INSTALLATION and SERVICE INSTRUCTIONS

USE and CARE INSTRUCTIONS

DS 61 GW

DUAL FUEL COOKER

distributed by

DèLonghi

Pty Ltd

2

Dear Customer,

Thank you for having purchased and given your

preference to our product.

The safety precautions and recommendations reported

below are for your own safety and that of others. They

will also provide a means by which to make full use of

the features offered by your appliance.

Please keep this booklet in a safe place. It may be

useful in future, either to yourself or to others in the

event that doubts should arise relating to its operation.

This appliance must be used only for the task it has

explicitly been designed for, that is for cooking

foodstuffs. Any other form of usage is to be considered

as inappropriate and therefore dangerous.

The manufacturer declines all responsibility in the

event of damage caused by improper, incorrect or

illogical use of the appliance or be faulty installation.

PRODUCT LABEL

Important:

This appliance is designed and manufactured solely for the cooking of domestic

(household) food and is not suitable for any non domestic application and therefore should not be used in a commercial environment.

The appliance guarantee will be void if the appliance is used within a non domestic environment i.e. a semi commercial, commercial or communal environment.

3

FIRST TIME USE THE OVEN

It is advised to follow these instructions:

■ Clean the interior of the oven with cloth soaked in water and detergent

(neutral) then dry carefully.

■ Fit the wire racks as described at chapter “Use and care”.

■ Insert shelves and tray.

■ Switch on the empty oven on max to eliminate grease tracks from the heating

elements.

IMPORTANT PRECAUTIONS AND RECOMMENDATIONS FOR

USE OF ELECTRICAL APPLIANCES

Use of any electrical appliance implies the necessity to follow a series of fundamental

rules. In particular:

■ Never touch the appliance with wet hands or feet;

■ do not operate the appliance barefooted;

■ The appliance is not intended for use by young children or infirm persons

with supervision

■ Young children should be supervised to ensure they do not play with the

appliance

The manufacturer cannot be held responsible for any damages caused by improper,

incorrect or illogical use of the appliance.

4

IMPORTANT PRECAUTIONS AND RECOMMENDATIONS

After having unpacked the appliance, check to ensure that it is not damaged.

In case of doubt, do not use it and consult your supplier or a professionally qualified technician.

Packing elements (i.e. plastic bags, polystyrene foam, nails, packing straps, etc.) should not

be left around within easy reach of children, as these may cause serious injuries.

■ Do not attempt to modify the technical characteristics of the appliance as this may

become dangerous to use.

■ Do not carry out cleaning or maintenance operations on the appliance without hav-

ing previously disconnected it from the electric power supply.

■ After use, ensure that the knobs are in off position.

■ Do not allow children or other incapable people to use the appliance without super-

vision.

■ During and after use of the cooker, certain parts will become very hot. Do not touch

hot parts.

■ Keep children away from the cooker when it is in use.

■ Some appliances are supplied with a protective film on steel and aluminium parts.

This film must be removed before using the appliance.

■ Fire risk! Do not store flammable material in the oven, and in the accessory draw-

er.

■ Make sure that electrical cables connecting other appliances in the proximity of the

cooker cannot come into contact with the hob or become entrapped in the oven

door.

■ Do not line the oven walls with aluminium foil. Do not place baking trays or the drip

tray on the base of the oven chamber.

■ The manufacturer declines all liability for injury to persons or damage to property

caused by incorrect or improper use of the appliance.

■ IMPORTANT NOTE: This appliance shall not be used as a space heater,

especially if installed in marine craft or caravans.

This cooker has been designed and constructed in accordance with the following

codes and specifications:

AGA101 (AS 4551) Approval Requirements for Domestic Gas cooking appliances

AS/NZS 3350-1 General Requirements for Domestic electrical appliances

AS/NSZ 3350-2-6 Particular Requirements for Domestic electrical cooking appliances

AS/NSZ 1044 Electromagnetic Compatibility Requirements.

5

CAUTION:

■

This appliance must be installed in accordance with these installation

instructions.

■

This appliance shall only be serviced by authorized personnel.

■

This appliance is to be installed only by an authorised person.

■

Incorrect installation, for which the manufacturer accepts no responsibility,

may cause personal injury of damage.

■

Always disconnect the cooker from mains power supply before carrying out

any maintenance operations or repairs.

■

In the room where the cooker is installed, there must be enough air to

allow the gas to burn correctly, according to the current local regulations.

INSTALLATION

ELECTRICAL REQUIREMENTS

■ The appliance must be connected to the mains checking that the voltage corre-

sponds to the value given in the rating plate and that the electrical cable sections can withstand the load specified on the plate.

■ The plug must be connected to an earthed socket in compliance with safety

standards.

■ If the appliance is supplied without a plug, fit a standard plug which is suitable

for the power consumed by the appliance.

■ The appliance must be connected directly to the mains placing a two pole

switch with minimum opening between the contacts of 3 mm between the

appliance and the mains.

■ The power supply cable must not touch the hot parts and must be positioned so

that it does not exceed 50°C above ambient.

■ Once the appliance has been installed, the switch or socket must always be

accessible.

■

If the supply cord is damaged it must be replaced by the manufacturer or

it’s Service Agent or a similarly qualified person in order to avoid a hazard.

WARNING: This cooker must be connected to electrical supply using

V105 insulated cable.

N.B. The connection of the appliance to earth is mandatory.

If the installation requires alterations to the domestic electrical system call a qualified

electrician. He should also check that the socket cable section is suitable for the power

drawn by the appliance.

