Page 1

CITIZEN

User's Manual

Model : CBM-270

Line Thermal Printer

Rev 1.00 Newly issued on 07.Oct.1998

Rev 2.00 Newly issued on 24.Nov.1998

Manufacturer’s Name : : Japan CBM Corporation

Manufacturer’s Address : CBM Bldg., 5-68-10, Nakano, Nakano-ku

Declare the Product

Product Name Line Thermal Printer

Model Number(s) CBM-270

Japan CBM Corporation

Information Systems Div.

Declaration of Conformity

Tokyo, 164-0001, Japan

(CBM-270R, CBM-270P)

(S.No.9880001 - )

Page 2

Conform to the following Standards

LVD : EN60950 : A4

EMC : EN55022 : 1994 Class A

: EN61000-3-2 : 1995

: EN50082-1 : 1992

: IEC801-2 : 1991 4KV CD, 8KV AD

: IEC801-3 : 1984 3V/m, 26MHz-1000MHz AM1KHz 80%

: IEC801-4 : 1988 ±0.5KV Signal Line ±1KV AC mains

Supplementary Information

“The product complies with the requirements of the Low Voltage Directive 73/23/EEC, 93/68/EEC and

the EMC Directive 89/336EEC, 92/31/EEC, 93/68EEC”

Place Tokyo, Japan Signature

Date July.1998

Europe Contact :

Norco Declaration AB

Box 7146 S-250 07 Helsingborg Sweden

CBM-270 User’s Manual

Full Name : Mikio Moriya

Position : General Manager

R & D Department

Warning

This is a Class A products. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

This declaration is applied only for 230V model.

IMPORTANT SAFETY INSTRUCTIONS

•Read all of these instructions and save them for future reference.

•Follow all warnings and instructions marked on the product.

•Unplug this product from the wall outlet before cleaning. Do not use liquid or aerosol cleaners. Use a

damp cloth for cleaning.

•Do not use this product near water.

•Do not place this product on an unstable cart, stand or table. The product may fall, causing serious

damage to the product.

•Slots and openings on the back or bottom of the case are provided for ventilation. To ensure reliable

operation of the product and to protect it from overheating, do not block or cover these openings. The

openings should never be blocked by placing the product on a bed, sofa, rug of other similar surface.

This product should never be placed near or over a radiator or heater. This product should not be placed

in an built-in installation unless proper ventilation is provided.

•This product should be operated from the type of power source indicated on the marking label. If you re

Page 3

CBM-270 User’s Manual

not sure of the type of power available, consult your dealer or local power company.

•Do not allow anything to rest on the power cord. Do not place this product where the cord will be walked

on.

•If an extension cord is used with this product, make sure that the total of the ampere ratings of the

products plugged into the extension cord does not exceed the extension cord ampere rating. Also, make

sure that the total of all products plugged into the wall outlet does not exceed 15 amperes.

•Never push objects of any kind into this product through cabinet slots as they may touch dangerous

voltage points or short out parts that could result in a risk of fire or electric shock. Never spill liquid of

any kind on the product.

•Except as explained elsewhere in this manual, do not attempt to service this product by yourself. Opening

and removing the covers that are marked “Do Not Remove” may expose you to dangerous voltage

points or other risks. Refer all servicing on those compartments to service personnel.

•Unplug this product from the wall outlet and refer servicing to qualified service personnel under the

following conditions:

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the product.

C. If the product has been exposed to rain or water.

D. If the product does not operate normally when the operating instructions are followed. Adjust only

those controls that are covered be the operating instructions since improper adjustment of other

controls may result in damage and will often require extensive work by a qualified technician to

restore the product to normal operation.

E. If the product has been dropped or the cabinet has been damaged.

F. If the product exhibits a distinct change in performance, indicating a need for service.

•Please keep the poly bag which this equipment is packed in away from children or throw it away to

prevent children from putting it on. Putting it on may cause suffocation.

WICHTIGE SICHERHEITSANWEISUNGEN

•Lesen Sie die nachfolgenden Anweisungen sorgfältig durch und bewahren Sie sie auf.

•Befolgen Sie alle auf dem Drucker vermerkten Hinweise und Anweisungen. Vor dem Reinigen

grundsätzlich Stecker aus der Steckdose ziehen. Keine Flüssigkeiten oder Aerosolreiniger benutzen.

Nut mit einem feuchten Tuch abwischen.

•Der Drucker darf nicht in der Nähe von Wasser aufgestellt werden.

•Drucker nicht auf einem unstabilen Wagen, Stand oder Tisch aufstellen. Der Drucker könnte

herunterfallen und dabel beschädigt werden.

•Schlitze und Öffnungen im Gehäuse, in der Rückwand und im Boden dienen der Belüftung. Sie dürfen

keinesfalls zugedeckt oder blockiert werden, da sich der Drucker sonst überhitzt. Drucker nicht auf ein

Bett, Sofa, Teppich oder dergleichen stellen. Drucker nicht in der Nähe eines Heizkörpers aufstellen.

Drucker darf nicht eingebaut werden, falls nicht für ausreichende Belüftung gesorgt ist.

•Drucker nur mit der auf dem Typschild angegebenen Spannung betreiben. Wenn Sie sich nicht sicher

sind, fragen Sie ihren Händler oder ihr zuständiges Elektrizitätswerk.

•Nichts auf das Stromanschlußkabel stellen. Kabel muß so verlegt werden, daß man nicht darauftreten

kann.

•Ein etwaiges Verlängerungskabel muß der Stromstärke aller daran angeschlossenen Geräte entsprechen.

•Keine Gegenstände in die Gehäuseschlitze schieben.

•Drucker darf nur da gewartet werden, wo im Handbuch angegeben, Öffnen und. Abnehmen von

Page 4

CBM-270 User’s Manual

Abdeckungen, die mit “Do not remove” gekennzeichenet sind, könnte gefährliche spannungführende

Stellen oder sonstige Gefahrenpunkte freilegen. Die Wartung solcher Stellen darf grundsätzlich nur von

besonders ausgebildetem Fachpersonal vorgenommen werden.

A. Wenn das Stromanschlußkabel oder der Stecker beschädigt oder durch-gescheuert ist.

B. Wenn Flüssigkeit auf dem Drucker verschüttet wurde.

C. Wenn der Drucker im Regen gestanden hat oder Wasser darauf verschüttet wurde.

D. Wenn der Drucker trotz genauer Befolgung der Betriebsvorschriften nicht richtig arbeitet. Nur die

in der Bedienungsanleitung angegebenen Einstellungen vornehmen. Ein Verstellen anderer

Bedienungselemente könnte den Drucker beschädigen und macht umständliche Arbeiten eines

qualifizierten Technikers erforderlich, um den Drucker Wieder auf den normalen Betrieb

einzustellen.

E. Wenn der Drucker heruntergefallen ist oder das Gehäuse beschädigt wurde.

F. Wenn der Drucker in seiner Leistung nachläßt.

•Bitte halten Sie den Kunststoffbeutel, in den die Ware verpackt ist, von Kindern entfernt,

oder werfen Sie ihn weg, damit er nicht in die Hande von Kindern gerät. Das Überstülpen

des Beutels kann zum Ersticken führen.

Lärmemission kleiner 70dBA

Page 5

CBM-270 User’s Manual

IMPORTANT: This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used in accordance with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A computing device

pursuant to Subpart J of Part 15 off FCC Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference, in which case the user at his own expense will be required to take

whatever measures may be necessary to correct the interference.

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Grät angebracht und leicht zugänglich sein.

For Uses in Canada

This digital apparatus does not exceed the class A limits for radio noise emissions from digital, apparatus,

as set out in the radio interference regulations of the Canadian department of communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les émissions de bruit radio émanant

d’appareils numériques, tel que prévu dans les réglements sur l’interférence radio du départment Canadien

des communications.

<CAUTIONS>

1. Prior to using the equipment, be sure to read this User's Manual thoroughly. Please keep it handy for reference

whenever it may be needed.

2. The information contained herein may be changed without prior notice.

3. Reproduction of part or all of this User's Manual without permission is strictly prohibited.

4. Never service, disassemble, or repair parts that are not mentioned in this User's Manual.

5. Note that we will not be responsible for damages attributable to a user's incorrect operation/ handling or an

improper operating environment.

6. Operate the equipment only as described in this User's Manual; otherwise accidents or problems may result.

7. Data are basically temporary; they cannot be stored or saved permanently or for a long time. Please note that we

will not be responsible for damages or losses of profit resulting from losses of the data attributable to accidents,

repairs, tests, and so on.

8. If you have any questions or notice any clerical errors or omissions regarding the information in this manual,

please contact our office.

9. Please note that, notwithstanding Item 8 above, we will not be responsible for any effects resulting from

operation of the equipment.

Page 6

CBM-270 User’s Manual

Page 7

CBM-270 User’s Manual

SAFETY PRECAUTIONS ----- BE SURE TO OBSERVE

In order to prevent hazards to an operator or other persons and damage to property, be sure to

observe the following precautions.

• The following describes the degrees of hazard and damages that can occur if the given instructions are

neglected or the equipment is incorrectly operated.

WARNING Negligence of this precaution may result in death or serious injury.

CAUTION Negligence of this precaution may result in injury or damage to property.

This is an illustration mark used to alert your attention.

This is an illustration mark used to indicate such information as an instruction or the like.

Page 8

CBM-270 User’s Manual

WARNING

• Never handle the equipment in the following manners, as it may break, become out of order, or overheat

causing smoke and resulting in fire or electric shock.

If the equipment is used in an abnormal condition, such as when broken, then problems, smoke

emission, abnormal odor/noise, and fire can result. If an abnormal condition exists, be sure to

disconnect the power plug from a plug socket, and contact our dealer. Never repair the equipment on

your own - it is very dangerous.

• Do not allow the equipment to receive a strong impact or shock, such as kicking, stomping, hitting,

dropping, and the like.

• Install the equipment in a well-ventilated place. Do not use it in such a manner that its ventilation port

will be blocked.

• Do not install the equipment in a place like a laboratory where chemical reactions are expected, or in a

place where salt or gases are contained in the air.

• Do not connect/disconnect a power cord or a data cable, while holding the cable. Do not pull, install,

use, or carry the equipment in such a manner that force will be applied to the cables.

• Do not drop or insert any foreign substances, such as clips or pins, into the equipment.

• Do not spill any liquid or spray any chemical-containing liquid over the equipment. If any liquid is

spilled on it, turn off the power, disconnect the power cable and power cord from the plug socket, and

so on, and contact our dealer.

• Never disassemble or remodel the equipment. Negligence of this may cause fire or

electric shock.

• Use the equipment only with the specified commercial power supply and AC adapter. Negligence of

this may result in fire, electric shock, or problems.

• If you drop or break the AC adapter, or if water or the like gets inside it, unplug it immediately from the

socket and contact your dealer.

• Do not damage, break, process, bend/pull by force, twist, or head an AC adapter cord. Also, do not put

a heavy substance on it or heat it. The AC adapter cord could be broken, resulting in fire, electric

shock, or trouble. If the AC adapter cord is damaged, contact our dealer.

• Do not connect/disconnect the AC adapter with wet hands.

• Do not overload a single electrical outlet, using a table tap or a current tap socket.

• An equipment packing bag must be discarded or kept away from children. A child can suffocate if the

bag is placed over the head.

Page 9

CBM-270 User’s Manual

PRECAUTIONS FOR INSTALLATION

• Do not use or store the equipment in a place exposed to fire, moisture, or direct sunshine, or in a place

near a heater or thermal device where the prescribed operating temperature and humidity are not met, or

in a place exposed to much oil, iron powder, or dust. The equipment may become out of order, emit

smoke, or catch fire.

• Do not install or use the equipment in a place like a laboratory where chemical reactions are expected,

or in a place where salt or gases are contained in the air. There is a danger of fire or electric shock.

• Install the printer on a flat, stable desk or table that is free from vibration, in a well-ventilated place.

• Do not install the printer at a location where its operation could be hindered.

• Do not place anything on the printer or leave small objects, like a clip or pin, around it. A foreign object

could cause trouble if it gets inside.

• Do not use any sharp-pointed object, such as a pen, for example, to touch the operation panel of the

printer. It could cause trouble.

• Do not use the equipment near a radio or TV receiver. Do not share the power from a plug socket a

radio or TV receiver is connected to. It may cause a reception problem.

• Use the equipment only at the specified power supply, voltage and frequency. Otherwise, it may emit

smoke and catch fire or cause other problems.

• Connect only the specified power source. Use of an unspecified power source could cause trouble or

smoke/fire.

• Confirm that a plug socket used for connection has sufficient capacity.

