Page 1

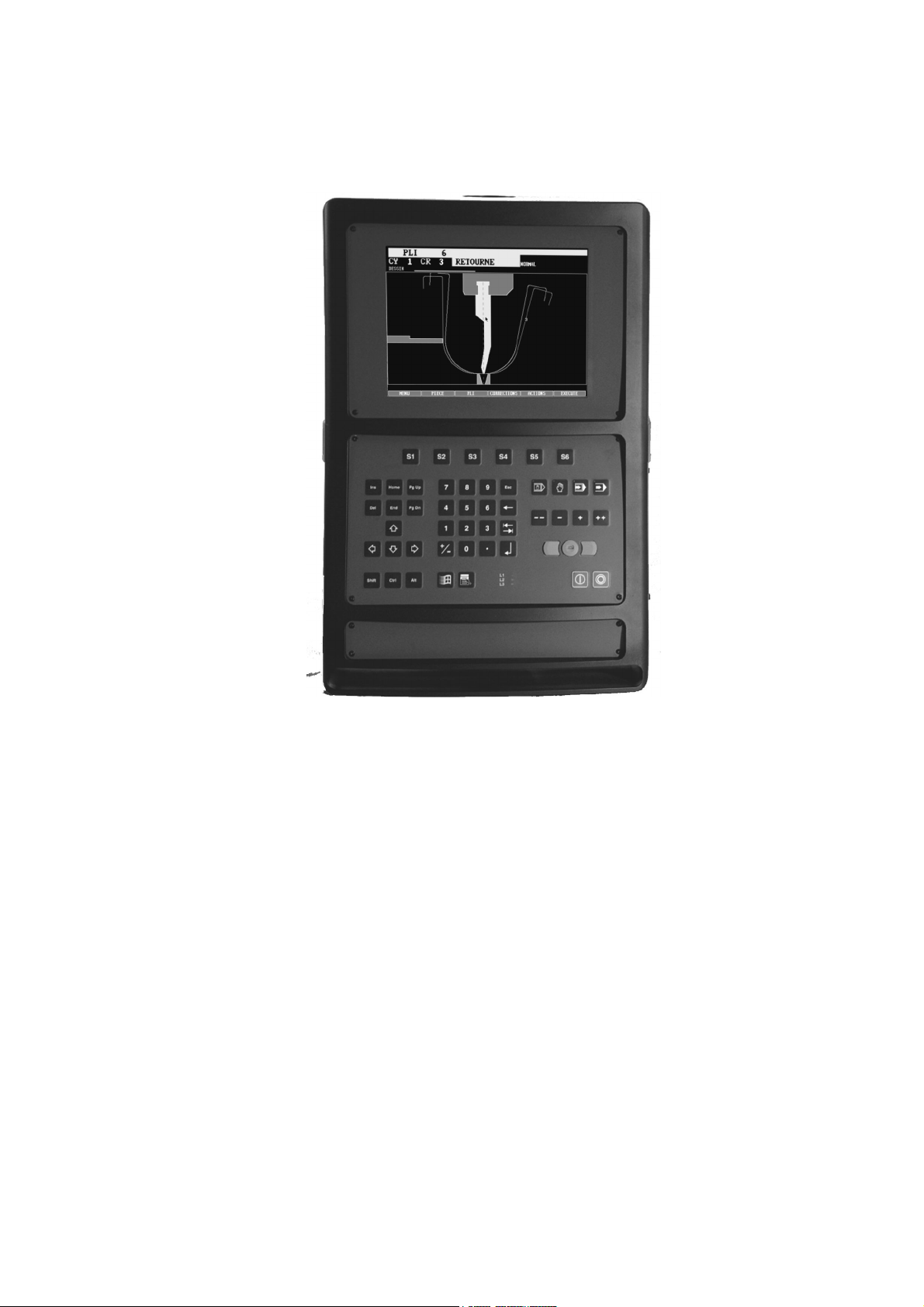

PC / DNC 1200

User Guide (2D + 3D)

CYBELEC SA Tel. ++ 41 24 447 02 00

RUE DES UTTINS 27 Fax ++ 41 24 447 02 01

CH - 1400 YVERDON-LES-BAINS E-Mail: info@cybelec.ch

SWITZERLAND

V-DOC-12PS23D-EN

Page 2

Information in this document is subject to change without notice, and does not represent

a commitment on the part of CYBELEC SA.

The software described in this document is furnished under a license agreement or nondisclosure

agreement. The software may be used or copied only in accordance with the terms of the agreement. It is

against the law to copy the software on any medium except as specifically allowed in the license or

nondisclosure agreement.

Copyright CYBELEC SA. 1991

All rights reserved.

Important:

This notice explains normal and standard programming operations for the numerical control.

In view of the fact that numerical controls can be equipped with configurable functions by the press

manufacturer for his own specific purposes, please refer to the manufacturer-supplied complementary

instructions regarding the programming of these functions.

Autocad

is a registered trade mark of Autodesk Inc..

CYBELEC is a registred trademark of CYBELEC SA.

Ethernet

is a registered trade mark of Xerox Corporation.

IBM , PC/AT , PC Network , Token Ring Network

are registered trade marks of the International Business Machines Corporation.

MS-DOS

MS-Windows

Novell Netware

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Novell, Incorporated.

Windows NT is a registered trade mark of Microsoft Corporation.

Page 3

S

AFETY AND MAINTENANCE INSTRUCTIONS

The operator must be trained for working with the

machine on which the numerical control is installed.

Improper use of the numerical control can cause

heavy damage on equipment and/or injuries to

people.

Modification of machine parameters can cause

important material damage or lead to irregular

product quality.

The rear panel may only be removed by a qualified

technician (danger of electrocution).

Do not expose the numerical control to excessive

humidity so as to avoid any risk of electrocution and

any deterioration of the equipment.

Make sure the numerical control is disconnected

from the mains power before carrying out any

cleaning. Do not use liquids based on alcohol or

ammoniac.

In case of malfunction of the numerical control, call a

technician.

Do not expose the numerical control to direct sun

rays or any other heat source.

Do not place the numerical control in the

neighbourhood of magnetic equipment such as

transformers, motors or devices which generate

interference (welding machines, etc.)

Replace fan filters at regular intervals so as to avoid

overheating.

SAFETY AND MAINTENANCE INSTRUCTIONS PAGE I

Page 4

This page has been left blank intentionally.

PAGE II USER GUIDE PC/DNC 1200 2D&3D

Page 5

LICENSE AGREEMENT FOR CYBELEC SOFTWARE

GENERAL COPYRIGHT

The CYBELEC software is protected by Copyright, and all the copying rights are reserved.

The CYBELEC software may only be installed and used in authorized equipments (PC or DNC).

The user manuals are also covered by copyright, and all rights to use and to copy are reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated or reduced

without prior consent, in writing, from CYBELEC.

SPECIAL DISKETTE COPYRIGHT

The legal users of this software product are authorized only to copy the contents of the diskette into the

memory of the computer to run the program, and to make one backup copy of the original diskette for

safety purposes in case of loss of the original program.

Unauthorized copying, duplicating, selling or otherwise distributing this product is a violation of the law.

SPECIAL EPROM COPYRIGHT

The CYBELEC DNC and CNC units in which the original software made by CYBELEC has been

replaced by a copy not made by CYBELEC, and without written authorization of CYBELEC, will

immediately lose their warranty.

WARRANTY

CYBELEC does not warrant that its software products will function properly in every computer and

programming environment.

The limitations of use of a software product and its technical specifications are decided by CYBELEC

only; CYBELEC solely is entitled to decide upon conformity and performance of a given software.

The CYBELEC software does not compensate for incompatibilities in operating system revisions or

versions.

Running the CYBELEC software under various revisions or versions, or switching between different

versions or revisions may result in loss or alteration of data.

LICENSE AGREEMENT PAGE III

Page 6

SOFTWARE UPDATE SERVICE

Purchase of the CYBELEC software entitles the user, during one year, to delivery of software updates of

the "correction" type.

During the use of a revised or corrected version of the software it may occur that data (program,

parameters, etc.) is lost, or that the equipment or its connections need to be modified; these effects are not

always foreseeable and do not engage CYBELEC's responsibility.

TERMINATION

This agreement shall automatically terminate upon any act of bankruptcy by or against licensee, upon any

assignment for the benefit of creditors of the licensee, upon any attachment execution of judgement or

process against licensee or its assets that substantially inhibits its ability to do business, or upon

dissolution of licensee.

CYBELEC has the right to terminate this agreement immediately, should the licensee violate the

aforementioned conditions.

Within 30 days of termination of this agreement for any reason, licensee shall at his option, either:

return to CYBELEC or authorized dealer all existent copies of such software and related materials, or

furnish to CYBELEC evidence satisfactory that the original and all copies of the software, in whole

and in any form, have been destroyed.

LIMITATION OF LIABILITY

The foregoing warranty is instead of all other warranties, expressed or implied.

Licensee further agrees that CYBELEC shall not be liable for any lost profits, lost savings, loss of use, or

other incidental or consequential damages arising from the use or inability to use the software, or for any

claim or demand against licensee by any other party.

In no event shall CYBELEC be liable for consequential damages, even if CYBELEC has been advised of

the possibility of such damages.

CYBELEC does not warrant that the functions contained in the software will meet the licensee's

requirement or that the operation of the software will be totally error free.

Should the software prove defective, the licensee (and not CYBELEC or an authorized dealer or

representative) will assume the entire cost of all necessary service, repair or correction.

CYBELEC warrants the diskettes, EPROMS or other magnetic support or cassettes on which the

programs are supplied to be free of defects in material and workmanship under normal use for a period of

90 days from the date of shipment to the licensee as evidenced by a copy of the packing slip.

PAGE IV LICENSE AGREEMENT

Page 7

LIMITATION OF REMEDIES

CYBELEC's entire liability and the licensee's exclusive remedy shall be as follows:

The replacement of any diskettes or EPROMS or magnetic support media or cassettes not meeting

CYBELEC's limited warranty and which materials are returned to CYBELEC or an authorized

CYBELEC representative with a copy of the packing slip, or

If CYBELEC or its representative is unable to deliver replacement diskettes, magnetic support media,

EPROM or cassettes which are free of defects in materials or workmanship, the licensee may terminate

this agreement under the terms and conditions herein mentioned, and the purchaser's money will be

refunded.

GENERAL

The licensee acknowledges that he has read this agreement, understands it and agrees to be bound by its

terms and conditions.

The licensee agrees to hold CYBELEC harmless on all liability associated with licensee's breach of this

agreement including, but not limited to, all reasonable attorney's fees and court costs, if any.

This license agreement shall be governed by Swiss law; place of jurisdiction is Lausanne, Switzerland.

MAINTENANCE

CYBELEC will provide one year of software maintenance.The extent of maintenance, and response time

for furnishing same, shall be at the sole discretion of CYBELEC.Maintenance shall normally include

correction of errors in code, correction of errors in supporting documentation, update versions of the

covered software which may be released by CYBELEC during the maintenance period.

In no event shall CYBELEC be obliged to provide technical support in attempting to resolve problems or

difficulties resulting from licensee's modification of the licensed software; any such modification by

licensee is entirely at licensee's own risk.

LICENSE AGREEMENT PAGE V

Page 8

This page has been left blank intentionally.

PAGE VI LICENSE AGREEMENT

Page 9

March 2002 V. 2.3

CONTENTS

SAFETY AND MAINTENANCE INSTRUCTIONS ...........................................................................I

LICENSE AGREEMENT FOR CYBELEC SOFTWARE..................................................................III

INTRODUCTION..............................................................................................................................5

Safety, Copyright & License agreement..............................................................................5

DNC with Windows operating system 5

About this Manual................................................................................................................6

Software Installation ............................................................................................................7

Typographical Conventions.................................................................................................7

Definitions............................................................................................................................7

QUICK START .................................................................................................................................9

Leaving the Software 10

L-ALPHA (2D) PROGRAMMING .....................................................................................................11

Step by Step ........................................................................................................................12

Clear the Work Zone 12

Punch Adjustment 13

Die Adjustment 15

Choice of Tools 16

General Data 18

Programming Section 1 18

Programming Section 2 19

Product Calculation 21

Bending Range (BEND 2D) 21

Position of Axes, other Functions 23

DIRECT PROGRAMMING (BEND NUM) ........................................................................................25

Step by Step ........................................................................................................................26

Clear the Work Zone 26

General Data 27

Choice of Tools 28

Entering the Data (1) 28

Entering the Data (2) 30

BENDING, TESTS AND CORRECTIONS.......................................................................................33

12QS23DWIN_EN.DOC

CONTENTS PAGE 1

Page 10

3D PROGRAMMING ....................................................................................................................... 35

Creation of the Product....................................................................................................... 35

Step by Step ....................................................................................................................... 36

Clear the Work Zone 36

MEMORIZE OR SEARCH A PRODUCT ........................................................................................ 43

Memorize a Product ........................................................................................................... 43

Search a Product................................................................................................................44

Organization of the Memories ............................................................................................ 48

PROTECTION OF THE ACCESS LEVELS .................................................................................... 49

General Information............................................................................................................ 49

The Users ........................................................................................................................... 50

Access by Password .......................................................................................................... 51

Access to Levels superior to 3............................................................................................ 52

Change Password .............................................................................................................. 53

Password forgotten 54

BRIEF OVERVIEW OF THE PAGES.............................................................................................. 57

Menu Page ......................................................................................................................... 57

List of Products Page ......................................................................................................... 57

List of Graphical Products Page......................................................................................... 58

Product / Criteria Search Page........................................................................................... 58

Transfer Page ..................................................................................................................... 58

List of Punches Page.......................................................................................................... 59

List of Dies Page................................................................................................................. 59

Punch Programming Page ................................................................................................. 60

Die Programming Page ...................................................................................................... 60

Welcome Page ................................................................................................................... 61

Initialization Page................................................................................................................ 61

Machine Parameters Page ................................................................................................. 62

Product Num Page ............................................................................................................. 62

Tools Position Page............................................................................................................ 63

Comments Page ................................................................................................................. 63

Bend Numerical Page......................................................................................................... 64

Bend 2D Page ....................................................................................................................64

Bend 3D Page ....................................................................................................................65

Bend Function Page ........................................................................................................... 65

Bend. Tools Page ............................................................................................................... 66

Corrections Page................................................................................................................66

INSTALLATION OF THE PC/DNC 1200 SOFTWARE ................................................................... 67

PC Protection key ...............................................................................................................67

Minimum configuration ....................................................................................................... 69

Software support PC 1200 Windows.................................................................................. 69

Software support DNC 1200 Windows............................................................................... 69

Software support DNC 1200 DOS...................................................................................... 70

INSTALLATION OF PC1200 WINDOWS ....................................................................................... 71

INSTALLATION OF PC1200 / PC900 DOS VERSION................................................................... 73

Installation of DNC Windows .............................................................................................. 74

PAGE 2 USER GUIDE PC/DNC 1200 2D&3D

Page 11

If the keyboard of the DNC doesn't work: 74

Installation of DNC DOS......................................................................................................75

If the keyboard of the DNC doesn't work: 76

INDEX ..............................................................................................................................................77

CONTENTS PAGE 3

Page 12

This page has been left blank intentionally.

PAGE 4 USER GUIDE PC/DNC 1200 2D&3D

Page 13

I

NTRODUCTION

AFETY

S

, C

DNC WITH WINDOWS OPERATING SYSTEM

OPYRIGHT

Please consult the safety instructions, copyright and license agreement on the

first pages of the manual.

The CYBELEC DNCs equipped with Windows have been installed in the

factory with a configuration especially realised for the numerical control

(see technical information).

This configuration ensures that a minimum of files are present on the DNC,

offering in this way a maximum speed to execute the programs. This

configuration also ensures that the drivers are correct and that the whole

guarantees an optimal functioning of the numerical control.