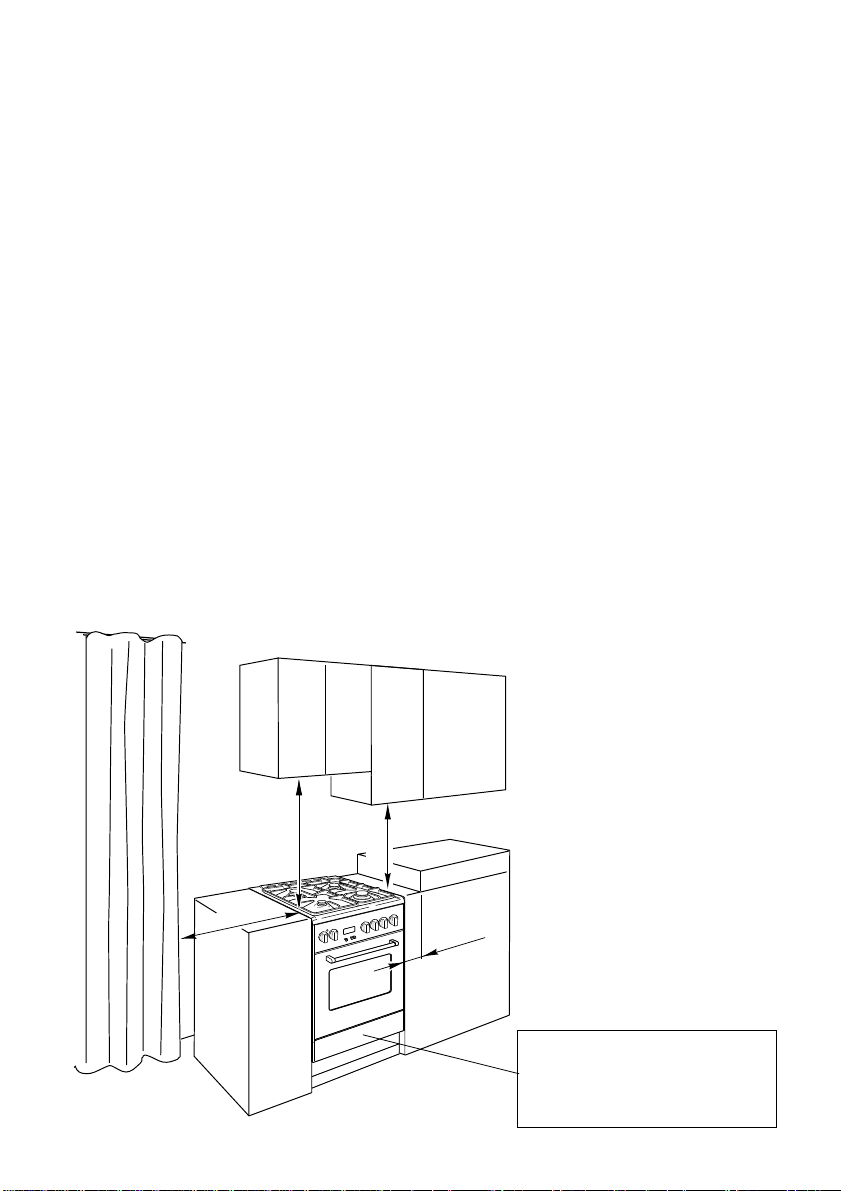

CLEARANCES

Installation clearances and protection of combustible surfaces shall comply with

the current local regulations eg. AG 601 (AS 5601) Gas Installations code.

Installation shall comply with the dimension in Fig 1 bearing in mind that

Overhead Clearances

In no case shall the clearances between the highest part of the cooker be less than

600mm or for an overhead exhaust fan 750mm. AII other downward facing combustible surfaces less than 600mm above the cooker surface shall be protected for the

full width of the cooking surface in accordance with the standards noted above. In no

case shall the clearance be less than 450mm.

Rear and Side Clearances

Where the dimensions from the periphery of the nearest burner to any vertical combustible surface is less than 200mm the surface shall be protected in accordance with

the standards to a height of not less than 150mm above the cooking surface for the

full width or depth of the cooking surface

Where the dimensions from the periphery of the nearest burner to any horizontal combustible surface is less than 200 mm, the horizontal surface shall be greater than 10

mm below the surface of the hob, or the horizontal surface requirement above.

Protection of combustible surfaces.

The standards above specify that where required protection shall ensure that the surface temperature of the combustible surface does not exceed 65°C above room temperature.

If the cooker is located on a pedestal it is necessary to provide safety

measures to prevent falling out.

6

Figure 1

105 m

m

m

in

500 mm

750 mm

450 mm

Cooker overall dimensions [mm]

• height: min 900 - max 935

• width: 600

• depth: 600

7

Figure 2

ANTI-TILT BRACKET

Warning: This appliance must be restrained to prevent accidental tipping by fitting a

bracket to the rear of the appliance and securely fixing it to the wall.

Fixing the anti-tilt bracket:

■ After you have located where the cooker is to be positioned mark, on the wall,

the place where the 2 screws of the anti-tilt bracket have to be fitted. Please follow the indications given in the drawing below.

■ Make two holes of diameter 8mm diameter on the wall and insert the plastic

plugs.

■ Attach the anti-tilt bracket loosely by means of 2 screws.

■ Move the cooker to the wall and adjust the height of the anti-tilt bracket so that

it can engage in one slot of the cooker back.

■ Attach the anti-tilt bracket tight.

■ Push the cooker against the wall so that the anti-tilt bracket is fully inserted in

one slot of the cooker back.

