Page 1

Specifications

CONTROL BOARD

MODEL

Rev. 1.00 Issued on October 10, 2006

BD2-2220/2221

Page 2

Revision

Rev. Date Comment

1.00 2006.10.10 Newly issued

CITIZEN is a registered trade mark of CITIZEN WATCH CO., LTD., Japan.

CITIZEN es una marca registrada de CITIZEN WATCH CO., LTD., Japón.

Page 3

CONTENTS

1. GENERAL OUTLINE......................................................................................1

1.1 FEATURES................................................................................................................1

1.2 ACCESSORIES ..........................................................................................................2

1.3 MODEL CLASSIFICATION............................................................................................2

1.4 CONFIGURATION (BLOCK DIAGRAM)........................................................................... 3

2. BASIC SPECIFICATIONS .............................................................................4

2.1 PRINTING SPECIFICATIONS .......................................................................................4

2.2 CHARACTER AND BARCODE SPECIFICATIONS ................................................................5

2.3 PRINT PAPER SPECIFICATIONS (THERMAL PAPER)........................................................6

2.4 MECHANISM AND PERIPHERALS USED .........................................................................7

2.5 POWER SUPPLY........................................................................................................7

2.5.1 Specifications...................................................................................................................7

2.5.2 Precautions......................................................................................................................7

2.6 ENVIRONMENT: TEMPERATURE, HUMIDITY...................................................................8

3. APPEARANCE SPECIFICATIONS ..................................................................9

4. CONNECTOR CONNECTION ....................................................................... 10

4.1 INTERFACE CONNECTORS.........................................................................................10

4.1.1 Interface Connector Pin Assignment (CN1) .......................................................................10

4.1.2 USB Interface Connector Pin Assignment (CN8) * Only USB model .....................................11

4.1.3 CN1 Connection Example ................................................................................................12

4.2 MECHANISM CONNECTOR (CN2) ..............................................................................13

4.2.1 Mechanism Connector Pin Assignment (CN2) .................................................................... 13

4.2.2 FFC-compliant Cable.......................................................................................................14

4.3 HEAD UP, PAPER-END DETECTING CONNECTOR (CN3, CN7) .......................................14

4.4 MOTOR CONNECTOR (CN4).....................................................................................15

4.5 AUTO CUTTER CONNECTOR (CN5) ............................................................................15

4.6 PAPER NEAR-END SENSOR CONNECTOR (CN6) * OPTION ...........................................16

4.6.1 Paper Near-End Sensor Connector Pin Assignment (CN6)...................................................16

4.6.2 Reference Circuits ..........................................................................................................16

5. OPERATION PANEL ...................................................................................17

5.1 OUTPUT LED .........................................................................................................17

5.2 DETAILS ON ERROR AND LED INDICATION.................................................................17

5.3 FEED SWITCH ........................................................................................................24

5.3.1 Self-printing...................................................................................................................25

5.3.2 Hexadecimal Dump Printing ............................................................................................26

5.3.3 Memory Switch Setting Mode ..........................................................................................27

Page 4

6. INTERFACES .............................................................................................. 28

6.1 BIDIRECTIONAL PARALLEL INTERFACE (IEEE1284) ...................................................28

6.1.1 Specification ..................................................................................................................28

6.1.2 Description of Input/Output Signals .................................................................................29

6.1.3 Connection to Parallel Port ..............................................................................................32

6.2 RS-232C SERIAL INTERFACE ..................................................................................33

6.2.1 Specification ..................................................................................................................33

6.2.2 Description of Input/Output Signals .................................................................................33

6.2.3 Connection to Serial Port.................................................................................................36

6.3 USB INTERFACE.....................................................................................................36

7. FUNCTION SELECTION.............................................................................. 37

7.1 JUMPER ................................................................................................................37

7.2 DIP SWITCH (ONLY SERIAL INTERFACE) ...................................................................37

7.3 MEMORY SWITCHES................................................................................................38

8. PRINT CONTROL COMMANDS ...................................................................40

9. CHARACTER CODE TABLE.......................................................................... 43

9.1 CODE PAGE............................................................................................................43

9.1.1 Codepage 00H to 7FH & PC437 (USA, Europe Standard)....................................................43

9.1.2 Codepage 00H to 7FH & Katakana ................................................................................... 44

9.1.3 Codepage 00H to 7FH & PC850/858 (Multilingual).............................................................45

9.1.4 Codepage 00H to 7FH & PC860 (Portuguese)....................................................................46

9.1.5 Codepage 00H to 7FH & PC863 (Canadian-French)............................................................47

9.1.6 Codepage 00H to 7FH & PC865 (Nordic)...........................................................................48

9.1.7 Codepage 00H to 7FH & PC852 (Eastern Europe).............................................................. 49

9.1.8 Codepage 00H to 7FH & PC866 (Russian).........................................................................50

9.1.9 Codepage 00H to 7FH & PC857 (Turkish) .........................................................................51

9.1.10 Codepage 00H to 7FH & PC864 (Arabic)...........................................................................52

9.1.11 Codepage 00H to 7FH & WPC1252...................................................................................53

9.1.12 Codepage 00H to 7FH & Thaicode18................................................................................54

9.2 INTERNATIONAL CHARACTER CODE TABLE .................................................................55

Page 5

1. GENERAL OUTLINE

・This control board is used for controlling LT222X/232X through computer, etc.

・As it has a variety of functions, it can meet various kinds of applications.

* This specification applies only to control board BD2-2220/2221

* The information contained herein is subject to change without prior notice.

* Transfer, copy, reproduction, or alteration of this document is prohibited without permission of

Citizen Systems Japan Co., Ltd.

1.1

Features

1) Ultra-small design

2) High speed (150 mm/sec) printing

3) Applicable to the width of 80 mm (LT232X) and 58 mm (LT222X).

4) Built-in input buffer

5) Barcode printing (By special command)

6) Free printing layout by page mode

7) Registration of user-defined characters and logos into flash memory

8) Auto cutter control

9) No paper and paper near-end detection

10) Various kinds of functional selection by memory switch

11) Support JIS level 1 and level 2

12) User-defined characters are available. (94 characters)

13) Mounting hole position is the same as that of LT2X20.

1

Page 6

Accessories

1.2

After unpacking the product, make sure the following components are present.

Control board ... 1

Interface cable ... 1 (A cable of 300 mm long)*

Mech FFC ... 1 (With 100-mm-long cable)

* Mini-USB cable is not supplied for USB model.

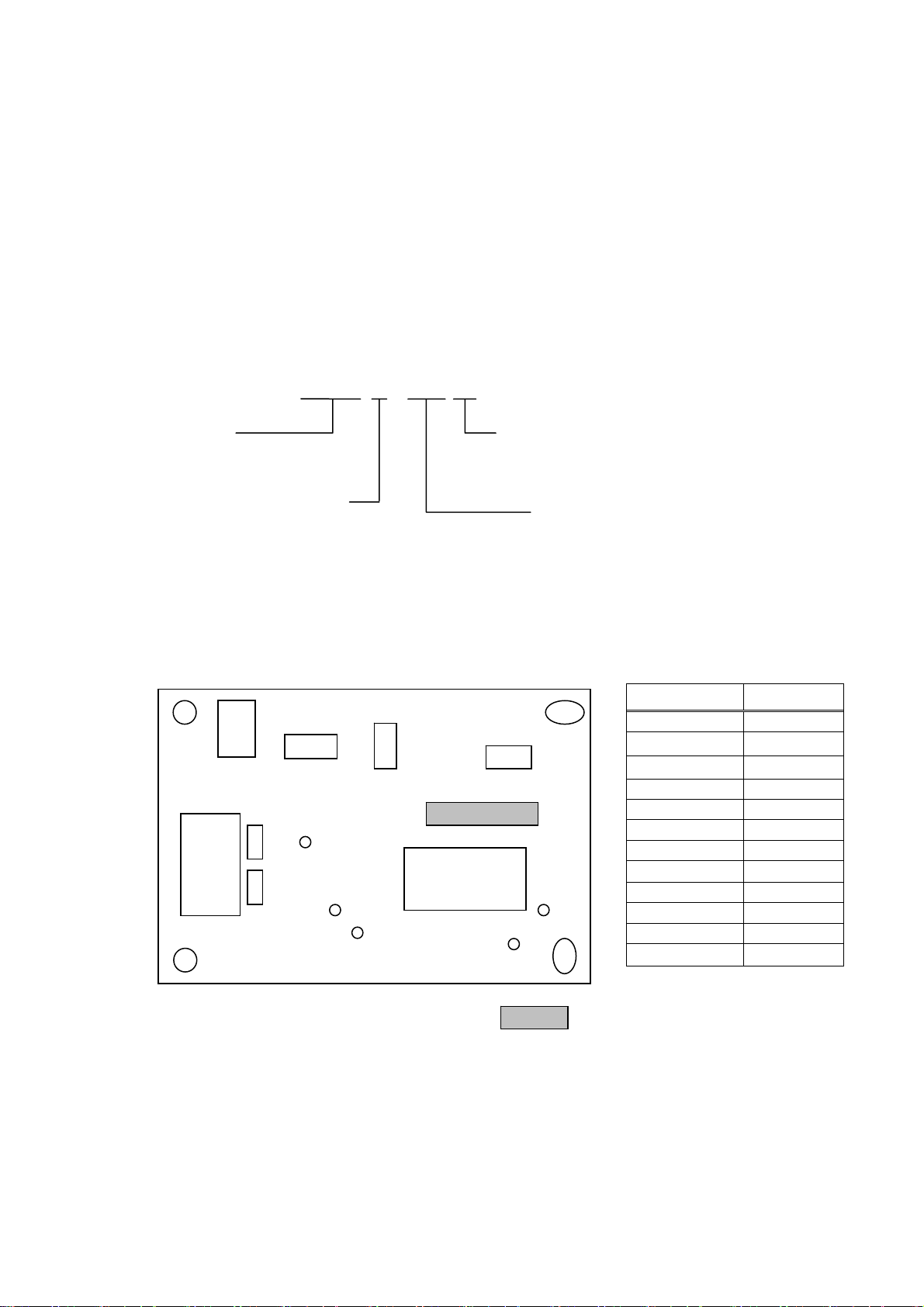

1.3

Model Classification

BD2 ― 222 0 RS J

Model name

Mechanism used

0: LT2X20

1: LT2X21

Destination

J: Japan (Kanji supported)

U: Universal standard

Interface

RS: Serial RS-232C

PA: Parallel IEEE1284

UB: USB

Control board model can be identified by the stamp on the jumper side of the control board.

Stamped designation is shown below.

JP2

BD2-222

JP3 JP5

JP1

JP4

Model Name Designation

BD2-2220RSJ 0RSJ

BD2-2220PAJ 0PAJ

BD2-2220UBJ 0UBJ

BD2-2220RSU 0RSU

BD2-2220PAU 0PAU

BD2-2220UBU 0UBU

BD2-2221RSJ 1RSJ

BD2-2221PAJ 1PAJ

BD2-2221UBJ 1UBJ

BD2-2221RSU 1RSU

BD2-2221PAU 1PAU

BD2-2221UBU 1UBU

Stamped designation:

2

Page 7

V

V

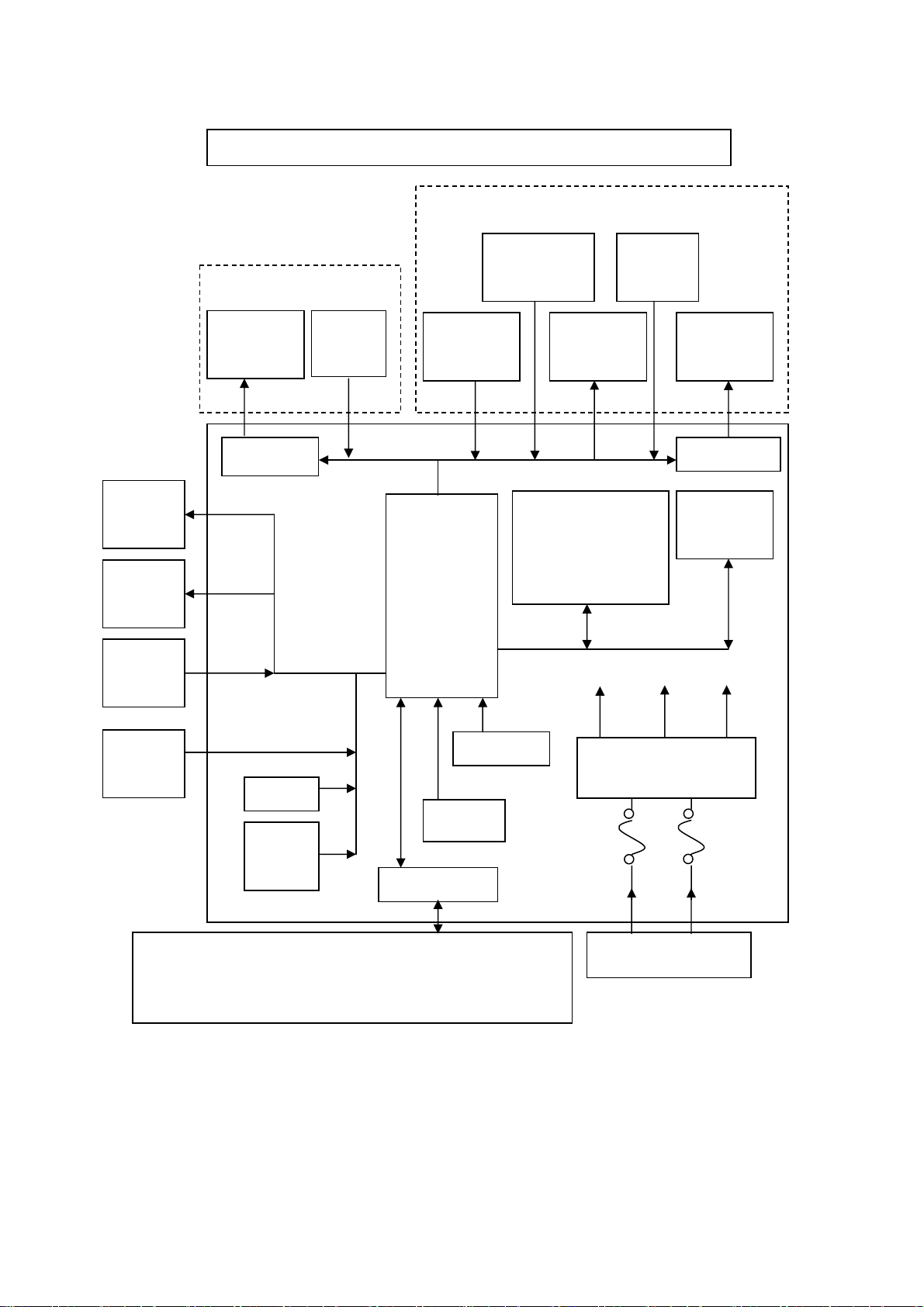

Configuration (Block Diagram)

