Canon LBP-860 Service Manual

LBP-860

SERVICE

MANUAL

Canon

PREFACE

This Service Manual contains basic information required for after-sales service of the LBP-860

laser beam printer

service trchnirian in maintaining the high print quality and performance of the printer.

The

rasselle

equipment, which rontenis are also described in this manual.

This manual consists of the following chapters:

lhereinafter referred to as the “printer”). This information is vital to the

paper feeder and envelope feeder are prepared for the printer as an optional

Chapter 1: General

Chapter 2: Operation

Chapter 3: The Mechanical System

Chapter 4:

Chapter 5:

Chapter 6: Troubleshooting

Appendix:

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this printer. based on information in this Manual and Service

Information Bulletins, is required for maintaining its performance and for locating and

repairing the cause of malfunctions.

Desrriplion

Features. specifications. and operation

ancl

A description of the operating principles and timing sequences of the electrical and

mechanical

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

lnstallatlon

Kequirements

handling of EP-E cartridges

Mainlmanre and Servicing

Parts replacement schedule, tools, lubricants. and solvents

Heferenrr values and adjustments: troubleshooting procedures

General timing chart, general circuil diagram, PCB circuit diagrams, etc.

Timing

systems.

for a suitable location, installation procedures, plus the storage and

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I.

FEATURES

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . .

II.

III. A SAFETY INFORMATION..... 1-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l-l

1-2

CHAPTER 2 OPERATION AND TIMING

IV. PARTS OF THE PRINTER . . . . . . . .

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V.

l-8

1-12

I.

BASIC OPERATION

A.

Functions..

B. Outline of the Electrical

System

.............................. 2-2

C. DC Controller Input

Signals

..............................

D. DC Controller Input/

Output Signals

E. Basic Sequence of

Operations..

II.

LASER/SCANNER SYSTEM..

A.

Outline

.............................. 2-7

B.

Scanning Exposure

C.

Laser Control Circuit..

D.

Scanner Drive..

III. IMAGE FORMATION SYSTEM . 2-15

. Outline..

B.

Printing Process..

C. High-Voltage Power Supply 2-23

lV.

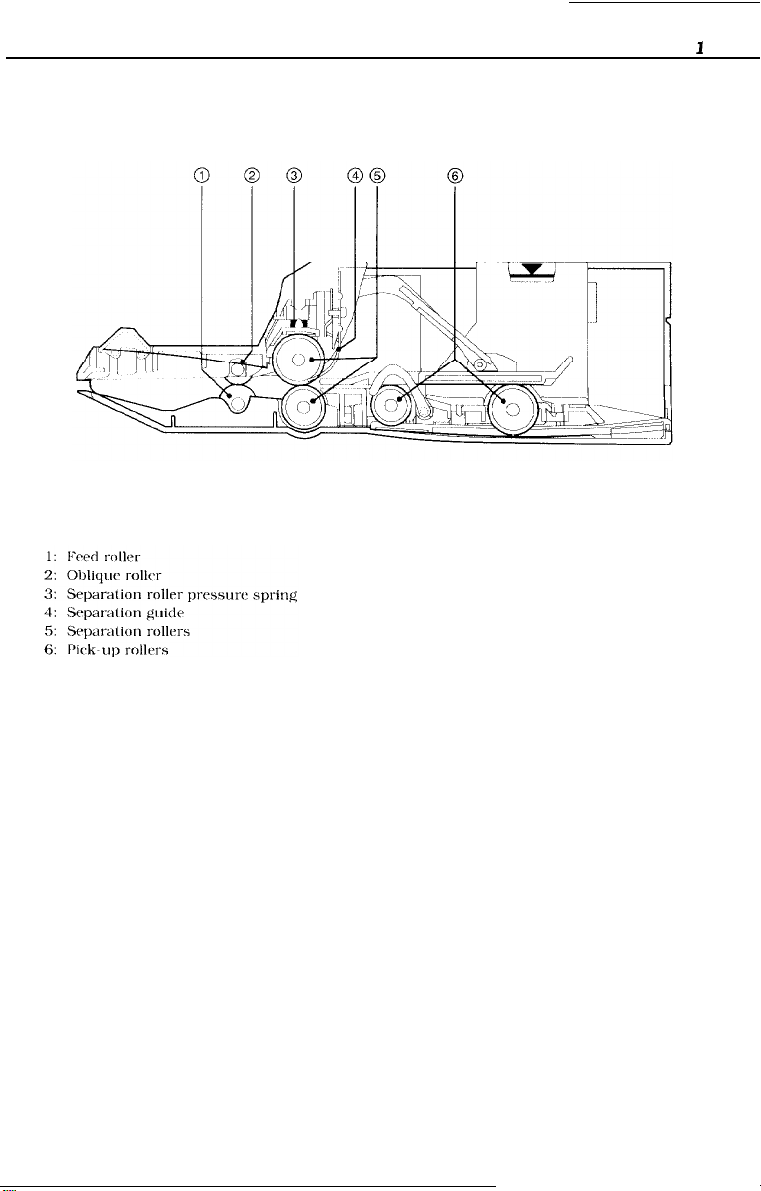

PICK-UP/FEED SYSTEM..

A.

Outline..

B.

Paper

Size

C.

Cassette Feed..

.................

........................

.................. 2-4

.......................

............

.......

..................

............................

..............

.......

............................

Detection

.........

..................

2-

1

2-l

2-3

2-6

...

2-7

2-S

2-10

2-13

2-15

2-17

2-27

2-27

2-28

2-29

CHAPTER 3 THE MECHANICAL SYSTEM

D. Fixing and Delivery Unit....2-30

E.

Paper Jam Detection..

V.

OVERALL CONTROL SYSTEM. 2-35

. Outline..

B.

Operation..

C.

Video Controller PCB..

D.

Control Panel..

E.

Self-test..

F.

Status/Error Message..

VI.

POWER SUPPLIES

. Outline..

B.

Protective System

VII. ENVELOPE FEEDER

A. Outline of the Electrical

System..

B. Pick-up/Feed System

C.

Paper Jam Detection..

VIII. PAPER FEEDER......................

A. Outline of the Electrical

System

B.

Pick-up/Feed System

C.

Paper Jam Detection..

............................ 2-35

........................

........................... 2-41

............................

............................

..............................

.......

.......

..................

......

..................

.............

...............

........

.......

........ 2-61

....... 2-61

2-33

2-36

2-37

2-40

2-42

2-55

2-56

2-55

2-56

2-56

2-57

2-59

2-60

2-60

I.

EXTERNAL8

A.

Covers and Panels

B.

Exhaust Fan..

C.

Control Panel Unit..

II.

DRIVE

A. Drive Unit.. ........................

B.

Main

........................... 3-1

....................

SYSTEM

Motor..

......................

......................

III. PAPER TRANSPORT SYSTEM..3-7

............. 3-1 A.

...........

3-4

3-5 C. MP Tray Pick-up Roller..

3-6 D. Separation Pad

3-6

3-6

B.

E.

IV.

EXPOSURE SYSTEM..

Paper Pick-up Unit..

Cassette Pick-up Roller..

Paper Delivery Unit

...........

..................

...........

............. 3-l 1

....

....

3-7

3-Q

3-Q

3-10

3-10

B.

A.

Laser/Scanner Unit . . . . . . . . . . .

V.

ELECTROSTATIC IMAGING/

DEVELOPING/CLEANING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

EP-E Cartridge . . . . . . . . . . . . . . . . . . .

B. Transfer Charging Roller.... 3-13

VI.

FIXING SYSTEM . . . . . . . . . . . . . . . . . . . . .

A.

Fixing Unit

VII. ELECTRONIC COMPONENTS . . 3-18

A.

Video Controller Unit . . . . . . . .

..,..

. . . . . . . . . . . . . . . . . .

3-11

3-12

3-12

3-14

.

3-14

3-18

Video Controller PCB..

C.

DC Controller

D. Pick-up Motor Driver PCB.. 3-21

E.

SensorPCB..

F.

Power Supply..

G. High-voltage Power

Supply

VIII. ENVELOPE FEEDER...............

IX.

PAPER FEEDER..

CHAPTER 4 INSTALLATION

I.

CHOOSING A LOCATION..

II.

UNPACKING AND Cartridges

INSTALLATION

111. STORAGE AND HANDLING OF

CARTRIDGES

.......................

.........................

.......4- 1

4-2 B. Storage of Unsealed

4-6

A. Storage of Sealed

Cartridges

C.

Handling Suggestions

CHAPTER 5 MAINTENANCE AND SERVICING

I.

PARTS REPLACEMENT A.Standard Tools

SCHEDULE..

II.

EXPECTED SERVICE LIVES

OF CONSUMABLES..

III. PERIODIC SERVICE

SCHEDULE..

IV.

LISTS OF TOOL6..

........................... 5-1 B.

V.

LIST OF LUBRICANTS.

............... 5-1

...........................

.................. 5-2

5-l

CLEANERS

VI.

SERVICE CHECKPOINTS

VII. MAINTENANCE BY

CUSTOMER..

Special Tools..

.......

PCB

.............

...................... 3-21

...................

PCB........................

....................

.........................

.........................

........

..................

...................

.............................

........

..........................

3-19

3-20

3-22

3-23

3-24

3-28

4-6

4-6

4-7

5-2

6-3

5-4

5-5

5-7

CHAPTER 6 TROUBLESHOOTING

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . .

I.

A.

Initial Check . . . . . . . . . . . . . . . . . . . . .

B.

Basic Procedure . . . . . . . . . . . . . . . . .

C. How to Use the

Troubleshooting Tables...... 6-3

EXPLANATION FOR SPECIAL

II.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOOL

A.

Printer Driver Tester . . . . . . . . .

III. MEASUREMENT AND

ADJUSTMENT

A.

Image Adjustment . . . . . . . . . . . . .

B.Mechanical Adjustment . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

6-l

6-l

6-2

6-4

6-4

6-7

6-7

6-7

C.

Electrical Adjustment . . . . . . . .

IV.

IMAGE DEFECTS . . . . . .

A. Examples of Image Defects 6-14

B. Troubleshooting Image

Defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V.

TROUBLESHOOTING

MALFUNCTIONS

VI. PAPER TRANSPORT

TROUBLESHOOTING

A.

Print Paper Jams . . . . . . . . . . . . . . .

B.Incomplete Paper Feed . . . . . .

..,.

,...........a.

. . . . . . . . . . . .

1..

. . . . . . . . . . .

1.1..

6-9

6-14

6-15

6-28

6-42

6-42

6-45

VII. LOCATION OF ELECTRICAL VIILVARIABLE RESISTORS,

PARTS/FUNCTION.. . . . . . . . . . . . . . . . .

A.

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.Sensors and Solenoids . . . . . . .

C.

Motor and Others . . . . . . . . . . . . . .

D.

PC Boards . . . . . . . . . . . . . . . . . . . . . . . . . .

E.

Connectors . . . . . . . . . . . . . . . . . . . . . . . .

6-46 TEST PINS, JUMPERS, AND

6-46 SWITCHES ON PC BOARDS..... 6-56

6-48 A.

6-50 B. High-voltage Power

6-52

6-54

DC Controller PCB . . . . . . . . . . . . .

Supply PCB . . . . . . . . . . . . . . . . . . . . . . . .

C. Pick-up Motor Driver PCB..

D. Paper Feeder Driver PCB.... 6-58

APPENDIX

VI.

I.

GENERAL TIMING CHART . . . . . . A-l

II.

LIST OF SIGNAL6 . . . . . . . . . . . . . . . . . . .

HI.

GENERAL CIRCUIT . . . . . . . . . . . . . . . . .

Iv.

DC CONTROLLER . . . . . . . . . . . . . . . . . . .

V.

PICK-UP MOTOR DRIVER . . . . . . .

A-3

A-5

A-7

A-9

SENSOR CIRCUIT . . . . . . . . . . . . . . . . . . .

VII.

PAPER FEEDER DRIVER . . . . . . . . A-12

VIII. ENVELOPE FEEDER DFUVER . . A-13

IX.

VIDEO CONTROLLER . . . . . . . . . . . . .

X.

EXPANSION ROM CURCUIT . . . . A-19

LEDS,

6-56

6-57

6-58

A-l 1

A-14

CHAPTER 1

GENERAL DESCRIPTION

I.

FEATURE3

II.

SF’ECIFICATIONS . . . .

III.

ASAFETY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INFORMATION..... 1-7

a...

. . . . . . . . . . . .

l-l

l-2

IV.

PARTS OF THE PRINTER..

OPERATION.. .......................... 1-12

V.

