Carrier 42CA, 42CE, 42CK, 42VA, 42CG Installation, Start-up And Service Instructions Manual

...

42C,D,V Series

Fan Coil Air Conditioners

Installation, Start-Up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,2

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 3

PRE-INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Unpack and Inspect Units. . . . . . . . . . . . . . . . . . . . . . . . 4

Protect Units From Damage. . . . . . . . . . . . . . . . . . . . . . 4

Prepare Jobsite for Unit Installation. . . . . . . . . . . . . . 4

Identify and Prepare Units . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-49

Step 1 — Place Units in Position . . . . . . . . . . . . . . . . 33

• 42C UNITS

• 42V UNITS

• 42D UNITS

Step 2 — Make Piping Connections . . . . . . . . . . . . . 34

• VALVE PACKAGES

• DRAIN CONNECTIONS

• WATER SUPPLY/RETURN CONNECTIONS

• STEAM CONNECTIONS

• DIRECT EXPANSION (DX) REFRIGERANT PIPING

• TEST AND INSULATE

Step 3 — Make Electrical Connections . . . . . . . . . . 46

• FACTORY-INSTALLED OPTIONS

• STANDARD WIRING PACKAGES

Step 4 — Make Duct Connections. . . . . . . . . . . . . . . 47

Step 5 — Frame and Finish Unit. . . . . . . . . . . . . . . . . 47

Step 6 — Cut Out Openings for Grilles and

Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Step 7 — Make Final Preparations . . . . . . . . . . . . . . 48

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49, 50

Cooling/Heating System . . . . . . . . . . . . . . . . . . . . . . . . 49

Air System Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Water System Balancing . . . . . . . . . . . . . . . . . . . . . . . . 49

Water Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Controls Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50, 51

Excessive Condensation on Unit. . . . . . . . . . . . . . . . 50

To Clean Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Check Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Motor Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clean Fan Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clean Electric Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Clean or Replace Air Filters . . . . . . . . . . . . . . . . . . . . . 51

Electrical Wiring and Controls . . . . . . . . . . . . . . . . . . 51

Valves and Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page

APPENDIX A — POTENTIOMETER

ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

APPENDIX B — EVO/ECM 4-SPEED

ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

APPENDIX C — 42CE/DC RETURN

MODIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . 54, 55

START-UP CHECKLIST FOR 42C,D,V SERIES

FAN COIL AIR CONDITIONERS . . . . . . . CL-1, CL-2

SAFETY CONSIDERATIONS

Installation of this unit can be hazardous due to electrical components and equipment location (such as a ceiling or elevated

structure). Only trained, qualified installers and service

mechanics should install and service this equipment.

When installing this unit, observe precautions in the literature,

labels attached to the equipment, and any other safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves. Never wear bulky

or loose fitting clothing when working on any mechanical equipment. Gloves should be worn for proper protection against heat and other possible injuries. Safety

glasses or goggles should always be worn when drilling,

cutting, or working with chemicals such as refrigerants

or lubricants.

• Use care in handling and installing this unit.

• Never pressurize any equipment beyond specified test

pressures. Always pressure test with an inert fluid or gas

such as clear water or dry nitrogen to avoid possible

damage or injury in the event of a leak or component

failure during testing. Always protect adjacent flammable material when welding or soldering. Use a suitable

heat-shield material to contain sparks or drops of solder.

Have a fire extinguisher readily available.

WARNING

ELECTRIC SHOCK HAZARD. To avoid the possibility

of electrical shock, open and tag all service switches before

installing this equipment.

INTRODUCTION

Carrier fan coil units represent a prudent investment offering trouble-free operation and long service with proper installation, operation, and regular maintenance. Your equipment is

initially protected under the manufacturer’s standard warranty;

however, this warranty is provided under the condition that the

steps outlined in this manual for initial inspection, proper installation, regular periodic maintenance, and everyday operation of the equipment be followed in detail. This manual should

be fully reviewed in advance before initial installation, start-up,

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53420011-01 Printed in U.S.A. Form 42-6SI Pg 1 11-17 Replaces: 42-5SI

and any maintenance. Should any questions arise, please

contact your local sales representative or the factory BEFORE

proceeding.

This document contains general installation instructions for

the 42C,D,V unit fan coils. Refer to the unit wiring diagram installed on the blower housing or specific manufacturer literature for any other type of factory-mounted controls.

See drawings for unit configurations, dimensions, clearances,

and pipe connections. Refer to unit wiring label for all electrical

connections; follow NEC (National Electrical Code) and local

codes.

PHYSICAL DATA

Component weight data, shipping weights, and filter data of

the 42C,D,V units are provided in Tables 1-4.

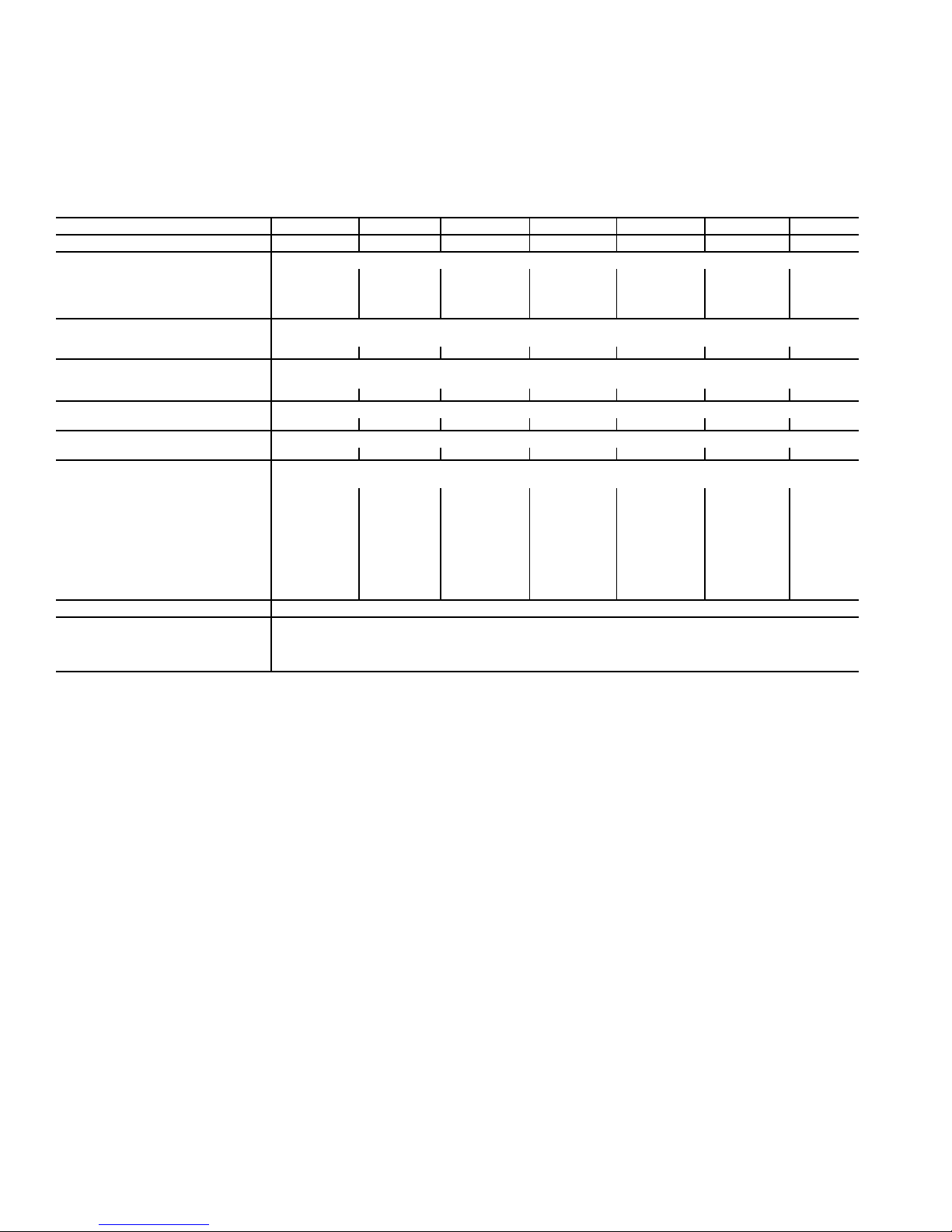

Table 1 — Physical Data — 42C Series Units

UNIT SIZE 42C 02 03 04 06 08 10 12

NOMINAL AIRFLOW (cfm) 200 300 400 600 800 1000 1200

SHIPPING WEIGHT (lb)*

42CA 36 39 49 59 64 95 107

42CE 55 60 70 82 95 135 154

42CG 98 118 126 168 176 215 245

42CK 115 120 135 150 155 227 241

COIL WATER WEIGHT

(Approx lb per row of coil)

42CA, CE, CG, CK 0.7 0.8 1.0 1.4 1.7 2.3 2.7

COILS

FPI 10 fins/inch

Coil Face Area (sq ft) 0.8 1.1 1.4 1.9 2.3 3.2 3.7

MOTOR (qty)

42C Series 111 1 1 22

BLOWER (qty)

42CA, CE, CG, CK 112 2 2 44

FILTERS

Nominal Size (in.) (1-in. thick)

42CA NA NA NA NA NA NA NA

42CE† 10 x 18 10 x 22 10 x 28 10 x 33 10 x 40 10 x 54 10 x 62

42CG

Bottom Return 10 x 23

Rear Return 8 x 23

42CK

Bottom Return 10 x 28 10 x 28 10 x 33 10 x 45 10 x 45 10 x 62 10 x 62

Rear Return 7 x 21 7 x 21 7 x 27 7 x 38 7 x 38 7 x 52 7 x 52

Qty 111 1 1 11

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS (Sweat) (in. OD)

Coil Outlet and Inlet

Drain Connection

Tell-Tale Drain

*Calculate Operating Weight of Unit: Shipping Weight + Coil Water

Weight x Number of Coil Rows.

1

/

2

1

/

2

10 x 28 10 x 321/

8 x 28 8 x 321/

2

2

10 x 37 10 x 41 10 x 541/

8 x 37 8 x 41 8 x 541/

5

/

8

7

/

8

5

/

8

10 x 63

2

8 x 63

2

†Filter size if located in return-air plenum.

