Page 1

SERVICE MANUAL

INDEX

(without price)

ELECTRONIC CASH REGISTER

CE-3700 (EX-278)

CE-3750 (EX-279)

DEC, 1994

Page 2

CONTENTS

Page

1. SPECIFICATION.......................................................................................... 1

2. OPTION SPECIFICATIONS......................................................................... 3

3. INSTALLATION ........................................................................................... 3

4. INITIALIZE.................................................................................................... 4

5. MAJOR COMPONENT ................................................................................ 6

6. BLOCK DIAGRAM....................................................................................... 7

7. CIRCUIT EXPLANATIONS .......................................................................... 8

8. DISASSEMBLY / ASSEMBLY METHOD .................................................. 12

9. DIAGNOSTIC OPERATION....................................................................... 13

10. PROGRAMMING THE CE-3700 SERIES CASH REGISTERS................. 17

11. OPERATION .............................................................................................. 19

12. ERROR CODES......................................................................................... 20

13. IC DATA ..................................................................................................... 21

14. PCB LAYOUT ............................................................................................ 22

15. CIRCUIT DIAGRAM................................................................................... 23

16. PARTS LIST............................................................................................... 33

Page 3

Product introduction

This machine CE-3700(EX-278) is a succession machine for CE-3400(EX-253).

The simultaneous boot model is EX-279.

EX-278: The drawer not separation type.

EX-279: The drawer separation type.

The Rom/Ram is the internal organs.

1. SPECIFICATION

1-1. Product

Operating temperature: 0 °C ~ 40 °C

Operation air moisture: 10 % ~ 90 %

Storage temperature: -25 °C ~ 65 °C

Storage air moisture: 10 % ~ 95 %

Bombardment strength: To add bombardment from 10 high cm by single support, and there

isn’t the problem.

1-2. Package status

Storage temperature: -25 °C ~ 65 °C

Storage air moisture: 10 % ~ 95 %

Vibration strength: 1.5 G

Bombardment strength: To add bombardment from 60 high cm by single support, and there

isn’t the problem.

1-3. Accessory specifications

Roll paper: P-4575 (EX-P-4574), 45 X 12 X 30 D

Stamp logotype: CSP-2030ASA-2

Ink for supplement: Super Ink KC

Ink roll: IR-92 (EX-INK-IR-92-OP)

Dust cover: Only 1 part neighborhood

1-4. Printer

CR-812A-009-14-001A: Europe

CR-812A-009-15-001A: USA, Canada, UK, Europe

Printing type: ring select mode

Output sheet number: 2

Chart specifications

Paper width: 44.5 ± 0.5 mm

Maximum paper diameter: Ø 83 mm

Maximum paper thickness: 0.06 ~ 0.085 mm

Materials: Regular paper

Inking: Ink roll

Validation

Print specifications: Yes

Sensor: No

Paper cut: Manual

Stamp

Color: Purple

Seal side dimension: 30 mm (W) X 20 mm (H)

— 1 —

Page 4

1-5. The durability specifications

Switch

Key board switch: 5,000,000 times

Control lock: 20,000 times

Operation key 100,000 times

Feed switch 5,000,000 times

Receipt on/off switch 10,000 times

Reset switch 100,000 times

Drawer:

Printer

MCBF: 2,000,000 line

Ink roll 400,000 line

Stamp

Ink: 50,000 times

mechanism: 500,000 times

1-6. Electric specifications

Power consumption

Area 120 V 220 V 230V 240V

In action Max. 0.40 A 0.20 A 0.20 A 0.20 A

In holding Min. 0.09 A 0.05 A 0.05 A 0.05 A

Power off 0.08 A 0.04 A 0.04 A 0.04 A

1,000,000 times

1-7. Memory Protection

Protection battery: Vanadium Lithium secondary battery

Model: VL3032/IF2

Guard period: 90 days (25 °C) In perfection charge status

Galvanic cell life expectancy: 5 years

Recharge time: 48 hours in secondary battery

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according

to the manufacture’s instructions.

1-8. Clock, date facility

Clock precision: Less than ±30 seconds (25 °C)

Automatic calendar: Until 2099

1-9. Electric power supply for an emergency (B-6)

Operating hour: 3 hours

Driving condition

Processing time per customer one person: 60 sec./ person

Purchase item number: 10 item / person

1 item registration amount of money number of digits: 4 digits / item

The handling number of people for 1 hour: 30 person /hour

Recharge time: 8 hours

— 2 —

Page 5

)

2. OPTION SPECIFICATIONS

2-1. Ink roll: IR-92

2-2. Waterproofing cover: WT-70

2-3. Roll paper: P-4575 (45×12×75D)

2-4. Electric power supply for an emergency: B-6

The parts for adding B-6 are not equipped. They should be ordered separately from service department.

The following parts are necessary to add B-6.

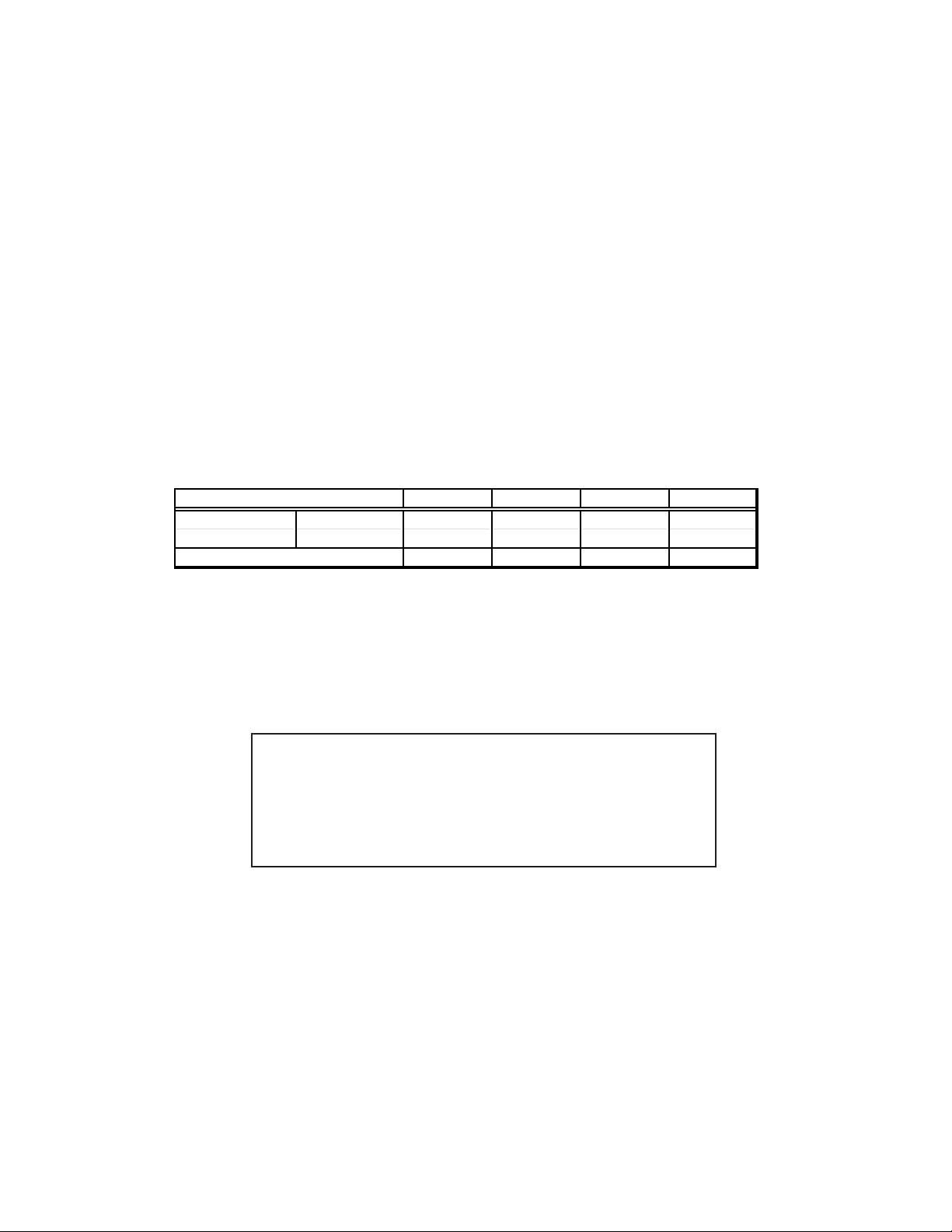

No. Code No. Parts Name Specification Q'ty

Q1 2200 3577 Transistor 2SA1015(GR,O,Y

ZD1 2310 8879 Zener diode RD18EB1 1

D6,D7 2301 0011 Diode 1S2471 2

C5 2804 5476 Electrolytic capacitor 50RE47 1

R2,R3,R5 2600 7313 Carbon film resistor R-25-10K-J 3

R1 2600 5612 Carbon film resistor R-25-2K-J 1

6221 4218 Connector sub assembly E311294-1(#22) 1

2-5. Keyboard Conversion Kit: CVK-S2/-L2/-LLL2/-FS2

1

2-6. Ink for supplement Super ink K

3. INSTALLATION

Connection is done of earth-line of drawer and main frame like lower chart.

