Page 1

INSTRUCTION MANUAL

EVD 3

APPLICARE

TARGA

CARATTERISTICHE

2012/07

Edition 04

Page 2

Via Emilia, 45

40011 Anzola dell’Emilia (BO)

ITALY

+ 39 051 6505111

+ 39 051 732178

Þcarpigiani.com

We wish to thank you for purchasing one of Carpigiani’s machines.

Since 1993, Carpigiani manufactures utilising the Quality Control Management System that is today certified according to UNI-EN-ISO 9001-2008.

Carpigiani’s machines conform to the requirements of the following European Directives:

t “Machinery” Directive 2006/42/EC;

t “Low Voltage” Directive 2006/95/EC;

t “EMC” Directive 2004/108/EC;

t “PED” Directive 97/23/EC;

t Regulation 2004/1935/EC relating to “Materials and articles in contact with foodstuffs”.

This manual contains the ORIGINAL INSTRUCTIONS and can be reproduced, transmitted, copied and filed in a

retrieval system or translated in other languages ONLY by prior written agreement with Carpigiani.

The purchaser has the right to reproduce copies only for his/her own use.

Carpigiani’s policy pursues constant research and development and therefore it reserves the right to make changes

and revisions whenever deemed necessary and without being bound to the purchaser for any previous statements.

EDITION DATE MODIFICATIONS

04 2012/07 -

EDITOR VERIFIED APPROVED

AM LP/SB/RF RV

Page 3

EVD 3

GENERAL INDEX

FOREWORD .......................................................................................... 6

Instruction manual .................................................................................................... 6

Purpose ...................................................................................................................... 6

Manual structure ....................................................................................................... 6

Additional documentation ........................................................................................ 6

Standard symbols ...................................................................................................... 7

Qualification of the personnel .................................................................................. 7

Safety .......................................................................................................................... 8

Warning ...................................................................................................................... 8

1. GENERAL INFORMATION .............................................................9

1.1 General information ...............................................................................9

1.1.1 Manufacturer’s identification data ............................................................... 9

1.1.2 Information about maintenance ................................................................... 9

1.1.3 Information for the user .............................................................................. 10

1.2 Information about the machine .......................................................... 10

1.2.1 General data ................................................................................................. 10

1.2.2 Technical features ....................................................................................... 10

1.2.3 Location of machine groups ....................................................................... 11

1.3 Intended use ......................................................................................... 11

1.4 Noise ..................................................................................................... 11

1.5 Storing a machine ................................................................................ 12

1.6 Disposal of packing materials ............................................................12

1.7 WEEE (Waste Electrical and Electronic Equipment) ......................... 12

1.8 Bacterial contamination detection ..................................................... 12

2. INSTALLATION.............................................................................. 14

2.1 Space necessary to use the machine ................................................ 14

2.2 Water supply connection .................................................................... 14

2.3 Machine with air-cooled condenser ...................................................14

2.4 Machines with water-cooled condenser ........................................... 14

2.4.1 Water valve adjustment ..............................................................................14

2.5 Electrical connection ........................................................................... 15

2.5.1 Replacing the power cable ......................................................................... 15

2.6 Location ................................................................................................ 15

2012/07 - Ed. 04 - EN

3

Page 4

EVD 3

2.7 Refilling ................................................................................................. 15

2.8 Machine testing.................................................................................... 15

3. INSTRUCTIONS FOR USE ........................................................... 16

3.1 Machine safety warnings .................................................................... 16

3.2 Machine configuration ........................................................................ 16

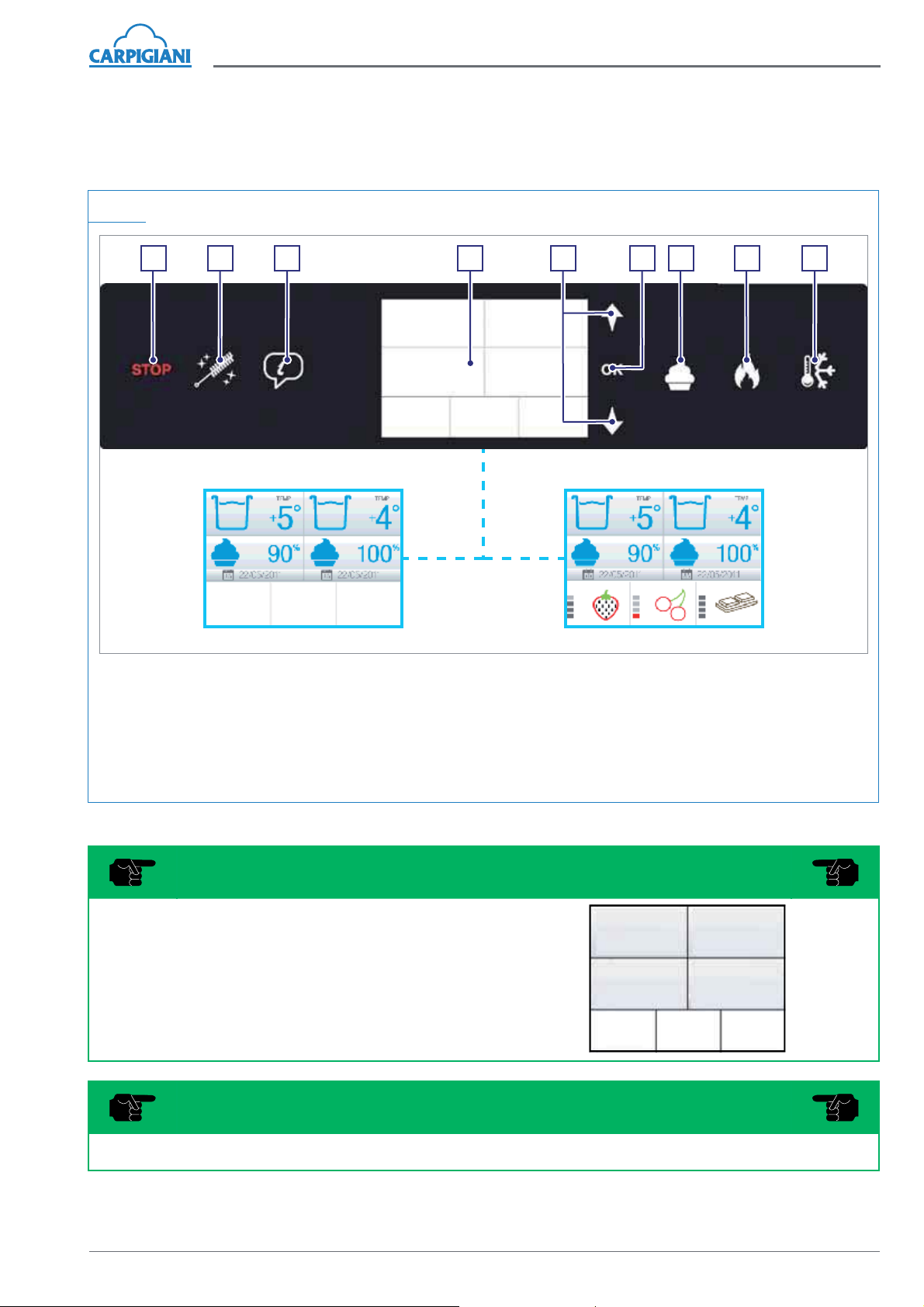

3.3 Controls ................................................................................................ 17

3.3.1 Push-button panel ....................................................................................... 17

3.4 Dispensing handles ............................................................................. 34

3.4.1 Modify the quantity of product dispensed ................................................ 34

3.4.2 Self closing ................................................................................................... 34

3.5 Machines fed by pump and semi-submersible pump ...................... 34

3.6 Gravity-fed machines – feed needle ................................................... 35

3.8 Preliminary operations, washing and sanitising ............................... 36

3.9 Commissioning the machine ..............................................................36

3.9.1 Starting the machine that has a pump ...................................................... 36

3.9.2 Starting a gravity-fed machine ................................................................... 37

3.9.3 Loading the syrup circuits (Variegated version only) ............................... 37

3.9.4 Syrup adjustment (Variegated version only) ............................................. 37

3.9.5 Dry filling (if present) ................................................................................... 38

3.10 Production ............................................................................................ 39

3.11 Pasteurisation (for the “SP” machines) ............................................. 40

3.12 Daily cleaning – Opening and closing procedures ........................... 40

3.12.1 Daily closing procedures ........................................................................... 40

3.12.2 Daily opening procedure ............................................................................. 43

4. SAFETY DEVICES ......................................................................... 46

4.1 Alarms ................................................................................................... 46

4.1.1 Blackout ....................................................................................................... 48

5. DISASSEMBLY, CLEANING AND REASSEMBLY

OF THE PARTS IN CONTACT WITH THE PRODUCT ................49

5.1 General description ............................................................................. 49

5.2 Washing conditions ............................................................................. 49

5.3 Suggestions .......................................................................................... 49

5.4 How to use cleaning/sanitising solution ........................................... 49

4

2012/07 - Ed. 04 - EN

Page 5

EVD 3

5.5 Daily cleaning ....................................................................................... 50

5.6 Scheduled cleaning ............................................................................. 50

5.7 Tank emptying ...................................................................................... 50

5.7.1 Machines that have a pump .......................................................................51

5.8 Washing and sanitisation of the syrup lines

(only for the Variegated version) ......................................................... 52

5.9 Machines with pumps – pump removal ............................................. 54

5.11 Disassembly of the door ..................................................................... 57

5.12 Disassembly of beaters ...................................................................... 59

5.13 Disassembly and cleaning of the drip drawer,

the pump drip tubes, the drip tray and the tank lid .......................... 60

5.14 Cleaning and sanitising of the components ...................................... 61

5.15 Reassembly of the tank beater .......................................................... 61

5.16 Reassembly of the beater ................................................................. 61

5.17 Reassembly of the dispensing door ................................................... 62

5.18 Machines with pumps – reassembling the pump .............................63

5.19 Gravity-fed machines – reassembly of the feed needle ................... 66

5.20 Complete sanitisation of the machine ............................................... 66

5.20.1 Sanitising the hopper .................................................................................. 66

5.20.2 Draining the cleaning/sanitising solution ................................................. 66

6. MAINTENANCE ............................................................................ 68

6.1 Maintenance ......................................................................................... 68

6.2 Instructions for replacement of the peristaltic pump tube

(Variegated version) ............................................................................. 69

6.2.1 Removal of the pump tube .........................................................................69

6.2.2 Installing of the pump tube ......................................................................... 69

6.3 Water-cooling ....................................................................................... 69

6.4 Ordering spare parts ........................................................................... 69

6.5 Supplied accessories .......................................................................... 70

7. TROUBLESHOOTING GUIDE ...................................................... 71

2012/07 - Ed. 04 - EN

5

Page 6

EVD 3

FOREWORD

Instruction manual

In writing this manual, the European Community directions on safety standards as well as on free circulation

of industrial products within the E.C. were taken into

due account.

Purpose

This manual was conceived taking machine users’

needs into due account.

Issues regarding the correct use of the machine have

been analysed in order to keep the longstanding quality

features characterising CARPIGIANI’s machines all over

the world unchanged.

A significant part of this manual refers to the conditions

required for using machine and, above all, to the necessary procedures to follow while cleaning and during

routine and special maintenance.

Nevertheless, this manual cannot meet all demands in

details. In case of doubts or missing information, please

apply to:

Manual structure

This manual is divided in sections, chapters and

subchapters in order to be consulted more easily.

Section

A section is the part of the manual identifying a specific

topic related to a machine part.

Chapter

A chapter is that part of a section describing an assembly or concept relevant to a machine part.

Subchapter

It is that part of a chapter detailing the specific component of a machine part.

Any person employed to use the machine must have

first read and fully understood the parts of the manual that refer to his/her competence and in particular:

t the Operator must have read the chapters regarding

starting the machine, the functioning of the machine

units and the prescribed safety precautions;

t a skilled technician involved in the installation, main-

tenance, repair, etc., of the machine must read all

parts of this manual.

Via Emilia, 45

40011 Anzola dell’Emilia (BO)

ITALY

+ 39 051 6505111

+ 39 051 732178

Þ carpigiani.com

Additional documentation

Along with an instruction manual, each machine is

also supplied with additional documentation:

t Spare parts list: a list of spare parts provided with

the machine for its maintenance.

t Wiring diagram: a diagram of wiring connections

placed in the machine.

WARNING

Before using the machine read the instruction

manual carefully.

Pay attention to the safety instructions.