2

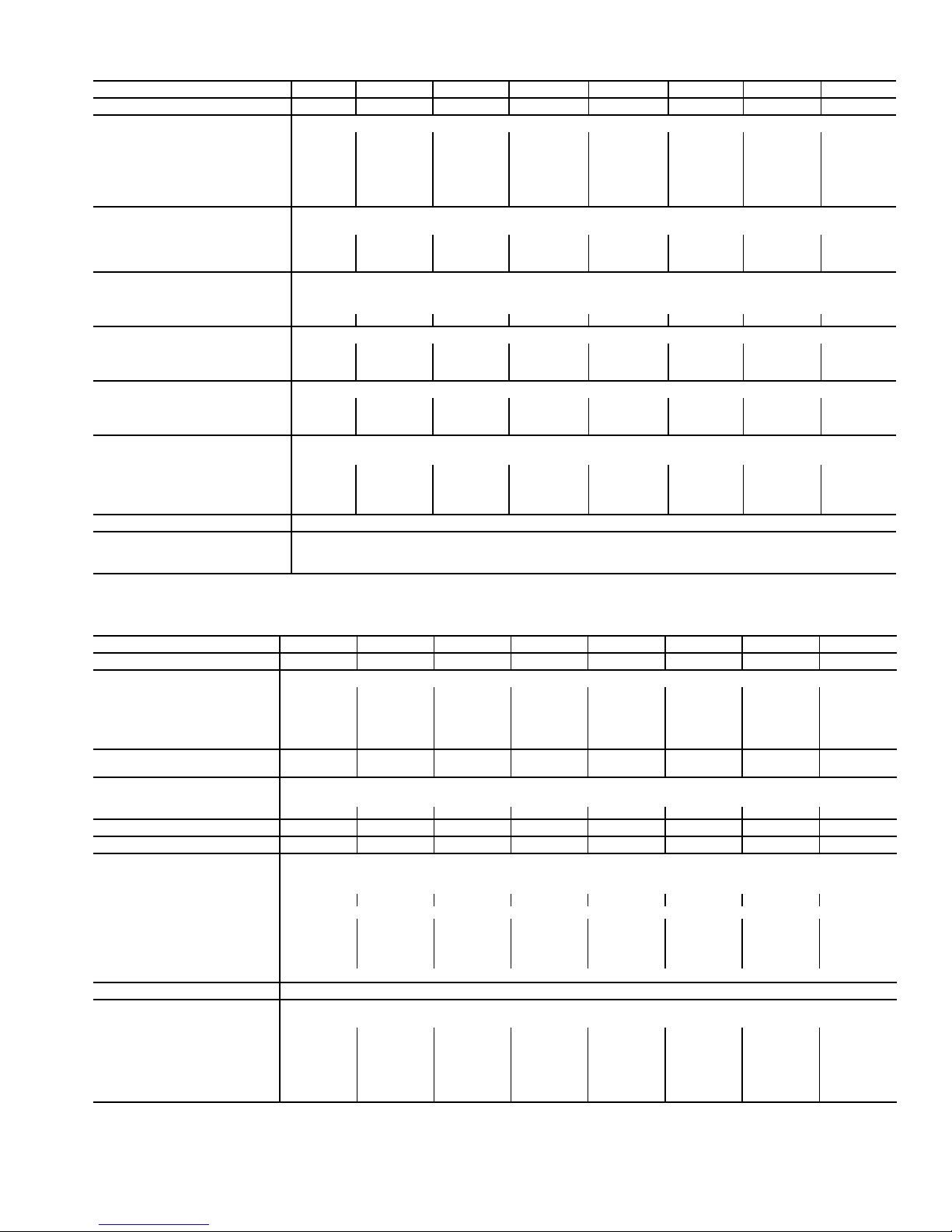

Table 2 — Physical Data — 42V Series Units

UNIT SIZE 42V 01 02 03 04 06 08 10 12

NOMINAL AIRFLOW (cfm) 150 200 300 400 600 800 1000 1200

SHIPPING WEIGHT (lb)*

42VA — 42 47 57 77 79 108 127

42VB — 63 68 82 99 101 133 154

42VC — 50 60 72 110 — — —

42VE — 72 100 108 154 — — —

42VF — 64 69 83 100 102 135 156

42VG 40 — 74 — — — — —

COIL WATER WEIGHT

(Approx lb per row of coil)

42VA, VB, VC†, VF — 0.7 0.8 1.0 1.4 1.7 2.3 2.7

42VE — 0.9 1.2 1.6 2.3 — — —

42VG 0.4 — 1.0 — — — — —

COILS

FPI (42VA, VB, VF) 12 fins/inch

FPI (42VC, VE, VG) 10 fins/inch

Coil Face Area (sq ft) 0.8 0.8 1.1 1.4 1.9 2.3 3.2 3.7

MOTOR (qty)

42VA, VB, VF —111 1122

42VC, VE —1 1 1 2 — — —

42VG 1— 2 — — — — —

BLOWER (qty)

42VA, VB, VF —112 2244

42VC, VE —2 2 2 4 — — —

42VG 1— 2 — — — — —

FILTERS

Nominal Size (in.) (1-in. thick)

42VA, VB, VF —7

42VC, VE —7 x 21

42VG 10 x 14

Qty 1111 1111

3

/4 x 213/473/4 x 213/473/4 x 313/473/4 x 413/473/4 x 433/473/4 x 573/473/4 x 653/

3

/

7 x 263/

1

/

2

4

— 10 x 28 — — — — —

7 x 343/

4

7 x 483/

4

4

———

4

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS (Sweat) (in.)

Coil Outlet and Inlet

Drain Connection

*Calculate Operating Weight of Unit: Shipping Weight + Coil Water Weight x

Number Of Coil Rows.

†Available in sizes 02-06.

5

/8 OD

3

/4 MPT

Table 3 — Physical Data — 42D Series Units

UNIT SIZE 42D 0608101214161820

NOMINAL AIRFLOW (cfm) 600 800 1000 1200 1400 1600 1800 2000

SHIPPING WEIGHT (lb)*

42DA 64 79 90 108 119 124 141 151

42DC 94 107 150 169 174 178 195 220

42DD 135 145 155 180 190 200 215 230

42DE 150 160 170 195 205 215 230 235

42DF 157 167 177 202 215 225 240 255

COIL WATER WEIGHT

(Approx lb per row of coil)

COILS

FPI 10 fins/inch

Coil Face Area (sq ft) 1.62.12.53.03.54.14.65.0

MOTOR (qty) 11122222

BLOWER (qty) 11122222

FILTERS

Nominal Size (in.) (1-in. thick)

42DA NA

42DC 14 x 21 14 x 26 14 x 30 14 x 35 14 x 40 14 x 45 14 x 50 14 x 54

42DD

(Front Return) 12

(Bottom Return) 12

42DE 14 x 14

42DF 14 x 14 14 x 20 14 x 24 14 x 28 14 x 34 14 x 38 14 x 44 14 x 48

Qty

SUPPLY DUCT COLLAR 1-in.

PIPING CONNECTIONS

Coil Inlet/Outlet (in. OD)

1 and 2 Row

3 Row

4 Row

5 Row

6 Row

8 Row 11/

1.31.61.92.32.73.03.43.7

3

/4 x 21 123/4 x 26 123/4 x 30 123/4 x 35 123/4 x 40 123/4 x 45 123/4 x 50 123/4 x 54

3

/4 x 20 123/4 x 25 123/4 x 29 123/4 x 34 123/4 x 39 123/4 x 44 123/4 x 49 123/4 x 53

3

/

14 x 193/

4

14 x 233/

4

14 x 283/

4

14 x 333/

4

14 x 383/

4

14 x 433/

4

14 x 473/

4

4

1

11/

5

/

8

5

/

8

7

/

8

7

/

8

7

/

8

8

5

/

8

5

/

8

7

/

8

7

/

8

7

/

8

8

11/

5

/

8

7

/

8

7

/

8

7

/

8

7

/

8

8

5

/

8

7

/

8

7

/

8

7

/

8

7

/

8

11/

8

11/

11/

15/

5

/

8

7

/

8

7

/

8

8

8

8

11/

11/

11/

15/

5

/

8

7

/

8

8

8

8

8

11/

11/

11/

15/

5

/

8

7

/

8

8

8

8

8

11/

11/

11/

15/

5

/

8

7

/

8

8

8

8

8

*Calculate Operating Weight of Unit: Shipping Weight + Coil Water Weight x Number of Coil Rows.

3

PRE-INSTALLATION

Unpack and Inspect Units —

inspected at the factory throughout the manufacturing process

under a strict detailed quality assurance program, and, where

possible, ALL major components and sub-assemblies are carefully tested for proper operation and verified for full compliance with factory standards. Operational testing of some customer-furnished components such as electronic control valves

and digital controllers may be a possible exception.

Each unit is carefully packaged for shipment to avoid damage during normal transit and handling. Equipment should always be stored in a dry place, and in the proper orientation as

marked on the carton. All shipments are made F.O.B. factory

and are the responsibility of the receiving party to inspect the

equipment upon arrival. Any obvious damage to the carton

and/or its contents should be recorded on the bill of lading and

a claim should be filed with the transportation company, and

Carrier should be advised. After determining the condition of

the carton exterior, carefully remove each unit from the carton

and inspect for hidden damage. At this time, check to make

sure that “furnished only” items such as thermostats, grilles etc.

are accounted for whether packaged separately or shipped at a

later date. Any hidden damage should be recorded and immediately reported to the transportation company, a claim should

be filed with the transportation company, and Carrier should be

notified. In the event a claim for shipping damage is filed, the

unit, shipping carton, and all packing must be retained for

physical inspection by the transportation company. All equipment should be stored in the factory shipping carton with internal packing in place until installation.

At the time of receipt, the equipment type and arrangement

should be verified against the order documents. Should any

discrepancy be found, the local sales representative should be

notified immediately so that proper action may be taken.

Should any questions arise concerning warranty repairs, the

factory must be notified BEFORE any corrective action is taken. Where local repairs or alterations can be accomplished, the

factory must be fully informed of the extent and expected cost

of those repairs before work is begun. Where factory operations are required, the factory must be contacted for authorization to return equipment and a Return Authorization Number

will be issued. Unauthorized return shipments of equipment

and shipments not marked with an authorization number will

be refused. In addition, any claims for unauthorized expenses

will not be accepted by the manufacturer.

All units are carefully

Protect Units from Damage — All equipment is de-

signed and fabricated with robust materials and presents a

rugged appearance. Still, great care must be taken to assure

that no force or pressure is applied to the coil, piping, or drain

stub-outs during handling. Depending on the options and accessories, some units may contain delicate components that

may be damaged by improper handling. All units shall be handled by the chassis or as close as possible to the unit mounting

point locations. In the case of a full cabinet unit, the unit must

be handled by the exterior casing. This is acceptable provided

the unit is maintained in an upright position, and no force is applied that may damage internal components or painted

surfaces.

The equipment must always be properly supported. Temporary supports used during installation or service must be adequate to hold the equipment securely. Equipment should always be stored in the proper orientation as marked on the carton. To maintain warranty, protect units against hostile

environment (such as rain, snow, or extreme temperatures),

theft, vandalism, and debris on jobsite. Equipment covered in

this manual is not suitable for outdoor installations. Do not allow foreign material to fall into drain pan. Prevent dust and debris from being deposited on motor, fan wheels and cooling/

heating coils. Failure to do so may have serious adverse effects

on unit operation, and in the case of the motor and blower assembly, may result in immediate or premature failure. Manufacturer's warranty is void if foreign material is allowed to be

deposited on the motor or blower wheels of any unit. Some

units and/or job conditions may require some form of temporary covering during construction.

Prepare Jobsite for Unit Installation — To save

time and to reduce the possibility of costly errors, set up a complete sample installation in a typical room at jobsite. Check all

critical dimensions such as pipe, wire, and duct connection

requirements. Refer to job drawings and product dimension

drawings as required (see Fig. 1-28). Instruct all trades in their

part of the installation.

Identify and Prepare Units — Be sure power require-

ments match available power source. Refer to unit nameplate

and wiring diagram.

1. Check all tags on unit to determine if shipping screws are

to be removed. Remove screws as directed.

2. Rotate the fan wheel by hand to ensure that the fan is

unrestricted and can rotate freely. Check for shipping

damage and fan obstructions. Adjust blower motor as

required.

3. Perform "Dry Fit" of valve assembly that may be shipped

unattached to unit coil assembly. Should any questions

arise on fit up please contact your local representative.

4. Horizontal plenum type 42CE units may be shipped with

a bottom return-air inlet. These units may be converted to

rear return as outlined in Appendix C.

5. Hi-Performance plenum-type 42DC units may be

shipped with a bottom return-air inlet. These units may

be converted to rear return as outlined in Appendix C.

