LBP6670dn/6680x Series

Product Description

Technology

Disassembly/Assembly

Maintenance and Inspection

Trouble Shooting

Appendex

Service Manual

54321

F-0-1

0

0-2

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason,

there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release

technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short

period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual

may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

0

(C) CANON INC. 2012

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

0-2

0

0-3

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Used to show permission. Remove the screw.

Used to show prohibition. Tighten the screw.

Check. Remove the claw.

Check visually. Insert the claw.

Check the noise. Use the bundled part.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric signal.

The expression "turn on the power" means ipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High",

while '0' is used to indicate "Low". (The voltage value, however, differs from circuit to

circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on

when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines are not

discussed: they are explained in terms of from sensors to the input of the DC controller

PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

0

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Turn on the power.

T-0-1

0-3

Contents

Safety Precautions

Safety Information ------------------------------------------------------------0-6

Laser Safety ------------------------------------------------------------------------- 0-6

CCDRH Regulation ---------------------------------------------------------------- 0-6

Toner Safety ------------------------------------------------------------------------- 0-6

About Toner ---------------------------------------------------------------------------------- 0-6

How to Handle Adhered Toner ---------------------------------------------------------- 0-6

Ozone Safety ----------------------------------------------------------------------- 0-6

How to Handle the Laser Scanner Unit -------------------------------------- 0-7

Points to Note when Replacing/Discarding a Lithium Battery ---------- 0-7

Points to Note when Performing Disassembly/Assembly---------------- 0-7

Product Description

Product Lineups ---------------------------------------------------------------1-2

Main unit ----------------------------------------------------------------------------- 1-2

Options ------------------------------------------------------------------------------- 1-2

Features -------------------------------------------------------------------------1-2

Specication --------------------------------------------------------------------1-3

Product Specications ------------------------------------------------------------ 1-3

Printing Speed --------------------------------------------------------------------- 1-3

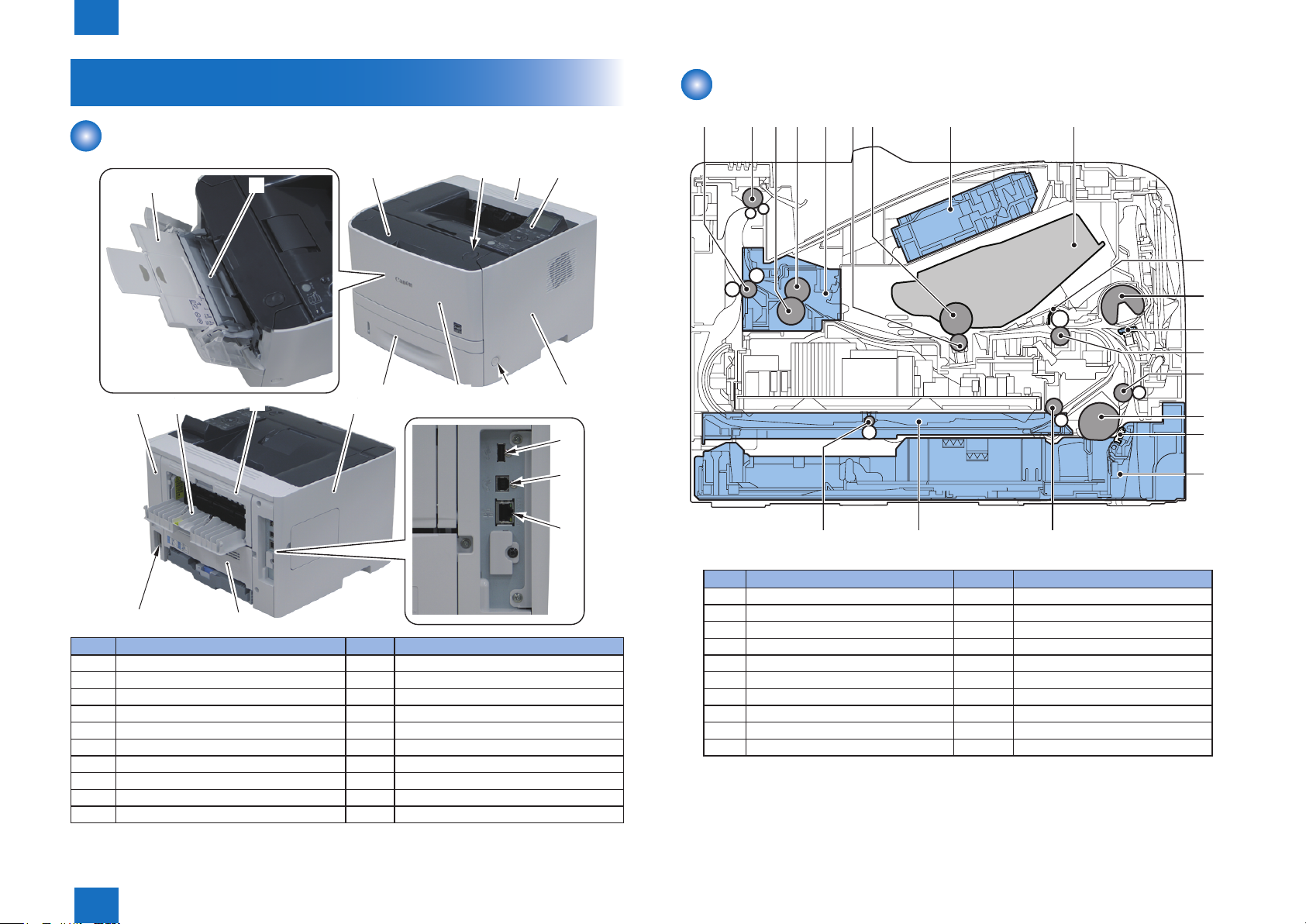

List of Parts ---------------------------------------------------------------------1-4

External View ----------------------------------------------------------------------- 1-4

Cross Sectional View ------------------------------------------------------------- 1-4

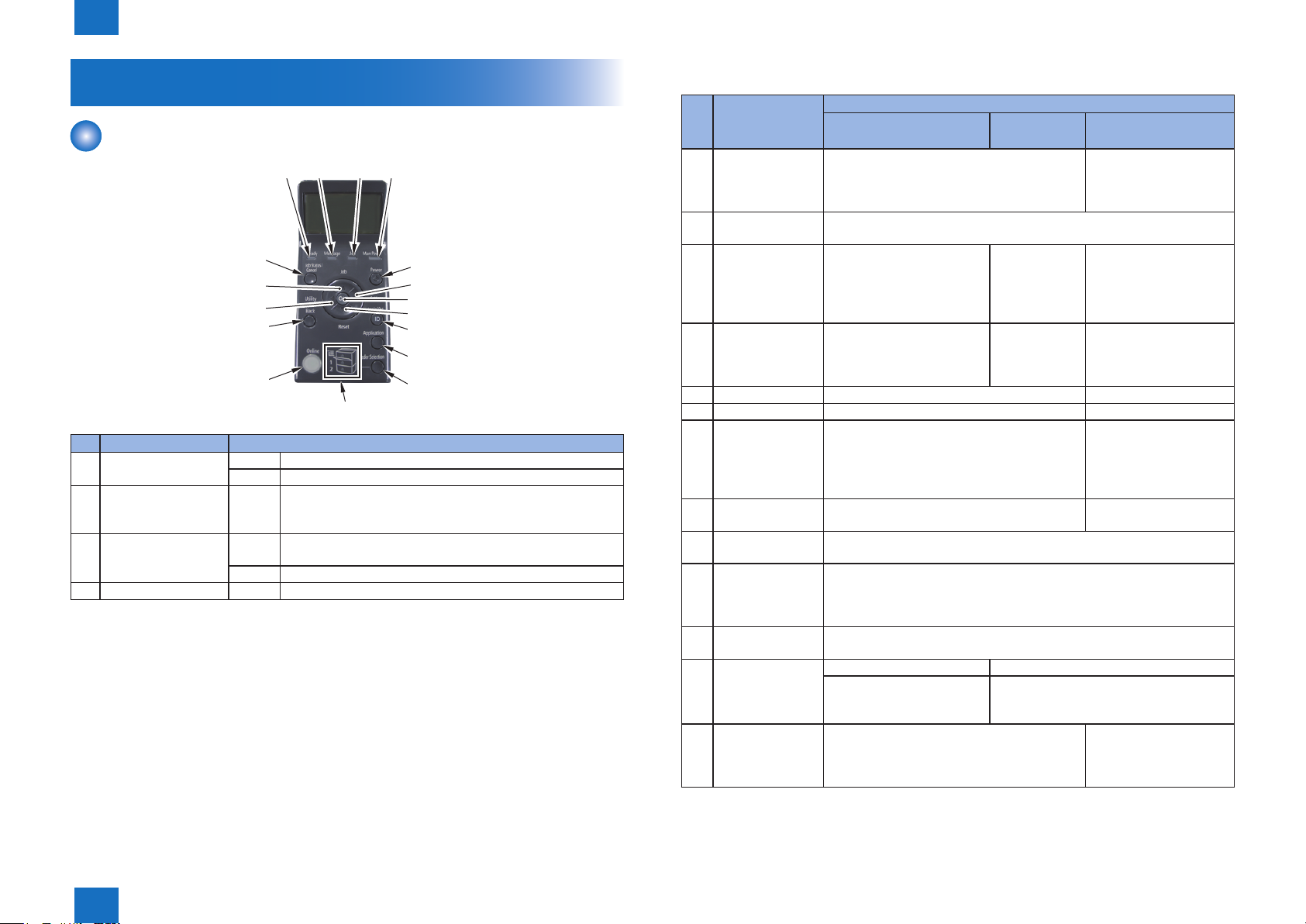

Operation ------------------------------------------------------------------------1-5

Control panel ------------------------------------------------------------------------ 1-5

Technology

Basic Operation ---------------------------------------------------------------2-2

Function Structure ----------------------------------------------------------------- 2-2

Sequence of Operation ------------------------------------------------------2-2

Outline -------------------------------------------------------------------------------- 2-2

Laser Exposure System -----------------------------------------------------2-3

Outline -------------------------------------------------------------------------------- 2-3

Optical Unit Failure Detection --------------------------------------------------- 2-3

Image Formation System ---------------------------------------------------2-4

Outline -------------------------------------------------------------------------------- 2-4

Image Formation Process ------------------------------------------------------- 2-4

Outline ----------------------------------------------------------------------------------------- 2-4

Latent image formation block ------------------------------------------------------------ 2-5

Developing block---------------------------------------------------------------------------- 2-5

Transfer block ------------------------------------------------------------------------------- 2-6

Fixing block ----------------------------------------------------------------------------------- 2-6

Drum cleaning block ----------------------------------------------------------------------- 2-6

High-voltage Power Supply ----------------------------------------------------- 2-7

Outline ----------------------------------------------------------------------------------------- 2-7

Fixing System ------------------------------------------------------------------2-8

Outline -------------------------------------------------------------------------------- 2-8

Fixing control circuit --------------------------------------------------------------- 2-9

Small Size Paper Printing Speed Control (Throughput Reduction Control) - 2-9

Fixing temperature control---------------------------------------------------------------2-10

Protective function -------------------------------------------------------------------------2-10

Failure detection ---------------------------------------------------------------------------2-11

Pickup Feeding System --------------------------------------------------- 2-12

Outline -------------------------------------------------------------------------------2-12

Jam Detection ---------------------------------------------------------------------2-13

Outline ----------------------------------------------------------------------------------------2-13

Pickup Delay Jam -------------------------------------------------------------------------2-13

Pickup Stationary Jam--------------------------------------------------------------------2-13

Delivery Delay Jam ------------------------------------------------------------------------2-13

Fixing Paper Wrap Jam -----------------------------------------------------------------2-13

Delivery Stationary Jam ------------------------------------------------------------------2-13

Reverse Delay Jam -----------------------------------------------------------------------2-13

Reverse Stationary Jam -----------------------------------------------------------------2-14

Internal Residual Jam --------------------------------------------------------------------2-14

Door Open Jam ----------------------------------------------------------------------------2-14

Controller System ----------------------------------------------------------- 2-15

Outline -------------------------------------------------------------------------------2-15

DC Controller ----------------------------------------------------------------------2-15

Outline ----------------------------------------------------------------------------------------2-15

Motor control --------------------------------------------------------------------------------2-16

Fan control ----------------------------------------------------------------------------------2-17

Failure Detection ---------------------------------------------------------------------------2-17

Low-voltage Power Supply ----------------------------------------------------- 2-17

Outline ----------------------------------------------------------------------------------------2-17

Protective function -------------------------------------------------------------------------2-18