6

2012/07 - Ed. 04 - EN

Page 7

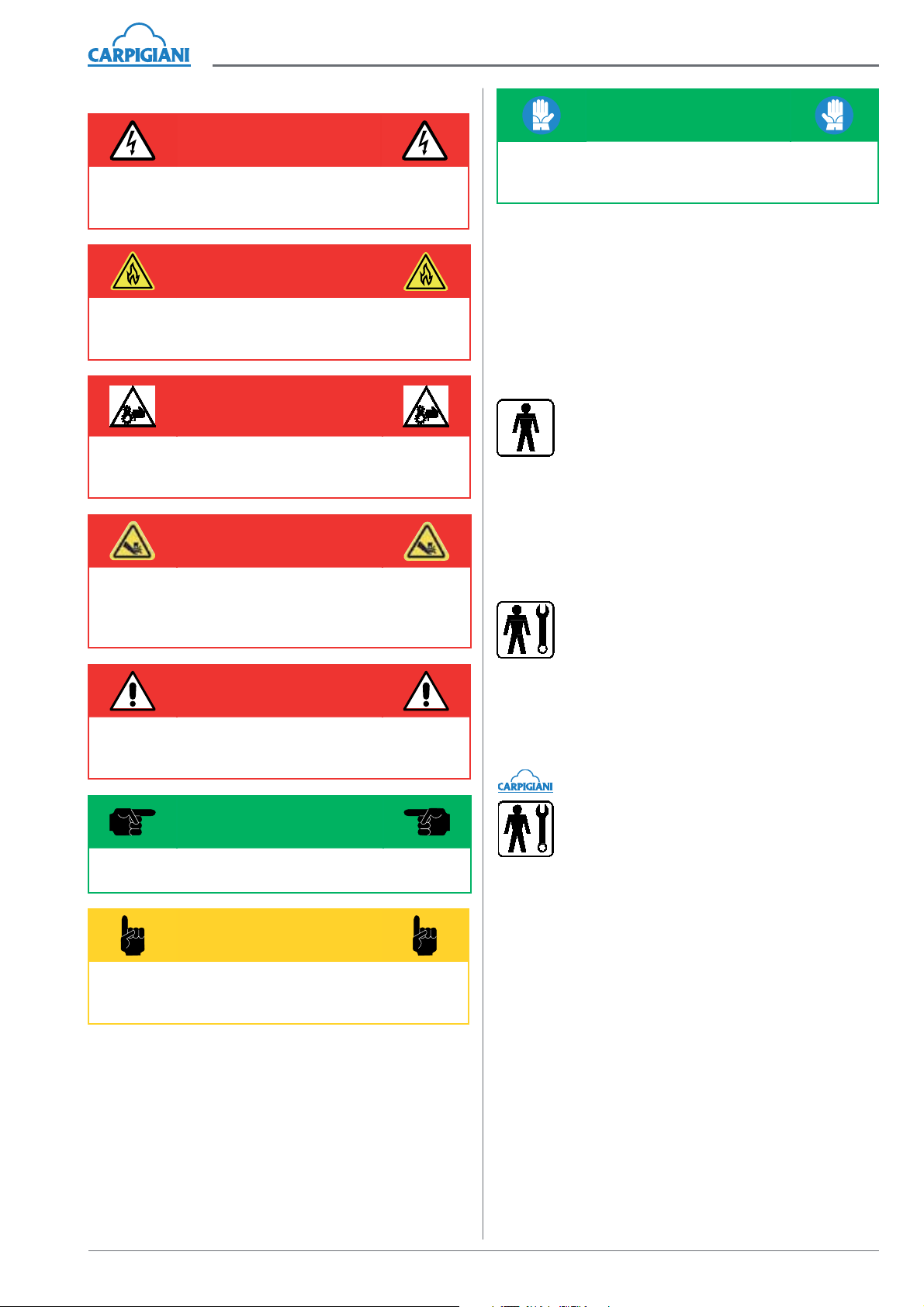

Standard symbols

ELECTRIC SHOCK

DANGER

This warns personnel concerned that the operation described could cause electric shock if not

carried out while respecting safety norms.

EVD 3

PROTECTION

This symbol located next to description means

that the operator must use personal protection

against an implicit risk of accident.

DANGER FROM HIGH

TEMPERATURES

This warns personnel concerned that the operation described could cause burns and scalds if not

carried out while respecting safety norms.

DANGER

MOVING PARTS

This warns personnel concerned about the presence of moving organs and the risk of physical injury if safety norms are not respected.

CRUSHING

HAZARD

This warns personnel concerned about the risk of

having a finger, hand or other body part crushed

if the described operation is not carried out while

respecting safety norms.

GENERAL

HAZARD

This warns personnel concerned that the operation described may cause injury if not carried out

respecting safety norms.

NOTE

This points out significant information for the personnel concerned.

Qualification of the personnel

Personnel using/working on the machine can be differentiated according to training and responsibility as

follows:

OPERATOR

This term identifies unqualified personnel who

have no specific technical qualifications and

who can carry out only simple tasks such as

operating the machine using the controls on

the keyboard, loading and unloading product utilised

during production, loading of any consumable materials, basic maintenance operations (cleaning, removing

simple obstruction, controlling instrumentation, etc.).

MAINTENANCE ENGINEER

He/she is a skilled engineer for the operation

of the machine under normal conditions; he/

she is able to carry out interventions on me-

chanical parts and all adjustments, as well as

maintenance and repairs. He/she is qualified for interventions on electrical and refrigeration components.

CARPIGIANI ENGINEER

He/she is a skilled engineer that the manufac-

turer has assigned to field interventions for

complex jobs under particular conditions or in

accordance with agreements made with the

machine’s owner.

WARNING

The personnel involved is warned that the non-observance of warning may cause loss of data and

damage to the machine.

2012/07 - Ed. 04 - EN

7

Page 8

EVD 3

Safety

When using the machine be aware that drive mechanisms (rotary motion), high voltage components and

parts subject to high temperatures may cause serious

injury/damage to persons and things.

The person in charge of plant safety must check

that:

t any incorrect use or handling is avoided;

t safety devices are not removed or tampered with;

t the machine is regularly maintenanced;

t only original spare parts are used especially with

regards to those components with safety functions

(e.g., protection microswitches, thermostats, etc.);

t suitable personal protective equipment is worn;

t great care is taken during hot product cycles;

t particular attention is paid to organs in movement.

To achieve the above, the following is necessary:

t at the work station an instruction manual relevant to

the machine must be available;

t the documentation must be carefully read and re-

quirements must consequently be met;

t only adequately skilled personnel should be as-

signed to electrical equipment.

Warning

When installing the machine, insert a differential thermomagnetic protection switch on all poles of the line,

adequately sized to the absorption power shown on

machine data plate and with contact opening of 3 mm

at leas.

t Never put your hand into the machine during pro-

duction and cleaning operations. Before carrying out

any maintenance operation, make sure that the machine is in the Stop position and the main switch has

been switched OFF.

t Using a jet of pressurized water to wash the machine

is forbidden.

t Removing panels in order to reach the machine in-

side before the machine has been disconnected is

forbidden.

t Carpigiani will not respond to accidents that might

happen during the use, cleaning and/or maintenance

of its machines if the specified safety norms have not

been complied with.

IMPORTANT

Ensure that technical personnel do not carry out operations that are not within their capabilities, knowledge

and responsibility.

NOTE

According to the norms in force, a SKILLED ENGINEER is a person who, thanks to his/her:

t training, experience and education;

t knowledge of rules, prescriptions and interven-

tions on accident prevention;

t knowledge of machine operating conditions.

Is able to recognize and avoid any danger and has

also been authorised by the person in charge of

plant safety to carry out all types of interventions.

8

2012/07 - Ed. 04 - EN

Page 9

EVD 3

1. GENERAL INFORMATION

1.1 General information

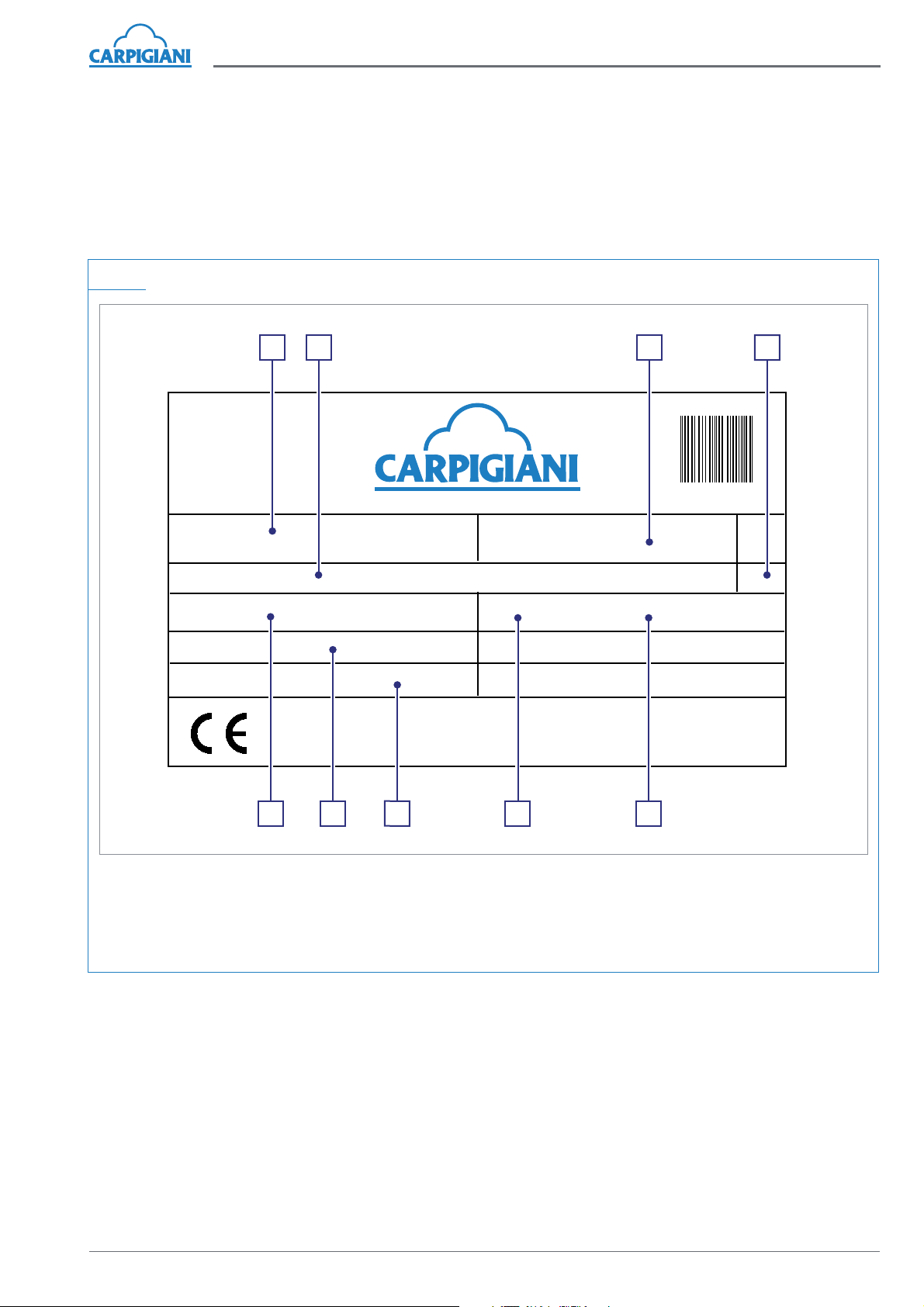

1.1.1 Manufacturer’s identification data

The machine has a data plate that was assigned to the machine when it was manufactured, showing the manufacturer’s data, machine type and serial number.

A copy of the machine data plate can be found on the first page of this manual.

Fig. 01

A B F

100089654588-4

ANZOLA EMILIA - BOLOGNA - ITALY

Matr.

Cod.

V Hz kW

A

Gas kg

G

DC

A Serial number

B Machine type

C Voltage

D Main-switch amperometric value

E Gas type and weight

E

F Machine code

G Condensation (A= Air - W= Water)

H Frequency

I Power input

IH

1.1.2 Information about maintenance

All operations of routine maintenance are hereby described in the section “Maintenance”. Any additional operation

requiring a technical intervention on the machine must be cleared with the manufacturer who will also examine the

possibility of a factory technician field intervention.

2012/07 - Ed. 04 - EN

9

Page 10

EVD 3

1.1.3 Information for the user

t Carpigiani is at the disposal of the user

for any clarification or necessary/integrative information regarding the functioning of the machine or any improvement modifications to the machine.

t Contact the area distributor in the event of any prob-

lems or the manufacturer if a distributor is not available.

t The customer assistance service is available at any

time to respond to customer requirements regarding

the functioning of the machine, requests for spare

parts or technical assistance that may eventually be

necessary.

1.2 Information about the machine

1.2.1 General data

It is an electronic machine for the production and instant distribution of variegated ice cream that has the

following main characteristics:

Carpigiani recommends using top quality raw materials

always in the production of ice cream and confectionery

products to satisfy the most demanding requirements

of customers. Any cost saving of the mix utilized affects

the quality and much greater losses will occur apart

from the economic losses.

Taking into account everything mentioned above,

the following recommendations should be taken

into account:

t only you produce the mix using top quality natural

products, or receive supplies from serious and trustworthy companies;

t scrupulously follow the mix preparation instructions

that are supplied by the supplier;

t Do not modify suggested recipes without knowing

the characteristics of the ingredients;

t taste the final product and place it on sale only if you

are completely satisfied;

t advise your personnel that the machine must always

be kept clean.

Contact only the Carpigiani Technical Assistance Service for any repairs to the machine.

t refrigerated upper tank;

t electronic control of product consistency via the

“Hard-o-tronic” system;

t automatic pasteurisation system of the product con-

tained in the tank and cylinder during non-production periods (e.g., at night) (only for “SP” machines);

t system for the production of variegated ice cream

(only for “R” machines);

t Dry Filling (only for “DF” machines);

t height adjustment system of the machine’s produc-

tion unit (optional).

1.2.2 Technical features

TANK

75g

MODEL*

CONES

HOUR **

/

CAPACITY

l V Phase Hz kW Kg

FLAVOURS

ELECTRICAL

POWER SUPPLY

***

CONDENSER

***

INSTALLED

POWER

OUTPUT

NET

WEIGHT

EVD 3 670 13 + 13 2+1 400 3 50 Air 5,5 320

* Available in the following models:

EVD 3 SP (with an automatic pasteurising system);

EVD 3 R (with a syrup system for variegating the ice cream);

EVD 3 DF (with a Dry Filling system).

** The hourly production and mix quantity for each ice cream can vary depending on the temperature and type of

mix utilised and on the increase in volume (overrun) required.

*** Also available with a water-cooled condenser and other types of electrical power supply.

Performances refer to room temperature of 25°C at a water temperature of 20°C in the condenser.

