Carrier 42CA, 42D, 42CE, 42CG, 42CK Product Data

...

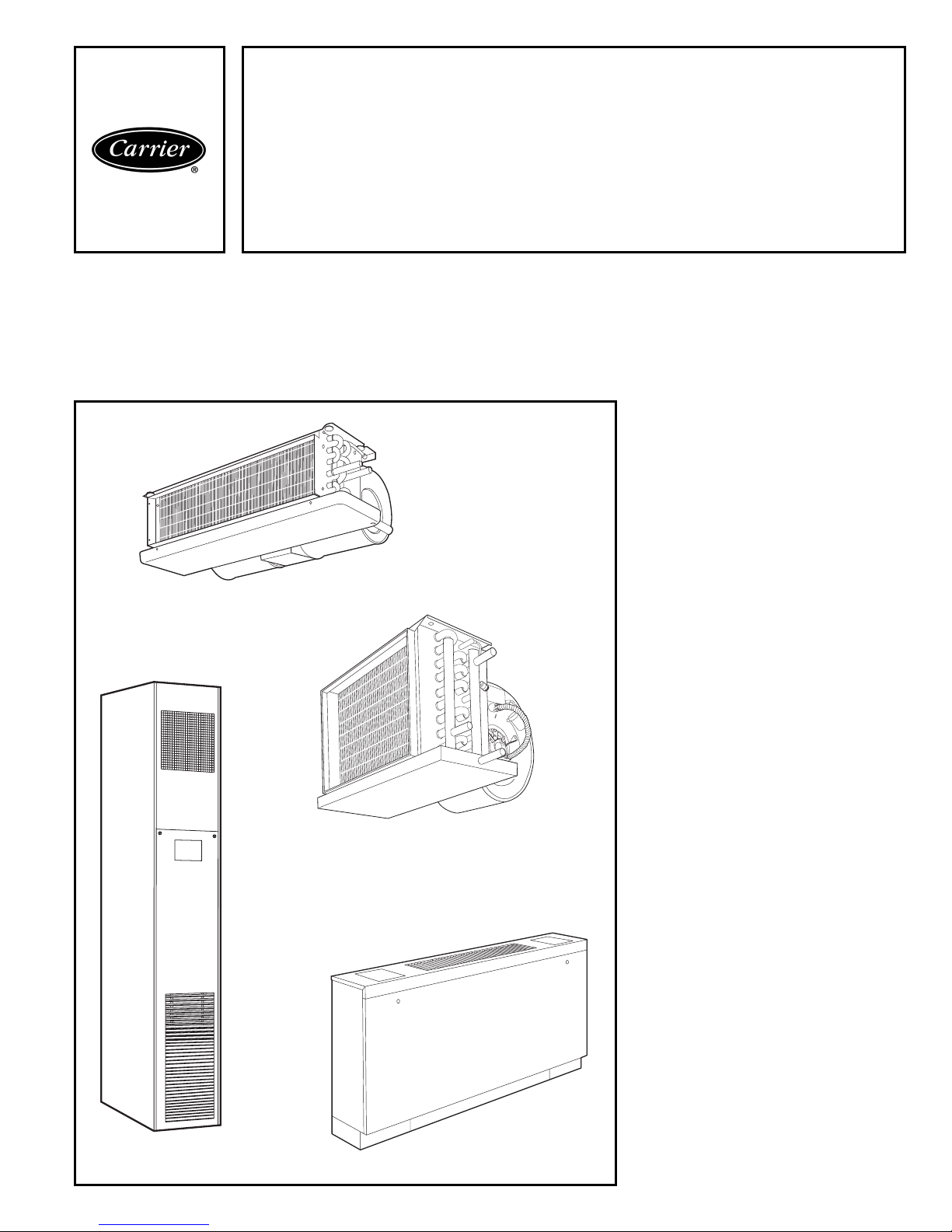

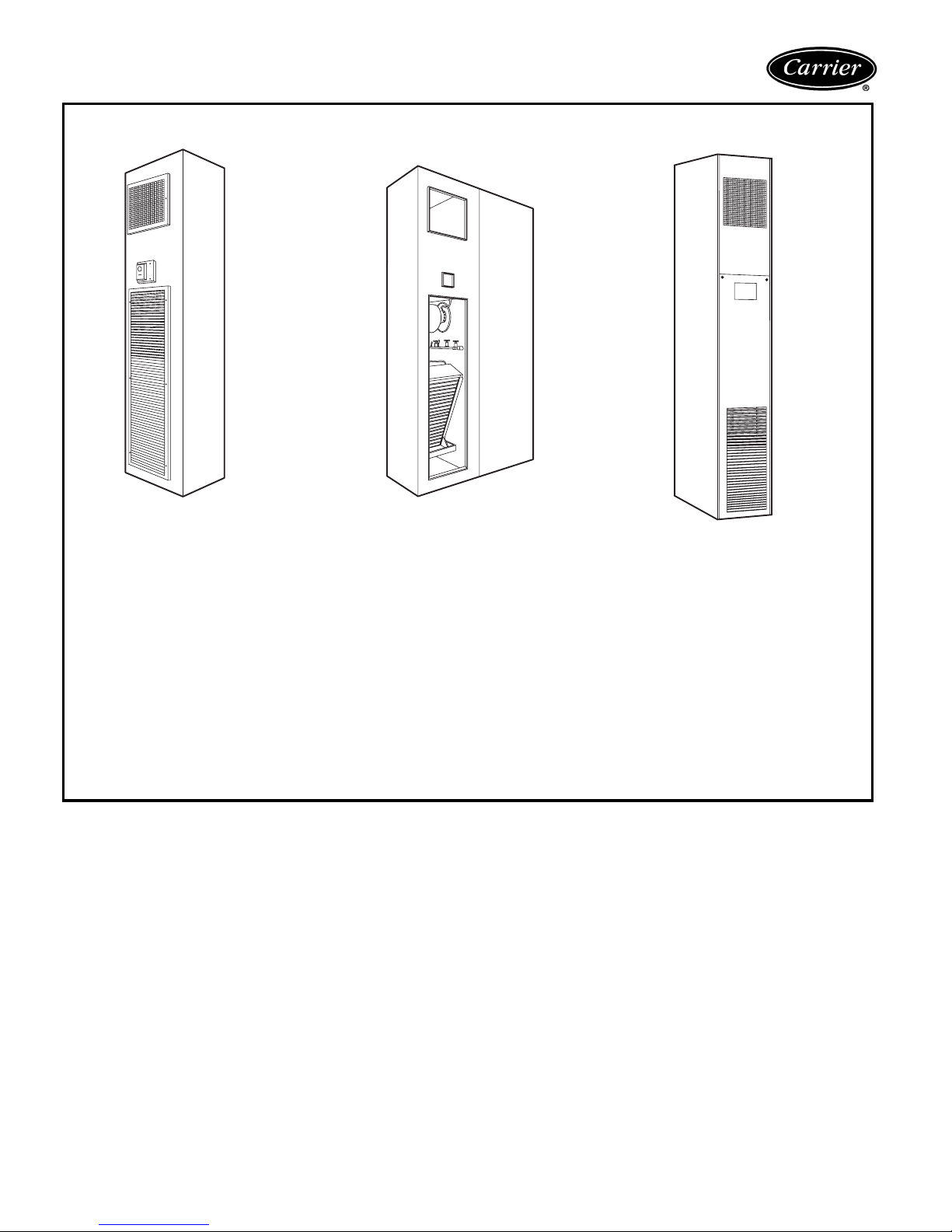

42SH STACK

Product

Data

42CA HORIZONTAL

42DA DUCTED

42VB VERTICAL

42C,D,S,V Series

Fan Coil

Air Conditioners

50/60 Hz

150 to 2000 cfm

Carrier’s 42C,D,S,V Series fan-coil

units combine design flexibility with

easy, low-cost installation.

Features/Benefits

Versatility

If room fan coils are the answer to your

job requirements, choose from Carrier’s

extensive range of superior fan-coil

units.

With Carrier’s 42 series fan coils, you

can select from 5 horizontal, 6 vertical,

5 ducted or 3 stacked models; furred-in

or cabinet style, slant top or low silhouette, in 150 through 2000 cfm capacities. Coils are available with 1, 2, 3, 4,

or 5 rows (depending on model), to

satisfy a variety of application requirements. The units are ideal for installation in motels, apartments, and other

multi-room buildings. Many optional

control packages are available, including

2-pipe heating and cooling, 2-pipe

heating and cooling with auxiliary electric heat, 2-pipe cooling with total electric heat, and 4-pipe heating and cooling. Also offered are manual and automatic changeover controls and several

thermostat options.

Casings and frame are fabricated from

tough, heavy gage galvanized steel. Optional decorative colors allow the unit to

blend with any interior design.

Low-cost installation and

operation

Each unit is designed to occupy a

minimum space. No complex system

controls are required for Carrier fan coil

units. Piping, drain, and wiring connections are readily accessible and mounting holes and slots are pre-drilled to

save installation time and field labor

expense.

Copyright 2004 Carrier Corporation Form 42-2PD

42 Series quality reduces

service and maintenance

expenses

Condensate drain pan is heavy gage

galvanized steel with closed-cell, fire retardant foam insulation. Units come

standard with Tuf-Skin™ II insulation

for energy savings, sound absorption

and Indoor Air Quality (IAQ) preservation. Water never touches the pan, so

corrosion is minimized and long,

trouble-free life is assured.

Efficient operation

All units use permanent split capacitor

motors for minimum electrical consumption. Blower wheels are

centrifugal-type, forward curved,

double width, and double inlet sized

for maximum efficiency.

Quiet, dependable

performance

All units are built to operate unobtrusively with quiet motors and fans. In ad-

1

dition,

/2-in. thick sound-absorbing,

multi-density, matt faced, neoprenecoated fiberglass insulation is used to

line the cabinet.

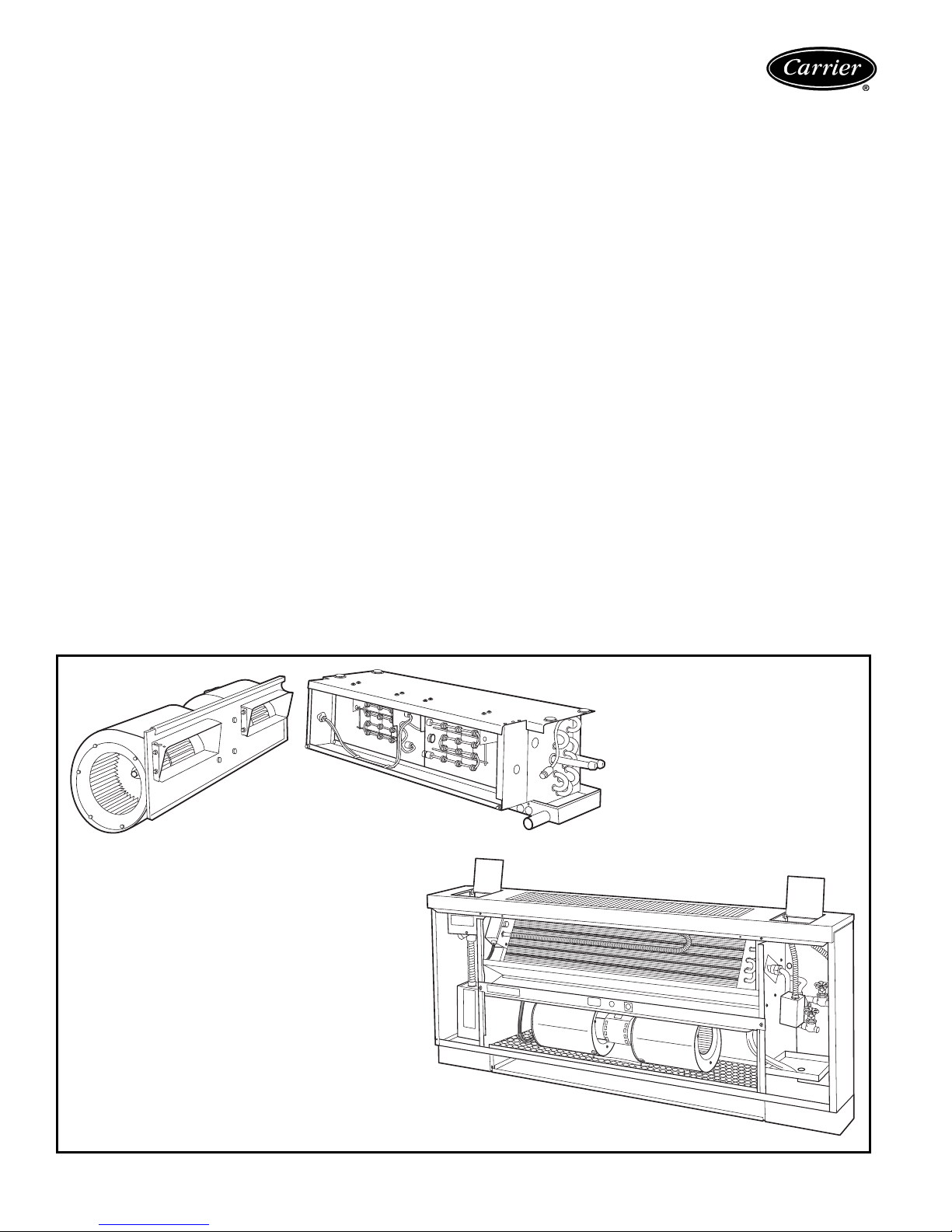

42C series horizontal, 42V

series vertical units

Carrier room fan-coil units operate at

exceptionally low sound levels. A generous amount of insulation absorbs

operating sound and rugged, rigid construction ensures vibration free operation at all fan speeds.

Economical, three-speed fans deliver

just the right amount of conditioned air

for your comfort needs at any load,

and each unit can be shut off when not

in use. Permanent split capacitor motors deliver peak operating efficiency.

By choosing Carrier units, you can

match your application with a wide

range of custom-designed options and

accessories, including electric heat. Filters are cleanable or throwaway type.

Motor bearings are heavy-duty

sleeve type, with oversize oil reservoirs

to assure long bearing life. All coils are

factory leak-tested at 350 psig minimum air pressure.

Carrier room fan-coil units provide

unsurpassed year-round comfort, with

heating and cooling performance

certified in compliance with ARI (Air

Conditioning & Refrigeration Institute)

440-98.

42D ducted units

A drip lip (removable drain pan extension) is provided for field installation on

ceiling models 42DA,DC,DE and DF

when a motorized valve package is ordered. The drip lip is also available as

an accessory for use with other

controls.

Motor/blower assembly can be easily removed from the unit for ease of

service. Removing this assembly provides clear access to the entering air

face of the coil, making coil cleaning a

relatively simple matter. Removable

panels make access to components

and connections easy.

42S stacked units

Each Carrier stack unit comes factoryequipped with insulated supply, return,

and drain risers. The design of the 42S

units allow them to be set one on top

of the other in a vertical column rising

floor to floor up the building. Each

riser has a 3-in. belled section at

the top, so the riser piping can be

connected by only one sweat connection per riser. Field-installed couplings

or internal pipe connections are not

needed.

Each stack unit is factory pre-wired

with all control, motor, and optional

electric heat wiring conveniently terminating in a single, accessible junction

box. Each stack unit requires only one

field power connection.

Field-mounted accessories, such as

the 3-speed switch/thermostat package for furred-in units, are equipped

with a pre-wired quick disconnect plug

for easy installation.

The riser size for the stack units can

be specified to match building requirements so that cutting, sorting, and handling of the risers is not necessary. All

units arrive tagged as specified by the

customer for efficient delivery to the

correct building location.

Units can be loaded onto delivery

trucks so that they can be off-loaded in

the proper installation sequence.

Table of contents

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-25

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

42C,V

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Sound data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,30

Physical Data and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-42

Accessory Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43-47

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-63

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64-66

42D

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Sound data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Physical Data and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68-73

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74-76

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77-86

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87-89

42S

Model Number Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ARI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Sound data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Physical Data and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91-94

Accessory Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95-97

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98-103

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Guide Specifications — 42C Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105,106

Guide Specifications — 42D Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107,108

Guide Specifications — 42S Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109-111

Guide Specifications — 42V Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112,113

Page

2

Features/Benefits (cont)

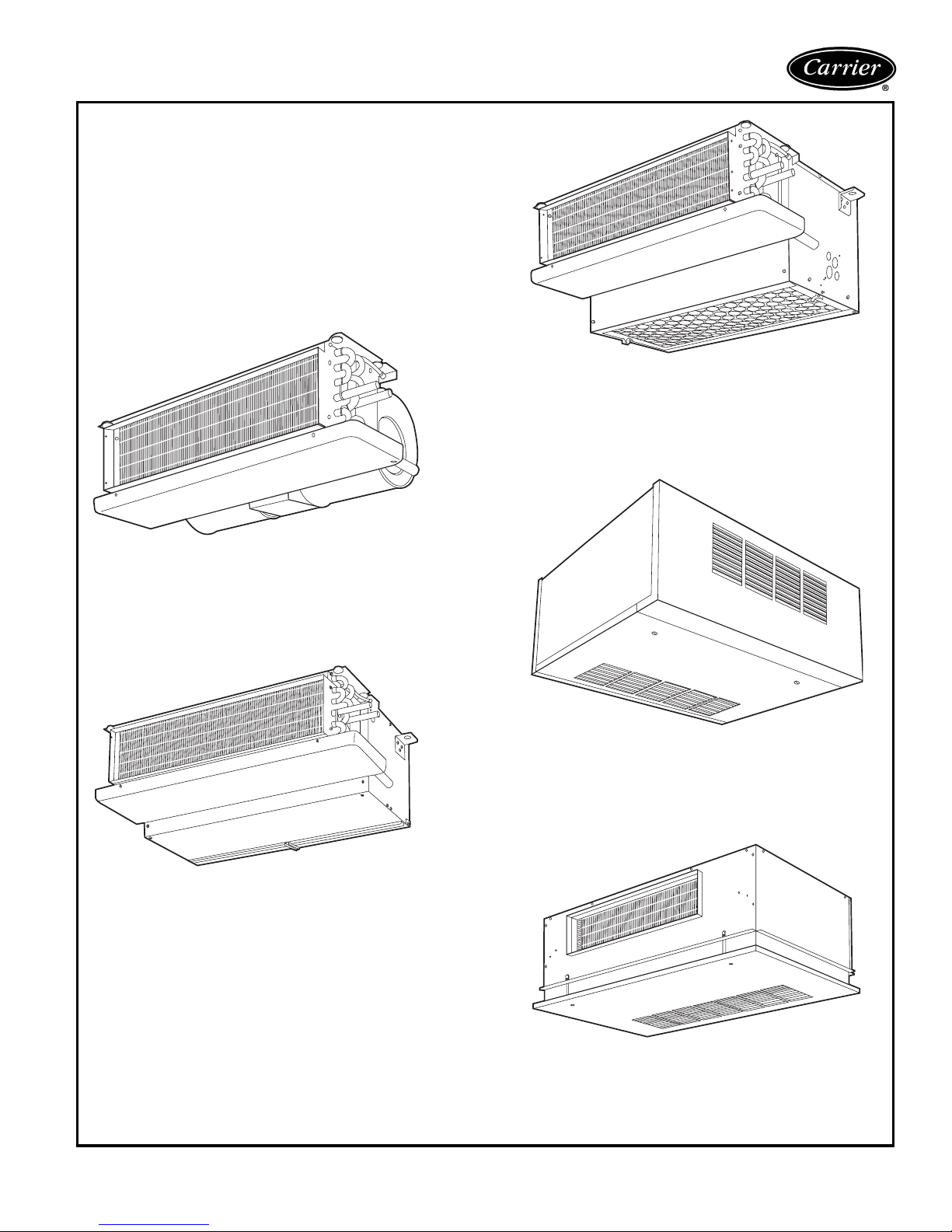

42CF

High-static, furred-in model.

