Page 1

Installation Instructions

Fig. 1 — Model 30GTN (020 Shown)

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION

Step 1 — Rig and Place the Unit

• RIGGING

• PL A C ING UNIT

• MOUNTING UNIT

Step 2 — Check Compressor Mounting

Step 3 — Cooler Fluid and Drain Piping

Connections

• PREPARATION FOR YEAR-ROUND

OPERATION

• PREPARATION FOR WINTER SHUTDOWN

Step 4 — Make Electrical Connections

• POWER SUPPLY

• POWER WIRING

Step 5 — Install Accessories

• ELECTRICAL

• HOT GAS BYPASS

Step 6 — Refrigerant Circuit

• LEAK TESTING

• DEHYDRATION

• REFRIGERANT CHARGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip-

ment can be hazardous due to system pressures, electrical components, and equipment location (roofs, elevated structures,

etc).

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance func-

tions such as cleaning coils. All other operations should be performed by trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Keep quenching cloth and fire extinguisher nearby when

brazing.

• Use care in handling, rigging, and setting bulky

equipment.

• See Tables 1A and 1B for Physical Data.

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . 3

. . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . 11

30GTN015-035

Reciprocating Liquid Chillers

with ComfortLink™ Controls

50/60 Hz

INSTALLATION

Step 1 — Rig and Place the Unit

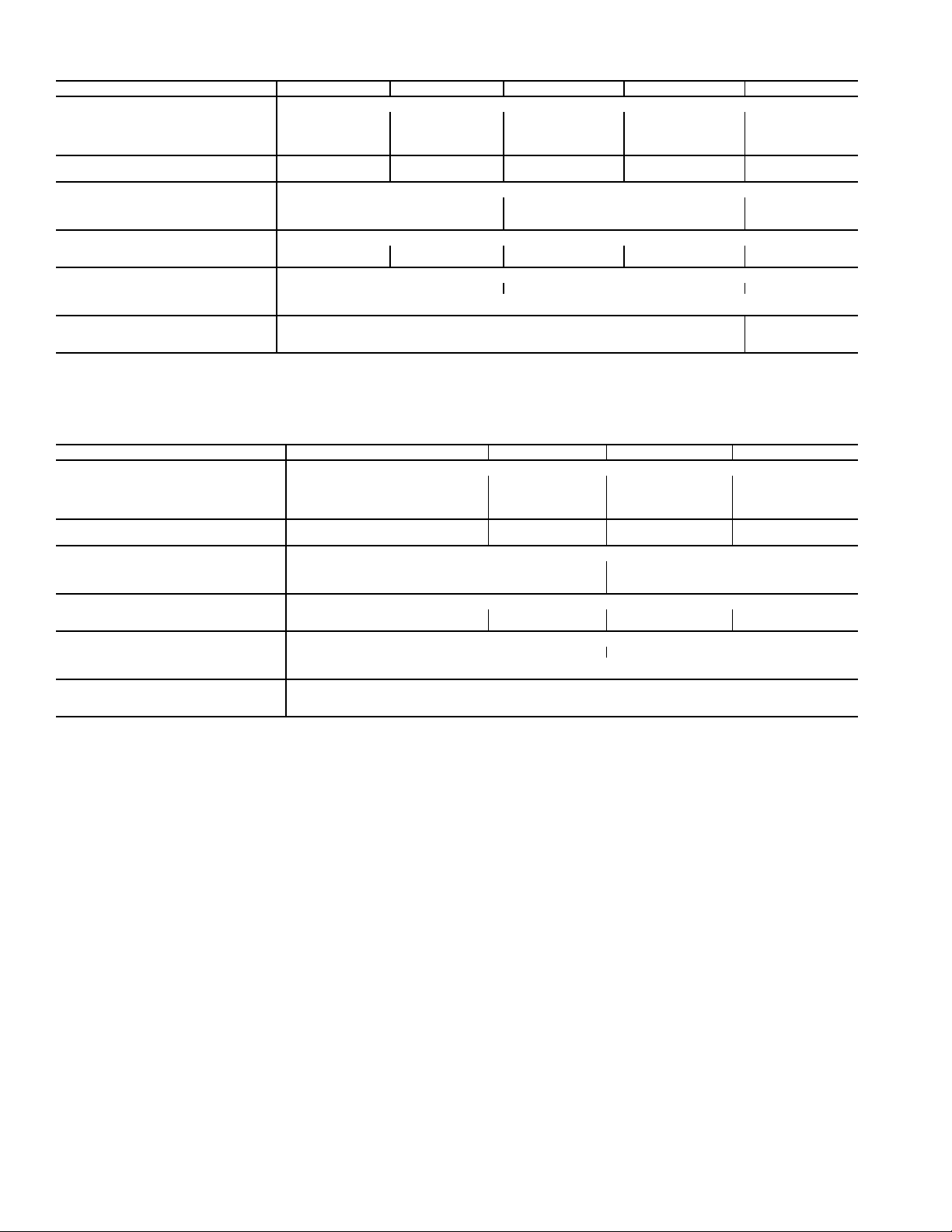

RIGGING — Preferred method is with spreader bars from

above the unit. Use 2-in. (50 mm) OD pipe or hooks in lifting

holes. Rig with 4 cables and spreader bars. All panels must be

in place when rigging. See rigging label on unit for details concerning shipping weights, distance between lifting holes, center

of gravity, and spreader bar dimensions. See Fig. 2.

If overhead rigging is not possible, place chiller on skid or

pad for rolling or dragging. When rolling, use a minimum of

3 rollers. When dragging, pull the pad. Do not apply force to

the unit. When in final position, raise from above to lift unit off

pad.

All panels must be in place when rigging.

PLACING UNIT — There must be at least 4 ft (1.2 m) for

service and for unrestricted airflow on all sides of unit, and a

minimum of 8 ft (2.4 m) clear air space above unit. Provide