0

+ 35

6

0

0

m

m

3

6

5

2

3

5

5

0

0

1

4

n

1

i

x

m

a

m

8

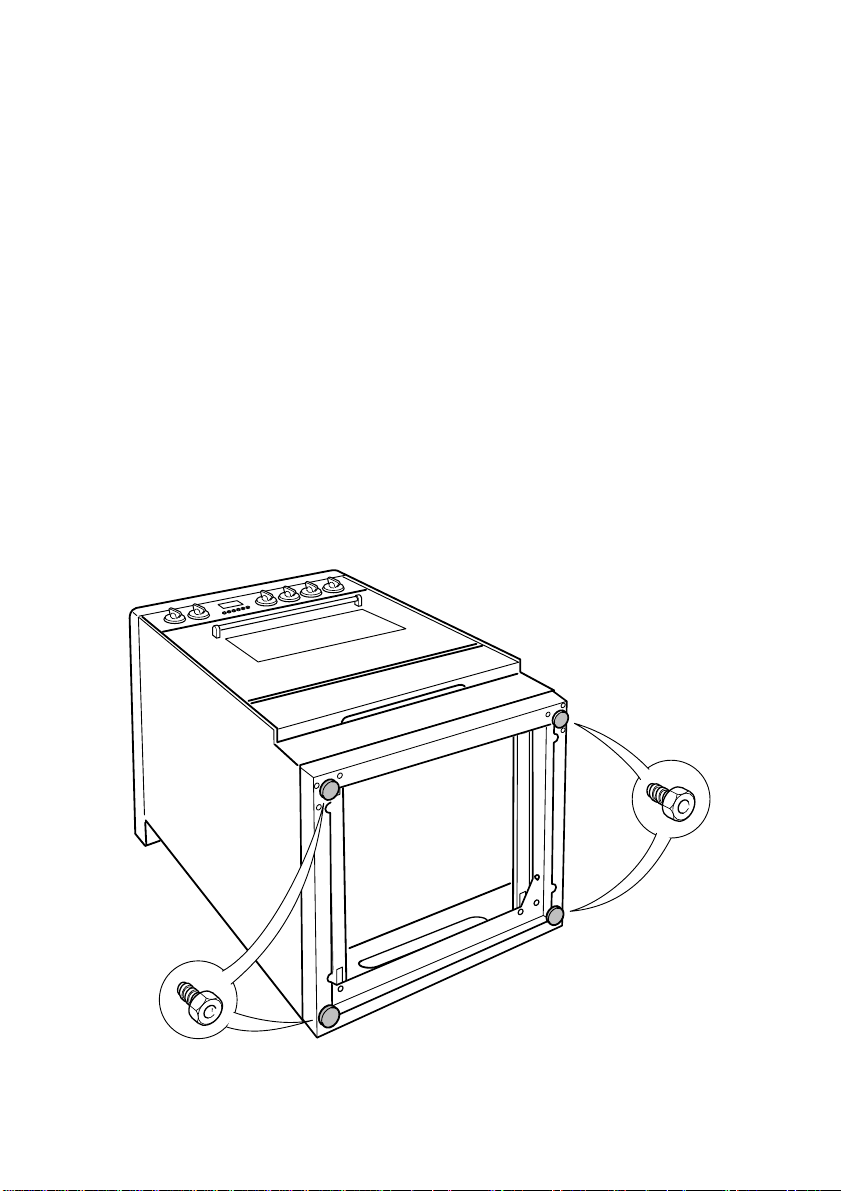

LEVELLING

The cooker is equipped with 4 levelling feet which must be fitted to the base of the

cooker in the following manner:

■ Place the cooker on its back as shown in the figure 3.

■ Screw the 4 leveling feet to the cooker.

■ Stand the cooker and level it by screwing or unscrewing the feet with a span-

ner.

Figure 3

9

GAS SUPPLY:

■ The connection must be performed by an authorised person according to the

relevant standards.

■ Before connecting the appliance to the gas main, mount the brass conical adap-

tor onto the gas inlet pipe, upon which the gasket has been placed (figs. 4-5).

Conical adaptor and gasket are supplied with the appliance (packed with con-

version kit for use with Natural gas or Propane gas).

■ This appliance is suitable for use with Natural Gas or Propane gas. (Check the

“gas type” sticker attached to the appliance).

■ For Natural Gas models the gas supply is connected to the pressure regulator

which is supplied with the appliance (fig. 5). Adjust the regulator to obtain a test

point pressure of 1 kPa with the two semi-rapid (SR) burners operating at maximum.

■ For Propane gas models the gas supply is connected to the test point adaptor

which is supplied with the appliance (fig. 4) and ensure that the supply pressure

is regulated to 2.75 kPa.

■ The connection must be made at the rear of appliance (left or right); the pipe

does not cross the cooker.

■ The inlet not used must be closed off with the cap and sealing gasket supplied.

■ IMPORTANT: Use two spanners to tighten or loosen the connecting pipe (fig. 6)

Gas connection for

PROPANE GAS

Figure 5

Figure 4

Gas connection for

NATURAL GAS

Gas inlet pipe

Nipple

Gasket

Brass conical adaptor

(Thread tight: use

suitable seal)

Gas inlet pipe

Nipple

Gasket

Brass conical adaptor

(Thread tight: use

suitable seal)

Gas regulator

Test point adaptor

Test

point

Test

point

10

Figure 6

Figure 7

1. After connecting the gas supply, check the piping and connections for leaks using

a soap and water solution. The presence of bubbles indicates a leak, tighten or

replace connections as appropriate.

Warning: Do not use any naked flame to check for leaks.

2. Adjust the test point pressure or supply pressure to the value which is appropriate

for the gas type.

3. The operation of the appliance must be tested when installation is completed.

4. Turn on the appliance gas controls and light each burner individually and in combination. Check for a well defined blue flame without any yellow tipping. If any

abnormality is evident then check that the burner cap is located properly and the

injector nipple is aligned correctly.

5. Check the minimum burner setting by quickly rotating the gas control knob from

the maximum to the minimum position, the flame must not go out. If adjustment is

required carry out the “minimum burner setting adjustment" procedure described

6. If satisfacfory performance cannot be obtained, the installer shall check the installation and notify the local gas supply authority for a gas supply problem, or if it is an

appliance problem, our Customer Service Centre should be called to obtain the

nearest authorized Delonghi Service Agent.

WARNING, This appliance IS NOT SUITABLE for installation with a hose

assembly.

Plug

11

Figure 8a

Figure 8b

J

J

CONVERSION PROCEDURE (to convert to LPG Propane)

REPLACING THE INJECTORS

This appliance is suitable for use with Natural gas or Propane gas (check the “gas type”

sticker attached to the appliance). A label stating the type of gas used after replacing

the injectors must be attached at the rear of the appliance, in proximity of the gas

inlet connection. The nominal gas consumption and injector size details are provided

in table at page 13.

To replace the injectors proceed as follows:

■ Remove pan supports and burners from the cooktop.

■ Using a spanner, remove the injector J (fig. 8a, 8b) and replace it with one

according to the gas type (see following tables - page 13).

■ Affix to the rear of the appliance, in proximity of the gas inlet connections, the

warning label (supplied with the conversion kit) stating that the cooker has

been converted for use with Propane gas / Natural gas.

IMPORTANT

■ If the cooker is suitable for use with Natural gas and must be converted for use

with Propane gas, before connecting to gas main remove the appliance gas

regulator and replace with test point adaptor (see fig. 4-5)

■ If the cooker is suitable for use with Propane gas and must be converted for use

with Natural gas, before connecting to the gas main remove the appliance test

point adaptor and replace with gas regulator (see figs. 4-5).

NOTE:

Gas regulator and test point adaptor are supplied with the appliance (packed with

conversion kit)

The burners are designed so that regulation of primary air is not required.

