Page 1

P.O. Box 4069 • Winston-Salem, NC 27115 • 336-661-9893 • 336-661-9895 (Fax)

UC – 711 E Gravity and Pump

Soft Serve Freezer

Single Flavor Counter Model

OPERATION MANUAL

1

Page 2

2

Page 3

Foreword

Thank you for selecting Carpigiani to meet your operation and growing demands.

Your Carpigiani freezer has been manufactured utilizing the most advanced technology and

modern equipment available in the industry. We at Carpigiani, take great pride and care in

the manufacturing of each and every freezer, using only the finest components available, to

provide you with many years of trouble free operation.

Many years of experience in the manufacturing of soft serve dispensing equipment

have guided us in the preparation of this Operation Manual. PLEASE READ IT

CAREFULLY and keep it in an available place for future reference and most of all, follow

the instructions carefully.

On the following pages, you will find important information and procedures, which

describe the proper installation, sanitizing, operation, and maintenance of your Carpigiani

freezer. We feel certain that your compliance with these instructions will assure excellent

performance, trouble-free operation and profitable business for years to come.

All technical data, pictures and drawings contained in this operation manual are not binding on the manufacturer, nor can the

manufacturer be held liable for any modification to the freezer in part or completely.

3

Part Number:

Page 4

4

Page 5

Foreword Page #

Part I Installation

A) Uncrating 7

B) Positioning the Machine 7-8

C) Electrical Requirements 8

D) Completing the Installation

Part II Explanation of Controls

A) Electronic Control Panel 9-10

B) Dispensing Handle 10

C) Photo Sensor Switch 10

D) Dispensing Head Safety Switch 10

E) Electric Control Panel 10-11

F) Other Controls 11

Part III Initial Cleaning Procedure

A) Gravity Fed Cleaning Procedure 12

B) Pump Fed Cleaning Procedure 13

C) Disassembling the Dispensing Head 14

D) Disassembling the Beater / Auger 15

E) Cleaning Operations 15

Part IV Assembling the Freezer

A) Assembling the Beaters / Augers 16-17

B) Assembling the Dispensing Head 17-18

C) Assembling the Gravity Feed Tube 19

D) Assembling the Mix Injection Pump 20-21

Part V Sanitizing the Freezer 22-23

Part VI Starting the Freezer

A) Gravity Fed Machines 24

B) Pump Fed Machines 25

Part VII Operating the Freezer

A) Stand By Mode 26

B) Gravity Fed Machines – How to Operate and Make Adjustments 27

C) Pump Fed Machines – How to Operate and Make Adjustments 27

Part VIII Periodic Cleaning Procedures

A) Gravity Fed Machines 28-29

B) Pump Fed Machines 29-30

Part IX Technical Information

A) Refrigeration 31

B) Beater Drive Motor 31

C) Thermal Overload 31

D) Proximity Switch 31

Part X Maintenance

A) Troubleshooting Guide 33-34

B) Alarms 35

5

Page 6

6

Page 7

!! IMPORTANT !!

Failure to closely follow operational and maintenance

procedures may result in damage to the unit and / or

void your warranty. Carpigiani Corporation will not be

responsible for any machine not properly operated or

maintained.

Part I – Installation

Before starting this procedure, ensure that the shipping

carton does not show any evidence of damage due to

dropping or mishandling. This may indicate that the

freezer was damaged during transit or delivery.

!! IMPORTANT !!

Should the outside of the shipping carton give any

indication of possible damage, state this on the bill of

lading prior to signing. Contact the freight carrier and

request an inspection of damage. If this procedure is

not adhered to, you will forfeit your rights to file a

damage claim and be responsible for subsequent repair

costs.

A) Uncrating the Freezer

1) The outer shipping carton is secured to the shipping

pallet with strapping. When cutting this strapping, do so

with caution as it may spring out quickly. After cutting

the strapping, lift the shipping carton straight up and off

of the freezer.

Prior to choosing a location keep in mind that the

freezer should be accessible for periodic maintenance

and have adequate space for necessary airflow.

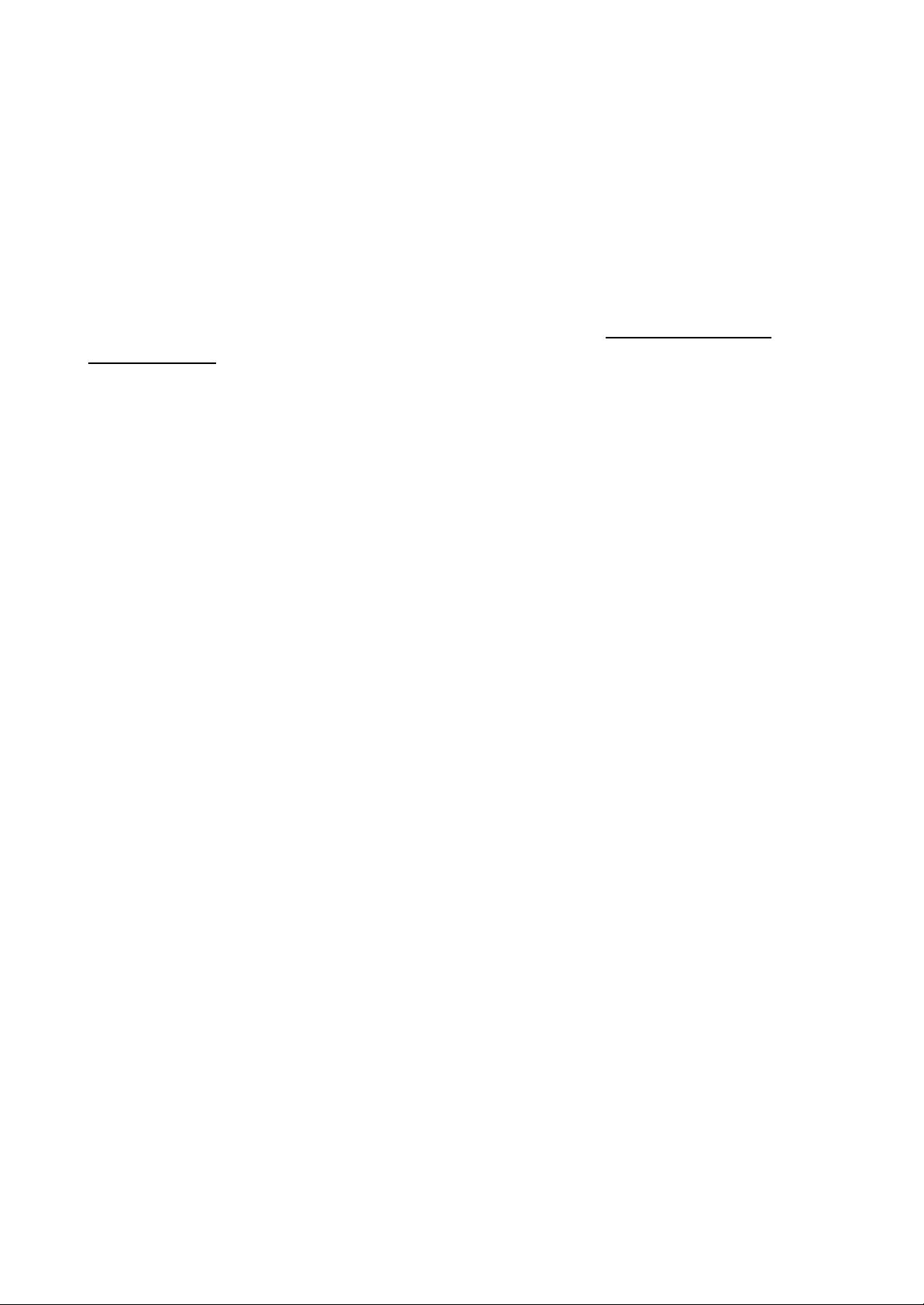

Figure 1

1) The freezer is equipped with adjustable legs to

allow for ease of leveling. To level the freezer, turn

the lower leg adjustment. The freezer must also be

level to ensure proper drainage from the mix tank and

cylinder.

2) Remove the protective foam boards and plastic

wrapping from the outside of the freezer.

3) The freezer is also secured to the shipping pallet

with strapping. Again, exercise caution when cutting

this strapping since it may spring out quickly.

4) You must now remove the side panels from the

freezer prior to lifting the freezer off of the pallet with

a lift truck. To remove the side panels, first remove the

side drip chutes and lower chute cover on both side

panels. Next remove the screws in each side panel and

gently pull down and away from the machine frame.