ample room for servicing cooler. For cooler removal see clearance requirements in Fig. 3-5. For multiple units, allow 8 ft

(2.4 m) separation between units for airflow and service.

If unit is to be used in an area with high solar radiation,

mounted position should be such that control box is not exposed to direct solar radiation. Exposure to direct solar radiation could affect the temperature switch controlling cooler

heaters. See Table 2.

ELECTRIC SHOCK HAZARD

Open all remote disconnects before servicing

this equipment.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 563-068 Printed in U.S.A. Form 30GTN-10SI Pg 1 1-00 Replaces: New

Page 2

Table 1A — Physical Data — 60 Hz

UNIT 30GTN 015 020 025 030 035

COMPRESSOR Reciprocating, Semi-Hermetic

No. ...Type 1...06DG537 1...06E2250 1...06E7265 1...06E7275 1...06E7299

No. Cyls (ea)...Speed, Rpm (r/s) 6...1750 (29) 4...1750 (29) 6...1750 (29) 6...1750 (29) 6...1750 (29)

Capacity Steps 32 3 3 3

Oil Charge*, Pt (L) 8 (3.8) 17 (8.0) 21 (9.9) 21 (9.9) 19 (9.0)

REFRIGERANT CHG, R-22

Total/Over Clear Glass, lb (kg) 25.0 (11.3)/5.0 (2.3) 31.0 (14.1)/7.0 (3.2) 40.0 (18.1)/12.0 (5.4) 47.0 (21.3)/14.0 (6.4) 57.0 (25.9)/8.0 (3.6)

→

CONDENSER FANS, Type Propeller Type, Direct Drive

No. ...Diameter, in. (mm) 2...30 (762) 2...30 (762) 3...30 (762)

Total Airflow, Cfm (L/s) 10,600 (5000) 15,700 (7400) 23,700 (11 200)

Speed, Rpm (r/s) 1140 (19) 1140 (19) 1140 (19)

CONDENSER COIL, Type Horizontal Plate Fin

Rows...Fins/in. (Fin Spacing mm) 2...19 (1.34) 3...17 (1.49) 2...19 (1.34) 3...17 (1.49) 3...17 (1.49)

Total Face Area, sq ft (m

COOLER Shell and Tube, Direct Expansion

Net Water Volume, gal. (L) 6.8 (25.7) 9.9 (37.5) 12.8 (48.4)

Maximum Design Working Pressure

psig (kPa)

WATER CONNECTIONS, in.

Inlet and Outlet 2 FPT 2

Drain

*See Oil Charge section for Carrier-approved oil.

2

) 23.5 (2.18) 23.5 (2.18) 39.2 (3.64) 39.2 (3.64) 58.4 (5.43)

Refrigerant Side — 235 (1620)

Water Side — 150 (1034)

1

3

/4 MPT

/2 FPT

3

/4 MPT

Table 1B — Physical Data — 50 Hz

UNIT 30GTN 015 020 025 030

COMPRESSOR Reciprocating, Semi-Hermetic

No. ...Type 1...06E2250 1...06E7265 1...06E7275 1...06E7299

No. Cyls (ea)...Speed, Rpm (r/s) 4...1450 (24.2) 6...1450 (24.2) 6...1450 (24.2) 6...1450 (24.2)

Capacity Steps 2333

Oil Charge*, Pt (L) 17 (8.0) 21 (9.9) 21 (9.9) 19 (9.0)

