Canon LBP 800, LBP 810 Service Manual

Revision of Service Manual for LBP-800/810

RY8-13A0-01Y

The Service Manual for LBP-800 will have been revised to contain updated

information and error corrections over the revised edition 1.

Part number for the Service Manual is below:

RY8-13A0-000 : Revised edition 0 of Service Manual

RY8-13A0-010: Revised edition 1 of Service Manual

Please be advised to keep at hand the revised edition of the Service Manaul.

Issued by Peripheral Products Quality Assurance Center, Canon Inc.

SE RVICE INFORMATION

NO.

DATE

LOCATION

SUBJECT

Printed in Japan

Imprime au Japon

MODEL :

RBB-12E-0001

Feb. 28, 2001

SERVICE

MANUAL

REVISION 1

COPYRIGHT 2001 CANON INC. CANON LBP-800/810 REV.1 FEB. 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

FEB. 2001

RY8-13A0-010

COPYRIGHT © 2001 CACON INC

Printed in Japan

Imprimé au Japon

Prepared by

PERIPHERAL PRODUCTS QUALITY PLANNING DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki-Pref. 302-8501, Japan

Use of this manual should

be strictly supervised to

avoid disclosure of confidential information.

PREFACE

This Service Manual contains basic information required for after-sales service of the laser beam

printer LBP-800/810 (hereinafter referred to as the "printer"). This information is vital to the

service technician in maintaining the high print quality and performance of the printer.

This manual consists of the following chapters:

Chapter 1: Product information

Features, specifications, operation, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly and adjustment

procedures

Chapter 4: Troubleshooting

Troubleshooting procedures, reference values and adjustments, maintenance and

servicing, etc.

Appendix: General timing chart, general circuit diagram, etc.

Information in this manual is subject to change as the product is improved or redesigned. All

relevant information in such cases will be supplied in the Service Information Bulletins.

A thorough understanding of this printer, based on information in this Manual and Service

Information bulletins, is required for maintaining its performance and for locating and repairing

the causes of malfunctions.

PREFACE

P - 1

PREFACE

P - 2

DTP system

This manual was produced on an Apple PowerMacintosh G4/500MHz personal computer and output by a

Canon COLOR LASER SHOT LBP-2260PS laser beam printer; final pages were printed on AGFA Selectset

avantra 25.

All graphics were produced with Macromedia FreeHand (J), and all documents and page layouts were

created with QuarkXPress (E).

The video images were captured with SONY degital video camcorder and Radius PhotoDV capture board

system, and modified with Adobe Photoshop (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

PREFACE

P - 3

I. FEATURES................................ 1-1

II. SPECIFICATIONS...................... 1-2

A. Printer ................................. 1-2

III. SAFETY INFORMATION........ 1-4

A. Handling the Laser/Scanner

Unit ..................................... 1-4

B. Toner Caution...................... 1-4

C. Ozone Safety ....................... 1-4

IV. PARTS OF THE PRINTER.......... 1-5

A. External View ...................... 1-5

B. Cross Section....................... 1-6

V. INSTALLATION ......................... 1-7

A. Precautions.......................... 1-7

B. Storage and Handling of EP-22

Cartridge ............................. 1-8

VI. MAINTENANCE AND CHECKS

BY THE CUSTOMER ................. 1-10

VII. OPERATION.............................. 1-11

A. Canon Advanced Printing

Technology (CAPT)............... 1-11

B. Microsoft Windows NT4.0 .... 1-12

C. Microsoft Windows 2000...... 1-48

D. Microsoft Windows

95/98/Me............................ 1-59

E. Printing Environment Setting

and Test Printing................. 1-71

I. BASIC OPERATION ................... 2-1

A. Functions ............................ 2-1

B. Basic Operation Sequence.... 2-2

C. Power-ON Sequence ............. 2-3

II. ENGINE CONTROL SYSTEM...... 2-4

A. Engine Controller PCB ......... 2-4

B. Fixing Control Circuit.......... 2-8

C. High-Voltage Power Supply

Circuit ................................. 2-10

D. Low-Voltage Power Supply

Circuit ................................. 2-12

E. Video Interface.................... 2-14

III. LASER/SCANNER SYSTEM ....... 2-17

A. Outline ................................ 2-17

B. Laser Control Circuit ........... 2-18

C. Scanner System................... 2-21

IV. IMAGE FORMATION SYSTEM.... 2-23

A. Outline ................................ 2-23

B. Print Process ....................... 2-24

V. PICK-UP/FEED SYSTEM ........... 2-31

A. Outline ................................ 2-31

B. Jam Detection ..................... 2-33

VI. VIDEO CONTROL SYSTEM........ 2-34

A. Interface Controller PCB

(LBP-800)............................. 2-34

B. Interface Controller PCB

(LBP-810)............................. 2-36

I. PREFACE.................................. 3-1

II. EXTERNALS ............................. 3-2

A. Locations............................. 3-2

B. External Covers ................... 3-2

III. MAIN UNITS ............................. 3-5

A. Laser/Scanner Unit.............. 3-5

B. Drive Unit............................ 3-6

C. Feed Unit............................. 3-7

D. Delivery Unit ....................... 3-8

E. Fixing Film Unit .................. 3-8

IV. MAIN PARTS............................. 3-10

A. Locations............................. 3-10

CHAPTER 2 OPERATION AND TIMING

CHAPTER 3 THE MECHANICAL SYSTEM

PREFACE

P - 4

B. Pick-up Roller...................... 3-11

C. Separation Pad .................... 3-11

D. Transfer Charging Roller...... 3-13

E. Pressure Roller .................... 3-13

V. SWITCHES/SENSORS/LEDS ..... 3-15

A. Locations............................. 3-15

B. Paper Top Sensor/

Paper-out Sensor ................. 3-16

C. Power Switch/Test Print Switch/

Door Open Detection Switch/

Paper Delivery Sensor.......... 3-16

D. Display Unit LED ................. 3-16

VI. MOTOR/SOLENOID .................. 3-17

A. Locations............................. 3-17

B. Main Motor .......................... 3-18

C. Pick-up Solenoid.................. 3-18

VII. PCBs......................................... 3-19

A. Locations............................. 3-19

B. Interface Controller PCB

(LBP-800)............................. 3-20

C. Interface Controller PCB

(LBP-810)............................. 3-21

D. Engine Controller PCB ......... 3-22

E. Display PCB ......................... 3-24

I. PREFACE.................................. 4-1

A. Malfunction Diagnosis

Flowchart ............................ 4-1

B. Initial Check........................ 4-4

C. Test Print ............................ 4-5

II. IMAGE DEFECTS

TROUBLESHOOTING................. 4-7

III. JAMS TROUBLESHOOTING....... 4-13

IV. TRANSPORT

TROUBLESHOOTING................. 4-16

V. MALFUNCTION

TROUBLESHOOTING................. 4-17

VI. MALFUNCTION STATUS

TROUBLESHOOTING................. 4-18

VII. MEASUREMENT AND

ADJUSTMENT........................... 4-21

A. Mechanical Adjustment ....... 4-21

B. Electrical Adjustment .......... 4-21

C. LEDs, Test Pins, Jumpers,

and Switches on PCBs.......... 4-22

VIII.MAINTENANCE AND

SERVICING............................... 4-23

A. Periodic Replacement

Parts.................................... 4-23

B. Expected Servicing Lives of

Consumable Parts ................ 4-23

C. Periodic Service................... 4-23

D. Cleaning During a Service

Visit .................................... 4-24

E. Standard Tools..................... 4-26

F. Special Tools ....................... 4-26

G. List of Lubricants and

Cleaners .............................. 4-27

IX. LOCATION OF CONNECTORS.... 4-28

I. GENERAL TIMING CHART ........ A-1

A. Timing Chart for Printing

Two A4-size Sheet

Continuously ....................... A-1

II. GENERAL CIRCUIT DIAGRAM... A-2

A. Engine Controller PCB ......... A-2

B. Interface Controller PCB

(LBP-800)............................. A-3

C. Interface Controller PCB

(LBP-810)............................. A-4

III. LIST OF SIGNALS ..................... A-5

A. Engine Controller ............... A-5

IV. MESSAGES TABLE.................... A-7

A. Message List ........................ A-7

APPENDIX

CHAPTER 4 TROUBLESHOOTING

CHAPTER 1

PRODUCT INFORMATION

I. FEATURES................................ 1-1

II. SPECIFICATIONS...................... 1-2

III. SAFETY INFORMATION........ 1-4

IV. PARTS OF THE PRINTER.......... 1-5

V. INSTALLATION ......................... 1-7

VI. MAINTENANCE AND CHECKS

BY THE CUSTOMER ................. 1-10

VII. OPERATION.............................. 1-11

I. FEATURES

1. Small-Sized Printer with High Speed and High Resolution

This printer has paper pick-up trays on its top for space saving, and is compact enough to set

on a desk. In addition, it has realized high speed of 8 pages per minute (A4) and high resolution of 600 dpi.

