Carrier 30HR Product data

The Flotronic™ Plus Chiller Combines These Extra-Performance Features for Increased Energy Savings:

• microprocessor-based control

system

• electronic expansion valve

• increased part-load efficiency

• multiple compressors — extra capacity steps

Features/Benefits

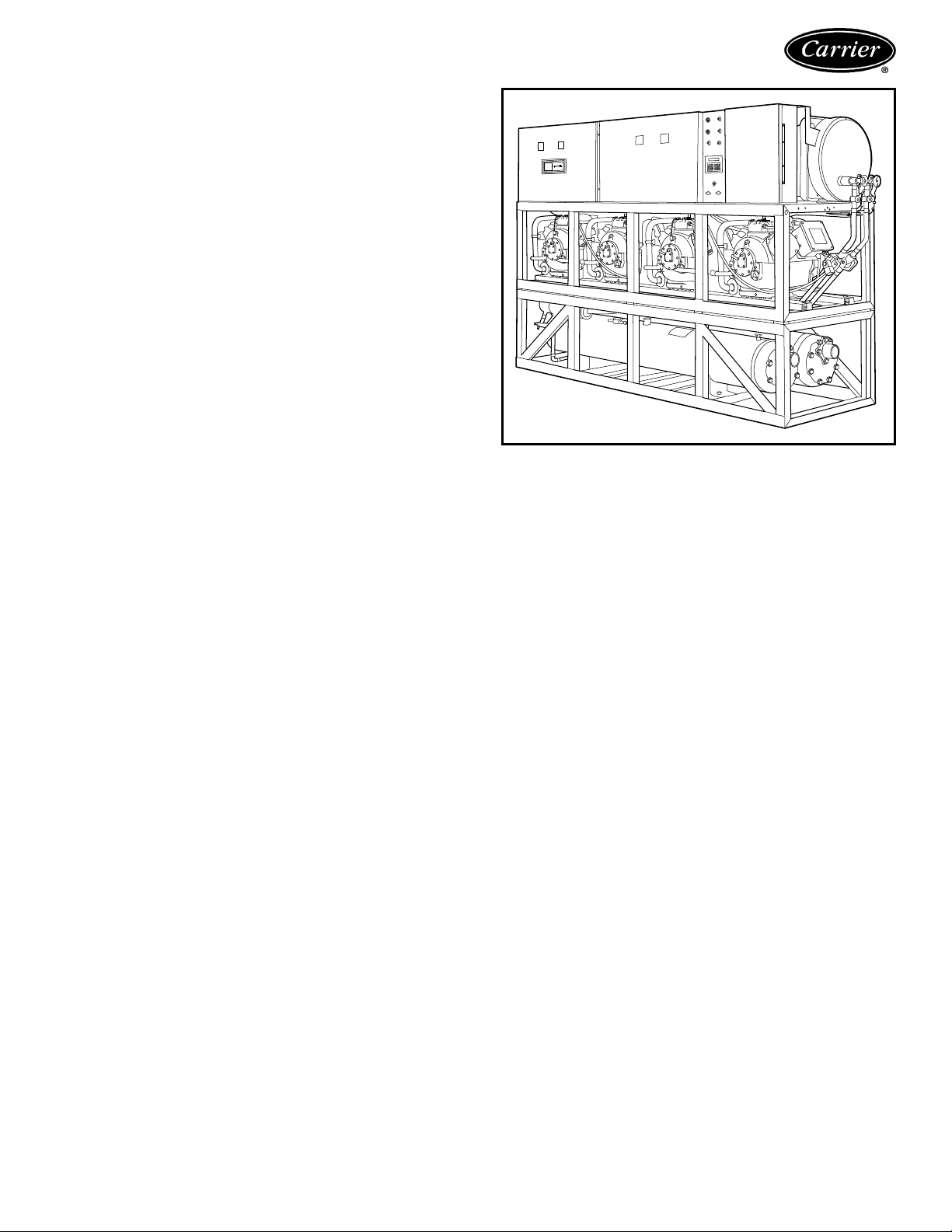

30HR,HS units are designed

for easy installation and

maintenance

Starting with installation, these machines keep costs low. Each is

completely factory engineered and

assembled to ensure a perfectly balanced refrigeration system that can be

installed with minimal field labor.

Only external fluid and power connections need to be completed at the

jobsite to make the fluid-cooled (30HR)

units operational. Condenserless (30HS)

units require the addition of a remote

condenser.

The 30HR model is a packaged

unit complete with cooler, condensers,

compressors, controls, refrigerant

and oil charge, and internal piping and

wiring. The 30HS unit is a condenserless version of the basic 30HR,

shipped with a holding charge of refrigerant and specially designed for applications with remote fluid- or

air-cooled, or evaporative type, condensers. All the easy-rigging 30H

series chillers are extremely trim and

compact. They can pass easily

through standard doorways, and require minimal floor space on the job.

Product

Data

30HR,HS

Model E

Reciprocating Liquid Chillers

Nominal Capacities:

70 to 160 Tons (250 to 560 kW)

Copyright 1994 Carrier Corporation Form 30HR,HS-4PD

Rated in accordance with

ARI Standard 590-92.

Additional features ensure smooth,

trouble-free operation. Compressors are mounted on heavy-duty spring

vibration isolators to minimize potentially damaging vibration transmission to the building structure. Sounddeadening mufflers dampen hot gas

pulsations. Servicing is made easy by

bolted, readily-accessible semi-hermetic

compressors that can be removed

with minimal field labor when adjustments or repairs are needed.

Flotronic™ Plus control system regulates the refrigerant cycle for optimum

efficiency

The 30HR,HS Flotronic Plus chillers

feature an electronic expansion valve

(EXV) operated by a microprocessorbased control system. The system

monitors safety functions and controls

unit capacity to maintain leaving

chilled fluid temperature. The microprocessor controls loading and unloading of compressors to match

changing cooling load requirements.

The control system consists of a

control box with a keypad and display

module, an EXV for each refrigeration circuit, and thermistors (temperature sensors) which provide analog

inputs to the microprocessor. The

control also operates a quick test program to check input and output signals to and from the microprocessor.

The 30HR,HS control system is self

contained and can operate on a

stand-alone basis if desired.

Components

The control box — All the

microprocessor-based controls required to optimize chiller operation

and protect it against unsafe conditions are contained in the control

box. This includes the processor module, relay module, EXV driver module, keypad and display module, relays,

and transformers. The box has a

hinged door for ready access.

The EXV driver — The driver positions the EXVs (based on commands

from the microprocessor) and

monitors the status of the oil and

refrigerant pressure switches.

