chock

Ÿ Dirty air cleaner

Loading...

Loading...