Page 1

PIXMA MP 780

PIXMA MP 750

SER VICE

MANUAL

Canon

Copyright 2004, Canon U.S.A. This technical publication is the proprietary and confidential information of Canon U.S.A. which

shall be retained for reference purposes by Authorized Service Facilities of Canon U.S.A. Its unauthorized use is prohibited.

Page 2

PIXMA MP750/780

SERVICE

MANUAL

REVISION 0

PIXMA MP750 H12-4562 120V USA

PIXMA MP750 H12-4563 230V EMB

PIXMA MP750 H12-4564 230V GB

PIXMA MP750 H12-4565 230V EUM

PIXMA MP750 H12-4566 120V CND

PIXMA MP750 H12-4568 230V AUS

PIXMA MP780 H12-4582 120V USA

PIXMA MP780 H12-4583 230V EE/NE

PIXMA MP780 H12-4584 230V GB/ME/NORD/ZA

PIXMA MP780 H12-4585 230V AT/CH/DE

PIXMA MP780 H12-4586 230V WEST

PIXMA MP780 H12-4587 120V CND/LTN

PIXMA MP780 H12-4588 230V AUS

PIXMA MP780 H12-4589 230V AE

PIXMA MP780 H12-4597 230V CHN

HY8-13A3-000

COPYRIGHT2004 CANON INC. CANON PIXMA MP750/780 NOV. 2004

Page 3

Scope

This manual has been issued by Canon Inc., to provide the service technicians of this product with the

information necessary for qualified persons to learn technical theory, installation, maintenance, and repair of

products. The manual covers information applicable in all regions where the product is sold. For this reason, it

may contain information that is not applicable to your region.

Revision

This manual could include technical inaccuracies or typographical errors due to improvements or changes made

to the product. When changes are made to the contents of the manual, Canon will release technical information

when necessary. When substantial changes are made to the contents of the manual, Canon will issue a revised

edition.

The following do not apply if they do not conform to the laws and regulations of the region where the manual or

product is used:

Trademarks

Product and brand names appearing in this manual are registered trademarks or trademarks of the respective

holders.

Copyright

All rights reserved. No parts of this manual may be reproduced in any form or by any means or translated into

another language without the written permission of Canon Inc., except in the case of internal business use.

Copyright © 2004 by Canon Inc.

CANON INC.

Inkjet MFP Quality Assurance Div.

5-1 Hakusan 7-Chome, Toride-city, Ibaraki 302-8501, Japan

Page 4

I. MANUAL OUTLINE

This manual consists of the following three parts to provide information necessary to service the PIXMA

MP750/MP780:

Part 1: Maintenance

Information on maintenance and troubleshooting of the PIXMA MP750/MP780

Part 2: Technical Reference

New technology and technical information such as FAQ's (Frequently Ask ed Questions) of th e PIXMA

MP750/MP780

Part 3: Appendix

Block diagrams and pin layouts of the PIXMA MP750/MP780

Reference:

This manual does not provide sufficient information for disassembly and reassembly procedures. Refer

to the graphics in the separate Parts Catalog.

Page 5

II. TABLE OF CONTENTS

Part 1: MAINTENANCE

1 - 1 1. MAINTENANCE

1 - 1 1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement

Consumables by Service Engineer

1 - 3 1-2. Customer Maintenance

1 - 4 1-3. Product Life

1 - 4 1-4. Special Tools

1 - 5 1-5. Serial Number Location

1 - 6 2. LIST OF ERROR DISPLAY / INDICATION

1 - 6 2-1. Users Error Messege

1 - 9 2-2. Users Error Code

1 - 9 2-3. Service Call Errors

1 - 14 2-4. New Error Codes and Recovery Methods

1 - 16 2-5. Warnings

1 - 17 2-6. Troubleshooting by Symptom

1 - 22 2-7 Processing Communication Problems (MP780 only)

1 - 22 2-7-1 Initial Identification of Problems

1 - 24 2-7-2 Procedures for Processing Communication Problems

1 - 25 2-7-3 Procedures for Processing Communication Problems with Canon Facsimile.

1 - 26 2-7-4 Procedures for Processing Communication Problems with other Manufacturer's

Facsimiles.

1 - 27 3. REPAIR

1 - 27 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling)

1 - 30 3-2. Special Notes on Repair Servicing

1 - 30

3-2-1 Flexible Cable and Harness Wiring, Connection

1 - 33 3-3. Adjustment / Settings

1 - 33 3-3-1 Paper Feed Motor Adjustment

1 - 33 3-3-2 Gear Phase Adjustment

1 - 35 3-3-3 Lift Cam Shaft Ass’y Adjustment

1 - 36 3-3-4 Solenoid Cam Spring Location

1 - 36 3-3-5 Carriage Shaft Clip Location

1 - 37 3-3-6 White Sheet Location

1 - 39 3-3-7 Grease Application

1 - 41 3-3-8 Waste Ink Counter Setting

1 - 41 3-4. User Data Flow

1 - 46 3-5. Service Switches

1 - 46 3-5-1 Hardware Switches

1 - 46 3-5-2 Service Data Setting

1 - 47 3-5-3 Service Data Registration / Setting Method

1 - 48 3-5-4 Service Data Flowchart

1 - 54 3-5-5 Explanation of service data

1 - 55 3-5-6 New SSSWs / parameters added to this model

1 - 60 3-5-7 SSSW Default Setting

1 - 78 3-6. Test Mode / Factory Mode

1 - 78 3-6-1 Test Mode / Factory Mode Overview

Page 6

1 - 79 3-6-2 Test Mode Menu

1 - 80 3-6-3 Factory Mode

1 - 81 3-6-4 Operation Panel Test

1 - 83 3-6-5 Print Test

1 - 85 3-6-6 CD-R Calibration (230V only)

1 - 85 3-7. Upgrading the version of SPCNT Flash ROM

1 - 86 3-8. Verification Items

1 - 86 3-8-1 Users Report Service Test Print

1 - 87 3-8-2 Service EEPROM Information Print

1 - 88 3-8-3 System Data List (MP780 only)

1 - 95 3-8-4 System Dump List (MP780 only)

1 - 99 3-8-5 Service Activity Report (sending/receiving) (MP780only)

1 - 101 3-8-6 EEPROM Information Print

1 - 102 4. Cleaning Your Machine

1 - 102 4-1 Caution

1 - 102 4-2 Cleaning the Exterior

1 - 102 4-3 Cleaning the Scan Area

1 - 103 4-4 Cleaning the Interior

1 - 103 4-5 Cleaning the Feeder Cover

1 - 104 4-6 Cleaning the Rubber Sheet / Paper Feed Rollor / Separate Rollor

1 - 104 4-7 Cleaning the Paper Feed Rollor

1 - 105 4-8 Cleaning the Bottom Plate

1 - 106 5. Transportation

Part 2: TECHNICAL REFERENCE

2 - 1 1. New Technologies

2 - 3 2. Cleaning Mode and Amount of Ink Purged

2 - 5 3. Print Mode

2 - 9 4. FAQ (Problems Specific to the MP750/MP780 and C orrecti ve Ac ti ons)