4

1

2

3

1

(25)

3

(76)

B

A

2-1/4

(64)

1-1/8

(29)

6

(152)

1-1/2

(38)

D’

A’

5

4

E

MTG. HOLES

H

6

3/4

(19)

3/4

(19)

11

5

16

(406)

SUPPLY

AIR

F

G

7/8

(22)

7

10

8

9

17-1/2

(445)

8-3/8

(213)

1

(25)

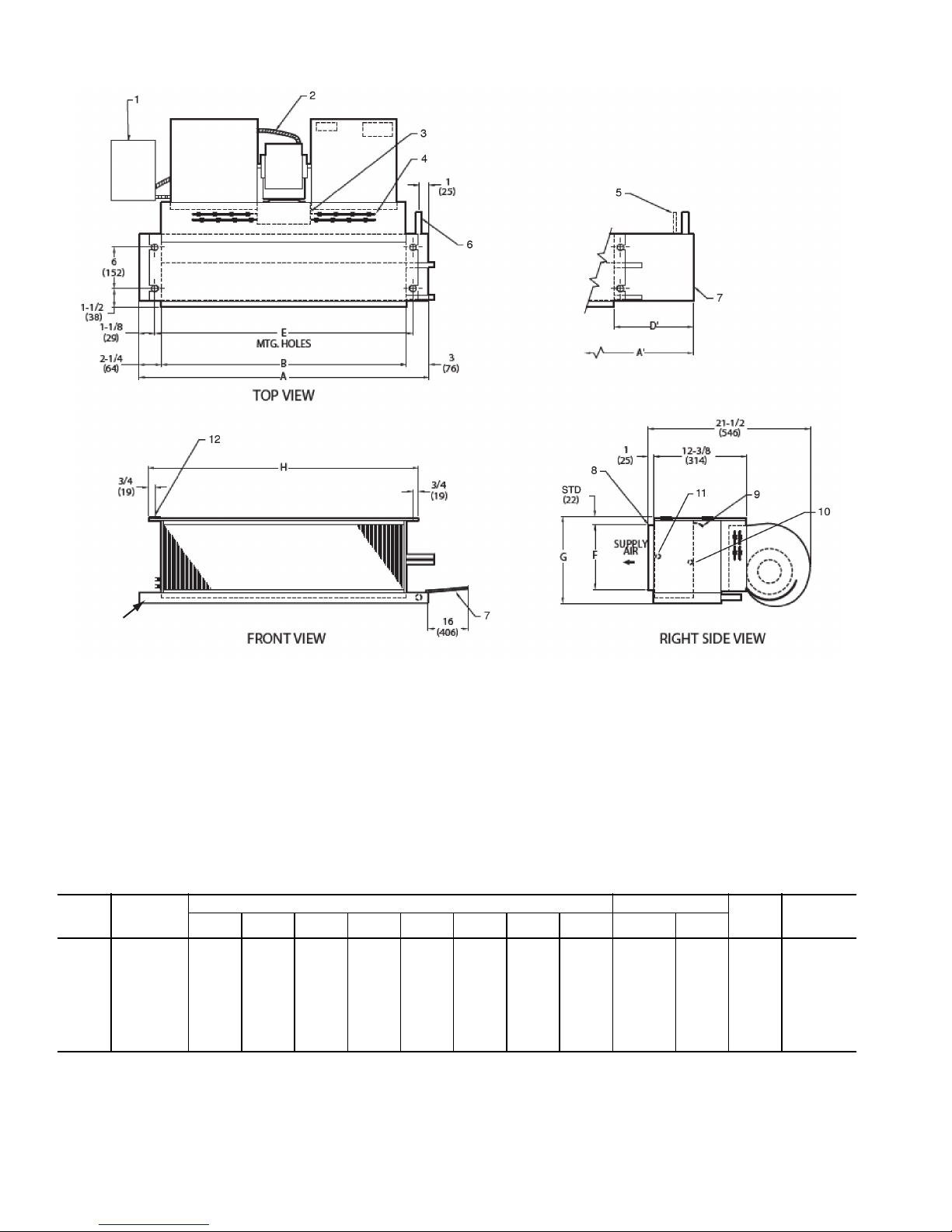

LEGEND

1—Junction Box (remote mount)

2—Flexible Metal Conduit

3—Drain Conn,

7

/8-in. OD

4 — Tell-Tale Drain Conn, 5/8-in. OD (optional)

5—Drip Lip (optional, shipped loose)

6—Hanger Slots (4), Rubber Grommet

has

3

/8-in. Diameter Hole

7—Supply Duct Collar, 1-in.

8—Air Vent,

1

/8-in. MPT

9—Return Conn,

5

/8-in. OD

10 — Supply Conn,

5

/8-in. OD

11 — Drain Pan

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’BD’E F G H

Blower Motor

02 200 21

1

/4311/

4

16 13 181/

4

61/

4

83/

4

193/

4

1 1 0.83 36

03 300 25

1

/4361/

4

20 14 221/

4

61/

4

83/

4

233/

4

1 1 1.08 39

04 400 31

1

/4431/

4

26 15 281/

4

61/

4

83/

4

293/

4

2 1 1.35 49

06 600 36

1

/4431/

4

31 10 331/

4

71/

2

10 343/

4

2 1 1.88 59

08 800 43

1

/4571/

4

38 17 401/

4

71/

2

10 413/

4

2 1 2.31 64

10 1000 57

1

/4651/

4

52 11 541/

4

71/

2

10 553/

4

4 2 3.16 95

12 1200 65

1

/4751/

4

60 13 621/

4

71/

2

10 633/

4

4 2 3.65 107

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±5/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Overall unit dimension increases by 4 in. with optional electric

heat.

5. Not shown: 3-speed fan switch; wall plate; closed cell foam on

main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

a42-4099.eps

Fig. 1 — 42CA Furred-In Horizontal Unit Dimensions

5

13

LEGEND

1—Junction Box (remote mount)

2—Flexible Metal Conduit

3 — Strip Heater High Limit

4 — Electric Strip Heater Element

5 — Tell-Tale Drain Conn,

5

/8-in. OD (optional)

6—Drain Conn, 7/8-in. OD

7—Drip Lip (optional, shipped loose)

8—Supply Duct Collar, 1-in.

9—Air Vent,

1

/8-in. MPT

10 — Return Conn, 5/8-in. OD

11 — Supply Conn,

5

/8-in. OD

12 — Hanger Slots (4), Rubber Grommet

has

3

/8-in. Diameter Hole

13 — Drain Pan

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Overall unit dimension increases by 4 in. with optional electric

heat.

5. Not shown: 3-speed fan switch; wall plate; closed cell foam on

main drain pan.

