Page 1

Clarion ( Malaysia) Sdn. Bhd.

Phase 3, Free Trade Zone One, 11900 Bayan Lepas, Penang, Malaysia

Tel: (60) 4-6439-106, Fax: (60) 4-6439-108

Clarion Co. Ltd.

Export Division : 5-35-2, Hakusan, Bunkyouku, Tokyo, 112-8608 Japan Tel: 03-3400-1121

Service Manual

SPECIFICATIONS

Radio section

Model: PE-2504B-A

Tuning system: PLL synthesizer tuner

Receiving frequencies:FM 87.9 to 107.9MHz

AM 530 to 1,710kHz (10 kHz steps)

Model: PE-2506K-A

Tuning system: PLL synthesizer tuner

Receiving frequencies:FM 87.5 to 108MHz (0.05 MHz steps)

AM 531 to 1,602kHz (9 kHz steps)

CD player section

System: Compact disc audio system

Usable disc: Compact disc

Frequency response: 10Hz to 20kHz (±1dB)

Signal to Noise ratio: 100dB (1kHz) IHF-A

Dynamic range: 95dB (1kHz)

Distortion: 0.01%

General

Max. Power Output: 50W x 4

Line Output: 1.7V (with CD 1kHz, 10kΩ)

Bass Control Action: ±13dB (30Hz)

Trible Control Action: ±12dB (10 kHz)

Power supply voltage: DC 14.4V (10.8 to 15.6V allowable

negative ground)

Current consumption: Less than 15A

Speaker impedance: 4Ω (4Ω to 8Ω allowable)

Dimensions (mm): 178 (W) x 50 (H) x 152 (D)mm

Weight: 1.0kg

Specification and design are subject to change without notice for

further improvement.

(0.20 MHz steps)

Published by Clarion (Malaysia)

298-5945-00 MAR. 2002P

Printed In Malaysia

AM/FM RADIO CD COMBINATION

Model

NOTE

1. We cannot supply PWB with component parts in

FEATURES

COMPONENTS

PE-2504B-A/PE-2506K-A

Main unit 1

Mounting bracket 300-7742-20 1

Escutcheon (Outer-Es) 370-9006-06 1

Extension Lead 854-6391-60 1

Part’s bag 1

Removal key 331-2497-20 2

DB125

(Model:PE-2504B-A) For U.S.A

(Model:PE-2506K-A) For Other Countries

principle. When a circuit on PWB has failure, please

repair it by component parts base. Parts which are

not mentioned in service manual are not

supplied.

1. Rotary Encoder Volume Control

2. Z-Enhancer with 3 Mode Sound Selector

3. MAGI-TUNE® FM Reception System

4. Seek/Manual Up/Down Tuning

5. 8-Times Oversampling Digital Filter and Dual 1-Bit

D/A Converters

6. Preset Station Scan (PS), Automatic Store (AS)

7. 2-Channel RCA Line Level Output

8. AM 1 band, FM 3 bands each 6 channels total 24

channels, Preset Memory Function

9. Repeat/Random Play/Intro Music Scan

10. 200W (50 W x 4) Maximum Power Output

To engineers in charge of repair or

inspection of our products.

Before repair or inspection,make sure to follow the

instructions so that customers and Engineers in charge of

repair or inspection can avoid suffering any risk or injury.

1. Use specified parts.

The system uses parts with special safety features

against fire and voltage. Use only parts with equivalent

characteristics when replacing them.

The use of unspecified parts shall be regarded as remodeling for which we shall not be liable.The onus of

product liability (PL) shall not be our responsibility in

cases where an accident or failure is as a result of

unspecified parts being used.

2. Place the parts and wiring back in their original

positions after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding, gaps to PWB, etc, is involved. The wiring connection and routing to the PWB are specially planned

using clamps to keep away from heated and high voltage parts. Ensure that they are placed back in their

original positions after repair or inspection.

If extended damage is caused due to negligence during repair, the legal responsibility shall be with the repairing company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back

securely in their original position after repair. Ensure

for safety reasons there is no possibility of secondary

problems around the repaired spots.

If extended damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

4. Caution in removal and making wiring connection to

the parts for the automobile.

Disconnect the battery terminal after turning the ignition key off. If wrong wiring connections are made with

the battery connected, a short circuit and/or fire may

occur. If extensive damage is caused due to negligence

of repair, the legal responsibility shall be with the repairing company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality is observed in their appearance. Always replace them

with new ones. (The chip parts include resistors, capacitors, diodes, transistors, etc). The negative pole of

tantalum capacitors is highly susceptible to heat, so

use special care when replacing them and check the

operation afterwards.

6. Cautions in handling flexible PWB.

Before working with a soldering iron, make sure that the

iron tip temperature is around 270°C. Take care not to

apply the iron tip repeatedly (more than three times) to the

same patterns. Also take care not to apply the tip with

force.

7. Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

8. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface

through the lens of the optical pickup. When checking

that the laser optical diode lights up, keep your eyes

more than 30cms away from the lens. Prolonged

viewing of the laser within 30cms may damage your

eyesight.

9. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged

by electrostatic charge caused by your clothes and body.

Make sure to avoid electrostatic charges on your clothes

or body, or discharge static electricity before handling

the optical pickup.

9-1.Laser diode

The laser diode terminals are shorted for transportation

in order to prevent electrostatic damage. After

replacement, open the shorted circuit. When removing

the pickup from the mechanism, short the terminals by

soldering them to prevent this damage.

9-2.Actuator

The actuator has a powerful magnetic circuit. If a

magnetic material is put close to it. Its characteristics

will change. Ensure that no foreign substances enter

through the ventilation slots in the cover.

9-3.Cleaning the lens

Dust on the optical lens affects performance. To clean

the lens, apply a small amount of isopropyl alcohol to

lens paper and wipe the lens gently.

CAUTIONS

Use of controls, adjustments, or performance of

procedures other those specified herein, may resault in

hazardous radiation exposure.

The compact disc player should not be adjustment or

repaired by anyone expext properly qualified service

personnel.

(Model:PE-2504B-A)

Bottom View of

Main Unit

- 1 -

DB125

DB125

- 2 -

Page 2

TROUBLESHOOTING

Power does not turn on (or no

sound is produced).

MAIN UNIT SECTION

CauseProblem Measure

Fuse is blown. Replace with a fuse of the same amperage as the

old fuse.

Compact disc cannot be

loaded.

Sound skips or is noisy.

Sound is bad directly after

power is turned on.

Another compact disc is already

loaded.

Compact disc is dirty.