Part 3: APPENDIX

3 - 1 1. Wiring Diagram

3 - 2 2. Circuit Diagram

3 - 3 2-1 NCU Circuit Diagram1

3 - 4 2-2 NCU Circuit Diagram2

3 - 5 2-3 Relay Circuit Diagram

3 - 6 3. Specification

Page 7

Part 1

Maintenance

Page 8

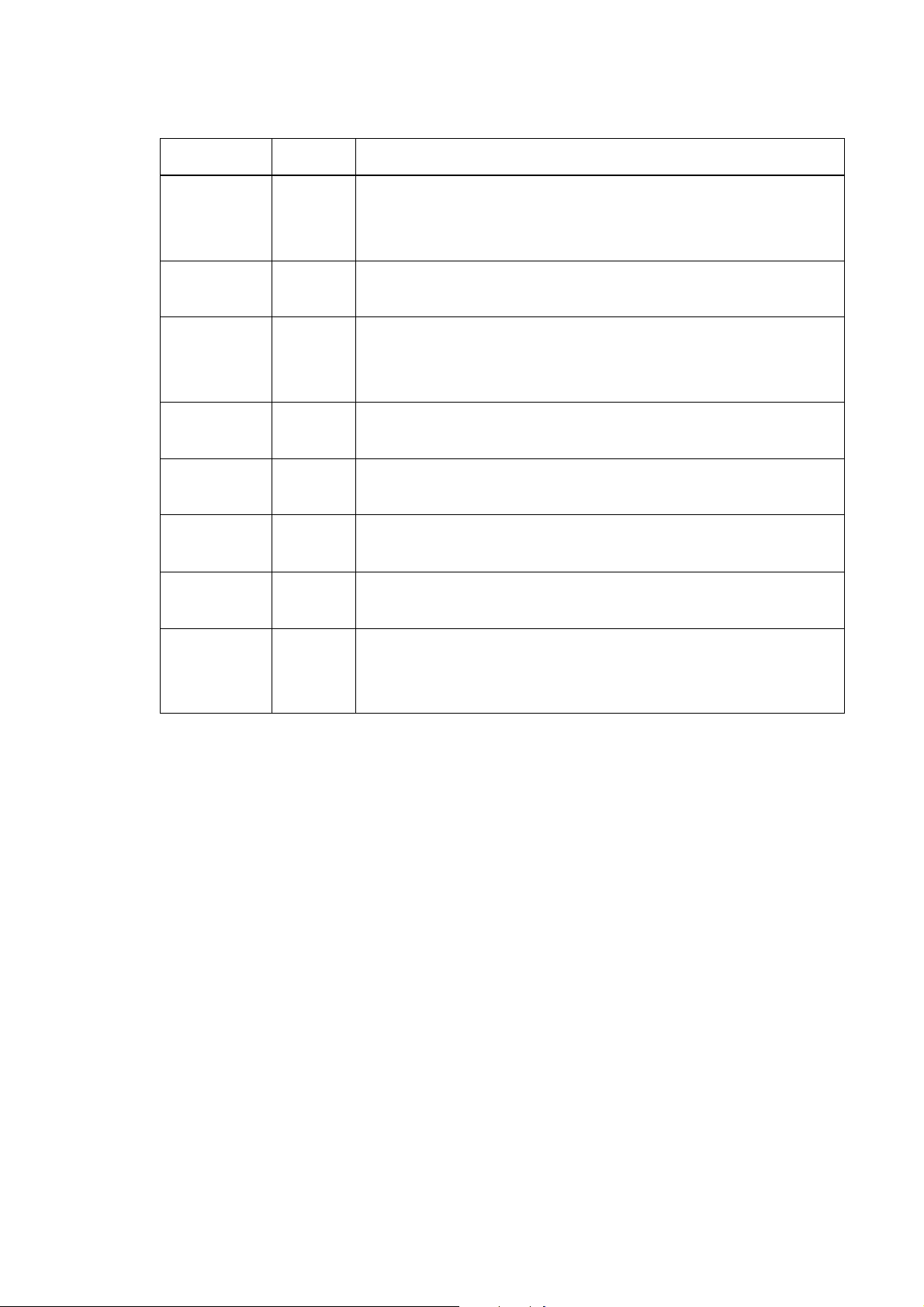

1. MAINTENANCE

1-1 Adjustment, Periodic Maintenance, Periodic Replacement Parts, and

Replacement Consumables by Service Engineer

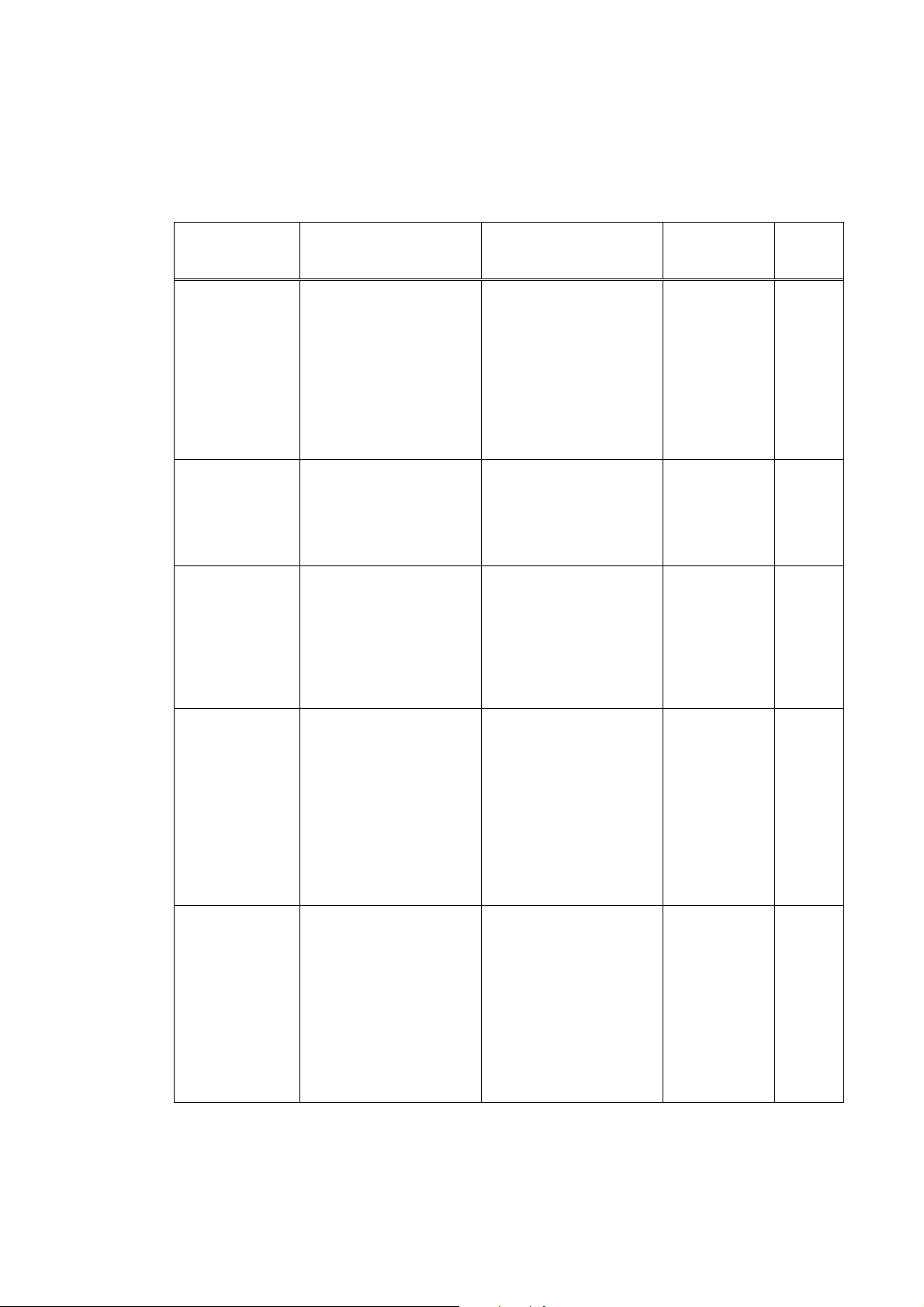

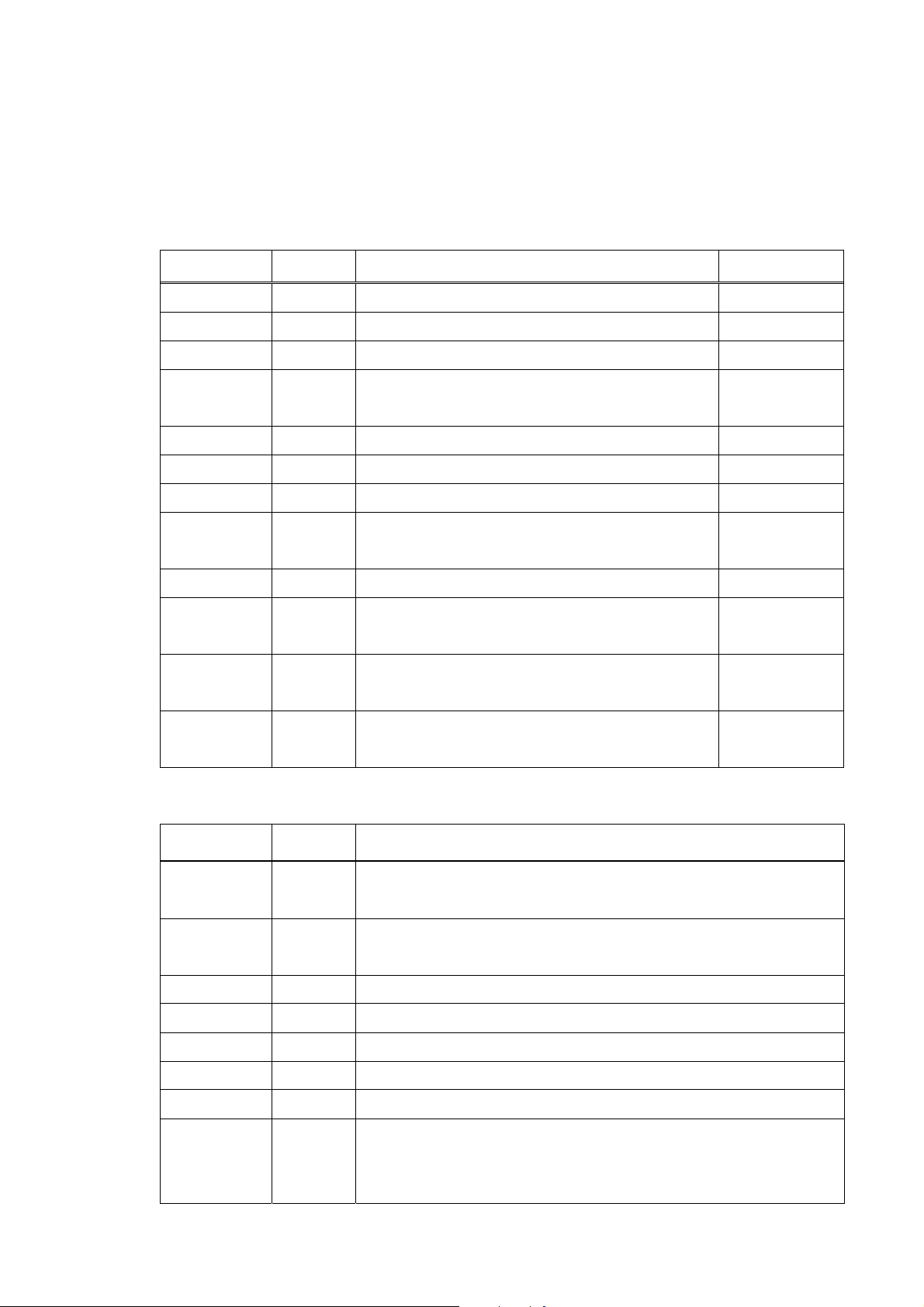

(1) Adjustment

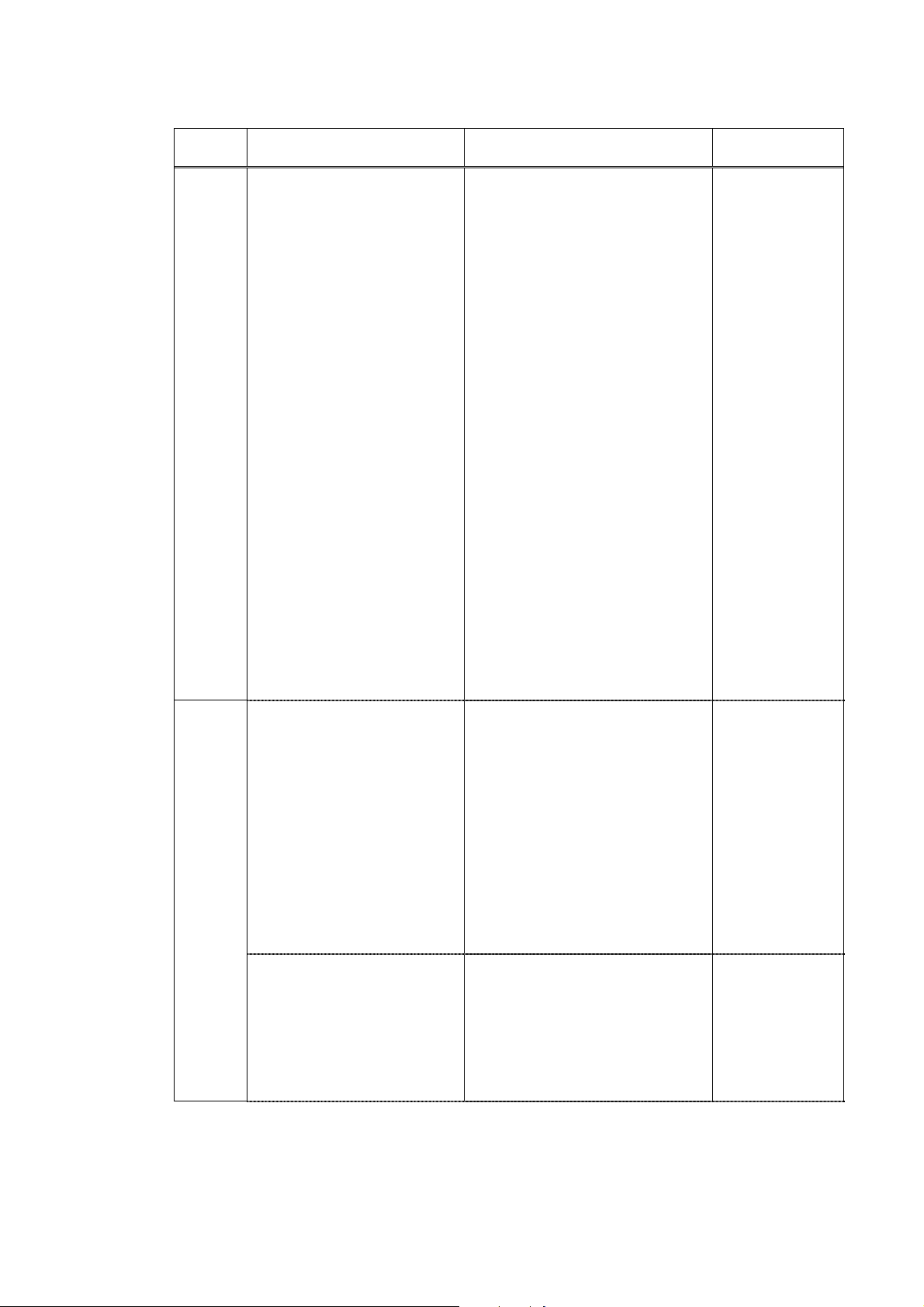

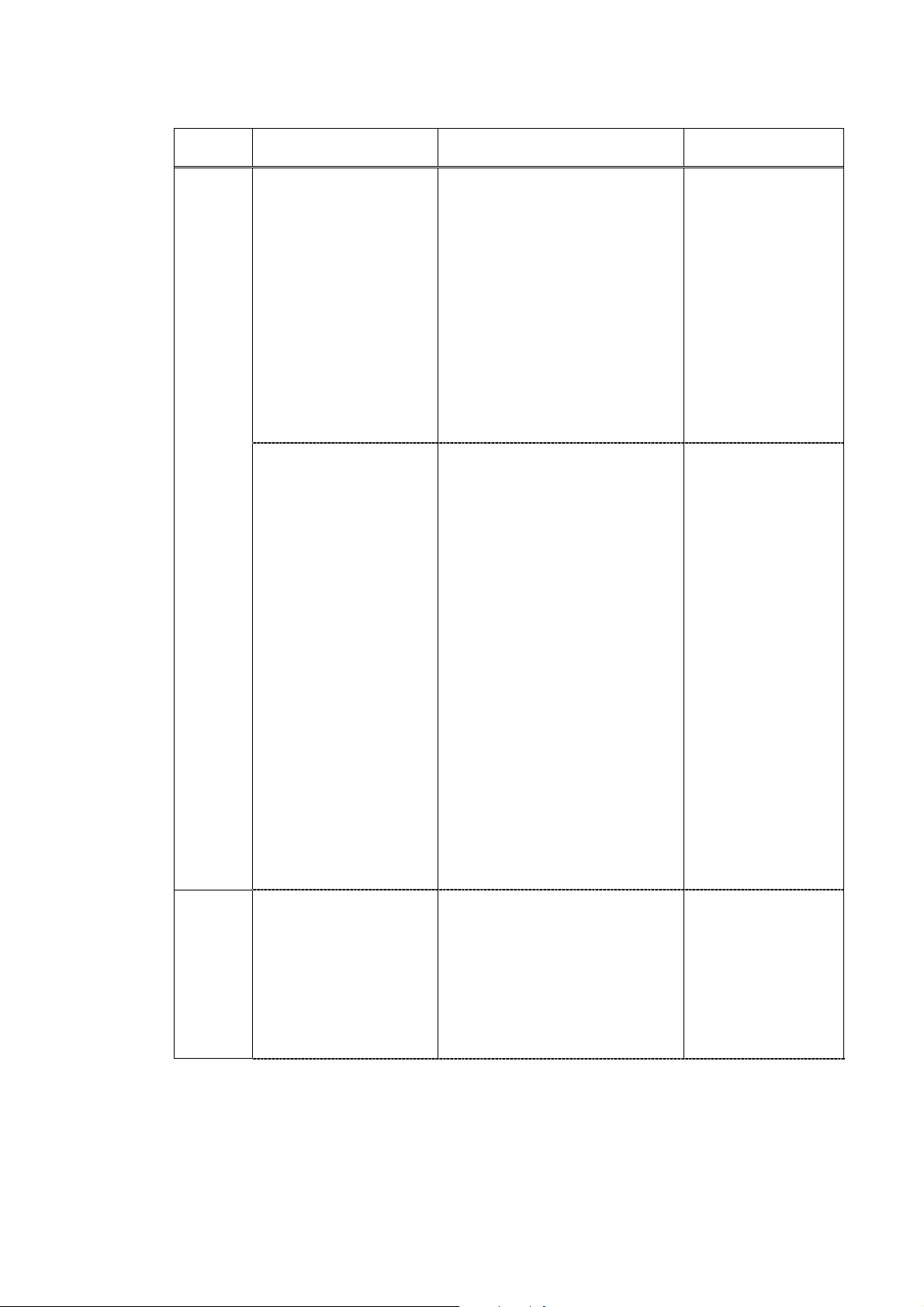

Adjustment Timing Purpose Tool

ALL CLEAR

(EEPROM

initialization)

*1

TYPE settings

(EEPROM

settings)

*1

Waste ink

counter resetting

(EEPROM

settings)

Waste ink

counter setting

(EEPROM

initialization)

CD-R sensor /

automatic print

head alignment

sensor correction

(EEPROM

settings)

(230V only)

At SPCNT BOARD ASS’Y

replacement

-At SPCNT BOARD ASS’Y

replacement

-At excecuting All clear

At bottom case unit

replacement

At ink absorber INK

ABSORBER

(HY7-2885/2886/2887/28

88/2889/2890/2891/2953)

At SPCNT BOARD ASS’Y

replacement

At SPCNT BOARD ASS’Y

replacement

At carriage unit

replacement

To initialize settings other

than the following

-1-touch speed dialing

(MP780 only)

-Service/User soft SW

(MP780 only)

-Tx/Rx infomation

(MP780 only)

-Various counters

-TYPE Setting

-To set the type

-To set the destination

To reset the waste ink

counter.

Waste ink counter setting None

To correct the CD-R and

automatic print head

alignment sensor.

None

To initialize

the settings,

select #8

CLEAR–ALL

in the service

mode

None

Select #5

TYPE in the

service mode

Power SW

OFF/ON*1

None

Select #7

PRINTER in

the service

mode, and

input “0” at #5

INK ABS

CAPA.

Print out the

EEPROM

information,

and select #7

PRINTER in

the service

mode.

Then, register

at #5 INK ABS

CAPA.

None.

(Correction

performed

through

FACTORY

MODE-[2]PRI

NTER-SHUK

KEN at the

same time as

printing.)

Approx

time

1 min

1 min

1min

1 imn

1 min

1 - 1

Page 9

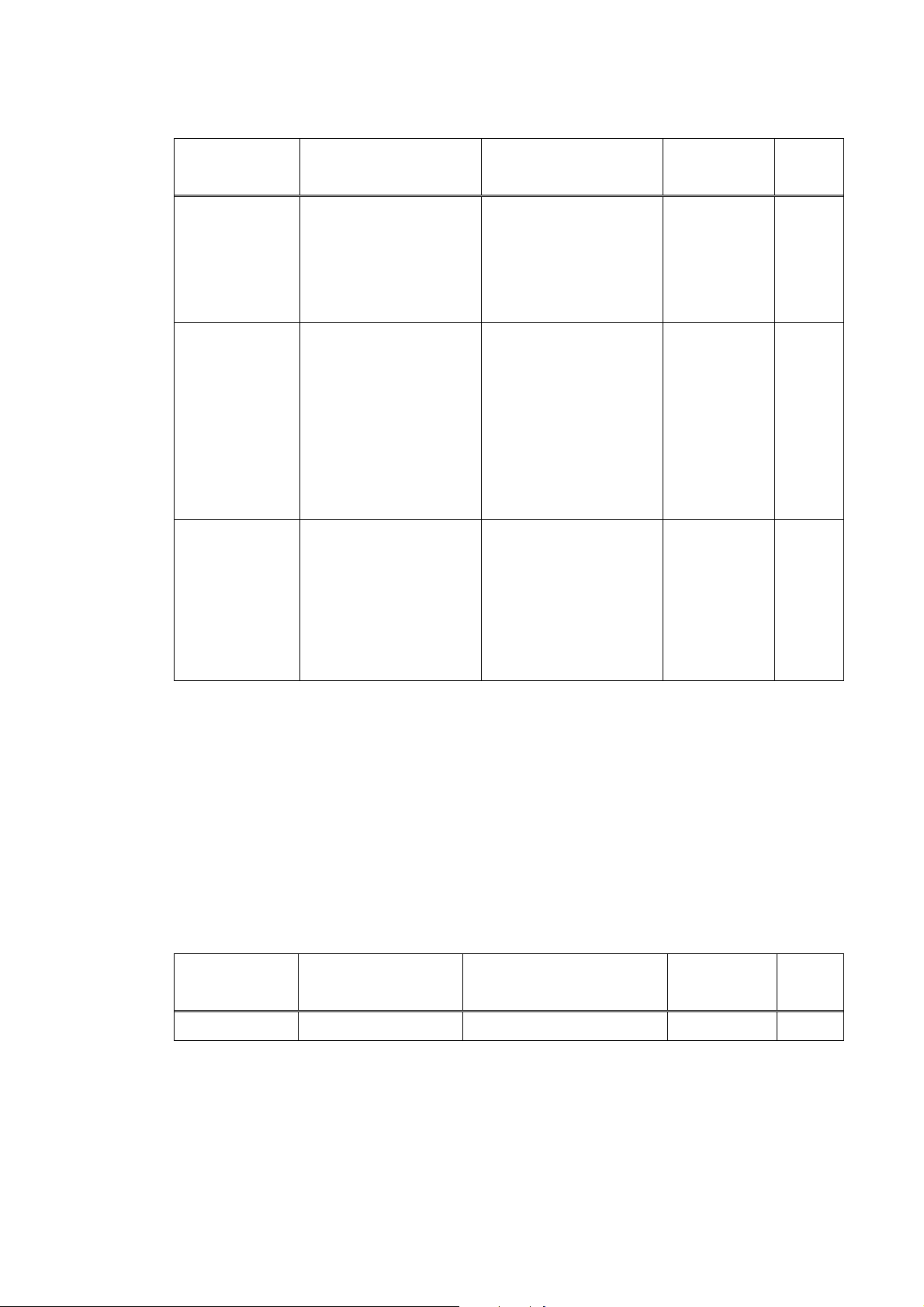

Adjustment Timing Purpose Tool

Print head

alignment

Paper feed motor

position

adjustment*

*2

Grease

application

Note: DO NOT loosen the red screws on both sides of the main chassis, securing the carriage shaft

positioning.

*1: When SPCNT BOARD ASS’Y is replaced, be sure to select the settings of [#8CLEAR]-[ALL]

and [#5TYPE] in Service Mode, and turn the power OFF/ON with the Power button (Software

Power: OFF/ON). DO NOT turn the power OFF/ON by removing and inserting the power code

(Hardware Power: OFF/ON). In this case, data may not be written correctly.

*2: Red screws of paper feed motor

The red screws securing the paper feed motor may be loosened only at replacement of the paper

feed motor unit.