• Avoid connecting a power cable to a plug socket shared by other devices or extending the wiring too

far. It may result in the cable catching fire or a power outage. Also, do not step on or apply an

excessive force (Pull, load) to the cable, and do not use the printer with such a force applied to it.

• Never connect a grounding cable (Frame ground) to a gas pipe. There is a danger of explosion. When

connecting or disconnecting the grounding cable, be sure to disconnect the power cable and the power

plug from the plug socket.

• When connecting/disconnecting the cables, be sure to turn off the power first, including the connected

side, and then connect/disconnect them, holding a plug and a connector. Pulling the cable itself could

cause it to snap or become damaged.

• Connect a power cable or a connector cable securely. If a reverse-polarity connection is made, internal

elements may be broken or a mating device may be adversely affected.

• Use a shielding wire or twisted pair wire for a signal line, in order to minimize noise effect. Do not

route the cable too long or connect it to a noisy device. Connection to a noisy device could cause

erroneous printing due to corrupt data, and so on.

• Use the equipment in an environment where there is a plug socket near the main body and you can

easily disconnect the power plug from it, to shut off the power.

• When the equipment will not be used for a long period of time, unplug it and remove the paper roll from

it.

• When transporting the equipment, remove the paper roll from the paper holder.

Page 10

CBM-270 User’s Manual

PRECAUTIONS FOR HANDLING

Do not handle the equipment in the following manners, because problems may result.

• Do not use any other power source besides the accessory AC adapter. Also, do not use the AC adapter

for other purposes.

• Do not print without paper.

• Do not drop or put any foreign object, such as a clip, pin, or the like, inside the printer.

• Do not spill any liquid or spray any chemical-containing liquid over the equipment.

• Never use a pointed object, such as a pen, to operate the operation panel.

• Do not use Scotch tape to fasten paper together for continuous use. It could damage the printing head.

• Never pull the set paper forcibly. When opening/closing the printer cover, take care that the paper will

not be caught. It could cause the paper to jam.

• Be sure to use the specified paper. Use of other paper could deteriorate the print quality or cause a

problem with the printing head.

To Prevent Injury and Spreading of Damage

• Never touch the printing head, motor, or paper cutting blade. Your finger may be cut.

• During power-on or immediately after printing, do not touch electrical parts or moving parts, such as the

mechanism, motor, internal gear, etc. They may be very hot and can burn your hand/finger.

• Be careful to avoid bodily injure or damaging other objects with an edge of sheet metal.

• Should any error occur while operating the equipment, stop it immediately and disconnect the power

plug from the plug socket.

• Only a qualified serviceman is allowed to disassemble or repair the printer.

• Should a problem occur, leave solving it to our serviceman. Do not disassemble the equipment on your

own.

• When opening/closing the printer cover, and so on, be careful not to catch your hand or finger on the

equipment.

• After using the equipment, turn off the power switch and unplug the AC adapter from a plug socket.

Page 11

CBM-270 User’s Manual

DAILY MAINTENANCE

• At the time of maintenance, be sure to turn off the power switch of the printer and unplug it from the

socket.

• Use a dry soft cloth to wipe off stains and dust from the surfaces of the main body case. For severe

soiling, dip the cloth in water and wring it, for wiping off the soil. Never use organic solvents, such as

alcohol, thinner, trichlene, benzene, ketone, or chemical dusters.

• If the equipment is contaminated with paper powder, use a soft brush to clean it. Be careful not to

damage the printing head.

CAUTION: The printing head and motor are very hot. Be careful not to touch them immediately

after printing. Do not touch the heating surface of the head with a bare hand or metal.

• Cleaning the Printing Head

1. Referring to "4.5 Removing Paper Jam," detach the platen roller unit.

2. Moisten gauze slightly with alcohol, and clean the heating surface of the printing head with it.

3. Reattach the platen roller unit.

CAUTION: The printing head and motor are very hot. Be careful not to touch them immediately

after printing. Do not touch the heating surface of the head with a bare hand or metal.

When detaching or reattaching the platen roller unit, be sure to raise up the printing

head; otherwise, they could be damaged. Handle the detached platen roller unit

carefully so as not to damage it.

Page 12

CBM-270 User’s Manual

CONTENTS

1. OUTLINE.........................................................................................................................................................15

1.1 Features......................................................................................................................................................................15

1.2 Unpacking..................................................................................................................................................................15

2. BASIC SPECIFICATIONS.............................................................................................................................. 16

2.1 Model Classifications.................................................................................................................................................16

2.2 Basic Specifications...................................................................................................................................................17

2.3 Paper Specifications...................................................................................................................................................18

2.3.1 Recommended Paper......................................................................................................................................... 18

2.3.2 Printing Position................................................................................................................................................19

2.3.3 Head and Paper Cutter Layout.......................................................................................................................... 19

3. OUTER APPEARANCE AND COMPONENT PARTS....................................................................................20

4. OPERATION...................................................................................................................................................22

4.1 Connecting AC Adapter............................................................................................................................................. 22

4.2 Connecting Interface Cable........................................................................................................................................23

4.3 Inserting the Paper .....................................................................................................................................................24

4.4 How to Remove Remaining Paper Roll.....................................................................................................................25

4.5 Eliminating the Paper Jam ......................................................................................................................................... 26

4.6 FEED Switch Function.............................................................................................................................................. 27

4.6.1 When Thermal Paper is Used............................................................................................................................ 27

4.6.2 When Label Paper is Used................................................................................................................................ 27

4.6.3 When the Macro is Executed ............................................................................................................................27

4.6.4 When the Label is Fed to the Paper Cutting Position by the Command...........................................................27

4.7 Paper End Function....................................................................................................................................................27

4.8 Paper Near End Function...........................................................................................................................................28

4.9 Auto-Loading Function.............................................................................................................................................. 29

4.10 Self-Print Function.....................................................................................................................................................29

4.11 Operation Panel and Display of Error........................................................................................................................ 30

4.12 Red/Black Print (Precations for use)..........................................................................................................................31

5. DIP SWITCH SETTING..................................................................................................................................32

5.1 Location of DIP Switch..............................................................................................................................................32

5.2 DIP Switch Function..................................................................................................................................................32

5.3 Jumper Wire Function................................................................................................................................................33

6. PARALLEL INTERFACE ...............................................................................................................................34

6.1 Specifications.............................................................................................................................................................34

6.2 Connector's Pin Configuration...................................................................................................................................34

6.3 Input and Output Signals............................................................................................................................................35

6.3.1 Input and Output Signals................................................................................................................................... 35

6.3.2 Electrical Characteristics................................................................................................................................... 36

6.3.3 Timing Chart..................................................................................................................................................... 37

6.3.4 Data Receiving Control.....................................................................................................................................37

6.3.5 Buffering ...........................................................................................................................................................37

7. SERIAL INTERFACE .....................................................................................................................................38

7.1 Specifications.............................................................................................................................................................38

7.2 Connector's Pin Configuration...................................................................................................................................38

7.3 Input and Output Signals............................................................................................................................................39

7.3.1 Input and Output Signals................................................................................................................................... 39

7.3.2 Data Configuration............................................................................................................................................40

Page 13

CBM-270 User’s Manual

7.3.3 Error Detection..................................................................................................................................................40

7.3.4 Data Receiving Control.....................................................................................................................................41

7.3.5 Buffering ...........................................................................................................................................................41

7.3.6 Electrical Characteristics................................................................................................................................... 41

8. POWER CONNECTOR...................................................................................................................................42

9. MAINTENANCE AND SERVICE...................................................................................................................43

10. PRINT CONTROL FUNCTIONS.....................................................................................................................44

10.1 Command List............................................................................................................................................................ 44

10.2 Command Details.......................................................................................................................................................46

10.2.1 Descriptions of Each Items...............................................................................................................................46

10.2.2 Command Details..............................................................................................................................................47

11. CHARACTER CODES TABLE.......................................................................................................................88

11.1 International............................................................................................................................................................... 88

11.2 Domestic ....................................................................................................................................................................88

11.3 International Character Codes Table..........................................................................................................................89

APPENDIX 1. BLOCK DIAGRAM ..................................................................................................................90

APPENDIX 2. DRAWING.................................................................................................................................91

APPENDIX 3. WALL MOUNTING HOLES LAYOUT DRAWING......................................................................92

<<< German >>>

4. BETRIEB.......................................................................................................................................................100

4.1 Anschließen des Netzteils........................................................................................................................................100

4.2 Anschließen des Schnittstellenkabels ...................................................................................................................... 101

4.3 Einsetzen des Papiers...............................................................................................................................................102

4.4 Entnehmen der eingesetzten Papierrolle..................................................................................................................103

4.5 Beheben von Papierstau...........................................................................................................................................104

4.6 FEED-Schalterfunktion............................................................................................................................................104

4.6.1 Bei Verwendung von Thermalpapier..............................................................................................................104

4.6.2 Bei Verwendung von Etikettenpapier............................................................................................................. 104

4.6.3 Bei Ausführung eines Makros......................................................................................................................... 104

4.6.4 Wenn das Etikett mit Befehl bis zur Papierschneideposition vorgeschoben wird..........................................104

4.7 Papierende-Funktion................................................................................................................................................105

4.8 Papiermangel-Funktion............................................................................................................................................105

4.9 Autoladefunktion .....................................................................................................................................................107

4.10 Selbstdruckfunktion................................................................................................................................................. 107

4.11 Bedienfeld und Fehleranzeigen................................................................................................................................ 108

4.12 Rot/Schwalts-Druck(Vorsichtsmaßregeln):.............................................................................................................110

5. DIP-SCHALTEREINSTELLUNG .................................................................................................................111

5.1 Lage der DIP-Schalter.............................................................................................................................................. 111

5.2 DIP-Schalterfunktion............................................................................................................................................... 111

Page 14

CBM-270 User’s Manual

5.3 Jumperdraht-Funktion..............................................................................................................................................111

9. WARTUNG UND DIENST............................................................................................................................ 113

Page 15

CBM-270 User’s Manual

1. OUTLINE

This small line thermal printer is designed for various types of data communication terminals and measuring

instrument terminals. Its abundant built-in features allow you to widely use this printer for different

applications. Prior to using it, read and understand this manual thoroughly.

1.1 Features

1. Small, lightweight, and installable in a narrow area

2. High speed and low noise, owing to line thermal print

3. Long-life printing head and high reliability, owing to the simple mechanism

4. Easy paper-loading, owing to the auto-loading function

5. Built-in input buffer

6. Capable of printing a bar code (Special command)

7. Capable of accommodating both thermal paper and label paper

8. A little discharge (1 sheet) of the label paper at power-on or paper replacement

9. Capable of printing in two colors (when special paper is used)

10. External characters registration function(94 kanji characters, 95 ANK characters)

1.2 Unpacking

When unpacking the package, confirm that the following parts are provided:

•Printer body ----- 1 unit

•Sample paper roll ----- 1 roll

•AC adapter ----- 1 piece

•AC cord ----- 1 piece

•User's manual ----- 1 copy

CAUTION

• Install the printer body on a flat and stable desk or mount it onto the wall, etc., using a hook, etc.

• Do not install the printer near a heater or in a place exposed to the direct sunshine.

• Do not use the printer in a high-temperature, high-humidity, or contaminated environment.

• Do not allow dew condensation to form on the printer. If such condensation should form, do not turn on the

power until it has completely gone away.

• Use only the accessory AC adapter. Do not use it for any other purpose.

• If you do not use the printer for a long period, disconnect the power cable from the socket.

• Keep this manual carefully at hand for ready reference.