10

2012/07 - Ed. 04 - EN

Page 11

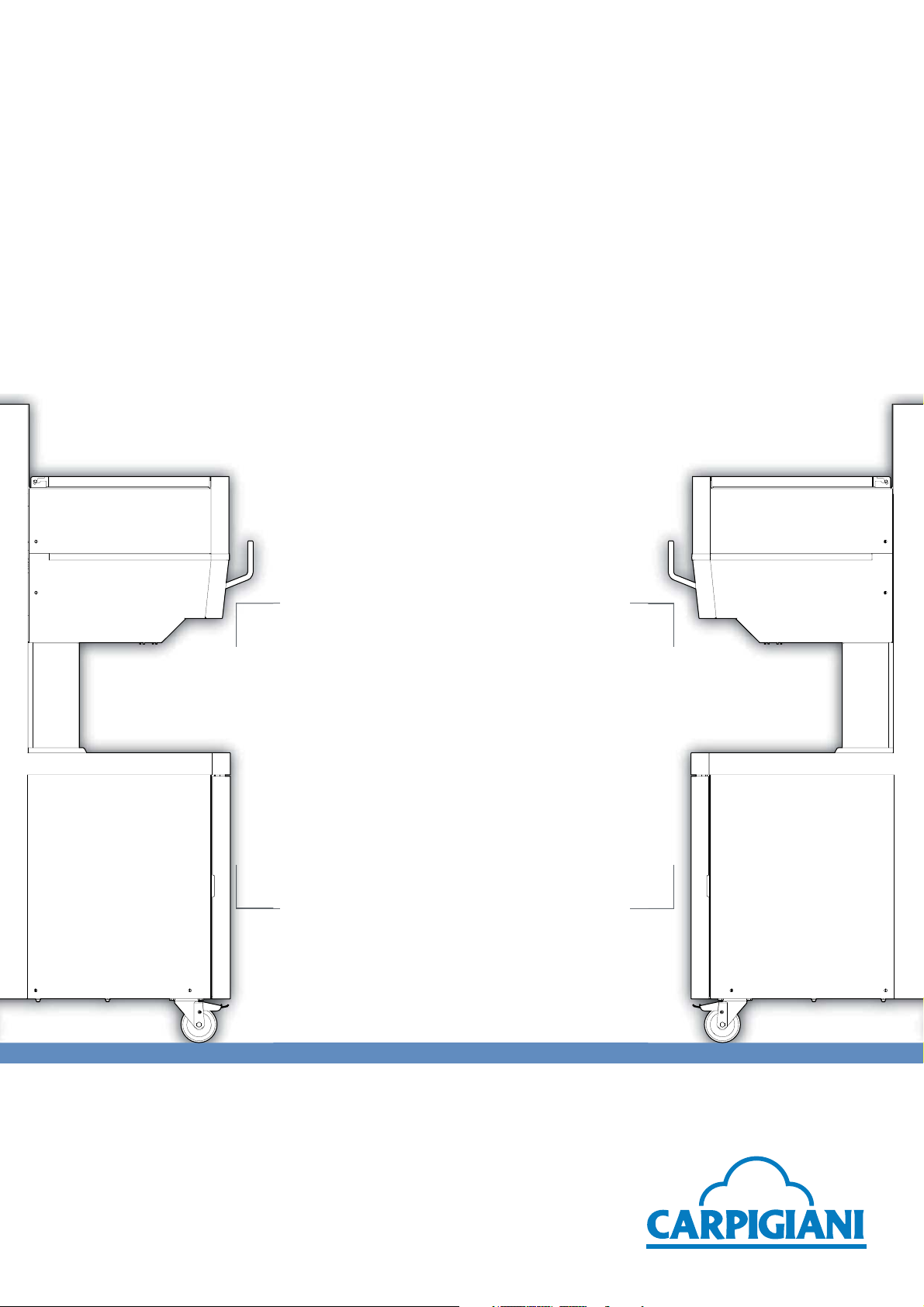

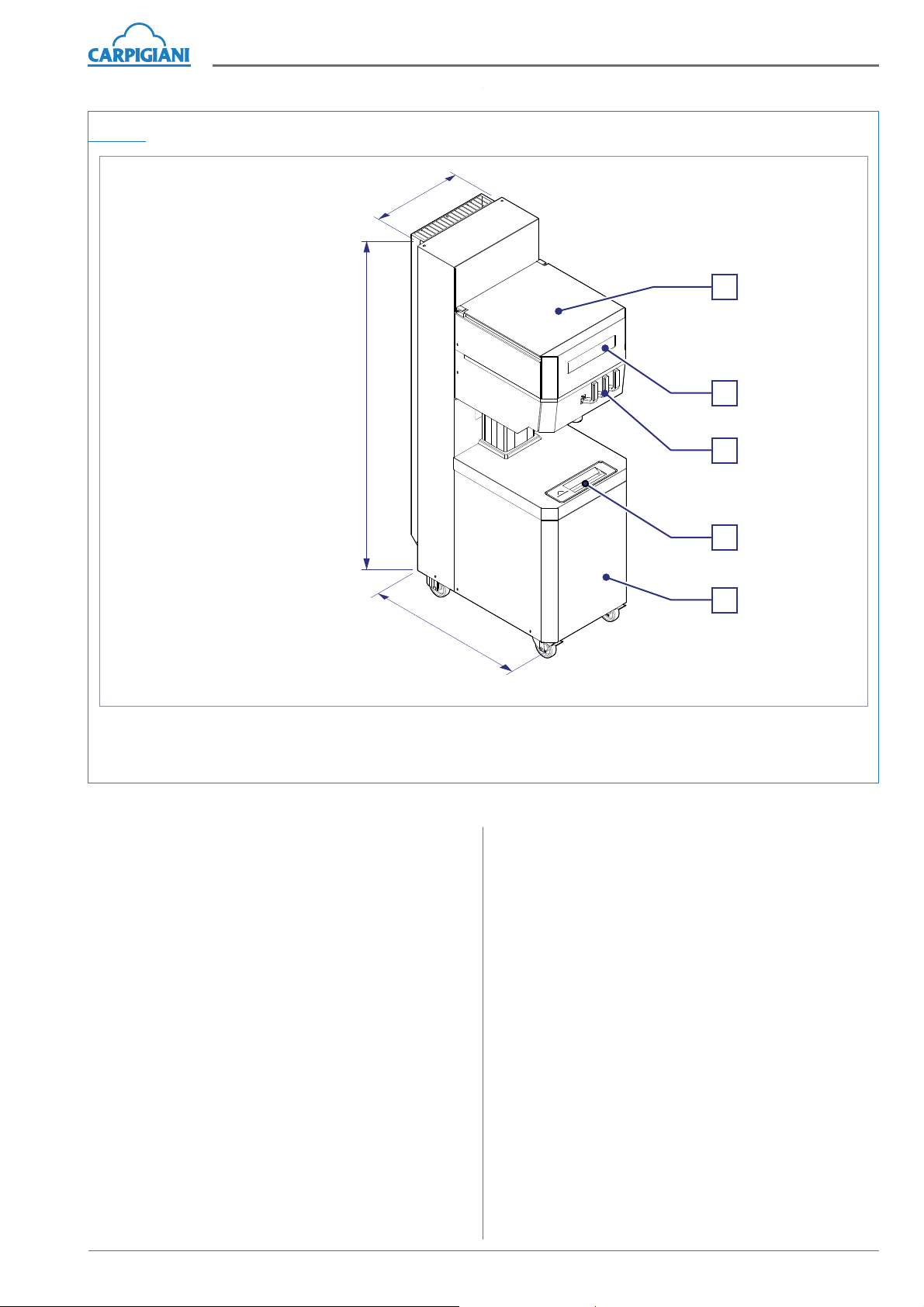

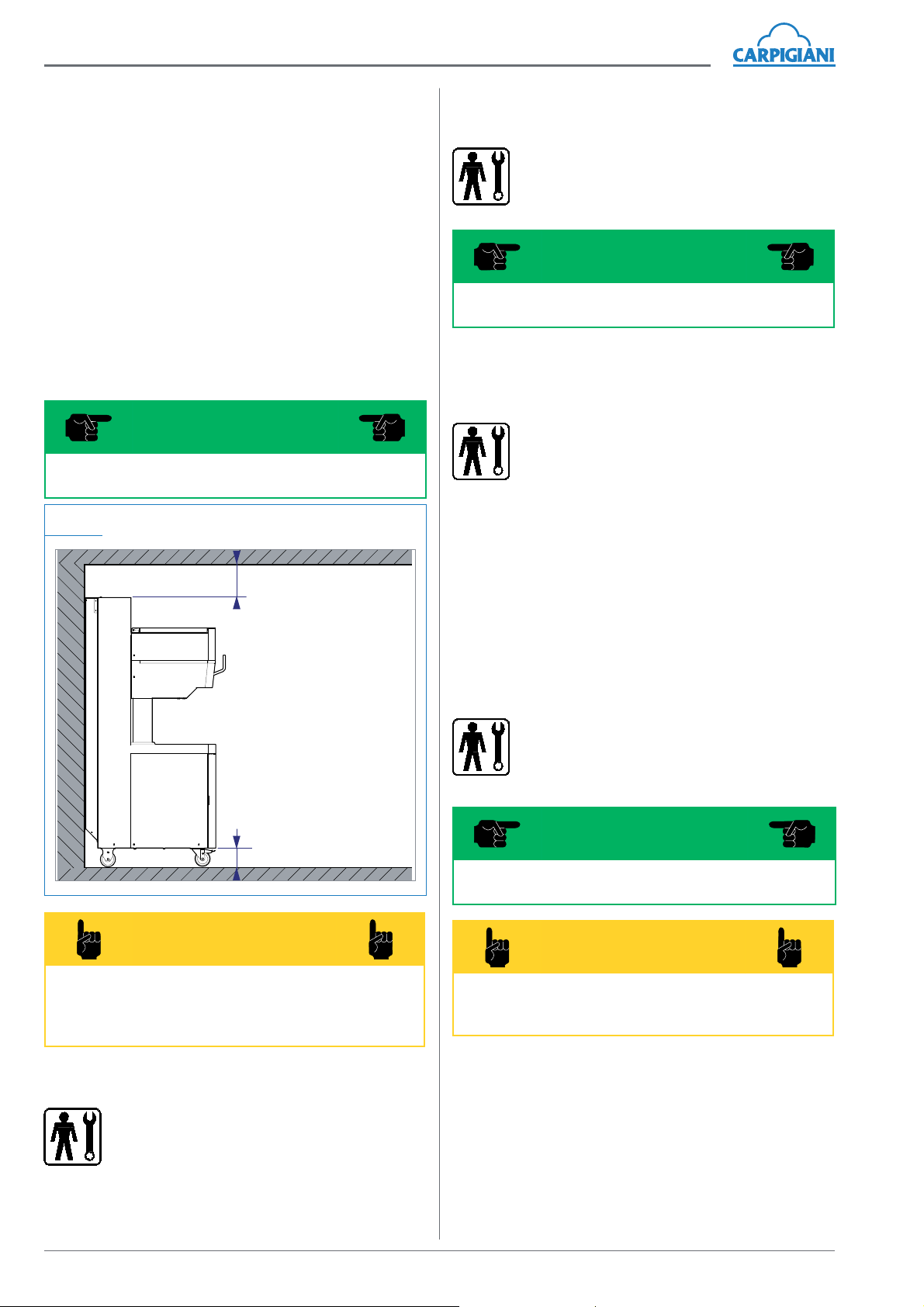

1.2.3 Location of machine groups

Fig. 02

500 mm

1780 mm

EVD 3

1

2

3

800 mm

1 Tank lid

2 Control panel

3 Product dispensing door

1.3 Intended use

The machine must only be used for the production of ice

cream and patisserie products, in compliance with what

has been stated in paragraph 1.2.1 “General information”,

and within the operating limits indicated here below.

t Voltage: ±10%

t Min. air temperature: 10°C

t Max. air temperature: 43°C

t Min. water temperature: 10°C

t Max. water temperature: 30°C

t Min. water pressure: 0,15 MPa (15 bar)

t Max. water pressure: 0,8 MPa (8 bar)

t Max. relative humidity: 85%

4

5

4 Drip tray

5 Cabinet

1.4 Noise

Continuous acoustic pressure level equivalent to

Weighting A in the working place is less than 70 dB(A)

for both water-cooled and by air-cooled machines.

This machine has been designed for use in rooms not

subject to explosion-proof laws and therefore it can

only be utilised in rooms that conform to a normal atmosphere.

2012/07 - Ed. 04 - EN

11

Page 12

EVD 3

1.5 Storing a machine

The machine must be stored in a dry and damp-free

environment.

Before storing the machine, cover it with a sheet to protect it against dust and dirt.

1.6 Disposal of packing materials

When removing the machine from its packaging, subdivide the packing materials into the various types and

dispose of them in accordance with the norms in force

in the destination country.

WARNING

It is forbidden to dispose of packaging materials

in the environment.

1.8 Bacterial contamination

detection

A qualified bacteriologist must periodically analyse

samples of the product to check for the presence of

bacteria. The bacteria count in the samples should be

below the following figures:

Standard Plate Count (SPC) ................................ 50,000

Coliforms .................................................................... 10

If the bacteria count exceeds the above-mentioned figures, there is a source of bacterial contamination. This

source must be immediately identified and eliminated. A

high bacteria count means that the product is not fit for

consumption and a correct cleaning and sanitization of

the machine must be carried out to eliminate the continued bacterial contamination of the product.

GENERAL

HAZARD

Do not leave packaging materials within reach of

children because they could cause suffocation.

1.7 WEEE (Waste Electrical and

Electronic Equipment)

In conformity with the European Directives

2006/66/EC, on batteries and accumulators

and waste batteries and accumulators, and

2002/96/EC, also known as WEEE, the presence of this symbol on the side of the product

or packaging means that the product must not

be disposed of with normal urban waste. Instead, it is

the user’s responsibility to dispose of this product by

returning it to a collection point designated for the recycling/treatment of electrical and electronic equipment

waste.

Differentiated collection of this waste material helps to

optimise the recovery and recycling of any reclaimable

materials and also reduces the impact on human health

and the environment.

For more information concerning the correct disposal of

this product, please contact your local authority or the

retailer where this product was purchased.

NOTE

Soft yogurt normally has a high bacteria count and

therefore it is necessary to highlight the product. In

any case, coliform bacteria contamination IS NOT

ACCEPTABLE in any type of product. The following information will help you to prevent coliform

bacteria contamination problems.

The following list indicates the possible sources of bacterial contamination and the methods to prevent it.

SOURCES OF

CONTAMINATION

Operator contact.

Residues / deposits of

material (milk clots).

