Page 1

N2X

Parameters

CYBELEC SA Tel. ++ 41 24 447 02 00

RUE DES UTTINS 27 Fax ++ 41 24 447 02 01

CH - 1400 YVERDON-LES-BAINS E-Mail: info@cybelec.ch

SWITZERLAND

V-DOC-N2X-EN

Page 2

Information in this document is subject to change without notice, and does not represent a commitment on the

part of CYBELEC SA. The software described in this document is furnished under a license agreement or

nondisclosure agreement. The software may be used or copied only in accordance with the terms of the

agreement. It is against the law to copy the software on any medium except as specifically allowed in the license

or nondisclosure agreement.

Copyright CYBELEC SA. 1991

All rights reserved.

Important:

This notice explains normal and standard programming operations for the numerical c ontrol.

In view of the fact that numerical controls can be equipped with configurab le functions by the pr ess manufacturer

for his own specific purposes, please refer to the manufacturer-supplied complementary instructions regarding the

programming of these functions.

Arcnet

CYBELEC is a registred trademark of CYBELEC SA

Ethernet

IBM

Business Machines Corporation.

MS-DOS

Novell Netware

ZeroNet

is a registered trade mark of Datapoint Corporation.

is a registered trade mark of Xerox Corporation.

, PC/AT , PC Network , Token Ring Network are registered trade marks of the International

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Novell, Incorporated.

is a registered trade mark of Applied Knowledge Groups, Incorporated.

Page 3

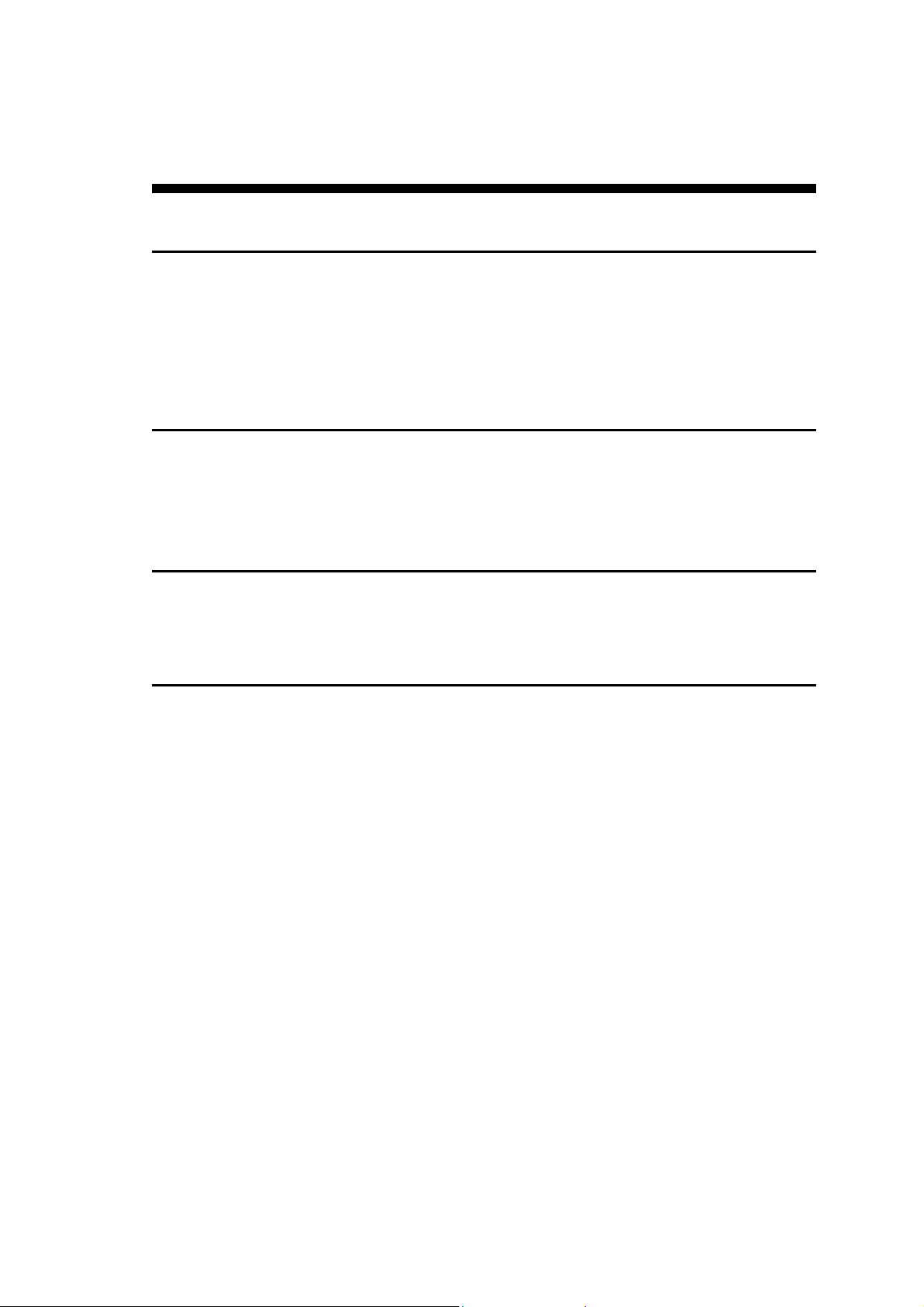

N2X MANUAL V

ER

7

V

ERSION

For the versions prior to the ones mentioned under version 3, please refer to N2X

version 2.

V

ERSION

Valid for versions

V

ERSION

Valid for versions

2

3

N2XDN and following

N2XEM and following

N2XFB and following

4

V

ERSION

Valid for versions

N2XDW and following

N2XEV and following

N2XFK and following

5

N2XDC2 and following

N2XEB2 and following

N2XFS and following

N2XFHA and following

Page 4

V

ERSION

Valid for versions

6

N2XHC and following

N2XFU and following

V

ERSION

Valid for versions

7

N2XHB and following

N2XFU and following

Page 5

February 02, 2006 Vers. 7.1

TABLE OF CONTENTS

LICENSE AGREEMENT FOR CYBELEC SOFTWARE..................................................................3

N2X BOARD IMPLANTATION.........................................................................................................7

N2X 200 board ....................................................................................................................7

N2X DIO 7xx board .............................................................................................................8

Carte MAX...........................................................................................................................9

N2X BOARD PARAMETERS...........................................................................................................11

CONVENTIONS AND DEFINITIONS...............................................................................................13

Conventions.........................................................................................................................13

Units for the "Encoder Resolution" parameter (P02) 13

Parameters with options 13

Definitions............................................................................................................................14

AC POSITIONING DIAGRAM .............................................................................................15

NAX TYPE POSITIONING ..................................................................................................15

DC POSITIONING DIAGRAMS...........................................................................................16

Unidirectional positioning with final approach overrun and advanced stop 16

Bidirectional positioning with final approach 16

Functioning of final approach (detail) 17

Direct bidirectional positioning 17

DESCRIPTION OF THE PARAMETERS.........................................................................................19

P00 Axis Type......................................................................................................................19

P01 Operating Mode............................................................................................................20

P02 Encoder resolution .......................................................................................................22

P03 Positioning Tolerance...................................................................................................23

P04 Advanced stop..............................................................................................................24

P05 Overrun distance..........................................................................................................24

P06 Slow speed distance ....................................................................................................24

P07 SP/SN Time .................................................................................................................25

P08 Acceleration time..........................................................................................................26

P09 Deceleration time .........................................................................................................26

P10 Positioning speed.........................................................................................................26

P11 Final approach speed...................................................................................................26

P12 Indexing speed.............................................................................................................27

P13 Manual slow speed.......................................................................................................27

P14 Manual high speed.......................................................................................................27

P15 Preset voltage ..............................................................................................................28

P16 Maximum voltage.........................................................................................................28

P17 Minimum voltage..........................................................................................................29

P18 Offset voltage...............................................................................................................30

P19 Closed loop tolerance...................................................................................................31

P20 Maximum following error..............................................................................................31

P21 Surveillance time..........................................................................................................31

P22 Proportional gain..........................................................................................................32

P23 Integral gain..................................................................................................................32

N2X7E.DOC

TABLE OF CONTENTS PAGE 1

Page 6

P24 Differential gain............................................................................................................ 32

P25 Index mode..................................................................................................................33

P26 Index position ..............................................................................................................33

P27 Minimum limit -............................................................................................................34

Programming limits for the minimum and maximum limits depending on the

resolution 34

P28 Maximum limit + .......................................................................................................... 34

ADJUSTMENT OF THE AXES FUNCTION PARAMETERS..........................................................35

Axis and verification definitions........................................................................................... 35

Verification of rotation and counting directions ................................................................... 35

Offset adjustment and minimum voltage............................................................................36

Adjusting the positioning parameters.................................................................................. 37

DC axis with PID adjustment 37

DC Axis in NAX mode (without PID loop) 41

AC Axis 42

Final regulation of the parameters......................................................................................44

Programming the secondary parameters 44

1st indexation of the N2X axes............................................................................................45

Procedure 45

ADDITIONAL N2X SOFTWARE ON MASTER...............................................................................47

N2X parameters..................................................................................................................48

Example AC 2 speed motor 51

Example DC Motor +/- 10VDC 53

INDEX..............................................................................................................................................55

PAGE 2 USER GUIDE N2X7

Page 7

LICENSE AGREEMENT FOR CYBELEC SOFTWARE

G

ENERAL COPYRIGHT

The CYBELEC software is protected by Copyright, and all the copying rights are reserved.

The CYBELEC software may only be installed and used in authorized equipments (PC or DNC).