12

MINIMUM BURNER SETTING ADJUSTMENT

Check whether the flame spreads to all burner ports when the burner is lit with the gas

tap set to the minimum position. If some ports do not light, increase the minimum gas

rate setting.

Check whether the burner remains lit even when the gas tap is turned quickly from

the maximum to the minimum position. If the burner does not remain lit, increase the

minimum gas rate setting.

The procedure for adjusting the minimum gas rate setting is described below.

■ Turn on the burner

■ Turn the tap to the MINIMUM position

■ Take off the knob

■ With a small flat screwdriver turn the screw “F” (fig. 9) to the correct regulation.

Normally for Propane gas, the regulation screw is tightened up.

Figure 9

F

13

Natural gas Propane gas

Test Point Pressure [kPa] 1.0 2.75

BURNER

Auxiliary (A) 0.85 3.60 0.53 3.60

Semi-rapid (SR) 1.12 6.30 0.70 6.30

Triple ring (TC) 1.65

13.30

0.95 11.90

Gas

Consumption

[MJ/h]

Injector

Orifice Dia.

[mm]

Gas

Consumption

[MJ/h]

Injector

Orifice Dia.

[mm]

TABLE FOR THE CHOICE OF THE INJECTORS

LUBRICATION OF THE GAS TAPS

If the gas tap becomes stiff, it is necessary to dismantle it carefully and clean it with petroleum

spirit. Specialist high temperature resistant grease should be used to lubricate the tap before

replacing.

The operations must be carried out by an authorised person/service agent.

Figure 10

14

USE and CARE

CAUTION:

■ This appliance must be used only for the task it has explicitly been designed for,

that is for domestic cooking of foodstuffs. Any other form of usage is to be considered as inappropriate and therefore dangerous.

■ Do NOT place combustible materials or products on this appliance at any time.

■ Do NOT spray aerosols in the vicinity of this appliance while it is in use.

SLIDING SHELVES

■ They facilitate the insertion and removal shelves during cooking. These shelves

support all accessories and the dishwarmer safe.

■ The shelves block when pulled to the maximum position.

■ The sliding shelves can be removed easily by lifting slightly and detaching them

from the oven walls.

■ Removing the sliding shelves improves access to the oven ceiling for cleaning

(after the grill heating element has been lowered).

Figure 11 Figure 12

15

USING THE OVEN FOR THE FIRST TIME

■ Slide off the sliding shelves and the catalytic liners to the oven wall as in Fig. 11.

The grill is secured to the rear wall of the oven on a hinge system that allows it

to be lowered to allow proper access when cleaning the oven ceiling (fig. 12).

■ Clean the inside of the oven with a cloth soaked in water and neutral detergent

and dry thoroughly.

■ Slide in the catalytic liners and sliding shelves on the oven wall as in Fig. 11.

■ Slide in the grease filter on the back of the oven as in Fig. 13b.

■ Position the shelf and tray on the sliding shelves.

■ To eliminate traces of grease in manufacture it is necessary to pre-heat the oven

at the maximum temperature.

• For 60 minutes in the position, for 30 minutes in the position and for

another 15 minutes in the position.

GREASE FILTER

■ A special screen is provided at the back of the oven to catch grease particles,

mainly when meat is being roasted (fig. 13b).

■ When baking pastry etc. this filter should be removed.

■ Always clean the filter after cooking as any solid residues on it might adversely

affect the oven performance.

Figure 13a

Figure 13b

16

GAS BURNERS Natural Gas Propane gas

MJ/h MJ/h

1. Auxiliary burner (A) 3.6 3.6

2. Semi-rapid burner (SR) 6.3 6.3

3. Semi-rapid burner (SR) 6.3 6.3

4. Triple ring burner (TC) 13.3 11.9

Figure 14

GAS HOB

2

1

3

4

17

LIGHTING GAS BURNERS

FITTED WITH SAFETY VALVE DEVICE AND ELECTRONIC IGNITION

Figure 15

■ Check that the electricity is

switched on to allow spark ignition.

■ Make sure that all controls are

turned to zero.

■ The gas flow to the burner is

controlled by taps with safety

cutout device. If the burner

flame should go out, the safety

cut-off valve will automatically

stop the gas flow. The switch for

the electric ignition is incorporated in the knobs.

■ You control the flow by turning the knob indicator to line up with the following

symbols:

– Symbol ● : tap closed

(burner off)

– Symbol : High (maximum)

– Symbol : Low (minimum)

■ To ignite automatically, push the required knob down and turn it to maximum,

keeping the knob down until the burner lights. When the flame is lit, wait for

about ten second with the knob down (safety cut-off activation delay).

■ You can control the temperature by the knob to “High” from “minimum”.

■ To switch off, turn the knob clockwise until you hear the safety click.

■ Note that, if you are using a burner at the minimum setting, you turn the knob

clockwise past the maximum setting before reaching the off position.

■ Whenever the lighting of the burners is difficult due to peculiar conditions of

the gas features or supply, it is advised to repeat the ignition with the knob on

“minimum” position.

■ If when lighting any of the burners an abnormal flame appears, switch the

burner off and relight using the minimum setting.

■ If the flame is still not correct, turn the burner off and call our Customer Service

center for your nearest Authorized Delonghi Service Agent.

■ In the case of a mains failure light the burner with a match or lighted taper.

18

CHOICE OF BURNER

Burners Pan diameter

Auxiliary 12 - 14 cm

Semi-rapid 16 - 24 cm

Triple ring 26 - 28 cm

Wok max 36 cm

The burner must be chosen according to the diameter of the pans and energy

required.

For optimum efficiency use a wok or pan no smaller than 230mm diameter.

Saucepans with handles which are excessively heavy, in relationship to the weight

of the pan, are safer as they are less likely to tip.

Pans which are positioned centrally on burners are more stable than those which

are offset.

It is far safer to position the pan handles in such a way that they cannot be

accidentally knocked.

When deep fat frying fill the pan only one third full of oil.

DO NOT cover the pan with a lid and DO NOT leave the pan unattended.

In the unfortunate event of a fire, leave the pan where it is and turn off all

controls.

Place a damp cloth or correct fitting lid over the pan to smother the flames.

DO NOT use water on the fire.

Leave the pan to cool for at least 30 minutes.