Safety -----------------------------------------------------------------------------------------2-18

Low-voltage power supply unit failure detection -----------------------------------2-18

Energy Saving Function ---------------------------------------------------------2-18

MEAP -------------------------------------------------------------------------- 2-19

Introduction -------------------------------------------------------------------------2-19

References by purpose ------------------------------------------------------------------2-19

About MEAP -----------------------------------------------------------------------2-19

Overview -------------------------------------------------------------------------------------2-19

About SMS -------------------------------------------------------------------------2-20

Overview -------------------------------------------------------------------------------------2-20

About the MEAP Application Management Screen -------------------------------2-20

About the MEAP Application Installation Screen ----------------------------------2-20

About System Management ------------------------------------------------------------2-21

Preparation for Using SMS -----------------------------------------------------2-21

Preparation of PC for Accessing SMS -----------------------------------------------2-21

Device Settings -----------------------------------------------------------------------------2-22

How to Check the Serial Number ------------------------------------------------------2-27

Login to SMS -----------------------------------------------------------------------2-28

Procedure to Log in -----------------------------------------------------------------------2-28

Installing an MEAP Application ------------------------------------------------2-31

Outline ----------------------------------------------------------------------------------------2-31

Procedure to install applications -------------------------------------------------------2-31

Resource Information ------------------------------------------------------------2-33

About MEAP Application Management Page ---------------------------------------2-33

MEAP Specications -------------------------------------------------------------2-34

What is MEAP Specications (MEAP Spec Version)? ---------------------------2-34

MEAP Application Management ----------------------------------------------2-36

Outline ----------------------------------------------------------------------------------------2-36

Starting, Stopping, or Uninstalling the MEAP Application -----------------------2-36

Managing the License File --------------------------------------------------------------2-38

Other License File Management Functions -----------------------------------------2-42

Enhanced System Application Management-------------------------------2-45

Outline ----------------------------------------------------------------------------------------2-45

About Login Service-----------------------------------------------------------------------2-45

Default Authentication overview--------------------------------------------------------2-45

Other Log in service-----------------------------------------------------------------------2-45

Procedure Changing Login Services -------------------------------------------------2-45

Procedure Installing Login Services --------------------------------------------------2-46

Procedure Uninstalling Login Services -----------------------------------------------2-47

System Application Management ---------------------------------------------2-47

Procedure to manage System Application ------------------------------------------2-47

System Information ---------------------------------------------------------------2-48

Outline ----------------------------------------------------------------------------------------2-48

Checking the System Information -----------------------------------------------------2-48

Display of System Information Details------------------------------------------------2-48

Printing the System Information of a MEAP Application -------------------------2-49

Content of MEAP system information ------------------------------------------------2-49

MEAP Application Information -------------------------------------------------2-50

Outline ----------------------------------------------------------------------------------------2-50

Procedure to Check MEAP Application Information ------------------------------2-50

Check License ---------------------------------------------------------------------2-51

Outline ----------------------------------------------------------------------------------------2-51

Procedure to Check the License File -------------------------------------------------2-51

Changing SMS Login Password ----------------------------------------------2-51

Outline ----------------------------------------------------------------------------------------2-51

Procedure to Change the SMS Login Password ----------------------------------2-51

MEAP Application Setting Information Management and Log

Management -----------------------------------------------------------------------2-52

Outline ----------------------------------------------------------------------------------------2-52

Advantages Obtained When Using the Services ----------------------------------2-52

MEAP Application Setting Information Management -----------------------------2-53

MEAP Application Log Management -------------------------------------------------2-53

Maintenance -----------------------------------------------------------------------2-54

When Replacing the PCB ---------------------------------------------------------------2-54

Actions to be taken when E616 is displayed. ---------------------------------------2-55

MEAP Safe Mode --------------------------------------------------------------------------2-56

Using USB Devices -----------------------------------------------------------------------2-57

Reference material ---------------------------------------------------------------2-58

Glossary --------------------------------------------------------------------------------------2-58

Embedded RDS ------------------------------------------------------------- 2-61

Product Overview -----------------------------------------------------------------2-61

Overview -------------------------------------------------------------------------------------2-61

Features and benets --------------------------------------------------------------------2-61

Service cautions -------------------------------------------------------------------2-62

E-RDS Setup -----------------------------------------------------------------------2-62

Conrmation and preparation in advance -------------------------------------------2-62

E-RDS setting items (service mode) --------------------------------------------------2-63

Steps to E-RDS settings -----------------------------------------------------------------2-63

Initializing E-RDS settings ---------------------------------------------------------------2-65

FAQ -----------------------------------------------------------------------------------2-66

Troubleshooting -------------------------------------------------------------------2-67

Error code and strings -----------------------------------------------------------2-69

Disassembly/Assembly

Preface --------------------------------------------------------------------------3-2

List Of Parts --------------------------------------------------------------------3-2

External View ----------------------------------------------------------------------- 3-2

List of Main Unit -------------------------------------------------------------------- 3-3

Motor ---------------------------------------------------------------------------------- 3-4

Solenoid ------------------------------------------------------------------------------ 3-5

Heater / Thermo Switch / Thermistor / Switch ------------------------------ 3-5

Sensor -------------------------------------------------------------------------------- 3-6

PCB ----------------------------------------------------------------------------------- 3-6

Connector Layout Drawing -------------------------------------------------3-7

Connector List ---------------------------------------------------------------------- 3-7

Main Controller PCB ----------------------------------------------------------------------- 3-7

Engin Controller PCB ---------------------------------------------------------------------- 3-7

Internal ---------------------------------------------------------------------------------------- 3-7

External Cover, Internal Cover ---------------------------------------------3-9

Removing the Left Cover -------------------------------------------------------- 3-9

Removing the Right Cover ------------------------------------------------------ 3-9

Removing the Rear Cover Unit / Duplex Feed Unit ---------------------- 3-10

Removing the Upper Cover Unit ---------------------------------------------- 3-11

Removing the Cartridge Cover Unit ------------------------------------------ 3-11

Controller System ----------------------------------------------------------- 3-12

Removing the Main Controller Board ---------------------------------------- 3-12

Actions before Replacement ------------------------------------------------------------3-12

Removing the Main Controller Board -------------------------------------------------3-12

Actions before Replacement (LBP6670 only) --------------------------------------3-13

Remove the Sleep Interface PCB --------------------------------------------3-14

Remove the Duplex Reverse Sensor Unit ----------------------------------3-14

Remove the All-Night Power Supply PCB ----------------------------------3-15

Remove the Power Supply PCB ---------------------------------------------- 3-15

Removing the Engine Controller Board -------------------------------------3-16

Removing the Control Panel Unit ---------------------------------------------3-18

Removing the Main Motor ------------------------------------------------------3-19

Removing the Main Fan ---------------------------------------------------------3-19

Removing the Main Drive Unit -------------------------------------------------3-20

Removing the Duplex Drive Unit ----------------------------------------------3-21

Removing the Cassette Pickup Solenoid ----------------------------------- 3-22

Removing the Multi-purpose Solenoid ---------------------------------------3-22

Removing the Duplex Reversal Solenoid -----------------------------------3-23

Laser Exposure System --------------------------------------------------- 3-24

Removing the Laser Scanner Unit --------------------------------------------3-24

Image Forming System ---------------------------------------------------- 3-25

Removing the Transfer Roller --------------------------------------------------3-25

Removing the Registration Unit ----------------------------------------------- 3-25

Fixing System ---------------------------------------------------------------- 3-27

Removing the Fixing Unit ------------------------------------------------------- 3-27

Paper Pickup/Transport/Output System ------------------------------- 3-29

Removing the Cassette Pickup Roller ---------------------------------------3-29

Removing the Cassette Separation Pad ------------------------------------3-30

Removing the Multi-purpose Pickup Roller ---------------------------------3-30

Removing the Multi-purpose Separation Pad------------------------------3-31

Maintenance and Inspection

Periodically Replaced Parts ------------------------------------------------4-2

Periodically Replaced Parts ----------------------------------------------------- 4-2

Consumable Parts ------------------------------------------------------------4-2

Durables Replaced by the Service Person ---------------------------------- 4-2

Periodical Service -------------------------------------------------------------4-2

Periodical Service ------------------------------------------------------------------ 4-2

Cleaning -------------------------------------------------------------------------4-2

Cleaning at Service Visit --------------------------------------------------------- 4-2

Trouble Shooting

Trouble Shooting --------------------------------------------------------------5-2

Test Pages --------------------------------------------------------------------------- 5-2

Engine-test page ---------------------------------------------------------------------------- 5-2

Controller-Test page ----------------------------------------------------------------------- 5-2

Device Log List --------------------------------------------------------------------- 5-3

Adjustment of Fixing System ---------------------------------------------------- 5-3

Nip-width specications ------------------------------------------------------------------- 5-3

Error Codes ---------------------------------------------------------------------5-4

Error Code Details ----------------------------------------------------------------- 5-4

Jam Codes -------------------------------------------------------------------------- 5-7

Service Mode ------------------------------------------------------------------5-8

ADJUST GR. --------------------------------------------------------------------------------- 5-8

OPTION GR. --------------------------------------------------------------------------------- 5-8

FUNCTION GR. ----------------------------------------------------------------------------- 5-8

LOG GR. -------------------------------------------------------------------------------------- 5-9

PANEL GR ------------------------------------------------------------------------------------ 5-9

F/W UPDATE GR. -------------------------------------------------------------------------- 5-9

NETWORK GR. ----------------------------------------------------------------------------- 5-9

SP.ADMIN.MODE ------------------------------------------------------------------------- 5-11

Version Upgrade ------------------------------------------------------------ 5-12

Overview ----------------------------------------------------------------------------5-12

Overview of Version Upgrade ----------------------------------------------------------5-12

Checking the Version ---------------------------------------------------------------------5-12

Version Upgrade Using UST ---------------------------------------------------5-13

Preparation ----------------------------------------------------------------------------------5-13

Downloading the Firmware --------------------------------------------------------------5-14

Updater ------------------------------------------------------------------------ 5-17

Overview ----------------------------------------------------------------------------5-17

Outline ----------------------------------------------------------------------------------------5-17

System Conguration ---------------------------------------------------------------------5-18

List of Functions ----------------------------------------------------------------------------5-18

Distribution Flow ---------------------------------------------------------------------------5-19

Limitations and Cautions-----------------------------------------------------------------5-20

Preparation ----------------------------------------------------------------------------------5-21

System Management Operations------------------------------------------------------5-27

a. UGW-linked Download and Update (Full-remote Update) -------------------5-30

b. UGW-linked Download (Remote Distribution Update) ------------------------5-30

Deleting the Scheduled Firmware Delivery -----------------------------------------5-31

Updating the Downloaded Firmware (Application of Firmware) ---------------5-31

Deleting the Downloaded Firmware --------------------------------------------------5-32

Maintenance --------------------------------------------------------------------------------5-33

FAQ -------------------------------------------------------------------------------------------5-34

Error Messages ----------------------------------------------------------------------------5-37

Error Codes ---------------------------------------------------------------------------------5-43

Debug log --------------------------------------------------------------------- 5-48

Sublog -------------------------------------------------------------------------------5-48

Function Overview ------------------------------------------------------------------------5-48

How the log is written ------------------------------------------------------------5-48

Collecting Sublog -----------------------------------------------------------------5-49

Flow of collecting Sublog ----------------------------------------------------------------5-49

Installing the Sublog Board--------------------------------------------------------------5-49

Generating the log -------------------------------------------------------------------------5-49

Collecting log -------------------------------------------------------------------------------5-50

Backup/Restoration by Expansion ROM for servicing and Sublog

Board --------------------------------------------------------------------------- 5-53

Function Overview ----------------------------------------------------------------5-53

What to Prepare ----------------------------------------------------------------------------5-53

Prerequisites --------------------------------------------------------------------------------5-53

Target Data for Backup -------------------------------------------------------------------5-53

Backup and Restoration (Export and Import) ------------------------------ 5-54

Flow of Export and Import ---------------------------------------------------------------5-54

Installing the Expansion ROM for servicing and Sublog Board ----------------5-54

Backup Procedure (Export) -------------------------------------------------------------5-55

Restoration Procedure (Import) --------------------------------------------------------5-55

Others -------------------------------------------------------------------------------- 5-56

Deletion (Erase) ----------------------------------------------------------------------------5-56

List of Error Messages -------------------------------------------------------------------5-57

Appendex

Service Tools --------------------------------------------------------------------- II

Special Tools --------------------------------------------------------------------------- II

Solvents and Oil List ----------------------------------------------------------------- II

General Timing Chart ----------------------------------------------------------III

General Timing Chart ------------------------------------------------------------------------ III

General Circuit Diagram ------------------------------------------------------ IV

General Circuit Diagram ----------------------------------------------------------- IV

Backup Data ---------------------------------------------------------------------- V

SafetyPrecautions

■LaserSafety

■CCDRHRegulation

■TonerSafety

■OzoneSafety

■HowtoHandletheLaserScannerUnit

■Points to Note when Replacing/Discarding a Lithium

Battery

■PointstoNotewhenPerformingDisassembly/Assembly

0

Safety Precautions > Safety Information > Ozone Safety

0-10

Safety Information

Laser Safety

Laser beam radiation sometimes causes a danger to human body. To prevent such a danger,

the optical laser system used in this machine is hermetically closed by the protection housing

and external cover so that a laser beam does not leak to outside. Therefore, a laser beam

does not leak out of this machine as long as a user operates the machine in an ordinary

manner.