The user manuals are also covered by copyright, and all rights to use and to copy are reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated or reduced

without prior consent, in writing, from CYBELEC.

S

PECIAL DISKETTE COPYRIGHT

The legal users of this software product are authorized only to copy the contents of the diskette into the

memory of the computer to run the program, and to make one backup copy of the original diskette for

safety purposes in case of loss of the original program.

Unauthorized copying, duplicating, selling or otherwise distributing this product is a violation of the law.

S

PECIAL EPROM COPYRIGHT

The CYBELEC DNC and CNC units in which the original software made by CYBELEC has been

replaced by a copy not made by CYBELEC, and without written authorization of CYBELEC, will

immediately lose their warranty.

W

ARRANTY

CYBELEC does not warrant that its software products will function properly in every computer and

programming enviro nment.

The limitations of use of a software product and its technical specifications are decided by CYBELEC

only; CYBELEC solely is entitled to decide upon conformity and performance of a given software.

The CYBELEC software does not compensate for incompatibilities in operating system revisions or

versions.

Running the CYBELEC software under various revisions or vers i ons, or switching between d ifferent

versions or revisions may result in loss or alteration of data.

LICENSE AGREEMENT PAGE 3

Page 8

S

OFTWARE UPDATE SERVICE

Purchase of the CYBELEC software entitles the user, during one year, to delivery of software updates of

the "correction" type.

During the use of a revised or corrected version of the software it may occur that data (program,

parameters, etc.) is lost, or that the equipment or its connections need to be modified; these effects are not

always foreseeable and do not engage CYBELEC's responsibility.

T

ERMINATION

This agreement shall automatically terminate upon any act of bankruptcy by or against licensee, upon any

assignment for the benefit of creditors of the licensee, upon any attachment execution of judgement or

process against licensee or its assets that substantially inhibits its ability to do business, or upon

dissolution of licensee.

CYBELEC has the right to terminate this agreement immediately, should the licensee violate the

aforementioned conditions.

Within 30 days of termination of this agreement for any reason, licensee shall at his option, either:

return to CYBELEC or authorized dealer all existent copies of such software and related materials, or

furnish to CYBELEC evidence satisfactory that the original and all copies of the software, in whole

and in any form, have been destroyed.

L

IMITATION OF LIABILITY

The foregoing warranty is instead of all other warranties, expressed or implied.

Licensee further agrees that CYBELEC shall not be liable for any lost profits, lost savings, loss of use, or

other incidental or consequential damages arising from the use or inability to use the software, or for any

claim or demand against licensee by any other party.

In no event shall CYBELEC be liable for consequential damages, even if CYBELEC has been advised of

the possibility of such damages.

CYBELEC does not warrant that the functions contained in the software will meet the licensee's

requirement or that the operation of the software will be totally error free.

Should the software prove defective, the licensee (and not CYBELEC or an authorized dealer or

representative) will assume the entire cost of all necessary service, repair or correction.

CYBELEC warrants the diskettes, EPROMS or other magnetic support or cassettes on which the

programs are supplied to be free of defects in material and workmanship under normal use for a period of

90 days from the date of shipment to the licensee as evidenced by a copy of the packing slip.

PAGE 4 USER GUIDE N2X7

Page 9

L

IMITATION OF REMEDIES

CYBELEC's entire liability and the licensee's exclusive remedy shall be as follows:

The replacement of any diskettes or EPROMS or magnetic support media or cassettes not meeting

CYBELEC's limited warranty and which materials are returned to CYBELEC or an authorized

CYBELEC representative with a copy of the packing slip, or

If CYBELEC or its representative is unable to deliver replacement diskettes, magnetic support media,

EPROM or cassettes which are free of defects in materials or workmanship, the licensee may terminate

this agreement under the terms and conditions herein mentioned, and the purchaser's money will be

refunded.

G

ENERAL

The licensee acknowledges that he has read this agreement, understands it and agrees to be bound by its

terms and conditions.

The licensee agrees to hold CYBELEC harmless on all liability associated with licensee's breach of this

agreement including, but not limited to, all reasonable attorney's fees and court costs, if any.

This license agreement shall be governed by Swiss law; place of jurisdiction is Lausanne, Switzerland.

M

AINTENANCE

CYBELEC will provide one year of software maintenance.The extent of maintenance, and response time

for furnishing same, shall be at the sole discretion of CYBELEC.Maintenance shall normally include

correction of errors in code, correction of errors in supporting documentation, update versions of the

covered software which may be released by CYBELEC during the maintenance period.

In no event shall CYBELEC be obliged to provide technical support in attempting to resolve problems or

difficulties resulting from licensee's modification of the licensed software; any such modification by

licensee is entirely at licensee's own risk.

LICENSE AGREEMENT PAGE 5

Page 10

This page has been left blank intentionally.

PAGE 6 USER GUIDE N2X7

Page 11

N2X BOARD IMPLANTATION

N2X 200

BOARD

2

N2X

E

1

A

B

I

E

2

A

B

I

SP1

8

SN1

GV1

B

SP2

1

SN2

GV2

24V

1

SP1

SN1

GV1

SP2

SN2

GV2

IN0

8

IN1

IN2

B

IN3

2

IN4

IN5

1

D0

D1

D3

D4

AN 1

4

B

3

AN 2

1

ENCODER AXIS 0

LED SIGNAL A AXIS 0

LED SIGNAL B AXIS 0

LED INDEX AXIS 0

ENCODER AXIS 1

LED SIGNAL A AXIS 1

LED SIGNAL B AXIS 1

LED INDEX AXIS 1

OUT SIGNAL SP1 AXIS 0

OUT SIGNAL SN1 AXIS 0

OUT SIGNAL HS1 AXIS 0

OUT SIGNAL SP2 AXIS 1

OUT SIGNAL SN2 AXIS 1

OUT SIGNAL HS2 AXIS 1

OUT + 24V

GND

LED SIGNAL SP1 AXIS 0

LED SIGNAL SN1 AXIS 0

LED SIGNAL HS1 AXIS 0

LED SIGNAL SP2 AXIS 1

LED SIGNAL SN2 AXIS 1

LED SIGNAL HS2 AXIS 1

INPUT PAUSE AXIS 0

INPUT SERVOAPM. OK AXIS 1

INPUT ZONE INDEX AXIS 0

INPUT PAUSE AXIS 1

INPUT SERVOAMP. OK AXIS 1

INPUT ZONE INDE X AXIS 1

N.C.