2. Employment of Canon Advanced Printing Technology

With Canon Advanced Printing Technology, data can be processed within a host computer. This

frees the printer from the PDL conversion and image processing, increasing the speed performance and reducing the cost.

3. Shortened Wait Time & Low Power Consumption

By adopting an on-demand fixing method that drives the heater only during printing, the printer has shorten the wait time and reduced the consumption power during standby.

4. Low Noise

In addition to an on-demand fixing method, the printer has increased its heat exhaust efficiency so as to remove the fan for realizing a low noise level.

5. Direct Connection to the Network

The printer enables the user to connect directly to the printer by utilizing a specified network

adapter.

6. Employment of USB Interface as a Standard (LBP-810 Only)

The printer employs an USB interface as a standard, allowing easy connection to peripherals.

CHAPTER 1

1 - 1

II. SPECIFICATIONS

A. Printer

1. Printer Engine

1) Type Desktop page printer

2) Printing method Electrophotography

3) Printing speed (Note1) 8 pages/minute (A4)

4) First print time (Note2)

•Face-down 18 seconds or less

•Face-up 17 seconds or less

5) Wait time (Note3) 8 seconds or less

6) Resolution

•Horizontal 600 dots/inch

•Vertical 600 raster lines/inch

7) Image formation system

•Laser Semiconductor laser

•Scanning system Rotating four-faced prism mirror

•Photosensitive drum OPC

•Charging Roller charging

•Exposure Laser scanning

•Toner Magnetic single-component dry toner

•Development Toner projection development system

•Toner supply Replaceable EP-22 toner cartridge (able to print approx. 2,500 A4sized print sheets: with image density set in the middle, and 4 %

dot density ratio)

•Image transfer Roller transfer

•Separation Curvature separation

•Cleaning Blade

•Fixing method On-demand fixing

8) Feeding Manual feed slot

Multi-purpose tray

Paper types Plain paper, recycled paper, colored paper, labels, OHT, index

cads, postcards and envelops

Paper size (Note4)

•Manual feed slot 76.2 mm(W) x 127 mm(L) ~ 216 mm(W) x 356 mm(L) sized paper

(64 g/m2to 105 g/m2Canon recommended paper) and above mentioned paper

•Multi-purpose tray 76.2 mm(W) x 127 mm(L) ~ 216 mm(W) x 356 mm(L) sized paper

(64 g/m2to 105 g/m2Canon recommended paper) and above mentioned paper

Capacity

•Manual feed slot one sheet

•Multi-purpose Depth 12.5 mm (Approx. 125 sheets of 75 g/m

2

paper)

9) Delivery (Note5) Face-down/face-up

•Face-down tray capacity Approx. 50 sheets of 75 g/m

2

paper

10) Duplex printing

•Manual duplex printing The paper is picked up from the multi-purpose tray and delivered

(Note6) face-up. Only plain paper (64-105 g/m2Canon recommended

paper) can be printed duplex.

11) Operating environment

Temperature 10 ~ 32.5 ÞC

Humidity 20 ~ 80 % RH

CHAPTER 1

1 - 2

Air pressure 613 ~ 1013 hPa (460 ~ 760 mmHg)

12) Power consumption Approx. 770 W or less (Room temperature 20 °C, with rated line

voltage on)

13) Noise level (Officially announced noise emission level in accordance with ISO 9296)

Sound power level (1B = 10 dB) 6.2 B or less (printing)

Dark sound level (standby)

Sound pressure level 48 dB or less (printing)

(Bystander position) Dark sound level (standby)

14) Dimensions 345(W) x 312 mm(D) x 266 mm(H)

15) Weight Approx. 6.6 Kg (printer only), Approx. 0.71 Kg (cartridge)

16) Power supply 100-127V ±10% (50/60 Hz ±2 Hz)

220-240V +6%-10% (50 Hz ±2 Hz)

Notes: 1. A test print when the room temperature is 20 °C and the rated power voltage is input.

2. The time taken from that the Print signal is received from the video controller until

that an A-4 sized paper is delivered completely, and also when the printer is in the

Ready mode at room temperatures of 20 °C.

3. The time taken from that the power plug is plugged in until that the printer becomes

ready to print (Ready or Standby mode.)

4. Paper with the width of less than 182 mm should not exceed 235 mm in length.

5. Only plain paper and recycled paper can be delivered face-down.

6. To print duplex manually, uncurl the face-up delivered paper and set it in the multi-

purpose tray.

2. Interface controller

1) Printing System Canon Advanced Printing Technology

2) ROM capacity 8 KB

3) RAM capacity 512 KB

4) Interface Bi-directional 8 bit parallel interface (Centronics specifications)

Specifications are subject to change with product improvement.

CHAPTER 1

1 - 3

III. SAFETY INFORMATION

A. Handling the Laser/Scanner Unit

An invisible laser beam is emitted within the laser/scanner unit.

The laser beam can cause eye damage if exposed, so be sure not to disassemble the

laser/scanner unit. It is not necessary to adjust the laser/scanner unit in this printer in the

filed.

The following label is attached to the laser/scanner cover.

Figure 1-3-1

B. Toner Caution

The toner is non-toxic substance composed of plastics and minute color pigments.

If toner adheres to the skin or clothing, remove as much as possible with dry tissue first, then

wash with cold water, Hot water should not be used, as the toner will solidify and become difficult to remove.

Toner will easily decompose vinyl materials, therefore avoid the toner to come close to vinyl.

C. Ozone Safety

An infinitesimal amount of ozone gas (O3) is generated during corona discharge from the charging roller. The ozone gas is emitted only while the printer is operating.

This printer meets the ozone emission reference value set by Underwriters Laboratory (UL) at

the time it is shipped from the factory.

CHAPTER 1

1 - 4

DANGER

CAUTION

RAYONNEMENT LASER INVISIBLE EN CAS D'O UVERTURE.

EXPOSITION DANGEREUSE AU FAISCEAU.

UNSICHTBARE LASERSTRAHLUNG. WENN ABDECKUNG GEOFFNET.

NICHT DEM STRAHL AUSSETZEN.

RADIAZIONE LASER INVISIOILE IN CASO DI APERTURA.

EVITARE L'ESPOSIZIONE AL FASCIO.

RADIACION LASER INVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

AVATTAESSA OLET ALTTIINA NAKYMATTOMALLE

LASERSATEILYLLE. ALA KATSO SATEESEEN.

OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

BETRAKTA EJ STRALEN.

USYNLIG LASER STRALING. NAR DENNE ER ABEN.

UNDGA BESTRALING.

USYNLIG LASERSTRALING NAR DEKSEL APNES.

UNNGA EKSPONERING FOR STRALEN.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

INVISIBLE LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO BEAM.