1.4

BD2-2220/2221 BLOCK DIAGRAM

MECHANISM

CUTTER

HEAD

Thermistor

PE

SENSOR

CUTTER

MOTOR

CUTTER

SW

HEAD UP

SENSOR

PRINTER

HEAD

STEPPING

MOTOR

DRIVER

DRIVER

ERROR

LED

PE LED

CPU

FLASH MEMORY

8Mbit: Foreign

16Mbit: Domestic

SDRAM

16Mbit

SENSOR

PNE

DC5.0V DC3.3

DC24.0

FEED

SW

DIP SW

VOLT

SENSOR

INTERFACE

OSC

POWER SUPPLY

RESET

Serial Interface Parallel Interface USB Interface

RS-232C IEEE1284 Ver 1.1

Centronics

DC24.0V DC5.0V

3

Page 8

2. BASIC SPECIFICATIONS

Printing Specifications

2.1

1) Print method: Line thermal print method (Thermal printing system)

2) Dot configuration: LT222X: 432 dots/line, LT232X:576 dots/line

3) Dot density: 8 dots/mm (203 dpi)

4) Print area: LT222X: Max. 54 mm, LT232X: Max. 72 mm

5) Number of print columns:

LT222X: Max. 36 columns, LT232X: Max. 48 columns (12×24: Font A)

LT222X: Max. 48 columns, LT232X: Max. 64 columns (9×24: Font B)

LT222X: Max. 54 columns, LT232X: Max. 72 columns (8×16: Font C)

LT222X: Max. 18 columns, LT232X: Max. 24 columns (24×24: Kanji Font A)

LT222X: Max. 27 columns, LT232X: Max. 36 columns (16×16: Kanji Font C)

6) Character spacing: Selectable by use of command

7) Print speed: Max. 1200 dot-lines/sec (150 mm/sec)

8) Paper feed: Feed pitch: 0.125 mm

9) Line feed width: 4.23 mm (1/6 inch) settable by user

10) Print head: Line thermal print head

11) Emulation: ESC/POS compliant

Notes:

• The above printing speed is under the condition of 24.0 V, 25°C, printing duty of 12.5%.

• Print speed may be delayed depending on the setting of printing condition or combination of

commands.

4

Page 9

Character and Barcode Specifications

2.2

1) Character type

ANK characters: 96characters

Code pages: 128 characters × 12 pages

International characters: 12 characters × 14 countries

Japanese Kanji: JIS (JIS C6226-1983)

Non-kanji: 577 characters

JIS level 1: 2965 characters

JIS level 2: 3388 characters

(Only when destination is Japan)

2) Character size/configuration

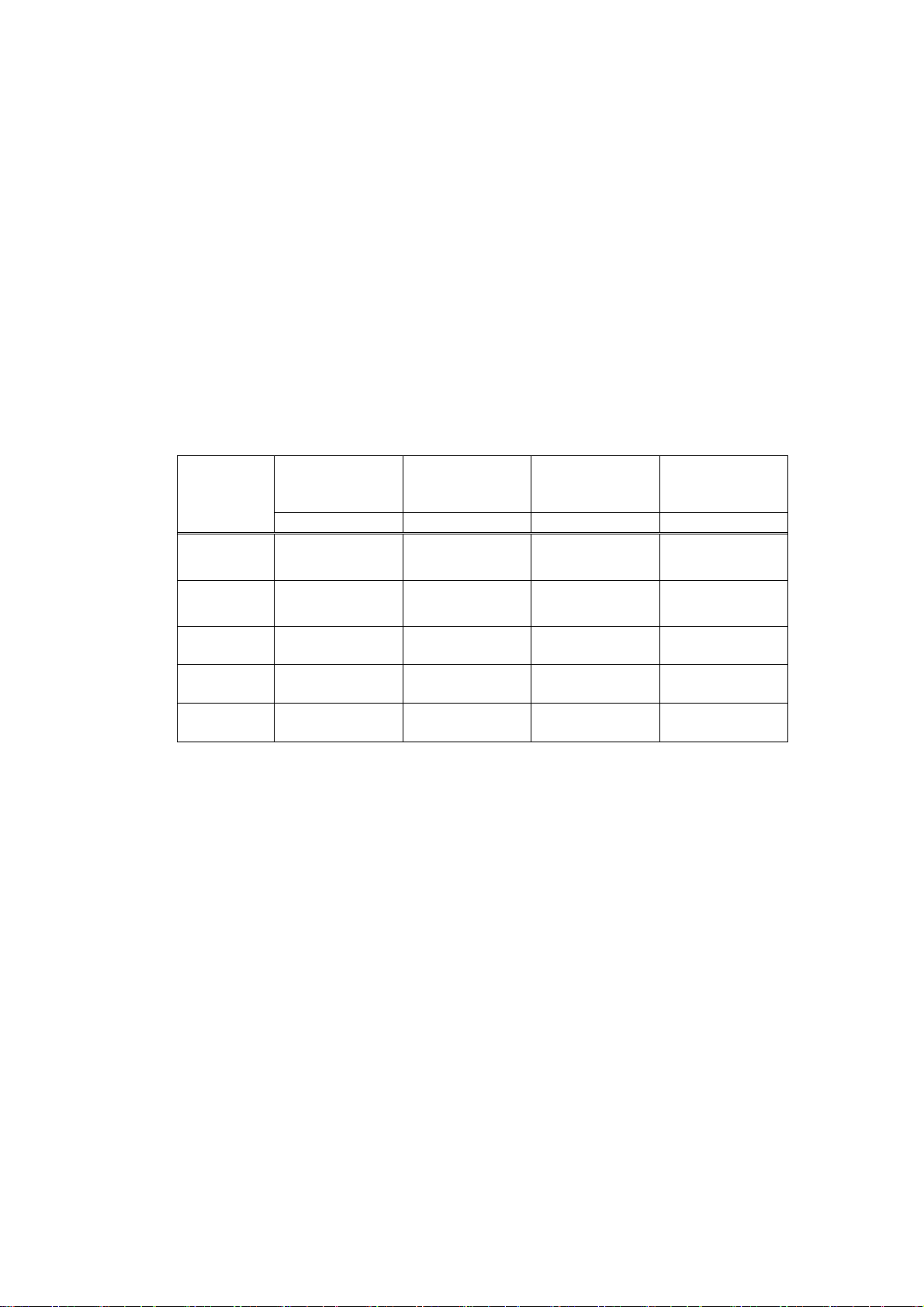

Table 1 Character Size

Font A

12×24

Standard Double Height Double Width

W×H (mm) W×H (mm) W×H (mm) W×H (mm)

1.5×3.0 1.5×6.0 3.0×3.0 3.0×6.0

Double Height

and Double

Width

Font B

9×24

Font C

8×16

Kanji A

24×24

Kanji C

16×16

1.13×3.0 1.13×6.0 2.26×3.0 2.26×6.0

1.0×2.0 1.0×4.0 2.0×2.0 2.0×4.0

3.0×3.0 3.0×6.0 6.0×3.0 6.0×6.0

2.0×2.0 2.0×4.0 4.0×2.0 4.0×4.0

Notes:

• Actual character may be smaller than the above as it includes space inside character font.

• Characters can be enlarged up to 8 times height and width in multiple steps of standard size.

3) Barcode

: UPC-A

: UPC-E

: JAN/EAN-8

: JAN/EAN-13

: ITF

: CODE39

: CODE93

: CODE128

: CODABAR (NW-7)

5

Page 10

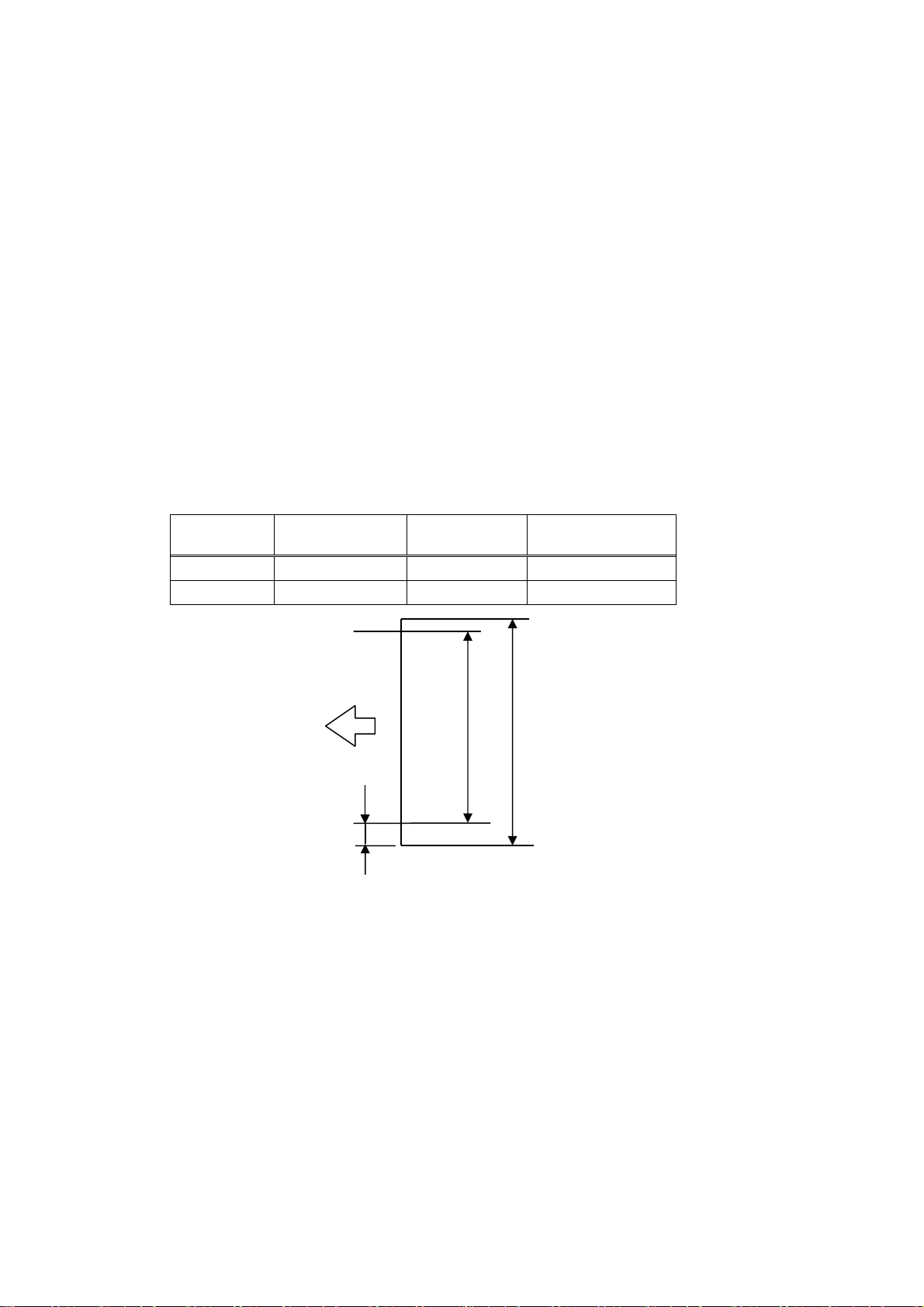

Paper Width

Print Paper Specifications (Thermal Paper)

2.3

1) Paper width : LT222X: 58 +0,-1mm, LT232X: 80 +0,-1mm

2) Paper thickness : 60µm ~ 150µm

3) Recommended paper

Nippon Paper Industries TF50-KS-E2D

Mitsubishi Paper P220AC Or equivalent

Print density setting should be changed according to the type and thickness of paper.

Change the density setting by the Customize value setting GS ( E command. (See “7.3

Memory Switch”.)

*When paper other than the specified, difference in print density may occur.

*Pay full attention to temperature, humidity, and environment when storing printed paper.

Otherwise, the printed data may be lost.

*For the details of paper, refer to the specifications of each mechanism.

4) Effective print width (Print area)

Mechanism

LT222X 58+0,-1 2±2 54

LT232X 80+0,-1 4±2 72

Paper Width

(mm)

Left Margin

(mm)

Effective Print

Width (mm)

Paper feed

direction

HHHHHHH……HHHH

Effective Print Width

Left margin

5) Other

・Chromophoric surface: Roll outside

・Terminating process: Do not apply paste to fix the roll paper and core.

Do not fold paper at the end of the paper.

6

Page 11

Mechanism and Peripherals Used

2.4

The following mechanism and peripheral units can be connected to this control board.