Compact disc is heavily scratched

or warped.

Water droplets may form on the

internal lens when the car is

parked in a humid place.

Eject the compact disc before loading the new

one.

Clean the compact disc with a soft cloth.

Replace with a compact disc with no scratches.

Let dry for about 1 hour with the power on.

ERROR DISPLAYS

To protect the system, this unit has been equipped with self diagnostic functions. If a fault arises, a warning is

issued by various error displays. Follow the corrective measures and remove the fault.

Error Display

CD ER2

This error display indicates that a fault has arisen in the mechanism of the

source unit (for example, the disc cannot be ejected).

-Check the source unit

Corrective Measure

This error display indicates that the pickup focus is off because of a scratched

CD ER3

CD ER6

disc or some other factor during source unit play.

-Check the compact unit

This indicates that the CD’s TOC (table of contents) cannot be read, because

the selected disc is upside-down.

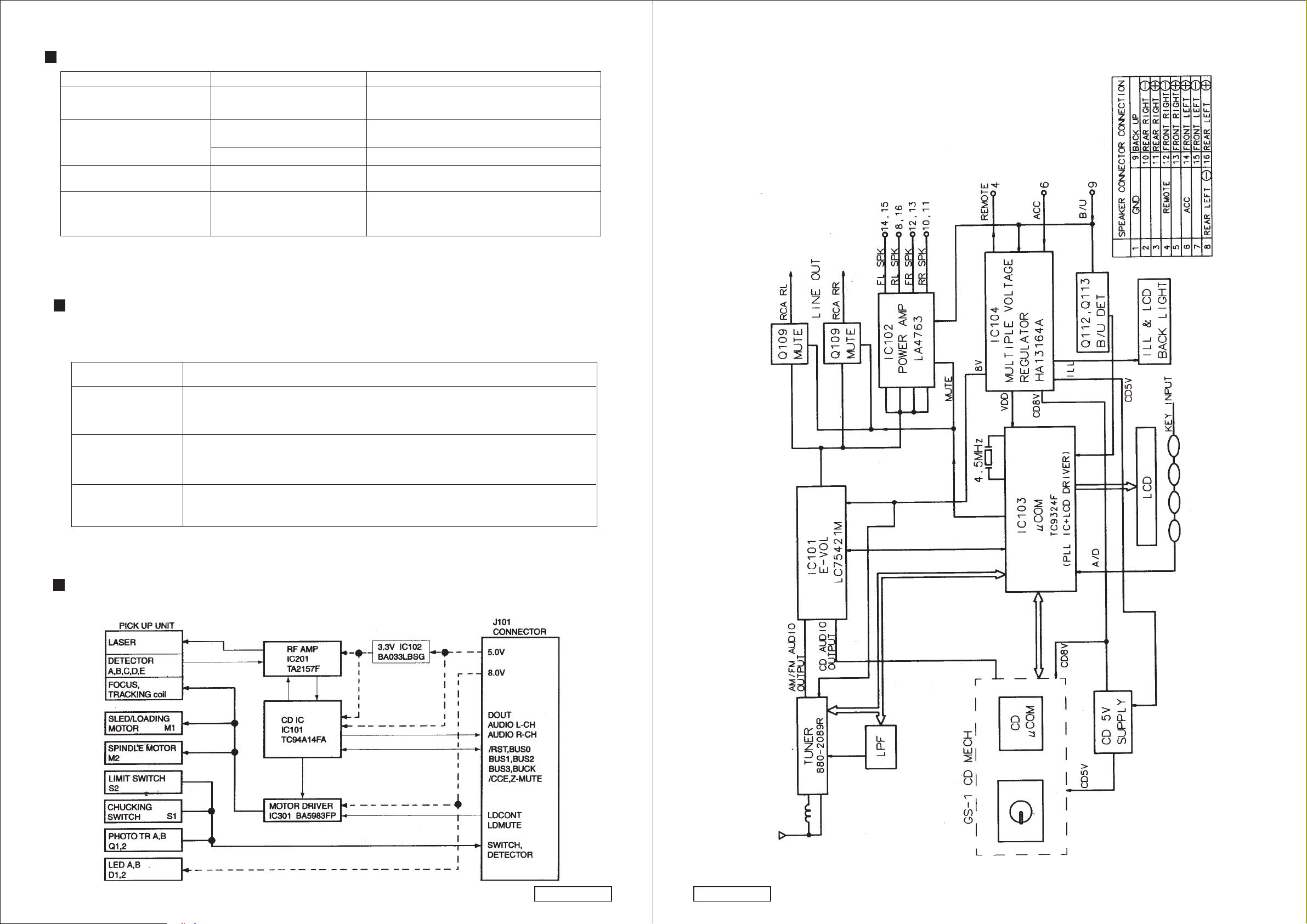

BLOCK DIAGRAM

CD MECHANISM SECTION 929-0220-80

- 3 - - 4 -

DB125

DB125

Page 3

EXPLANATION OF IC

TC9324F-006 052-1932-00

Master Micro computer

Outward Form

100 pins, plastic QFP

Terminal Description

Pin No Symbol I/O Function

1 COM1 O COMMON signal 1 output for LCD

2 COM2 O COMMON signal 2 output for LCD

3 COM3 O COMMON signal 3 output for LCD

4 COM4 O COMMON signal 4 output for LCD

5 S1 O S1 output for LCD

6 S2 O S2 output for LCD

7 S3 O S3 output for LCD

8 S4 O S4 output for LCD

9 S5 O S5 output for LCD

10 S6 O S6 output for LCD

11 S7 O S7 output for LCD

12 S8 O S8 output for LCD

13 S9 O NC

14 S10 O S10 output for LCD

15 S11 O S11 output for LCD

16 S12 O NC

17 S13 O S13 output for LCD

18 S14 O S14 output for LCD

19 S15 O NC

20 S16 O S16 output for LCD

21 S17 O S17 output for LCD

22 S18 O S18 output for LCD

23 S19 O S19 output for LCD

24 S20 O S20 output for LCD

25 S21 O NC

26 S22 O S22 output for LCD

27 S23 O S23 output for LCD

28 S24 O NC

29 S25 O S25 output for LCD

30 S26 O S26 output for LCD

31 S27 O S27 output for LCD

32 S28 O S28 output for LCD

33 S29 O S29 output for LCD

34 S30 O S30 output for LCD

35 CD-RESET O C D MECH connect to RESET

36 CD5V ON O CD5V ON signal output pin (Active

High)

37 LD-CONT O Laser Diode Control pin

38 LD-MUTE O Mechanical photo sensor input terminal.

Terminal to detect the disc. Position in

loading status, chucking status and

other machine status. With disc, ‘H’ is

input, without disc ‘L’ is input.