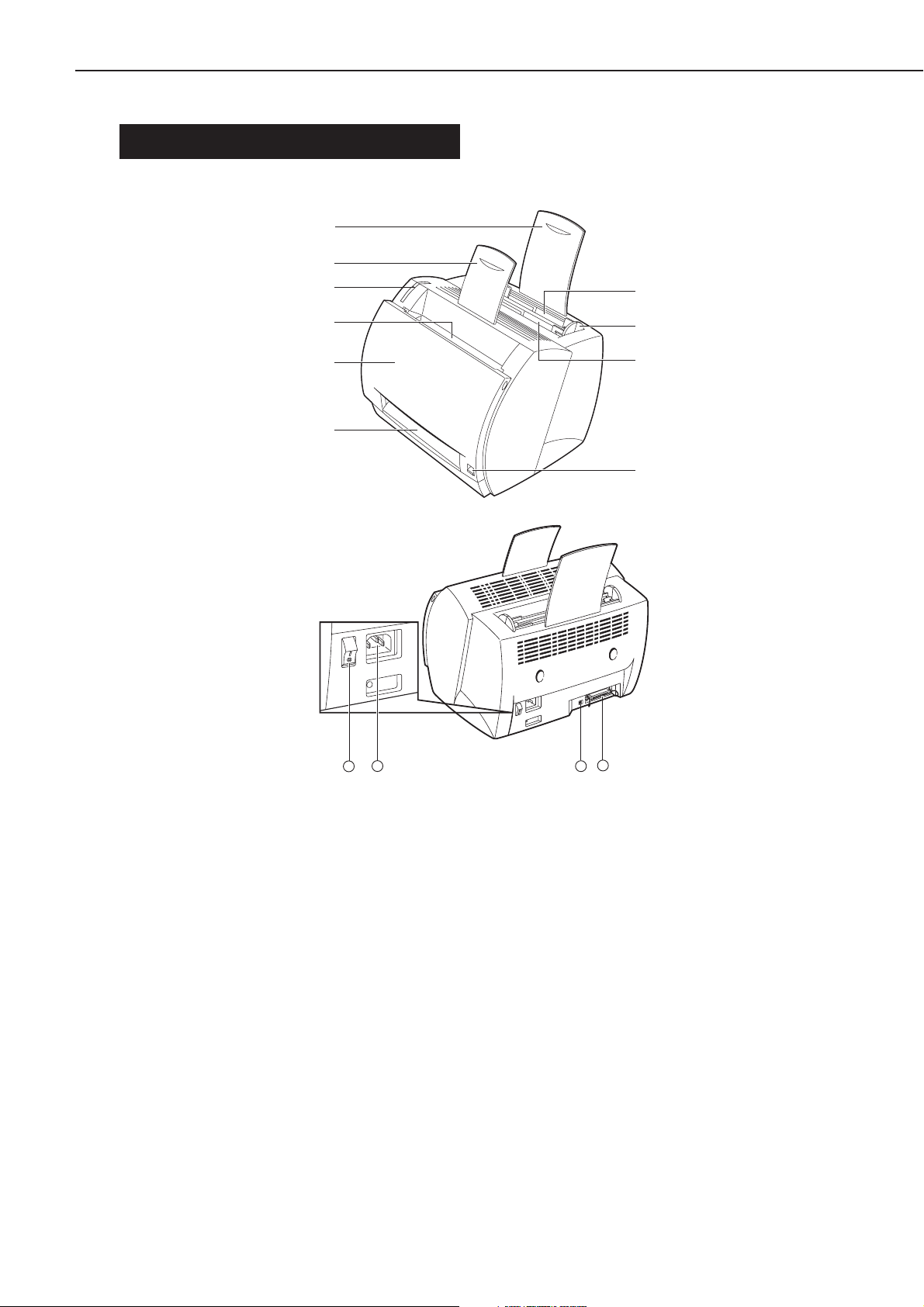

IV. PARTS OF THE PRINTER

A. External View

1: Multi-purpose tray 2: Paper width guide

3: Manual feed slot 4: Delivery switching lever

5: Face-up delivery port 6: Cartridge cover unit

7: Face-down delivery tray 8: Display unit

9: Delivery guide 10: Paper pickup sub tray

11: Parallel port 12: USB port

13: Power receptacle 14: Power switch

Figure 1-4-1

CHAPTER 1

1 - 5

➉

➈

➇

➀

➆

➅

➁

➂

➄

➃

13

14

11

12

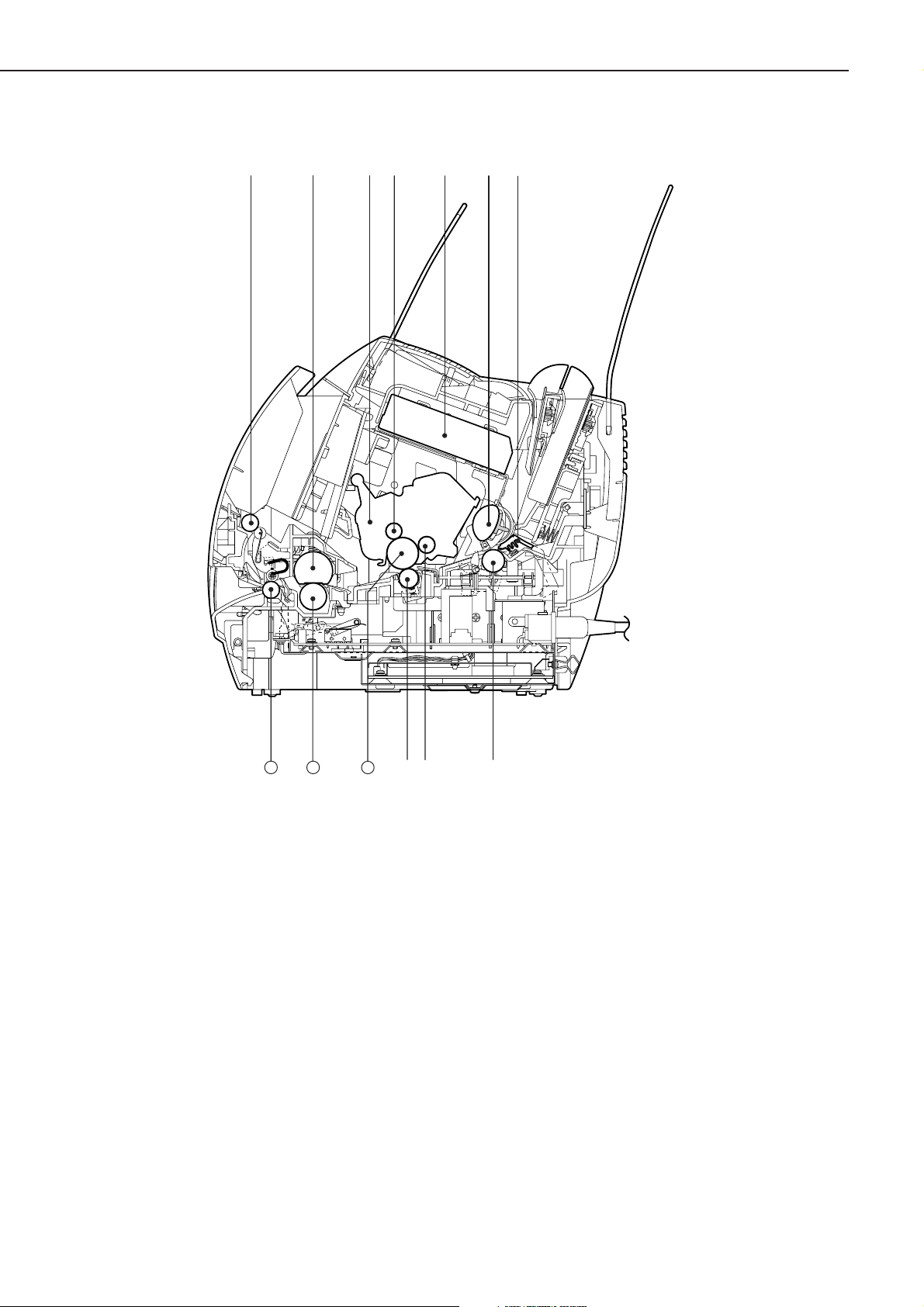

B. Cross Section

1: Face-down delivery roller 2: Fixing film unit

3: EP-22 cartridge 4: Primary charging roller

5: Laser/scanner unit 6: Pick-up roller

7: Separation pad 8: Feed roller

9: Developing cylinder 10: Transfer charging roller

11: Photosensitive drum 12: Pressure roller

13: Fixing delivery roller

Figure 1-4-2

CHAPTER 1

1 - 6

➀

➁

➂

➃

➄

➅

➆

13

12

11

➈

➉

➇

V. INSTALLATION

A. Precautions

This product has been carefully adjusted and strictly inspected before packing and shipping. To

make the operation as intended, it is important to install it correctly. Service engineers must

understand the performance of the printer sufficiently, install it in the appropriate environment

with proper procedures, and operate the necessary checks.

The following requirements must be met when installing the printer.

The service engineer should inspect the installing site before taking the printer to the cus-

tomer’s premises.

• Power must be directly connectable to a single socket with a supply voltage within ± 10 % of

the rated voltage (100-127V) or +6 % to -10 % of the rated voltage (220-240V.)

• The temperatures should be in a range from 10 to 32.5 ÞC and the relative humidity from

20 to 80 %. Avoid areas closed to water faucets, boilers, humidifiers, or refrigerators.

• Avoid areas near open flames, dusty locations, windy locations, areas which emit ammonia

gas, and areas directly exposed to sunlight. When exposure to direct sunlight is unavoidable, hanging curtains is recommended.

• The room should be well ventilated.

• The printer should be placed on a level surface.

• If the printer is set up on a desk, be sure a study desk is used.

