Code 3 H2Covert Siren User Manual

INSTALLATION & OPERATION MANUAL

MODEL 3599L5

H2CovertTM Remote Siren System with Hand-Held Controller

WARNING

WARNING

Sirens produce loud sounds that may damage hearing

• Wear hearing protection when testing

• Use siren only for emergency response

•Roll up windows when siren is operating

•Avoid exposure to the siren sound outside of vehicle

|

|

|

Contents: |

|

|

|

|

Introduction |

2 |

|

|

|

Standard Features |

3 |

|

|

|

Unpacking & Pre-Installation |

3 |

|

|

|

Installation & Mounting |

3 |

|

|

|

Connections |

4 |

|

|

|

Operation |

7 |

|

|

|

Specifications |

12 |

|

|

|

Maintenance |

12 |

|

|

|

Parts List |

12 |

|

|

|

Troubleshooting |

14 |

|

|

|

Notes |

15 |

|

|

|

Warranty |

16 |

|

|

Read all instruction and warnings before installing and using. |

|

|

IMPORTANT: |

|

|

||

|

|

This manual must be delivered to the end user of this equipment. |

|

|

|

INSTALLER: |

|

||

1

Introduction

The 3599L5 uses an easily concealable remote hand held controller coupled to an electronic siren, all designed to meet the needs of emergency vehicles. This series incorporates many of the popular features of existing Code 3 siren systems as well as some new features such as new siren tones, 4 auxiliary controls, EU Lock, and Title 13 Compliance. The purpose of this document is to aid in the setup and installation of the 3599L5, and to provide instructions for its proper operation.

Sirens are an integral part of an effective audio/visual emergency warning system. However, sirens are only short range secondary warning devices. The use of a siren does not insure that all drivers can or will observe or react to an emergency warning signal, particularly at long distances or when either vehicle is traveling at a high rate of speed. Sirens should only be used in a combination with effective warning lights and never relied upon as a sole warning signal. Never take the right of way for granted. It is your responsibility to be sure you can proceed safely

SIREN PRODUCTS before entering an intersection driving against traffic, or responding at a high rate of speed.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring. Read and follow the manufacturer’s instructions before installing this device.The vehicle operator should check the equipment daily to insure that all features of the device operate correctly.

Tobeeffective,sirensmustproducehighsoundlevelsthatpotentiallycaninflicthearingdamage.

Installers should be warned to wear hearing protection, clear bystanders from the area and not to operate the siren indoors during testing. Vehicle operators and occupants should assess their exposure to siren noise and determine what steps, such as consultation with professionals or use of hearing protection should be implemented to protect their hearing.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user should check all applicable city, state and federal laws and regulations. Code 3, Inc., assumes no liability for any loss resulting from the use of this warning device.

Proper installation is vital to the performance of the siren and the safe operation of the emergency vehicle. It is important to recognize that the operator of the emergency vehicle is under psychological and physiological stress caused by the emergency situation. The siren system should be installed in such a manner as to: A) Not reduce the acoustical performance of the system, B) Limit as much as practical the noise level in the passenger compartment of the vehicle, C) Place the controls within convenient reach of the operator so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly protect and use caution around live electrical connections. Grounding or shorting of electrical connections can cause high current arcing, which can cause personal injury and/or severe vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

2

Standard Features

The 3599L5 system offers the following features:

-Primary Tones: Wail, Yelp, Hi-Lo, Hyper-Yelp, Hyper-Lo, Whoop, Manual Wail, Air Horn

-Vehicle Light Control Buttons – 7 levels: 3 Progressive, Auxiliary

-PA with Built-In Noise Cancelling Microphone

-Integrated Volume Control

-Radio rebroadcast

-Stand-By

-Siren Scroll

-Park Kill

-Horn Ring Transfer

-EU Lock

-Backlit Buttons with On/Off Color Change

-Three (3) Backlight Dimming Levels and Backlight Off Option

-Two (2) Push Button Programmable Siren Controls

-Two (2) Programmable Air Horn Pitch Controls

-Externally accessible 20A fuse

-25’ Extension Cable

Unpacking & Pre-Installation

After unpacking the siren, carefully inspect the unit and associated parts for any damage that may have been caused in transit. Report any damage to the carrier immediately.

Parts included in the box:

-Siren (amplifier)

-Hand-Held Controller with Base

-25’ Extension Cable

-Parts Bag

Installation & Mounting

The hand-held controller may be mounted in various locations in the vehicle: below the dash, on the tunnel, etc. using the hardware supplied. Ease of operation and convenience to the operator should be the prime consideration when mounting the siren and controls. The amplifier may be mounted at an appropriate location within the vehicle, and the 25’ extension cord can be used to couple the hand-held controller to the amplifier.

All devices should be mounted in accordance with the manufacturer's instructions and securely fastened to vehicle elements of sufficient strength to withstand the forces applied to the device.

Ease of operation and convenience to the operator should be the prime consideration when mounting the siren and controls. Adjust the mounting angle to allow maximum operator visibility. Do not mount the Hand-Held Controller in a location that will obstruct the drivers view. Mount the Hand-Held Controller mounting base in a convenient location to allow the operator easy access.