ICENSE AGREEMENT

& L

As Windows is a very open system, it is advised to not modify the Windows

installation nor to install other programs. You risk to disturb the functioning

of the the numerical control.

If you wish to install a network or a printer, please call a specialist.

Remember that the DNC is equipped with a CD-ROM reader and that it is

very easy or even tempting to install external softwares, utilities or games

coming from specialized magazines.

CYBELEC accepts no responsibility in case of misfunctioning of

the numerical control if other programs have been installed or if

the original configuration has been modified.

We also remind you that the Windows environment is infested with virus and

utmost caution is to be taken when using data or softwares coming from

outside. A regular back-up enables you to get your data in safety.

We certify that our numerical controls are delivered virus free.

INTRODUCTION PAGE 5

Page 14

BOUT THIS MANUAL

A

This User Guide treats some simple examples, in order to rapidly acquire the

programming concept.

The Reference manual furnishes supplementary information to this

document.

Remark: In this manual, it is assumed that the DNC has an operational

This manual describes the software version U3 or higher.

This manual can evolve, it is you, the operators, who can contribute to help

you more. If you have any remarks concerning this manual, please write to us

at:

configuration (i.e. machine parameters and tools are

programmed).

Some represented figures can possibly not correspond with

previous versions.

CYBELEC S.A.

Dpt Communication

Rue des Uttins 27

CH-1401 Yverdon-les-Bains

Fax ++ 41 24 447 02 01

@

E-Mail: info

cybelec.ch

PAGE 6 USER GUIDE PC/DNC 1200 2D&3D

Page 15

OFTWARE INSTALLATION

S

See at the end of this manual, page 67.

YPOGRAPHICAL CONVENTIONS

T

Arial bold Quotations of text as seen on the screen.

Arial bold italic Used to indicate the name of a DNC input or

Italic Reference to a written element, a paragraph or a

Indicates a double click on the key.

output.

manual.

For example: See Typographical Conventions.

EFINITIONS

D

In this manual the following terms are used:

Select This term designates a choice operation.

According to the situation the choice can be

done in different ways.

To validate a field, just leave the field or press

the

The word "select" will also be used to reach a

specific page.

Point out Position the cursor on the described point.

Use therefore the cursor keys

Mouse/Tracksensor Means a mouse for a PC,

a tracksensor for a DNC.

Click Press the left tracksensor button.

Click right Press the right tracksensor button.

Click left/right Press simultaneously the left and right

tracksensor buttons.

(Enter) key.

or the tracksensor.

Round robin lists or multiple choice fields:

They are violet coloured and signify that several

options are available.

The choice of the content is made by pressing

the

INTRODUCTION PAGE 7

key or click right.

Page 16

A window appears with the list of the available

choices for this field.

To validate the choice:

- enter the number indicated next to the choice

or

- place the cursor on the choice and press the

key.

It is possible, without displaying the choice

window, to make appear one after the other the

choices by pressing the

key.

To validate, leave the field.

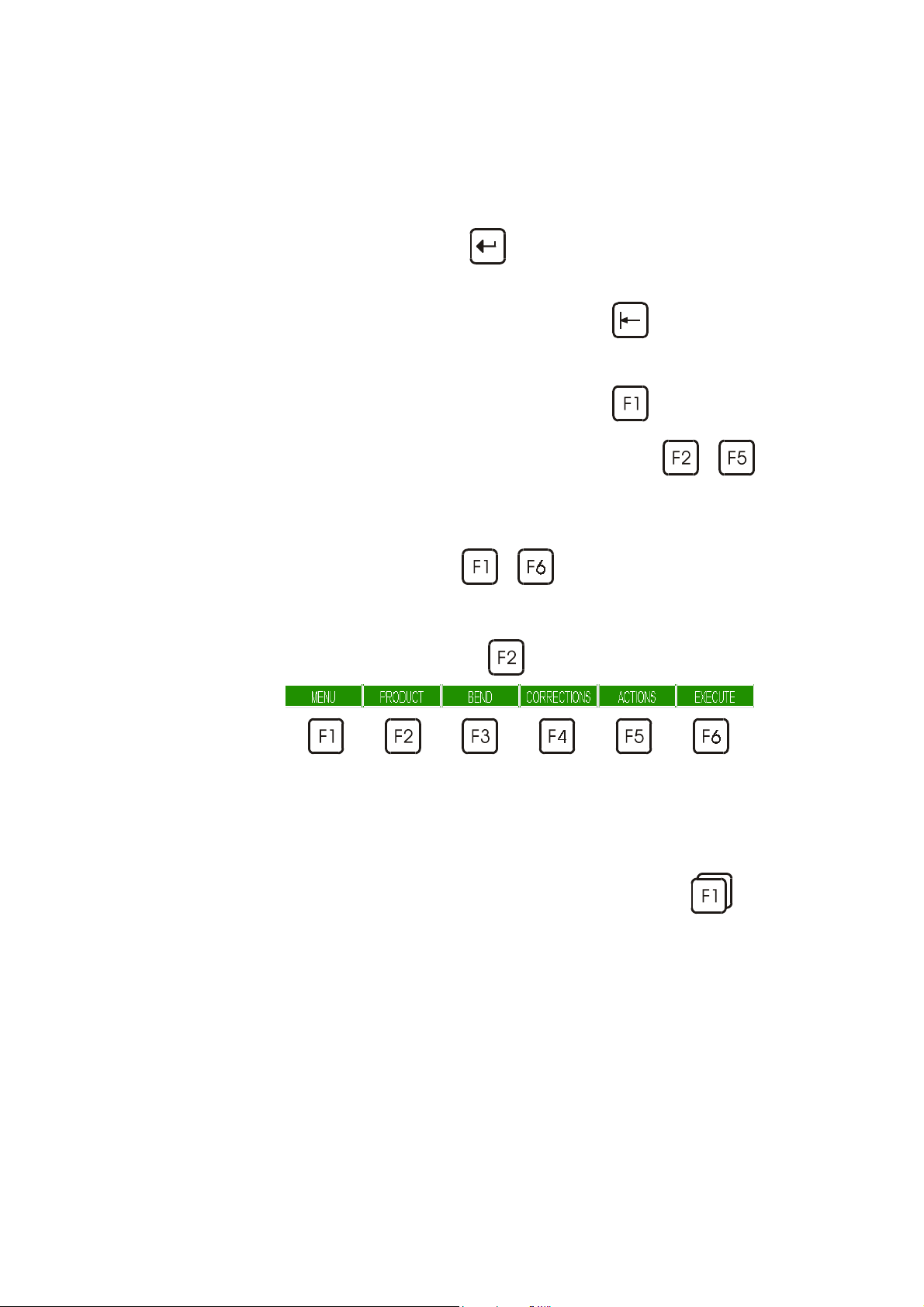

Menu Designates the main menu page which can be

reached by pressing the key.

A choice window "Menu Menuname" is also

called when pressing one of the

to

keys.

Function key Each time you are asked to press a function key

to , the corresponding menu

appears.

Generally the name of the function key is used.

For example: press PIECE designates the

key

.

Rapid validation To facilitate the operator's work, the DNC

For more information, see the same paragraph in the Reference Manual.

PAGE 8 USER GUIDE PC/DNC 1200 2D&3D

memorizes the last choice made in a menu.

To validate a menu option quickly, simply

double click on a function key (e.g.:

to validate directly the last page selected.

),

Page 17

Q

UICK START

This chapter describes, by means of some simple examples, diverse ways of

using your DNC.

L-alpha Programming.

This method is the fastest and the most currently used in the workshop

when the operator has to create himself a product from a paper

drawing.

Direct Programming.

This type of programming is often used for simple products or by

operators having worked on conventional pressbrakes without

numerical controls.

This page is very close to what an operator has to do, since he has on

one single screen all the information and fields necessary for the

programming of his product.

3D Programming.

This type of programming enables the user to visualize the

construction of its product in 3D. This mode also enables more

elaborated constructions and modifications than in 2D mode.

We assume in this part that all the necessary tools have already been

programmed as well as the machine parameters.

Access levels We presume that the operator knows how to reach level 1, or that the key of

the front panel (option) is on position 1. Should this not be the case, see

chapter Protection of the Access Levels further in this manual.

The screens of this manual have been captured with the PC 1200 Windows

software. The screens however are identical in the DNC 1200 2D.

Reminder:

You will find the correspondence between the keys of the DNC and those of

a PC keyboard in the 2D Reference Manual under External keyboard.

These procedures indicate to the operator a programming method

recommended by CYBELEC, enabling to assimilate by the example the

functioning of the software.

For additional information, please consult the 2D Reference Manual and/or

the 3D Reference Manual, which each contains a table of contents and a

detailed index facilitating the search for information.

QUICK START PAGE 9

Page 18

LEAVING THE SOFTWARE

It is possible at any time to quit the task after having memorized the current

state. However it is important to leave the software in the correct way by

calling up the MENU page

The same procedure can be used on the PC software, or press the

keys on any page.

and pressing the QUIT key.

+

PAGE 10 USER GUIDE PC/DNC 1200 2D&3D

Page 19

L-

ALPHA

(2D) P

This chapter describes, by means of a concrete example, how to create a

product by using the "L-alpha" method (length-angle).

This method is fast and easy and allows to display the product in 2D, which

usually is sufficient when products are being programmed in the workshop.

The product being used as an example is composed of 2 sections (profiles),

but the procedure is identical for one or several sections.

0

.

0

0

2

ROGRAMMING

40.0

3

0

.

0

45.0

15

0.

0

2

0

.

0

The side flaps with the oblong holes, which are included in section 1, will be

made first, so that a punch of identical length as that for section 2 can be

used.

To make this product, we will use 2 mm thick ST37 type steel.

L-ALPHA PROGRAMMING PAGE 11

Page 20

TEP BY STEP

S

CLEAR THE WORK ZONE

The user has to clear the work memory before creating a new product.

Call the PRODUCT NUMERICAL page, which enables the data

introduction in L-Alpha mode.

Clear the work zone to

create a new product

Press the PRODUCT

Select PRODUCT NUMERICAL. For that, enter the number

indicated next to the choice

or place the cursor on the choice and press

or click on the choice.

The figure below shows the PRODUCT NUMERICAL page containing a

previous product.

function key.

key

PAGE 12 USER GUIDE PC/DNC 1200 2D&3D

Page 21

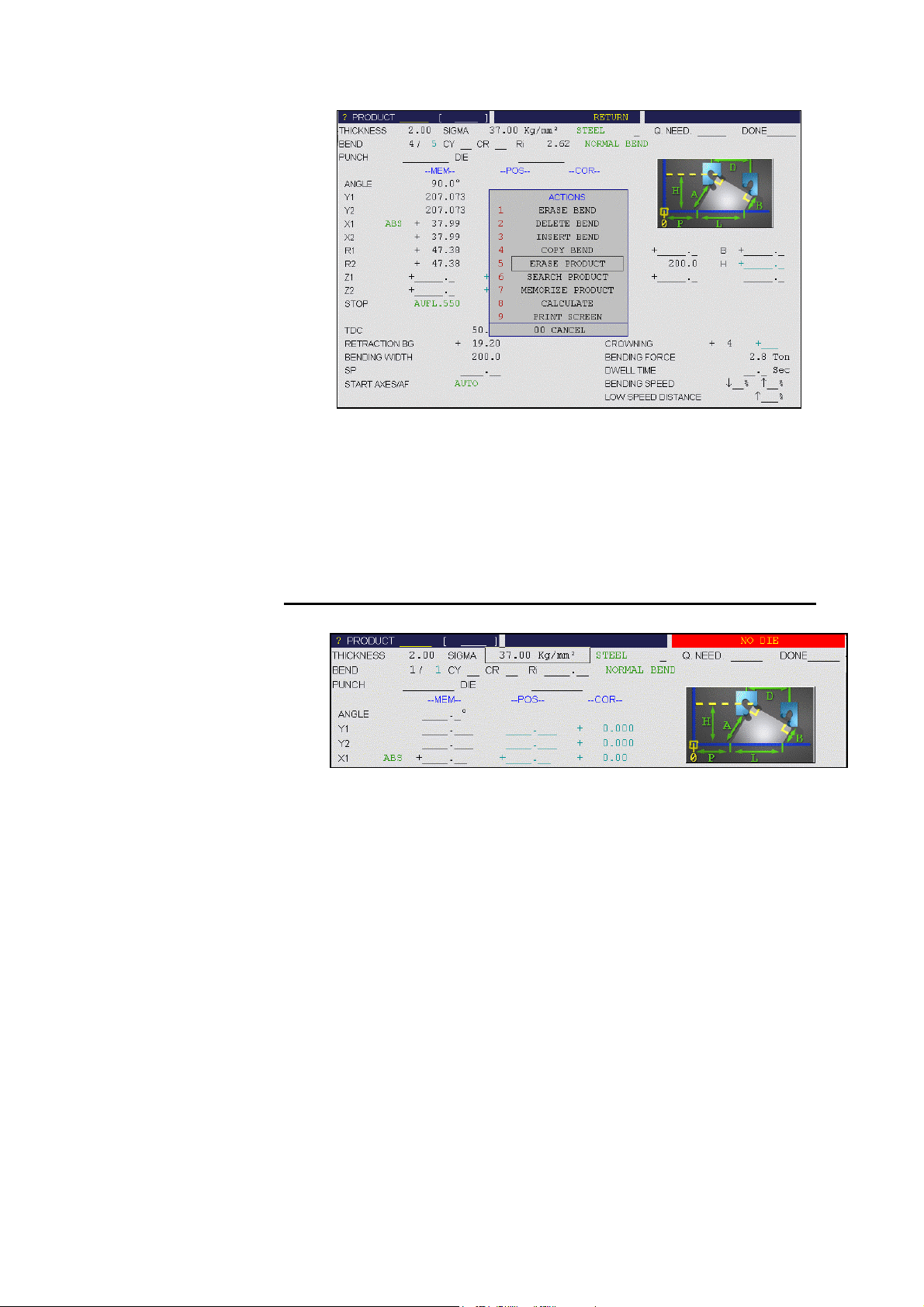

Press the ACTION

Select ERASE PRODUCT. For that, enter the number indicated next

to the choice

or place the cursor on the choice and press

or click on the choice, and then CONFIRM (

This operation erases only the data of the work memory. That means that the

product which is possibly located in the work memory is not lost if it has

been saved beforehand.

key.

key

).

PUNCH ADJUSTMENT

Punch adjustment

Window without any

tools selection

This chapter as well as the following Die Adjustment are optional when

programming in 2D mode.

It is interesting to look them over, for the TOOLS POSITION page enables

to define several places of work and hence to the operator to visualize the

tools assembly.

If the tools assembly is not important, skip these two chapters.

The tools definition will be made directly in the PRODUCT NUMERICAL

page (page in which you still are at this stage of the procedure).

Call the TOOLS POSITION page by pressing the PRODUCT

function key and select TOOLS POSITION.

Selection field : P or D

Field L (total available length)

L-ALPHA PROGRAMMING PAGE 13

Page 22

Check that a punch or / and the letter P are displayed in the right-hand

window (selection field).