The keypad and display module

— This module consists of a key-

pad with 11 function keys and 12 numeric keys (0 to 9,.,-)andan

alphanumeric 8-character liquid crystal

display. The module allows the operator to perform the following

functions:

• read and change set point

• configure unit

• run quick test unit checkout

• observe diagnostic information

• schedule chiller operation

Control features

Leaving fluid temperature control

with return compensation —

The rate at which the compressors

are turned on will depend on the difference between the actual leaving

fluid temperature and the set point,

the rate of change of leaving fluid

temperature, the return fluid temperature, and the number of compressor

stages on. The control is primarily

from leaving fluid temperature, and

the other factors are used as compensation. Because the control operates

from leaving fluid, the chiller is independent of cooling gpm (L/s). It is a

true droopless control.

Return temperature reset — The

control system is capable of handling leaving fluid temperature reset

based on return cooler temperature.

Because the change in temperature

through the cooler is a measure of the

building load, the return temperature

reset is in effect an average building load reset method. All sensors required to activate return reset are

standard with the unit.

Space and outdoor-air temperature reset — Space temperature

reset and outdoor-air temperature

reset allow for the reset of the leaving

fluid temperature based on an external temperature sensor. (Accessory

thermistor required.)

Energy management system reset

— Many energy management sys-

tems have the capability to transmit a

4 to 20 mA signal in proportion to

the desired leaving chilled-fluid set

point. The Flotronic Plus chillers have

the ability to recognize a proportioned signal to establish the reset

condition (field-installed components

are required).

Remote alarm — Upon initialization

of an alarm condition, an internal

contact will close to activate a signal

suitable for remote alarm activation.

Load shed (demand limit) — A

2-step demand limit can be programmed through the Flotronic Plus

controls. The control limits total power

draw of the unit by controlling the

number of steps of capacity operating

during the demand limiting period.

Pulldown control — Pulldown control is used to minimize compressor

usage and reduce the peak kW that

occurs at start-up, when the cooler

fluid temperature is very warm but the

load is small. When activated, this

feature limits the pulldown rate to

1° F (.56° C) per minute.

Unit checkout (quick test) — The

quick test feature allows determination

of the status (on or off) of various

Flotronic Plus control components (i.e.,

solenoid valves, compressors, and

unloaders). When the unit is in standby

mode, these steps will energize these

components and indicate whether

or not the components are operational.

Diagnostics — The Flotronic Plus

control system features extensive selfdiagnostics as standard. The display

will show a 2-digit diagnostic code,

and will scroll an explanation of the

code for failures that cause the unit to

shut down, terminate a reset option,

or use a default value as set point.

Time schedule — The Flotronic Plus

control system has an integral function that allows scheduling of the circulating pump and chiller operation

for up to 8 occupied/unoccupied periods per schedule, with 7 different

schedule days.

Table of contents

Page

Features/Benefits ........................................ 1-4

Model Number Nomenclature ............................... 4

Physical Data ........................................... 5-8

Accessories (Field Installed) ................................. 9

Base Unit Dimensions .................................... 10-12

Application Data ........................................13-16

Selection Procedure ....................................... 17

Performance Data .......................................18-28

Electrical Data ............................................29

Typical Field Control Wiring ..................................30

Controls ............................................... 31

Typical Piping and Wiring ................................... 32

Guide Specifications ......................................33-36

2

Increased part-load performance reduces operating

costs

Multiple compressors — Multiple

compressors on a refrigerant circuit further enhance part-load efficiency. This allows compressor to

operate fully loaded with 100% of

cooler and condenser surface active at

50% unit capacity, optimizing evaporating and condensing temperatures.

Since the chiller normally works at

part load for 97% of its operating

time, a substantial reduction in operating cost can be realized.

Suction cutoff unloading — Unloading on 06E compressors eliminates

unnecessary pumping of refrigerant

1—CompressorON Lights

2—Alarm Light

3—Keypad and Display

Module

4—RUN/STANDBY

Switch

5—Control CircuitFuses

6—Control Power ON

Light

gases during unloader operation. This

substantially reduces part-load power

consumption.

Liquid refrigerant subcooling —

Integral subcooler uses coldest

condenser fluid to increase system

capacity without extra horsepower.

CONTROL PANEL

–

KEYPAD AND DISPLAY

MODULE

SUBCOOLER

ELECTRONIC EXPANSION

VALVE (EXV)

06E COMPRESSOR

3

Features/Benefits (cont)

Safety features provide

protection and increase

reliability

Auto. lead/lag control — Control

balances operating hours between

refrigerant circuits.

Standby protection — If a malfunction or safety cutout occurs, these

2-circuit chillers have the capability for

standby operation. This benefit is

especially desirable in commercial applications where even brief equipment shutdowns can be extremely

costly.

Electronic expansion valve (EXV)

— The EXV is controlled to main-

tain approximately 20 F (11 C) refrigerant superheat entering the

compressor cylinders. (Ordinary thermostatic expansion valves typically

operate at 45 F [25 C] superheat

entering compressor cylinders.) Precise superheat control is obtained

through actuation of the 760-step,

long-stroke,

3

⁄4-in. (19 mm) valve

positioner to ensure optimized refrigerant metering. The accurate refrig-

erant metering provided by the EXV

reduces compressor motor temperature

and extends motor life.

Filter drier — Refrigerant circuits are

kept free of harmful moisture and

contaminants by a factory-installed

filter drier.

Crankcase heater — The compressor crankcase heater protects the

compressors against refrigerant migration and oil dilution.

Moisture-indicating sight glass —

Easy-to-read color indicator immediately shows moisture content of refrigerant system.

Oil pressure safety switch —

Safety switch shuts compressor(s) off if

the oil pressure drops below a safe

operating point.

Protection against single-phasing

— Manual reset, magnetic trip cir-

cuit breakers protect the compressor

motors against both overload and

single-phasing, and eliminate potential

problems before they become service headaches.

Motor overtemperature protection — Servicing dollars are saved

because the compressor motors are

thoroughly protected against overheating by quick-sensing elements.

Other safeties — Additional safeties

include: Loss of refrigerant charge

protection, low fluid flow protection,

low chilled fluid temperature protection, low and high superheat protection, low oil protection for each

compressor circuit, and low control voltage (to unit) protection.