- At print head

replacement

- At SPCNT BOARD ASS’Y

replacement

-At paper feed motor unit

replacement

-At carriage unit

replacement

-At chassis' upper gear

replacement

-At LIFT CAM SHAFT

replacement

To ensure accurate dot

placement.

To adjust the belt tension.

(Position the paper

feed motor so that the belt

is stretched tight.)

-To maintain sliding

properties of the carriage,

carriage shaft, and shaft

lift.

-To protect the chassis'

upper gear.

-To LIFT CAM SHAFT

replacement

None.(Main

body

buttons)

Computer

(settings via

the printer

driver)

None

For the

adjustment,

refer to [3-3

Adjustment/Se

ttings

(1) PAPER

FEED

MOTOR

Installation

Adjustment.

-FLOIL

KG-107A

-MOLYKOTE

HP300

Approx

time

2 min

2 min

1 min

(2) Periodic maintenance

Adjustment Timing Purpose Tool Approx.

time

None

1 - 2

Page 10

(3) Periodic replacement parts

Adjustment Timing Purpose Tool Approx.

None

(4) Replacement consumables

Adjustment Timing Purpose Tool Approx.

None

1-2 Customer Maintenance

time

time

Adjustment Timing Purpose Tool

Print head

alignment

Print head cleaning When print quality is

Print head deep

cleaning

Ink tank

replacement

Paper feed roller

cleaning

CD-R print position

adjustment

(230V only)

Bottom plate

cleaning

At print head

replacement.

not satisfying.

When print quality is

not satisfying, and not

improved by print head

cleaning.

When an ink tank

becomes empty.(No ink

error)

When paper does not

feed properly.

At CD-R printing, when

necessary

When the back side of

the paper is smeared

To ensure accurate dot

placement.

To improve nozzle

conditions.

To improve nozzle

conditions.

- -

To clean the paper feed

rollers.

To correct CD-R print

position.

To clean the platen ribs. None

None

Main body

buttons

Computer

(automatic

settings

via the printer

driver)

None

Main body

buttons

Computer

(settings via the

printer driver)

None

Computer

(setting via the

printer driver)

.

None

Main body

buttons

None

Computer

(application

software)

Computer

(application

software)

Approx.

time

3min

1 min

2min

2min

2min

2min

1min

1 - 3

Page 11

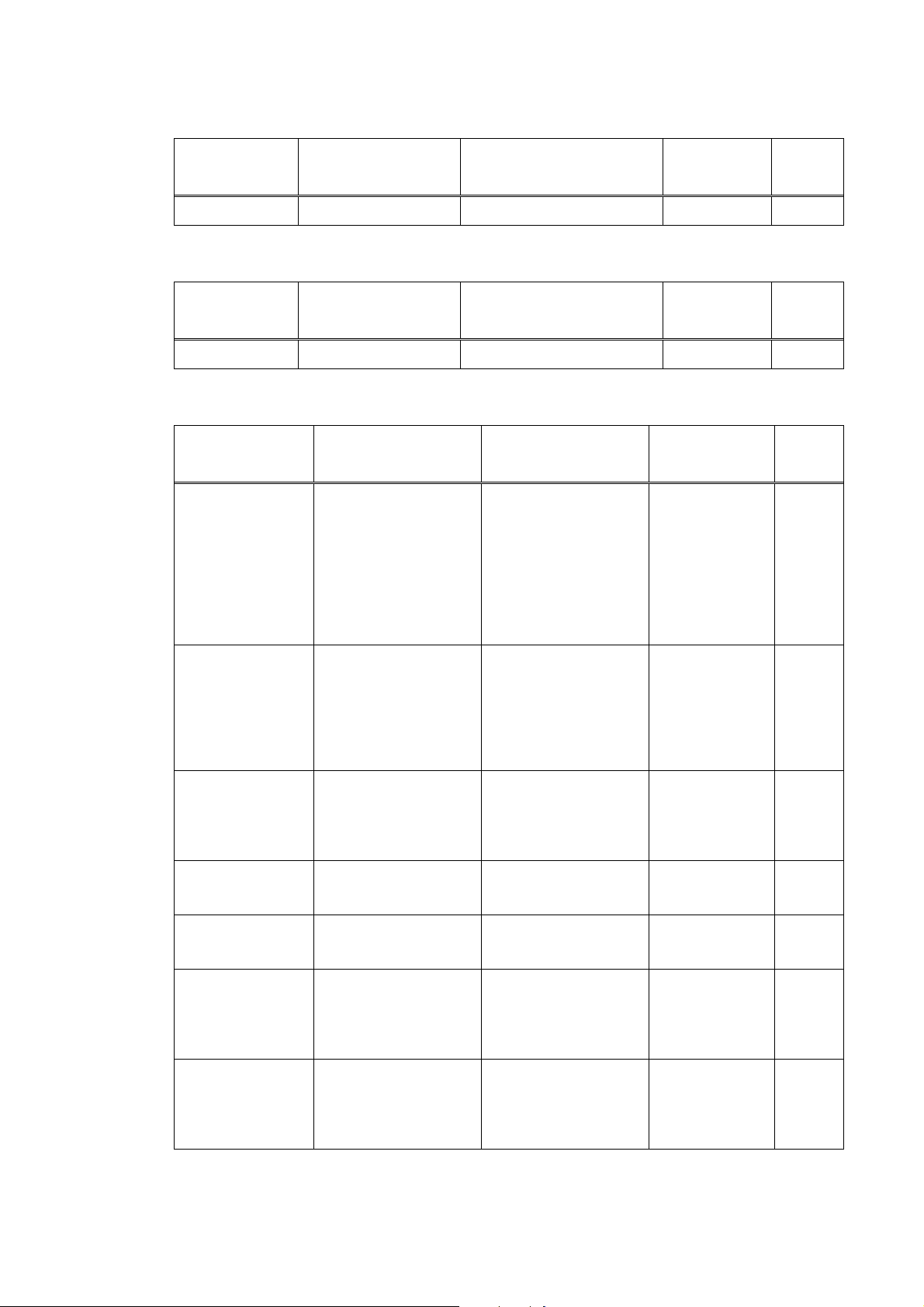

1-3 Product Life

h

(1) Main body

Specified print volume (a), (b), or the years of use (c), whichever comes first.

(a) Scanning Section: 15,000 pages

(b) Printing Section: 18,000 pages

Copy Print FAX

Bk

1,500 character pattern + Post card

Address printing

1,500 character pattern - - 360 pages

Color

(c) Years of use

(2) Ink tank

BCI-3eBK: 900 pages (JEIDA ST D pat t e rnJ1 , pl ain paper standerd mode)

A4, 7.5% duty per color pattern 2,520 pages 2,880 pages A4, photo, borderless printing 180 pages 360 pages L, photo, borderless printing 1,080 pages 1,980 pages Postcard, photo, borderless printing 360 pages 1,260 pages -

5 years of use

3,240 pages

(MP780)

3,420 pages

(MP750)

3,780 pages

(MP780)

3,960 pages

(MP750)

-

(MP780)

740 pages (Black 1,500 character pattern, plain paper / standard mode)

1,300 pages (ISO JIS-SCID No. 5 / plain paper / standard mode)

BCI-6C: 550 pages (ISO JIS-SCID No. 5 / plain paper / standard mode)

BCI-6M: 430 pages (ISO JIS-SCID No. 5 / plain paper / standard mode)

BCI-6Y: 360 pages (ISO JIS-SCID No. 5 / plain paper / standard mode)

BCI-6BK: 2,000 pages (ISO JIS-SCID No. 5 / plain paper / standard mode)

1-4 Special Tools

Name Tool No. Application Remarks

MOLYKOTE

HP300

FLOIL KG-107A QY9-0057-000 To be applied to the sliding portion of the

CK-8012-000 To be applied to the chassis' upper gear,

and to the sliding portion of the shaft lift.

carriage and the bearing portion of the

carriage shaft.

New

In common wit

other models.

1 - 4

Page 12

1-5 Serial Number Label Location

On the right side of the backside in the bottom case (close to the rating plate)

Figure1-1 Serial Number Label Location

1 - 5

Page 13

2. LIST OF ERROR DISPLAY / INDICATION

User error messages

Look for the applicable error message and execute the appropriate countermeasures.

Error Codes

As for the causes and countermeasures, only the error codes that are newly incorporated in the unit remedies

unique to the product are included in New Error Codes and Recovery Methods. For the causes and

countermeasures of other error codes, refer to the separate G3/G4 Facsimile Error Code List (Rev. 2).

Service error code output

When service data #1 SSSW SW01 Bit0 is set to “1”, the following service error codes are displayed when

an error occurs.

2-1 User’s error messege

"CARTRIDGE JAMMED"

Printing position correction failed

Cause: Carriage movement prevented by one of the following.

Damaged shaft.

Parts deformed. (Carriage or guide frame)

Insufficient grease.

Solution: Replace the shaft.

Replace the deformed parts.

Apply more grease.

Cause: Bi-directional print displacement correction failed because the carriage motor is

out of step, or some similar reason.

Solution: Replace the carriage motor.

Home position error

Cause1: Tried to stop the carriage unit that has been moving or to move the carriage unit at a pouse by

force.

Solution1: Do not touch the carriage unit other than cartridge replacement position.

Cause2: Foreign body in carriage section.

Solution2: Open flatbed ass’y and remove the foreign body .

Cause3: Loose carriage belt.

Solution3: Replace carriage unit

Cause4: Carriage motor does not work.

Solution4 (1) Switch power OFF/ON.

(2) Replace carriage motor.

Cause5: The position of the carriage cannot be detected (due to smears on the carriage

encoder film or SPCNT board failure).

Solution5: (1) Switch power off/on.

(2) Wipe the carriage encoder film with a cloth soaked with alcohol.

(3) Replace the carriage encoder film.

(4) Replace the SPCNT board.

1 - 6

Page 14

Note:

This error message means the same as service error codes ##338 and ##340. When this error occurs in

this model, it is not treated as a service error, but as a user error, and the error message is displayed.

“COVER OPEN”

Cause: You opened the scanning unit (printer cover) during an operation.

Solution: Close the scanning unit (printer cover).

Cause: Damaged scanner open arm ass’y, damaged scanner sensor arm, or SPCNT board ass’y failure.

Solution: Replace the scanner open arm ass’y, replace the scanner sensor arm, or replace the SPCNT board

ass’y.

“CHECK PRINTER (PRESS [OK])” (##334 - ##336, ##343, ##345, ##346, ##352, ##356 - ##362)

Cause: The carriage unit does not move due to a foreign body in the carriage section.

Solution: Open flatbed ass’y and remove the foreign body. If there is a paper jam, clear the paper jam.

Cause: The printer’s internal unit has malfunctioned.

Solution: Reinstall the BJ cartridge.

Turn the power off and on.

Check the service error code and refer to an appropriate solution.

Cause: The waste ink tank (absorber) is nearly full.

Solution: Replace the waste ink tank (absorber).

Note:

When replacing the waste ink absorber, you need to reset the waste ink volume counter. [Refer to 3-3

Adjustment/Settings (6) Service mode.]

“MEMORY FULL”

Cause: The machine’s memory is full because you tried to copy a very detailed document.

Solution: Divide the document and copy each part separately.

Cause: The machine’s memory is full because it has received too many documents in the memory

receiving mode. (MP780 only)

Solution: Print out any documents, which are stored in memory. Then start the operation again. If the

memory contains any documents yo u d o not need , del et e th em.

“MEMORY CLEARED (PRESS [OK])”

Cause: After receiving data in the memory receiving mode, the power is off due to a service interruption,

etc., and then the image data received in the memory receiving mode is cleared.

Solution: Press [OK] to go back to the standby status.

1 - 7

Page 15

Memo:

Until you press [OK] button, the machine displays this message continuously and you cannot perform any

operations. The memory clear list of the cleared image data is not displayed in this machine. For the

other party information, confirm in the communication management report.

1 - 8

Page 16

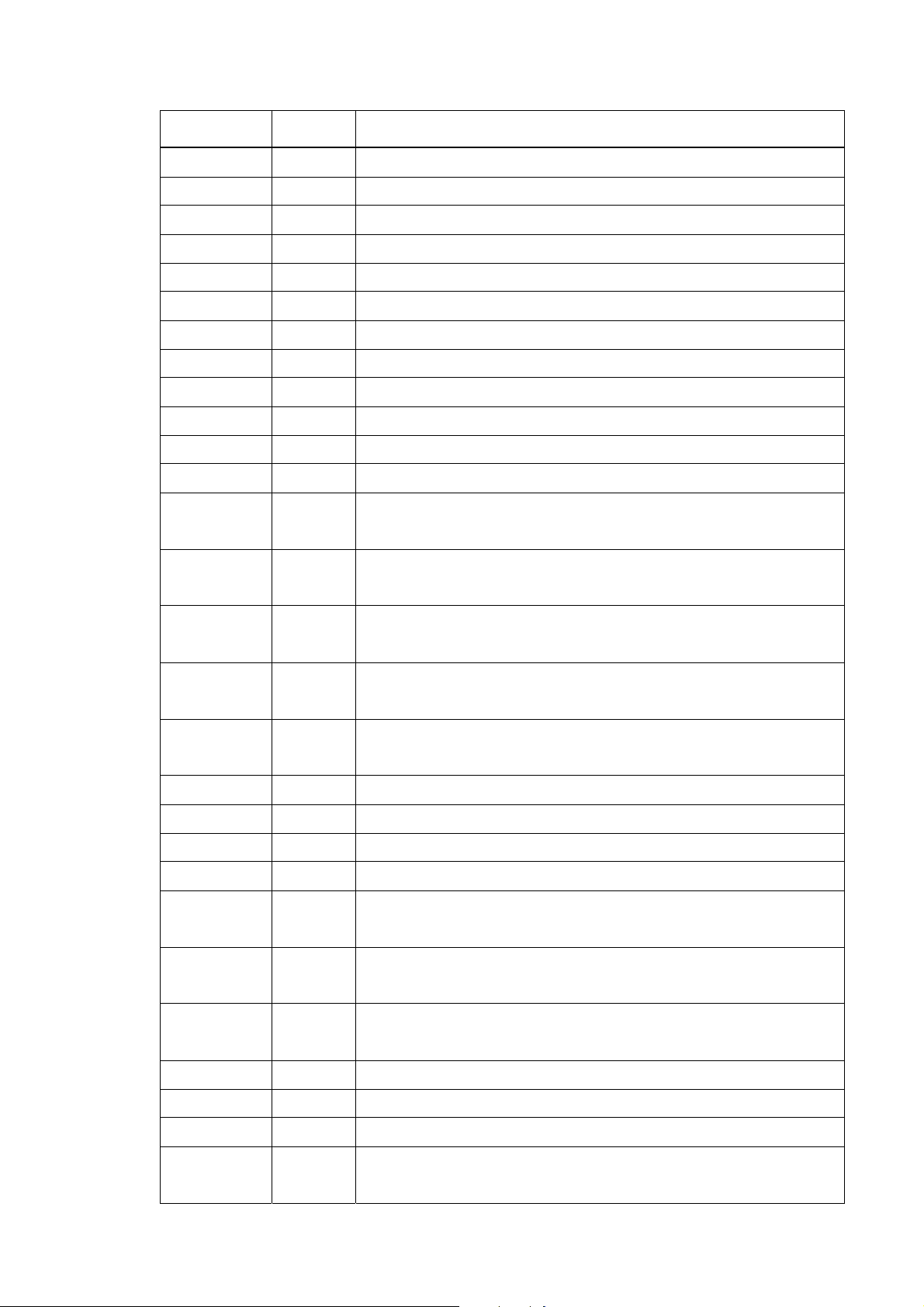

2-2 User error code

The error codes that have newly been added starting with the product are identified

by the notation “new” those error codes for which remedies unique to the product are

offered are identified by the notation “UNQ (UNIQUE).”