— 3 —

Page 6

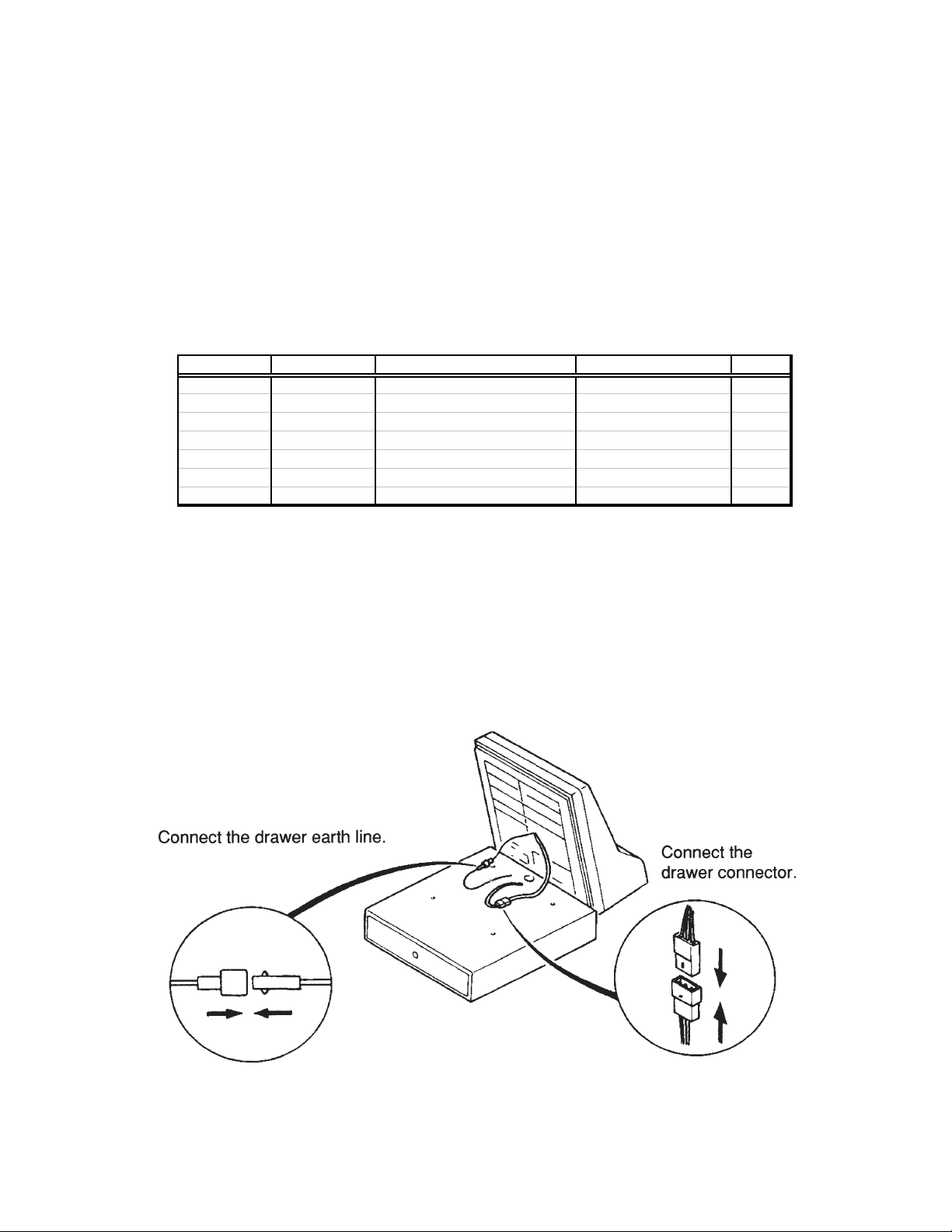

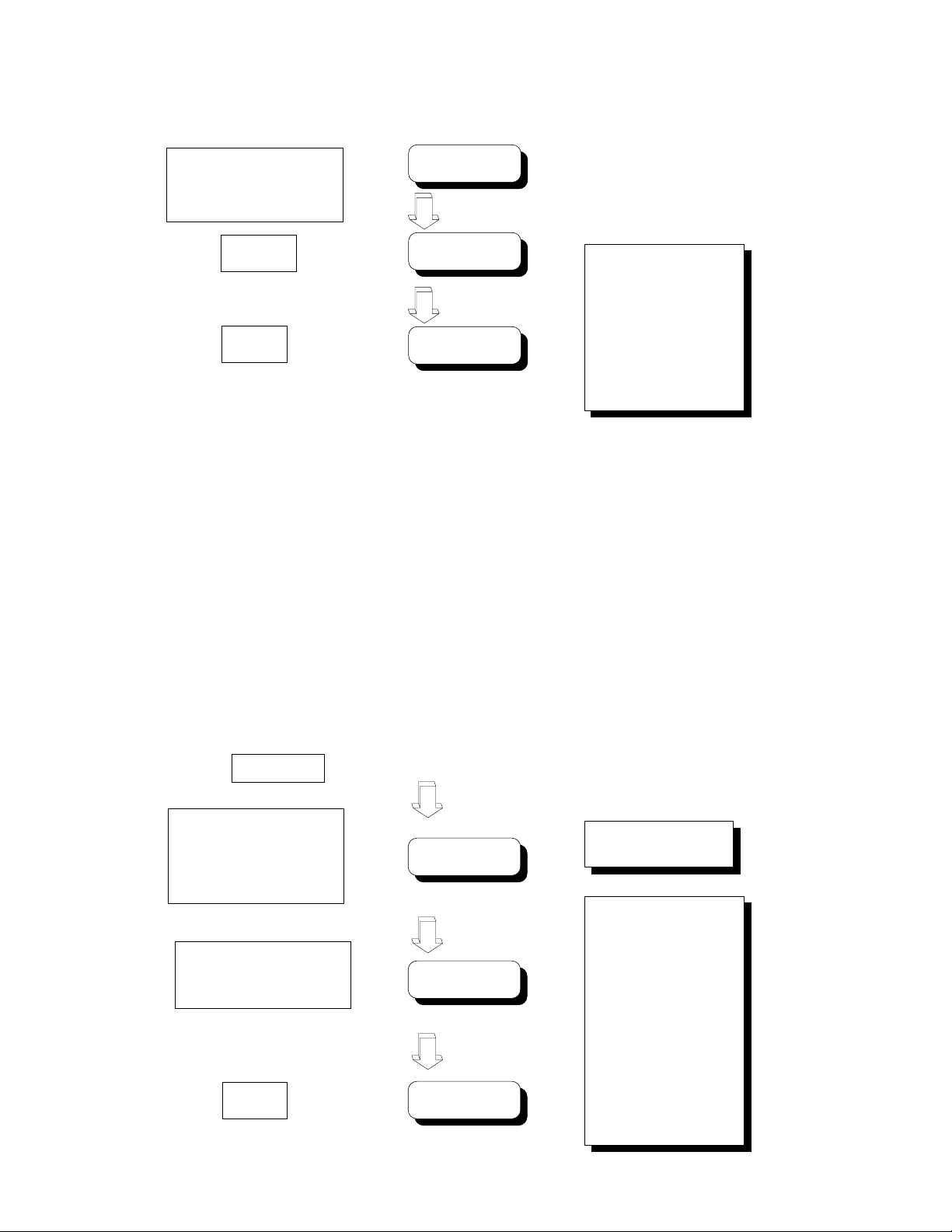

4. INITIALIZE

By Initialize code

Init. A: The format is done of EEPROM, and, without it is read, and Init. Code is written in.

Init. B: The data is read from EEPROM.

4-1. MAC

To hang initial start-up of CPU and peripheral device, and All Clear makes memory.

When there is Data backed up by EEPROM, by Initialize code, to develop it on Memory top.

Operation Display Printing

Power off

To continued pushing

J-feed button, and

To set the MODE

switch to Program.

Header printing

To release from the

J-feed button.

D1 ~ D5

#-2

Input value D1 ~ D5

D1 0: YYMMDD

D2 1: General (Add2, DDMMYY)

D3,D4 Department No. General 15

D5 Clerk specification Switch: 1,2,4

0000000000

D1D2D3D4D5

P1

0

1: MMDDYY

2: DDMMYY

2: US (Add2, MMDDYY)

3: General (Add3, DDMMYY)

5: Canada (Add2, MMDDYY)

US 30

Password No.: 0 (U.S.A. & Canada)

XXXX: Rom Control No.

-- XXXX - D1D2D3D4D5

---------------

Note: Operation code with Init.B is set up as with settlement in “00000”

— 4 —

Page 7

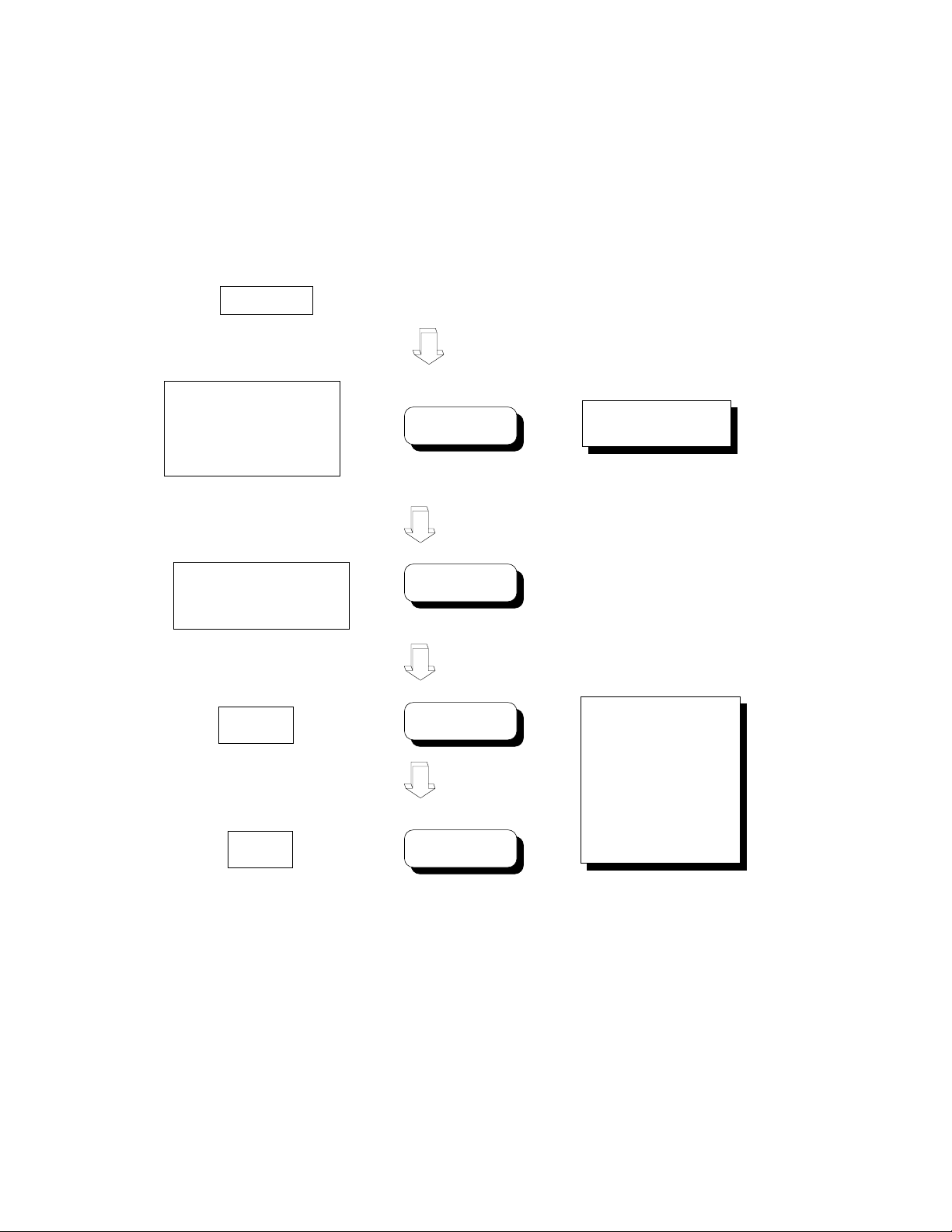

4-2. Auto or Reset switch initialize

Operation Display Printing

To push Reset SW.

or

Power on In Low batt.

D1 ~ D5

#-2

Input value D1 ~ D5

D1 0: YYMMDD

D2 1: General (Add2, DDMMYY)

D3,D4 Department No. General 15

D5 Clerk specification Switch: 1,2,4

0000000000

D1D2D3D4D5

P1

0

1: MMDDYY

2: DDMMYY

2: US (Add2, MMDDYY)

3: General (Add3, DDMMYY)

5: Canada (Add2, MMDDYY)

US 30

Password No.: 0 (U.S.A. & Canada)

XXXX: Rom Control No.

-- XXXX - D1D2D3D4D5

---------------

Note: Operation code with Init.B is set up as with settlement in “00000”.

4-3. Flag clear

To do Initialization of work memory, and make the operation sequence with the latest status.

Operation Display Printing

Power off

To continued pushing

R-feed button, and

Header printing

To set the MODE

switch to Program.

XXXX: Rom Control No.

To release from the

J-feed button.

#-2

FFFFFFFFF

P1 0

-- XXXX - P1P2P3P4P5P6P7P8

X1X2X3X4

M1M2-D1D2-Y1Y2

--------------Password for P1~P8

Password for X1~X4:

X2/Z2

M1M2D1D2Y1Y2

D1D2D3D4D5

— 5 —

Page 8

5. MAJOR COMPONENT

CPU UPD78044AGF080-3B9

Ram LC36256PLL

256K bit SRam

Printer Model CR812A-009-15-001A

MCBF 2,000,000 lines

Drawer USA DL-2416 D-15TC-A55SP-1*

Canada DL-2351 D-15TC-A54SP-1*

UK DL-2751 D-15TC-A84SP-1*

Other Countries DL-2350 D-15TC-A54P-1*

DL-2750 D-15TC-A84P-1*

Germany DL-2752 D-15BC-A84S-1*

CPU Pin Description

Pin Port Name I n/ Description Pin Port Name In / Description

No. No. Out No. No. Out

1 94 FIP6 O Display Digit Signal (Dg7) 41 32 TO2 O Receipt Common Signal

2 93 FIP5 O Display Digit Signal (Dg6) 42 31 TO1 O Auto cutter

3 92 FIP4 O Display Digit Signal (Dg5) 43 30 TO0 O Stamp

4 91 FIP3 O Display Digit Signal (Dg4) 44 3 INTP3 I Drawer sensor

5 90 FIP2 O Display Digit Signal (Dg3) 45 2 INTP2 I Key scan timing plus

6 81 FIP1 O Display Digit Signal (Dg2) 46 1 INTP1 I Power Down

7 80 FIP0 O Display Digit Signal (Dg1) 47 0 INTP0 I Printer

8 Power (VDD) 48 Gnd for Vpp (IC)

9 27 SCK0 I/O Data 7 49 7 0 O Address decoder (A12/D0)

10 2 6 SO1 I/O Data 6 5 0 7 1 O A13/Decod1

11 2 5 SI0 I/O Data 5 51 72 O A14/Decod1

12 2 4 BUSY I/O Data 4 5 2 Power (VDD)

13 2 3 STB I/O Data 3 53 12 7 FIP33 O Printer Head (HD8)

14 2 2 SCK1 I/O Data 2 54 126 FIP32 O Printer Head (HD7)

15 2 1 SO1 I/O Data 1 5 5 12 5 FIP31 O Printer Head (HD6)

16 2 0 SI1 I/O Data 0 56 124 FIP30 O Printer Head (HD5)

1 7 Reset Signal 57 12 3 FIP29 O Printer Head (HD4)

1 8 74 O CE(Ram Chip Enable) 58 1 22 FIP28 O Printer Head (HD3)

19 73 O R/W(Ram Write Enable) 59 121 FIP27 O Printer Head (HD2)

20

21 17 ANI7 I Key Input Signal (KI7) 61 11 7 FIP25 O Printer Head (HD10)

22 16 ANI6 I Key Input Signal (KI6) 62 11 6 FIP24 O Printer Head (HD9)

23 15 ANI5 I Key Input Signal (KI5) 63 11 5 FIP23 O Printer J-feed

24 14 ANI4 I Key Input Signal (KI4) 64 11 4 FIP22 O Printer R-feed

25 13 ANI3 I Key Input Signal (KI3) 65 11 3 FIP21 O Printer Motor

26 12 ANI2 I Key Input Signal (KI2) 66 11 2 FIP20 O Key Common Signal (KC9)

27 11 ANI1 I Key Input Signal (KI1) 67 11 1 FIP19 O

28 10 ANI0 I Key Input Signal (KI0) 68 11 0 FIP18 O

29

30

31 Clock Terminal 71

32 Clock Terminal 72 105 FIP15 O

33

34 System Clock 4.19MHz 74 103 FIP13 O

35 System Clock 4.19MHz 75 102 FIP12 O

3 6 37 O EEPROM CE 76 101 FIP11 O

3 7 36 BUZ O Buzzer 77 100 FIP10 O Key Scan Timing Plus

3 8 35 PCL O Decoder CE 7 8 97 FIP9 O Display Digit Signal (Dg10)

3 9 34 TI2 O DW1&2 79 96 FIP8 O Display Digit Signal (Dg9)

4 0 33 TI1 O Journal Common Signal 80 95 FIP7 O Display Digit Signal (Dg8)

Analog electric potential of AD

converter (Gnd) 60 120 FIP26 O Printer Head (HD1)

Display Digit Signal / Key

Common Signal (SGdb/KC8)

Display Digit Signal / Key

Analog electric power supply of

AD converter (Vcc) 69 107 FIP17 O

Reference voltage input of AD

converter (Gnd) 70 106 FIP16 O

Analog electric potential of AD

converter(Gnd) 7 3 104 FIP14 O

Common Signal (SGtr/KC7)

Display Digit Signal / Key

Common Signal (SGg/KC6)

Display Digit Signal / Key

Common Signal (SGf/KC5)

Pull Down electric potential for

Fip (VN)

Display Digit Signal / Key

Common Signal (SGe/KC4)

Display Digit Signal / Key

Common Signal (SGd/KC3)

Display Digit Signal / Key

Common Signal (SGc/KC2)

Display Digit Signal / Key

Common Signal (SGb/KC1)

Display Digit Signal / Key

Common Signal (SGa/KC0)