REFRIGERANT CHG, R-22

Total/Over Clear Glass, lb (kg) 26.0 (11.8)/6.0 (2.7) 35.0 (15.9)/8.0 (3.6) 42.0 (19.0)/12.0 (5.4) 49.0 (22.2)/14.0 (6.4)

→

CONDENSER FANS, Type Propeller Type, Direct Drive

No. ...Diameter, in. (mm) 2...30 (762) 2...30 (762)

Total Airflow, Cfm (L/s) 10,600 (5000) 15,700 (7400)

Speed, Rpm (r/s) 950 (15.8) 950 (15.8)

CONDENSER COIL, Type Horizontal, Plate Fin

Rows...Fins/in. (Fin Spacing mm) 2...19 (1.34) 3...17 (1.49) 2...19 (1.34) 3...17 (1.49)

Total Face Area, sq ft (m

COOLER Shell and Tube, Direct Expansion

Net Water Volume, gal. (L) 6.8 (25.7) 9.9 (37.5)

Maximum Design Working Pressure

psig (kPa)

WATER CONNECTIONS, in.

Inlet and Outlet 2 FPT

Drain

*See Oil Charge section for Carrier-approved oil.

2

) 23.5 (2.18) 23.5 (2.18) 39.2 (3.64) 39.2 (3.64)

Refrigerant Side — 235 (1620)

Water Side — 150 (1034)

3

/4 MPT

1201

2

Page 3

MAXIMUM

UNIT

30GTN

SHIP WT

Lb Kg in. mm in. mm in. mm in. mm

015 1876 851 94.0 2388 48.0 1219 23.0 583 49.5 1256

020 2031 921 94.0 2388 47.5 1207 23.0 583 49.5 1256

025 2415 1095 94.0 2388 51.0 1295 34.5 876 73.5 1867

030 2606 1182 94.0 2388 51.0 1295 34.5 876 73.5 1867

035 3365 1526 127.0 3225 66.5 1689 35.5 901 73.5 1867

LIFTING

HOLES

“A”

CENTER OF GRAVITY

“B” “C”

“D”

Fig. 2 — Rigging with Spreader Bars

(Field Supplied)

Table 2 — Temperature Limits for Standard Units

TEMPERATURE F C

Maximum Ambient Temperature 125 52

Minimum Ambient Temperature 0–18

Maximum Cooler EWT* 95 35

Maximum Cooler LWT 70 21

Minimum cooler LWT† 38 3.3

LEGEND

EWT — Entering Fluid (Water) Temperature

LW T — Leaving Fluid (Water) Temperature

*For sustained operation, EWT should not exceed 85 F (29.4 C).

†Unit requires modification below this temperature.