2. BASIC SPECIFICATIONS

2.1 Model Classifications

The models are classified by the following designation method:

CBM-270 - R F 120 - N

Model Name

CBM-270: Standard Model

Label Paper Print Function

N: None

L : Label interval detection

M: Black mark detection

Page 16

∗ Special Switching Power Source and Power Cord

Switching power source : 27AD (Input: 100 to 240V AC)

Power cord : 100V AC --- 2-core cord

120V AC --- 2-core cord

230V AC --- 2-core cord

Cord length : Power cord(For AC Input) --- Approx. 1.8 m

Secondary side (For DC Output) --- Approx. 1.8 m

CBM-270 User’s Manual

International Characters

F: International

Interface

R: Serial (RS-232C)

P: Parallel

(CENTRONICS Compliant)

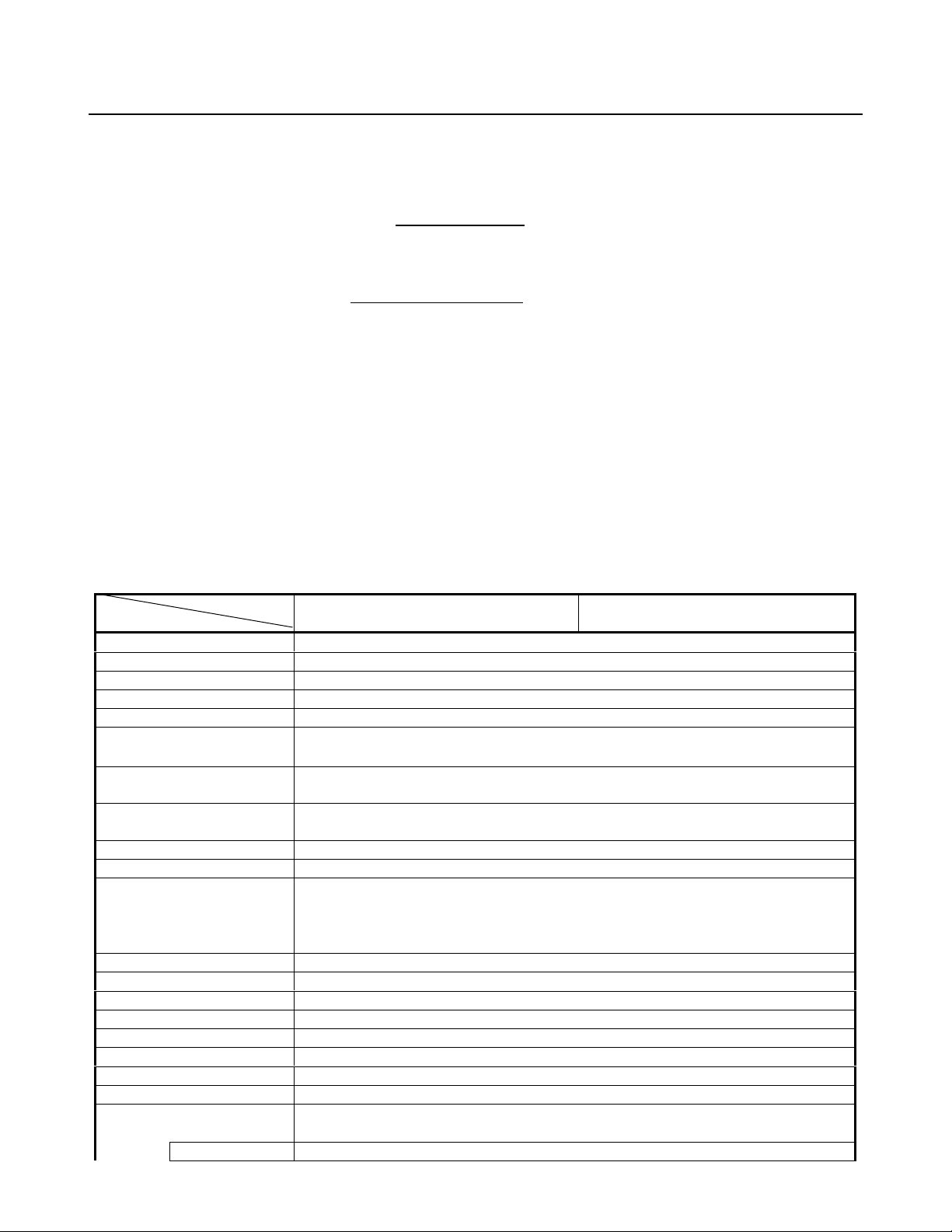

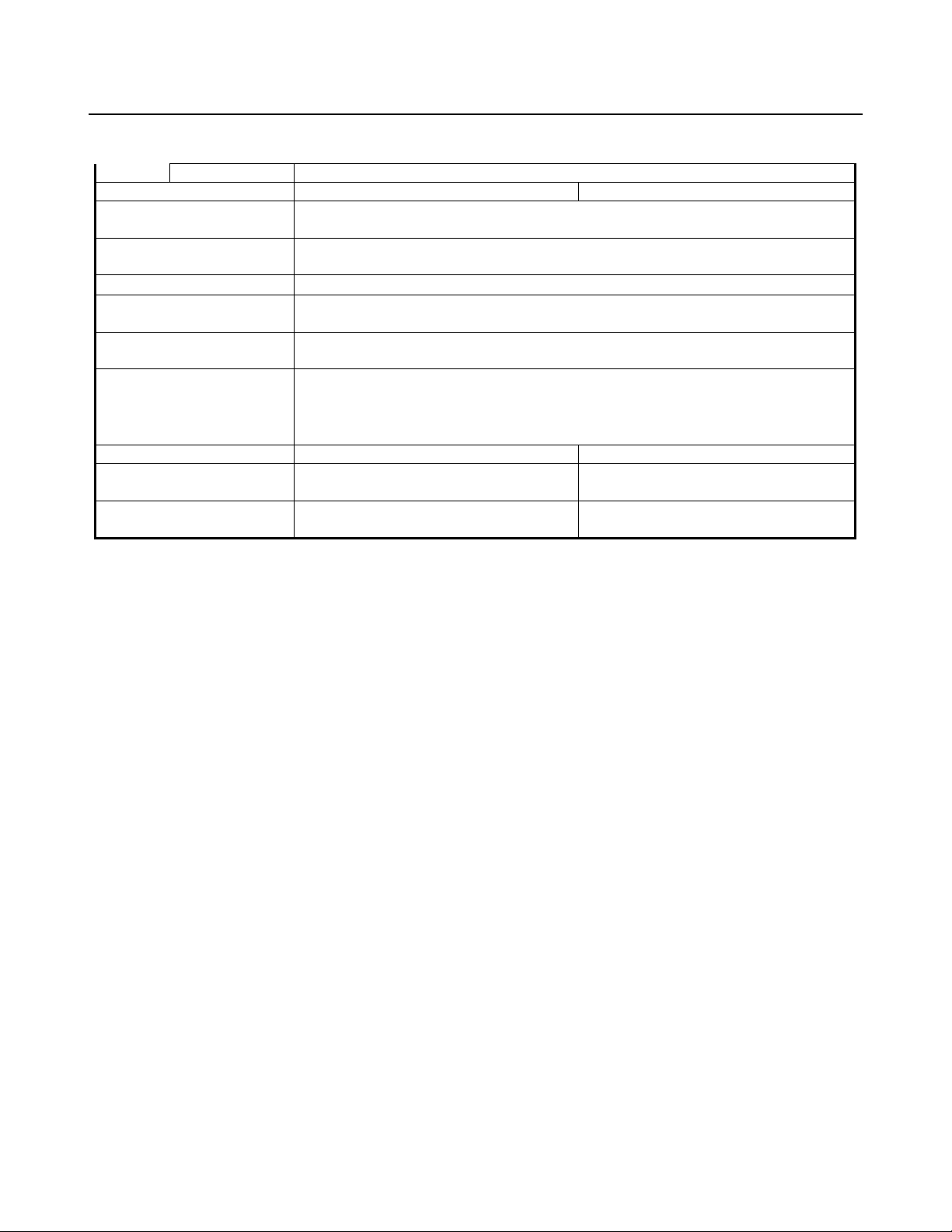

2.2 Basic Specifications

Model

Item

Printing system Line thermal dot printing

Printing width 48 mm (384 dots/line)

Dot density 8 dots/mm (Width, Length)

Paper feed pitch 0.125 mm

Printing speed Approx. 11 lines/sec. (At maximum)

Printing columns and

character size

Line interval Initial value: 4.23 mm (1/6 inch)

Character types Alphanumerals, symbols, international characters

Character code Domestic characters, IBM characters #2 (Choose either)

Bar code type UPC-A/E, JAN(EAN) 13-/8-column, ITF, CODE 39, CODE 128, CODABAR

Paper

(See Paper Specifications)

Interface Serial (RS-232C), Parallel (CENTRONICS compliant)

Input buffer 2 KB

Download characters Font A, B: 95 characters each

Auto-loading Provided (Can be enabled/disabled with the DIP switch)

Paper end function Provided

Paper near end function Provided (Can be enabled/disabled with the DIP switch)

Label detecting function Capable of selecting label interval detection, black mark detection, or none.

Printing color Capable of printing in two colors (red/black) with the special thermal paper.

AC adapter

Type 27 AD

32 columns (12 × 24 Font A) 1.25 × 3.00 mm

42 columns (9 × 24 Font B) 0.88 × 3.00 mm

Can be set with a command (1/360 inch at minimum)

(Choose from 10 countries)

Thermal paper roll : 58 + 0/- 1 mm xφ83 (max.) mm, 60∼75µm thick

Thermal label paper : 58 + 0/- 1 mm xφ83 (max.), 150µm thick (max.)

(L and M Spec. only) Label width: 56 mm (max.)

Rated input : 100∼240 V, 50/60 Hz, 40 VA

Rated output : 7.2 V DC, 2 A

CBM-270-RF120-*

CBM-270-PF120-*

Label length: 25 mm/sh. (min.)

CBM-270-RF230-*

CBM-270-PF230-*

Page 17

CBM-270 User’s Manual

AC cord 2-core cord (Depends on the destination)

Supply voltage 120 V AC +/- 10%, 60 Hz 230 V AC +/- 10%, 50/60 Hz

Power consumption At non-printing: Approx. 2 W

At printing: Approx. 15 W (approx. 20 W at maximum)

Weight Main body: Approx. 600 g (Paper roll excluded)

AC adapter: Approx. 350 g

Outer dimensions

Operating temperature and

humidity

Storage temperature and

humidity

Reliability

EMI *1 FCC Class-A EN55022 Class-A

Applicable standard (Main

body) *1

Applicable standard (Power

source)

∗ *1 indicates the standard satisfied when the AC adapter 27AD is used.

∗ GS and CE Marking are satisfied when the main body and AC adapter are combined.

106 (W) × 184 (D) × 110 (H) mm

5∼40°C, 35∼85 % RH (No dew condensation)

-20∼60°C, 10∼90% RH (No dew condensation)

Printing head life: (25°C)

Pulse resistance : 50 million pulses or more (Print rate 12.5%)

Wear resistance : 50 km or more (With recommended thermal paper at normal

temperature and humidity)

GS, CE Marking

UL, C-UL GS

Page 18

2.3 Paper Specifications

2.3.1 Recommended Paper

(1) Thermal paper roll

•Type : Thermal paper

•Paper width : 58 + 0/- 1 mm

•Paper thickness : 60∼75µm

•Roll diameter : φ83 mm or less

•Printing surface : Outside of the roll (Surface)

•Recommended paper : TF50KS-E2C (Monochrome) made by NIPPON SEISHI or its equivalent

PB670(2-color, Red based) made by MITSUBISHI SEISHI or its equivalent

•Core :φ12 mm(Inner dia.), φ18 mm (Outer dia.)

(2) Thermal label paper(L and M spec. only)

•Type : Thermal paper (Printing surface)

•Paper width : 58 + 0/- 1 mm

•Label width : 56 mm or less

•Label length : 25∼300 mm (For label interval detection)

25∼300 mm (For black mark detection) ∗ Black mark section excluded

•Label interval : 3∼300 mm (Black mark interval for the black mark detection)

•Black mark width : 15 mm or more (From the center of the paper, black paper only)

•Paper thickness : 150µm or less

•Roll diameter : φ83 mm or less (Depends on the outer diameter of the core)

•Printing surface : Outside of the roll (Surface)

•Recommended paper : For label interval detection

its equivalent

•Core : φ12 mm or more (Inner dia.), 3 mm thick

CBM-270 User’s Manual

735FA(2-color, Black based) made by RICOH or its equivalent

KPT86S P22 G63BC (Monochrome) made by OHJI TUCK or

For black mark detection

KPT865P (Monochrome) made by OHJI TUCK or its equivalent

CAUTION:

1. Use of non-specified paper may cause irregularity of print density. If this is the case, use the DIP switch to

reset print density. (See 5. DIP SWITCH SETTING)

2. Do not paste the paper to the core.

3. If the paper comes in contact with a chemical or oil, it may discolor or lose a record.

4. Do not rub the paper surface strongly with a nail or hard metal. It may discolor.

5. Discoloring starts at about 70°C. Watch out for effects of heat, humidity, light, and so on.

6. Do not use the label paper when the printer has been set for thermal paper, and vice versa. Be careful not to

mistake a type of label paper. It could cause malfunctioning or damage the printing head.