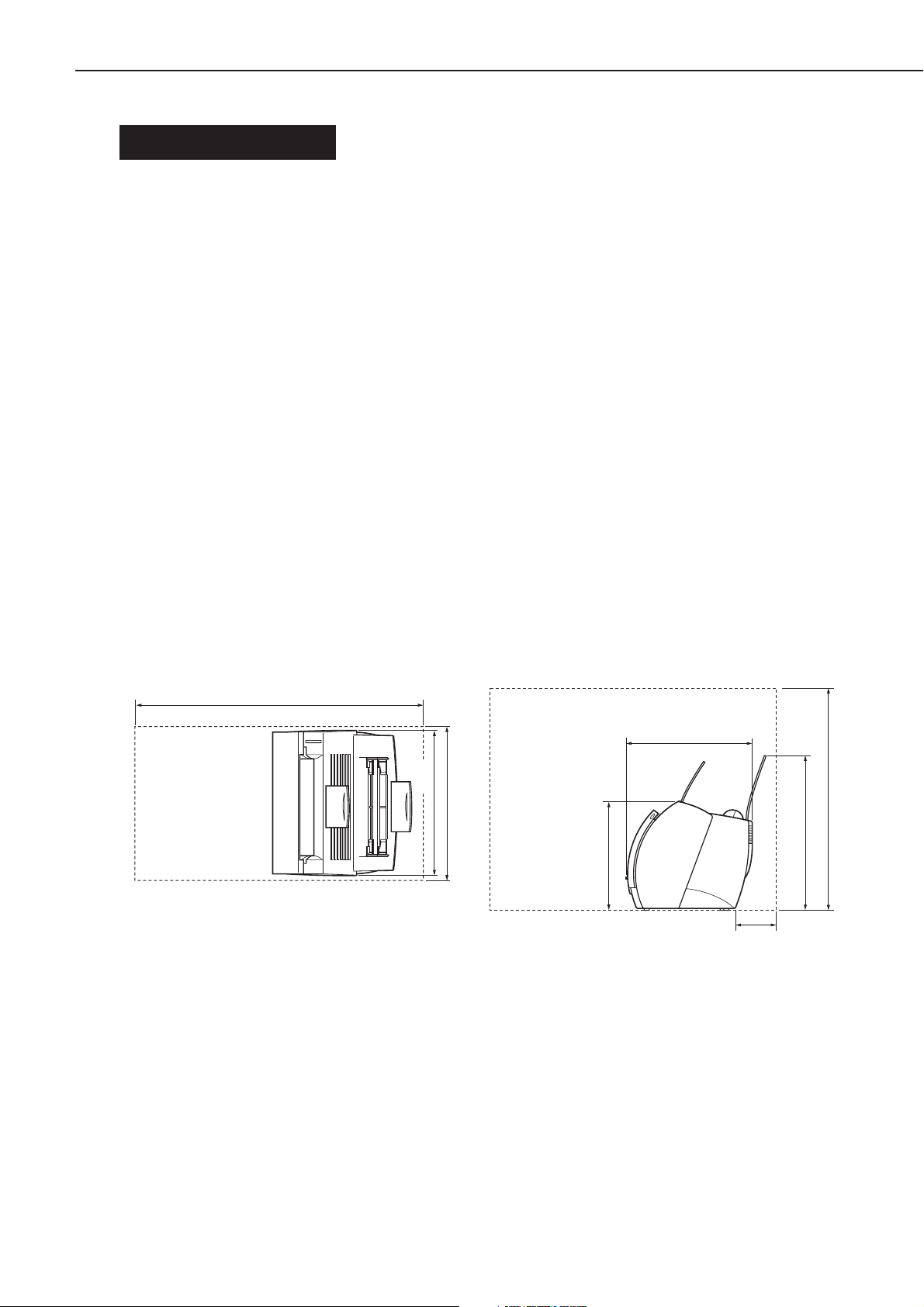

• Set the printer at a suitable distance from the wall for easy operation (See Figure 1-5-1.)

There must be enough space around the printer to operate.

Following dimensions should be taken into consideration to select an installation space for

the printer.

Figure 1-5-1

When metals are moved from a cold area to warm area, condensation may appear. This can

lead to various troubles during an operation. When the printer needs to be moved from a cold

area to warm area, leave it packed in its box for at least an hour to acclimatize to room temperature.

CHAPTER 1

1 - 7

768

312

345

405

550

378

266

100

B. Storage and Handling of EP-22 Cartridge

As time passes, the natural environment will change the cartridge, whether sealed or installed

in the printer, or regardless of the number of prints. The progression of this natural change

depends largely on the storage and installation environment, therefore, take special care on storage and handling the cartridge.

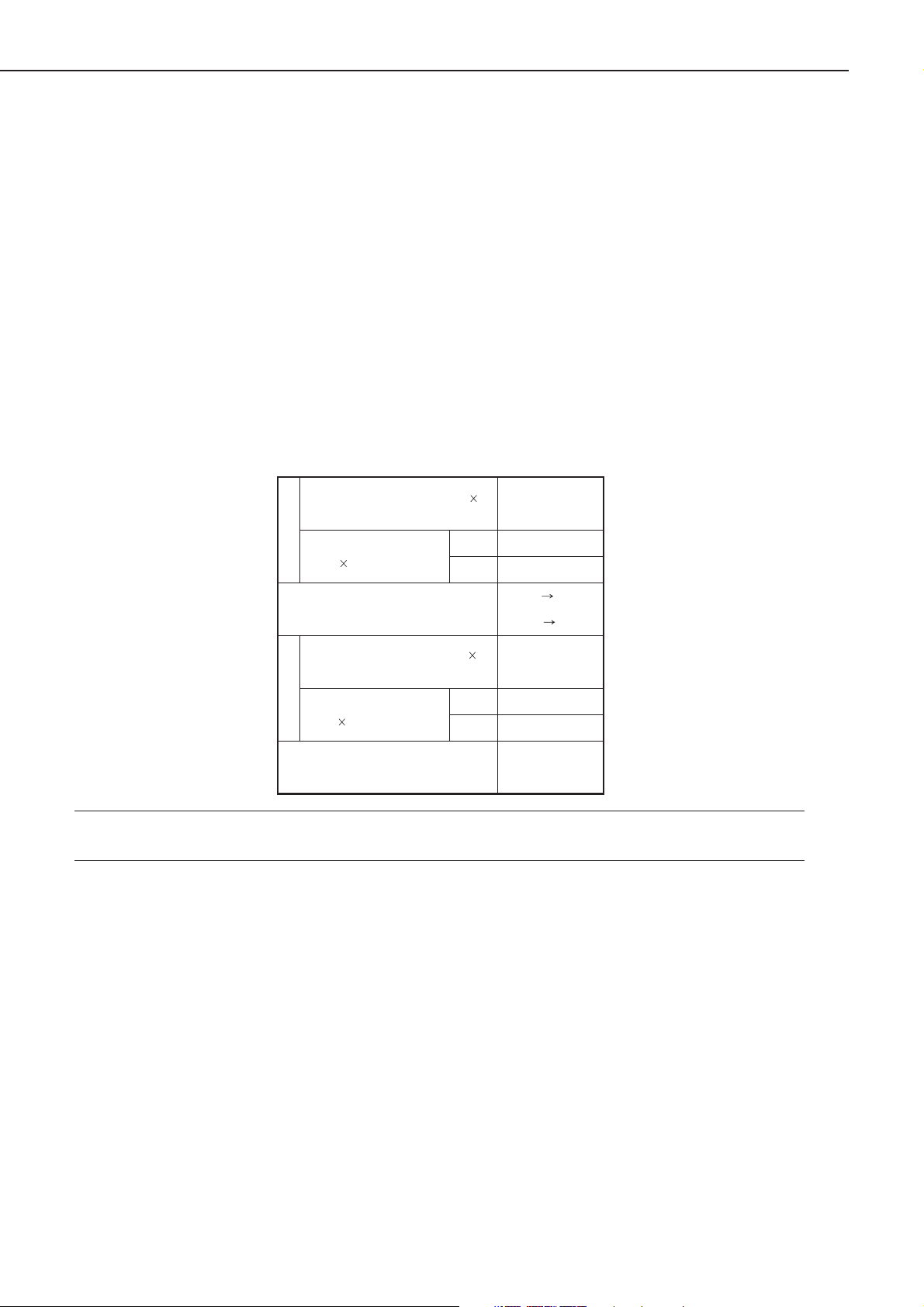

a. Storage of Sealed EP-22 Cartridge Package

When storing EP-22 cartridge in warehouses or workshops, be sure that they are kept within

humidity/storage conditions range shown in Table 1-5-1.

Also note the following:

1) Avoid areas exposed to direct sunlight.

2) Do not place them in locations which are subject to severe vibration.

3) Do not bump or drop the cartridge.