GND

LED SIGNAL INPUT PAUSE AXIS 0

LED SIGNAL INPUT SERVOAMP. OK AXIS 0

LED SIGNAL INPUT PAUSE AXIS 1

LED SIGNAL INPUT SERVOAMP. OK AXIS 1

+/-10V ANALOG OUTPUT SIG N AL AXIS 0

0V ANALOG AXIS 0

+/-10V ANALOG OUTPUT SIGNAL AXIS 1

0V ANALOG AXE 1

N2X BOARD IMPLANTATION PAGE 7

Page 12

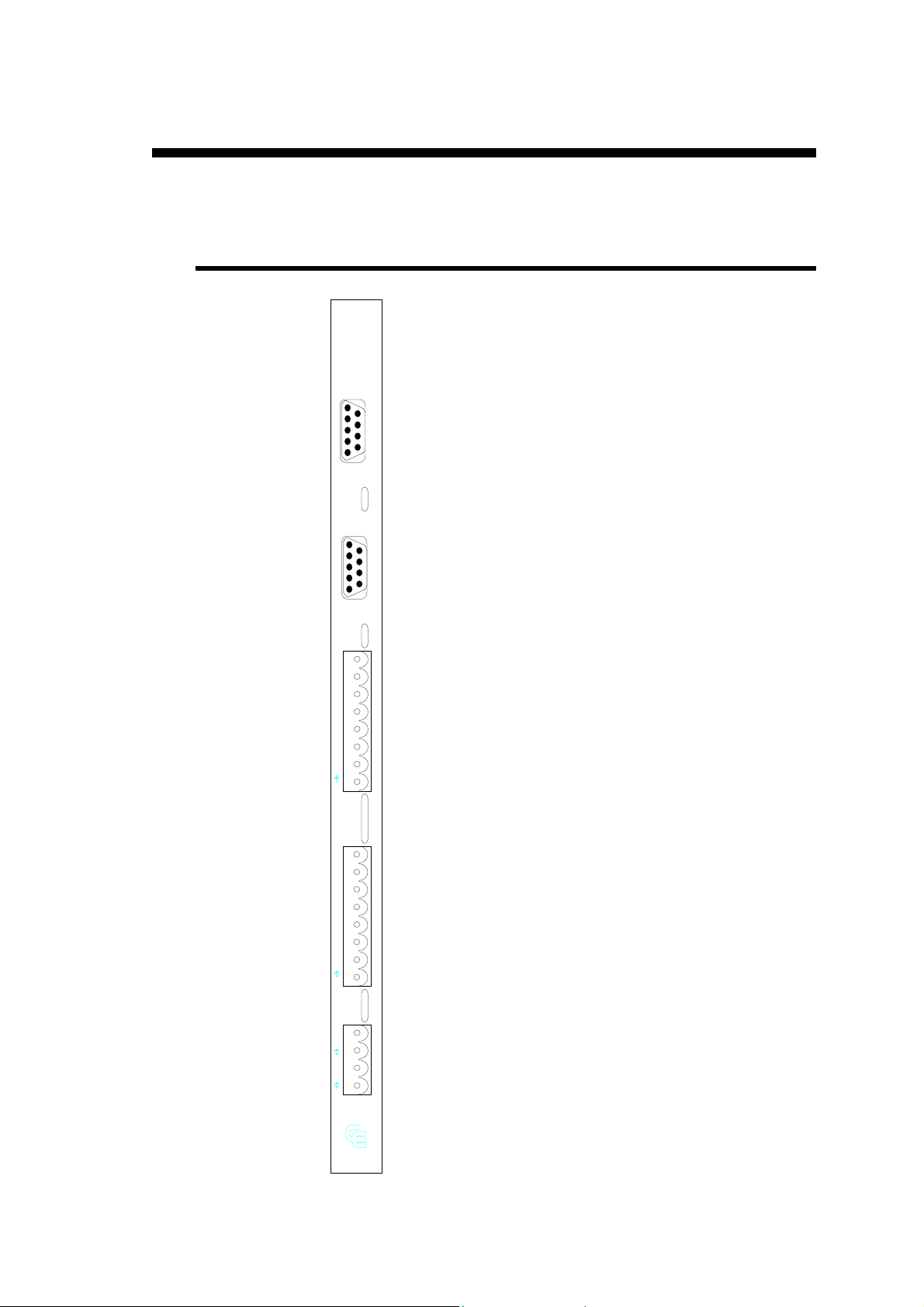

N2X DIO 7

XX BOARD

CYBAN

CYBAN

CYBAN

CYBAN

LED SIGNAL A AXIS 0

LED SIGNAL B AXIS 0

LED INDEX AXIS 0

AXIS 0

ENCODER AXIS 0

LED SIGNAL A AXIS 1

LED SIGNAL B AXIS 1

LED INDEX AXIS 1

AXIS 1

ENCODER AXIS 1

LED SIGNAL A AXIS 2

LED SIGNAL B AXIS 2

LED INDEX AXIS 2

AXIS 2

ENCODER AXIS 2

LED SIGNAL A AXIS 3

LED SIGNAL B AXIS 3

LED INDEX AXIS 3

AXIS 3

ENCODER AXIS 3

DIO 7xx

OFFSET

OFFSET

OFFSET

OFFSET

CYBAN

CYBAN

CYBAN

CYBAN

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

CYBIO

ANALOG OUTPUT +/-10V AXIS 0

GND OUTPUT AXIS 0

ANALOG OUTPUT +/-10V AXIS 1

GND OUTPUT AXIS 1

ANALOG OUTPUT +/-1 0V AXIS 2

GND OUTPUT AXIS 2

ANALOG OUTPUT +/-1 0V AXIS 3

GND OUTPUT AXIS 3

OUTPUT SIGNA L SP AXIS 0

OUTPUT SIGNA L SN AXIS 0

OUTPUT SIGNA L HS1 AXIS 0

INPUT SIGNAL PAUSE AXIS 0

INPUT SIGNAL SERVOAPM. OK AXIS 0

INPUT SIGN AL ZONE INDEX AXIS 0

OUTPUT SIGNA L SP AXIS 1

OUTPUT SIGNA L SN AXIS 1

OUTPUT SIGNA L HS1 AXIS 1

INPUT SIGNAL PAUSE AXIS 1

INPUT SIGNAL SERVOAPM. OK AXIS 1

INPUT SIGN AL ZONE INDEX AXIS 1

OUTPUT SIGNA L SP AXIS 2

OUTPUT SIGNA L SN AXIS 2

OUTPUT SIGNA L HS1 AXIS 2

INPUT SIGNAL PAUSE AXE 2

INPUT SIGNAL SERVOAPM. OK AXIS 2

INPUT SIGNAL INDEX ZONE AXIS 2

OUTPUT SIGNA L SP AXIS 3

OUTPUT SIGNA L SN AXIS 3

OUTPUT SIGNA L HS1 AXIS 3

INPUT SIGNAL PAUSE AXIS 3

INPUT SIGNAL SERVOAPM. OK AXIS 3

INPUT SIGNAL INDEX ZONE AXIS 3

INPUT +24V

INPUT GND

PAGE 8 USER GUIDE N2X7

Page 13

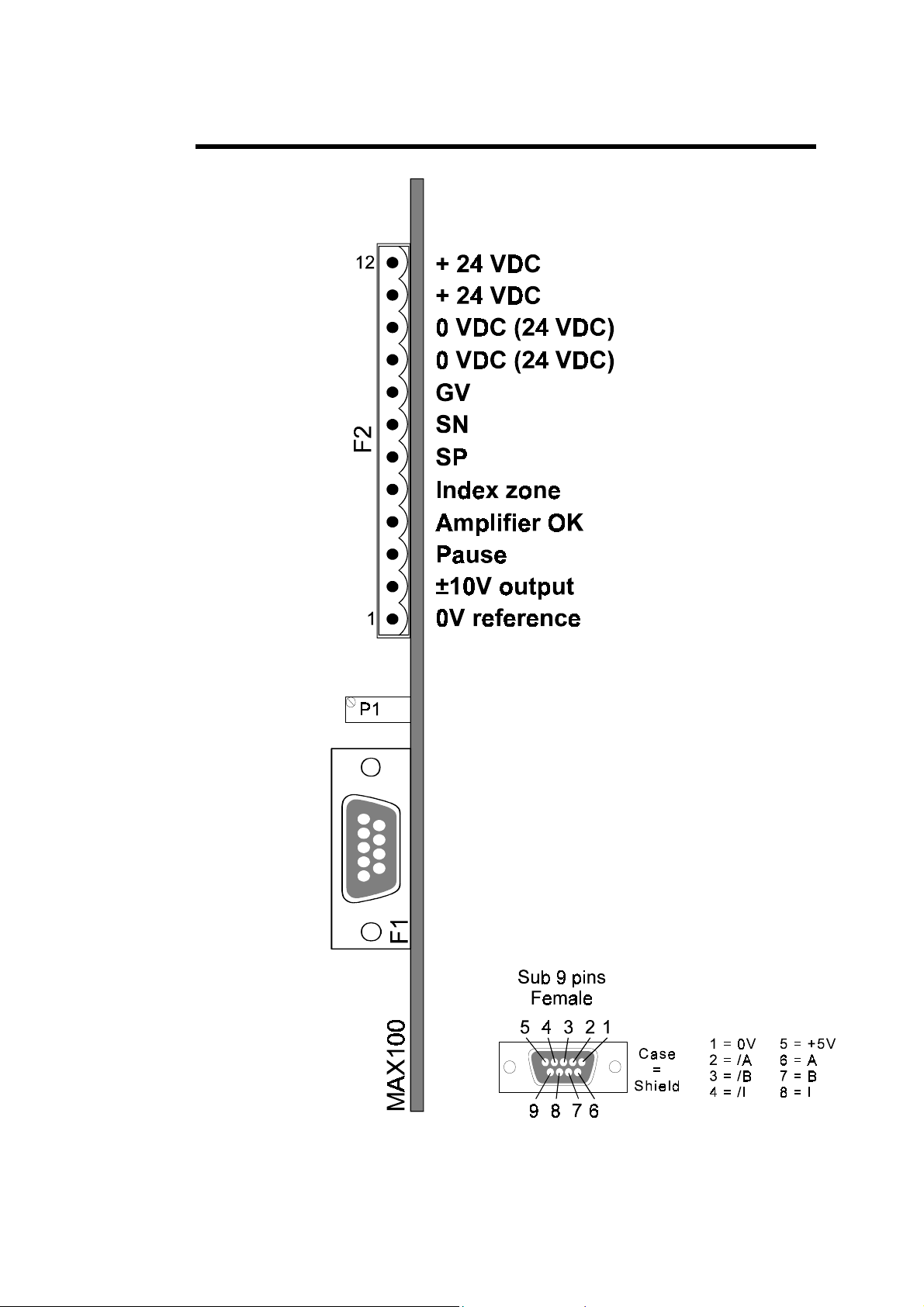

ARTE

C

MAX

N2X BOARD IMPLANTATION PAGE 9

Page 14

This page has been left blank intentionally.

PAGE 10 USER GUIDE N2X7

Page 15

N2X BOARD PARAMETERS

--AXES-- -X- Inherent

values

0 Axis type -- 0=DC DC/AC

1 Operating mode -- 0 DC/AC

2 Encoder resolution ---,--- 100,000 DC/AC

3 Positioning Tolerance -,-- 0,01 DC/AC

4 Advanced Stop -,-- 0,00 DC/AC

5 Overrun Dist +--,-- 0,00 DC/AC

6 Slow Speed Distance --,-- 0,00 DC/AC

7 SP/SN Time -,--- 0 DC/AC

8 Acceleration Time -,--- 0,500 DC

9 Deceleration Time -,--- 0,500 DC/AC

10 Positioning Speed ----,-- 30,00 DC

11 Final Approach Speed --,-- 0,00 DC

12 Indexing Speed ----,-- P10/2 DC

13 Manual Slow Speed ---,-- P10/8 DC

14 Manual High Speed ----,-- P10/2 DC

Types of

parameters

15 Preset Voltage +-,--- 0,000 DC

16 Maximum Voltage -,--- 9,999 DC

17 Minimum Voltage -,--- 0,000 DC

18 Offset Voltage +-,--- 0,000 DC

19 Closed loop tolerance (%) +-- 100 DC/AC

20 Max. Following Error --,-- disabled DC

21 Surveillance Time -,--- disabled DC/AC

22 Proportional Gain ---- 1000 DC

23 Integral Gain ---- 500 DC

24 Differential Gain ---- 0 DC

25 Index Mode -- 0 DC/AC

26 Index Position +-----,-- DC/AC

27 Minimum Limit - +-----,-- DC/AC

28 Maximum Limit + +-----,-- DC/AC

* Parameters temporarily not or partially in use

N2X BOARD PARAMETERS PAGE 11

Page 16

This page has been left blank intentionally.