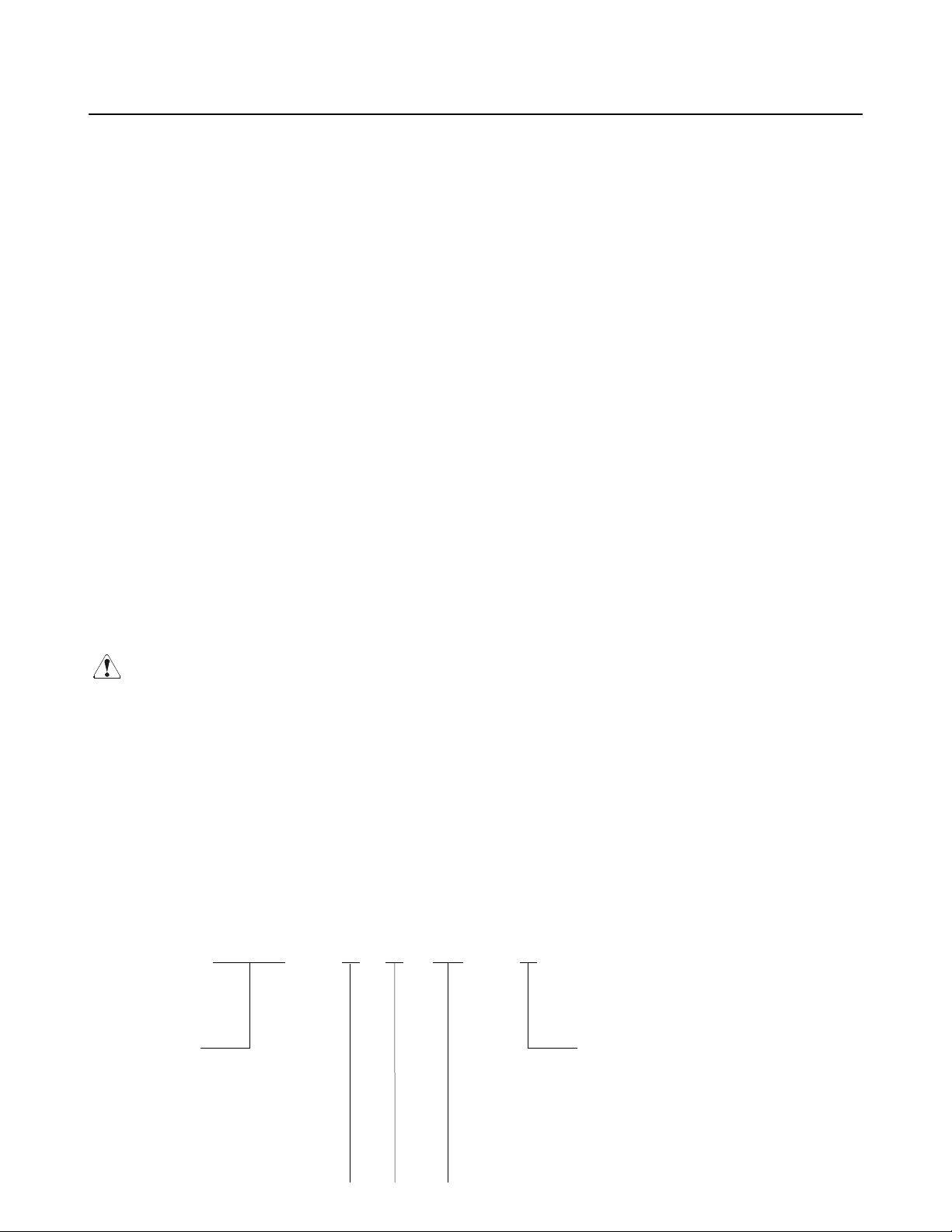

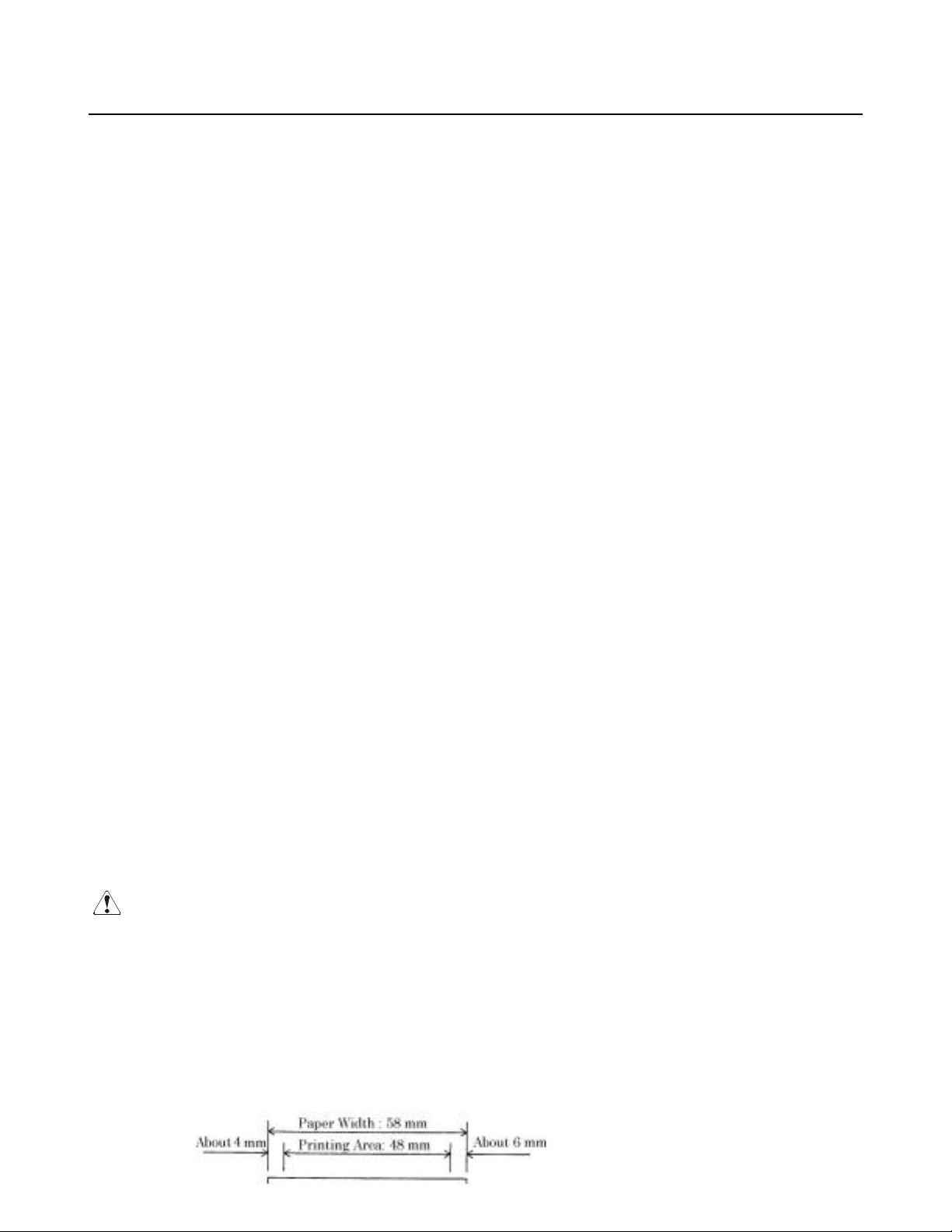

2.3.2 Printing Position

(1) Thermal paper

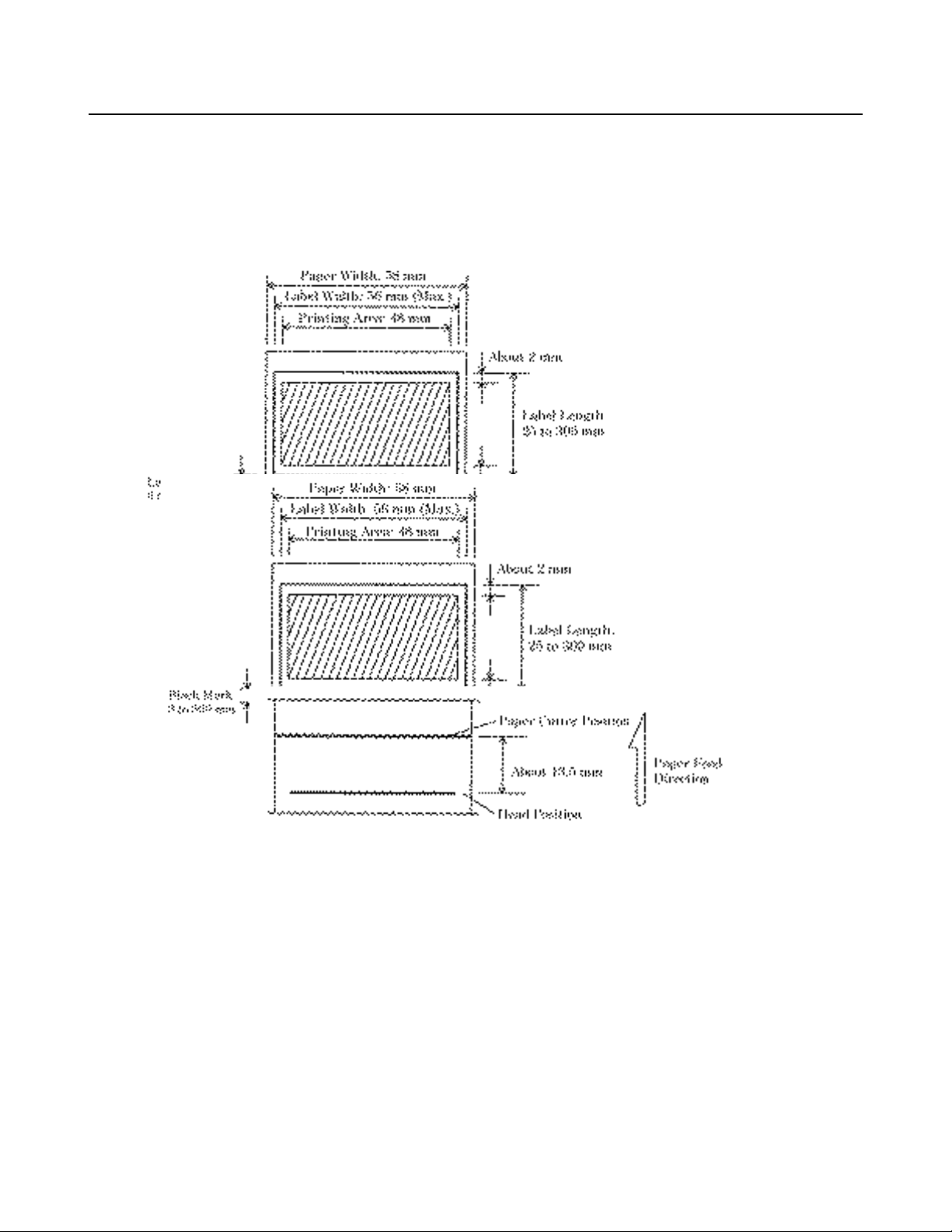

Page 19

(2) Label paper (For label interval detection) ∗ L spec. only

(3) Label paper (For black mark detection) ∗ M spec. only

CBM-270 User’s Manual

2.3.3 Head and Paper Cutter Layout

Page 20

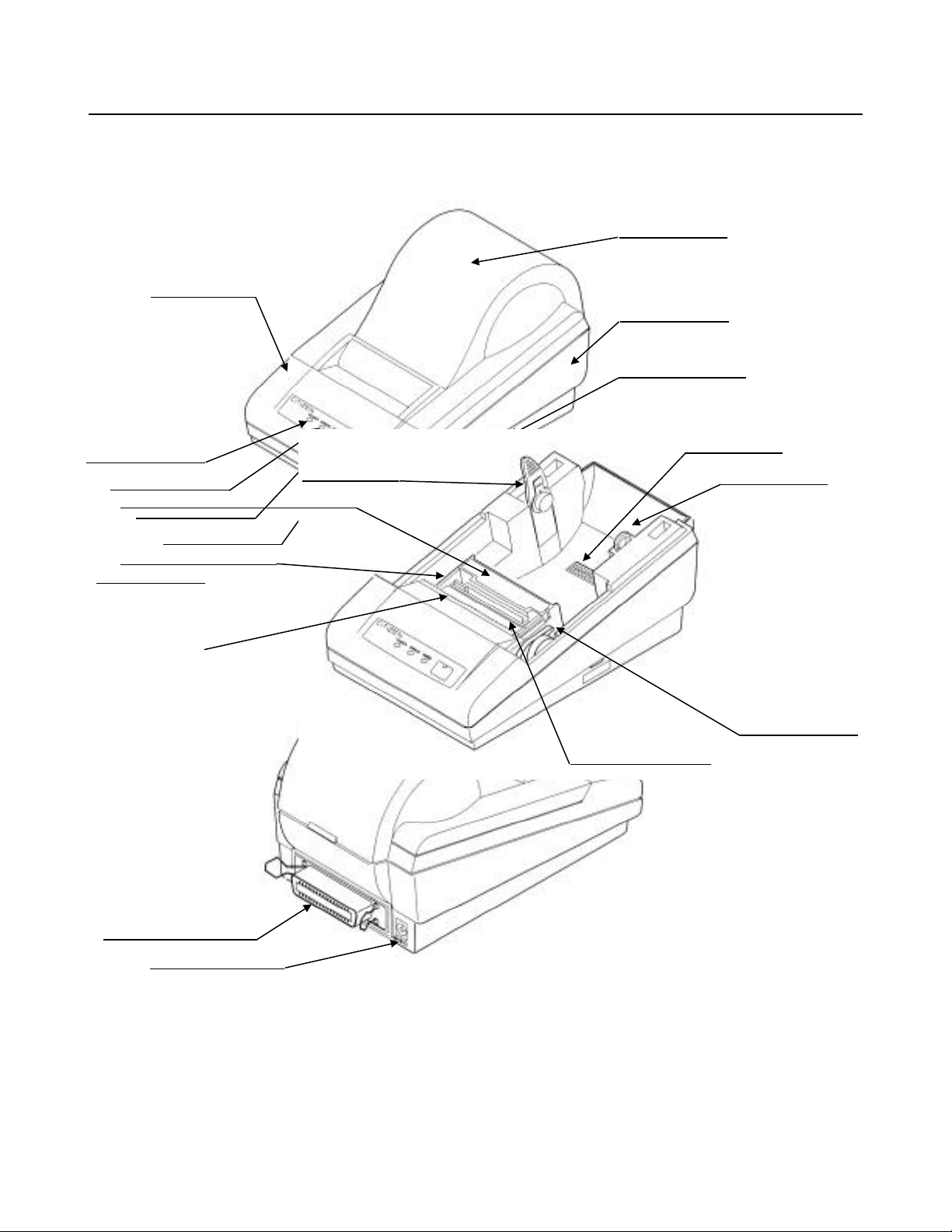

3. OUTER APPEARANCE AND COMPONENT PARTS

Printer Cover

CBM-270 User’s Manual

Upper Cover

POWER Lamp

ERROR Lamp

FEED Switch

Label Detection Sensor

PAPER Lamp

Printer Mechanism

(L and M spec. Only)

Paper Cutter

PNE Sensor

Bottom Cover

POWER Switch

DIP Switch

Paper Holder

Head-up Lever

(1) POWER switch

Turns on/off the power for the printer body.

Interface Connector

(2) POWER lamp

Power Connector

Illuminated when the power switch is turned on.

(3) ERROR lamp

Illuminated at the time of a head-up mechanical error, and blinks at the time of starting a macro.

(4) PAPER lamp

Illuminated when the paper is running out (when there is little paper left), and blinks when a label paper

cut is specified.

(5) FEED switch

Platen Roller Unit

Page 21

CBM-270 User’s Manual

Feeds the paper. It is fed continuously while the switch is held down. For the label paper, it is fed by

one label.

(6) Paper holder

Set the paper roll in this holder.

(7) PNE sensor

Detects that the paper is running out.

(8) DIP switch

Initially sets the printer at power-on and sets the functions.

(9) Label detection sensor (L and M spec. only)

Detects the labels. Deals with either the label interval or black mark.

(10) Platen roller unit

Detach this unit when the paper is jamming or when you clean the head.

(11) Head-up lever

Used when replacing the paper or detaching/reattaching the platen roller unit.

(12) Paper cutter

Cuts the printed paper.

(13) Power connector

Connects to the accessory AC adapter (27AD).

(14) Interface connector

Connects to a communication interface cable. There are two types, for serial and parallel interfaces.

(15) Printer cover

Detach this cover when replacing the paper.