— 6 —

Page 9

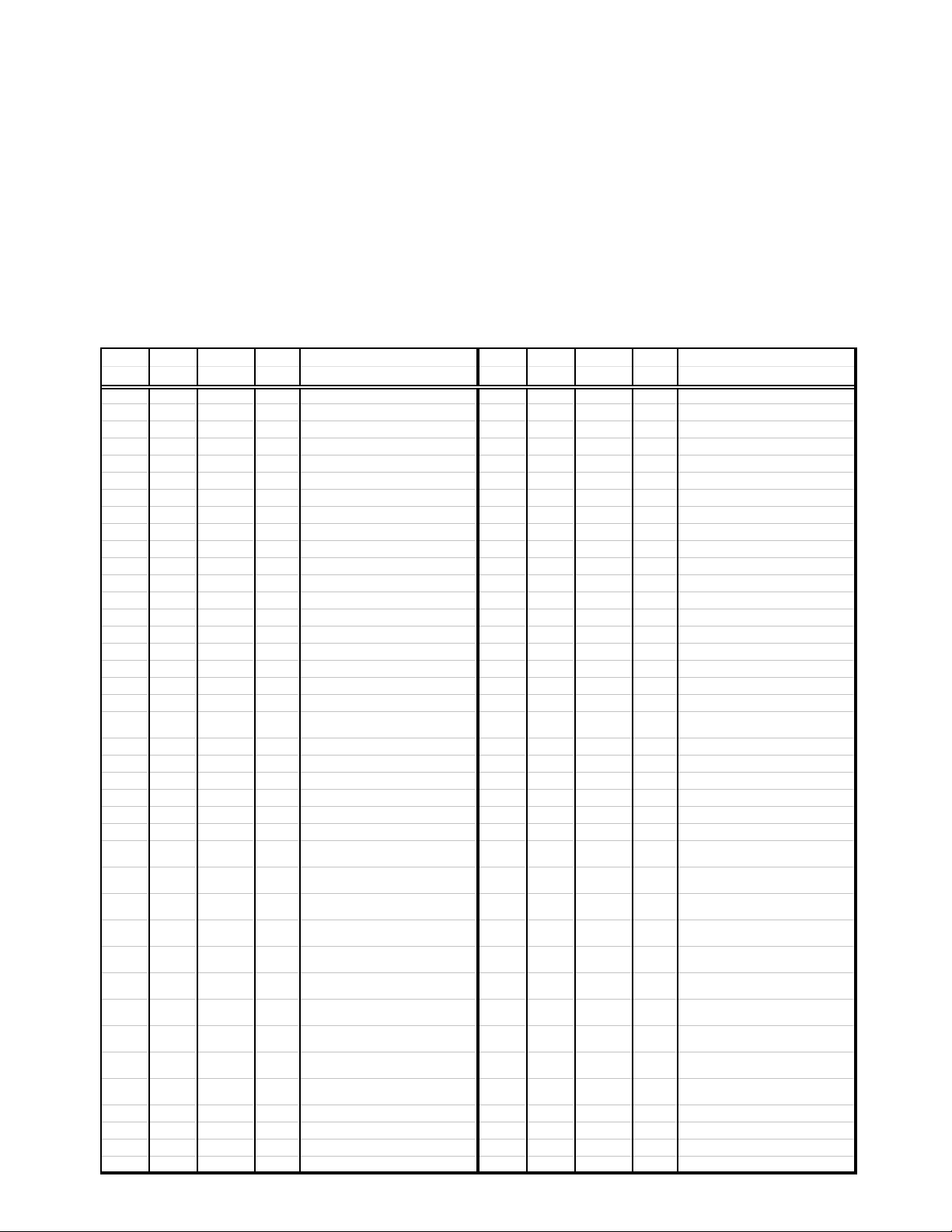

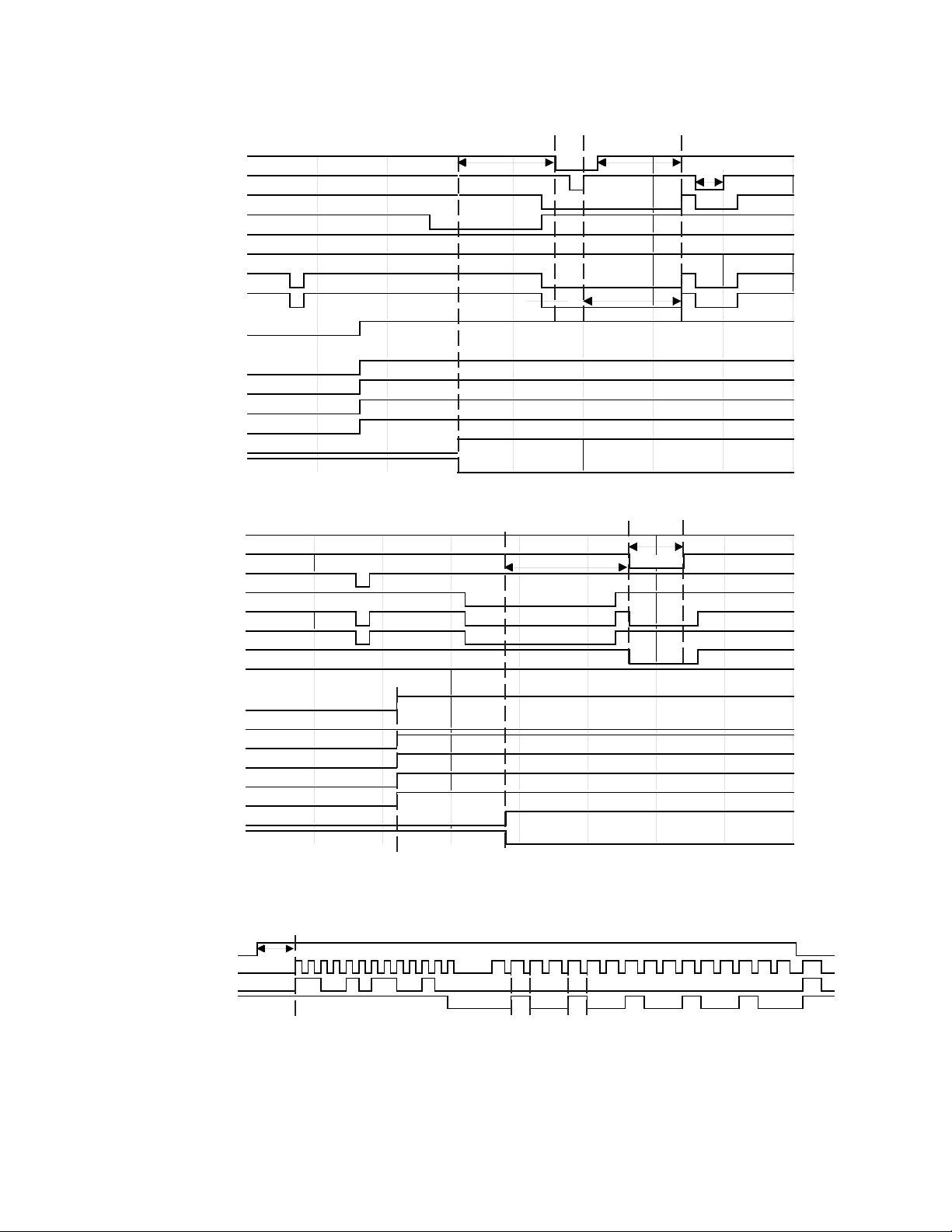

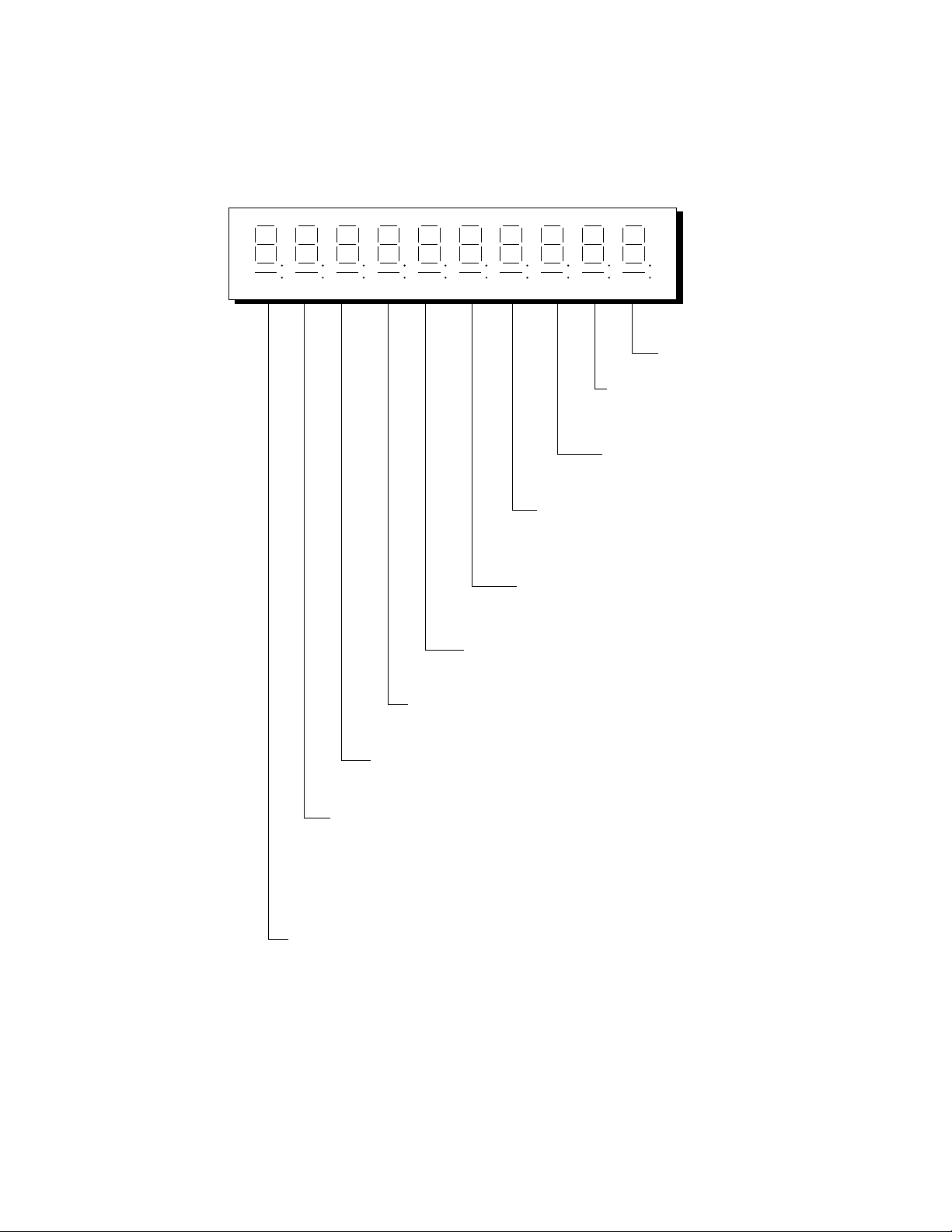

6. BLOCK DIAGRAM

Standard Option

Printer

(CR812A)

Main Display

(10 columns)

Pop-uo Display

(10 columns)

RAM

(32K byte)

EEPROM

(512 byte)

Key board

Drawer

CPU

Multi Drawer

Compulsory Drawer

(USA, Canada,Germany, UK)

Buzzer

Power Supply

Back-up battery

(Vanadium Lithium)

Battery operation

(B-6)

— 7 —

Page 10

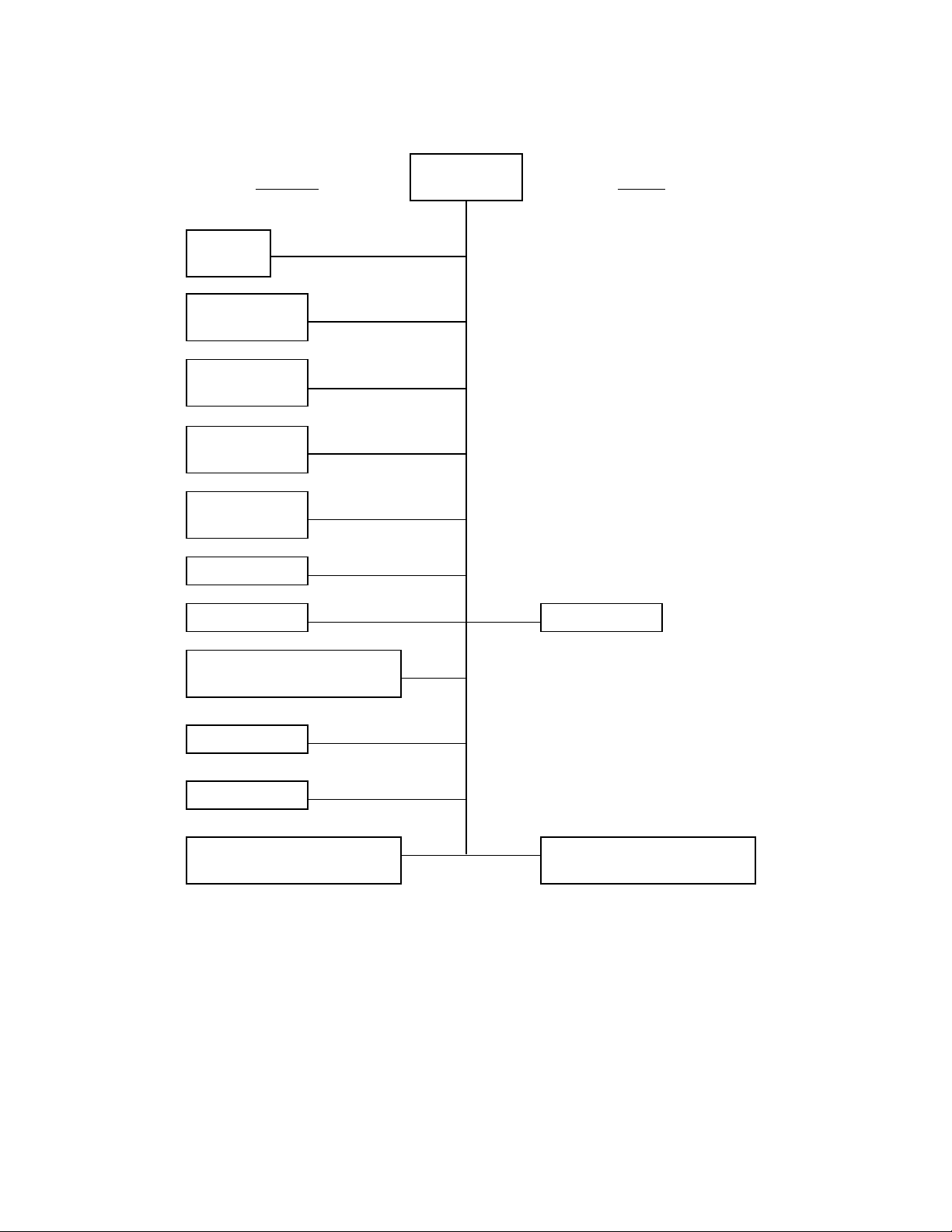

7. CIRCUIT EXPLANATIONS

7-1. Power supply circuit

1) Diodes rectification bridge

By diodes rectification bridge, alternating

voltage is converted into DC voltage, and the

electrical voltage is done filtering of by

Capacitor C4.