39 VDD1 - VDD

40 RESET I Reset Port

41 GND1 - GND

42 AM-ON O While ‘HI’=AM and ‘LO’=FM

(Active High)

43 FM-ON O While ‘LO’=AM and ‘HI’=FM

(Active High)

44 ST/SD I While AM/FM SD in, SD is ‘LO’

(Active High)

45 STBY O Power Amplifier IC control terminal

46 VREF - VDD

47 ANT-CONT O Antenna Control output pin. ‘HI’ is

ON, ‘LO’ is OFF

48 CTRL1 O Power Supply IC control terminal

(Active High)

49 CRTL 2 O NC

Pin No Symbol I/O Function

50 RF-MUTE O RF Mute is signal output pin

(Active High)

51 A1 O Test mode for CD

52 A2 O Digital output pin for CD MECH

53 AD1 I Key switch detection terminal for

A/D converter

54 AD2 I Key switch detection terminal for

A/D converter

55 GND2 - GND

56 VDD2 - VDD

57 TR-A I Mechanical photo sensor input terminal.

Terminal to detect the disc. Position in

loading status, chucking status and

other machine status. With disc, ‘H’ is

input, without disc ‘L’ is input.

58 E-VOL CE O E-VOL use

59 E-VOL DO O E-VOL use

60 E-VOL CLK O E-VOL use

61 AREA A I Area setting input.Ref. Table 1

62 AREA B I Area setting input.Ref. Table 1

63 CW I Use for rotary volume

64 CCW I Use for rotary volume

6 5 MUTE O Output mute.While it is ‘LO’,mute i

s ‘ON’

66 TEST I NC

67 HOLD I HOLD=ACC detect terminal

68 SBSY I Connected to CD MECH

69 B/U DET I B/U detecting terminal

70 AM-IF IN I AM IF INPUT

71 FM-IF IN I FM IF INPUT

72 GND3 - GND

73 FM-OSC I FM VCO input terminal

74 AM-OSC I AM VCO input terminal

75 VPLL O NC

76 VDD3 - VDD

77 DO1 O PLL detector output 1

78 DO2 O PLL detector output 2

79 TEST2 I NC

80 TR-B I Mechanical photo sensor input terminal.

Terminal to detect the disc. Position in

loading status, chucking status and

other machine status. With disc, ‘H’ is

input, without disc ‘L’ is input.

81 CHU SW I Mechanical photo sensor input terminal.

Terminal to detect the disc. Position in

loading status, chucking status and

other machine status. With disc, ‘L’ is

input, without disc ‘H’ is input.

82 S-STOP I Mechanical photo sensor input terminal.

Terminal to detect the disc. Position in

loading status, chucking status and

other machine status. With disc, ‘H’ is

input, without disc ‘L’ is input.

83 Z-MUTE O Zero Mute for CD MECH

(Active High)

84 BUCK O C D MECH data bus clock

85 CCE O CD MECH chip enable

Pin No Symbol I/O Function

86 BUS0 I/O CD MECH data bus

87 BUS1 I/O CD MECH data bus

88 BUS2 I/O CD MECH data bus

89 BUS3 I/O CD MECH data bus

90 B/U DET I B/U detecting terminal

91 CD-EJ I C D EJECT (Active Low)

92 VCPU - 10uF to GND

93 GND4 - GND

Table 1. Area Setting Table

AREA AREA A (Pin 61) AREA B (Pin 62)