4) Avoid high temperature environment, keep EP-22 cartridge below 35 °C.

Table 1-5-1

Note: Total storage time is the valid time span following the manufacture date displayed on

the cartridge box.

b. Storage of Unsealed EP-22 Cartridge

Since an organic photoconductor (OPC) is used for the photosensitive drum, intensive light will

damage the drum. Since toner is contained in the cartridge, it is necessary to thoroughly explain

the various storage and handling procedures of unsealed cartridges to customers.

Also, note the following:

1) Avoid areas which are exposed to direct sunlight such as near windows. Avoid leaving the

packages in cars for an extended period of time as high temperatures can damage them.

2) Avoid high temperature and high humidity, and low temperature and low humidity environment. Avoid areas where the temperature or humidity drastically change such as a location

near air conditioners.

3) Avoid dusty areas or locations which emit ammonia or organic solvent gases.

4) Keep EP-22 cartridge below 35 °C

5) Avoid placing the package near CRT displays, disk drive units, or floppy disks.

CHAPTER 1

1 - 8

Normal (total storage time

9/10)

Severe (total storage

time 1/10)

Temperature

Temperature change (within

3 minutes or so)

Normal (total storage time

9/10)

humidity

Severe (total storage

time 1/10)

Relative

Air pressure

High

Low -20 to 0˚C

High

Low

0 to 35˚C

35 to 40˚C

40˚C 15˚C

-20˚C 25˚C

35 to 85% RH

85 to 95% RH

10 to 35% RH

613 to 1013hPa

(460 to 760 mmHg)

c. Notes on Handling of Cartridge

1) Before installing a new EP-22 cartridge in the printer, hold the cartridge at both sides as

shown below, and gently slop it at about 45 Þ right-up and left-up 5 or 6 times to distribute

toner evenly. Do not rock the cartridge in any other way, as the toner may leak from the

developing unit or cleaner unit.

Figure 1-5-2

Print the test pattern of 3 to 5 sheets to ensure that output images are not spoiled by a toner

leak after installing the cartridge in the printer.

2) If blank spots appear on the output image due to an uneven distribution of toner in the cartridge, shake the cartridge to evenly distribute as shown in 1).

3) Do not place the cartridge on its end or upside down.

4) Do not open the protective shutter of the photosensitive drum and never touch the drum surface. Do not clean the photosensitive drum.

5) Do not disassemble EP-22 cartridge.

6) Do not give vibration or shock to the cartridge.

7) Intensive light easily damages the photosensitive drum, causing blank spots or black stripes

on the printed image. Faulty print images can be corrected by stopping the printer momentarily. However, if the drum is exposed too long, the blank spots and black stripes may

remain even after stopping the printer. To prevent this, be sure to always place the unsealed

cartridges in their boxes or under a cover. Do not leave them uncovered after removing from

the printer.

Reference: If the cartridge are exposed to ordinary light for five minutes and then left in a dark

area for another five minutes, the print quality will return to a virtually permissible

level. However, do not expose the cartridge to direct sunlight.

CHAPTER 1

1 - 9

VI. MAINTENANCE AND CHECKS BY THE CUSTOMER

The table below lists the maintenance points that should be performed by the customer to maintain the printer at optimum level.

Table 1-6-1

CHAPTER 1

1 - 10

Item

Cartridge Shake or replace the cartridge as necessary.

External Cover

Clean the external cover as necessary.

Customer maintenance

VII. OPERATION

A. Canon Advanced Printing Technology (CAPT)

Canon Advanced Printing Technology (hereafter referred to as CAPT) reduces the processing time

and simplifies the operations for printing in the Microsoft Windows environment.

The easy operations and speedy printing are supported by the following features of CAPT:

• Instead of converting print data sent from application into the printer’s page description language (PDL), CAPT translates the print data into resource data compatible to the graphic

drawing system commands (GDI data.)

• The resource data compatible to the GDI data is developed to dot data, and then passed to

a host computer.

• The printing environment can be set in the dialog box on the host computer screen.

• The printer status is shown on the host computer screen, so users can view and confirm the

print time, print paper status, error conditions, and etc..

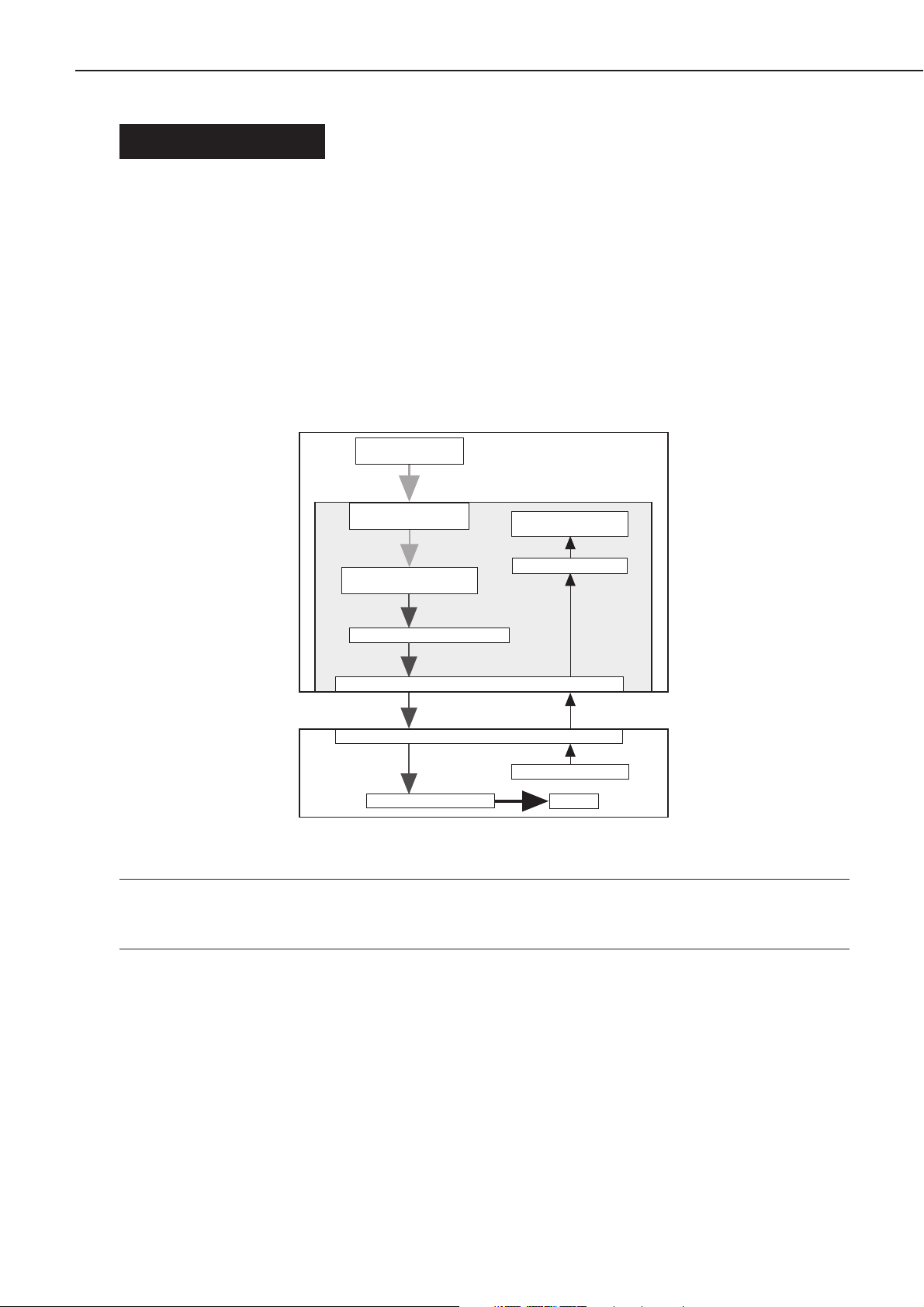

Figure 1-7-1

Note: GDI : Graphic Device Interface

A graphic drawing system that performs printing and displaying in the Windows environment, (and a graphic drawing system interface with the application.)

CAPT operates on Microsoft Windows NT4.0, Microsoft Windows 2000, or Microsoft Windows

95/98/Me. The installation is done using the Canon Advanced Printing Technology disk included with this printer.

CAPT specifies paper sizes, document sizes, number of copies, and print quality on the computer screen. The operation methods of the dialog boxes vary in Microsoft Windows NT4.0,

Microsoft Windows 2000, and Microsoft Windows 95/98/Me.