Thermistors — Six thermistors are

used for temperature sensing inputs to

microprocessor (a seventh may be

used as a remote temperature sensor

for space or outdoor-air temperature reset):

• Cooler leaving and entering (return)

chilled fluid temperature control

• Cooler saturation temperatures —

Circuit A and Circuit B

• Return gas temperatures entering

compressor cylinder —Circuit A

and Circuit B

• Remote temperature sensor

(accessory)

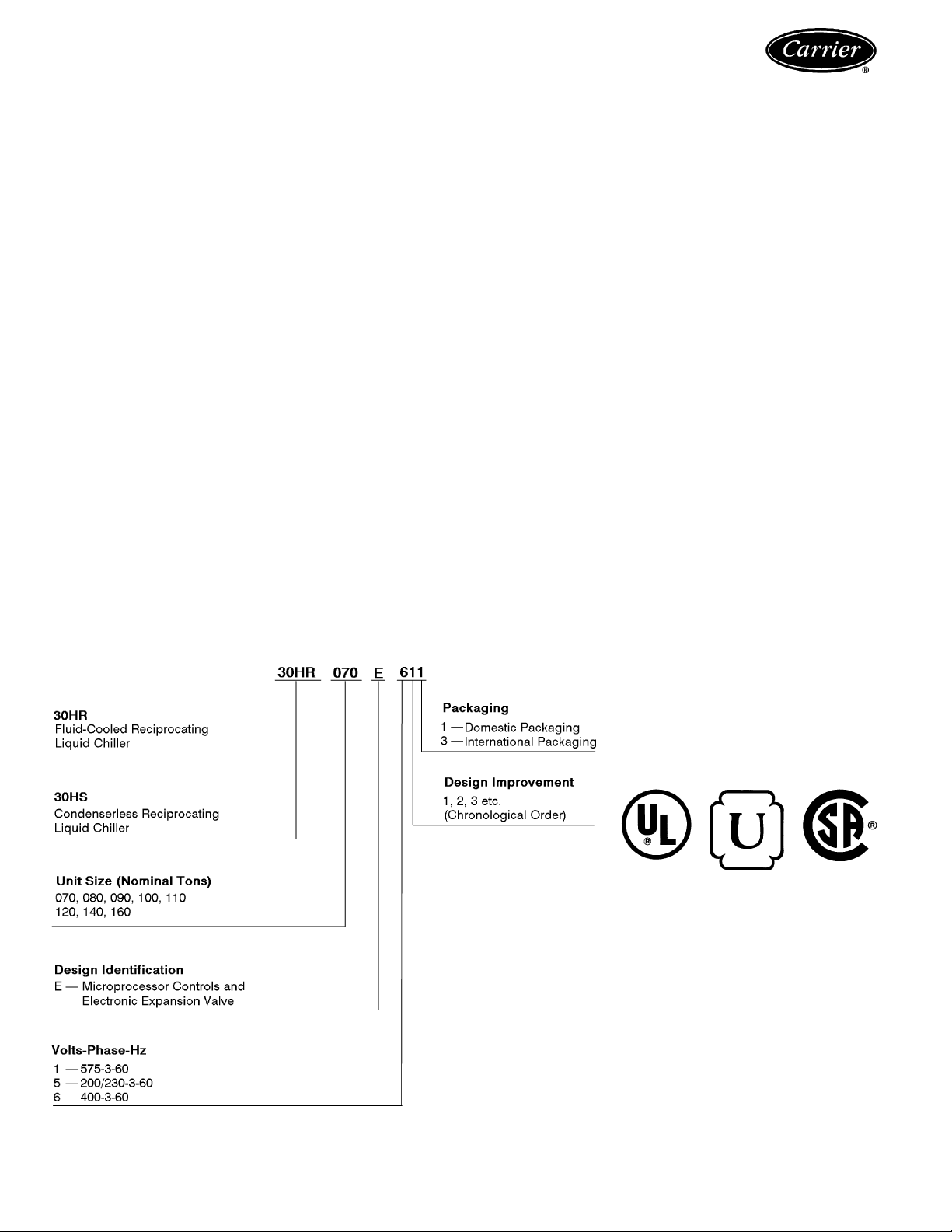

Model number nomenclature

NOTE: Refrigerant 134a is not available for these units.

These units are listed with Underwriters’ Laboratories (UL) and Canadian Standards Association (CSA), and

these pressure vessels have ASME

(American Society of Mechanical

Engineers) certification.

UNDERWRITERS’