If there is a die or the letter D, change it using the

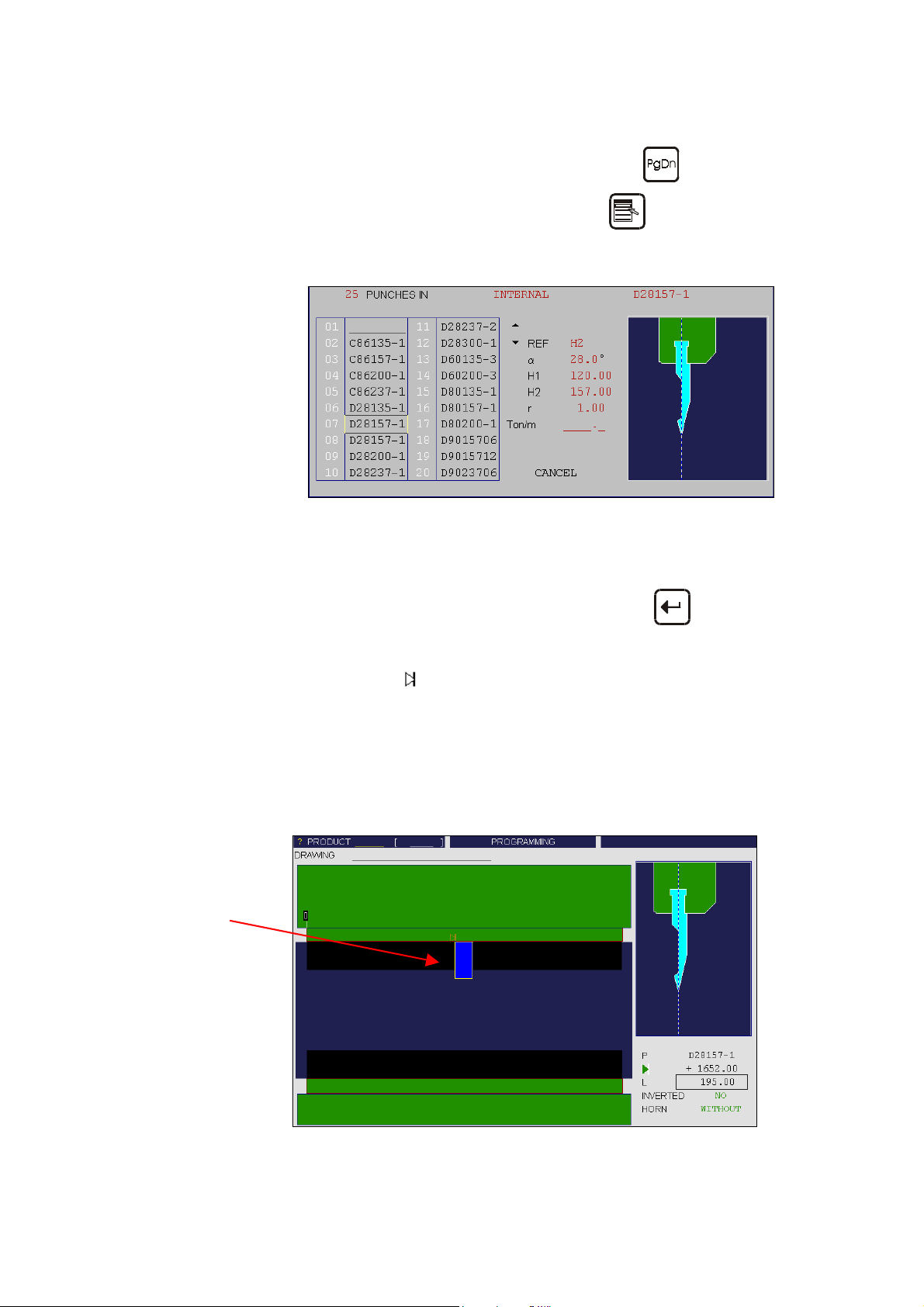

Place the cursor on the P field and press the

key.

key to open the

punch LIST OF CHOICES menu.

Select the required punch by entering the number indicated next to the

choice with a two-digit number. Example: 01 for 1, 02 for 2, etc…

or

Place the cursor on the choice and validate with the

key

or

Click on the requested choice.

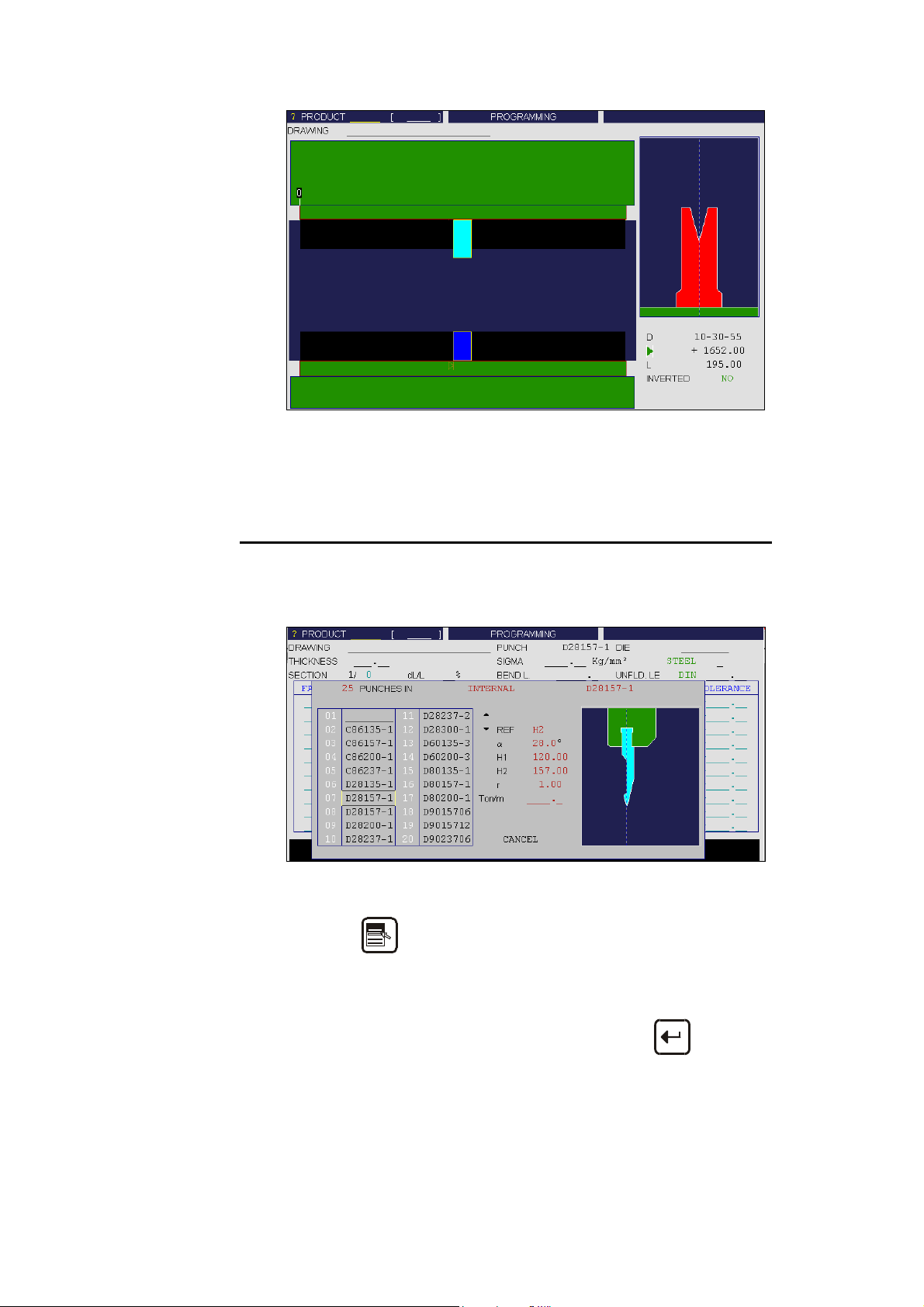

Punch adjustment

Punch placed in the

middle of the machine

Modify the

field by introducing a value equal to the half of field L

minus the half of the tool length, which corresponds to the central

point of the machine on which the punch is fixed. (In our example:

3500/2 – 195/2 = 1652.5 mm).

Modifiy the L field by introducing the value of 195 mm which

corresponds to the required tool length. In the front view the selected

tool appears in dark blue.

PAGE 14 USER GUIDE PC/DNC 1200 2D&3D

Page 23

DIE ADJUSTMENT

Die adjustment

Window with punch

selection but without

die

Same remark as for Punch Adjustment.

Selection field : D

Stay on TOOLS POSITION page.

Select the die using the

Place the cursor on the D field and press the

die choice menu.

Select the required die by entering the number indicated next to the

choice with a two-digit number. Example: 01 for 1, 02 for 2, etc…

or

Place the cursor on the choice and validate with the

or

Click on the requested choice.

key.

key to open the

key

Modify the

minus the half of the tool length, which corresponds to the central

point of the machine on which the die is fixed. (In our example:

3500/2 – 195/2 = 1652.5 mm).

Modify the L field by introducing the value of 195 mm which

corresponds to the required tool length.

L-ALPHA PROGRAMMING PAGE 15

field by introducing a value equal to the half of field L

Page 24

Die adjustment

Final mounting of the

tools

Window with selection

of the punch and the

die

Return to the PRODUCT NUMERICAL page via the PRODUCT

menu.

Choice of tools

CHOICE OF TOOLS

As mentioned above, if the tools position is not indispensable, you can define

the tools directly in the PRODUCT NUMERICAL page.

Cursor on PUNCH field (upper part of the screen)*.

Key or right click to display the LIST OF CHOICES.

Select the desired tool by by entering the number indicated next to the

choice with a two-digit number. Example: 01 for 1, 02 for 2, etc…

or

Place the cursor on the choice and validate with the

or

Click on the desired choice.

PAGE 16 USER GUIDE PC/DNC 1200 2D&3D

key

Page 25

Remark: Each window contains 20 tools. It is possible to reach the

next or previous 20 tools by using respectively the

or

keys.

Each database (punchs and dies) is limited to 200 tools.

You can also call the end of the list by introducing the value

999 or recall the begin of the list by introducing 001.

Proceed in the same way for the DIE.

Remark: It is possible to make the same choice, and in the same way,

in the TOOLS BEND page (via the BEND menu). This

enables to see the tools profile, along with their main

characteristics.

* The PUNCH and DIE fields in the upper part of the screen designate the

general tool for the calculation of the product. If a product is being

programmed via the PRODUCT NUMERICAL page, it is mandatory to

enter these two items.

The PUNCH and DIE columns in the table allow to specify a different tool

for a given bend.

In the BEND NUMERICAL page, there are also a PUNCH and a DIE field.

If the product has been programmed via the PRODUCT NUMERICAL

page, these fields will be empty or partially filled if tools have been entered

in the corresponding columns of the table of the PRODUCT NUMERICAL

page. This is so because these fields correspond to the ones in the table.

(Also see the section Direct Programming (BEND NUM) further in this

manual).

L-ALPHA PROGRAMMING PAGE 17

Page 26

GENERAL DATA

Enter:

- the punch

- the die

- the sigma/material

- the type of material

- the bending length

PROGRAMMING SECTION 1

Place the cursor on the THICKNESS field and enter the thickness of

the material being used.

Place the cursor on the SIGMA field and introduce the force/mm² of

the material used. (E.g.: Steel = 37 Kg/mm²)

Leave the round-robin list on STEEL.

Place the cursor on the BEND L. field and introduce the bending

length for the product (section 1 = 150.0 mm).

The dimensions of the faces are given in external cotation according to DIN.

See 2D Reference Manual, section Unfolded length.

45.0

45.0

When introducing the data in L-Alpha mode, just "begin" the profile by one

of the extremities and furnish one after the other the values of each face and

angle. At the last face there is no angle corresponding to.

Remark: As shown in the following figure, the profile of section 1 is

automatically drawn as a function of the introduced data

(length and angle), thus the value of the internal radius is

automatically calculated.

90.0°

45.0

90.0°

200.0

200.0

200.0

45.0

90.0°

45.0

90.0°

PAGE 18 USER GUIDE PC/DNC 1200 2D&3D

Page 27

Section 1

Automatically drawn profile

Procedure:

Place the cursor on the first field of the LENGTH column and

introduce the value of 45 mm which corresponds to the first length.

Place the cursor on the first field of the ANGLE column and introduce

the value of 90° which corresponds to the first angle to be bent.

Place the cursor on the second field of the LENGTH column and

introduce the value of 200 mm which corresponds to the second

length.

Place the cursor on the second field of the ANGLE column and

introduce the value of 90° which corresponds to the second angle to

be bent.

Place the cursor on the third field of the LENGTH column and

introduce the value of 45 mm which corresponds to the last length

before the edge of the product.

Hint: Introduce first all the lengths and then the angles. This way of operating is

much faster.

PROGRAMMING SECTION 2

The definition of the bending direction is done by inversing the angle sign,

however the choice of the side is arbitrary, but has to be constant for the

whole profile of the product.

45.0

-90.0°

45.0

90.0°

150.0

or

45.0

90.0°

45.0

-90.0°

150.0

L-ALPHA PROGRAMMING PAGE 19

-135.0°

20.0

135.0°

20.0

Page 28

Section 2

Procedure:

Stay on PRODUCT NUMERICAL page.

Place the cursor on the SECTION field, enter the value of 2 and leave

the field. This automatically initializes a new page for programming

section 2.

Place the cursor on the BEND L. field and enter the bending length

for this section (200).

Place the cursor on the first field of the LENGTH column and

introduce the value of 30 mm which corresponds to the first length.

Place the cursor on the first field of the ANGLE column and intro-

duce the value of 90° which corresponds to the first angle to be bent.

Place the cursor on the second field of the LENGTH column and

introduce the value of 40 mm which corresponds to the second length.

Place the cursor on the second field of the ANGLE column and

introduce the value of -90° which corresponds to the second angle to

be bent.

Place the cursor on the third field of the LENGTH column and

introduce the value of 150 mm which corresponds to the third length.

Place the cursor on the third field of the ANGLE column and

introduce the value of 135° which corresponds to the third angle to be

bent.

Place the cursor on the fourth field of the LENGTH column and

introduce the value of 20 which corresponds to the last length before

the edge of the product.

Remark: As shown in the previous figure, the profile of section 2 is

automatically drawn as a function of the introduced data

(length and angle), thus the value of the internal radius is

automatically calculated. The unfolded length too is

calculated.

PAGE 20 USER GUIDE PC/DNC 1200 2D&3D

Page 29

Calculation of the

unfolded lengths

PRODUCT CALCULATION

Stay on the PRODUCT NUMERICAL page.

Select CALCULATE in the ACTION menu.

The message CALCULATING... appears in the interactive field on

the top right-hand corner of the screen.

The data in the UNFLD. LE. DIN (Length of the unfolded sheet) and

Ri (Internal radius) fields appears.

Remark: If the CALCULATE function key is not activated, the

calculation will be carried out automatically as soon as an

other screen page is being accessed.

This function is to use for the software versions previous to

U2.

Searching for the

bending range

BENDING RANGE (BEND 2D)

Call the BEND 2D page (BEND menu).

In the SIMULAT. field, choose the option WITHOUT PROGR.

BENDS.

In the ACTION menu, choose SEARCH BENDING RANGE.

The message SIMULATING RUNS…, then CALCULATING...

appears in the interactive field on the top right-hand corner of the

screen.

L-ALPHA PROGRAMMING PAGE 21

Page 30

After this the succession of sequences can be visualized using the

Pg Dn

and

keys.

In the just programmed example we can see that the searching for the

bending range has first placed the section 1, and then the section 2.

The operator has the possibility to modify the bending range (see the

corresponding chapter in the 2D Reference Manual) or to ask the software to

respect specific criteria like minimum of swings or returns. For that, please

refer to the 2D Reference Manual, section Simulation criteria.

In case where the software program does not find any solution, the bending

range must be imposed manually.

See Bending order in the 2D Reference Manual.

PAGE 22 USER GUIDE PC/DNC 1200 2D&3D

Page 31

POSITION OF AXES, OTHER FUNCTIONS

Menu BEND, page BEND NUMERICAL.

It can be seen that the axis position, the bending force, the crowning and, if

applicable, the retraction and the top dead centre (depending on how they

have been defined in the machine parameters) are calculated automatically.

These values can be modified by the operator.