US L L

K H L

J L H

Pin No Symbol I/O Function

94 X-OUT2 - NC

95 X-IN2 - GND

96 VDD4 - VDD

97 X-OUT1 - X-TAL 4.5MHz

98 X-IN1 - X-TAL 4.5MHz

99 GND5 - GND

100 VEE - NC

- 5 -

DB125 DB125

- 6 -

Page 4

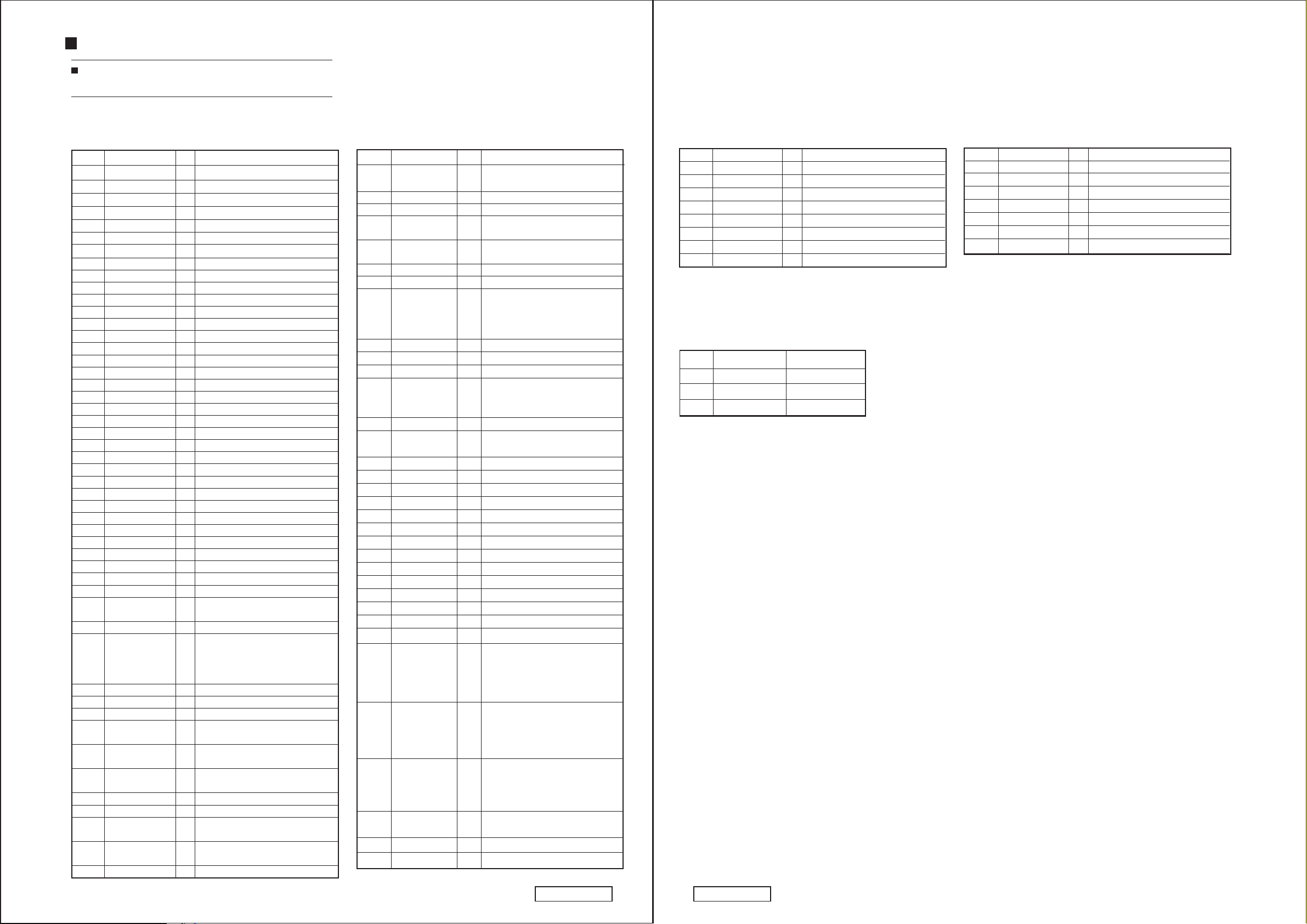

EXPLODED VIEW • PART LIST

Main Section

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

01 331-1861-00 EARTH PLATE 1

02 286-9910-00 SET PLATE (PE-2504B) 1

02 286-9912-00 SET PLATE (PE-2506K) 1

03 311-1848-00 LOWER CASE 1

04 310-1751-00 UPPER CASE 1

05 731-3004-80 TAPTIGHT (M3 x 4) 3

06 331-3366-00 MECHA BRACKET 3

07 714-2604-81 MACHINE SCREW (M2.6 x 4) 4

08 929-0220-80 CD MECHANISM 1

09 714-3006-81 MACHINE SCREW (M3 x 4) 1

10 731-3008-80 TAPTIGHT (M3 x 8) 5

11 731-3012-80 TAPTIGHT (M3 x 12) 3

12 816-2573-60 FLAT WIRE 1

13 778-2004-00 SCREW (2 x 4) 2

14 371-5717-00 FACE PLATE 1

15 373-0990-00 DIAL-CVR 1

16 335-0833-01 CABLE TIE 1

17 370-9612-00 ESCUTCHEON 1

18 382-6456-00 BUTTON ASSY 1

19 335-6719-00 ILLUMI PLATE 1

20 380-5539-00 KNOB 1

21 346-0072-02 LEATHER SHEET 1

22 335-4759-20 DISC GUIDE 1

23 382-6457-00 BUTTON ASSY 1

24 335-6720-00 ILLUMI PLATE 1

25 716-0778-00 WAVE SCREW (2 x 6) 6

26 347-6750-00 COPPER TAPE 2

27 016-9900-84 VR W / SHAFT 1

28 345-7148-13 RUBBER PART 2

29 017-0414--00 PILOT LAMP (8V 70mA) 2

30 001-7030-02 DIODE 1

31 335-6723-00 LED HOLDER 1

32 379-1226-40 INDICATOR 1

33 347-6634-00 FILM 1

34 347-6633-00 SHADE 1

35 335-6722-00 LCD ILLUMI 1

36 335-6721-00 LCD HOLDER 1

37 039-2067-01 MAIN PWB 1

(WITHOUT COMPONENT)