LABORATORIES

ASME

‘U’ STAMP

CANADIAN

STANDARDS

ASSOCIATION

4

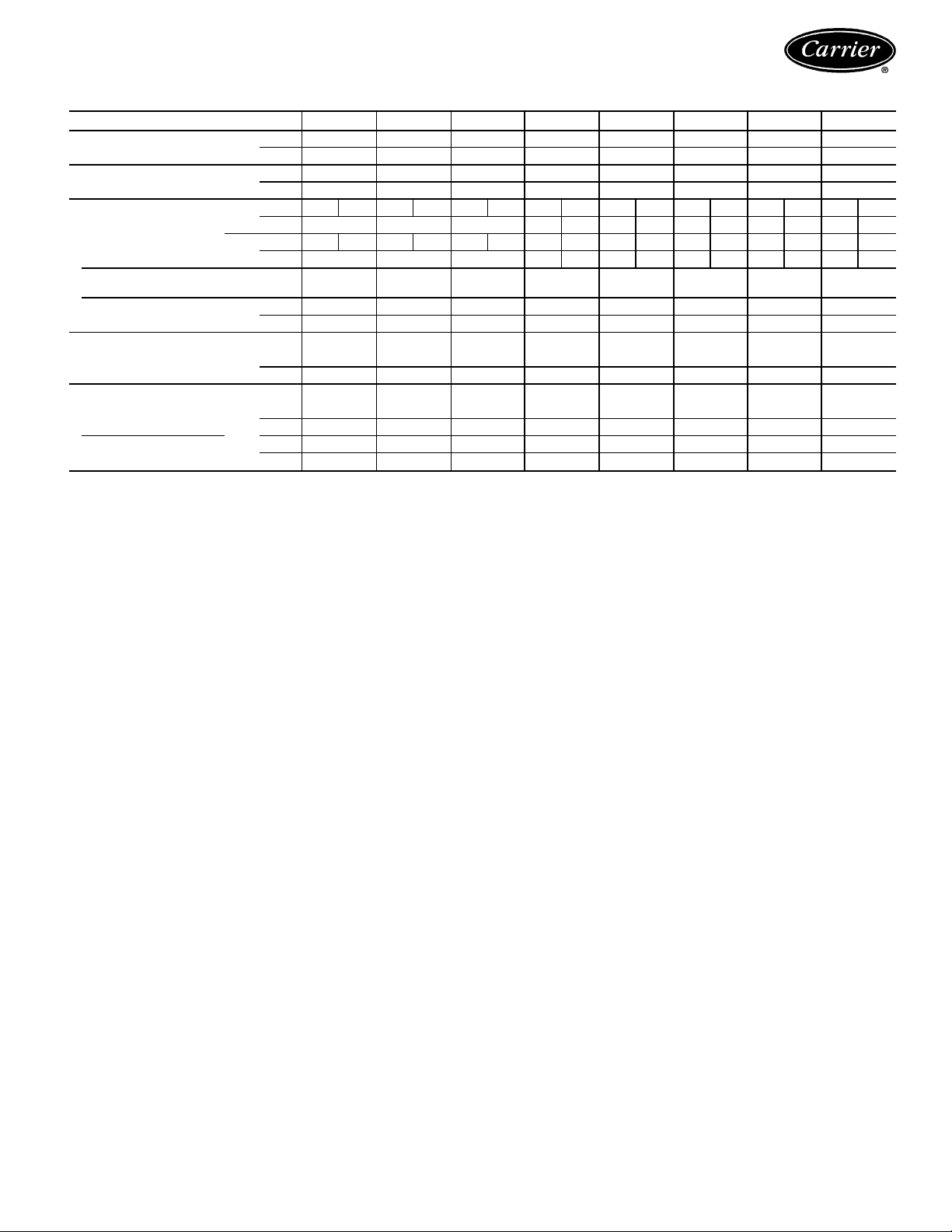

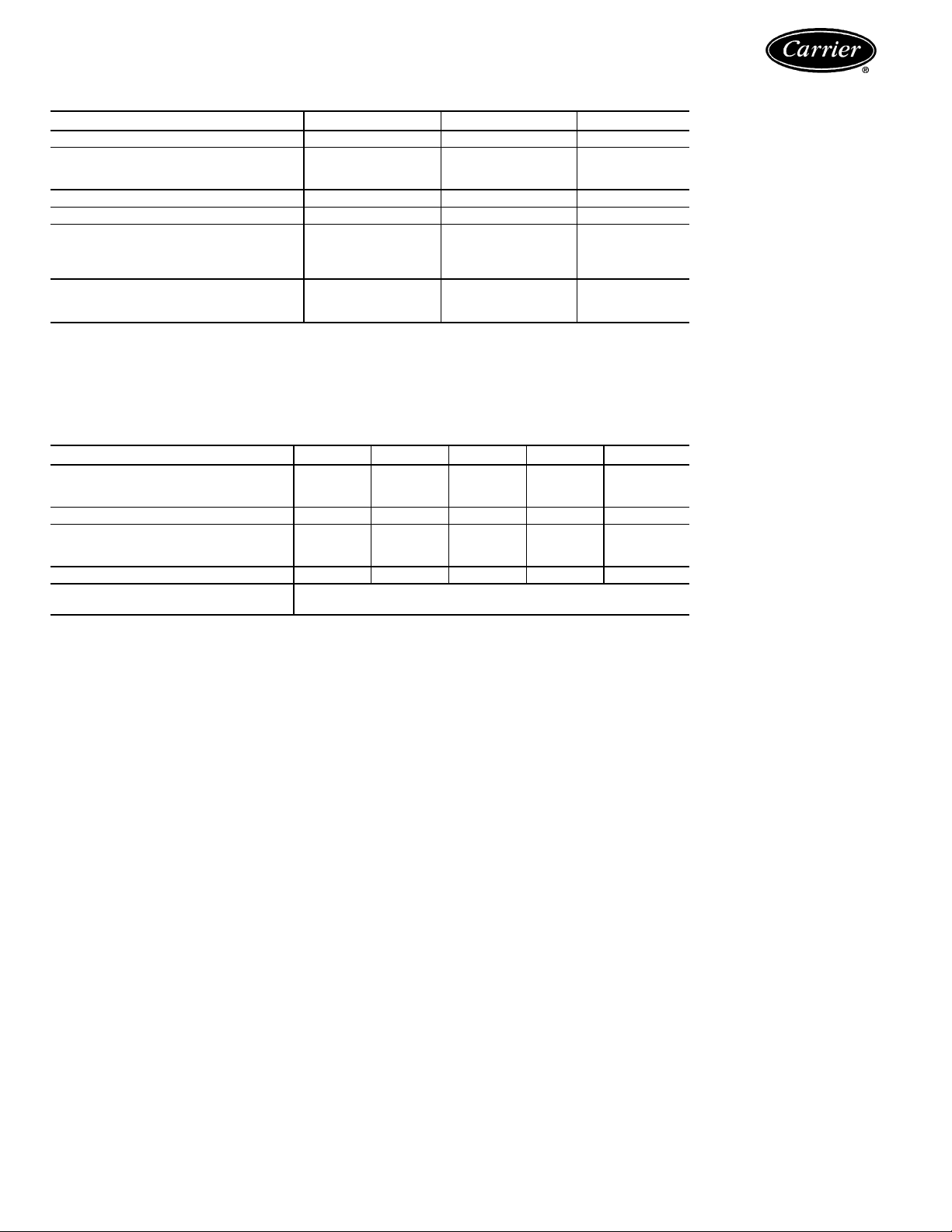

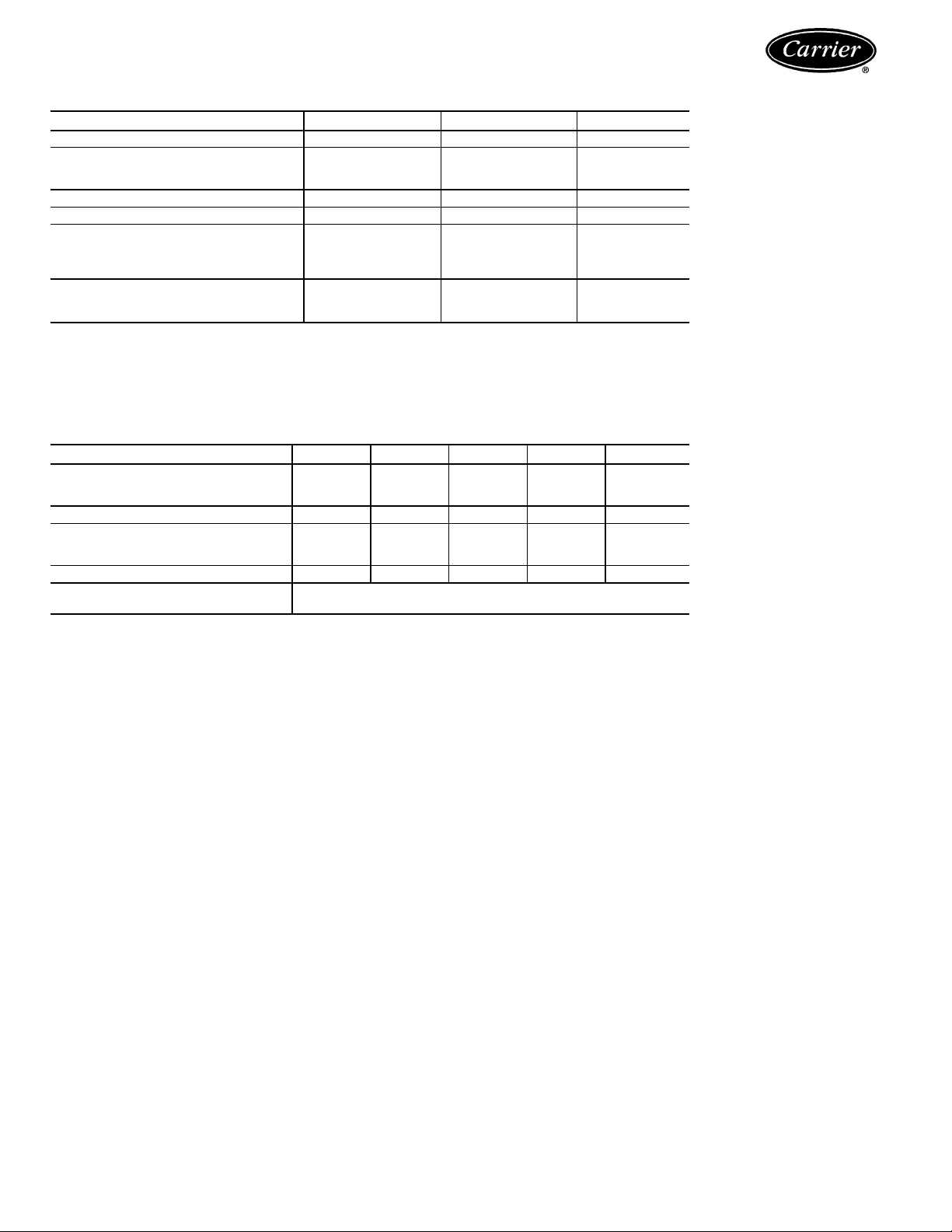

Physical data — English

30HR,HS UNIT AND COMPRESSOR

UNIT 30HR,HS SIZE 070 080 090 100 110 120 140 160

APPROXIMATE OPERATING

WEIGHT (lb)*

HR 4760 4945 5070 6436 6575 6714 7355 7775

HS 3305 3360 3420 4360 4420 4480 5065 5175

REFRIGERANT (R-22)

OPERATING CHG (lb)†

HR 104 119 129 138 146 154 172 192

HS 15.3 15.3 15.3 21.0 21.0 21.0 27.0 27.0

COMPRESSOR 06E**

(Reciprocating,

Semi-Hermetic,

1750 rpm)

HR

Ckt A 2150 A150 6175 A150 6175 F175 6175 A150 6175 F175 6175 F175 6299 F175 6299 F299

Ckt B 6175 6175 6175 6175 A150 6175 A150 6175 F175 6299 F175 6299 F299

HS

Ckt A 2250 A250 6275 A250 6275 F275 6275 A250 6275 F275 6275 F275 6299 F275 6299 F299

Ckt B 6275 6275 6275 6275 A250 6275 A250 6275 F275 6299 F275 6299 F299

Capacity Control Steps

(see page 31)

66688888

Circuit Split, % Capacity

Ckt A 57 62.5 67 50 55 50 50 50

Ckt B 43 37.5 33 50 45 50 50 50

CONDENSER PART NO. 09RP---

HR

Ckt A 043 054 070 054 070 070 070 084

Ckt B 033 033 033 054 054 070 070 084

REFRIGERANT CONN. (in. ODM)

Liquid Line

HS

Ckt A

7

⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

Ckt B

7

⁄

8

7

⁄

8

7

⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

Discharge Line

Ckt A 1

5

⁄

8

15⁄

8

21⁄

8

15⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

Ckt B 13⁄

8

13⁄

8

13⁄

8

15⁄

8

15⁄

8

21⁄

8

21⁄

8

21⁄

8

LEGEND

ODM — Outside Diameter Male