Figure 16

do not use pans with concave or convex bases

19

CORRECT USE OF TRIPLE-RING BURNER

■ The flat-bottomed pans are to be placed directly onto the pan-support.

■ To use the WOK, you must place the wok stand in the CORRECT position as

shown in Fig. 17-18.

Figure 17 Figure 18

WRONG

CORRECT

20

A

U

T

O

6

7

5

8

4

3

2

1

CONTROL PANEL - Controls description

1. Front right burner control knob

2. Rear right burner control knob

3. Rear left burner control knob

4. Front left burner control knob

5. Multifunction oven thermostat knob

6. Multifunction oven switch knob

7. Electronic programmer

Note: The electric ignition of the hob burners is incorporated in the knobs.

Pilot lamp:

8. Oven thermostat indicator light

MULTIFUNCTION OVEN

GENERAL FEATURES

With your new Multi-Function oven it is possible to cook a variety of food using the 7

different cooking functions.

These 7 functions are obtained using a combination of the 4 different heating elements

plus a defrost function using the fan only.

Figure 19

Please note: This appliance incorporates a safety cooling fan which you will hear

operating whenever the oven or grill are in use. This fan is to reduce the external

temperature of the appliance and cool the internal components.

WARNING:

The door is hot, use the handle.

During use the appliance becomes hot.

Care should be taken to avoid touching

heating elements inside the oven.

21

FUNCTION SELECTOR KNOB

Rotate the knob clockwise to set the

oven for one of the following functions.

THERMOSTAT KNOB

This only sets the cooking temperature

and does not switch the oven on.

Rotate clockwise until the required

temperature is reached (from 50 to

250°C).

OPERATING PRINCIPLES

Heating and cooking in the MULTI-FUNCTION oven are obtained in the following

ways:

a. by normal convection

The heat is produced by the upper and lower heating elements.

b. by forced convection

The fan draws in air contained within the oven housing at the rear of the oven and

forces it over the circular heating element. The hot air envelops the food in the oven

givin faster and more even cooking before it is drawn back into the housing to

repeat the cycle. It is possible to cook several dishes simultaneously due to the even

distribution of heat within the oven.

c. by forced semi-convection

The heat produced by the top and bottom heating elements is distributed throughout the oven by the fan.

d. by radiat heat

The food is grilled by the infra red grill element.

e. by radiat heat and ventilation

The food is grilled by the grill element is distributed throughout the oven

f. by ventilation

The food is defrosted by using the fan only function without heat.

Figure 20

22

DEFROST

Only the oven fan comes on. Use with the thermostat knob set to “●” - other temperature have no effect. The food is thawed by ventilation without heating.

Ideal for:

Quick thawing of frozen foods; one kg requires approximately 1 hour.

Thawing times vary according to the quantity and type of food to be thawed.

GRILLING

The infrared grill element at the top of the oven comes on. The heat is dispersed by

radiation.

Use with the oven door closed and the thermostat knob to position 225°C for max

15 minutes, then to position 175°C.

For cooking hints, see the chapter “USE OF THE GRILL”.

Ideal for:

Intense grilling, browning, cooking au gratin and toasting etc.

It is recommended that you do not grill for longer than 30 minutes at any

one time.

Attention: the oven door becomes very hot during operation.

Keep children away.

TRADITIONAL BAKE

The upper and lower heating elements come on. The heat being dispersed by

natural convection. The temperature range must be set between 50°C and 250°C

using thermostat.

The oven must be preheated before cooking.

Ideal for:

Food that requires the same degree of cooking both inside and out, for example

roasts, spare pork ribs, meringues etc.

OVEN LIGHT

By setting the knob to this position, only the oven light comes on (15 W).

It remains on in all the cooking modes.

23

MAINTAINING TEMPERATURE AFTER COOKING OR

SLOWLY HEATING FOODS

The upper element, the circular element and the fan come on.

The heat is circulated by forced convection with greater intensity in the upper part.

The temperature can be set to between 50° and 150°C via the thermostat knob.

Recommended for:

Keeping food warm after any type of cooking. Slow heating of cooked food.

MULTI-FUNCTION

The upper and lower heating elements come on and the fan come on - the heat from

the element being circulated by the fan.

The temperature range can be set to between 50° and 250°C using the thermostat.

Idea for:

Large bulky quantities of food that require even cooking throughout for example large

roasts, turkey, roast turkey, cakes etc.

FAN FORCED

The circular element and fan come on. The heat is dispersed by forced convection and

the temperature can be varied to between 50° and 250°C via the thermostat knob.

The oven does not require preheating.

Recommended for:

Food which has to be well-cooked outside and soft or rosy inside, for example lasagne,

lamb, roast beef, whole fish etc.

FAN GRILL

Both the grill and the fan come on. Most of the cooking is done by grilling and then

the hot air circulated around the oven. The oven door should be kept closed

The temperature can be set between 50°C and 175°C maximum.

The oven should be preheated for 5 minutes before cooking. For further cooking hints

see “GRILLING AND AU GRATIN”.

Ideal for:

Quick sealing in of food juices for example such as hamburger, chicken pieces, chops.

It is recommended that you do not grill for longer than 30 minutes at any

one time.

Attention: the oven door becomes very hot during operation.

Keep children away.

.

24

GRILLING AND “AU GRATIN”

As the hot air completely covers the food to be cooked, grilling may be done with

the food on rack in the oven. The knob should be switched to position .

The thermostat should be set to 175 °C and the oven pre-heated.

The food should be placed on a rack in the oven for the required cooking time.

Adding a few dabs of butter before the end of the cooking time gives the golden “au

gratin” effect.

It is recommended that you do not grill for longer than 30 minutes at any

one time.

COOKING ADVICE

STERILIZATION

Sterilization of foods to be preserved, in full and hermetically sealed jars, is done in the

following way:

a. Set the switch to position .

b. Set the thermostat knob to position 185 °C and preheat the oven.

c. Fill the dripping pan with hot water.

d. Set the jars onto the dripping pan making sure they do not touch each other and

the door and set the thermostat knob to position 135 °C.

When sterilization has begun, that is, when the contents of the jars start to bubble,

turn off the oven and let cool.

Check your recycle book for full instructions.

SIMULTANEOUS COOKING OF DIFFERENT FOODS

The oven set on position can cook several different foods together. Foods as

diverse as fish and cakes can be cooked together without the cross transference of

flavours. This is because the fats and cooking smell that would normally be

deposited on the different foods are oxidised and are not absorbed by the foods.