1) Thermal mechanism

58 mm Paper: LT222X

80 mm Paper: LT232X

2) Auto cutter

ACS-220/230 series

3) Paper near-end sensor (Option)

* For the details of specification, etc., refer to the relevant manual.

2.5

Power Supply

2.5.1 Specifications

1) Operating voltage

Driver power supply Vp:+24.0 VDC ±5%

Logic unit power supply Vdd:+5.0 VDC ±5%

:+3.3 VDC ±5% (*+5.0 VDC internal conversion in board)

2) Current consumption

Driver current Ip: Average current: Approx. 0.46 A (At ANK slide)

Peak current: Approx. 4.9 A (At full dot printing)

Logic unit current Idd: Average current: Approx. 230 mA (At ANK slide)

Approx. 200 mA (At standby)

2.5.2 Precautions

1. When powering on, enter Vp within 100 ms after Vdd.

2. When powering off, turn Vdd after Vp.

3. Before connecting or disconnecting the connector, be sure to turn the printer power off.

4. Be sure to use Vdd and Vp within the specified range.

5. Be sure to use the printer by connecting both Vp and P-GND.

6. For the power supply at Vp side, use the power supply with peak current removed.

7

Page 12

Cautions

・Using the power supply other than specified, bad effect may occur in printing operation, etc.

・Using the current without removing peak current may result in degradation of printing quality

depending on the printing status or occurrence of low-voltage error.

・Use the power supply that can be turned off easily to prepare for emergencies.

・Power supply with overvoltage protection, overcurrent protection, and various protection

circuits is recommended.

・This control board requires two different supply voltages. Use sufficient care not to make

erroneous wiring or operation. Error in operation may not only break the control board but

also have bad effect on human body or peripheral equipment.

・Though this control board has CN2 that has the same pin allocation as BD2-2880, it is different

in supply voltage. Use sufficient care in handling this control board.

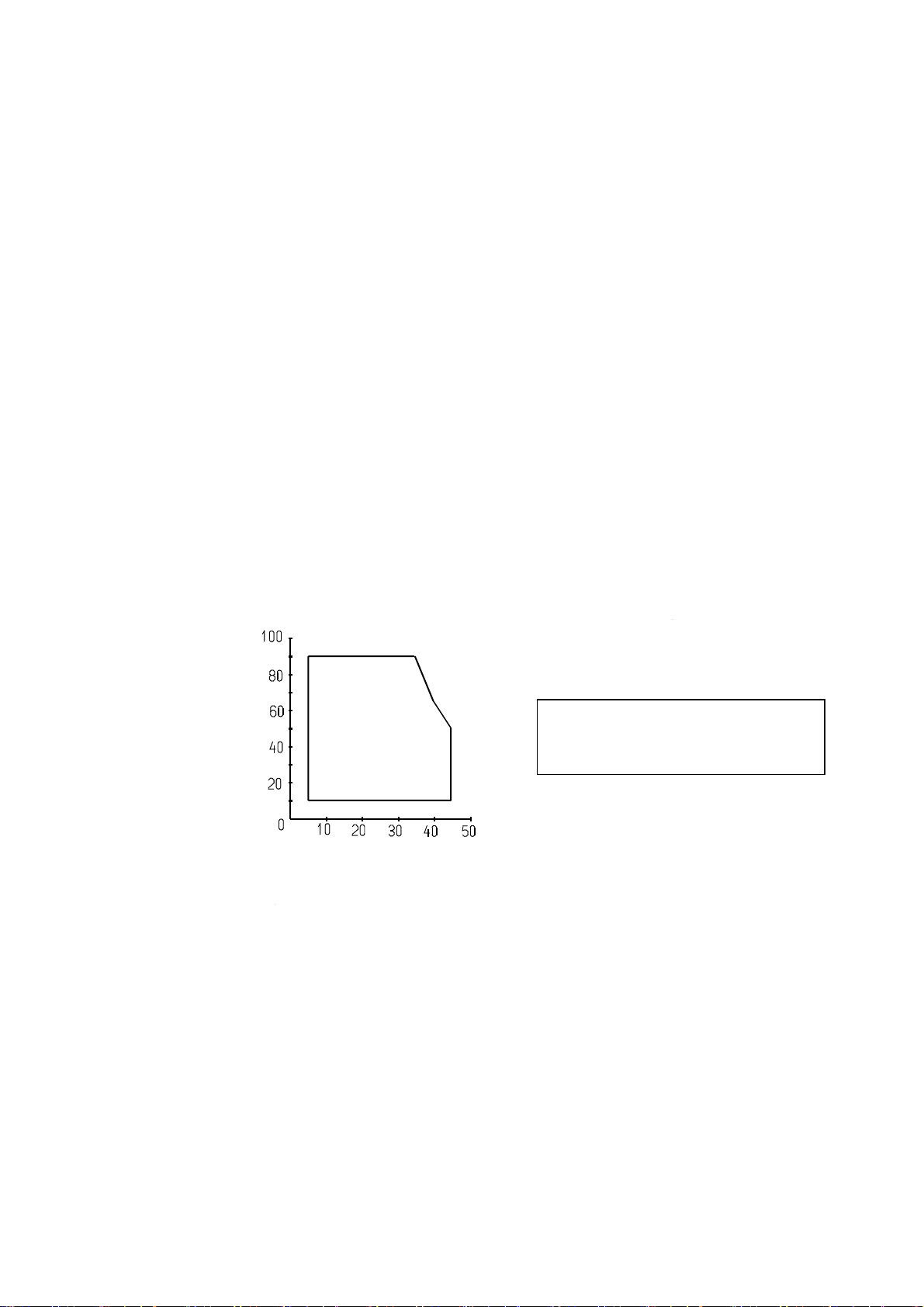

2.6

Environment: Temperature, Humidity

1) Operating

Temperature: 5°C ~ 45°C

Humidity: 10%RH ~ 90%RH (No dew condensation)

Relative humidity (% RH)

2) Storage (excluding roll paper)

Temperature: −20°C ~ 60°C

Humidity: 10% RH ~ 90% RH (No dew condensation)

Note: For storage at high temperature, high humidity, the combination of 40°C, 90% RH (no

condensation) shall be the worst value.

34°C, 90%

40°C, 65%

Operating

environment

range

Environment temperature (°C)

45°C, 50%

Relative humidity (%RH)

Operating environment range

Environment temperature (°C)

8

Page 13

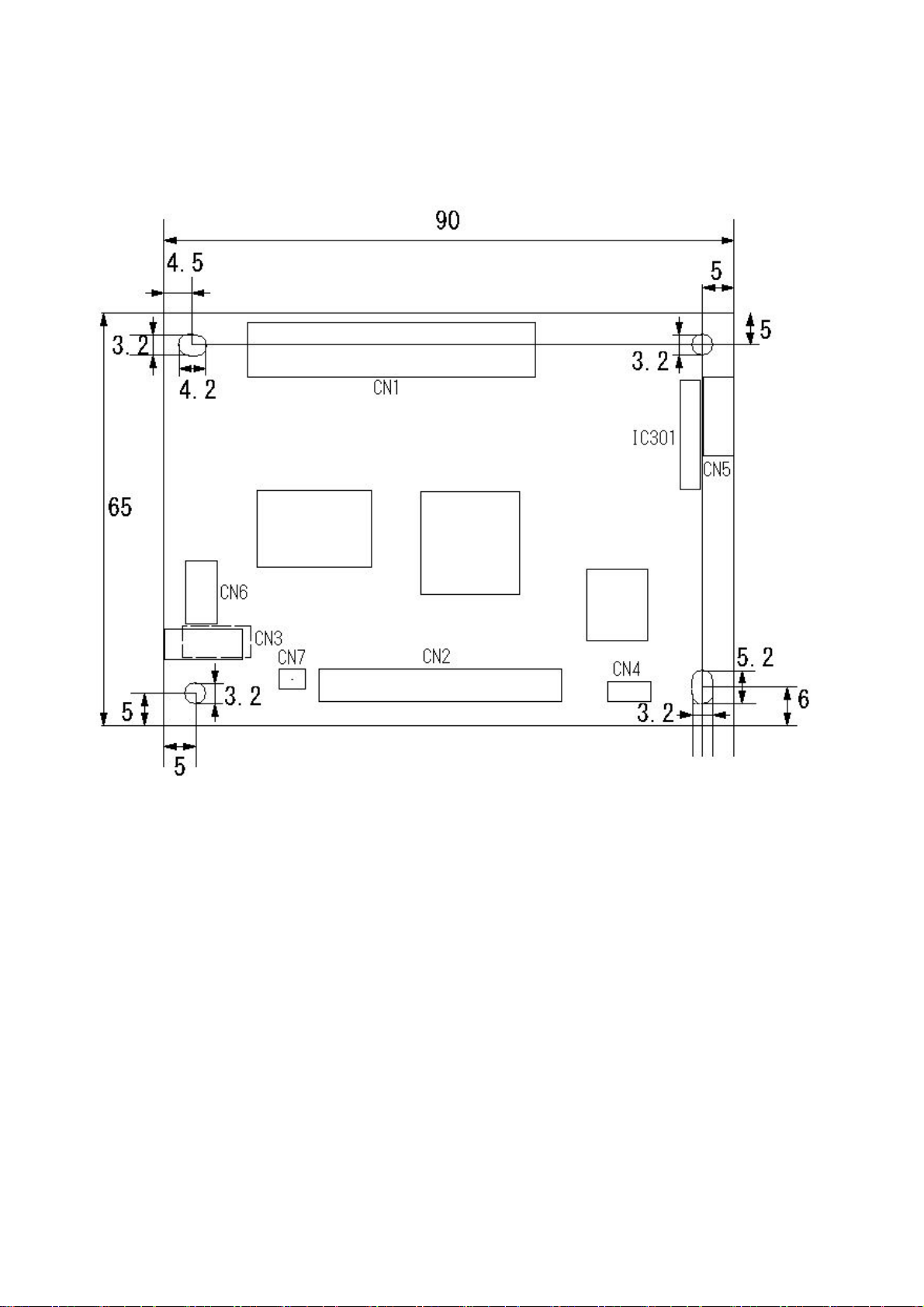

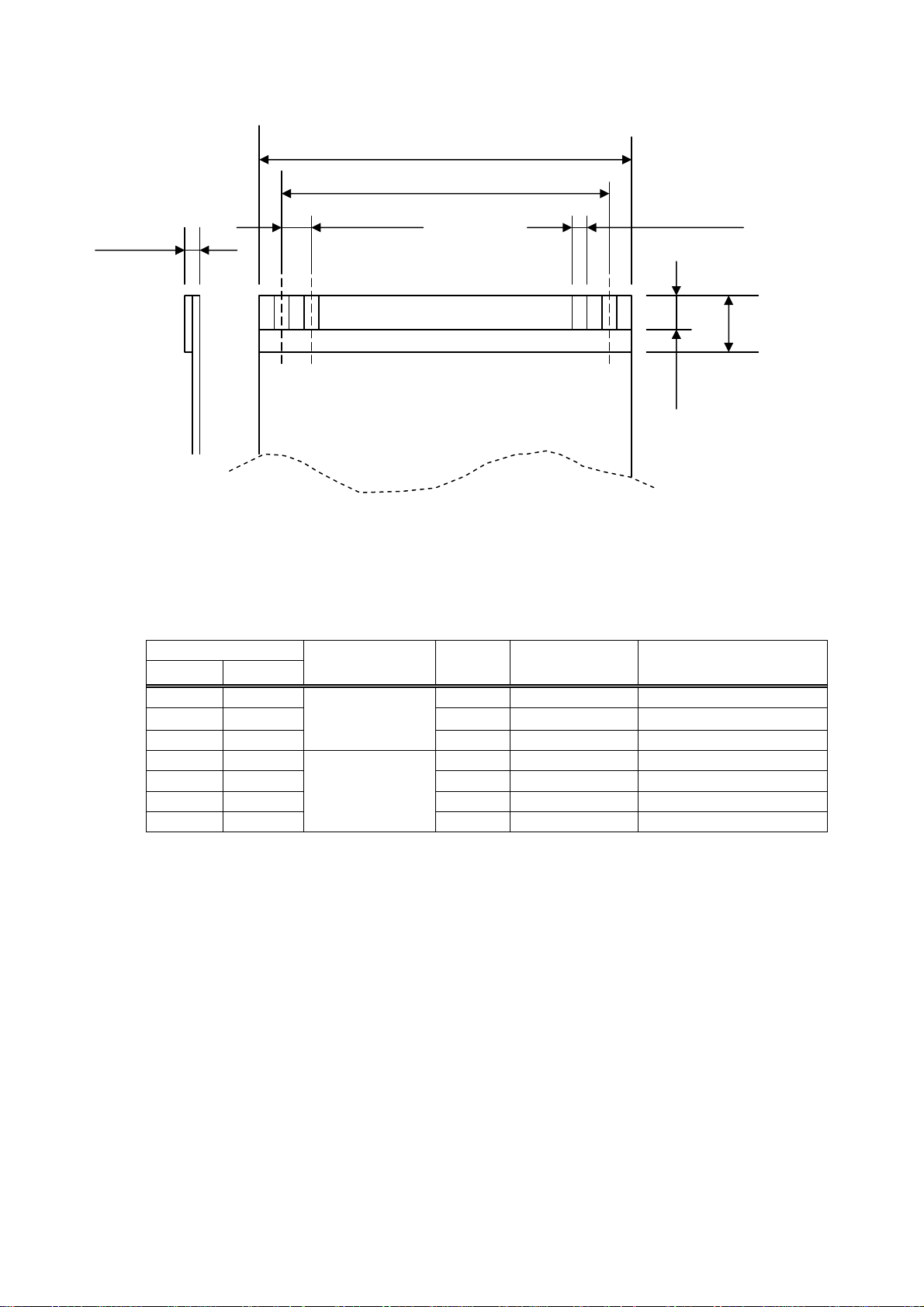

3. APPEARANCE SPECIFICATIONS

Weight : Approx. 37g (Only main body)

Dimensions Unit: mm

* Board size and screw hole position are common to all models.