PAGE 12 USER GUIDE N2X7

Page 17

CONVENTIONS AND DEFINITIONS

ONVENTIONS

C

U

NITS FOR THE "ENCODER RESOLUTION" PARAMETER

(P02)

All times are programmed in seconds.

All voltages are programmed in Volts.

Note: The unit of voltage for the parameters is the Volt (mV) to

facilitate their programming.

Example: 0.2 = 200 mV

All distances are in units.

All speeds are in units/s.

P

ARAMETERS WITH OPTIONS

The parameters which are programmed in bits (eg index mode and

operating mode) are defined by additioning the values of the chosen

bits:

D0 = data0 = Value 1

D1 2

D2 4

D3 8

D4 16

D5 32

D6 64

D7 128

Example: In a parameter where the bits of the chosen options are D0, D1,

D3 and D6, the programming is as follows: 1+2+8+64 = 75.

CONVENTIONS AND DEFINITIONS PAGE 13

Page 18

EFINITIONS

D

Master

SP

SN

HS

LS

D0

LSW+

LSW-

AC Axis

defines the numerical control software used by

the N2X.

The "Master" software is the part the operator

sees and uses.

Positive direction.

Negative direction.

High speed.

Low speed.

See parameter with options (previous page).

Maximum limit positive.

Minimum limit negative.

Defines a movement as described in the AC

positioning diagram page. It is a positioning

which manages for example a 2-speed three

phased (AC) unsynchronized motor. Not to be

confused with "brushless" motors.

DC Axis DC

Defines an axis movement commanded by a

nominal variable applied voltage of -10V to

+10V DC.

This management is suitable for conti nuous

current motors with servo-amplifiers,

"brushless" motors, unsynchronized motors

equipped with frequency servo-amplifiers with

an input voltage ±10V, etc.

PAGE 14 USER GUIDE N2X7

Page 19

AC POSITIONING DIAGRAM

(

)

with positive overrun

Slow speed dis tance

SP+HS

SP

Temp o

SP / SN

Overrun distance

SRET

NAX TYPE POSITIONING

Speed

Tolerance

Advanced stop(SAAV)

SN+HS

Fig. 1

without speed adjustment

Fig. 2

This type of positioning is selected by programming the proportional (P22)

and differential (P24) gain parameters at 0.

CONVENTIONS AND DEFINITIONS PAGE 15

Page 20

DC POSITIONING DIAGRAMS

U

NIDIRECTIONAL POSITIONING WITH FINAL APPROACH

OVERRUN AND ADVANCED STOP

B

IDIRECTIONAL POSITIONING WITH FINAL APPROACH

Fig. 3

PAGE 16 USER GUIDE N2X7

Fig. 4

Page 21

F

UNCTIONING OF FINAL APPROACH (DETAIL

Positioning value

Deceleration

time

Advanced stop

Final approach

speed

Slow speed

distance

Fig. 5

)

D

IRECT BIDIRECTIONAL POSITIONING

Positioning value

Acceleration

time

Deceleration

time

Fig. 6

Positioning

speed

CONVENTIONS AND DEFINITIONS PAGE 17

Page 22

This page has been left blank intentionally.

PAGE 18 USER GUIDE N2X7

Page 23

DESCRIPTION OF THE PARAMETERS

The number which precedes each parameter designates the parameter

described in this notice.

On certain CNC's, this number has no relation with the number of the

parameter of the same name which appears on the DNC.

The name of the parameter is used for reference.

A translation of these parameters is available at the end of this notice.

IMPORTANT:

The text which follows each parameter is its definition.

For adjustment of an axis, the procedure described in the "Parameter

adjustment" chapter (page 35) must be followed in order to understand the

interaction between the parameters.

P00 A

XIS TYPE

D0 & D1

D2 Rotary axis: P28 indicates the Modulo value of the axis.

D3

D4

Remark : The auto-offset system (D1 for P01) cannot be used in modes

Mode 0: DC Axis (±10V/SP/SN)

Mode 1: AC Axis or electrovalve (SP/SN/HS)

Mode 2: DC axis with a command voltage of

0 to +10V or 0 to -10V

The voltage polarity is determined by the

polarity of the parameter 15. (Preset Voltage)

With D2, the "Unotour" mode is accessed. In absolute movement, the N2X chooses the shortest possible way in order to

reach the position specified in the Modulo. Max. movement is 1

revolution.

DC axis (+/- 10V / validation)

The rotation direction is given by the polarity sign of the

voltage, the servo-amplifier being validated by the SP signal.

(Only N2XF_ & N2XE_)

1 and 2.

DESCRIPTION OF THE PARAMETERS PAGE 19

Page 24

P01 O

PERATING MODE

D0

D1

Closed loop:

In this mode the N2X makes sure that the axis does not move

away farther than the tolerance value (P03) of the target

position ( ⏐position⏐ ≤ ( ⏐target position⏐ ± tolerance)).

P19 indicates to the N2X at what distance from the target

position (% of P03) the regulator must be switched on.

DC axis

(D0, mode 0 or 2): PID is switched on.

AC axis

(D0, mode 1): An automatic positioning is carried out

immediately. This positioning will follow

the normal rules of the AC mode, i.e., with

overrun. If the bi-directional positioning

mode is chosen (without overrun), the axis

will "return" to the Slow speed distance

(P06) before positioning.

Offset recuperation:

The automatic offset compensation is active only at a standstill

when the axis is in the tolerance zone. If the offset is greater

than 100mV, the electric offsets must be regulated.

The N2X surveys the axis offset and will give a voltage in the

opposite direction to the axis movement.

Also functions for an open loop (DATA 0 not programmed). In

this case, the SP and SN outputs are permanently active. It is

not recommended to use this mode on its own but rather put it

with the closed loop regulation (D0 + D1).

D2

Positioning at maximum speed (not yet managed):

This operating mode permits rapid positioning. A very small or

zero acceleration time may also be chosen in this operating

mode.

The speed Vmax can only be obtained if a positioning speed

(P10) superior to the axis speed at maximum voltage (P16) is

programmed.

If however, the axis reaches the speed programmed in the P10

parameter, the N2X regulates the axis to a maximum at that

speed.

PAGE 20 USER GUIDE N2X7

Page 25

Positioning in "Positioning at maximum speed" mode (D2 = 1)

Maximum voltage (P16)

Fig. 7

D3

D4

D5

D6

Remark: If D5 and D6 are programmed simultaneously, only the D5

SP/SN signals not permanent in closed loop mode:

Operation identical to closed loop mode, except the SP and SN

signals are not active when the axis is within the tolerance zone

(see also P07 SP/SN TIME).

This mode may be used for an hydraulic axis, the SP/SN signals

could then manage ( by using the P07) the pressur ing up of the

valves.

In most cases, the automatic offset recuperation cannot be used

in this mode.

This mode is only valid if D0 is programmed.

Voltage Umin during regulation:

If this bit is programmed, the N2X does not take into account

the minimum operating volt age when it regulates at the

reference value with the integral gain.

Inversion of encoder count i ng direction ( quadrature mode).

Up/Down counting mode:

Input A = clock

Input B = counting direction.

function is validated, the D6 function being ignored.

DESCRIPTION OF THE PARAMETERS PAGE 21

Page 26

P02 E

NCODER RESOLUTION

This parameter defines the number of encoder impulses, that the DNC

receives per unit displayed (millimeters, degrees etc).

This parameter permits to work always with the maximum resolution allowed

by the encoder (using multiplication by 4).

This parameter allows to define a resolution up to 3 digits after the decimal

point.

This possibility allows to use practically any number of encoder impulses for

a given range and mechanical system.

The examples below demonstrate the use of this parameter. In the case where

the resolution does not allow to find a number of < 3 digits after the decimal

point, an example of the calculation of the resultant error allows you to

determine whether the error is acceptable or not.

Important : see P27

Examples

Lets take a mechanical kit, motor / ball screw directly coupled, to simplify the

examples.

Ball screw : pitch = 8mm/t

Example 1:

Display ----,--

Example 2:

Display ----,--

Example 3:

Display ----,--

MINIMUM LIMIT

Encoder:

200 imp/r.

Encoder:

250 imp/r.

Encoder:

100 imp/r.

, programming limit.

Resolution:

(200 * 4):8=100.000 that is 100 imp/mm

In this case we have 1 impulse per 100th

mm. (P02 = 100.000)

Resolution:

(250 * 4):8=125.000 that is 125 imp/mm

In this case there is no longer one impulse

per 100th mm.

The axis and the display behave as in

example 1. (P02 = 100.000)

Resolution:

(100 * 4):8=50.000 that is 50 imp/mm

In this case it is not possible to position

every 100th mm, but only every 2/100ths.

The display increments by 2/100ths.

Example 4:

Display ----,--

Example 5:

Display ----,--

PAGE 22 USER GUIDE N2X7

Encoder:

40 imp/r.

Ball screw : pitch = 15/32" (that is11,90625mm/t)

Encoder:

500 imp/r.

Resolution:

(40 * 4):8=20.000 that is 20 imp/mm

In this case the display increments by

5/100ths.

Resolution:

(500 * 4) : 11,90625 = 167,979

In this case the resolution allows correct

display for the whole length of the

trajectory, due to the 3 digits defined

after the decimal point.

Page 27

Ball screw : pitch = 5/8" (that is15,875mm/t)

Example 6:

Display ----,--

Distance covered : 1000mm

Theoretical number of impulses : 1000 x 125.984252 = 125984,252

Theoretical number of impulses = -125984,000

___________

Difference in number of impulses 0,252

Difference in mm 0.252 : 125.984252 = 0.002mm

Other method :

Programmed displacement * theoretical resolution

-----------------------------------------------------------------= effective distance

DNC resolution

1000 * 125,984252

--------------------------- = 1000.002 that is a difference of 0.002mm

125,984

Encoder:

500 imp/r.