38 816-2571-60 EXTENSION LEAD 1

39 816-2572-60 EXTENSION LEAD 1

40 074-1191-26 OUTLET SOCKET 1

41 880-2089R TUNER 1

42 009-9006-60 CHOKE 1

43 074-1214-00 OUTLET SOCKET 1

44 313-1838-00 HEAT SINK 1

45 092-4000-51 ANT-RECEPT 1

46 051-3295-00 IC 1

47 051-2031-31 POWER IC 1

48 331-3367-00 IC HOLDER 1

49 013-6005-51 TACT SWITCH 12

50 331-3368-00 PWB HOLDER 1

51 855-8000-08 RCA PIN CORD 1

52 345-3799-0L RUBBER PART 1

53 345-5164-00 RUBBER PART 1

54 347-6679-00 SHADE 1

55 013-6001-50 TACT SWITCH 2

56 345-8339-00 SPONGE 1

- 7 -

DB125 DB125

- 8 -

Page 5

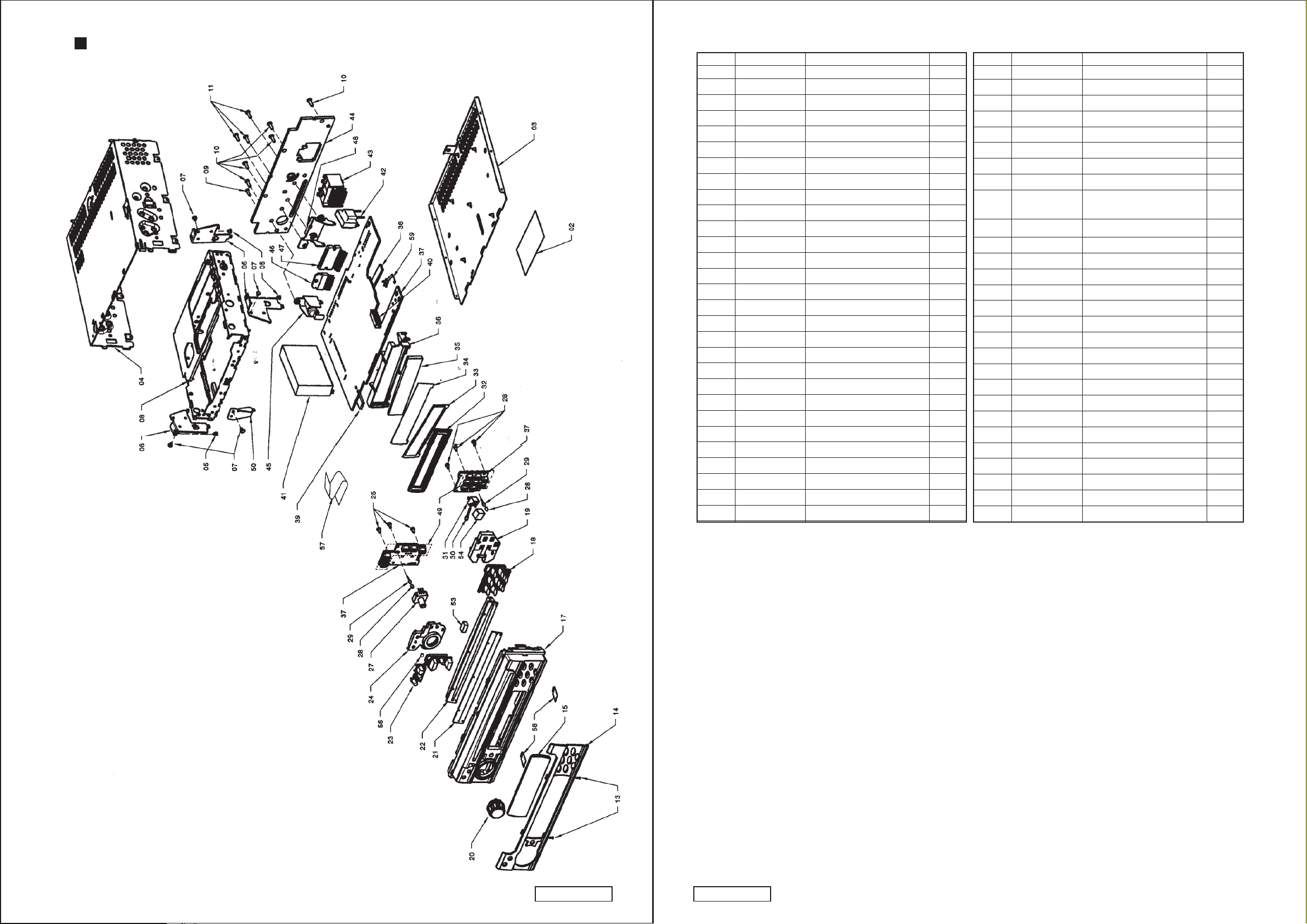

EXPLODED VIEW • PARTS LIST

CD mechanism section 929-0220-80

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q' TY

1 966-0595-24 DRIVE PLATE ASSY

1 966-0595-24 DRIVE PLATE ASSY 1

2 969-0060-30 PICK UP UNIT 1

3 039-1944-21 LED PWB (WITHOUT COMPONENT) 1

4 039-1945-20 CD PWB(WITHOUT COMPONENT) 1

5 SMA-182-100 MOTOR ASSY(SPINDLE) 1

6 SMA-183-100 MOTOR ASSY(SLED) 1

7 HBT-516-100 CLAMPER SUB ASSY 1

8 803-4906-60 VINYL COAT WIRE(ORG) 1

9 816-2566-50 LEAD WIRE(YEL) 1

10 620-1025-21 ID-LOCK PLATE 1

11 620-1026-21 SPRING PLATE 1

12 620-1027-24 LOWER CHASSIS 1

13 620-1028-21 UPPER CHASSIS 1

14 620-1029-21 SH-SPRING 1

15 621-0598-25 UPPER GUIDE 1

16 621-0599-25 ROLLER GUIDE 1

17 621-0600-23 SHIFT LEVER 1

18 621-0601-21 RACK 1

19 621-0602-22 LOCK ARM L 1

20 621-0603-23 LOCK ARM R 1

21 621-0604-21 GEAR BASE 1

22 621-0605-21 GEAR COVER 1

23 621-0606-21 IDLE CASE 1

24 805-4906-60 VINYL COAT WIRE(GRN) 1

25 621-0608-21 SECOND GEAR 1

26 621-0609-20 BASE GEAR 1

27 621-0610-20 IDLE GEAR A 1

28 621-0611-20 IDLE GEAR B 1

29 621-0612-21 ROLLER GEAR A 1

30 621-0613-20 ROLLER GEAR B 1

31 621-0614-20 ROLLER GEAR C 1

32 621-0615-21 ROLLER GEAR D 1

33 621-0616-20 POWER GEAR A 1

34 621-0617-20 POWER GEAR B 1

35 621-0618-20 POWER GEAR C 1

36 621-0619-20 POWER GEAR D 1

37 621-0620-20 THREAD GEAR A 1

38 621-0621-20 THREAD GEAR B 1

39 621-0622-20 ROLLER SLEEVE 2

40 621-0623-21 LS-HOLDER 1

41 621-0624-20 GUIDE RAIL 1

42 816-2566-52 LEAD WIRE(PUR) 1

43 816-2542-01 FLAT WIRE(10P) 1

44 716-3473-00 SCREW 2

45 621-0628-21 SH-BASE 1

46 621-0629-20 LOADING ROLLER 2

47 345-8704-20 CUSHION RUBBER 1

48 622-1571-20 ROLLER SHAFT 1

49 624-0018-01 LEAD SCREW 1

50 629-0081-20 DAMPER F 2

51 629-0082-20 DAMPER R 1

52 714-2003-81 MACHINE SCREW 2

53 716-1507-00 SCREW 8

54 716-1733-00 SCREW 2

55 716-3469-00 SPECIAL SCREW 2

56 716-3446-00 SCREW 2

57 750-3465-21 ROLLER SPRING L 1

58 750-3466-20 ROLLER SPRING R 1

59 750-3467-20 SHIFT SPRING 1

60 750-3468-20 RACK SPRING 1

61 750-3469-20 CLAMPER SPRING 1

62 750-3470-20 ID-LOCK SPRING 1

63 816-2566-51 LEAD WIRE(BLU) 1

64 750-3472-21 DR-SPRING F 2

65 750-3473-20 DR-SPRING RA 1

66 750-3474-20 DR-SPRING RB 1

67 750-3475-21 DR-SPRING C 1

- 9 -

DB125 DB125

- 10 -

Page 6

ELECTRICAL PARTS LIST

Main PWB Section (B1)