The installation procedures and operations are explained in the following pages:

Microsoft Windows NT4.0 : Page 1-12

Microsoft Windows 2000 : Page 1-48

Microsoft Windows 95/98/Me : Page 1-59

CHAPTER 1

1 - 11

Submits GDI data from

the application.

Converts into resource data

corresponding to GDI.

Analyzes the resource data and

develops them into print data

Formats bit images.

Printer

Canon Advanced

Printing Technology

Host computer interface

Printer interface

Engine unit

Host computer

Displays the printer status

on the screen.

Monitors the printer status.

Printer status information

Printing

B. Microsoft Windows NT4.0

1. Installation of CAPT

A Canon Advanced Printing Technology installation disk is packed with this printer.

The type and contents of the disc are as follows:

Type :

• A 5-inch CD-ROM disk

Contents :

• CAPT driver

• Language monitor

• Status window

• Parallel port driver

• Installer

• CD-ROM menu

• Uninstaller

• Trouble shooter

• On-line help

• On-line manual

• Voice message

a. Operating Environment

The following environment is required to install CAPT:

● PC hardware

This printer supports the IBM-PC and its compatible computers. The operating conditions are

as shown below:

<Minimum Operating Environment>

• CPU: Pentium or above

• RAM: 32 MB or above

• Available memory on the disk: 10 MB or above

• Printer port: Standard Centronics parallel port

• CD-ROM drive

• Sound: PCM sound module is required to use the voice message.

• Monitor size: 640 x 480 or above, 16 colors or above

• Network: 10 Base-T or 100 Base-TX is required to use the optional network adapter.

<Recommended Operating Environment>

• CPU: MMX Pentium 200 MHz or above

• RAM: 48 MB or above

● OS software

This printer operates only on Microsoft Windows NT x86 (Intel). It dose not operate on Alpha,

MIPS or PPC.

This printer does not operate on other OSs such as Windows NT3.x, Windows 3.x, Windows

for Workgroups, Windows CE, or Windows on OS/2. In general, Windows language and the

software language of this printer must match.

● Printer cable

• Use a bi-directional 8-bit parallel interface cable for the IBM-PC.

• Connections through the printer selector and printer buffer are not supported.

CHAPTER 1

1 - 12

b. Installation Procedures

●●

Connecting as a Local Printer

This section describes how to install CAPT for using the printer as a local printer. Install it to

the computer by following the procedures below.

For details, see the User’s Manual packed with the printer.

1. Switch on the computer to which the printer is connected and start up Microsoft Windows

NT.

2. Log in as an Administrator.

3. Perform one of the following methods to start up Add Printer Wizard.

• Start button / Settings / Printers / Printers folder / Open Add Printer.

• My Computer / Printers folder / Open Add Printer.

• Explorer / Desktop / My Computer / Printers / Open Add Printer.

4. Add Printer Wizard (Initial Screen)

Select either the printer is to be used as a local printer or network printer. The following procedures describe the installation for using the printer as a local printer by selecting My

Computer. For using the printer as a network printer, see Page 1-14 for details.

5. Add Printer Wizard (Selecting the Port)

Select the port to which the printer is connected. If the port is not available, click the Add

Port button to create a new port.

Clicking the check box for ‘Enable printer pooling’ enables the selecting of multiple ports

from the Available Ports list box simultaneously.

6. Add Printer Wizard (Selecting the Printer 1)

Insert the CD-ROM into the computer, click on the Have Disk button to open the Install From

Disk dialog box.

Enter the name of the CD-ROM drive in the text box of ‘Copy manufacture’s files from:’ and

then click the Browse button.

7. Add Printer Wizard (Selecting the Printer 2)

If the name of the printer appears in the Printers list box, and the printer you are installing

is selected, click the Next button. If you want to change the printer, click the Have Disk button to reselect the INF file.

8. Add Printer Wizard(Selecting Overwriting)

This window appears only when the same driver has already been installed.

Select whether or not the existing driver is to be overwritten by the newly installed driver.

9. Add Printer Wizard (Changing the Printer Name)

Enter the printer name to the Printer Name text box. Select whether or not the printer is to

be a default printer.

10. Add Printer Wizard (Selecting Shared/Not Shared)

Select whether or not the computer is to be designated as a print server and the printer is

to be shared by other client computers on a network. You can change this setting after

installing CAPT.

11. Add Printer Wizard (Selecting Printing a Test Page)

Select whether or not the printer is to print a test page after you have finished installing

CAPT.

12. Coping Files...

As the installation is started, the ‘Coping Files...’ dialog box appears.

13. End of Installation

When the installation has completed, restart Microsoft Windows as instructed by the onscreen message. When the printer is connected, you will be asked whether you want to print

a test page. Print a test page to confirm that the installation has been made properly.

CHAPTER 1

1 - 13

●●

Connecting to a Network Printer

When used on a network as a network printer, the printer is linked to the computer designated

as a network print server and is shared by clients on the network.

This section will describe the installation of CAPT on a client computer.

For details, refer to the User’s Manual packed with the printer.

Note: Precondition for the installation

• CAPT should be installed properly in the network print server to which the client

computer is to be connected, and the printer should be designated as a shared printer. See Page 1-23 for information on how to designate the printer as a shared printer.

• The network print server must be accessible to the client computer via the network.

• For the local installation, some functions are not available depending on the group to

which the client belongs. The network installation, on the other hand, has no limits

in functions even if the client logs into the network print server with any privilege.

For this printer, however, it is recommended that the network installation be implemented with the Administrators privilege.

1. Switch ON the client computer, start up Microsoft Windows NT and log in.

2. Use one of the following methods to start up the Add Printer Wizard.

• Start button / Settings / Printers / Printers folder / Open Add Printer.

• My Computer / Printers folder / Open Add Printer.

• Explorer / Desktop / My Computer / Printers / Open Add Printer.

3. Add Printer Wizard (Initial screen)

Select either the printer is to be used as a local printer or network printer. The following procedures describe the installation for using the printer as a network printer by selecting the

Network printer. For using the printer as a local printer, see Page 1-13 for details.

4. Connect to Printer

Double-click on the name of the print server listed in Shared Printers and select the printer

from the list. Click on the OK button to connect to the selected network printer.

If the connection could not be made, the Connected to Printer (printer connecting failure)

alert box will be displayed.

5. Add Printer Wizard (Installation completion)

This window tells you that the network printer has been successfully installed. Clicking on

the Finish button will finish Add Printer Wizard.

CHAPTER 1

1 - 14

2. Operation of CAPT

CAPT uses Properties to set print environment.

The tables on Page 1-71 list up the print environment that can be set by the Properties dia-

log boxes.

The following describe the Properties dialog boxes. Note that the LBP-800 and LBP-810 contain the same Properties dialog boxes. This section will exemplify the LBP-800 Properties dialog

boxes.

a. Properties

• How to open Properties.

Properties can be opened by the following methods.

From the Microsoft Windows desktop

1) Use one of the following methods to open the Printers folder:

• Start button / Settings / Printers

• Control Panel / Printers

2) Open the printer to which you want to connect from the Printers folder.

3) Select Properties by performing one of the following methods:

• Right-click on the Canon LBP-800 icon to select Properties.

• Double-click on the Canon LBP-800 icon to open the Canon LBP-800 Print Queue window,

and select Properties from the Printer menu.

From the Microsoft Windows applications

How to open Properties varies in application. See the application manual.

From the Microsoft Windows Shortcut

Create a shortcut and then select Properties by following one of the procedures below:

1) To create a shortcut, open the Printers folder, drag the Canon LBP-800 icon with the right

mouse button to the desktop, and select the Create Shortcut(s) Here. (See the Microsoft

Windows NT User’s Guide for details.)

2) Double-click on the shortcut icon to open the Printer window and select Properties from

the Printer menu.

Or,

1) To create a shortcut to the Printer folder, open My Computer, drag the Printer’s icon with

the right mouse button to the desktop, and select the Create Shortcut(s) Here. (See the

Microsoft Windows NT User’s Guide for details.)

2) Double-click on the shortcut icon to open the Printers folder, right-click on the Canon

LBP-800 icon, and select Properties.

CHAPTER 1

1 - 15

The Property dialog consists of tabs based on the Microsoft Windows NT User Interface model.

The Property consists of the following two types of tabs:

• Common tabs used in all the Property; General, Details, and Sharing

• Specified tabs used only in the printer driver; Page Setup, Finishing and Quality

To open a tab and set the items in the tab, you can click on the tab or move the focus and

then press right or left cursor.