Calculation of the accumulated error

Resolution:

(500 * 4) : 15,875 = 125,984252

In this case, the resolution obtained has

more than 3 digits after the decimal point.

(P02 = 125.984)

There will thus be an accumulated error

as a function of the distance covered.

The encod er giving the minimum error

for the distance covered must be selected.

P03 P

OSITIONING TOLERANCE

This parameter defines the distance around the positioning value in which the

axis is considered to be in position.

In order to execute a positioning, the axis must be outside the tolerance zone

of the chosen value. (AC or DC)

Note: See P01

AC Axis: With closed loop regulation (P01 = 1), if the axis is located

outside the tolerance zone, it immediately repositions

automatically. This positioning follows the normal positioning

rules for AC mode, that is with overrun. If two way positioning

is chosen (without overrun), the axis "overruns" at the

SPEED DISTANCE

The closed loop regulation operates when the axis lies within the tolerance

zone.

But, the axis is considered outside the tolerance zone (seen from the exterior)

the moment it passes the tolerance value.

(P06) before repositioning.

SLOW

DESCRIPTION OF THE PARAMETERS PAGE 23

Page 28

P04 A

DVANCED STOP

This parameter defines the distance in front of the programmed position

where the positioning orders and the voltage are cut.

This allows precise positioning of the axis by compensation of the breaking

distance due to the drive inertia.

Note: The advanced stop is not applied until the deceleration ramp

has been entered.

In the case of a positioning with final approach, the advanced

stop is not applied until after the final approach is started.

No positioning is possible in the

except when P05 is programmed greater than P04.

To prevent any troubles with AC axis, please programme P03

greater or equal than P04.

This parameter can also be used in order to accelerate the end of the

positioning of DC or brushless axes. When programming P03 = P04, the axis

card signals the end of the positioning as soon as the axis has reached the

tolerance zone of the target position.

ADVANCED STOP ZONE

,

P05 O

P06 S

VERRUN DISTANCE

The programming of this parameter allows a uni or bidirectional positioning

of the axis.

The

POSITIONING

defined).

For unidirectional positioning, the direction of the end of positioning is

defined by the polarity of this parameter:

+ = end of positioning in a positive direction (SP)

- = end of positioning in a negative direction (SN)

is bidirectional if this parameter is programmed at 0 (or not

LOW SPEED DISTANCE

DC axis

This parameter defines the distance of the final approach.

It is only active when the final approach must be equal to the overrun distance

(if programmed) in order for the positioning or overrun to be executed.

Note: Programming this parameter is unnecessary if NAX type

positioning is chosen.

AC axis

This defines the distance before the advanced stop where the engagement of

the axis is changed from high to slow speed (GV output).

If this parameter is programmed at 0, the positioning of the axis is made with

a single speed.

PAGE 24 USER GUIDE N2X7

Page 29

With DNC's equipped with N2X 102 or 103 boards, the GV output can only

be used if the indexation mode (P25) is defined without an index zone.

(Only one input-output is available either for the GV or the index zone).

P07 SP/SN T

DC axis

This delay is used in four different places:

IME

At the start of positioning where the SP/SN orders are not switched on.

This delay is used to introduce a dephasage between the switching on

of the SP/SN orders and the start of the management of the lead

voltage. This allows the system (eg. hydraulic pressure) to "prepare"

itself before the departure of the axis.

At the end of positioning at the overrun value.

After reaching the return value, the SP/SN delay is used to stabilize the

axis before starting positioning at the target value.

At the end of positioning on the target value.

After reaching the target value, the SP/SN orders are maintained (with

zero lead voltage) during the SP/SN delay to allow the servo-amplifier

to stabilize the axis at zero speed.

During closed loop regulation with D0 and D1 of P01 programmed:

when the axis leaves the tolerance zone, the SP/SN signals are

activated "SP/SN Time" seconds before the regulator intervenes.

Inversely, when the regulator has taken the axis to the aimed for value,

the same management is applied at the end of positioning at the aimed

for value.

Attention

For master softwares released before september 1990, (Refer to the list of main standard software below) and supplied with N2XDN, N2XEM, N2XFB and later software versions, the parameter P07 SP/SN Time (previously "overrun time") must be programmed to 0 with the following N2X softwares:

Main software list :

SNXEAE2 and later versions

SAXDAE2 and later versions

GTXDAB and later versions

VTXDAE and later versions

AC axis

This parameter corresponds to the waiting time before a change in the

positioning direction.

When changing the positioning direction, the positioning orders are stopped

for the time programmed in this parameter.

This allows time for the axis to stop before positioning in the other direction.

DESCRIPTION OF THE PARAMETERS PAGE 25

Page 30

P08 A

CCELERATION TIME

This parameter defines the linear acceleration time of the axis from 0 to the

POSITIONING SPEED

(P10).

P09 D

P10 P

ECELERATION TIME

DC axis

This parameter corresponds with the linear deceleration time of the axis form

the positioning speed (P10) to 0.

Note: When the software allows the operator to choose speeds less

than the "

positioning speed, the acceleration and deceleration times are

reduced and adapted automatically.

AC axis

This time corresponds to the axis stabilization time after the (SP/SN)

commands have been cut at the arrival at the advanced stop value.

Effectively, the cutting of the displacement commands being made at an

appreciable speed, the axis will continue, because of its inertia, to move

during a certain time before stabilizing on the positioning value. The P09 is

used to take into account this axis stabilization time before considering that

positioning is finished.

POSITIONING SPEED

OSITIONING SPEED

" (P10), for speeds less than the

This parameter defines the maximum axis speed for

mode.

Programming limits :

P10 * P02 < 2500.00 units/sec

P11 F

PAGE 26 USER GUIDE N2X7

INAL APPROACH SPEED

This parameter (if programmed) defines the type of DC positioning with final

approach.

It defines the axis speed at the end of positioning.

Programming limits:

P11 * P02 < 625.00 units/sec

POSITIONING

in automatic

Page 31

P12 I

NDEXING SPEED

This parameter defines the speed used to take up the index, or for leaving the

index zone.

If this parameter is not programmed, the index speed will be equal to half the

P10 speed.

Note : In AC mode, these movements will always be made at the

lowest speed.

Programming limits identical to P10.

P13 M

P14 M

ANUAL SLOW SPEED

This parameter defines slow speed in manual mode.

If this parameter is not programmed, the manual slow speed will be equal to

an 8th of the P10 speed.

ANUAL HIGH SPEED

This parameter defines high spee d in manual mode.

If this parameter is not programmed, the manual high speed will be equal to a

half of the P10 speed.

DESCRIPTION OF THE PARAMETERS PAGE 27

Page 32

P15 P

RESET VOLTAGE

This parameter determines the preset control voltage for an axis, regardless of

the influence of the P-I-D regulator.

This voltage is programmed for the maximum positioning speed (P10), and

automatically adapted proportionally for all other speeds (Manual,

acceleration, deceleration etc.).

For DC axes, programming of this parameter is especially useful for drive

systems which do not allow high gains. (E.g. hydraulic axes or drive systems

with considerable play).

The programmed value must not exceed the lead voltage for positioning at

maximum speed (P10).

If P15 has a negative sign, the applied voltage furnished by the N2X is

inversed. It is an inversion of the applied voltage polarity without changing

the references.

This parameter must be programmed for type 2 axes (controlled with a

voltage of 0 to +10 V or 0 to -10 V) and NAX-type positioning. (See "DC

axis in NAX mode", page 41).

The sign of the parameter determines the polarity of the lead voltage for a

type 2 axis.

Type 2 axis : commanded by a voltage included between 0 and 10 V only

or 0 and -10 V only.

P16 M

Programming limit :

The following ratio must be respected.

P15

--------- < 0,077

P10*P02

P15 [Volt]

P10 [units/s]

P02 [impulse/unit]

AXIMUM VOLTAGE

When calculating an output DA voltage, the axis card limits the voltage to a

maximum at that voltage at the value programmed in P16.

This voltage must correspond to the voltage with which the axis reaches its

maximum speed.

This parameter is optional but can be programmed to insure a certain safety if

at maximum speed the voltage is relatively weak (1 to 7 VDC for ex.).

PAGE 28 USER GUIDE N2X7

Page 33

P17 M

g

INIMUM VOLTAGE

This value is the minimum voltage which must be applied to the axis in order

to move it.

This parameter is particularly useful for overlap valves.

Example of an overlap valve :

Speed

Lead

voltage

Offset

Minimum volta

In this example, the offset voltage (P18) is used to make the two movement

directions symmetrical.

e

Fig. 8

DESCRIPTION OF THE PARAMETERS PAGE 29

Page 34

The figure above describes the functioning of the minimum operating voltage .

Ur (U regulator) being the voltage supplied by the regulator, to which is

superimposed the value of the offset and Umin, which gives the applied

voltage Uc (U applied) furnished by the axis card.

U

Umin

Offset

U r

t

P18 O

Note: The automatic offset compensation (D1 P01) is purposeless if

the system requires a minimum voltage.

FFSET VOLTAGE

Permits compensation of the drive offset.

(N2X board offset voltage, potential difference between the N2X, the servo-

driver etc.)

It can also be used to make the functioning of an overlap valve symmetric

(see figure 8).

Note: This parameter is added to the offset measured if an automatic

offset compensation is programmed (D1 P01).

Tolerance zone

Fig. 8a

PAGE 30 USER GUIDE N2X7

Page 35

P19 C

LOSED LOOP TOLERANCE

This parameter indicates to the N2X at what distance of the target position

(% of P03) the regulator must be activated in order to maintain the axis

within the positioning tolerance (P03).