9

Page 14

4. Connector Connection

4.1 Interface Connectors

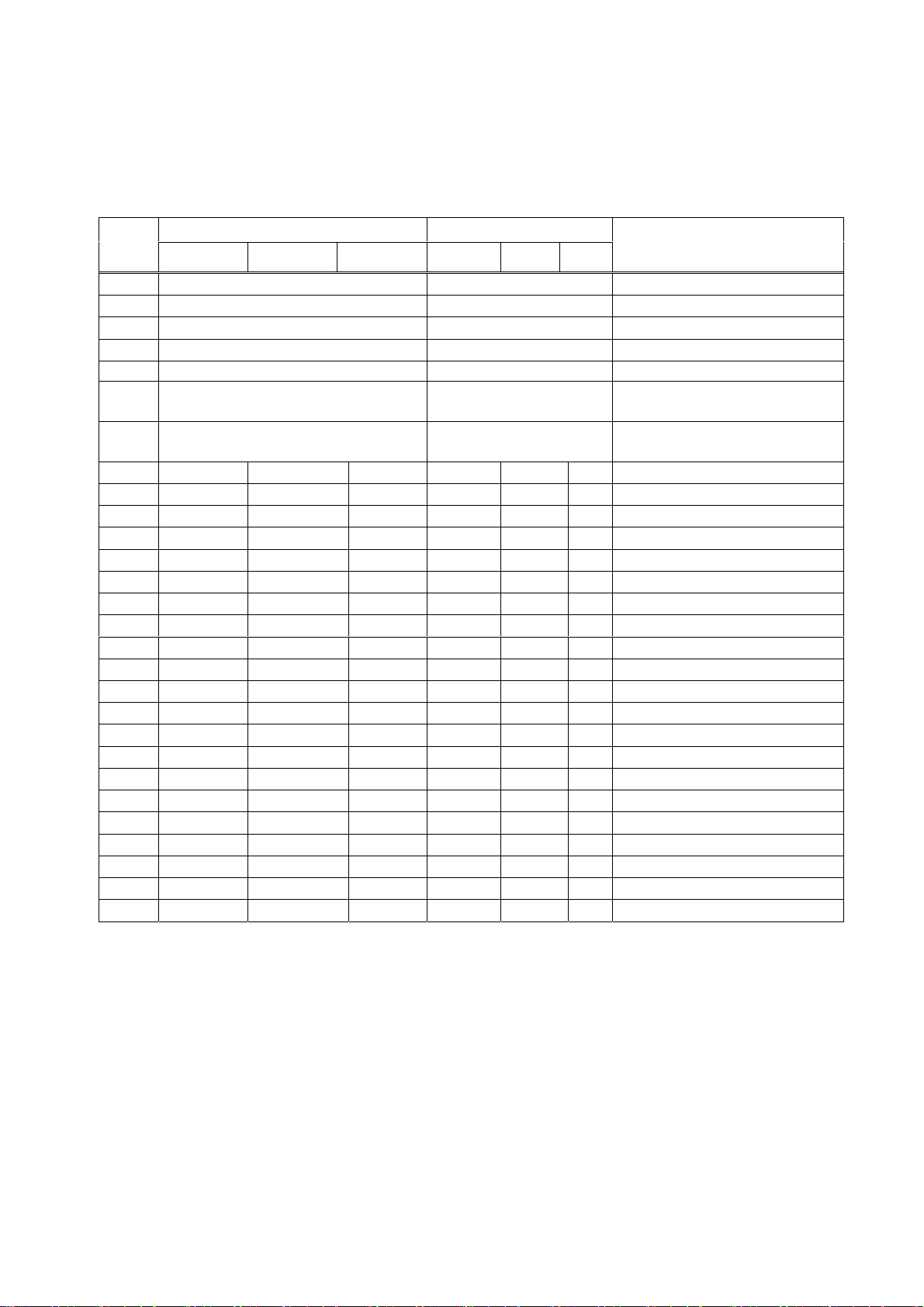

4.1.1 Interface Connector Pin Assignment (CN1)

Pin assignment

Signal Name Input/Output

Pin

RS PA UB RS PA UB

Function

1-2 Vdd

3-4 GND

5-10 Vp

11-16 P-GND

17 nFEED-SW Input FEED Switch (Paper feed)

18 nERROR Output

19 nPEOUT Output

20 DTR N.C N.C Output

21 TXD N.C

22 RXD N.C

23 DSR N.C

24 N.C DATA0

25 N.C DATA1

26 N.C DATA2

27 N.C DATA3

28 N.C DATA4

29 N.C DATA5

30 N.C DATA6

31 N.C DATA7

32 N.C nSTROBE

33 N.C BUSY

34 N.C nFAULT

35 N.C nSELECT

36 N.C PE

37 N.C nACK

38 N.C nAUTOFD

39 N.C nSELECTIN

40 N.C nRESET

Connector used : RS PA 53313-4015 (Molex) UB 53313-2015 (Molex)

Cable supplied

Housing : RS PA 51089-4005 (Molex) UB 51089-2005 (Molex)

Terminal used : 50212 (Molex)

Cable used : AWG26 (UL1007) or equivalent

Cable length : 300mm (Cut at the end)

* Signal name beginning with “n” indicates Low active signal.

-

-

-

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

Output

Input

Input

-

-

-

-

- -

- -

- -

- -

Input

Input

Input

Input

Input

Input

Input

Input

Input

Output

Output

Output

Output

Output

Input

Input

Input

Circuit PS (+5V)

Circuit GND

Drive PS (+24V)

Drive GND

ERROR output (directly

connectable)

PE LED output (directly

connectable)

Serial interface DTR

Serial interface TXD

Serial interface RXD

Serial interface DSR

-

Parallel interface DATA0

-

Parallel interface DATA1

-

Parallel interface DATA2

-

Parallel interface DATA3

-

Parallel interface DATA4

-

Parallel interface DATA5

-

Parallel interface DATA6

-

Parallel interface DATA7

-

Parallel interface nSTROBE

-

Parallel interface BUSY

-

Parallel interface nFAULT

-

Parallel interface nSELECT

-

Parallel interface PE

-

Parallel interface nACK

-

Parallel interface nAUTOFD

-

Parallel interface nSELECTIN

-

Parallel interface nRESET

10

Page 15

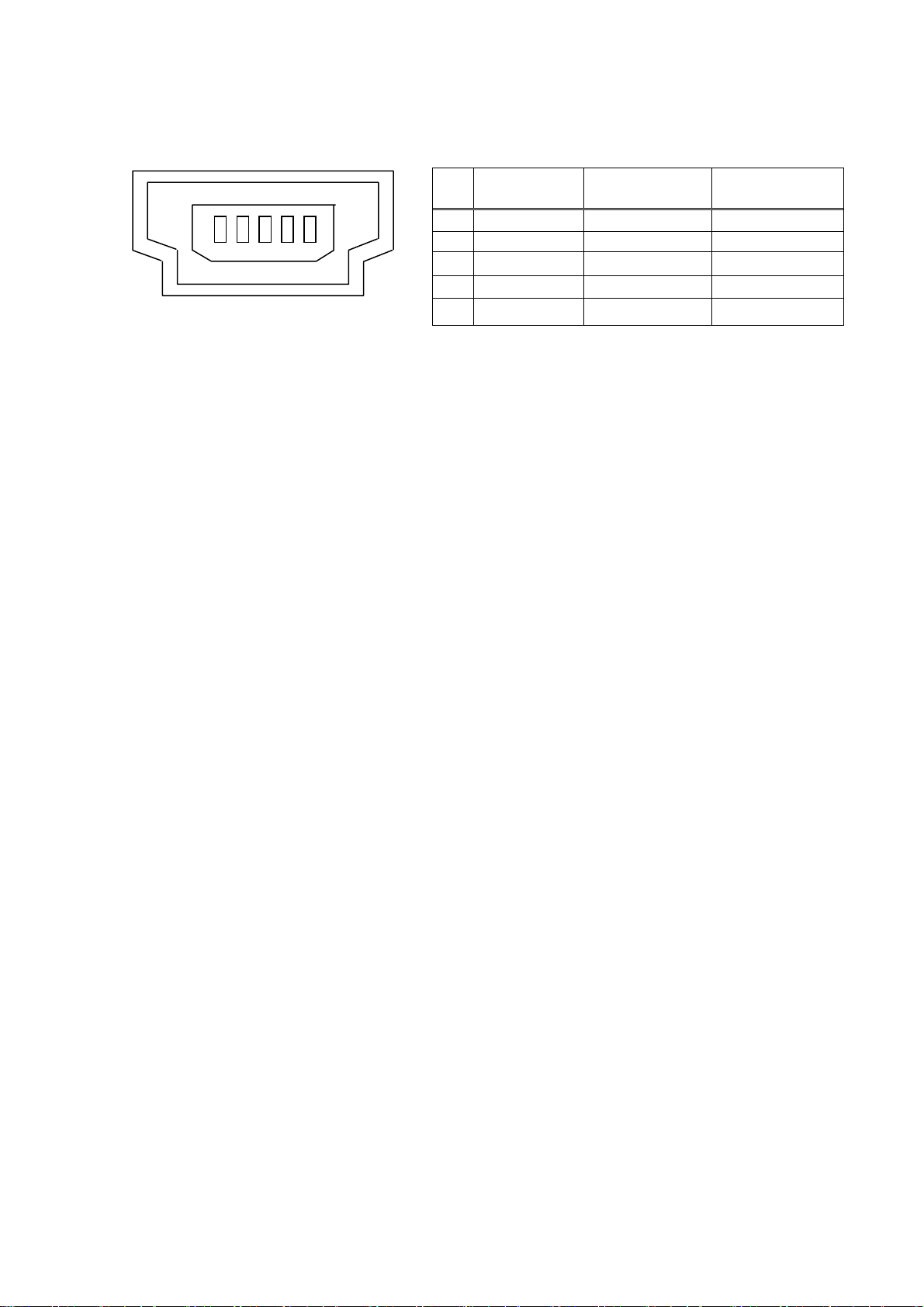

4.1.2 USB Interface Connector Pin Assignment (CN8) * Only USB model

Pin assignment

1 2 3 4 5

Series Min B plug

* Do not use a cable of longer than 5 m.

Pin

1 VBus(+5V)

2 -Data(D-) Input/Output USB D3 +Data(D+) Input/Output USB D+

4 N.C

5 GND

Signal

Name

Input/Output Function

-

-

-

USB PS

Not connectable

USB GND

11

Page 16

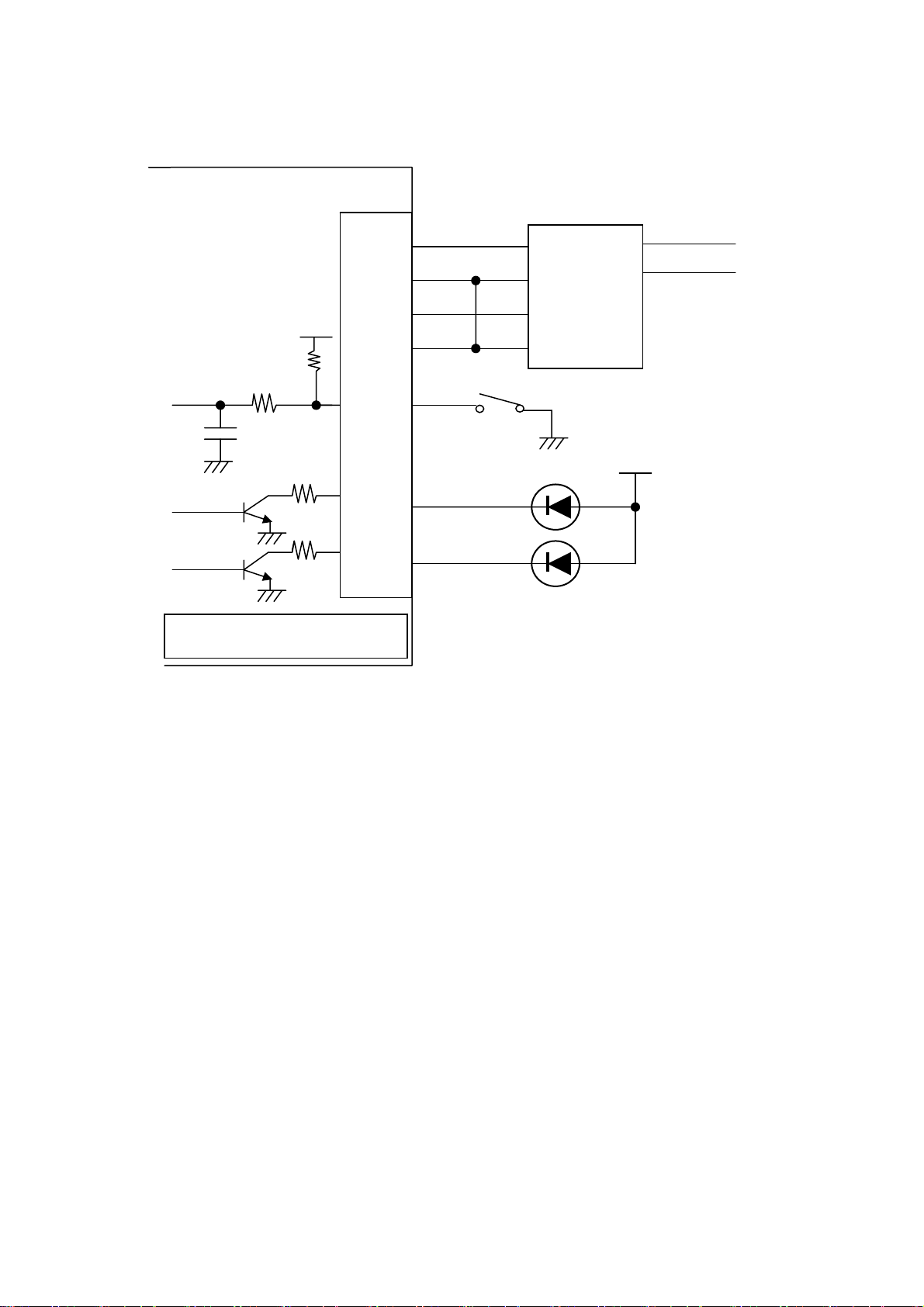

V

V

A

4.1.3 CN1 Connection Example

* For each interface connection, refer to each item.