*Includes refrigerant operating charge.

†The 30HR unit is shipped with full operating charge; 30HS unit is shipped with holding charge only

(cooler operating charge shown — condenser and interconnecting piping charge must be added for

total system charge).

**Prefix (no. of unloaders): A, F = none; 2, 6 = one.

5

Physical data — English (cont)

COOLER

30HR,HS SIZE 070,080,090 100,110,120 140,160

COOLER PART NO. 10HA401--- 664 684 704

DIMENSIONS

OD (ft-in.) 1-

3

⁄

4

1- 4 1-4

Length (ft-in.)* 6-9 6-11 9-0

NET FLUID VOLUME (gal.)† 21.7 40.4 52.4

REFRIGERANT CIRCUITS 222

MAXIMUM DESIGN WORKING

PRESSURE (psig)

Refrigerant Side 235 235 235

Fluid (Shell) Side 300 300 300

FLUID CONN. (in.)

Inlet and Outlet 4** 5** 6**

Drain

3

⁄4FPT

3

⁄4MPT

3

⁄4MPT

*Between tube sheets.

†Includes nozzles.

**Victaulic-type water connections.

CONDENSER

CONDENSER PART NO. 09RP--- 033 043 054 070 084

DIMENSIONS

OD (in.) 10

3

⁄

4

123⁄

4

123⁄

4

123⁄

4

14

Length (in.)* 67

1

⁄

2

77 833⁄

8

951⁄

4

83

NET FLUID VOLUME (gal.) 5.7 8.5 9.9 11.4 13.7

FLUID CONN. — in. diameter†

Inlet IPS** 2

1

⁄

2

3332

1

⁄

2

††

Outlet IPS** 21⁄

2

333 4

FLUID PASSES 33333or6

MAXIMUM DESIGN WORKING Refrigerant Side — 385

PRESSURE (psig) Fluid Side — 250

LEGEND

IPS — Iron Pipe Size

OD — Outside Diameter

*Between tube sheets.

†On part no. 084 condensers, data is for 3-pass only. For 6-pass, inlet and outlet connections are 2

1

⁄2inches.

**Field welded (flange with weld stub provided for all connections).

††The 09RP084 has 2 inlet connections.