CCDRH Regulation

CDRH (Center for Devices and Radiological Health), which belongs to Food and Drug

Administration in USA, put a regulation concerning laser products on August 2, 1976. This

regulation is applied to laser products manufactured on and after August 1, 1976, and sales

activities are prohibited in USA without receiving permission under the regulation.

The following gure shows the label indicating that permission has been received under the

CDRH regulation, and it is obliged to attach it on all products sold in USA.

Toner Safety

■About Toner

Toner is a nontoxic substance which consists of plastic, iron, and a small amount of pigment.

CAUTION:

Be sure not to throw toner into the re. Doing so may cause an explosion.

■How to Handle Adhered Toner

When toner adhered to skin or clothes, completely remove it with dried tissue and wash with

water.

If hot water is used, toner cannot be removed because it becomes gel and penetrates into

clothes permanently.

Do not make toner come into contact with vinyl because it easily reacts with a vinyl materia

Ozone Safety

An innitesimal amount of ozone gas (O3) is generated during corona discharge from the

charging roller

used in this printer. The ozone gas is emitted only during the printer operation.

The printer meets ozone emission reference value set by Underwriters Laboratory (UL) at the

time ofshipping from the manufacture.

CAUTION:

A part of the description may be different depending on the type of product model.

Safety Precautions > Safety Information > Ozone Safety

0

F-0-2

0-10

0

Safety Precautions > Safety Information > Points to Note when Performing Disassembly/Assembly

0-11

How to Handle the Laser Scanner Unit

An invisible laser beam is irradiated in the laser scanner unit.

If the laser beam enters an eye, it may cause damage to the eye. So, be sure not to

disassemble the laser scanner unit. No adjustment can be made to the laser scanner unit in

this machine in the eld.

The label shown in the following gure is attached to the bottom of the laser scanner unit.

F-0-3

Points to Note when Replacing/Discarding a Lithium

Points to Note when Performing Disassembly/Assembly

Be sure to follow the instruction shown below when performing disassembly/assembly.

1. Be sure to unplug the power plug for safety when performing disassembly/assembly.

2. If not otherwise specied, perform assembly in the procedure opposite to that of

disassembly.

3. Perform assembly using correct types of screws, etc. (length/diameter) at correct positions.

4. A washer screw is used as a screw to x a grounding wire and varistor, etc., to secure

electrical conduction. Be sure to use this screw when performing assembly.

5. In principle, do not operate the machine in the condition where parts are removed.

6. Do not remove a paint-locked screw when performing disassembly.

Battery

The main controller PCB in this machine contains a lithium battery as backup power supply

for various data just in the case when a blackout occurs or the power plug is removed.

CAUTION:

• The battery installed in this machine is xed and cannot be replaced.

• Do not replace the battery only.

• Replacing the battery with another type of battery can result in explosion.

• When disposing the old PCB with battery, remove the battery and follow the local

regulation.

Safety Precautions > Safety Information > Points to Note when Performing Disassembly/Assembly

0

0-11

Product

1

Description

Product Lineups

■

Features

■

List of Parts

■

Operation

■

Product Description

1

1

Product Description > Features

1-2

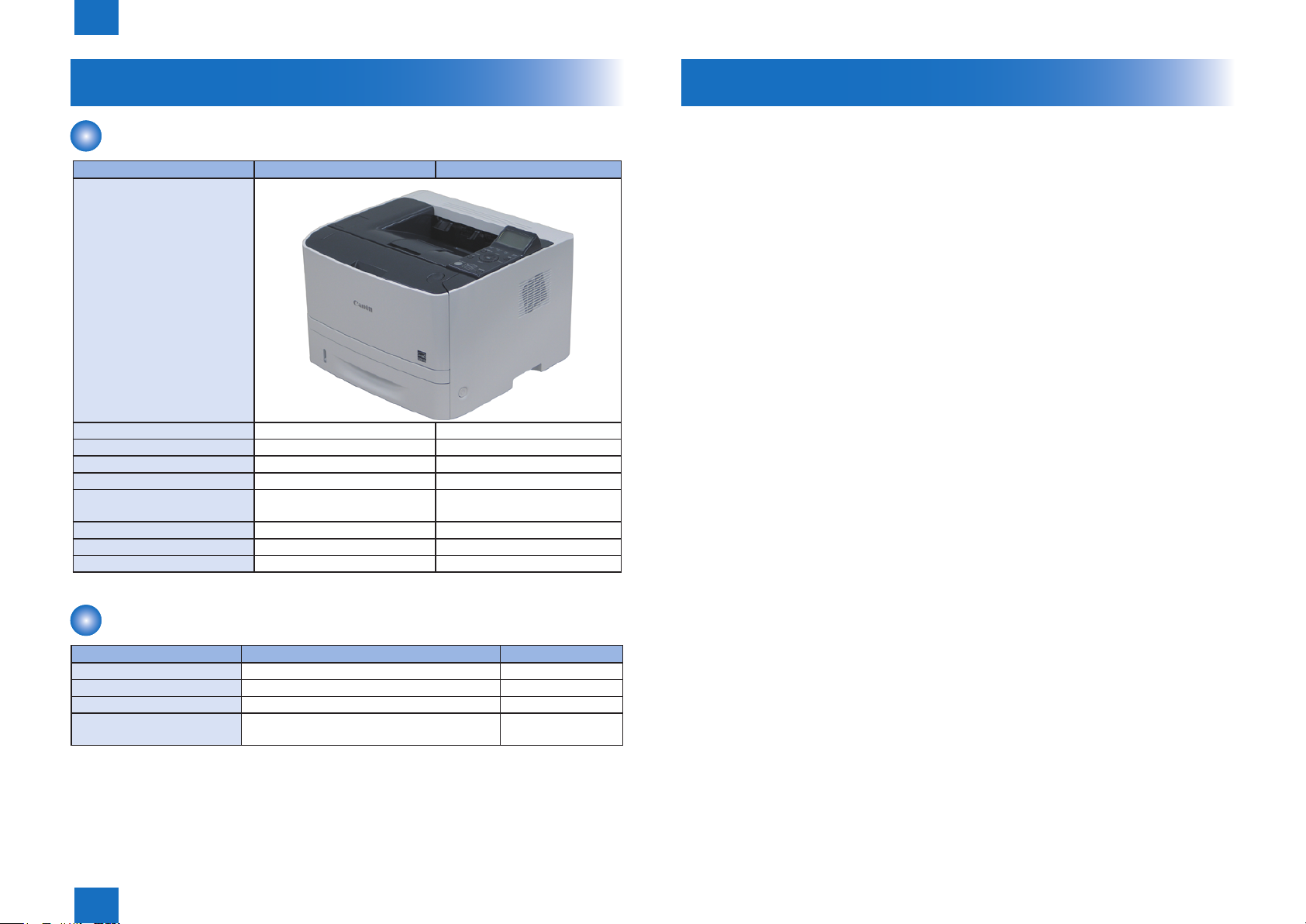

Product Lineups

Main unit

Function LBP6670 LBP6680

Appearance

Copy x x

Print o o

FAX x x

Remote UI o o

Automatic 2-sided Print (60 to

120g / m2 paper)

MEAP x o

Network o o

WLAN x x

o o

Features

1. Small and high-speed printer

The printer is compact size that realizes print speed of approximately 35 pages per minute

on letter-size media and approximately 33 pages per minute on A4-size media by i-SENSYS

LBP6670dn/ imageCLASS LBP6670dn/ i-SENSYS LBP6680x/ imageCLASS LBP6680x, and

approximately 33 pages per minute on letter-size and A4-size media.

2. Automatic duplex print

Automatic two-sided printing is available with standard equipped duplex unit.

3. High-volume continuous printing

In addition to the standard equipped universal cassette (holds up to 250 sheets of 80g/m2

paper) and Multi-purpose tray (holds up to 50 sheets of 80g/m2 paper), the printer supports

optional paper feeder (holds up to 500 sheets of 80g/m2 paper) for a total capacity of 800

sheets. Thus high-volume continuous printing is available.

F-1-1

T-1-1

Options

Name Description Remarks

Paper FeederUnit PF-44 Approx. 500 Sheets (Plain paper 80g/ m2) PS Printer Kit-AQ1 EUR/CHN/KOR

Barcode Printing Kit-F1

SD CARD-B1 USA/ EUR/ AUS/

ASIA

Product Description > Features

1

T-1-2

1-2

1

Product Description > Specication > Printing Speed

1-3

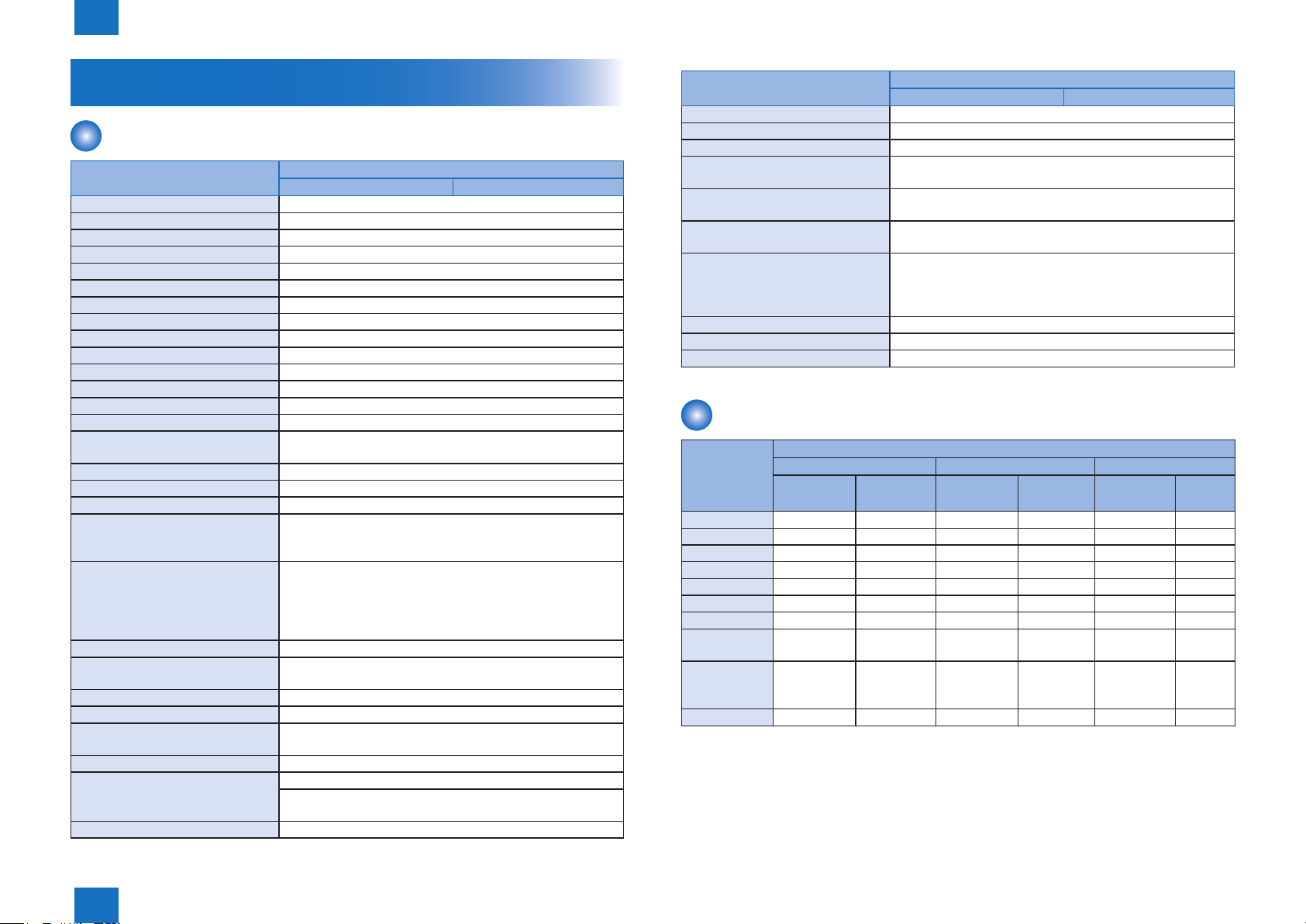

Specication

Product Specications

Item Specication/function

LBP6670 LBP6680

Installation Format Desktop type page printer

Photosensitive Element OPC drum

Exposure Principle Laser beam method

Development Principle Jumping development

Transfer Principle Roller transfer

Separation Principle Self stripping

Cassette Feed Principle Separate design

Multi Purpose Tray Principle Pad separation

Drum Cleaning Principle Rubber blade cleaning

Fixing Method On-demand

Paper Output Principle Face-down/Face-up

Toner Supply Principle Toner cartridgesNumber

Warm-up Time From power ON: max. 28 seconds

Recovery Time Approx. 10.0 seconds or less

Print Area Top 5.0 mm, Bottom 5.0 mm, Left/Right 5.0 mm

(Envelope: Top/Bottom/Left/Right 10.0 mm, Right 10.0 mm)