2) Power supply circuit for B-6

The electrical voltage which puts in resistor 3

when line voltage includes anomaly changes,

and transistor Q1 becomes on status, and

CS signal is done outgoing of by this, and VP

is supplied than Power supply B-6.

Note: The component for connection isn’t equipped with in plant shipping.

(service arrangement)

7-2. DC/DC converter circuit

2SD721(Q2) is Power voltage control transistor, and electric power supply is supplied in DCDC converter with 2SC3303(Q3). 2SC3303(Q3) does a work as oscillator. The frequency of

2SC3303(Q3) is controlled by signal done feed back of through RD27EB1.

7-3. Electrical voltage value in check point

Vc Vp Vcc/Vdd Vns Vs V f

Rated output electrical voltage Min: 23 V 20 V 5 V 32 V 27 V 4.75 V

Output voltage drift range Max: 42 V 2 V 0.3 V 1 0 % 1 0 % 7%

Output voltage drift range AC DC DC DC DC AC

— 8 —

Page 11

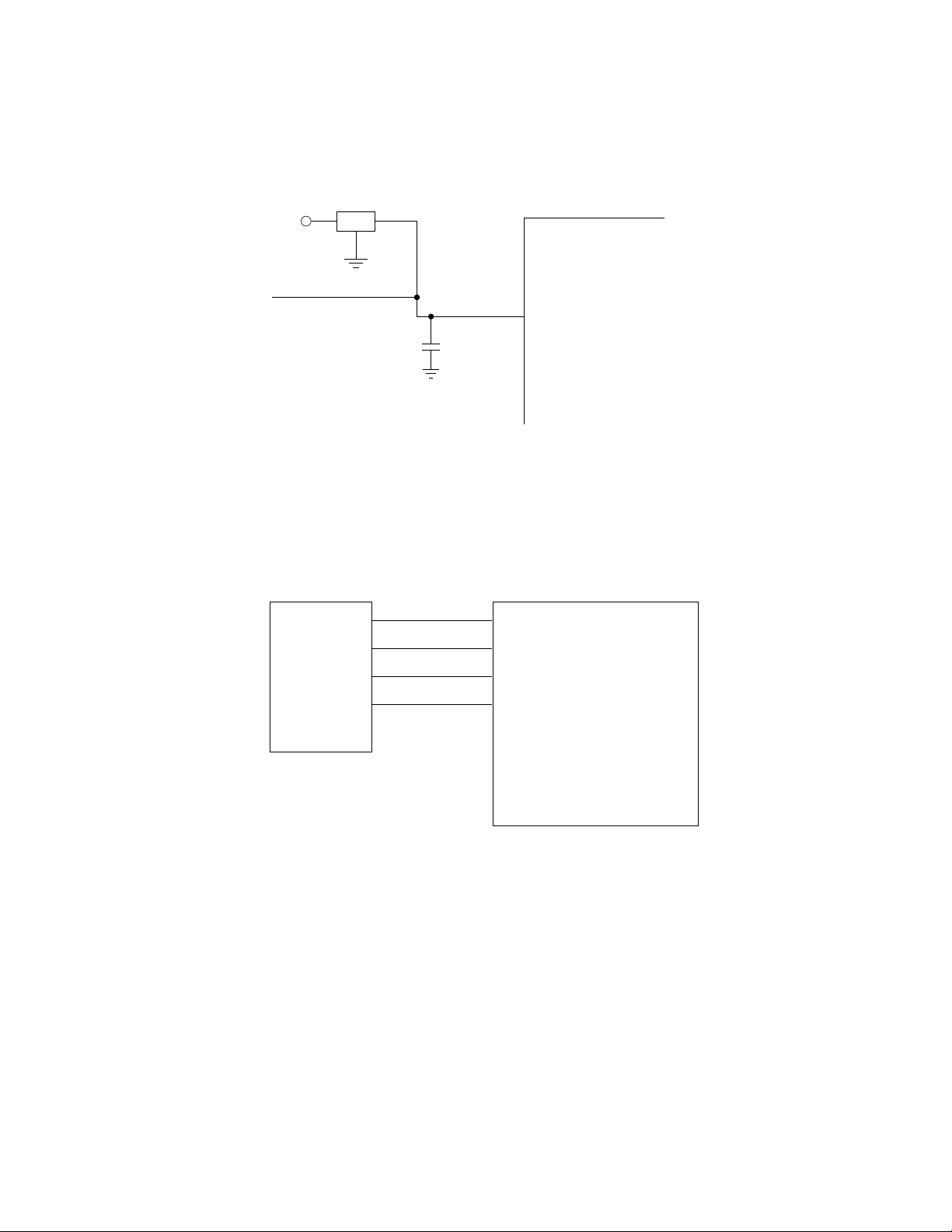

7-4. Reset circuit

The voltage fluctuation of VDD is controlled of IC10 (S-80727AN).

CPU is done Reset by pushing Reset Switch or drifting VDD.

S-80727AN

Vdd

2

Reset SW

1

3

17

CPU

Reset

7-5. Data communication between CPU and EEPROM IC11(BR93LC46A).

EEPROM is Rom that write / erase is possible electrically.

BR93LC46A is a non- volatile register, and serial data of 16 bit can be memorized with 64

register.

CPU

CS

SK

DI

DO

CS: Chip select

SK: Serial data clock

DI: Serial data input

DO: Serial data output

64 words X 16 bits 1,024 bits

EEPRom

1

2

3

4

36

14

15

16

EEPCS

AD2

AD1

AD0

— 9 —

Page 12

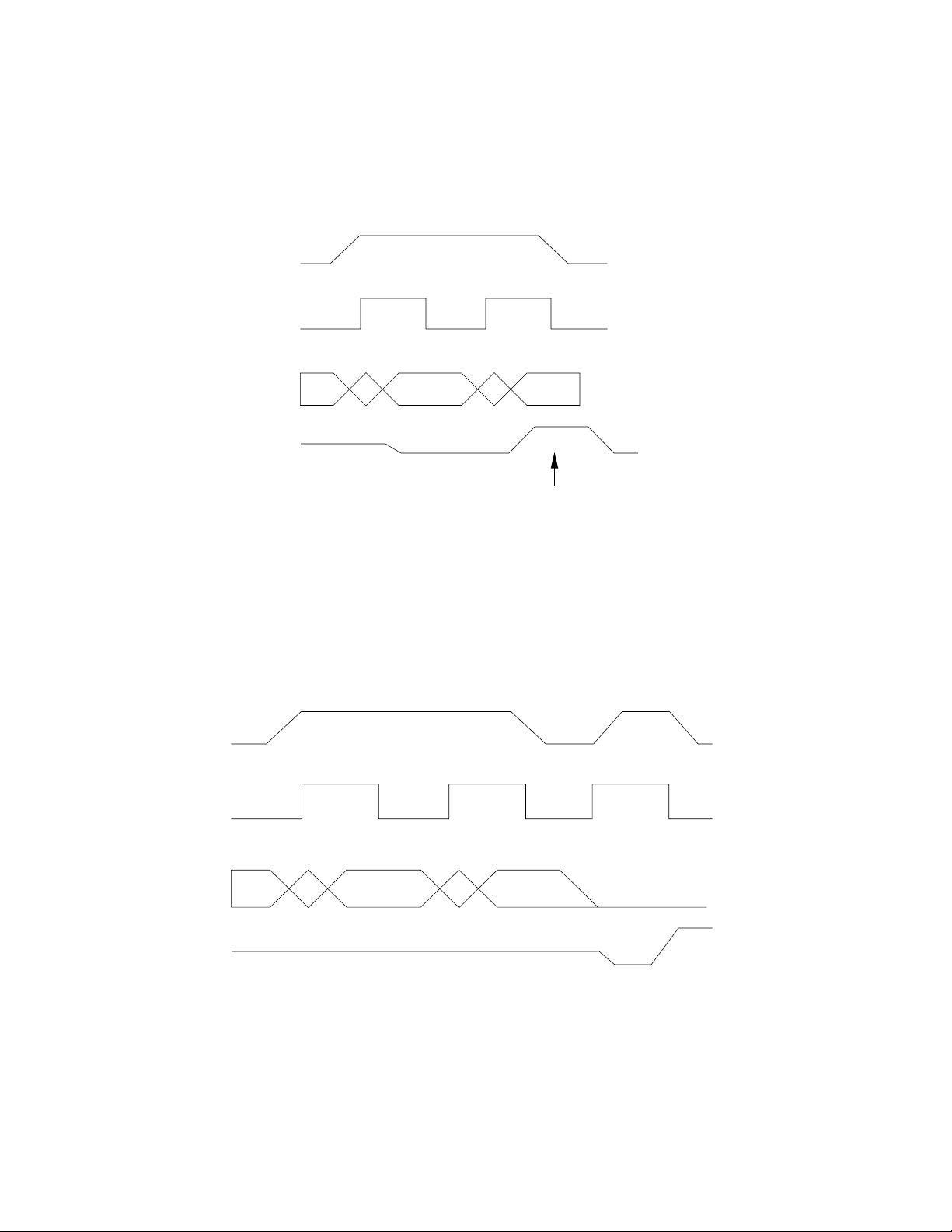

[ Data reading procedure ]

When the CPU read the data of EEPROM, CPU send the CS signal and SK signal to EEPROM.

Then CPU send the address to EEPROM, and then EEPROM return the data to CPU.

CS

SK

DI

DO

Address

Data

Output data here

[ Data writing procedure ]

When the CPU save the data to EEPROM, CPU sends the CS and SK signal to EEPROM.

And CPU send the address and data to EEPROM from pin No. 15.

When the EEPROM writes the data, EEPROM outputs the busy signal form DO terminal to CPU.

After finish writing, EEPROM outputs the ready signal from DO terminal to CPU.

Status

CS

SK

DI

DO

High Impedance

DataAddress

READY(H)

BUSY(L)

— 10 —

Page 13

7-6. Time chart

1) RAM writing timing

16.4 us 13.6us

A0 WE

A1 CE

A2 D0

A3 D1

A4 D2

A5 D3

A6 D4

A7 D5

1.4us 15.0us

B2 A0

B3

B4 A1

B5 A2

B6 A3

B7 A4

B0 A6

B1 A7

2) RAM reading timing

A0 WE

A1 CE 18.3us

A2 D0

A3 D1

A4 D2

A5 D3

A6 D4

A7 D5

3.95us

7.45us

B2 A0

B3

B4 A1

B5 A2

B6 A3

B7 A4

B0 A6

B1 A7

3) EEP-ROM Writing and reading timing

A0 CS

A1 SK

A2 DI

A3 DO

29us

— 11 —

Page 14

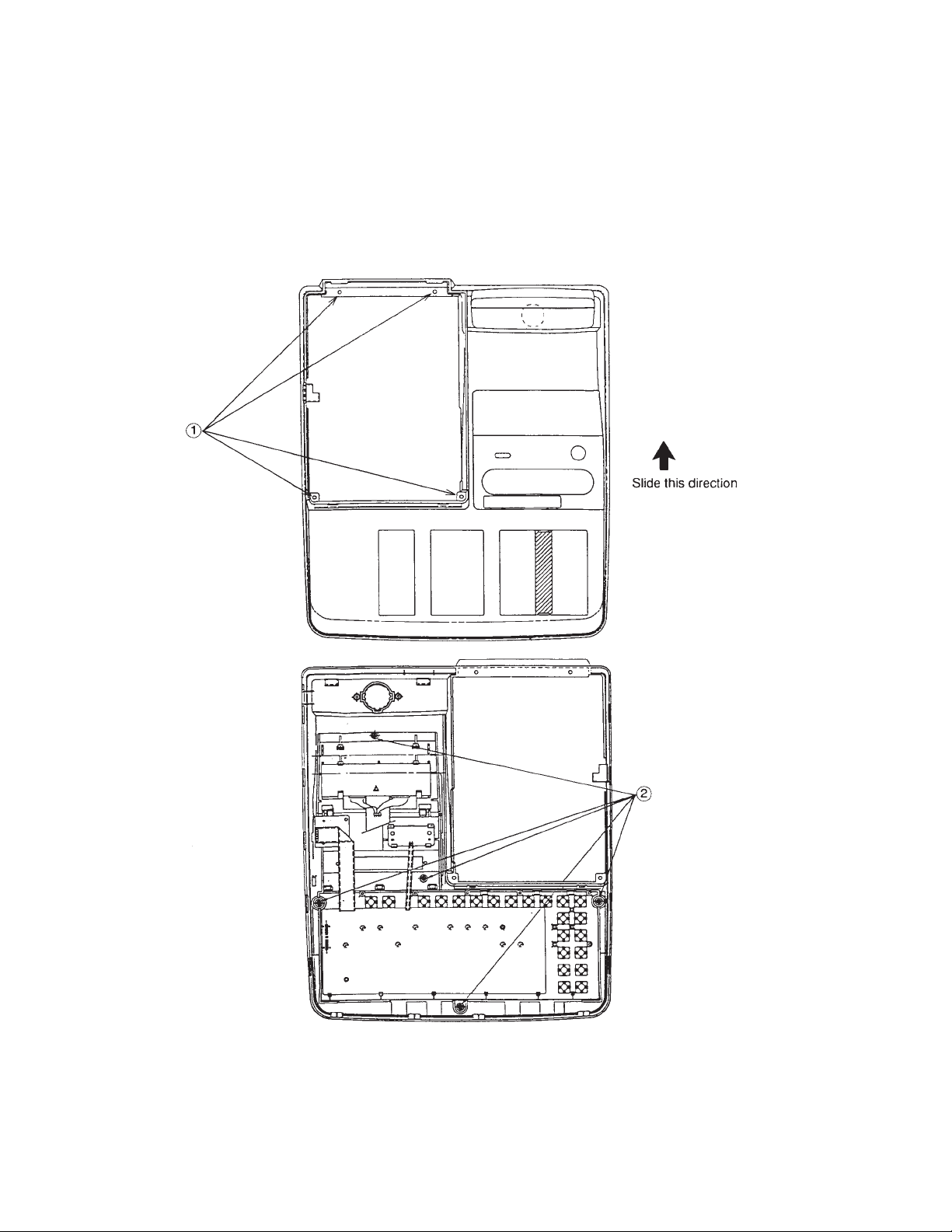

8. DISASSEMBLY / ASSEMBLY METHOD

1) Remove the Printer cover.

2) Upper case can remove it from by 4 places screws of printer four corners.