...... 1-S

CHAPTER

1. Non-impact page printer

This non-impart (low-noise) printer

2.

High print quality through use of

Toner having a particle size half that of conventional Canon loner and higher resolution (600

dpi) produce clearer images.

3. Easy maintenance

The photosensitive drum. toner. primary charging roller, and drum cleaning unit are combined

into

one

replaceable assembly called the “EP-E Cartridge”. By the use of the customerreplaceable cartridge, high printing quality is maintained by replacing the cartridge and simple

cleaning in I hr

4. Roller charging/transfer system

Instead of the conventional corona system, a charging roller/transfer system is used for the

charging and

product-d by the charging system and the roller transfer system makes paper feeding more

slable.

5. Space-saving front loading for paper feed

Front loading is used to make it easier to load paper. This, along with the built-in, mulli-

purpose

6. Four paper feed methods with various options

Four-way paper

(simply

tray and cassette. By combining the standard cassette with the paper feeder, up to about 750

sheets of paper

printer.

transfer processw.

tray, reduces the size of the printer and the space it takes

f’eed~ng

wiled the paper

is made possible by installing the optional cassette paper feeder

feeder below) and envelope feeder, in addition to the multi-purpose

van

be

loaded in both the upper and lower cassettes for continuous printing.

USPS

clectrophotographic, electronic, and laser technology

fine

toner and high resolution

The charging roller system considerably reduces the ozone

I600 dpil

up.

1

7. Automatic interface change function

Thr prinlcr has a parallel interface (Cenlronirs) and a serial interface

the

Lype

(parallel or serial) of data from the computer, and automatically l changes the

interface.

(Automatic interface function)

(RS-232C). It

recognizes

I-1

CHAPTER

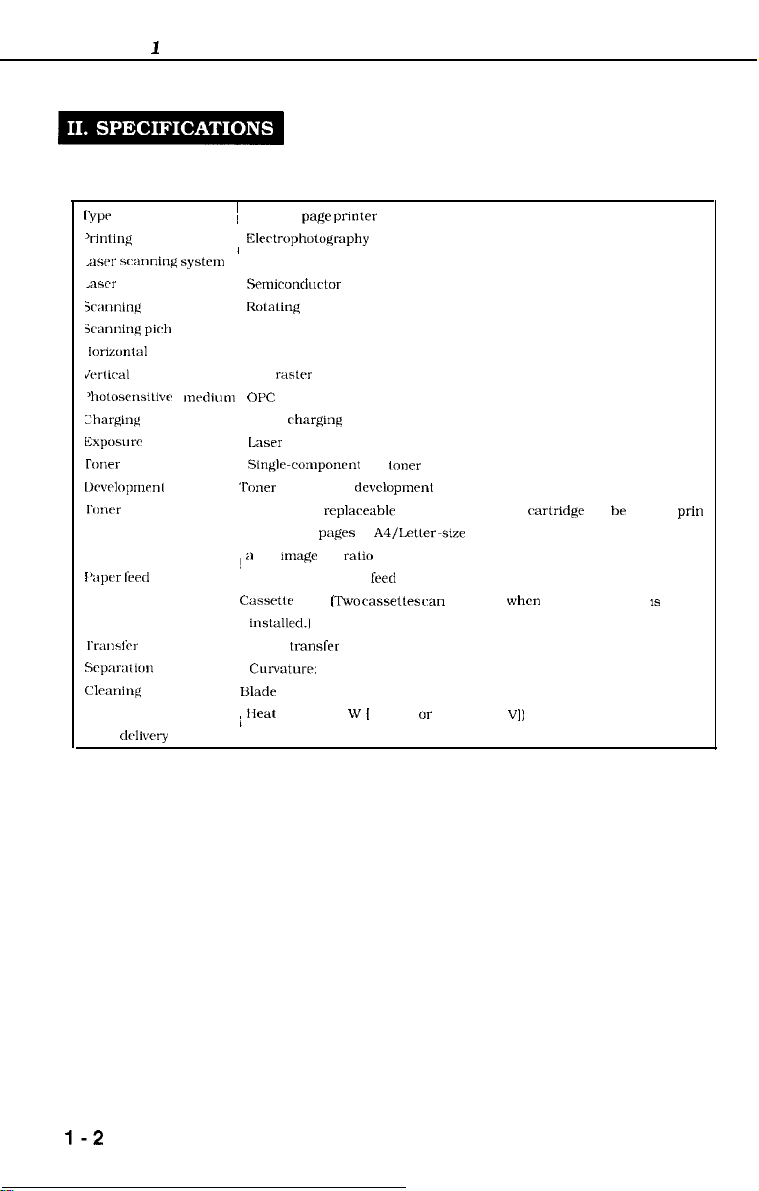

A. Construction

1

l‘vw

‘I-intinil.

method

,awr

scanning syste”,

<ascr

icar,ninc

system

jczmning

piclr

l<~i?Z”~t~l

JwUral

‘hotosrns~llvr mrdium

L’hargint(

Exposurr

roner

l~rvclop”w”l

I‘1mrr

supply

I’apf,r

fwd

I‘I-~U~Sfil-

Srp~~r-;ltK,”

Clrxring

Fixing

Print delivery

I

~ Desktop

I

OPC

‘lbner

about 6,000

! II

Cassrtk

Blade

; Heat

pa@ printer

Elcctropholoqaphy

Srmicondurtor

Rotaling

600 dots/inch

600 rastc-r lines/inch

Roller

Laser scanning

Singlr-componrnt

projection

Included in

4%

Multi-purpose tray feed

insla1led.l

Roller

Curvature:

roller (500

Fare-down

laser

six-faced prism mirror (Scanning mirror)

rharging

replaceabk

purges

m~agc

dot

ralio

feed [Two

transfer

(small drum radius/paper stiffness)

dry

toner

dcvclopmrnt

EP-E cartridge [The

of

A4/Letler-sxe

with the print density setting in the middle.)

cassetles ran

w

[

115 VI UT 500 w (240

paper. The average print coverage is

be used

r&ridge

when

the paper feeder

VI)

ran be used to

prin

IS

l-2

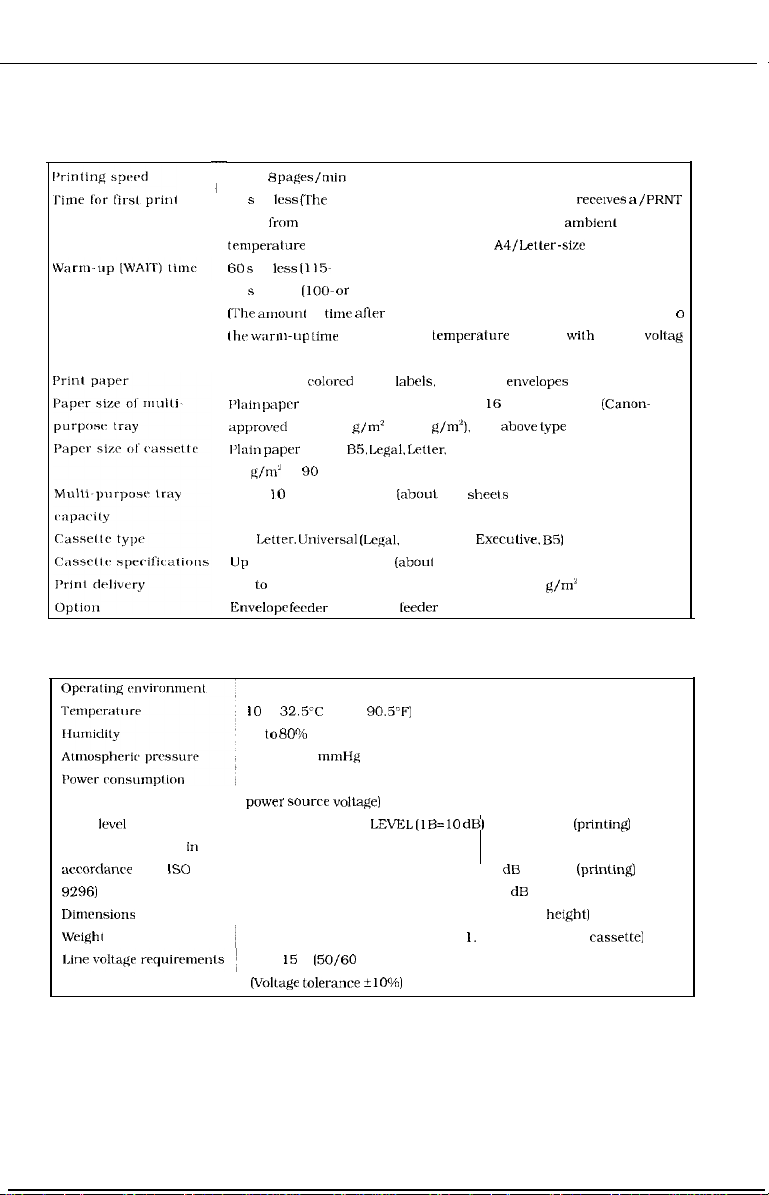

B. Performance

-

About 8

24 s or

pages/min

less (The

I

signal from the video controller when it is ready al an

temprralure

60 s or

less

75 s or less

(The ~~l~ount

the w;un-t~p

input.)

Plain paper,

l’lain

pap”’

approvrd

I’laitr paper

60

g/ml

to 90 g/m’)

Up lo 10 mm stack height

(A4 or Letter)

amount of time from when the printer

of 20°C until the deliver of an

A4/Letler-size

(115- or 2.40-v power source)

(loo- or

220-v power source)

of time

aflrr

the printer is turned ON until the completion

tinw at an ambient

colurcd

paprr. lahels. OHP film,

temperalure

of 20°C with a rated

rnvelopes

from 182 mm X 257 mm to 2 I6 mm X 356 mm (Canon-

paprr, 60

g/m’

to 128 g/m”), and

above type

of A4. B5, Legal. Letler, or Executive (Canon-approved paper

(about

100

shrels

of80 g/m’ paper)

CHAPTER 1

rer~wes a

amhienl

paper.)

of paper

/PRNT

o

voltag

C. Others

Noise levrl (DECLARED

NOISE EMISSIONS in

awordanrr

9296)

with

L)imrnsions

Wright

IS0

A4. Letter.

IJp

Up lo 25 mm stack height (about 250 sheets of 80

Enwlopr

liniwrsal (Lc@l,

to 25 mm stark height

ferdrr

and paper

IO

to

32.5’C

(50 to

90.5-F]

20 to

RO”/u

RH

570 to 760

mmHg

Letter. A4,

(aboul

Execuliw, B5)

250 sheets of 80 g/m’ paper)

leeder

g/m2

paper)

Max. about 660 W (at ambient temperature of 20°C and rated

power source Volta@)

SOUND POWER

LEVEL (lB=lO dB)

6.2 B or less (printin@

4.5 B or less (standby)

SOUND PRESSURE LEVEL 49 dB or less

(printi&

(Bystander positions) 33 dB or less (standby)

424 mm X 4 16 mm X 295 mm (width X depth X heIghtI

17.0 kg (printer). 1.5 kg (cartridge). 1. I kg (A4 or Letter

100-l I5 V

(50/60

Hz], 220-240 V (50 Hz)

(Voltage tolerance ilO%)

cassrttel

1-3

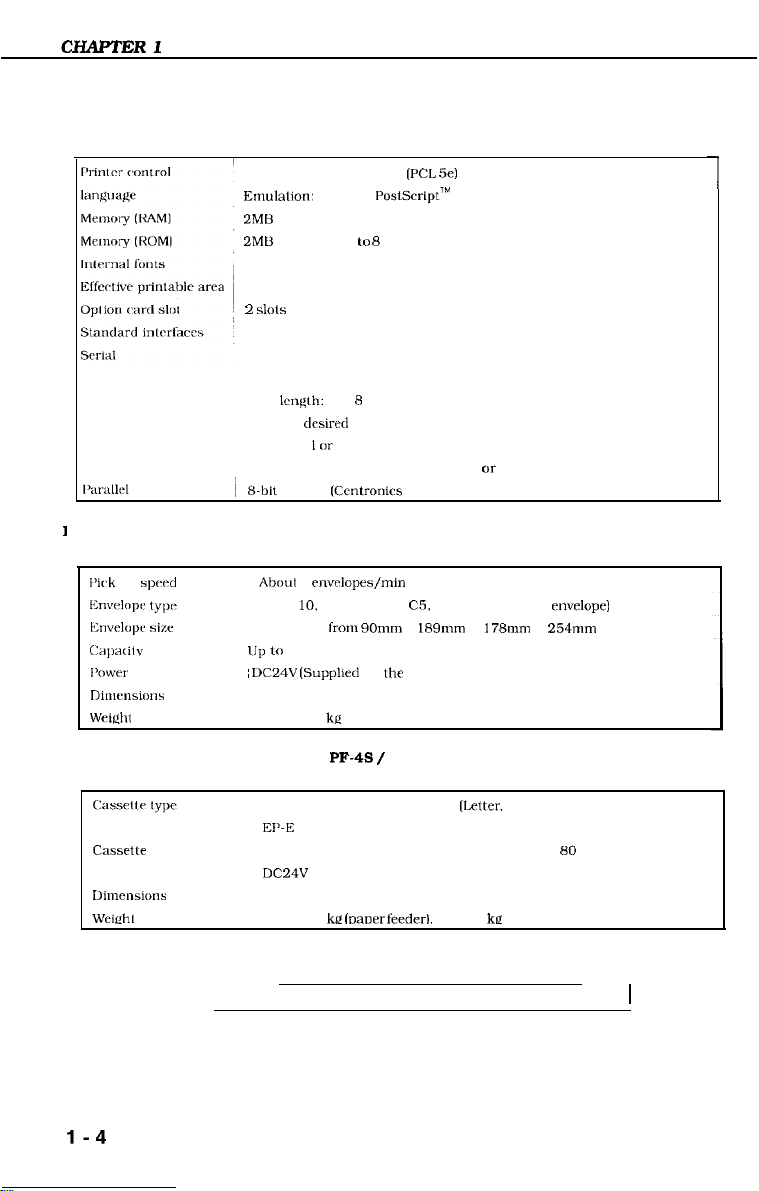

D. Video controller

Standard: Enhanced PCL

Emulahon:

2MB (Expandable to 66 Megabytes in total with optional RAM SIMM)

2MU (Expandable lo 8 Megabytes in total with optional ROM SIMM)

See table 1-I and 1-2.