Vdd

10kΩ

1000pF

100Ω

330Ω

CN1

1、2

3、4

5~10

11~16

17

18

Vdd

GND

Vp

P-GND

FEED SW

ERROR LED

+24

SW

+5

GND

GND

Constant

voltage

PS

GND for power supply or CN1-3, 4

+5V

330Ω

19

PEOUT LED

Control Board

Notes:

1) As resistance 330Ω is inserted in the circuit so that current value of ERROR LED and PEOUT

LED is 10 mA, use the LED with forward voltage of 2 V or so. Using LED exceeding 10 mA

may break the control board.

2) Power supply for circuit (Vdd and GND) will operate if it is applied to only one pin. However,

driving power supply (Vp and P-GND) shall be fed to all pins to retain current capacity.

3) Note that though a ceramic capacitor is provided in the circuit to prevent chattering, great

chattering may occur depending on the switch. In this case, the user is requested to take an

appropriate measure.

4) Do not conduct such operation that only paper feeding continues for more than 5 minutes.

Excessive single operation of paper feed motor may cause failure. * In case of printing

operation (12.5% coloring), continuous operation over 5 minutes causes no trouble.

5) The RESET terminal is pulled up with 3.3 kΩ at the circuit side. If it is not in use, it must be

set as Non Connect.

6) Serial interface is equipped with RS-232C driver and receiver. Be sure to use in RS-232C

level.

7) Unused pin shall be insulated so that cable end may not contact other terminal or part.

C100~240V

5V line of PS or CN1-1, 2

12

Page 17

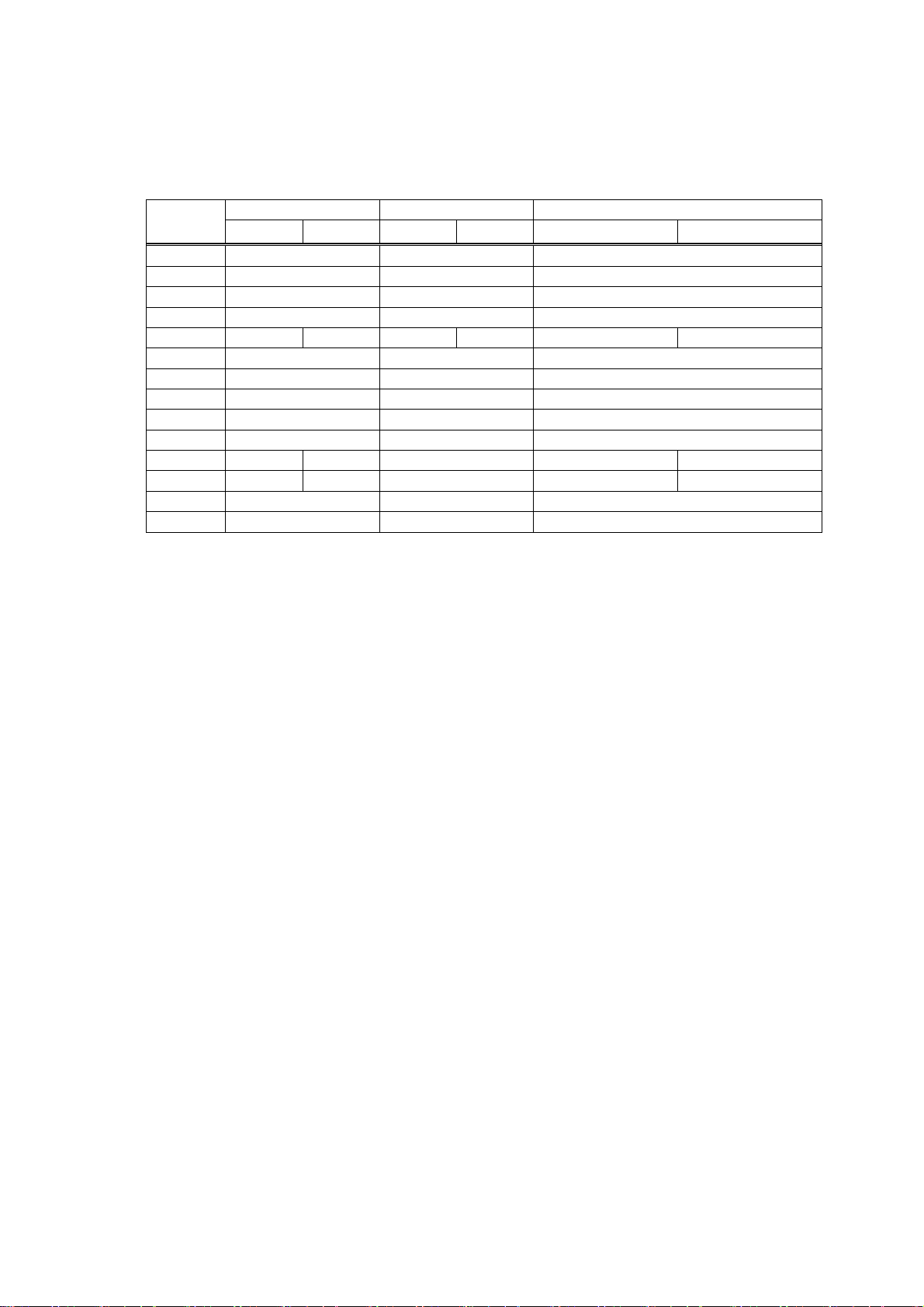

Mechanism Connector (CN2)

4.2

4.2.1 Mechanism Connector Pin Assignment (CN2)

Pin assignment

Pin

1 ~ 4 Vp - Thermal head PS

5 N.C - N.C

6 CLK Output Clock signal for data transmission

7 LAT Output Print data latch signal

8 N.C STB2 - Output N.C Strobe signal 2

9 STB1 Output Strobe signal 1

10 TM - Thermistor

11 ~ 19 GND - GND

20 TM - Thermistor

21 Vdd - Thermal head driver PS

22 STB3 STB4 Output Strobe signal 3 Strobe signal 4

23 STB2 STB3 Output Strobe signal 2 Strobe signal 3

24 DI Output Print data serial output

25 ~ 28 Vp - Thermal head PS

Connector used: 52045-2845 (Molex) or equivalent

52045-2845 (Molex)or equivalent

* Note that assignment of connector pins and control board pins is reversed.

Signal Name Input/Output Function

LT222X LT232X LT222X LT232X LT222X LT232X

13

Page 18

4.2.2 FFC-compliant Cable

36.25±0.1

33.75±0.1

0.3±0.05

1.25±0.05 0.8±0.03

Conductive side

4.3 Head Up, Paper-End Detecting Connector (CN3, CN7)

Min.4

Unit: mm

7

Reinforcing

board

dimension

Pin assignment

Pin

LT2X20 LT2X21

CN3-1 - HU-A Output

CN3-2 CN7-1 GND

CN3-3 CN7-2

CN3-4 CN3-4 PE-C Output

CN3-5 CN3-5 PE-K Input

CN3-6 CN3-6 PE-A Output

CN3-7 CN3-7

Connector used LT2X20 CN3:52045-0745 (Molex) or equivalent

LT2X21 CN3:5597-04CPB (Molex) or equivalent

LT2X21 CN7:53047-0210 (Molex) or equivalent

* In case of LT2X21, 4-pin type is used for CN3 and CN7 is short-circuited by JP4. (Platen

open sensor, if any, shall be removed.)

Sensor

Head Up sensor

Paper sensor

Signal

Name

HU-C Input Head Up signal input

PE-E Input Paper-End signal input

Input/Output Function

-

14

Page 19

Motor Connector (CN4)

4.4

Pin assignment

Pin

1 MOTOR A+ Output Motor driving signal A+

2 MOTOR B- Output Motor driving signal B3 MOTOR A- Output Motor driving signal A4 MOTOR B+ Output Motor driving signal B+

Connector used: 53047-0410 (Molex)

Signal

Name

4.5

Auto Cutter Connector (CN5)

Pin assignment

Pin

1 M+ Output Cutter Motor driving signal M+

2 M- Output Cutter Motor driving signal M3 GND

4 SW Input Cutter Switch input signal

Connector used: 5267-04A-X (Molex)

* Use dedicated cutter (ACS-220/230 series) for cutter.

* If cutter is not used, short the auto cutter feature of JP1.

Signal

Name

Input/Output Function

Input/Output Function

-

GND

15

Page 20

Paper Near-End Sensor Connector (CN6) * Option

4.6

4.6.1 Paper Near-End Sensor Connector Pin Assignment (CN6)

Pin assignment

Pin

1 PNE-A Output Photo interrupter anode

2 PNE-C Input Photo interrupter collector

3 GND

Connector used: 5267-03A-X (Molex)

* At the time of shipment, pins 2 and 3 are short-circuited by JP5 and paper detection is

disabled (always paper present is defined). In actual use, purchase the above connector.

Signal

Name

Input/Output Function

-

Photo interrupter cathode, emitter

4.6.2 Reference Circuits

Photo interrupter is used.

CPU

10kΩ

100Ω

68kΩ

Mechanical switch is used.

Vcc

3.3V

330Ω

1000

Control board

1

2

3

Photo interrupter GP2S24

Sensor

1

NC

2

SW

3

* In the above circuit, reflection type photo interrupter is taken as an example. With the above

sensor, the clearance from paper must be about 1 mm. As electric characteristic varies with

the sensor used, understand the sensor before use.

* Voltage detection range at the control board side (across 2 and 3) is.

0 ~ 0.4V: Paper Present

1V or more: No Paper

This is not warranted in the state other than the above.

Paper

1mm

16

Page 21

5. OPERATION PANEL

5.1 Output LED

1) PE LED

ON : Paper-End detection

OFF : Paper Present detection

2) ERROR LED

ON : Head Up (LT2220/2320 is used), Platen Open (LT2221/2321 is used). Paper-End

Blinking : Hex dump mode, memory switch setting mode, various errors, waiting for macro

execution

OFF : Normal operation

5.2

Details on Error and LED Indication

1) Error to recover automatically

(1) Head overheat error

Explanation: For overheat protection, when the temperature of head increases (approx.

65°C or more), the printing is stopped and ERROR LED blinks.

When the temperature of head declines (approx. 60°C or less), the printing

operation is started automatically.

PE LED: OFF

ERROR LED: Blinks with long illumination at ON

Restore Condition: Automatically restored by temperature decrease

PE LED ERROR LED

OFF

Blinks with long

illumination at ON

17

Page 22

Head Up error (LT2220/2320 is used and MSW3-8 OFF is set.)

(2)

Explanation: ERROR LED blinks during printing and when Head Up is set (with Head Up

lever raised).

PE LED: OFF

ERROR LED: Blinks with long illumination at ON

Restore Condition: Set Head Down (with Head Up lever down).

PE LED ERROR LED

OFF

(3) Platen Open Error (LT2221/2321 is used and MSW3-8 OFF is set.)

Explanation: ERROR LED blinks during printing and when Platen Open is set (with Platen

Open lever held down and platen retaining unit opened).

PE LED: OFF

ERROR LED: Blinks with long illumination at ON

Restore Condition: Close platen (close platen retaining unit and raise the Platen Open

lever).

PE LED ERROR LED

OFF

Blinks with long

illumination at ON

Blinks with long

illumination at ON

18

Page 23

2) Restorable error

(1) Head Up error (LT2220/2320 is used and MSW3-8 ON is set.)

Explanation: ERROR LED blinks during printing and with Head Up.

PE LED: OFF

ERROR LED: Blinks with long illumination at ON

Restore Condition: After Head Down, clear the error by a command.

* For details of DLE ENQ 1, DLE ENQ 2, and DLE DC4 (fn=8), refer to Command Reference.

PE LED ERROR LED

OFF

(2) Platen Open error (LT2221/2321 is used and MSW3-8 ON is set.)

Explanation: ERROR LED blinks during printing and when platen is opened.

PE LED: OFF

ERROR LED: Blinks with long illumination at ON

Restore Condition: After Platen Close, clear the error by a command.

* For details of DLE ENQ 1, DLE ENQ 2, and DLE DC4 (fn=8), refer to Command Reference.

PE LED ERROR LED

OFF

Blinks with long

illumination at ON

Blinks with long

illumination at ON

19

Page 24

Cutter lock error

(3)

Explanation: Cutter operation is disabled. Abnormality occurred.

PE LED: OFF

ERROR LED: ERROR LED repeats blinking 2 times fast and blinking 1 time slow.

Restore Condition: Remove the fault and restore by pressing the FEED switch (with

MSW3-1 set to OFF) or by DLE EMQ 1 or 2 command (with MSW3-1

set to ON).