According to his needs, the operator can modify the following items:

TDC

RETRACTION BG

SP

DWELL TIME

BENDING SPEED

LOW SPEED

DISTANCE

Complementary explications are found in the 2D Reference Manual.

To execute the product, see the Bending, Tests and Corrections section,

page 33.

the Top Dead Center. If not programmed, the

beam will rise to the maximum TDC.

the retraction of the backgauge.

the Switch Point (switching from High Speed

to Bending Speed).

the time during which pressure is being

maintained.

the bending speed downward, or the speed

during the upward moving phase until the

clamping point is reached.

allows to define that only a portion (expressed

in %) of the upward movement between the

TDC and the clamping point will be carried out

at low speed; the continuation of the upward

movement is made at high speed.

L-ALPHA PROGRAMMING PAGE 23

Page 32

This page has been left blank intentionally.

PAGE 24 USER GUIDE PC/DNC 1200 2D&3D

Page 33

D

IRECT PROGRAMMING

SECTION 2

40.0

(BEND NUM)

This type of programming is often used for simple products or by operators

having worked on conventional pressbrakes without numerical controls.

This page is very userfriendly, for the operator has on one single screen all

the information and fields necessary for the programming of his product.

SECTION 1

0

.

0

0

2

3

0

.

0

45.0

15

0.

0

2

0

.

0

The bending order is choosen by the operator, since he programs directly

each bend.

In this example, we first realize the side flaps with the oblong holes, which

are included in section 1, so that a punch of identical length as that for

section 2 can be used.

To make this product, we will use 2 mm thick ST37 type steel.

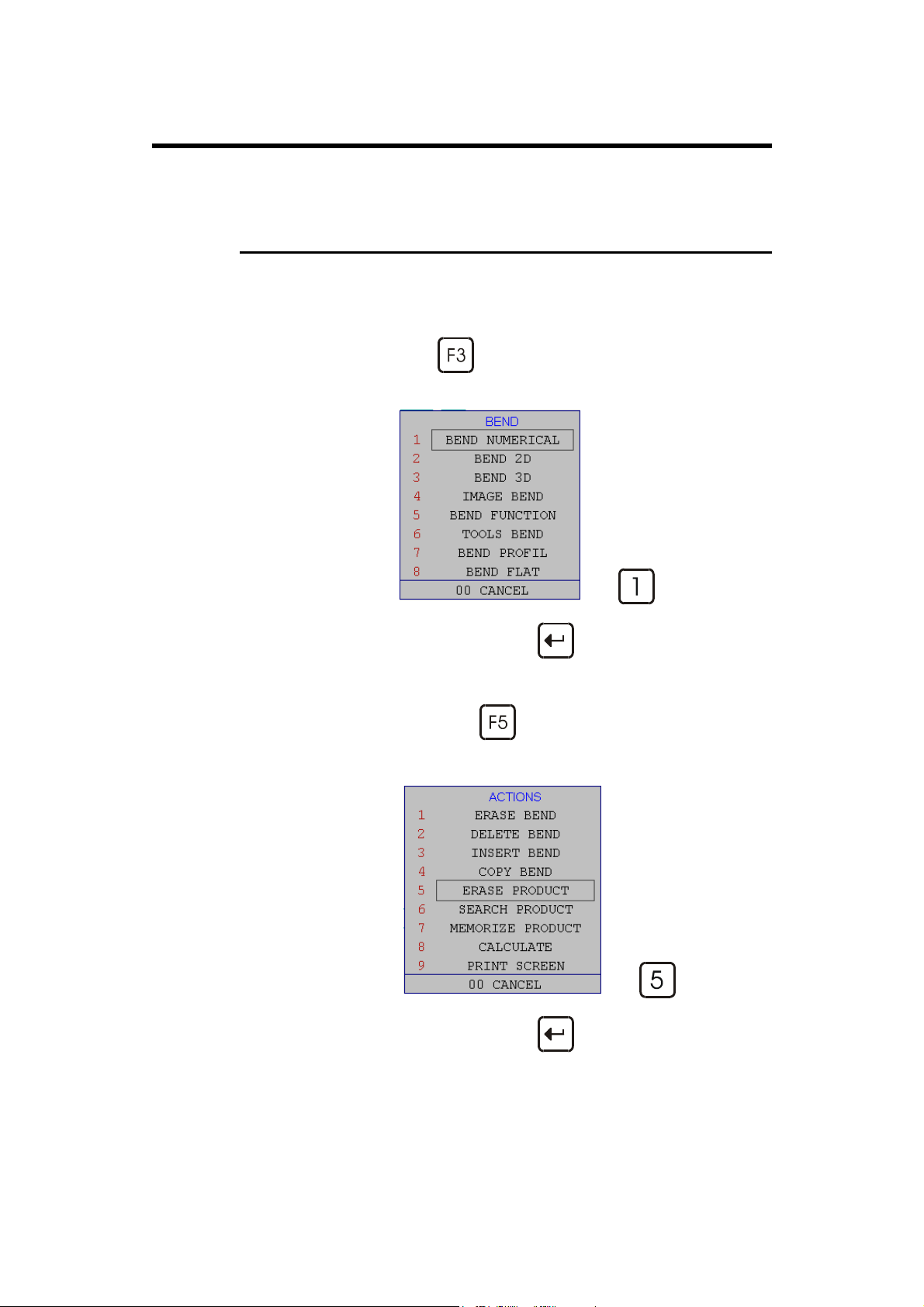

DIRECT PROGRAMMING PAGE 25

Page 34

TEP BY STEP

S

CLEAR THE WORK ZONE

The user has to clear the work memory before creating a new product.

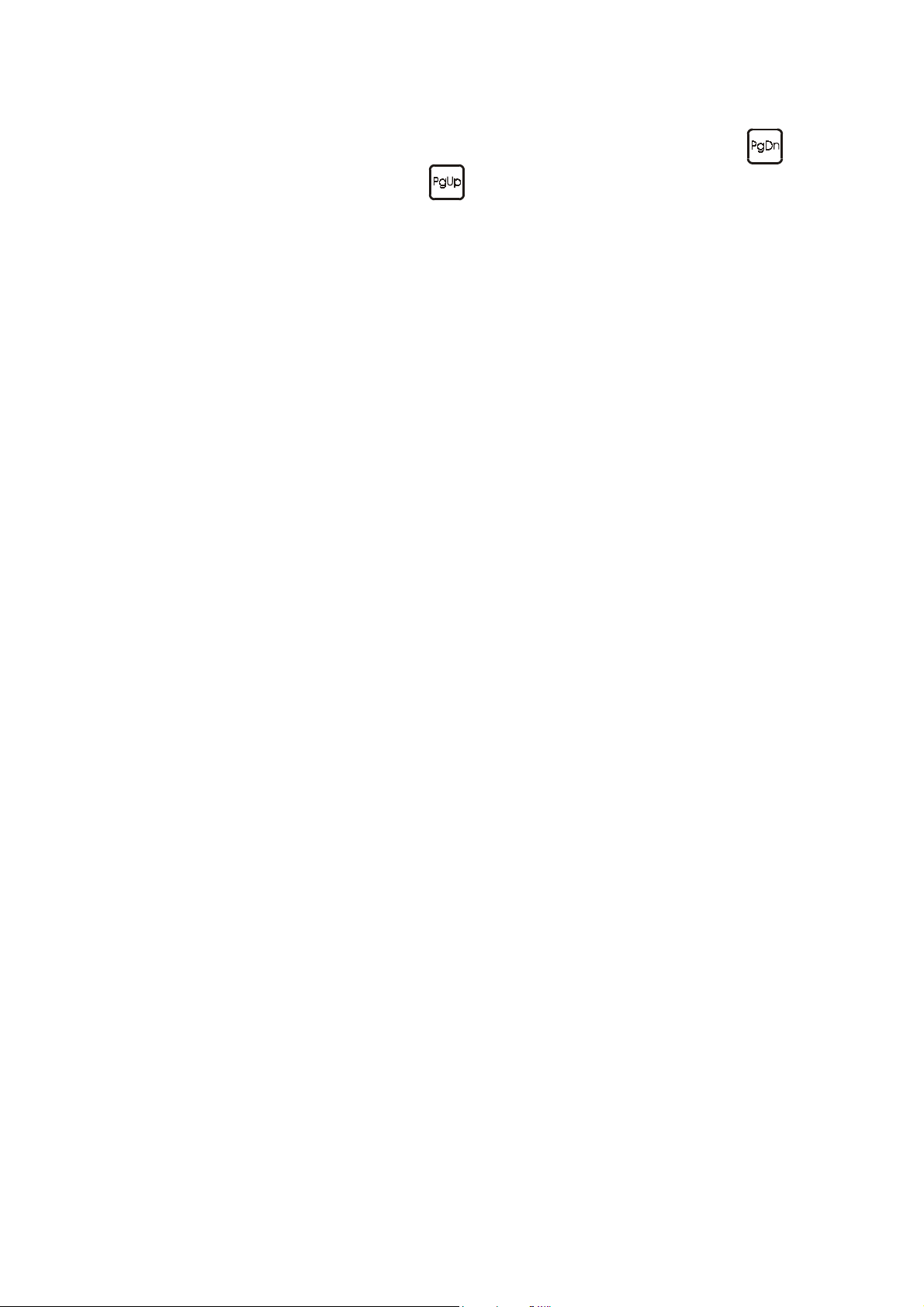

Call the BEND NUMERICAL page.

Press the BEND

Select BEND NUMERICAL. For that, enter the number indicated

next to the choice

or

place the cursor on the choice and press

or

click on the choice.

Press the ACTION key .

Choose ERASE PRODUCT. For that, enter the number indicated

function key.

: key

next to the choice

or

place the cursor on the choice and press

or

click on the choice, and then CONFIRM.

PAGE 26 USER GUIDE PC/DNC 1200 2D&3D

: key

Page 35

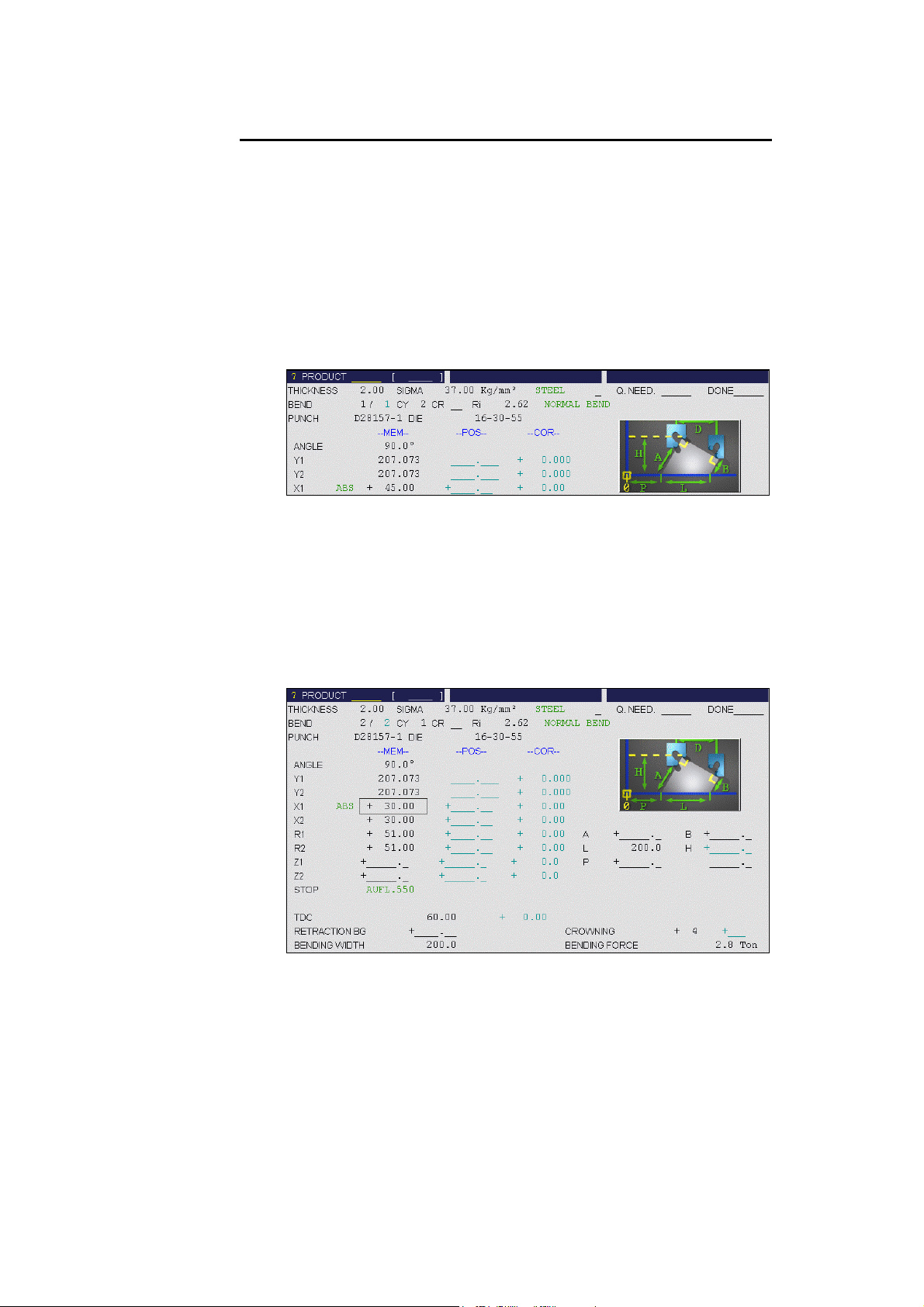

Clear the work zone to

create a new product

GENERAL DATA

Enter:

- the sigma/material

- the type of material

This operation erases only the data of the work memory. That means that the

product, which is possibly located in the work memory, is not lost if it has

been saved beforehand.

Place the cursor on the THICKNESS field and enter the thickness of

the material being used.

Place the cursor on the SIGMA field and introduce the force/mm² of

the material used. (E.g.: STEEL = 37 Kg/mm²).

Note: It is mandatory to program these data, as well as the tools.

(see following page)

DIRECT PROGRAMMING PAGE 27

Page 36

Choice of tools

CHOICE OF TOOLS

Stay on the BEND NUMERICAL page.

Cursor on the PUNCH field.

Key

Select the desired punch by typing the number situated next to the

choice with a two-digit number. Example: 01 for 1, 02 for 2, etc…

or

Place the cursor on the choice and validate with the

or

Click on the desired choice.

Proceed in the same way for choosing a DIE.

Remark: It is possible to make the same choice, and in the same way, in

or right click to display the CHOICE LIST.

the TOOLS BEND page (via the BEND menu). This enables

to see the tools profile, along with their main characteristics.

ENTERING THE DATA (1)

The conventional way of entering the data is to program in the

BEND NUMERICAL page:

the required angle (the Y depth will be calculated according to the

tools and the material already programmed). It is also possible to

directly enter the Y1 / Y2 values without programming the angle.

key

the real position of the backgauge.

the specific data for the current sequence (top dead center, bending

length and, if necessary, backgauge type, retraction, dwell time, etc.)