(400-1000 cfm)

42CA

Furred-in ceiling model with low silhouette.

(200-1200 cfm)

42CE

Furred-in ceiling model with factory-installed

plenum.

(200-1200 cfm)

42CG

Cabinet model for under-ceiling mount with

bottom or rear stamped louver return air grille.

(200-1200 cfm)

42CK

Cabinet model with telescoping flip-down panel

and stamped louver bottom return or duct

collar rear return.

(200-1200 cfm)

3

Features/Benefits (cont)

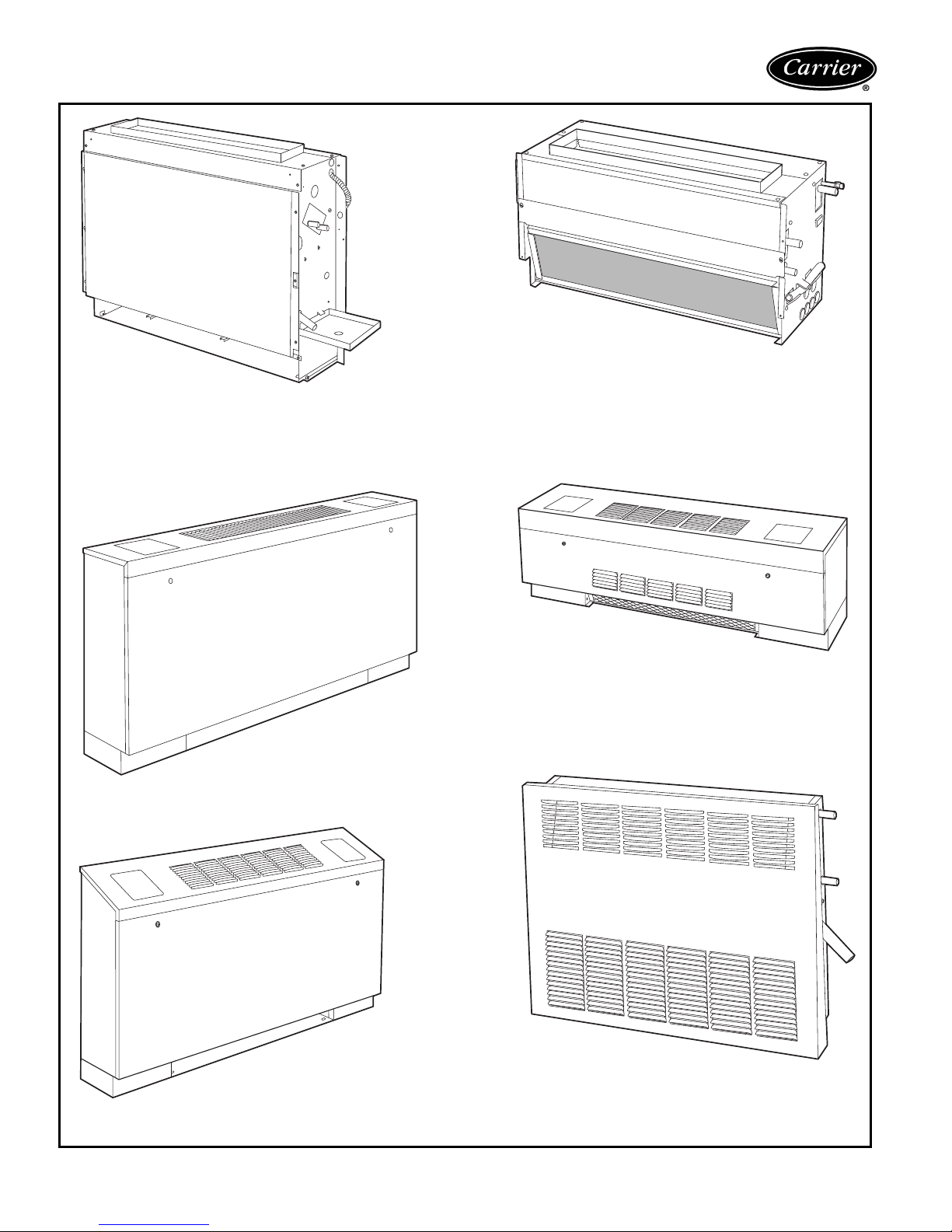

42VA

Furred-in model for under-the-window

applications with top or front discharge.

(200-1200 cfm)

42VC

Furred-in loboy model for concealed under-thewindow applications.

(200-600 cfm)

42VB

Cabinet model with top or

front discharge.

(200-1200 cfm)

42VF

Cabinet model with slant top and

top or front discharge.

(200-1200 cfm)

42VE

Cabinet loboy model with stamped louver discharge grille and 2 control access doors.

(200-600 cfm)

42VG

Furred-in wall model. Available with a 10-in.

valve compartment extension.

(150 and 300 cfm)

4

42DA

Furred-in model for installation in the

ceiling or over the closet.

42DD

Vertical model with galvanized casing.

Commonly for closet installation.

42DE

Ceiling model with galvanized casing.

42DC

Furred-in ceiling model with factory-installed

insulated plenum.

42DF

Exposed-ceiling cabinet model with integral double-deflection discharge grille and

a bar-type return-air grille.

5

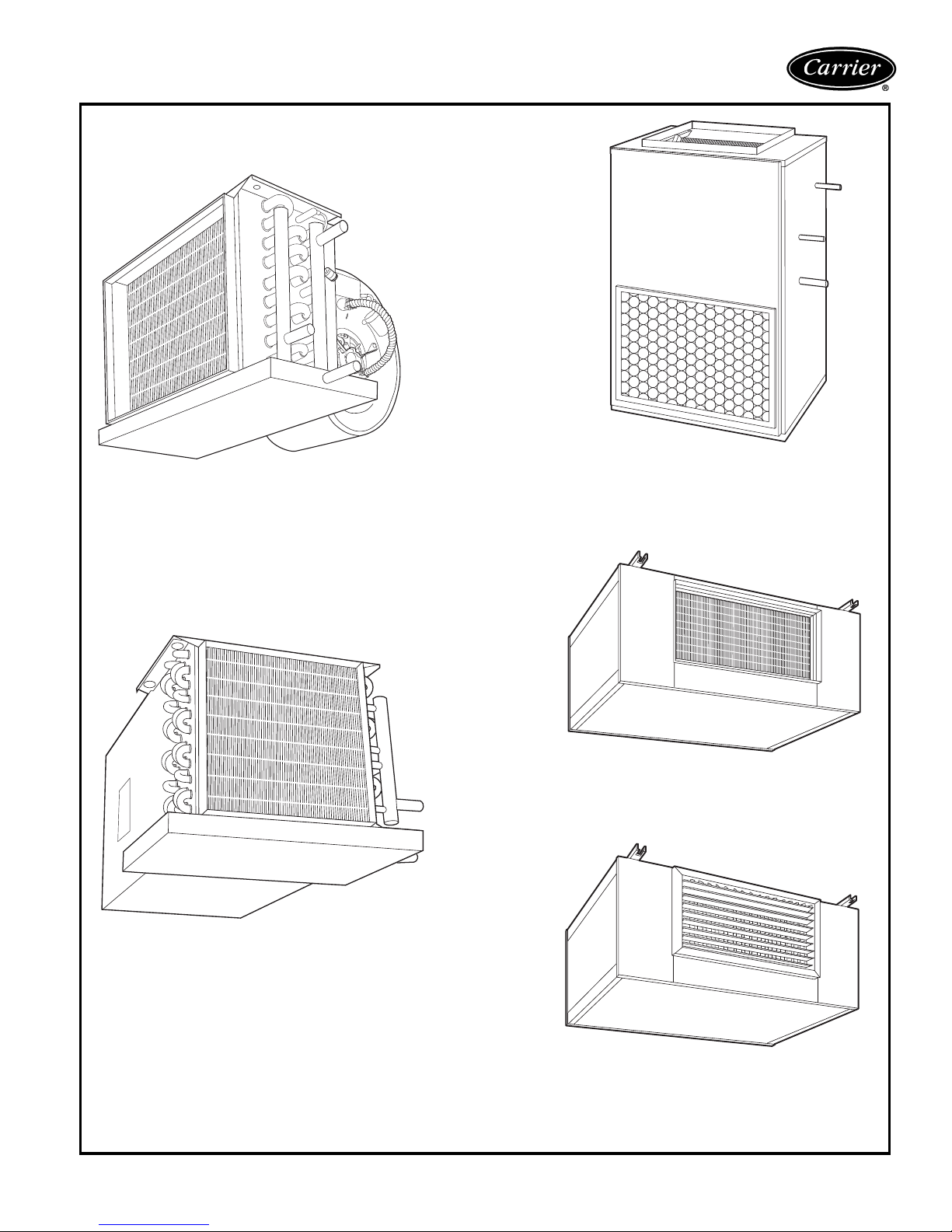

Features/Benefits (cont)

42SG — Furred-in-stack 42SJ — Back-to-back

furred-in stack

The furred-in-stack is a single unit, constructed of 18-gage galvanized steel

designed for concealed applications in

corners or along room walls. After installation of the unit, only the supply-air

grille, room thermostat, and decorative

return-air grille access panel are visible.

The return-air grille is removable to allow

access for servicing major components.

The grille is furnished in a arctic whitecolored enamel-baked finish. Other colors are available.

The 42SG is also available in master/

slave unit pairs. The pairs are actually 2

separate units shipped individually and

installed and piped together in the field.

The master unit includes risers with

stubout for field piping connections to the

slave unit which has no risers of its own.

The back-to-back furred-in stack is

designed for installation in the separation

wall between 2 separate rooms. The unit

is constructed of 18-gage galvanized

steel. The unit consists of 2 separate

units piped to a set of common risers.

Each unit has its own valves and controls. After installation of the unit, only

the supply-air grille, room thermostat,

and decorative return-air grille panel are

visible.

The return-air grille is removable to allow

access for servicing major components.

The grille is furnished in a arctic whitecolored enamel-baked finish. Other colors are available.

42SH — Cabinet stack

The cabinet stack unit is designed for

applications where concealed installations are not possible or practical. The

unit is constructed of 18-gage galvanized steel with a Arctic White-colored

enamel-baked finish. This model features a double-deflection supply-air grille

and an integral return-air grille access

panel. Controls are normally mounted on

the unit but may also be remote wall

mounted.

6

Options and accessories

Factory-installed options

Coils — Choice of a 2-pipe or 4-pipe system with the fol-

lowing chilled/hot water coil configurations:

• 2-Row Coil (42VC, VE, VG only)

• 3-Row Coil - 42C, D, V, S

• 4-Row Coil - 42D, S

• 4-Row High Capacity - 42V, C, S

• 3-Row High Capacity - 42VC, VE

• 3/1 Opposite End Coil Connections - 42C series,

42VA, 42VB, 42VF

• 3/1 Same End Coil Connections - 42C series, 42VA,

42VB, 42VF, 42S

• 2/1 Same End Coil Connection - 42VC, VE

• 3/2 Opposite End Coil Connections - 42C series,

42VA, 42VB, 42VF, 42S

• 3/2 Same End Coil Connection - 42C series, 42VA,

42VB, 42VF

• 4/1 Opposite End Connections - 42D

• 4/1 Same End Connections - 42D, 42S

• 4/1 High Capacity Opposite End Coil - 42C series,

42VA, 42VB, 42VF

• 4/1 High Capacity Same End Coil - 42C series, 42VA,

42VB, 42VF

• 4/2 Same End Coil Connections - 42D

• 4/2 Opposite End Connections - 42D

• 6-Row High Capacity Coil - 42D

• 6/1 Opposite End Connection - 42DA, DC, DE, DF

• 6/1 Same End Connection - 42DA, DC, DE, DF

• 6/2 Opposite End Connections - 42DA, DC, DE, DF

• 6/2 Same End Connection - 42DA, DC, DE, DF

Decorator colors — A wide variety of colors (Champagne Beige, Toffee Brown, Ermine Grey, and Polar

White) are available to match any interior décor. Select a

desired color from a paint chip chart, Catalog number

842-011, or provide paint chip for matching. Standard

color is now Arctic White; the other colors require a special

quote. Decorative colors may be applied to:

• Cabinet of 42VB, VF, VE, VG

• Cabinet of 42CG

• Panels 42S

• Bottom Panels of 42CK

• Wall Panels of 42VA

• Cabinet 42DF

Electric heaters — Coils are of high grade single-phase,

nichrome resistance wire, insulated by ceramic insulators in

plated steel brackets. Heater sizes available are shown in

the application data section for the respective units. Not

available on 42VG units.

Filters — Each unit (except the 42CA, VG unit) includes a

fiberglass throwaway filter sized for low velocity and maximum efficiency. The standard option will filter both returnand outside-air. Optional permanent aluminum filters with

cleanable, non-aluminum filter media are available for

42CE, CF, CG, CK, DC, DD, DE, all 42V series, and all

42S series units.

Manual air vents — Each standard coil includes a manual air vent to allow venting at the coil if necessary for

quick, complete air elimination.

Outside-air opening/damper — Damper is adjustable

from 0 to 25% and provides ventilation air to unit. (Available on 42VA, VB, VF and 42S series units.)

Single power source connection — Provides factoryinstalled junction box to allow use of single power source

for motor and heater when they are of the same voltage.

For 42D and 42S series units.

Stamped toe space return-air grille — (42VB,VF units.)

Tamperproof “Camloc” fasteners — Camloc fasten-

ers are installed on the access panels and are available for

all cabinet model units.

Thermostat control packages — The standard thermostat control option is line voltage. Unit-Mounted line

voltage and 24V thermostats are available on the 42V

series units. For thermostat control package options refer

to pages 10-12.

Field-installed accessories

Automatic air vents — Automatic air vents have fiber

washers which allow air in the pipes to pass through, automatically bleeding the system, and eliminating the need to

manually remove air from the system. When wet, washers

swell and seal the system.

Decorative wall panels — Wall panels are available for

use with fully recessed 42VA units.

Drip lips (removable drain extension) — Drip lips are

frequently used when valves are added after unit installation and space limitations will not permit use of an

extended drain pan. The drip lip is placed on the end of

the drain pan and is pitched toward the pan to ensure

proper drainage. The drip lip gives positive control of condensate from valves and controls on 42DA, DC units (available as an option on 42DE, DF units). Provided as standard

on these units when factory-supplied motorized valve package is ordered. The drip lip is also installed on the 42C

series ceiling fan coil units when 2-way or 3-way motorized

valve packages are ordered.

Panels, frames, and grilles — Panels, frames, and

grilles on the 42S series units can be chosen in a wide variety of combinations to suit room decorating requirements

and allow access to the unit for maintenance. Discharge

grilles are double deflection type, aluminum finish or

painted. Return-air access panels containing return-air

grilles are available in five different types as illustrated on

page 97.

PANELS, FRAMES AND GRILLES

PANEL

NO.

Standard, 18-gage galvanized steel. Coated with baked-on

1

Arctic White enamel finish. Attached to unit with

fasteners.

18-gage galvanized steel. Coated with baked-on Arctic White

2

enamel finish. Includes access door for concealed unitmounted controls.

Bar-type extruded aluminum with frame matching double

3

deflection supply grille. Fastens to wall and unit with 1

long screws.

4

18-gage galvanized steel. Coated with baked-on Arctic White

and

enamel finish. Frame mounted on sheetrock with screws.

5

Panel mounted in frame with

All Each panel provides access to all internal components.

DESCRIPTION

1

/4turn fasteners.

1

/4turn

1

/2in.

7

Options and accessories (cont)

Return-air grilles — Stamped-type return-air grilles are

standard on 42C, V, S units. Anodized aluminum hinged

bar-type grilles are installed on 42CG, CK and DF (available as an option on 42DA, DC, DE, DD) units.

Risers — The 42S series units can accommodate ¾-in.

(supply and return) and 1-in. (drain) to 2½-in. riser sizes in

2-pipe systems. For other applications, such as reverse

return risers or 4-pipe systems, it may be necessary to

accommodate the additional risers.

Condensate drains are available in sizes down to 1-in. for

greater cost economy. Riser size-reducers are factoryinstalled and for risers of over 115-in. length, filler pieces

can be furnished for field installation.

Riser expansion — When necessary, the 42S series

units are provided with factory-installed expansion loops.

These expansion loops provide up to 1 ½-in. of riser

expansion within the standard unit construction. This

means that the unit can be used on installations of up to 20

floors without any additional expansion devices.

Risers material and insulation — The 42S series unit

factory-installed supply, return, and drain risers can be furnished in type M or L copper. All factory-furnished risers

are insulated with flexible closed foam insulation in ½-in. or

¾-in. thickness.

Supply-air grilles — Two types of double deflection

supply-air grilles are available for horizontal and vertical

units; an integral steel grille painted to match the unit or a

separate unpainted anodized aluminum grille. Not applicable to 42VG units.

Tell-tale drain pan — A secondary drain connection is

located above the primary drain to act as a “tell-tale” in the

event that the primary drain becomes obstructed. They can

be applied to either the main drain pan or an extended

main drain pan. This option only available on the 42C,

42V (except 42VG), and 42DA, DC, DE, DF.

Thermostats control packages — The standard thermostat control option is line voltage. Wall-mounted line

voltage and 24-v thermostats are available on the 42 series

fan coil units. 24-v thermostat is not available on the

42VC,VE,VG unit. Thermostat control packages options

refer to page 10-12.

Trim strips — Strips are available for use with partially

recessed vertical 42VA units and 42S only.

Wall boxes — Wall boxes are all aluminum with insect

screen behind louvers. The wall boxes are available on all

42V series units except the 42VG units.