(Lower chart 1 reference)

3) It comes off while sliding of Upper case backward by raising it.

4) Key board can remove it from by 4 places screws. (Lower chart 2 reference)

— 12 —

Page 15

9. DIAGNOSTIC OPERATION

9-1. Start-up method

By the next operation, EX-278 enters Test mode.

1) Mode switch off.

2) To continued pushing J-feed button.

3) To set the Mode switch to Program.

4) To release from the J-feed button.

5) To input 9 9 9 9 9 0 0 0 0 0 #2

Printing out

00-00-00

00:00

0000

<Feed>

-- xxxx --

----------------

The cancellation of test mode do INIT.

9-2. Description

1) Key code representation: expect Value number, Clear and Feed button.

2) Various switches status display

3) Testing for Display, Print, DRW, RAM: Value number 1 column + #2

4) Testing for E2PROM: Value number 1 column + #2

9-3. Key code representation

RF JF 062 C 055 053 051 045 039 033 027 021 018

072 067 061 056 054 052 050 044 038 032 026 020 017

071 066 060 7 8 9 049 043 037 031 025 019 016

070 065 059 4 5 6 048 042 036 030 024 014 015

069 064 058 1 2 3 047 041 035 029 023 075 073

068 063 057 0 011 012 046 040 034 028 022 074 013

X: “Version No.” or “- - • • • • - -”

013: #1 key

014: #2 key

— 13 —

Page 16

9-4. Various switch status display

Push clerk

0: Non

1: Clerk 1

2: Clerk 2

3: Clerk 3

4: Clerk 4

Mode representation

1: PGM

2: RF

3: REG1

4: REG2

5: X

6: Z

7: X2Z2

8: Off

0: Disconnected

0: Fixed

For Taiwan

1: Journal mark sensor

0: Except it

For Taiwan

1: Receipt mark sensor

0: Except it

1: Fixed

Non taxable pad For Japan

0: Taxable (pat short)

1: Non-taxable (pat open)

Drawer sensor

0: Open

1: Close

Journal near end

1: Near end

0: Out of sense

Receipt off switch

0: Receipt on

1: Receipt off

Key clerk

0: Non

1~9, A~F:Clerk code (Hexadecimal representation)

— 14 —

Page 17

9-5. Print, Display, Drawer and Ram testing to do a various test by value number key. The following

code print by all means then.

1 #

3 #

4 #

5 #

96 #

8 #

9 #

1) All lighting, Ram, R/W, setting the time and date, drawer

1 #2

1 #2: All testing

3 #2: E2PRom r/w testing

4 #2: E2PRom reading testing

5 #2: Ram reading testing

96 #2:E2PRom Initialization

8 #2: Printing testing

9 #2: Clock testing

opening, printing, receipt(Japan) stamp and receipt issue.

Display: All lighting

Ram: R/W

normal end: To be continued

Abnormal end: To do the following printing then breaking

- - - - - - - 2

Receipt printing

Beeping one shot buzzer on

Setting date and time:

Date: Dec. 31st 1994

Time: 23:59

Drawer open:

Drawer No.1 and No.2 are opened.

Test printing:

To do the following print

The first line does print in receipt, journal independence.

The second line does print at receipt, journal same time.

01234567FS@

01234567FS@

Receipt stamp: (only japan)

Receipt issue:

Testing display: To do indication as follows till key or a state changes

1234567890

— 15 —

Page 18

2) This does R/W test of testing area of E2PRom during single word,

3 #2

and, at the time of normal, does normal termination print.

Abnormal end: To do the following printing then breaking

- - - - - - - 8

Receipt printing

Beeping one shot buzzer on

3) This does read only test of testing area of EEPRom during single word.

4 #2

This test is continued till off mode or electric power supply enters it.

Abnormal end: To do the following printing then breaking

- - - - - - - 8

Receipt printing

Beeping one shot buzzer on

4) Read only test .

5 #2

Outside Ram(0000H~7FFFH) read in testing

The address comparing data which comes under it

= (A0-A7) + (A8-A14)

This test is continued till off mode or electric power supply enters it.

Abnormal end: To do the following printing then breaking

- - - - - - - 2

Receipt printing

Beeping one shot buzzer on

5) Blanking (OFFH writing) of data in EEPRom entirely.

9 #26

6) All time ring print testing

8 #2

Time of day, a date are turned into zero entirely.

- - - - - - - 2

Receipt printing

7) Time of day representation testing

9 #2

Time of day indication is done till clear Key

23 -59 12

— 16 —

Page 19

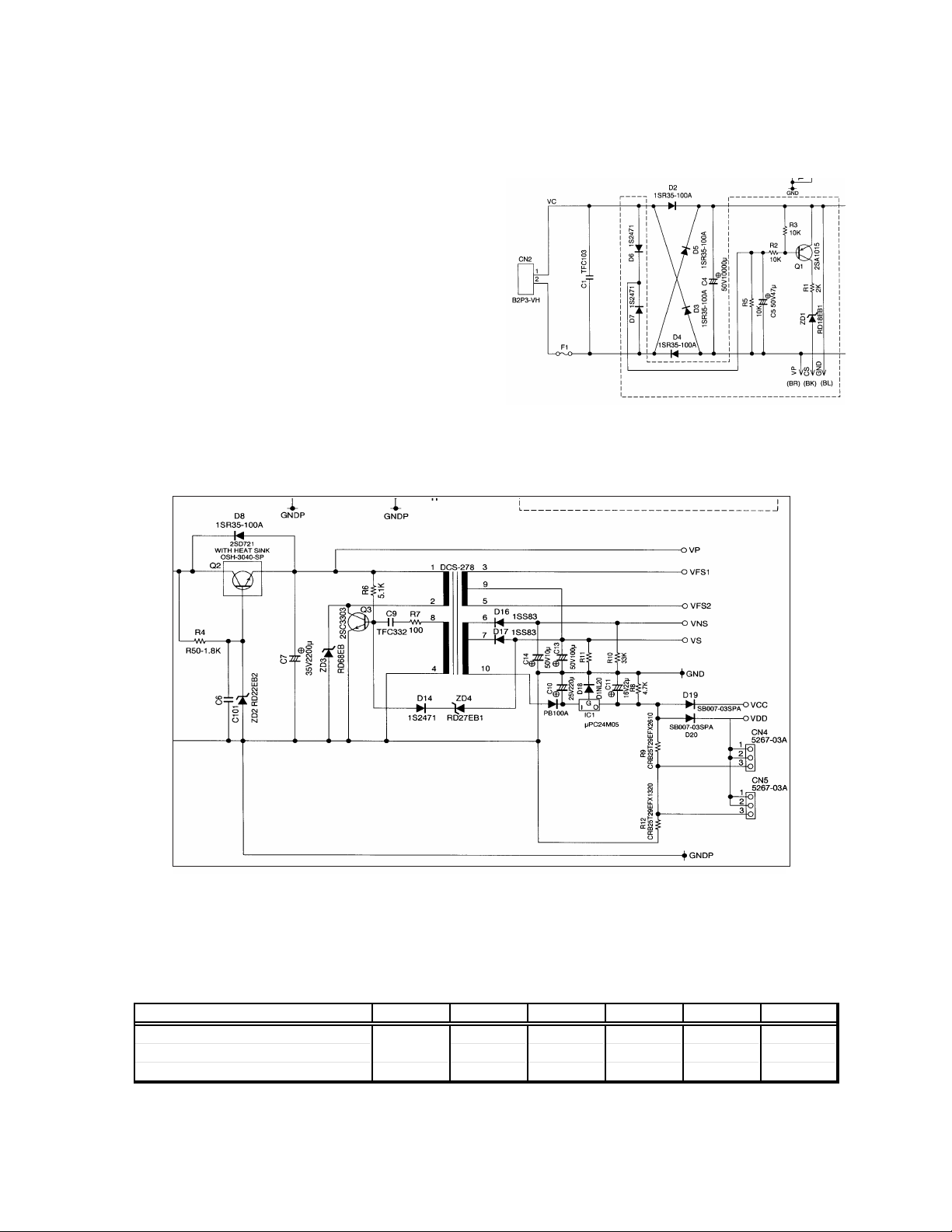

10. PROGRAMMING THE CE-3700 SERIES CASH REGISTERS

The Casio CE-3700 series is capable of a versatile range of features and function that give it the

capability to readily adapt to almost any retail environment. The cash register is programmed at the

factory with the most standard operating features and functions. Your local business requirements,

however, may call for other functions of a totally different keyboard layout.

This section explains the different functions available, as well as the procedures that you can use to

tailor the cash register to specific needs. Programming is simplified through the use of worksheets for

each function, and step-by-step flow charts that walk you through each procedure.

10-1. Setting the proper MODE for programming

• Program Modes and feature

Mode Purpose Mode indicator

Program 4

Program 3

Program 1

You should perform the procedure shown blow as the first step of programming. Notice that the

flowchart ends with an arrow on the bottom. This indicates that you should continue to the next

programming procedure for the mode you specify.

Assignment of 89 functions to programmable keys to create the

desired keyboard layout

Definition of machine features and key functions that enhance

printing, totalizing, reporting and overall operation

Programming of time, date and unit prices, amounts, rates, etc.

for enhanced security and automatic registration

P4

P3

P1

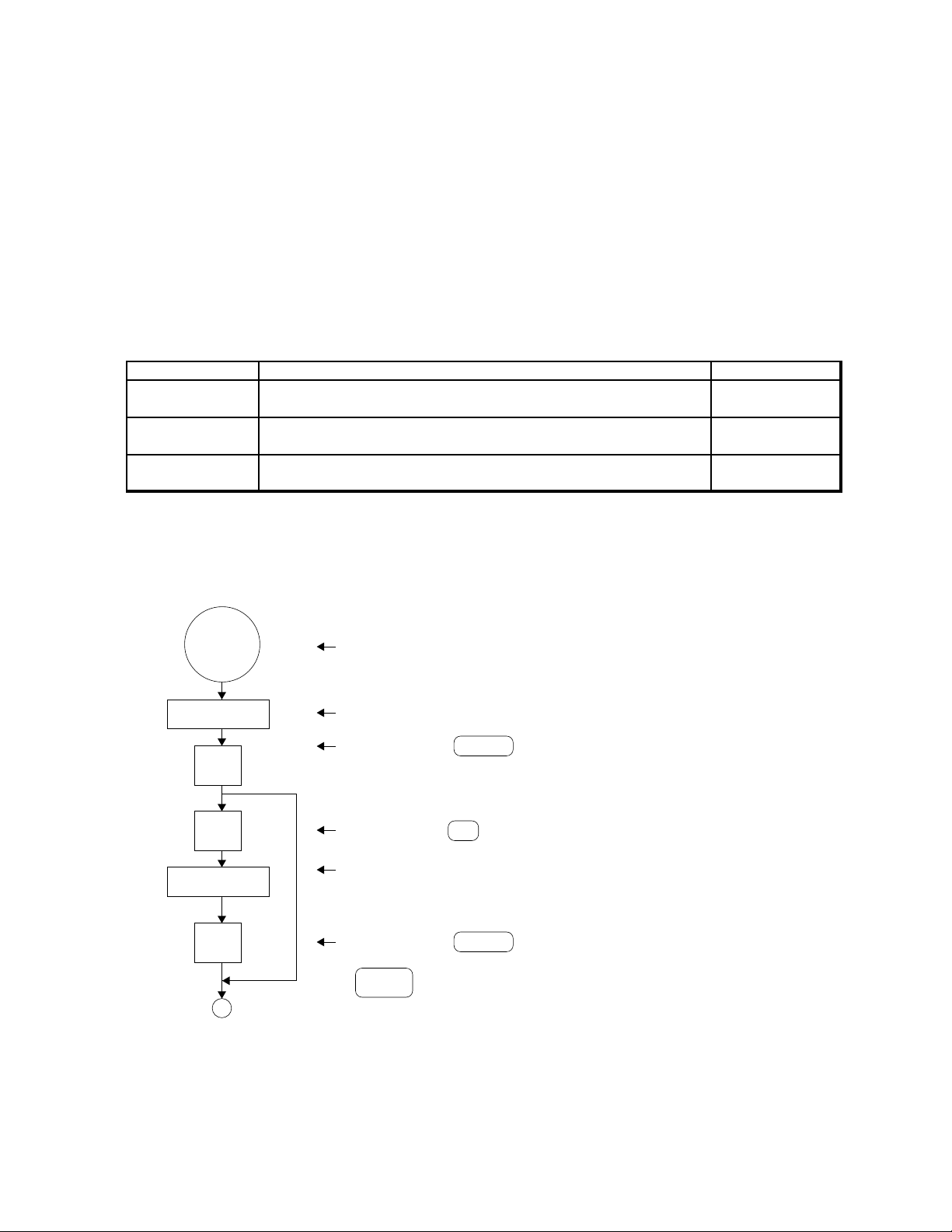

• Procedure

Program

Program mode

Sub

Total

#1*

Key

Program mode

Sub

Total

Set the Mode switch to Program

Enter a number to specify the program mode (1 ~ 4)

Press the

Sub total

key.

The display should show the letter “P” followed by the

program number you specified (i.e. P3 = Program mode 3).

Press the

# 1

key.

Enter 4-digit password.

Skip this step when the password is not programmed.

Press the

CA/Amt

Tend

Sub total

key.

key on standard keyboard.

Note: Program mode 1 is automatically set when the Mode switch is set to Program from

another setting.

• Recommended programming sequence

Generally, you should perform programming in the following sequence. Note that we recommend you

check what is programmed for each mode before proceeding to the programming operation.

— 17 —

Page 20

1 Use Program 4 to read the assignment of functions to programmable keys and then make

Sub total

changes.

2 Use Program 3 to read the definition of machine features and key functions and then make

changes.

3 Use Program 1 to read programming of time, date and unit price, amounts, rates, etc. and then

make changes.

10-2. Using the worksheets

The worksheets included in this manual for Program 3 and Program 1 help to make your

programming simple and accurate. We recommend that you fill out the pertinent worksheet before

attempting actual programming.

1) Carefully read each definition and specify a selection.

Each definition is following by a Specification column which contains numeric values(Usually to

indicate a simple YES or NO answer). Determine the correct value according to your need and

enter it in the Selection column to the right.

2) Total each set of selections to calculate each program code digit.

Three selections(a,b,c) make up a set. Add up each set of selections and fill in the totals in the

Program code column for data items D8 through D1.