6. Units have galvanized finish.

7. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’BD’E F G H

Blower Motor

02 200 21

1

/4311/

4

16 13 181/

4

61/

4

83/

4

193/

4

1 1 0.83 38

03 300 25

1

/4361/

4

20 14 221/

4

61/

4

83/

4

233/

4

1 1 1.08 41

04 400 31

1

/4431/

4

26 15 281/

4

61/

4

83/

4

293/

4

2 1 1.35 51

06 600 36

1

/4431/

4

31 10 331/

4

71/

2

10 343/

4

2 1 1.88 61

08 800 43

1

/4571/

4

38 17 401/

4

71/

2

10 413/

4

2 1 2.31 66

10 1000 57

1

/4651/

4

52 11 541/

4

71/

2

10 553/

4

4 2 3.16 97

12 1200 65

1

/4751/

4

60 13 621/

4

71/

2

10 633/

4

4 2 3.65 109

a42-4100.eps

Fig. 2 — 42CA Furred-In Horizontal Unit with Electric Heat Dimensions

6

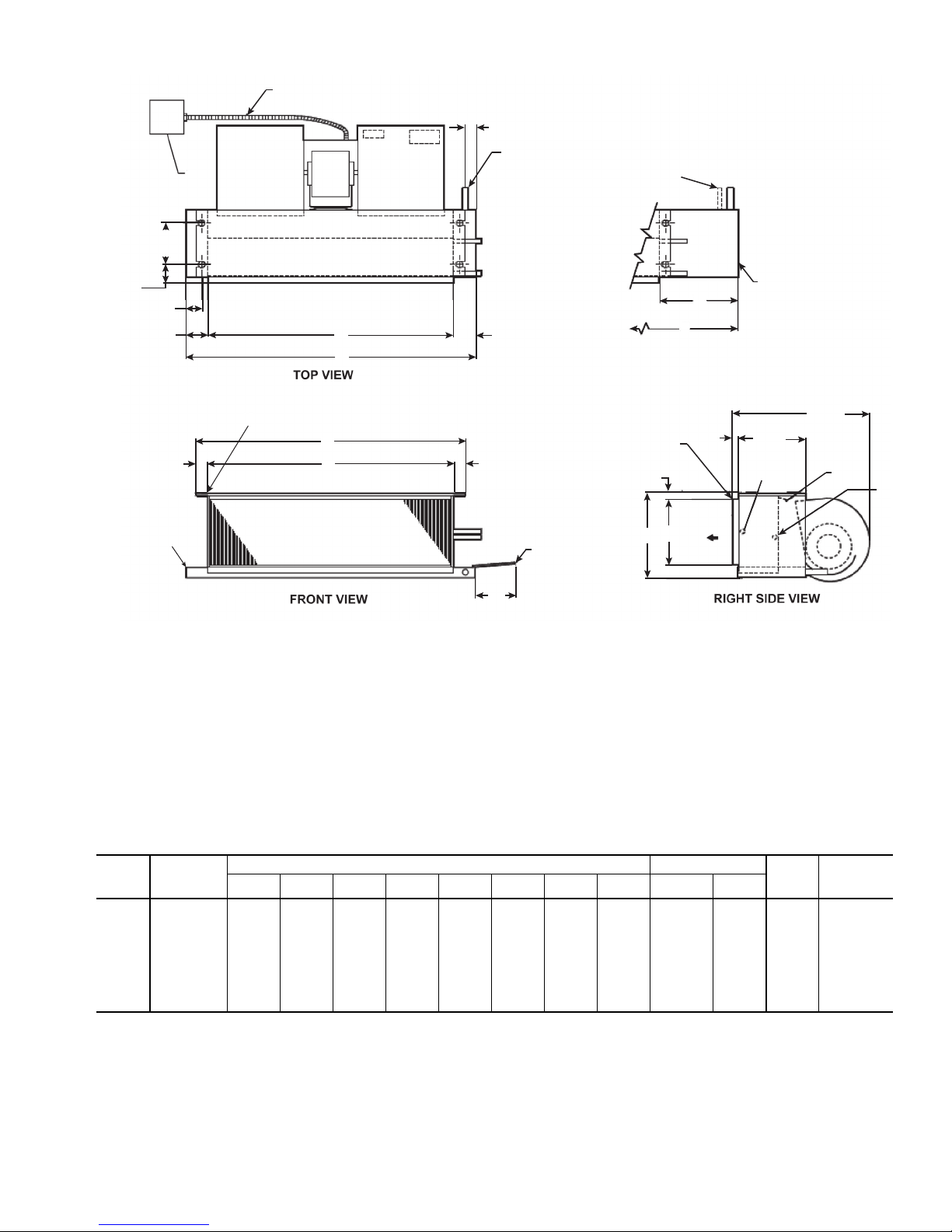

16

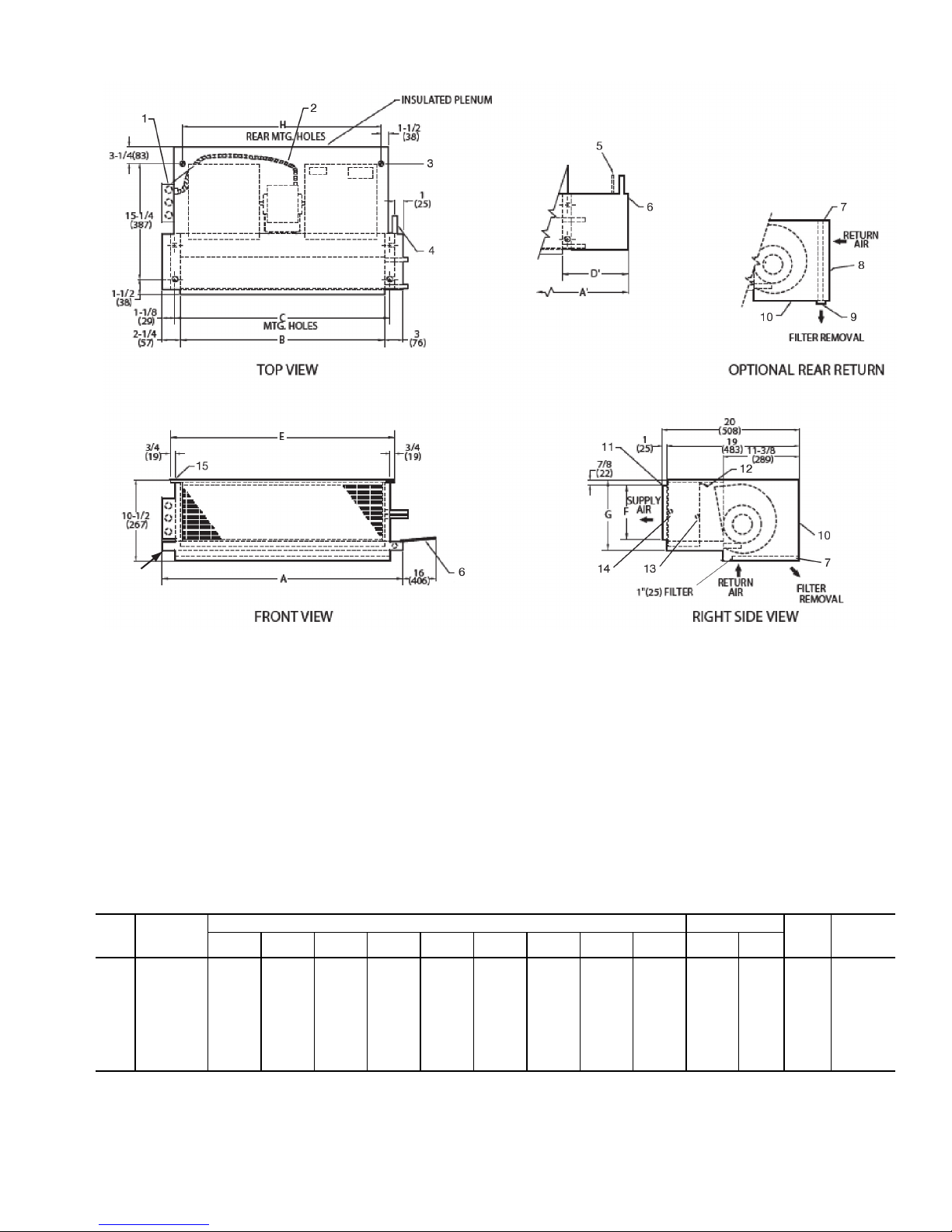

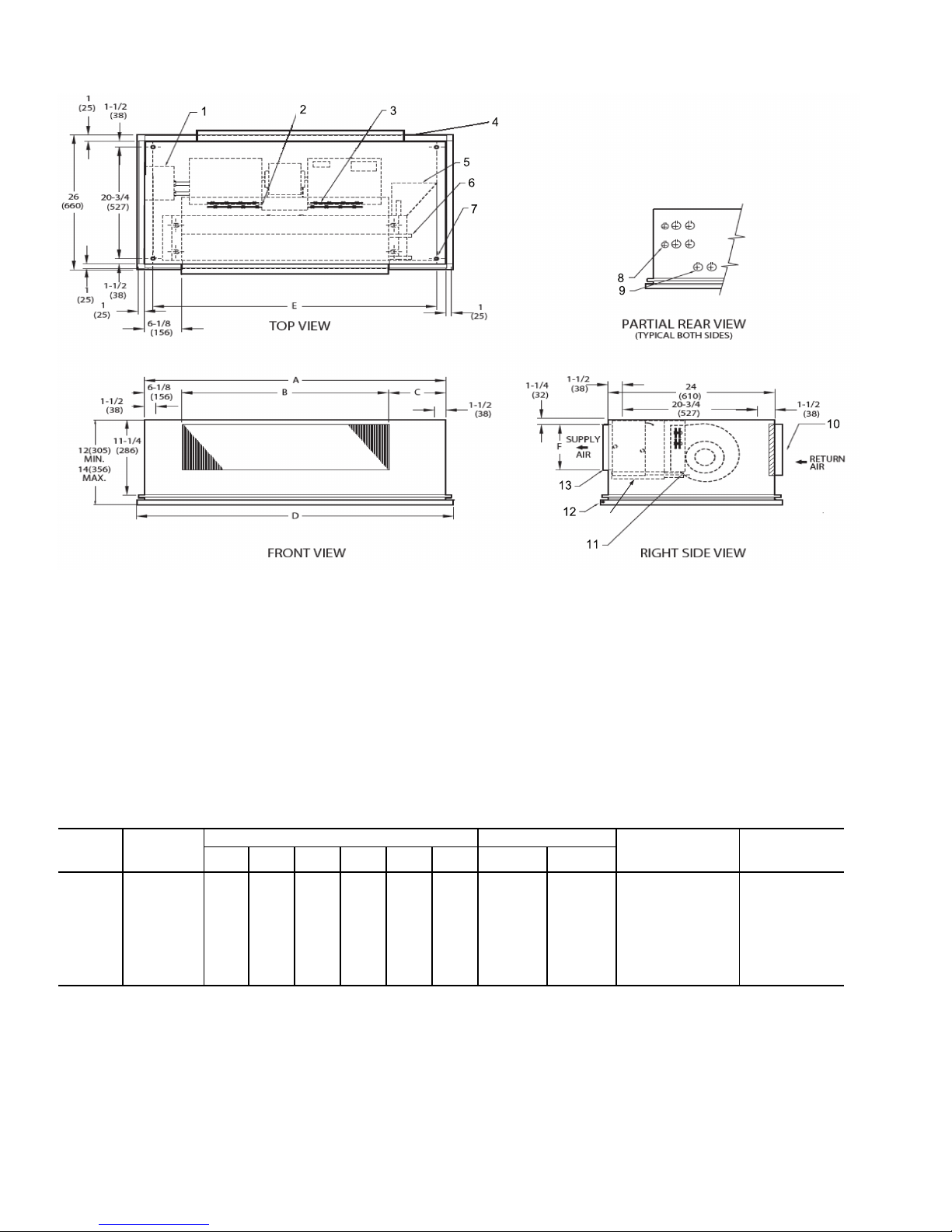

NOTES:

1. Right hand unit with standard 3-row coil shown; left hand unit opposite. Coil

connection locations are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08 have

one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Unit available with bottom or rear return air.

5. Overall dimension increases by 4 in. with optional electric heat.

6. Not shown: 3-speed fan switch; wall plate;

1

/2-in. fiberglass insulation on

inside of plenum, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42CA-203-1 using the Fan Coil Builder.

9. Dimensions shown in inches (mm).

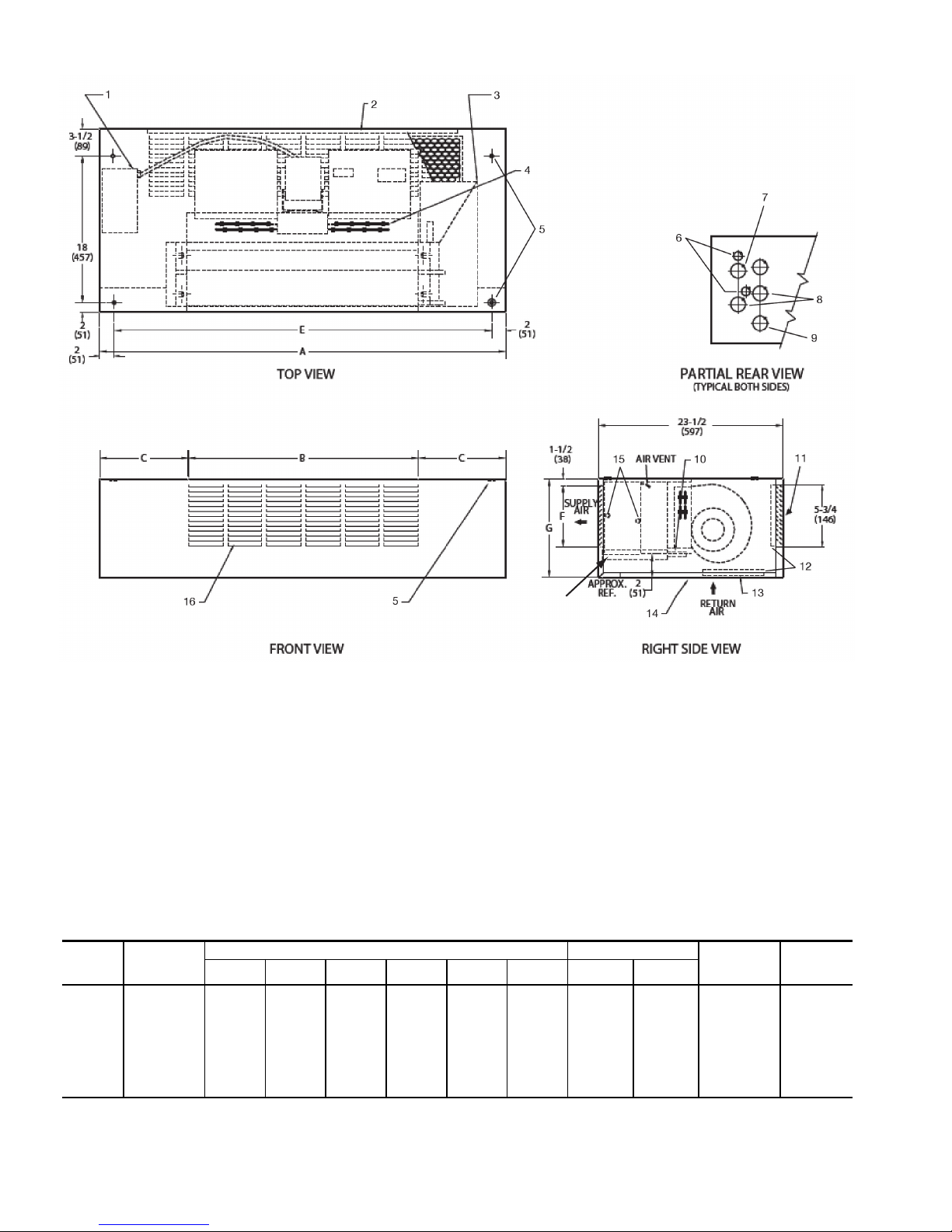

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Flexible Metal Conduit

3— Mounting Bracket

4— Drain Conn,

7

/8-in. OD

5— Tell-Tale Drain Conn,

5

/8-in. OD (optional)

6— Drip Lip (optional, shipped loose)

7— Filter

8— Return Duct Collar, 1-in.

9— Filter Access Panel

10 — Access Panel

11 — Supply Duct Collar, 1-in.