Note: Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

REF No. PART No. DESCRIPTION

C 101 166-2201-00 22pF

C 102 166-2201-00 22pF

C 103 182-4763-12 6.3V-47µF

C 104 042-0598-90 10V-470µF

C 106 168-1032-05 0.01µF

C 107 168-1045-06 0.1µF

C 108 182-1073-22 10V-100µF

C 110 182-1073-22 10V-100µF

C 111 168-1032-05 0.01µF

C 112 168-2732-05 0.027µF

C 113 168-2732-05 0.027µF

C 114 168-2232-05 0.022µF

C 115 168-1022-05 1000pF

C 116 178-1052-08 1µF

C 117 178-1052-08 1µF

C 118 178-1052-08 1µF

C 119 178-1052-08 1µF

C 120 182-3353-62 50V-3.3µF

C 121 168-1032-05 0.01µF

C 122 182-2263-32 16V-22µF

C 123 178-1052-08 1µF

C 124 178-1052-08 1µF

C 125 168-1522-05 1500pF

C 126 168-1522-05 1500pF

C 127 168-8232-08 0.082µF

C 128 168-8232-08 0.082µF

C 129 168-8232-08 0.082µF

C 130 168-8232-08 0.082µF

C 131 178-1842-08 0.18µF

C 132 178-1842-08 0.18µF

C 133 178-1842-08 0.18µF

C 134 178-1052-08 1µF

C 135 178-1842-08 0.18µF

C 136 178-1052-08 1µF

C 138 182-1063-33 16V-10µF

C 139 182-1063-33 16V-10µF

C 140 182-1053-62 50V-1µF

C 142 182-1053-62 50V-1µF

C 144 178-4742-08 0.47µF

C 145 178-4742-08 0.47µF

C 146 178-4742-08 0.47µF

C 147 178-4742-08 0.47µF

C 148 166-3311-00 330pF

C 149 166-1011-00 100pF

C 150 172-1041-11 0.1µF

C 151 166-1011-00 100pF

C 152 166-1011-00 100pF

C 153 172-1041-11 0.1µF

C 154 182-4763-32 16V-47µF

C 155 184-4773-12 6.3V-470µF

C 156 168-1045-06 0.1µF

C 157 178-2255-09 2.2µF

C 160 166-2201-00 22pF

C 159 172-1041-11 0.1µF

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C 161 166-2201-00 22pF

C 162 172-1041-11 0.1µF

C 163 172-1041-11 0.1µF

C 164 184-2283-32 16V -2200µF

C 165 182-1053-62 50V-1µF

C 166 168-1045-06 0.1µF

C 167 168-1045-06 0.1µF

C 168 168-1045-06 0.1µF

C 169 168-1045-06 0.1µF

C 170 168-1045-06 0.1µF

C 171 168-1045-06 0.1µF

C 172 182-1053-62 50V-1µF

C 173 182-1053-62 50V-1µF

C 174 168-1032-05 0.01µF

C 175 168-1045-06 0.1µF

C 177 168-6822-05 6800pF

C 178 168-1032-05 0.01µF

C 179 182-1053-62 50V-1µF

C 180 168-1032-05 0.01µF

C 181 168-4722-05 4700pF

C 183 182-1073-22 10V-100µF

C 185 168-1022-05 1000pF

C 186 168-1022-05 1000pF

C 187 166-4711-00 470pF

C 188 166-4711-00 470pF

C 189 168-1022-05 1000pF

C 190 168-1022-05 1000pF

C 191 168-1022-05 1000pF

C 192 168-1022-05 1000pF

C 193 168-1045-06 0.1µF

C 195 168-1022-05 1000pF

C 196 182-1073-22 10V-100µF

C 197 168-1032-05 0.01µF

C 199 168-1022-05 1000pF

C 200 168-1045-06 0.1µF

C 201 166-4711-00 470pF

C 202 182-1063-32 16V-10µF

C 203 166-4711-00 470pF

C 207 166-4711-00 470pF

C 208 168-1022-05 1000pF

C 209 182-3353-62 50V-3.3µF

C 210 168-1045-06 0.1µF

C 211 178-2255-09 2.2µF

C 212 184-4773-12 6.3V-470µF

C 213 182-2273-12 6.3V-220µF

C 214 166-2211-00 220pF

C 215 166-2211-00 220pF

C 216 166-2211-00 220pF

C 217 166-2211-00 220pF

C 218 166-2211-00 220pF

C 219 166 2211-00 220pF

C 220 166-2211-00 220pF

C 221 166-2211-00 220pF

C 222 168-1022-05 1000pF

C 223 168-1045-06 0.1µF

C 224 168-1045-06 0.1µF

C 225 168-1022-05 1000pF

C 226 168-1022-05 1000pF

C 229 178-2242-08 0.22µF

C 232 182-1073-12 6.3V-100µF

C 233 168-1045-06 0.1µF

D 104 001-0466-00 S5688B

D 105 001-0466-01 S5688G

D 106 001-0466-00 S5688B

D 107 001-0592-00 RM4Z

D 108 001-0466-00 S5688B

D 109 001-0376-26 MTZJ4.7B

D 110 001-0466-00 S5688B

D 111 001-0466-00 S5688B

D 112 001-0466-00 S5688B

D 113 001-0466-00 S5688B

D 114 001-0466-00 S5688B

D 115 001-0466-00 S5688B

D 116 001-0466-00 S5688B

D 117 001-0330-00 1SS119

D 120 001-0376-35 MTZJ6.2B

D 121 001-0376-35 MTZJ6.2B

D 122 001-0330-00 1SS119

D 123 001-0466-00 S5688B

D 207 001-0330-00 1SS119

D 208 001-0330-00 1SS119

IC 101 051-5022-90 LC75421M

IC 102 051-2031-31 LA4763

IC 103 052-1932-00 TC9324F-006

IC 104 051-3295-00 HA13164A

L 101 010-2003-04 COIL

L 102 010-2330-67 5.6µH

L 103 010-2330-86 220µH

L 104 010-2330-50 0.22µH

Q 101 100-1048-00 2SA1048

Q 102 125-2004-02 RN1402

Q 103 100-1298-00 2SA1298 O,Y

Q 104 125-2004-02 RN1402

Q 105 102-2712-51 2SC2712GR

Q 106 125-2004-03 RN1403

Q 107 102-2712-51 2SC2712GR