Remove the protective plastic coating from the outer

panel surfaces.

B) Positioning the Machine

After removing the machine from the shipping pallet, it

is now ready to be located in its final location.

6" 12"

Figure 2

2) If your freezer is air cooled, you MUST have

adequate spacing on both sides of the machine. You

should have a minimum of 6 inches of clearance on

the left side and 12 inches of clearance on the right

side of the machine. This will ensure an adequate

7

Page 8

airflow is maintained.(Ref. to Figure 2)

Note: If these clearances are not maintained, the

production capacity will be reduced, cycling will be

increased and the potential will exist that the machine will

stop completely

3) It is necessary to clean the air condenser each

month to remove dust, paper, etc., which may obstruct

airflow. Prior to cleaning the condenser from the

inside, disconnect the machines power supply.

4) The machine should be connected to a fused

disconnect no more than six feet away. Electrical

installation MUST comply with state and / local

electrical codes.

5) Never position the machine in direct sunlight or near

a heat source. This will reduce its performance and

possible damage the freezer.

6) Water connections (Water Cooled Only)are made

at the rear of the machine. A minimum of ½ inch (ID)

water supply and drain lines are recommended. Both

the water inlet and outlet lines must remain

unobstructed or the machine performance will be

affected.

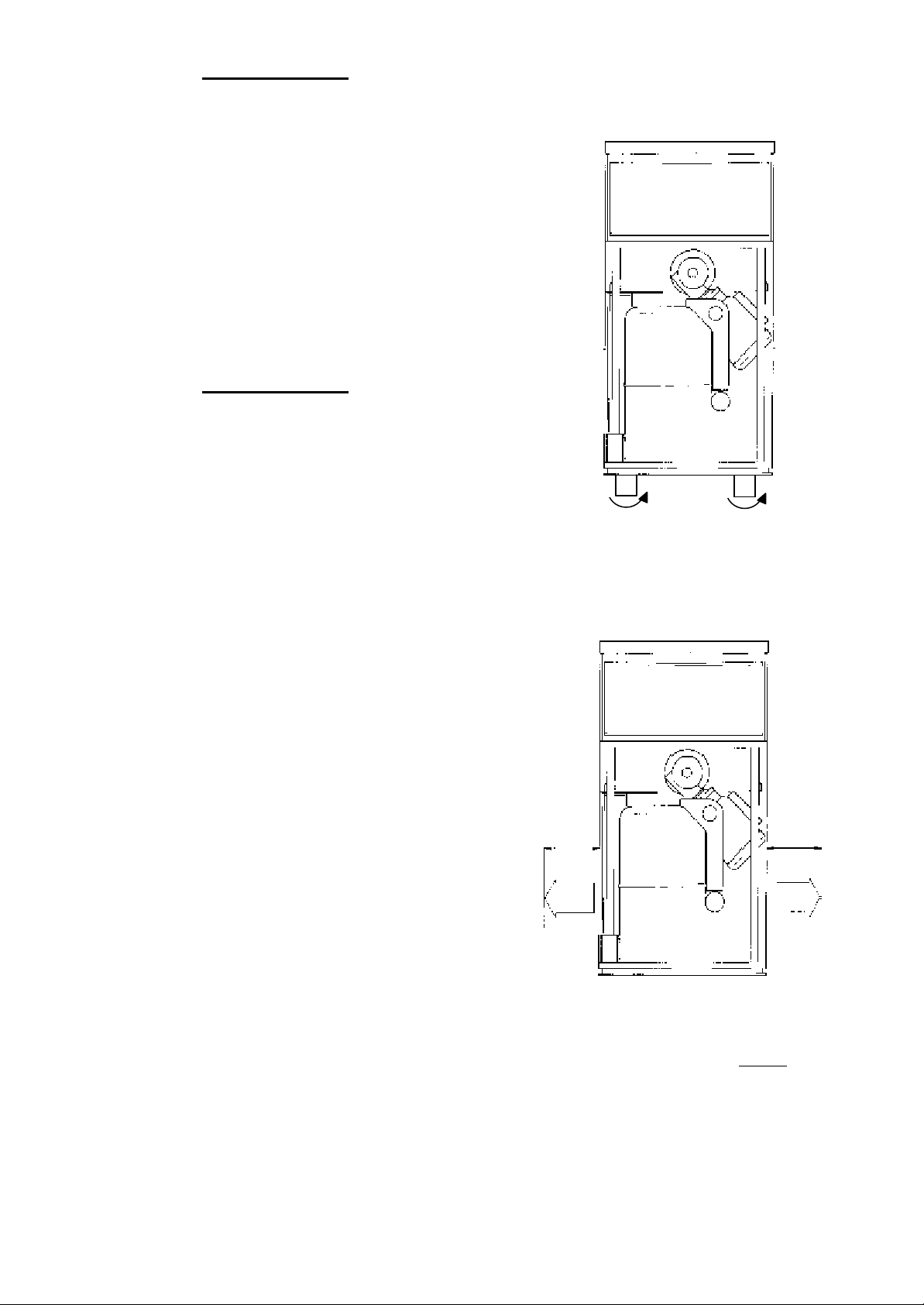

C) Electrical Requirements

main power connection box is located on the rear,

right side bottom of the frame. The connection box is

labeled “Connect Power Line Here”. Connect the

power supply wires to the machines using the

appropriate electrical hardware and strain relief

devices.

Figure 3

After the electrical connections are completed, turn

the power supply on. At this time you must check the

beater / auger motor rotation. The correct beater

rotation ( Facing the front of the machine ) should be

counter clockwise.

D) Completing the Installation

1) All of the setup and calibration of this freezer

should be performed by an approved Carpigiani

Service Technician. Failure to calibrate this freezer

properly can result in freezer damage and a voided

warranty.

All wiring installed to operate the freezer must be in

accordance with the National Electric Code and / or

local electrical codes and regulations.

!! IMPORTANT !!

This machine must be properly grounded.

Failure to properly ground the freezer may result

in dangerous and / or fatal electric shock.

The main machine power supply must meet

requirements at all times of operation. Voltage

fluctuations must not exceed plus or minus 5% of the

rated nameplate voltage.

All Carpigiani machines are equipped with step down

transformers for the control circuit supply. These

transformers have a “multi-tap” input which must be

wired to match the inlet voltage

(ie. 115 vac). Failure to wire to the correct supply

voltage can result in machine malfunction.

Electrical Connection – ( Refer to Fig. 3 )

2) After installation and calibration of both electrical

and refrigeration circuits, the side panels should be

reinstalled.

!! IMPORTANT !!

Failure to closely follow factory setup and maintenance

procedures will result in a voided warranty. Carpigiani

Corporation will not be responsible for any freezer

which is not setup or maintained in accordance with

factory procedures.

NOTE: Always turn the machine OFF and

disconnect the power supply switch to the freezer

prior to exposing any electrical connections or

moving parts.

On the following pages you will find important

information and procedures which describe the proper

sanitizing, operation, and maintenance of your

Carpigiani Freezer. We are certain that your full

compliance with instructions and procedures will result

in many years of trouble free operation.

Having removed the side panels from the frame, the

In the event this unit should malfunction or need

maintenance, please contact your local Carpigiani

Distributor or Authorized Service Agent.