Devices should be mounted only in locations that conform to their SAE identification code as described in SAE Standard J1849. For example, electronics designed for interior mounting should not be placed underhood, etc. Controls should be placed within convenient reach* of the driver or if intended for two person operation the driver and/or passenger. In some vehicles, multiple control switches and/or using methods such as “horn ring transfer” which utilizes the vehicle horn switch to toggle between siren tones may be necessary for convenient operation from two positions.

*Convenient reach is defined as the ability of the operator of the siren system to manipulate the controls from their normal driving/riding position without excessive movement away from the seat back or loss of eye contact with the roadway.

3

The 3599L5 amplifier is not waterproof. It must be mounted in a location that is sheltered from rain, snow, standing water, etc. It must be also installed in an adequately ventilated area. Do not install near heater ducts or under the vehicle’s hood.

Using the mounting holes on the amplifier as a template, scribe four drill position marks at the mounting locations. Be sure that both sides of the mounting surface are clear of parts that may be damaged. The siren accessory kit with mounting hardware supplied provides the user with a choice of mounting hardware. Secure the 3599L5 amplifier to the mounting surface, using the mounting hardware, including lock washers.

Connection between the hand-held controller and the 3599L5 amplifier box is an RJ45 connector.

Larger wires and tight connections will provide longer service life for components. For high current wires it is highly recommended that terminal blocks or soldered connections be used with shrink tubing to protect the connections. Do not use insulation displacement connections (e.g. 3M) Scotchlock type connectors. Route wiring using grommets and sealant when passing

through compartment walls. Minimize the number of splices to reduce voltage drop. High ambient temperatures (e.g. underhood) will significantly reduce the current carrying capacity of wires, fuses, and circuit breakers. Use “SXL” type wire in engine compartment.

All wiring should conform to the minimum wire size and other recommendations of the manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to anchor and protect all wiring.

Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized to protect the wiring and devices. Particular attention should be paid to the location and method of making electrical connections and splices to protect these points from corrosion and loss of conductivity. Ground (Earth) terminations should only be made to substantial chassis components, preferably directly to the vehicle battery.

The user should install a circuit breaker sized to approximately 125% of the maximum Amp capacity in the supply line to protect against short circuits. For example, a 30 Amp circuit breaker should carry a maximum of 24 Amps.

DO NOT USE 1/4” DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS. Circuit breakers are very sensitive to high termperatures and will “false trip” when mounted in hot environments or operated close to their capacity.

Connections

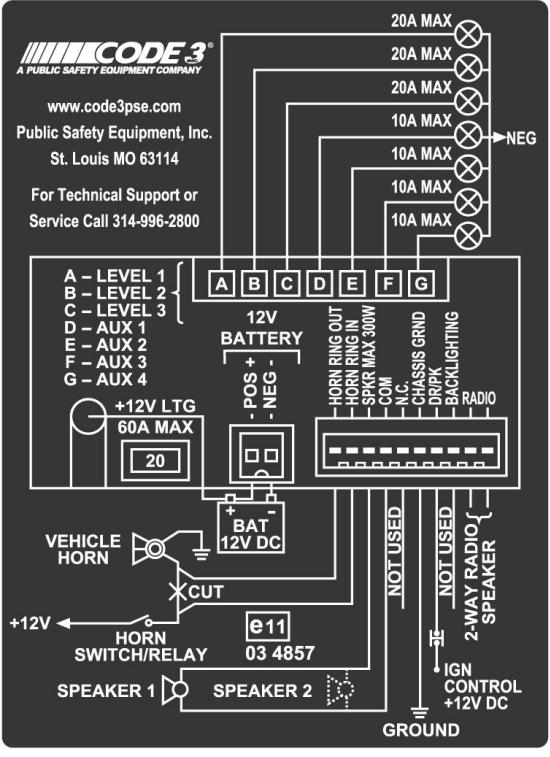

Reference Figure 1 – Wiring Diagram

1.Disconnect the cable on the negative end of the battery before performing installation. Do not connect the 3599L5 system to vehicle battery until all other electrical connections are made and mounting of all components is complete. Verify the polarities of the cable and ensure that no short circuits exist before connecting to the battery terminals. If routing the extension cable requires drilling a hole in sheet metal or other material, drill a 5/8″ hole in the material and install a 5/8″ grommet (not supplied) to protect the cable.

2.User-supplied 12-gauge red and black wires are required for positive (+12V) and negative (NEG) connections. Usersupplied 18-gauge wires are required for the speaker, door/park-siren-off input, radio input, chassis ground, horn ring out and horn ring in connections.

3.Attach the handheld controller to the amplifier by inserting the RJ45 connector on the end of the coil cord into the mating port on the amplifier. If the amplifier is remotely mounted, use the included 25’ extension cord and extension adaptor.

4.Configure the dip switches on the front of the siren amplifier to suit your needs. See page 9 for the list of dip switches and their impact on the system.

4

Figure 1 - Wiring Diagram

5.To install the positive and negative power wires, strip 1/4” of insulation from the end of the wires, insert the red wire into the left port of the two-position, pluggable connector (color green), which corresponds to the “+12V” position, and the black wire into the right port, which corresponds to the “NEG” position, and tighten the screws. The “+12V” position may be connected either directly to a +12V source (such as a battery), or through a switch (such as an ignition switch).

5

Loading...

Loading...