HOW TO PREVENT

CONTAMINATION

t Wash hands and forearms

thoroughly.

t Wear rubber gloves if they

are cut or have skin problems.

t Wash hands several times a

day.

t Utilise the appropriate brush-

es.

t To clean thoroughly, scrub

the parts and components

to prevent the formation of

milk clots because milk clots

are fertile material for the

proliferation of bacteria that

could contaminate the fresh

milk.

12

2012/07 - Ed. 04 - EN

Page 13

EVD 3

SOURCES OF

CONTAMINATION

Worn or damaged

parts.

Cleaning and

wrong hygienic

procedures.

HOW TO PREVENT

CONTAMINATION

t Lubricate all rubber parts

that come into contact with

the mix using a food-grade

lubricant.

t Replace damaged O-rings

only with original spare

parts.

t Systematically check the

drip drawers to avoid excessive dripping.

t The container in which the

pieces are washed must be

perfectly clean and contain

enough detergent/sanitising solution to completely

cover even the largest components. Use the brushes to

clean and sanitise the machine regularly.

t Utilise the appropriate

brushes, lubricants and disposable cloths.

t Store and utilize the deter-

gents as per the manufacturer’s instructions.

t Follow expert personnel’s

cleaning habits. Ensure the

personnel can complete

cleaning procedures coherently, correctly and without

interruption.

t Leave the sanitising solution

in the cylinder and tank at

least for the time suggested

by the manufacturer of the

sanitising solution.

t Each time after using, wash

and sanitise the utensils

used for cleaning and the

tube containing the lubricant. Always replace the cap

on the tube.

t The machine components

and the brushes must be left

to dry in the open. Do not

put them back into the machine whilst they are wet or

damp.

t Always carry out the daily

cleaning procedure. Regularly clean the outside of the

machine and the dispenser

with a sanitized cloth.

SOURCES OF

CONTAMINATION

Wrong method of

storing the mix.

HOW TO PREVENT

CONTAMINATION

t Utilise leftovers of mixes

with the oldest date first. Be

careful of the expiry date.

t Put the mix directly in the

fridge. Do not accumulate

mix outside in direct sunlight

before putting it in the fridge.

t In the fridge, leave at least

2-3 cms of space between

the mix and other products

to allow air to circulate.

t The mix must not be left at

ambient temperature for

long periods of time.

t The storage temperature of

the tank must be maintained

at 4.4°C (40°F). Storage

temperatures above 4.4°C

would permit the multiplication of bacteria to dangerous

levels within less than one

hour.

t Once the mix has been

placed inside the tank, place

the lid on the tank to store

the mix at the correct temperature and minimise the

possibility of contamination.

2012/07 - Ed. 04 - EN

13

Page 14

EVD 3

2. INSTALLATION

2.1 Space necessary to use the

machine

The machine must be positioned so that there is enough

space for air to freely circulate from the bottom to the

top of the machine.

Space for access to the machine must be left free in

order to enable the operator to act without constraint

and also to immediately leave working area if necessary.

It is also advisable to have a minimum access operating area for the machine of at least 150 cms, bearing in

mind the space occupied by the opening of the cabinet

door.

NOTE

Insufficient air circulation affects the operation

and the output capacity of the machine.

Fig. 03

2.3 Machine with air-cooled condenser

Machines with an Air-cooled condenser must

be installed leaving a minimum distance (at

least 50 cms) above the chimney for the free

circulation of the condensation air.

NOTE

An insufficient air circulation affects operation and

output capacity of the machine.

2.4 Machines with water-cooled

condenser

A water-cooled machine must be connected

to a mains water supply or to a cooling tower

to operate it.

The water must have a pressure of between 0.15 MPa

and 0.8 MPa (1.5-8 bar) and a flow capacity at least

equal to the estimated hourly consumption.

500 mm

154 mm

WARNING

Machines with an air-cooled condenser must be

installed leaving a minimum distance (at least 50

cms) above the chimney for the free circulation of

the condensate air.

Connect the inlet pipe marked by the “Water Inlet” plate

to the water supply by installing a shut-off valve and

the outlet tube marked by the “Water Outlet” plate to a

drainage pipe by installing a shut-off valve.

2.4.1 Water valve adjustment

IMPORTANT

If the water valve needs be reset, this operation must be carried out only by skilled personnel.

NOTE

Water consumption increases if the temperature of

the inlet water is above 20°C.

WARNING

Do not leave the machine in a room with a temperature below 0°C without first draining the water from the condenser.

2.2 Water supply connection

Connect the machine to a drinking water supply that has a pressure of not more than

0.8 MPa (8 bar).

14

2012/07 - Ed. 04 - EN

Page 15

EVD 3

2.5 Electrical connection

Before connecting the machine to the mains

supply, check that the machine voltage indicated on the data plate corresponds with the

mains supply voltage.

Position a class D section thermomagnetic circuit

breaker switch correctly rated to the absorption power

required and with a contact aperture of at least 3 mm.

The machines are delivered with a 5 wire cable: the blue

wire must be connected to the neutral lead.

IMPORTANT

The yellow/green ground wire must be connected to an

adequate ground plate.

2.5.1 Replacing the power cable

Should the machine’s power cable become

damaged, it must be replaced immediately by

one with similar characteristics.

The replacement must be carried out only by a skilled

technician.

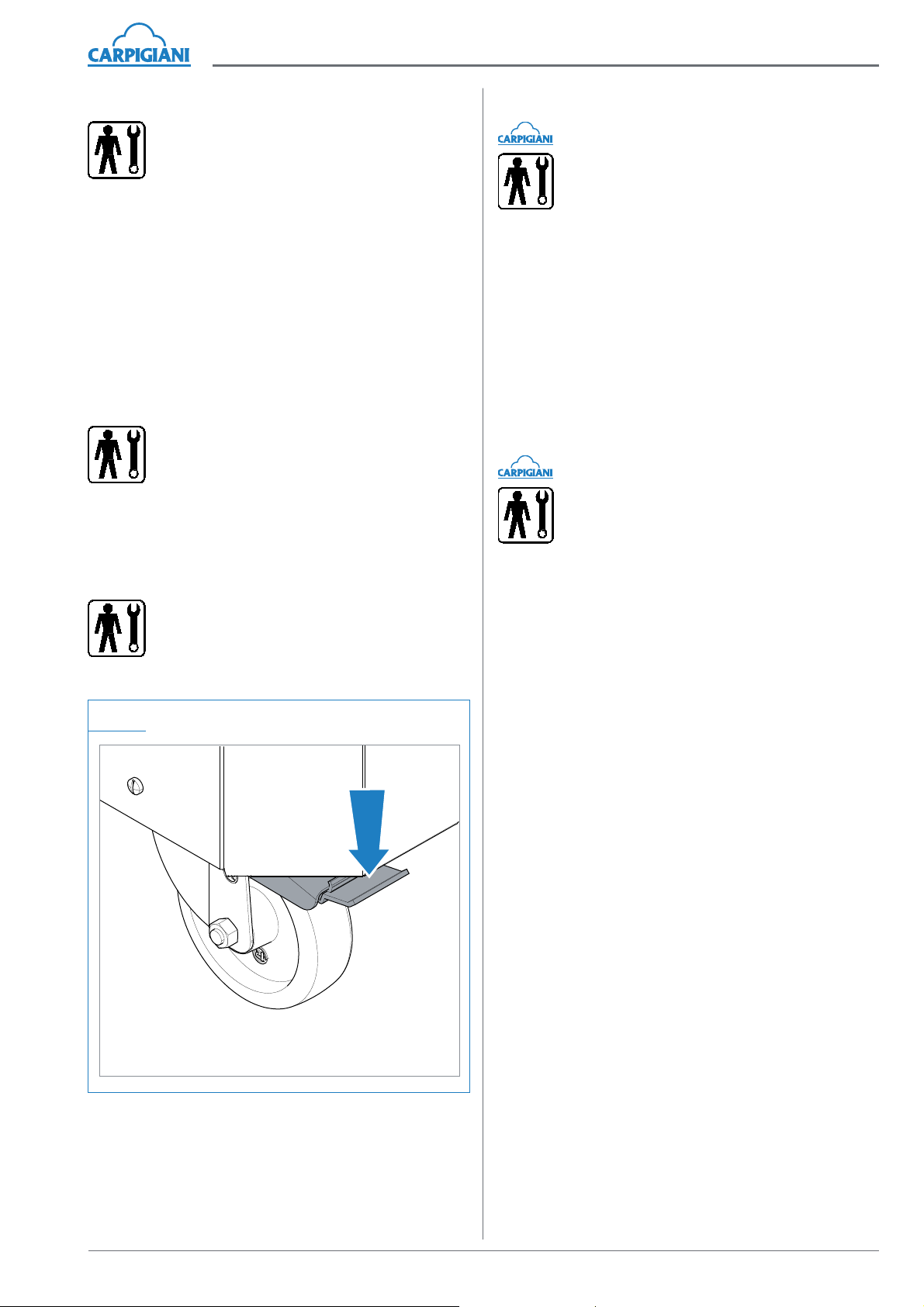

2.6 Location

The machine is equipped with wheels to facilitate its positioning. There are mechanical

blocking devices that once engaged stop the

machine from being moved about and ensure

that it is maintained in a safe position.

2.7 Refilling

The type of motor installed in the machine is a

lubricated-for-life motor. No checking/replacing or topping up is necessary.

The correct quantity of gas for the refrigeration circuit

is put in by Carpigiani when testing the machine. A new

machine does not need any topping up or refilling.

If it becomes necessary to top up or fill the system with

gas, the procedure must be carried out in conditions of

safety and by a qualified technician capable of establishing the cause of the anomaly prior to topping up.

2.8 Machine testing

The machine is tested by Carpigiani at the end

of the assembly procedure. The foreseen operational and production functions are checked.

Machine testing on the end user’s premises

must be carried out by skilled technicians or

by one of Carpigiani’s engineers.

After positioning the machine and making the correct

connections, carry out all operations necessary for functionality check and operational testing of the machine.

Fig. 04

2012/07 - Ed. 04 - EN

15

Page 16

EVD 3

3. INSTRUCTIONS FOR USE

3.1 Machine safety warnings

When using industrial equipment and plant, be aware

that drive mechanisms (rotary motion), high voltage

components, as well as parts subject to high temperatures may cause serious injury/damage to persons and

things.

The person in charge of plant safety must check

that:

t any incorrect use or handling is avoided;

t safety devices are not removed or tampered with;

t the machine is regularly maintenanced;

t only original spare parts are used especially with

regards to those components with safety functions

(e.g., protection microswitches, thermostats, etc.);

t suitable personal protective equipment is worn;

t great care is taken during hot product cycles.

To achieve the above, the following is necessary:

t at the work station an instruction manual relevant to

the machine must be available;

t the documentation must be carefully read and re-

quirements must consequently be met;

t only adequately skilled personnel should be as-

signed to electrical equipment;

t ensure that technical personnel do not carry out op-

erations that are not within their capabilities, knowledge and responsibility.

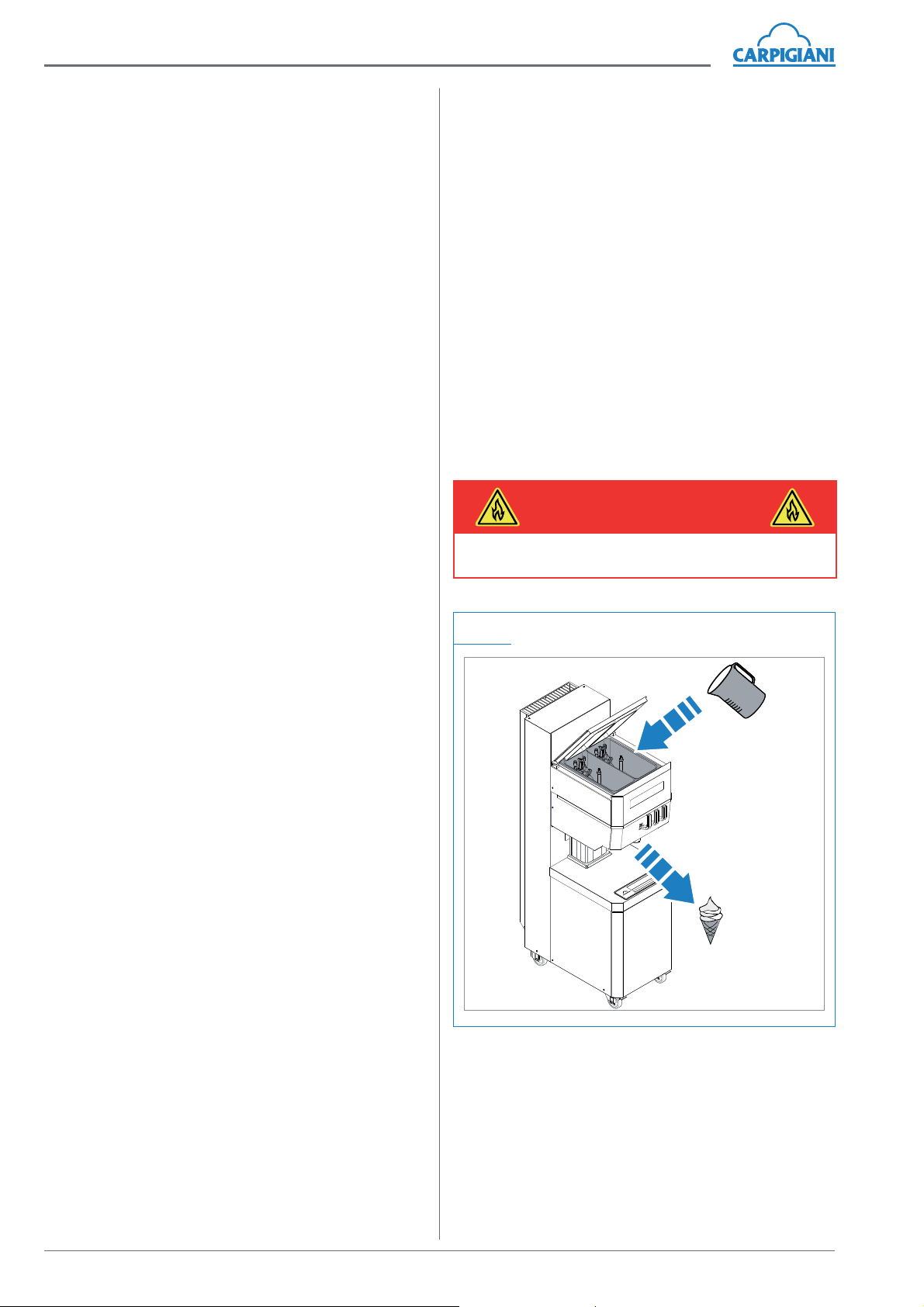

3.2 Machine configuration

The machine is composed of a motor for operating the

beater unit, a cooling system with a water-cooled or aircooled condenser and electronic management of the

main functions.