PAGE 28 USER GUIDE PC/DNC 1200 2D&3D

Page 37

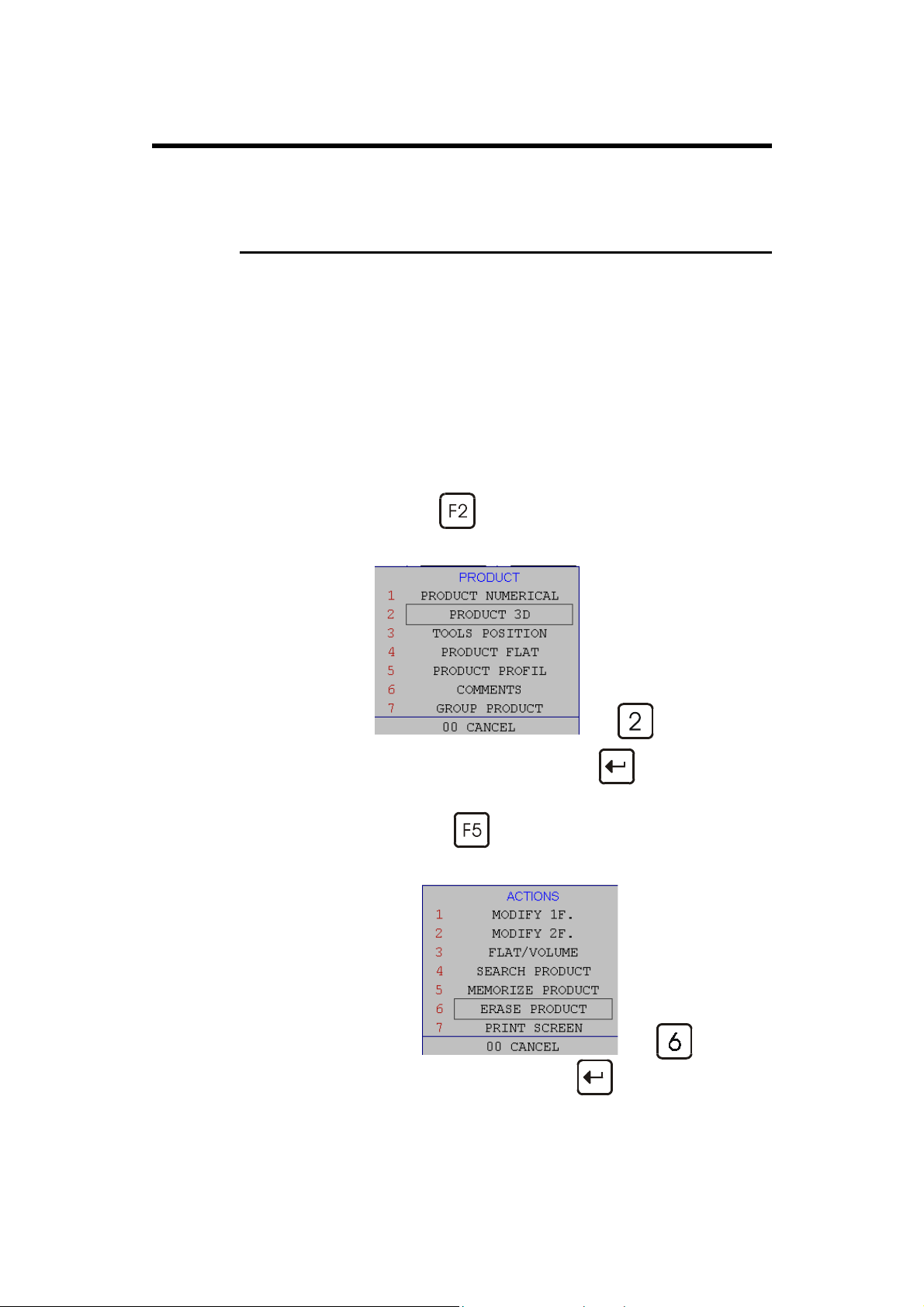

Below is shown the screen with the values for these two bends.

The page shown above illustrates how to program the two flaps with the

oblong holes (section 1).

The two bends being identical, enter 2 in the CY field. Program the angle to

90°, the X axis to its absolute value (43.00) and enter the bending length

(150).

The bending force and the crowning will be calculated automatically.

The operator can, of course, modify these values if necessary.

According to his needs, the operator can also modify:

TDC

the Top Dead Center. If not programmed, the

beam will rise to the maximum TDC.

RETRACTION BG

SP

the retraction of the backgauge.

the Switch Point (switching from High Speed

to Bending Speed).

DWELL TIME

the time during which pressure is being

maintained.

BENDING SPEED

the bending speed downward, or the speed

during the upward moving phase until the

clamping point is reached.

LOW SPEED

DISTANCE

allows to define that only a portion (expressed

in %) of the upward movement between the

TDC and the clamping point will be carried out

at low speed; the continuation of the upward

movement is made at high speed.

DIRECT PROGRAMMING PAGE 29

Page 38

ENTERING THE DATA (2)

HINT The way of programming described above (section Entering the Data (1))

requires of the operator to subtract the steel thickness from the external

dimension of the product. The procedure described below will facilitate the

programming. It has, however, some limitations depending on the product

and the chosen bending order.

The hint consists of entering the external dimension in the X field of the

backgauge, and to program a constant negative correction corresponding to

(approximately, according to your experience, to the tools and to the

material) the material thickness for the entire product.

This procedure is described hereafter:

BEND NUMERICAL page, same remark as underneath the

preceding screen illustration, except for the fact that X has been

programmed with the external dimension, as explained. (45)

This sequence carries out the bending of the two flaps of 45.0 mm

with the oblong holes.

To create the subsequent sequence, press the ACTION key and

choose COPY BEND.

It can be seen that all the data has been copied onto the second

sequence.

Enter the first flap of the second section, i.e. X = 30.00.

Modify the field CY = 1 or leave it unprogrammed.

Modify the bending length (BEND L. = 200) and possibly the other

fields according to your needs.

Press the ACTION key and choose COPY BEND.

PAGE 30 USER GUIDE PC/DNC 1200 2D&3D

Page 39

Program X = 40.00.

Press the ACTION key and choose COPY BEND.

For the last bend, enter ANGLE = 135.0° and X = 20.00.

Call the CORRECTIONS page (key

).

In the PRODUCT column, enter the value to be subtracted from the

external dimension in order to obtain a correct backgauge position

(generally, a value close to the material thickness). In our example, a

value of – 2.00 mm.

DIRECT PROGRAMMING PAGE 31

Page 40

This page has been left blank intentionally.

PAGE 32 USER GUIDE PC/DNC 1200 2D&3D

Page 41

B

ENDING

, T

ESTS AND CORRECTIONS

This chapter explains how to proceed in order to execute a product. This way

of doing is destined only to demonstrate how to use the numerical control.

The testing and adjusting operations can be carried out in the order decided

by the operator.

Go into semi-automatic mode

If necessary, move to the first sequence by means of the

Pg Dn

keys.

Press the start key

sequence.

Carry out the bend with a trial product.

Measure the flap and the obtained angle.

Go to or remain in the CORRECTIONS page.

in order to position the axes on the first

.

or

If necessary, correct the flap (in this example, a correction of

X = - 0.10 is assumed) for the current bend.

Reminder: In the above screen page the correction of -2.00 mm

corresponds to the material thickness programmed in the

example Entering the Data (2) above.

Position the cursor on the ANGLE field, BEND column, and enter

the measured angle (93.0 in this case). The software automatically

calculates the necessary correction (-0.292,which can be seen in the

Y1, Y2 fields, in the BEND column). Also see the 2D Reférence

Manual in the Corrections section.

Carry out a second test bend (on the same sequence, with a second

test product). If necessary, make a new correction.

Depending on the material, the machine adjustment and the exactness

of the data introduced, 2 or 3 corrections can be necessary for a bend.

This can be considered as being a normal situation.

BENDING, TESTS AND CORRECTIONS PAGE 33

Page 42

Once the current bend has been adjusted correctly:

Move on to the next sequence by pressing the

Pg Dn

key.

Make corrections as described before.

When all the bends of the product turn out as expected:

Go into automatic mode and choose the work page you like:

⇒ BEND NUMERICAL

⇒ BEND 2D

⇒ BEND 3D for 3D softwares

PAGE 34 USER GUIDE PC/DNC 1200 2D&3D

Page 43

3D P

Solid example of the

product

ROGRAMMING

REATION OF THE PRODUCT

C

This chapter describes, by means of a concrete example, how to create a

product by using the 3D programming method (available only on the

PC 1200 and DNC 1200 softwares with 3D).

In the following example we are going to execute the same product as in the

previous pages, namely:

L-alpha (2D) Programming and Direct Programming (BEND NUM).

The definitions of the different icons you will meet by passing through these

pages are described in the 3D Reference Manual, chapter Definition of the

Icons.

3D PROGRAMMING PAGE 35

Page 44

TEP BY STEP

S

CLEAR THE WORK ZONE

The user has to clear the work memory before creating a new product.

3 possibilities are given:

1. By means of the BEND NUMERICAL page (see Clear the Work Zone).

2 By means of the PRODUCT NUMERICAL page (see Clear the Work

Zone).

3 By means of the method below.

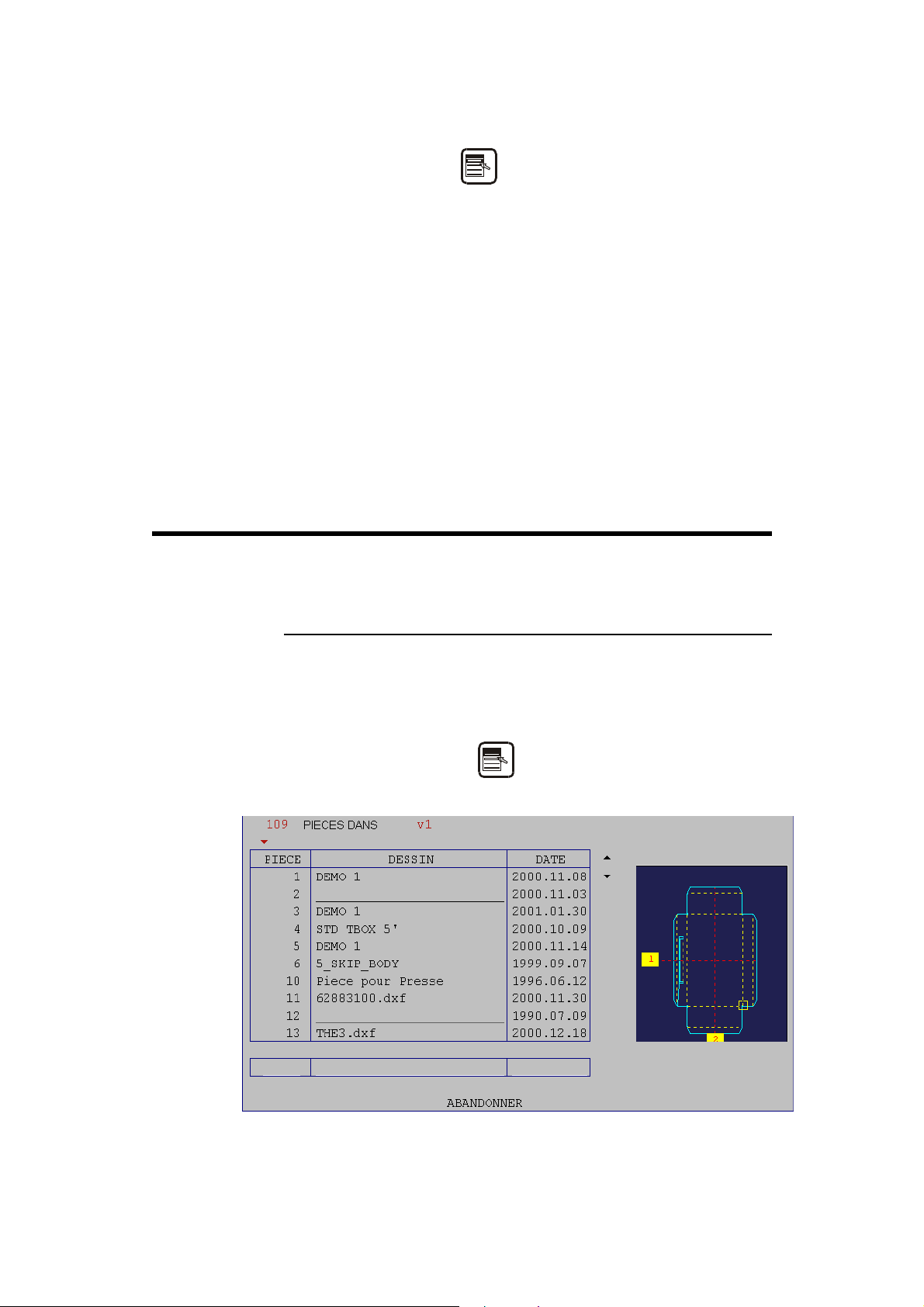

Call the PRODUCT 3D page.

Press the MENU

Select PRODUCT 3D. For that, enter the number indicated next to

the choice

or place the cursor on the choice and press

or click on the choice.

Press the ACTION

Choose ERASE PRODUCT. For that, enter the number indicated

function key.

: key ,

,

key.

next to the choice

or place the cursor on the choice and press

or click on the choice, and then CONFIRM.

PAGE 36 USER GUIDE PC/DNC 1200 2D&3D

: key ,

,

Page 45

Deletion of the

work memory

This operation erases only the data of the work memory. That means that the

product, which is possibly located in the work memory, is not lost if it has

been saved beforehand.

Introduce the

product data

Field: PRODUCT DATA

Click on the PRODUCT DATA field.

Introduce the THICKNESS and SIGMA values in the corresponding

fields (2.00 and 37).

Introduce MATERIAL: Click right to open the round robin list.

Introduce PUNCH and DIE according to the method mentioned

before (see Choice of Tools) in this document.

Click on QUIT to confirm the chosen values.

The program returns to the previous window. To continue, press the

key and choose MODIFY 1W or key

or MODIFY 2W or key

.

,

3D PROGRAMMING PAGE 37

Page 46

Difference between the two functions:

MODIFY 1W: Shows the product in plan mode (2D)

MODIFY 2W: Shows the product in plan mode and in axonometric mode

(3D).

Creation of the

base element

Current choice:

MODIFY 2W

Axonometric mode

Plan mode

• Click on

. The red rectangle (at right) is lighting up, attesting that

the function is active.

• The base rectangle appears in plan mode in the work window as well as

in axonometric mode. The diagram and the value table are adapted.

• Introduce the dimensions A and B. In our example: 150 and 200.

PAGE 38 USER GUIDE PC/DNC 1200 2D&3D

Page 47

Add a side

• Click on

. The red rectangle (at right) is lighting up, attesting that

the function is active.

• Click on the segment of the outline to which the side is to be added.

• Adjust the height of the side: value of the A field (45.00). The angle

value is 90° by default. The internal radius is already calculated.

Add a second side

The same function is still active.

• Click on the lower segment where the side is to be added.

• The value A has been memorized and is automatically attributed to the

new side.

3D PROGRAMMING PAGE 39

Page 48

Add a third side

The same function is still active.

• Click on the left segment where the side is to be added.

Add a fourth side

• The value A has been memorized and is automatically attributed to the

new side. Modify the A field with a new value: 40.00.

The same function is still active.

• Click on the left segment where the side is to be added.

• The value A has been memorized and is automatically attributed to the

new side. Modify the A field with a new value: 30.00, and modify the

angle value too: - 90.0°.

PAGE 40 USER GUIDE PC/DNC 1200 2D&3D

Page 49

Add the last side

Control the

construction

The same function is still active.

• Click on the right segment where the last side is to be added.

• The value A has been memorized and is automatically attributed to the

new side. Modify the A field with a new value: 20.00, and modify the

angle value too: - 135.0°.

The product is now finished.

Display the product in solidview.

• Press the

key and then key .

To come back to the construction mode:

• Press the key and then key .

3D PROGRAMMING PAGE 41

Page 50

This page has been left blank intentionally.

PAGE 42 USER GUIDE PC/DNC 1200 2D&3D

Page 51

M

EMORIZE OR SEARCH A PRODUCT

EMORIZE A PRODUCT

M

The memorizing of a product can be carried out from all pages containing the

PRODUCT field at the top of the screen.

Set the DNC in programming mode .

Place the cursor on the PRODUCT field and introduce the storage

number (1 to 89'999).

Menu ACTION, select MEMORIZE PRODUCT.