No. Tx or Rx Definition Remarks

#001 TX

#003 TX/RX

#005 TX/RX

#009 RX

Document has jammed

Document is too long, or page time-over

Initial identification (T0/T1) time-over

Recording paper has jammed or the recording

paper has run out

#011 RX

#012 TX

#018 TX/RX

#021 RX

Polling reception error

The other party has run out of recording paper

Auto dialing transmission error

The other party has rejected the machine

during polling reception

#022 TX

#037 RX

Call fails

Memory has overflowed when receiving

images

#085 TX

Other party does not support ITU-T Color

Faxing

#995 TX/RX

Memory Communication reservation

2-3 Service Call Errors

No. Tx or Rx Definition

##100 TX

##101 TX/RX

##102 TX

##103 RX

##104 TX

##106 RX

##107 RX

##109 TX

cancellation

The number allowed for retransmission of the procedure signal

was exceeded during transmission

The modem speed of the machine does not match that of the

other party

Fallback is not possible

EOL cannot be detected for 5 sec (15 sec if CBT)

RTN or PIN has been received

The procedure signal cannot be received for 6 sec while in wait

The transmitting machine cannot be use fallback

After transmitting DCS, a signal other than DIS, DTC, FTT,

CFR, and CRP was received, exceeding the permitted number

of transmissions of the procedure signal

1 - 9

Page 17

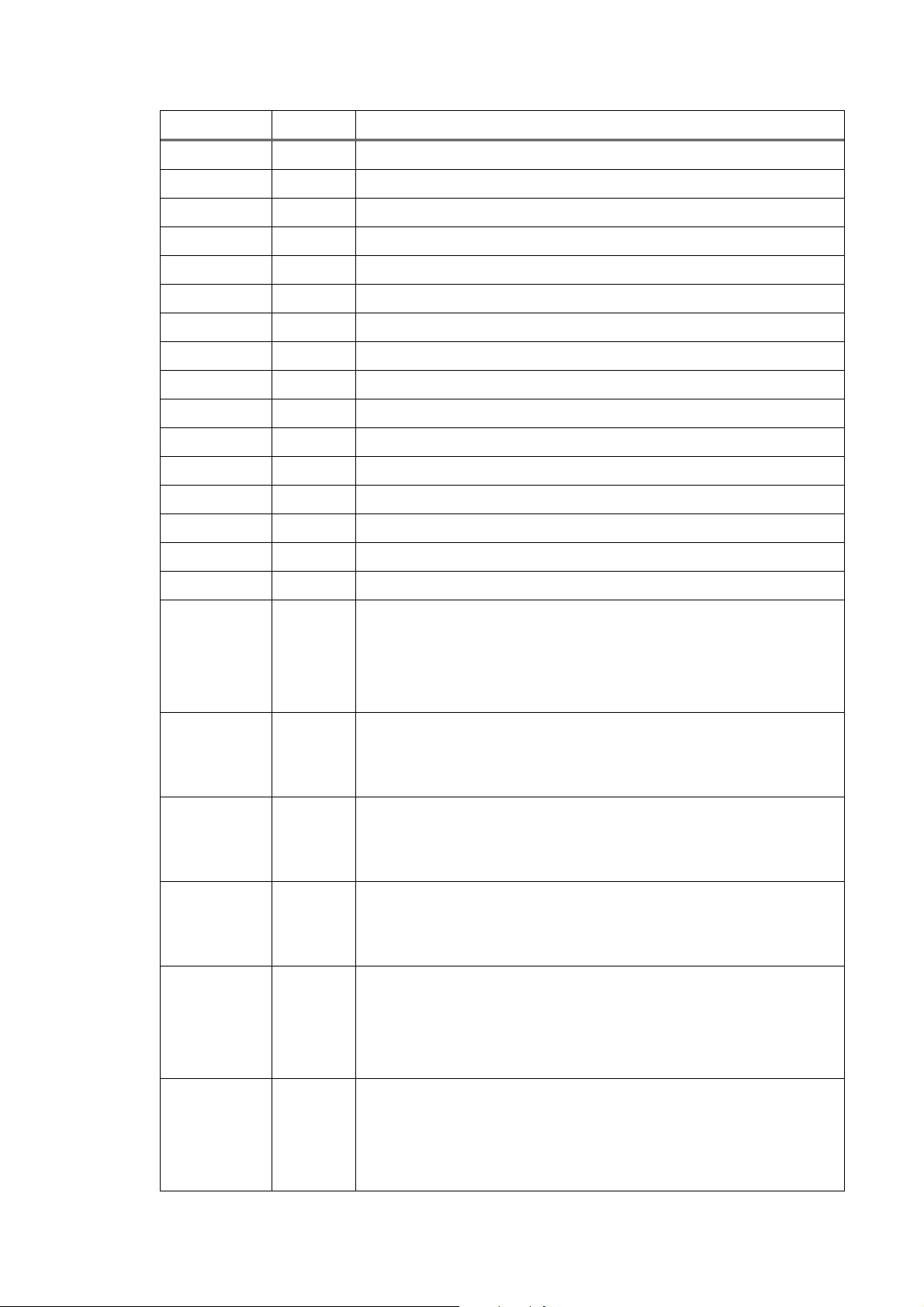

No. Tx or Rx Definition

##111 TX/RX

##114 RX

##200 RX

##201 TX/RX

##204 TX

##220 TX/RX

##224 TX/RX

##226 TX/RX

##229 RX

##232 TX

##237 RX

##238 RX

##261 TX/RX

Memory error

RTN was transmitted

During image reception, a carrier is not detected for 5 sec

DCN was received through a non-normal procedure

Receive DTC without Tx data

System error (e.g., main program may have gone away)

Fault occurred in the communication procedure signal

Stack Pointer Not within RAM Range

The recording system became locked for 1 min

The IC used to control the encoder malfunctioned

The IC used to control the decoder malfunctioned

The unit used to control recording malfunctioned

System error occurred between the modem and system control

board

##280 TX

The number of re-transmissions of the procedure signal has

been exceeded

##281 TX

The number of re-transmissions of the procedure signal has

been exceeded

##282 TX

The number of re-transmissions of the procedure signal has

been exceeded

##283 TX

The number of re-transmissions of the procedure signal has

been exceeded

##284 TX

##285 TX

##286 TX

##287 TX

##288 TX

DCN has been received after transmission of TCF

DCN has been received after transmitting EOP

DCN has been received after transmitting EOM

DCN has been received after transmitting MPS

After transmitting EOP, a signal other than PIN, PIP, MCF,

RTP, or RTN was received

##289 TX

After transmitting EOM, a signal other than PIN,PIP,MCF,

RTP, or RTN was received

##290 TX

After transmitting MPS, a signal other than PIN,PIP,MCF,

RTP, or RTN was received

##332 TX/RX

##333 TX/RX

##334 TX/RX

##335 TX/RX

Printer control DRAM check error

Printer control ROM check error

Printer control EEPROM check error

Data transmission error between the system control section and

printer control section

1 - 10

Page 18

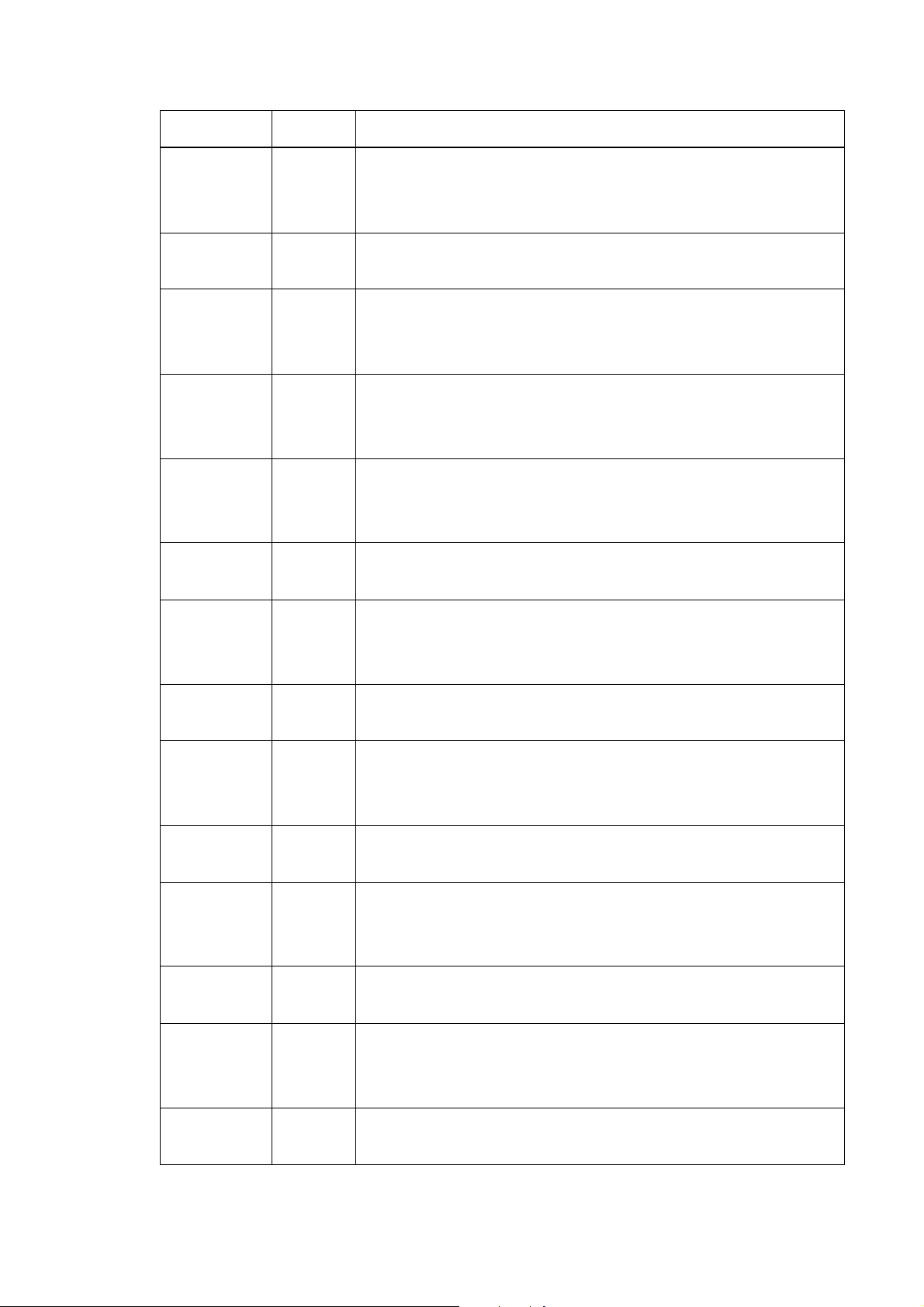

No. Tx or Rx Definition

##336 TX/RX

##337 RX

UNQ ##341 TX/RX

UNQ ##342 TX/RX

UNQ ##343 TX/RX

##345 TX/RX

##346 TX/RX

NEW ##352 RX

NEW ##355 RX A motor to lift up for CD-R print is malfunctioned

NEW ##356 TX/RX ASF cam sensor error

NEW ##357 TX/RX ASF paper feed (AP) position error

NEW ##358 TX/RX USB Host VBUS overcurrent error

NEW ##359 TX/RX Paper feed position error

NEW ##360 TX/RX Paper feed cam sensor error

NEW ##361 TX/RX Valve sensor error

NEW ##362 TX/RX Motor driver malfunctioned error

BJ head abnormal temperature error

BJ head temperature sensor error

Maintenance Jet Waste Ink Tank Full

Cleaning absorption waste ink capacity full

Ink Detection Waste Ink Tank Full

BJ cartridge head cleaning error

Inside temperature error

Printer control EEPROM head information error

##670 TX

In V.8 late start, the V.8 ability was detected in DIS from the

other party and, in response, CI was transmitted; however, the

procedure failed to advance, causing a T1 time-over condition

##671 RX

In V.8 call arrives, the procedure fails to advance to phase 2

after CM detection, causing a T1 time-over condition

##672 TX

In V.34 transmission, the procedure fails to move from phase 2

to phase 3 and later, causing a T1 time-over condition

##673 RX

In V.34 reception, the procedure fails to move from phase 2 to

phase 3 and later, causing a T1 time-over condition

##674 TX

In V.34 transmission, the procedure fails to move from phase 3

or phase 4 to a control channel or later, causing a T1 time-over

condition

##675 RX

In V.34 reception, the procedure fails to move from phase 3 or

phase 4 to a control channel or later, causing a T1 time-over

condition

1 - 11

Page 19

No. Tx/Rx Definition

##750 TX

In ECM transmission, no significant signal can be received

after transmission of PPS-NULL, and the allowed number of

procedure signal re-transmissions was exceeded

##752 TX

In ECM transmission, DCN was received after transmission of

PPS-NULL

##753 TX

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T5 time-over (60 sec)

condition occurred after transmission of PPS-NULL

##754 TX

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded after transmission of

PPS-NULL

##755 TX

In ECM transmission, no significant signal can be received

after transmission of PPS-MPS, and the allowed number of

procedure signal re-transmissions was exceeded

##757 TX

In ECM transmission, DCN was received after transmission of

PPS-MPS

##758 TX

##759 TX

##760 TX

##762 TX

##763 TX

##764 TX

##765 TX

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T5 time-over (60 sec)

condition occurred after transmission of PPS-MPS

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded after transmission of PPS-MPS

In ECM transmission, no significant signal can be received

after transmission of PPS-EOM, and the allowed number of

procedure signal re-transmissions was exceeded

In ECM transmission, DCN was received after transmission of

PPS-EOM

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T1 time-over (60 sec)

condition occurred after transmission of PPS-EOM

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded after transmission of PPS-EOM

In ECM transmission, no significant signal can be received

##767 TX

after transmission of PPS-EOM, and the allowed number of

procedure signal re-transmissions was exceeded

In ECM transmission, DCN was received after transmission of

PPS-EOM

1 - 12

Page 20

No. Tx or Rx Definition

##768 TX

##769 TX

##770 TX

##772 TX

##773 TX

##774 TX

##775 TX

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T5 time-over (60 sec)

condition occurred after transmission of PPS-EOM

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded after transmission of PPS-EOM

In ECM transmission, no significant signal can be received

after transmission of EOR-NULL, and the allowed number of

procedure signal re-transmissions was exceeded

In ECM transmission, DCN was received after transmission of

EOR-NULL

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T5 time-over (60 sec)

condition occurred after transmission of EOR-NULL

In ECM transmission, ERR was received after transmission of

EOR-NULL

In ECM transmission, no significant signal can be received

##777 TX

##778 TX

##779 TX

##780 TX

##782 TX

##783 TX

after transmission of EOR-MPS, and the allowed number of

procedure signal re-transmissions was exceeded

In ECM transmission, DCN was received after transmission of

EOR-MPS

In ECM transmission, the allowed number of procedure signal

e-transmissions was exceeded or a T5 time-over (60 sec)

ondition occurred after transmission of EOR-MPS

In ECM transmission, ERR was received after transmission of

OR-MPS

In ECM transmission, no significant signal can be received

after transmission of EOR-EOM, and the allowed number of

rocedure signal re-transmissions was exceeded

In ECM transmission, DCN was received after transmission of

OR-EOM

In ECM transmission, the allowed number of procedure signal

re-transmissions was exceeded or a T5 time-over (60 sec)

##784 TX

condition occurred after transmission of EOR-EOM

In ECM transmission, ERR was received after transmission of

OR-EOM

1 - 13

Page 21

No. Tx/Rx Definition

##785 TX

In ECM transmission, no significant signal can be received

after transmission of EOR-EOP, and the allowed number of

procedure signal re-transmissions was exceeded

##787 TX

In ECM transmission, DCN was received after transmission of

OR-EOP

##788 TX

In ECM transmission, the allowed number of procedure signal

retransmissions was exceeded or a T5 time-over (60 sec)

condition occurred after transmission of EOR-EOP

##789 TX

In ECM transmission, ERR was received after transmission of

EOR-EOP

##790 RX

In ECM reception, ERR was transmitted after reception of

EOR-Q

##791 TX/RX

During an ECM mode procedure, a signal other than a

significant signal was received

##792 RX

In ECM reception, PPS-NULL between partial pages cannot be

detected

##793 RX

In ECM reception, no effective frame was detected while

signals were received at high speed, and a time-over condition

occurred

2-4 New Error Codes and Recovery Methods

Those error codes that have been added starting with the product and those error codes for

which remedies unique to the product are offered are shown together with causes and

remedies, where applicable.

##341 Maintenance jet waste ink capacity full

Solution: Replace the waste ink absorber as follows in the error occurs:

(1) Select [7] PRINTER TEST in the service mode and select [5] INK ABS CAPA under the [7], then

input “0”.

(2) Check to make sure that no image exist in memory; then, turn off the power, remove the appropriate

parts, and replace the waste ink absorber.