DRIP LIP

(Horizontal Unit)

“TELL-TALE” DRAIN PAN

(Horizontal Unit)

8

AVAILABLE OPTIONS AND ACCESSORIES

FAC TORY-INSTALLED OPTIONS AND

FIELD-INSTALLED ACCESSORIES

AIR VENT

Automatic Air Vent •••••••••••••••• • • •

Manual Air Vent Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

CABINET CHANGES

Front Panel, 16 Gage ••

Front Panel, 18 Gage Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

Extended Cabinet w hen Electric Heat

or Valves are Installed

Valve Compartment Extension, 10 in. •

Stamped Toe Space Return Gr ille ••

COILS

2-Row (Cooling Only) Std Std Std

3-Row (2-Row Cooling, 1-Row Heating) ••

3-Row (High-Capacity) Std Std Std Std Std Std Std Std • • • • • • • Std S td Std

4-Row (3-Row Cooling, 1-Row Heating) • ••••••• ••••• • • •

4-Row (High-Capacity) • ••••••• StdStdStdStdStd• • •

5-Row (4-Row Cooling, 1-Row Heating) •••••••• ••••• • • •

5-Row (3-Row Cooling, 2-Row Heating) •••••••• •••••

6-Row (4-Row Cooling, 2-Row Heating) •••••

6-Row (High-Capacity) •••••

7-Row (6-Row Cooling, 1-Row Heating) •••••

8-Row (6-Row Cooling, 2-Row Heating) •••••

DAMP ERS

Manual — Adjustable through Return

Air Opening

Manual Adjustment, Remote Mounted ••• • • •

Manual — Rear Opening with ••• • • •

Sliding Damper — No t Filtered •••

Outdoor Air Connection (6 in.), with

Filter and with or without Damper

Damper, Linkage and Motor Wired to

Auxiliary Contact o f 3-Speed Swit ch

DECORATIVE COLORS

(See Carrier Fan Coil Paint Sele ctor

Guide)

DISCHARGE GRILLES

Stamped Front Discharge Std Std Std Std Std

Double Deflection, Installed ••••

Double Deflection, Shipped Loose • • • • Std Std Std Std Std Std Std Std

DRAIN PANS

Sprayed on Closed-Ce ll Foam on Inside

Main Drain Pan

Auxiliary Plastic Drain Pan Std Std Std

Auxiliary Steel Drai n Pan Std Std

AuxiliaryDripLip—Includedwith2-or

3-Way Motorized Valves

Tell-Tale, with Second Drain Connection •••••••••• ••••

Stainless Steel •••••••••••••••• • • •

DUCT COLLAR

Discharge Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

ELECTRIC HEATERS

Nichrome Wire Strip Heater ••••• ••••• • • •

Sheath Type Heater •••••

FAN SW ITC H

Unit-Mounted, Wired and Installed Std Std Std Std S td Std

Wall-Mounted with Plate for

Field-Mounting

FILTERS

Permanent Filter •••• ••••• •• • • • •

Throwaway Filter Std Std Std Std Std Std Std Std Std

LEVELING LEGS • • • • • Std Std Std Std Std Std Std

INSULATION

Foil Faced Insulation •••••••••••••••• • • •

Tuf -S kin II Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

Tuf-Skin RX Insulation •••••••••••••••• • • •

MOTORS

120-1-60, 3-Spee d Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

208-1-60, 3-Spee d •••••••••• ••••• • • •

230-1-60, 3-Spee d •••••••••• ••••• • • •

277-1-60, 3-Spee d •••••••••• ••••• • • •

220-1-50, 3-Spee d •••••••••• ••••• • • •

MOTOR QUICK-DISCONNECT PLUG Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

OUTSIDE-AIR WALL BOX •••

RETURN AIR GRILLE, Shipped Loose

Stamped Return Grille Std Std Std Std Std Std Std Std Std Std Std Std Std Std

Hinged Panel Std Std • • • Std •

TAMPERPROOF LOCKS (Camloc)

Access Panels ••• •• • • •

Access Doors ••• ••

VALVE PACK AGE S •••••••••••••••• • • •

WALL PANELS (for Recessed Unit) •

WIRING PACKAG ES •• •••••••••••••• • • •

• — Available as a Factory-Installed Option or a Field-Installed Accessory

Std — Stan dard

AVAILABLE

LEGEND

Ceiling — Horizontal Floor — Vertical Ducted — Horizontal Stack — Vertical

CA CE CG CK CF VA VB VF VC VE VG DA DC DE DF DD SG SH SJ

••• • • •

•••

•••

•• ••• •• • • • •

Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

••••• StdStd••

Std Std Std Std Std Std Std Std Std Std Std Std Std

UNIT SERIES — 42

••

9

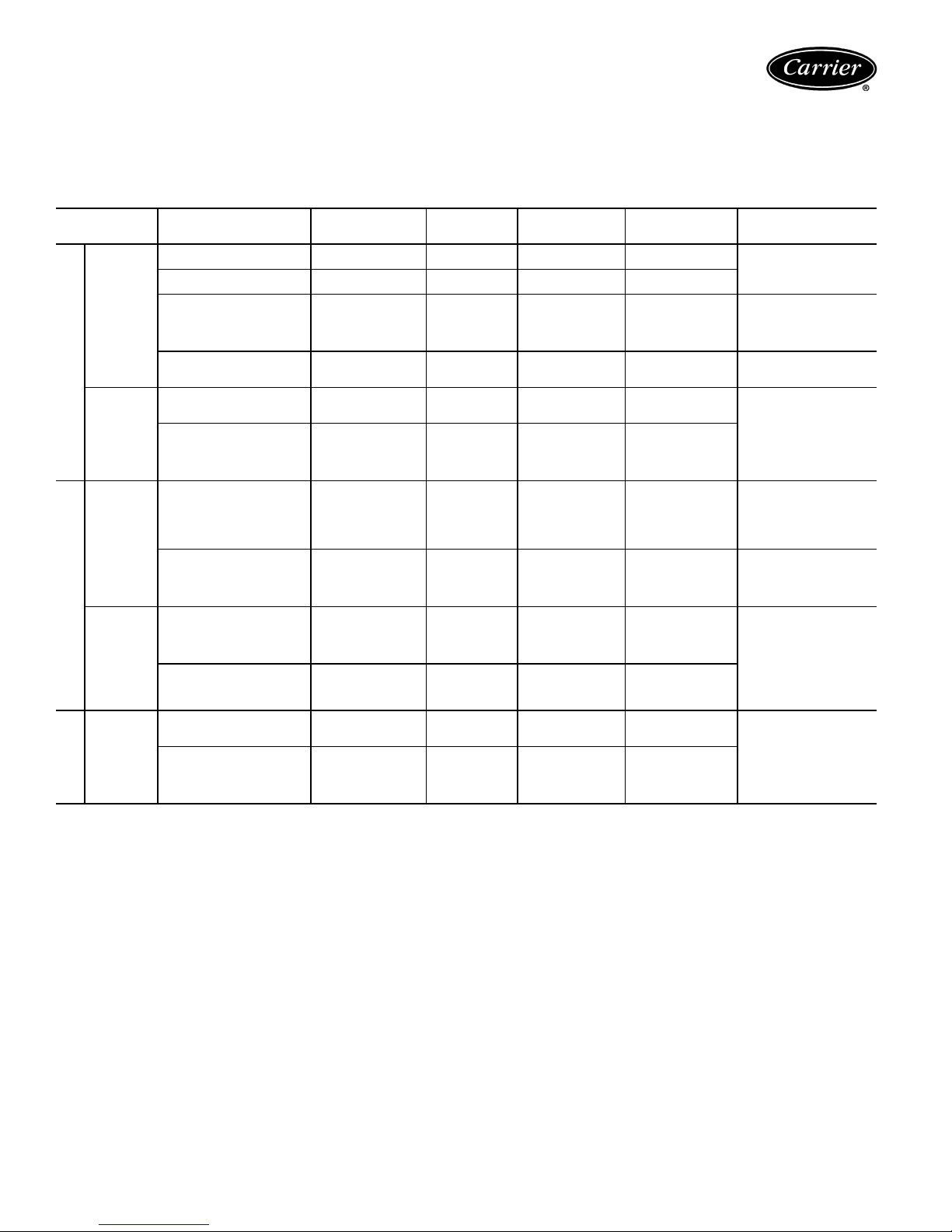

Controls

Use the Control Selection guide to make sure that all

necessary components are provided for and that the components are compatible with the required control system.

NOTE: When thermostatic fan control is selected or when

unit outside air dampers are used, unit-mounted thermostats are not recommended as their use will result in poor

room temperature sensing.

CONTROL SELECTION GUIDE

SYSTEM DESCRIPTION THERMOSTAT

Fan

Control

(2-Pipe)

Twoposition

electric

valves

2-PIPE HEATING-COOLING*

(2-pipe)

Twoposition

electric

valve with

Auxiliary

Electric

Heat

(2-pipe)

Twoposition

electric

ELECTRIC HEAT

valve with

total

electric

heat

(2-pipe)

Twoposition

electric

valves

(4-pipe)

4-PIPE

*If system is HEATING-ONLY or COOLING-ONLY, no changeover or bypass is required.

NOTE: Unit-mounted thermostats are not recommended with either fan-cycle control or applications with outside air dampers.

Fan manually cycled None None None Standard 3-SpeedSWNot recommended

Thermostat cycles fan on-off

from speed set with fan switch.

Thermostat cycles fan on-off

from fan speed set with switch.

Mode automatically switched

by changeover sensing water

temp.

Thermostat cycles fan from

high to low on cooling and low

to off on heating.

Thermostat cycles valve

open or closed.

Thermostat cycles valve

open or closed. Mode automatically switched by

changeover sensing water

temp.

Thermostat cycles valve

open or closed. 2° F after

valve closes, thermostat

activates electric heater.

Heater cannot turn on if hot

water is in coil.

Thermostat cycles valve

open or closed. Manual

changeover switch changes

thermostat to heat to activate

electric heater.

Thermostat cycles valve

open or closed. Manual

changeover switch changes

thermostat to heat to activate

electric heater.

Thermostat cycles valve

open or closed. 2° F after

valve closes, thermostat activateselectricheater.

Thermostat cycles cooling and

heating valves open or closed.

Thermostat cycles cooling

valve open or closed. 2° F

after valve closes, thermostat

cycles heating valve open or

closed.

Wall mounted includes

heat-cool switch.

Wall moun ted.

Heating/cooling

Thermostat

Wall or unit mounted Yes None No Standard 3-Speed

Wall mounted includes

heat-cool switch.

Wall or unit mounted.

Heating/cooling

Thermostat

Wall or unit mounted.

Sequenced heating

and cooling.

Wall moun ted

includes heat-cool

switch.

Wall mounted includes

heat-cool switch.

Wall or unit mounted.

Sequenced heating

and cooling

Wall mounted includes

subbase with heatcool switch.

Wall or unit mounted.

Sequenced heating

and cooling.

CHANGEOVER

ON

SUPPLY PIPE

None None Thermostat has inte-

Yes None Standard

None Motorized (N.C.)

Yes Motorized (N.C.)

Ye s .

Two Required.

None Motorized 3-way or

None Motorized (N.C.)

None Motorized (N.C.)

None Motorized (N.C.)

None Motorized (N.C.)

VALVE

3-way or 2-way,

no bypass required.

3-way or 2-way

Motorized 3-way or

2-way

2-way, no bypass

required

3-way or 2-way,

no bypass required

3-way or 2-way,

no bypass required

3-way or 2-way

(requires 2 valves)

3-way or 2-way

(requires 2 valves)

gral 3-Speed SW

3-Speed SW

Switch, ON-OFF toggle SW only

Thermostat has integral 3-Speed SW

Standard 3-Speed

SW. Others have thermostats with integral

3-Speed SW

Standard 3-Speed

SW. Others have thermostats with integral

3-Speed SW

Thermostat has integral 3-Speed SW

Thermostat has integral 3-Speed SW

Standard 3-Speed

SW

Thermostat has integral 3-Speed SW

Standard 3-Speed

SW. Others have

thermostats with integral 3-Speed SW

FA N

SWITCH (SW)

NOTES

for high humidity

application

Unit-mounted thermostats

provide very poor room

temperature control

Best fan cycle control for

high humidity applications

Valve packages with belled

end(s) for field soldering to

coil.

Valve packages with belled

end(s) for field soldering to

coil.

Valve packages with belled

end(s) for field soldering

to coil.

Valve packages with belled

end(s) for field soldering

to coil.

Valve packages with belled

end(s) for field soldering

to coil.

10

Remote-mounted controls

Standard 3-speed switch — This standard switch has 4

positions: OFF, HIGH, MEDIUM, and LOW. Switch has

auxiliary contact that is energized when switch is in HIGH,

MEDIUM or LOW position.

Some of the options common with the 3-speed switch are:

1. Unit-mounted switch on Furred-In Vertical Model.

(Available as special order on Horizontal Models)

2. Switch without OFF position.

3. Key-operated switch.

Optional remote-mounted thermostat

Line voltage T155 thermostat — Features 50 to 90 F

temperature range, manual 3-speed fan control, mount is a

standard 2 x 4 in. box, 4-pipe, 2-pipe and autochangeover

applications. Available in vertical or horizontal styles.

Unit-mounted controls

MED

HI

F

F

O

LO

Standard remote-mounted thermostat or

optional unit-mounted thermostat

R

COOL

AUTO

HEAT

24-V Debonair® thermostat — Features large Thermoglow™ display, Neverlost™ memory, Exact Fit™ locking

cover, Smart Fan™ dynamic fan speed control, 4-pipe,

2-pipe automatic changeover applications with adjustable

dead band. Programmable and non-programmable models

available.

Standard 3-speed switch — Switch has OFF, HIGH,

MED and LOW positions. Switch is also equipped with

auxiliary connection energized when switch is in HIGH,

MED or LOW position.

MED

HI

OFF

LO

Combination thermostat/3-speed switch — Includes

thermostat for 2-pipe or 4-pipe system and standard

3-speed switch. Thermostat and 3-speed switch are unitmounted in a common electrical junction box. The special

combination allows for the fan coil unit to have control for

the valve cycle only.

11

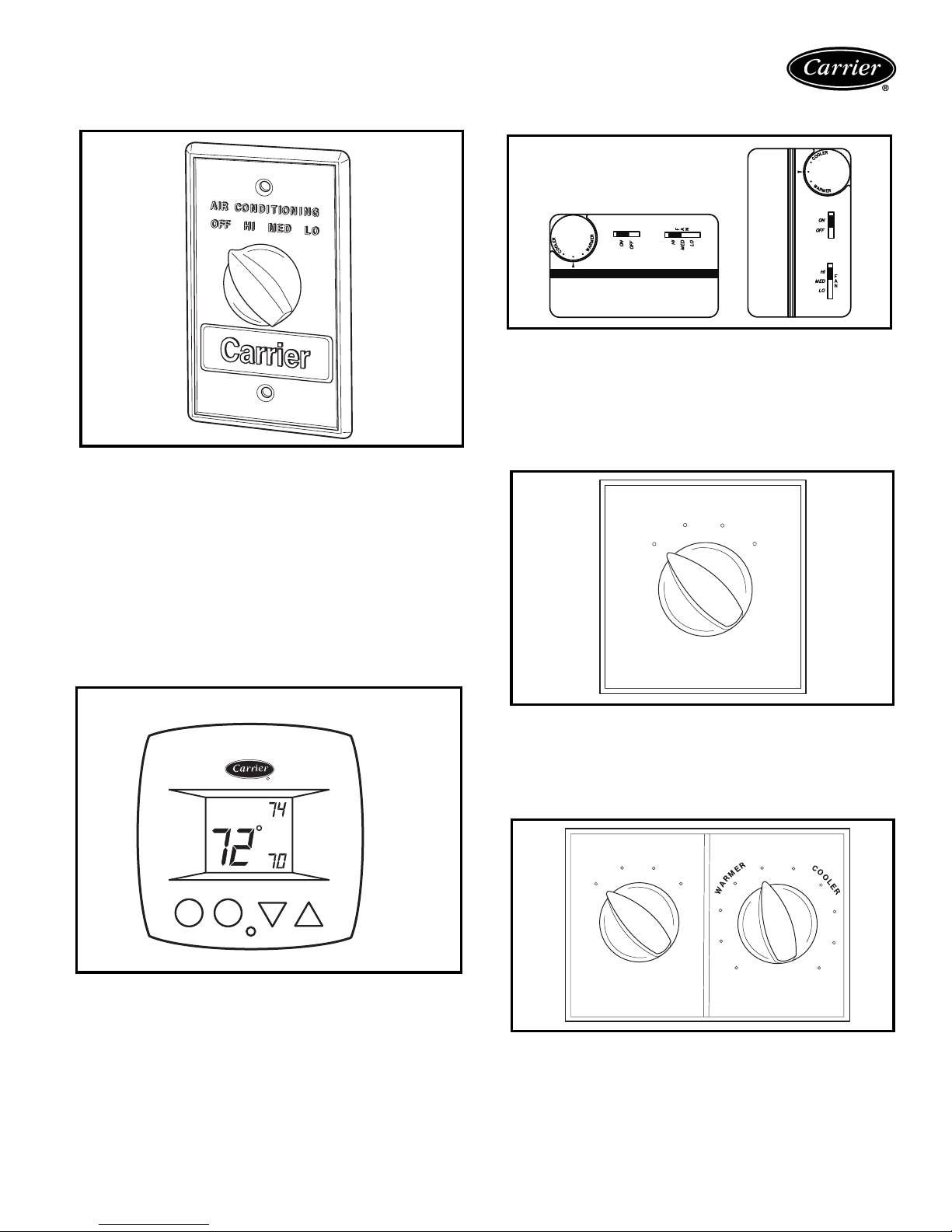

Controls (cont)

Four-pipe thermostat, model TH104 — With this

thermostat, heating and cooling are sequenced (automatic

changeover) with 6 degree separation between HEATING

ON and COOLING ON. The standard temperature range

is 60 to 90 F.

Two-pipe thermostat, model TF103 — Single-pole

double-throw (SPDT) thermostat has snap action contacts.

The standard temperature range is 60 to 90 F.

Automatic changeover (Summer-Winter switch) —

The automatic-changeover thermostat is a single-pole

double-throw (SPDT) thermal switch in a moistureproof

and dust-proof enclosure. Thermostat mechanism and lead

ends are hermetically sealed in a polypropylene enclosure

with epoxy resin. Device clamps on coil supply pipe with

end snap-on clip.

The set point temperatures are factory set. When water

temperature rises above 80 F (approximately), the thermostat switches to the winter cycle. When water temperature

drops below approximately 70 F, the thermostat switches

to the summer cycle. Switch reset is automatic.

Fan coil control relay board — The fan coil relay board

is used in conjunction with the Debonair thermostat or a

CCN fan coil controller to regulate a single-speed or multispeed fan. The fan coil relay board can also be used to connect the fan coil controller to a line voltage valve actuator.

The fan coil relay board is factory shipped as a PC board

with four

1

/2-in. stand-offs attached for field mounting.

NOTE: One fan coil relay board is used for each application. Fan coils with two or more fan motors use a fan coil

relay board for each fan motor. A maximum of three fan

coil relay boards can be wired to one fan coil control.