If the message EXISTS appears, this indicates that the N° selected is

already in use.

CANCEL and choose an other number

or

CONFIRM in order to erase the existing product.

List of products page If you wish to do this memorizing by having a global view of the existing

products:

Call the LIST OF PRODUCTS page by means of the MENU

key and by selecting the option LIST OF PRODUCTS of the menu.

In the DRAWING field, introduce a reference, if needed.

MEMORIZE OR SEARCH A PRODUCT PAGE 43

Page 52

If you want to memorize the product elsewhere than in the internal

memory, place the cursor on the INTERNAL field of PRODUCTS

AND GROUPS IN

and make your choice.

Place the cursor on the PRODUCT field and introduce the storage

number (1 to 89.999).

Press the ACTION key.

Select the MEMORIZE option.

The message SAVING... appears in the interactive field on the top

right-hand corner of the screen.

The number of the product recorded will then appear in the list.

See the following section and also Active peripherals and Product

management in the 2D Reference Manual.

EARCH A PRODUCT

S

Rapid method

or click right to cause the list to appear,

This method is valid only from the version W2 on.

L

From any page displaying the PRODUCT field:

Position the cursor in the PRODUCT field.

Click right or press the

The following window is displayed:

key.

The products are initially listed in increasing order by product number.

To browse, place the cursor in the table and displace with the

PAGE 44 USER GUIDE PC/DNC 1200 2D&3D

Page 53

Sorting:

increasing / decreasing

To search a product:

To load the product: click or press the

or keys.

key.

To list in decreasing order:

place the cursor on the title of the column and click left

or press the

key.

The order is inversed (the red arrow is turned upwards ).

To sort by drawing name or date, proceed likewise in the titles of the

corresponding columns (DRAWING or DATE).

Position the cursor in the table in the desired column and introduce

there the product number, the drawing name or the searched date.

Your introduction is displayed on the last line (in white), and the

cursor positions on the first line of the table. The names are sorted in

increasing order, the first corresponding on the first line.

For more explanations, please refer to the 2D Reference Manual.

MEMORIZE OR SEARCH A PRODUCT PAGE 45

Page 54

Standard Method

If you want to search the product at a location other than the internal

memory, place the cursor on the INTERNAL field of PRODUCTS

AND GROUPS IN ...

and make your choice.

In the list, place the cursor on the number of the desired product and

press the key,

or

Place the cursor in the PRODUCT field, introduce the product

number and choose LOAD via the ACTION menu.

The product is now in the work memory (its number is displayed in

the PRODUCT field).

If you know the number of the product to be searched (provided that it is in

the active peripheral), you can search a product in all the pages displaying

the PRODUCT field on the top left of the screen.

To this end:

Introduce the product number in the PRODUCT field.

Choose SEARCH PRODUCT in the ACTION menu.

or click right to cause the list to appear,

PAGE 46 USER GUIDE PC/DNC 1200 2D&3D

Page 55

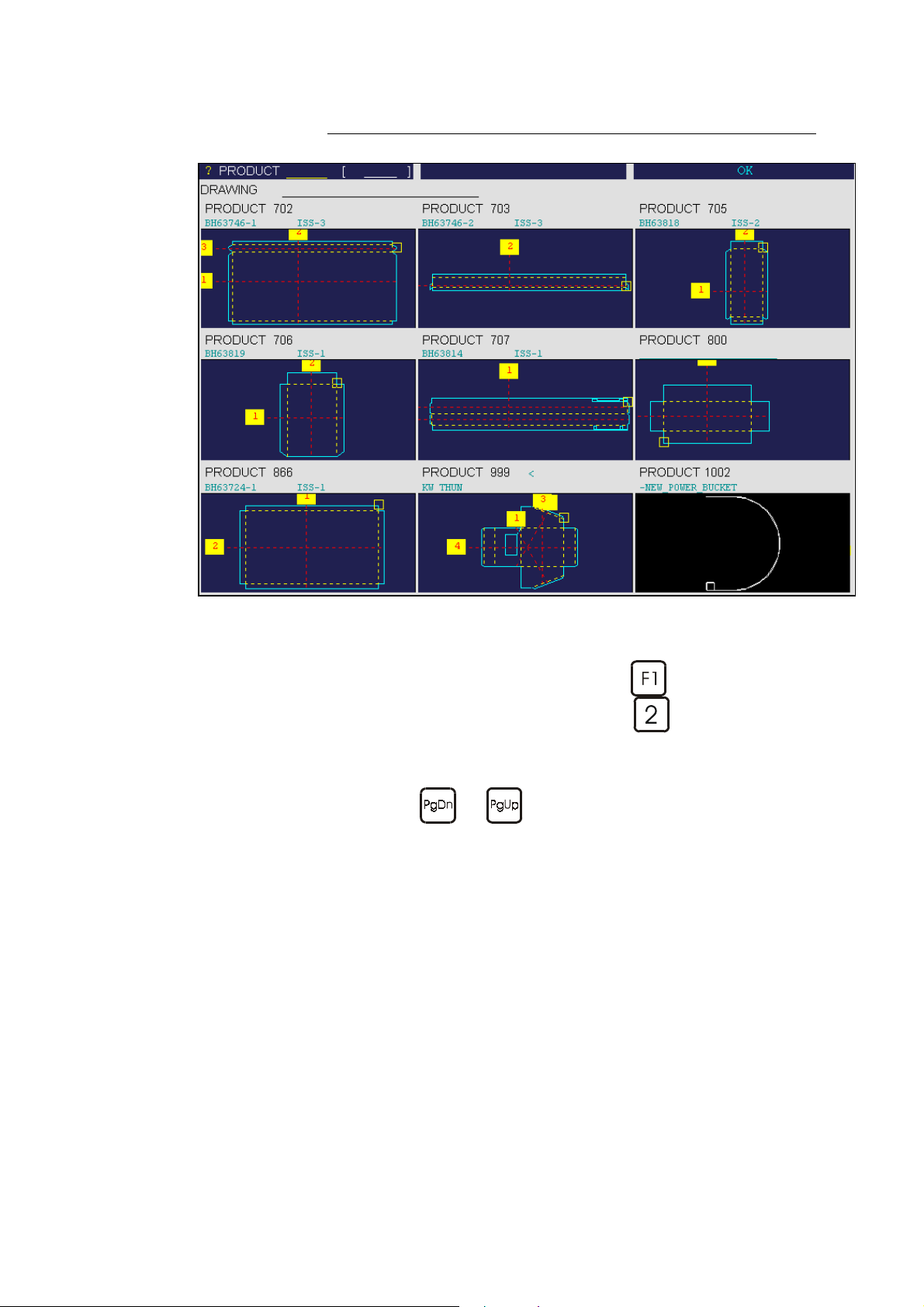

Graphic Method

Procedure:

Pass to the MENU page by means of the

List of graphical products page (key

The above window is displayed and allows you to make a search of

the products.

The functions

The product selection is identical to the standard mode.

and allow to scroll the list of graphical products.

key and call the

).

MEMORIZE OR SEARCH A PRODUCT PAGE 47

Page 56

RGANIZATION OF THE MEMORIES

O

This chapter is intended to furnish the essential elements to the DNC

functioning. For more complete information about the memories, please

consult the 2D Reference Manual.

The numerical control contains various memories. When the operator

programs a product or modifies the contents of a product, he is doing it in a

work memory, sometimes called buffer memory.

The work memory is non-volatile, that means, when you switch off the DNC,

the data of the current product remain stored in the memory until they are

replaced by an other product or deleted.

Floppy

INTERNAL

Work memory

or

buffer

Network

ENC

It is not necessary to save the product which has been programmed in the

work memory, if this one is of no more use once the product executed.

Generally, the product will be saved only if it has to be kept for future use.

A non-saved product in the work memory is recognizable, for the

PRODUCT field is empty.

The ENC is also provided with a memory which contains a copy of the

product located in the work memory. This copy is transferred to the ENC

when switching to semi-automatic or automatic mode.

An other memory, belonging to the DNC again, is the Floppy (disk).

Generally, the Floppy is used for the saving (backup) of important products,

the tools, and/or the machine parameters.

Therefore, the transfer page is used.

Although a product can be searched or stored directly in the Floppy, this

operation will be made very rarely because of the access speed.

Complementary memories can be those offered by a network access.

When normally configurated, the DNC always memorizes and searchs its

products in the INTERNAL memory. It is possible to attribute an other

memory by default to it (see Active Peripherals in the 2D Reference

Manual).

PAGE 48 USER GUIDE PC/DNC 1200 2D&3D

Page 57

P

ROTECTION OF THE ACCESS LEVELS

ENERAL INFORMATION

G

Depending on the version, the DNC 1200 can or can not be equipped with a

4positions physical key.

However the protection levels 0-1-2 and 3 still exist.

For the case where the physical key doesn't exist, the access is made by

password.

Thus, in this manual we will always speak of a (virtual) key position like

e.g.: "Key in position 3".

Levels There exist 4 access levels, 0 to 3.

0 = Programming prohibited.

1 = Creation, correction, modification, saving, deleting, transfer of one (or

more) product(s).

2 = Creation, correction, modification, saving, deleting, transfer of the tools.

3 = Programming, modification and transfer of the machine parameters.

Access These levels are reached by pressing the

Alt

+ ,

Remark: Release the numerical key before the Alt key.

The key position is displayed as a small pictograph at the right bottom of the

screen.

When passing to non-authorized level, a password modification will be

requested.

When the password has been introduced, you can "navigate" in the inferior

levels and equal to the authorized one without reintroducing the password.

The fact to pass on level 0 reinitializes the password request.

Users A number of different users are predefined. A user is not a physical person in

particular, but can be e.g. all the operators having the authorization to work

on the machine.

Each predefined user possesses his own password and a maximum level

which he can reach. See further under Table of users, access and passwords.

Password Certain users can modify their own password. For the others, the password

can only be changed by a user having a superior access.

Characteristics The password can be composed of alphanumerical characters if such a

keyboard is disposable. Otherwise only of numerical characters.

Alt

+ ,

Alt

+ or

Alt

+ keys.

Loss of the password In case of loss of the password, a user of a superior level has to reprogram

the password.

PROTECTION OF THE ACCESS LEVELS PAGE 49

Page 58

HE USERS

T

Table of users, access and passwords.

Level Names of

predefined

users

1

2

3

4 WSSUPER OK OK 3 817 Workshop supervisor

5 MACHMAN NO OK 3 Machine manufacturer's

6 MACHMAN0 OK OK 3 Responsible of the

A predefined user is just a role.

Many physical persons can have the same role. E.g., many physical operators can be a EUL1 (level 1).

After installing the machine it is advised to modify the password by default of level 4 (WSSUPER =

Workshop supervisor) and of level 3 (EUL3 = Operators with authorization level 3), because the

passwords are in this manual.

EUL1 NO NO

EUL2 NO NO

EUL3 NO NO

Changing of

the personal

password

Changing of

passwords of

the

subordinateds

Level

virtual key

1

2

3

Password

by default

111 Operators having the access

222 Operators having the access

333 Operators having the access

User generally attributed to:

authorization of level 1

authorization of level 2

authorization of level 3

Service technicians

technicians at the machine

manufacturer's

PAGE 50 USER GUIDE PC/DNC 1200 2D&3D

Page 59

CCESS BY PASSWORD

A

By starting the software, the virtual key is always positioned at 0.

When the operator selects one of the combinations

, the following message appears:

Level 1

Password

Enter the password.

Press

The authorized level is shown in the bottom right box in the screen.

Otherwise a message indicating that the user is not authorized is

displayed.

Once the authorization acquired, the operator can change the level among

those authorized to him without reappearing of a new password request.

For instance, a user with access on level 3 can navigate between levels 1, 2

and 3 without having to give his password again.

If level 0 is activated, the access on any other level will require to introduce

the password again.

This request also will appear when the user passes to a superior level (from 0

to 1, from 1 to 2, from 2 to 3, etc.) and he has no access authorization.

.

+ , or

or 2 or 3

according to

the keys

combination

Advice If you have accessed to level 3, access to level 0 after your intervention. This

will avoid to make undesired changings by inadvertence.

PROTECTION OF THE ACCESS LEVELS PAGE 51

Page 60

CCESS TO LEVELS SUPERIOR TO

A

Certain users can access to levels superior to 3, which enables them, among

other things, to modify the passwords.

In order to know the authorizations, see Table of users, access and

passwords.

3

Press the keys combination

The following message appears:

Changing key position

User WSSUPER

Password

Validate

Cancel

Password forgotten

Change password

Choose the desired user level (see table).

For that, place the cursor in the User field and press the

then make your choice and validate with

Place the cursor in the Password field and enter the password

corresponding to the requested level and validate with the

The DNC passes to level 1. The operator can "navigate" between

levels 1 and 3 without reintroducing his password.

If his access level enables him, he can call the procedure of password

modification (see next paragraph).

+ .

key,

.

key.

At the end of the intervention, don't forget to pass to level 0 in order

to leave the current level.

PAGE 52 USER GUIDE PC/DNC 1200 2D&3D

Page 61

HANGE PASSWORD

C

It is possible to modify the passwords attributed by default.

Certain users can do it for themselves, others not.

In order to know the authorizations, see Table of users, access and

passwords.

Procedure:

Press the keys combination

+

.

The following message appears:

Changing key position

User WSSUPER

Password

Validate

Cancel

Password forgotten

Change password

Log in as at least WSSUPER.

Introduce your password.

Click on Change password.

The following window appears:

Change password

User WSSUPER

New password

Confirm password

Validate

Cancel

Choose the user whose password is to be changed. For that, place the

cursor in the User field and press the

choice and validate with

.

key, then make your

Introduce the new password.

Type the new password in Confirm password.

Place the cursor on Validate and press

(or click on validate).

PROTECTION OF THE ACCESS LEVELS PAGE 53

Page 62

PASSWORD FORGOTTEN

If a user has lost / forgotten his password, ask to the responsible of the

machine.

If this password is definitively lost however, there are 2 possibilities: .

a) The user is not authorized to change his password himself.

2 solutions for this case:

- Ask the "superior" user to modify his password.

(See section Change Password).

- Use the method described below.

b) The user is authorized to change his password.

Proceed as described hereinafter.

Note:

If the forgotten password concerns levels 1, 2 or 3, ask the workshop

supervisor to modify the passwords of these levels according to the

procedure described in section Change Password.

Procedure:

Press the keys combination

+

.

The following message appears:

Changing key position

User WSSUPER

Password

Validate

Cancel

Password forgotten

Change password

Choose the user whose password is forgotten. For that, place the

cursor in the User field and press the

choice and validate with

.

key, then make your

Click on the choice Password forgotten.

PAGE 54 USER GUIDE PC/DNC 1200 2D&3D

Page 63

The following window appears:

Password forgotten

User WSSUPER

Auxiliary code Kl2398saf58sdf7

Please contact your supplier

Exit

The operator has to note the displayed auxiliary code and contact his

supplier. The latter disposes of a software enabling to generate a new

password.

In order to recover a forgotten password, proceed as follows:

Call the Password forgotten function.

Note the displayed auxiliary code.

Obtain the new password from the supplier by communicating him the

auxiliary code. You will be informed of the lost password.

PROTECTION OF THE ACCESS LEVELS PAGE 55

Page 64

This page has been left blank intentionally.

PAGE 56 USER GUIDE PC/DNC 1200 2D&3D

Page 65

B

RIEF OVERVIEW OF THE PAGES

Many complementary explications of these pages and/or the functions are

described in the 2D Reference Manual.

This manual is organized like a dictionary, with a table of contents and a very

detailed index for easy reference.

ENU PAGE

M

The MENU page

appears when the

MENU key

pressed.

To validate: place the

cursor on the required

option and press the

key, or type the

number next to the

choice.

is

IST OF PRODUCTS PAGE

L

This page allows to

extract the products

stored in the NC, in

numerical increasing

order.