The preparation of soft ice cream occurs by placing the cold mix (+4°C) inside the tanks and starting an automatic production cycle until the set programmed optimum consistency of the ice cream is

reached.

The mix enters into the whipping cylinders already

mixed with air. The ice cream is produced only at the

moment in which it is served.

By using the ice cream dispensing levers positioned on

the front of the machine, a portion of soft ice cream requested will be dispensed.

Simultaneously, an equal quantity of mix passes from

the upper refrigerated tanks to the whipping cylinder.

DANGER FROM HIGH

TEMPERATURES

Be extremely careful during pasteurisation phase;

contact could cause burns.

Fig. 05

16

2012/07 - Ed. 04 - EN

Page 17

EVD 3

3.3 Controls

3.3.1 Push-button panel

The machine is equipped with a push-button panel fitted on the front panel; each button is marked by an explanatory symbol of the assigned function.

Fig. 06

1 32 4 7 8 965

STANDARD

(Display esemplificativo)

1 Stop the machine from functioning

2 Cleaning

3 Information

4 Touch screen display

5 Production unit movement.

6 Confirm

GELATO VARIEGATO

(Display esemplificativo)

7 Production

8 Pasteurisation

9 Storage/Alarm Reset

NOTE

The display is touch screen with 7 sensitive zones:

The keypad emits an acoustic signal when the key pressed has been accepted.

2012/07 - Ed. 04 - EN

NOTE

17

Page 18

EVD 3

3.3.2 Functions

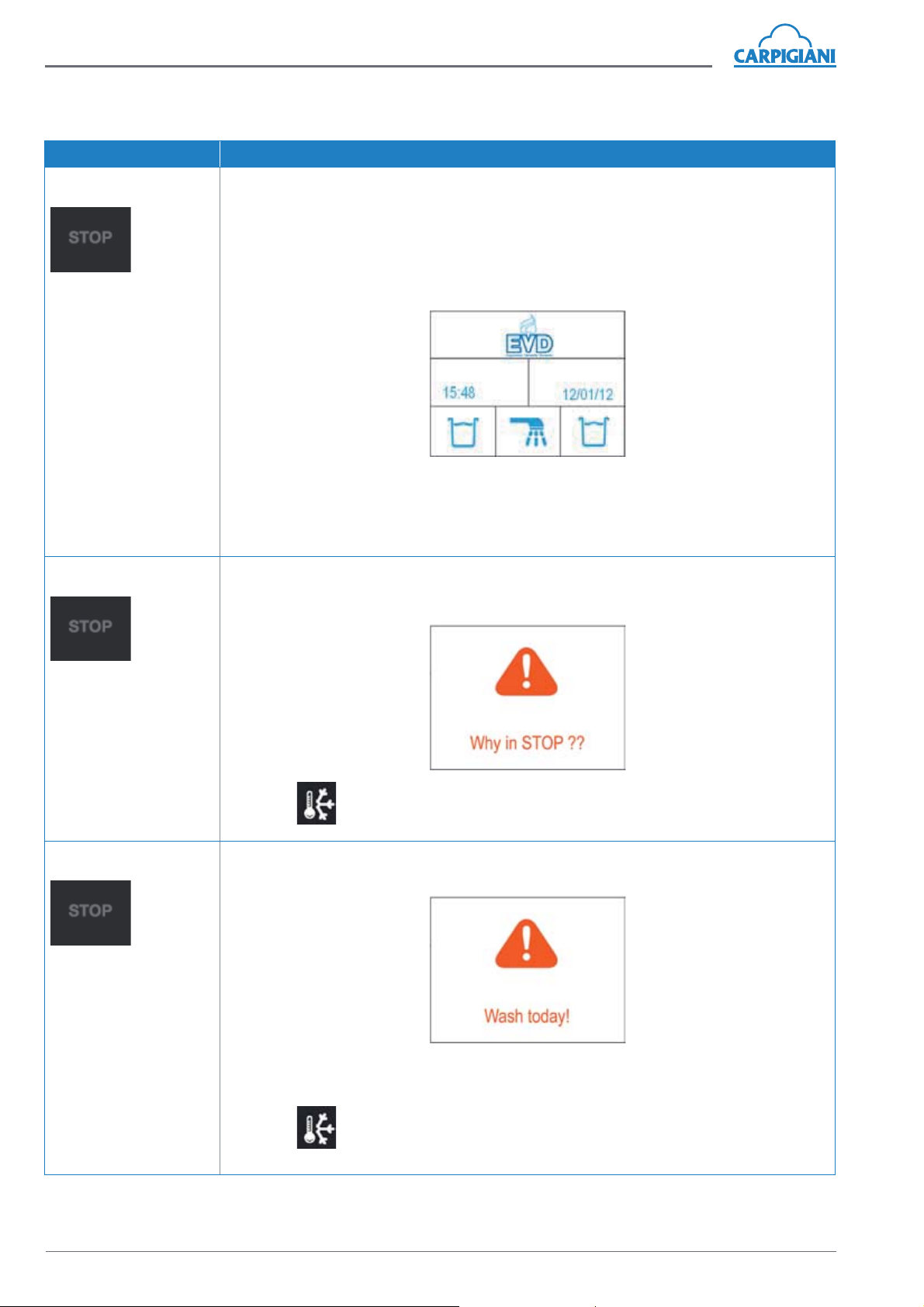

BUTTONS DESCRIPTION OF FUNCTIONS

STOP

In Stop mode, with the Stop key back lit, the machine is at stop.

From the Stop position any machine function can be accessed.

To change function, returning first to Stop IS ALWAYS REQUIRED.

The display indicates the time, date and the indication of the tank and water sprayer

levels (if present).

To place the machine in Stop mode whilst in Production, Pasteurisation or Storage

mode, press the Stop key for approximately 2 seconds. This avoids making wrong selections by lightly brushing the key with the finger.

WHY IN STOP ??

With the machine in

Stop mode for more

than 30 seconds.

WASH TODAY!

With the machine in

Stop mode for more

than 24 hours.

If the machine is left in Stop mode with the level covered, after 30 seconds the message

“Why in STOP ??” is visualised to alert the user to put the machine into Production,

Pasteurisation or Storage mode.

Press the key to cancel the alarm message from the display. Refer to alarms.

From Stop mode, there is a time countdown if the tank level is covered.

If this time exceeds 24 hours, the display visualises the message “Wash today!”.

18

The user must carry out machine washing procedure before restarting Production.

Press the

key to cancel the alarm message from the display. Refer to alarms.

2012/07 - Ed. 04 - EN

Page 19

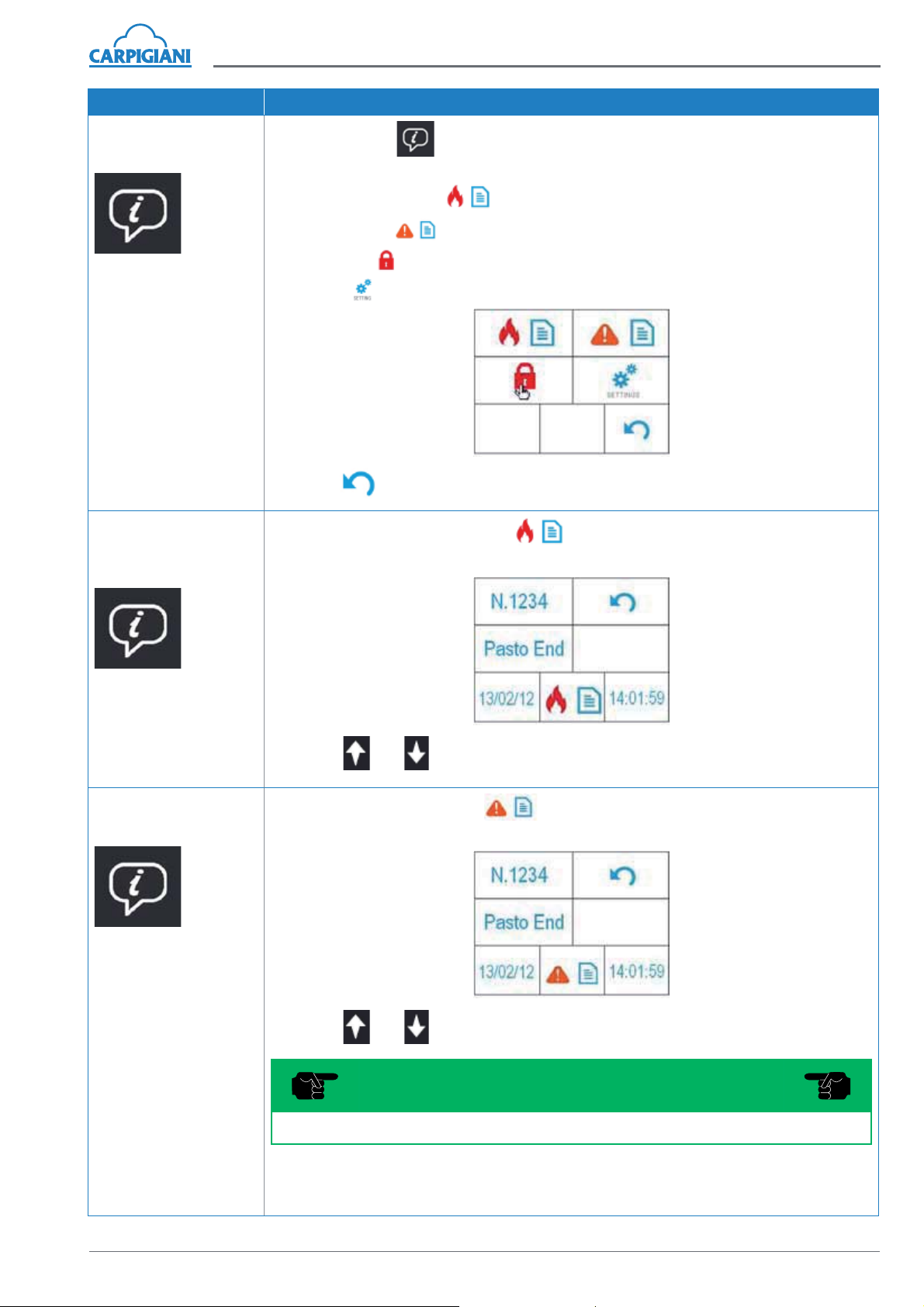

BUTTONS DESCRIPTION OF FUNCTIONS

INFO whilst in Stop

mode

Pressing the Info

key whilst in Stop mode, the display visualises the following

functions that can be selected directly on the touch screen:

t Pasteurisation history

t Events history

t Key locking

EVD 3

Functions that can be

selected from INFO

whilst the machine is in

Stop mode:

t Pasteurisation

history

t Events history

t Key locking

t Settings

INFO –

PASTEURISATION

HISTORY

With the machine in

Stop mode press:

t INFO

t PASTEURISATION

HISTORY

t Settings

.

Press the

Pressing the Pasteurisation History

key to go back to the previous page.

key the display visualises the list of pasteuri-

sations carried out successfully.

Utilise the and arrow keys to scroll the different events.

INFO – EVENTS

HISTORY

With the machine in

Stop mode press:

t INFO

t EVENTS HISTORY

Pressing the Historical Events

key the display visualises the list of events that

include function changes, alarms and pasteurisation steps.

Utilise the and arrow keys to scroll the different events.

NOTE

The maximum number of memorizable events is 1000.

When a successive event occurs the last event is removed.