8

Page 9

Part II – Explanation of Controls

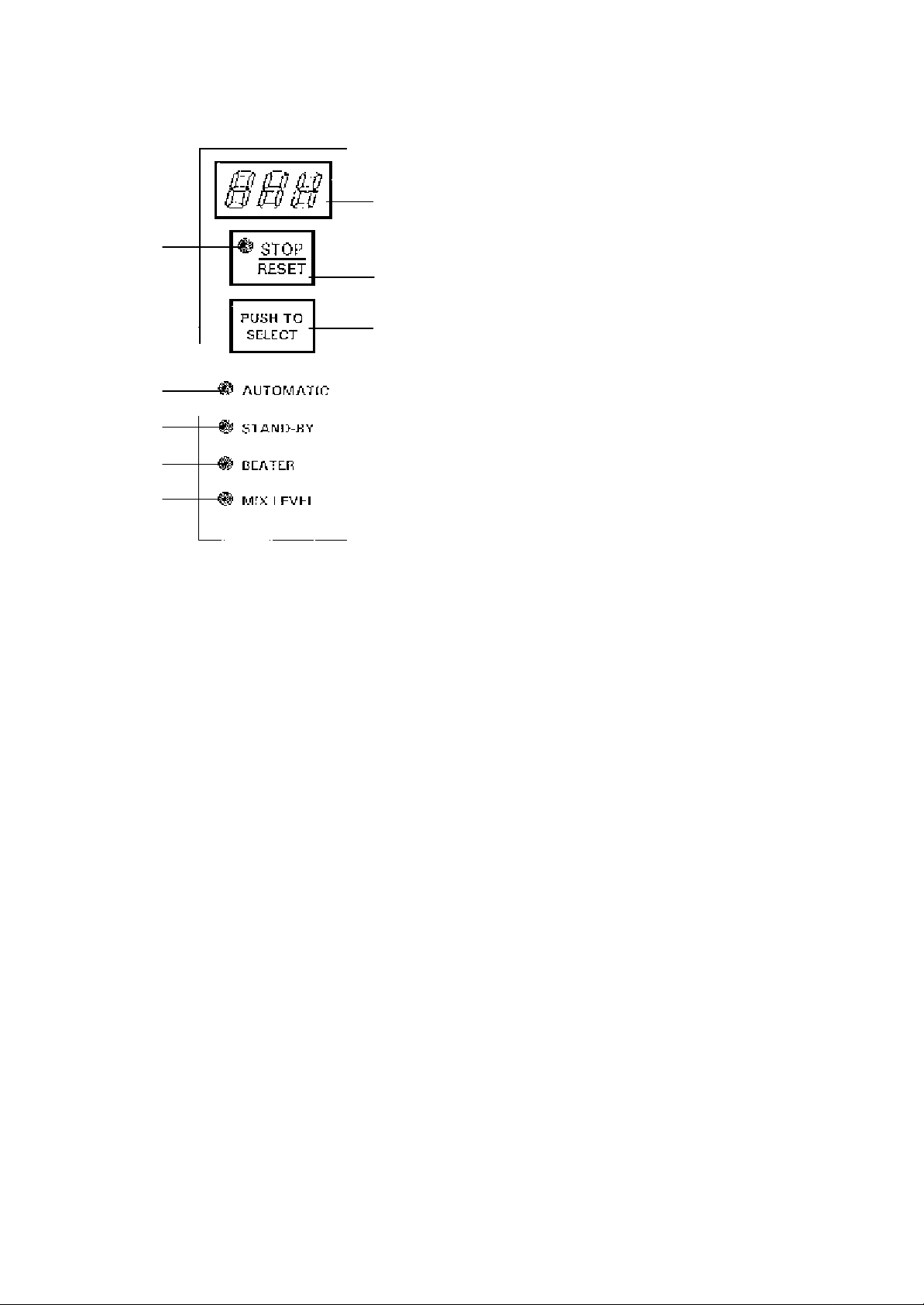

A) Electronic Touch Pad – (Refer to figure 4)

570

Push to Select – Position 571.2

By pressing this button you can select any of the

following machine modes:

- Automatic

- Stand-by

- Beater

The indicator light will illuminate corresponding to

the mode selected with the touch pad.

L1

571.1

571.2

L2

L3

L4

L5

Figure 4

This machine is equipped with one electronic touch

control pads. This electronic touch pad operates all

controls of the freezer.

Indicator Lights – L1 through L4

These indicators illuminate to show the selected machine

function. When illuminated, the machine is in that

respective mode.

Indicator Light – L5

This light will illuminate when the mix tank is low or out

of mix. It is also possible to activate a low mix level

beeper in the programming mode.

Monitor – Position 570

This numerical monitor will display the cylinder product

consistency while the machine is freezing product in the

automatic mode. When not freezing the product in the

cylinder, it will display mix tank temperature in ALL

modes.

Stop / Reset – Position 571.1

When in this mode, the indicator light L1 will be lit and

the machine functions off. From this mode you can

access the programming mode or switch to operating

modes.

Automatic Mode

When placed in this mode the indicator light L2 will

illuminate and the machine will start the freezing

process in the cylinder. During this freezing process,

a number indicating the cylinder consistency will be

displayed (monitor #570, the lower the number,

softer the product). The machine will continue to

freeze the product in the cylinder (numbers will

increase) until the preset HOT number value is

achieved. After achieving the preset cylinder

consistency number (HOT) the machine will then

start cooling the mix tank and display mix tank temperature.

Stand-By Mode

When placed in this mode the indicator light L3 will

illuminate. This mode is used during prolonged idle

periods. The mix temperature in both cylinder and

mix storage tank is maintained below 40 degrees F

by the electronic temperature probes. Product should

not be served while in this mode as it will be too soft.

The Monitor (#570) will only display the temperature

in the mix tank while in this mode.

NOTE: If the mix level in the tank is below ½ full,

a warmer than actual temperature will be

displayed on the Monitor #570. The actual mix

temperature will remain at a safe temperature

below 40 degrees F.

Beater Mode

When placed in this mode the indicator light L4 will

illuminate. This mode is used during the start-up

(pump fed), cleaning and sanitizing of the machine.

While in this mode the ONLY the beater / auger

drive motor will operate. This mode has a built in

safety device which will automatically switch the

machine to the stop mode after 15 minutes of

operation. This safety prevents an operator from

inadvertently leaving the freezer in this mode for

extended periods of time, which could damage the

freezer.

Mix Tank Low Level Indicator

When low on mix in the mix storage tank, the

indicator light L5 will illuminate. This will indicate

9

Page 10

that more mix is needed to operate the freezer. Each

mix tank has a maximum capacity of 10 quarts each.

DO NOT attempt to operate the freezer while low on

mix or your freezer may be damaged. It is also

possible to activate a beeper to sound when mix is low

in the Automatic and Stand-By modes. This is done

through the programming mode.

B) Dispensing Handle – (Refer to Figure 5)

The dispensing handle control the flow and extraction

rate of finished product.

You should ONLY dispense product when the machine

is in the automatic mode.

Figure 6

D) Dispensing Head Safety Switch

This machine is equipped with a dispensing head

safety switch. With the dispensing head removed, the

machine will not operate and Alarm 9 (AL9) will

appear on the front touch pad monitor. Please refer to

machine alarms on page 28 for more details.