Q 108 125-0002-03 RN2403

Q 109 103-1306-00 D1306

Q 110 103-1306-00 D1306

Q 112 125-0002-04 RN2404

Q 113 102-2712-51 2SC2712GR

Q 114 100-1298-00 2SA1298 O,Y

Q 117 125-2004-02 RN1402

Q 118 102-2712-51 2SC2712GR

Q 119 102-2712-51 2SC2712GR

Q 120 100-1298-00 2SA1298 O,Y

Q 121 125-2004-03 RN1403

Q 122 102-2712-51 2SC2712GR

Q 123 102-2712-51 2SC2712GR

R 101 119-2221-10 1/16W 2.2KΩ

R 102 111-2221-91 1/4WS 2.2KΩ

R 103 119-2231-10 1/16W 22KΩ

R 104 111-1021-91 1/4WS 1KΩ

R 105 119-1011-10 1/16W 100Ω

R 106 111-2221-91 1/4WS 2.2KΩ

R 107 119-2221-10 1/16W 2.2KΩ

R 108 119-2231-10 1/16W 22KΩ

R 109 119-1021-10 1/16W 1KΩ

R 110 119-1031-10 1/16W 10KΩ

R 112 119-3331-10 1/16W 33KΩ

R 113 119-3331-10 1/16W 33KΩ

R 115 119-1231-10 1/16W 12KΩ

R 116 111-4721-91 1/4WS 4.7KΩ

R 117 119-1021-10 1/16W 1KΩ

R 118 119-1021-10 1/16W 1KΩ

R 119 119-4741-10 1/16W 470KΩ

R 120 119-8221-10 1/16W 8.2KΩ

R 121 119-8221-10 1/16W 8.2KΩ

R 122 119-3921-10 1/16W 3.9KΩ

R 123 119-3921-10 1/16W 3.9KΩ

R 124 119-1031-10 1/16W 10KΩ

R 125 119-1031-10 1/16W 10KΩ

R 126 119-1031-10 1/16W 10KΩ

R 127 119-1031-10 1/16W 10KΩ

R 128 119-1031-10 1/16W 10KΩ

Right ES-PWB (B2)

REF No. PART No. DESCRIPTION

D 201 001-7030-02 LED

J 104 816-2571-60 EXTENTION

LEAD(4PIN)

PL 201 017-0414-00 PILOT LAMP

R 201 111-3911-91 1/4WS 390Ω

R 202 119-1521-10 1/16W 1.5KΩ

R 204 119-2221-10 1/16W 2.2KΩ

Left ES-PWB (B3)

REF No. PART No. DESCRIPTION

J 103 816-2572-60 EXTENTION

LEAD(7PIN)

PL 202 017-0414-00 PILOT LAMP

R 203 119-1521-10 1/16W 1.5KΩ

R 205 119-2221-10 1/16W 2.2KΩ

R 207 119-2721-10 1/16W 2.7KΩ

R 209 119-3921-10 1/16W 3.9KΩ

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTIONREF No. PART No. DESCRIPTION

R 129 119-1031-10 1/16W 10KΩ

R 130 119-1031-10 1/16W 10KΩ

R 131 119-1031-10 1/16W 10KΩ

R 132 119-2221-10 1/16W 2.2KΩ

R 133 119-2221-10 1/16W 2.2KΩ

R 134 119-2221-10 1/16W 2.2KΩ

R 135 119-2221-10 1/16W 2.2KΩ

R 136 119-1031-10 1/16W 10KΩ

R 137 119-1031-10 1/16W 10KΩ

R 138 119-1041-10 1/16W 100KΩ

R 139 119-3311-10 1/16W 330Ω

R 140 119-3311-10 1/16W 330Ω

R 141 119-2221-10 1/16W 2.2KΩ

R 142 119-1041-10 1/16W 100KΩ

R 143 119-1041-10 1/16W 100KΩ

R 144 119-4731-10 1/16W 47KΩ

R 145 119-4731-10 1/16W 47KΩ

R 146 119-4731-10 1/16W 47KΩ

R 147 119-5631-10 1/16W 56KΩ

R 150 119-1231-10 1/16W 12KΩ

R 151 111-2231-91 1/4WS 22KΩ

R 154 119-8221-10 1/16W 8.2KΩ

R 155 119-2231-10 1/16W 22KΩ

R 156 119-4731-10 1/16W 47KΩ

R 157 119-1031-10 1/16W 10KΩ *

R 158 119-1031-10 1/16W 10KΩ #

R 159 119-1031-10 1/16W 10KΩ

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R 206 119-2721-10 1/16W 2.7KΩ

R 208 119-3921-10 1/16W 3.9KΩ

R 210 119-6821-10 1/16W 6.8KΩ

R 212 119-1231-10 1/16W 12KΩ

R 214 119-3331-10 1/16W 33KΩ

S 202 013-6001-50 TACT SWITCH

S 204 013-6005-51 TACT SWITCH

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R 211 119-6821-10 1/16W 6.8KΩ

R 213 119-1231-10 1/16W 12KΩ

R 215 119-3331-10 1/16W 33KΩ

S 201 013-6005-51 TACT SWITCH

S 203 013-6005-51 TACT SWITCH

S 205 013-6005-51 TACT SWITCH

S 207 013-6005-51 TACT SWITCH

R 163 060-0108-90 1/4WS 0Ω

R 165 119-4731-10 1/16W 47KΩ

R 167 119-2231-10 1/16W 22KΩ

R 168 119-1031-10 1/16W 10KΩ

R 169 119-4731-10 1/16W 47KΩ

R 170 119-1831-10 1/16W 18KΩ

R 171 119-1031-10 1/16W 10KΩ

R 172 111-1021-91 1/4WS 1KΩ

R 173 119-4721-10 1/16W 4.7KΩ

R 175 119-1231-10 1/16W 12KΩ

R 176 119-1031-10 1/16W 10KΩ

R 179 119-4731-10 1/16W 47KΩ

R 180 119-3931-10 1/16W 39KΩ

R 181 119-1041-10 1/16W 100KΩ

R 182 119-1021-10 1/16W 1KΩ

R 183 119-1021-10 1/16W 1KΩ

R 184 119-1031-10 1/16W 10KΩ

R 186 119-4731-10 1/16W 47KΩ

RCA101 855-8000-08 RCA PIN CORD

SUP 101 060-0122-20 DSP-141N-S00B

T 101 009-9006-60 CHOKE

X 101 061-1064-00 4.5MHz

S 206 013-6005-51 TACT SWITCH

S 208 013-6005-51 TACT SWITCH

S 210 013-6005-51 TACT SWITCH

S 212 013-6005-51 TACT SWITCH

S 214 013-6005-51 TACT SWITCH

S 216 013-6001-50 TACT SWITCH

S 215 013-6005-51 TACT SWITCH

S 217 013-6005-51 TACT SWITCH

V R1 016-9900-84 VR W/SHAFT

- 11 -

DB125

DB125

- 12 -

Page 7

CD PWB (B4), (B5), (B6)