G

G2/(W)

G3/(Y)

COM

FAN

(VALVE)

(COOL)

HI

(HEAT)

MED

LO

AUTOMATIC CHANGEOVER

(Summer-Winter) SWITCH

12

STEMCO

416-79

L80 8220

Application data

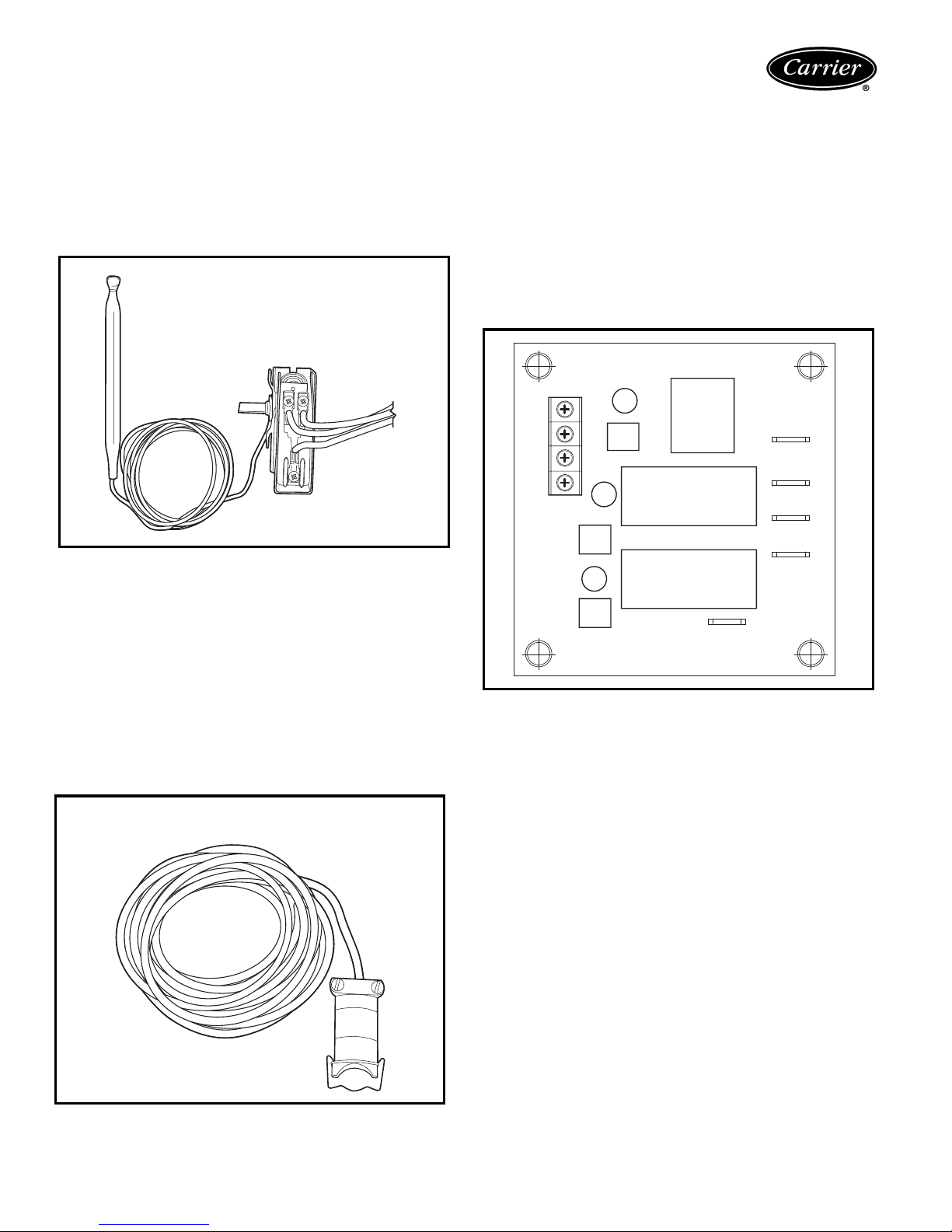

Basic definitions

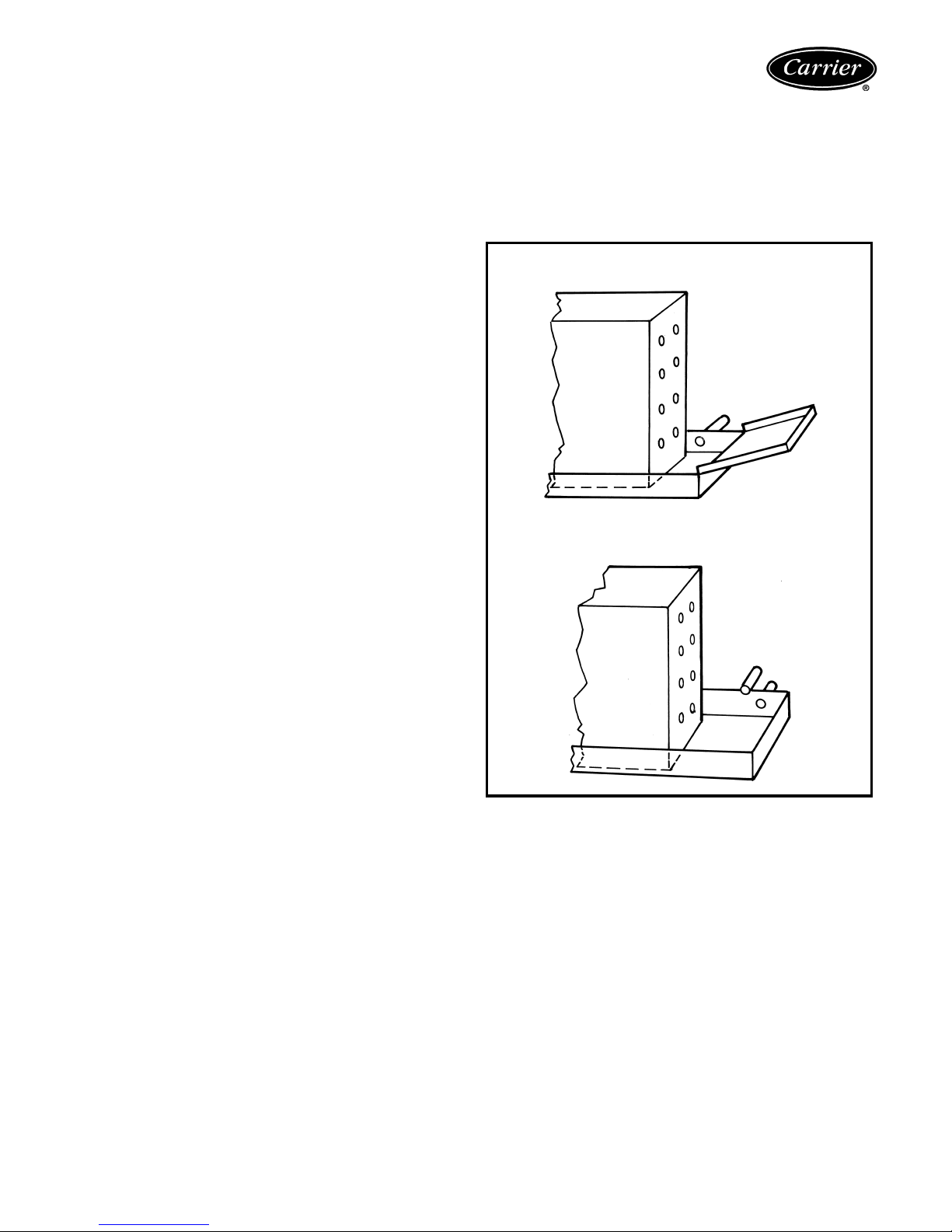

Unit hand — When facing the supply air outlet from the

front of the unit (air blowing in your face), your right hand

will be the right hand side of the unit and your left hand the

left hand side of the unit.

UNIT HAND

Same end connection (2 pipe or 4 pipe) — All piping

connections are on the same end (side) of the unit. Controls and electrical connection will be on the end (side)

opposite the piping connection.

Standard 2-pipe units will be the same end connection.

Opposite end connection (4-pipe option) — Hot

water (HW) piping connections and electrical will be on the

end (side) opposite the chilled water (CW) and drain

connections.

OPPOSITE END CONNECTION

SAME END CONNECTION

NOTE: Piping determines the hand of the unit.

NOTE: Chilled water piping determines the hand of the unit.

13

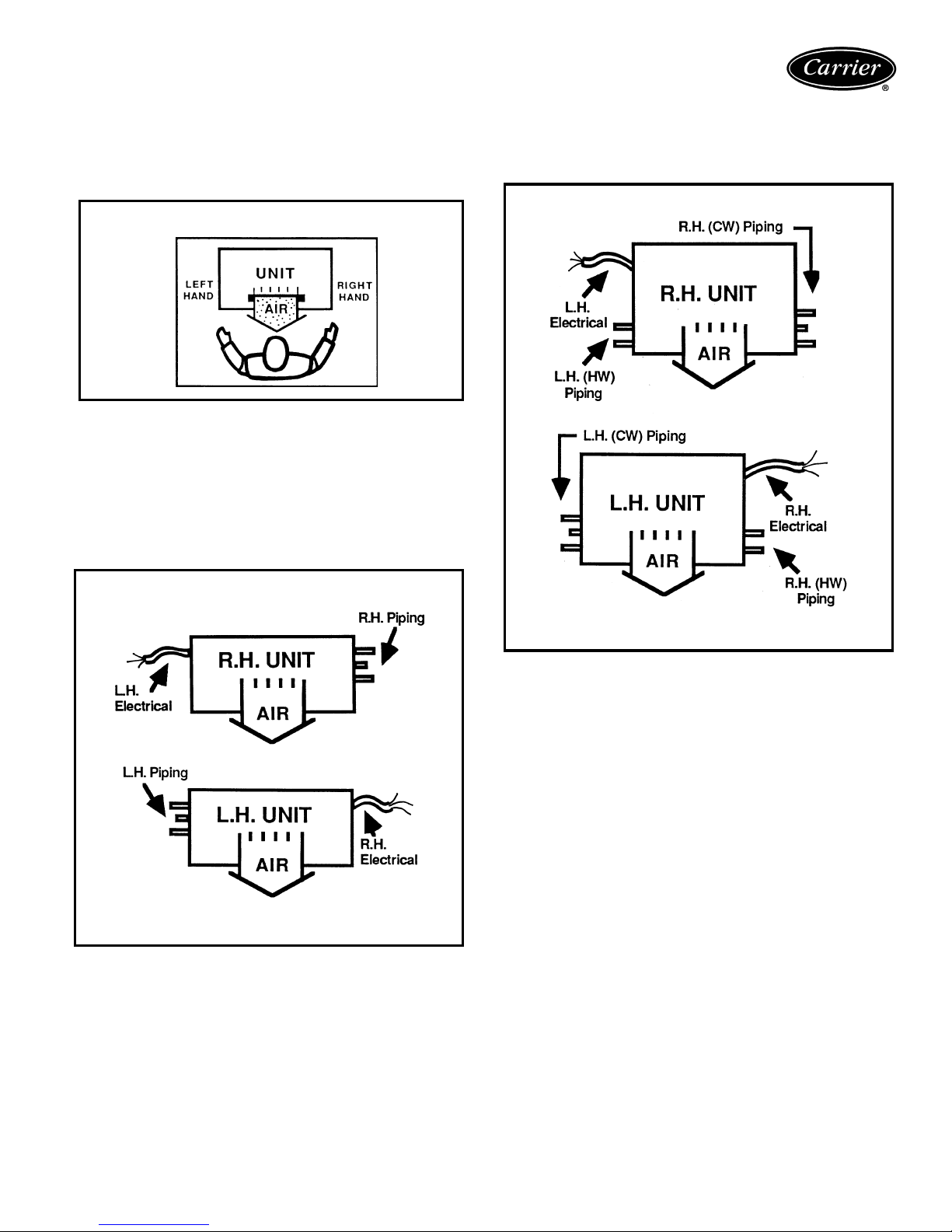

Application data (cont)

System piping

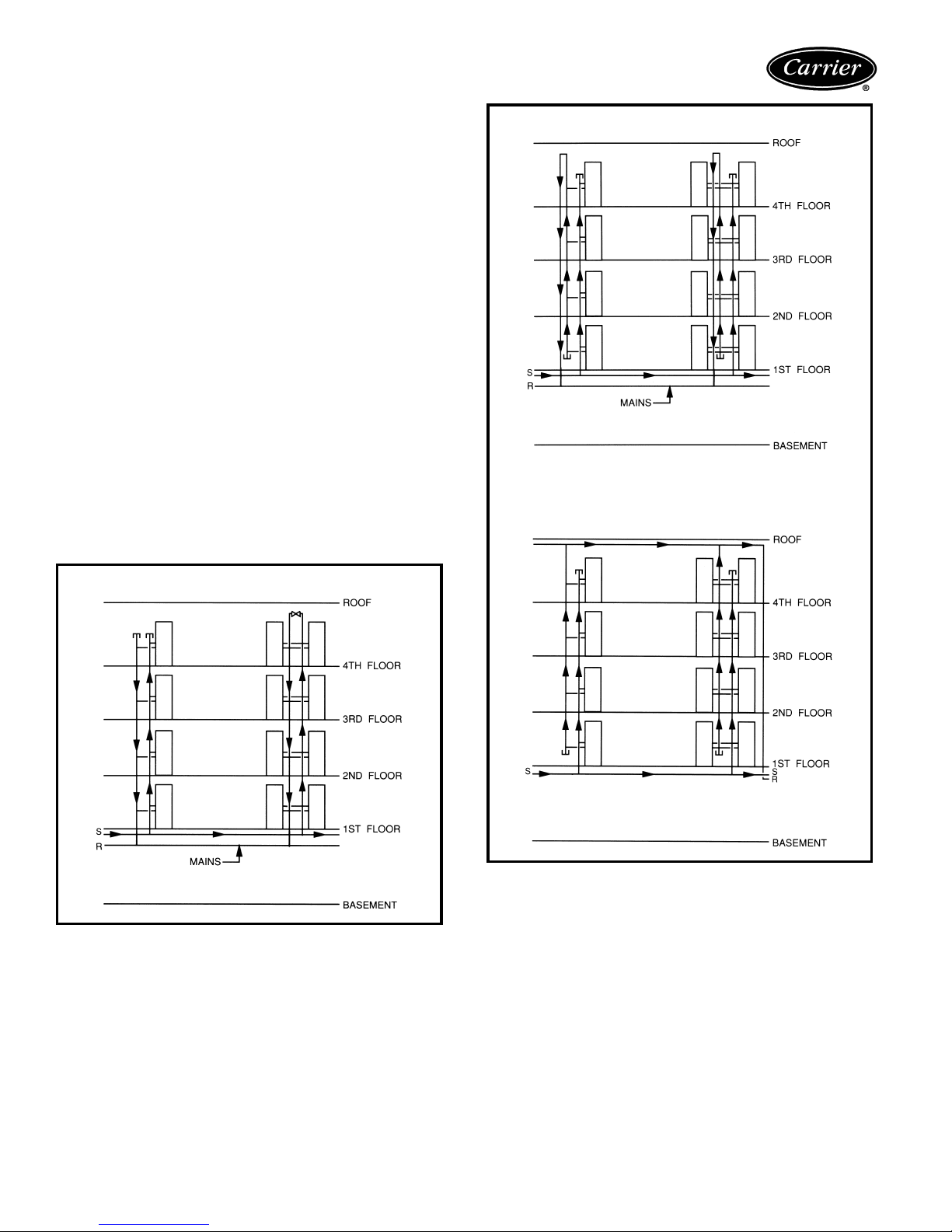

The following diagrams show some common methods

used to pipe the 42S series units. Only the 2-pipe systems

are shown; however, the methods would be the same for

4-pipe systems.

System 1, the “direct return” system, is the most common.

It is economical to install since it supplies and returns the

water for a riser column from the same location, at the top

or the bottom of a building. This type of riser arrangement

does require more attention to individual unit water flow

balancing. The risers are normally capped at the end as

shown in the diagrams.

System 2, the “reverse return” system, is used to minimize

the requirement for individual unit balancing. This system

is usually referred to as the self-balancing system. The

arrangement of the risers allows the water flow for each

unit in a column to be equalized. In the reverse return system both the supply and return mains are located at the

top or the bottom of a building requiring an additional

return riser to be furnished in the units.

System 3, the “common reverse return” system, typically

has the supply and return mains located remotely from

each other — such as one at the top and one at the bottom

of a building. This eliminates the need for a reverse return

riser in the units.

SYSTEM 2 — REVERSE RETURN

SYSTEM 3 — COMMON REVERSE RETURN

SYSTEM 1 — DIRECT RETURN

14

Risers

Riser diameter is an important consideration in the design

of stack series systems. Standard units can accommodate

3

/4-in. to 21/2-in. riser sizes in 2-pipe systems. For other

applications, such as reverse return risers or 4-pipe systems, it may be necessary to accommodate the additional

risers.

Riser size is based on the water flow needed for a given

tier of units. Unit risers are sized according to the diameter

and length requirements as specified by the customer. To

determine riser size, water velocity should be limited to 5 to

8 ft/second. Thus, if 10 units are to be stacked vertically

with each unit requiring 3 gpm, the maximum flow in the

risers is 30 gpm. Through 1

of 7.5 ft/second. The maximum flow rate of 30 gpm

occurs only at the supply and return points. As the water

moves upward, the flow in the supply riser is reduced by

3 gpm per floor, so that after 3 floors, the total flow is

21 gpm and riser size can be reduced to one inch. See

chart on page 103.

1

/4 in. risers, this is a velocity

Condensate drains are available in sizes down to one

inch for greater first cost economy.

Riser size-reducers are factory installed and caps are pro-

vided at customer request.

For risers of over 115 in. length, filler pieces can be fur-

nished for field installation.