Printing Resolution 600 dpi

First Print Output Time Approx. 7.0 seconds or less

Printing Speed A4: 33 , LTR: 35 pages/minute

Cassette Paper Size Standard sizes: A4, B5, A5, A6, Legal, Letter, Executive

Custom size range (user-specied):

(Width 105.0 to 215.9 mm, Length 148.0 to 355.6 mm)

Multi Purpose Paper Size Standard sizes: A4, B5, A5, A6, Legal, Letter, Executive,

Postcard, Reply-paid Postcard, Four-side Postcard, Japanese

Western-style Envelope Size No. 3, Envelope Size No. 3

Custom size range (user-specied):

(Width 76.2 to 215.9 mm, Length 127.0 to 355.6 mm)

Cassette Paper Type Plain paper (60 to 90 g/m2), Heavy paper (91 to 120 g/m2),

Multi Purpose Paper Type Plain paper (60 to 90 g/m2), Heavy paper (91 to 163 g/m2),

OHP lm, label paper, postcard, envelope

Cassette Paper Capacity Approx. 250 sheets (Plain paper 80 g/m2)

Multi Purpose Paper Capacity Approx. 50 sheets (Plain paper 80 g/m2)

Output Tray Paper Capacity Face-down output: approx. 150 sheets (80 g/m2), face-up

output: 1 sheet

Duplex Printing Principle Auto Duplex

Interfaces USB: HI-Speed USB/USB2.0

Network: 10 Base-T/100BASE-T common (RJ-45)

Full duplex/half duplex

Memory Capacity Standard: 16 MB, Option: None

Item Specication/function

LBP6670 LBP6680

Hard Disk Capacity Standard: None, Option: None

Ambient Temperature Range for Use 10 to 30 degrees Celsius

Ambient Humidity Range for Use 20 to 80% RH

Operation Noise Level 53.5 dB or less (During printing: rated sound emission level

according to ISO9296)

Power Requirements 120 to 127V( +/- 10%), 50/60( +/- 2Hz)

220 to 240V( +/- 10%), 50/60( +/- 2Hz)

Max. Power Consumption 1060 W or less (120 V)

1140 W or less (230 V)

Power Consumption Average power consumption during operation: approx.

approx. 550 W (120 V), approx. 560 W (230 V)

Average power consumption during standby: approx. 13.2 W

(120 V), approx. 13.9 W (230 V)

Dimensions 400 (W) x 376 (D) x 289 (H) mm

Weight Printer main unit: approx. 11.6 kg (excl. toner cartridges)

Option Paper Feeder

Printing Speed

Face-down output

Cassette feed Manual tray feed OP cassette feed

Single-sided Duplex print Single-sided Duplex print Single-sided Duplex

print

A4 33 16.8 33 16.8 33 16.8

LTR 35 17 35 17 35 17

LGL 28.7 13.5 28.7 13.5 28.7 13.5

B5/EXE 13.7>12>8>6 16>12>8>6 10.7>8>6

A5 15.2>12>8>6 17>12>8>6 11.7>8>6

A6 17.3>12>8>6 17>12>8>6 13.2>12>8>6

16K 17>14 17>14

Strip (90 – 297

mm)

Envelope

(Japanese

Western-style)

Postcard 12>8>6>4

3

17>12>8>6

T-1-3

T-1-4

Product Description > Specication > Printing Speed

1

1-3

1

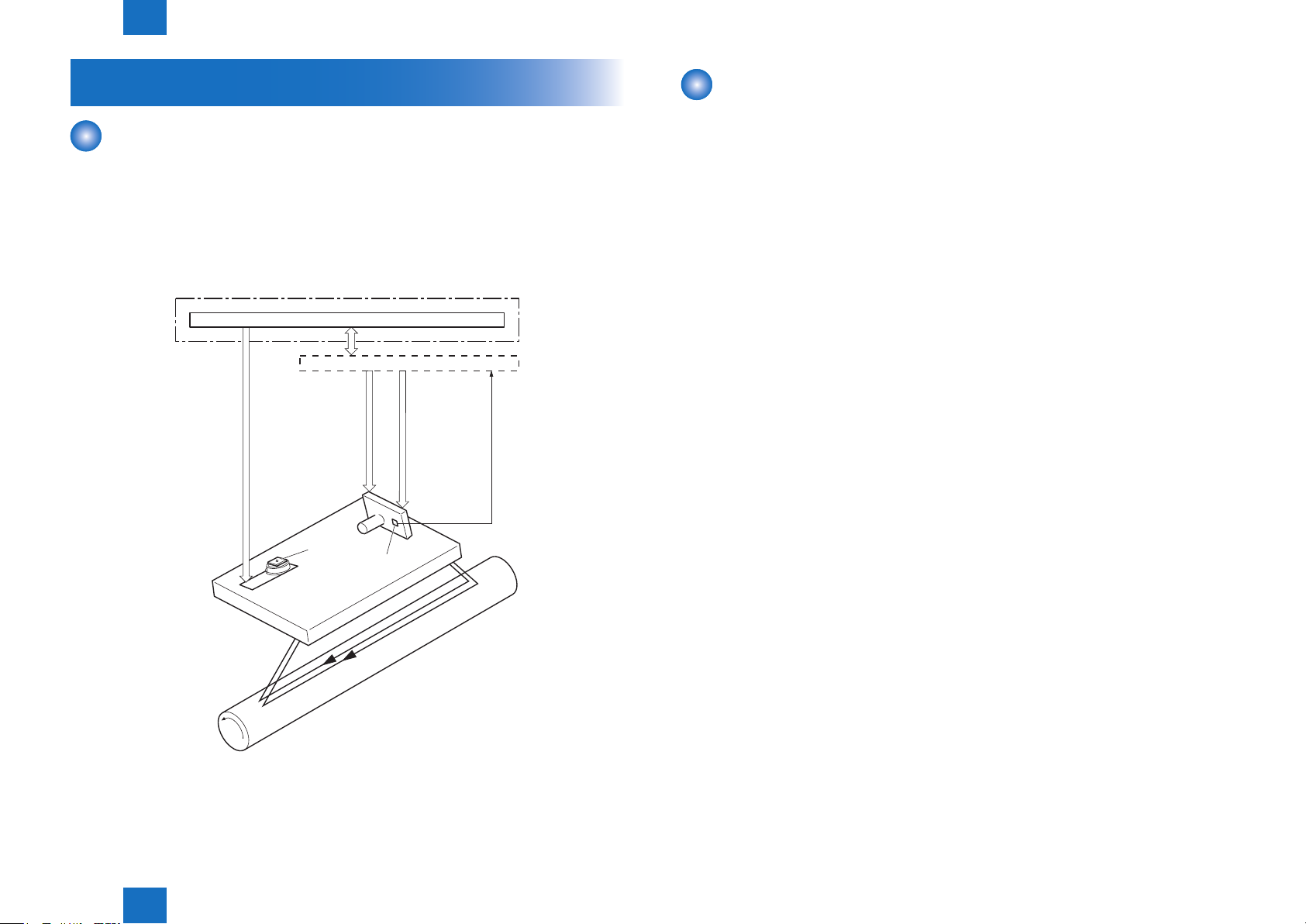

[3]

[4]

[5] [6]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Product Description > List of Parts > Cross Sectional View

1-4

List of Parts

External View

[1]

[11] [13] [14]

[12]

[19]

No. Name No. Name

[1] Auxiliary Tray [11] Rear Cover

[2] Multi-purpose Tray [12] Face-up Output Tray

[3] Front Cover [13] Pressure Release Cover

[4] Open Button [14] Left Cover

[5] Upper Cover [15] USB Host

[6] Control Panel [16] USB Device

[7] Right Cover [17] LAN Port

[8] Power Switch [18] Duplex Unit Cover

[9] Face-down Output Tray Cover [19] Power Socket

[10] Paper Cassette

[18]

[2]

[10]

Cross Sectional View

[10]

[11]

[12]

[13]

[14]

[8][9]

[7]

[15]

[16]

[17]

T-1-5

[19][20]

No. Name No. Name

[1] Fixing Delivery Roller [11] Multi-purpose Tray Pickup Roller

[2] Face-down Delivery Roller [12] Multi-purpose Tray Separation Pad

[3] Pressure Roller [13] Registration Roller

[4] Fixing Film Unit [14] Feed Roller

[5] Fixing Unit [15] Cassette Pickup Roller

[6] Transfer Roller [16] Cassette Separation Pad

[7] Photosensitive Drum [17] Cassette

[8] Laser Scanner Unit [18] Duplex Re-pickup Roller

[9] Cartridge [19] Duplex Feed Unit

[10] Registration Shutter [20] Duplex Feed Roller

[18]

[15]

[16]

[17]

F-1-2

T-1-6

Product Description > List of Parts > Cross Sectional View

1

1-4

1

[1]

[2]

[3]

[4]

Product Description > Operation > Control panel

Operation

Control panel

[5]

[7]

[8]

[12]

[15]

[16]

No. Name Discription

[1] Ready Indicator On The printer is ready to print.

Blinking The printer is preparing to print.

[2] Message Indicator Blinking Aproblem has occurred and printing cannot be performed.

(If the printers Sleep Mode when it is ofine, the Message

indicator comes on even when no problem is occuring)

[3] Job Indicator On The printer is receiving data.

Data remains in the printer memory.

Blinking The printer is processing data.

[4] Main Power Indicator On The power of the printer is ON.

[6]

[9]

[10]

[11]

[13]

[14]

[17]

F-1-3

T-1-7

1-5

No. Name Function

When the printer is online When the

printer is ofine

[5] Status/Cancel Key If pressed when the Job indicator is on or

blinking (When data is being processed or

received), diaplay the job list. Select a job from

the list to cancel the job.

[6] Power Key If [Sleep Mode] is set to a setting other than [Off], the printer enters Sleep

Mode.

[7] Job Key Displays the [Job] menu. You

can print various log list.

[8] Utility Key Display the [Utility Menue]

menu. Prints information

about the printer settings

including the current settings.

[9] Settings Key Displays the [Setup] menu. Gose down the hierarchy

[10] OK Key Does not function. Gose down the hierarchy

[11] Reset Key Display the [Reset] menu. Performs the printer

reset operation, the print data output, and the

shutdown operation.

[12] Back Key Does not function. Goes back up the

[13] Log In/Out Key The log in screen for using MEAP functions is displayed. Enter the Dept.

ID/PIN and log in to the printer.

[14] Application Key It will transition to the Menu Screen. Whenever the key is pressed, the

Printing Screen switches to → MEAP Application 1 → MEAP Application

2.Meap Application 8 → USB Direct Print → Printing Screen → Menu

Screen

[15] Online Key Switches between online and ofine . The printer is online when the

indicator under the key is on and is ofine when the indicator is off.

[16] Paper Source

Indicator

[17] Feeder Selection

Key

On A paper source is selected.

Blinking Printing cannot be performed because no

Displays the [Select Feeder] menu. Specify

which paper source is used to print between

the paper drawer and multi-purpose tray and

the paper size.

Does not

function.

Does not

function.

paper is loaded.

The paper drawer is not installed.

When the menu is

displayed

Does not function.

Select the next upper item

in the same hierarchy.

When the setting value

is numeric, increase the

value.

Goes back up the

previous hierarchy.

Select the next lower item

in the same hierarchy.

When the setting value

is numeric, reduces the

value.

previous hierarchy.

Does not function.