##342 Cleaning absorption waste ink capacity full

Solution: Replace the waste ink absorber as follows in the error occurs:

(1) Select [7] PRINTER TEST in the service mode and select [5] INK ABS CAPA under the [7], then

input “0”.

1 - 14

Page 22

(2) Check to make sure that no image exist in memory; then, turn off the power, remove the appropriate

parts, and replace the waste ink absorber.

##343 Ink detection waste ink capacity full

Solution: Replace the waste ink absorber as follows in the error occurs:

(1) Select [7] PRINTER TEST in the service mode and select [5] INK ABS CAPA under the [7], then

input “0”.

(2) Check to make sure that no image exist in memory; then, turn off the power, remove the appropriate

parts, and replace the waste ink absorber.

##352 Printer control EEPROM head information error

Cause: The EEPROM for printer control is faulty.

Solution: (1) Turn off and then on the power.

(2) Turn off the power, and replace the print head.

(3) Replace the SPCNT board.

NOTE:

In the presence of ##352, the carriage unit will not move to print head replacement position even when the

inner cover is opened. Moreover the carriage will not be locked in position even when the power is turned

off. When replacing the print head, be sure to turn off the power, and draw out the carriage before

replacement.

##355 Lit-up motor for CD-R print malfunctioned

Cause: In performing a CD-R print, the motor to lift up the carriage shaft is malfunctioned.

Solution: (1) Turn off and then on the power.

(2) Check the connection from the SHEET FEED unit to the SPCNT board ass’y (JPM1).

(3) Replace the SHEET FEED ASS’Y.

(4) Replace the SPCNT board.

##356 ASF cam sensor error

Cause: An error occurs at the ASF cam sensor in the ASF (Auto Sheet Feeder) unit.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2) Replace the SHEET FEED ASS’Y.

##357 ASF paper feed (AP) position error

Cause: An error occurs at the AP positioning in the ASF (Auto Sheet Feeder) unit.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2) Replace the SHEET FEED ASS’Y.

(3) Replace the SPCNT board.

1 - 15

Page 23

##358 USB Host VBUS overcurrent error

Cause: Overcurrent is applied to the VBUS signal of USB.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2) Replace the SPCNT board.

##359 Paper feed position error

Cause: An error occurs at the paper feed positioning.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2) Replace the SHEET FEED ASS’Y.

(3) Replace the SPCNT board.

##360 Paper feed cam sensor error

Cause: An error occurs at the paper feed cam sensor.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2) Replace the SHEET FEED ASS’Y

(3)

Replace the SPCNT board.

##361 Valve sensor error

Cause: An error occurs at the valve sensor in the Purge unit.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

Replace the SPCNT board.

(2)

##362 Motor driver malfunctioned error

Cause: The motor driver is malfunctioned due to heating, etc.

Solution: (1) To reboot, press [OK] button or turn off and then on the power.

(2)

Replace the SPCNT board.

2-5 Wa rnings

Main body (no LCD indications)

Displayed warning Remarks

None None

1 - 16

Page 24

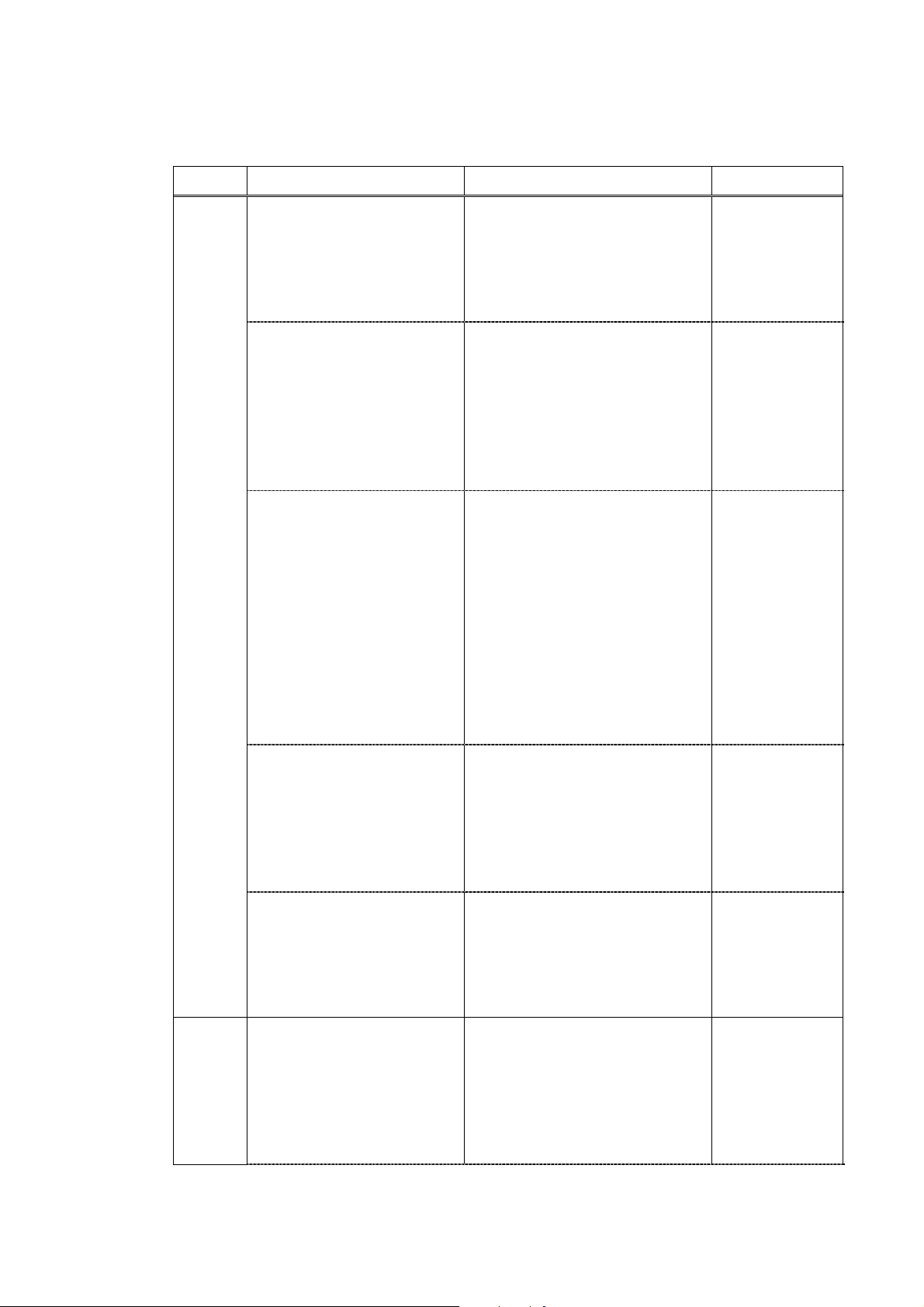

2-6 Troubleshooting by symptom

Symptom Solution Remarks

General

errors

The unit does not power on.

Nothing is displayed.

(1) Check the power cord

connection.

(2) Check the connection between

the SPCNT board (JPSU1) and

power supply unit.

(3) Replace the power supply unit.

(1) Check the connection

between the Operation panel

unit and SPCNT board

(JPANEL1).

(2) Replace the SCANNER

unit.

(3) Replace the SPCNT board.

Part of the LCD panel does

not display anything.

(1) If the test mode can be

used, check for faulty dot in

LCD display.

(2) Check the connection

between the Operation panel

unit and SPCNT board

(JPNL1).

(3) Replace the SCANNER

UNIT.

(4) Replace the SPCNT board

ass’y

.

The keys do not work.

(1) Check the connection

between the SCANNER UNIT

and SPCNT board (JPNL1).

(2) Replace the SCANNER

UNIT.

(3) Replace the SPCNT board.

No sound from the speaker

(MP780 only)

(1) Check the connection of

the speaker and SPCNT board

(JSPK1).

(2) Replace the speaker.

Printing

problems

The paper is not feed

properly.

(The Paper feed motor does

not run.)

(3) Replace the SPCNT board.

(1) Check the connection from

the sheet feed unit to the

SPCNT board assy (JPM1).

(2) Replace the sheet feed unit.

(3) Replace the SPCNT board

ass’y.

1 - 17

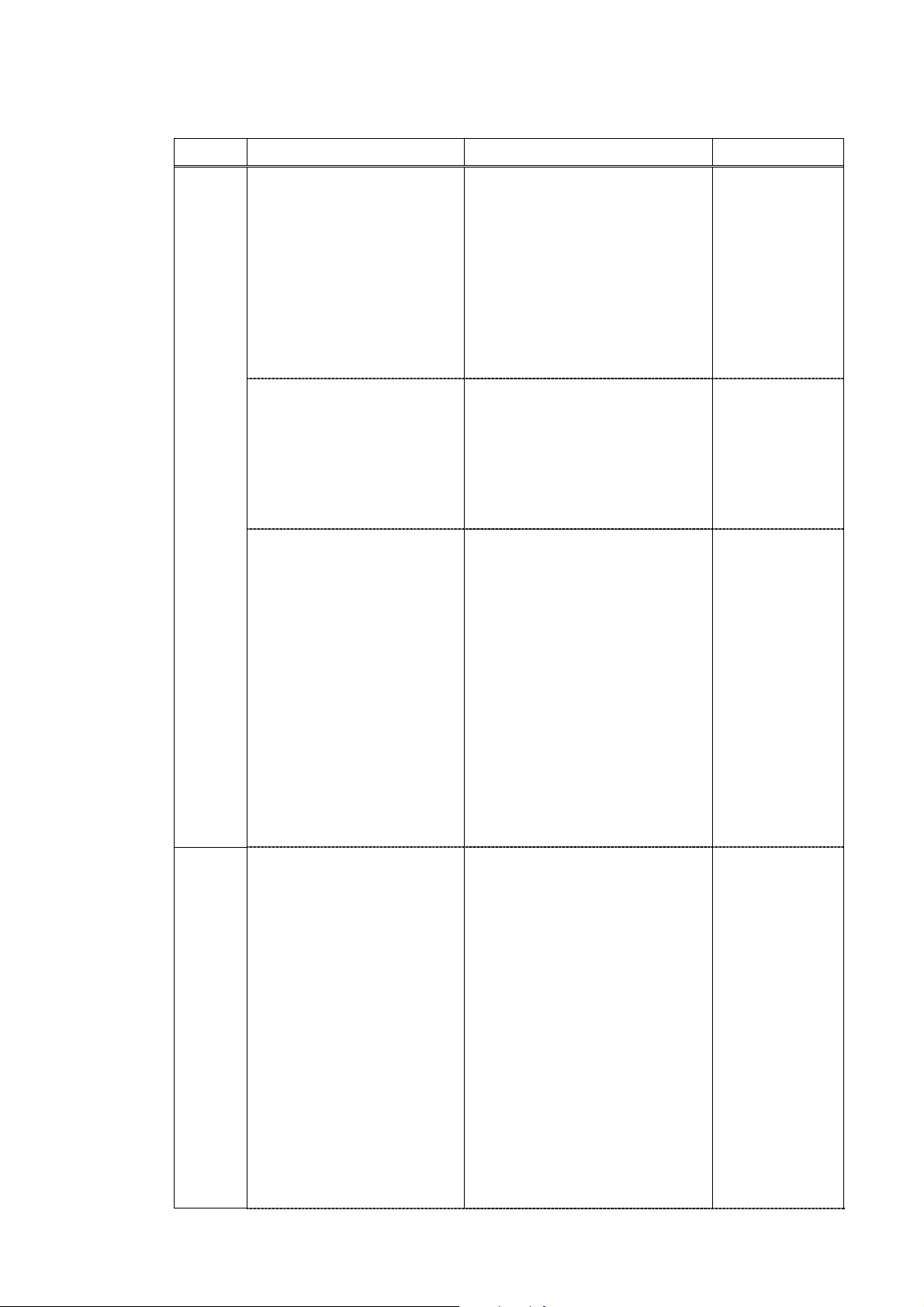

Page 25

Printing

problems

The paper is not picked up

from the auto sheet feeder.

Symptom Solution Remarks

(1) Check the foreign matter in

the paper feed section.

(2) Check the connection

SHEET FEED UNIT to the

SPCNT board ass’y (JPM1).

(3) Replace the SHEET FEED

UNIT.

(4) Replace SPCNT board

ass’y.

The carriage motor does not

run.

(1) Check the connection from

the SHEET FEED unit to the

SPCNT board ass’y (JPM1).

(2) Replace the SHEET FEED

unit.

(3) Replace the SPCNT board

ass’y.

Carriage error

(The carriage comes into

contact with the push-on

plates at the left and right

sides, resulting in noise.)

(1) Check if grease adheres to

the carriage encoder film.

(2) Using lint-free paper

impregnated with alcohol,

wipe the carriage encoder film

with care so as not to scratch

the film.

(3) If a lot of grease adheres to

the carriage, replace the

carriage board because grease

might be spread to the sensor

on the carriage board.

(4) Replace the carriage

encoder film.

Printing

Quality

error

• The printer does not at all.

• Printing stops midway.

• Certain colors are not

printed.

(1) Remove the print head and

re-install it.

(2) Carry out nozzle cleaning

on the print head five times

with the cleaning operation,

than visually cheek the test

print for non-discharge of ink

from nozzle. (Fig. 1-2)

(3) Remove and reinstall the

print head.

(4) Replace the appropriate ink

tank.

(5) Replace the print head.

(6) Replace the SPCNT board

ass’y.

(7) Replace the purge unit.

1 - 18

Page 26

Symptom Solution Remarks

Printing

Quality

error

Blotches appear

Blank ink appear

(1) Remove and reinstall the

print head.

(2) Carry out nozzle cleaning

on the print head five times

with the cleaning operation,

than visually cheek the test

print for non-discharge of ink

from nozzle. (Fig. 1-1)

(3) Perform print head

refreshing, and print out

Nozzle check pattern.

Visually check the test print

for non-discharge of ink from

nozzle. (Fig. 1-1)

(4) Replace the appropriate ink

tank.

(5) Replace the print head.

(6) Check the connection of

the carriage ribbon cable and

the SPCNT board.

(JHD1, JHD2)

(7) Replace the carriage unit.

(8) Replace the SPCNT board.

(9) Replace the purge unit.

Scanning

problems

The document is not fed.

(The document feed motor

does not run.)

1) Check the connection from

the document feed motor to

the ADF board ass’y..

(2) Check the connection from

the ADF board ass’y and

SPCNT board ass’y (JADF1).

(3) Replace the document feed

motor.

(4) Replace the ADF board

ass’y.

(5) Replace the SPCNT board.

The document slips against

the rollers. (Evaluation

criteria: Check it visually.

Stretched copy image.)

(1) Cleaning the ADF

section’s parts. See this

Chapter 4. Cleaning Your

Machine

(2) Replace the ADF section's

rollers.

1 - 19

Page 27

Symptom Solution Remarks

Scanning

problems

The

Scanning

Image

Is

Abnormal

The document does not

separate.

Faulty scanner unit's

sensors (The placed

document or

transported document is

not detected.)

Nothing is printed.

1) Check whether the

document feed motor is

driving all the rollers. (Check

for any damaged gears or

foreign matter stuck inside.)

(2) ) Cleaning the Separate

Rollor and RubberSheet. See

Chapter 4. Cleaning your

Machine.

(3) Replace the separation

roller ass’y and Upper guide

ass’y.

1) Check for any faulty

sensors while executing the

copying operation and test

mode.

(2) Check the connection from

Document sensor and

Document edge sensor to the

ADF board.

(3) Check the connection from

the ADF board to the sensor

board sub PCB (JADF1).

(4) Check the connection from

the sensor board (JADF1) and

SPCNT board.

(5) Replace the Document

sensor.

(6) Replace the ADF board

ass’y.

(7) Replace the SPCNT board

ass’y.

(1) Check the connection

between the contact sensor

and SPCNT board (JCCD1).

(2) Replace the SCANNER

unit.

(3) Replace the SPCNT board

ass’y.

1 - 20

Page 28

Symptom Solution Remarks

The

Scanning

Image

Is

Abnormal

Faulty

CD-R

(MP780

only)

Other

The image has vertical

stripes.

The halftone image

contains black dots.

The CD-R Tray is not

recognized.

(As-received failure)

The display appers in

English.

(1) Clean the Document glass.

(2) Check the connection

between the contact sensor

and SPCNT board (JCCD1).

(3) Replace the SCANNER

unit.

(4) Replace the SPCNT board

ass’y.