BRIEF OVERVIEW OF THE PAGES PAGE 57

Page 66

IST OF GRAPHICAL PRODUCTS PAGE

L

This page allows to

extract the products

stored in the NC, in

numerical increasing

order, and with the

graphic associated to

them.

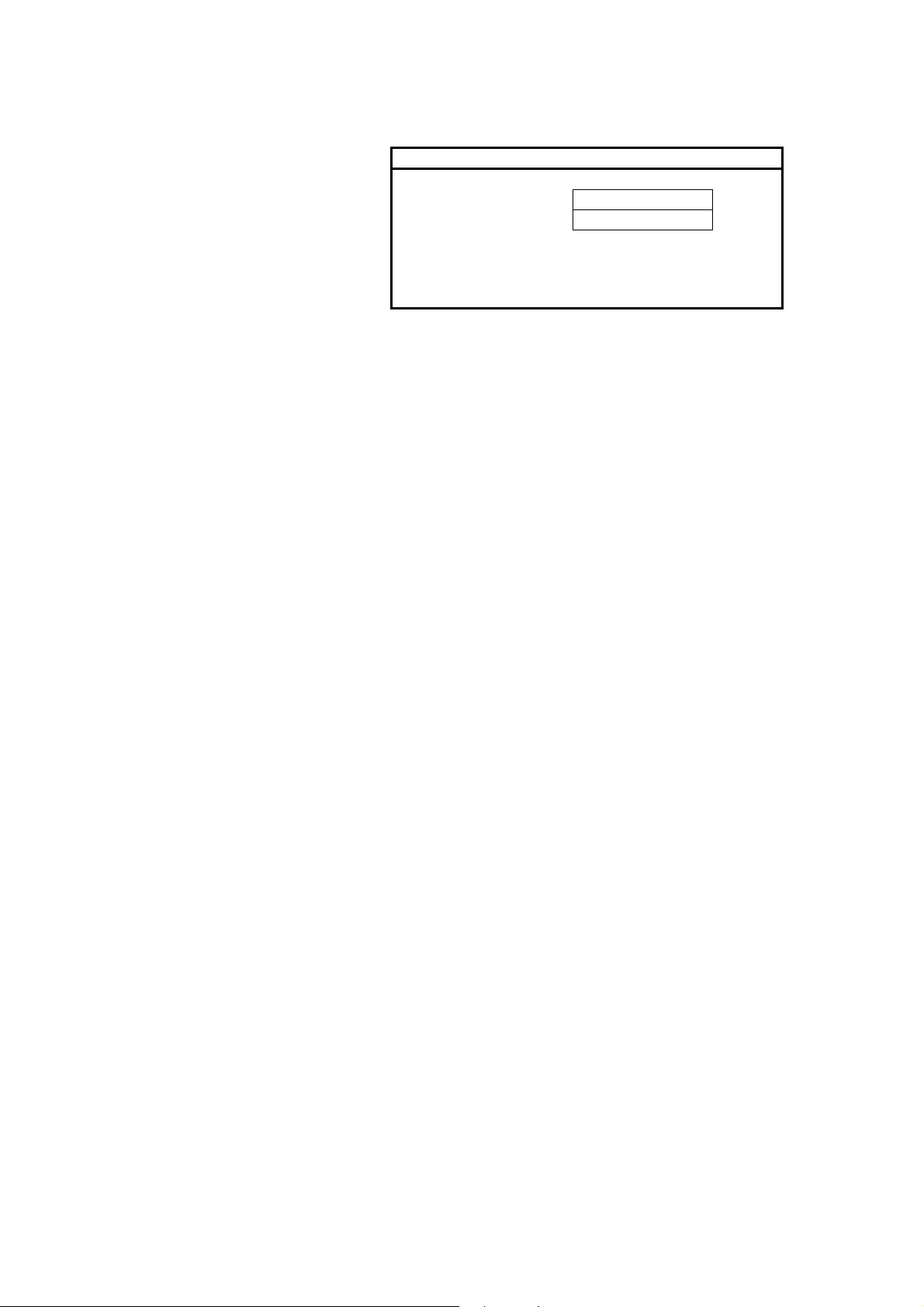

RODUCT

P

This page allows to

search for different

products stored in the

numerical control

according to certain

criteria.

RANSFER PAGE

T

Allows to select and

command data

transfers from one

memory to another.

(Floppy, network, etc...)

RITERIA SEARCH PAGE

/ C

PAGE 58 USER GUIDE PC/DNC 1200 2D&3D

Page 67

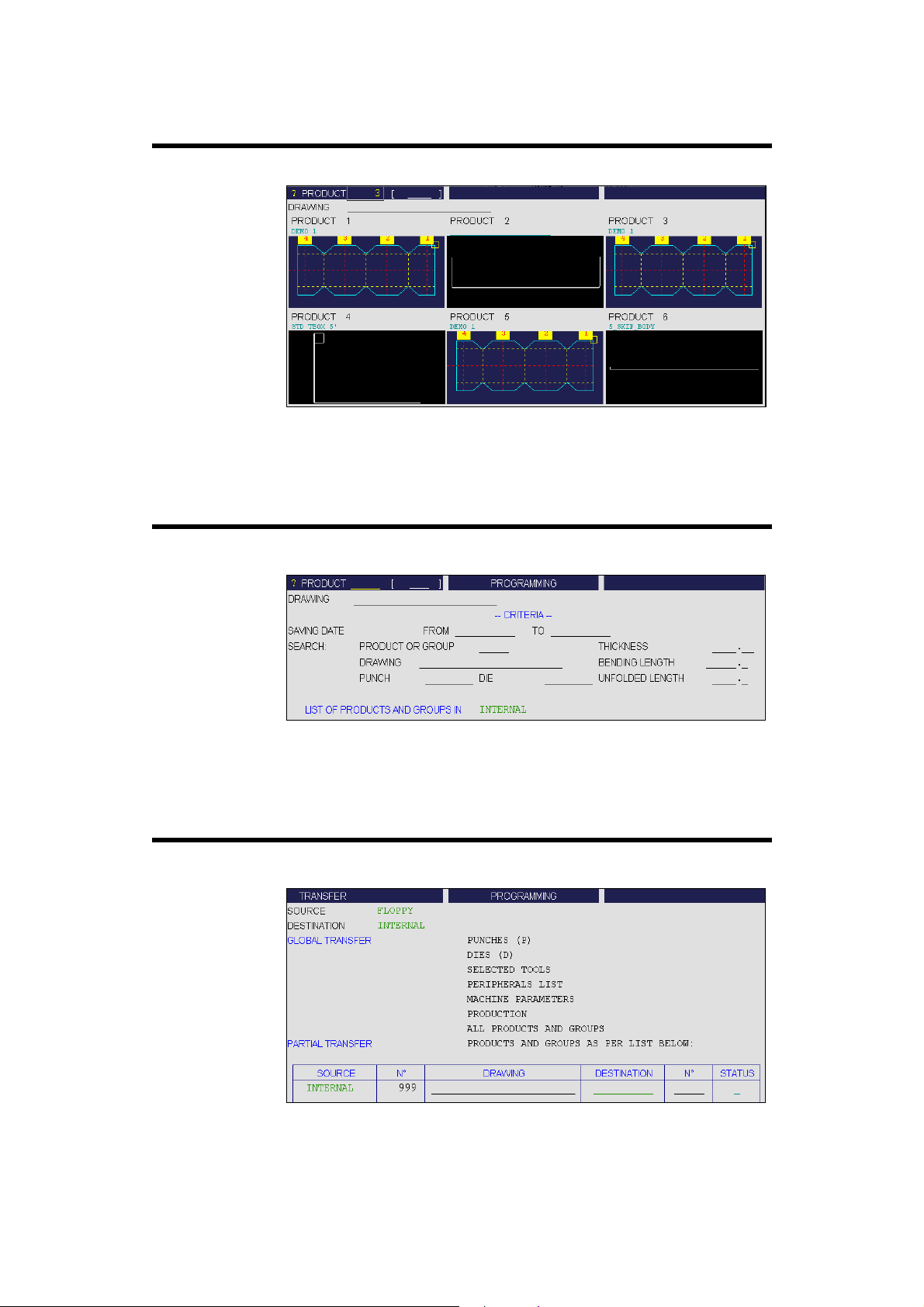

IST OF PUNCHES PAGE

L

This page gives a quick

glimpse at the main

parameters of the

punches stored in the

numerical control.

In this list, if you wish to see the complete description of the tool, just place

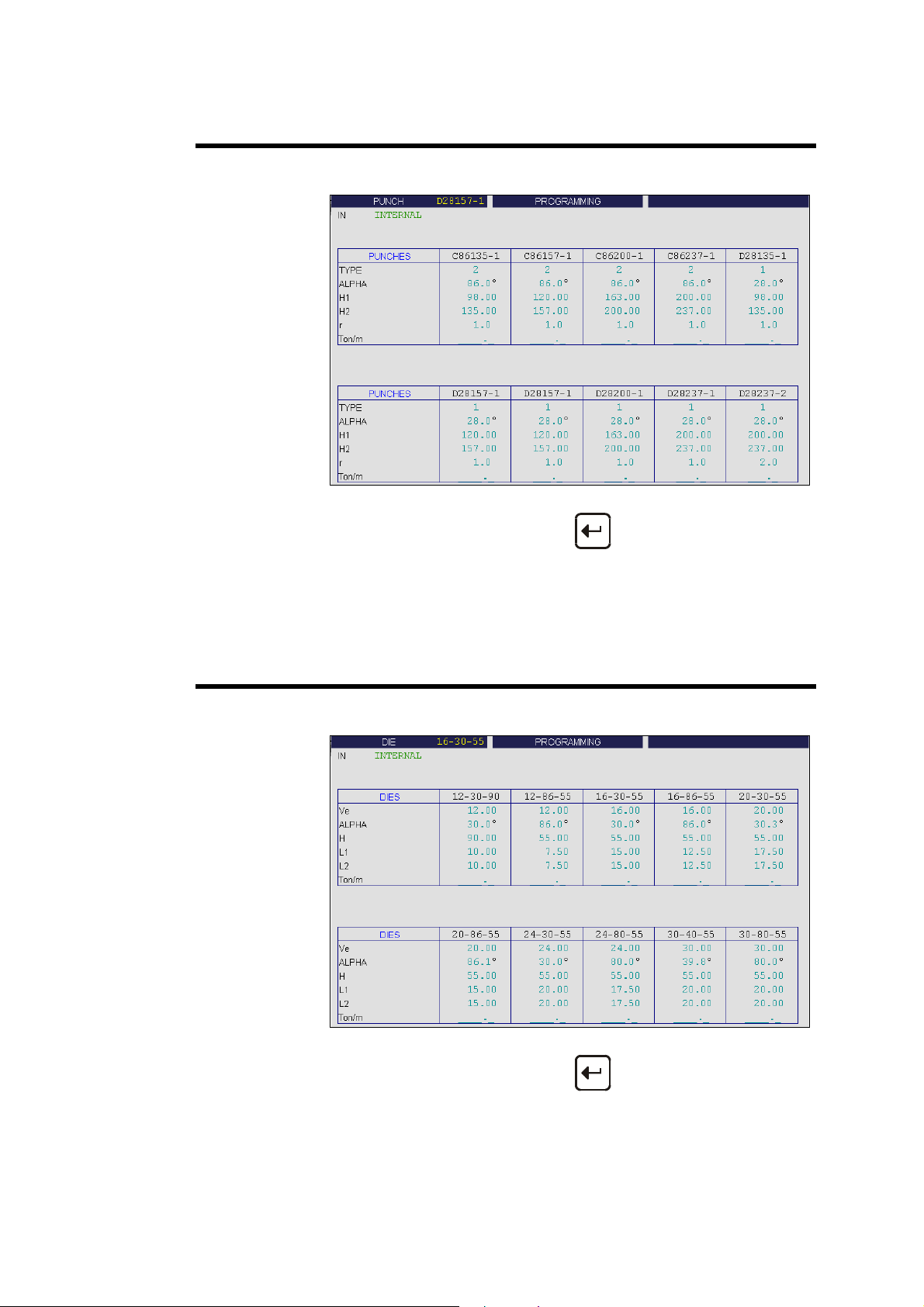

IST OF DIES PAGE

L

This page gives a quick

glimpse at the main

parameters of the dies

stored in the numerical

control.

the cursor on the tool's name and press

The PROGRAMMING PUNCHES page is then displayed.

, or click.

In this list, if you wish to see the complete description of the tool, just place

the cursor on the tool's name and press

The PROGRAMMING DIES page is then displayed.

BRIEF OVERVIEW OF THE PAGES PAGE 59

, or click.

Page 68

UNCH PROGRAMMING PAGE

P

Programming of all

punches is done from

this page.

All the dimensions

relative to the tool are

introduced here.

A drawing representing

the tool is displayed on

the right of the screen.

IE PROGRAMMING PAGE

D

Programming of all dies

is done from this page.

All the dimensions

relative to the tool are

introduced here.

A drawing representing

the tool is displayed on

the right of the screen.

PAGE 60 USER GUIDE PC/DNC 1200 2D&3D

Page 69

ELCOME PAGE

W

Main data for the

machine and the

numerical control.

The fields of green

colour are multiple

choice fields which can

be modified.

NITIALIZATION PAGE

I

This page is reserved

for the technical

maintenance of the

numerical control or the

machine.

This page allows to

clear the DNC data and

to modify the physical

indices of the machine.

The use of the front

panel key is necessary

to intervene on this

page.

BRIEF OVERVIEW OF THE PAGES PAGE 61

Page 70

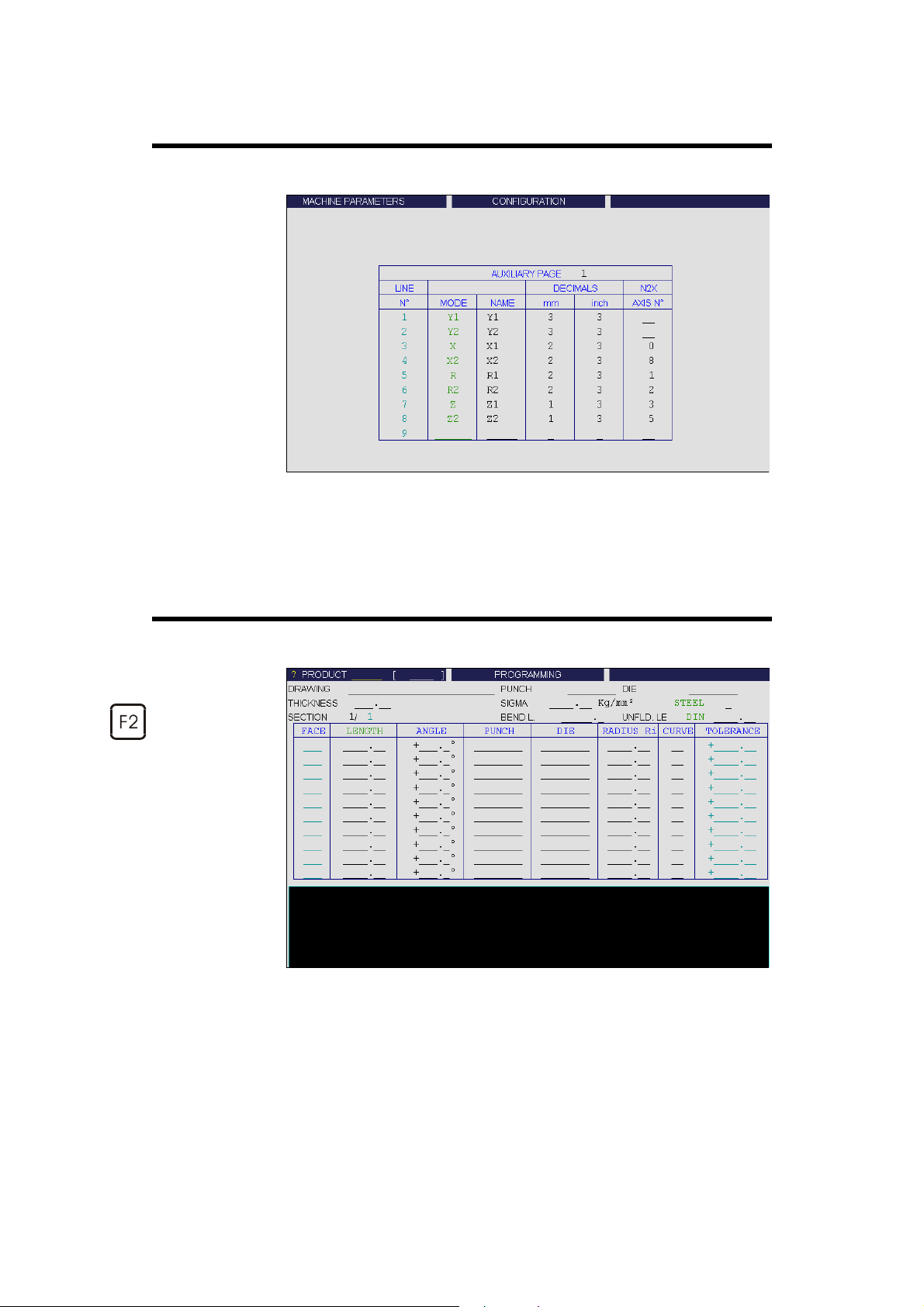

ACHINE PARAMETERS PAGE

M

This page is the first of

the pages which

constitute the list of all

the parameters which

condition the

functioning of the

numerical control.