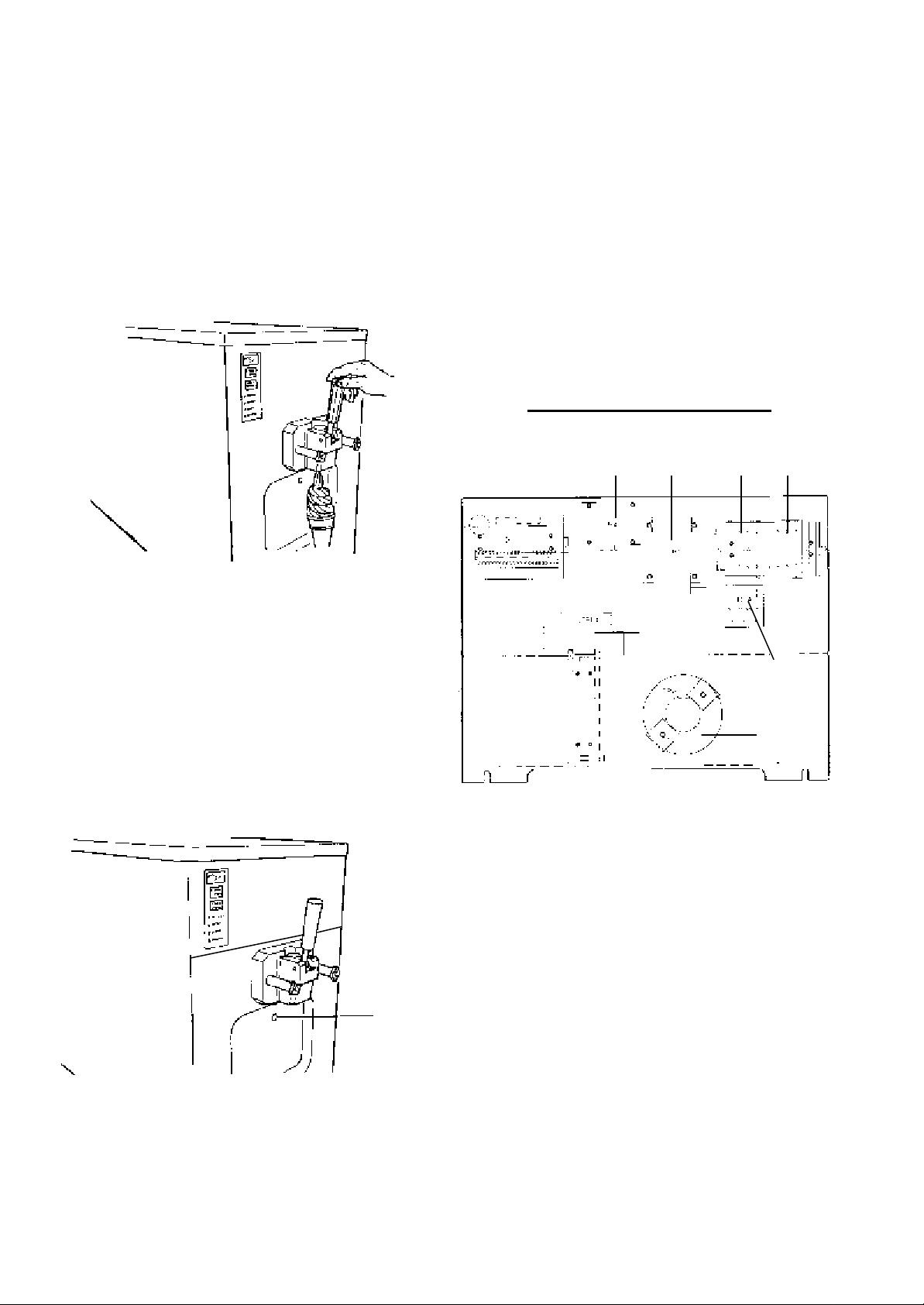

E) Electrical Control Panel – (Refer to figure 7)

The electrical control panel is located on the top of

the front panel. This control panel contains all of the

machines electrical control components. ONLY a

Carpigiani Authorized Technician should access this

control panel.

!! IMPORTANT WARNING !!

Disconnect the freezer power supply before

opening the Electrical Control Panel and / or

7

4

21

servicing.

Figure 5

C) Photo Sensor Switch -(Refer to Figure 6)

In the Automatic mode the Photo Sensor Switch

(Position #152) activate the beater / auger motor to

dispense product. To activate the photo sensor switch,

simply place your hand with a cone or cup under the

dispensing head, pull the dispensing handle and

dispense product.

NOTE: You must activate the photo sensor switch,

starting the beater drive motor prior to dispensing

product.

152

5

3

6

Figure 7

The following is an explanation of some of the

components inside the electrical control panel.

1) Beater Motor Contactors - Activates the beater

drive motor. In the “BEATER” mode, the contactor is

energized by the front switch pad. In the “AUTO”

mode, the contactor is energized by the photo sensor

or

10 minute cycling timer.

2) Compressor Contactor – Activates the refrigeration

compressor. When the unit is in the “AUTO” mode,

the compressor contactor can be energized by the

electronic HOT setting or the Tev Temperature probe.

10

Page 11

In the “Stand-By” mode, the contactor is energized by

the Tev and Tec temperature probes.

3) Beater Motor Overload Protector - Monitors the

current draw of the beater drive motor. If the motor

draws excessive amperage, the overload will trip and

Alarm 1 (RtA) will be displayed on the touch pad monitor.

4) Main Transformer – This transformer reduces the

incoming line voltage to 24 volts for the primary

control circuit.

5) Electronic Control Board – This board controls and

monitors ALL functions of the machine.

6) Current Monitoring Transformer – This

transformer monitor the current draw of the beater

drive motor.

7) Secondary Transformer – This transformer reduces

the voltage from 24 volts to 11 volts for the electronic

control circuit.

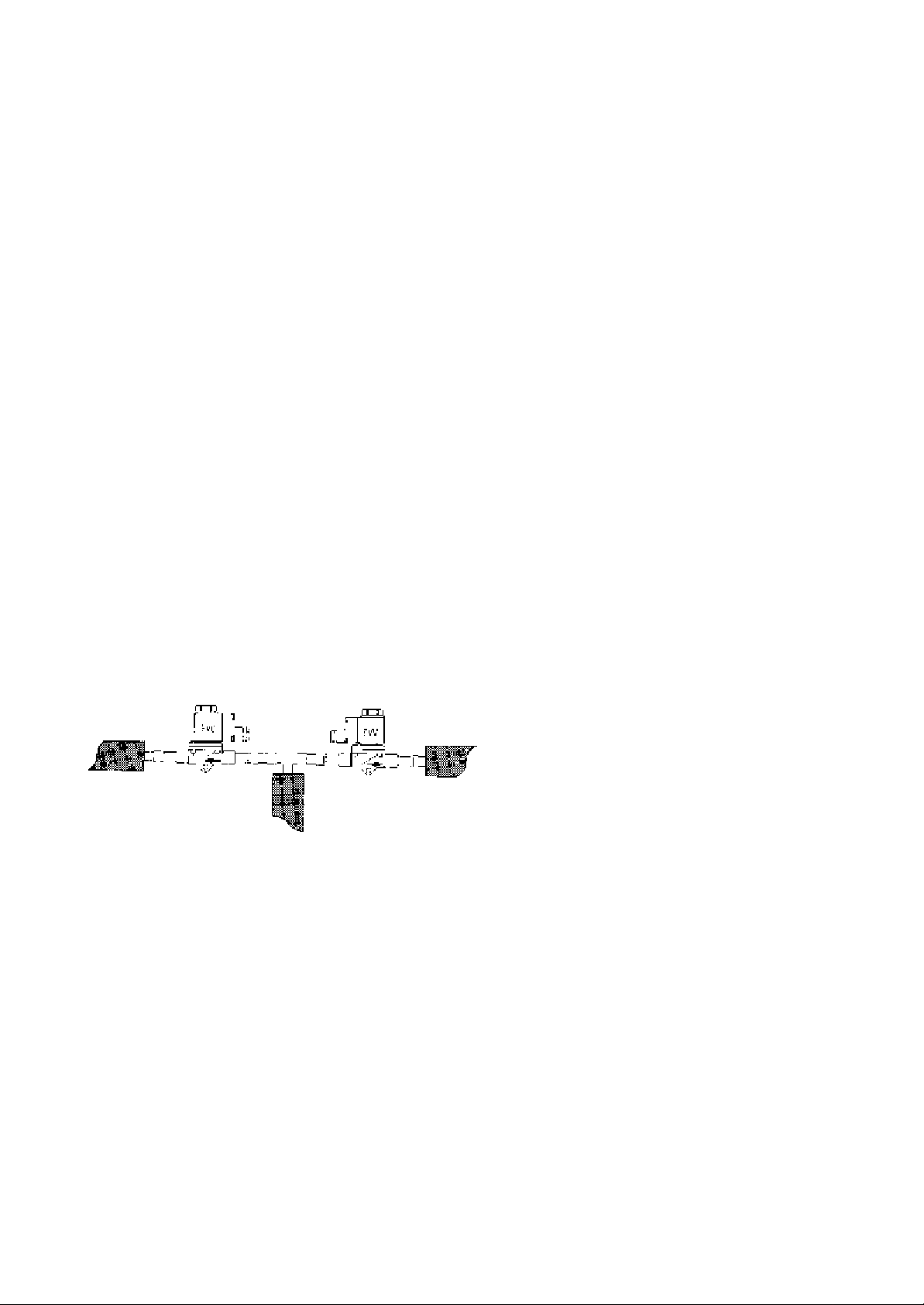

F) Other Controls

1) Refrigeration Solenoid Valves – These valves are

located behind the front panel. These valves are used

to control the flow of refrigerant to the cylinders or

mix storage tanks. These valves are designated with

EVC for each cylinder and EVV for the mix storage

tank. (Refer to Figure 8)

Figure 8

2) High Pressure Safety Switch – In the event of

restricted airflow (Air Cooled) or restricted water

flow (Water Cooled), this switch will turn off the

compressor contactor. While tripped, the beater

motors will continue to run until the refrigerant

pressure is reduced enough to reset the safety switch.

After resetting, both the compressor and motor will

resume operation.

11

Page 12

Part III–Initial Cleaning Procedure

!! IMPORTANT !!

Before starting this procedure, place the machine in

the STOP mode on the touch pad.

This is a new machine and although clean, it must be

completely disassembled, washed and sanitized

before adding fresh product. Please proceed as

follows:

Next remove the outer regulating sleeve from the center

tube by pulling straight off.

1) Remove the mix tank cover and spare parts items

packed inside the mix tank. The spare parts kit will

include: spatula, cleaning brushes, sanitary

lubricant, oring removal tool, sanitizer packets,

spare orings and seals, and operation manual. Place

these items in a convenient place for future

reference.