The cooking temperature of the foods, however must be within 20°-25°C of each

other. The food with the longest cooking time will be put into the oven first and

the other foods are added as necessary according to their cooking times.

ROASTING

To obtain classical roasting, it is necessary to remember:

■ that it is advisable to maintain a temperature between 180° and 200 °C.

■ that the cooking time depends on the quantity and the type of foods.

USE OF THE GRILL

Preheat the oven for about 5 minutes with the door closed.

Introduce the food to be cooked, positioning the rack as close to the grill as possible.

The dripping pan should be placed under the rack to catch the cooking juices and

fats.

Do not grill for longer than 30 minutes at any one time.

25

N.B. For fan ovens reduce the temperature

by 10-20°C. For any dish taking one hour or

over to cook, reduce the cooking time by 10

minutes per hour.

*

Shelf positions have been counted from

the top of the oven to the base.

A fan oven creates more even temperature

throughout, therefore the shelf positions are

not as critical.

Food °C °F Gas Shelf Cooking

Mark Position* Time (approx)

CAKES

Victoria sandwich 190 375 5 2 or 3 20-25 mins

Small cakes/buns 190 375 5 1 and 2 15-20 mins

Maidera cake 180 350 4 2 or 3 20 mins

Fruit cake 170 325 3 3 1

3

/4 hours

Rich fruit cake 150 300 2 3 or 4 2

1

/2 hours

Scones 225 425 8-9 2 8-10 mins

PASTRY

Puff 225 425 8-9 2 10-20 mins

Short crust 200 400 6 2 20-30 mins

Plate tarts 200-210 400-410 6 1 or 2 30-35 mins

Quiches and flans 200-210 400-410 6 1 or 2 40-45 mins

YEAST

Bread loaf 225 425 7-8 2 35-55 mins

Bread rolls 220 425 7 1 or 2 15-20 mins

Pizza dough 230 450 8 2 20 mins

ROAST MEAT

Beef – Medium 190 375 5 2 or 3 20 mins/lb + 20 mins

Lamb 190 375 5 2 or 3 25-30 mins/b + 25 mins

Pork 190-200 375-400 5-7 2 or 3 30 mins/lb + 30 mins

Veal 190 375 5 2 or 3 30 mins/b + 30 mins

Chicken 190 375 5 2 or 3 30 mins/b + 30 mins

Turkey up to 10lb 180 350 4 2 or 3 18-20 mins/b + 20 mins

Stews/casseroles 150-170 300-325 2-3 2 or 3 1

1

/2 2 hours

RECOMMENDED COOKING TEMPERATURE

26

Description of the buttons:

Timer

Cooking time

End of cooking time

Manual position and cancellation of the inserted cooking program

Plus function to increase the number shown on the display

Minus function to decrease the number shown on the display or to change the

buzzer frequency

Description of the illuminated symbols:

AUTO -flashing - Programmer in automatic position but not programmed

AUTO - always illuminated - Programmer in automatic position with program inserted.

Automatic cooking taking place

Timer in operation

and AUTO - flashing - Program error.

(The time of day lies between the calculated cooking start and end time).

Note:

Select a function by the respective button and, in 5 seconds, set the required time

with the / buttons (“one-hand” operation).

A power cut makes the clock go to zero and cancels the set programs.

ELECTRONIC PROGRAMMER

The electronic programmer is a device which groups together the following functions:

■ 24 hours clock with illuminated display

■ Timer (up to 23 hours and 59 minutes)

■ Program for automatic oven cooking

■ Program for semi-automatic oven cooking

Figure 21

A

U

T

O

27

ELECTRONIC CLOCK (fig. 22)

The illuminated figures on the clock represent hours and minutes on 24 hour clock.

When first connected, or after a power failure, three zeros will flash on the display.

To set the time press the button and then the or

Please note that changing the hour button deletes any cooking program.

NORMAL COOKING WITHOUT THE USE OF THE PROGRAMMER

To manually use the oven without the aid of the programmer, it is necessary to cancel

the flashing AUTO by pushing the button (

AUTO

will be switched off and the

symbo l will come on - Fig. 23).

Attention: If the AUTO symbol is steady a cooking program has already been

programmed, by pushing the button you have cancelled of the program and the

switched to manual.

If the oven is switch on, you must switch off manually.

Figure 23

Figure 22

28

ELECTRONIC TIMER

The timer program consists only of a buzzer which may be set for a maximum period

of 23 hours and 59 minutes. If AUTO is flashing on the panel, push the button.

To set the time, push the button and the or until you obtain

the desired time in the panel (fig. 24).

Having finished the setting, the clock hour will appear on the panel and the

symbol will be lighted.

The countdown will start immediately and may be seen at any moment on the panel

by simply pressing the button .

At the end of the time, the symbol will be switched off and an intermittent buzzer

will go off; this can be stopped by pressing any of the buttons.

Figure 24

SETTING THE FREQUENCY OF THE AUDIBLE SIGNAL

The selection from 3 possibilities of sound can be made by pressing the button.

A

U

T

O

29

AUTOMATIC OVEN COOKING

To cook food automatically in the oven, it is necessary to:

1.Set the length of the cooking time

2.Set the end of the cooking time

3.Set the temperature and the oven cooking program.

These operations are performed as follows:

1.Set the length of the cooking time by pushing the button and the button to

advance, or to go back if you have passed the

desired time (fig. 25).

The AUTO and the symbol will be on

2.Set the end of the cooking time by pressing the button (the cooking time already

added to the clock time will appear), and the button (fig. 26); if you pass the

desired time you may get back by pushing the button.

After this setting, the symbol will go off. If after this setting, the AUTO flashes on

the panel and a buzzer sounds, it means there was an error in the programming. In

this case, modify the end of cooking time or the cooking time itself by following

again the mentioned instructions above.

3.Set the temperature and the cooking program by using the switch and thermostat

knobs of the oven (see specific chapters).

The oven is now set to turn on and off at the programmed times.

During cooking, the symbol remains on. By pushing the button you can see

the time that remains until the end of cooking.

The cooking program may be cancelled in any time by pushing .

At the end of the cooking time the oven will turn off automatically, the symbol will

turn off, AUTO will flash and a buzzer will sound, which can be turned off by pushing any of the bottons.