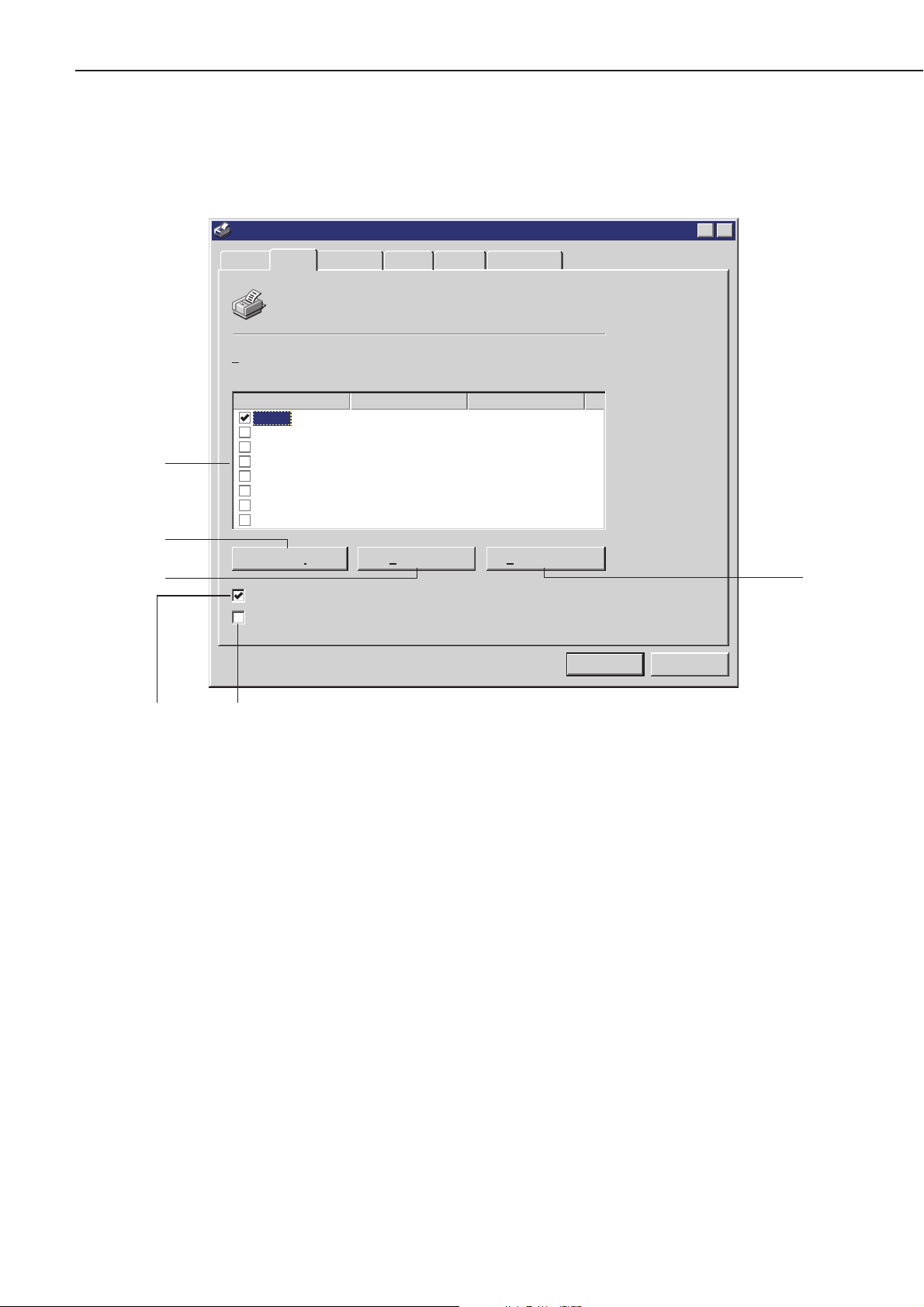

Figure 1-7-2

(1) General : Sets the entire printer-driver- related items.

(2) Ports : Selects the port to which the printer is connected.

(3) Scheduling : Sets print schedule.

(4) Sharing : Designates whether the printer is shared.

(5) Security : Sets the security for the printer.

(6) Select Forms : Sets user defined paper.

To store the items set in each of the tabs, click the OK button and close the Properties dia-

log box. Or, to close the box without storing the items, click the Cancel button.

Figure 1-7-3

(1) OK : Changes the items in this dialog box and closes the box.

(2) Cancel : Closes this dialog box without changing its items.

The following sections will describe the details of the tabs

CHAPTER 1

1 - 16

(1)

Canon LBP-800 Properties

(2)

(3) (4) (5) (6)

X

?

General

Scheduling

Ports

Canon LBP-800

Sharing

Security

Select Forms

OK

(1) (2)

Cancel

●●

General Tab

The settings in this tab apply to the entire printer driver. This tab can be opened by clicking the

General tab in the Properties dialog box.

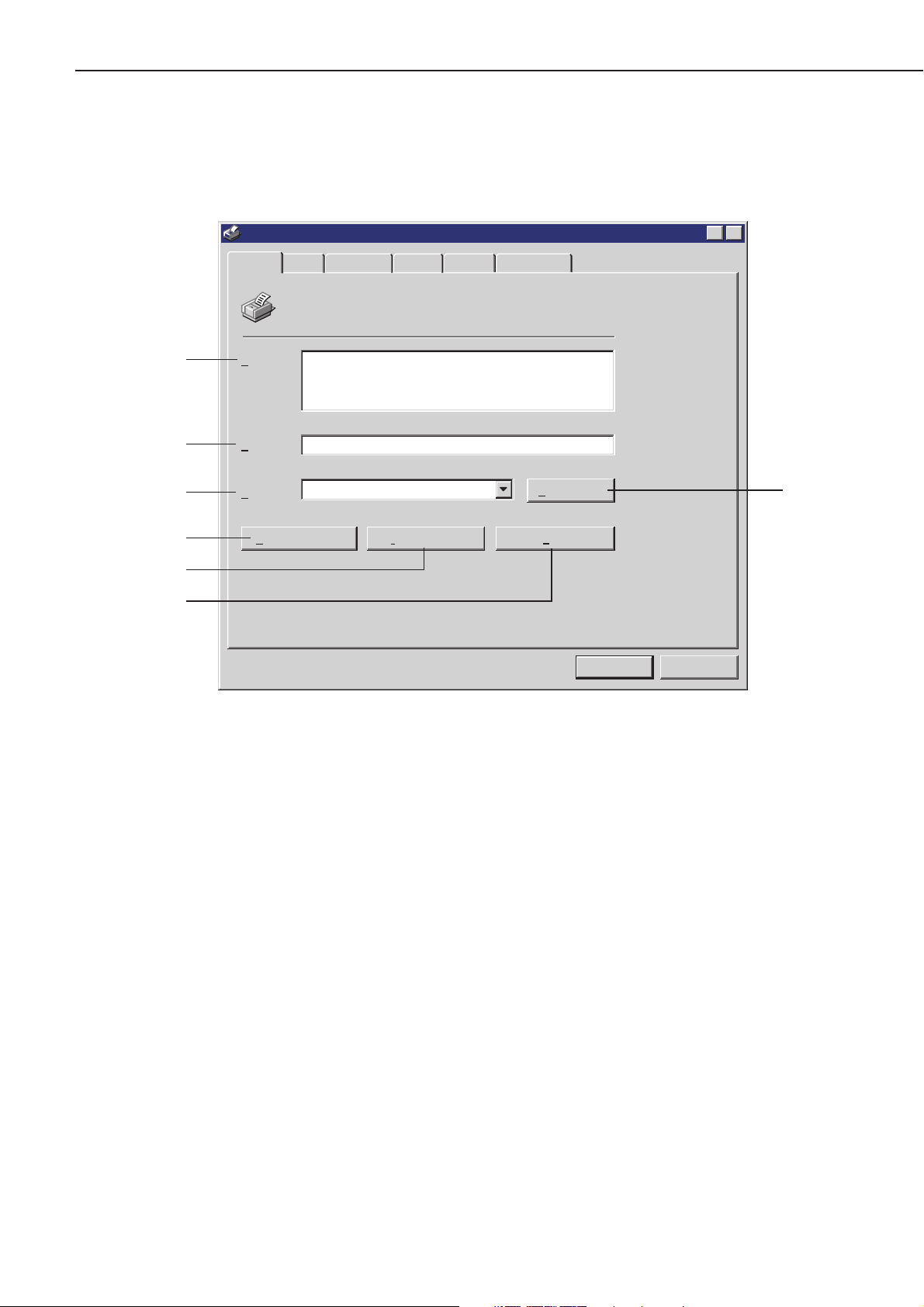

The General tab is shown in Figure 1-7-4.