See P01.

If this parameter is set to 0, with P01, Closed Loop, at 1, when the axis

regulates at the position, the voltage on the regulator is maintained even if

the axis returns to the tolerance zone, which in this case corresponds to

one impulse. In no rmal functioning mode, t he regulator d oes not intervene

any more as soon as the axi s has been brought back to its close d loop

position.

P20 M

P21 S

AXIMUM FOLLOWING ERROR

This parameter defines the maximum deviation between the theoretic and real

axis position.

If the maximum is exceeded, the positioning of the axis is stopped and an

error is displayed in the interactive field.

This is a security parameter. It is thus recommended to program it

correctly.

To do this, once the axis is perfectly adjusted, a series of positionings at full

speed should be made and this parameter reduced until the limit at which the

axis functions without creating any errors is found. T hen a value giving a

safety margin is programmed (increase approx. 20%).

The values found are largely dependant on the reaction time of the drive

system.

If not programmed = no test is made.

URVEILLANCE TIME

This parameter defines the maximum time which passes between the

reception of two impulsions by the axis board from the moment an axis

movement is commanded.

An error is signalled in the event of a malfunction.

If an error occurs, an emergency stop is made.

It is a security parameter. It is thus recommended to program it

correctly.

To do this, once the axis is perfectly adjusted, a series of positionings at

minimum spee d should be made and this parameter reduced until the limit at

which the axis functions without creating any errors is found. Then a value

giving a safety margin is programmed (increase approx. 20%).

The values found are largely dependant on the reaction time of the drive

system.

DESCRIPTION OF THE PARAMETERS PAGE 31

Page 36

P22 P

ROPORTIONAL GAIN

This gain intervenes during the entire positioning of the axis as well as during

the running of a closed loop.

This parameter corrects the difference between the real axis position and

theoretical trajectory.

P23 I

P24 D

NTEGRAL GAIN

The integral gain can intervene at the end of positioning when the theoretical

trajectory finishes before the end of positioning.

It is especially active during the closed loop regulation, when in position.

Note: The closed loop regulation in position is switched on as soon as the

axis has reached its tolerance value.

IFFERENTIAL GAIN

The differential regulation is active during the whole of positioning as well as

during a closed loop in position.

This parameter is used especially for stabilizing the drive system during

acceleration and deceleration.

Its programming is needed particularly for servo-valve drives and hydraulic

valves, and also for DC motor drives without tacho.

Note: Programming 0 on parameters P22 and P24 defines the NAX

type of functioning mode.

In this mode, no speed adjustment is made during positioning

until the beginning of the deceleration ramp is reached, and the

preset voltage (P15) is used.

A linear deceleration ramp is applied in relation to the

distanced covered (and not in relation to time).

PAGE 32 USER GUIDE N2X7

Page 37

P25 I

NDEX MODE

D0

D1

D2

D3

D4

D5

D6

If this parameter is not programmed, the DNC does not require an index on

the relevant axis.

An error is signalled if at the beginning of indexing, the axis lies on the index

zone, having programmed an index mode with an index zone but without an

automatic outlet from the zone.

if index zone 24 V

if index 5 V (if not indexing uniquely on the index zone)

if index take up in SN (if not SP)

when taking the index maintains the axis in the index zone. (If

not automatically leaves the index zone).

axis equipped with an absolute encoder (compatible).

(This option is only available on certain Master softwares).

Authorization to use relative 2 mode.

The counter is reset before the start of positioning (This option

is only available on certain Master softwares).

N2XF_ and N2XH_ only:

Set of continuous indexing mode. If the conditions set by D0

and D1 are respected, the axis will index. However, the D1

weight is essential.

P26 I

AC axes

For the AC axes, on the N2X 102 and 103 boards, a two-speed (GV) function

is not possible unless the index is 5 V, the index zone input being no longer

available (used for the HS output).

As only one Input/output is available per axis, the index zone function can

only be used if the AC axis is not using the HS output for a second speed.

The programming or not of operation with an index zone in this parameter

configurates the board with a "HS output" or an "index zone" input.

The programming of the slow speed distance also decides the utilization of

the output for the HS.

NDEX POSITION

This parameter defines the index position at which the axis counter is loaded

on reaching the index.

DESCRIPTION OF THE PARAMETERS PAGE 33

Page 38

P27 M

INIMUM LIMIT

This parameter defines minimum axis limit.

If this parameter is not programmed, the axis is never activated.

Attention: Certain software, having a configuration which can be

P

ROGRAMMING LIMITS FOR THE MINIMUM AND

-

modified, have the particularity to validate the axis using this

parameter.

It is thus indispensable to program this parameter as soon as the

machine is installed.

The non-programming of this parameter in this type of software

suppresses the axis display on the screen and necessitates a

modification of the axis wiring list.

P28 M

MAXIMUM LIMITS DEPENDING ON THE RESOLUTION

The programming of t he minimum and maximum limits and the resolution

encoder is limited to a ratio with the following formula :

(|P28 - P27|)*P02 must be less than 8386608

P28 = LSW+ in units

P27 = LSW- in units

P02 = Resolution encoder in impulses/unit

|P28 - P27| = physical separation between the LSWs

If P28 is programmed at 99999.99 and P27 at -99999.99, the maximum

RESOLUTION ENCODER

Note: only the overruns (or screw backlash adjustment) programmed in P5

will be able to bypass the electronic limit switches.

AXIMUM LIMIT

This parameter defines the maximum axis limit.

Its programming is necessary for security reasons.

P02 will be 41.000 imp/unit.

+

Programming limits : see P27

PAGE 34 USER GUIDE N2X7

Page 39

ADJUSTMENT OF THE AXES FUNCTION PARAMETERS

Important All parameters not mentioned will be considered as undefined.

Effectively, the different methods of adjustment take into

account their inherent values.

XIS AND VERIFICATION DEFINITIONS

A

Define the type of axis (P00):

Undefined = DC axis or brushless (±10 V)

Define the resolution encoder (P02):

Undefined = 100.000 impulse/mm

For DC or brushless axes:

Define the proportional gain (P22) at a low value (eg. 10).

Define the integral gain (P23) at 0.

Define the limits (LSW):

negative (P27) and positive (P28) with a sufficient safety margin, and

in such a way that they can be reached with a manual movement (see

P27 "Programming limits").

Load a value into the axis counter:

(Axis set) taking into account the same origin as for the definition of

the LSWs (P27 and P28).

ERIFICATION OF ROTATION AND COUNTING

V

DIRECTIONS

Verification of the applied voltage:

Make a number of brief manual movements (manual LS)

The rotational direction of the axis must correspond to that of the

command (manual + or manua l -).

If this is not the case two solutions are applicable:

a) Inverse the applied voltage connections

b) Program P15 at a negative value (eg. -0,001).

Verification of the encoder:

Make a number of brief manual movements (manual LS)

The counting direction (see position display) must correspond to that

of the command (manual + or manual -).

If this is not the case, inverse the encoder signals, or program the

inversion of the counting direction (D5 of P01).

ADJUSTMENT OF THE AXES PAGE 35

Page 40

FFSET ADJUSTMENT AND MINIMUM VOLTAGE

O

It is important to go through this stage of adjustment to balance the axis

function before starting adjustment of positioning.

AC axis (asynchronous 1 or 2 speed motors):

For an AC axis, it is not necessary to make this adjustment.

DC axis or brushless without minimum voltage:

able to remain in closed loop so the automatic offset compensation

does not cause any vibration.

Just program D1 of P01. Make a manual movement, then when

stopped verify that the system offset is less than 100mV.

Unable to remain in closed loop

a) Program the gain parameter P22 at 0.

b) Try a manual movement in both direc tions.

Program a voltage opposite to the direction of movement in the offset

voltage parameter (P18).

Adjust P18 until the axis movement is as little as possible.

Remark: If the absolute value of the measured offset voltage is greater

than 100 mV, the cause must be found in the system. Such a

high offset voltage is not considered to be normal.

Axis with overlap voltage: (See P17)

(Typically for proportional valves)

a) Program the parameters P17, P22 and P23 at 0.

b) Increase the minimum voltage (P17) until an axis movement in

either direction during a manual displacement command (

or

c) Retain this value (Ua).

d) Continue to increase P17 until an axis movement in the other

direction can be detected, and retain this value (Ub).

e) Program the value (Ua + Ub)/2 in the M

parameter.

f) The

overlap.

The

manner:

P18 = Ub - Umin (P17) if Ub corresponds to positive direction.

P18 = Umin (P17) - Ub if Ub corresponds to negative direction.

keys) can just be detected.

OFFSET VOLTAGE

OFFSET VOLTAGE

(P18) allows to symetrically adjust the

(P18) is programmed in the following

INIMUM VOLTAGE

(P17)

PAGE 36 USER GUIDE N2X7

Page 41

DJUSTING THE POSITIONING PARAMETERS

A

All positioning tests can be made (unless otherwise specified) with

movements in manual high speed (HS).

The positioning values to be reached being, in this case, the positive and

negative Limit Switches (LSW).

DC

AXIS WITH

Important: The use of a digital storage oscilloscope, connected to the lead

a) Program the

(P14) to the nominal positioning speed recommended by the

manufacturer.

b) Increase the

reach the level of HS speed (with a sufficiently long movement). That

is a stable applied voltage situated between +9,5V and -9,5V

depending o n the direction of movement.

PID

ADJUSTMENT

voltage, facilitates adjustment and interpretation of the results.