2012/07 - Ed. 04 - EN

19

Page 20

EVD 3

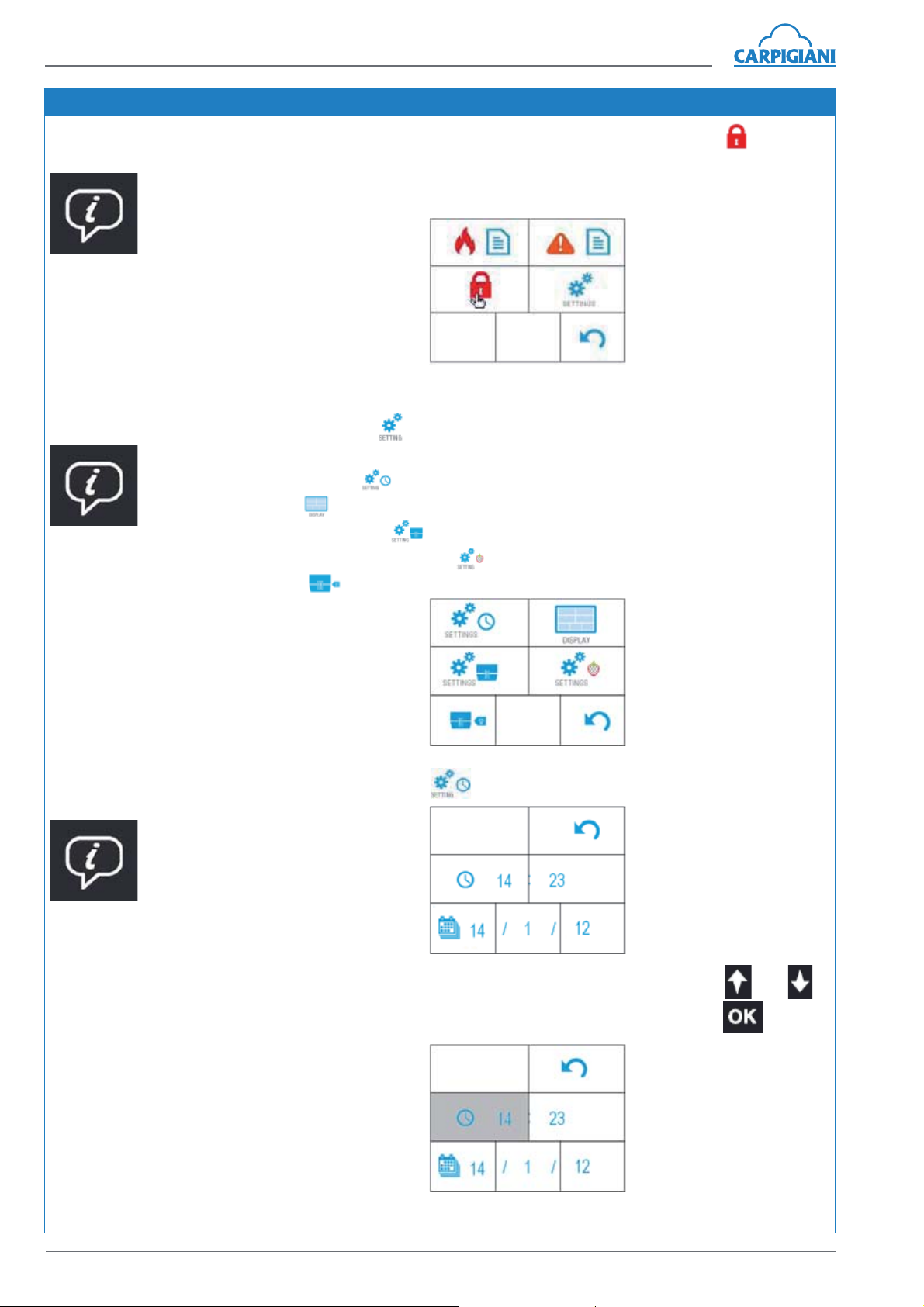

BUTTONS

INFO – KEY

LOCKING

The key locking key is present in all functions of the machine. Pressing the

key for 10 seconds (wait for the visualisation of the display to return to the source function) and all keys are disenabled, except for those inside the display. To permit the front

panel to be cleaned without accidentally activating functions, the machine returns to the

previous function.

With the machine in

Stop mode press:

t INFO

t KEY LOCKING

To re-enable the keys press any key; The window with a lock will re-appear: press it for 10

seconds to enable the keys.

INFO - SETTINGS

Pressing the Settings

selected directly on the touch screen:

With the machine in

Stop mode press:

t INFO

t SETTINGS

Functions that can be selected from SETTING mode:

t Setting the time

t Display

t Setting the machine

t Setting the syrups

t LED bar

DESCRIPTION OF FUNCTIONS

key locking

key, the display visualises the following functions that can be

t Setting the time

t Display

t Setting the machine

t Setting the syrups (if present)

t LED bar

INFO – SETTING

THE TIME

With the machine in

Stop mode press:

t INFO

t SETTINGS

t SETTING THE TIME

Pressing the Setting the time

key, the display visualises:

Pressing on the hour the background of the key becomes grey and the and si

arrow keys light up so that the hour can be modified. Confirm using the

key.

To modify minutes and date follow the same procedure.

20

2012/07 - Ed. 04 - EN

Page 21

EVD 3

BUTTONS

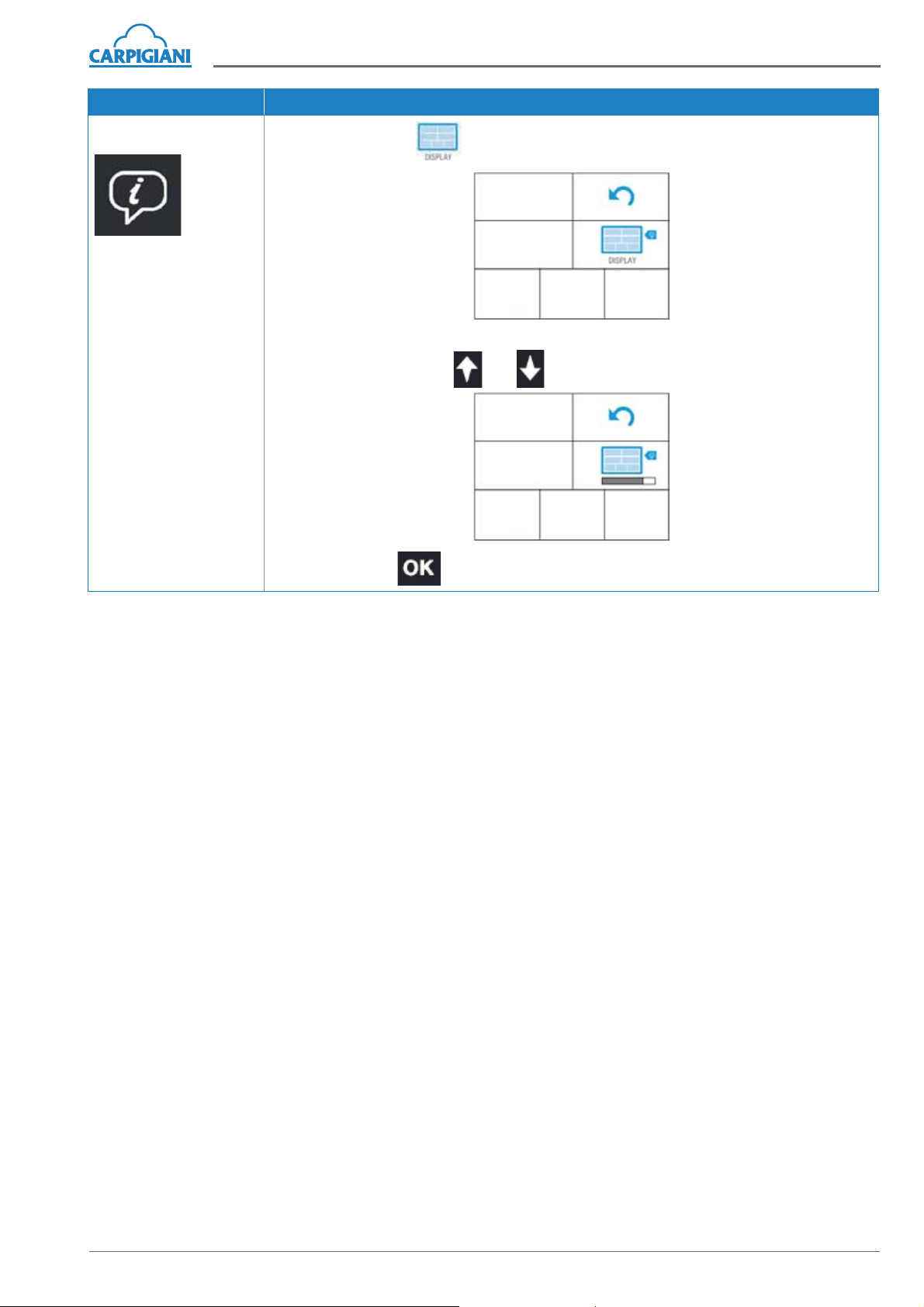

INFO - DISPLAY

With the machine in

Stop mode press:

t INFO

t SETTINGS

t DISPLAY

DESCRIPTION OF FUNCTIONS

Pressing the Display

The display luminosity bar (intensity of the backlight) of the display appears when press-

ing on the display and the

key, the display visualises:

and arrow keys light up to allow modification.

Confirm using the key.

2012/07 - Ed. 04 - EN

21

Page 22

EVD 3

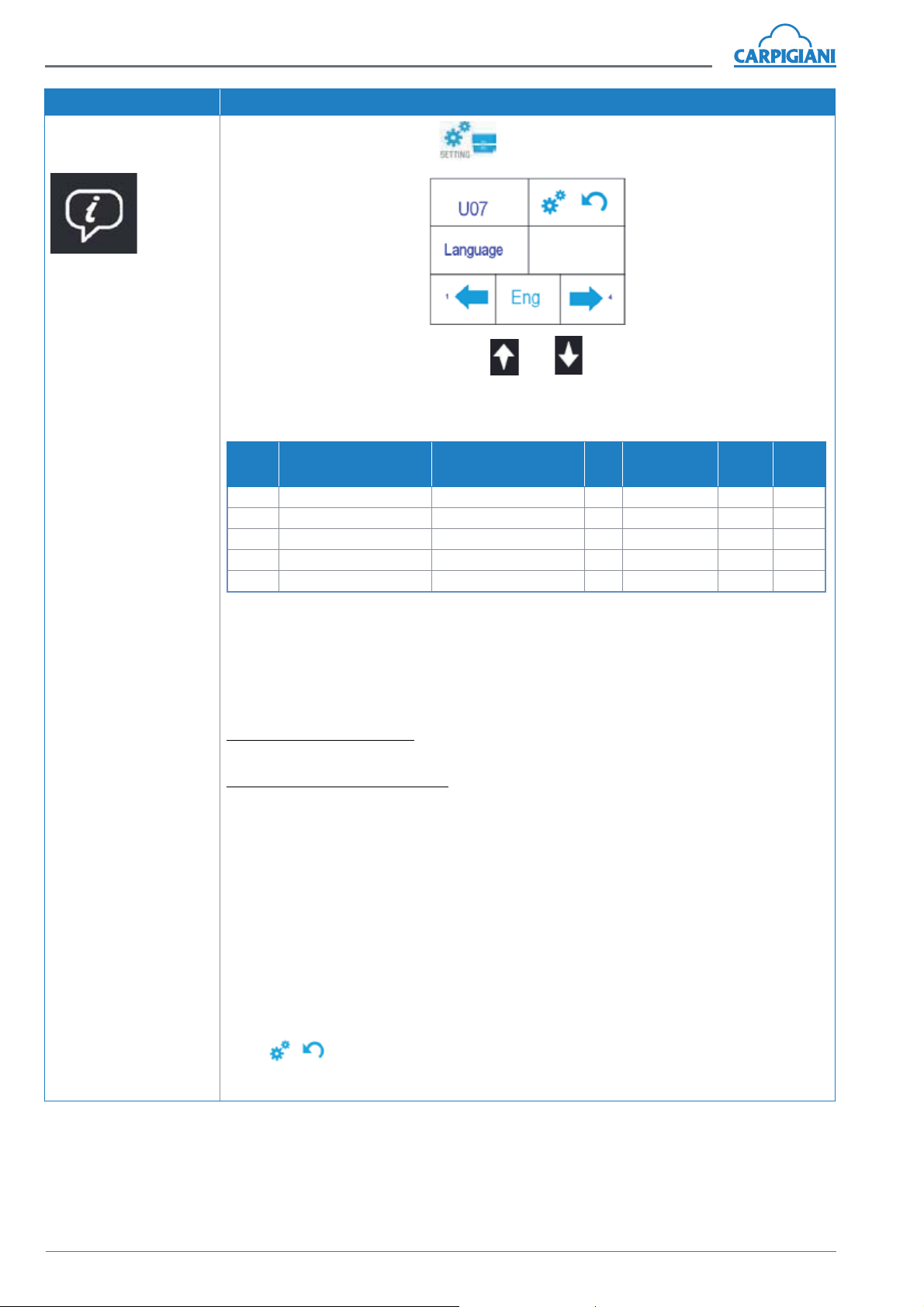

BUTTONS

INFO – MACHINE

SETTING

With the machine in

Stop mode press:

t INFO

t

SETTINGS

t

MACHINE SETTING

(Programming)

DESCRIPTION OF FUNCTIONS

Pressing the Machine setting key, access is gained to the first step of user

programming.

To scroll the various steps, utilise the and . arrow keys. The display visualises

the first step of user programming. E.g., U07 - Language: Eng. The value is modifiable

using the left and right arrow keys visualised on the touch screen. Refer to the Programming table.

De-

Step

U07 Linguaggio Language Ita Esp Ita

U08 Ora Avvio Prod. Start Prod. Time 00 23+no+auto 08

U09 Ora Avv.Pas-Con Start Past. Stor. 00 23+no 02

U10 Abilita Beep Liv Lev. Beep Enable No Yes Yes

U15 Lato Attivo Active Side 1 3 3

Display ITA Display ENG Min Max

fault

Notes

U07 - Language: Setting the language in Italian, English, German or Spanish.

U08 - Start Prod. Time: Setting of the start hour of automatic Production. Set at “No”

automatic Production will not start. Set at “auto” automatic Production starts as soon

as the Pasteurisation cycle has been completed.

U09 - Start Past. Stor.:

For pasteurising machines: Setting of the start hour of automatic Pasteurisation. Set at

“No” automatic Pasteurisation will not start.

For non-pasteurising machines: Setting of the start hour of automatic Storage. Set at

“No” automatic Storage will not start.

U10 - Lev. Beep Enable: Set at “Yes” an intermittent acoustic beep sounds when the

medium level is uncovered, except when the machine is in Stop mode which remains

off even when enabled.

U15 - Active Side: There are three settings (1, 2 or 3). Set the side on which to operate.