C 101 166-2201-00 22pF

C 102 166-2201-00 22pF

C 101 168-1042-08 0.1µF

C 102 045-4701-50 47pF

C 103 046-4722-58 4700pF

C 104 168-1042-08 0.1µF

C 105 046-1532-78 0.015µF

C 106 046-1032-78 0.01µF

C 107 046-1032-78 0.01µF

C 108 046-4722-58 4700pF

C 109 046-1522-58 1500pF

C 110 046-3332-78 0.033µF

C 111 168-1042-08 0.1µF

C 112 046-3332-78 0.033µF

C 113 168-1042-08 0.1µF

C 114 168-1042-08 0.1µF

C 115 046-4712-58 470pF

C 116 046-4712-58 470pF

C 117 043-0533-50 0.047µF

C 118 043-0533-50 0.047µF

C 119 045-2701-50 27pF

C 120 045-1801-50 18pF

C 121 163-1063-35 16V-10µF

C 122 178-1052-08 1µF

C 123 046-1032-78 0.01µF

C 124 163-1073-05 4V-100µF

C 125 168-1042-08 0.1µF

C 126 168-1042-08 0.1µF

C 129 178-1052-08 1µF

C 201 163-3363-05 4V-33µF

C 202 168-1042-08 0.1µF

C 203 178-1052-08 1µF

C 204 163-1073-05 4V-100µF

C 205 163-3363-05 4V-33µF

C 206 168-1042-08 0.1µF

C 207 043-0533-50 0.047µF

Note: Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTIONREF No. PART No. DESCRIPTION

C 208 046-6822-58 6800pF

C 209 168-1042-08 0.1µF

C 210 043-0533-50 0.047µF

C 211 168-1042-08 0.1µF

C 212 168-1042-08 0.1µF

C 213 045-5096-50 5pF

C 214 045-5601-50 56pF

C 215 043-0533-50 0.047µF

C 216 178-1052-08 1µF

C 217 045-1011-50 100pF

C 301 163-1073-35 16V-100µF

C 302 168-1042-08 0.1µF

C 303 043-0533-50 0.047µF

D 1 001-7058-90 AN1105W-RR

D 2 001-7058-90 AN1105W-RR

D 201 001-0516-00 MA111

IC 101 051-6376-00 TC94A14FA

IC 102 051-3279-90 BA033LBSG

IC 201 051-5710-90 TA2157F

IC 301 051-6049-08 BA5983FP-E2

J 1 074-1138-60 10P

J 101 074-1228-76 26P

J 201 074-1138-65 15P

J 301 074-1138-60 10P

L 101 010-2285-57 BLM21B102SPT

L 102 010-2285-57 BLM21B102SPT

L 103 010-2285-57 BLM21B102SPT

L 104 010-2285-57 BLM21B102SPT

L 105 010-2285-57 BLM21B102SPT

L 401 010-3050-93 10µH

Q 1 060-4015-90 PS1192H

Q 2 060-4015-90 PS1192H

Q 201 131-1188-50 2SB1188

R 102 033-5621-15 1/16W 5.6kΩ

R 104 033-4731-15 1/16W 47kΩ

R 105 033-1041-15 1/16W 100kΩ

R 108 033-1531-15 1/16W 15kΩ

R 109 033-1031-15 1/16W 10kΩ

R 110 033-1051-15 1/16W 1MΩ

R 111 033-3321-15 1/16W 3.3kΩ

R 114 033-2211-15 1/16W 220Ω

R 115 033-2211-15 1/16W 220Ω

R 116 033-1031-15 1/16W 10kΩ

R 117 033-1021-15 1/16W 1kΩ

R 131 033-4711-15 1/16W 470Ω

R 132 033-2211-15 1/16W 220Ω

R 201 117-2201-15 1/10W 22Ω

R 202 117-2201-15 1/10W 22Ω

R 203 033-1041-15 1/16W 100kΩ

R 204 033-1041-15 1/16W 100kΩ

R 205 033-1041-15 1/16W 100kΩ

R 206 033-1041-15 1/16W 100kΩ

R 207 033-1041-15 1/16W 100kΩ

R 208 033-8231-15 1/16W 82kΩ

R 209 033-6811-15 1/16W 680Ω

R 210 033-6831-15 1/16W 68kΩ

R 211 033-1831-15 1/16W 18kΩ

R 212 033-2721-15 1/16W 2.7kΩ

R 213 033-1011-15 1/16W 100Ω

R 214 033-1021-15 1/16W 1kΩ

R 215 033-1031-15 1/16W 10kΩ

R 217 033-1041-15 1/16W 100kΩ

R 218 033-2211-15 1/16W 220Ω

R 301 117-6811-15 1/16W 680Ω

R 304 033-3921-15 1/16W 3.9kΩ

R 305 033-3921-15 1/16W 3.9kΩ

R 306 033-1041-15 1/16W 100kΩ

R 307 033-2211-15 1/16W 220Ω

S 1 013-7414-50 CHUCKING

S 2 013-7413-50 LIMIT

X 102 060-1528-90 16.934M

Step 1

Cut cable tie and remove all screw from Heat Sink,

(G), (H) & (I)

Step 2

Remove Heat Sink, (F)

Step 3

Remove Lower Case, (A)

Step 4

Unsolder extention lead 7 pin, (J)

Step 5

Unsolder extention lead 4 pin, (K)

Step 6

Remove Escutcheon, (L)

Step 7

Unsolder 3 point on the main PWB, (B)

Step 8

After unsolder main PWB remember to remove flat

wire (C) between main PWB (B), and Mechanism, (E)

Step 9

Remove Main PWB, (B)

Step 10

Unscrew the mechanism from the upper case, (D)

REMOVING MAIN PWB FOR REPAIR

No Part Number Part Name QTY

A 311-1848-00 LOWER CASE 1

B 039-2067-00 MAIN PWB 1

C 816-2573-60 FLAT WIRE 1

D 731-3004-80 TAPTIGHT 3

E 929-0220-80 MECHANISM 1

F 313-1838-00 HEAT SINK 1

G 731-3008-80 TAPTIGHT 5

H 714-3006-81 MACHINE SCREW 1

I 731-3012-80 TAPTIGHT 3

J 854-2572-60 EXTENTION LEAD 7P 1

K 854-2571-60 EXTENTION LEAD 4P 1

L - ESCUTCHEON 1

- 13 -

DB125

DB125

- 14 -

Page 8

CIRCUIT DIAGRAM 1/2

Main P.W.B. section (B1)

- 15 -

DB125

Page 9

PRINTED WIRING BOARD

Section (B1), (B2), (B3)

(B)

(B2)

- 16 -

(B3)

DB125

Page 10

CIRCUIT DIAGRAM 2/2

Main PWB Section (B2) & (B3)

(B3)

(B2)

DB125

- 17-

Page 11

CIRCUIT DIAGRAM OF THE CD MECHANISM

CD Mechanism PWB (B4), (B5), (B6)

PRINTED WIRING BOARD OF THE CD MECHANISM

CD Mechanism Section (B4), (B5), (B6)

(B6)

(B4)

(B5)

(B5)

DB125

(B6)

- 18 -

Loading...

Loading...