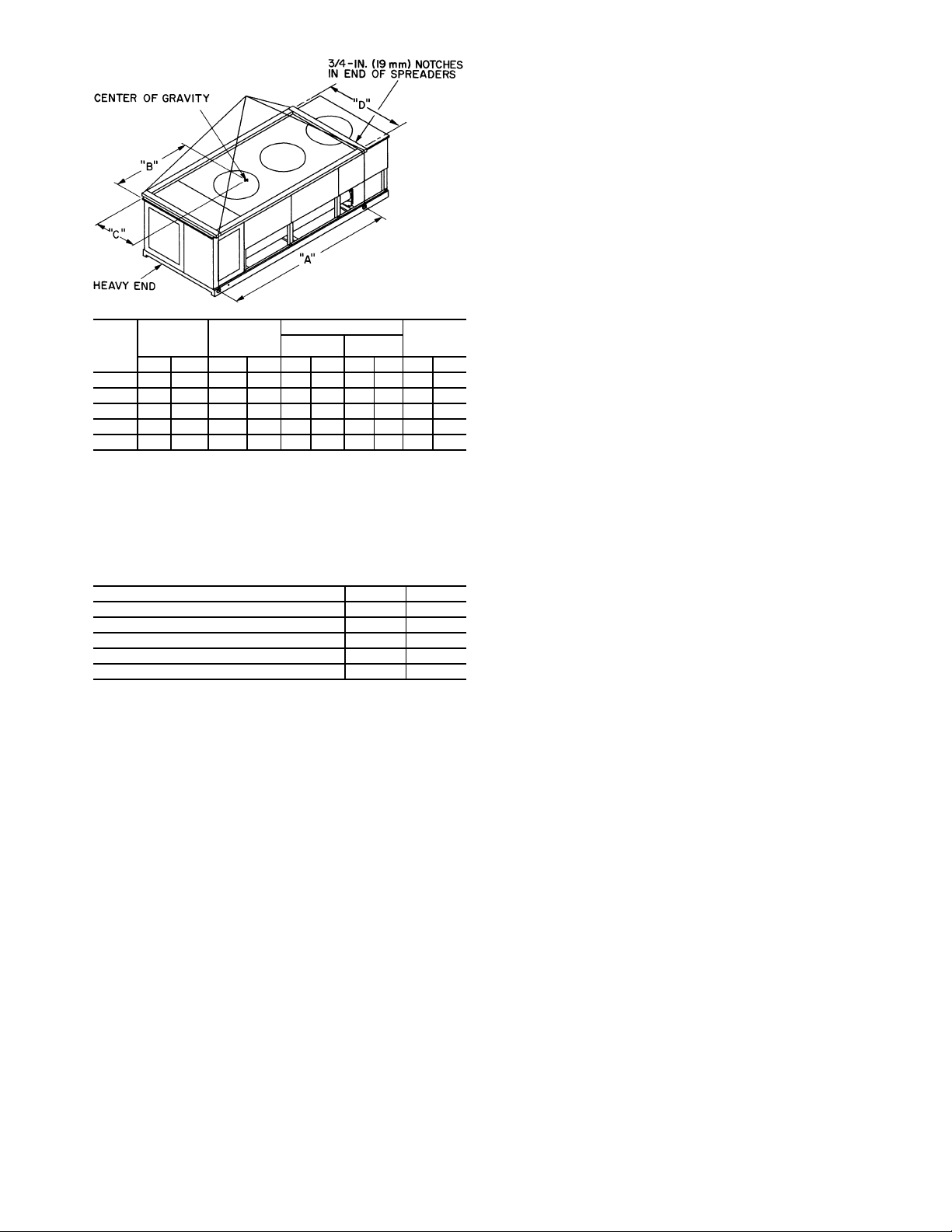

MOUNTING UNIT — When unit is in proper location, use

of mounting holes in base rails is recommended for securing

unit to supporting structure, or for mounting unit on vibration

isolators if required. See Fig. 3-5. Fasteners for mounting unit

are field supplied. Be sure unit is level to ensure proper oil

return to compressor.

Step 2 — Check Compressor Mounting —

As

shipped, compressor is held down by 4 bolts. After unit is installed, loosen each bolt using nut indicated in Fig. 6 until the

flat washer (

3

/8 in.) can be moved with finger pressure.

Step 3 — Cooler Fluid and Drain Piping Connections —

turn water connection is on the left and the leaving water connection is on the right. See Fig. 3-5 and 7. Install a minimum

40-mesh strainer in the cooler fluid inlet line just ahead of and

as close as possible to the cooler. Provide a means of venting

air from the high point of the field-installed piping.

After field piping is complete, freeze-up protect ion is recommended using inhibited ethylene glycol or other suitable inhibited antifreeze solution and electric heat tapes in area where

piping is exposed to low ambient temperatures (34 F [1 C] or

below). Heat tapes should possess a rating for area ambients

and be covered with a suitable thickness of closed-cell

insulation. Route power for heating tapes from a separatelyfused disconnect. Identify disconnect as heat tape power source

with a warning that power must not be turned off except when

unit is being serviced.

The cooler drain connection is at the opposite end from th e

compressor (See Fig. 3-5). Insulate the drain piping (in the

same manner as the chilled water piping) for at least one ft

(305 mm) from cooler.

PREPARATION FOR YEAR-ROUND OPERATION — If

unit is on year-round operation, add sufficient inhibited ethylene glycol or other suitable inhibited antifreeze solution to

chilled water to prevent freezing under low-ambient operating

conditions. Consult local water authority on characteristics of

area water and add a recommended inhibitor to the chilled

water.

PREPARATION FOR WINTER SHUTDOWN — Do not

shut off control power disconnect during off-season shutdown.

At end of cooling season:

1. Drain water from system.

2. Replace drain plug and put 2 gall ons (8 liters) of inhibited ethylene glycol (or other suitable inhibited antifreeze) in cooler to prevent freezing of residual water.

(Remove plug on top of leaving chilled water noz zle to

add liquid.)

3. At the beginning of the next cooling season, refill cooler

and add recommended inhibitor.

When facing the cooler side of the unit, the re-

3

Page 4

NOTES:

1. There must be minimum 8 ft (2.4 m) clear air space above unit.

2. Dimensions in [ ] are in millimeters.

3. The approximate operating weight of the unit is:

60 Hz

UNIT Lb Kg

30GTN015 1640 744

30GTN015C 1732 786

30GTN020 1821 826

30GTN020C 1945 882

UNIT A

30GTN015

30GTN020

(1219)

4

(1207)

′′′′

3

-11

′′′′-0″″″″

1

″″″″

/

2

50 Hz

UNIT Lb Kg

30GTN015 1741 790

30GTN015C 1833 831

30GTN020 1864 846

30GTN020C 1988 902

LEGEND

C—Copper Coils

COMPR — Compressor

MTG — Mounting

NEC — National Electrical Code (U.S.A.)