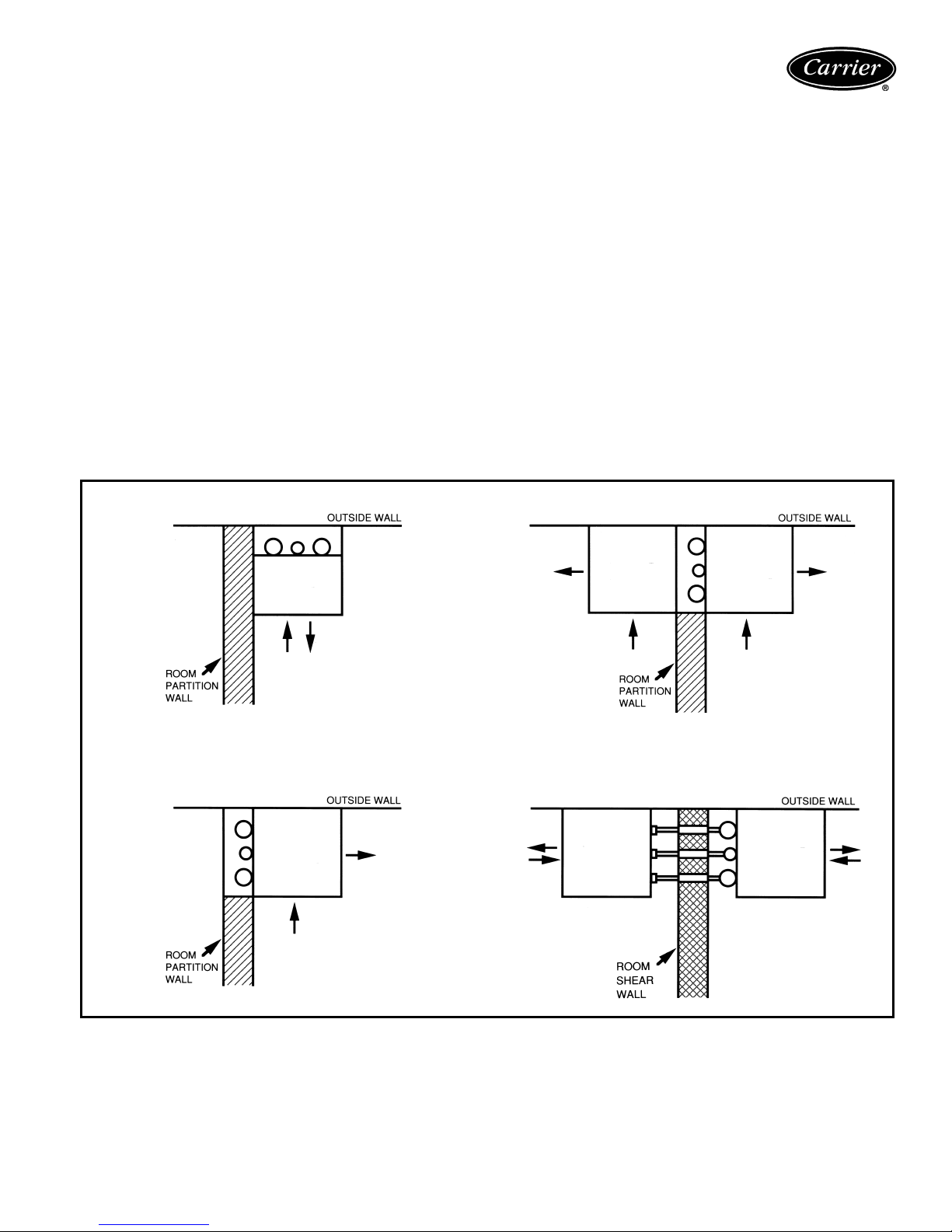

Typical arrangements

Typical arrangement applications for each model type are

shown below. The fan coil units feature almost an unlimited number of arrangements to meet the needs of new

construction, renovation, or reconstruction. Consult the

factory for the arrangement (standard or special) to meet

your particular need.

42SH — EXPOSED CABINET

42SG — FURRED-IN STACK

42SJ — BACK-TO-BACK FURRED-IN STACK

42SG — FURRED-IN STACK MASTER/SLAVE UNIT

15

Application data (cont)

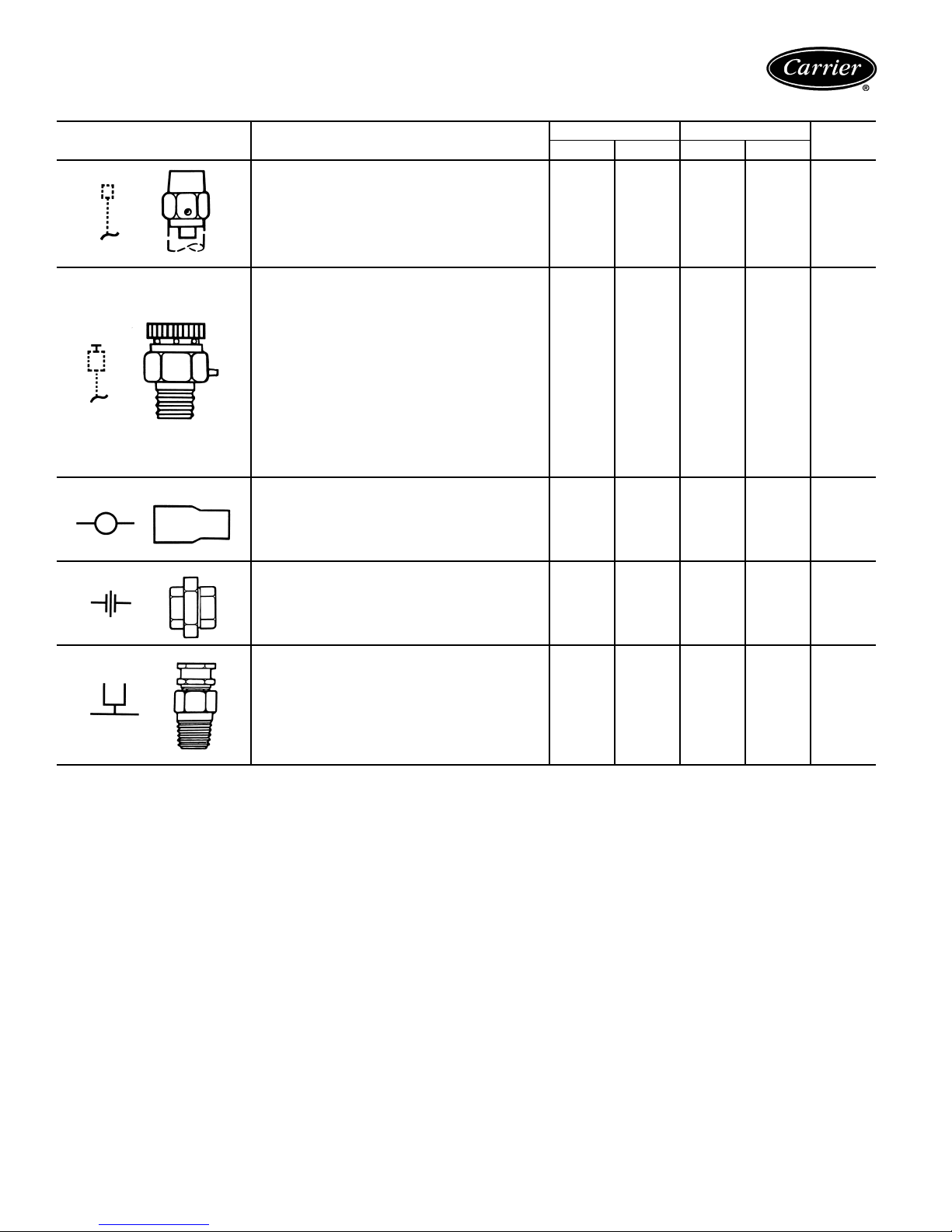

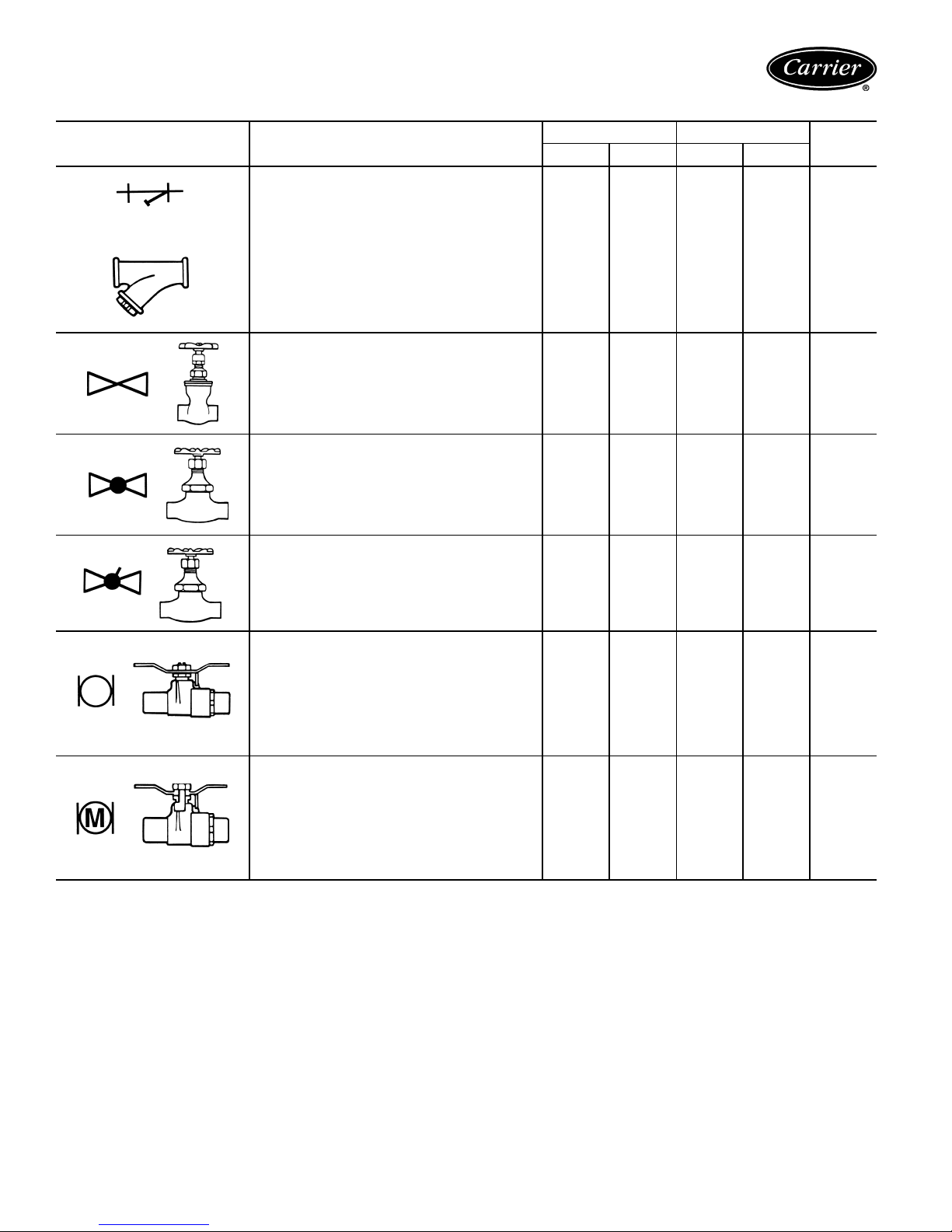

PIPING COMPONENTS

SYMBOL/SKETCH DESCRIPTION

MANUAL AIR VENT: Threaded brass needle

valve with screwdriver slot for adjustment.

Application — Body brazed into high point of

heating and cooling coils for bleeding air from

coil. Standard item on all hydronic coils (not

used on steam or DX coils). Should not be

used in lieu of main system air vents.

AUTOMATIC AIR VENT: Nickel plated brass

valve, fiber-disc type, with positive shut-off

ballcheck and quick vent feature via knurled

vent screw.

Application — Optional replacement for manual air vent. Automatically passes minute

quantities of air through the fiber discs which

expand upon contact with water, completely

sealing the valve. As air accumulates, the fiber

discs dry and shrink, repeating the cycle. Not

recommended for removing large quantities of

air encountered during initial start-up or subsequent draining and refilling. Should not be

used in lieu of main system air vents.

SWAGE: Copper tube end expanded to accept

a copper tube of the same size for factory or

field brazing.

Application — Used where possible for all tubing joints for best joint integrity.

UNION: Combination wrought copper/cast

brass union assembly, solder by solder.

Application — Used for quick connect (and disconnect) of valve package components to minimize field labor and facilitate servicing of unit.

INSERTION TEST PORT: Brass body valve

for acceptance of test probe (up to

diameter).

Application — Installed on one (or both) sides

of the coil to allow for temperature or pressure

sensing. Used for close tolerance water balancing and service analysis.

1

/8in.

CVFACTOR RATING*

1

/

2

3

/

4

PSI F

STEAM

USE

N/A N/A 400 100 NO

N/A N/A 125 240 NO

N/A N/A 300 200 YES

N/A N/A 300 200 YES

N/A N/A 250 250 NO

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

*Check all system component pressure ratings (coils, values, pumps,

etc.) with manufacturer and any applicable local or national piping

codes prior to specifying system pressure rating.

16

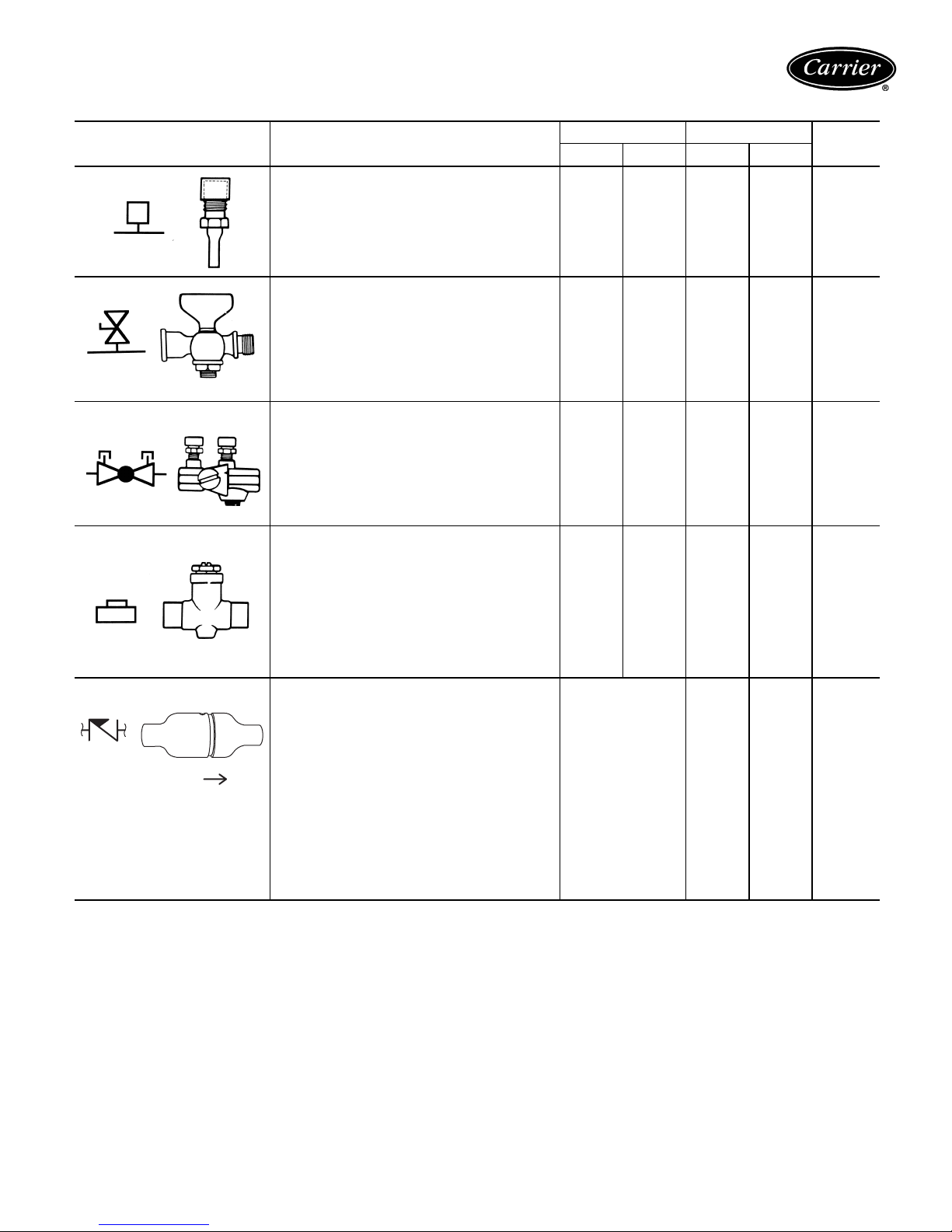

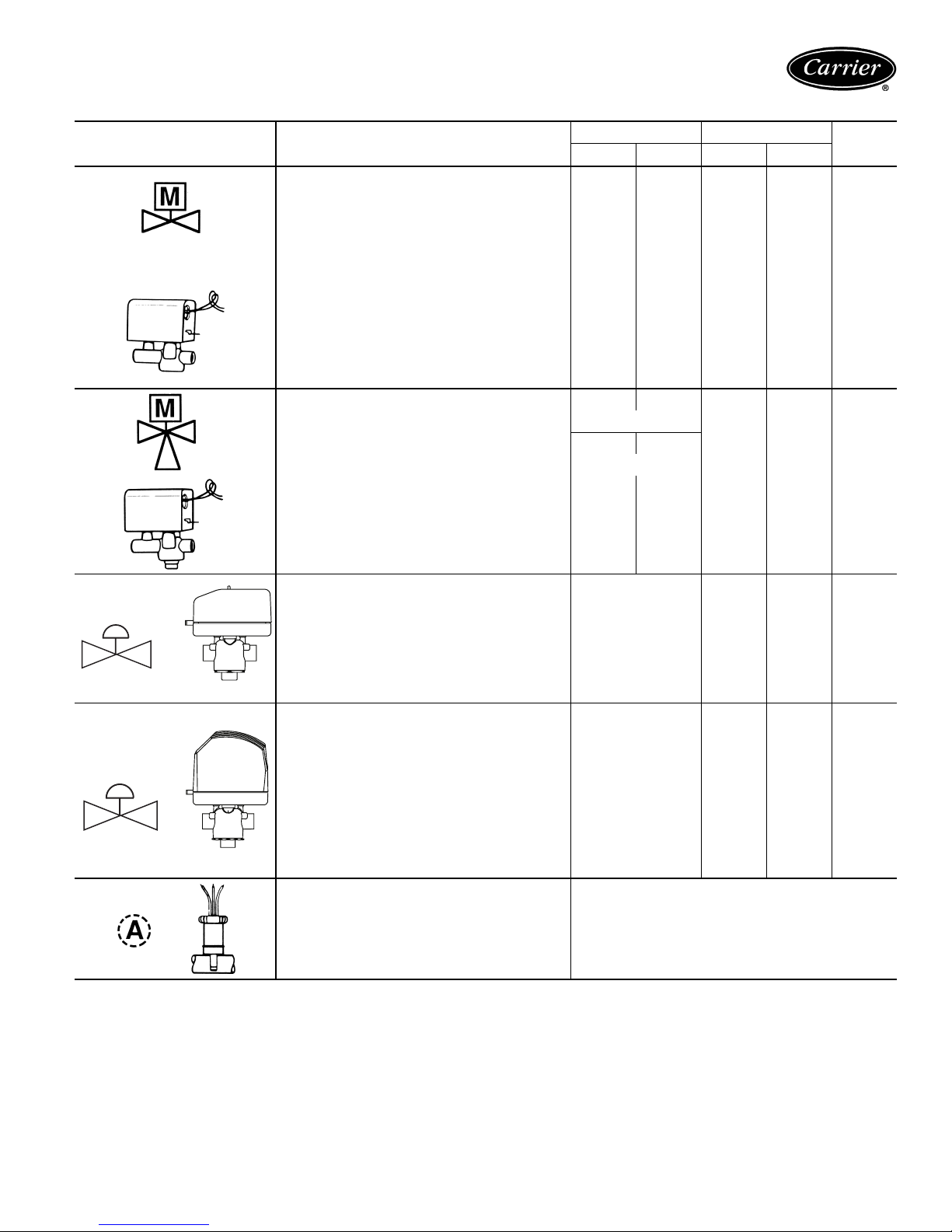

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

PRESSURE TEST PORT: Brass body

vice access fitting with removable depressor

type core.