NOTES:

1. The 2

1

⁄2-in. and 3-in. condenser connections are equipped with slip-on flanges bolted to the condensers and

designed for field welding of field-supplied 21⁄2-in. and 3-in. schedule 40 pipe.

The 4-in. condenser connections are equipped with welding neck flanges bolted to the condensers and designed

for field welding of field-supplied 4-in. schedule 40 pipe.

2. Standard 30HR,HS160 unit is supplied with 3-pass condensers. To convert from 3 to 6 pass, proceed as follows:

a. Remove 4-in. outlet flanges.

b. Cover 4-in. (09RP084) 3-pass condenser water outlets with blind flanges (field supplied).

3. Water outlet and inlet connections are rated according to ANSI/ASME B 16.5 (American National Standards

Institute/American Society of Mechanical Engineers) latest revision.

6

Physical data —SI

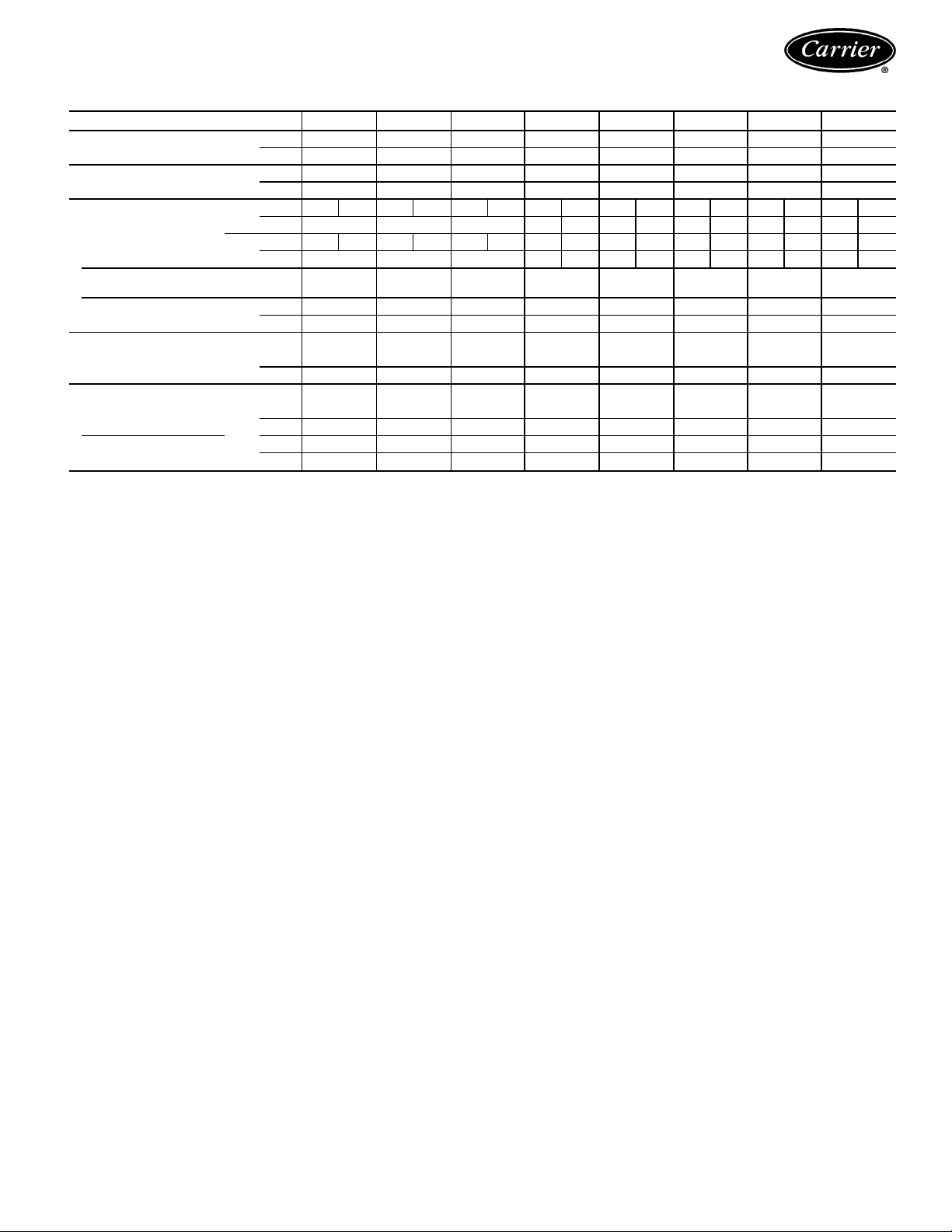

30HR,HS UNIT AND COMPRESSOR

UNIT 30HR,HS SIZE 070 080 090 100 110 120 140 160

APPROXIMATE OPERATING

WEIGHT (kg)*

HR 2159 2243 2300 2919 2982 3045 3336 3527

HS 1499 1524 1551 1978 2005 2032 2297 2347

REFRIGERANT (R-22)

OPERATING CHG (kg)†

HR 47 54 59 63 66 70 78 87

HS 6.9 6.9 6.9 9.5 9.5 9.5 12.2 12.2

COMPRESSOR 06E**

(Reciprocating,

Semi-Hermetic,

29.2 r/s)

HR

Ckt A 2150 A150 6175 A150 6175 F175 6175 A150 6175 F175 6175 F175 6299 F175 6299 F299

Ckt B 6175 6175 6175 6175 A150 6175 A150 6175 F175 6299 F175 6299 F299

HS

Ckt A 2250 A250 6275 A250 6275 F275 6275 A250 6275 F275 6275 F275 6299 F275 6299 F299

Ckt B 6275 6275 6275 6275 A250 6275 A250 6275 F275 6299 F275 6299 F299

Capacity Control Steps

(see page 31)

66688888

Circuit Split, % Capacity

Ckt A 57 62.5 67 50 55 50 50 50

Ckt B 43 37.5 33 50 45 50 50 50

CONDENSER PART NO. 09RP---

HR

Ckt A 043 054 070 054 070 070 070 084

Ckt B 033 033 033 054 054 070 070 084

REFRIGERANT CONN. (in. ODM)

Liquid Line

HS

Ckt A

7

⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

Ckt B

7

⁄

8

7

⁄

8

7

⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

11⁄

8

Discharge Line

Ckt A 1

5

⁄

8

15⁄

8

21⁄

8

15⁄

8

21⁄

8

21⁄

8

21⁄

8

21⁄

8

Ckt B 13⁄

8

13⁄

8

13⁄

8

15⁄

8

15⁄

8

21⁄

8

21⁄

8

21⁄

8

LEGEND

ODM — Outside Diameter Male

*Includes refrigerant operating charge.