3) Program the feature or function.

Be sure that you have filled in all of the selections and program code digits for the entire worksheet,

and follow the procedure noted for the feature or function you are programming.

4) Check the printed program receipt against the worksheet.

Perform program read operation in each program mode to print setting which you have

programmed, to check then against the worksheet. We recommend that you do so and keep a copy

on record to help out should it become necessary for you to change the program.

10-3. Clearing a machine lock up

If you make a mistake in operation, the cash register may lock up to avoid damage to programs and

preset data. Should this happen, you can use the following procedure to clear the lock-up without

losing any memory data.

• Procedure

Off

Set the Mode switch off.

Press receipt

feed key

RECEIPT

FEED

While holding down the Key, set the mode switch

to X1.

Off

Press receipt

feed key

Release the key.

RECEIPT

FEED

You should see “FFFFFFFFFF” on the display. If 10 of F’s are

not shown on the display or if another character is shown,

immediately set the mode switch to OFF and start from the

beginning of this procedure. IF you don’t see “ FFFFFFFFFF”

Sub

Total

on the display, do not press the

Finalize the procedure.

key.

— 18 —

Page 21

11. OPERATION

Operation of your cash register is designed to be simple enough to master without any special technical knowledge. Anytime you make a mistake in operation, an error tone sounds and further operation

becomes impossible to protect your valuable data. Whenever this happens, you can resume normal

operation after pressing the “C” key.

Printing of the symbol “—” can be programmed when the “C” key is operated in the REG1, REG2, and

RF modes. The number of the “C” key operations can also be programmed for printing on the general

control Read/Reset reports.

As you become familiar with the key layout of the cash register, you may find that your keyboard

entries are getting ahead of the receipt and journal printer. But you never need to worry that the cash

register will miss anything. A built-in key input buffer memory holds entries for up to eight keys to let

the cash register catch up when you slow down or stop.

Another thing you don’t need to worry about is power outages. Your register features built-in rechargeable lithium batteries that return such information as program data, registration records, data, item, and

consecutive number.

These and other features and functions of the CE-3700 series electronic cash register make it a

welcome addition to any retail environment.

• Performing daily cash register operations

The actual operations that you perform with your cash register will depend in the nature of your own

business. The following outline shows the most common operations in the order they are usually

performed.

Operation Mode switch

1

2

3

4

5

6 Register transaction.

7

8

9

10

11 Carry the journal, reports and cash to the office. OFF

Confirm that enough receipt and journal paper are present, and

load new paper rolls if necessary.

Read daily totals to confirm that the RESET operation was

performed for the previous day's totals.

Preset unit prices for department keys, PLUs and function keys if

necessary.

Set the MODE switch to REG and identify a clerk using a clerk

secret number.

Check the date and time set on the cash register.

Normal sales

Received on account and paid out

Returns

Perform READ and RESET operation as required, after counting

the money in the cash drawer and registering the amount.

Read daily sales totals.

Read periodic sales totals

Reset daily sales totals

Reset periodic sales totals

Remove the printed journal, reports from the cash register.

Set the MODE switch to OFF and remove the key.

Empty the cash drawer and leave it open.

OFF

X1

Program

REG1/REG2

REG1/REG2

REG1/REG2

REG1/REG2

REG1/REG2/RF

X1

X2/Z2

Z1

X2/Z2

REG1/REG2

OFF

OFF

— 19 —

Page 22

12. ERROR CODES

g

)

Error codes appear on the display whenever you make a mistake during operation. The following table

shows the actual error codes, their meanings, and the actions to take to correct the situation.

Error Code Meaning Action

E 01

E 02

E 03

E 04

E 08

E 09

E 11

E 16

E 27 Transaction cancel buffer is full. Finalize the transaction.

E 31

E 32

E 33

E 35 Change amount exceeds press limit. * Re-input amount tendered.

E 38

E 41 Validation is not performed. Perform validation operation.

E 94 Printer error

Position of MODE switch changed before

finalizing the current operation.

Setting of the receipt ON/OFF button

Changed before finalizing of the registration

under another settin

Prohibited clerk/cashier number(7 ~ 15)

is entered during cashier interrupt registration.

Initialization or unit lock clear operation

in progress.

Registration without entering the clerk

secret number.

Operation attempted without entering the

password in the PRG 1, 3, 4, 6 or X2/Z2.

Registration attempted while the drawer

of the ECR is open.

The drawer is left open longer than the

program time (Drawer Open Alarm

Two consecutive transactions attempted

in the refund mode.

Finalizing of a transaction attempted

without confirmation of the subtotal.

Finalizing of a transaction attempted

without confirmation of the Food stamp

subtotal. *

Finalize operation attempted without

entering the amount tendered.

READ/RESET operation attempted

without declare of money in drawer. *

Return the MODE switch to its original

setting and finalize the operation before

changing the position of the MODE switch.

Return the receipt ON/OFF switch to its

original setting and finalize the transaction

changing the setting.

Enter correct number (1 ~ 6).

Complete operation

Enter the clerk secret number.

Enter the password.

Close the drawer before attempting to

perform registration.

Shut the drawer to stop the alarm. When

the optional compulsory drawer is used.

Switch to another mode and then back

to the RF mode for the next transaction.

Press the "SUB TOTAL" key.

Press the "FS/ST" key.

Enter the amount tendered.

Perform money declaration.

Turn the power off, and remove jammed

roll paper from the printer.

Remark: Denoted * which these error only occur when certain function are

programmed as compulsory prohibited.

— 20 —

Page 23

13. IC DATA

1) TC74HC138

2) TC74HC174

3) TC74HC367

— 21 —

Page 24

14. PCB LAYOUT

1

4

1

CN9

E

Q7

R33

D34

B

R40

CN10

1

C26

2

3

S-80727AN

Q13

B

1

D36

R55

CN11

R56

13

B

E

CN12

Q14

R57

D-8

DW1

BK

DW2

CN8

BZ1

C-9

F2

BK

BR

R

BR

R

2

B

Q10

B-16

C-10

IC10

D37

Q8

E

B

E

D38

D32

D33

C20

Q9

EB E

R34 R35

E

Q11

B

R36

R37

C24

R41

D35

ZD5

R42

E

B

Q12

R43

R44

R45

3

C37

E-7

C38

C39

C40

R58

C25

C22

1

B-21

R59

R60

R61

D-7

C23

R38

F-1

B-17

C27

B-18

C-11

R46

D-12

J-14

D-14

D-15

D-16

CA1

B-2

CA2

E-1

CA3

E-2

IC3

BA12003

IC4

E-3

IC5

R47

C28

IC9

BA10393

D-13

R62

C-42

C-43

C41

IC11

B-22

B-23

BR93LC66A

125V 2.5A

B-1

F1

1

D4

D5

C2C3

D13

CN1

31

WARNING - FOR CONTINUED

PROTECTION AGAINST

FIRE HAZARD.

K-1

IC2

BA12003

C15

BA12003

BA12003

H-3

B-24

R63

C44

C45

F-26

R48

R51

R64

F-2

R49

R52

F-27

C46

B-13

R50

B-14

C29

1

2

CN2

D2

C1

D3

C4

VP

C9

J-1

B-19

C-15

F-3

D14

E-6

F-4

B

C11

E

Q4

B

B

B-12

F-5

C-14

B-20

B-25

IC12

Q3

ZD4

R7

13

µPC24M05

D27

R27

C31

X1

B-26

LC36256PLL-10/12/15

Q15

B-4

R6

C10

REPLACE ONLY WITH

THE SAME TYPE AND

RATING OF FUSE.

CA4

D-2

C-3

D-3

D-4

H-1

C-12

C-13

C30

R53

D6

D7

E

IC1

C

B-9

VCC

R26

E

R28

R29

µPD78044

D-17

B-27

B

E

Q1

B-5

D15

A

E

Q5

B

Q6

IC6

C32

C33

B-28

B

R5

DCSI

C-2

D18

R8

R9

A

C

D19

VDD

AGF

X2

R54

C35

F-24

B-29

R1

R2

R3

C5

B-6

D20

D28

F-25

BL BK BR

CS

VP

GND

ZD1

E

Q2

D8

R4

C6

ZD2

ZD3

D-1

D16

D17

R10

R11

R12

3

3

CN5

1

1

CN4

L-1

J-2

J-3

IC7

E-4

C16

R30

C34

IC13

GND

H-2

D-9

D-10

B-30

74HC174

C18

C-4

D-11

RA2

D-18

C-17

F-6

B

E

C12

VN

VS

CA5

74HC367

D-6

F-7

F-8

B-31

C47

IC14

C-1

C13

R18

R31

C17

IC8

F-9

F-10

CA6

C-18

74HC174

R19

R20

74HC367

F-11

F-12

F-23

B-32

C48

R32

F-13

C49

FG

R13

R21

B-11

C19

C7

B-7

R22

R23

D-5

C-5

E-5

C-6

F-14

C36

74HC138

IC15

B-3

R16

R17

C14

RA3

R24

D9

R14

R15

R25

RA1

D29

D30

D31

B-15

C-16

12

D10

B-8

CA7

CN3

D11

D21

R39

D12

D22

D43

F-15

F-16

F-17

F-18

F-19

F-20

F-21

F-22

D23

C-8

C-19

C-20

C-21

D1

CN7

D39

D40

D41

D42

C8

D24

CN14

D25

CN13

1

CN6

32

D26

18

B-10

1

2

1

1

5

— 22 —

Page 25

15. CIRCUIT DIAGRAM

BCDEFGHI JKA

1

3PIN

B-6

OPTION

32PIN

18PIN

FFC

E278-E2-2

FFC FFC

10PIN 12PIN

E278-E2-1

PCPC

E241

-E3-2

RECEIPT

ON/OFF

E278-E4

FPC

E278-E6

PUSH CLERK

MODE-KEY

VP

PC

VCC

15mS

PWD

RST

CPU-CLK

40mS

300mS

15V

min

1.5S

2

VOLTAGE

SELECTOR

POWER

TRANSFORMER

2PIN

3

PRINTER

CR812A

RESET SW

4

2PIN

NEAR END SENSER

E278-1

31PIN

2PIN

OPTION

1

2

3

4

5

6

7

3PIN 3PIN 3PIN

BATTERY DRAWER DRAWER

OPTION

RECEIPT

FEED

RECEIPT

NS

%–

—

RF

JOURNAL

FEED

VALID

#

PLU

ERR.CORR

CANCEL

X

DATE

OPEN PRICE CPN VAT

C

TIME

789

456

123

000

•

51015

4914

3813

2712

1611

RC PD

CR 1 CR 2

CHK

CH

TEND

SUB TOTAL

CA

AMT

TEND

RECEIPT

JOURNAL

FEED

FEED

RECEIPT

VALID

NS

PRICE

%–

—

ERR.CORR

RF

CANCEL

#

PLU

CLK#

C

X / FOR

OPEN

DATE

TIME

789

456

123

000

•

12 18 24

6

11 17 23

5

10 16 22

4

91521

3

81420

2

71319

1

30

29

28

27

26

25

PD

T/S1RCT/S2

CR 1 CR 2

CHK

CH

TEND

SUB

MD/ST

TOTAL

CA

AMT

TEND

8

Board No.

BLOCK DIAGRAM for CE-3700

Drawing No.

E240032

5

6

7

8

BCDEFGHI JKA

— 23 —

Page 26

BCDEFGHI JKA

1

3PIN

B-6

OPTION

32PIN

18PIN

FFC

E278-E2-2

FFC FFC

10PIN 12PIN

E278-E2-1

PC

E241

-E3-2

RECEIPT

ON/OFF

E278-E4

FPC

15V

VP

MODE-KEY

VCC

1.5S

PC

15mS

PWD

RST

CPU-CLK

40mS

300mS

min

2

POWER

TRANSFORMER

2PIN

3

PRINTER

CR812A

4

RESET SW

NEAR END SENSER

2PIN

31PIN

2PIN

OPTION

E278-1

1

2

3

4

5

6

3PIN

BATTERY

3PIN 3PIN

DRAWER DRAWER

OPTION

5PIN

KEY CLERK

RECEIPT

JOURNAL

FEED

FEED

RECEIPT

VALID

NS

%–

—

ERR.CORR

RF

CANCEL

#

PLU

X

DATE

OPEN PRICE CPN VAT

C

TIME

789

456

123

000

•

51015

4914

3813

2712

1611

RC PD

CR 1 CR 2

CHK

CH

TEND

SUB TOTAL

CA

AMT

TEND

7

8

Board No.

BLOCK DIAGRAM for CE-3750

Drawing No.