This data can only be

modified with the front

panel key in position 3.

This data may be

modified only with the

aid of competent

technical support.

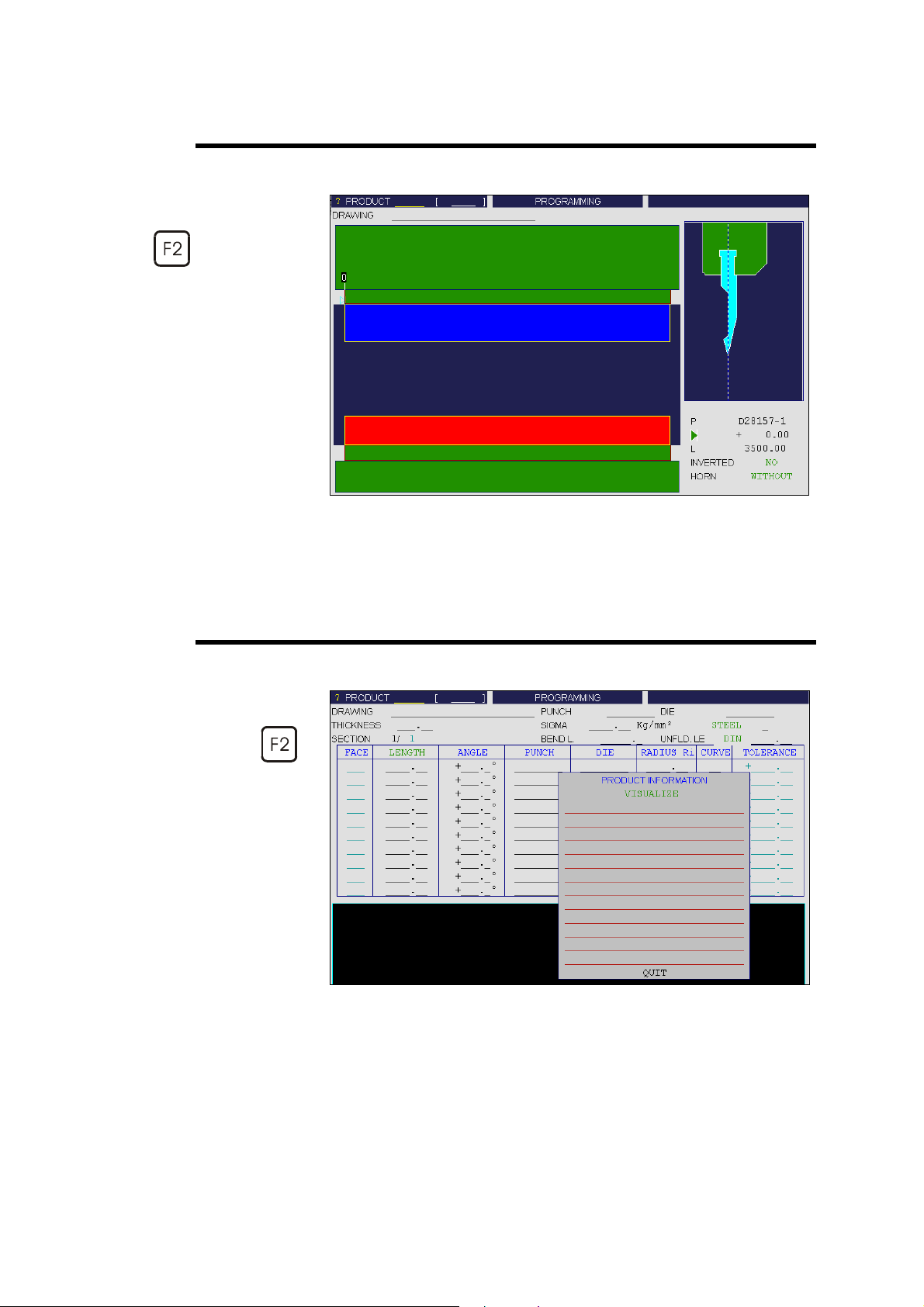

RODUCT NUM PAGE

P

This page appears

when the PRODUCT

key is pressed

and PRODUCT

NUMERICAL is

chosen.

This page allows to

construct and calculate

a product and to

visualize the profile of

the cut in real time.

PAGE 62 USER GUIDE PC/DNC 1200 2D&3D

Page 71

OOLS POSITION PAGE

T

This page appears

when the PRODUCT

key is pressed

and TOOLS POSITION

is chosen.

This page allows to

define several work

stations.

OMMENTS PAGE

C

This page appears

superimposed when

the PRODUCT

key is pressed and

COMMENTS is chosen.

This page allows to

complete the product

data with a series of

commentaries. These

commentaries are

programmed using a

PC software.

BRIEF OVERVIEW OF THE PAGES PAGE 63

Page 72

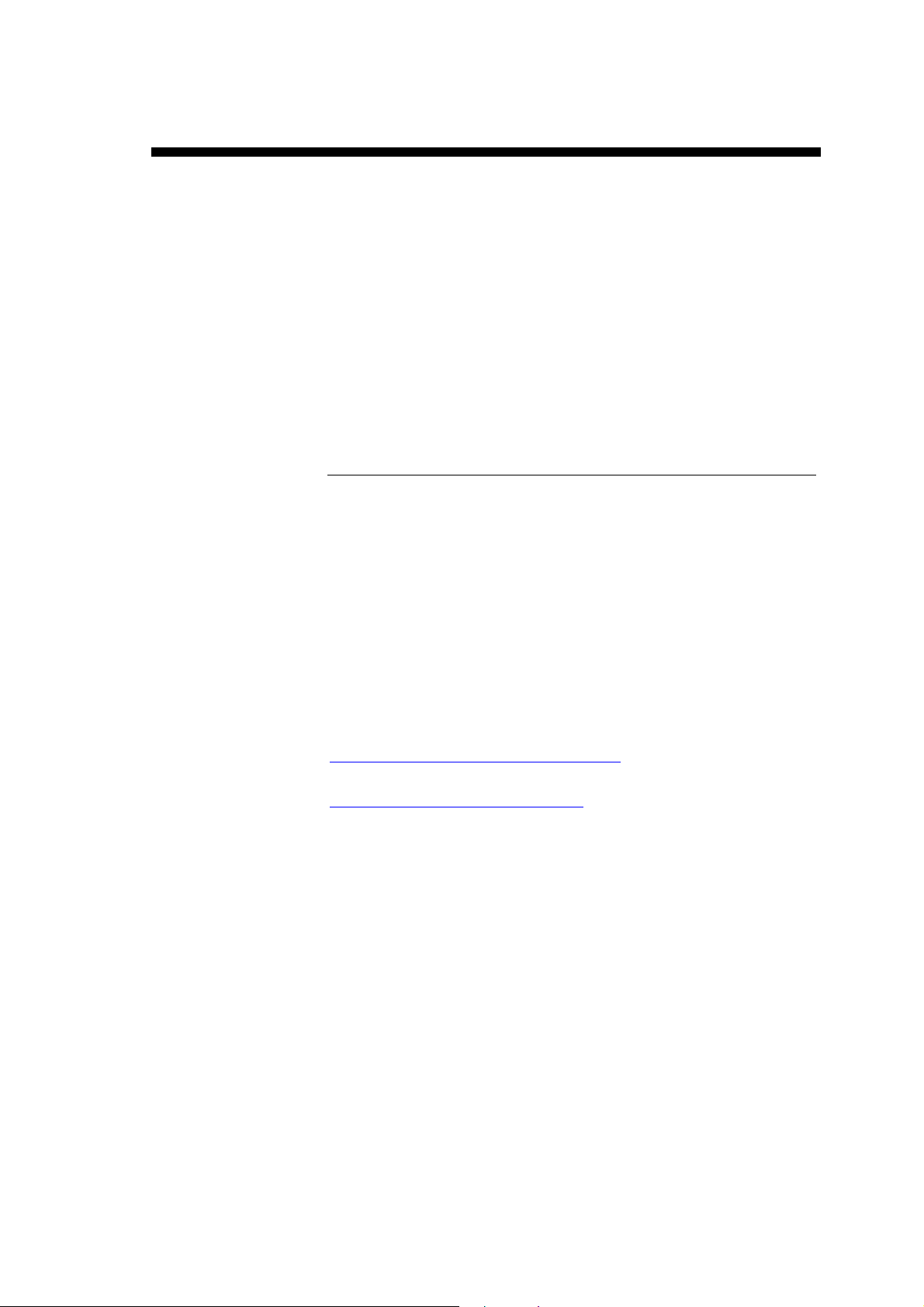

END NUMERICAL PAGE

B

This page appears

when the BEND

key is pressed and

BEND NUMERICAL

is chosen.

This page recapitulates

all the data for the

current sequence.

END

B

2D P

AGE

This page appears

when the BEND

key is pressed and

BEND 2D is chosen.

This page allows to

simulate the feasibility

of the product and to

correct the bending

order if necessary.

PAGE 64 USER GUIDE PC/DNC 1200 2D&3D

Page 73

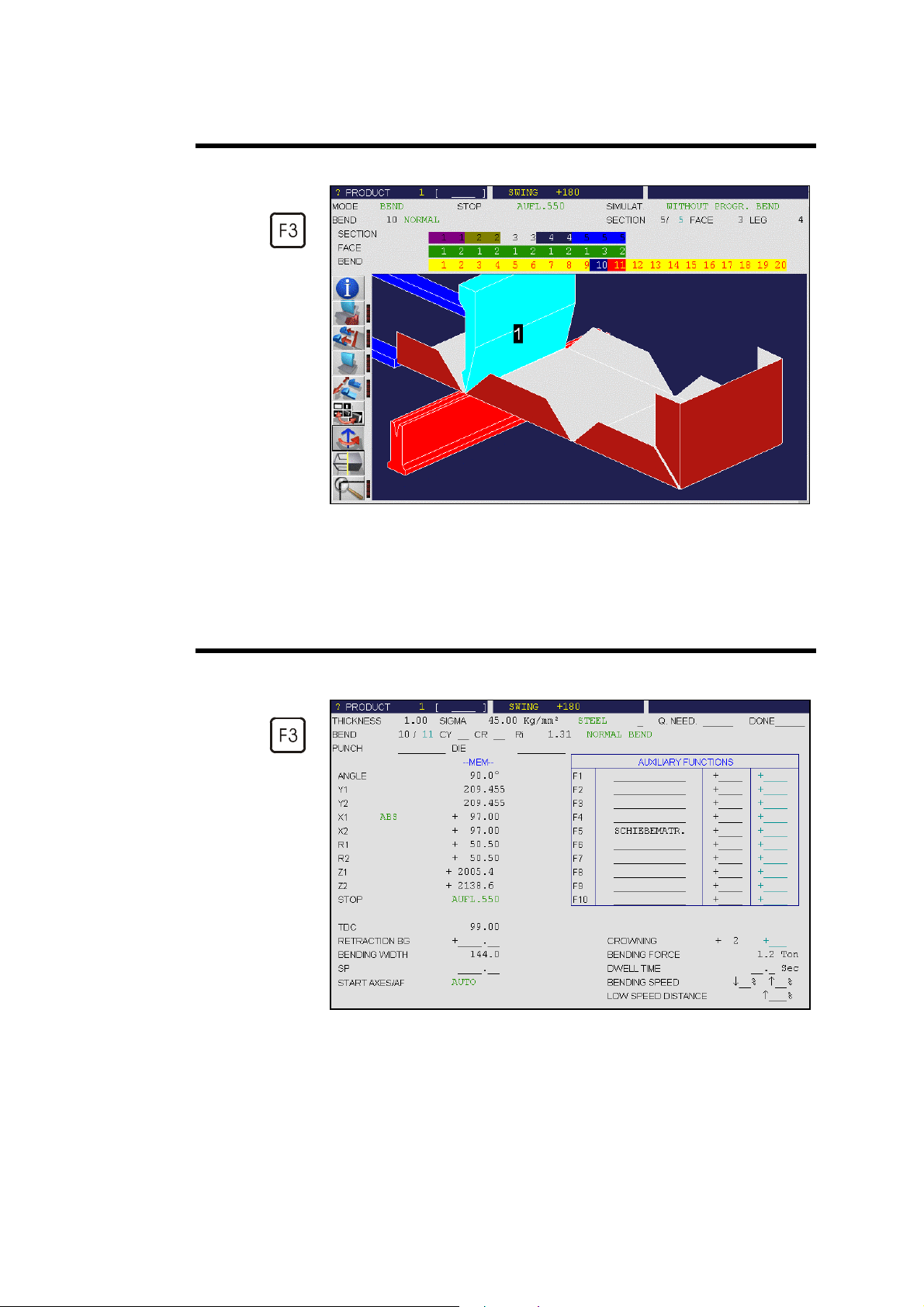

END

B

This page appears

when the BEND

key is pressed and

BEND 3D is chosen.

This page allows to

simulate the feasibility

of the product and to

correct, if necessary,

the stop position as well

as the position of the

product relating to the

tools.

3D P

AGE

END FUNCTION PAGE

B

This page appears

when the BEND

key is pressed and

BEND FUNCTION is

chosen.

This page allows to

program any possible

auxiliary functions of

the machine.

BRIEF OVERVIEW OF THE PAGES PAGE 65

Page 74

END

B

This page appears

when the BEND

key is pressed and

BEND. TOOLS is

chosen.

This page allows to

modify the position and

the width of the tools

mounted on the

machine. Certain safety

factors can also be

modified here.

OOLS PAGE

. T

ORRECTIONS PAGE

C

This page appears

when the

CORRECTIONS key is

pressed and

CORRECTIONS is

chosen.

This page allows to

apply the corrections to

the different machine

axes as a function of

the results obtained

during bending.

PAGE 66 USER GUIDE PC/DNC 1200 2D&3D

Page 75

I

NSTALLATION OF THE

There are 4 figures to be distinguished:

1. Installation of PC 1200 Windows on a PC station.

2. Installation of PC 1200 Version DOS* or PC 900 (DOS) on a PC

station equipped with Windows.

3. Installation of the DNC 1200 Windows software.