†The 30HR unit is shipped with full operating charge; 30HS unit is shipped with holding charge only

(cooler operating charge shown — condenser and interconnecting piping charge must be added for

total system charge).

**Prefix (no. of unloaders): A, F = none; 2, 6 = one.

7

Physical data — SI (cont)

COOLER

30HR,HS SIZE 070,080,090 100,110,120 140,160

COOLER PART NO. 40HA401--- 664 684 704

DIMENSIONS

OD (mm) 324 406 406

Length (mm)* 2057 2108 2743

NET WATER VOLUME (L)† 82.1 152.9 198.3

REFRIGERANT CIRCUITS 222

MAXIMUM DESIGN WORKING

PRESSURE (kPa)

Refrigerant Side 1620 1620 1620

Fluid (Shell) Side 2068 2068 2068

FLUID CONN. (in.)

Inlet and Outlet 4** 5** 6**

Drain

3

⁄4FPT

3

⁄4MPT

3

⁄4MPT

*Between tube sheets.

†Includes nozzles.

**Victaulic-type water connections.

CONDENSER

CONDENSER PART NO. 09RP--- 033 043 054 070 084

DIMENSIONS

OD (mm) 273 324 324 324 356

Length (mm)* 1715 1956 2118 2419 2108

NET FLUID VOLUME (L) 21.6 32.2 37.5 43.1 51.9

FLUID CONN. — in. diameter†

Inlet IPS** 2

1

⁄

2

3332

1

⁄

2

††

Outlet IPS** 21⁄

2

333 4

FLUID PASSES 33333or6

MAXIMUM DESIGN WORKING Refrigerant Side — 2654

PRESSURE (kPa) Fluid Side — 1724

LEGEND

IPS — Iron Pipe Size

OD — Outside Diameter

*Between tube sheets.

†On part no. 084 condensers, data is for 3-pass only. For 6-pass, inlet and outlet connections are 2

1

⁄2inches.

**Field welded (flange with weld stub provided for all connections).

††The 09RP084 has 2 inlet connections.

NOTES:

1. The 2

1

⁄2-in. and 3-in. condenser connections are equipped with slip-on flanges bolted to the condensers and

designed for field welding of field-supplied 21⁄2-in. and 3-in. schedule 40 pipe.

The 4-in. condenser connections are equipped with welding neck flanges bolted to the condensers and designed

for field welding of field-supplied 4-in. schedule 40 pipe.

2. Standard 30HR,HS160 unit is supplied with 3-pass condensers. To convert from 3 to 6 pass, proceed as follows:

a. Remove 4-in. outlet flanges.

b. Cover 4-in. (09RP084) 3-pass condenser fluid outlet with blind flanges (field supplied).

3. Water outlet and inlet connections are rated according to ANSI/ASME B 16.5 (American National Standards

Institute/American Society of Mechanical Engineers) latest revision.

8

Accessories (field installed)

Condenser manifold package — This accessory is available for all 30HR models except the size 160 unit. The

manifold provides common fluid inlet and outlet connections and consists of 2 steel manifolds, each in 2 sections.

Field welding is required.

Control circuittransformer —Fieldinstalled transformer

provides 115-v control circuit power if separate control

power source is not available.

Remote reset thermistor — Enables control for space

and outdoor-air temperature reset.

Unit sound enclosure panels — These panels, with fiberglass insulation, completely enclose the compressor and

condenser sections.

Gage panelpackage — One packageis required perunit.

Package includes one suction pressure gage and one discharge pressure gage per circuit mounted on a common

panel. Each gage is equipped with a shutoff valve.

Temperaturereset — Leaving fluid temperature reset accessory board may be installed in chiller to provide reset of

LCWT (leaving chilled fluid temperature) in constant fluid

flow systems. Three reset control options are: from returnfluid temperature, space temperature, and outdoor-air

temperature.

Demand limit control — This control provides 2 demand

limit steps: 1) between 50% and 100% of maximum compressor displacement; or 2) between 0% and 49% displacement. The external switching device determines when to

limit unit capacity.

Chilled Fluid Flow Switch — Although low fluid flow detection is provided by the unit internal control devices, this

accessory is available for field installation for redundant

protection.

Oil-pressure safety switch — Standard on condenserless (30HS) models, accessory on fluid-cooled (30HR) models. Switch protects compressors against loss of oil pressure

in the event of a loss of lubricating oil. One switch package

is needed for each lead compressor.