Helpful Suggestion: Before proceeding with the

disassembly of the freezer, we recommend the use of

a clean plastic pan or pail to place the removed parts

into. This will minimize the possibility of misplacing

or damaging these components.

A) Gravity Fed Cleaning Procedure

Proceed with the disassembly process by removing

the gravity feed tube, which is located inside the mix

storage tank. The tube should be pulled straight up

and out of the tank.

Finally remove the orings on the end of the center tube

using ONLY the oring removal tool included in your

spare parts kit.

!! WARNING !!

Never use anything other than the oring remover

provided in your tool kit. Removing the orings with

other objects or tools can possibly damage the orings

and plastic parts.

Once removed, the gravity feed tube must be

disassembled. To disassemble, first remove the

splash guard from the center of the tube.

12

Page 13

B) Pump Fed Cleaning Procedure

Proceed with the disassembly of the mix injection

pump located in the mix storage tank. First slide the

connecting tube forward away from the mix pump

faceplate. This should free the feeding elbow assembly

from the pump assembly. Pull the feed elbow assembly

straight up and out of the mix storage tank.

Disassemble the mix pump assembly as pictured

below. When disassembling the orings from the other

components, use only the oring removal tool provided

in the spare parts tool kit. Using other tools to remove

the orings from their grooves can result in damaging

both the oring and component.

Next remove the mix pump assembly by rotating

clockwise until the hook stud on the rear of the pump

disengages from the pump hub. After disengaging,

slide the pump away from the rear of the machine and

out of the mix storage tank.

13

Page 14

C) Disassembling the Dispensing Head

Loosen and remove the two dispensing head-retaining

knobs. The knobs are removed by turning counter

clockwise until loose.

Pull the handle-retaining rod out far enough to allow

the handle to disengage.

Return the retaining rod to its original position. Using

the metal rod as a base, lever the piston from the

dispensing head with the handle.

Remove the dispensing head by pulling straight out and

away from the machine.

Disassemble the dispensing head by first opening the

dispensing handle.

Using the oring removal tool, remove the orings from

each of the piston.

Turn the dispensing head over and remove the large

oring from the rear of the dispensing head.

14

Page 15

D) Disassembling the Beater / Auger

Remove the beater / auger assembly from the cylinder

by pulling straight out of the machine towards you.

Disassemble the beater / auger by first removing the

rear rubber beater shaft seal.

Finally, remove the beater / auger end pusher by

pulling straight out of the beater / auger frame.

Remove the scraper blades from the beater / auger frame by gently rotating the blade out of the frame

support brackets.

The machine is now completely disassembled. The

removed parts must now be washed, rinsed, and

sanitized.

E) Cleaning Operation

Next disassemble the center idler from the beater /

auger frame. To remove, pull the idler straight out of

the front of the beater / auger.

Wash the removed machine parts in luke warm (80-90

F) water and mild non-foaming detergent. Scrub each

of the parts with the cleaning brushes provided in the

machines spare parts kit.

!! IMPORTANT !!

DO NOT use hot water on any of the plastic parts as

this may result in damaging these parts.

4) Air Dry

3) Sanitize

2) Rinse

1) Wash

Using your three-tank sink, wash rinse, and sanitize all

of the disassembled machine parts. Mix the sanitizing

solution to a 200ppm concentration with warm water.

Allow the parts to soak in the sanitizing solution for 35 minutes before removing. Allow the parts to air-dry

on the clean, sanitized counter at the end of the sink.

DO NOT towel or sponge dry these parts.

15

Page 16

Part IV - Assembling the Freezer

A) Assembling the Beater / Augers

After completing the Cleaning Operation, you are

now ready re-assemble the freezer. First locate the

parts needed to assemble the beater / auger.

A) End pusher, B) Beater frame,

C) Idler, D) Beater seal, E) Scraper Blades (2per),

F) Blade bumpers (2 per blade)

D

C

B

E

F

A

Install the idler into the beater frame by placing it

through the end pusher.

NOTE: When installed correctly, the idler should

rotate freely inside the beater frame. If the idler

does not rotate freely, it is incorrectly installed

and MUST NOT be installed into the machine.

Repeat the above instructions until the idler is

installed correctly .

Next, lubricate the rear of the metal washer on the

beater frame with three 3/8 ” drops of the sanitary

lubricant spaced equally on the washer.

Install the rubber bumpers into each scraper blade.

NOTE: Keep the large end of the bumper

opposite the blade groove.

Assemble the scraper blades onto the beater frame

by inserting the blade into the support and rotating

downward. Install the end pusher into the beater

frame making sure to engage the alignment notch of

both the beater and end pusher.

Slide the rubber beater seal onto the beater frame

end. Using the sanitary lubricant, place three more 3/

8” drops of lubricant on the flat side of the beater seal

(next to the beater shaft). DO NOT lubricate the “V”

groove of the seal as this is not the sealing surface of

the seal.

16

Page 17

Insert the beater assembly into the freezing cylinder.

Holding the beater horizontal, gently slide it straight into

the cylinder until it can go no farther.

B) Assembling the Dispensing Head

Locate the parts that will be needed to assemble the

dispensing head. These parts include: A) Dispensing

head oring, B) Dispensing head, C) Piston orings (2),

D) Piston, G) Handle retaining rod, H) Dispensing

handle, and I) Retaining rod oring.

D

Once installed, rotate the beater assembly to engage the

beater frame into the drive coupling in the transmission.

This engagement will allow the beater frame to go

another ¾” into the cylinder. Push the beater frame until

it can go no further.

A

C

H

B

G

I

After locating all of the required parts, start by

assembling orings onto the piston.

After installing and engaging the beater assembly, rotate

the center idlers to a vertical position. This will ensure

that they will correctly engage the pins on the rear of the

dispensing head.

17

Once the orings have been installed onto the piston,

place a bead of lubricant between the orings.

Page 18

Spread the lubricant to lightly coat the piston

surface between and including the orings. This

will ensure free movement of the pistons and

dispensing handle.

Insert the piston into the chamber of the

dispensing head. When installing, align the

square handle recess with the rectangular cut

out of the head.

Install the dispensing handle onto the head by placing the

rounded side of the metal cam into the piston notch.

Insert the metal retaining rod into the dispensing head

and piston cams. When the handle is installed, affix the

small oring into the metal retaining rods oring groove.

You are now ready to install the dispensing head

assembly onto the front of the freezer.

Turn over the dispensing head and insert the

two large orings into the grooves in the

dispensing head. Lightly lubricate the outside of

these orings.

Finger tighten the two metal dispensing head-retaining

knobs.

18

Page 19

C) Assembling the Gravity Feed Tube

Lightly lubricate both orings on each tube with the

sanitary lubricant. When finished, place a feed tube

Locate the parts needed to assemble the gravity feed

tubes. This should include: A) Splash guard, B) Orings

(2per), C) Outer regulating sleeve, D) Center gravity

feed tube

D

Insert the splash guard into the top hole of the

gravity feed tube.

B

C

A

Next, slide the two orings onto the center gravity feed

tube oring grooves.

uninstalled at the bottom of each mix tank.

Lubricate

The machine is now completely assembled and

ready to be sanitized.

Slide the outer regulating sleeve onto the center feed

tube. Make sure that the two finger hooks are at the top

of the feed tube (farthest away from the orings at the

bottom).

19

Page 20

D) Assembling the Mix Injection Pump

Before assembling the mix injection pump, locate all of

the parts that will be required. (See Below)

207

1117

1197

105

1126

32

8

550

39

248

1178

38

245

206

1126

31

38A

202

Install the two orings (#1126) into the bottom grooves

of the feeding elbows (#32) then lightly lubricate.

Install the assembled pressure relief plunger into the

feed elbows, small end first. Next install the assembled

connecting tube into the mix feed elbow, check valve

first. The feeding elbows are now completely

assembled and can be placed into the bottom of the

mix storage tanks.

271

1126

First install the small oring (#31) onto the pressure

relief plunger (#105) and lightly lubricate the oring.

NOTE: Oring #1126 is slightly smaller than the

other orings used on this assembly. Locate these

orings first and install.

Assemble the connecting tube (#207) with the check

valve (#1126) and orings (#1126) and (#1117). Lightly

lubricate the check valve before installing into the

connecting tube. Lightly lubricate both orings.

To assemble the mix pumps, first locate the pump

gears (#38&A) and pump body (#39). Lightly

lubricate the top, bottom, and inside bore of the gears.

Install the gear into the appropriate gear well. Install

and lubricate oring (#1178) into the pump body (#39).