Application — Installed on both sides of the

coil to allow for pressure sensing. Attach

pressure gages to facilitate close tolerance

water balancing.

GAGE COCK: Brass shut-off valve with

1

/4FPT fitting for attachment of pressure

gages.

Application — Installed on both sides of the

coil to allow for pressure sensing. Attach

pressure gages to facilitate close tolerance

water balancing. May be used in bleed

bypass line to regulate water flow.

CIRCUIT SETTER: Variable water flow balancing valve with manual adjustment knob,

pointer, percent-open scale, memory stop

and integral pressure read-out ports.

Application — Used for close tolerance water

flow balancing. Positive shut-off ball valve

feature allows usage as combination balancing and shut-off valve.

BALANCE VALVE: Varia ble water flow man ual balancing valve with screwdriver slot

adjustment screw.

Application — Often used in conjunction with

test port fittings for water flow balancing. Balance by temperature differential or coil pressure drop (check specifications for service

fittings required if balancing by pressure

drop). May be used in 3-way valve bypass

line to permit equal flow balancing.

FIXED FLOW VALVE: Flexible orifice type

(non-adjustable).

Application — Used for water flow balancing.

Valve automatically adjusts the flow to within

10% of set point. Requires 15 psi

(35 ft) of additional pump head for proper

FLOW

operation.

1

/4ser-

C

FACTOR RATING

V

1

/

2

3

/

4

PSI F

N/A N/A 400 210 NO

N/A N/A 200 250 N/A

2.12 3.9 300 250 NO

3.0 8.9 150 200 NO

Valve orifice size

determines C

V

factor. The orifice of

these fixed flow

valves changes as

flow is regulated.

As the water pressure increases,

the orifice size

150 160 NO

decreases,

thereby automatically limiting the

flow rate to the

specified gpm

(±10%).

STEAM

USE

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

17

Application data (cont)

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

STRAINER: Y-type body with 50 mesh stain-

less steel screen.

Application — Used for removal of small parti-

cles from system water during normal system

operation. Should not be used in lieu of main

system strainers. Strainer screen may have to

be removed during initial high pressure system flushing during start-up. Screen should be

removed and cleaned per normal maintenance schedule (provisions for strainer blowdown not provided).

GATE VALVE: Manual shut-off valve.

Application — Used for unit isolation during

system flushing, servicing, etc. Do not use for

water balancing.

GLOBE VALVE: Standard pattern, manual

shut-off and throttling valve.

Application — Used for unit isolation. Not recommended for high flow rates due to relatively

high pressure drop.

C

FACTOR RATING

V

1

/

2

9.0

Clean

3

/

4

19.0

Clean

PSI F

400 250 N/A

STEAM

USE

19.8 36.0 200 200 NO

1.8 3.9 200 200 NO

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

COMPRESSION STOP VALVE:

Manual shut-off valve.

Application — Used for unit isolation during

system flushing, servicing, etc. Not recommended for high flow rates due to relatively

high pressure drop.

BALL VALVE: Manual balance and shut-off

valve.

Application — Used for unit isolation and

water flow balancing. Without memory stop

feature water balance point must be marked

by installer (if necessary). Check specifications for service fittings required when used

for water balancing.

BALLVALVEWITHMEMORYSTOP:

Manual balance and shut-off valve.

Application — Used for unit isolation and

water flow balancing. The adjustable memory

stop feature allows return to the balance point

after shut-off. Check specifications for

service fittings required when used for water

balancing.

2.3 5.4 150 200 NO

4.0 7.5 400 200 YES

4.0 7.5 400 200 N/A

18

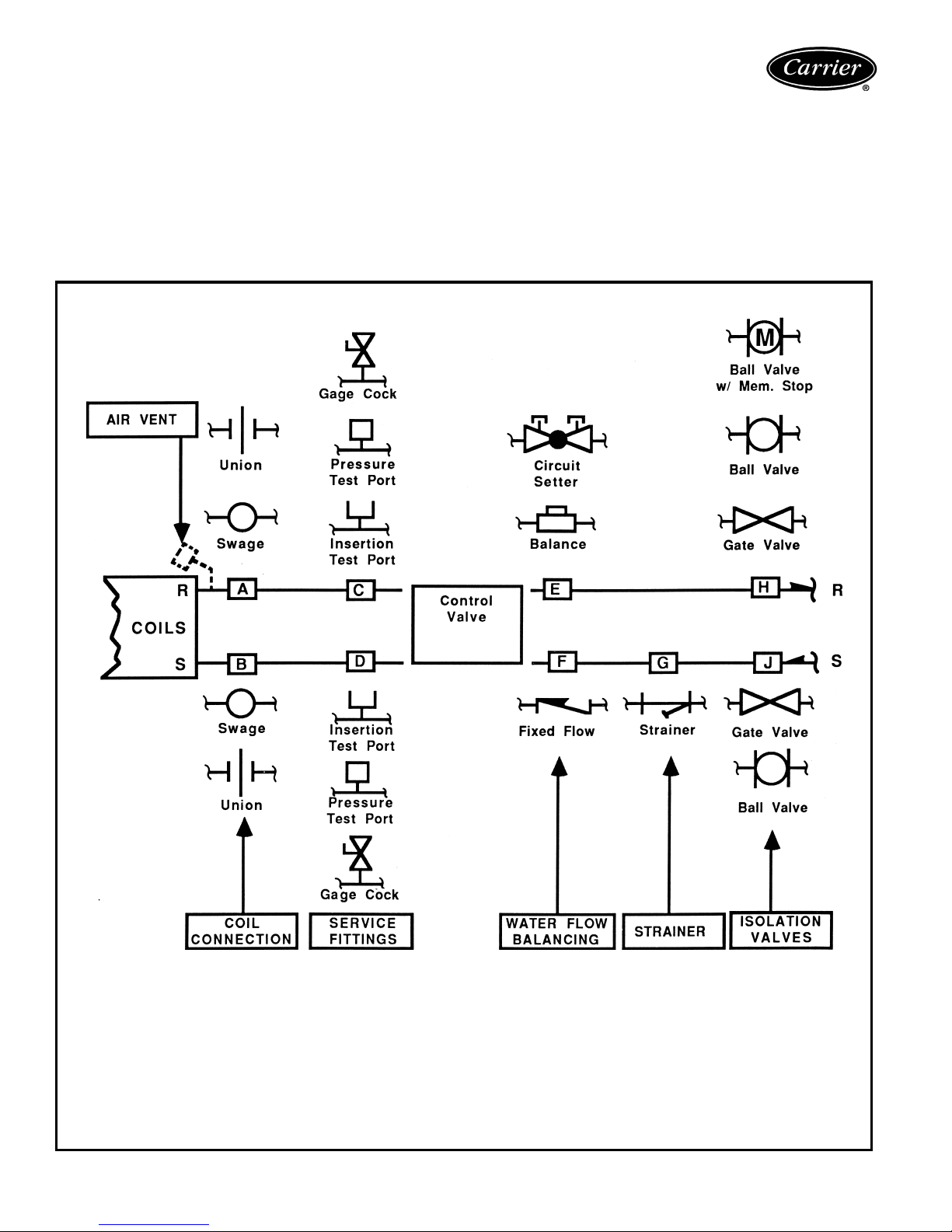

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

2-WAY MOTORIZED VALVE: Electric 2-posi-

tion flow control valve (open/closed). Normally

closed body with manual override lever.

Installedinsupplylinetounit.

Application — All standard control and valve

packages are based upon normally closed

valves (valve electrically powered open and

closed by spring return when electric power

removed). Manual override lever allows valve

to be placed in the open position for secondary (unit) flushing, constant water flow prior to

start-up, etc. Manual override is automatically

disengaged when valve is electrically activated. Consult factory for normally open

valve applications.

3-WAY MOTORIZED VALVE: Electric

2-position flow control valve (closed to coil/

open to bypass or open to coil/closed to

bypass). Normally closed with manual override lever. Installed in supply line to unit.

Application — Same comments as 2-way

motorized valve except with manual override

lever engaged the valve is open to both ports

and water flow will take the path of least resistance through the valve package (not necessarily 100% through the coil).

C

FACTOR RATING

V

1

/

2

3

/

4

PSI F

2.3 2.3 300 200

5.0 5.0

SERVICE

2.8 2.8

BYPASS

300 200 N/A

STEAM

USE

YES

15

PSI

MAX.

MODULATING VALVE

(Non-Spring Return): Modulating valves are

designed to control the flow in the circuit by

making incremental adjustments to the flow

path within the valve.

Application — To control fluid flow in fan coil

units.

MODULATING VALVE

(Spring Return): Modulating valves are

designed to control the flow in the circuit by

making incremental adjustments to the flow

path within the valve.

Application — Same comments as non-spring

return except when powered, the actuator

moves to the desired position, at the same

time tensing the spring return system. When

power is removed for more than two minutes

the spring returns the actuator to the normal

position.

AQUASTAT: Water temperature sensing electrical switch.

Application — Clips directly on nominal

1

/2in. or3/4in. copper tubing for water

size

temperature sensing. Must be correctly

located for proper control operation.

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

NOTES:

1. Motorized 2-way valves have a maximum close-off differential of 25 psi.

2. Motorized 3-way valves have a maximum close-off differential of 10 psi.

4.0

4.0

300 200 N/A

300 200 N/A

19

Application data (cont)

Valve p acka g es

There are limitations on physical size of pneumatic valves,

quantity and type of matching components, and required

control interface. See Symbols and Placement of Valves

diagram.

Consult factory before ordering any special valve pack-

age components that are not covered in this book.

SYMBOLS AND PLACEMENT OF VALVES

Valve packages are shipped with the units or in unit cartons. Valve packages include belled ends for field soldering

to coil connections.

All factory-furnished cooling valve packages are

arranged to position as much of the package as possible

over an auxiliary drain pan or drip lip. This helps minimize

field piping insulation requirements.

Coil Connections (Positions A & B) — When isolation valve only is added to supply or return line, the isolation valve will be factory

brazed to the coil stub-out. Addition of any other component or connection to the supply or return line will change the respective coil

connection(s).

Service Fittings (Positions C & D) — Optional fittings for attaching pressure/temperature sensing devices to obtain pressure drop or temperature differential across coil. Used with ball valve or balance valve where extremely accurate water flow balancing is required.

Water Flow Balancing (Positions E, F, & H) — Only one device per total valve package to be used for balancing water flow through the

coil. When isolation valve (ball valve or ball valve with memory stop at position H) is used for water flow balancing, do not specify additional

balancing device at position E or F. When balancing device is specified at position E or F, isolation valve does not require balancing feature

at position H (with a 3-way motorized valve, a bypass balancing valve may be specified in the bypass line to permit equal flow balancing).

Strainer (Position G) — Does not include blow down fitting and should not be used in lieu of main piping strainers.

Isolation Valves (Positions H & J) — Normally requires one each on supply and return line (see exception under circuit setter). When

position H is used for balancing (ball valve or ball valve with memory stop), check specifications for service valve requirements.

20

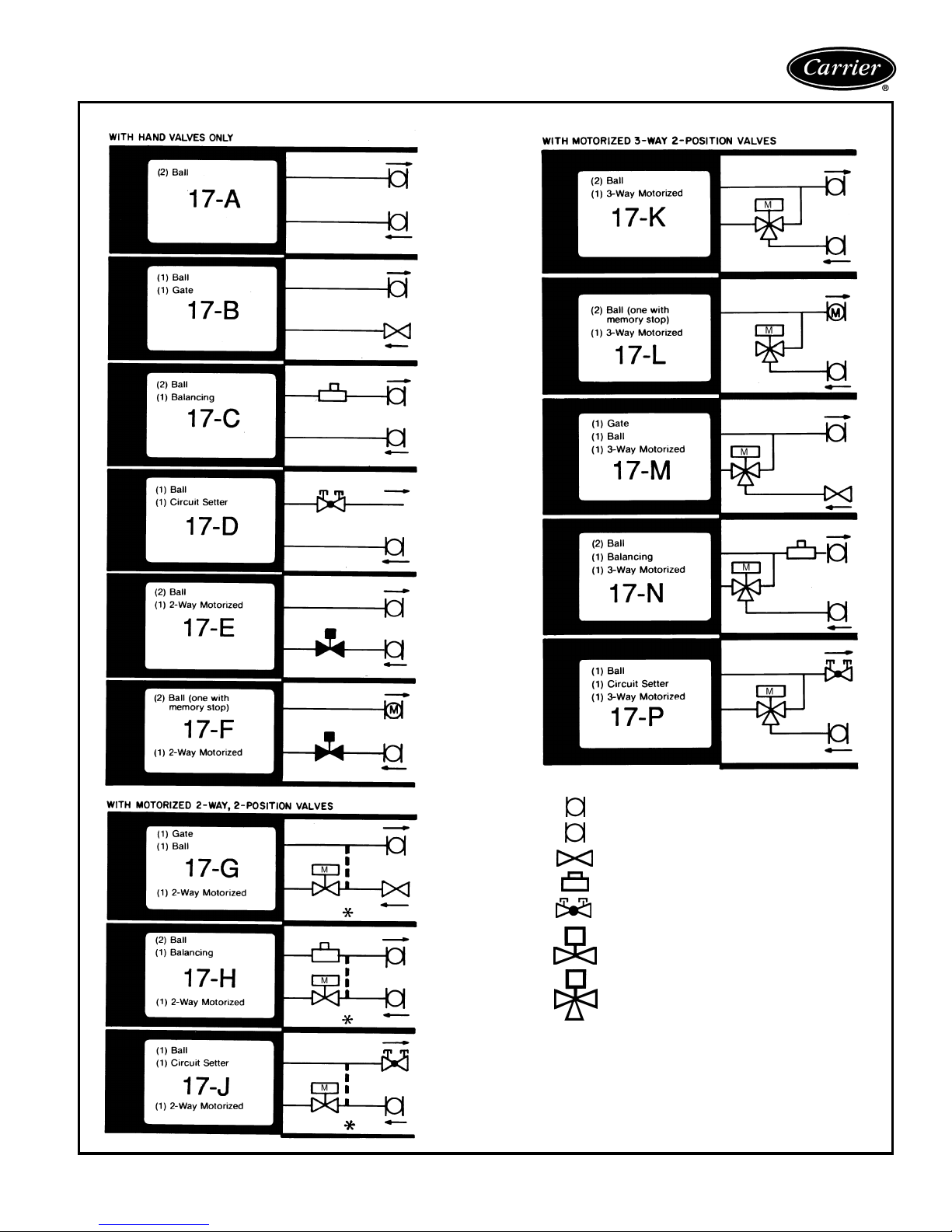

VALVE PACKAGE ARRANGEMENTS

LEGEND

Ball Valve

M

Ball Valve with Memory Stop

Gate Shut Off Valve

Balancing Valve

Circuit Setter

M

Motorized 2-Way Valve

M

Motorized 3-Way Valve

*When aquastat is used for automatic changeover, bypass is

required as indicated by dashed line.

NOTES:

1. Packages factory furnished and installed.

2. Valves are

3. If an automatic flow control valve is added, it will be located on

supply line between shutoff valve and coil (or motorized control

valve, if supplied).

4. Packages 17-A,B,C,D,E,F,G,H,J,K,L,M,N and P are listed on

current price pages.

5

/8-in. ODS unless otherwise specified.

21

Application data (cont)

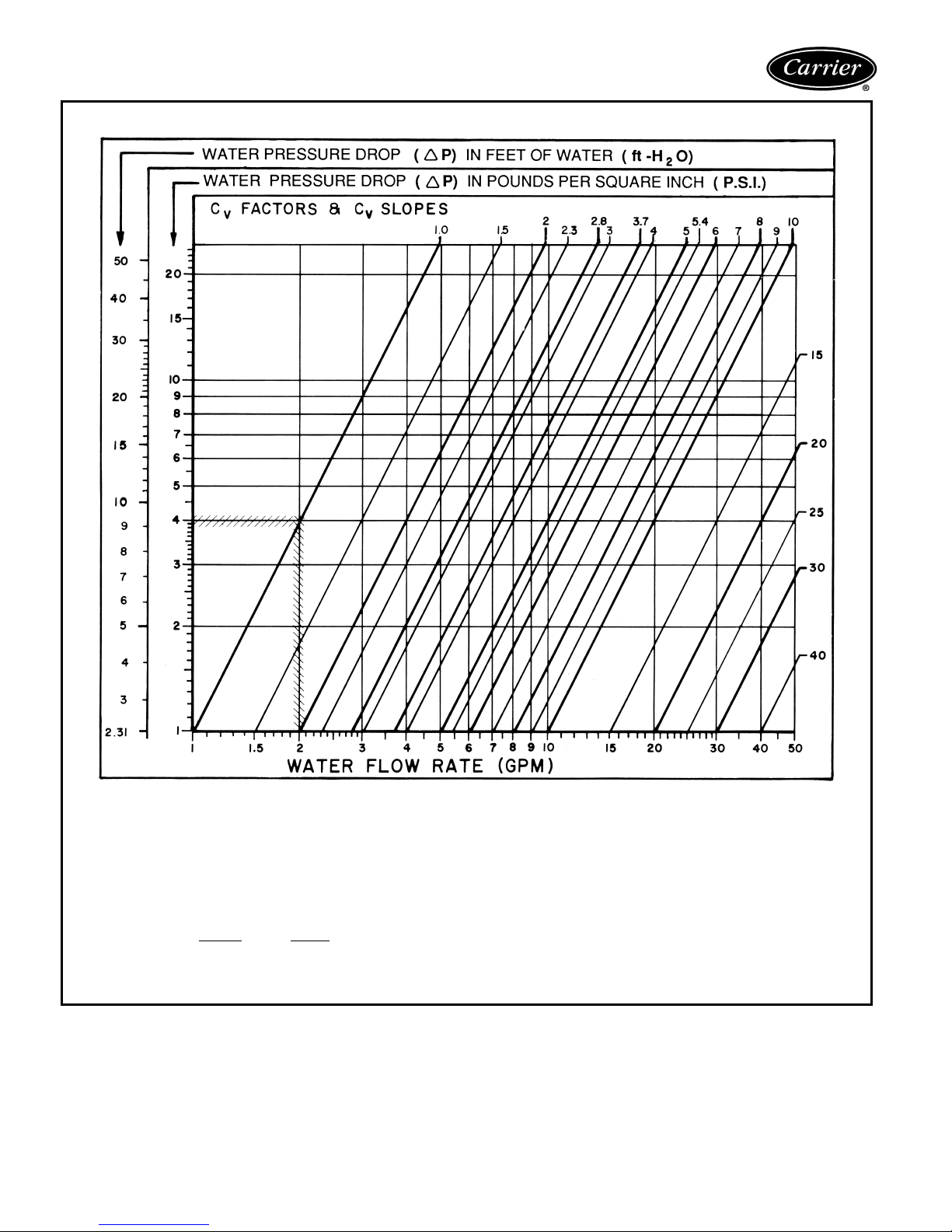

Cv FACTOR VS WATER PRESSURE DROP

CVFAC TOR :

The flow rate in gallons per minute (gpm) through a piping component when the pressure drop (∆P) in pounds per square inch (psi)

across the component is 1.0 (psi).