E240046

5

6

7

8

BCDEFGHI JKA

— 24 —

Page 27

BCDEFGHI JKA

1

2

3

4

5

6

7

CN6 IMSA-9604S-32C

3231 2324 25 26 27 28 29 30 2 9 8 5 6 3 1314 15 1617 1819 20 2122 7 12 11 10 4 1

D21

MCOM

R33 CRH100-1

CN9

B38-XH

RYOUSYUU

5

4

3

2

CN14

IL-G-5P

KEY CLERK

1

CN3

NEDS

B28-EH

VCC

R31

56K

CN8

TAIWAN

GND

RESET

CN10

IL-G-2P

GND

AD2

AD1

AD0

CD7

CD6

PCOM

003

D39

002

D40

001

D41

000

D42

KCOM

D1

CD7

PCOM

KCOM

IC7

56K

R39

14

12

11

IC7

74HC367

100

GND

IC14 74HC174

1

10

A6

11

AD0

6

AD1

7

A7

13

AD2

12

A8

8

TF103

1

10

A0

11

AD0

6

AD1

7

A1

13

AD2

12

A2

8

1

2

3

4

CD5

CD4

CD3

CD2

CD1

CD0

D34

VP

1SR35-100

Q7

2SD1853

GNDP

15

13

VDD

R44

16

VCC

CLR

Q1

D1

D2

Q2

D3

Q3

GND

C49

IC13 74HC174

CLR

Q1

D1

D2

Q2

D3

Q3

GND

CS

SK

DI

DO

BR93LC46A

C35

TF103

IC11

GND

Q6

D6

D5

Q5

D4

Q4

CLK

VCC

Q6

D6

D5

Q5

D4

Q4

CLK

VCC

NC

NC

GND

2

3

14

15

4

5

9

16

2

3

14

15

4

5

9

SD

VF1

VF1

VP

R58

1.8K

S-80727AN

A11

AD5

AD4

A10

AD3

A9

C48

A5

AD5

AD4

A4

AD3

A3

C47

VCC

GND

8

7

6

5

GND

SE

SG

VCC

Q15

DTA143ZS

2

GND

VCC

C101

C101

C41

TF103

CNB8X101K

SF

SH

DG9

DG8

DG7

DG6

RSTAMP

VCC

RA1RGLD8X222J

IC10

1

3

VDD

VDD

R45

56K

C37

C102

GND

LC36256PLL-10/12/15

1

DECD2

A14

2

DECD0

A12

3

A7

A7

4

A6

A6

5

A5

6

A4

7

A3

8

A2

A2

9

A1

A1

10

A0

A0

11

AD0

I/O0

12

AD1

I/O1

13

AD2

I/O2

14

VSS

GND

CA6

AD0

GND

DG5

DG4

DG3

DG2

CD0

R25

10 4 10 4

74HC367

9595

IC8

RGLD8X563J

RA2

VCC

WE

A13

IC12

A8

A9

A11

OE

A10

CE

I/O7

I/O6

I/O5

I/O4

I/O3

AD1

AD2

AD3

AD4

AD5

SA

SB

SCOM

CD3

CD4

R22

R21

IC8

IC7

TF103

DECD1

A8

A9

A11

A10

AD7

AD6

AD5

AD4

AD3

AD7

SC

CD5

CD6

R20

R19

IC7

IC7

C42

C43

GND GND

SDP

CD7

R18

IC7

VDD

R52R51

VDD

C44

GND

DG1

DG0

CD1

CD2

R24

R23

IC8

2626

3737

IC8

VDD

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AD6

VF2

100 X8

R32

D31

D29

D30

C16

GND

C101

VF2

VCC

56K

GND

C45

10K 10K

C101

R64

C12

TFC103

GND

KCOM

PCOM

MCOM

VDD

C101

C101

56K

VDD

CNB8X221K

CA5

VP

PKM22EPP-2002

CN13 B28-EH

12

D43

CD7

KCOM

DG6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

BZ1

P94

P93

P92

P91

P90

P81

P80

VDD

P27

P26

P25

P24

P23

P22

P21

P20

RESET

P74

P73

AVSS

P17

P16

P15

P14

R40

3.7K

9

10

11

12

13

14

15

16

DG5

DG4

DG3

DG2

DG1

DG0

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

CE

KI7

KI6

KI5

KI4

RSTAP

KCOM

PCOM

MCOM

LE2

LE1

VCC

KC0

KC1

KC2

KC3

KC4

D22

D23

D24

D25

D26

VN

DG8

DG9

DG10SASBSCSDSESFSGSDP

807978777675747372717069686766

P95

P96

P97

P100

P101

P102

P103

P104

P105

IC6 µPD78044

P13

P12

P11

P10

AVDD

AVREF

XT1

XT2

VSSX1X2

252627282930313233343536373839

KI3

KI2

KI1

KI0

VP

X2

C-002RXC32

GND

DECD2

DECD1

DECD0

BUZZ

R54

C46

330K

C33 C120

Y6

Y5

Y4

Y3

Y2

Y1

Y0

VCC

C36

EEPCE

14

C24

C101

74HC138

GND

Y7

G1

G28

G2A

IC15

TF103

C

B

A

IC5

3

8

7

6

5

4

3

2

1

GND

KC5

KC6

D12

D11

P106

VLOAD

C46

C101

GND

KC7

KC8

KC9

D10

D9

56KR13

GND

SH

P107

P110

P111

P112

P114

P115

P116

P117

P120

P121

P122

P123

P124

P125

P126

P127

IC(VPP)

P37

P36

P35

P34

40

VCC

DECCE

R62

X1

CST4.19MGW

R63

56K

GND

C101

R17

R16

R15

R14

65

P113

VDD

P70

P71

P72

P00

P01

P02

P03

P30

P31

P32

P33

JCOM

GND

56K

R59

C40

C8

R60

C39

VP

D35

ZD5

R41

15EB3

100K

1K

R42

56K

56K

56K

56K

D28

64

63

62

61

60

59

58

57

56

55

54

53

52

51DECD0

50DECD1

49DECD2

48

47TP

46

45

44

43

42

41

GND

VCC

10KX3

R61

C38

C101X3

VN

DWS

C18

C34

2SC945

C26

RFEED

JFEED

HD9

HD10

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HD8

TF104

+

Q12

+

50V1µ

GND

R30

56K

GND

C31

C101

16V100µ

P53

GND

PWD

GND

15

10

STAMP

ACUT

RCOM

56K

R43

56K

C101

C27

R4810K

R47

IC9

BA10393

7

C29

C102

C30

12

IC8

14

74HC367

CN7 IMSA-9604S-18C

18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

KI2

KI1

KI3

KI4

KC1

KC2

KC3

KC4

KI0

KI0

KI1

KI2

KI3

KI4

KI5

KI6

KI7

CNB8X101K

R28

4.7K

1

IC5

16

R35

4.7K

2SA1015

C20

Q8

D33

GNDP

1SR35-100

GND

Q6

2SC945

R27

Q11

C101

100K

+

–

C101

15

13

IC8

VDD

GND

VCC

5

6

GND

2

C23

C101

R36

2SA1015

4.7K

R46

8.2K

IC5

GND

R4916K

R50

VP

VCC

D38

10K

R37

10K

CA7

C21

C101

2SB926

Q10

R56

10K

KI5

10K

KC5

KI0

4

5

3

6

4

2

1

5

6

2

4

7

R34

10K

KC6

KI1

RA3

R26

R38

R55

1.8K

R57

1.8K

KC0

KC7

KI6

KI2

KI3

KI4

RGLD8X563J

1.8K

Q4

D27

2SD2015

Q5

1K

R29

IC5

13

6

IC5

12

2

IC3

14

7

IC4

11

5

IC4

13

3

IC4

15

1

IC3

16

10K

IC3

12

IC2

11

IC2

13

IC2

15

IC3

10

VP

G9

2SB926

1SR35-100

VP

Q13

2SD1853

Q14

2SD1853

KC8

KI5

GNDP

6

7

5

3

1

4

KC9

KI6

C22

C101

KI7

KI7

VP

D13

C3 C101

2SD2015

IC5

11

IC3

15

IC4

10

IC4

12

IC4

14

IC4

16

IC3

11

IC2

10

IC2

12

IC2

14

IC2

16

IC3

13

D32

GNDP

UL-TSCR-0.8A

F2

1SR35-100

VP

D36

1SR35-100

OTP ONLY

1S2471

BA12003

1SR35-100

STAMP

JFEED

RFEED

JCOM

JHD1

JHD2

JHD3

JHD4

JHD5

JHD6

JHD7

JHD8

JHD9

JHD10

MOTOR

RCOM

RHD1

RHD2

RHD3

RHD4

RHD5

RHD6

RHD7

RHD8

RHD9

RHD10

ACUT

TP

C15

C101

GNDVP

VP

GNDP

TO BLOCK DIAGRAM (2/3) PRINTER

BK

BR

PAD

R

1

DW1

2

3

IL-G-3P

CN11

BK

BR

R

1

2

3

IL-G-3P

CN12 DW2 PAD

1

2

3

4

5

6

7

8

Board No.

MAIN PCB E278-1 (1/3)

Board No.

E240033

8

BCDEFGHI JKA

— 25 —

Page 28

BCDEFGHI JKA

1

VP

1

2

3

TO BLOCK DIAGRAM (1/3) PRINTER

4

VC

5

CN2

1

2

B2P3-VH

6

F1

7

VP

CA1

CNB5X101K

234672345678923456789234

TFC103

C1

CA2

1

CNB8X101K

1S2471

D6

1S2471

D7

VP

1

D2

1SR35-100A

D4

1SR35-100A

CA3

CNB8X101K

D5

D3

VP

1SR35-100A

C4

50V10000µ

1SR35-100A

CA4

1

CNB3X101K

R5

10K

VP

VCC

R2

10K

C5 50V47µ

STAMP

JFEED

RFEED

JCOM

JHD1

JHD2

JHD3

JHD4

JHD5

JHD6

JHD7

JHD8

JHD9

JHD10

MOTOR

RCOM

RHD1

RHD2

RHD3

RHD4

RHD5

RHD6

RHD7

RHD8

RHD9

RHD10

ACUT

TP

C2

TFC103

GND

R3

10K

Q1

R1

ZD1

VP

CS

(BR) (BK)

HBLB31-S2J

CN1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

2SA1015

2K

RD18EB1

GND

(BL)

Q2

R4

R50-1.8K

D8

1SR35-100A

2SD721

WITH HEAT SINK

OSH-3040-SP

C6

ZD2 RD22EB2

C101

GND

GNDP

C7

BA10393

4

GND

TFC103

BA12003*3

8

GND

35V2200µ

IC9

C28

IC2

IC3

IC4

ZD3

VP

COM

2SC3303

RD68EB

8

9

Q3

VP

VP

R6

GND

GNDP

5.1K

C9

TFC332

74HC367*2

8

GND

C17

C19

BA12003

8

GND

C25

R7

100

D14

1S2471

IC7

IC8

IC5

COM

1

2

8

4

VCC

TFC103

TFC103

9

TFC103

DCS-278

ZD4

RD27EB1

VCC

16

VP

RESET SW

1

2

KEY CLERK

BATTERY

R11

D18

D1NL20

G

O

I

IC1

µPC24M05

J-Y7541

R10

C11

5

4

3

2

1

1

2

3

3

9

5

D16

1SS83

6

D17

1SS83

7

C13

C14

50V10µ

C10

PB100A

50V100µ

25V220µ

10

JPM1030-0101

VL3032/1F2

33K

R8

4.7K

16V22µ

R9

CRB25T29EFX2610

R12

CRB25T29EFX1320

VP

VFS1

VFS2

VNS

VS

GND

D19

SB007-03SPA

SB007-03SPA

D20

GNDP

VCC

VDD

1

2

3

1

2

3

CN4

5267-03A

CN5

5267-03A

1

2

3

4

5

6

7

8

Board No.

MAIN PCB E278-1 (2/3)

Drawing No.