1= Left side

2= Right side

3= Both sides

To exit from user programming, do not press any key for approximately 30 seconds or

press

exiting user programming, if the table has been updated, the message “Table Updated

M.” appears on the display.

on the display. At this point the machine returns to the previous menu. On

22

2012/07 - Ed. 04 - EN

Page 23

EVD 3

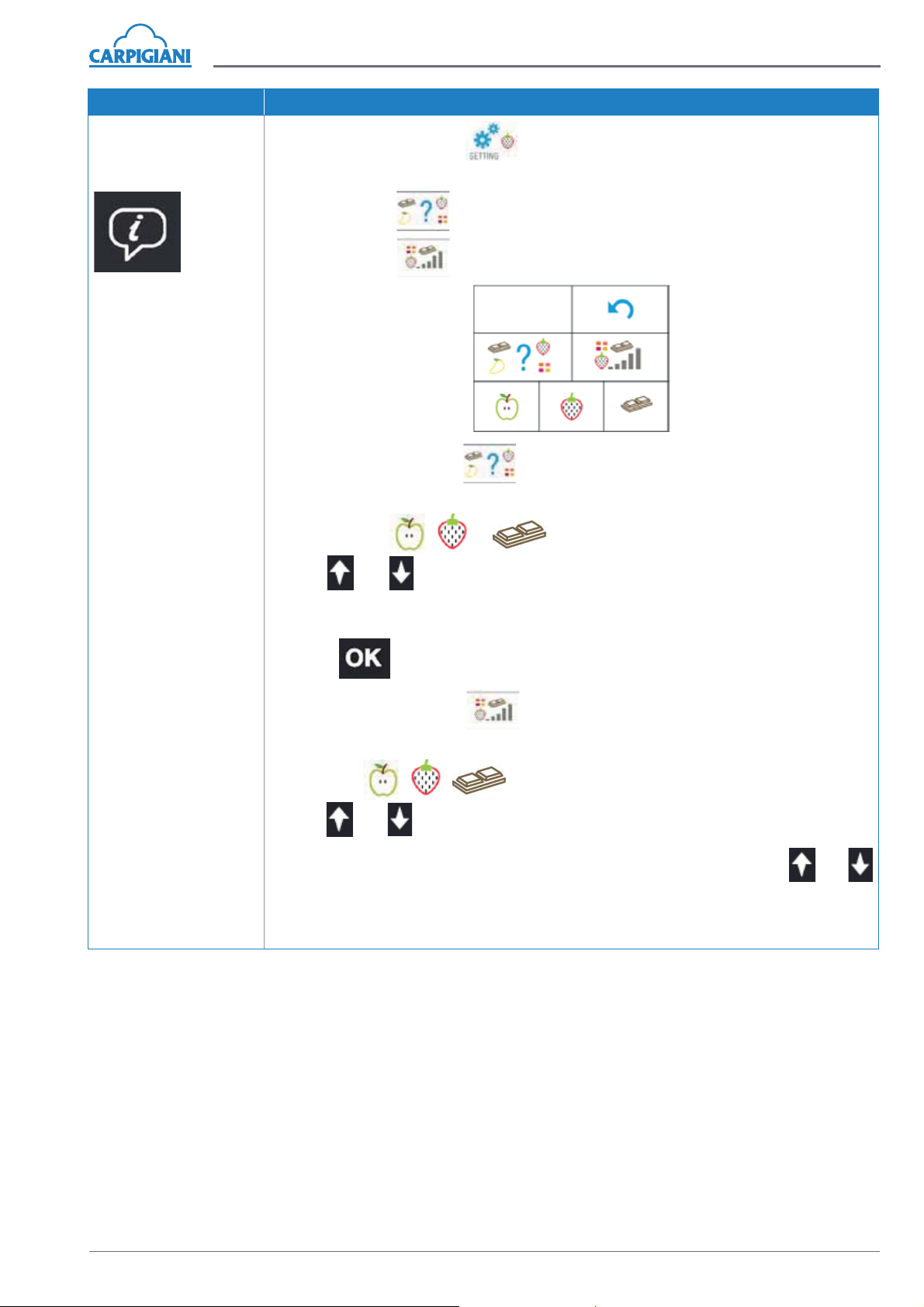

BUTTONS

INFO – SYRUP

SETTING

(if present)

With the machine in

Stop mode press:

t INFO

t SETTINGS

t SYRUP SETTING

Functions that can be

selected from SYRUP

SETTING:

t Icon selection

t Syrup quantity

DESCRIPTION OF FUNCTIONS

Pressing the Syrup Setting

key, the display visualises the following functions

that can be directly selected on the touch screen:

t Icon selection

t Syrup quantity

Pressing the Icon selection key, the background of the key becomes grey (selected).

Pressing a syrup

, or , key, the background of the key becomes grey

and the

and . arrow keys light up. Using these keys, the icon associated to the

key selected can also be selected (Apple, Banana, Chocolate, Strawberry, Amarena,

Chestnut, Green and Red).

Press the

Pressing the Syrup quantity

key or the relative syrup icon key to confirm the image chosen.

key, the background of the key becomes grey (se-

lected).

Pressing any

and the

and arrow keys light up.

A number lights up and the quantity of syrup can be adjusted by pressing the

, , , syrup key the background of the key becomes grey

and

arrow keys.

The number on the side increases and decreases accordingly.

2012/07 - Ed. 04 - EN

23

Page 24

EVD 3

BUTTONS DESCRIPTION OF FUNCTIONS

INFO – LED BAR

With the machine in

Stop mode press:

t INFO

t SETTINGS

t LED BAR

(colour and intensity)

Pressing LED Bar

Pressing the LEFT key (LED bar colour), the LED bar lights up as do the

and arrow keys which allow the colour of the LED bar to be modified from

a selection of eight possible colours.

the display visualises:

Confirm by pressing the key.

Pressing the

and arrow keys which allow the intensity of the LED bar colour to be modified.

Confirm by pressing the key.

RIGHT key (LED bar intensity), the LED bar lights up as do the

24

2012/07 - Ed. 04 - EN

Page 25

EVD 3

BUTTONS

INFO from

Production mode

Functions that can be

selected from INFO

whilst the machine is in

Production mode:

t Cones and Software

Versions

t Setting

t Modify Set Hot

t Key locking

t Water Sprayer

INFO – CONES AND

SOFTWARE VERSIONS

DESCRIPTION OF FUNCTIONS

Pressing the

key whilst in Production mode, the display visualises the following

functions that can be selected directly on the touch screen:

t Cones and Software Versions

t Setting (if present)

t Modify Set Hot

t Key locking

t Water Sprayer

Use the key to return to the previous page.

Pressing the Cones and software versions

key, the display visualises the only

read page that reports the following data:

t Daily cones

t Total cones

t SW versions

With the machine

in production mode

press:

t INFO

t CONES AND SOFT-

WARE VERSIONS

INFO - SETTING

(if present)

With the machine

in production mode

press:

t INFO

t SETTINGS

To return to the previous function press the key or wait 15 seconds.

Pressing the Setting key, access is gained to the whipping cycle selection menu

(if present).

To return to the previous function press the key or wait 15 seconds.

2012/07 - Ed. 04 - EN

25

Page 26

EVD 3

BUTTONS

INFO – MODIFY

SET HOT

With the machine

in production mode

press:

t INFO

t MODIFY SET HOT

INFO - KEY LOCKING

DESCRIPTION OF FUNCTIONS

Pressing the Modify Set Hot

and the

After having set the desired value, confirm by pressing the key.

If the

Pressing the

those inside the display. To permit the front panel to be cleaned without accidentally acti-

vating functions, the machine returns to the previous function.

and arrow keys light up to permit the modification of the value.

key is pressed again, the value is not memorised.

key locking key for 10 seconds and all keys are disenabled, except for

key, the background of the key becomes grey

With the machine

in production mode

press:

t INFO

t KEY LOCKING

INFO - WATER

SPRAYER

(if present)

With the machine

in production mode

press:

t INFO

t WATER SPRAYER

To re-enable the keys, press any key and the window with the lock appears. Pressing the

Key locking key for 10 seconds, all keys are re-enabled.

Pressing the Water Sprayer

Sprayer positioned inside the cabinet of the machine.

The dispensing stops after 3 minutes or by pressing the same key again.

key activates the dispensing of water via the Water

26

2012/07 - Ed. 04 - EN

Page 27

EVD 3

BUTTONS

INFO whilst in

Cleaning mode

Functions that can be

selected whilst in INFO

mode with the machine

in Cleaning mode:

t Key locking

INFO whilst in

Pasteurisation mode

DESCRIPTION OF FUNCTIONS

Pressing the

functions that can be selected directly on the touch screen:

t Key locking

Pressing the key locking key for 10 seconds and all keys are disenabled, except for

those inside the display. To permit the front panel to be cleaned without accidentally acti-

vating functions, the machine returns to the previous function.

To re-enable the keys, press any key and the window with the lock appears. Pressing the

Key locking key for 10 seconds, all keys are re-enabled.

Using the

Pressing the

ing functions that can be selected directly on the touch screen:

t Key locking

key whilst in Cleaning mode, the display visualises the following

key the menu returns to the previous page.

key whilst in Pasteurisation mode, the display visualises the follow-

Functions that can be

selected whilst in INFO

mode with the machine

in Pasteurisation mode:

t Key locking

INFO whilst in

Storage mode

Functions that can be

selected whilst in INFO

mode with the machine

in Storage mode:

t Key locking

Pressing the key locking key for 10 seconds and all keys are disenabled, except for

those inside the display. To permit the front panel to be cleaned without accidentally acti-

vating functions, the machine returns to the previous function.

To re-enable the keys, press any key and the window with the lock appears. Pressing it for

10 seconds, all keys are re-enabled.

Using the

Pressing the

functions that can be selected directly on the touch screen:

t Key locking

Pressing the key locking key for 10 seconds and all keys are disenabled, except for

those inside the display. To permit the front panel to be cleaned without accidentally acti-

vating functions, the machine returns to the previous function.

To re-enable the keys, press any key and the window with the lock appears. Pressing the

Key locking key for 10 seconds, all keys are re-enabled.

Using the

key the menu returns to the previous page.

key whilst in Storage mode, the display visualises the following

key the menu returns to the previous page.

2012/07 - Ed. 04 - EN

27

Page 28

EVD 3

BUTTONS

CLEANING

Functions that can

be selected whilst in

Cleaning mode:

t Beating

t Heated beating

t Pump

t Water dispensing

t Syrup cleaning

DESCRIPTION OF FUNCTIONS

Pressing the Cleaning

key the display visualises the following functions that can

be selected directly on the touch screen:

t Beating

t Heated beating

t Pump

t Water dispensing (if present)

t Syrup cleaning (if present)

CLEANING – BEATING

Press:

t CLEANING

t BEATING

The last line visualises the temperature of the cylinder and the consistency of the product .

The keys that can be activated have a coloured icon (blue or red) and once pressed the

background becomes grey.

The keys that cannot be activated have a grey icon. Refer to the key

on the above

display.

The 2

Pressing the Beating

and functions can be activated simultaneously.

key the beater motor is activated/deactivated.

When the motor is functioning, the background of the relative function becomes grey.

After 30 seconds the symbol returns to a white background and the motor switches off.

The Beating function is utilised to wash the cylinder and facilitate the emptying of the

product from the cylinder.

CLEANING – PUMP

Press:

t CLEANING

t PUMP

28

Pressing the Pump

key (only machines with a pump), the pump motor is activated/

deactivated.

When the motor is functioning, the background of the relative function becomes grey.

After 30 seconds the symbol returns to a white background and the pump switches off.

The function is utilised to load the mix from the tank to the cylinder and to pressurize the

cylinder to facilitate the dispensing of the product.

2012/07 - Ed. 04 - EN

Page 29

BUTTONS DESCRIPTION OF FUNCTIONS

CLEANING - HEATED

BEATING

Pressing Heated Beating the beater motor with heating is activated/deactivated.

When Heated Beating is activated the background of the function becomes grey.

The cylinder is heated until a set temperature is reached.

EVD 3

Press:

t

CLEANING

t

HEATED BEATING

CLEANING - WATER

DISPENSING

Press:

t

CLEANING

t

WATER DISPENSING

CLEANING – SYRUP

CLEANING

Press:

t CLEANING

t SYRUP CLEANING

On reaching this temperature the symbol changes back to the white background and

Heated Beating is deactivated.

Pressing the Water Sprayer key activates/deactivates (only if present) the dispensing of water via the Water Sprayer positioned inside the cabinet of the machine. The

maximum dispensing time is 3 minutes. To stop the water dispensing before 3 minutes,

press the Water Sprayer key again.

When Water Sprayer is active, the background of the function becomes grey; when it is

deactivated the symbol changes back to the white background.

If the machine has the syrup option, once the Cleaning key is pressed the display visualises:

Pressing the Syrup Cleaning key the display visualises three Syrup Cleaning icons at the

bottom of the display.

Pressing a Syrup key, its associated key lights up with a grey background and

the associated syrup pump is activated for 20 seconds at maximum speed so that the

syrup line can be washed

NOTE

It is not possible to select two syrups simultaneously.

To stop the cleaning in advance press the same key.

Once the syrup cleaning procedure is completed, the associated syrup icon changes

back to white.

To return to the Cleaning screen press the

the display.

key again or one of the four keys on

2012/07 - Ed. 04 - EN

29

Page 30

EVD 3

BUTTONS DESCRIPTION OF FUNCTIONS

PRODUCTION

Production can be accessed only when the minimum level is covered.

Pressing the key

Where:

The tank level.

minimum uncovered.

Number of cones that can be dispensed with the level uncovered. It ap-

pears only if the minimum level becomes uncovered.

Temperature in the tank. If <40°C the temperature visualised is blue.

If >=40°C the temperature visualised is red.

Arrow lit: when the tank is cooling.

the display visualises:

Standard Machine

version

: minimum and medium covered, : medium uncovered, :

Variegated Ice Cream

machine version

PRODUCTION –

CHANGE OF

FLAVOUR

Set consistency to be reached.

Product cannot be sold yet. When it reaches consistency it becomes

.

Current consistency.

Arrow lit: if the cylinder is cooling.

Number of days left to Cleaning

14

Flavour (syrup) selected (if foreseen). All flavours can also be disabled

(white background) (neutral).

The machine brings set ice cream in the cylinder to the right consistency every 10 minutes.

Press the

CHANGE OF FLAVOUR PROCEDURE

Pressing the

cooling is deactivated of the side relative to the pressed cone key. Beating is activated

and the pump operates for one minute to permit the emptying of the cylinder and the tank

of product. If the product has not been completely removed after one minute, reactivate

key to force this time. The consistency will conform to the set value.

key for 10 seconds the symbol on the display turns grey and

30

the function for a further minute by pressing the

empty tank with a different flavour.