(1) Clean the Document glass.

(2) Check whether the

document is not skewed.

(3) Check the connection

between the SCANNER unit

and SPCNT board (JCCD1).

(4) Replace the SCANNER

unit.

(5) Replace the SPCNT board

ass’y.

(1) Remove the CD-R Tray,

and place the CD-R Tray

again.

(2) Check the connection

between the CARRIAGE

UNIT and SPCNT board

ASS’Y (JHD1, JHD2).

(3) Replace the CARRIAGE

UNIT.

(4) Replace the SPCNT

BOARD ASS’Y.

Select the settings of

[#8CLEAR]-[ALL] and

[#5TYPE] (Type setting) in

Service Mode, and turn the

power OFF/ON with the

power button (Software

Power: OFF/ON).

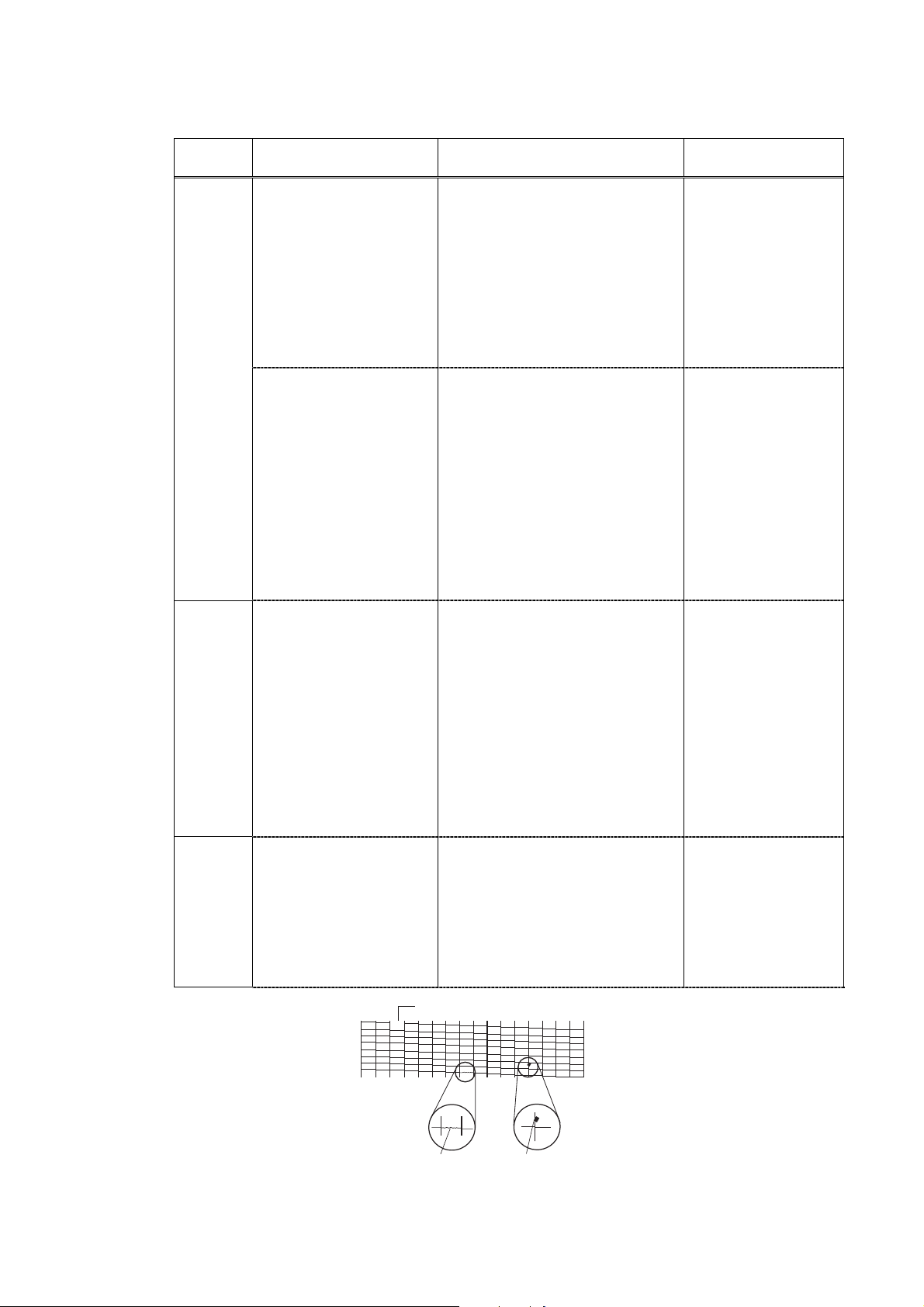

Missing dots

Unstable printing Splashed dots

Figure1-2 Defective Pattern (Sample)

1 - 21

Page 29

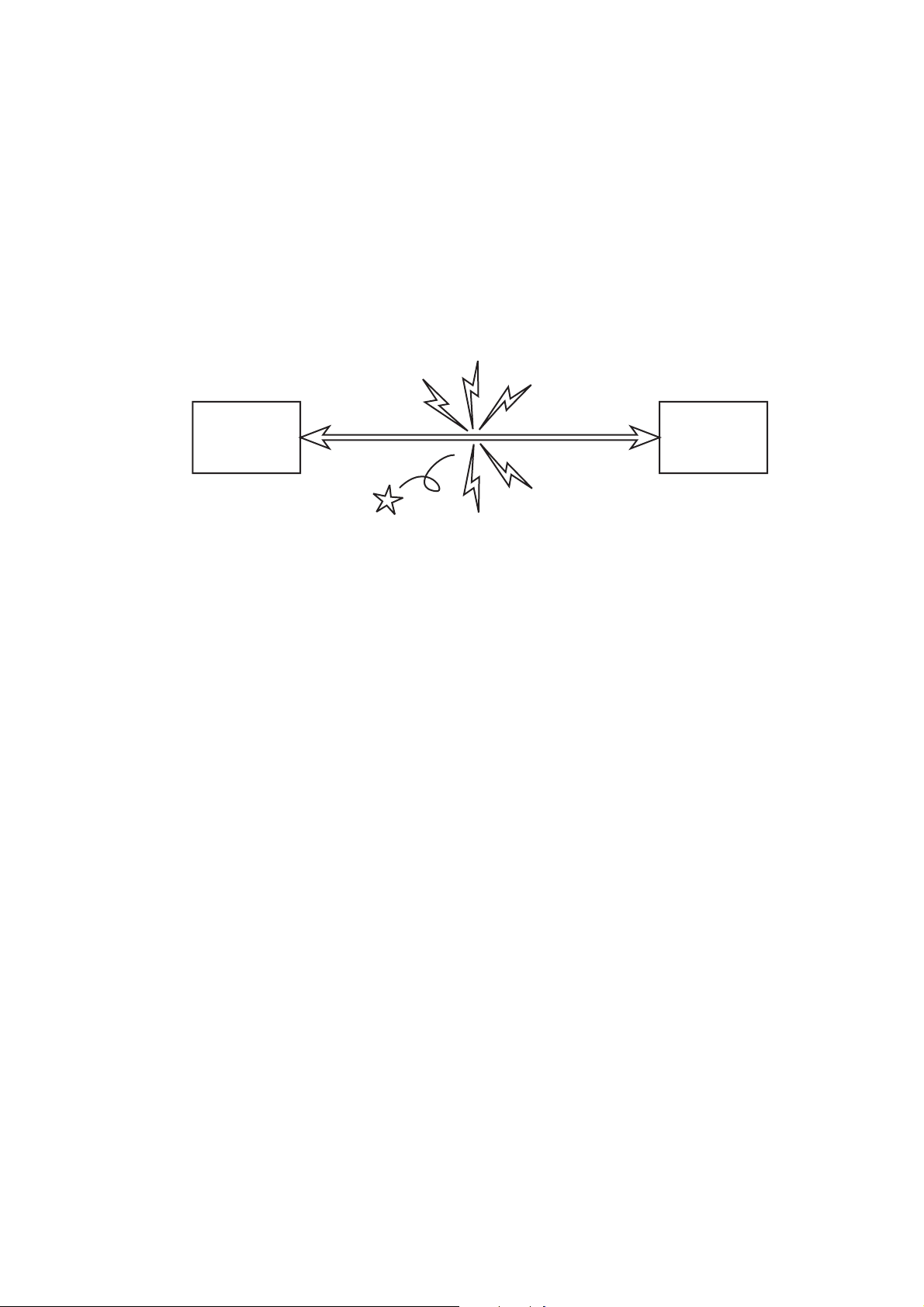

2-7 Processing Communication Problems (MP780 only)

2-7-1 Initial identification of problems

Since the facsimile must transmit picture information, a transmitter, a receiver and telephone lines

are required for this purpose. Transmissions may cause problems if one or more of the there is

poor.

Communication

trouble

FAX FAX

Your

customer's

machine

Figure1-3 Communication Trouble

Communication

companion

machine

1 - 22

Page 30

To process communication problems, first of all, it is necessary to narrow down the cause of the problem. Thus,

the procedures appearing below must be checked accordingly.

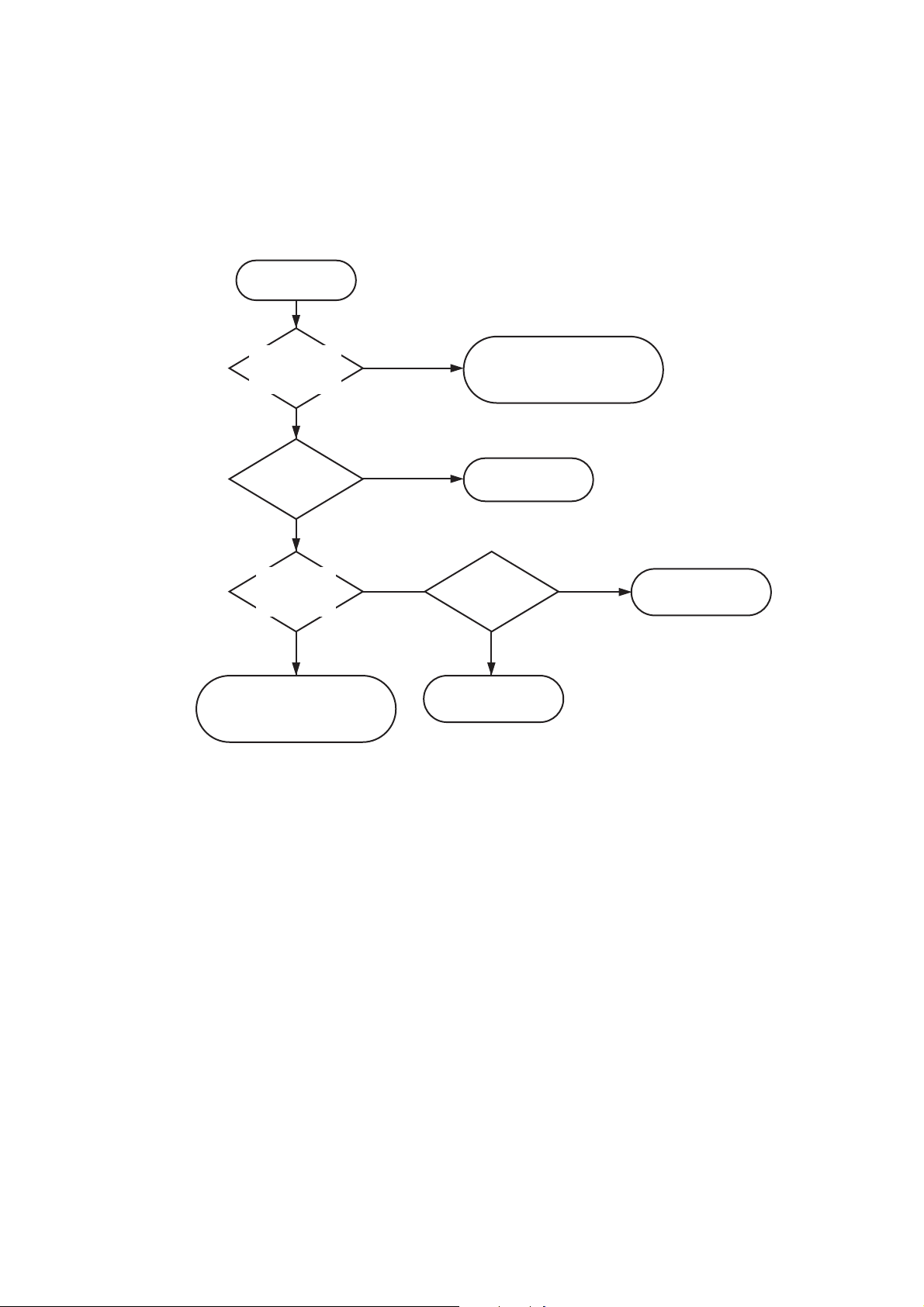

Start

Does an error

appear on the

display?

NO

Is copying

being done?

OK

Do copying

Is copy

picture OK?

OK

Communication problems

exist. Carry out the procedures

on the next page.

YES

NG

NG

Errors show on the display.

error massage page 1-6

error code page 1-9

General error

Page 1-17

Test print

OK

Scanning problem

Page 1-19

NG

Printing problem

Page 1-17

Figure 1-4 Procedures for Initial Identification of Trouble

1 - 23

Page 31

2-7-2 Procedures for processing communication problems

If the problem proves to be communication trouble, deal with it according to the following procedures.

(1) Study the conditions at the time of trouble as closely as possible. Record or keep the items listed

below.

a) Operations at the time of trouble.

Document number, transmission mode, error occurrence timing call set-up method (auto dialing etc.)

b) Sample of defective picture (When receiving)

c) LCD display at the time of trouble.

d) Communication management report at the time of trouble.

e) User's name, telephone number (to contact), Fax number, model name.

f) User's name, of the other party, telephone number (to contact), Fax number, model name, name of

servicemen in charge.

g) Frequency of trouble and error code (##100 etc.).

h) Condition of the other party's facsimile:

Transmitted/received page number? Automatic or manual?

Error occurred? The receive condition? etc.

NOTE:

When visiting a user with a trouble report, a) can be known by outputting the error protocol data (or

error dump), and g) can be known by outputting the total transaction report (or the system error data

list).

(2) Test communication according to flowchart procedures appearing on the next page.

* Carry out the tests with the actual lines on each item, verify the symptoms and record it.

* In the case of trouble with another manufacturer's facsimile, refer to the flowchart for troubles with

other manufacture's.

(3) Finally, process over by judging systematically all the data.

NOTE:

If the other party's facsimile is that of another manufacturer and there is nothing wrong with your

customer's machine, it is recommended that you ask your customer to contact the facsimile user of

the other party, so that the other party's facsimile is checked by the dealer. "Call the service station"

in the flowchart means that problems may occur with regard to the communication compatibility of

facsimile, consult the matter with the staff in charge at the service station. To quicken the resolving of

the problem, report the information listed in (1) above.

1 - 24

Page 32

2-7-3 Procedures for processing communication problems with Canon facsimile.

The process for carrying out communications at three points as shown in the figure.

Trouble

Start

Transmission

or reception?

Reception

C A

NG

Check A.

Transmission

OK

B C

Chec

NG

k B.

FAX:A

FAX:B

FAX:C

A: Your customer's facsimile

B: Facsimile of other communication party

C: Facsimile for check in the same region. (C should

be the same model of facsimile as A.)

OK

A C C B

NG

Check A. Check B.

OK

NG

OK

Check the

line.

Figure 1-5 Flowchart for Processing Communication Troubles

with Canon Facsimile

1 - 25

Page 33

2-7-4 Procedures for processing communication problems with other manufacturer's facsimiles.

When problems occur with other manufacturer's facsimiles, make the user of the other party's

facsimile call the serviceman in charge. Perform communication at the four points listed in the

figure.

Start

FAX:A

Trouble

FAX:B

Is the group

the same?

(G1/G2/G3)

No

Unable to

receive

Yes

FAX:C FAX:D

Is there the

similar

trouble case?

Yes

Process according

to the case

Transmitter

or receiver?

receiver

OK OK

C A A C

NG

Check A. Check A.

No

A: Your customer's facsimile

B: Facsimile of other communication

party

C: Facsimile for check in the same

region. (C should be the same mode

of facsimile as A.)

D: Other manufacturer's facsimile for

check that is in the same region.

Transmitter

NG

D A

NG

OK

Call the service

station.

OK NG

OK

OK

B D

NG

Check B.