Pressure drop (ft-H

O) = 2.31 x psi (pressure drop)

2

GRAPH EXAMPLE:

∆P for 2.0 gpm through a component with a C

FORMULA EXAMPLE:

∆P(ft-H

O) =

2

(gpm)

(C

v

2

2

)

x2.31=

(2.0)

(1.0)

2

2

TOTAL PRESSURE DROP is the Sum of the pressure drop of all piping and components in the water flow path.

22

of 1.0 is 4.0 psi x 2.31 = 9.24 ft-H2O

V

x 2.31 = 9.24 ft-H2O

ENTHALPY AT SATURATION

TEMPERATURE

(F)

40 15.230 60 26.46

41 15.697 61 27.15

42 16.172 62 27.85

43 16.657 63 28.57

44 17.149 64 29.31

45 17.650 65 30.06

46 18.161 66 30.83

47 18.680 67 31.62

48 19.211 68 32.42

49 19.751 69 33.25

50 20.301 70 34.09

51 20.862 71 34.95

52 21.436 72 35.83

53 22.020 73 36.74

54 22.615 74 37.66

55 23.22 75 38.61

56 23.84 76 39.57

57 24.48 77 40.57

58 25.12 78 41.58

59 25.78 79 42.62

ENTHALPY AT

SATURATION

(Btu per lb.

of dry air)

TEMPERATURE

(F)

80 43.69

ENTHALPY AT

SATURATION

(Btu per lb

of dry air)

ALTITUDE COOLING CORRECTION FACTORS STEAM PRESSURE CORRECTION FACTORS

ELEVATION (ft) TOTAL HEAT SENSIBLE HEAT

1000 .990 .960

2000 .980 .930

3000 .970 .896

4000 .960 .864

5000 .940 .830

6000 .930 .800

7000 .920 .770

8000 .910 .750

9000 .900 .730

ENTERING AIR

TEMP (F)

40 1.202 1.265

50 1.134 1.196

60 1.067 1.125

70 1.000 1.054

NOTE: Steam Heating Capacity (Btuh) = Base Capacity x Pressure

Correction Factor x SH (SH value found in Cooling Capacity Correction

Factors table on page 60).

STEAM PRESSURE (PSIG)

25

AIRFLOW CORRECTION FACTORS

CFM RATIO

(Actual/Base)

1.40 1.25 1.26

1.35 1.22 1.23

1.30 1.19 1.20

1.25 1.16 1.17

1.20 1.13 1.14

1.15 1.10 1.11

1.10 1.07 1.08

1.05 1.04 1.04

1.00 1.00 1.00

0.95 0.97 0.97

0.90 0.94 0.93

0.85 0.90 0.89

0.80 0.86 0.85

0.75 0.82 0.81

0.70 0.78 0.77

0.65 0.74 0.72

0.60 0.70 0.67

0.55 0.66 0.62

0.50 0.62 0.57

0.45 0.58 0.52

0.40 0.53 0.47

0.35 0.48 0.42

0.30 0.43 0.38

0.25 0.38 0.33

LEGEND

CFM — Cubic Feet per Minute

Cs — Sensible Airflow Correction Factor

Ct — Total Airflow Correction Factor

ESP — External Static Pressure

TOTAL (Ct) SENSIBLE (Cs)

23

Application data (cont)

Electric heat

Electric heaters are available for installation on Carrier fan

coil units in the following applications.

Total electric heat — This system provides complete

heating during the heating season; no boiler is required.

Heating and cooling are now available on an individual

basis throughout the year with a 2-pipe system.

Chilled water is used for cooling and the electric heater is

used for heating. Individual room controls can be supplied

for either manual or automatic changeover.

Auxiliary electric heat — This system is used for heating between seasons or during the cooling season when

chilled water is being circulated. Individual room controls

are supplied to provide electric heat only when chilled

water is being circulated through the system. Water flow

through the unit is shut off when the heater is turned on.

During the winter heating season, heating is provided by

hot water circulated through the system. A changeover

device locks out the electric heat when the hot water is

circulated.

Heater construction

Strip heaters are used with Model 42C ceiling units,

Model 42D ducted units and Model 42S stack units.

These heaters consist of coils of the highest grade resistance wire, insulated by ceramic insulators in aluminized

brackets.

All heaters except those used in 42S stack units are positioned on the incoming (preheat) side of the unit coil. On

42S stack units, the strip heater is located in the fan discharge on the leaving side of the coil.

Sheath heaters are used with Model 42V vertical units.

These heaters consist of the highest grade resistance wire,

centered in a

The wire is insulated from the sheath by magnesium oxide

powder packed around it. To increase the heater surface

exposed to air, a 1

wound around the sheath in a continuous spiral that makes

5 turns per lineal inch. Sheath and fin are permanently

bonded together by copper brazing.

The heaters are positioned on the leaving (reheat) side of

the unit coil. On special units with high efficiency motors, a

strip heater will be installed in the fan discharge on the

incoming (preheat) side of the unit coil.

1

/2-in. diameter copper-plated steel sheath.

1

/4-in. OD fin of copper-plated steel is

Heater electrical data

1. Load voltage may be 120, 208, 240 or 277 volts. For

unit size and kW limitations, refer to the specific unit

catalogs.

2. All heaters are single stage and single phase.

3. Unless a single power-source option is selected, the

electric heat units require 2 separate power sources.

With the single power-source option, only one line circuit need be brought into the unit. Fuse protection is

added to the motor/control circuit to protect these

components. This is separate from the field-furnished

total unit overcurrent protection.

MODEL 42V VERTICAL UNIT

WITH ELECTRIC SHEATH HEATER

MODEL 42C CEILING UNIT

WITH ELECTRIC STRIP

HEATER

24

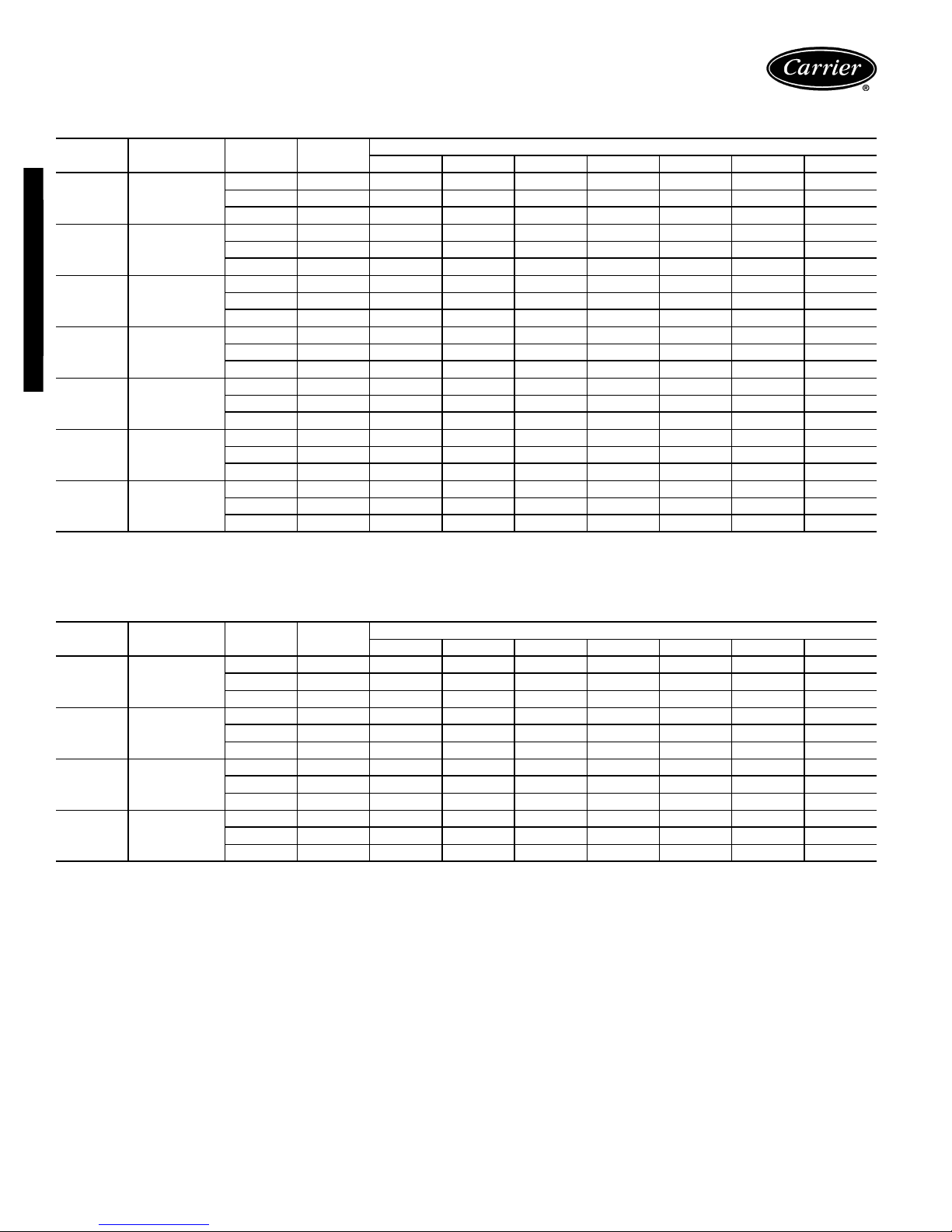

42C SERIES

42D SERIES

HEATER

VOLTAGE

120

208,

240,

277

240,277 10.0 34,150 *

CAPACITY

kW

(Btuh)

0.5 1,708 * *

1.0 3,415 * * *

1.5 5,123 * *

2.0 6,830 * * * * * * *

3.0 10,245 * * * *

0.5 1,708 * *

1.0 3,415 * * *

1.5 5,123 * *

2.0 6,830 * * * * * * *

3.0 10,245 * * * *

4.0 13,660 * * * *

5.0 17,075 * *

6.0 20,490 * * * *

8.0 27,320 * *

02 03 04 06 08 10 12

UNIT SIZE

42V SERIES

HEATER

VO LTAGE

120

208,

240,

277

240,277 6.0 20,490 *

NOTE: All heaters are single-stage and single-phase. Contact your

Carrier representative for heater availability for 220-1-50 units.

CAPACITY

kW

0.5 1,708 * *

1.0 3,415 * * * *

1.5 5,123 * * *

2.0 6,830 * * *

3.0 10,245 ****

1.0 3,415 * * * *

1.5 5,123 * * *

2.0 6,830 * * *

3.0 10,245 ****

4.0 13,660 * * *

5.0 17,075 * *

(Btuh)

02 03 04 06 08 10 12

UNIT SIZE

HEATER

VO LTAGE

120

208,

240,

277

NOTE: All heaters are single-stage and single-phase.

CAPACITY

kW

(Btuh)

2.0 6,830 * * *

3.0 10,245 * * *

2.0 6,830 * * *

3.0 10,245 * * *

4.0 13,660 ********

5.0 17,075 *******

6.0 20,490 *******

7.0 23,905 ******

8.0 27,320 *****

9.0 30,735 *****

10.0 34,150 ****

12.0 40,980 * * *

14.0 47,810 *

06 08 10 12 14 16 18 20

UNIT SIZE

42S SERIES

HEATER

VOLTAGE

120

208

240,

277

kW

10.0 * *

03 04 06 08 10 12

1.0******

1.5******

2.0******

3.0******

1.0******

1.5******

2.0******

3.0******

4.0 *****

5.0 ****

6.0 ***

8.0 ***

1.0******

1.5******

2.0******

3.0******

4.0 *****

5.0 ****

6.0 ***

8.0 ***

UNIT SIZE

25

Selection procedure

Refer to the Carrier Electronic Selection Program for information to determine unit sizing for your needs. The following selection procedure applies to all Carrier 42 series

units and may be used as a guide to determine unit

performance.

FORMULAS

TC = TC

SC = SCb x Cs x E

x Ct x E

b

t

s

Where:

C

= Sensible Airflow Correction Factor

s

C

= Total Airflow Correction Factor

t

= Sensible Elevation Correction Factor

E

s

E

= Total Elevation Correction Factor

t

SC = Sensible Capacity

= Base Sensible Capacity from Base Cooling

SC

b

Capacities by Gpm charts

TC = Total Capacity

TC

= Base Total Capacity from Base Cooling

b

Capacities by Gpm charts

QUICK SELECTION

EXAMPLE:

To rate the performance at sea level for a 42DCA06 unit

with four-row coil at 80 F/67 F EAT, 45 F EWT, and

10 gpm water flow at high speed fan with 0.25 in. wg

ESP:

1. Enter the Base Cooling Capacities by Gpm, Standard

Capacity Units (Four Row) table on page 77 at 80 F/

67 F EAT and 45 F EWT.

2. Locate the appropriate row for unit size 06 and

10 gpm.

Record the tabulated base performance.

TC

= 21.5 MBtuh

b

SC

= 15.2 MBtuh

b

∆T = 4.3° F

3. Select the actual cfm from the Air Delivery table on

page 82.

Record actual cfm for 42DCA06 with four-row coil

with high speed and 0.25 in. wg ESP.

Cfm Actual = 580

4. Divide Cfm Actual by Cfm Nominal to determine Cfm

Ratio.

Cfm Ratio = 580/600 = .967

5. Select the cfm correction factors, C

and Cs, from the

t

Airflow Correction Factors table on page 23. (Interpolation may be required.)

C

= 0.98

t

= 0.98

C

s

6. Select the elevation correction factors, E

and Es, from

t

the Altitude Correction Factors table on page 23.

E

= 1.00

t

= 1.00

E

s

7. Calculate actual performance.

TC = TC

x Ct x E

b

t

= 21.5 x 0.98 x 1.00

= 21.1 MBtuh

SC = SC

x Cs x E

b

s

= 15.2 x 0.98 x 1.00

= 14.9 MBtuh

8. Calculate water pressure drop. From the Cv Factor by

Coil and Unit Size table on page 86, find the Cv value

for unit size 06 with four rows.

Cv = 4.00

∆P = [GPM/(0.658 x Cv)

= [10.0/(0.658 x 4.00)

2

2

= 14.4 feet of H2O

26

Model number nomenclature

42CAA03ARCY5––––

42 – Series Fan-Coil Unit

Model

Vertical Units

VA – Furred-In

VB – Cabinet

VC – Furred-In Lowboy

VE – Cabinet Lowboy

VF – Slant-Top Cabinet

VG – Furred-In Wall Unit

Ceiling Units

CA – Furred-In

CE – Furred-In with Plenum

CF – High Static, Furred-In

CG – Cabinet

CK – Telescoping Bottom Panel

Design Series (A or B*)

Unit Size (Airflow, cfm)

01 – 150 (42VG Only) 06 – 600

02 – 200 08 – 800

03 – 300 10 – 1000

04 – 400 12 – 1200

Coil

A–3 Row (Standard)

2 Row (VC, VE, VG Standard)

B–4 Row High Capacity

3 Row High Capacity (VC, VE Only)

C–3/1 Opposite End Connection

2/1 Opposite End Connection (VC, VE Only)

D–3/1 Same End Connection

2/1 Same End Connection (VC, VE Only)

E–3/2 Opposite End Connection

F–3/2 Same End Connection

G–4/1 Opposite End Connection

H–4/1 Same End Connection

Arrangement

42V:

5–Front Return, Top Supply

7–Front Return, Front Supply

42C:

5–Bottom Return, Front Supply

6–Rear Return, Front Supply

Electric Heaters

Y–None

A-Z, 1 – 42V

A-Z, 1-9 – 42C

Motor

C–120V Permanent Split Capacitor (PSC) (Standard)

D–208/1/60 PSC

E–230/1/60 PSC

F–277/1/60 PSC

V–220/1/50 PSC

Hand

R–Right

L–Left

42C,V Series Units

*Model 42CG only.

27

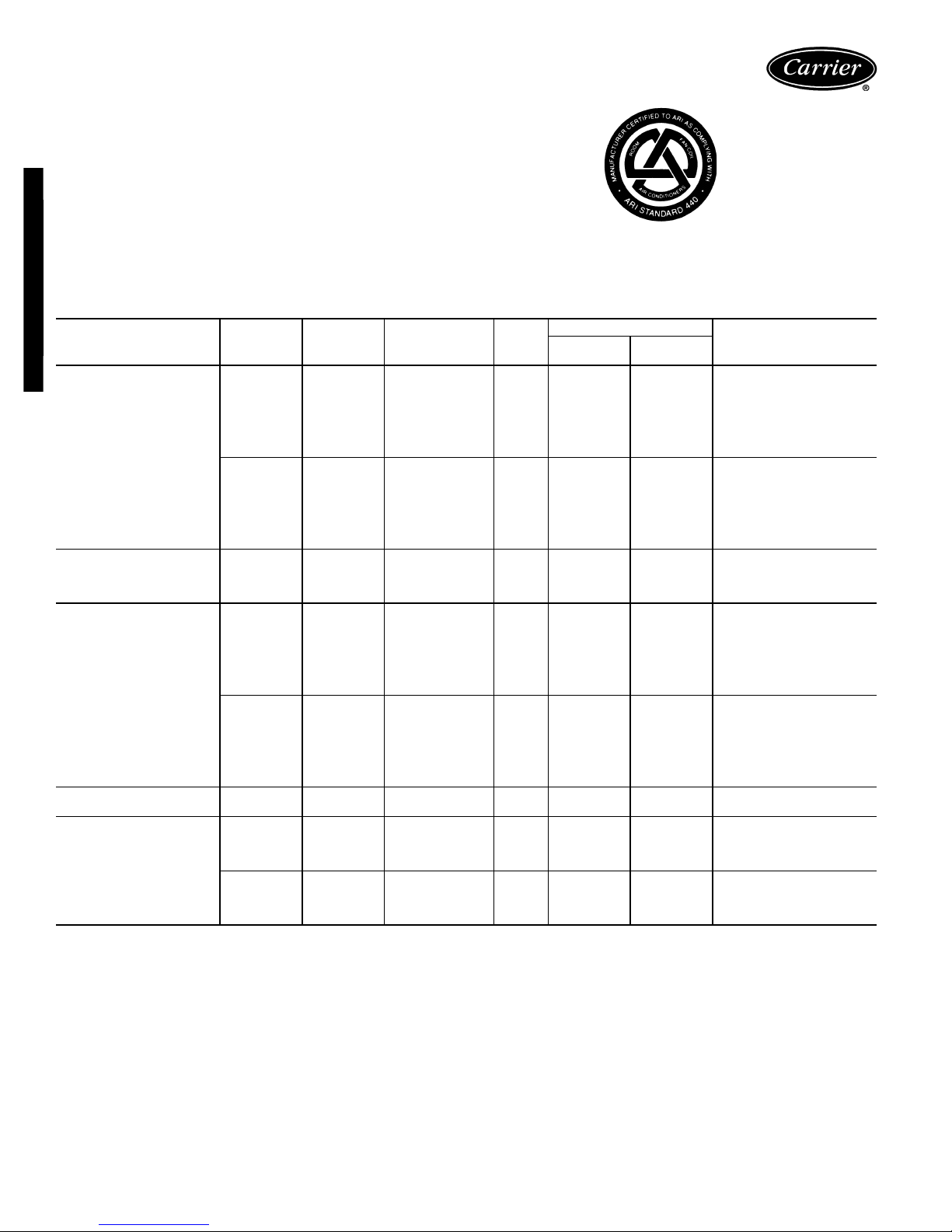

ARI capacity ratings

The 42C, V series fan coil units are certified in compliance

with the Air Conditioning and Refrigeration Institute (ARI)

Industry Standard 440-98 for room fan coil units. Approved standard ratings are tabulated below:

ARI APPROVED STANDARD RATINGS*

42C,V Series Units

GPM — Gallons per minute

MBtuh — Capacity (Btuh in thousands)

*Ratings based on motor at high fan speed, standard air and dry coil oper-

ation, 10° F water temperature rise; entering-air temperature 67 F wb;

80 F db; entering water temperature 45 F.

†Motor type permanent split capacitor operating at 115-1-60 voltage.