See figure l-l.

2

KS-232C. asynchronous. 300, 600. 1200. 2400, 4800.9600. 19200. or

38400 baud

Data Icngth: 7 or 8 bits

Parity: 11

Slop bits:

Handshaking: XON-XOFF. ETX-ACK, or DTR

s-bit

1

E. Envelope feeder (Envelope Feeder EF-4)

[‘irk

up

spwd

Envrlolx typ’

~~~~v~~lol~~

size Envelopes from 90mm X 189mm to 178mm X 254mm

i:;lpx ilv

I’0wer supply ~

Dimensions

Wright About 2.6

Up to

Optional PoslScript’M

SlOlS

desired

I or

2

parallel

(Ccntronirs

Aboul

6

env&prs/min

COM-

10.

DL. Monarch. C5, B5 (recommended envelope)

55 mm stark height (about 75 envelopes)

DC24V

(SuppIled by the printer)

306.5 X 293 X 127.9 mm (width X depth X height)

kri

(PCL

5e)

standard) interface

1

F.

Paper feeder (Paper Feeder Unit PF-4s / PF-4L)

EP-E Cassette 500 Universal S

EI’-E

Cassette 500 Universal L (Legal, Letter, A4, Executive)

Casseile

specifications

Power supply

Dimensions

Wciehl

Specifications are subject to change with product improvement.

Up to 50 mm slack height (about 500 sheets of 80 g/m’ paper)

DC24V

(Supplied by the printer)

416 X 470 X 132 mm (width X depth X height) (including legal cover)

About 3.9 ke loauer feedert. about 2 kc (universal cassette1

l-4

[letter,

A4. Executive)

1

CHAPTER 1

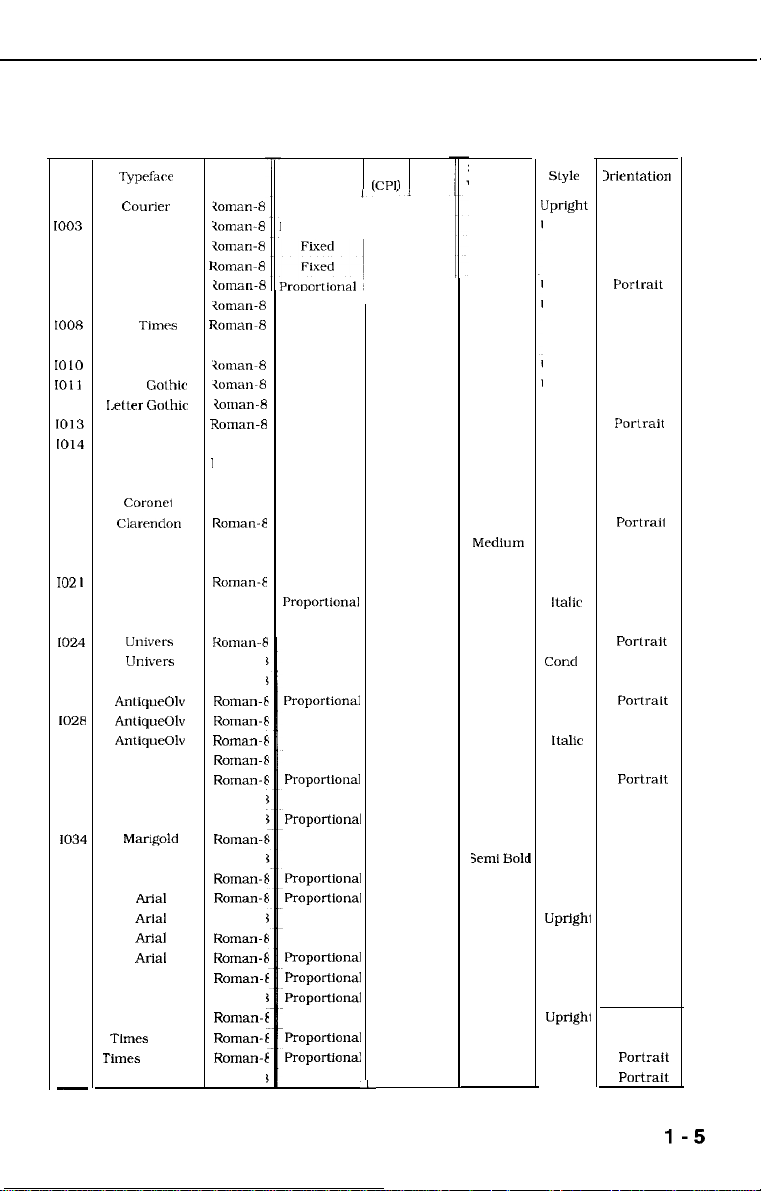

*Scalable Fonts

Font

1000

IO03

1004

1007

IO08

1010

IO11

1012

1013

1014

1015

1016

1017

1018

1019

102

1023

IO24

1025

1028

ID

I

Typefact-

C0llIier

Courier

Courier

Courier

CG Times

CG Times

CG

Time

CG Times

Letter Gothic

Letter GOthic

Letter

CG Omega

CG Omega

CG Omega

CG omega

COi-OlX9

ClX?lldOll

Univrrs

Univrrs

Univers

Univrrs

Univers

Univrrs

Univcrs

Univers

AnliqueOlv

AntiqueOh

AntiqueOh

Garmond

103 1

Garmond

Garmond

1033

1034

1035

1036

1037

1038

1039

1040

104 1

1042

1043

1044

1045

1046

-

Garmond

Marlgold

Aibertus

Aibertus

ArIai

A&l

Aria1

Ariai

Symbol

Times New

Times Bd

Times

Times

New Bdi

Wingdings

Golhir

New It

Symbol

I

ioman-

I

ioman-

I

ioman-

I

ioman-

I

<ornan-

1

ioman-

1

ioman-

I

7oman-8

I

ioman-

I

iOmaw8

I

ioman-

I

ROIIIX-8

I

Roman-8

I

Roman-8

Roman-8

Roman-8

ROKK3n-E

Roman-t

Roman-E

Roman-$

Roman-E

Roman-E

Koman-t

Roman-t

Roman-E

ROITIX-E

ROman-t

Roman-F

Roman-t

ROITXX-t

Roman-F

Roman-E

ROIIXXVE

Roman-E

Roman-E

Roman-E

Roman-E

ROIK%Vt

ROIIlan-E

ROlllan-E

Roman-E

ROman-E

ROllXUl-E

t

ROman-E

Roman-E

set

Table l-l

Spacing

Fixed

Proportional

Proportional

Proportional

Proportional

Fixed

Fixed

Fixed

Proportional

Proportional

Proportional

Proportional

Proportional

Proportional

Proportional

Proportional

Proportional

PrOpOrtiOIlal

Proportional

Proportional

Proportional

Proportional

Proporliondl

Proportional

Proportional

Proportional