B C C B

NG

D C C D

NG NG

Call the service

station.

OK

OK

Check B.

OK

D B

NG

Check B.

Figure 1-6 Flowchart for Processing Communication Troubles with

other manufacturer’s facsimile

1 - 26

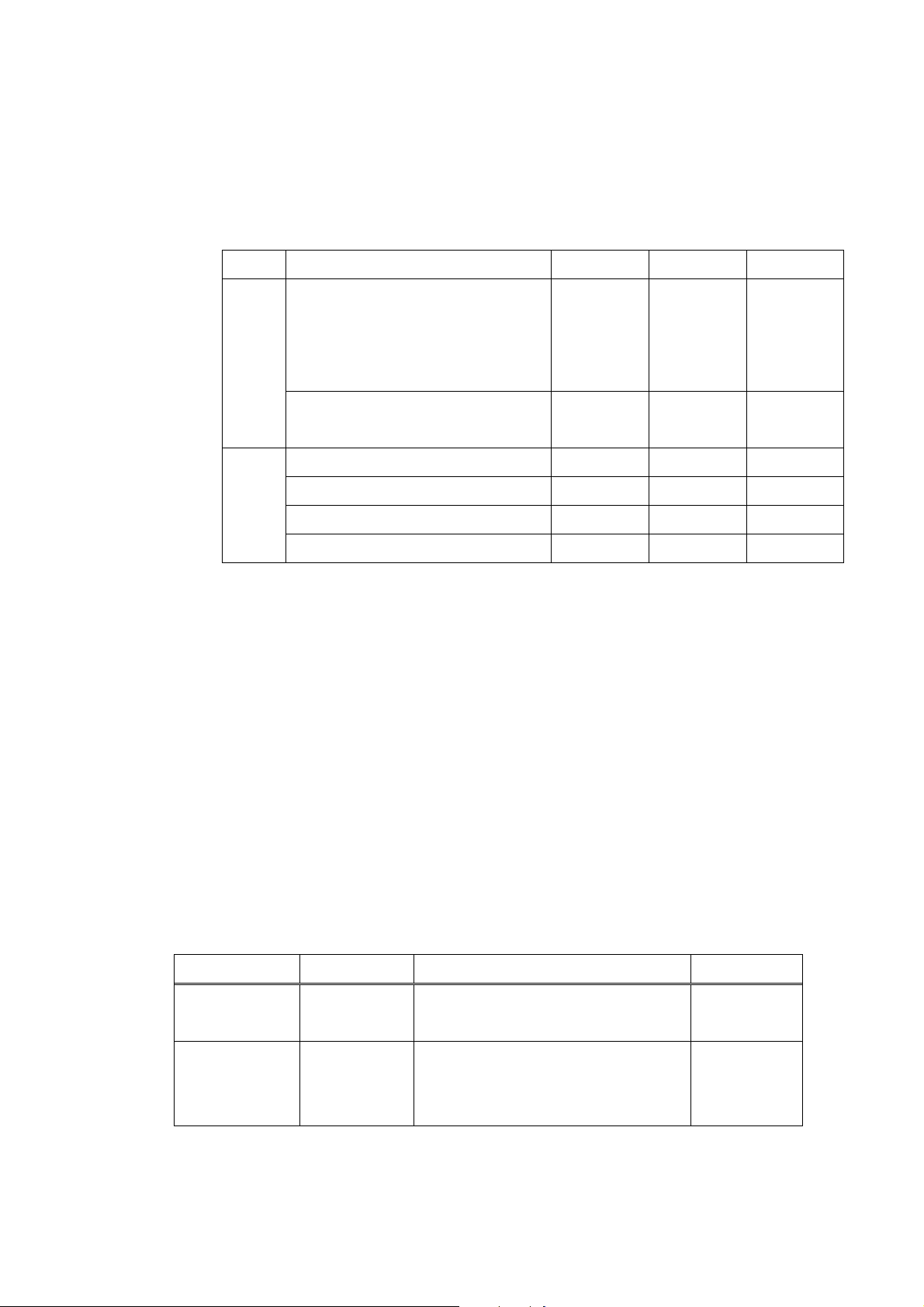

Page 34

3. REPAIR

3-1 Notes on Service Part Replacement (and Disassembling / Reassembling)

Service part Notes on replacement*1

SPCNT BOARD ASS’Y

(MP750: HY7-2931

MP780: HY7-3082)

INK ABSOBER

(HY7-2885/2886/2887/

2888/2889/2890/2891/

2953)

CARRIAGE UNIT

(HY7-2862)

P APER FEED MOT OR

(HY7-2912)

- Before removal of the

SPCNT board ass'y, remove

the power cord, and allow for

approx. 1 minute (for

discharge of capacitor's

accumulated charges), to

prevent damages to the

SPCNT board ass'y.

- Before replacement, check

the waste ink amount (by

service test print or EEPROM

information print).

-SYSTEM DA T A LIST

- The JP2 short plug (for

voltage drop protection) is

half connected. Remove the

plug once, and insert it again

for short-circuiting status.

(MP780 only)

[See Fig1-7]

Apply grease to the sliding

portions.

[See 3-3. Adjustment /

Settings, 3-3-7 Grease

application.]

-The red screws securing the

paper feed motor are allowed

to be loosened. (DO NOT

loosen any other red screws.)

Adjustment / settings Operation check

After replacement:

1.Clear ALL *2

(Initialize the EEPROM.)

2.TYPE setting *2

Power SW OFF/ON

3. Reset the waste ink counter.

4. Service data setting

5. CD-R sensor calibration

[See 3-6 Test mode 3-6-5 CD-R

Calibration]

[See 3-6. Service SW, for details

of 1 to 4]

6. Perform the print head

alignment in the user mode.

- EEPROM information

print

- Service test print

- SYSTEM DATA LIST

- Copy

- Sending and Receiving

(MP780 only)

- Printing via parallel or

USB connection

- Direct printing from a

digital camera

After replacement:

1. Reset the waste ink counter.

[See 3.3. Adjustment / Settings,

3-3-8 Waste ink counter setting]

- EEPROM information

print

1. CD-R sensor calibration

[See 3-6-5. CDR Calibration]

2. Perform the print head

alignment in the user mode.

-Service test print (Confirm

CD-R and automatic print

head alignment sensor

correction.)

1. Adjust the paper feed motor.

[See 3-3. Adjustment / Settings,

3-3-1 Paper feed motor

adjustment.]

1 - 27

Page 35

Service part Notes on replacement*1 Adjustment / settings*2 Operation check

LIFT CAM SHAFT

(HY7-2902)

TIMING SLIT STRIP

FILM

(HY7-2863)

TIMING SLIT DISK

FILM

(HY7-3083)

- Grease application to the

sliding portions

[See 3-3. Adjustment /

Settings, 3-3-7 Grease

application.]

-

Upon contact with the film,

wipe the film with ethanol.

- Confirm no grease is on the

film. (Wipe off any grease

thoroughly with ethanol.)

- Do not bend the film

After replacement:

1. LIFT CAM SHAFT phase

adjustment

See 3-3. Adjustment / Settings,

3-3-3 LIFT CAM SHAFT.]

After replacement:

1. Perform the print head

alignment in the user mode.

Service test print

-

-Service test print

PRINT HEAD

(QY6-0049)

After replacement:

1. Perform the print head

alignment in the user mode.

-Service test print

PAPER EXIT TRAY

UNIT

(HY7-2907)

LEFT COVER

(MP750: HY7-3079

MP780: HY7-2893)

RIGHT COVER

Align the three claws of the

(HY7-2923)

Align the left side of the tray

with the T-part’ angle of

Solenoid Cam Gear to insert

(after removing the tray, the

angle returns to almost

vertical by the force exerted

by the spring). Then pull the

tray open a little (approx. 30 –

60 degrees) and move it

toward the left side to insert

the other side of the shaft (see

the photo in Figure 1-7).

Align the two claws of the

bottom frame with the claws

of the left cover (see the photo

in Figure 1-8).

bottom frame with the claws

of the right cover (see the

photo in Figure 1-9).

*1: General notes:

- Make sure that the flexible cables and wires in the harness are in the proper position and connected correctly.

[See 3-2. Special Notes on Repair Servicing, 3-3-1 Flexible cable and harness wiring, connection, for details.]

- Do not drop the ferrite core, which may cause damage.

- Protect electrical parts from damage due to static electricity.

- Before removing a unit, after removing the power cord, allow the printer to sit for approx. 1 minute (for capacitor dischar ging

to protect the logic board ass'y from damages).

- Do not touch the timing slit strip film and timing slit disk film. No grease or abrasion is allowed.

- Protect the units from soiled with ink.

- Protect the housing from scratches.

- Exercise caution with the red screws, as follows:

i. The red screws of the paper feed motor may be loosened only at replacement of the paper feed motor unit (DO NOT

loosen them in other cases).

ii. DO NOT loosen the red screws on both sides of the main chassis, securing the carriage shaft positioning (they are not

*2: When SPCNT BOARD ASS’Y is replaced, be sure to select the settings of [#8CLEAR]-[ALL] and [#5TYPE] in Service Mode,

adjustable in servicing).

and turn the power OFF/ON with the Power button (Software Power: OFF/ON). DO NOT turn the power OFF/ON by removing

and inserting the power code (Hardware Power: OFF/ON). In this case, data may not be written correctly.

1 - 28

Page 36

Figure1-7 Solenoid Cam Gear

d

r

Y

p

r

n

t

To attach the PAPER EXIT TRA

UNIT, align the tray with the

T-

art of the Solenoid Cam Gea

to insert. Then pull the tray ope

a little and move it toward the lef

side to insert the other side of the

shaft.

The following photos show the left and the right cover claws. Align them for assembling.

Figure1-8 LEFT COVER Figure1-9 RIGHT COVER

Battery

Short plug

As shown in

Figure 1-10,

remove an

connect the

short plug fo

the

short-circuiting

status.

(Open) (Short)

Figure 1-10 SPCNT Short Plug location

(MP780 only)

1 - 29

Page 37

3-2 Special Notes on Repair Servicing

N

N

N

3-2-1 Flexible cable and harness wiring, connection

Be careful of wiring of the flexible cables and harness. Improper wiring or connection may cause

breakage of a line, leading to ignition or emission of smoke.

(1)

(2)

(3)

(4)

(1) Cable guide wiring

CU BOARD - POWER

SUPPLY UNIT

CU BOARD - RELAY

BOARD

CU BOARD

CAMERA DIRECT

BOARD

SPCNT BOARD

Figure 1-11 Flexible cable and harness wiring, connection

RELAY BOARD A

SPCNT BOARD

(JPSU1) POWER SUPPLY

UNIT

SPCNT BOARD

(JCCD1)SCANNER UNIT

Figure 1-12 Cable Guide wiring

1 - 30

Page 38

(2) SPCNT BOARD ASS’Y wiring

SPCNT BOARD (JPSU1) POWER SUPPLY UNIT

SPCNT BOARD (JHD1/JHD2) - CARRIAGE UNIT

SPCNT BOARD

(JADF1) ADF BOARD ASS’Y

SPCNT BOARD (JSOL1) SOLENOID

SPCNT BOARD (JPSC1)CAMERA DIRECT BOARD

SPCNT BOARD (JSPK1) SPEAKER UNIT

SPCNT BOARD

(JEXT1) RELEY BOARD ASS’Y

SPCNT BOARD

(JPM1) CARRIAGE/

LF/AP/PAPER FEED

MOTOR

SPCNT BOARD

(JMC1) PURGE UNIT

SPCNT BOARD

(JINK1) PLATEN UNIT

SPCNT BOARD

Figure 1-13 SPCNT BOARD ASS’Y wiring

(JVLV1) PURGE UNIT

1 - 31

Page 39

N

N

N

(3) RELAY BOARD ASS’Y wiring

RELAY BOARD (JSNS2) LF Encoder / PE Sensor

POWER SUPPLY (CN3) -

CU BOARD

SPCNT BOARD (JEXT1) RELAY BOARD (JREL)

(4) POWER SUPPLY UNIT wiring

Figure 1-14 RELAY BOARD ASS’Y wiring

POWER SUPPLY (CN4) SPCNT BOARD (JPSU1)

POWER SUPPLY (CN3) -

CU BOARD

RELAY BOARD

(JSNS1) -

PF Encoder /

PF PE Encoder /

AP Encoder

RELAY BOARD

(JNCU) -

CU BOARD

REGULATOR POWER SUPPLY

(CN6)

Figure 1-15 POWER SUPPLY UNIT wiring

1 - 32

Page 40

3-3 Adjustment / Settings

3-3-1 PAPER FEED MOTOR Adjustment

Perform the following adjustments when the paper feed motor unit is replaced:

1) When attaching the motor, fasten the screws so that the belt is properly stretched (in the

direction indicated by the blue arrow in the figure below).

2) After replacement, be sure to perform the service test print, and confirm that no strange noise or

faulty print operation (due to dislocation of the belt or gear, or out-of-phase motor, etc.) occurs.

Red screws securing the

PAPER FEED MOTOR

Figure 1-16 PAPER FEED MOTOR Adjustment

Note:

The red screws securing the paper feed motor may be loosened only at replacement of the paper

feed motor unit. DO NOT loosen them in other cases.

3-3-2 CARRIAGE SHAFT Gear Adjustment

In installing a carriage shaft, the gear phase should be adjusted.

(1) Insert the metallic pin shown below to the hole in the PURGE UNIT (see the photo (a) below) (until

it reaches the end).

[Metallic pin]

- Diameter: 2.0 mm or less, and Length: 20.0 mm or more

(Use “CARRIAGE SHAFT L SPRING: HY7-2867”, or an unbended clip can be used in place of the

pin.)

(2) With the metallic pin inserted, turn the LIFT GEAR 2 clockwise (in the direction indicated by the

arrow in the photo (b) below) until it reaches the end. (Stop when it cannot turn farther any more.)

Under the conditions above, confirm that the ASF ARM LOCK LEVER is located upward (see Photo

(c)) and the capping section is located at the capping position (see Photo (d)).

2.0mm or less 20.0mm or more

1 - 33

Page 41

p

R

R

m

(a) (b)

CARRIAGE SHAFT

LEFT GEAR 2

(c) ASF ARM LOCK LEVER (d) CAPPING

(3) Install the LEFT GEAR 1 by aligning it on the cutout of the CR SHAFT CAM R.

Align the two parts

so that both surfaces

shown at the top are

horizontal.

Or, adjust so that the

art of the C

SHAFT CAM

shown at the botto

is just at the bottom.

LEFT GEAR 1

Figure 1-17 CARRIAGE SHAFT gear adjustment

1 - 34

Page 42

3-3-3 Positioning in LIFT CAM SHAFT ASS’Y adjustment

(1) Remove the PRESSURE ROLLER SPRING from the hook of the chassis, and apply it to the gash

of the LIFT CAM SHAFT ASS’Y.

Figure 1-18 Positioning in LIFT CAM SHAFT ASS’Y adjustment 1

PRESSURE ROLLER SPRING

LIFT CAM SHAFT ASS’Y

(2) Turn the gear of the LIFT CAM SHAFT ASS’Y in the direction indicated by the arrow “a” in the

photo (clockwise) until it reaches the end.

(3) Turn the gear of the LIFT CAM SHAFT ASS’Y in the direction indicated by the arrow “b” in the

photo below (counterclockwise) until it reaches the end.

a

b

Figure1-19 Positioning in LIFT CAM SHAFT ASS’Y adjustment 2

1 - 35

Page 43

3-3-4 SOLENOID CAM location

(1) Install the spring so that the Short end of the spring is at the top and the Long end of the spring is at

the bottom. (The part has a protection against reverse installation.)

SOLENOID

CAM

SPRING

Short

SOLENOID

Long

Figure 1-20 SOLENOID CAM spring location

3-3-5 CARRIAGE SHAFT CLIP location

(1) Adjust the ellipse area of CARRIAGE SHAFT CLIP and the edge of TIMING SLIT STRIP FILM

Red screws

Ellipse Area of

CARRIAGE SHAFT

CLIP

Figure 1-21 CARRIAGE SHAFT CLIP location

1 - 36

Page 44

3-3-6 Applying White Sheet

(1) Rib bumps are provided in the vertical and the horizontal directions (locatio n marks) on the back

side of the document cover. Temporally attach the white sheet to the top right corner (no mark),

which is the intersection point of the lines that link the marks.