VAV — Variable-Air Volume

Fig. 3 — Dimensional Drawing, 30GTN015,020

4

Page 5

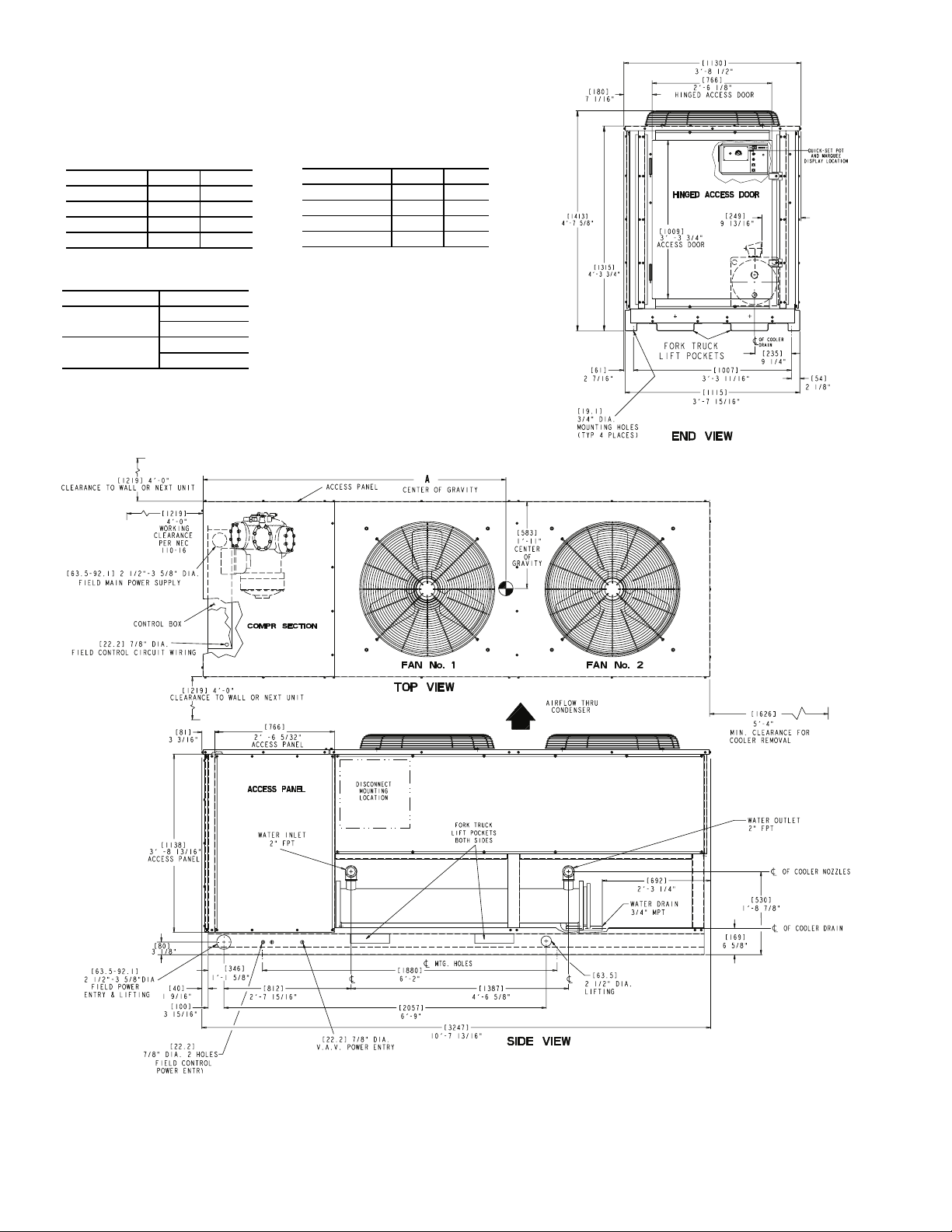

NOTES:

1. There must be minimum 8 ft (2.4 m) clear air space above unit.

2. Dimensions in [ ] are in millimeters.

3. The approximate operating weight of the unit is:

60 Hz

UNIT Lb Kg

30GTN025 2170 984

30GTN025C 2324 1054

30GTN030 2268 1029

30GTN030C 2474 1122

LEGEND

C—Copper Coils

COMPR — Compressor

MTG — Mounting

NEC — National Electrical Code (U.S.A.)