1) Determination of the POSITIONING SPEED parameter (P10)

POSITIONING SPEED

PROPORTIONAL GAIN

High speed positioning

(P10) and the

(P22) up to a value allowing to

MANUAL HIGH SPEED

~8-9V

Fig. 10

c) The lead voltage for the cruising speed should be in the region of 8V

or 9V (8V if important load variations are expected).

Three cases can be observed:

1. The lead voltage is located around the recommended values (Refer

to paragraph "Determination of the positioning speed (c)", page

37). The speed (P10) can be considered as correct.

ADJUSTMENT OF THE AXES PAGE 37

Page 42

2. The lead voltage is less than the recommended values (Refer to

paragraph "Determination of the positioning speed (c)", page 37).

If the programmed speed correspond in reality to the systems

maximum speed and the voltage for that speed is too weak

(<7V), the servo-amplifier must be adjusted so that it needs, for

this speed, a command voltage as near as possible to the

recommended values.

If on the contrary, the programmed speed does not correspond

to the maximum speed of the system, the P10 and P14 speeds

can be increased until the required voltage is obtained.

3. The lead voltage is greater than the recommended values (9,5 to

10V).

The programmed speed is too high and the system cannot function

in good conditions at this speed.

If the programmed speed really correspond to the performance

desired, either the system must be re-dimensioned (motor,

servo-amplifier), or the system's functioning checked to find the

cause of this unexpected performance.

In the opposite case, measure the voltage again by decreasing

the speeds P10 and P14 until the desired voltage is obtained.

2) Determination of the PROPORTIONAL GAIN (P22)

a) Increase the

PROPORTIONAL GAIN

progressively until oscillations

(vibrations) or an important overshoot of the target position (FC)

occurs.

Fig. 11

b) Program P22 at a value equal to the proportional gain as found above

less 10 to 20%.

3) Determination of the DIFFERENTIAL GAIN (P24)

Programming this parameter is not usually necessary for all axes fitted with a

currant loop.

In all cases P24 is useful for improving the acceleration / deceleration ramps.

It allows especially to program acceleration times which, without the

differential gain, would have saturated the lead voltage.

a) First program P24 at 1 then progressively increase its value until

either oscillations (vibrations) or an overshoot occur.

PAGE 38 USER GUIDE N2X7

Page 43

b) Program P24 at a value equal to the differential gain as found above

less 20%.

4) Determination of the ACCELERATION TIME (P08)

a) Program P08 at a value sufficient to allow to reach the maximum high

speed without saturating the lead voltage. (It is preferable to use an

oscilloscope on the lead voltage)

P08

~0,5 s

Fig. 12a

b) Decrease progressively the acceleration time until a saturation during

the acceleration ramp appears.

P08 saturation +/-10V

Fig. 12b

c) Program P08 at a value equal to the limit acceleration time as found

above plus 10 to 20%.

ADJUSTMENT OF THE AXES PAGE 39

Page 44

ok

Fig. 12c

5) Determination of the DECELERATION TIME (P09)

a) Program P09 at a value sufficiently high to allow to reach the target

value without overshooting.

b) Decrease progressively the deceleration time until an overshoot

appears.

c) Program P09 to a value equal to the limit deceleration time as found

above plus 10 to 20%.

6) Determination of the INTEGRAL GAIN (P23)

a) Increase progressively the integral gain until a deterioration in the

positioning precision (Overshoot) is noted.

b) Program P23 to a value equal to the limit integral gain as found above

less 10 to 20%.

Remark: This value must be further reduced if, in the case of a

positioning in a closed loop (D0 of P01), oscillations or

vibrations appear at the end of positioning.

Proceed with the final adjustment of the parameters (refer to page 44).

PAGE 40 USER GUIDE N2X7

Page 45

DC A

XIS IN

NAX

MODE (WITHOUT

PID

LOOP

)

This mode is selected by programming the

DIFFERENTIAL

This type of positioning is especially useful for the axes which do not support

the PID loop adjustment.

NAX positioning should also be easier to adjust for axes where performance

is not the main criteria.

1) Definition of the main parameters

Program the

taking into account the axis's dynamism.

Attention: A too short time would unnecessarily charge the system

Program, initially, a relatively long

(usually 1.000s).

Program the

manufacturer (the precision of this parameter is of only secondary

importance). Program P14 at the same value.

Program the

the maximum speed.

2) Determination of the FINAL APPROACH SPEED (P11) and the ADVANCED STOP (P04)

GAINS

(P24)

ACCELERATION TIME

(mechanics, motor, hydraulics etc.).

POSITIONING SPEED

PRESET VOLTAGE

to 0. (see NAX positioning diagram)

PROPORTIONAL

(P08) as short as possible but

DECELERATION TIME

(P10) recommended by the

(P15) at the voltage necessary to reach

(P22) and

(P09)

a) Program, initially, a

POSITIONING SPEED

the

b) Decrease progressively this value (P11) until relatively precise

positioning is obtained.

c) Regulate the value of the

as precise as possible.

3) Determination of the DECELERATION TIME (P09)

a) Decrease progressively the value of the

until a deterioration of the positioning precision is noted.

b) Program P09 to a value equal to the deceleration time as found above

plus 10 to 20%.

4) The INTEGRAL GAIN (P23)

can be determined, if you wish to use it, in the same way as in chapter

"Determination of the integral gain" (page 40).

FINAL APPROACH SPEED

(P10).

ADVANCED STOP

(P11) equal to 10% of

(P04) to obtain positioning

DECELERATION TIME

(P09)

ADJUSTMENT OF THE AXES PAGE 41

Page 46

AC A

XIS

1) Definition of the main parameters

a) For unidirectional positioning:

1 Program, initially, a relatively long

(eg. 15% of the maximum axis movement).

The polarity of this parameter defines the direction in which you

wish positioning to be finished.

2 Program, initially, an SP/SN

2.000s).

b) For a 2 speed AC axis :

Program, initially, a relatively long LS

the maximum axis movement ).

c) The

a) Program P04 at 0 or verify that it is not programmed.

b) Make several manual LS movements (

c) Note the axis overshoot in relation to the reference position (the limit

DECELERATION TIME

dephasage between the cutting of the SP/SN orders and the end of

positioning signal.

2) Determination of the ADVANCED STOP (P04)

direction in which positioning must finish. These movements must be

made right up to the limit switch so that the axis can finish its

positioning.

switch) and program this value on the advanced stop (P04).

parameter (P09) can be used to introduce a

OVERRUN DISTANCE

TIME

(P07) relativel y high ( eg.

DISTANCE

(P06) (eg. 10% of

or key) in the

(P05)

d) Make several other movements, of different lengths, (always on the

limit switch and in manual LS) and regulate, if necessary, the

ADVANCED STOP

obtained.

3) Determination of the LS DISTANCE (P06)

(only for a 2 speed AC axis)

a) Make several movements, up to the limit switch, in manual LS (always

in the direction of the end of positioning) then decrease progressively

the LS distance until the positioning precision diminishes.

b) Program P06 at a value equal to the limit LS distance as found above

plus 10 to 20%.

(P04) until a positioning as precise as possible is

PAGE 42 USER GUIDE N2X7

Page 47

4) Determination of the SP/SN TIME (P07)

(only for unidirectional positioning)

a) Make several positioning with overrun (in auto and semi-auto) and

observe, on the motor or position display, where the axis stops before

changing direct ion.

b) Decrease progressively the SP/SN

(P07) until the axis changes

TIME

direction before stopping completely.

c) Program P07 at a value equal to the limit overrun time as found above

plus 10 to 20%.

5) Determination of the OVERRUN DISTANCE (P05)

(only for unidirectional positioning)

a) Make several positioning, with overrun, of different lengths (in auto

and semi-auto) then decrease progressively the

OVERRUN DISTANCE

(P05) until the positioning precision diminishes.

b) Program P05 at a value equal to the limit overrun distance as found

above plus 10 to 20%.

ADJUSTMENT OF THE AXES PAGE 43

Page 48

INAL REGULATION OF THE PARAMETERS

F

P

ROGRAMMING THE SECONDARY PARAMETERS

Closed loop (DO P01), Tolerance (P02), High speed voltage (P15), etc.

1) Regulation of the MINIMUM and MAXIMUM LIMIT S (P27 and P28)

Program the min imum and maximu m limits for normal use of the axis .

2) Programming the INDEX MODE (P25)

(If you wish the origin to be taken automatically)

Regulation of the i ndex value (P26).

Programming, if necessary, of the indexing speed (P12)

3) Verification and regulation of positioning

Finally several positioning (in auto and semi auto) must be made with long,

average and then very short (minimum movement which can be asked of the

axis) movements in both directions. Then regulate (if necessary) certain

parameters to improve the precision or the rapidity of positioning.

For the DC axes, P14 (Vmax/2 by default) can be deleted or programmed at

the desired value.

PAGE 44 USER GUIDE N2X7

Page 49

ST

INDEXATION OF THE

1

Note : The availability of this function depends on the "master"

software.

N2X

AXES

P

ROCEDURE

a) switch on the DNC or reset.

b) position the stop manually against a known reference value (or against

c) select the axis set page (key in position 2), execute the set of the

d) select the Machine parameter pages (key in position 3)

e) press the start key

Remark : the taking of the index can only be done separately, axis by

the die for the X axis), or measure its position exactly.

axis(es), (refer to the DNC programming manual).

- program the index mode required.

- position the cursor on the "index value" field.

- the axis goes to take its index.

- once the index is found, the DNC displays the "Index OK"

message in the interactive field.

axis.

ADJUSTMENT OF THE AXES PAGE 45

Page 50

This page has been left blank intentionally.