NOTE: DO NOT lubricate the gear teeth since this

is removed when the pump starts running.

20

Page 21

Install the mix pump drive shaft seal into the rear of

the mix pump body. Lightly lubricate the inside of the

shaft seal then install the drive shaft into the pump seal

engaging it into the drive gear.

Assemble the plastic suction tube (#271) by installing

the oring (#1126) into the groove and lightly lubricate.

Next lightly lubricate the base (flat part) of the relief

valve (#245) and install into the well of the mix pump

cover (#202).

Install the spring (#206) onto the relief valve in the

pump well. Install the suction tube with lubricated

oring into the pump cover well engaging the spring into

the suction tube recess. To lock the suction tube onto

the pump cover, rotate, the tube until the adjustment

lever is pointed away from the pump cover (6 o’clock

position).

Install the pump body assembly into the rear hub inside

of each mix storage tank. Slide the drive shaft into the

rear hub and rotate the pump until the hook stud

engages the pin on the rear hub. At this point, you

must ensure that the drive shaft is engaged into the

rear drive coupling by turning the drive gear until it

completely engages.

You are now ready to install the pump cover with

suction tube onto the pump body assembly, which is

installed on the rear pump hub in the mix storage tank.

To install the cover, first ensure that the oring (#1178)

is installed into the pump body (#39). Next, affix the

pump cover onto the pump body using the two metal

retaining knobs (#8).

The freezer is now completely assembled and must be

sanitized prior to adding fresh mix and operating.

21

Page 22

Part V - Sanitizing the Freezer

Prior to filling the machine with fresh liquid mix, the

assembled machine must be sanitized. The frequency

of cleaning and sanitizing must comply with your local

and / or state health regulations. If uncertain of these

regulations, contact your local Health Departments or

Department of Agriculture.

Sanitizing your freezer is very important. This procedure will retard the growth of bacteria and insure

excellent product bacteria test results performed by

your local inspectors.

To begin, you will need the sanitizer, spatula, large

cleaning brush, (all included in the start up kit), and

clean pail.

Mix the sanitizer (Stera Sheen green label or

equivalent) into the clean pail with at least two gallons

of warm water. Mix the sanitizer and water to make a

200-PPM. concentration of sanitizer solution. Using

the spatula, stir the solution until the sanitizer is

completely dissolved.

With the dispensing handle closed, pour an even

amount of the sanitizer solution into the mix tank. With

the large cleaning brush, clean all surfaces of the mix

storage tank with the sanitizing solution.

With the cylinder full of the sanitizer solution, push the

“Push to Select” button on the front touch pad

(#571.2) until the beater mode is selected. Allow the

machine to run in the beater mode for approximately

30 seconds.

!! IMPORTANT !!

!! IMPORTANT !!

Do not exceed the formula recommended by the

sanitizer manufacturer as it will not add to the

sanitizing effectiveness. DO NOT use straight

chlorine bleach since it does not clean properly

and will damage plastic components. Do not leave

the sanitizing solution in the freezer longer than

one hour as it can corrode some parts.

Do not select the “Automatic” or “Stand-By”

modes while sanitizer is in the machine as this can

possibly damage your freezer. Select only the

“Beater “mode while cleaning or sanitizing the

freezer.

571.2

22

Page 23

Press the “Stop – Reset” button (#571.1) and place

the machine in the OFF / Stop mode. Allow the

sanitizer to remain in contact with all of the product

surfaces for

3 to 5 minutes.

“Push to Select” button on the front touch pad

(#571.2) until the beater mode is selected. Allow the

machine to run in the beater mode for approximately

10 seconds then push the “Stop” button on the touch

pad. This will remove any of the remaining sanitizer

from the cylinder.

571.1

Place the clean pail under the dispensing head and pull

the handles, allow the sanitizer to completely drain

from the freezer.

After the sanitizer has completely drained, close the

dispensing handle.

!! IMPORTANT !!

With your spatula, direct any remaining liquid in the

bottom of the tank to the cylinder feed hole.

The freezer is now sanitized and ready to be filled

with fresh liquid mix. Do not wipe out any residual

sanitizing solution from the bottom of the mix

storage tanks as this will contaminate the machine

with bacteria. Prior to dumping the sanitizing

solution from the pail, submerse your hands to

sanitize since you must next install the Gravity

Feed Tube or Pump Feed Elbow into the cylinder

feed hole.

23

Page 24

Part VI – Starting the Freezer

Only after completing the cleaning and sanitizing

procedures should you fill the machine with fresh

mix. The mix being used MUST be free of ice,

seeds, pulp, and completely dissolved if made from

powder. The products used in these freezers must

be a homogenous liquid.

You may now start the freezing process by pressing the

“Select” button (#571.2) and selecting the Automatic

mode.

571.2

L2

A) Gravity Fed Machine

The cylinder of this freezer are designed to allow

for simple start up and minimal product loss due to

improper overrun.

Fill the mix tank with fresh liquid mix. The mix tank

has a maximum capacity of 10 quarts. The minimum

recommended mix quantity is 3 quarts.

L3

The initial freeze time is approximately 4-7 minutes. Do

not dispense product until the machine has cycled off.

Before dispensing product you must also open the outer

regulating sleeve on the feed tube. The draw rate, portion

size, and mix viscosity will determine the final regulating

sleeve setting. Our standard setting is 2 or 3 notches up

from the bottom. Adjust for your specific application.

Allow the cylinder to fill with mix. When the air

bubbles stop coming out of the cylinder feed hole,

mix has filled the cylinder to its maximum capacity.

Install the assembled gravity feed tube into the

cylinder feed holes. Set to the closed position

(bottom).

24

Page 25

B) Pump Fed Machines

With your clean, sanitized hands, install the feeding

elbow into the cylinder feed hole. Next slide the elbow

connecting tube into the pump cover hole.

Holding the connecting tube inside the pump cover hole,

slide the feeding elbow away from the pump. This will

seat the tube and elbow to prevent the tube from sliding

out when under pressure.

With the mix tanks filled with liquid mix and the

elbows connected to the pumps, you can now prime

the cylinders. To prime the cylinders, press the

“Select” button on the touch pad, selecting the

“Beater” only mode. Allow the machine to run for

approximately one minute the press the “Stop”

button.

570

571.1

571.2

Carefully push the plastic bleed plunger, which

extends from the front of the feeding elbow. This

will allow the air to escape from the cylinder.

Fill each mix tank with fresh liquid mix. Each mix tank

has a maximum capacity of 10 quarts. The minimum

recommended mix quantity is 3 quarts.

When all of the pressure is released, press the

“Select” button and switch to the “Beater” only

mode for one minute. After one minute, press the

“Stop” button and carefully push the plastic bleed

plunger, which extends from the front of the feeding

elbow.

Repeat this process until a steady stream of mix only

is flowing from the bleed hole on the feeding elbow.

You may now start the freezing process by pressing

the “Select” button (#571.2) and selecting the

Automatic mode.

The initial freeze time is approximately 4-7 minutes.

Do not dispense product until the machine has

cycled off. The draw rate, portion size, and mix

viscosity will determine the final regulator tube

setting. Adjust for your specific application.

25

Page 26

Part VII – Operating the Freezer

A) Stand-By Mode

The machine will automatically stop the freezing process

after achieving the pre-set “consistency” value (number

displayed on the touch pad monitor). This will indicate

that the product is ready to be served. At this time the

compressor will continue to run and automatically switch

to cooling the mix storage tanks.

To serve product, simply place a cup, container, or cone

under the dispensing spout and slowly pull the dispensing

handle down. At this time the beater / auger drive motor

should start and product start coming out. As the product

begins to flow, move the container in a circular fashion

to create a tapering tower if frozen product.

During long pauses between servings, press the

“Push to Select” button (#571.2) and select the

“Stand-By” mode of operation. In this mode, you

will significantly reduce the energy consumption of

the freezer. When placed in this mode the indicator

light L3 will illuminate. The mix temperature in both

cylinders and mix storage tanks are maintained

below 40 degrees F by the electronic temperature

probes. Product should not be served while in this

mode as it will be too soft. The Monitor (#570) will

only display the temperature in the mix tank while in

this mode.

570

L1

571.1

571.2

When the desired portion has been dispensed, close the

handle and pull the container with product straight down

to add a peak.

Dispense the product without exceeding the freezers

production capacity. If you do not exceed this pace and

are careful to refill the machine with fresh mix, you can

be sure you will rarely have to pause in selling product,

even during peak times. A standard draw rate is ¾ to 1

ounce of product dispensed per second. The larger the

portion size, the slower it should be drawn.