4. OPERATION

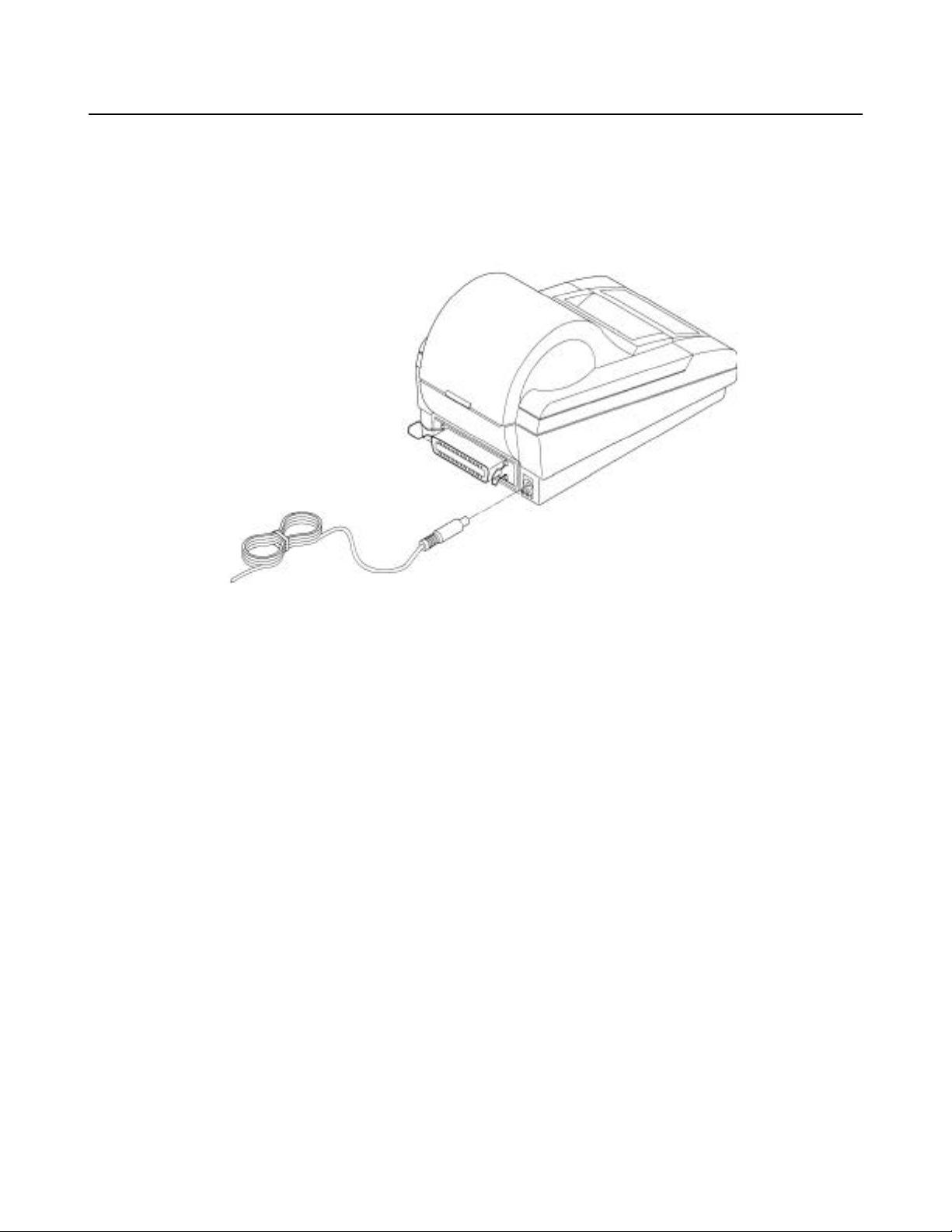

4.1 Connecting AC Adapter

1. Turn off the power.

2. Connect the cable connector of the AC adapter to the power connector located on the back of the printer.

3. Connect the AC power cord of the AC adapter, and plug it into a socket.

CAUTION:

1) Use only the specified AC adapter.

2) When disconnecting/reconnecting the cable connector of the AC adapter, be sure to hold the connector.

3) Separate the AC adapter from other noise-generating devices.

4) Pulling the AC power cord may damage it, resulting in a fire, electric shock, or snapping.

5) If a thunder/lightning storm is nearby, disconnect the AC adapter from the socket and do not use the printer,

because a fire or electric shock may occur.

6) Do not put the AC power cord close to a heating device. Its coating can melt and cause a fire or electric

shock.

7) Install the printer in a well-ventilated place, because the AC adapter generates heat when it is used.

8) Use the specified AC power source. Connect to a power source with sufficient capacity. If the capacity is

Page 22

CBM-270 User’s Manual

insufficient, a fire may result from heat generation.

9) After using the printer or when not using it for a long period of time, be sure to unplug the AC adapter from

a plug socket for your safety.

Page 23

CBM-270 User’s Manual

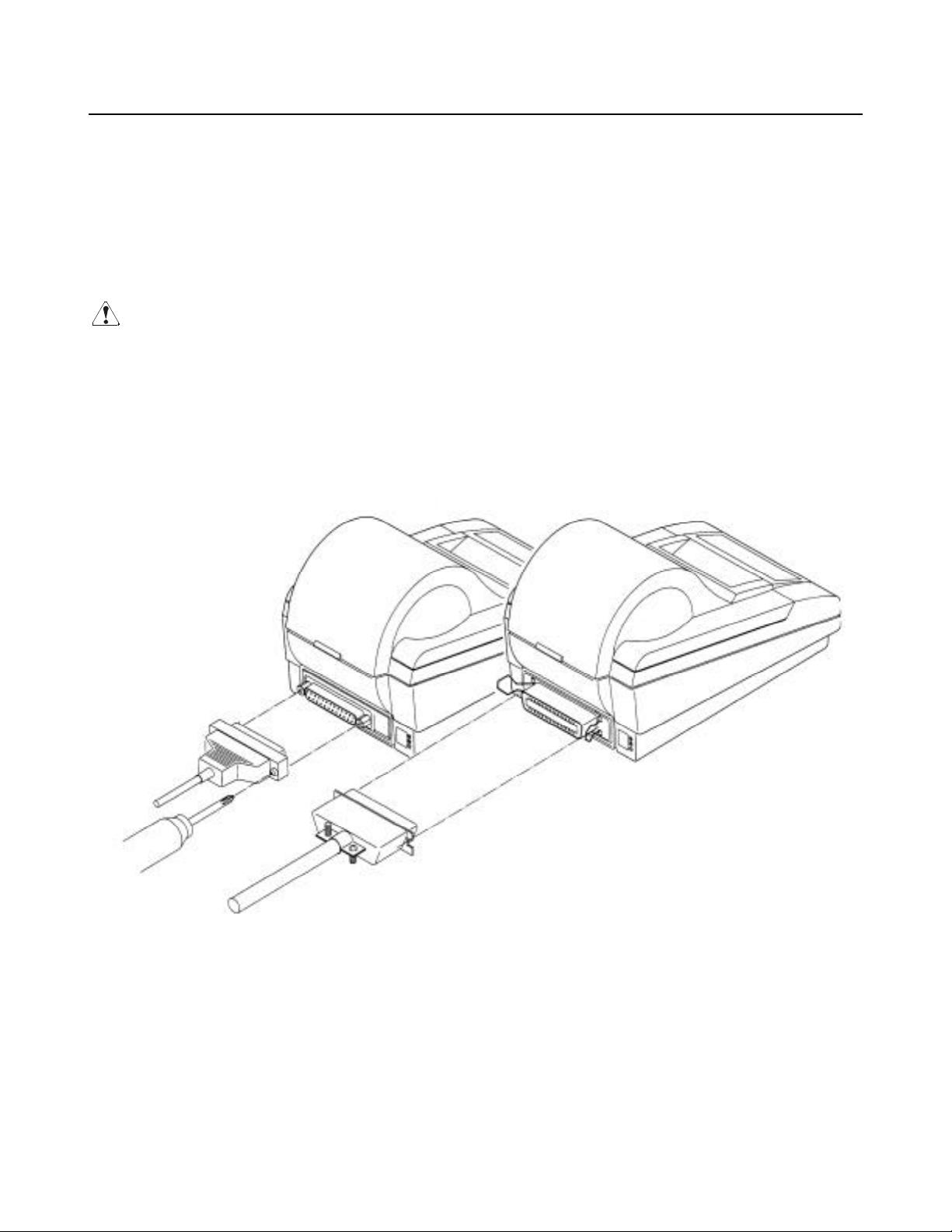

4.2 Connecting Interface Cable

1. Turn off the power. (Mating side included)

2. Check the top and bottom of cable terminals, and connect to the interface connector.

3. Fix the cable terminals. Serial interface : Tighten screws, to fix it.

Parallel interface : Turn a stopper, to fix it.

4. Connect the cable to the host computer.

CAUTION:

1) Referring to "6. PARALLEL INTERFACE" and "7. SERIAL INTERFACE," check the pin configuration of

the interface connector and cable. Wrong wiring could cause trouble or malfunctioning to not only the

printer body but also the host computer.

2) When disconnecting/reconnecting the interface cable, be sure to hold the connector. Pulling the cable itself

may snap the internal wires.