**Shaded pole motor.

UNIT

42CA,CE,CG,CK

42CF

42VA,VB,VF

42VG

42VC,VE

LEGEND

UNIT

SIZE

02

03 300 1.8 9.0 6.9 85

04 400 2.5 13.3 10.3 165

06 600 3.6 18.0 14.6 225

08 800 4.6 22.6 16.9 235

10 1000 5.5 27.5 21.0 305

12 1200 6.6 32.8 25.0 435

02

03 300 2.1 9.8 6.5 85

04 400 2.8 13.8 9.8 145

06 600 4.0 19.6 14.3 220

08 800 5.1 25.5 18.8 235

10 1000 6.2 31.0 23.0 300

12 1200 7.5 37.2 27.7 425

04

06 600 4.4 21.8 16.0 205

08 800 5.3 26.5 19.6 225

10 1000 7.5 37.2 27.6 355

02

03 300 1.5 7.2 5.3 80

04 400 2.4 11.2 7.9 130

06 600 3.0 13.9 10.4 180

08 800 4.0 19.1 13.5 210

10 1000 4.8 22.0 16.8 240

12 1200 5.3 26.3 20.0 370

02

03 300 2.0 9.9 7.0 80

04 400 2.7 13.1 8.6 130

06 600 3.8 18.6 13.6 170

08 800 4.2 20.6 14.1 195

10 1000 5.9 29.5 19.6 240

12 1200 7.8 35.3 26.3 370

01

03 300 1.5 5.2 4.7 225**

02

03 300 2.0 8.6 6.7 135

04 400 2.6 12.3 8.3 150

06 600 3.6 18.3 13.2 260

02

03 300 2.4 10.9 7.1 130

04 400 3.0 13.4 8.8 145

06 600 4.1 21.1 14.6 250

COIL

ROWS

3

4

4

3

4

2

2

3

NOMINAL

CFM

200 1.2 6.0 4.6 50

200 1.4 6.9 5.0 50

400 3.2 16.0 11.6 170

200 1.0 4.8 3.5 50

200 1.4 6.6 4.1 50

150 0.6 2.1 1.6 115**

200 1.2 5.1 3.6 68

200 1.3 5.5 3.8 68

GPM

COOLING CAPACITY

Tota l

MBtuh

Sensible

MBtuh

INPUT (WATTS)†

POWER

28

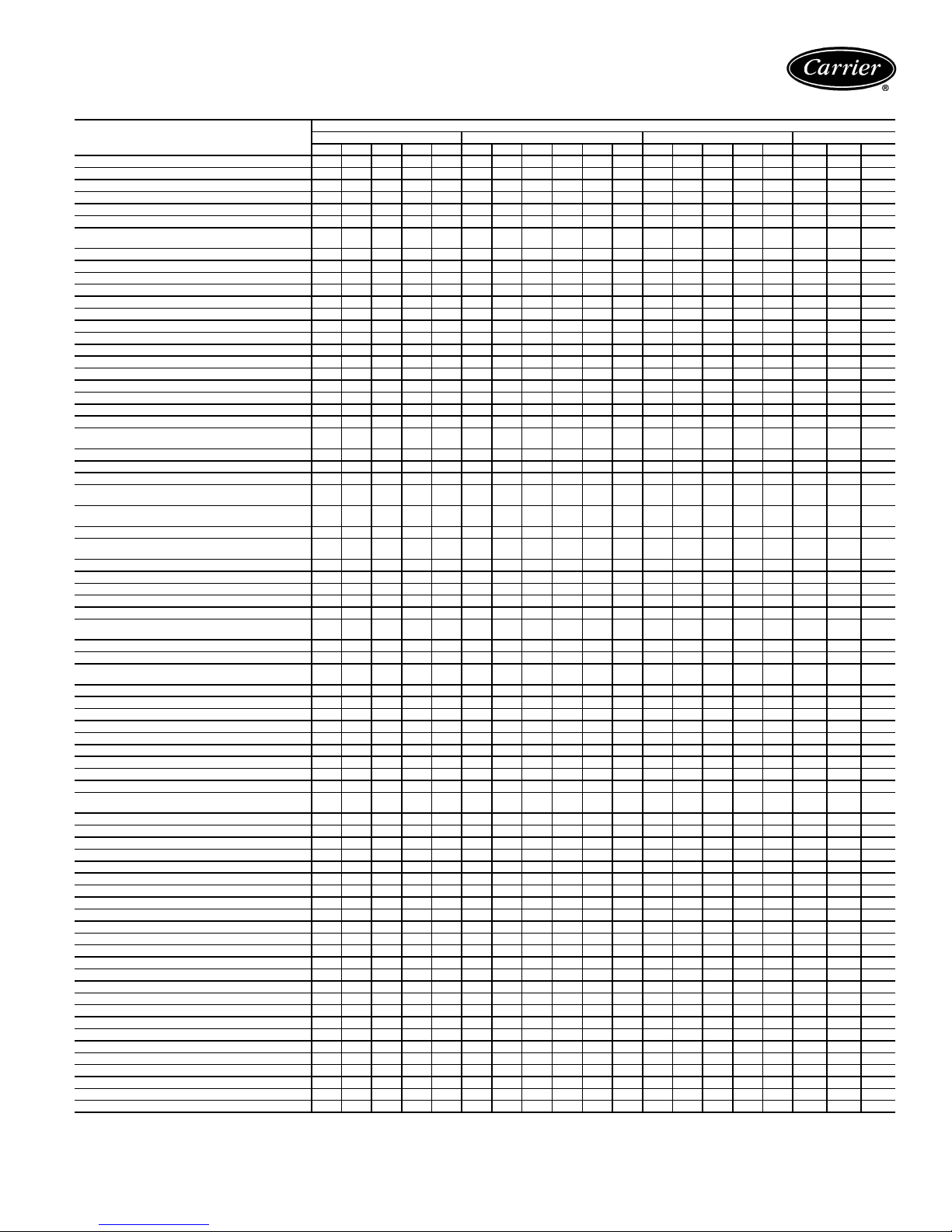

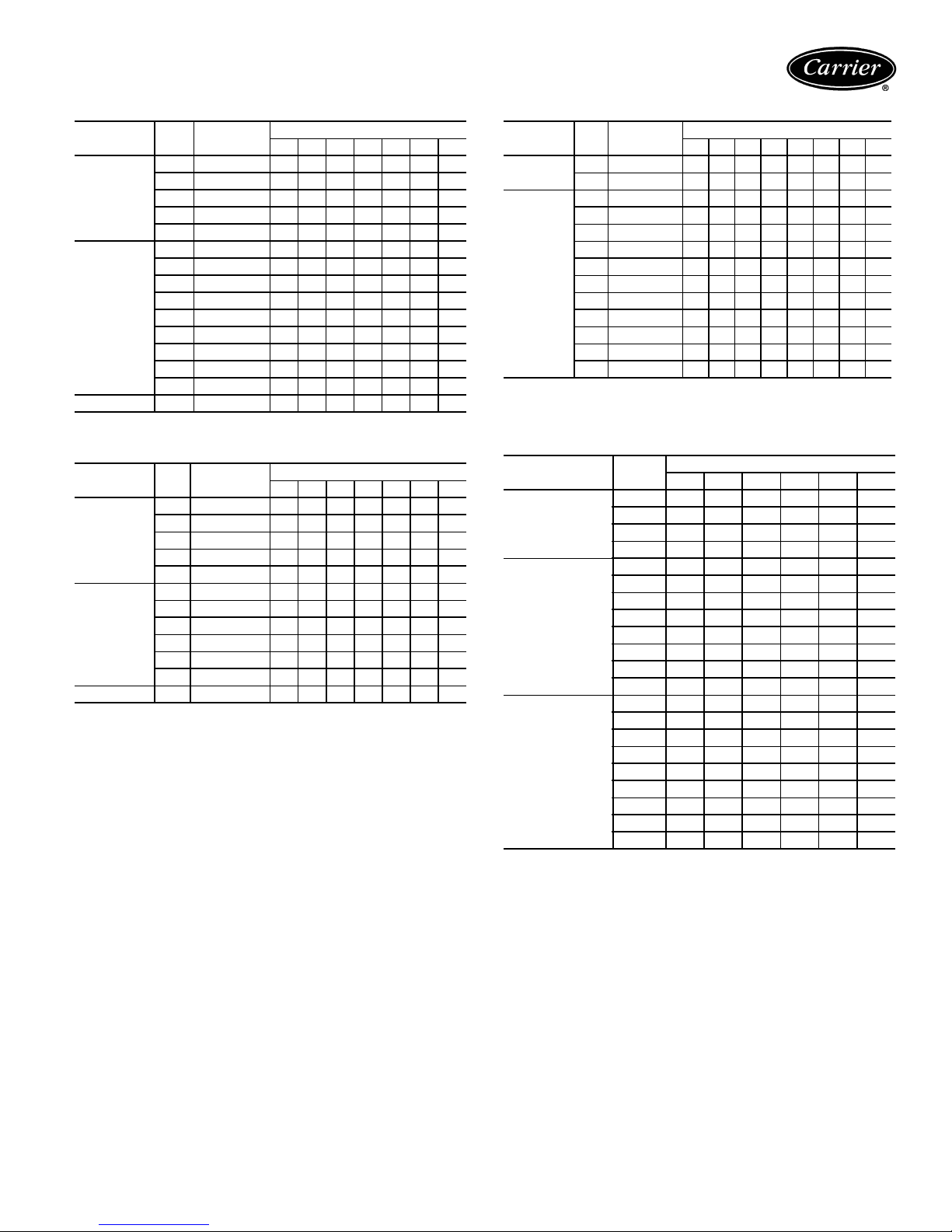

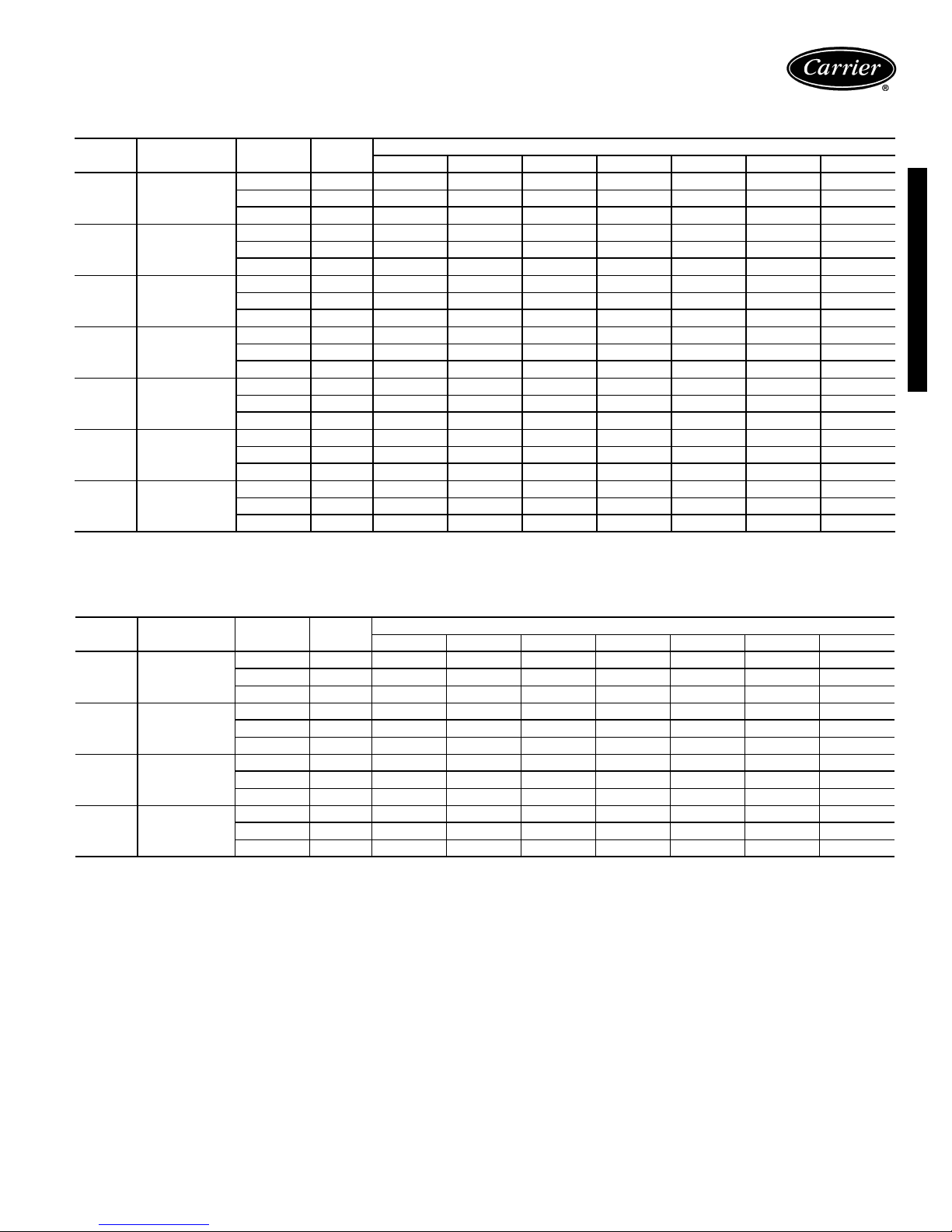

Sound data

42CA,CG,CE,CK SOUND RATINGS — OCTAVE BAND POWER LEVEL RATINGS* (dB)

SOUND POWER DATA

SIZE

02 200

03 300

04 400

06 600

08 800

10 1000

12 1200

*Testing per ARI Standard 350-86.

NOMINAL

CFM

High 1130 59 58 59 57 52 49 46

Medium 1060 54 54 55 51 42 42 41

Low 940 45 49 51 47 43 37 33

High 1125 61 59 61 58 54 51 47

Medium 1025 55 54 54 51 46 42 41

Low 925 43 48 49 46 42 36 31

High 1400 62 61 62 59 55 51 46

Medium 905 54 54 54 50 46 41 26

Low 725 49 48 47 42 34 — —

High 1525 63 62 63 60 56 53 48

Medium 1100 55 54 54 51 47 41 31

Low 690 51 50 49 44 36 — —

High 1500 66 66 67 64 60 58 53

Medium 1045 59 56 59 55 47 42 37

Low 675 51 51 50 46 38 — —

High 1365 73 70 71 68 64 62 58

Medium 785 62 60 61 57 51 48 46

Low 700 56 56 57 52 46 40 34

High 1540 78 75 76 73 68 67 63

Medium 1155 68 67 68 64 59 56 54

Low 740 59 60 60 56 50 43 37

SPEED RPM

CENTER FREQUENCY — Hz

125 250 500 1000 2000 4000 8000

42C,V Series Units

42CF SOUND RATINGS — OCTAVE BAND POWER LEVEL RATINGS* (dB)

SIZE NOMINAL CFM SPEED RPM

High108562656563585447

04 400

06 600

08 800

10 1000

*Testing per ARI Standard 350-86.

Medium98060626260565143

Low 840 57 59 59 56 51 46 37

High107562656563585447

Medium95560626260565143

Low 740 57 59 59 56 51 46 37

High104562656563585447

Medium86560626260565143

Low 715 57 59 59 56 51 46 37

High110062656563585447

Medium 1015 60 62 62 60 56 51 43

Low 900 57 59 59 56 51 46 37

CENTER FREQUENCY — Hz

125 250 500 1000 2000 4000 8000

29

Sound data (cont)

42VA,VB,VF SOUND RATINGS — OCTAVE BAND SOUND POWER LEVEL RATINGS* (dB)

SOUND POWER DATA

SIZE

02 200

03 300

04 400

42C,V Series Units

06 600

08 800

10 1000

12 1200

*Testing per ARI Standard 350-86.

NOMINAL

CFM

SPEED RPM

High 1130 63 58 53 46 40 34 25

Medium 1090 58 57 51 45 39 32 —

Low 1025 61 57 50 44 37 30 —

High 1120 65 60 54 48 42 35 26

Medium 1070 60 59 53 47 41 34 —

Low 1000 63 59 52 46 39 32 —

High 1520 66 67 64 58 50 45 39

Medium 1085 58 60 53 47 40 32 —

Low 840 52 55 47 40 33 — —

High 1625 67 68 65 59 53 48 42

Medium 1310 61 62 56 52 46 40 —

Low 825 54 56 48 41 34 — —

High 1610 68 68 65 60 55 51 44

Medium 1300 63 64 59 54 50 45 36

Low 820 55 56 49 43 37 28 —

High 1530 68 69 65 61 54 49 44

Medium 1095 66 66 60 56 50 45 38

Low 850 58 58 52 46 38 31 —

High 1625 70 71 67 63 56 51 46

Medium 1310 69 69 63 59 53 48 42

Low 830 60 61 54 48 41 34 —

125 250 500 1000 2000 4000 8000

CENTER FREQUENCY — Hz

42VC,VE SOUND RATINGS — OCTAVE BAND SOUND POWER LEVEL RATINGS* (dB)

SIZE

02 400

03 600

04 800

06 1000

*Testing per ARI Standard 350-86.

NOMINAL

CFM

SPEED RPM

High 1325 60 63 60 56 53 50 47

Medium 890 53 53 51 46 43 38 32

Low 655 50 48 43 38 33 — —

High 1570 64 67 63 60 56 54 50

Medium 1205 56 58 53 50 47 43 37

Low 835 49 51 47 41 36 29 —

High 1520 65 68 64 61 57 55 51

Medium 1105 57 59 54 51 48 44 38

Low 765 50 52 48 42 37 30 —

High 1575 66 67 63 61 56 53 50

Medium 1205 58 58 55 53 48 43 37

Low 835 51 50 47 44 38 30 —

125 250 500 1000 2000 4000 8000

CENTER FREQUENCY — Hz

30

Loading...

Loading...