12 — Air Vent,

1

/8-in. MPT

13 — Return Conn,

5

/8-in. OD

14 — Supply Conn, 5/8-in. OD

15 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

16 — Drain Pan

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’BCD’E F G H

Blower Motor

02 200 21

1

/4311/

4

16 181/

4

13 193/

4

61/

4

83/

4

153/

8

1 1 0.83 55

03 300 25

1

/4361/

4

20 221/

4

14 233/

4

61/

4

83/

4

193/

8

1 1 1.08 60

04 400 31

1

/4431/

4

26 281/

4

15 293/

4

61/

4

83/

4

253/

8

2 1 1.35 70

06 600 36

1

/4431/

4

31 331/

4

10 343/

4

71/

2

10 303/

8

2 1 1.88 82

08 800 43

1

/4571/

4

38 401/

4

17 413/

4

71/

2

10 373/

8

2 1 2.31 95

10 1000 57

1

/4651/

4

52 541/

4

11 553/

4

71/

2

10 513/

8

4 2 3.16 135

12 1200 65

1

/4751/

4

60 621/

4

13 633/

4

71/

2

10 593/

8

4 2 3.65 154

a42-4101

Fig. 3 — 42CE Furred-In Horizontal Unit with Plenum Dimensions

7

18

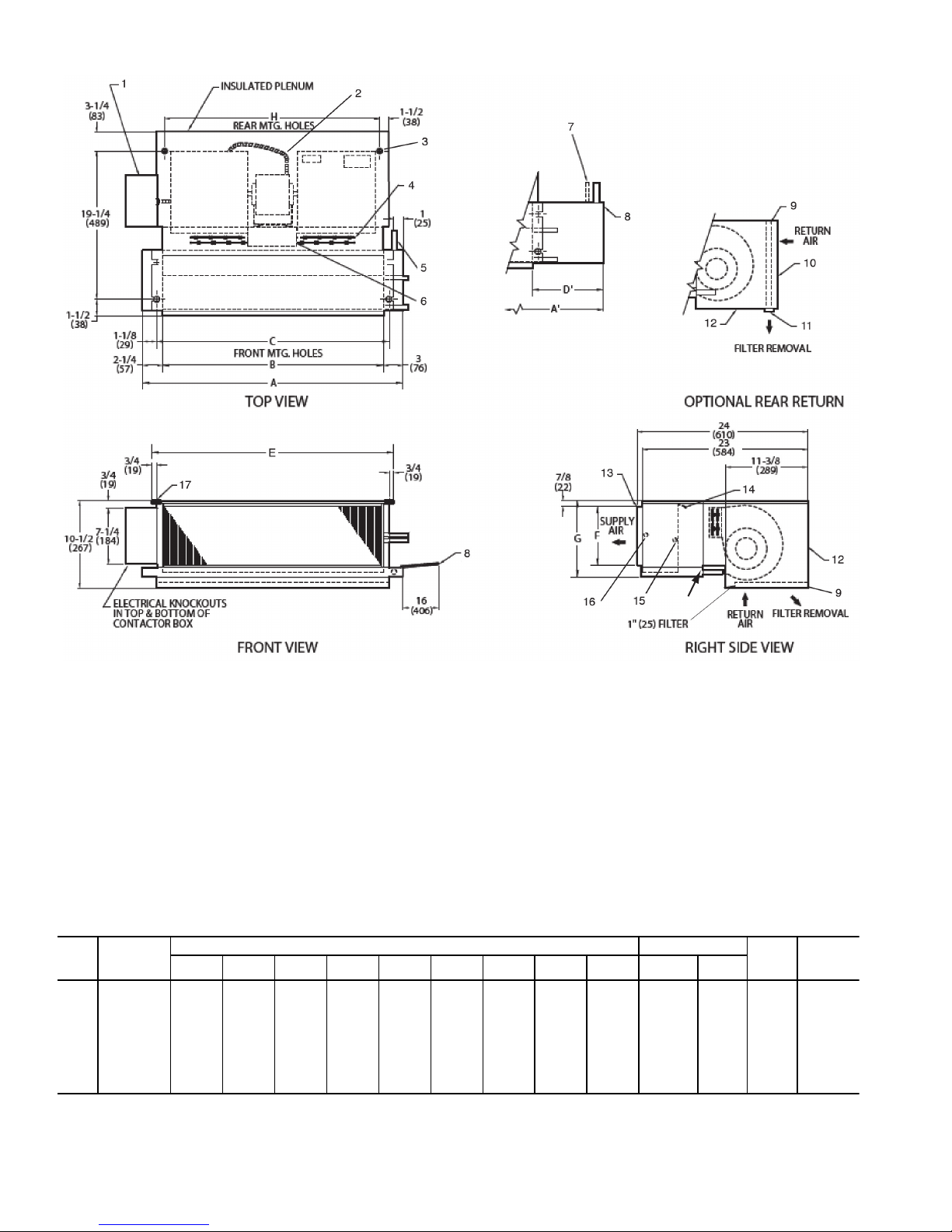

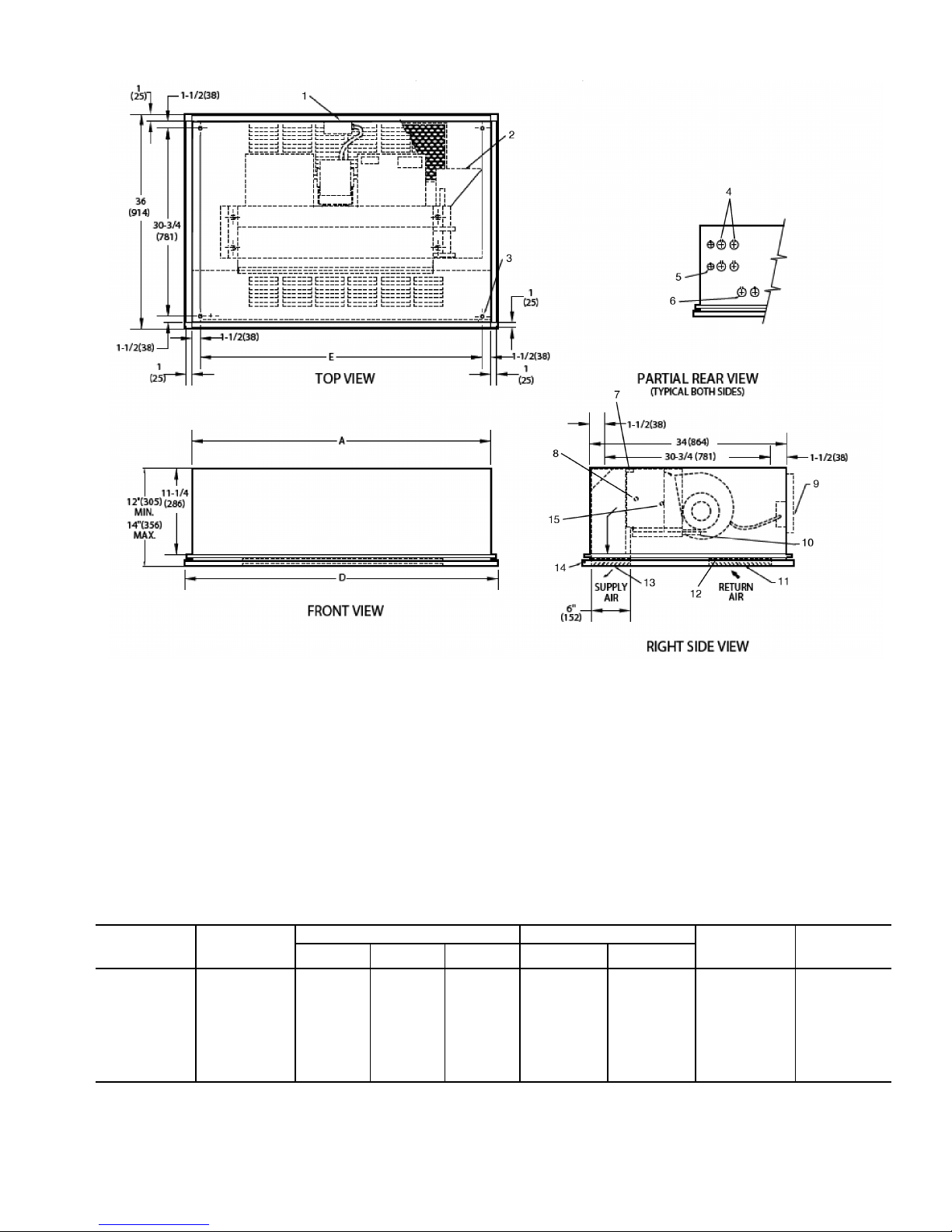

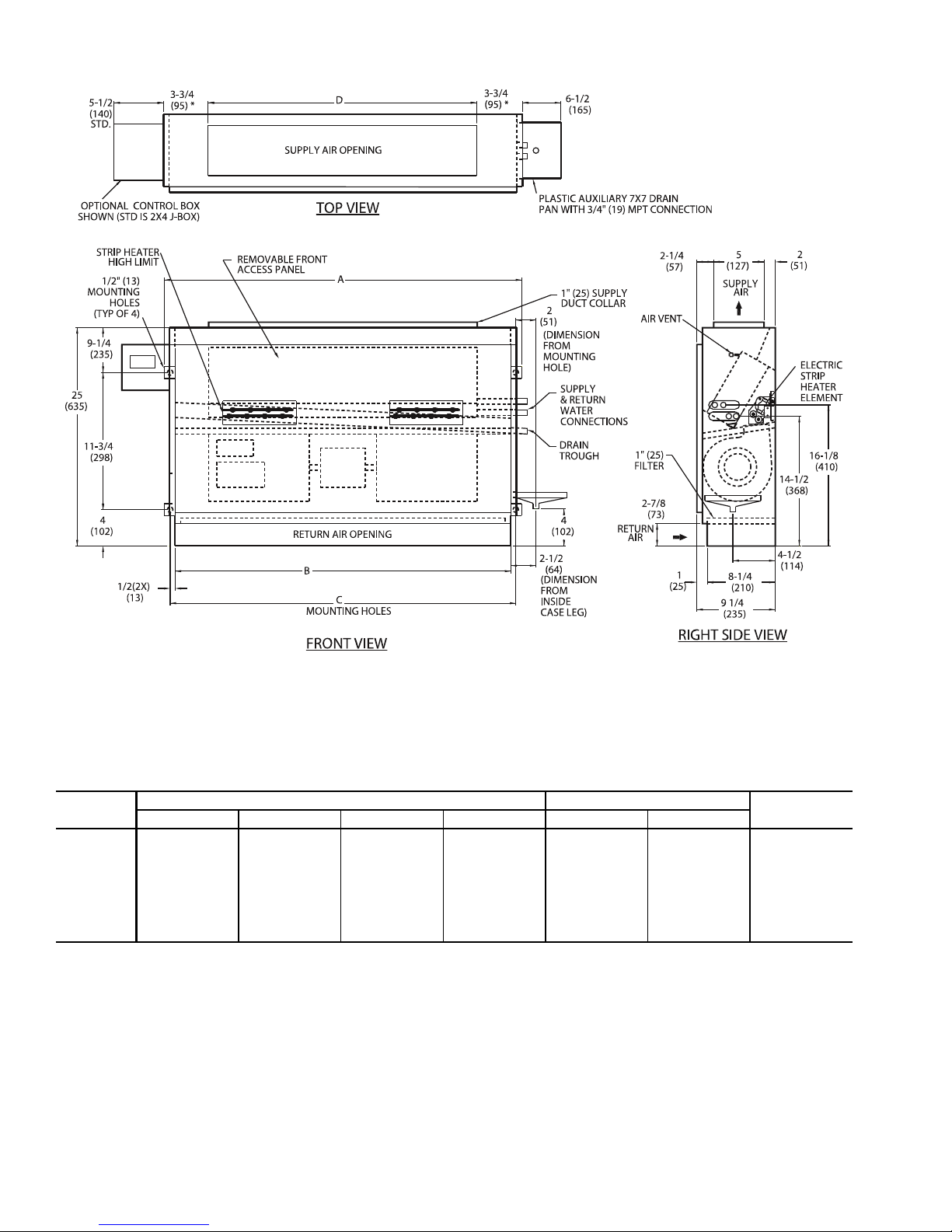

NOTES:

1. Right hand unit with standard 3-row coil shown; left hand unit opposite. Coil

connection locations are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08 have

one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Standard 3-row coil shown.

4. Unit available with bottom or rear return air.

5. Overall dimension increases by 4 in. with optional electric heat.

6. Not shown: 3-speed fan switch; wall plate;

1

/2-in. fiberglass insulation on

inside of plenum, closed cell foam on main drain pan.

7. Units have galvanized finish.

8. For optional coil connections, view 42CA-203-1 using the Fan Coil Builder.

9. Dimensions shown in inches (mm).

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Flexible Metal Conduit

3— Mounting Bracket

4— Electric Strip Heater Element

5— Drain Conn,

7

/8-in. OD

6— Strip Heater High Limit

7— Tell-Tale Drain Conn,

5

/8-in. OD (optional)

8— Drip Lip (optional, shipped loose)

9— Filter

10 — Return Duct Collar, 1-in.

11 — Filter Access Panel

12 — Access Panel

13 — Supply Duct Collar, 1-in.