T-1-8

Product Description > Operation > Control panel

1

1-5

Technology

2

Basic Operation

■

Sequence of Operation

■

Laser Exposure System

■

Image Formation System

■

Fixing System

■

Pickup Feeding System

■

Controller System

■

MEAP

■

Embedded RDS

■

2

Technology

2

Technology > Sequence of Operation > Outline

2-2

Basic Operation

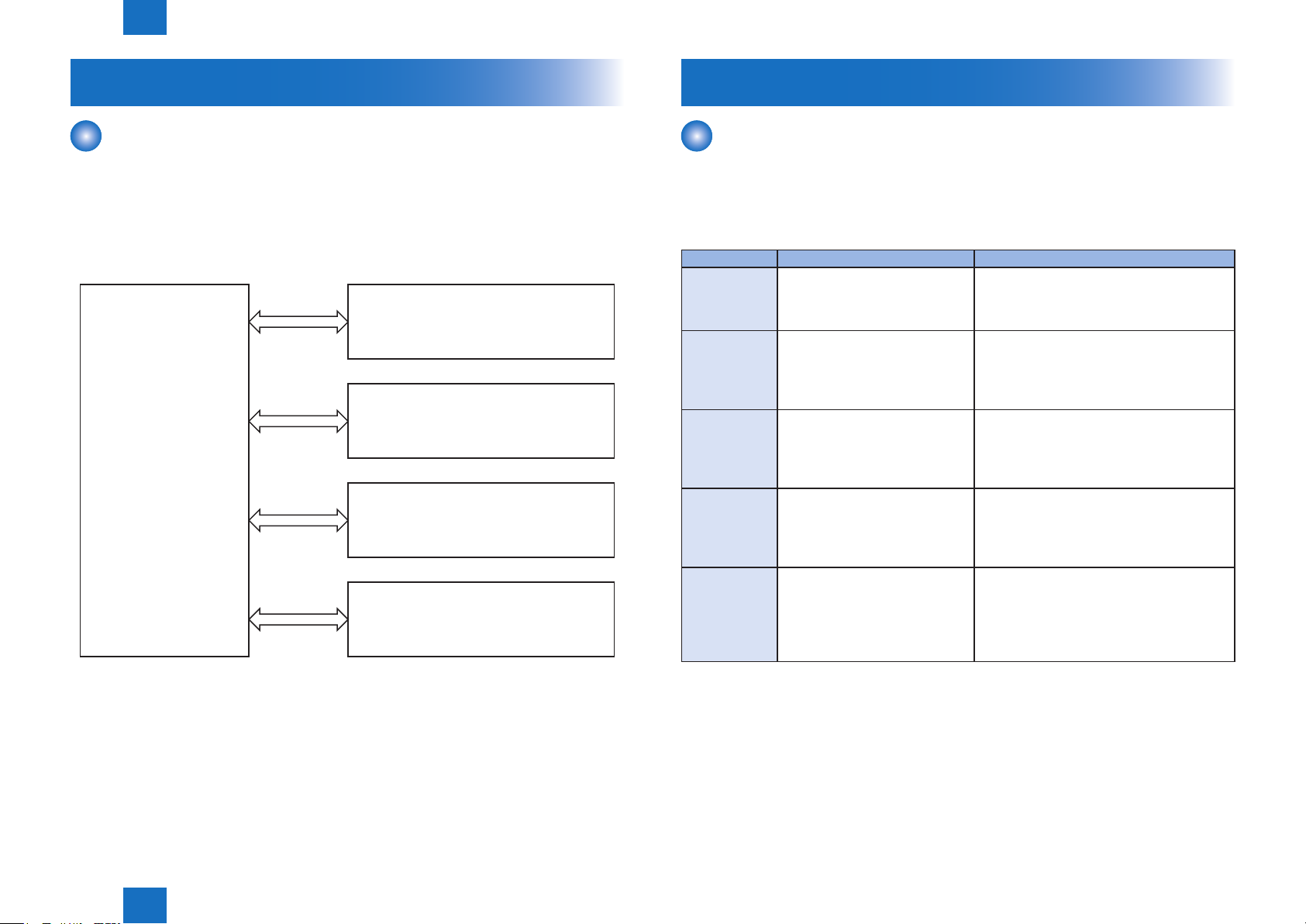

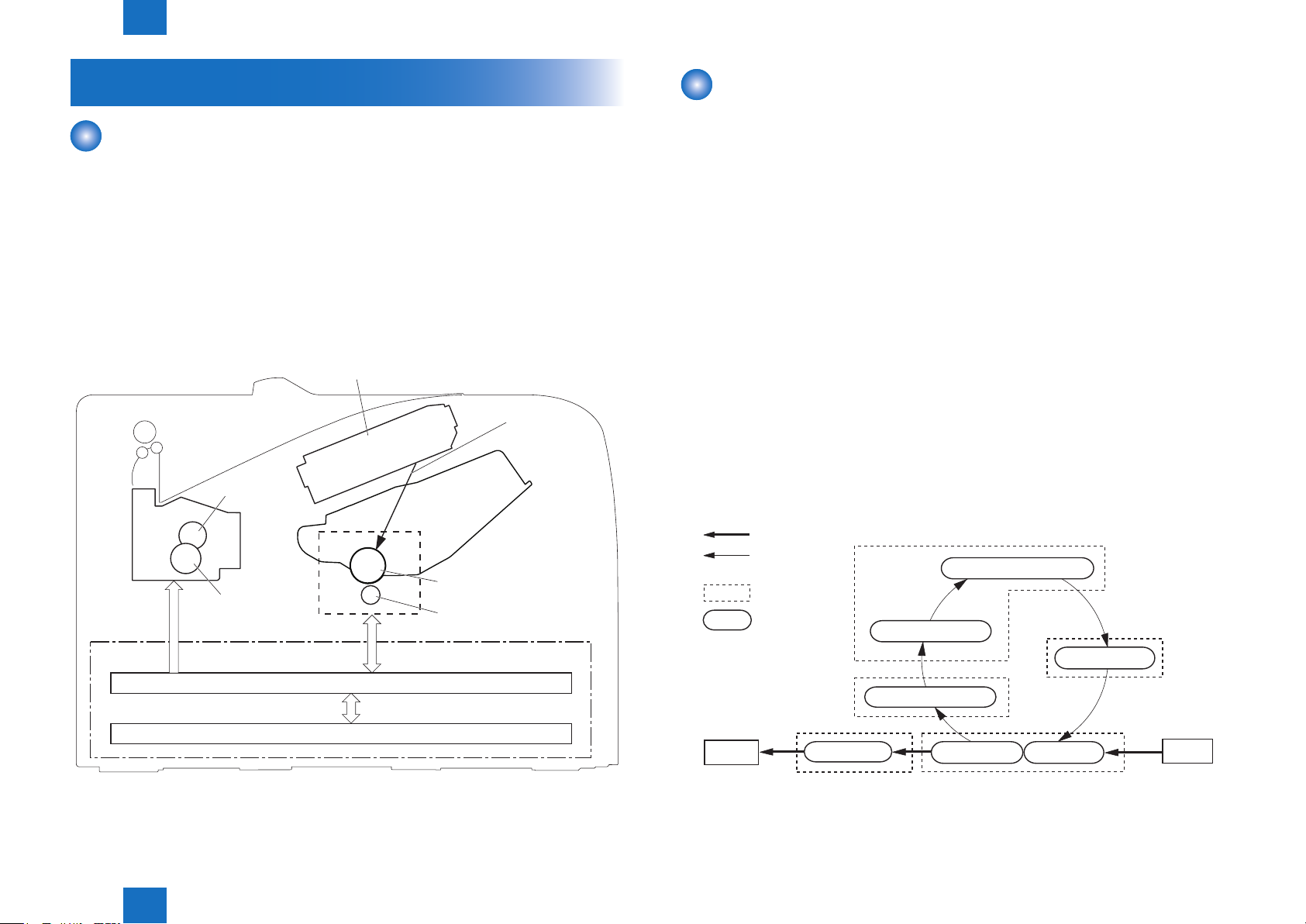

Function Structure

The function structure of the printer contains the following ve systems:

• Engine control system

• Laser scanner system

• Image-formation system

• Media feed system

• Option

LASER SCANNER SYSTEM

IMAGE-FORMATION SYSTEM

ENGINE CONTROL

SYSTEM

MEDIA FEED SYSTEM

OPTION

F-2-1

Sequence of Operation

Outline

The operation sequence is controlled by the DC Controller in the engine control system.

Operations for each period of a print operation from the machine is turned on until the motor

stops rotating are described below.

Period Duration Operation

WAIT From the time power switch is

turned on or the dooe is closed

unitil the printer gets ready for a

print operation.

STBY

(Standby)

INTR

(Initial rotation)

PRINT From the end of INTR period unit

LSTR

(Last rotation)

From the end of WAIT or LSTR

period until either the print

command is received the main

controller or the power switch is

turned off.

From the time print command is

received from the main controller

unit the temperature of the

xing unit reaches its targeted

temperature.

the last media completes the xing

operation.

From the end of PRINT period unit

the motor stops rotationg.

Brings the printer to printable condition.

The rpinter performs the following during this

period:-Detects cartridge presence.

Maintains the printer in printable condition.

Starts up each high-voltage biases, laser

scanner and xing unit in preparing for print

operation.

Forme the image on the photosensitive drum

based on the VIDEO signals from the main

controlloer.

Transfers and fuses the toner image to the

print media.

Moves the last printed sheet out of the printer.

Stops laser scanner operation and highvoltage biases output.

The printer enters INTR period as the LSTR

period is completed if the main controller

sends another print command.

T-2-1

Technology > Sequence of Operation > Outline

2

2-2

2

Engine controller

Technology > Laser Exposure System > Optical Unit Failure Detection

2-3

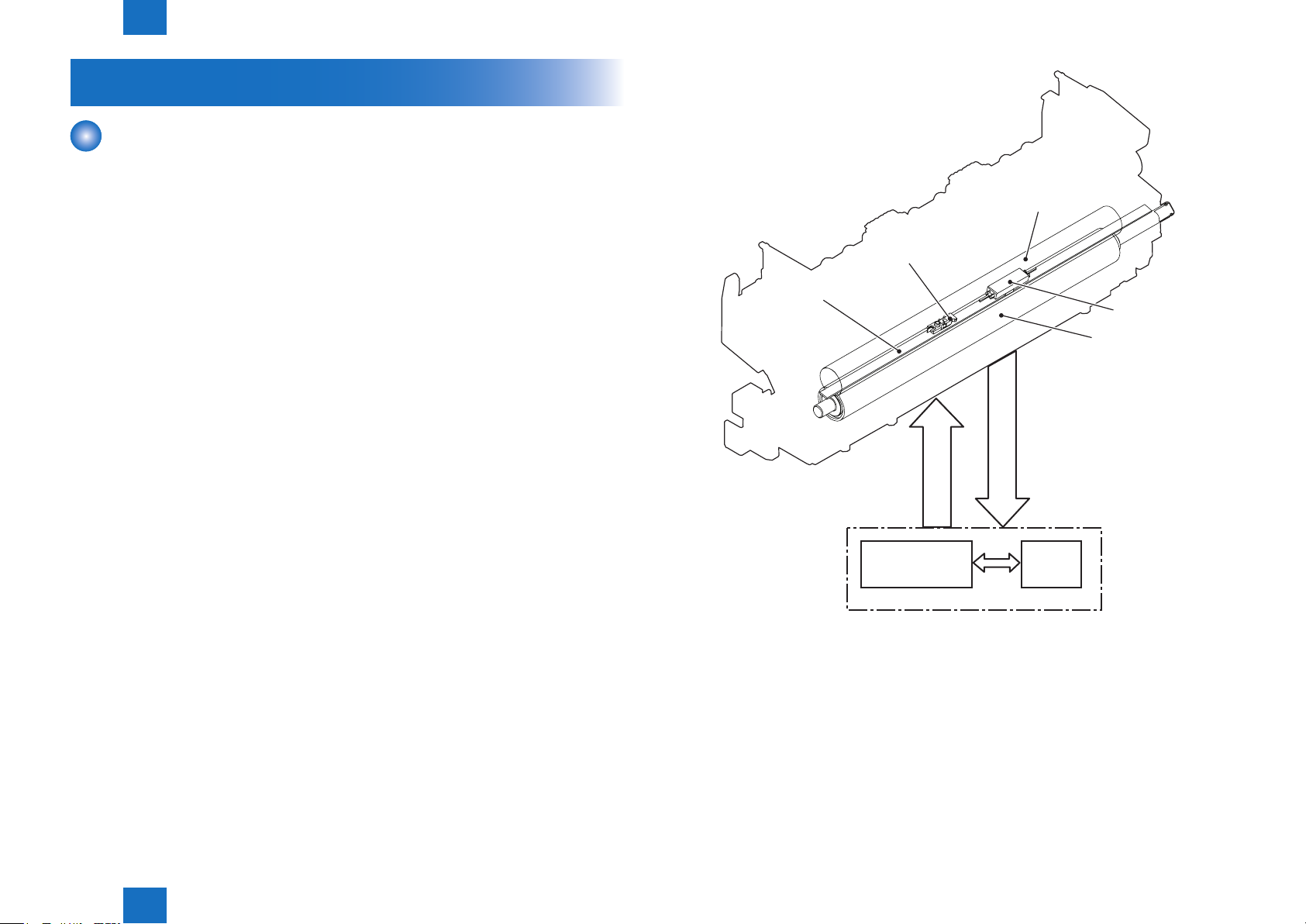

Laser Exposure System

The laser exposure system forms a latent image on the photosensitive drum according to the

VIDEO signalssent from the Main Controller.