ProportIonal

Proportional

ProportIonal

Proportional

Proportional

ProportIonal

ProportIonal

Proportional

Proportional

Proportionai

ProportIonal

Proportlonai

Proportional

PrOpOltIO~.3i

ProportIonal

Proportional

Pitch Point

ICPil Size

,.

‘L

Scalable

I

Stroke

Weight

Medium

Bold

Medium

Bold

Medium

Bold

Mrdium

Bold

Medium

Bold

Medium

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Bold

Medium

Medium

Bold

Medium

Bold

Medium

3mlI BoIc

Ex Bold

Medium

Bold

Medium

Bold

Medium

Medium

Bold

Medium

Bold

Medium

I

Style

Lipright

Upright

Italic

Italic

Upright

Upright

Italic

Italic

Upright

Upright

Italic

Upright

Upright

Italic

Italic

Italic

Upright

Upright

Upright

italic

italic

Cond

Cond

Cond It

Cond It

Upright

Upright

Italic

Upright

Upright

Italic

Italic

Upright

Upright

Upright

Upright

UprIght

Italic

Italic

Upright

Upright

UprIght

Italic

Italic

Upright

1rIr‘ntation

Portrait

Portrait

Portrait

Portrait

Porlrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portraii

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Pot-trait

POrtrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

Portrait

I

1-5

CHAPTER 1

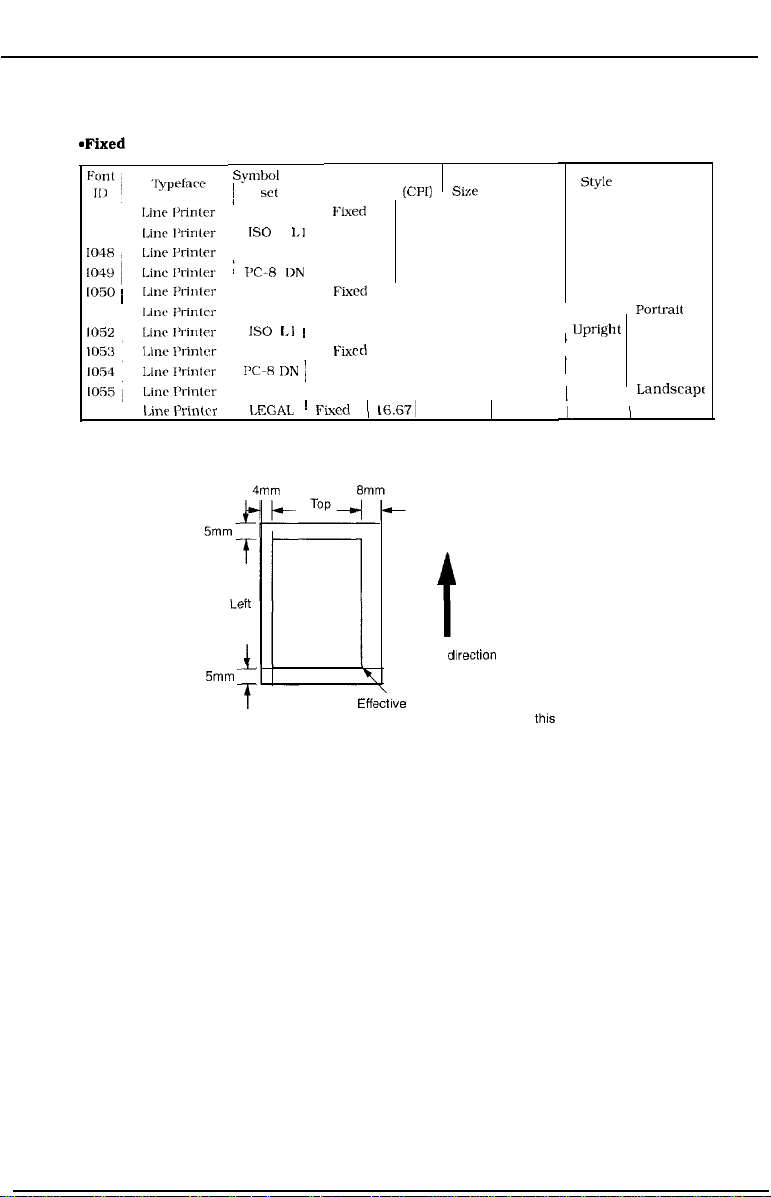

*Fixed

1002

1047

I050 i

1051

1052

1056

Fonts

Linr I’rintcr

Symbol

1

I

Roman-8

:

J’C-R

LEGAL

I

5mm

f

set

IS0

LJ

PC-8

DN

PC-850

IS0

LJ ~

PC-8

PC-R IIN

PC-850

I,EGAL

Table l-2

Sparing

FIxed

Fixed 16.67 8.5

Fixed

Fixed

Fixed

Fixed

Fixed 16.67 8.5

Fixr d

Fixed

I

Fixed

~

Fixed

Bottom

Pitch Point

(CPJJ

sixe

16.67 8.5

16.67: 8.5

16.67 8.5

16.67 8.5

16.67 8.5

16.67’ 8.5

16.67 8.5

16.67, 8.5

(

16.671

8.5

Right

t

Feed-out dIrection

~ff(

sctlve printing area

(Image quality is guaranteed in this area.)

Figure l-l

Stroke

Weight

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

Medium

T

Upright Landscape

Upright Portrait

Upright

I

I

I

I

Orientation

Style

Upright Portrait

Upright Portrait

Upright

Upright

Upright Landscape

Upright Landscape

Upright

Upright , Landscape

Portrait

Portrait

Landscape

Landscapc

1-6

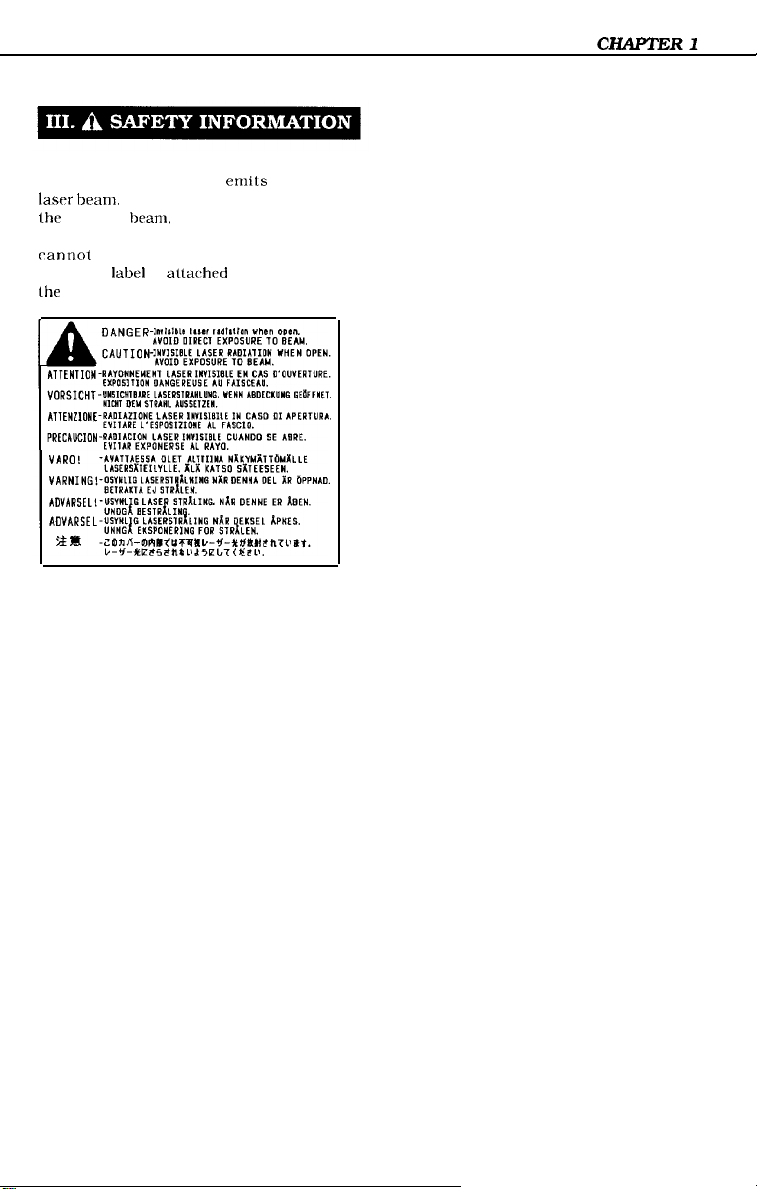

A. Handling the Laser/Scanner Unit

The laser/scanner unit

lasrr

beam.

lhc reflected

possibly damage your eyes. The unit

rannot

following

lhe unit:

Never disassemble the unit;

bram.

be adjusted in the field. The

label

is altached to the cover of

emits

invisible

although invisible. ran

Figure 1-2

1-7

CHAPTER

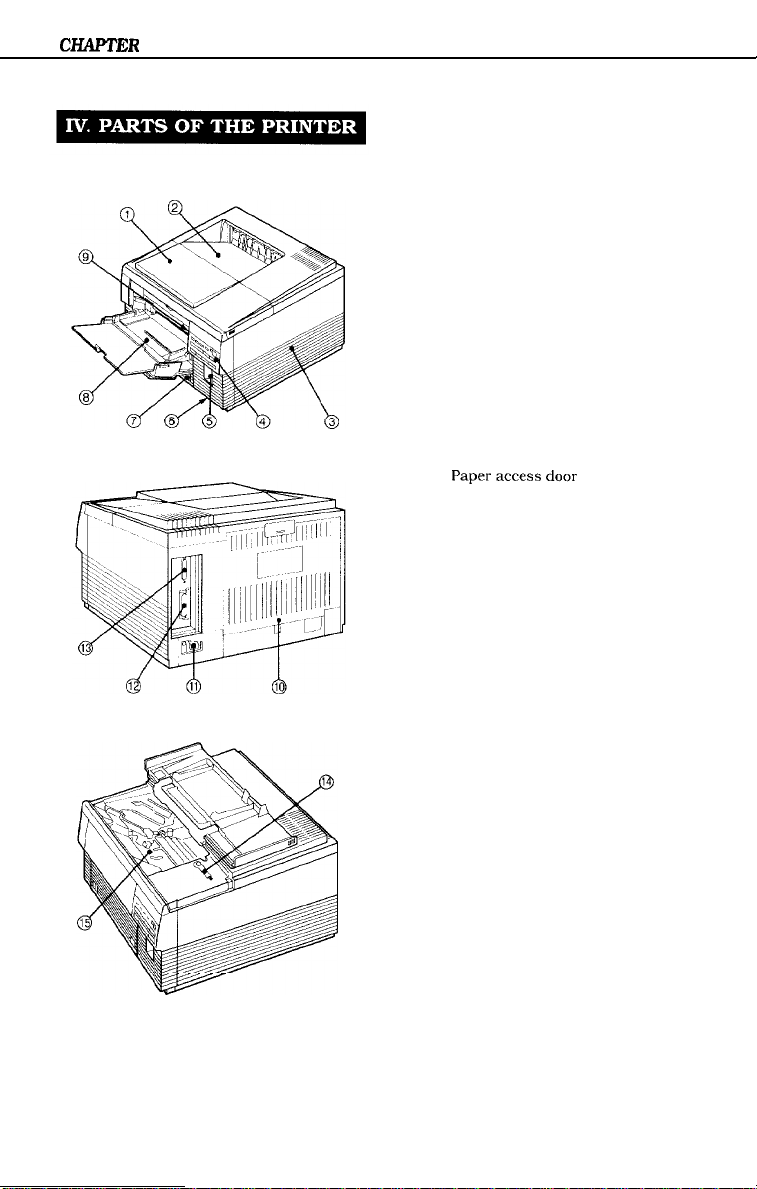

A. External View

1. Printer

1

Figure l-3

I: Upper cover

2:

Face-down tray

3:

Right rover

4:

Control panel

5: Font card slot

6:

Power switch

7:

Cassette

8:

Multi-purpose tray

9: Test print switch

10:

Delivery cover

11:

Power receptacle