14 — Air Vent,

1

/8-in. MPT

15 — Return Conn, 5/8-in. OD

16 — Supply Conn,

5

/8-in. OD

17 — Hanger Slots (4), Rubber Grommet has

3

/8-in. Diameter Hole

18 — Drain Pan

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

AA’B CD’E F G H

Blower Motor

02 200 21

1

/4311/

4

16 181/

4

13 193/

4

61/

4

83/

4

153/

8

1 1 0.83 57

03 300 25

1

/4361/

4

20 221/

4

14 233/

4

61/

4

83/

4

193/

8

1 1 1.08 62

04 400 31

1

/4431/

4

26 281/

4

15 293/

4

61/

4

83/

4

253/

8

2 1 1.35 72

06 600 36

1

/4431/

4

31 331/

4

10 343/

4

71/

2

10 303/

8

2 1 1.88 84

08 800 43

1

/4571/

4

38 401/

4

17 413/

4

71/

2

10 373/

8

2 1 2.31 97

10 1000 57

1

/4651/

4

52 541/

4

11 553/

4

71/

2

10 513/

8

4 2 3.16 137

12 1200 65

1

/4751/

4

60 621/

4

13 633/

4

71/

2

10 593/

8

4 2 3.65 156

A42-4102

Fig. 4 — 42CE Furred-In Horizontal Unit with Plenum and Electric Heat Dimensions

8

16

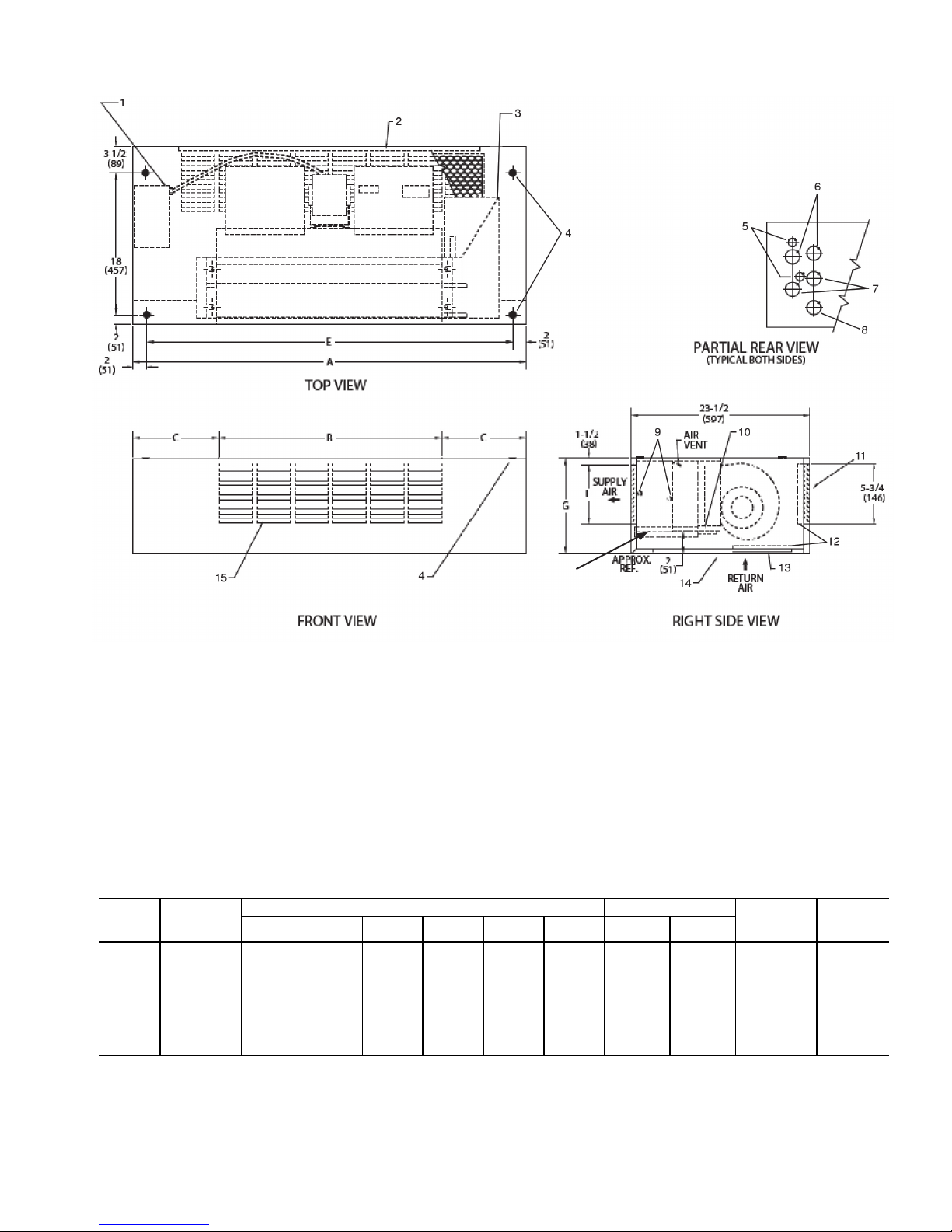

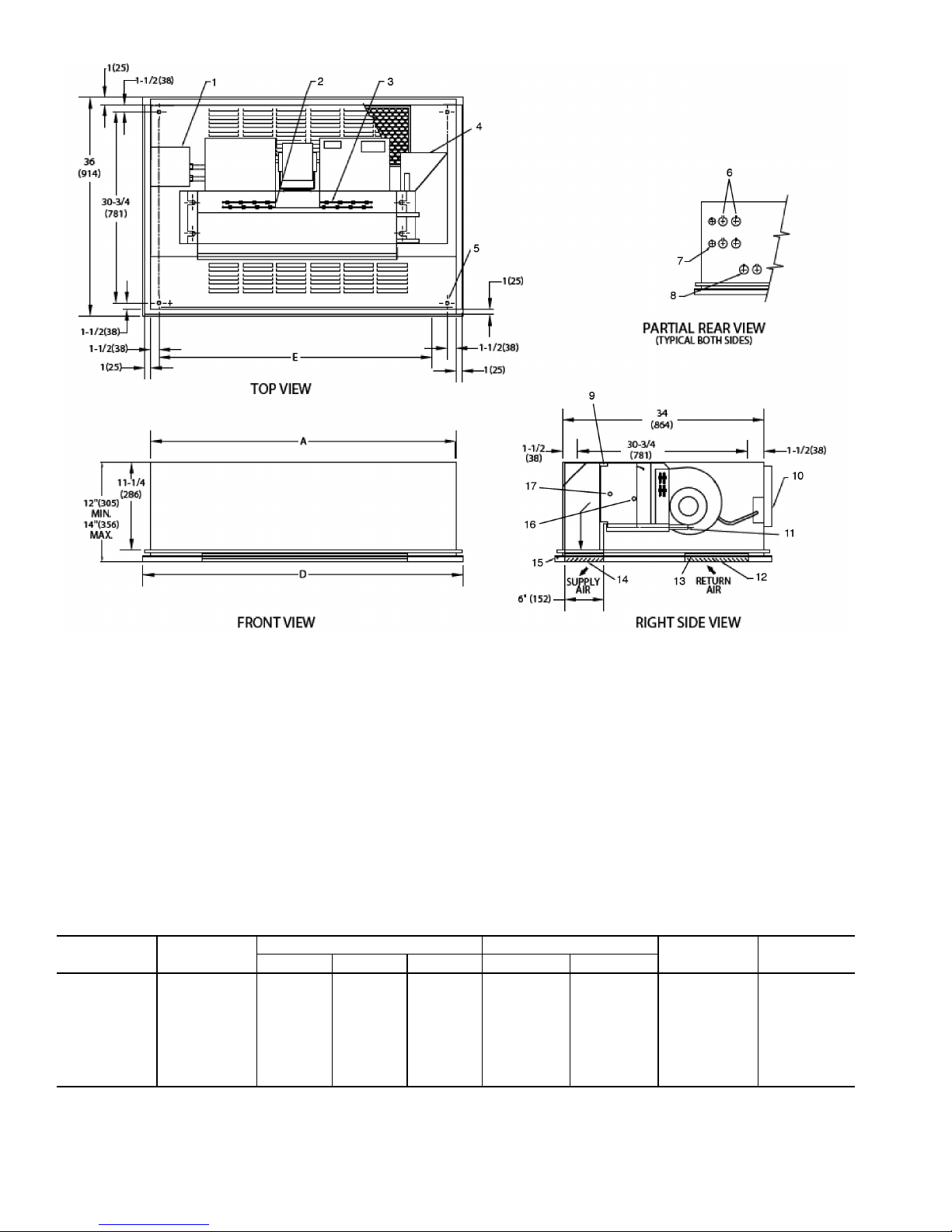

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Optional Return Air Location

3— Drip Lip (optional, shipped loose)

4— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

5— Electrical Knockout,

7

/8-in. Diameter

6— Return Knockout, 1-in. Diameter

7— Supply Knockout, 11/2-in. Diameter

8— Drain Knockout, 1

1

/2-in. Diameter

9— Supply, Return Connections,

5

/8-in. OD

10 — Drain Connection,

7

/8-in. OD

11 — Optional Valve Package (inside cabinet)

12 — Filter

13 — Standard Stamped-Return Air Grille

14 — Removable Hinged Access Panel

15 — Supply Grille, Stamped, Standard

16 — Drain Pan

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCEFG

Blower Motor

02 200 38 17

1

/

8

107/

16

34 53/

4

11 1 1 0.83 98

03 300 42 21

1

/

2

101/

4

38 53/

4

11 1 1 1.08 118

04 400 48 25

7

/

8

111/

16

44 53/

4

11 2 1 1.35 126

06 600 53 34

5

/

8

93/

16

49 63/

4

12 2 1 1.88 168

08 800 60 39 10

1

/

2

56 63/

4

12 2 1 2.31 176

10 1000 74 52

1

/

8

1015/

16

70 63/

4

12 4 2 3.16 215

12 1200 82 60

7

/

8

109/

16

78 63/

4

12 4 2 3.65 245

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection locations

are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04 through 08

have one motor, 2 blowers; sizes 10 and 12 have 2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out locations.

5. Not shown: optional drip lip, 3-speed fan switch; wall plate;

1

/2-in. fiber-

glass insulation on inside of casing, closed cell foam on main drain pan.

6. For optional coil connections, view 42CA-203-1 using the Fan Coil

Builder.

7. Valve package is factory-installed inside the cabinet when ordered with

the unit (based on component size).

8. Dimensions shown in inches (mm).

A42-4105

Fig. 5 — 42CG Horizontal Cabinet Unit Dimensions

9

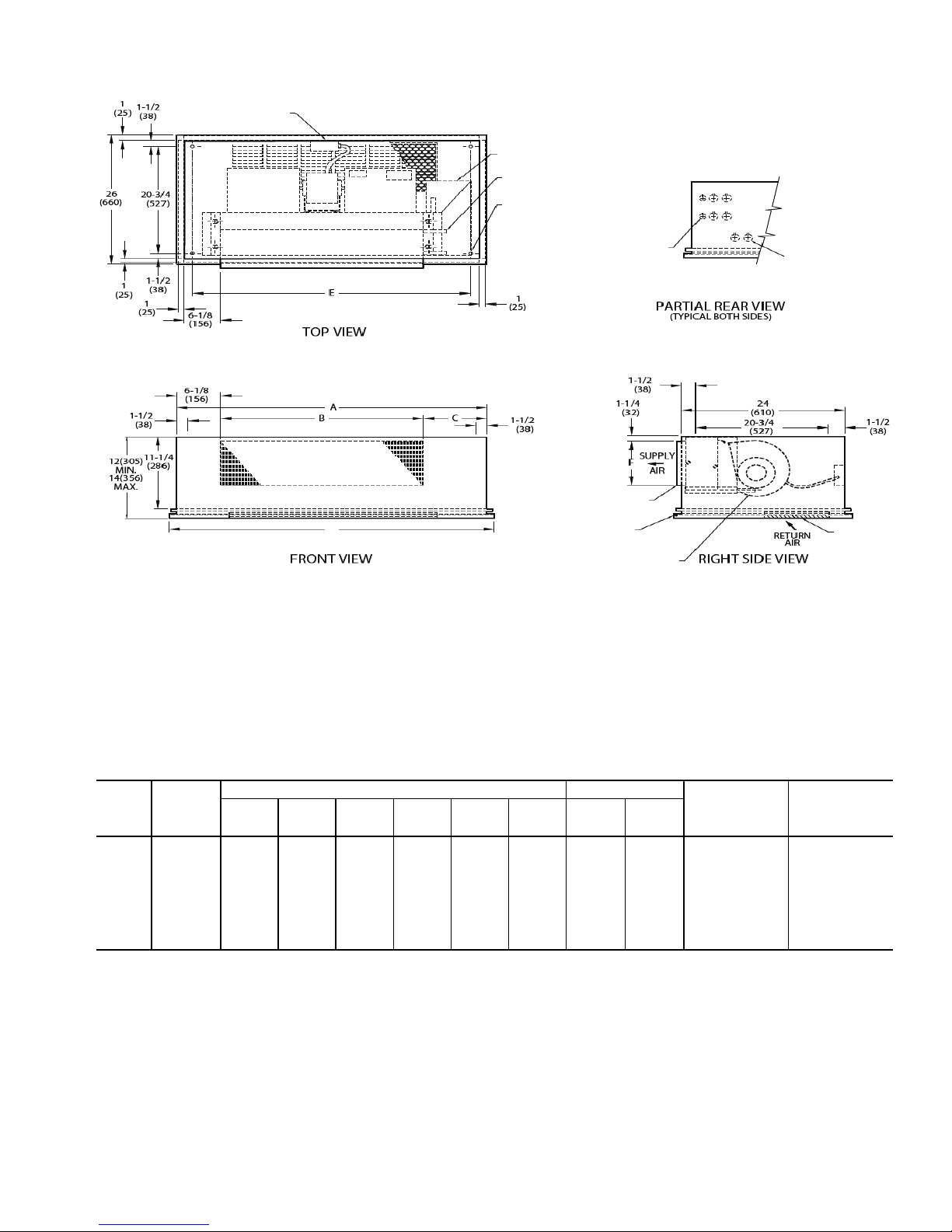

17

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Optional Stamped Rear Return Grille

3— Drip Lip (optional, shipped loose)

4— Electric Strip Heater Element

5— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

6— Electrical Knockout, 7/8-in. Diameter

7— Return Knockout, 1-in. Diameter

8— Supply Knockout, 1

1

/2-in. Diameter

9— Drain Knockout, 1

1

/2-in. Diameter

10 — Drain Connection,

7

/8-in. OD

11 — Valve Package (optional, inside cabinet)