To exit from the procedure, press the

back to blue.

key again. At this point fill the

key for 10 seconds and the key changes

2012/07 - Ed. 04 - EN

Page 31

EVD 3

BUTTONS

PRODUCTION –

SYRUP PUMP

SPEEDS

only for syrup version

PRODUCTION -

LED BAR

DESCRIPTION OF FUNCTIONS

MODIFY QUANTITY OF SYRUP DISPENSED

To modify the speed of the syrup pump and consequently the quantity of syrup dispensed

select the flavour by, for example, pressing the

Press the key

point modify the speed utilising the

from 90 to 245.

To exit from the procedure, press the key again for three seconds until the and

arrow keys are switched off, or wait one minute.

LED BAR

The LED bar lights up in intermittent/slow mode during the phase of reaching consistency

of the product.

When the product has reached the right consistency, the LED bar remains lit in fixed mode

and the product can be dispensed via the ice cream dispensing handles.

When the medium level is uncovered in one or both tanks, the LED bar flashes in intermittent/fast mode.

again for three seconds until the and arrow keys light up. At this

and arrow keys. The values can be modified

key and the background becomes grey.

PRODUCTION

VERSIONS WITH

WATER SPRAYER

AND MIXER

VERSIONS WITH WATER SPRAYER AND MIXER

The versions of the machine that do not have the syrup function show the information

indicated as follows on the third line of the display:

Basic machine.

The cone indicates that the machine is

in Production mode.

The key is not active.

Machine with a water sprayer.

The cone indicates that the machine

is in Production mode. The key is not

active. The water sprayer is an active

(blue) key. Pressing the

water solenoid valve is opened which

allows water to be dispensed by manually activating the water sprayer.

Dispensing stops after 3 minutes or by

pressing the same key again.

Machine with a mixer.

The cone indicates that the machine is

in Production mode.

The grey key is not active.

The mixer is an active (blue) key.

Machine with a mixer and a water

sprayer.

The cone indicates that the machine is in

Production mode. The key is not active.

The mixer is an active (blue) key.

The water sprayer is an active (blue) key.

key the

2012/07 - Ed. 04 - EN

31

Page 32

EVD 3

BUTTONS DESCRIPTION OF FUNCTIONS

PASTEURISATION

Pasteurisation can be accessed only when the medium level is covered.

Pressing the Pasteurisation

Where:

The tank level.

: minimum and medium covered, : medium uncov-

ered

Temperature in the tank. If <40°C the temperature visualised is

blue.

If >=40°C the temperature visualised is red.

Arrow lit to one side of the temperature: Up if the tank is in heating mode and Down if in cooling mode.

Temperature in the cylinder. If <40°C the temperature visualised

is blue.

: minimum uncovered.

key for 5 seconds, the display visualises:

If >=40°C the temperature visualised is red.

Function active: heating. Do not remove product.

Water dispenser if foreseen.

If the machine pasteurises, the Pasteurisation cycle occurs automatically every

day at a predetermined time (if set in User Programming).

When the machine is in Production or Storage mode at the time set for pasteurisation, it

automatically goes into Pasteurisation mode.

To activate Manual Pasteurisation, keep the

If the Pasteurisation cycle is not successfully completed, the machine CANNOT gain access to Production mode until a Pasteurisation cycle is completely carried out.

During the Pasteurisation cycle, the product in the tank or in the cylinder is heated to

65°C, maintained at this temperature for 30 minutes (fixed) and then cooled until the

storage temperature is reached.

key pressed for 5” seconds.

32

At the end of the cycle, the display visualises

week, which means that the pasteurising process has been carried out correctly.

with the hour and the day of the

2012/07 - Ed. 04 - EN

Page 33

BUTTONS DESCRIPTION OF FUNCTIONS

STORAGE/ALARM

RESET

VERTICAL TANK

MOVEMENT

(if present)

The Storage cycle is automatically carried out every day at an established time.

Storage has the function of bringing the product in the tank and the cylinder to a temperature of 4°C.

Once entering the Storage cycle the display shows as follows:

To start Storage manually keep the key pressed for 5 seconds.

The button allows also to reset the alarms that might be shown on the display.

CRUSHING

HAZARD

Remove all objects from the surface before activating the movement of the head.

The presence of objects could cause malfunctioning.

No liability is accepted by Carpigiani for malfunctioning, breakages or damages

arising from misuse of tank movement.

EVD 3

To make the cleaning of the tank easier, the tank column can be moved vertically (if

provided).

To raise or lower the tank utilise the

By pressing the

tank in the most suitable position. The maximal height is set by reaching the uppemost

limit switch.

Pressing the

warning messages to avoid the danger of being crushed.

Pressing the

key and keeping it pressed, the tank rises; release the key to stop the

key starts tank lowering procedure but in this case the display visualises

key the display visualises:

and .

2012/07 - Ed. 04 - EN

The key flashes for 5 seconds. If no key is pressed within that time period the

display returns to the previous page.

If the

the tank starts to be lowered with a beeping tone signal.

As soon as the

turns to the previous page.

key is pressed instead, the key stops flashing and by pressing the key

key is released the movement of the tank stops and the display re-

33

Page 34

EVD 3

3.4 Dispensing handles

To dispense the product, place a cup or a

cone underneath the dispensing door and,

with the machine in production mode, slowly

lower the dispensing handle.

As soon as the product starts to come out, move the

cup or cone with a circular motion to give the ice cream

a conical shape.

Once a sufficient amount of product has been dispensed, close the dispensing handle and move the

cup or cone quickly downwards to give the portion a

pointed tip.

The product dispensing handle can also be easily removed by lifting it upwards.

In this way it can also be used as a key to stop the machine being used.

Fig. 07

3.4.1 Modify the quantity of product

dispensed

To modify the quantity of product dispensed by the various handles, carry out the following procedure:

t Remove the ice cream dispensing handle (5).

t Adjust the three knobs. Rotating them in an anti-

clockwise direction the quantity of product dispensed is reduced. Rotating them in a clockwise

direction increases the quantity.

Fig. 10

-

+

-

+

-

+

3.4.2 Self closing

The machine is equipped with an automatic return system that brings the ice cream dispensing handle to rest

automatically.

This occurs via a spring system connected to the dispensing piston.

NOTE

Fig. 08

t Open the door cover panel

Fig. 09

When the symbol is visualised in Production

mode, remove a cone by lowering the dispensing

handle until it stops. Re-position the handle in the

closed position.

3.5 Machines fed by pump and

semi-submersible pump

5

The pump allows a variation in the proportion of air/mix

sent to the cooling cylinders. Therefore, within certain

limits, it allows to adjust the volume increase (overrun)

suitable to the type of mixed used. By turning the middle handle counter-clockwise the overrun is increased.

Fig. 11

34

2012/07 - Ed. 04 - EN

Page 35

EVD 3

3.6 Gravity-fed machines – feed

needle

Instructions for achieving and maintaining the good

functioning of the machine.

t Always keep the level of the mix in the tank high (at

least more than half). The mix in the tank is stored at

4°C whether in Production mode or Storage mode.

t During the day periodically stir the mix in the tank

using a spatula to avoid the separation of the mix,

especially after long stoppage periods in Storage

mode.

t Always use a fluid mix free of large lumps. A very

dense mix with large lumps could block the slot of

the feed needle thereby stopping the loading of the

whipping cylinder.

t Keep the cursor of the feed needle (pos. 52) in a

position that permits the mix to fall correctly from

the tank into the whipping cylinder. Rotating the slot

of the cursor in correspondence to the lower hole

diameter, the quantity of mix is reduced that drops

into the tank. Rotating the slot of the cursor in correspondence to the upper hole diameter, the quantity

of mix is increased that drops into the tank.

t Position the feed needle in such a way that the entry

hole of the product is turned towards the centre of

the tank.

t Do not exceed the production indicated in para-

graph 1.2.2 and maintain regularity in the distribution

of cones and tubs. Exceeding the limits of production capacity indicated could block the machine. In

this case the alarm message “ICE” could appear on

the display. If this occurs, reset the functionality of

the machine as follows:

Place the machine in Stop mode.

Remove the feed needle to allow a free fall of mix

into the cylinder.

Place the machine in Cleaning mode for a few

minutes.

Ensure that a liquid product pours out from dis-

pensing tap.

Replace the feed needle checking that the cursor

is sufficiently open.

Switch on the machine again and put it into Pro-

duction mode. Wait for it to stop and then commence distribution again.

Fig. 12

3.7 Utilizzo corretto del coperchio

vasca

Il coperchio vasca EVD 3 ha tre posizioni:

t Cover closed.

Fig. 13

t Cover open at 90°, useful for the disassembly of tank

components and for the removal of the same cover.

Fig. 14

90°90°

t Cover open at 60°, useful for loading the mix into the

tanks.

Fig. 15

60°60°

2012/07 - Ed. 04 - EN

35

Page 36

EVD 3

Follow this procedure to close the cover that is open 60°:

t Pull the cover forwards (towards the user).

t Close the cover by lowering it.

Fig. 16

AVVERTENZA

Loading the tank:

t Take a tub of mix from the refrigerator.

N.B. Load a mix that has a temperature of 4-5°C.

t Pour a small quantity of mix (approximately 100 ml)

into the tanks, lower the ice cream dispensing levers

and let the mix flow completely out so as to eliminate

any residues of water and detergent/sanitising solution. Bring the ice cream dispensing levers back to

the original position and continue to pour the mix so

that it fills the cylinder by gravity.

t

When the cylinder is full and the tank almost empty,

press the

verify the correct functioning of the pump (the flow of

the mix must be a good jet). In the event of malfunctioning, refer to paragraph 6.1. To deactivate the func-

tion press the

Fig. 17

key and then press the key to

key again.

During the closing phase do not place pressure on

the lower part of the cover because it could be

damaged.

3.8 Preliminary operations,

washing and sanitising

Before using the machine for the first time, thorough-

ly clean all component parts as well as sanitising the

parts that come into contact with the ice cream.

Refer to section 5 of this manual for machine disassembly and cleaning procedures.

NOTE

Cleaning and sanitisation are operations that must

be carried out with maximum care to ensure production quality and compliance with required hygienic norms.

3.9 Commissioning the machine

Assembling the compression tube:

t

With clean, sanitised hands (or wearing disposable

gloves) take the compression tube from the sanitising solution and place it onto the bottom of the tank.

t Rotate the compression tube counter-clockwise in

order to align it with the pump. Insert the connecting

tube (pos. 207) into the pump and rotate it until it is

fastened.

t Pour the mixture into the tanks until they are full.

NOTE

The level of mix in the tanks must not exceed the

maximum level indicated on the tank walls.

Fig. 18

After installing the machine in compliance with the instructions contained in the “Installation” chapter of this

manual and after thoroughly washing and sanitising the

machine, proceed as follows:

3.9.1 Starting the machine that has a

pump

Remove the compression tube from the bottom of the

tank and plunge it into the cleaning/sanitising solution

for 5/10 minutes (refer to the indications of the manufacturer of the product used).

36

MAX

MIN

2012/07 - Ed. 04 - EN

Page 37

EVD 3

3.9.2 Starting a gravity-fed machine

Remove the feed needle from the bottom of the tank

and immerse it in the detergent/sanitising solution for

5/10 minutes (in accordance with that indicated by the

manufacturer of the product utilised).

Loading the tank:

t Take a pack of mix from the refrigerator. NB.: Utilise

a mix that has a temperature of 4°C/5°C.

t Pour a small quantity of mix (approximately 100 ml)

into the tanks, lower the ice cream dispensing levers

and let the mix flow completely out so as to eliminate

any residues of water and detergent/sanitising solution. Bring the ice cream dispensing levers back to

their original positions and continue to pour the mix

so that it fills the cylinder by gravity.

t During this phase only the cylinders are filled. The

tank remains empty to carry out the following described operations.

Assembly of the feed needle:

t Using clean and sanitised hands (or wearing dispos-

able gloves), remove the feed needle from the sanitising solution and insert it into the bottom of the tank.

NOTE

t Close the tank lid (Refer to paragraph 3.7).

t Place the machine in Production mode by pressing

the

t After few minutes the product can be dispensed.

key.

3.9.3 Loading the syrup circuits

(Variegated version only)

t Connect the syrup tubes to their appropriate con-

tainers.

t Place an empty container under the door.

t Press the key, then the key and then

press the

t As soon as the syrup flows out from the door press

and throw away the dispensed syrup.

t Repeat the operation for all syrup lines.

t Clean the syrup compartment and the door of the

compartment utilizing a clean and sanitised cloth.

icon associated with the syrup.

The level of mix in the tanks must never exceed

the height of the feed needle.

Fig. 19

60°60°

NOTE

After having cleaned the machine and, more precise-

ly, after having closed the front door, press the

key to start production within 60 minutes. After 60

minutes, the machine accepts the

and it automatically sets to heat-treatment function.

In other words, carry out the “Complete sanitisation

of the machine” and the “Mix priming” within 60 min-

utes, then press the

key.

key no longer

3.9.4 Syrup adjustment

(Variegated version only)

From Stop press the key.

Pressing the

cessed:

Pressing the key, the background of the key

becomes grey (selected).

Pressing a Syrup

background becomes grey and the arrow keys

light up. A number lights up and the corresponding

syrup pump is activated for a time set in Programming.

During this time, the quantity of syrup can be adjusted

key the following page is ac-

, key or key the key

and

2012/07 - Ed. 04 - EN

by pressing the

and arrow keys. The number

37

Page 38

EVD 3

at the side consequently increases and decreases. To

stop the dispensing in advance, press the same key.

Press the key to go back to previous page.

3.9.5 Dry filling (if present)

WARNING

All machines predisposed for the dry filling function must have an exclusive connection to the

drinking water mains system.

If the microbiological characteristics of the water

are not periodically checked and/or the powdered

food preparatives utilised are not sterile, CARRYING OUT PASTEURISATION HEAT TREATMENT IS

HIGHLY RECOMMENDED each time they are loaded and topped up.

LOADING THE MIX - How to carry out a Dry Filling

after cleaning and sanitising machine

Carrying out a DF procedure must take place only once

the machine has been cleaned. The DF procedure is

enabled if the Medium level or the Minimum level is uncovered (and consequently the Medium level).

t By pressing the key the display shows:

t The and keys lights up to allow the modifi-

cation of the quantity in litres shown on display.