12: Parallel interface connector

13: Serial interface connector

14:

Cleaning brush

15:

Paperaccessdoor

1-8

Figure 1-4

Figure 1-5

2. Paper feeder

Figure 1-6

3. Envelope feeder

Figure

l-7

1: Paper feeder

2: Cassette

1: Envelope side guide

2:

Exlension

3: Weight

(500

sheets can be placed)

tray

1-9

CHAPTER 1

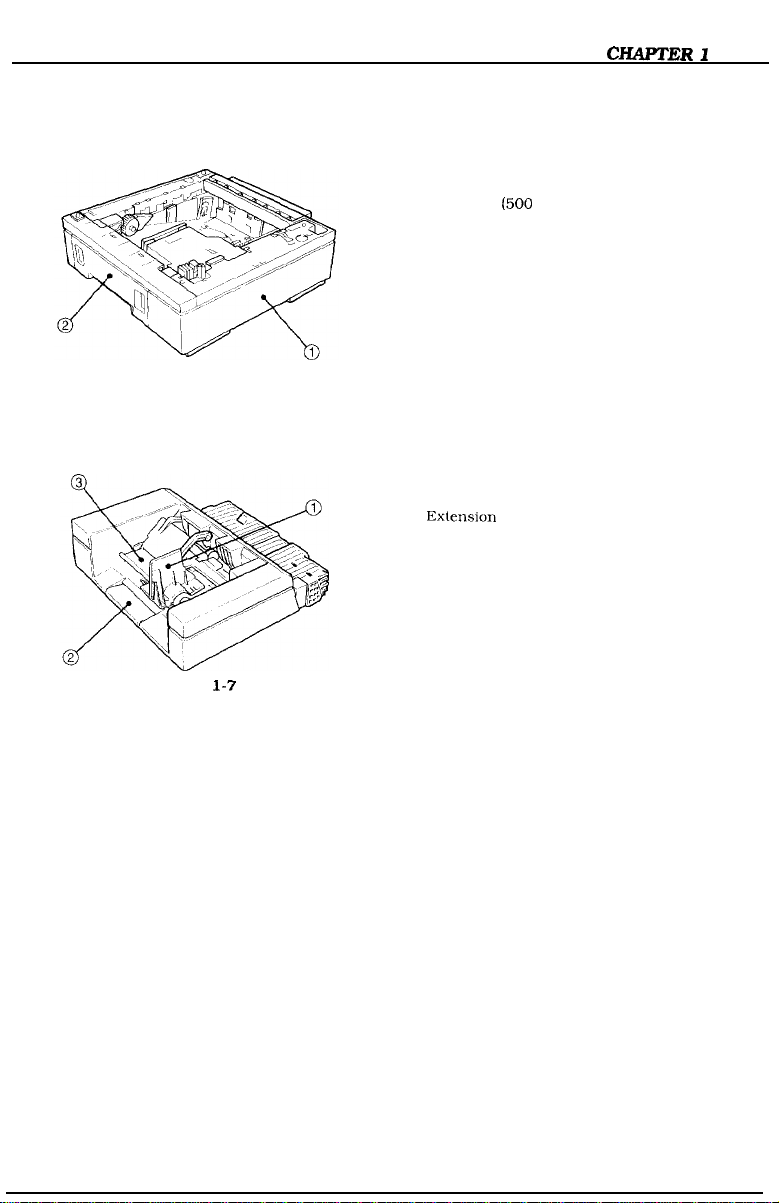

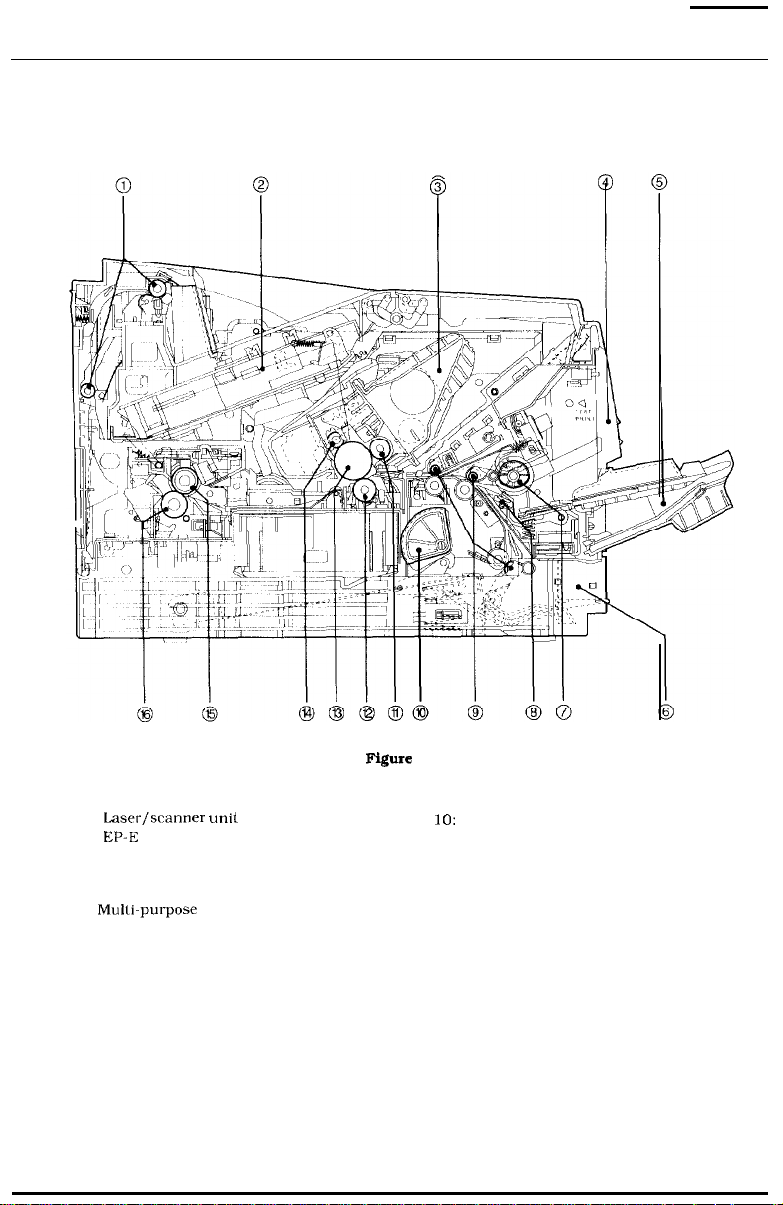

B. Cross Sectional View

1. Printer

1:

Delivery rollers

2:

Lasw/scanner unit

3:

EP-E

cartridge

4:

Control

5:

6:

7: Mulli-purpose tray pick-up roller

8:

panel

Multi-purpose tray

Cassette

Separation pad

l-10

Figure

1-s

9:

Oblique rollers

10:

Cassette pick-up roller

11:

Developing cylinder

12: Transfer charging roller

13:

Photosensitive drum

14: Primary charging roller

15: Upper fixing roller

16: Lower fixing roller

3. Envelope feeder

Figure 1-9

CHAPTER

1

l-11

CHAPTER 1

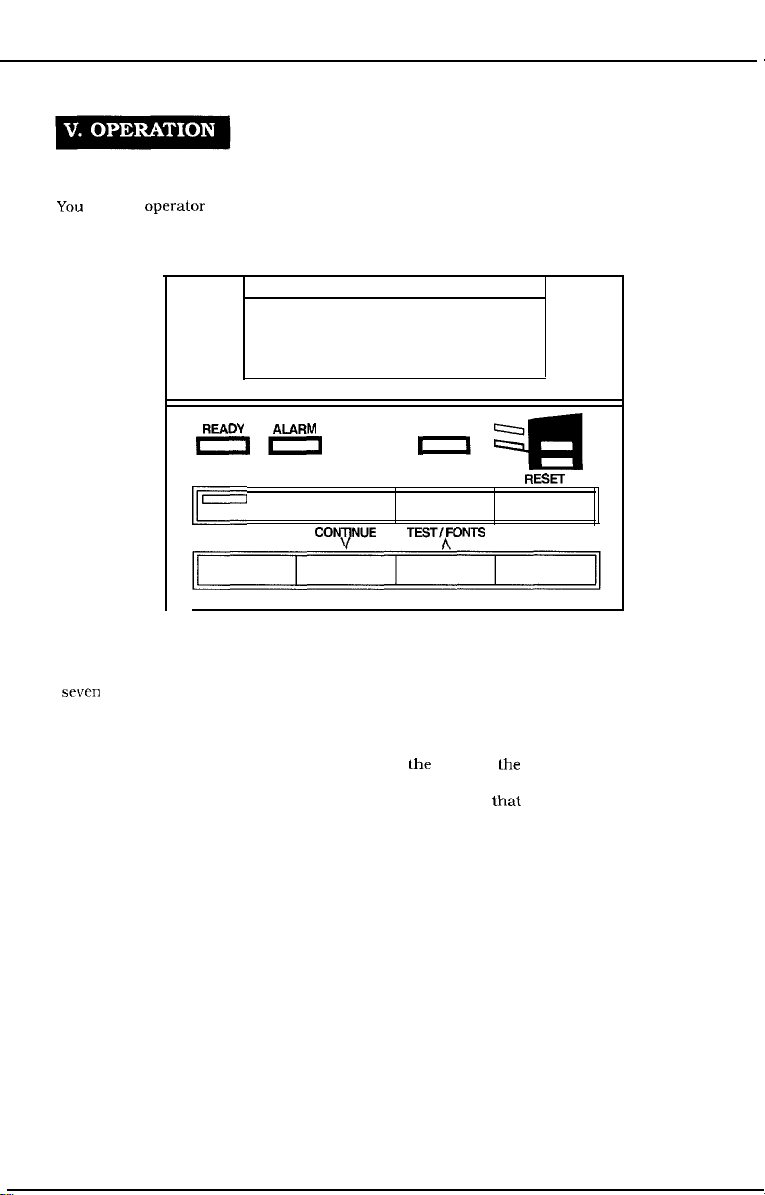

A. The Operator Panel

You

use the operalor panel to perform basic printer operations, make printer configuration

changes your software application cannot control, identify available typefaces, and check the

status of the printer.

READY

on

I-

ALARM

ON LINE

MENU COPQINUE

DATA

1

FORM FEED RESET

TEST/fONTS

a

4zl

ENTER

Figure l-10

The operator panel consists of the message/menu display window, eight indicator lights, and

sewn menu and operation keys.

1. Message/Menu Display Window

The message/menu display window can display as many as 16 characters. It displays menu

items you can select, and messages that describe

lhe

status of

lhe

printer and error conditions.

This chapter describes the menu items you can display in the window. See Chapter 6

‘Troubleshooting, for information about the types of messages that may appear in the window.

1-12

CHAPTER

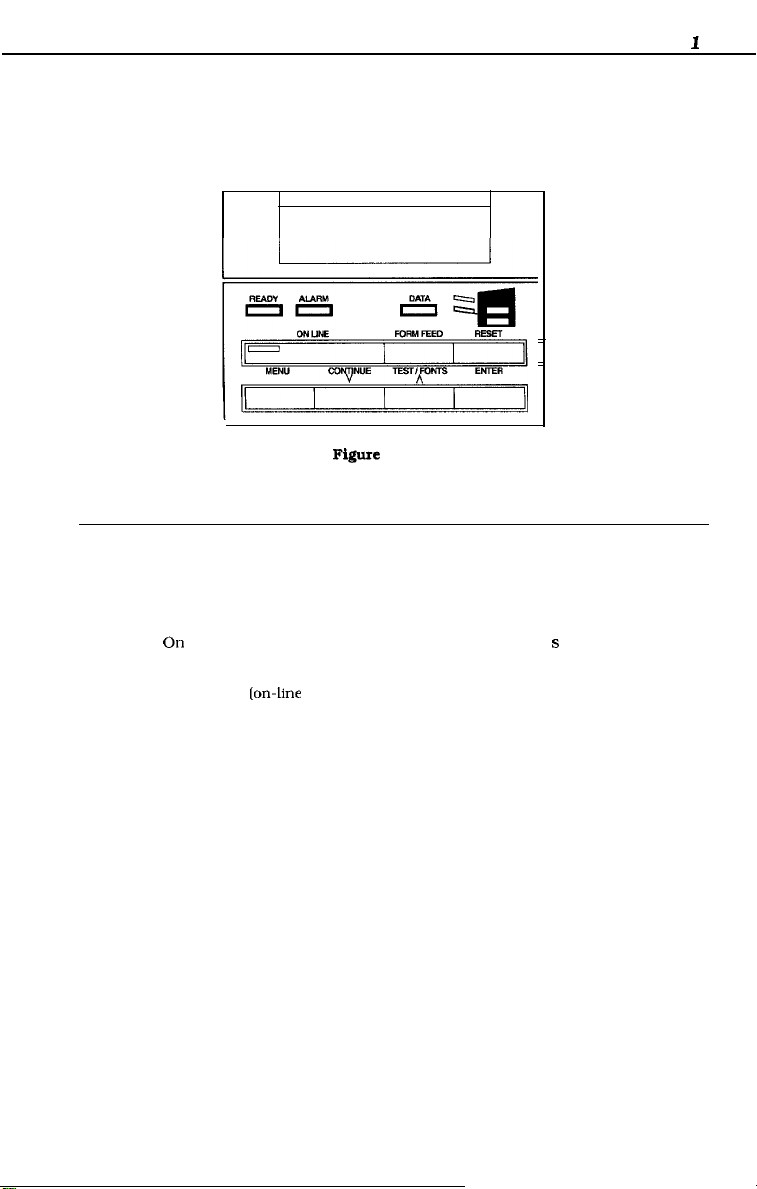

2. Indicator Lights

The indicator lights provide status information about the printer. The lights have different

meanings depending on whether they are on, off, or flashing.

-_

-

Figure l-11

Indicator

light Mode

READY

ALARM

DATA

ON LINE

Off

Flashing

On

Off

On

Off

On

Off

Description

The printer is ready to print.

An error or attendance message appears in the display.

The printer is receiving data.

An error has occurred and printing is disabled. An error or

attendance message appears in the display.

No error has occurred.

Print data is currently stored in the printer’ s buffer.

No buffered data is in the printer.

The printer is ready to accept and print data from the computer

[on-line

status).

The printer cannot accept print data from the computer (off-line

status). When the printer is off-line.

1

1-13

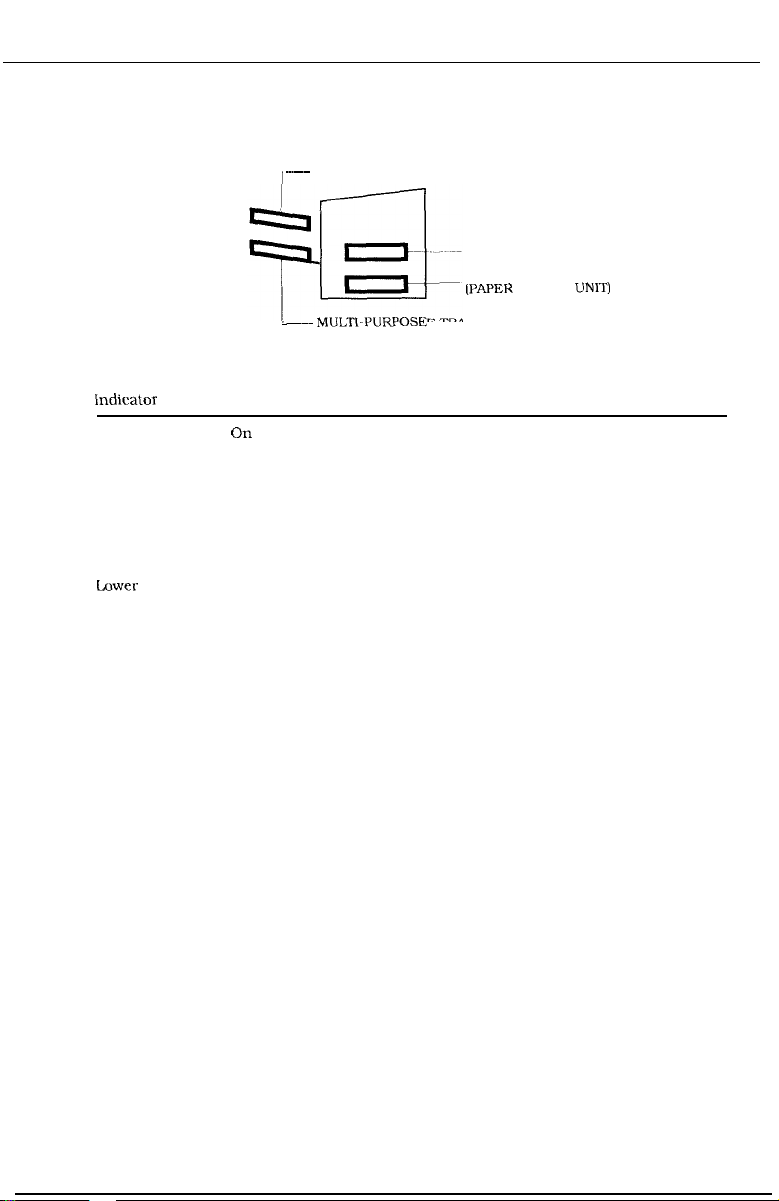

CHAPTER 1

The paper input source indicators are:

~~~~

-~~ MUCKPURPOSE

ENVELOPE FEEDER

TRAY

Figure 1-12

STANDARD CASSETTE

LOWER CASSETTE

(PAPER

FEEDER UNIT)

indicator light

Envelope

Feeder

Multi-purpose

tray

Standard

cassette

Lower

cassette

Mode

On

Flashing

Description

The optional Envelope Feeder is the input source.

The optional Envelope Feeder is selected, but does not

contain envelopes.

On

Flashing

The multi-purpose tray is the input source.

The multi-purpose tray is selected, but does not contain

paper.

On

Flashing

The paper cassette tray is the input source.

The paper cassette tray is selected, but does not contain

paper.

On

The optional Paper Feeder Unit is the input source.

Flashing The optional Paper Feeder Unit is selected, but does not

contain paper.

1-14

CIIAPTER

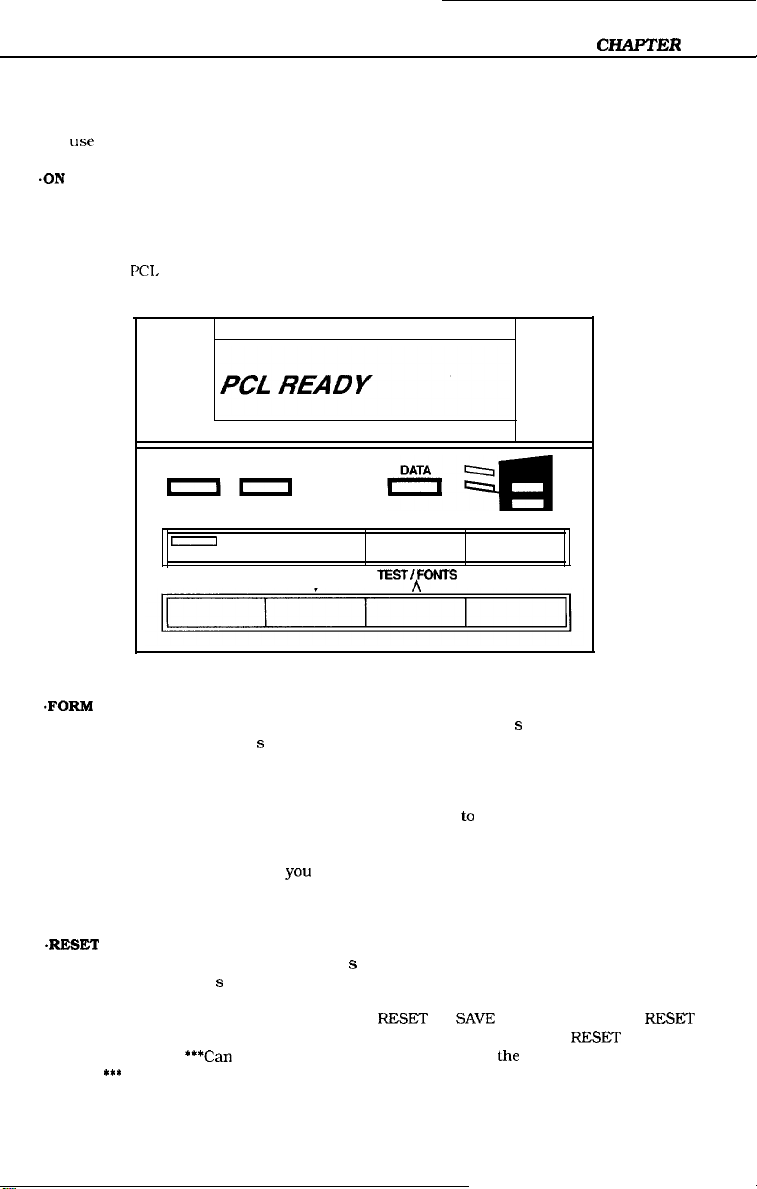

3. Operation Keys

You

USC

the operation keys to control the basic functions of the printer.

.ON

LINE key

You use the ON LINE key to switch the printer between on-line and off-line. The printer must

be on-line to receive information from your computer. To use any of the other keys on the

operator panel, the printer must be off-line.

The message PCL READY appears in the display window when the printer is on-line and ready

to receive data.

1

READY

ALARM

III

ON LINE

I

MENU

.FORM

FEED key

You use the FORM FEED key to print the data stored in the printer’ s buffer. For example. if the

last page stored in the printer’ s memory is a full page but your software does not send a

command to print it, you can press ON LINE to set the printer off-line and then press FORM

FEED to print the last page.

Keep in mind that complex pages may take several minutes to process. Make sure the READY

indicator light has stopped flashing before you press FORM FEED lo print the last page.

The printer must be off-line before

Pressing the FORM FEED key does not force a blank sheet through the printer.

*RESET

key

You use the RESET key to clear the printer’ s buffer and remove all temporary typefaces and

macros from the printer’ s memory.

After you change a menu item, you may see the RESET TO SAVE message. If so, press RESKT

to make your menu selections the permanent default settings. The message RESET appears in

the display window.

appear?

***

***Can

CO NUE

V

yoou

press FORM FEED.

we be more specific here? When does lhe RESET TO SAVE message

FORM FEED RESET

TEsT/pNrs

Figure 1-13

ENTER

l-15

CHAPTER

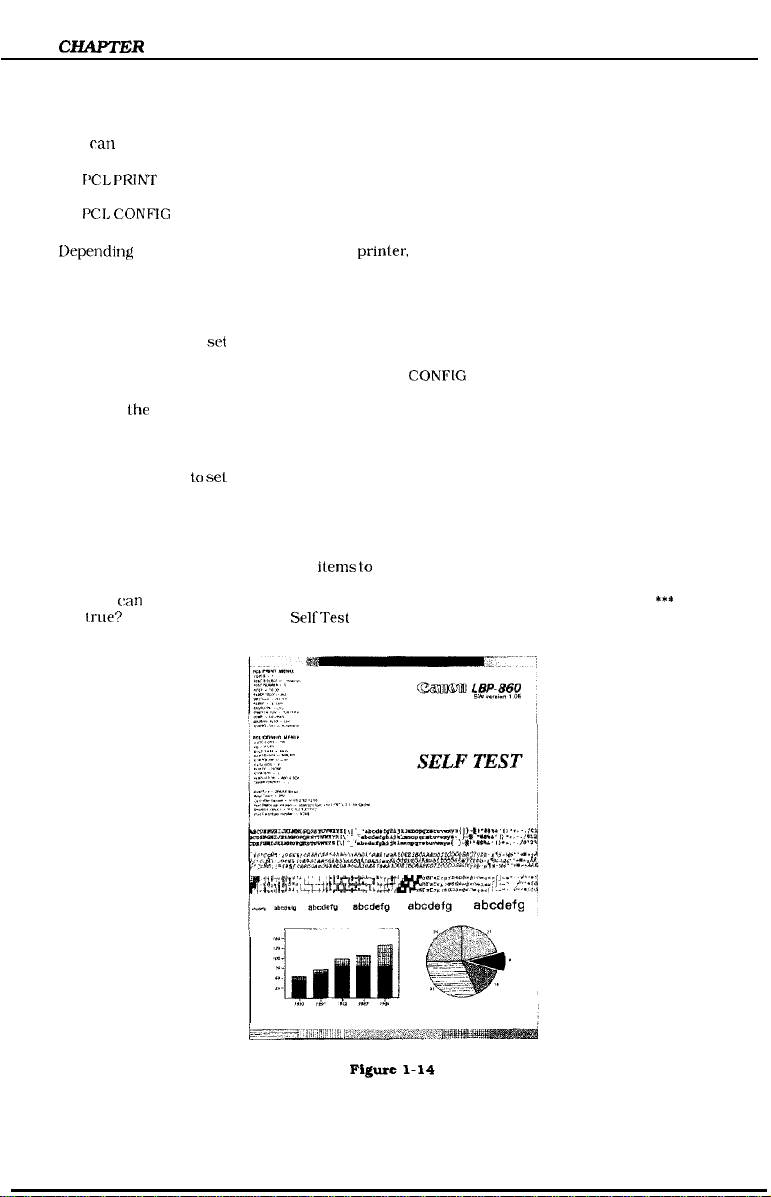

.TEST/FONT key

You use the TEST/FONT key to print the Self Test or the Font List.

When lhe printer is off-line, press the TEST/FONT key once to start the Self Test. Press and

hold the TEST/FONT key to print the Font List. The Self Test and Font List are described later

in this chapter.

*CONTINUE key

You use the CONTINUE key to allow the printer to resume printing after it was placed off-line

by an operational condition. Most operational conditions are identified by a message, such as

PRINT OVERRUN. Before you continue printing, you need to press CONTINUE to clear the

message and

The CONTINUE key sets the printer on-line just like the ON LINE key, but you can also use it

in the following ways:

1

se1

the printer back on-line.

You can press CONTINUE to override the paper or envelope size

media loaded in the multi-purpose tray, lhe optional Envelope Feeder, or a paper cassette.

This means you could use it to print a letter-size page on legal-size paper if legal-size paper

is loaded in the multi-purpose tray

You ran press CONTINUE to override a request to manually feeder paper or an envelope.

When you do this. the printer selects paper from the next available source.

Menu Keys

You use the menu

section briefly describes each key. See the Operator Panel Menus section for information about

accessing and selecting menu items.

4XENU

key

The

MENlJ

The printer must be off-line when you press the MENU key.

You use the and keys to step through all available choices for a particular menu item. For

example. after you access the

display the

You can use the key to display the choices in reverse order. Lf you hold down either arrow key,

the system scrolls rapidly through all choices for the menu option.

.ENTER key

You use the ENTER key to save a selection in the printer’ s permanent memory. An asterisk

appears next to the selection in the menu display window indicating it is the current default

selection. This default selection remains in effect even when you turn off or reset the printer.

If you press ENTER when buffered or temporary data is present, the system only marks the

selections with an asterisk. When you press ON LINE or MENU, the system displays the RESET

TO SAVE message. At this point, you have three choices:

ke.vs

to access the various menus and select the available menu items. This

key cycles through the

LEXTER,

LEGAL, EXEC, A4, COMIO, MONARC. DL,

ME’T

PCI,

PRINT MENU and the PCL CONFIG MENU.

SIZE option from the PCL PRINT MENU, you press to

selecttons

B5.

and C5 choices.

regardless of the

[*I

n

Press RESET to clear the page buffers, remove temporary data, and return all items to their

permanent default setlings.

n

Press ON LINE to place the printer on-line without performing a reset. The selections you

1-16

mad?

in the menu are marked with an asterisk but do not become active until the printer

detects a job boundary or you reset the

W

Press

CONTINUE to set the printer off-line withoul performing a reset.

*** Need to verify all of this ***

CHAPTER 1

prinler.

1-17

CHAFTER

B. Operator Panel Menus

You

n PCL PRINT MENU

n

1

(‘LIT,

access the following menus though the operator panel:

PCL

CONFlG MENU

LIepending

1. Accessing and Selecting Menu Items

Follow these steps to access the menus and make selections:

1.

2. Press MENU once to display the PCL PRINT MENU. Press and hold MENU (for

3.

4.

5. When the selection appears in the display window, press ENTER to save it as the default

6.

2. Confirming Your Menu Selections

There are two ways you ran review the selections you made through the operator panel:

n

n

on the options installed in your

Press ON LINE to

approximately five seconds) to display the PCL CONFIG MENU.

Press MENU until you display the item you want to change.

When

the

the available choices.

setting. An asterisk appears next to your selection in the display window.

Press ON LINE to

You ran scroll through the menu ilems lo check all selections marked with an asterisk.

You

can

print a Self Test. The printed output lists all settings that are in effect.

Irue?

*** See the Printing the

se1

the printer off-line.

item you want Co change appears in the display window, press or to step through

se1

the printer on-line.

SelfTest

prinler,

other menus may display.

section for more information.

***

Is this

1-18

CHAPTER1

3. Restoring the Default Settings

There are several types of default settings:

n

Factory

default settings are those set for each menu item at the factory. The printer uses

these settings until you change them.

n

Temporary drfaull settings are those set by your application software for the current print

job.

n

Permanent default setlings are those you set through the operator panel. These selections

remain in effect even when you turn off the printer or send a different request through your

application.

You

can

restore the factory default settings by performing a cold reset. To perform a cold reset,

press and hold the ON LINE key while you turn on the printer.