PE LED ERROR LED

OFF

3) Error impossible to restore

(1) Memory check error

Explanation: CPU self-diagnoses the circuit. When it detects abnormality in external RAM

PE LED: OFF

ERROR LED: Blinking quickly

Restore Condition: Irreparable

memory, ERROR LED blinks quickly.

However, it can be restored by turning power OFF, replacing external

RAM, and removing the cause of the abnormality.

PE LED ERROR LED

OFF

Repeats blinking 2 times fast

and blinking 1 time slow.

ERROR LED blinks

quickly.

20

Page 25

Low voltage error

(2)

Explanation: Occurs when the Vp voltage supplied to the printer is lowered.

If occurred, immediately turn the power OFF.

PE LED: OFF

ERROR LED: ERROR LED repeats blinking 3 times fast and blinking 1 time slow.

Restore Condition: Irreparable

However, it can be restored by turning the power OFF and then

raising the Vp voltage to the range of DC 16.9 to 27.8 V.

PE LED ERROR LED

OFF

(3) High voltage error

Explanation: Occurs when the Vp voltage supplied to the printer is raised.

If occurred, immediately turn the power OFF.

PE LED: OFF

ERROR LED: ERROR LED repeats blinking 4 times fast and blinking 1 time slow.

Restore Condition: Irreparable

However, it can be restored by turning the power OFF and then

raising the Vp voltage to the range of DC 16.9 to 27.8 V.

PE LED ERROR LED

OFF

Repeats blinking 3 times fast

and blinking 1 time slow.

Repeats blinking 4 times fast

and blinking 1 time slow.

21

Page 26

) Others

4

(1) Paper near-end

Explanation of status: When the diameter of the roll paper deceases to a certain degree

(* differs with the status of using Near-End sensor), the Paper

Near-End sensor responds and allows PE LED to light to indicate

roll paper is low.

PE LED: ON

ERROR LED: OFF

Restore Condition: Set another paper roll.

PE LED ERROR LED

ON OFF

(2) Paper-end

Explanation of status: When roll paper becomes empty, the paper sensor in the paper

path near the print head detects the paper end and causes PE LED

and ERROR LED to light and the printing operation to stop.

PE LED: ON

ERROR LED: ON

Restore Condition: Set another paper roll.

PE LED ERROR LED

ON ON

22

Page 27

Head Up (when LT2220/2310 is used)

(3)

Explanation: When Head Up is set, ERROR LED lights.

PE LED: OFF

ERROR LED: ON

Restore Condition: Set Head Down.

PE LED ERROR LED

OFF ON

(3) Platen Open (when LT2221/2321 is used)

Explanation: When Platen is opened, ERROR LED lights.

PE LED: OFF

ERROR LED: ON

Restore Condition: Close Platen.

PE LED ERROR LED

OFF ON

(4) Waiting for a macro execution

Explanation: The printer is waiting for a macro execution by ESC/POS’s commands.

PE LED: OFF

ERROR LED: ERROR LED blinks slowly.

Restore Condition: Push the FEED SW.

PE LED ERROR LED

OFF

Repeats blinking slow.

23

Page 28

Feed Switch

5.3

Function

• When pressed once, paper feed of one line occurs based on the amount of line feed set by ESC 2

and ESC 3.

However, paper feed is not available in the following cases.

(1) When the FEED switch is set to disable by ESC c 5

(2) When paper-end detector detected no paper

(3) With Head Up. (LT2220/2310 is used)

(4) With Platen Open (LT2221/2321 is used)

(5) When error occurred

(6) When waiting for macro execution (execution of macro by the FEED switch), pressing the

FEED switch causes the macro to be executed.

• At the time of Cutter Lock error, pressing the FEED switch after removing the cause clears the

error. (Depending on the status of MSW3-1)

24

Page 29

5.3.1 Self-printing

1) Function

Function to enable the printer setting status to be verified by printing

2) Start of self-printing

When the power is turned on with the FEED switch pressed and held in print ready state,

printer status is printed on the roll paper.

Explanation of printed item is as shown below.

(1) Printer type name BD2-2220

(2) ROM version VX.XXXXXX

(3) Mechanism used

(4) Interface setting

(5) Buffer size

(6) Content of DIP switch setting (Only serial interface)

(7) Jumper settings (Only JP1 to 3. JP4, 5 are not printed.)

(8) Content of memory switch

(9) Font A (20H ~ FFH)

(10) Font B (20H ~ FFH)

(11) Font C(20H ~ FFH)

(12) Kanji Font A 192 characters (Only Kanji specification)

(13) Kanji Font C 192 characters (Only Kanji specification)

(14) Line is fed up to cut position.

3) End of self-printing

Print a specified print pattern and perform resetting after printing for initialization.

25

Page 30

5.3.2 Hexadecimal Dump Printing

1) Function

Prints the data sent from the host in hexadecimal code and the corresponding characters.

2) Starting hexadecimal dump

With paper set and Head Up (or Platen Open), turn the power on while pressing and holding

the FEED switch. Set Head Down (or Platen Close). Then “HEX dump print mode” is printed

on the roll paper followed by the printing of data received thereafter in hexadecimal numbers

and corresponding characters.

Example: When dump printing is executed in Kanji mode.

Example: When dump printing is executed in non-Kanji mode.

• During hexadecimal dump, command other than Real time command has no function.

• When print data is less than one line, offline factor occurs to print the line.

3) End of hexadecimal dump

• Press the FEED switch consecutively three times. In this case “Completed” is printed and

paper is fed to the cut position and then a reset occurs. Otherwise, turn the power OFF or

perform a reset by the I/F signal.

HEXダンプ印字モード

1B 40 31 32 33 34 35 36 .@123456

37 38 39 30 0A 7890.

HEX DUMP PRINT MODE

1B 40 31 32 33 34 35 36 .@123456

37 38 39 30 0A 7890.

Completed

Completed

26

Page 31

5.3.3 Memory Switch Setting Mode

1) Settable memory switch

MSW1、MSW2、MSW3

2) Starting memory switch setting mode

With paper set and Head Up (or Platen Open), turn the power on while pressing and holding

the FEED switch and then press the FEED switch twice, set Head Down (or Platen Close) to

start the setting mode.

After the setting mode is started, the guidance of setting content and operation method is

printed.

3) Selecting memory switch

By pressing FEED SW shortly (less than 500 ms), the memory switches to be set is selected in

the following order.

In doing so, the status of selected memory switch is printed. However, when f is selected,

the verification of flash memory writing is printed.

(1) MSW1

(2) MSW2

(3) MSW3

(4) Recording / Initialization of the setting

* By pressing the FEED switch long (2s or more) when c to e is selected, setting the

selected memory switch is started. (Goes to the following 4) Setting memory switch.)

* By pressing the FEED switch long when (4) is selected, current memory switch settings are

all written into the flash memory and Reset operation is carried out. (Goes to the

following 5) Terminating memory switch setting mode.)

By pressing the FEED switch long with Head Up (or Platen Open) when (4) is selected, a reset

operation is executed with current memory switch settings discarded and factory setting

restored. (Goes to the following 5) Terminating memory switch setting mode.)

4) Setting memory switch

(1) Print the status of bit which is currently set.

(2) Pressing the FEED switch short (less than 500 ms) causes the selected bit to be inverted.

Here, if the bit is ON, error LED lights.

(3) Pressing the FEED switch long (more than 2s) causes current bit to be saved. If any

change occurs, the status of the bit is printed.

Setting the following bits is started.

The order of change of bit is shown below.

Bit 0 → Bit 1 →…→ Bit 6 → Bit 7 → Bit 0 →…

(4) The setting is terminated with Head Up (or Platen Open). Then by Head Down, current

status of memory switch is printed and returns to 3) Selecting memory switch.

5) Terminating memory switch setting mode

After setting, the settings are saved and initializing operation (Reset) is carried out and

normal printable condition is restored.

27

Page 32

6. INTERFACES

6.1 Bidirectional Parallel Interface (IEEE1284)

6.1.1 Specification

1) Compatibility Mode (Host → Printer Communication: Centronics Compliant)

(1) Outline

Compatibility Mode is a standard of Centronics interface that has been used for long.

(2) Specification

Data transfer system: 8 bit parallel

Synchronization: By the nStrobe signal supplied from outside

Handshake: By the nAck signal and Busy signal

Signal level: All signals are TTL compatible.

2) Reverse Mode (Printer → Host Communication)

Transfer of status data from this printer to the host is made in the Nibble or Byte Mode.

(1) Outline

This mode specifies the data transfer from the asynchronous printer controlled by the

host.

Data transfer in the Nibble Mode is carried out through existing control line and data is

transferred in steps of 4 bits (Nibble).

In the Byte Mode, data is transferred through the 8-bit data line treated for bidirectional

transmission.

In any case, as concurrent execution with Compatibility Mode is not available,

communication is made in half duplex mode.

When using this mode, use CN1-38 and 39 pins in addition to the parallel interface

terminal of the interface cable.

CN1-38 pin: nAUTOFD

CN1-39 pin: nSELECTIN

Unless these two pins are used, bidirectional communication cannot be implemented. If

you don’t want to use bidirectional communication, set the terminal to be Non Connect.

* The first “n” of a signal name indicates “LOW” active signal. If any one of the above

signals is missing, bidirectional communication is impossible. Always use twisted pair line

for signal lines of interface while connecting the return side to the signal ground level. All

the interface conditions shall be based on C-MOS level and satisfy the following

characteristics. Rising and falling time of each signal shall be 0.5 µs. Never carry out

data transfer by ignoring the nAck signal or Busy signal. Otherwise, data transfer may

result in loss of data. Interface cable shall be minimum necessary length.

28

Page 33

6.1.2 Description of Input/Output Signals

1) Input/Output Signals

Explanation of input/output signals

[1] Input/Output Signals (Compatibility Mode)

(1) Input signals to the printer

・DATA0 ~ 7: 8 bit parallel signal (positive logic)

・nSTROBE: Strobe signal for reading out 8-bit data (negative logic)

・nRESET: Applies reset by the nRESET signal in Compatibility Mode.

(Can be disabled by the setting:Msw3-3)

Reset signal is invalid for nSelectIn/1284-Active “HIGH”.

nSELECT

nRESET

150 msec min

・nSELECTIN : Signal to set “HIGH” when transferring to the IEEE 1284 mode

(negative logic)

(2) Output signals from the printer

・nACK: 8-bit data request signal (negative logic)

・BUSY: Signal to indicate the printer is in the Busy state.

State to become BUSY

1. Period from Reset (including reset by NV memory write

command, I/F signal, and test print command) or just after

printer power on to printer operation ready state.

2. Under test printing

3. Input buffer full state (Refer to “(4) Buffer full state”.)

4. During Head Up (or Platen Open)

5. Under line feeding with FEED switch

6. Waiting for pressing FEED switch at the execution of macro

7. No paper state

8. Error state

BUSY regardless of memory SW setting under the above 1 to 3

conditions.

Does not become BUSY in other case as specified by setting.

29

Page 34

・SELECT: Always non-active (“LOW”).

・nFAULT: Signal to set “LOW” when the printer is in the error state (negative

logic).

・PE: Signal to be output with No paper or near-end state (by command

setting) (positive logic)

Note: When using a command followed by FROM writing, printer may temporarily

become BUSY (DTR) at the time of write operation. In this case, as the

printer cannot make any processing, data transmitted may possibly be

discarded.

2) Electrical Characteristics

[1] Input signal level (nStrobe, Data0 ~ 7)

All input signals are C-MOS level.

”HIGH ” level: 2.0V min.

”LOW ” level: 0.8V max.

[2] Output signal level

All output signals are C-MOS level.

”HIGH ” level: 4.4V min.

”LOW ” level: 0.1V max.

[3] I/O conditions

All input/output signals are pulled up with 3.3 kΩ.

[Printer side] [Host side]

Vcc

Twisted pair wire

[Printer side] [Host side]

Vcc

Twisted pair wire

3.3KΩ

3.3KΩ

30

Page 35

T2T6 T1T3T4T

3) Timing chart (Compatibility Mode)

Data input and print timing

Power supply

DATA

nSTROBE

BUSY

nACK (Note)

5

T1,T2,T3 : 0.5 µs MIN

T4 : 270ns MAX

T5 : 2.3 µs TYP

T6 : 1200ms MIN (At power on)

Figure Timing Chart

Note: ACK output position can be changed to ACK in BUSY, ACK while BUSY, or ACK after

BUSY by the setting of customize value.

4) Buffer full state

Buffer full state is when the remaining capacity of input buffer is as shown below.

Table Input Buffer Full

Set Value Buffer Full Clear

4K bytes Remaining 128 bytes Remaining 256 bytes

45 bytes Remaining 16 bytes Remaining 26 bytes

・When the remaining capacity of input buffer is 0 byte, data received is read and

discarded.

31

Page 36

5) Reverse Mode (Nibble/Byte) mode allows status to be transmitted from the printer.

(Using GS a, DLE EOT n, GS r, of GS I command)

・The transmitting buffer of the printer is 99 bytes. The host must transfer to Reverse

Mode to prevent loss of status. Being in the Reverse Idle state is desired when using

ASB. If this is not possible, always monitor the presence or absence of the transmitting

data from the printer. The ASB not transmitted but accumulated is transmitted

together (OR) with the latest status.

・Identification of information on each status is available.

Command, Code Status

GS I

GS r

XON

XOFF

DLE EOT

ASB (1st byte)

ASB (2nd byte)

6.1.3 Connection to Parallel Port

1) Connection to 36-pin/25-pin parallel port

CN1

36-pin

Parallel interface

Identification of Status

<0**0****>B

<0**0****>B

<00010001>B

<00010011>B

<0**1**10>B

<0**1**00>B

<0**0****>B

CN1

25-pin

Parallel interface

2) Connection to other parallel port

To connect to the connector other than the above, verify the status of various signals and

connect properly.