12 — Filter

13 — Standard Stamped-Return Air Grille

14 — Removable Hinged Access Panel

15 — Supply, Return Connections,

5

/8-in. OD

16 — Supply Grille, Stamped, Standard

17 — Drain Pan

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Cabinet has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: 3-speed fan switch; wall plate;

1

/2-in. fiberglass

insulation on inside of casing, closed cell foam on main drain

pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT FACE

AREA

(sq ft)

UNIT

WEIGHT*

(lb)

ABCEFG

Blower Motor

02 200 38 17

1

/

8

107/

16

34 53/

4

11 1 1 0.83 98

03 300 42 21

1

/

2

101/

4

38 53/

4

11 1 1 1.08 118

04 400 48 25

7

/

8

111/

16

44 53/

4

11 2 1 1.35 126

06 600 53 34

5

/

8

93/

16

49 63/

4

12 2 1 1.88 168

08 800 60 39 10

1

/

2

56 63/

4

12 2 1 2.31 176

10 1000 74 52

1

/

8

1015/

16

70 63/

4

12 4 2 3.16 215

12 1200 82 60

7

/

8

109/

16

78 63/

4

12 4 2 3.65 245

A42-4106

Fig. 6 — 42CG Horizontal Cabinet with Electric Heat Dimensions

10

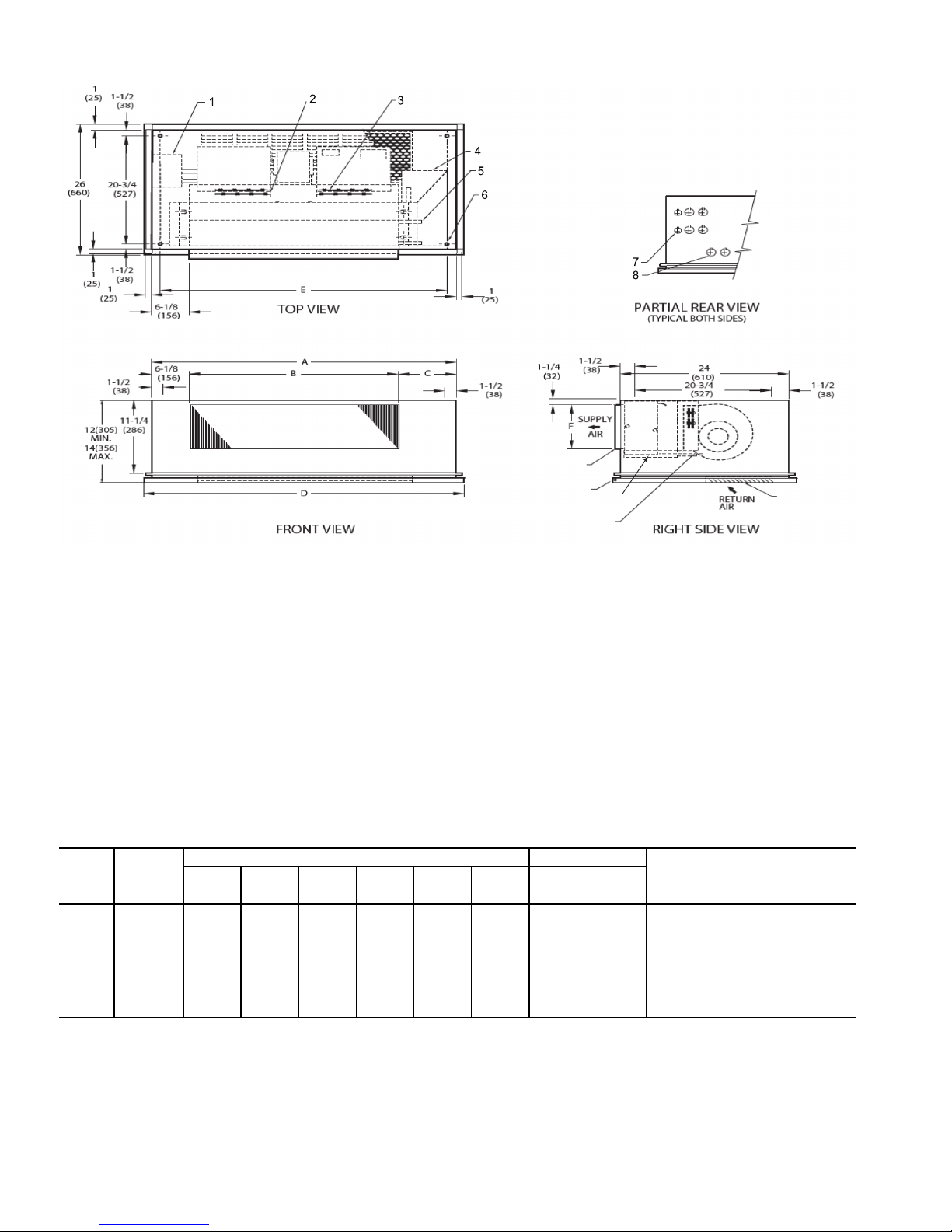

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT BOTTOM

RETURN

FILTER SIZE

(in.)

UNIT WEIGHT*

(lb)

ABCDEFBlowerMotor

02 200 35 16 12

3

/

4

37 32 6 1 1 10 x 231/

2

115

03 300 35 20 8

3

/

4

37 32 6 1 1 10 x 28 120

04 400 41 26 8

3

/

4

43 38 6 2 1 10 x 321/

2

135

06 600 53 31 15

3

/

4

55 50 7 2 1 10 x 37 150

08 800 53 38 8

3

/

4

55 50 7 2 1 10 x 41 155

10 1000 75 52 16

3

/

4

77 72 7 4 2 10 x 541/

2

227

12 1200 75 60 8

3

/

4

77 72 7 4 2 10 x 63 241

LEGEND

1 — Junction Box

2 — L-shape Drip Lip (optional, shipped loose)

3 — Chilled/Hot Water Supply and Return Connection

4 — Resilient Mounting Grommets with

3

/8-in. Diameter Hole

(typically 4)

5 — Electrical Knockout,

7

/8-in. Diameter

6 — Drain Knockout, 11/2-in. Diameter

7 — Stamped Return Air Grille and 1-in. Filter

8 — Condensate Drain Connection,

7

/8-in. OD

9 — Hinged Bottom Return Air Panel

10 — Supply Duct Collar, 1-in. OD

A42-4149

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with cabinet

knockouts.

3. Dimensions shown in inches (mm). All dimensions are ±

1

/4 inches.

4. Bottom panel is Arctic White polyester powder coat paint.

7

8

9

10

6

5

4

3

2

1

D

Fig. 7 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, and Bottom Return Dimensions

11

12

11

10

9

13

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are

±

1

/4 inches.

4. Bottom panel is Arctic White polyester powder coat paint.

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT BOTTOM

RETURN

FILTER SIZE

(in.)

UNIT WEIGHT*

(lb)

ABCDEFBlowerMotor

02 200 35 16 12

3

/

4

37 32 6 1 1 10 x 231/

2

117

03 300 35 20 8

3

/

4

37 32 6 1 1 10 x 28 122

04 400 41 26 8

3

/

4

43 38 6 2 1 10 x 321/

2

137

06 600 53 31 15

3

/

4

55 50 7 2 1 10 x 37 152

08 800 53 38 8

3

/

4

55 50 7 2 1 10 x 41 157

10 1000 75 52 16

3

/

4

77 72 7 4 2 10 x 541/

2

229

12 1200 75 60 8

3

/

4

77 72 7 4 2 10 x 63 243

a42-4150

LEGEND

1 — Contactor Box

2 — Strip Heater High Limit

3 — Electric Strip Heater Element

4 — L-shape Drip Lip (optional, shipped loose)

5 — Chilled/Hot Water Supply and Return Connection

6 — Resilient Mounting Grommets with

3

/8-in. Diameter Hole

(typically 4)

7 — Electrical Knockout, 7/8-in. Diameter

8 — Drain Knockout, 1

1

/2-in. Diameter

9 — Stamped Return Air Grille and 1-in. Filter

10 — Condensate Drain Connection,

7

/8-in. OD

11 — Hinged Bottom Return Air Panel

12 — Supply Duct Collar, 1-in. OD

13 — Drain Pan

Fig. 8 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, Bottom Return, and Heater Dimensions

12

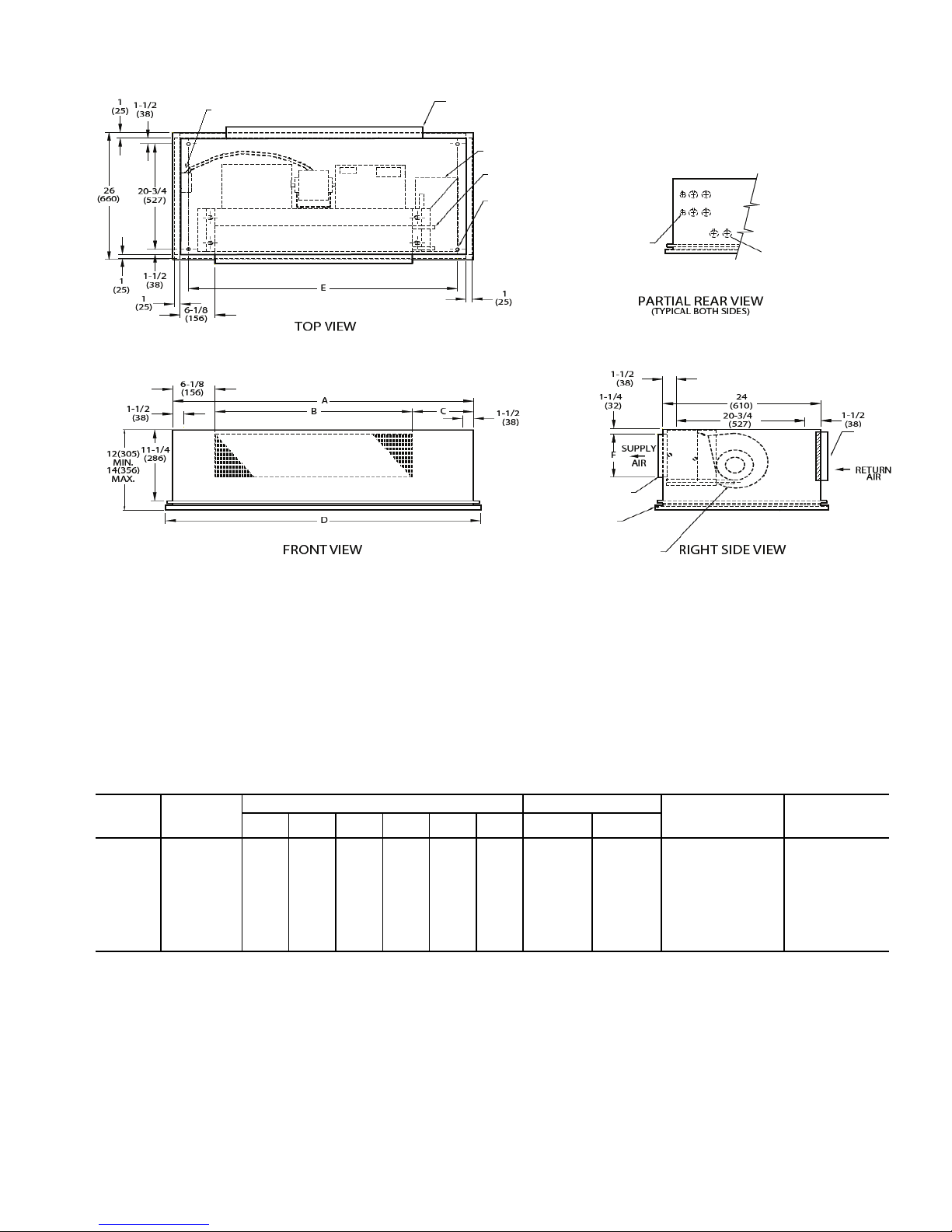

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

REAR RETURN

FILTER SIZE (in.)