E240034

8

BCDEFGHI JKA

— 26 —

Page 29

BCDEFGHI JKA

1

IC1

UPC24M05HF

IC2

BA12003

IC3

BA12003

IC4

BA12003

IC5

BA12003

IC6

UPD78P044GF-080

IC7

TC74HC367AP

IC8

TC74HC367AP

IC9

2

3

4

5

6

7

BA10393

IC10

S-80727AN-Z

IC11

BR93LC66A

IC12

LC36256PLL10/12/15

IC13

TC74HC174AP

IC14

TC74HC174AP

IC15

TC74HC138AP

C1

ECQ-B1H103KFW

C2

ECQ-B1H103KFW

C3

RT-HE40TKYB101K-T

C4

LP5-50V103MS45

C5

RE3-50V470M-T2

C6

RT-HE40TKYB101K-T

C7

RE3-35V222M-T2

C8

RT-HE40TKYB101K-T

C9

ECQ-B1H332JFW

C10

RE3-25V221M-T2

C11

RE2-16V220M-T2

C12

ECQ-B1H103KFW

C13

RE3-50V101M-T2

C14

RE2-50V100M-T2

C15

RT-HE40TKYB101K-T

C16

RT-HE40TKYB101K-T

C17

ECQ-B1H103KFW

C18

ECQ-V1H-104-JZW

C19

ECQ-B1H103KFW

C20

RT-HE40TKYB101K-T

C21

RT-HE40TKYB101K-T

C22

RT-HE40TKYB101K-T

C23

RT-HE40TKYB101K-T

C24

RT-HE40TKYB101K-T

C25

ECQ-B1H103KFW

C26

RE2-50V1R0M-T2

C27

RT-HE40TKYB101K-T

C28

ECQ-B1H103KFW

C29

RT-HE50TKYB102K-T

C30

RT-HE40TKYB101K-T

C31

RT-HE40TKYB101K-T

C32

RT-HE40TKCH150J-T

C33

RT-HE40TKCH120J-T

C34

RE3-16V101M-T2

C35

ECQ-B1H103KFW

C36

ECQ-B1H103KFW

C37

RT-HE50TKYB102K-T

C38

RT-HE40TKYB101K-T

C39

RT-HE40TKYB101K-T

C40

RT-HE40TKYB101K-T

C41

ECQ-B1H103KFW

C42

ECQ-B1H103KFW

C43

RT-HE40TKYB101K-T

C44

RT-HE40TKYB101K-T

C45

RT-HE40TKYB101K-T

C46

RT-HE40TKYB101K-T

C47

RT-HE40TKYB101K-T

C48

RT-HE40TKYB101K-T

C49

ECQ-B1H103KFW

R1

CR-25-2KOHM-J-T

R2

CR-25-10KOHM-J-T

R3

CR-25-10KOHM-J-T

R4

R50XT-08J182

R5

CR-25-10KOHM-J-T

R6

CR-25-5.1KOHM-J-T

R7

CR-25-100OHM-J-T

R8

CR-25-4.7KOHM-J-T

R9

CRB25T29EFX3300

R10

CR-25-33KOHM-J-T

R11

R12

CRB25T29EFX1500

R13

CR-25-56KOHM-J-T

R14

CR-25-56KOHM-J-T

R15

CR-25-56KOHM-J-T

R16

CR-25-56KOHM-J-T

R17

CR-25-56KOHM-J-T

R18

CR-25-100OHM-J-T

R19

CR-25-100OHM-J-T

R20

CR-25-100OHM-J-T

R21

CR-25-100OHM-J-T

R22

CR-25-100OHM-J-T

R23

CR-25-100OHM-J-T

R24

CR-25-100OHM-J-T

R25

CR-25-100OHM-J-T

R26

CR-25-1.8KOHM-J-T

R27

CR-25-10KOHM-J-T

R28

CR-25-4.7KOHM-J-T

R29

CR-25-1KOHM-J-T

R30

CR-25-56KOHM-J-T

R31

CR-25-56KOHM-J-T

R32

CR-25-56KOHM-J-T

R33

CRH100-FC10-J-1R0

R34

CR-25-10KOHM-J-T

R35

CR-25-4.7KOHM-J-T

R36

CR-25-4.7KOHM-J-T

R37

CR-25-10KOHM-J-T

R38

CR-25-10KOHM-J-T

R39

CR-25-56KOHM-J-T

R40

CR-25-4.7KOHM-J-T

R41

CR-25-100KOHM-J-T

R42

CR-25-1KOHM-J-T

R43

CR-25-56KOHM-J-T

R44

CR-25-100OHM-J-T

R45

CR-25-56KOHM-J-T

R46

CR-25-8.2KOHM-J-T

R47

CR-25-100KOHM-J-T

R48

CR-25-10KOHM-J-T

R49

CR-25-16KOHM-J-T

R50

CR-25-10KOHM-J-T

R51

CR-25-10KOHM-J-T

R52

CR-25-10KOHM-J-T

R53

CR-25-56KOHM-J-T

R54

CR-25-330KOHM-J-T

R55

CR-25-1.8KOHM-J-T

R56

CR-25-10KOHM-J-T

R57

CR-25-1.8KOHM-J-T

R58

CR-25-1.8KOHM-J-T

R59

CR-25-10KOHM-J-T

R60

CR-25-10KOHM-J-T

R61

CR-25-10KOHM-J-T

R62

CR-25-56KOHM-J-T

R63

CR-25-56KOHM-J-T

R64

CR-25-56KOHM-J-T

D1

1S2471 T-77-T

D2

1SR35-100A-T-32-T

D3

1SR35-100A-T-32-T

D4

1SR35-100A-T-32-T

D5

1SR35-100A-T-32-T

D6

1S2471 T-77-T

D7

1S2471 T-77-T

D8

1SR35-100A-T-32-T

D9

1S2471 T-77-T

D10

1S2471 T-77-T

D11

1S2471 T-77-T

D12

1S2471 T-77-T

D13

1SR35-100A-T-32-T

D14

1S2471 T-77-T

D15

RB100A-T32-T

D16

1SS83TD

D17

1SS83TD

D18

D1NL20-4070

D19

SB007-03SPA

D20

SB007-03SPA

D21

1S2471 T-77-T

D22

1S2471 T-77-T

D23

1S2471 T-77-T

D24

1S2471 T-77-T

D25

1S2471 T-77-T

D26

1S2471 T-77-T

D27

1S2471 T-77-T

D28

1S2471 T-77-T

D29

1S2471 T-77-T

D30

1S2471 T-77-T

D31

1S2471 T-77-T

D32

1SR35-100A-T-32-T

D33

1SR35-100A-T-32-T

D34

1SR35-100A-T-32-T

D35

1S2471 T-77-T

D36

1SR35-100A-T-32-T

D37

1SR35-100A-T-32-T

D38

1S2471 T-77-T

D39

1S2471 T-77-T

D40

1S2471 T-77-T

D41

1S2471 T-77-T

D42

1S2471 T-77-T

D43

1S2471 T-77-T

ZD1

RD18EB1-T1

ZD2

RD22EB1-T1

ZD3

RD68EB-T1

ZD4

RD27EB1-T1

ZD5

RD15EB3-T1

Q1

2SA1015GR.O.Y)TPE2

Q2

2SD721

Q3

2SC3303-Y

Q4

2SD2015

Q5

2SD2015

Q6

2SC945(K.P.Q.R)-T

Q7

2SD1853-AA

Q8

2SB926(T.U)-AA

Q9

2SB926(T.U)-AA

Q10

2SA1015GR.O.Y)TPE2

Q11

2SA1015GR.O.Y)TPE2

Q12

2SC945(K.P.Q.R)-T

Q13

2SD1853-AA

Q14

2SD1853-AA

Q15

DTA143ZS-TP

RA1

RGLD8X222J

RA2

RGLD8X563J

RA3

RGLD8X563J

CA1

CNB5X101K

CA2

CNB8X101K

CA3

CNB8X101K

CA4

CNB3X101K

CA5

CNB8X221K

CA6

CNB8X101K

CA7

CNB8X101K

X1

CST4.19MGW

X2

C-002RX(M90-76)

CN1

HBLB31-S2J

CN2

5277-02A

CN3

CN4

53253-0310

CN5

53253-0310

CN6

IMSA-9604S-32C

CN7

IMSA-9604S-18C

CN8

CN9

B3B-XH

CN10

IL-G-2P-S3T2-E

CN11

IL-G-3P-S3T2-E

CN12

IL-G-3P-S3T2-E

CN13

B2B-EH

CN14

IL-G-5P-S3T2-E

CN15

E412198*1

CN16

CN17

BZ1

PKM22EPP-2002

SW1

T1

F1

F1

F1

F2

JPM1030-0201

OSH-3040-SPL

DCS-278

UF-0033

21801.6

23702.5

UL-TSCR-0.8A-N1

1

2

3

4

5

6

7

8

Board No.

MAIN PCB E278-1 (3/3)

Drawing No.

E240035

8

BCDEFGHI JKA

— 27 —

Page 30

BCDEFGHI JKA

1

SH101MA

MODE KEY SW.1

2

2

1

10

9

8

3

7

6

3

4

5

4

5

8

7

6

6

5

4

3

2

1

KSL-B85FA02-B1J

X2/Z2

Z1

X1

REG2

REG1

RF

PGM

OFF

C

C

MODE KEY SW.2

KSL-84FG01-B1J

OFF

C

5

4

3

2

1

9

8

0

4

3

2

1

0

9

8

C

C

C

6

7

8

9

10

1

2

3

4

MODE KEY SW.1PUSH CLERK

5

1

2

3

4

5

6

TO E278-E6

7

A,D,B,BU

1

2

RECEIPT

ON/OFF

TO E278-E3

PGM

RF

REG1

REG2

X1

Z1

X2/Z2

OFF

C

C

CLCOM

SWI0

SWI1

SWI2

SWI3

SWI4

SWI5

SWI6

PCOM

MODE KEY SW.2

1 4 876532

C

OFF

D2

D3

D4

D5

D6

D7

D1

123456789

D26

D25

D24

D23

D22

D21

D14

D13

D12

D11

D20

D19

D18

D17

D10

D9

D8

D15

D16

101112131415161718192021222324

1S2471 T-77-T

12

11

10

9

8

7

6

5

4

3

2

1

IMSA-9604S-12C

10

9

8

7

6

5

4

3

2

1

IMSA-9604S-10C

CN2

CN3

1

2

3

4

5

6

7

MCOM

PCOM

CD7

CD6

CD5

CD4

CD3

CD2

CD1

CD0

1210987654331242528273020191817161514131211262122232932

CN1 IMSA-9604S-32C

VF1SDSESGSFSHDG9

DG8

DG7

DG6

DG5

DG4

DG3

DG2

DG1

DG0

SCOMSASBSCSDP

VF2

8

Board No.

DISPLAY PCB E278-E2-1

Board No.

E240036

7

8

BCDEFGHI JKA

— 28 —

Page 31

BCDEFGHI JKA

1

KC3

12

KC5

8

KC6

7

KC1

14

KC0

6

KC2

13

KC7

5

2

3

4

TO E278-1

KC8

3

KC9

2

KC4

11

K18K12K6

K17K11K5

K16K10K4

K15K9K3

K14K8K2

K13K7K1

K78K72K66K60K54K48K42K36K30K24

KI7

1

K77K71K65K59K53K47K41K35K29K23

KI6

4

K76K70K64K58K52K46K40K34K28K22

KI5

9

K75K69K63K57K51K45K39K33K27K21

KI4

15

K74K68K62K56K50K44K38K32K26K20

K73K67K61K55K49K43K37K31K25K19

KI3

KI2

16

18

TO E278-1

1

2

3

4

KI1

17

5

KEY CONTACT POSITION

78

72

66

60

54

48

42

36

30

24

18

12

6

6

5

4

3

2

11

10

9

8

17

16

15

14

23

22

21

20

29

28

27

26

35

34

33

32

41

40

39

38

47

46

45

44

53

52

51

50

59

58

57

56

65

64

63

62

7

61

55

49

43

37

31

25

19

13

7

1

71

70

69

68

67

77

76

75

74

73

KI0

10

8

5

6

7

8

Board No.

KEYBOARD E278-E4

Board No.

E240037

BCDEFGHI JKA

— 29 —

Page 32

BCDEFGHI JKA

1

2

US. CANADA

(C, L)

(US. CANADA SPEC.)

*

240V

230V

220V

120V

100V

*

EUROPE

(B, F, G)

240V

230V

*

2

220V

120V

100V

*

2

3

1

0V

L5T18X6X10

TE-278-E2U

4

L5T18X6X10

FG

L5T18X6X10

L5T18X6X10

L5T18X6X10

FG

0V

L5T18X6X10

TE-278-E2U

1

1

2

3

4

U.K.

(D)

5

*

L5T18X6X10

6

L5T18X6X10

FG

240V

230V

220V

120V

100V

0V

TE-278-E2U

*

2

1

L5T18X6X10

(U)

7

(LIMITED AREAS SPEC.)

S–J2875–05

*

L5T18X6X10

L5T18X6X10

FG

240V

230V

220V

120V

100V

0V

TE-278-E2U

*

5

2

1

L5T18X6X10

6

7

8

8

Board No. Drawing No.

E340043POWER SUPPLY

BCDEFGHI JKA

— 30 —

Page 33

ABCD

1

SH1019A

2

1

2

3

4

3

1

2

5

6

7

8

9

101112

1314151617181920212223

24

3

4

VF1SDSESGSFSHDG9

CN1 IMSA-9604S-10C CN2 IMSA-9604S-12C

5

6

ABCD

DG8

DG7

DG6

DG5

DG4

DG3

1

2345678910 123456789101112

Board No.

2ND DISPLAY E278-E2-2

— 31 —

DG2

DG1

DG0

SCOMSASBSCSDP

Drawing No.

4

VF2

5

6

E440039

Page 34

ABCD

1

2

1

3

TO E278-E2

2

1

2

SWI6

3

R ON

PCOM

R OFF

4

5

6

ABCD

Board No. Drawing No.

SWITCH PCB

— 32 —

E440040

4

5

6

Page 35

16. PARTS LIST

1. Main PCB ass'y

2. Button ass'y

3. E278-E2 ass'y, Display ass'y

4. 2nd Display ass'y

5. Upper case

6. Lower case

7. Printer unit

8. Drawer

8-1. DL-2350 (Europe)

8-2. DL-2351 (Canada)

8-3. DL-2416 (U.S.A.)

8-4. DL-2750 (Japan, Germany, Europe)

8-5. DL-2751 (U.K.)

8-6. DL-2752 (Germany)

Notes:

1. Price and specifications are subject to change without notice.

2. As for order / supply of spare parts, refer to the "GUIDE BOOK for spare parts supply" a separate

publication.

3. Numbers in the item column correspond to the same numbers in exploded drawing.

4. MARKS:

N: New parts

Q: Quantity used per unit

M: Minimum order/supply quantity

R: Rank

A: Essential

B: Stock recommended

C: Less recommended

X: No stock recommended

— 33 —

Page 36

— 35 —

Page 37

— 36 —

Page 38

— 37 —

Page 39

— 38 —

Page 40

1-04

1-05

1-07

— 39 —

1-28

1-29

1-08

1-09

1-10 1-21

~

1-02

1-03

1-06

1-13

1-30

1-32

1-01

1-31

Page 41

— 41 —

Page 42

— 42 —

Page 43

— 43 —

Page 44

— 44 —

Page 45

2-05

2-26

2-25

2-07

2-21

2-01

2-91

2-92

2-16

2-93

2-23

2-21

2-07

2-24

2-21

2-29

2-04

— 45 —

2-24

2-14

2-12

2-03

2-20

2-13

2-08

2-81

2-09

2-10

2-16

2-11

2-02

1-01

4-15

1-25

1-26

1-24

1-27

2-06

2-17

3-15

4-01

3-14

3-06

3-12

3-13

3-11

3-10

Page 46

— 47 —

Page 47

— 48 —

Page 48

506

517

406

518

516

405

601

519

600

508

509

505

503

514

507

500

504

502

503

501

611

612

515

512

613

101

513

100

905

906

104

103

102

904

404

410

409

403

411

412

407

427

427

411

431

610

609

428

511

430

433

607

608

417

510

434

416

420

415

520

605

414

606

604

432

421

430

431

427

602

603

203

421

300

204

419

201

427

425

200

429

301

422

202

426

903

424

901

902

302

303

900

423

400

402

401

409

408

418

410

413

— 49 —

Page 49

— 50 —

Page 50

DL-2350

5-01

5-02

5-18

5-15

5-17

5-20

5-19

5-13

5-14

5-12

5-08

5-37

5-16

5-05

5-06

5-07

5-09

5-04

5-22

5-26

5-25

5-36

5-40

5-38

5-23

5-24

5-39

— 51 —

Page 51

— 52 —

Page 52

DL-2351

6-01

6-02

6-17

6-13

6-14

6-18

6-12

6-08

6-37

6-15

6-20

6-19

6-16

6-05

6-06

6-07

6-09

6-04

6-22

6-26

6-36

6-40

6-25

6-38

6-24

6-23

6-39

— 53 —

Page 53

— 54 —

Page 54

DL-2416

7-01

7-02

7-17

7-13

7-14

7-18

7-12

7-08

7-37

7-15

7-20

7-19

7-16

7-05

7-06

7-07

7-09

7-04

7-22

7-26

7-36

7-40

7-25

7-38

7-24

7-23

7-39

— 55 —

Page 55

— 56 —

Page 56

DL-2750

8-01

8-02

8-17

8-14

8-13

8-18

8-12

8-08

8-37

8-15

8-20

8-19

8-16

8-05

8-06

8-07

8-09

8-04

8-22

8-26

8-36

8-40

8-25

8-38

8-24

8-23

8-39

— 57 —

Page 57

— 58 —

Page 58

DL-2751

9-01

9-17

9-14

9-13

9-18

9-02

9-15

9-20

9-19

9-16

9-12

9-05

9-06

9-07

9-09

9-04

9-36

9-08

9-37

9-40

9-25

9-38

9-22

9-26

9-24

9-23

9-39

— 59 —

Page 59

— 60 —

Page 60

DL-2752

10-01

10-17

10-14

10-13

10-18

10-02

10-15

10-20

10-19

10-16

10-12

10-05

10-06

10-07

10-09

10-04

10-08

10-36

10-37

10-40

10-38

10-22

10-26

10-25

10-24

10-23

10-39

— 61 —

Page 61

8-11-10, Nishi-Shinjuku

Shinjuku-ku, Tokyo 160, Japan

Telephone: 03-3347-4926

Loading...

Loading...