32

Page 37

RS-232C Serial Interface

6.2

6.2.1 Specification

1) Synchronization: Asynchronous

2) Baud rate

2400, 4800, 9600, 19200, 38400, 57600, 115200 bps (User selection)

3) Word configuration

Start bit: 1 bit

Data bit: 7 bits or 8 bits (User selection)

Parity bit: Odd, even, or no parity (User selection)

Stop bit: 1 bit or more

4) Signal polarity

RS-232C

・Mark =Logic ”1” (-3V to-12V)

・Space =Logic ”0” (+3V to +12V)

6.2.2 Description of Input/Output Signals

1) Input/Output Signals

(1) RD

Receive Data

When the host is connected, the unstable TD signal that can occur at the rise (fall) of

host power is defined as a break signal and the data is read and discarded.

(When the host power is turned off, the host may cause unstable state in TD. Printing

of such data shall be avoided.)

(2) TD

Transmit Data

(3) DSR

When DTR/DSR control is selected, data is transmitted after confirming that this signal

is a space.

When XON/XOFF control is selected, data is transmitted by ignoring DSR.

(4) DTR

Space sets the printer is in the Busy state and mark sets the printer in the Ready state.

Condition to become Busy can be switched by the setting (MSW1-3).

33

Page 38

・State to become BUSY

1.Period from Reset (including reset by NV memory write command, I/F signal, and

test print command) or just after printer power on to printer operation ready state.

2.Under test printing

3.Input buffer full state (Refer to “(2) Buffer full state”.)

4.During Head Up (or Platen Open)

5.Under line feeding with FEED switch

6.Waiting for pressing FEED switch at the execution of macro

7.No paper state

8.Error state

BUSY regardless of memory SW setting under the above 1 to 3 conditions. Does not

become BUSY in other case as specified by setting.

Note: When XON/XOFF control is selected, mark state occurs only in the state of 1

and 2. In other case, space state is set. Used to know the status of

connection between the printer and host.

The state other than item 3 is defined as offline.

XON/XOFF output condition

・XON transmission

1.Period from Reset (includin g reset by NV memory write command, I/F signal,

and test print command) or just after printer power on to printer operation

ready state.

2.When input buffer full state is cleared. Does not output if the printer is

offline even memory switch setting is OFF.

3.When the printer changed from offline to online. Does not output in buffer

full state.

・XOFF transmission

1.When input buffer becomes buffer full state.

2.When the printer changed from online to offline. Does not output in buffer

full state.

34

Page 39

2) Buffer full state

Buffer full state is when the remaining capacity of input buffer is as shown below.

Table Input Buffer Full

Set Value Buffer Full Clear

4K bytes Remaining 128 bytes Remaining 256 bytes

45 bytes Remaining 16 bytes Remaining 26 bytes

・When the remaining capacity of input buffer is 0 byte, data received is read and

discarded.

3) Data receive error

When any of the following error occurs, data is printed as “?” or read and discarded

(Msw1-4).

・Parity error

・Framing error

・Overrun error

Note: When a command accompanying flash ROM write is used, the printer may

become BUSY (DTR) temporarily at write operation. In this case, as the printer

cannot process anything, the transmitted data may possibly be discarded.

4) Electrical Characteristics

[1]RS-232C circuit (MAX 232 or equivalent)

Input (RD, DSR)

[Printer side] [Host side]

Output (DTR, TD)

35

Page 40

6.2.3 Connection to Serial Port

1) Connection to 25-pin/9-pin serial port

CN1

25-pin

Serial interface

CN1

9-pin

Serial interface

*The above wiring is an example of standard connection to the host. If the cable

is relayed, it is necessary to take such measures as connecting DTR/DSR and

RXD/TXD reversely, etc.

2) Connection to other serial port

To connect to the connector other than the above, verify the status of various signals and

connect properly.

6.3

USB Interface

(1) Whole specification: Based on the specification of USB1.1

(2) Communication speed: USB full-speed mode (12 MHz)

(3) Communication method: USB bulk forwarding method

(4) Power supply: 0 mA (Power is supplied from the printer.)

36

Page 41

7. Function Selection

When using this control board, some functions can be set to default.

7.1

Jumper

Turn the printer power off before changing jumper setting.

Jumper No. Function Open Short

JP1 Auto cutter Enable ●Disable

JP2 Mechanism used ●LT2220/2221 LT2320/2331

JP3 Auto loading ●Enable Disable

JP4* Platen Open sensor ●Enable Disable

JP5 PNE sensor Enable ●Disable

* Disabled (Short) for BD2-2221.

●Default (factory setting)

7.2

DIP switch (Only Serial Interface)

DIP switch is located on the RS-232C serial interface board.

Change the DIP switch setting with power set to OFF.

Switch

No.

1

2 Handshake

3 Bit length 7 bits ● 8 bits

4 Parity check With parity ● None

5 Parity selection Even parity ● Odd parity

6

7

8 Reserved

● Default (factory setting)

Selecting Baud Rate

Switch No.

Baud Rate (bps)

2400 OFF OFF

4800 ON OFF

9600 ● OFF ● ON

19200 ON ON

● Default (factory setting)

Baud rate (38400, 57600, 115200 bps) other than the above can be set by command.

Function ON OFF

Communication

condition setting

method

Baud rate selection See “Selecting Baud Rate” below.

● Depend on DIP switch

setting

XON/XOFF ● DTR/DSR

-

6 7

Depend on customer’s

value setting.

● Fixed

37

Page 42

Memory Switches

7.3

Memory switch is a generic name for the following:

Memory switches MSW1, MSW2, and MSW3

Customize value

Serial Interface Communication Conditions

1) Memory switches MSW1, MSW2, and MSW3

Memory switch setting table

No. Function OFF ON

MSW1-1 Power ON notice setting ● Enable Disable

MSW1-2 Input buffer ● 4K bytes 45 bytes

MSW1-3 Busy condition ● Full/Off line Buffer full

MSW1-4 Receive error character ● Character “?” Disable

MSW1-5 CR mode ● Disable Enable

MSW1-6 Reserved ● Fixed ―

MSW1-7 DSR signal selection ● Disable Enable

MSW1-8 Reserved ● Fixed ―

MSW2-1 Reserved ― ● Fixed

MSW2-2 Reserved ― ● Fixed

MSW2-3 Buffering ● Disable Enable

MSW2-4 Full digit printing ● Line feed WaitData

MSW2-5 Head Down restore * ● Next Top

MSW2-6 Reserved ― ● Fixed

MSW2-7 Reserved ● Fixed ―

MSW2-8 Reserved ● Fixed ―

MSW3-1 Auto Cutter recovery ● L/F Enable L/F Disable

MSW3-2 Reserved ● Fixed ―

MSW3-3 Parallel Reset ● Reset Ignored

MSW3-4 Reserved ● Fixed ―

MSW3-5 Reserved ● Fixed ―

MSW3-6 Reserved ● Fixed ―

MSW3-7 Reserved ● Fixed ―

MSW3-8 Head Up in printing * ● Automatic recovery Recoverable error

● Default (factory setting)

* When LT2221/2321 is used, function for Platen Close/Platen Open is applied.

38

Page 43

2) Customize value

Customize value can be set by the GS (E command.

Function Value

Specify the user NV memory capacity

Select the print density

(Verification required)

(Verification required)

● Default (factory setting)

3) Serial interface communication conditions

Communication conditions can be set by the GS(E command.

Function Value

Baud rate

Parity

Flow control ● DSR/DTR control XON/XOFF control

Data length 7-bit length ● 8-bit length

● Default (factory setting)

1K bytes 64K bytes

128K bytes ● 192K bytes

70% 75%

80% 85%

90% 95%

● 100% 105%

110% 115%

120% 125%

130% ―

ACK-in-Busy ● ACK-while-Busy ACK output position

ACK-after-Busy ―

● 1 2 At Input Buffer Full, BUSY output timing

3 4

2400 bps 4800 bps

● 9600 bps 19200 bps

38400 bps 57600 bps

115200 bps ―

● None Odd

Even ―

39

Page 44

8. PRINT CONTROL COMMANDS

○ Print Control Commands

Control

Command

LF Printing and paper feed

CR Back to printing

FF Printing in page mode and recovery P

ESC FF Printing data in PAGE MODE P

ESC J Printing and feeding paper in minimum pitch

ESC d Printing and feeding the paper by “n” lines

○ Print Character Commands

Control

Command

CAN Canceling print data in PAGE MODE P

ESC SP Setting the right spacing of the character

ESC ! Collectively specifying the printing mode

ESC % Specifying/canceling download character set

ESC & Defining the download characters

ESC - Specifying/canceling underline

ESC ? Deleting download characters

ESC E Specifying/canceling emphasis printing

ESC G Specifying/canceling double strike printing

ESC M Selection of character fonts

ESC R Selecting the international character set

ESC V Specifying/canceling 90°-right-turned characters S

ESC t Selecting the character code table

ESC { Specifying/canceling the inverted characters S

GS ! Specifying the character size

GS B Specifying/canceling the black/white inverted printing

GS b Specifying/canceling the smoothing

○ Print Position Commands

Control

Command

HT Horizontal tab

ESC $ Specifying the absolute positions

ESC D Setting horizontal tab position

ESC T Selecting the character printing direction in PAGE MODE P

ESC W Defining the print area in PAGE MODE P

ESC \

ESC a Aligning the characters S

GS $

GS L Setting the left margin S

GS W Setting the print area width

GS \

Specifying the relative position

Specifying the absolute vertical position of characters in

PAGE MODE

Specifying the relative vertical position of a character in

PAGE MODE

Function Mode GS P

S・P

S・P

S・P ○

S・P

Function Mode GS P

S・P ○

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

S・P

Function Mode GS P

S・P

S・P ○

S・P

S・P ○

P

S・P ○

S・P ○

○

○

○

40

Page 45

○ Line Feed Span Commands

Control

Command

ESC 2 Specifying 1/6-inch line feed rate

ESC 3 Setting line feed rate of minimum pitch

Function Mode GS P

S・P

S・P ○

○ Bit Image Commands

Control

Command

ESC * Specifying the bit image mode

GS * Defining the download bit image

GS / Printing the downloaded bit image

Function Mode GS P

S・P

S・P

S・P

GS v 0 Printing of raster bit image S

○ Status Commands

Control

Command

DLE EOT Sending status in real-time

GS a Enabling/disabling ASB (Automatic Status Back)

GS r Sending status

Function Mode GS P

S・P

S・P

S・P

○ Paper Detecting Commands

Control

Command

ESC c 3

Selecting the Paper Sensor valid for Paper-end signal

output

ESC c 4 Selecting the Paper Near-end Sensor valid for print stop

Function Mode GS P

S・P

S・P

○ Panel Switch Commands

Control

Command

ESC c 5 Enabling/disabling the panel switches

Function Mode GS P

S・P

○ Macro Commands

Control

Command

GS : Starting/ending macro definition

GS ^ Executing the macro

Function Mode GS P

S・P

S・P

○ Cutter Commands

Control

Command

ESC i Cutting the paper partially

ESC m Cutting the paper partially

GS V Cutting the paper

Function Mode GS P

S・P

S・P

S・P ○

41

Page 46

Bar Code Commands

○

Control

Command

GS H Selecting of printing position of HRI characters

GS f Selecting the font of HRI characters

GS h Specifying the height of the bar code

GS k Printing the bar code

GS w Specifying the horizontal size (magnification) of bar code

Function Mode GS P

S・P

S・P

S・P

S・P

S・P

○ Commands for Flash Memory

Control

Command

FS p

FS q

Printing the bit image in flash memory S

Defining the bit image in flash memory S

Function Mode GS P

○ Printer Setting Commands

Control

Command

Function Mode GS P

GS ( E User-defined command S

GS ( K Selecting print control method S

GS ( M Customizing the printer S

○ Other Commands

Control

Command

DLE ENQ Real-time request to printer

DLE DC4 Clearing buffer

ESC = Data input control

ESC @ Initializing the printer

Function Mode GS P

S・P

S・P

S・P

S・P

ESC L Selecting PAGE MODE S

ESC S Selecting STANDARD MODE P

GS ( A Execution of test printing S

GS I Sending the printer ID

GS P Specifying the basic calculation pitch

S・P

S・P

Notes:

• In the Mode column: S = STANDARD MODE, P = PAGE MODE.

• { = shows the command affected by GS P.

42

Page 47

9. CHARACTER CODE TABLE

9.1 Code Page

9.1.1 Codepage 00H to 7FH & PC437 (USA, Europe Standard)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ ╨ α≡

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü æ í ▒ ┴ ╤ β ±

" 2 B R b r é Æ ó ▓ ┬ ╥ Γ ≧

# 3 C S c s â ô ú │ ├ ╙ π ≦

$ 4 D T d t ä ö ñ ┤ ─ ╘ ∑ ⌠

% 5 E U e u à ò Ñ ╡ ┼ ╒ σ ⌡

& 6 F V f v å û a ╢ ╞ ╓ μ÷

' 7 G W g w ç ù o ╖ ╟ ╫ τ

≈

( 8 H X h x ê ÿ ¿ ╕ ╚ ╪ Φ 。

) 9 I Y i y ë Ö ⌐ ╣ ╔ ┘ θ ∙

* : J Z j z è Ü ¬ ║ ╩ ┌ Ω ∙

+ ; K [ k { ï ¢ ½ ╗ ╦ █ δ √

FF FS

C

CR GS

D

E

F

Note: Kanji code table shows the shape of characters but does not show actual print result.