UNIT WEIGHT*

(lb)

ABCDEFBlowerMotor

02 200 35 16 12

3

/437 32 6 1 1 7 x 21 115

03 300 35 20 8

3

/437 32 6 1 1 7 x 21 120

04 400 41 26 8

3

/443 38 6 2 1 7 x 27 135

06 600 53 31 15

3

/455 50 7 2 1 7 x 38 150

08 800 53 38 8

3

/455 50 7 2 1 7 x 38 155

10 1000 75 52 16

3

/477 72 7 4 2 7 x 52 227

12 1200 75 60 8

3

/477 72 7 4 2 7 x 52 241

a42-4151

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align with

cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are

±

1

/4 inches.

4. Bottom panel is Arctic White polyester powder coat paint.

LEGEND

1 — Junction Box

2 — 1-in. Ducted Rear Return and 1-in. Filter

3 — L-shape Drip Lip (optional, shipped loose)

4 — Chilled/Hot Water Supply and Return Connection

5 — Resilient Mounting Grommets with

3

/8-in. Diameter Hole

(typically 4)

6 — Electrical Knockout, 7/8-in. Diameter

7 — Drain Knockout, 1

1

/2-in. Diameter

8 — 1-in. Ducted Rear Return and 1-in. Filter

9 — Condensate Drain Connection, 7/8-in. OD

10 — Hinged Bottom Return Air Panel

11 — Supply Duct Collar, 1-in. OD

8

9

10

11

7

6

5

4

3

2

1

Fig. 9 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, and Rear Return Dimensions

13

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Internal factory valve package and drains may not align

with cabinet knockouts.

3. Dimensions shown in inches (mm). All dimensions are

±

1

/4 inches.

4. Bottom panel is Arctic White polyester powder coat paint.

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

REAR RETURN

FILTER SIZE (in.)

UNIT WEIGHT*

(lb)

ABCDEFBlowerMotor

02 200 35 16 12

3

/437 32 6 1 1 7 x 21 117

03 300 35 20 8

3

/

4

37 32 6 1 1 7 x 21 122

04 400 41 26 8

3

/

4

43 38 6 2 1 7 x 27 137

06 600 53 31 15

3

/

4

55 50 7 2 1 7 x 38 152

08 800 53 38 8

3

/

4

55 50 7 2 1 7 x 38 157

10 1000 75 52 16

3

/

4

77 72 7 4 2 7 x 52 229

12 1200 75 60 8

3

/

4

77 72 7 4 2 7 x 52 243

a42-4152

LEGEND

1 — Contactor Box

2 — Strip Heater High Limit

3 — Electric Strip Heater Element

4 — 1-in. Ducted Rear Return and 1-in. Filter

5 — L-shape Drip Lip (optional, shipped loose)

6 — Chilled/Hot Water Supply and Return Connection

7 — Resilient Mounting Grommets with

3

/8-in. Diameter Hole

(typically 4)

8 — Electrical Knockout,

7

/8-in. Diameter

9 — Drain Knockout,11/2-in. Diameter

10 — 1-in. Ducted Rear Return and 1-in. Filter

11 — Condensate Drain Connection,

7

/8-in. OD

12 — Hinged Bottom Return Air Panel

13 — Supply Duct Collar, 1-in. OD

14 — Drain Pan

14

Fig. 10 — 42CK Horizontal Cabinet Unit with Telescopic Access Panel,

Front Supply, Rear Return, and Heater Dimensions

14

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Drip Lip (optional, shipped loose)

3— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

4— Piping Knockout, 1

1

/2-in. Diameter

5— Electrical Knockout,

7

/8-in. Diameter

6— Drain Knockout, 1

1

/2-in. Diameter

7— Supply Duct Collar

8— Return Connection,

5

/8-in. OD

9— Optional Rear Return. Consult factory for

collar dimensions

10 — Drain,

7

/8-in. OD

11 — Stamped Bottom Return Air Grille

12 — Filter

13 — Stamped Air Supply Grille

14 — Hinged Bottom Access Panel

15 — Supply Connection,

5

/8-in. OD

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

NOM

AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT WEIGHT*

(lb)

ADE

Blower Motor

02 200 35 37 32 1 1 0.83 115

03 300 35 37 32 1 1 1.08 120

04 400 41 43 38 2 1 1.35 135

06 600 53 55 50 2 1 1.88 150

08 800 53 55 50 2 1 2.31 155

10 1000 75 77 72 4 2 3.16 227

12 1200 75 77 72 4 2 3.65 241

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±5/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Bottom access panel has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: 3-speed fan switch; wall plate;

1

/2-in. fiberglass

insulation on inside of casing, closed cell foam on main drain

pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Bottom return or bottom supply is an ETO (engineering to order)

request.

9. Dimensions shown in inches (mm).

A42-4107

Fig. 11 — 42CK Horizontal Cabinet Unit with Bottom Supply and Return and Telescopic Access Panel

Dimensions

15

LEGEND

1— Junction Box, 4 in. x 4 in.

2— Strip Heater High Limit

3— Electric Strip Heater Element

4— Drip Lip (optional, shipped loose)

5— Mounting Holes (4), Rubber Grommets

have

3

/8-in. Diameter Hole

6— Piping Knockout, 1

1

/2-in. Diameter

7— Electrical Knockout,

7

/8-in. Diameter

8— Drain Knockout, 1

1

/2-in. Diameter

9— Supply Duct Collar

10 — Optional Rear Return. Consult factory for

collar dimensions.

11 — Drain,

7

/8-in. OD

12 — Stamped Bottom Return Air Grille

13 — Filter

14 — Stamped Air Supply Grille

15 — Hinged Bottom Access Panel

16 — Supply Connection,

5

/8-in. OD

17 — Return Connection,

5

/8-in. OD

NOTES:

1. Right hand unit shown; left hand unit opposite. Coil connection

locations are ±

5

/8-inch.

2. Unit sizes 02 and 03 have one motor, one blower; sizes 04

through 08 have one motor, 2 blowers; sizes 10 and 12 have

2 motors, 4 blowers.

3. Bottom access panel has an Arctic White baked finish.

4. Refer to supply and return connections above for coil stub-out

locations.

5. Not shown: 3-speed fan switch; wall plate;

1

/2-in. fiberglass

insulation on inside of casing; closed cell foam on main drain

pan.

6. For optional coil connections, view 42CA-203-1 using the Fan

Coil Builder.

7. Valve package is factory-installed inside the cabinet when

ordered with the unit (based on component size).

8. Bottom return or bottom supply is an ETO (engineering to order)

request.

9. Dimensions shown in inches (mm).

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT SIZE

NOM AIRFLOW

(Cfm)

DIMENSIONS (in.) QTY/UNIT

FACE AREA

(sq ft)

UNIT WEIGHT*

(lb)

ADEBlowerMotor

02 200 35 37 32 1 1 0.83 117

03 300 35 37 32 1 1 1.08 122

04 400 41 43 38 2 1 1.35 137

06 600 53 55 50 2 1 1.88 152

08 800 53 55 50 2 1 2.31 157

10 1000 75 77 72 4 2 3.16 229

12 1200 75 77 72 4 2 3.65 243

A42-4108

Fig. 12 — 42CK Horizontal Cabinet with Bottom Supply and Return and Telescopic Access Panel and Electric

Heat Dimensions

16

FRONT VIEW

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

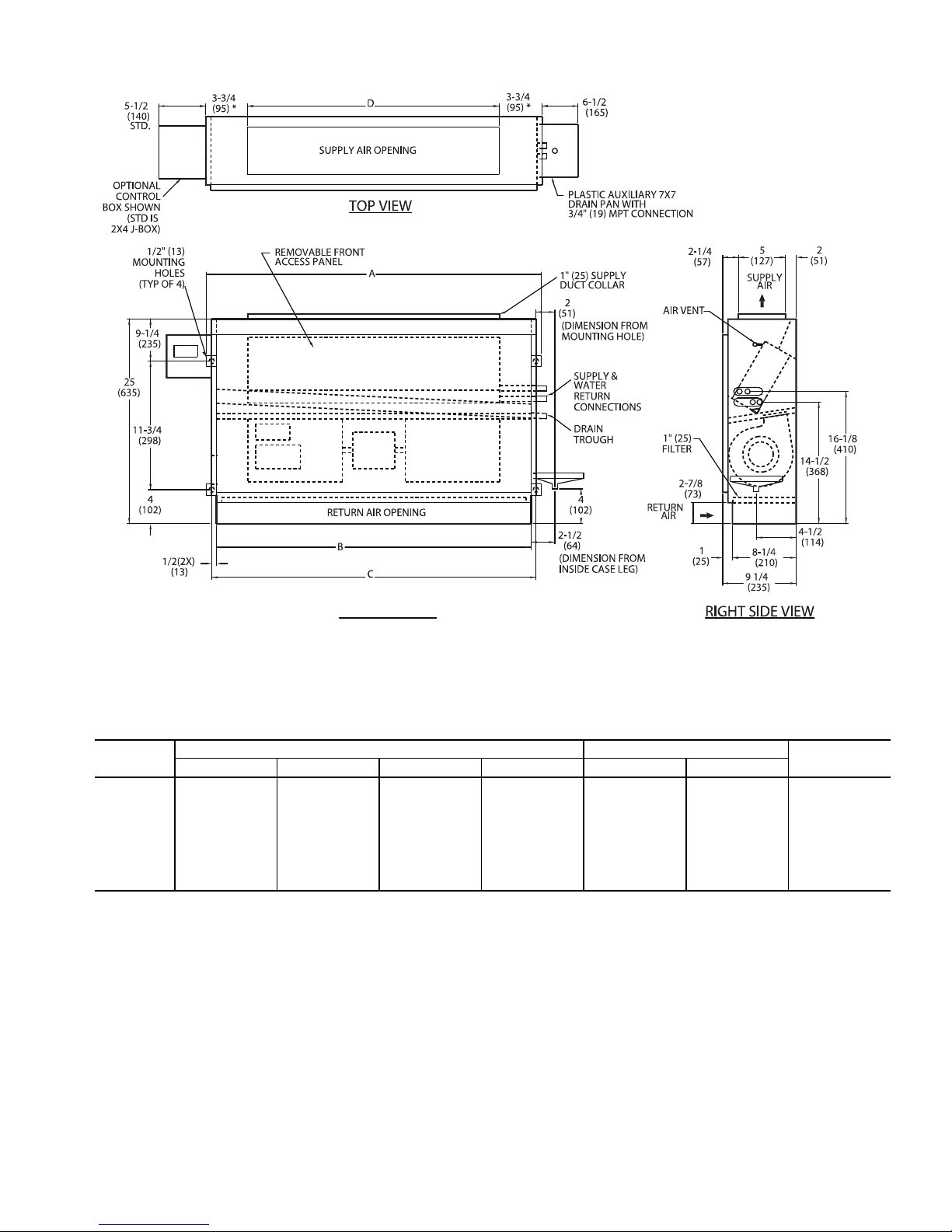

UNIT

SIZE

DIMENSIONS (in.) QTY/UNIT

UNIT WEIGHT*

(lb)

ABCDBlowerMotor

02 24

3

/

16

22 23 16 1 1 42

03 24

3

/

16

22 23 18 1 1 47

04 34

3

/

16

32 33 26 2 1 57

06 44

3

/

16

42 43 36 2 1 77

08 46

3

/

16

44 45 38 2 1 79

10 60

3

/

16

58 59 52 4 2 108

12 68

3

/

16

66 67 60 4 2 127

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Dimensions shown in inches (mm). All dimensions are

±

1

/4 inches.

a42-4381

Fig. 13 — 42VA Furred-In Vertical Unit Dimensions

17

a42-4382

*Unit weights are based on dry coils and minimum rows. Weights exclude packaging, valves, and other components.

UNIT

SIZE

DIMENSIONS (in.) QTY/UNIT

UNIT WEIGHT*

(lb)

ABCDBlowerMotor

02 24

3

/

16

22 23 16 1 1 42

03 24

3

/

16

22 23 18 1 1 47

04 34

3

/

16

32 33 26 2 1 57

06 44

3

/

16

42 43 36 2 1 77

08 46

3

/

16

44 45 38 2 1 79

10 60

3

/

16

58 59 52 4 2 108

12 68

3

/

16

66 67 60 4 2 127

NOTES:

1. Right hand unit shown; left hand unit opposite.

2. Dimensions shown in inches (mm). All dimensions are

±

1

/4 inches.

Fig. 14 — 42VA Furred-In Unit with Electric Heat Dimensions

18

Loading...

Loading...