The main components of the laser scanner are the laser unit and the scanner motor unit,

which arecontrolled by the signals sent from the DC controller.

Diagram of the Laser Scanner Unit is shown below.

Outline

DC controller

Main controller

VIDEO signal

LASER CONTROL signal

Laser unit

SCANNER MOT OR SPEED CONTROL signal

Scanner mirror

BD sensor

Optical Unit Failure Detection

The optical unit failure detection manages the laser scanner failure detection functions.

The DC controller determines an optical unit failure and noties E100 to the Main controller if

the laser scanner encounters the following conditions:

• If the scanner motor does not reach a specied rotation within a specied period of start-up.

• If the rotation of the scanner motor is out of specied range for a specied period during

drive.

• If an out of specied BD interval is detected during a print operation.

BD INPUT signal

Scanner motor unit

Photosensitive drum

Technology > Laser Exposure System > Optical Unit Failure Detection

2

F-2-2

2-3

2

Laser scanner

Media path

Technology > Image Formation System > Image Formation Process > Outline

2-4

Image Formation System

Outline

The image formation system forms a toner image on print media.

The following are the main components of the image formation system:

• Cartridge

• Transfer roller

• Fixing unit

• Laser scanner\

The DC controller controls the laser scanner and high-voltage power supply to form the toner

imageon the photosensitive drum. The image is transferred to the print media and xed.

Diagram of the image formation system is shown below.

Laser beam

Cartridge

Photosensitive drum

Transfer roller

Engine controller

Fixing unit

Fixing film

Pressure roller

High-voltage power supply

Image Formation Process

■

Outline

The image formation process consists of the following seven steps divided among ve

functional blocks:

Latent image formation block

Step 1: Primary charging

Step 2: Laser-beam exposure

Developing block

Step 3: Developing

Transfer block

Step 4: Transfer

Step 5: Separation

Fixing block

Step 6: Fixing

Drum cleaning block

Step 7: Drum cleaning

Latent image formation

Direction of

the drum rotation

Block

Step

1. Primary charging

Drum cleaning

7. Drum cleaning

2. Laser-beam exposure

Developing

3. Developing

DC controller

Technology > Image Formation System > Image Formation Process > Outline

2

F-2-3

6. FixingDelivery

Fixing

Transfer

Pickup4.Transfer5. Separation

F-2-4

2-4

2

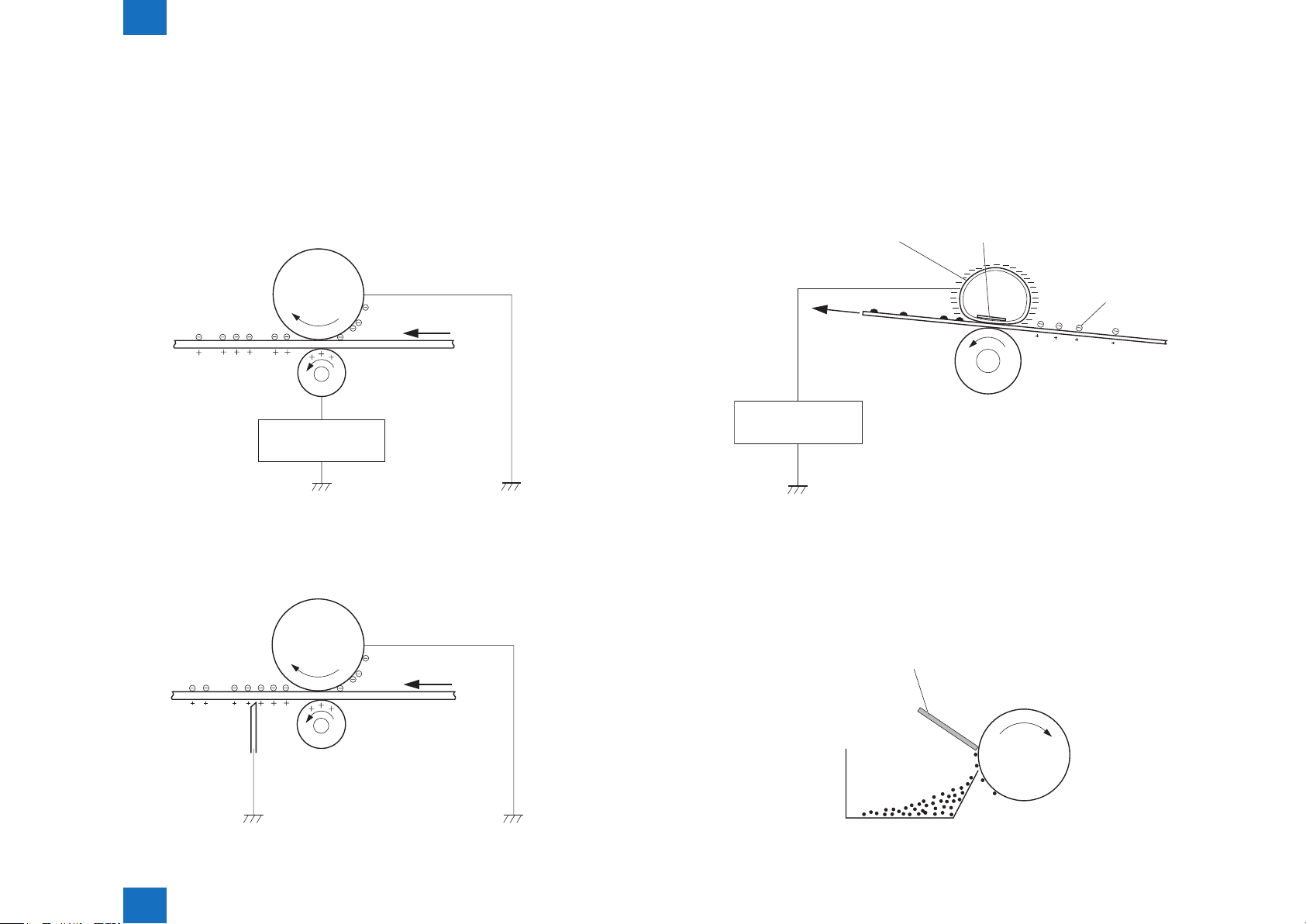

Primary charging roller

Laser beam

Technology > Image Formation System > Image Formation Process > Developing block

2-5

■Latent image formation block

During the two steps that comprise this block, an invisible latent image is formed on the

photosensitivedrum.

Step 1: Primary charging

To prepare for latent image formation, the surface of the photosensitive drum is charged

with a uniform negative potential. The primary charging bias is applied to the primary

charging roller and the roller charges the drum directly.

Photosensitive drum

Step 2: Laser-beam exposure

The laser beam scans the photosensitive drum to neutralize the negative charge on

portions of the drum surface. An electrostatic latent image forms where the negative charge

was neutralized.

Primary charging bias

F-2-5

■Developing block

Toner adheres to the electrostatic latent image on the photosensitive drum, which becomes

visible.

Step 3: Developing

Toner acquires a negative charge from the friction that occurs when the developing roller

rotates against the developing blade. The negatively charged toner is attracted to the

latent image on the photosensitive drum surface because the drum surface has a higher

potential. The developing bias is applied to the developing roller.

Blade

Developing rolle

Exposed

area

Unexposed

area

Photosensitive drum

Unexposed

area

Exposed

area

Developing bias

F-2-7

2

Unexposed area Exposed area

F-2-6

2-5

Technology > Image Formation System > Image Formation Process > Developing block

2

Fixing film

Fixing heater

Cleaning blade

Technology > Image Formation System > Image Formation Process > Drum cleaning block

2-6

■Transfer block

During the two steps that comprise this block, a toner image on the photosensitive drum is

transferred to the print media.

Step 4: Transfer

The transfer bias is applied to the transfer roller to charge the print media positive. The

positively charged media attracts the negatively charged toner from the photosensitive

drum surface.

Photosensitive

drum

Media

Transfer roller

Transfer bias

F-2-8

Step 5: Separation

The elasticity of the print media and the curvature of the photosensitive drum cause the

media to separate from the drum surface. The static charge eliminator reduces back side

static discharge of the media for stable media feed and image quality.

Photosensitive

drum

■Fixing block

The toner image is xed onto the print media.

Step 6: Fixing

The printer uses an on-demand xing method. The toner image is permanently afxed to

the print media by heat and pressure. The xing bias is applied to the xing lm to improve

image quality.

Toner

Media

Pressure roller

Fixing bias

F-2-10

■Drum cleaning block

The residual toner is cleared from the photosensitive drum surface.

Step 7: Drum cleaning

The cleaning blade scrapes the residual toner off the surface of the photosensitive drum.

The residual toner is deposited in the toner collection box.

Media

Static charge

eliminator

Technology > Image Formation System > Image Formation Process > Drum cleaning block

Transfer roller

F-2-9

2

Toner

collection box

Photosensitive

drum

F-2-11

2-6

2

Engine controller

Technology > Image Formation System > High-voltage Power Supply > Outline

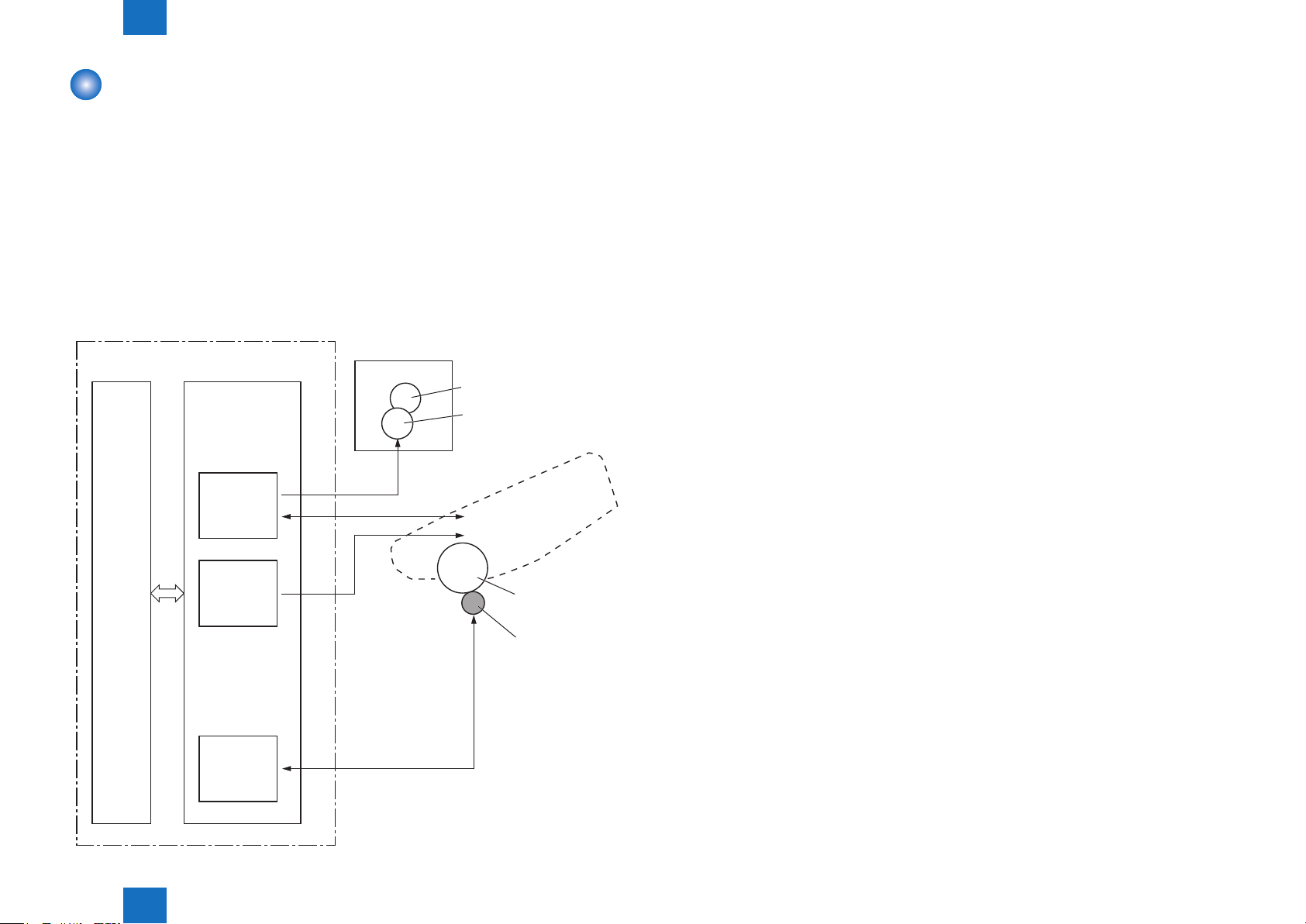

High-voltage Power Supply

■Outline

The high-voltage power supply applies biases to the following components:

• Primary charging roller

• Developing roller

• Transfer roller

• Fixing lm

The DC controller controls the high-voltage power supply to generate biases. See "IV.