RS

, < L \ l | î £ ¼ ╝ ╠ ▃ ∞ ⁿ

- = M ] m } ì ¥ ¡ ╜ ═ ▌ φ ²

. > N ^ n ~ Ä

Pt

« ╛ ╬ ▐ ∈ ■

/ ? O _ o ・ Å ƒ » ┐ ╧ ▄ ∩

43

Page 48

9.1.2 Codepage 00H to 7FH & Katakana

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p ▁ ┴SP-タ ミ ═ ×

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ▂ ┬ º ア チ ム ╞ 円

" 2 B R b r ▃ ┤┌イツ メ ╪ 年

# 3 C S c s ▅ ├┘ウテ モ ╡ 月

$ 4 D T d t ▆ ─、エト ヤ ◢ 日

% 5 E U e u ▇ _ ・ オ ナ ユ ◣ 時

& 6 F V f v █ |ヲカニ ヨ ◥ 分

' 7 G W g w ▉ ▕ ァ キ ヌ ラ ◤

秒

( 8 H X h x ▏ ┌ィクネ リ ♠ 〒

) 9 I Y i y ▎ ┐ゥケノ ル ♥ 市

* : J Z j z ▍ └ェコハ レ ♦ 区

+ ; K [ k { ▌ ┘ォサヒ ロ ♣ 町

FF FS

C

CR GS

D

E

F

RS

, < L \ l | ▋ ╭ ャ シ フ ワ ● 村

- = M ] m } ▋ ╮ ュ ス ヘ ン ○ 人

. > N ^ n ~ ▊ ╰ ョ セ ホ “ ╱ ▒

/ ? O _ o ・ + ╯ ッ ソ マ ゜ ╲ SP

44

Page 49

9.1.3 Codepage 00H to 7FH & PC850/858 (Multilingual)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ ð Ó ―

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü æ í ▒ ┴ Ð β ±

" 2 B R b r é Æ ó ▓ ┬ Ê Ô =

# 3 C S c s â ô ú │ ├ Ë Ò ¾

$ 4 D T d t ä ö ñ ┤ ─ È õ ¶

% 5 E U e u à ò Ñ Á ┼ € Õ §

& 6 F V f v å û a  ã Í μ÷

' 7 G W g w ç ù o À Ã Î þ

,

( 8 H X h x ê ÿ ¿ © ╚ Ï Þ °

) 9 I Y i y ë Ö ® ╣ ╔ ┘ Ú ¨

* : J Z j z è Ü ¬ ║ ╩ ┌ Û ∙

+ ; K [ k { ï ø ½ ╗ ╦ █ Ù ¹

FF FS

C

CR GS

D

E

F

RS

, < L \ l | î £ ¼ ╝ ╠ ▃ ý ³

- = M ] m } ì Ø ¡ ¢ ═ ¦ Ý ₂

. > N ^ n ~ Ä × « \ ╬ Ì ¯ ■

/ ? O _ o ・ Å ƒ » ┐ ¤ ▄ ′

45

Page 50

9.1.4 Codepage 00H to 7FH & PC860 (Portuguese)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ ╨ α≡

1

2

3

4

5

6

7

8

9

A

B

XON

XOF

F

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü À í ▒ ┴ ╤ β ±

" 2 B R b r é È ó ▓ ┬ ╥ Γ ≧

# 3 C S c s â ô ú │ ├ ╙ π ≦

$ 4 D T d t ã õ ñ ┤ ─ ╘ ∑ ⌠

% 5 E U e u à ò Ñ ╡ ┼ ╒ σ ⌡

& 6 F V f v Á Ú a ╢ ╞ ╓ μ÷

' 7 G W g w ç ù o ╖ ╟ ╫ τ

≈

( 8 H X h x ê Ì ¿ ╕ ╚ ╪ Φ °

) 9 I Y i y Ê Õ Ò ╣ ╔ ┘ θ

* : J Z j z è Ü ¬ ║ ╩ ┌ Ω ∙

+ ; K [ k { Í ¢ ½ ╗ ╦ █ δ √

FF FS

C

CR GS

D

E

F

RS

, < L \ l | Ô £ ¼ ╝ ╠ ▃ ∞ ⁿ

- = M ] m } ì Ù ¡ ╜ ═ ▌ ∅ ₂

. > N ^ n ~ Ã

Pt

« ╛ ╬ ▐ ∈ ■

/ ? O _ o ・ Â Ó » ┐ ╧ ▄ ∩

46

Page 51

9.1.5 Codepage 00H to 7FH & PC863 (Canadian-French)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É ¦ ░ └ ╨ α≡

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü È ´ ▒ ┴ ╤ β ±

" 2 B R b r é Ê ô ▓ ┬ ╥ Γ ≧

# 3 C S c s â ô ú │ ├ ╙ π ≦

$ 4 D T d t Â Ë ¨ ┤ ─ ╘ ∑ ⌠

% 5 E U e u à Ï

ゝ

╡ ┼ ╒ σ ⌡

& 6 F V f v ¶ û ³ ╢ ╞ ╓ μ ÷

' 7 G W g w ç ù - ╖ ╟ ╫ τ

≈

( 8 H X h x ê ¤ Î ╕ ╚ ╪ Φ 。

) 9 I Y i y ë Ô ⌐ ╣ ╔ ┘ θ

* : J Z j z è Ü ¬ ║ ╩ ┌ Ω ∙

+ ; K [ k { Ï ¢ ½ ╗ ╦ █ δ √

FF FS

C

CR GS

D

E

F

RS

, < L \ l | Î £ ¼ ╝ ╠ ▃ ∞ ⁿ

- = M ] m } = Ù ¾ ╜ ═ ▌ ∅ ²

. > N ^ n ~ À

Û

« ╛ ╬ ▐ ∈ ■

/ ? O _ o ・ § ƒ » ┐ ╧ ▄ ∩

47

Page 52

9.1.6 Codepage 00H to 7FH & PC865 (Nordic)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ ╨ α≡

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü æ í ▒ ┴ ╤ β ±

" 2 B R b r é Æ ó ▓ ┬ ╥ Γ ≧

# 3 C S c s â ô ú │ ├ ╙ π ≦

$ 4 D T d t ä ö ñ ┤ ─ ╘ ∑ ⌠

% 5 E U e u à ò Ñ ╡ ┼ ╒ σ ⌡

& 6 F V f v å û a ╢ ╞ ╓ μ÷

' 7 G W g w ç ù o ╖ ╟ ╫ τ

≈

( 8 H X h x ê ÿ ¿ ╕ ╚ ╪ Φ 。

) 9 I Y i y ë Ö ⌐ ╣ ╔ ┘ θ

* : J Z j z è Ü ¬ ║ ╩ ┌ Ω ∙

+ ; K [ k { Ï ø ½ ╗ ╦ █ δ √

FF FS

C

CR GS

D

E

F

RS

, < L \ l | Î £ ¼ ╝ ╠ ▃ ∞ ⁿ

- = M ] m } Ì Ø ¡ ╜ ═ ▌ ∅ ₂

. > N ^ n ~ Ä

Pt

« ╛ ╬ ▐ ∈ ■

/ ? O _ o ・ Å ƒ ¤ ┐ ╧ ▄ ∩

48

Page 53

9.1.7 Codepage 00H to 7FH & PC852 (Eastern Europe)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ đ ó -

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü Ĺ í ▒ ┴ Đ β ”

" 2 B R b r é í ó ▓ ┬ Ď Ó 、

# 3 C S c s â ú ú │ ├ Ë Ń ˇ

$ 4 D T d t ä ö Ą ┤ ─ ď ń ˘

% 5 E U e u ů Ľ ą Á ┼ Ň ň §

& 6 F V f v ć Ĭ Ž Â Ă Í Š ÷

' 7 G W g w ç Ś ž Ě ă î š

ゝ

( 8 H X h x ł ś Ę Ş ╚ ĕ Ŕ ゚

) 9 I Y i y ë Ö ę ╣ ╔ ┘ Ú ¨

* : J Z j z Ő Ü ║ ╩ ┌ ŕ ∙

+ ; K [ k { ő Ť ź ╗ ╦ █ Ű ű

FF FS

C

CR GS

D

E

F

RS

, < L \ l | î Č ╝ ╠ ▃ ý Ř

- = M ] m } Ź Ł ş Ż ═ Ţ Ý ř

. > N ^ n ~ Ä × « ż ╬ Ů ţ ■

/ ? O _ o ・ Ć č » ┐ ¤ ▀ ´

49

Page 54

9.1.8 Codepage 00H to 7FH & PC866 (Russian)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p ΑРа ░ └ ╨ р Ë

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q Б С б ▒ ┴ ╤ с ë

" 2 B R b r В Т в ▓ ┬ ╥ т Є

# 3 C S c s ГУг│├ ╙ у є

$ 4 D T d t ДФд┤─ ╘ ф Ї

% 5 E U e u Е Х е ╡ ┼ ╒ ц ї

& 6 F V f v Ж Ц ж ╢ ╞ ╓ ц ў

' 7 G W g w З Ч з ╖ ╟ ╫ ч

( 8 H X h x И Ш и ╕ ╚ ╪ х ゚

) 9 I Y i y Й Щ й ╣ ╔ ┘ ш ・

* : J Z j z К Ъ к ║ ╩ ┌ щ ∙

+ ; K [ k { Л Ы л ╗ ╦ █ ъ √

FF FS

C

CR GS

D

E

F

RS

, < L \ l | М Ь м ╝ ╠ ▃ ы

- = M ] m } Н Э н ╜ ═ Ţ э ¤

. > N ^ n ~ О Ю о ╛ ╬ Ů ю ■

/ ? O _ o ・ ПЯп┐ ╧ ▀ я

No

.

50

Page 55

9.1.9 Codepage 00H to 7FH & PC857 (Turkish)

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p Ç É á ░ └ o ó ―

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ü æ í ▒ ┴ a β ±

" 2 B R b r é Æ ó ▓ ┬ Ê ô

# 3 C S c s â ô ú │ ├ Ë ò ¾

$ 4 D T d t à ö ñ ┤ ─ È õ ¶

% 5 E U e u ä ò Ñ Á ┼ Õ §

& 6 F V f v å û Ĝ Â ã Í μ ÷

' 7 G W g w ç ù ĝ À Ã Î

ゝ

( 8 H X h x ê Í ¿ © ╚ Ï × ゚

) 9 I Y i y ë Ö ® ╣ ╔ ┘ Ú ¨

* : J Z j z è Ü ¬ ║ ╩ ┌ Û .

+ ; K [ k { ï ø ½ ╗ ╦ █ Ù ¹

FF FS

C

CR GS

D

E

F

RS

, < L \ l | î £ ¼ ╝ ╠ ▃ Ì ³

- = M ] m }

I

Ø ¡ ¢ ═ ¦ ÿ ²

. > N ^ n ~ Ä Ş « ¥ ╬ Ì - ■

/ ? O _ o ・ Å ş » ┐ ¤ ▀ ´ SP

51

Page 56

9.1.10 Codepage 00H to 7FH & PC864 (Arabic)

52

Page 57

9.1.11 Codepage 00H to 7FH & WPC1252

0 1 2 3 4 5 6 7 8 9 A B C D E F

NUL DLE

0

0 @ P ` p € ° À Ð à ð

1

2

3

4

5

6

7

8

9

A

B

XON

XOFF

EOT DC4

ENQ

CAN

HT

LF

ESC

! 1 A Q a q ‘ ¡ ± Á Ñ á ñ

" 2 B R b r ¸ ’ ¢ ² Â Ò â ò

# 3 C S c s ƒ “ £ ³ Ã Ó ã ó

$ 4 D T d t ,, ” ¤ ´ Ä Ô ä Ô

% 5 E U e u

...

‧ ¥ µ Å Õ å Õ

& 6 F V f v † ‐ ¦ ¶ Æ Ö æ ö

' 7 G W g w ‡ ‒ § · Ç × ç

÷

( 8 H X h x ˆ ~ ¨ ¸ È Ø è ø

) 9 I Y i y ‰

© ¹ É Ù é ù

™

* : J Z j z Š š ª º Ê Ú ê ú

+ ; K [ k { ‹ › « » Ë Û ë û

FF FS

C

CR GS

D

E

F

RS

, < L \ l | Œ œ ¬ ¼ Ì Ü ì ü

- = M ] m } ½ Í Ý í ý

. > N ^ n ~ Ž ž ® ¾ Î Þ î þ

/ ? O _ o ・ Ÿ ¯ ¿ Ï ß ï ÿ

53

Page 58

9.1.12 Codepage 00H to 7FH & Thaicode18

54

Page 59

International Character Code Table

9.2

Country 23 24 40 5B 5C 5D 5E 60 7B 7C 7D 7E

0 USA

1 France

2 Germany

3 UK

4 Denmark I

5 Sweden

6 Italy

7 Spain I

8 Japan

9 Norway

10 Denmark II

# $ @ [ ╲ ] ^ ' { | } ~

# $ à ° ç § ^ ' é ù È ¨

# $ § Ä Ö Ü ^ ' ä ö ü β

£ $ @ [ ╲ ] ^ ' { | } ~

# $ @ Æ Ø Å ^ ' æ ø å ~

# ¤ É Ä Ö Å Ü é ä ö å ü

# $ @ ° ╲ é ^ ù à ò è ì

Pt $ @ ¡ Ñ ¿ ^ ' ¨ ñ } ~

# $ @ [ ¥ ] ^ ' { | } ~

# ¤ É Æ Ø Å Ü é æ ø å ü

# $ É Æ Ø Å Ü é æ ø å ü

11 Spain II

12 Latin America

13 Korea

# $ á ¡ Ñ ¿ é ' ì ñ ó ú

# $ á ¡ Ñ ¿ é ü ì ñ ó ú

# $ @ [ ₩ ] ^ ' { | } ~

55

Loading...

Loading...