L2

L3

L4

L5

When you want to begin serving product again,

press the “Push to Select” button (#571.2) and

select the “Automatic” mode. Allow the machine to

cycle off on the consistency control before serving

product.

26

Page 27

B) Gravity Fed Machines

C) Pump Fed Machines-Operation

The gravity feed tube consists of two tubes, one

sliding inside of the other, and a center splash guard.

The inner tube blends the flow of air and mix into

the freezing cylinder. Air enters through the top of

the tube, mix through the bottom.

(Refer to figure 9)

Air Intake

Max. Fill Level

Mix Intake

Maximum

Standard

The mix injection pump runs whenever the beater drive

motor is turning. To regulate the amount of mix being

injected into the cylinder, pivot the pump suction tube

either to the right (less mix/more air) or to the left (more

mix/ less air). (Refer to figure 10)

min

max

271

Figure 9

The outer tube is actually a regulating valve. Lifting

or closing this outer tube changes the hole opening

size on the inner tube which allows more or less mix

to enter the freezing cylinder. Since the air inlet hole

size does not change, the air inlet is constant.

You can vary the overrun (yield) by allowing more

or less mix to enter the cylinder by changing. You

do this by opening or closing the outer regulator

sleeve setting on the inner feed tube.

The inner splash guard keeps mix from splashing the

underside of the mix tank cover as well as eliminate

clogging of the feed tube.

The draw rate, portion size, and mix viscosity will

determine the final regulating sleeve setting. Our

standard setting is 2 to 3 notches up from the

bottom. Open the outer tube to increase the mix

amount. Close the outer tube to decrease the mix

amount. Adjust for your specific application.

Figure 10

The air intake is through the front two holes of the pump

cover. Since the two air inlet holes are fixed, the air

intake is constant. To adjust your overrun (yield) you

must regulate the amount of mix being pumped into the

cylinders. The mix pump suction tube will change the

orifice size on the tube to allow either more or less mix to

be pumped into the cylinder.

You will also have to adjust your pump suction tube

during daily operation to either a larger (Left) or smaller

(Right) orifice setting depending on your draw rate and

product viscosity.

For heavy draw rates and / or thick viscosity mixes, a

setting of center, one, two, or three positions to the left of

center will be necessary in order to operate the machine

properly.

For light draw rates and / or thin viscosity mixes, a

setting of center, one, or two positions to the right of

center will be necessary.

The “Normal” operating position for the suction tubes on

this freezer is either one position to the left, center, or

one position to the right.

27

Page 28

Part VIII – Periodic Cleaning

Procedures

Cleaning and sanitizing schedules for your freezer are

determined by your local Health Department and / or

Department of Agriculture and must be followed

accordingly. Check with your local organization prior to

determining your cleaning schedule.

After determining your schedule, proceed as follows:

A) Gravity Fed Machine

With frozen mix in the machine, select the Beater mode

on the front touch pad by pressing the Push to Select

button (#571.2) until pilot light #L4 illuminates. Allow the

machine to operate in the beater mode for 4 to 5

minutes. This will soften the product and allow for easier

product removal.

With the machine still in the Beater mode, place a

pail under the dispensing head. Slowly pull the handle

and allow all of the product to drain from the

machine.

After the product has drained, press the Stop / Reset

button (#571.1) on the front touch pad. This will turn

the machine to the OFF mode.

570

L1

571.1

571.2

L2

L3

L4

L5

Remove the gravity feed tube assembly from the mix

tank by pulling straight up and out of the tank.

571.1

Fill the mix tank with luke warm (80-90F) water and

a non-foaming dish washing detergent solution.

Press the Push to Select button on the front touch

pad (#571.2), and carefully select the Beater mode.

Allow the machine to run for 1 – 2 minutes then

push the Stop / Reset button (#571.1) on the touch

pad. Drain all of the water and soap solution from

the machine. Repeat this process until the water

drained is clear. Prior to draining the last time, brush

clean all surfaces of the mix storage tanks with the

cleaning brushes provided with the freezer.

28

Page 29

Drain the remaining water and soap solution from the

freezer.

You are now ready to disassemble and clean your

freezer. Please refer to Part III – Initial Cleaning Procedure of this operation manual for instructions on

how to proceed.

B) Pump Fed Machines

With frozen mix in the cylinder, select the Beater

mode on the front touch pad by pressing the Push to

Select button (#571.2) until pilot light #L4 illuminates.

Allow the machine to operate in the beater mode for 4

to 5 minutes. This will soften the product and allow for

easier product removal.

571.2

Place a pail under the dispensing head, holding it up

against the bottom of the head as high as possible and

slowly pull the dispensing handle. This will allow the

mix to drain from the machine.

!! IMPORTANT !!

You MUST disassemble the machine after

draining and follow the described cleaning and

sanitizing procedures as described in this operation

manual in order to maintain acceptable hygienic

levels in your product.

After the frozen product is removed and liquid mix is

dispensing from the machine, press the Stop / Reset

button (#571.1) on the touch pad. Placing the machine

in the OFF mode, close both of the dispensing handles.

Slowly push in on the pressure relief plungers to

remove any remaining pressure from the cylinders.

29

571.1

Page 30

Remove the feeding elbow assembly from the mix

tank by first sliding the connecting tube away from

the pump cover, Then turn the elbow assembly

slightly and pull the assembly straight up and out of

the mix tank.

Remove the mix pump assembly from the mix tank

by rotating the pump clockwise until the hook stud

disengages from the rear pump hub. After

disengaging the hook stud, pull the pump assembly

straight forward and out of the mix storage tank.

Please ensure that the mix pump drive shaft and

seal must also be removed at this time.

Press the Push to Select button on the front touch pad

(#571.2), and carefully select the Beater mode. Allow

the machine to run for 1 – 2 minutes then push the Stop /

Reset button (#571.1) on the touch pad. Drain all of the

water and soap solution from the machine. Repeat this

process until the water drained is clear.

571.2

L2

L3

Prior to draining the last time, brush clean all surfaces of

the mix storage tank with the cleaning brushes provided

with the freezer.

After removing the parts from the mix storage tank,

fill the mix tank with luke warm (80-90F) water and

a non-foaming dish washing detergent solution.

Drain the remaining water and soap solution from the

freezer.

30

Page 31

You are now ready to disassemble and clean your

freezer. Please refer to Part III – Initial Cleaning Procedure of this operation manual for instructions on

how to proceed.

!! IMPORTANT !!

You MUST disassemble the machine after

draining and follow the described cleaning and

sanitizing procedures as described in this operation

manual in order to maintain acceptable hygienic

levels in your product.

Part IX – Technical Information

A) Refrigeration:

Compressor – Hermetic / Low Temperature

Suction Pressure (Cylinder) – 18-21 psig.

(Mix Tank) – 20-25psig.

Discharge Pressures – 250 to 260psig.

Refrigerant Type – R-404A ONLY

Cooling Type – Air or Water

Cylinder valve type – TXV w/equalizer

Mix tank valve type – AXV

Refrigerant Charge- See Machine Data Plate

D) Proximity Switch

The sensitivity of this switch can be adjusted

with a small screwdriver. The trimmer location

is on the switch body nearest the front panel. To

adjust, the adjustment screw should be turned

very carefully either in a clockwise

direction to increase the range or counter

clockwise to decrease the range of

operation.

B) Beater / Auger Drive Motors

Motor Type – Leeson - ODP with C flange

Beater Rotation-(facing front of freezer)-CCW

H.O.T Amps – 7.0 single phase

Minimum Operating Voltage – 110vac.

Maximum Operating Voltage – 130vac.

C) Thermal Overload

Overload Setting – 8.0 single phase

Overload Ranges – 7.5-11 amps – single phase

Thermal Overload – Calibrations and Settings

(Top View)

AMP.

CALIBRATION

MAN AUT

ALWAYS IN

R POSITION

31

Page 32

Part X – Maintenance

Your Carpigiani freezer has been designed,

engineered, and manufactured to achieve high performance and long durability. The life expectancy of

any machine depends not only on the quality of

engineering, and components used, but also on the

basic maintenance procedures.

It is important for you to become familiar with a few

of the basic operating procedures.

OFF mode and disconnect power to the freezer.

If your machine is Water Cooled, it is important that it is

not stored at a temperature below 32 degrees F. Before

storing at a temperature below 32 degrees you must

remove all liquids from the freezer and winterize the

water condenser coil. This should be performed by an

authorized service technician to avoid damage to the

freezer.