9

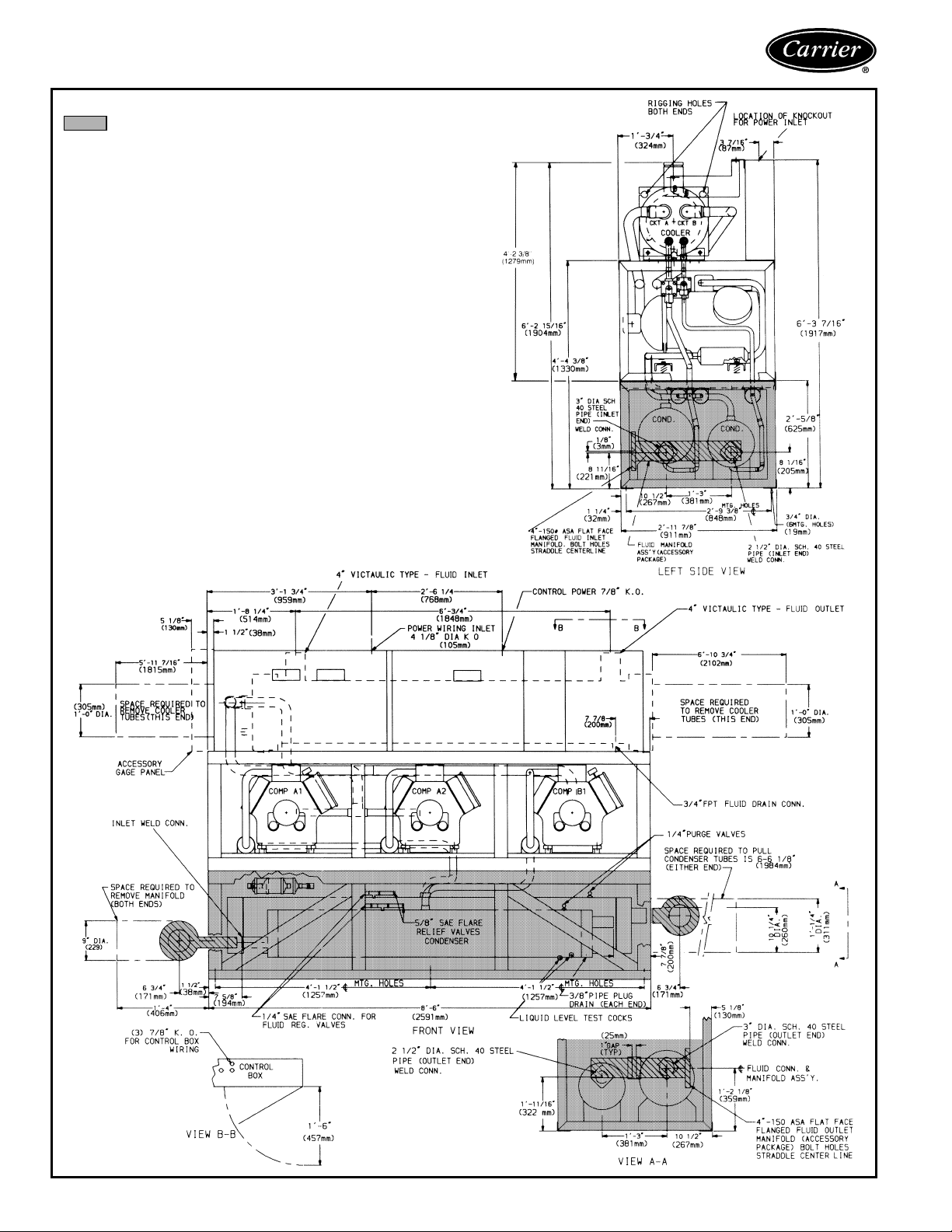

Base unit dimensions — 30HR,HS070-090

CONDENSER SECTION — 30HR ONLY

LEGEND

ASA — American Standards Association

COMP — Compressor

COND — Condenser

CONN — Connection

KO — Knockout

MTG — Mounting

REG — Regulatory

SAE — Society of Automotive Engineers (U.S.A.)

SCH 40 — Schedule 40 Pipe

NOTES:

1. Allow 24 in. in front of unit to fully open electric panel door.

2. Shaded piping indicatesaccessory manifold fluid package availablewith

weld connections for connections to stub of condenser fluid connections. Sleeve coupling permits customer adjustment before welding.

10

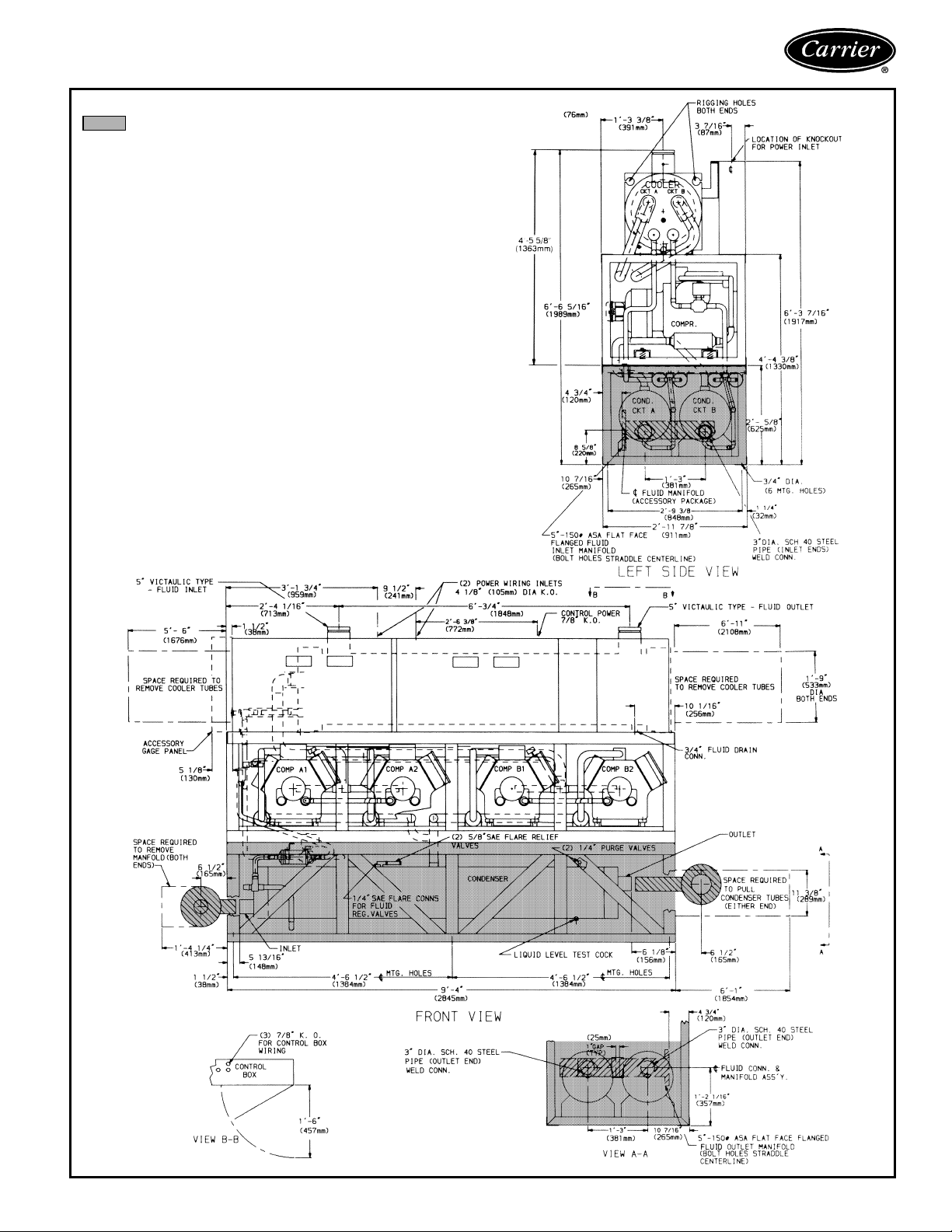

Base unit dimensions — 30HR,HS100-120

CONDENSER SECTION — 30HR ONLY

LEGEND

ASA — American Standards Association

COMP — Compressor

COND — Condenser

CONN — Connection

KO — Knockout

MTG — Mounting

REG — Regulatory

SAE — Society of Automotive Engineers (U.S.A.)

SCH 40 — Schedule 40 Pipe

NOTES:

1. Allow 24 in. in front of unit to fully open electric panel door.

2. Shaded piping indicates accessory manifold fluid package available with weld connections for connections to stub of condenser

fluid connections. Sleeve coupling permits customer adjustment

before welding.

11

Loading...

Loading...