VAV — Variable-Air Volume

50 Hz

UNIT Lb Kg

30GTN025 2193 995

30GTN025C 2347 1065

30GTN030 2332 1058

30GTN030C 2538 1151

Fig. 4 — Dimensional Drawing, 30GTN025,030

5

Page 6

NOTES:

1. There must be minimum 8 ft (2.4 m) clear air space above unit.

2. Dimensions in [ ] are in millimeters.

3. The approximate operating weight of the unit is:

60 Hz

UNIT Lb Kg

30GTN035 2965 1345

30GTN035C 3273 1485

LEGEND

C—Copper Coils

COMPR — Compressor

MTG — Mounting

NEC — National Electrical Code (U.S.A.)

Fig. 5 — Dimensional Drawing, 30GTN035

6

Page 7

NOTE: All dimensions are in inches.

Fig. 6 — Compressor Mounting

WATER INLET

(RETURN WATER)

Liquid Chiller

IN

WATER OUTLET

(LEAVING WATER)

OUT

REFRIGERATING

MACHINE

U.N.2857

WATER

DRAIN

Fig. 7 — Water Connection Locations

Step 4 — Make Electrical Connections

POWER SUPPLY — Electrical characteristics of available

power supply must agree with unit nameplate rating. Supply

voltage must be within limits shown in Tables 3A and 3B.

IMPORTANT: Operating unit on improper supply voltage or with excessive phase imbalance constitutes abuse

and may affect Carrier warranty.

POWER WIRING — All power wiring must comply with applicable local and national codes. Install field-supplied branch

circuit fused disconnect(s) per NEC (N ational Electrical Code,

U.S.A.) of a type that can be locked OFF or ON. Disconnect(s)

must be within sight from and readily accessible from unit in

compliance with NEC Article 440-14.

General Wiring Notes

1. The control circuit power must be from a separate source

and must be brought through a field-supplied fused disconnect rated at 15 amps for 230-v and 30 amps for 115-v

control power. Two terminal blocks are provided for

field-wired control devices.

2. Crankcase and cooler heaters are wired in the control circuit so they are always operable as long as the control

power disconnect is on and safety de vice is open or the

Enable-Off-Remote contact switch is in t he Off position.

Heaters are wired so that they ar e energized even when

power to the Main Base Board (MBB) is off. They are

protected by a 7-amp fuse in field-supplied control power

supply disconnect.

3. The control circuit field-supplied disconnect should never

be off except when unit is being serviced or is to be down

for a prolonged period, in which case cooler should be

drained. When operation is resumed, crankcase heater

should be energized for 24 hours before start-up.

4. Power entry is at one end only.

5. Maximum field wire sizes allowed by lugs on terminal

block are:

350 kcmil for 30GTN030,035 (208/230-3-60) and

30GTN030 (230-3-50) units.

2/0 A WG for all other units.

6. Termina ls for field power supply are suitable for copper,

copper-clad aluminum, or aluminum conductors. Insulation must be rated 167 F (75 C) minimum.

Field Connections

Main Power — Bring wires from the fused disconnect switch

through hole in bottom rail of unit to control box (Fig. 3-5) and

connect to terminals on terminal block TB1 (See Fig. 8).

Control Power — Bring separate source power (see Fig. 8,

note 2) into unit as shown in Fig. 3-5. This supplies power for

control circuit, compressor crankcase heater, and cooler heater.

Connect incoming wires to TB4 in unit control box (L1 to

and L2 to ). Neutral side must be connec ted to the neutral

terminal block (by C-A1) for 380-3-60 and 400-3-50 V units

only. In the auxiliary power supply a field-supplied disconnect

with 15-amp circuit protection must be provided to accommodate crankcase heater and cooler heater cable.

To co mply with NEC Article 440-14, the disconnect must

be located within sight from and readily accessible from unit.

IMPORTANT: To ensure power to the heaters, make

sure auxiliary power to unit is always on (except for

servicing or prolonged shutdown).

A toggle switch (marked Emergency On-Off on the unit

label diagram and by the switch) allows the control circuit to be

manually disconnected when necessary. This switch does not

affect the crankcase heater and cooler heater cable.

7

Page 8

Table 3A — Electrical Data — Standard Unit

UNIT

SIZE

30GTN

015

020

025

030

035

See Legend and Notes on page 9.