3) Connect the interface cable securely. Otherwise, communications may not be obtained due to a connection

failure.

Page 24

CBM-270 User’s Manual

4.3 Inserting the Paper

CAUTION:

1) Be sure to use the specified paper roll.

2) Use of non-specified paper may not guarantee the print quality, printing head life, and so on.

3) Do not use thermal paper when the printer has been set for label paper, and vice versa. It could cause

malfunctioning of the printer or damage the printing head.

1. Hold the convexity on the rear of the printer cover, and raise it upward.

2. Cut the front end of the paper roll almost at a right angle.

CAUTION:

1) The printer cover is not stationary (Opening/Closing). After detaching it, be careful not to lose or break it.

2) Do not insert a ragged or dog-eared end of the paper roll, because it could result in a paper jam or insertion

error.

3. Make sure that the power is turned on.

4. Pull the head-up lever to this side to raise up the printing head.

5. If there is still some paper remaining after a paper-out indication, eliminate the paper roll according to

"4.4 How to Remove the Remaining Roll Paper."

6. Insert the front end of the paper roll straight into a paper insertion slot.

7. Set the paper roll firmly in the paper holder.

8. Put back the head-up lever. The paper roll is automatically pulled in by the platen roller to feed a

constant amount of paper. (When auto-loading is enabled.) (For the label paper, it is fed to the print start

position of the 2nd sheet.)

9. Put back the printer cover.

CAUTION:

1) If the paper roll is still slack, rewind the paper to remove the slack.

2) If the paper roll is tilted, raise the head-up lever to correct the paper roll position, or pull out the paper roll

and set it again.

3) Do not open the printer cover while printing.

4) Do not hold or press the paper roll while printing, because it could cause a paper jam.

5) After the paper is set, the printer is made ready to start printing. Note that if data is remaining in the buffer,

the printer will start printing after the paper is set.

6) Do not run the printer with its cover removed, because it could cause malfunctioning or an irregularity of the

sensor.

Page 25

4.4 How to Remove Remaining Paper Roll

1. Remove the printer cover.

2. Raise the head-up lever.

3. Gently pull out the paper to the near side. If the paper roll is still remaining, cut it just before the paper

insertion slot before pulling it out.

CBM-270 User’s Manual

CAUTION:

1) Do not pull out the paper roll in the opposite direction.

2) If you do so with the label paper, the labels may come off.

3) Never take out paper with the head-up lever lowered, because it could damage the printing head.

4) The printer mechanism may be very hot just after printing, so be duly careful.

Page 26

CBM-270 User’s Manual

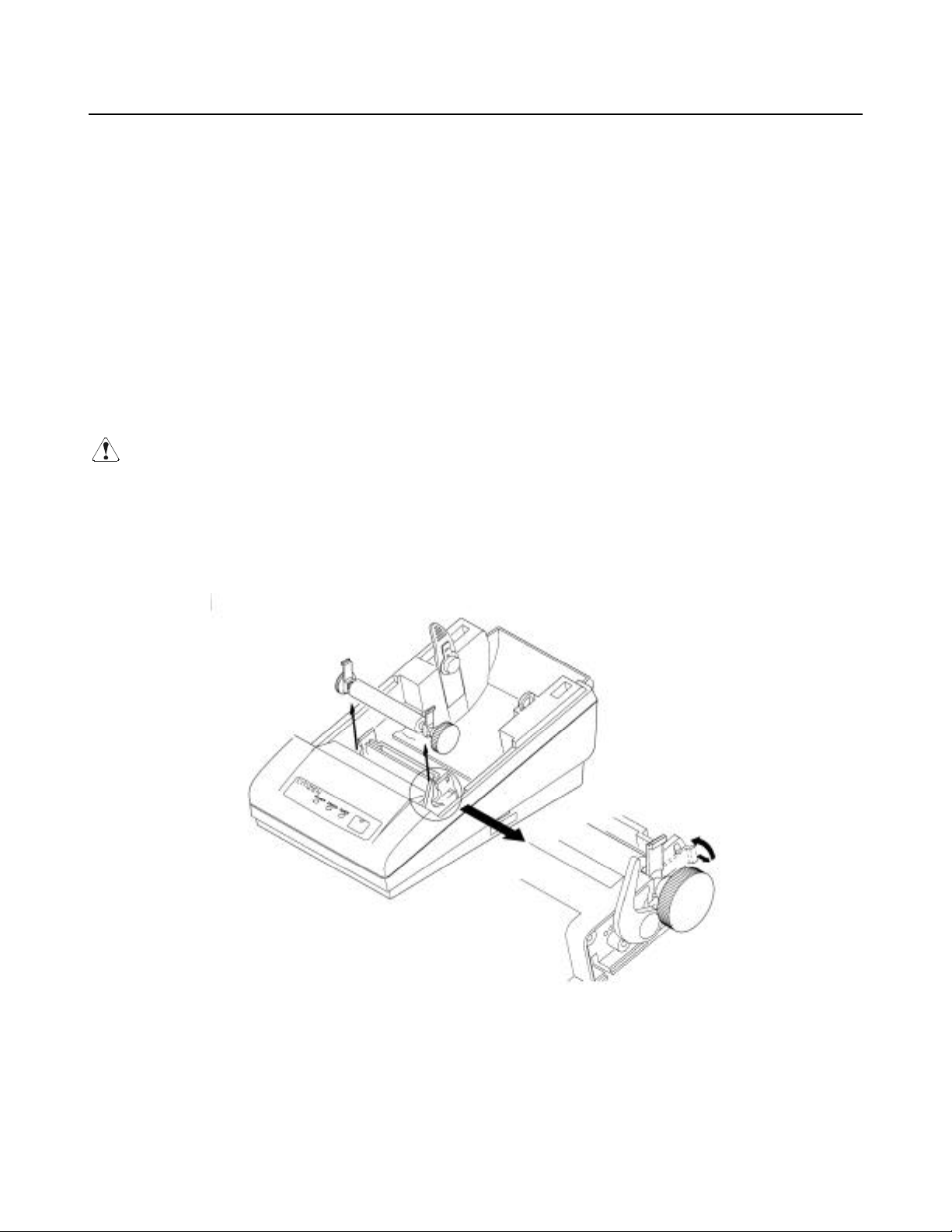

4.5 Eliminating the Paper Jam

1. Turn off the power.

2. Detach the printer cover.

3. Cut the paper roll near the paper insertion slot.

4. Raise the head-up lever.

5. Raise the blue levers located on both sides of the platen roller unit, to gently detach the unit. The platen

roller unit can be detached by manually raising the blue levers.

6. Remove the remaining paper roll completely from the paper passage.

7. If the label paper is used, some paste may be adhered. Dip soft cloth, etc. in alcohol and wipe away the

paste carefully so as not to damage the printing head.

8. Confirming the direction of the platen roller unit, reattach it to the mechanism. Shift down the blue

levers on both sides, to fix the unit.

9. Lower the head-up lever.

CAUTION:

1) Do not carry out this work just after printing because the printing head is very hot.

2) Be sure to turn off the power when detaching the platen roller unit.

3) When eliminating remaining paper, do not touch the heating surface of the head with a bare hand or metal

piece.

4) Do not detach the platen roller unit unless necessary, such as for a paper jam.

5) When putting back the platen roller unit, be sure to confirm that it is correctly reattached.

6) Never detach or reattach the platen roller unit with the head-up lever lowered.

Page 27

CBM-270 User’s Manual

4.6 FEED Switch Function

4.6.1 When Thermal Paper is Used

Pressing the switch, feed the paper by 1 line. If the switch is held down, the paper will be fed

continuously.

4.6.2 When Label Paper is Used

Pressing the switch, feed the paper by 1 line. If the switch is held down for 1 second or more, the paper

will be fed by one label.

4.6.3 When the Macro is Executed

If the ERROR lamp is blinking while waiting for execution of a macro, press the FEED switch. The

waiting state continues until the switch is pressed.

4.6.4 When the Label is Fed to the Paper Cutting Position by the Command

The PAPER lamp blinks. After cutting the paper, pressing the FEED switch searches for the head of the

next label. The waiting state continues until the switch is pressed.

CAUTION:

If the label paper is fed by 1 line by pressing the FEED switch, the label head position will be dislocated. Note

that if printing starts in this state, the label will be printed dislocated. (It is recommended to feed the paper by 1

label.)

4.7 Paper End Function

If the printing paper runs out, the parallel interface will output BUSY, FAULT, and PE to the host, and the

serial interface will output DTR to stop printing, respectively. If some data are still remaining in the buffer,

printing will be resumed after replacing the paper. Replace the paper according to "4.3 Inserting the Paper."

After replacing the paper, cancel BUSY (DTR), FAULT, and PE outputs. For details, see "4.8 Near Paper

End Function."

Page 28

4.8 Paper Near End Function

If the paper is running out, the PNE sensor informs the host computer that the paper is running out, by

means of a signal output or the PAPER lamp on the panel. The PAPER lamp is illuminated unconditionally.

1. If the PNE sensor detects that the paper is running out, the PAPER lamp will be illuminated.

2. If PNE is enabled, the parallel interface will output PE. (At initial setting)

3. Printing is allowed up to about 1.5 m. (Initial value) After printing or feeding the paper by a specified

amount, the parallel interface will output BUSY and FAULT, and serial interface will output DTR to stop

printing, respectively.

4. Replace the paper according to the procedure in "4.3 Inserting the Paper."

5. After replacing the paper, cancel the BUSY (DTR), FAULT, and PE outputs.

(1) The following lists the outputs made by the near paper end function and the paper end function. The

output state can be changed by the DIP switch or a command.

DS1-1

State

OFF Disabled

ON Enabled

PNE

Function

PE Signal Output Setting

by Command

*When PE is selected *When PE is detected *When PE is detected *At PNE

When PNE is selected When PNE is detected When PE is detected At PNE

When PE is selected When PE is detected When printing stops due

*When PNE is selected *When PNE is detected *When printing stops

PE Output

PNE : Paper Near End PE : Paper End

BUSY (DTR)/

FAULT Output

to PNE

due to PNE

CBM-270 User’s Manual

PAPER

Lamp

At PNE

*At PNE

*Mark : Default setting

(2) Print amount after detecting PNE

When PNE is enabled, a printable amount after PNE detection can be adjusted. PNE is detected when

the remaining amount of the paper roll is about 2∼3 m. (It depends on the paper quality used, paper

thickness, and operating environment.)

An initial value is 1.5 m. Up to 1.5 m can be printed after detecting PNE. At this time, with the

approx. 70µm-thick recommended paper, the remaining amount of the paper will be about 0.5∼1.5 m

when printing stops.

It can be adjusted between 0 and 2.55 m with a command. Adjust it depending on the operating

environment and paper quality.

Depending on an adjustment value, paper end may be detected (Printing stop) first.

If PNE is detected at power-on, a set amount of printing will be done from that point. (The default is

1.5 m)

Page 29

CBM-270 User’s Manual

4.9 Auto-Loading Function

This printer has a function to automatically set the paper. If the paper end sensor, near paper end sensor, and

head-up lever are cancelled, the paper will be automatically fed by a constant amount in about 1 second.

(Up to the print start position of the second sheet in the case of label paper.)

In order to smooth operation, cancel the head-up mechanism last.

Also, you can use the DIP switch to enable/disable the function. If disabled, auto-loading will not be

performed. (The paper is fed to the print start position in the case of label paper.)

CAUTION:

1) When auto-loading is being activated, do not touch the paper roll, because it could result in a paper feed

failure or cause the paper to be one-sided.

2) Be sure to set the paper until it comes into contact with the platen roller; otherwise, the paper cannot be fed

and the printing head could be damaged.

3) In the case of label paper, if the label section or black mark (Between the labels) cannot be detected in

feeding the paper by a constant amount, the printer will illuminate the ERROR lamp and stop operation,

regarding it as a paper error.

4.10 Self-Print Function

This printer has a function to perform preset printing. Turn on the power with the FEED switch held down.

It will print the ROM version, DIP switch state, characters used, kanji, etc. After self-printing is completed,

the printer restores its normal operating conditions.

In the case of label paper, it is fed to the print start position of the next label.

CAUTION:

1) Do not use this function when the paper roll is running out.

2) If the label length is short in printing on label paper, printing will extend over several labels.

3) Data communication cannot be done during self-printing.

4) The print contents differ between thermal paper and label paper.