(2) Attach the whole part of the white sheet, by align ing the top edge and the right edge of the white

sheet on the lines that link the location marks in the top side and the right side on the back side of

the document cover.

(2)

(1)

White sheet

(3) Confirm the location to apply the white sheet. For the confirmation, lift up the document cover

just a little, and look into to visually confirm that the edges of the white sheet are not placed on

the scanner top cover (molded part).

OK Example: The edges of the white sheet are not located on the scanner top cover.

(2)

Rib bumps (location marks)

Figure 1-22 Applying white Sheet

White Sheet Corners

Figure 1-23 Location confirmation to apply the white sheet (the rear side and the right side)

(OK example)

1 - 37

Page 45

NG Example: The edges of the white sheet are located on the scanner top cover.

Figure 1-24 Location confirmation to apply the white sheet (the rear side and the right side)

(NG example)

1 - 38

Page 46

3-3-7 Grease application

(2)

(2)

(3) (4)

(1)

(9)

(10)

(8)

Figure 1-25 Grease application1

1 - 39

Page 47

(5)

(7)

(6)

Figure 1-26 Grease application2

Part name Where to apply grease / oil Grease / oil name

Chassis

LIFT CAM SHAFT

CARRIAGE SHAFT 8 CARRAGE and CARRIAGE SHAFT

CARRIAGE SHAFT

SPRING L

CARRIAGE SHAFT

SPRING R

Note: 1 drop = 9 to 18 mg

1 Entire surface the CARRIAGE

SLIDER contacts

2 CARRIAGE SHAFT sliding portion FLOIL KG107A

3 CARRIAGE SHAFT CAM L sliding

portion

4 CARRIAGE SHAFT CAM R sliding

portion

5 LIFT CAM SHAFT sliding portion FLOIL KG107A

6 SPRING sliding portion (4 points) FLOIL KG107A

7 PRESSURE ROLLER ASS’Y sliding

portion (4 points)

sliding portion

9 CARRIAGE SHAFT sliding portion

(over the area more than 2/3 from the

top end of the spring)

10 CARRIAGE SHAFT sliding portion

(over the area more than 2/3 from the

top end of the spring)

FLOIL KG107A

MOLYKOTE

HP300

MOLYKOTE

HP300

FLOIL KG107A

FLOIL KG107A

FLOIL KG107A

FLOIL KG107A

Grease / oil

amount

3 drops

4 drops

2 drops

1 drop

1 drop

1 drop

x 4 points

1 drop

x 4 points

200 to 400mg

1 drop

1 drop

1 - 40

Page 48

3-3-8 Waste ink counter setting

When the SPCNT board ass'y is replaced, check the amount of the waste ink capacity before the

replacement. After the replacement, register the amount of the waste ink capacity on the new

SPCNT board ass’y that has been replaced.

To check the waste ink capacity, print out the EEPROM information print.

To register the waste ink capacity, select [7] PRINTER – [5] INK ABS CAPA in the service mode,

and input a value between 0 – 100 (%) with the numeric keys.

3-4 User data flow

Press the [ENLARGE/REDUCE] button PRESET RATIO 400% MAX. 400% MAX.

ZOOM 25 ~ 400 %

(USA) (EUROPE)

212% 4"x 6" -> LTR 141% A5 -> A4

170% 5"x 7" -> LTR 115% B5 -> A4

* 100% * 100%

95% A4 -> LTR 86% A4 -> B5

25% MIN. 70% A4 -> A5

25% MIN.

FIT-TO-PAGE

Press the [PAPER] button SIZE A4 * A4

TYPE * PLAIN CARD

Press the [DENSITY] button 9 STEP (- LIGHT + DARK)

Press the [IMAGE QUALITY] button NORMAL

FINE (PHOTO)

FAST

(USA) (EUROPE)

* LTR LTR

LGL LGL

4"x 6" B5

5"x 7" A5

CARD 4"x 6"

5"x 7"

GLOSSY

HIGH RES.

TRANS.

PHOTO PRO

PHOTO PLUS

OTHER

Figure 1-27 Use data flow (1/5)

1 - 41

Page 49

[COPY] button (*a)

[MENU]

1. SPECIAL COPY BORDERLESS COPY S IZE * A4

TYPE GLOSSY

IMAGE REPEAT MANUAL VERTICAL 4

HORIZONAL 4

(MP780 only) * AUTO

2. FAX SETTING (*b)

(USA) (EUROPA)

1. RECIEVE MODE * FAX/TEL AUTO SW FAX/TEL AUTO SW

FAX ONLY MODE * FAX ONLY MODE

DRPD DRPD

MANUAL MODE MANUAL MODE

ANS. MACHINE MODE ANS. MACHINE MODE

2. MEMORY REFERENCE

3. REPORTS / LISTS ACTIVITY REPORT

SPEED DIAL LIST

USER DATA LIST

DOC. MEMORY LIST

LTR

4"x 6"

5"x 7"

CARD

*PHOTO PRO

PHOTO PLUS

OTHER

3

*2

1

3

*2

1

4. TEL# REGISTRATION

MEMO:

(*a)(*b): Press the [FAX] button and then the [MENU] button to display this setting at the beginning.

Figure 1-28 Use data flow (2/5)

1 - 42

Page 50

Y

Y

Y

Y

K

Y

5. USER SETTINGS DATE / TIME S ETTING

DATE SETUP YYYY/DD/MM YYYY/DD/MM

UNIT TEL NUMBER

UNIT NAME

TX TERMINAL ID * TTI POSITION * ON

OFFHOOK ALARM * ON

VOLUME CONTROL CALLING VOLUME 3

RX CALL LEVEL STANDARD

TEL LINE TYPE ROTARY PULSE

ACTIVI TY REPORT * AUTO PRINT ON

(USA) (EUROPE)

* MM/DD/YYY

DD/MM/YYY

(USA) (EUROPE)

TEL NUMBER MAR

OFF

LINE MONITOR VOL. 3

*HIGH

*TOUCH TONE

AUTO PRINT OFF

MM/DD/YYY

* DD/MM/YYY

OFF

*2

1

*2

1

0

6. TX SETTINGS ECM TX * ON

OFF

(EUROPE)

UN/LOCK PHONE LOCK PHONE * ON

PASSWORD OFF

PAUSE TIME * 2 SEC (1-15 SEC)

AUTO REDIAL * ON

OFF

TX START SPEED 14400 bps

9600 bps

7200 bps

4800 bps

2400 bps

* 33600 bps

COLOR DIRECT TX * OFF

ON

TX REPORT OUTPUT NO

* PRINT ERROR ONL

OUTPUT YES

Figure 1-29 Use data flow (3/5)

1 - 43

Page 51

K

7. RX SETTINGS ECM RX * ON

FAX/TEL AUTO SW RING START TIME * 8 SEC (0~30)

DRPD: SELECT FAX NORMAL RING

INCOMING RING * OFF

MAN/SUTO SWITCH * OFF

REMOTE RX * ON

RX REDUCTION * ON

RX START SPEED 14400 bps

RX REPORT * OUTPUT NO

3. MAINTENANCE NOZZLE CHEC

CLEANING

HEAD REFRESHING

ALIGN PRINT HEAD

AUTO HEAD ALIGN

ROLLER CLEANING

BOTTOM CLEANING

CALIBRATION

OFF

(USA)

F/T RING TIME * 15 SEC (10~45)

(EUROPE)

* 22 SEC (10~60)

F/T SWITCH ACTION * RECEIVE

DISCONNECT

DOUBLE RING

SHORT-SHORT-LONG

SHORT-LONG-SHORT

OTHER RING TYPE

ON

ON

OFF

OFF

9600 bps

7200 bps

4800 bps

2400 bps

* 33600 bps

PRONT ERROR ONLY

OUTPUT YES

Figure 1-30 Use data flow (4/5)

1 - 44

Page 52

K

4. SYSTEM SETTINGS QUIET PRINTING * OFF

ON

EXTENSION AMOUNT * SMALL

LARGE

AUDIBLE TONES KEYPAD VOLUME 0

ALARM VOLUME 0

DISPLAY LANGUAGE * ENGLISH

FRENCH

SPANISH

PORTUGUESE

(EUROPE)

COUNTRY SELECT UK BELGIUM

GERMANY SWITZERLAND

FRANCE PORTUGAL

ITALY IRELAND

SPAIN GREECE

HOLLAND LUXEMBOURG

DENMAR

NORWAY CZECH

SWEDEN RUSSIA

FINLAND SLOVENIA

AUSTRIA SOUTHAFRICA

SUMMER TIME OFF

*ON

1

*2

3

1

*2

3

HUNGARY

OTHERS

POWER SAVE TIMER 15 MINUTES

TWO-SIDED COPY * REAR PG. SAME DIR

THICK PAPER * OFF

AUTO FEED SWITCH * OFF

* 1 HOUR

4 HOURS

8 HOURS

ROTATE REAR PAGE

ON

ON

Figure 1-31 Use data flow (5/5)

1 - 45

Page 53

3-5. SERVICE SWITCHES

3-5-1 Hardware Switches

There is no service hardware switch on the Circuit board.

3-5-2 Service Data Setting

Service data can be checked and changed with items on display menus. The effective

SSSWs/ parameters and their default values in this machine are shown in Service menut

in this chapter. Detailed description of each SSSW/parameter is not given in this manual

except the new SSSWs/parameters added to this model. See G3 Facsimile SERVICE

DATA HANDBOOK (Rev. 1) (supplied separately) for details of them. The new switches

for this model are described in 5.6 New SSSWs/Parameters Added to this Model.

#1 SSSW (Service soft switch settings)

These setting items are for basic fax service functions such as error management, echo

countermeasures, and communication trouble countermeasures.

#2 MENU (MENU switch settings)

These setting items are for functions required during installation, such as NL equalizer

and transmission levels.

#3 NUMERIC Param. (NUMERIC parameter settings)

These setting items are for inputting numeric parameters such as the various conditions

for the FAX/TEL switching function.

#4 NCU (NCU settings)

These setting items are for telephone network control functions such as the selection

signal transmission conditions and the detection conditions, for the control signals sent

from the exchange.

#5 TYPE (TYPE setting)

The type setting makes the service data conform to a specific country communications

standards. There is only one setting item in this block.

#6 GENESIS (UHQ function setting)

These setting items are for scanned image processing such as edge enhancement and error

diffusion processing.

#7 PRINTER (PRINTER function settings)

These setting items are for basic printer service functions such as the reception picture

reduction conditions. Also there is an item for resetting the printer section without

switching the power off-on.

#8 CLEAR (Data initialization mode)

Various data are initialized by selecting one of these setting items. There is a setting item

for checking/inputting the total number of pages printed and total number of pages

scanned by this machine.

#9 ROM (ROM management)

ROM data such as the version number and checksum are displayed.

1 - 46

Page 54

3-5-3 Service Data Registration / Setting Method

Service data can be registered/set by the following operations:

100% LTR NORMAL

PLAIN

(1) User data mode selection

Press the Menu key.

1.SPECIAL COPY

BORDERLESS COPY

(2) Sevice data mode selection

Press the SCAN, COPY, and then SCAN key.

SERVICE MODE

#1 SSSW

(3) Menu item selection

Select the menu item by pressing the key.

SERVICE MODE

#3 NUMERIC Param.

Standby

Press the OK key.

#3 NUMERIC Param.

01: 0

(4) Data registration

Input the data and press the OK key.

Press the Stop/Reset key to return to standby.

Figure 1-32 Service Data Setting Method

1 - 47

Page 55

3-5-4 Service Data Flowchart

Service Data

#1 SSSW

(Service soft switch setting)

#+No.

Caution:

The switches marked “-” are not used. Do not change their settings.

Bit

SW01

SW02

SW03

SW04

SW05

SW06

SW07

SW08

SW09

SW10

SW11

SW12

SW13

SW14

SW15

SW16

SW17

SW18

SW19

SW20

SW21

SW22

SW23

SW24

SW25

SW26

SW27

SW28

SW29

SW30

SW50

76543210

–––1––00

–––––––0

0000––0–

10–000––

–––00–––

–––0–00–

––––––––

––––––––

––––––00

––––––––

––––––––

0–000010

––––––––

––––––––

–0––––––

––––––––

––––––––

––––––00

––––––––

––––––––

––––––––

––––––––

––––––––

––––––––

––––––00

00––0––0

––––––––

––000000

––––––0–

––––––––

SW31 to SW50

Figure 1-33 Service Data (1/6)

Error management (MP780 only)

NETWORK connection condition settings/

memory clear list setting (MP780 only)

Echo solution setting (MP780 only)

Communication trouble

solution settings (MP780 only)

Standard function (DIS signal)

setting (MP780 only)

Scan condition settings

Not used

Not used

Communications result display

function settings (MP780 only)

Not used

Not used

Page timer settings

Not used

Not used

Dial-in FAX/TEL switching function setting (MP780 only)

Not used

Not used

Communication trouble solutions settings (2) (MP780 only)

Not used

Not used

Not used

Not used

Not used

Not used

Report display function settings (MP780 only)

Transmission function settings (MP780 only)

Not used

V.8/V.34 protocol settings (MP780 only)

Flash ROM version up

Not used

Not used

1 - 48

Page 56

#2 MENU

(Menu switch settings)

(MP780 only)

01:

02:

03:

04:

05:

06:

07:

08:

ON

OFF

DIAL

SERVICEMAN

OFF

10 (-10dBm)

(8~15)

3429 (baud)

3200

3000

2800

2743

2400

Not used

Not used

Not used

Not used

NL equalizer setting

Line monitor setting

Transmission level setting

V.34 Baud rate

Caution:

09:

33.6

V.34 Transmission speed

(2.4 kbps - 33.6 kbps)

10:

50 Hz

25 Hz

17 Hz

Items 11 to 20

Not used

20:

Figures in boldface indicate the default setting.

Figure 1-34 Service Data (2/6)

No.01 to 04, 10 to 20 are not used. Do not change their settings.

1 - 49

Page 57

#3 NUMERICParam.

(Numeric parameter settings)

Default Range

0

01:

10 (10%)

02:

15 (15 lines)

03:

12 (12 times)

04:

4

05:

4

06:

350

07:

0

08:

6 (6 digits)

09:

5500 (55 seconds)

10:

3500 (35 seconds)

11:

0

12:

1300

13:

0

14:

120 (1200 ms)

15:

4 (4 seconds)

16:

100 (1000 ms)

17:

0 (0 ms)

18:

200 (2000 ms)

19:

100 (1000 ms)

20:

0 (0ms)

21:

200 (2000 ms)

22:

44

23:

15

24:

60 (600 ms)

25:

44

26:

0

27:

(MP780 only)

(1~ 99)

(2~ 99)

(1~ 99)

(1~ 20)

(0~ 9999)

(0~9999)

(0~ 999)

(0~ 9)

(0~ 999)

999)

(0~

(0~ 999)

(0~ 999)

(0~ 999)

(0~ 999)

(Do not change)

(0~ 20)

(0~ 999)

(Do not change)

Not used

RTN signal transmission condition (1)

RTN signal transmission condition (2)

RTN signal transmission condition (3)

Not used

Not used

Not used

Not used

The number of digits in telephone number

compared against TSI signal to be matched

for restricted receiving function

Line connection detection time (T0 timer)

T1 Timer (Rx)

Not used

Not used

Not used

Hooking detection time

Pseudo RBT transmission from CML on time

until start

Pseudo RBT signal pattern: On time

Pseudo RBT signal pattern: off time (short)

Pseudo RBT signal pattern: off time (long)

Pseudo ring pattern: On time setting

Pseudo ring pattern: Off time (short)

Pseudo ring pattern: Off time (long)

FAX/TEL switching function signal detection level

Pseudo-RBT signal transmission level

Answering machine connection function

signal detection time

Answering machine connection no-sound detection level

Not used

Figure 1-35 Service Data (3/6)

Caution:

No. 01, 05 to 08, 012 to 14, 27 to 30 are not used. Do not change their settings.

The relationship between the settings and the detection levels is as follows:

Parameter 24

0:

Not used, 1: Not used, 2: Not used, 3: Not used, 4: Not used

5: -8 dBm, 6: -9 dBm, 7:-10 dBm, 8:-11 dBm, 9:-12 dBm, 10:-13 dBm, 11:-14 dBm,

12:-15 dBm, 13:-16 dBm, 14:-17 dBm, 15:-18 dBm, 16:-19 dBm, 17:-20 dBm, 18:-21 dBm,