Voltag e

V-Hz (3 Ph )

208/230-60 187 253 82.2 125 278.4 100 115-60 104 127 30

460-60 414 506 38.3 60 126.2 45 115-60 104 127 30

575-60 518 633 31.7 50 102.8 40 115-60 104 127 30

380-60 418 342 43.9 70 152.8 60 230-60 198 254 15

380/415-50 342 440 49.4 80 179.0 60 230-50 198 254 15

208/230-60 187 253 97.4 150 357.4 125 115-60 104 127 30

460-60 414 506 49.6 80 179.2 60 115-60 104 127 30

575-60 518 633 42.9 70 126.8 60 115-60 104 127 30

380-60 418 342 51.1 80 198.8 60 230-60 198 254 15

380/415-50 342 440 60.5 100 229.0 80 230-50 198 254 15

208/230-60 187 253 124.7 200 458.4 150 115-60 104 127 30

460-60 414 506 60.7 100 229.2 80 115-60 104 127 30

575-60 518 633 52.4 80 170.8 70 115-60 104 127 30

380-60 418 342 64.7 110 254.8 80 230-60 198 254 15

380/415-50 342 440 68.5 110 259.0 90 230-50 198 254 15

208/230-60 187 253 145.5 250 518.4 175 115-60 104 127 30

460-60 414 506 68.7 110 259.2 90 115-60 104 127 30

575-60 518 633 54.9 90 182.8 70 115-60 104 127 30

380-60 418 342 73.6 125 287.8 90 230-60 198 254 15

380/415-50 342 440 87.8 150 351.0 110 230-50 198 254 15

208/230-60 187 253 203.0 350 708.6 250 115-60 104 127 30

460-60 414 506 91.1 150 354.3 110 115-60 104 127 30

575-60 518 633 81.6 125 286.2 100 115-60 104 127 30

380-60 418 342 111.1 175 393.7 150 230-60 198 254 15

UNIT CONTROL CIRCUIT

Supplied*

Min Max Min Max

MCA MOCP ICF

Rec Fuse

Size

V-Hz

(Single Ph)

Supplied

MCA and

MOCP

8

Page 9

Table 3B — Electrical Data — Unit with Factory-Installed Motormaster® I Control

UNIT

SIZE

30GTN

015

020

025

030

035

ICF —

MCA —

MOCP —

*Units are suitable for use on electrical systems where voltage sup-

plied to unit terminals is not below or above listed minimum and

maximum limits.

NOTE: Never operate a motor where a phase imbalance in supply

voltage is greater than 2%. Use the following formula to determine

the percent voltage imbalance.

Percent Voltage Imbalance

= 100 x

Example: Supply voltage is 240-3-60.

Vo lt a ge

V-Hz (3 Ph )

208/230-60 187 253 82.2 125 278.4 100 115-60 104 127 30

460-60 414 506 38.3 60 129.3 45 115-60 104 127 30

575-60 518 633 30.8 50 105.6 40 115-60 104 127 30

380-60 418 342 43.9 70 152.8 60 230-60 198 254 15

380/415-50 342 440 51.9 80 181.5 70 230-50 198 254 15

208/230-60 187 253 97.4 150 357.4 125 115-60 104 127 30

460-60 414 506 49.6 80 182.3 60 115-60 104 127 30

575-60 518 633 42.0 70 129.6 50 115-60 104 127 30

380-60 418 342 51.1 80 198.8 60 230-60 198 254 15

380/415-50 342 440 63.0 100 231.5 80 230-50 198 254 15

208/230-60 187 253 124.7 200 458.4 150 115-60 104 127 30

460-60 414 506 60.7 100 232.3 80 115-60 104 127 30

575-60 518 633 51.5 80 173.6 70 115-60 104 127 30

380-60 418 342 64.7 110 254.8 80 230-60 198 254 15

380/415-50 342 440 71.0 110 261.5 90 230-50 198 254 15

208/230-60 187 253 145.5 250 518.4 175 115-60 104 127 30

460-60 414 506 68.7 110 262.3 90 115-60 104 127 30

575-60 518 633 54.0 90 185.6 70 115-60 104 127 30

380-60 418 342 73.6 125 287.8 90 230-60 198 254 15

380/415-50 342 440 90.3 150 353.5 110 230-50 198 254 15

208/230-60 187 253 203.0 350 708.6 250 115-60 104 127 30

460-60 414 506 91.1 150 357.4 110 115-60 104 127 30

575-60 518 633 80.7 125 289.0 100 115-60 104 127 30

380-60 418 342 111.1 175 393.7 150 230-60 198 254 15

Maximum Instantaneous Current Flow during starting

(the point in the starting sequence where the sum of

the LRA for the starting compressor, plus the total

RLA for all running compressors, plus the total FLA for

all running fan motors is maximum).