The

printer

comes on-line, the factory default settings are restored.

displays the message COLD RESET followed by WARMING UP. When lhe printer

l-19

CHAPTER

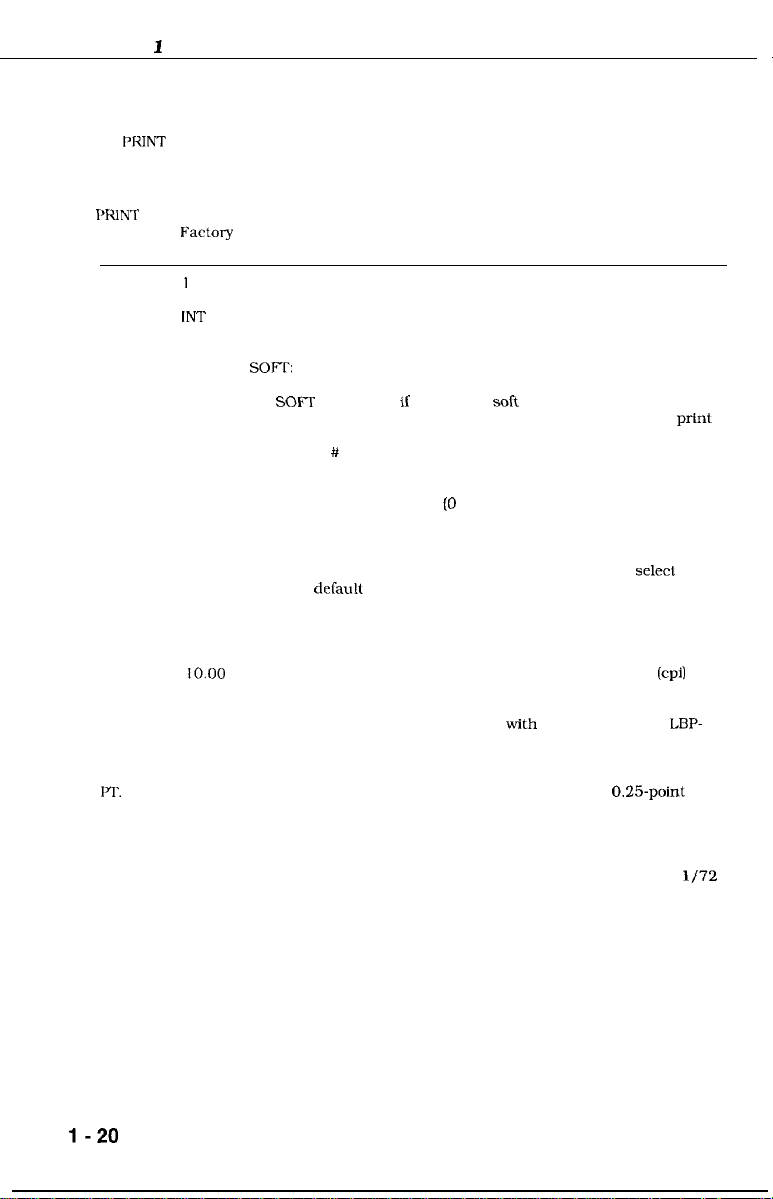

C. PCL PRINT MENU Options

The PCL PKINT MENU contains the most commonly used options. You can override or change

all options in this menu through your software application. The changes you make through the

operator panel become the permanent default settings.

1

I’RlNT

MENU

option

COPIES

FNT SRC

FNT

NUMBEK

PITCH

I-1‘.

SIZE

FX%Ory

default Description

I

IN?‘

0

10.00

Selects the number of copies [from 1 to 99) you want to print.

Selects the font source. You can select:

INT:

CART:

SOFl?:

You see the CART option only if a cartridge is installed, and you see

the

SO@T

If you do not know the font source and font number, you can print a

Font List. The letter you specify here must match the alpha portion

of the Font # on the Font List. For more information about printing

this list. see the Printing the Font List section.

Identifies the Font Number (0 through 999) as listed on the Font

List. Make sure you use the Font # not the Font ID.

If you have installed a font cartridge with a default mark, the

default-marked font overrides the factory default font. The cartridge

default font appears in the PCL PRINT MENU until you selecl a

different

application, you remove the cartridge. or insert a different cartridge

when the default number is 0. The symbol set for the PCL PRINT

MENU is not changed by the marked cartridge.

Selects pitch sizes from 0.44 to 99.99 characters per inch

scroll increments of 0.01. [Hold down the arrow key to increment

rapidly.) You can select a pitch if the font indicated by FNT SRC and

FNT NUMBER is a scalable typeface with fixed spacing. The

860 adjusts the height (point size) of the characters according to the

pitch you select.

12.00

Selects the point size from 4.00 to 999.75 points in 0.25.point

increments. The scroll increment is 0.25 or 1.00 (if you hold down

the arrow key). You can select the point size if the font indicated by

FNT SRC and FNT NUMBER is a scalable font with proportional

spacing.

Point size is a measure of the vertical height of a character in l/72

of an inch. The LBP-860 adjusts the character’s horizontal spacing

according to the point size you select.

Internal fonts

Cartridges

Permanent soft font

option only if permanent salt fonts are downloaded.

deCault

through the operator panel or your software

(cpi)

in

LBP-

l-20

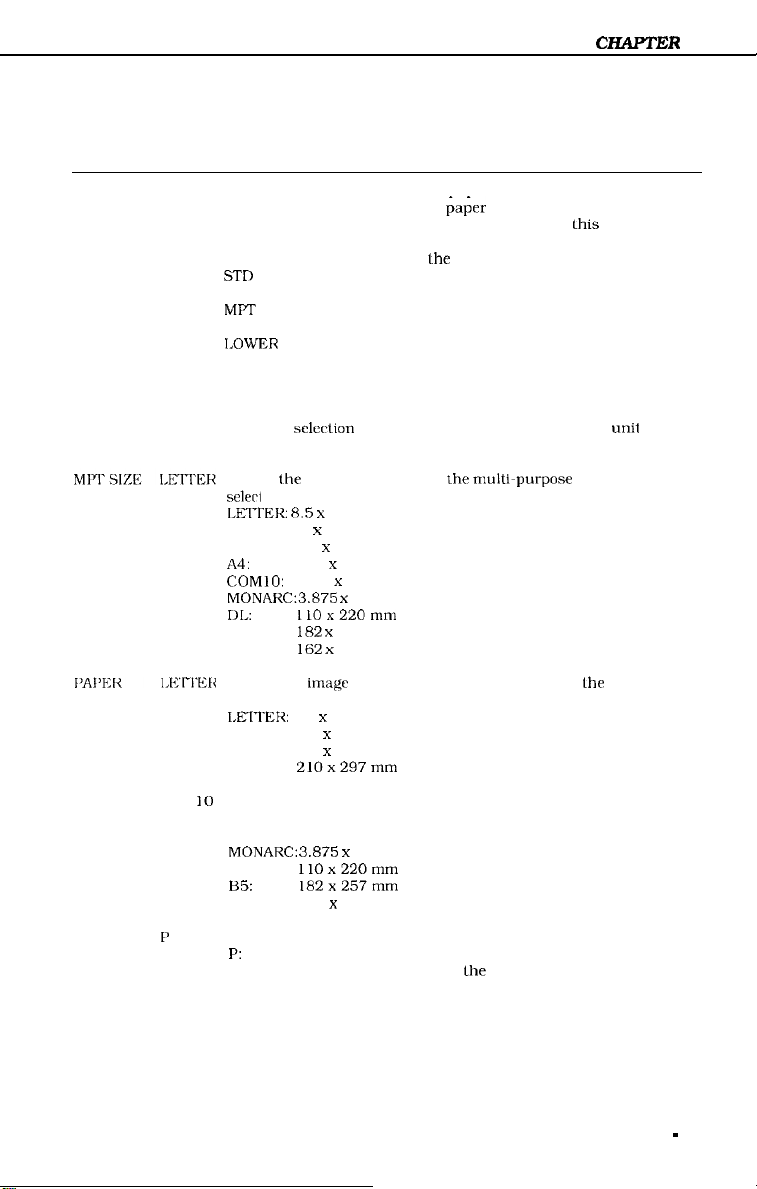

PRINT

MENU

option

TRAY ALL

Factory

default Description

Selects how the printer will load paper. You can select:

ALL Loads paper from any

STD

MPT

1,OWER

ENV

Selects

selerl :

LEKITEK: 8.5 x

LEGAL 8.5 x 14 inches

EXEC:

A4: 2 10 x 297 mm

COMlO: 4.125 x 9.5 inches

MONARC:3.875 x 9.5 inches

r)k

H5: 182 x

C5:

Selects the

a software command overrides it. You ran select:

LMTER:

LEGAL:

EXEC:

A4:

loads from the standard cassette first: if

empty, it loads from the lower cassette (if the Paper Feeder

Unit is installed) or lhe multi-purpose tray.

Loads from the standard paper cassette only: if this

cassette is empty, you see an error message.

Loads from the multi-purpose tray only; if this tray is

empty, you see an error message.

Loads from the optional Paper Feeder Unit only; if this

cassette is empty, you see an error message. You see this

selection only if the optional Paper Feeder Unit is installed.

Loads from the optional Envelope Feeder unit only; if this

feeder is empty, you see an error message. You see this

sclcrtion only if the optional Envelope Feeder

installed.

the

paper size loaded in the

11 inrhrs

7.5 x 10.5 inches

llOx220mm

257 mm

162

x 219 mm

image

size al which the printer formats

8.5 x 11 inches

8.5 x 14 inches

7.5 x 10.5 inches

21Ox297mm

l&&r

input source. The printer

multi~purpose

tray. You can

Lhis

CZ-LAPTER

cassette is

unil

is

the

page unless

1

ENVELOPE COM

ORIENTATI

ON

E’

10

Selects the image sue at which the printer formats the envelope

unless a software command overrides it. You see this menu item

only if the optional Envelope Feeder is installed. You can select:

MONARCz3.875 x

DL:

B5:

c5:

Selects the direction of print on the page.

P:

L:

You can print in reverse portrait or reverse landscape orientations

by making selections through your software application or using

printer commands. The LBP-860 has a font rotation feature which

makes all fonts available in all orientations.

9.5 inches

llOx220mm

l82x257mm

162 x 219 mm

Portrait prints along the width of the page

Landscape prints along lhe length of the page

1 - 21

CHAPTER 1

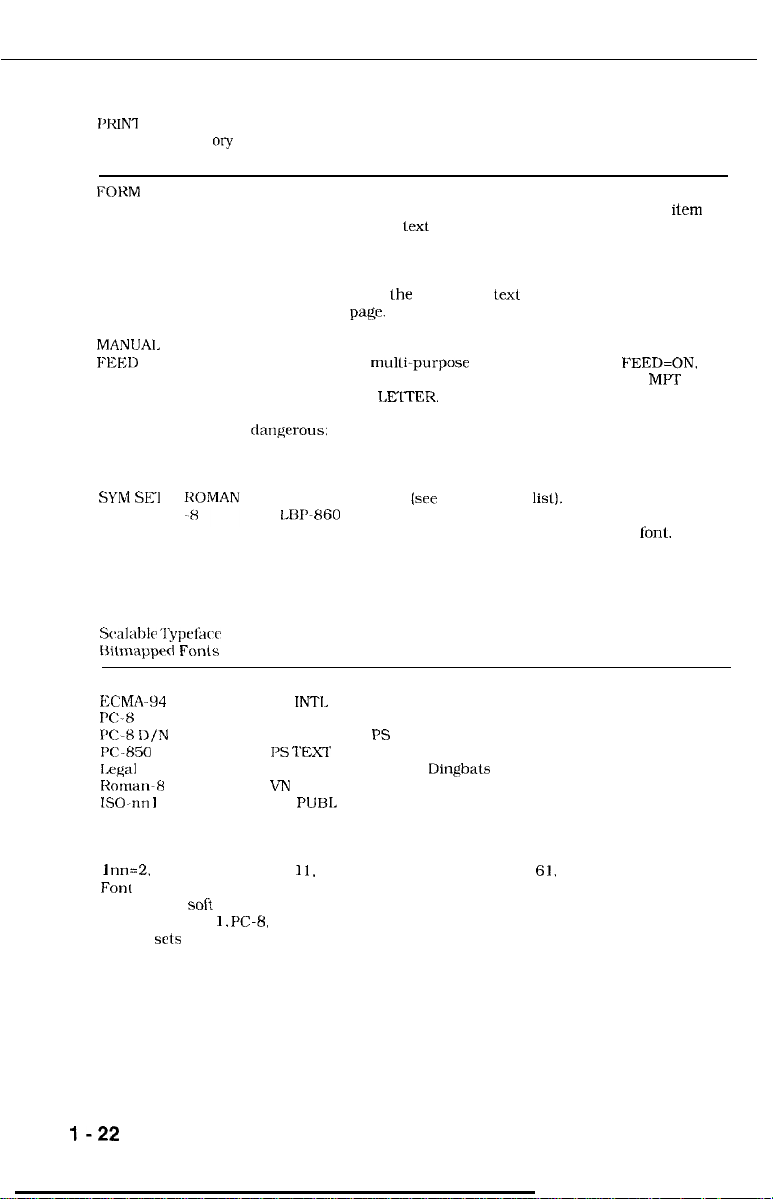

I’RIN’I

MENU

option

Fart

“l-y

default Description

FORM

MANIJAI,

FIXD

SYM SF1

Scalable ‘lypefkcc and

t%iLnlapprd Fonts

Roman-8

ECMA-94 Latin 1

X-8

PC-K D/N

PC850

Legal

Rornarl-8

ISO-nn

German

Spanish

60

LINES

OFF

I

Selects the number of lines to print on each page (5 through 128) as

well as the amount of space between lines. The FORM menu

places the first line of lext at the top margin, the last line of text at

the bottom margin. and spaces the remaining lines equally between

them. Make sure the text length setting in your software application

matches the value you use for this item. If it is set lo a greater value

in your application, lhe first line of texl may begin successively

lower on each

Turns the manual feed function ON or OFF. Manual feed is available

only through the mulli-purpose tray. When MANUAL FEED=ON. the

printer goes off-line when a print job is sent and displays MPT TRAY

followed by LOAD LELTER. Press the RESET key to manually feed

the media in the multi-purpose tray. *** Pressing the RESET key is

da~lgerous:

the buffer! *** To override a manual feed request, press the

CONTINUE key.

Selects the symbol set

The IBl’-860 provides 40 symbol sets you can choose. A symbol set

is a unique grouping of all the available characters in a

listing shows the internal symbol sets you can select from the

operator panel.

Scalable Typefaces Only

VN MATH WINDOWS

VN INTL DESKTOP

VN US

I’S MATH

I’S TFXT

MATH-8

VN

MS PUBL

page.

if the user presses the key loo long, it erases the data in

[see

VN DING

I

MATH WINDOWS

I’S DING

DING 1

DING 2

Dingbats

the following

lisl).

fonl.

item

This

1

nn=2.

4. 6 (US ASCII). 10.

Font

List printout shows all symbol sets for installed cartridges and permanent

downloaded soli fonts. Internal bitmapped font symbol sets are only shown in Roman-8,

ECMA-94, Latin I,

symbol srts appear on the PCL Font List printout only if selected as the default symbol set

from the operator panel.

PC-B,

1 I.

14, 15, 16. 17, 21, 25, 57, 60,

PC-8 D/N, PC-850, and Legal. The remaining selectable internal

61,

69, 84, or 85. The PCL

I-22

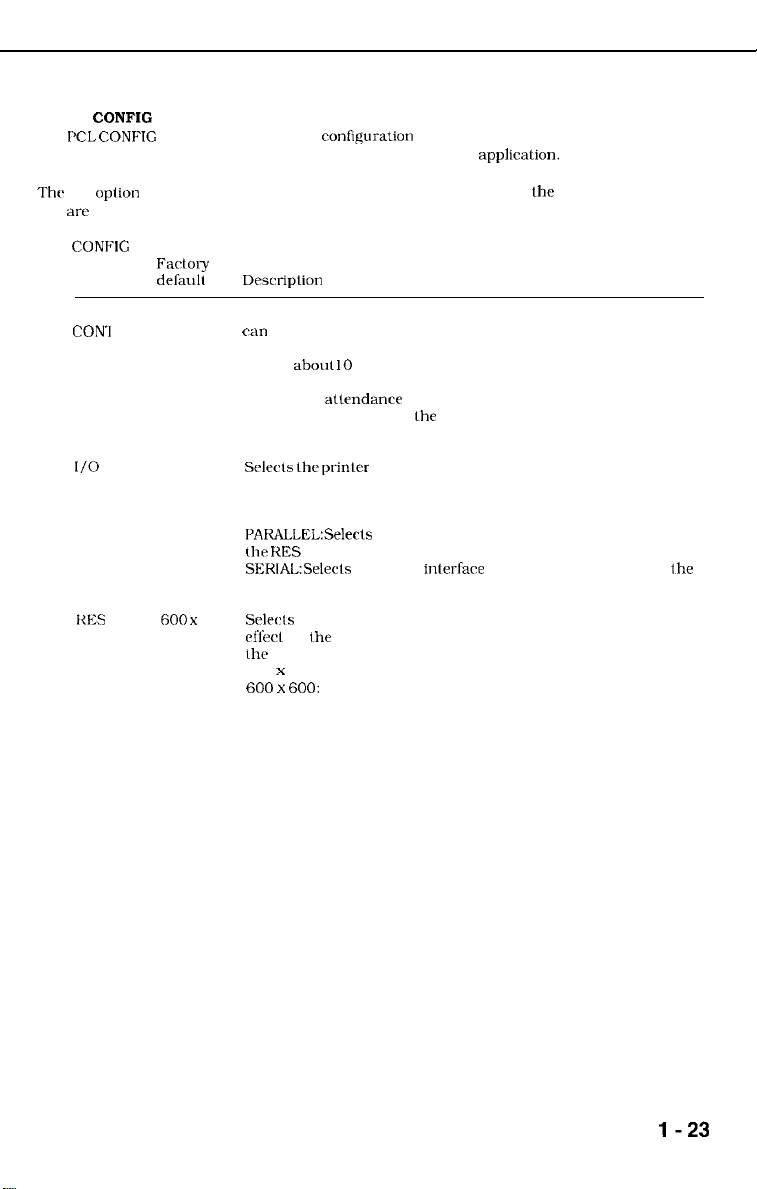

D. PCL CONFIG MENU Options

The PCL

CONFIG

override or change options in this menu through your software applicalion.

MENU controls certain

conflguration

settings for your LBP-860. You cannot

CHAPTER 1

The I/O oplion allows you to set up the communication parameters for

you

arc

using it).

CONFIG

MENU Farto1y

option

AUTO ON

CON-1

I/O

RES

del%ult

AUTO

tiO0 x

Desrriplion

Determines how the printer reacts Lo data and printer errors. You

can

select:

Any non-critical error message appears on the display for

ON:

aboul 10 seconds: then the PCL READY message appears

and printing resumes.

OFF:

Any atlrndancc or error message remains in the display

until you correct lhe problem, tell the printer to continue.

or both.

Selecls

thr-

AUTO: Allows the printer to determine the interface port. which

PAKALLEL:Selects the parallel interface only. The printer skips to

the

SEKIAL:Selects the serial inlerfare only. The printer displays the

communications options described in the next section.

Sclwls

600

eff&l

the

300 x 300:

600 x 600:

prinlcr interface. You can select:

can lx either parallel or serial. The printer displays the

communications options described in the next section.

KES menu option.

300 or 600 dpi. When you change resolution, it lakes

for ihe next print job or when you reset the printer through

operator panel. You can select:

for graphics and fonts designed for 300 dpi.

for graphics and fonts designed for 600 dpi; use

when document contains a mix of 300 and 600 dpi

bitmaps.

the

serial interface (if

l-23

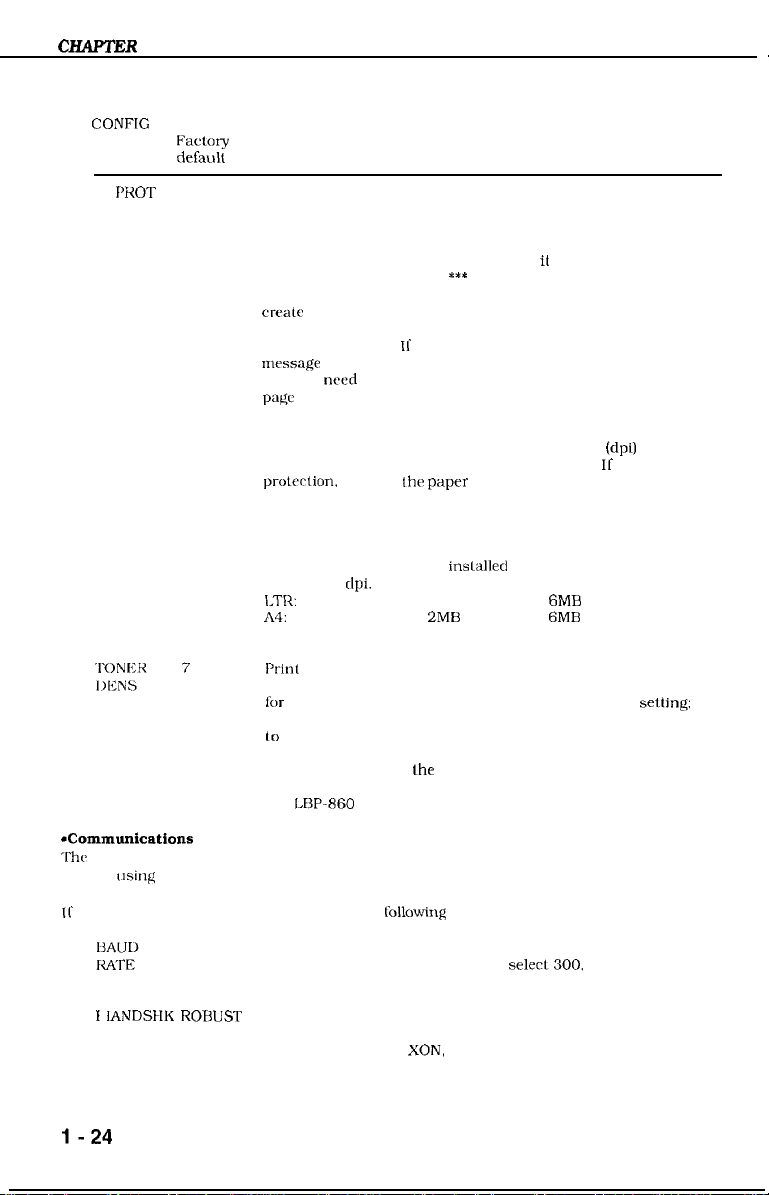

CHAPTER

1

CONFIG

MENU

option deSa&

PG I’ROT

FXtory

OFF

Description

Reserves additional memory for the page imaging process. This

allows the printer to create the complete page image in memory

before paper starts through the printer, which ensures the entire

page is printed. The value you set for page protection does not

lake effect until you reset the printer or it encounters a job

boundary. *** Is this true?

The complexity of a page may exceed the printer’s ability to

create

the image and keep pace with the printing process. If a

page is too complex. the page may print in parts. or only part of

the page may print. II data loss occurs, the PRINT OVERRUN

nwssage

appears in the display. If you often receive this message,

you may

page

The memory required for page protection is dependent on the

four times more memory than a page at 300 dpi. If you use page

you select. The figures shown here include 2MB of internal

wed

protection.

protcrtion. set it for

Makr sure you have sufficient memory installed for the option

memory. You can select:

OFF:

LTR:

124:

LGL:

t’rint

You ran experiment with different settings to find the best setting

lor

your print job. To make print darker, use a higher

make print tighter, use a lower setting. The selections are from 0

Io

15.

to install additional memory and set a value for

requires minimum inslalled memory of 2MH for 300 and

600

dpi.

requires 2MB for 300 dpi:

requires

requires 3MB for 300 dpi: 6MB for 600 dpi.

density is a measure of the darkness of print on the page.

***

A page at 600 dots per inch

the

paper size you expect to use most often.

2MB

for 300 dpi:

6MB

for 600 dpi.

6MB

for 600 dpi.

(dpi)

requires

selting:

to

NOTE: When you set lhe density to a higher level.

LANG

dhnmunications

Thhc

I/O option allows you lo set up the communication parameters for the serial interface (if

you arc {Ising it).

II you set I/O to AUTO or SERIAL. you see the

t

IANDSMK

ENGLISH

Menu

9600

ROBUST Selects the handshake method for controlling data transfer

The

LBP-860

supports the English language.

liillowing

menu options:

Determines the rate at which information is transferred between

the computer and printer. You can selecl300, 600. 1200, 2400.

4800, 9600. 19200. 38400, or 57600.

between the computer and printer. For RS-232C operation, you

can select ROBUST, XON, or N/W.

l-24

Loading...

Loading...