Figure 1-7-4

(1) Comment : Enter comments on the printer.

(2) Location : Enter information on the printer location.

(3) Driver : Displays the list of the installed printer drivers.

(4) New Driver... : Click on this button when installing a new or updated printer driver.

(5) Separator Page... : As this printer does not support separator pages, clicking on this but-

ton will not print a separator page.

(6) Print Processor... : Displays the Print Processor dialog box.

(7) Print Test Page : Print a test page supported by the Microsoft Windows NT standard.

CHAPTER 1

1 - 17

X

Canon LBP-800 Properties

Ports

General

Scheduling

Canon LBP-800

Sharing

Security

Select Forms

?

(1)

(2)

(3)

(5)

(6)

(7)

Comment:

Location:

Driver:

Separator Page...

Canon LBP-800

Print Processor...

New Driver...

Print Test Page

OK

(4)

Cancel

◆◆

Print Processor Dialog Box

In the Print Processor dialog box, you can specify the print processor and spool data type used

for this printer. The Printer Processor dialog box can be opened by clicking on the Print

Processor button in the General tab in the Properties dialog box.

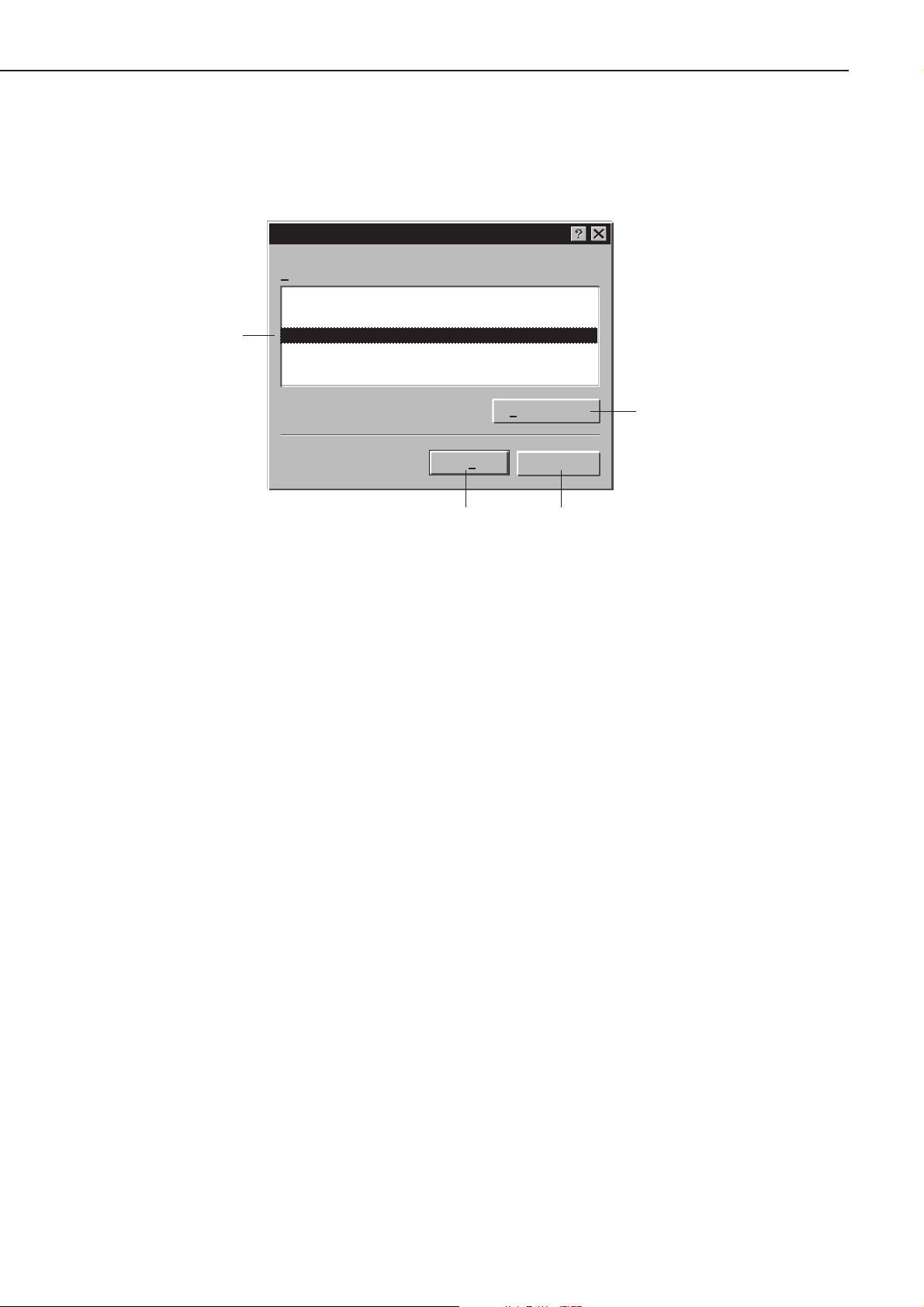

Figure 1-7-5 shows the Print Processor dialog box.

Figure 1-7-5

(1) Print Processor : Specifies the print processor used for this printer. Normally, Winprint

(Windows standard print processor) is available.

(2) Default Datatype : Displays the list of spool datatype available for the selected print proces-

sor in the Print Processor list box.

(3) Always spool RAW datatype : Click the check box when you want to always spool data as

RAW datatype.

(4) OK : Changes the items in this dialog box and closes the box.

(5) Cancel : Closes this box without changing its items.

CHAPTER 1

1 - 18

Print Processor

Selectinga diff erentprint processor mayresult in diff erentoptions

beingavailable f ordefault datatypes.Ifyour servicedoesnot

specifya datatypetheselection belowwillbe used.

PrintProcessor: DefaultDatatype:

winprint

(1)

Local Port

RAW

RAW[FF appended]

RAW[FF auto]

NTEMF 1.003

TEXT

(2)

(3)

Alwaysspool RA Wdatatype

OK

(4) (5)

Cancel

●●

Ports Tab

Use this tab to select the port to which the printer is connected. It can be opened by clicking

the Ports tab in the Properties dialog box.

The ports tab is shown in Figure 1-7-6.

Figure 1-7-6

(1) Print to the following port(s) : Lists the ports to which the printer can be connected. Select

one or more port(s) to which the printer is to be connected. The error dialog box will appear

if an nonexistent LPT port has been selected and a print is commanded.

(2) Add Port... : Opens Printer Ports so that you can add ports. (See Page 1-20.)

(3) Delete Port : Opens the Delete Port dialog box so that you can delete the selected ports.

(4) Configure Port : Opens the Configure LPT Port dialog box which enables you to set ports.

(See Page 1-21.)

(5) Enable bidirectional support : Selects whether or not the Language Monitor is used for bi-

directional communication between the computer and printer.

(6) Enable printer pooling : Selects whether or not the printer pool is used. Clicking the check

box enables you to select multiple ports in the following Printer Ports list box. The printer

does not support printer pool.

CHAPTER 1

1 - 19

X

Canon LBP-800 Properties

General

Scheduling

Sharing

Security

Select Forms

Ports

Canon LBP-800

Print to the following port[s]. Documents will print to the first free

checked port.

?

Printer

Canon LBP-800

(1)

Por t

LPT1:

LPT2:

LPT3:

COM1:

COM2:

COM3:

COM4:

FILE:

Description

Local Port

Local Port

Local Port

Local Port

Local Port

Local Port

Local Port

Local Port

(2)

Delete PortAdd Port...

(3)

Enable bidirectional support

Enable printer pooling

Configure Port...

OK

(4)

Cancel

(5) (6)

◆◆

Printer Ports Dialog Box

Use this dialog box to add ports to which the printer is to be connected if necessary. It can be

opened by clicking the Add Ports button in the Ports tab of the Properties dialog box.

The printer Ports dialog box is shown in Figure 1-7-7.

Figure 1-7-7

(1) Available Printer Ports : Displays the list of ports that can be added. Select one port from

the list. The printer cannot be connected to ports other than Local Port and AXIS CAPT Port

(network adapter port.)

(2) New Monitor... : Installs the print monitor. Not available for this printer.

(3) New Port... : Opens the Port Name dialog box so that you can enter the name of the port to

be added.

(4) Cancel : Returns to the Ports tab without changing the items.

CHAPTER 1

1 - 20

Printer Ports

Available PrinterPorts:

DigitalNetw orkPort

LexmarkDLCNetwork P ort

(1)

LexmarkTCP/IP Network Port

Local Port

New Port...

(3)

New Monitor...

Cancel

(4)

(2)