IMAGE-FORMATION SYSTEM"(Refer to page 2-4)for detailed information.

The Figure below shows the conguration of the High-voltage Power Supply.

2-7

DC controller

High-voltage

power supply

Primary

charging

bias circuit

Developing

bias circuit

Transfer

bias circuit

FB

PR

DV

TR

Fixing unit

Fixing film

Pressure roller

Cartridge

Primary charging roller

Developing roller

Photosensitive

drum

Transfer roller

Technology > Image Formation System > High-voltage Power Supply > Outline

2

F-2-12

2-7

2

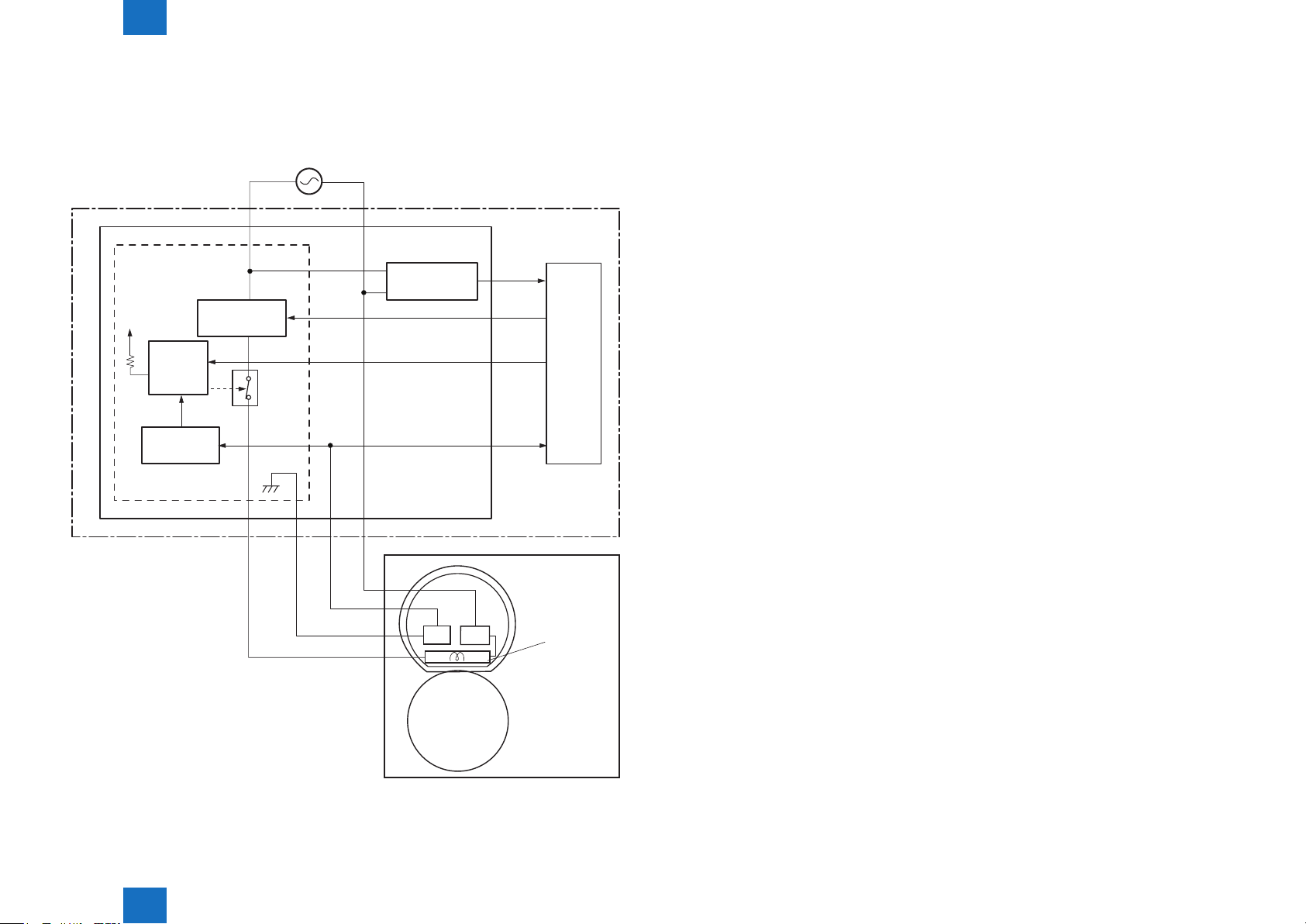

Technology > Fixing System > Outline

Fixing System

Outline

The xing/delivery unit xes the toner onto a print paper and delivers it to the delivery tray.

The operation of the xing/delivery unit is explained in the following.

1) The print paper fed from the pick-up/feed unit is fused the toner by the xing lm and the

pressure roller.

2-8

Fixing unit

Fixing film

2) The print paper delivered from the xing unit is delivered to the face-down delivery tray or

the face-up delivery slot. When the engine controller detects that the heater temperature

reaches 50 deg C after the last rotation is completed, it drives the main motor for 50 msec.

and dislocates the nip part. This prevents the toner adhering to the pressure roller.

The xing unit of this printer utilizes the on-demand xing method. It is structured as shown

below.

- Heater:

This xing unit incorporates one heater.

Fixing heater (H1): To heat the xing lm (ceramic heater)

- Thermistor:

This xing unit incorporates one thermistor.

Thermistor (TH1): Sit almost at the center of the xing lm. (contact type)

To control the temperature of the xing lm

- Thermal switch:

Thermoswitch (TP1): Sit almost at the center of the xing lm (contact type)

If the temperature of the heater rises abnormally high, the contact gets broken and

cuts off the AC voltage supply to the xing heater to interrupt the power supply to the

heater.

The temperature control of the xing unit incorporated as above is operated by the xing

temperature control circuit according to the command from the CPU (IC201) on the DC

controller.

The followings describe the each circuit and function of the temperature control of the xing

unit.

Fixing heater

Thermistor

Fixing heater

control circuit

FIXING TEMPERATURE

DETECTION signal

FIXNG HEATER

CONTROL signal

Engine controller PCB

Thermoswitch

Pressure roller

CPU

F-2-13

Technology > Fixing System > Outline

2

2-8

2

Technology > Fixing System > Fixing control circuit > Small Size Paper Printing Speed Control (Throughput Reduction Control)

2-9

Fixing control circuit

The xing control circuit controls the temperature in the xing unit. The printer uses an ondemand xing method.

The Figure below shows the conguration of the xing control circuit.

Fixing film

H1

TP1

TH1

Pressure roller

FIXING TEMPERA TURE signal

FIXNG HEATER CONTROL signal

■Small Size Paper Printing Speed Control (Throughput

Reduction Control)

During continuous printing, the throughput is changed to reduce heat buildup on parts not in

contact with paper, to improve xing characteristics and reduce curling.

The throughput reduction is implemented according to the following conditions.

Fixing Mode Throughput

Envelope 1 – 23 imprints 23 – 39 imprints 40 – 47 imprints 48 imprints or more

17 ppm 12 ppm 8 ppm 6 ppm

Envelope 2 1 – 27 imprints 28 – 62 imprints 63 – 174 imprints 175 imprints or more

17 ppm 12 ppm 8 ppm 6 ppm

Envelope 3 1 – 31 imprints 32 – 47 imprints 48 – 79 imprints 80 imprints or more

12 ppm 8 ppm 6 ppm 4 ppm

Postcard 1 – 31 imprints 32 – 47 imprints 48 imprints or more

12 ppm 8 ppm 6 ppm

16K 1 – 89 imprints 90 imprints or more

16 ppm 14 ppm

16K Rough 1 – 34 imprints 35 imprints or more

16 ppm 8 ppm

Long Narrow 1 imprint or more

3 ppm

T-2-2

DC controller

• Fixing heater (H1): Heats the xing lm

• Thermistor (TH1): Detects xing temperature (Contact type)

• Thermoswitch (TP1):Prevents an abnormal temperature rise of the xing heater

(Contact type)

These temperature controls in the xing unit are performed by the xing heater control circuit

and the xing heater safety circuit according to the commands from the DC controller.

Technology > Fixing System > Fixing control circuit > Small Size Paper Printing Speed Control (Throughput Reduction Control)

Fixing heater

control circuit

Fixing control circuit

Low-voltage power supply unit

Engine controller

Fixing heater

safety circuit

F-2-14

2

2-9

2

Technology > Fixing System > Fixing control circuit > Protective function

2-10

■Fixing temperature control

The xing temperature control maintains the temperature of the xing heater at its targeted

temperature.

Block diagram of this control is shown below.

Engine controller

Low-voltage power supply

Fixing control circuit

+24V

Fixing heater

safety circuit

Fixing heater

control circuit

Relay

control

circuit

Frequency

detection circuit

RL101

DC controller

FREQSNS

FSRD

RLYD

FSRTH

heater control circuit controls the xing heater depending on the signal so that the heater

remains at the targeted temperature.

■Protective function

The protective function detects an abnormal temperature rise in the xing unit and interrupts

power supply to the xing heater.

The following three protective components prevent an abnormal temperature rise of the xing

heater:

• DC controller

• Fixing heater safety circuit

• Thermoswitch

1) Thermoswitch

The contact of the thermoswitch is broken to interrupt power supply to the xing heater

under the following condition:

• Temperature fuse: 228°C (442.4°F) or higher

2) DC controller

The DC controller monitors the detected temperature of the thermistor. The DC controller

makes the FIXING HEATER CONTROL signal inactive and releases the relay to interrupt

power supply to the xing heater under the following condition:

• Thermistor: 240°C (464°F) or higher

Fixing film unit

TH1 TP1

Pressure roller

The DC controller monitors the FIXING TEMPERATURE (FSRTH) signal and sends the

FIXING HEATER CONTROL (FSRD) signal according to the detected temperature. The xing

Technology > Fixing System > Fixing control circuit > Protective function

H1: Fixing heater

TP1: Thermoswitch

TH1: Thermistor

Fixing unit

F-2-15

2

3) Fixing heater safety circuit

The xing heater safety circuit monitors the detected temperature of the thermistor.

The xing heater safety circuit releases the relay control circuit to interrupt power supply

to the xing heater under the following condition:

• Thermistor: 270°C (518°F) or higher

2-10

2

Technology > Fixing System > Fixing control circuit > Failure detection

■Failure detection

The DC controller determines a xing unit failure, makes the FIXING HEATER CONTROL

signal inactive, releases the relay to interrupt power supply to the xing heater and noties

the Main Controller of a failure state when it encounters the following conditions:

1) Start-up failure (E000)

• If the detected temperature of the thermistor is kept a specied degrees or higher for a

specied period of heater start-up during the wait period.

• If the detected temperature of the thermistor is kept a specied degrees or lower for a

specied period under the heater temperature control during the initial rotation period.

• If the detected temperature of the thermistor is kept a specied degrees or lower for a

specied period under the heater temperature control during the print period.

• If the detected temperature of the thermistor does not reach its targeted temperature within

a specied period under the heater temperature control during the initial rotation period.

2) Abnormal high temperature (E001)

• If the detected temperature of the main thermistor is kept a specied degrees or higher for

a specied period.

3) Abnormal low temperature (E003)

• If the detected temperature of the thermistor is kept a specied degrees or lower for a

specied period under the heater temperature control.