• Only remove orings with the oring extractor

provided in the machine spare parts kit.

• Clean and sanitize the freezer in accordance with

the instructions in this operation manual.

• Lubricate all orings and seals as instructed.

• The wearing or the improper cleaning of the

beater shaft seals will result in product leakage

into the rear of the machine. Check the side drip

chutes frequently and replace seals when

necessary.

• Replace any oring that is leaking or damaged.

• When all of the spare parts supplied in the spare

parts kit are used, re-order immediately. Do not

wait until the part is urgently needed or causes

the machine to be inoperative without it.

• NEVER use the Automatic or Stand-By mode

in

the cleaning, sanitizing or initial filling of the

freezer. This can damage the freezer and its

components.

• During the washing, cleaning and sanitizing

procedures, operate the machine in the

BEATER

mode as little as possible. This will minimize

component wear on the freezer.

• When removing and installing the freezer parts,

handle these with care. DO NOT drop or bang

together as this will damage the parts and affect

the freezers performance.

• NEVER use HOT WATER when washing,

cleaning, or sanitizing your freezer or its parts.

ALWAYS use luke warm water (80-90F).

The following is a recommended wearable parts

replacement schedule. This is for normal operation of the

freezer and will vary based on the volume and type of

product served as well as operational and cleaning

procedures.

Replacement Schedule

Orings and Seals – Every 6 months or as needed

Beater Scraper Blades - Every 6 months or as needed

Beater End Pusher – Every year or as needed

(Maximum

of 3 Seasons of Operation)

Drive Belts – Every 2 years or as needed

Pump Gears – Every 3 years or as needed

Pump Drive Bearings – As needed

Plastic Parts - As need when leaking, scratched, or

broken

Rebuild Mix Pumps – Every 5 years or as needed

Check Gearbox Grease Levels – Annually

Electrical Components – When malfunctioning.

!! IMPORTANT !!

Prior to opening any of the machines outer panels,

place both sides in the STOP / OFF mode and

disconnect the machines power supply. Failure to do

so can result in serious injury and or death.

!! IMPORTANT !!

If your machine is Air Cooled, its efficiency depends

on a clean air cooled condenser. The fins of the

condenser must be straight and cleaned a minimum

of every two or three months. Prior to cleaning the

air condenser, place the machine in the STOP or

32

Page 33

b) H.O.T. control set too low for product b) Set H.O.T. Setting to a higher value

c) Low on refrigerant c) Contact Authorized Service Agent

A) Trouble Shooting Guide – Gravity Fed Freezers

Problem Possible Cause Suggested Solution

1) Product too soft a) Drawing faster than the machine can produce a) Slow down draw rate

b) Gravity feed tube setting too small b) Open the feed tube setting to a larger hole opening

c) Beaters / augers assembled incorrectly c) Disassemble the freezer and reassemble (refer to Part IV)

2) No product dispenses from head a) No mix in mix tank a) Add Mix to mix tanks

b) Gravity feed sleeve open too wide b) Adjust the outer sleeve to a smaller opening

3) Low product overrun a) Defective / leaking oring on feed tube a) Replace all orings on feed tubes

b) Alarm #1 (RTA) on display monitor b) Motor has drawn excessive amps, press Stop/Reset on touch pad.

c) Control pad does not function c) Contact a Carpigiani Authorized Service Technician

d) Alarm #9 (IMS) on display monitor d) Assemble dispensing head on freezer or Contact Service Tech.

e) Power to the freezer but no functions work e) Contact a Carpigiani Authorized Service Technician

4) Machine will not start a) No power to the machine a) Check plug, disconnect, fuses or breaker for the machine

33

b) Low on refrigerant b) Contact a Carpigiani Authorized Service Technician

c) H.O.T. setting too high for product used c) Set the H.O.T. setting to a lower value

d) Scraper blades worn out d) Replace the beater scraper blades with new parts

e) Not enough mix in cylinder to reach H.O.T. e) Open feed tube and allow more mix in the cylinder

5) Machine Runs Continuously a) Restricted air flow (Air Cooled) a) Clean air condenser or contact a Carpigiani Authorized Service

Tech.

b) Low on refrigerant b) Contact a Carpigiani Authorized Service Technician

c) Compressor not functioning c) Contact a Carpigiani Authorized Service Technician

d) Insufficient power supply (low voltage) d) Contact a Carpigiani Authorized Service Technician

e) Insufficient water flow (water cooled) e) Contact a Carpigiani Authorized Service Technician

6) Machine will not Freeze product a) Restricted air flow (Air Cooled) a) Clean air condenser or contact a Carpigiani Authorized Service

Tech.

Page 34

b) Suction tube setting too large for draw rate b) Reset the suction tube to a smaller orifice setting (rotate CCW)

c) H.O.T. control set too low for product c) Set H.O.T. Setting to a higher value

d) Low on refrigerant d) Contact Authorized Service Agent

A.1) Trouble Shooting Guide – Pump Fed Freezers

Problem Possible Cause Suggested Solution

1) Product too soft a) Drawing faster than the machine can produce a) Slow down draw rate

b) Mix Pump assembled incorrectly b) Disassemble and reassemble pump accordingly (refer to Part IV)

c) Mix Pumps loosing prime c) Change pump gears or Contact Authorized Service Agent

d) Beaters / augers assembled incorrectly d) Disassemble the freezer and reassemble (refer to Part IV)

e) Pressure loss in mix feed system e) Change all machine orings and seals

2) No product dispenses from head a) No mix in mix tank a) Add Mix to mix tanks

b) Mix Pump suction tube setting too large b) Adjust the suction tube (rotate tube lever ccw)

3) Low product overrun a) Defective / leaking orings on mix feed system a) Replace all orings on freezer

b) Alarm #1 (RTA) on display monitor b) Motor has drawn excessive amps, press Stop/Reset on touch pad.

4) Machine will not start a) No power to the machine a) Check plug, disconnect, fuses or breaker for the machine

34

c) Control pad does not function c) Contact a Carpigiani Authorized Service Technician

d) Alarm #9 (IMS) on display monitor d) Assemble dispensing head on freezer or Contact Service Tech.

e) Power to the freezer but no functions work e) Contact a Carpigiani Authorized Service Technician

b) Low on refrigerant b) Contact a Carpigiani Authorized Service Technician

c) H.O.T. setting too high for product used c) Set the H.O.T. setting to a lower value

d) Scraper blades worn out d) Replace the beater scraper blades with new parts

e) Not enough mix in cylinder to reach H.O.T. e) Open suction tube (rotate cw) to allow more mix in the cylinder

5) Machine Runs Continuously a) Restricted air flow (Air Cooled) a) Clean air condenser or contact a Carpigiani Authorized Service

Tech.

b) Low on refrigerant b) Contact a Carpigiani Authorized Service Technician

c) Compressor not functioning c) Contact a Carpigiani Authorized Service Technician

d) Insufficient power supply (low voltage) d) Contact a Carpigiani Authorized Service Technician

e) Insufficient water flow (water cooled) e) Contact a Carpigiani Authorized Service Technician

6) Machine will not Freeze product a) Restricted air flow (Air Cooled) a) Clean air condenser or contact a Carpigiani Authorized Service

Tech.

Page 35

Figure 12

Yes if not resetting in 10 minutes

B) Machine Safety Alarms

This freezer is equipped with built in, self monitoring (Safety) devices, which will interrupt operation of the freezer if activated. When activated, the little red LED light

at the bottom right corner of the display monitor will illuminate and flash. (refer to Figure 12)

This LED will flash when the alarm has been activated. It will stop flashing, but remain lit when the machine has reset and resumed operation. To deactivate the

LED, press the Stop / Reset button on the touch pad. An alarm code will display (AL1 through AL9), press the Stop / Reset button again and the LED light should go

out.

Alarm Codes

Alarm # Description Call Technician

AL1 (rta) Motor overload tripped No- Press Stop / Reset

AL2 (te2) Secondary cylinder probe Yes if not resetting

AL3 (te1) TE1 Probe out of order Yes if not resetting

AL5 (tev) Mix tank probe out Yes if not resetting

35

AL6 (tec) Cylinder probe out Yes if not resetting

AL7 (tgv) Tank display probe out Yes if not resetting

the cylinders

AL8 (Ice) Cylinder too cold No- Allow more mix to enter

Yes if not resetting

AL9 (Ims) Dispensing head switch No- Install dispensing head or

Loading...

Loading...