PAGE 46 USER GUIDE N2X7

Page 51

DDITIONAL

A

Choice of the 8 I/O

configuration

N2X

In some cases, it's necessary to implant one or two axes managed by the

master. The additional axes should not be complicated, only some operating

modes are implanted. This or theses additional axes use inputs/ouputs and the

encoder of the Y2 Axis (1

On DNC 60, it's possible to implant one axis at the master, for this, choose

the 8 I/O configuration on the MACHINE PARAMETERS 01 and search

configuration by default in the inputs/outputs pages or configure at least the

output SP X3. When this is done, on the first machine parameters page, N2X

software version is displayed.

The parameters who are not longer managed, are displayed with a dot after

the parameter's number.

SOFTWARE ON MASTER

st

definite axis) or Y1.

N2X software on master

MACHINE PARAMETERS -01- IGNORE

Softs: GIXMDP/ZIAMBA3 PIC:AA5

N2XMnf/ZZAMBA3 N2XSA1 Key:0

Language: [GB] FR GB DE IT ES PT SE NL

CONFIGURATION 8 I/O: 1

X1: X1 X2: X2

00 Axis type __ __

01 Operating mode __ __

02 Encoder reso. (I/mm) ___.___ ___.___

03 Tolerance 0.05 0.05

04 Advanced stop _.__ _.__

05 Overrun distance ___.__ ___.__

06 Slow speed distance __.__ __.__

07 SP / SN time _.___ _.___

08 Acceleration time 0.300 0.300

09 Deceleration time 0.400 0.400

OUTPUT CONFIGURATION IGNORE

Put 1 in this field to

find configuration by

default

SEARCH CONFIGURATION BY DEFAULT _

--- MB6 J10 --- 10100000

09: CuthAuth 10: Blade Up

11: F1Dig SP 12: F1Dig SN

13: F2Dig SP 14: F2Dig SN

15: F5Dig SP 16: F5Dig SN

--- MB6 J11 --- 00000000

09: 10:

11: 12:

13: 14:

15: SP X3 16: SN X3

N2X SOFTWARE ON MASTER

PAGE 47

Page 52

N2X

PARAMETERS

For a complete description, see the paragraph above corresponding to the

parameter.

- D0 & D1: Mode 0 (DC Axis +/-10V/SP/SN), mode 1 (AC Axis) et mode 2

(DC Axis with a command voltage of 0 to +10V or 0 to –10V) controlled,

mode 3 non-controlled

- D4 DC Axis (+/-10V / Validation) controlled

- The other bits are not controlled.

- D0 Closed loop, makes a repositioning when leaving the positioning

tolerance (mode DC et AC).

- D5 Inversion of t he counting dire ction.

- The other bits are not controlled.

P00 Axis Type

P01 Operating Mode

P02 Encoder resolution

- Parameter controlled according to N2X description.

P03 Positioning tolerance

- Parameter controlled according to N2X description.

P04 Advanced stop

- Parameter controlled according to N2X description.

P05 Overrun distance

- Parameter controlled according to N2X description.

P06 Slow speed distance

- Parameter controlled according to N2X description.

P07 SP/SN Time

- Parameter controlled only in AC mode.

P08 Acceleration time

- This parameter defines the linear acceleration time of the axis from the

offset voltage to preset voltage (P15).

PAGE 48

P09 Deceleration time

- This parameter is used for the calculation of the braking ramp in case of

stopping or returning.

USER GUIDE N2X7

Page 53

P10 Positioning speed

- This parameter is used for the voltage calculation for:

- Positioning normal mode

- Positioning manual mode

- Positioning indexation mode.

P11 Final approach speed

- This parameter is used for the voltage calculation of the final approach. At

the end of positioning, the output voltage is limited to the final approach

voltage, even if the calculated voltage is lower.

P12 Indexing speed

- this parameter is used for the voltage calculation of the maximum voltage

when indexing.

P13 P14 Manual slow speed and Manual high speed

- These parameters are used for the calculation of the manual voltages SS and

HS.

P15 Preset voltage OBLIGATORY parameter

- This parameter is used as maximum voltage for the movements in

positioning speed. For the other movement types, the used voltage is only a

proportion of this voltage.

Example:

Manual slow speed

Manual voltage SS = Preset voltage —————————

Positioning speed

- If the sign of this machine parameter is negative, the output voltage is

inverted (same as N2X).

P16 Maximum voltage

- Parameter non-controlled.

P17 Minimal operating voltage

- Parameter non-controlled.

P18 Offset voltage

- Parameter controlled according to N2X description.

P19 Closed loop tolerance

- Parameter non-controlled.

P20 Maximum following error

- Parameter non-controlled.

N2X SOFTWARE ON MASTER

PAGE 49

Page 54

P21 Encoder surveillance time

- Parameter non-controlled.

P22 Proportional gain

- This parameter is used for the calculation of the voltage to apply on the

axis. The output voltage is equal to the remaining distance up to the aimed

dimension multiplied by the proportional gain. The resulting voltage is

limited to the final approach voltage and the limitation voltage according to

the movemen t type.

P23 Integral gain

- Parameter non-controlled.

P24 Differential gain

- Parameter non-controlled.

P25 Index mode

- Parameter partially controlled. The controlled data are the followings:

- D0 if 24V indexation zone.

- D1 if index 5V.

- D2 if index research in SN.

- D3 if axis blocking in the index zone with error message. No

automatic output possible.

- The other bits are not controlled.

P26 Index position

- Parameter controlled according to N2X description.

P27 et P28 Minimum limit - and maximum limit +

- Parameter controlled according to N2X description.

PAGE 50

USER GUIDE N2X7

Page 55

E

XAMPLE

Attention: In this example, only minimums parameter which allow the

AC 2

SPEED MOTOR

operation of the axis have a value.

MACHINE PARAMETERS -01- IGNORE

Softs: GIXMDP/ZIAMBA3 PIC:AA5

N2XSA1 Key:0

Language: [GB] FR GB DE IT ES PT SE NL

CONFIGURATION 8 I/O: 1

X3: X3

00 Axis type 1

01 Operating mode 1

02 Encoder reso. (I/mm) 100.000

03 Tolerance 0.1

04 Advanced stop 0.2

05 Overrun distance ___.__

06 Slow speed distance 1.50

07 SP / SN time 0.2

08 Acceleration time _.___

09 Deceleration time 0.400

MACHINE PARAMETERS -02- IGNORE

X3: X3

10 Positioning speed 30.00

11 Fin.approach speed __.__

12 Indexing speed ____.__

13 Manual slow speed ___.__

14 Manual high speed ____.__

15 A priori voltage __.___

16.Maximum voltage

17.Minimum voltage

18 Offset voltage __.___

19.Closed loop toler.

20.Max. follow.error

21.Surveillance time

22 Proportional gain _____

23 Integral gain

N2X SOFTWARE ON MASTER

PAGE 51

Page 56

(

)

MACHINE PARAMETERS -03- IGNORE

X3: X3

24 Differential gain

25 Index mode 2

26 Index position 980.35

27 Min. limit - 50.00

28 Max. limit + 1000.00

The parameters at undef ( __.__ ) allow to improve the adjustment of the axis.

Some parameters have a default value in spite of the fact they are at undef.

See the description in the paragraph N2X Board parameters.

SP+HS

Tempo

SP / SN

Slow speed distance

SP

Overrun distance

SRET

Speed

Tolerance

Advanced stop(SAAV)

SN+HS

PAGE 52

USER GUIDE N2X7

Page 57

E

XAMPLE

Attention: In this example, only minimums parameter which allow the

DC M

OTOR

operation of the axis have a value.

+/- 10VDC

MACHINE PARAMETERS -01- IGNORE

Softs: GIXMDP/ZIAMBA3 PIC:AA5

N2XSA1 Key:0

Language: [GB] FR GB DE IT ES PT SE NL

CONFIGURATION 8 I/O: 1

X3: X3

00 Axis type 0

01 Operating mode 1

02 Encoder reso. (I/mm) 100.000

03 Tolerance 0.1

04 Advanced stop _.__

05 Overrun distance ___.__

06 Slow speed distance 1.50

07 SP / SN time _.___

08 Acceleration time 0.300

09 Deceleration time 0.400

MACHINE PARAMETERS -02- IGNORE

X2: X2

10 Positioning speed 130.00

11 Fin.approach speed 5.00

12 Indexing speed 50.00

13 Manual slow speed ___.__

14 Manual high speed ____.__

15 A priori voltage +9.400

16.Maximum voltage

17.Minimum voltage

18 Offset voltage __.___

19.Closed loop toler.

20.Max. follow.error

21.Surveillance time

22 Proportional gain 10

23 Integral gain

N2X SOFTWARE ON MASTER

PAGE 53

Page 58

MACHINE PARAMETERS -03- IGNORE

X2: X2

24 Differential gain

25 Index mode 1

26 Index position 983.50

27 Min. limit - 35.00

28 Max. limit + 1000.00

The parameters at undef ( __.__ ) allow to improve the adjustment of the axis.

Some parameters have a default value in spite of the fact they are at undef.

See the description in the paragraph N2X Board parameters.

.

PAGE 54

USER GUIDE N2X7

Page 59

INDEX

1st indexation, 45

AC Axis, 14, 42

AC Positioning, 15

Acceleration time, 26, 41, 48

Adjustment, 35

Advanced stop, 24, 41, 42, 48

Axis display, 34

Axis is never activated, 34

Axis Type, 19, 48

Axis wiring list, 34

Bits, 13

Closed loop, 20, 25, 32

Closed loop tolerance, 49

Conventions, 13

Copyright, 3

Counting, 35

D0, 14

Index position, 33, 50

Index zone, 25

Indexing speed, 27, 49

Inertia, 24

Integral gain, 32, 40, 41, 50

Inversion of encoder count i ng, 21

Inversion polarity, 28

License, 3

LS, 14