Page 30

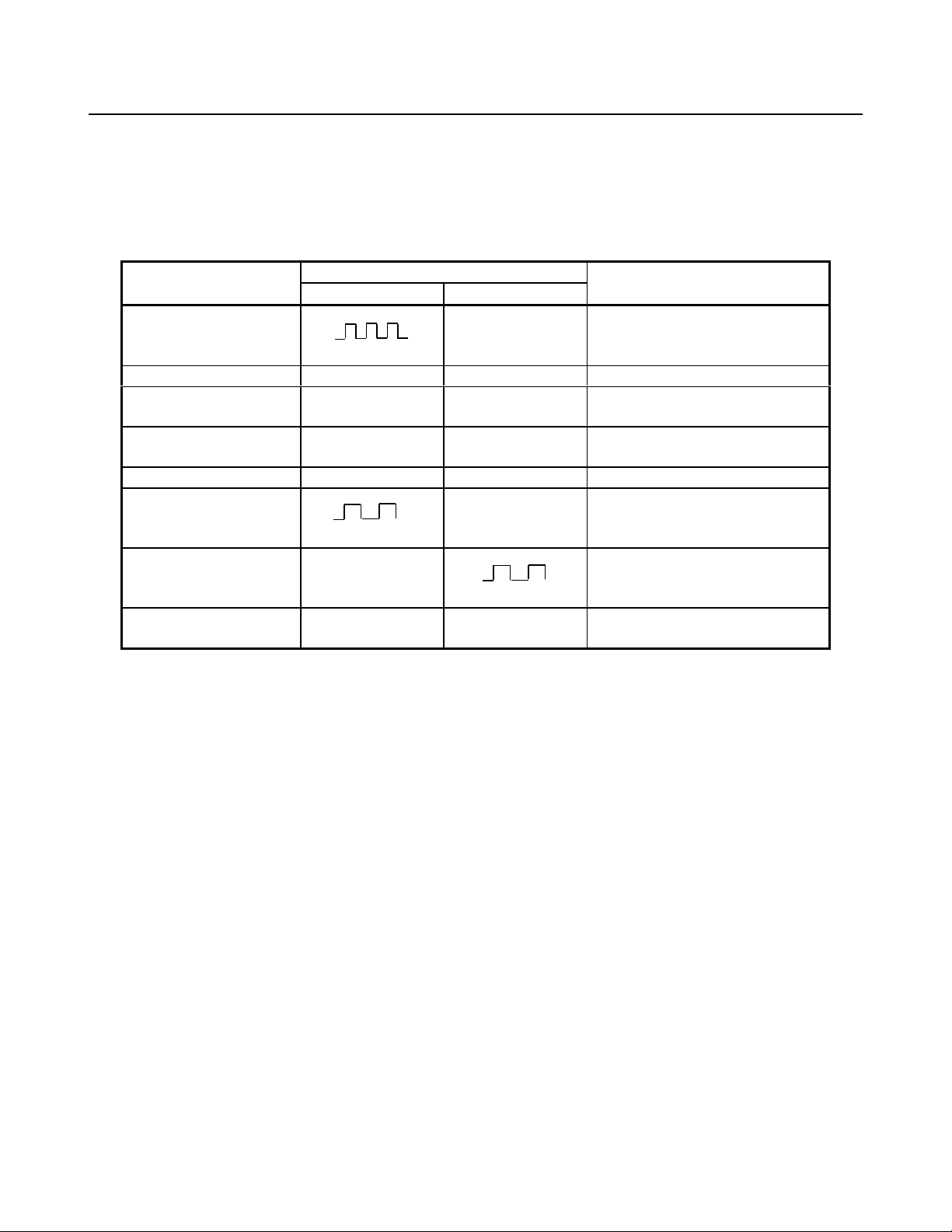

4.11 Operation Panel and Display of Error

1. POWER lamp (Green)

Illuminated if the power is turned on.

2. ERROR lamp (Red), PAPER lamp (Red)

Indicates an error by illuminating or blinking the lamps.

Error

ERROR Lamp PAPER Lamp

Display

CBM-270 User’s Manual

Reset

Memory check error

Quick blinking

Head-up ON OFF Lower the head-up lever.

Head overheat ON OFF

Paper near end OFF ON

Paper end OFF ON Set a new paper roll.

Macro execution wait

Slow blinking

Label paper cut wait OFF

Label paper error ON ON

OFF Cannot be reset

Automatically reset by a

temperature drop

Set a new paper roll after a print

stop.

OFF Press the FEED switch.

Press the FEED switch.

Slow blinking

Set the label paper suitable for the

specifications.

<Error Details>

Head-up ----- Occurs when the head-up lever is raised. The printer cannot feed the paper or print.

The parallel interface outputs BUSY and FAULT, and serial interface DTR,

respectively.

Head overheat ----- If the temperature of the printing head rises (About 60°C or more), in order to

protect it against overheating, a printing head temperature sensor will be activated to

stop printing. The parallel interface outputs BUSY and FAULT, and serial interface

DTR, respectively. If the temperature drops (About 55°C), printing will be

automatically resumed.

Paper near end ----- If the diameter of the paper roll decreases, the paper near end sensor will react to

inform you that the paper roll is running out. See "4.8 Paper Near End Function".

Paper end ----- If the paper roll runs out, the paper sensor near the printing head will react to stop

printing. See "4.7 Paper End Function".

Label paper error ----- Occurs if you set the thermal paper or non-specified label paper, when the label

paper has been selected. The parallel interface outputs BUSY and FAULT, and

serial interface DTR, respectively.

3. FEED switch

See "4.6 FEED Switch Function."

4.12 Red/Black Print (Precautions for Use)

(1) Types of paper

The red and black two-color thermal paper changes its colors by controlling the energy applied to the

thermal head. It is largely divided into two types, depending on the color development order. Select

Page 31

CBM-270 User’s Manual

either of them to suit your application.

1. Red-based two-color thermal paper (PB670: MITSUBISHI PAPER MILLS)

Red print (low energy) → Black print (high energy)

2. Black-based two-color thermal paper (735FA: RICOH)

Black print (low energy) → Red print (high energy)

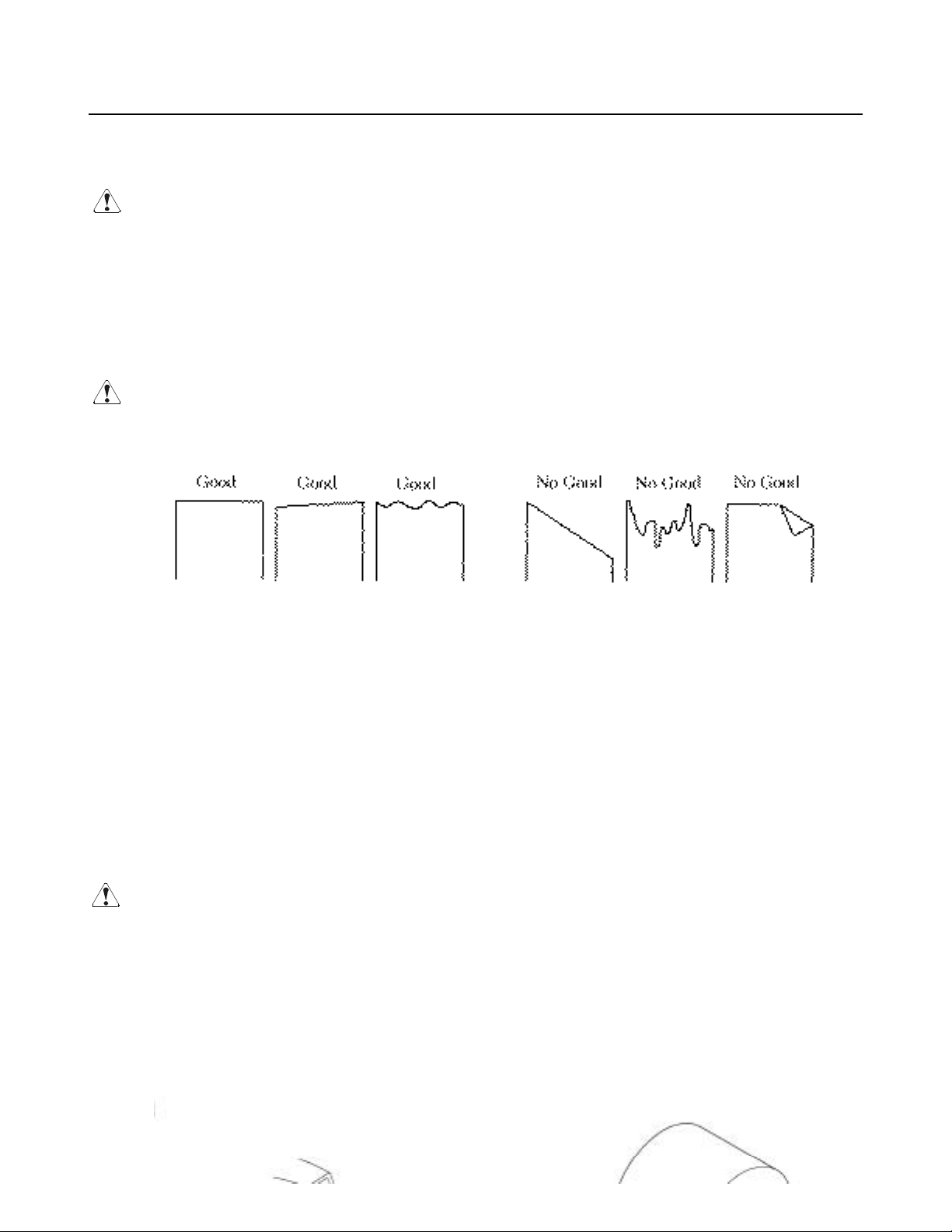

(2) High-energy printing rate

High-energy print (black print on red-based paper, or red print on black-based paper) required the

application of high energy to the thermal head. To protect the service life of the thermal head, use the

following printing rate as a guideline; use the fixed split (6-split) method.

1. Continuous print of high-energy print only : 6 % or less

2. Mixed continuous print of low-energy and high-energy print

: 30 % or less of the standard printing rate of

12.5 %

3. Printing rate per dot line : 50 % or less

(3) Minimum dots for high-energy print

When high-energy print is used, the recommended minimum area is 3 dots (length) × 3 dots (width) or

more. Depending on the set printing density, the paper used, or the printing characters, a sufficient

change of color tone may not be obtained even by high-energy print.

(Characters such as [, !, ', (, i, -, font B with small dot matrix)

It is recommended to use in such printing patterns as double-width characters, double-height characters,

double-width and -height characters.

CAUTIONS

1) If high-energy print is continuously carried out at a high operating ambient temperature, the thermal head

will become hot more quickly and the protective circuit will be activated, to stop printing more frequently.

Fully consider the working temperature and printing rate.

2) If a bar code is printed on the 2-color paper, both colors may appear in normal print and high-energy print,

or the bar code may not be correctly read by a bar code reader. Be fully aware of this when using the 2color paper.

3) Do not perform high-energy print on the single-color paper (regular thermal paper). It may deteriorate the

service life of the thermal head or the printing quality.

4) For setting, see Commands (DC3: Switching the Red/Black Printing).

Page 32

5. DIP SWITCH SETTING

5.1 Location of DIP Switch

1. Turn off the power.

2. Detach the printer cover, and take out the paper roll. (The switch is found under the paper roll.)

3. There are 2 switches (8-pole and 4-pole) for the serial interface, and 1 switch (8-pole) for the parallel

interface.

5.2 DIP Switch Function

DS1

No. Function ON OFF

1 PNE selection Enabled Disabled ON

2 CR switching LF operation Ignored OFF

3 ON

4

5 Paper selection Label paper Thermal paper OFF

6 Auto-loading Enabled Disabled ON

7 DTR/DSR, XON/XOFF XON/XOFF DTR/DSR OFF

8 Kanji code selection S-JIS JIS OFF

∗ DS1-7: Enabled only for the serial interface. Disabled for the parallel one.

DS2 (For Serial Interface Only)

No. Function ON OFF

1 OFF

2 OFF

3 OFF

4

Print density See Table 1

Baud rate and parity

setting

CBM-270 User’s Manual

Upon Shipment

OFF

Upon Shipment

See Table 2

OFF

Table 1

DS1-3 OFF ON OFF ON

DS1-4 OFF OFF ON ON

Table 2

DS2-4 DS2-3 DS2-2 DS2-1 Parity Baud Rate

OFF OFF OFF OFF None 9,600 bps

OFF OFF OFF ON None 1,200

OFF OFF ON OFF None 2,400

OFF OFF ON ON None 4,800

OFF ON OFF OFF None 9,600

OFF ON OFF ON None 19,200

OFF ON ON OFF Odd 1,200

OFF ON ON ON Odd 2,400

ON OFF OFF OFF Odd 4,800

ON OFF OFF ON Odd 9,600

ON OFF ON OFF Odd 19,200

ON OFF ON ON Even 1,200

ON ON OFF OFF Even 2,400

ON ON OFF ON Even 4,800

ON ON ON OFF Even 9,600

ON ON ON ON Even 19,200

5.3 Jumper Wire Function

The jumper wires have been set at shipment. The following lists the basic settings at shipment. Check the

Light Standard Slitly Dark Dark

Page 33

CBM-270 User’s Manual

settings by performing self-printing.