2-11

4) Drive circuit failure (E004)

• If a specied frequency of the FREQUENCY signal is not detected within a specied period

after the printer is turned on.

• If an out of specied frequency of the FREQUENCY signal is detected after the printer is

turned on and the signal is once detected.

Technology > Fixing System > Fixing control circuit > Failure detection

2

2-11

2

Technology > Pickup Feeding System > Outline

2-12

Pickup Feeding System

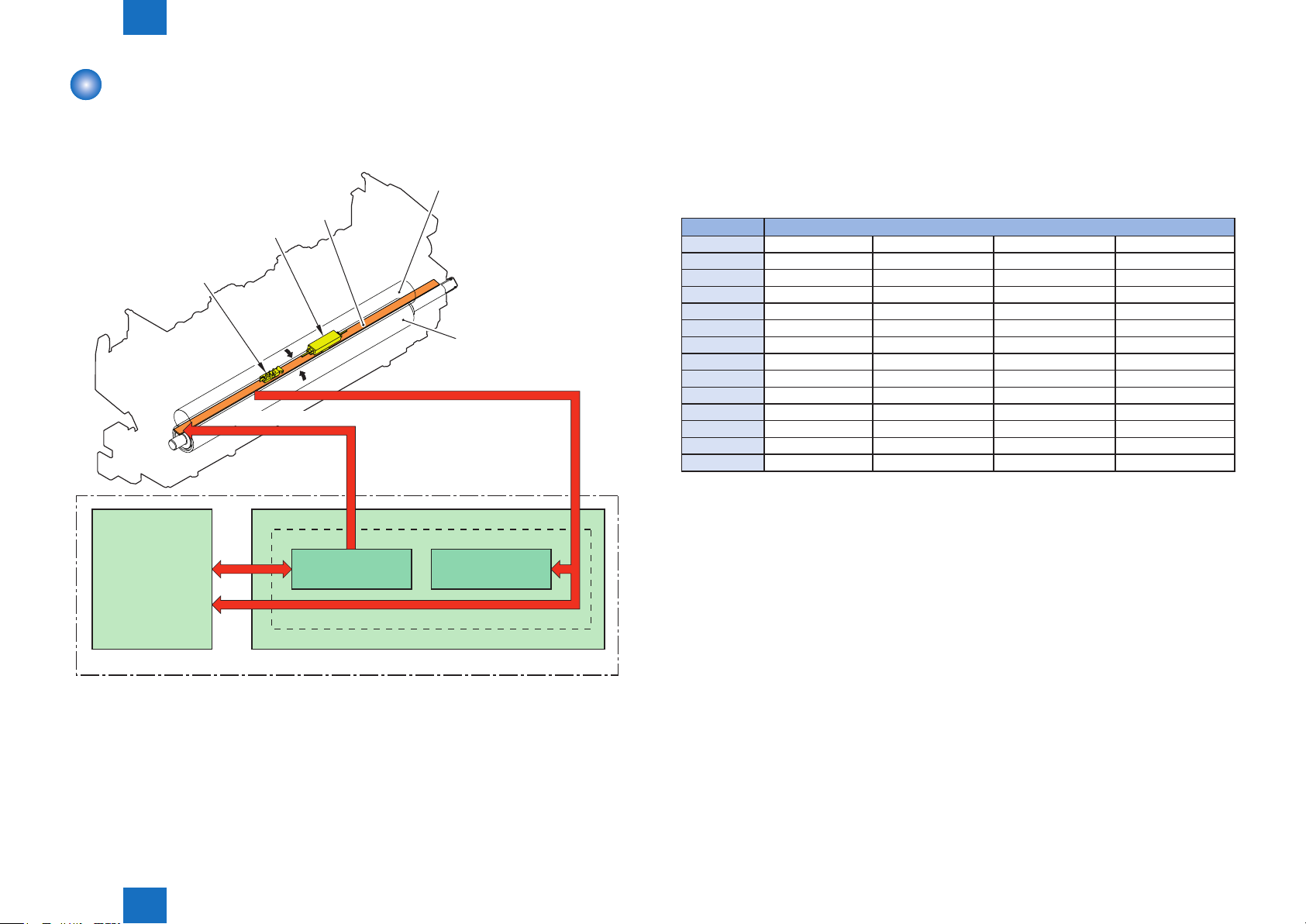

Outline

The pickup feeding system picks up, feeds and delivers the print media. It consists of several

types of rollers.

The duplex feed unit in the duplex model reverses and refeeds the print media to print on

both sides of media.

The media path is shown below.

Face-down delivery roller

Fixing film

Pressure

roller

Fixing delivery roller

: Simplex media path

: Duplex media path

Photosensitive drum

Duplex feed roller

Transfer roller

Duplex re-pickup roller

Cassette pickup roller

Registration roller

MP tray separattion roller

MP tray

separattion pad

Cassette

separation pad

F-2-16

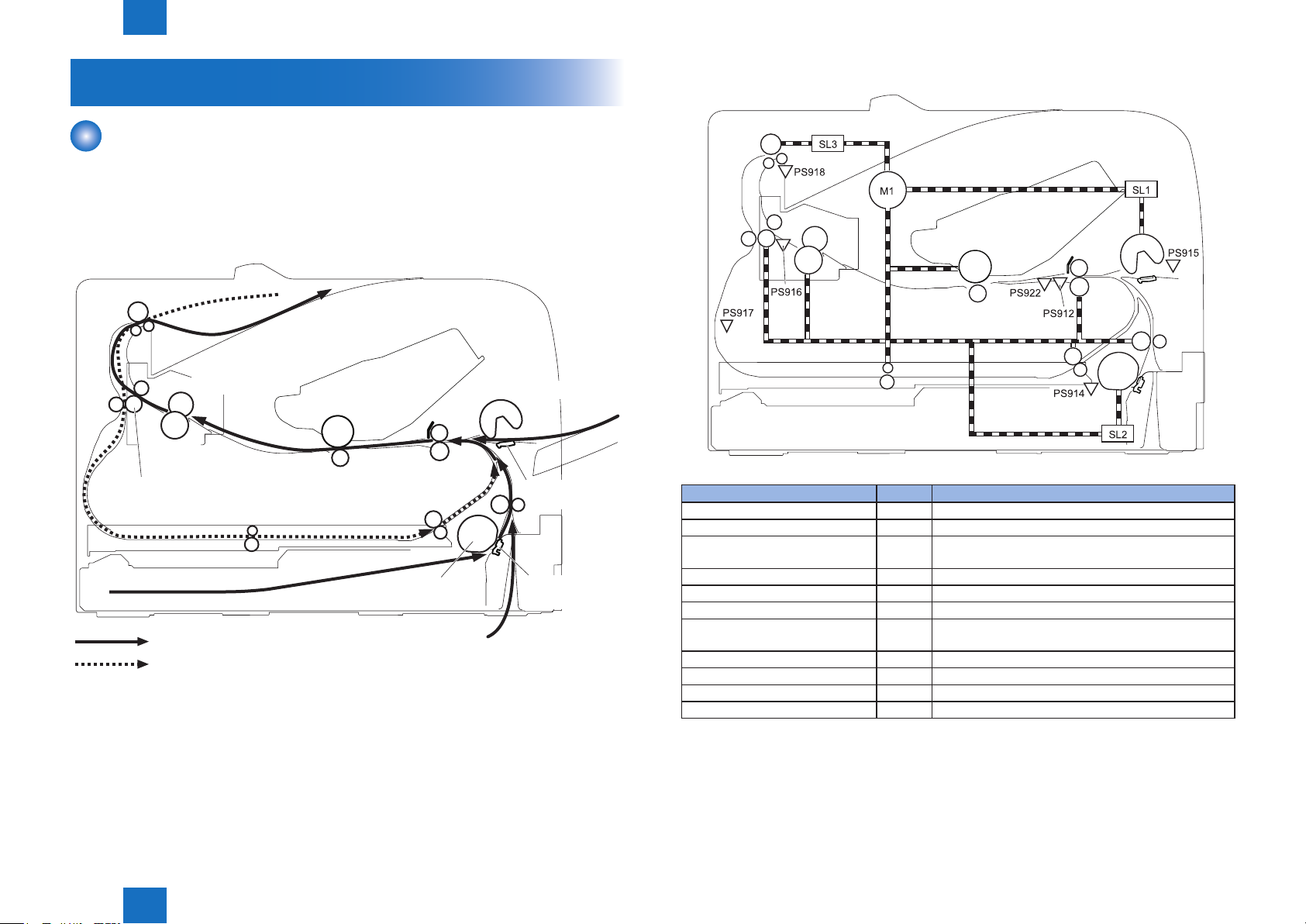

Diagram and table of the electrical components are shown below.

Electrical component Signal

Main Motor M1 Main Motor Control Signal

Cassette Pickup Solenoid SL1 Cassette Pickup Solenoid Control Signal

Multi-purpose Tray Pickup

Solenoid

Duplex Revrse Solenoid SL3 Duplex Reverse Solenoid Control Signal

TOP Sensor PS912 TOP Signal

Cassette Media Presence Sensor PS914 Cassette Media Presence Signal

Multi-purpose Tray Presence

Sensor

Fixing Delivery Sensor PS916 Fixing Delivery Signal

Duplex Reverse Sensor PS917 Duplex Reverse Signal

FD Tray Media Full Sensor PS918 FD Tray Media Full Signal

Media Width Sensor PS922 Media Width Signal

SL2 Multi-purpose Tray Pickup Solenoid Control Signal

PS915 Multi-purpose Tray Media Presence Signal

F-2-17

T-2-3

Technology > Pickup Feeding System > Outline

2

2-12

2

Technology > Pickup Feeding System > Jam Detection > Reverse Delay Jam

2-13

Jam Detection

■

Outline

The printer uses the following sensors to check whether media is being fed correctly or has

jammed:

• TOP sensor (PS912)

• Fixing delivery sensor (PS916)

• Duplex reverse sensor (PS917)

• Media width sensor (PS922)

PS916

PS917

PS922 PS912

■Pickup Delay Jam

When the TOP Sensor (PS912) cannot detect the leading edge of paper within the specied

time after starting pickup from a cassette, pickup retry is executed twice. After that, the sensor

still cannot detect the leading edge of paper within the specied time, it is judged as a pickup

jam.

■Pickup Stationary Jam

When the TOP Sensor (PS912) cannot detect the trailing edge of paper after the specied

time has passed since it detected the leading edge of paper, it is judged as a pickup

stationary jam.

■Delivery Delay Jam

When the Fixing Delivery Sensor (PS916) cannot detect the leading edge of paper after the

specied time has passed since the TOP Sensor (PS912) detected the leading edge of paper,

it is judged as a delivery delay jam.

■Fixing Paper Wrap Jam

After judging that it is not a delivery delay jam, execute the detection of xing paper wrap jam.

It is judged as a xing paper wrap jam when all of the following conditions are met: after the

specied time had passed since the Fixing Delivery Sensor (PS916) detected the leading

edge of paper, after the specied time had passed since the TOP Sensor (PS912) detected

the leading edge of paper, and the Fixing Delivery Sensor (PS916) detects no paper.

: Simplex media path

: Duplex media path

Technology > Pickup Feeding System > Jam Detection > Reverse Delay Jam

2

F-2-18

■Delivery Stationary Jam

After judging that it is not a xing paper wrap, execute the detection of delivery stationary jam.

When the Fixing Delivery Sensor (PS916) does not detect no paper within the specied time

since the TOP Sensor (PS912) detected the trailing edge of paper, it is judged as a delivery

stationary jam.

■Reverse Delay Jam

After judging that it is not a delivery stationary jam, execute the detection of reverse stationary

jam.

When the Duplex Reverse Sensor (PS917) does not detect paper after the specied time

has passed since the Fixing Delivery Sensor (PS916) detected the trailing edge of paper, it is

judged as a reverse delay jam.

2-13

2

Technology > Pickup Feeding System > Jam Detection > Door Open Jam

■Reverse Stationary Jam

When the Duplex Reverse Sensor (PS917) cannot detect the trailing edge of paper after the

specied time has passed since the sensor detected the leading edge of paper, it is judged

as a reverse stationary jam.

■Internal Residual Jam

When a paper is detected by the TOP Sensor (PS912), Fixing Delivery Sensor (PS916),

Paper Width Sensor (PS922), or Duplex Reverse Sensor (PS917) at the time of starting initial

rotation, it is judged as an internal residual jam.

■Door Open Jam

When a door-open is detected while feeding papers, it is judged as a door open jam.

2-14

Technology > Pickup Feeding System > Jam Detection > Door Open Jam

2

2-14

Loading...

Loading...