Turn the temperature and thermostat knobs to zero and set the programmer to “manual” by pressing the button.

Attention: A power failure makes the clock go to zero and cancels the set programs.

After a power failure, three zeros will flash on the panel.

Figure 25

Figure 26

A

U

T

O

A

U

T

O

30

SEMI - AUTOMATIC COOKING

This function is only used to set the END of the cooking time of the oven. There are

two ways of setting this function.

1. Set the length of the cooking time by pushing the button and the button

to advance, or to go backwards (Fig. 27). This sets the desired “stop” time.

or

2.Set the end of the cooking time by pushing the button and the button to

advance, or to go backwards if you have passed the desired time (Fig. 28).

AUTO and the symbol will be on.

Then set the temperature and the cooking program using the oven switch and

thermostat knob (see relevant sections for details).

The oven is switched on and it will be switched off automatically at the end of

the desired time.

During cooking, the symbol remains on and by pressing the button you

can see the time that remains till the end of the cooking.

The cooking time can be cancelled at any time by pushing the button.

At the end of the cooking, the symbol will turn off, the AUTO will flash and a

buzzer will sound. The buzzer can be cancelled by pressing any of the buttons.

Turn the temperature and thermostat knobs to zero and set the programmer to

“manual” by pressing the button.

Figure 27

Figure 28

A

U

T

O

A

U

T

O

31

GENERAL ADVICE

■ Before you begin cleaning, you must ensure that the appliance is

switched off.

■ It is advisable to clean when the appliance is cold and especially when

cleaning the enamelled parts.

■ Avoid leaving alkaline or acidic substances (lemon juice, vinegar, etc.) on the

surfaces.

■ Avoid using cleaning products with a chlorine or acidic base.

■ Do not use a steam cleaner because the moisture can get into the

appliance thus make it unsafe.

ENAMELLED PARTS

All of the enamelled parts must be washed only with a sponge and soapy water or

with non-abrasive products.

Dry, preferably, with chamois.

STAINLESS STEEL SURFACES

The stainless steel front panels on this cooker (facia, oven door, drawer) are protected

by a finger-print proof lacquer. To avoid damaging this lacquer, do not clean the

stainless steel with abrasive cleaners or abrasive cloths or scouring pads.

ONLY SOAP/WARM WATER MUST BE USED TO CLEAN THE STAINLESS STEEL

SURFACES.

Cleaning and Maintenance

Maintenance

Description

Period

Daily • Clean gas cooktop as per instructions below

• Remove burner caps, burner rings & base and clean using

non abrasive detergent & rinse in cold water & dry thoroughly

Monthly before replacing back on hob

• Clean ignitor tip & thermocouple using damp soapy cloth

and dry thoroughly

3 - 4 Yearly

• Contact your local authorized gas Service Agent to perform

a thorough check on all gas components on the gas cooker

32

BURNERS

They can be removed and washed only with soapy

water. Detergents can be used but must not be

abrasive or corrosive.

Do not use abrasive sponges or pads.

Do not put in dishwasher.

After each cleaning, make sure that the

burner-caps, as well as the burners, have

been well wiped off and CORRECTLY

POSITIONED.

It is essential to check that the burner flame

distributor F and the cap C has been correctly

positioned (see fig. 29) - failure to do so can

cause serious problems.

Check that the electrode S (fig. 29) is always

clean to ensure trouble-free sparking.

Check that the probe T (fig. 29) next to each

burner is always clean to ensure correct

operation of the safety valves. Both the probe

and ignition plug must be very carefully cleaned.

Note:

The electrode S must be very carefully

cleaned. To avoid damage to the electric

ignition do not use it when the burners are

not in place.

Figure 29

F

C

S

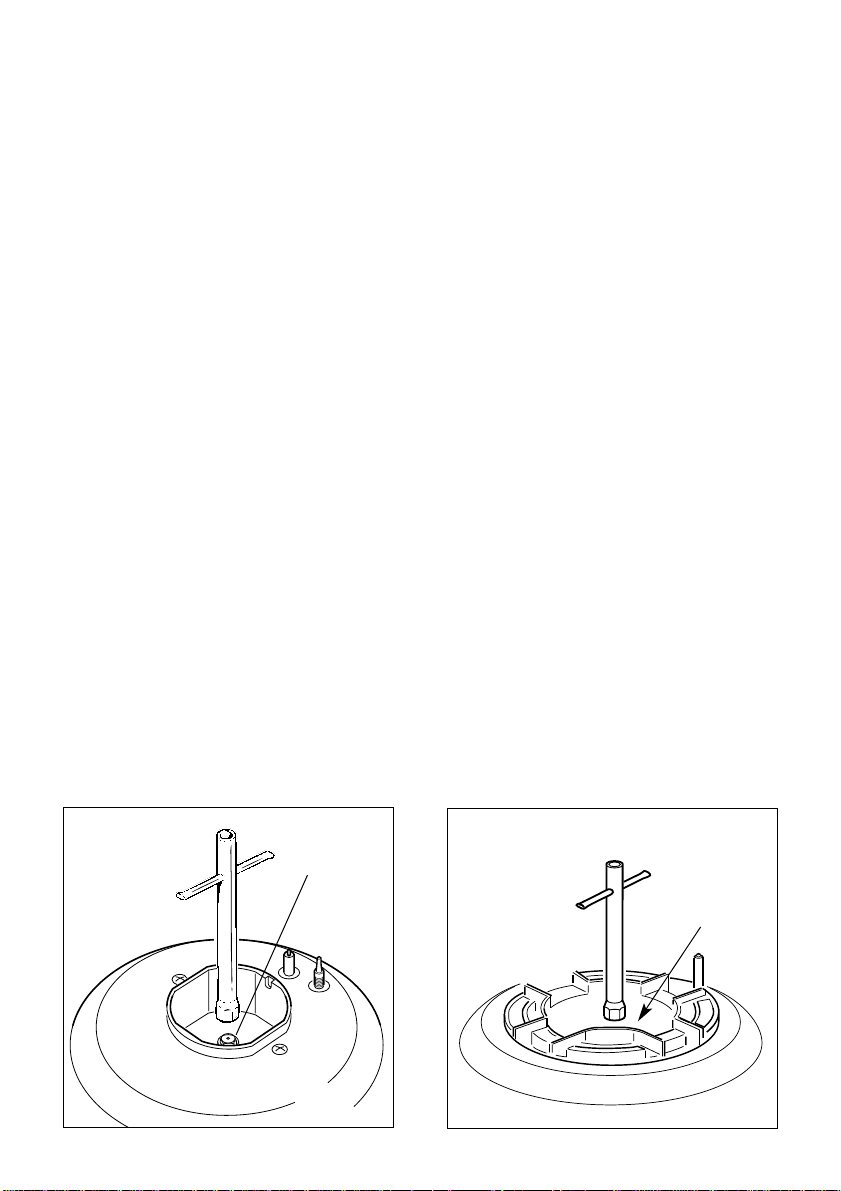

TRIPLE RING BURNER

The triple ring burner must be correctly positioned (see fig. 30); the burner rib must be

located in position as shown by the arrow.