Jumper Wires

No. Function Short Open

Upon

Shipment

J1 Short

J2 See Table 3 Short

J3

International character

Short

J4 Data bit length 7 bits 8 bits Open

J5 Unused

− −

Open

J6 Label detection Black mark Label interval Open

J7 Unused

− −

Open

J8 Com munic ation error mar k Ignored "?" printed Open

∗ J4: Serial interface only. Disabled for the parallel one.

∗ J5∼J7: Do not change the shipment settings.

Table 3

No. USA France Germany U.K.

Denmark-I

Sweden Italy Japan

J1 Short Open Short Open Short Open Short Open

J2 Short Short Open Open Short Short Open Open

J3 Short Short Short Short Open Open Open Open

CAUTION:

1) Never change the settings of the jumper wires.

2) If you want to change their settings, consult us.

3) Never disassemble the printer body. It could cause trouble, etc.

Page 34

6. PARALLEL INTERFACE

6.1 Specifications

•Data input system : 8-bit parallel (DATA1 to DATA8)

•Control signals : ACK, BUSY, STROBE, FAULT, PE, RESET

•Applicable connectors : Printer side : 57LE-40360 (Anphenol) or its equivalent

Cable side : 57-30360 (Anphenol) or its equivalent

6.2 Connector's Pin Configuration

No. Signal Name No. Signal Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

STROBE

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

DATA 8

ACK

BUSY

PE

+ 5V DC

GND

FRAME GND

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

CBM-270 User’s Manual

TWISTED PAIR GND

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

RESET

FAULT

GND

Page 35

6.3 Input and Output Signals

6.3.1 Input and Output Signals

(1) Input signals to the printer

•DATA : 8-bit parallel signal (Positive logic)

•STROBE : Strobe signal to read the 8-bit data (Negative logic)

•RESET : Signal to reset the entire printer (Negative logic); 1 ms or more

(2) Output signals from the printer

•ACK : 8-bit data request signal. A pulse signal to be output at the end of the BUSY signal

(Negative logic)

•BUSY : Signal to indicate that the printer is busy. Input new data when it is "Low." (Positive

logic)

•FAULT : Turned to "Low" when the printer has an alarm. At this time, all the control circuits in

the printer stop. (Negative logic)

•PE : Output if the printing paper has run out or is running out. (Positive logic)

CBM-270 User’s Manual

(3) Power source and the related

•+5 V DC : 5 V output pulled up by a 10kΩ resistor

•GND : Common ground for the circuits

6.3.2 Electrical Characteristics

Page 36

CBM-270 User’s Manual

(1) Input signal level

All the input signals are at the TTL level.

High level --- 2.0 V at minimum

Low level --- 0.8 V at maximum

(2) Output signal level

All the output signals are at the TTL level.

High level --- 2.4 V at minimum

Low level --- 0.4 V at maximum

(3) Input and output conditions

The STROBE and RESET input signals are pulled up at 10kΩ, and the other input signals at 50kΩ,

respectively.

[Printer Side] [Host Side]

All the output signals are pulled up at 50kΩ.

[Printer Side] [Host Side]

6.3.3 Timing Chart

Data Input and Print Timings

Page 37

CBM-270 User’s Manual

T1, T2, T

T

T

T

3

4

5

6

6.3.4 Data Receiving Control

The data can be received from the host when the BUSY signal is at "Low," but cannot be received when it

is "High."

6.3.5 Buffering

The host side is immediately freed, because 2 KB data can be buffered.

0.5 µs MIN

270 ns MAX

2.3 µs TYP

500 ms MIN (At power-on)

Page 38

7. SERIAL INTERFACE

7.1 Specifications

(1) Synchronous system : Asynchronous

(2) Baud rate : 1,200, 2,400, 4,800, 9,600, 19,200 bps (Selected by the user)

(3) 1-word configuration

Start bits : 1 bit

Data bits : 8 bits or 7 bits (Setting upon shipment)

Parity bits : Odd, even, or no parity (Selected by the user)

Stop bits : 1 bit or more

(4) Signal polarity

RS-232C

•Mark = Logic "1" (-3 ∼ -12 V)

•Space = Logic "0" (+3 ∼ +12 V)

(5) Received data (RXD signal)

•Mark = 1

•Space = 0

(6) Reception control (DTR signal)

•Mark : Data not transferable

•Space : Data transferable

(7) Transmission control (TXD signal)

•DC1 code(11H) X-ON : Data receivable

•DC3 code(13H) X-OFF : Data not receivable

CBM-270 User’s Manual

7.2 Connector's Pin Configuration

No. Signal Name Input/Output Function

1 FG Frame Ground

7 GND Signal Ground

3 RXD Input Received Data

20 DTR Output Printer BUSY Signal

2 TXD Output Transmitted Data

6 DSR Input Data Set Ready

[Note] 1. The RS-232C signals are based on the EIA RS-232C.

2. The received data should be always maintained in the Mark status when no data is being

transferred.

Applicable connectors (D-Sub connectors)

Printer side : 17LE-13250 (Anphenol) or its equivalent

Cable side : 17JE-23250 (Anphenol) or its equivalent

7.3 Input and Output Signals

Page 39

7.3.1 Input and Output Signals

(1) RXD

Serial received data signal. If a framing error, overrun error, or parity error takes place, the relevant data

will be printed as "?".

(2) DTR

Write the data or a command when this signal is Ready. If you write at Busy, the previous data will be

ignored, resulting in an overrun error. The data can be written in the input buffer even during printing.

Busy is also issued at power-on, during test printing, at on-line, or at reset.

(3) TXD

If the remaining capacity of the input buffer comes to 128 bytes or less while receiving the data,

DC3(13H) will be output as a data not receivable signal. If the remaining capacity comes to 256 bytes or

more, DC1(11H) will be output to the host side as a data receivable signal.

When sending the status information, it is confirmed that DSR is a space prior to sending the data, if

DTR/DSR control has been selected. If DTR/DSR control has not been selected, the data will be sent,

ignoring the DSR signal.

(4) FG

Ground for the case

(5) GND

Common ground for the circuits

CBM-270 User’s Manual

7.3.2 Data Configuration

Mark

Space (1) (2) (3)

(1) Start bit

The system reads the status again after a lapse of 1/2 bit from a fall edge from the mark to space, and if it

is a space, this bit will be recognized as the start bit.

If it is a mark, the system will not recognize the bit as the start bit and try to detect the start bit again

without judging it as an error.

t

b0, b1, b2, • • • •

(1) Start Bit

(2) Data Bit (+ Parity Bit)

(3) Stop Bit (1 or More)

Page 40

(2) Data bits + Parity bit

The system samples the data bits and parity bit for the 1 bit worth of time from 1/2 start bit and assumes

the then status as the data for the relevant bits. The bits are called Bit 0, Bit 1, ..., Parity bit, counting

from the one closest to the start bit.

(3) Stop bit

The stop bit is the Mark level of 1 bit or more. If a space is detected in detecting the stop bit, a framing

error will result.

7.3.3 Error Detection

The system detects a parity, framing, or overrun error. If an error is detected, the relevant data will be

stored in the buffer as "?".

(1) Parity error

With a parity check specified, if an error is detected at parity check time, the relevant data will be

stored in the buffer as "?".

(2) Framing error

This error results if the Space status is detected at stop bit detection time. The relevant data will be

stored in the buffer as "?".

(3) Overrun error

If an overrun error is detected, the relevant data will be stored in the buffer as "?".

7.3.4 Data Receiving Control

If DTR/DSR control has been selected, the data from the host side will be received when the BUSY signal

is at "Low," but not received when at "High." If DTR/DSR has not been selected, the data from the host

side will be received after sending XON, but not after sending XOFF.

CBM-270 User’s Manual

7.3.5 Buffering

To transfer the data to the input buffer, there are two control signals available: DTR signal and TXD

signal. The host side is immediately freed, since the data can be buffered up to 2 KB.

(1) DTR signal (See 7.3.1-(2))

(2) TXD signal (See 7.3.1-(3))

7.3.6 Electrical Characteristics

RS-232C Circuit

Input (RXD, DSR)

[Printer Side] [Host Side]

Equivalent MAX232

Output (TXD, DTR)

[Printer Side] [Host Side]

RXD

Mark=(-8V): Stop bit

Space=(+8V): Start bit

Equivalent to MAX232

Mark=(-8V): At Busy Mark=(-8V): 1

Space=(+8V): At Busy Space=(+8V): 0

TXDDTR

Page 41

8. POWER CONNECTOR

This connector is to supply the power from the special AC adapter(27AD).

Connector Schematic

No. Function

1

2

1 2

Jack used : HEC0470-01-640 (HOSHIDEN) or its equivalent

Applicable plug : JXP series type A (I.D.: 2.45 mm, O.D.: 5.5 mm) (HOSHIDEN) or its equivalent

7.2V

GND

CBM-270 User’s Manual

Inner terminal : Minus pole (GND)

Outer terminal : Plus pole

CAUTION:

1) Be sure to use the specified AC adapter. Use of any other power source could cause trouble to or break the

printer.

2) Do not connect the power source with different polarity.

3) After using the printer or when not using it for a long period of time, be sure to unplug the AC

adapter from a plug socket for your safety.

Page 42

CBM-270 User’s Manual

9. MAINTENANCE AND SERVICE

For the information on maintenance and service, please contact our dealer or at the following address.

North America Other Areas

CBM America Corporation Japan CBM Corporation

Service Center Information Systems Division

365 Van Ness Way 1-1-7 Okubo Shinjuku-ku,

Suite 510 Tokyo 169-8553 Japan

Torrance, CA 90501, U.S.A

TEL +1-310-781-1460 TEL +81-3-3200-6970

FAX +1-310-781-9157 FAX +81-3-3200-6297

Page 43

CBM-270 User’s Manual

s n m [a

m n1 n2

10. PRINT CONTROL FUNCTIONS

10.1 Command List

Command

1 HT Horizontal tab 09H 33

2 LF Printing and paper feed 0AH 34

3 CR Print 0DH 35

4 ESC SP Setting the right spacing of the character 1BH 20H n 35

5 ESC ! Collective Specifying the printing mode 1BH 21H n 36

6 ESC % Specifying/Canceling download character set 1BH 25H n 37

7 ESC & Defining download characters

8 ESC * Specifying the bit image mode

ESC −

9

Specifying/Canceling underline 1BH 2DH n 41

10 ESC 2 Specifying 1/6-inch line feed rate 1BH 32H 41

11 ESC 3 Setting line feed rate of minimum pitch 1BH 33H n 42

12 ESC = Data input control 1BH 3DH n 42

13 ESC @ Initializing the printer 1BH 40H 43

14 ESC D Setting horizontal tab position 1BH 44H [n]k 00H 43

15 ESC E Specifying/Canceling highlighting 1BH 45H n 44

16 ESC G Specifying/Canceling double printing 1BH 47H n 44

17 ESC J Printing and feeding paper n/203 inch 1BH 4AH n 45

18 ESC R Selecting the international character set 1BH 52H n 46

19 ESC V

Specifying/Canceling 90°-right- turned characters

20 ESC a Aligning the characters 1BH 61H n 48

21 ESC c 3

22 ESC c 4

Selecting the paper near end sensor valid for a paper end

signal output

Selecting the paper near end sensor valid for print stop 1BH 63H 44H n

23 ESC c 5 Enabling/Disabling the panel switches

24 ESC d Printing and feeding the paper by n lines. 1BH 64H n 50

25 ESC i NOP

26 ESC m NOP

27 ESC n Setting a remaining amount of printout 1BH 6EH n 51

28 ESC t Selecting the character codes table 1BH 74H n 51

29 ESC v Transmitting the printer status 1BH 76H n 52

30 ESC { Specifying/Canceling the inverted characters 1BH 7BH n 53

31 ESC $ Specifying the absolute positions 1BH 24H n1 n2 54

32 ESC \ Specifying the relative positions 1BH 5CH n1 n2 55

Function Code Page

1BH 26H

p1 p2…psxa] mn+1

1BH 2AH

[d]k

1BH 56H n 47

1BH 63H 33H n

1BH 63H 45H n

38

39

49

49

50

Page 44

CBM-270 User’s Manual

n1 n2

n1 n2 n3

30H m n

31H n1

32H n1

3BH N1

Command

33 GS k Printing the bar code

34 GS w

Specifying the horizontal size(Scale factor) of bar code

Function Code Page

1DH 6BH n [‘d’] k

00H

70

1DH 77H n 74