Minimum Circuit Amps (complies with National Electrical Code [NEC, U.S.A.], Section 430-24)

Maximum Overcurrent Protection

max voltage deviation from average voltage

average voltage

Supplied*

Min Max Min Max

LEGEND

UNIT CONTROL CIRCUIT

MCA MOCP ICF

4

239

Supplied

MCA and

MOCP

Rec Fuse

Size

Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 v

(BC) 239 – 236 = 3 v

(AC) 239 – 238 = 1 v

Maximum deviation is 4 v. Determine percent voltage imbalance:

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: Contact your local electric utility company

immediately if the supply voltage phase imbalance is more

than 2%.

V-Hz

(Single Ph)

= 1.7%

Average voltage =

AB = 243 v

BC = 236 v

AC = 238 v

243 + 236 + 238

= 239 v

3

9

Page 10

C — Compressor Contactor

CB — Circuit Breaker

CCN — Carrier Comfort Network

CWFS — Chilled Water Flow Switch

CWP — Chilled Water Pump

CWPI — Chilled Water Pump Interlock

FC — Fan Contactor

GCS — Ground Current Sensor

LEN — Local Equipment Network

MBB — Main Base Board

NEC — National Electrical Code

TB — Te rm in al Bl oc k

TDR — Time Delay Relay

TRAN — Transformer

LEGEND

(U.S.A. Standard)

Field Power Wiring

Field Control Power Wiring

Field Control Wiring

Factory-Installed Wiring

Field-Installed Device

TB4

REMOTE

ON-OFF

NOTES:

1. Factory wiring is in accordance with the National Electrical Code. Any field modifications or additions must be in compliance with all applicable codes.

2. Connect separate source of control power from field supplied fused disconnect

to terminal 1 of TB4. Neutral side must be connected to terminal 2. This provides

power for the unit control circuit, cooler heater and compressor crankcase

heater.

3. All field interlock contacts must have minimum rating of 360 va pilot duty plus

capacity required for field-installed equipment.

4. For internal unit wiring reference wiring book or unit wiring label diagram.

5. For GCS accessory, remove jumper wire between terminals 5 and 8 on terminal

block TB2.

6. For part wind start accessory, remove gray jumper wire between C-A1-C1 and

C-A1A-C1. Time delay relay shown in suggested mounting position.

7. Voltage requirements:

MAIN POWER CONTROL POWER

208/230-3-60 115-1-60

460-3-60 115-1-60

575-3-60 115-1-60

380-3-60 220-1-60

380/415-3-50 230-1-50

Fig. 8 — Field Wiring Schematic

10

Page 11

Step 5 — Install Accessories

ELECTRICAL — A number of electrical accessories are

available to provide the following optional features (for details,

refer to the Controls, Start-Up, Operation, Service, and

Troubleshooting book):

• Energy Management Module (used for any of the following types of temperature reset, demand limit and ice

features):

— 4 to 20 mA leaving fluid temperature reset (requires

field-supplied 4 to 20 mA generator)

— 4 to 20 mA cooling set point reset (requires field-

supplied 4 to 20 mA generator)

— Discrete inputs for 2-step demand limit (requires field-

supplied dry contacts)

— 4 to 20 mA demand limit (requires field-supplied 4 to

20 mA generator)

— Discrete input for Ice Done switch (requires field-

supplied dry contacts)

• Chilled fluid flow switch/interlock

• Navigator display:

Provides hand-held, mobile capability using easy to read

4-line display . Keypad function is the same as the Scrolling

Marquee module. Features magnet for ‘hands free’ service

of components.

HOT GAS BYPASS — Hot gas bypass usually is not recommended because it results in application of equipment out

of its normal design application range. However, if its use is

required, the appropriate hot gas bypass package may be used.

For installation details, refer to separate instructions supplied

with the accessory package.

Step 6 — Refrigerant Circuit

LEAK TESTING — Units are shipped with complete operating charge of R-22 (see Tables 1A-1B) and should be

under sufficient pressure to conduct a leak test. If there is no

pressure in the system, use standard refrigeration practices to

search for the leak. Repair the leak using good refrigeration

practices. After leaks a re repaired, system must be evacuated

and dehydrated prior to recharging with refrigerant.

DEHYDRATION — Refer to Carrier Standard Service Techniques Manual, Chapter 1, Refrigerants, Sections 6 and 7 for

details. Do not use compressor to evacuate system.

REFRIGERANT CHARGE (Refer to Table 1A or 1B) —

Immediately ahead of filter drier in each circ uit is a factoryinstalled liquid line service valve. Each valve has a

Schrader connection for charging liquid refrigerant.

1

/4-in.

11

Page 12

Copyright 2000 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 563-068 Printed in U.S.A. Form 30GTN-10SI Pg 12 1201 1-00 Replaces: New

Loading...

Loading...