The burner correctly positioned must not rotate (fig. 31).

Then position the cap A and the ring B (fig. 31).

A

B

Figure 30 Figure 31

T

33

GRILL HEATING ELEMENT

■ The heating element is self-cleaning and does not require maintenance. The

grill is secured to the rear wall of the oven on a hinge system that allows it

to be lowered to allow proper access when cleaning the oven ceiling (fig.

12 at page 14).

Advice for use and maintenance of catalytic panels

The catalytic panels are covered with special microporous enamel which absorbs

and does away with oil and fat splashes during normal baking over 200°C. If,

after cooking very fatty foods, the panels remain dirty, operate the oven “idling”

on max temperature for about 30 minutes. These panels do not require to be

cleaned, however it is advised to periodically remove them from the oven (at least

the side panels) and to wash them with tepid soapy water and then wipe off with

a soft cloth.

DO NOT CLEAN OR WASH THEM WITH ABRASIVE PRODUCTS OR WITH

PRODUCTS CONTAINING ACIDS OR ALKALIS.

The side panels are reversible and when the catalytic microporous enamel

degrades, they can be turned to the other side.

GAS TAPS

If the gas taps are not working properly, call our Customer Service Centre to obtain the

nearest Authorized Delonghi Service Agent.

OVEN

+

The oven should always be cleaned after use when it has cooled down. The cavity should

be cleaned using a mild detergent solution and warm water. Suitable proprietary

chemical cleaners may be used after first consulting with the manufacturers

recommendations and testing a small sample of the oven cavity. Abrasive cleaning

agents or scouring pads/cloths should not be used on the cavity surface.

+

NOTE: The manufacturers of this appliance will accept no responsibility for

damage caused by chemical or abrasive cleaning.

GREASE FILTER

■ Clean the filter after any cooking! The grease filter can be removed for

cleaning and should be washed regularly in hot soapy water (fig. 13b).

■ Always dry the filter properly before fitting it back into the oven.

34

OVEN DOOR AND DRAWER

The internal glass of the oven door can be easily removed for cleaning by

unscrewing the two lateral fixing screws (fig. 32).

The drawer (fig. 33) comes out like a normal drawer.

Attention: Do not store flammable material in the oven, or the accessory

drawer.

REPLACING THE OVEN LIGHT

Before any maintenance is started involving electrical parts of the

appliance, it must be disconnected from the power supply.

The bulb must be a type resistant to high temperatures (300° C).

Figure 32

Figure 33

35

REMOVING THE OVEN

DOOR - Type “A”

The oven door can easily be removed

as follows:

■ Open the door to the full extent

(fig. 35).

■ Attach the retaining rings to the

hooks on the left and right

hinges (fig. 36).

■ Hold the door as shown in fig.

34.

■ Gently close the door and with-

draw the lower hinge pins from

their location (fig. 37).

■ Withdraw the upper hinge pins

from their location (fig. 38).

■ Rest the door on a soft surface.

■ To replace the door, repeat the

above steps in reverse order.

Figure 34

Figure 35

Figure 36

Figure 37

Figure 38

36

L

H

REMOVING THE OVEN

DOOR - Type “B”

To facilitate oven cleaning, it is possible

to remove the door.

Please follow the instructions carefully:

■ Open the door completely.

■ Push down the lever “L” (fig. 39) and,

keeping it in this position, slowly

close the door in order to block the

hinge.

■ Grip the door (as indicated in fig. 40)

and, while closing it, release the two

hinges as shown in fig. 41.

DOOR ASSEMBLY

■ Grip the door with your hands

placed near the hinges and raise the

levers “H” with your forefingers (fig.

41).

■ Insert the hinges in their position until

levers “H” are hooked.

■ Open the door completely to obtain

the release of levers “L”.

Figure 41

Figure 39

Figure 40

37

If the ignition spark fails to ignite or does not light the gas, check the following

items before calling our Customer Service Centre to obtain the nearest Authorised

Service Agent:

■ Burner is reassembled and located correctly.

■ Spark electrode and white ceramic are clean and dry.

■ 240 VAC power supply is connected.

Contact the local gas utility or our Customer Service Centre to obtain the nearest

Authorized Service Agent.

■ You can smell gas when all burners are turned on.

■ The burners do not remain alight at the minimum marked setting.

■ The burner flame is yellow or emits an unusual odour.

Note that a bi-annual inspection of the appliance by an authorized service agent

or your locate gas utility will ensure many years of trouble free operation of your

appliance.

Service and Maintenance

38

WIRING DIAGRAM

ELECTRIC DIAGRAM KEY

F1 Oven switch

TM Oven thermostat

PR Electronic programmer

S1 Thermostat pilot lamp

LF Oven lamp

C Top element

G Grill element

V Fan

S Bottom element

TL Thermal overload

CIR Circular element

PA Ignition switches

A Ignition coil

M Terminal block

T Earth connection

CF Cooling fan

PR

1

1a

CF

N/7

L/8

TL

S1

F1

1

2

2a

3

3a

494a

5

5a

61a6a

7

7a

8

8a

9a

10

10a

11

11a

LF

TM

°C

PA

A

C

CIR

G

V

S

1131311

T

M

L

N

39

Descriptions and illustrations in this booklet are given as simply indicative. The manufacturer reserves the right,

considering the characteristics of the models described here, at any time and without notice, to make eventual

necessary modifications for their construction or for commercial needs.

cod. 1102921 - ß1

Loading...

Loading...