Canon lbp2410 Service Manual

LBP-2410

REVISION 0

FEB.2003

COPYRIGHT© 2003 CANON INC. 2000 2000 20000 CANON LBP-2410 REV.0 FEB. 2003 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13HX-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2003 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2003 CANON INC. 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

INTRODUCTION

This Service Manual provides basic facts and figures needed to service the Laser Beam

Printer LBP-2410 (hereafter, the machine or the printer) in the field. It also contains descriptions of the 250-sheet paper feeder available for the machine.

This Service Manual consists of the following chapters:

Chapter 1 Outline of the Product: features, specifications, installation, how to operate the

machine

Chapter 2 Outline of Operations: principles of mechanical/electrical operations according to

functions; timing of operations

Chapter 3 Mechanical System: mechanical construction, disassembly/assembly and adjust-

ments

Chapter 4 Troubleshooting: corrective measures; standards, adjustments, maintenance/in-

spection

Appendix: general timing chart, general circuit diagrams, list of signals

The descriptions herein are subject to change for product improvement or the like, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to go through the contents of this document and the applicable Service Information bulletins and be fully familiar with the machine, thereby equipping themselves with the knowledge and skill needed to maintain its quality and performance.

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

i

CONTENTS

Contents

CHAPTER 1 PRODUCT INFORMATION

1 FEATURES ...................................... 1-1

1.1.1 Compact color printer .......... 1-1

1.1.2 Reduced wait time and low

power consumption ............. 1-1

1.1.3 EP-87 DRUM

CARTRIDGE ...................... 1-1

1.1.4 Employment of Canon

Advanced Printing

Technology .......................... 1-1

2 SPECIFICATIONS .......................... 1-2

2.1 Printer......................................... 1-2

2.1.1 Printer engine ....................... 1-2

2.1.2 Interface controller .............. 1-3

2.2 Options ....................................... 1-4

2.2.1 Universal 250-sheet paper

feeder ................................... 1-4

3 SAFETY INFORMATION .............. 1-5

3.1 Laser Safety ............................... 1-5

3.2 Toner Safety ............................... 1-5

3.3 Ozone Safety .............................. 1-5

3.4 Power Supply Safety.................. 1-5

4 PARTS OF THE PRINTER ............. 1-6

4.1 External View ............................. 1-6

4.1.1 Printer .................................. 1-6

4.1.2 Universal 250-sheet paper

feeder ................................... 1-7

4.2 Cross Sectional View ................. 1-8

4.2.1 Printer .................................. 1-8

4.2.2 Universal 250-sheet paper

feeder ................................... 1-9

5 INSTALLATION............................ 1-10

5.1 Outline ..................................... 1-10

5.2 Selecting a location .................. 1-10

5.2.1 Power supply ..................... 1-10

5.2.2 Operating environment ...... 1-10

5.2.3 Space .................................. 1-11

5.3 Unpacking and Installation ....... 1-12

5.3.1 Printer ................................ 1-12

5.3.2 EP-87 Drum Cartridge ....... 1-12

5.3.3 EP-87 Toner cartridge ........ 1-14

5.3.4 Paper feeder ....................... 1-17

5.3.5 Confirming the

performance ....................... 1-17

5.4 Notes for Storing and Handling

the EP-87 Drum Cartridge and

EP-87 Toner Cartridge ............. 1-17

5.4.1 Storing the sealed

cartridges ............................ 1-17

5.4.2 Storing the unsealed

cartridges ............................ 1-18

6 MAINTENANCE AND SERVICING

BY THE CUSTOMER ................... 1-21

6.1.1 EP-87 Toner cartridge ........ 1-21

6.1.2 EP-87 Drum Cartridge ....... 1-21

6.1.3 Mylar sheet ........................ 1-21

6.1.4 Pressure Roller

(fixing assembly) ............... 1-22

6.1.5 Density sensor/ITB home

position sensor ................... 1-23

7 USING THE MACHINE ............... 1-24

7.1 Control Panel ........................... 1-24

7.2 Canon Advanced Printing

Technology (CAPT) ................. 1-25

7.3 Microsoft Windows 2000-/XP .. 1-26

7.3.1 Installing CAPT ................. 1-26

7.3.2 Operating Environment ..... 1-26

7.3.3 Installation ......................... 1-27

7.4 Microsoft Windows 98/Me ...... 1-28

7.4.1 Installing CAPT ................. 1-28

7.4.2 Operating Environment ..... 1-29

7.4.3 Installing CAPT ................. 1-29

ii

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 2 OPERATION AND TIMING

CONTENTS

1 BASIC OPERATION ....................... 2-1

1.1 Outline ....................................... 2-1

1.2 Basic Operation Sequence ......... 2-2

1.3 Power-on sequence .................... 2-3

2 ENGINE CONTROL SYSTEM ...... 2-4

2.1 Outline ....................................... 2-4

2.2 DC controller ............................. 2-4

2.2.1 Outline ................................. 2-4

2.2.2 Operations ............................ 2-6

2.2.3 Motor/fan control ................. 2-7

2.3 High-voltage Power Supply

PCB .......................................... 2-13

2.3.1 Outline ............................... 2-13

2.3.2 Primary charging bias

generation .......................... 2-14

2.3.3 Developing bias

generation ........................... 2-14

2.3.4 Primary transfer bias

generation .......................... 2-14

2.3.5 Secondary transfer bias

generation .......................... 2-15

2.3.6 Auxiliary ITB cleaning bias

generation .......................... 2-15

2.3.7 ITB cleaning bias

generation .......................... 2-15

2.3.8 Fixing bias generation ....... 2-16

2.4 Power Supply Unit ................... 2-16

2.4.1 Outline ............................... 2-16

2.4.2 Fixing control circuit ......... 2-17

2.4.3 Low-voltage power supply

PCB.................................... 2-22

2.5 Video Interface Control ........... 2-24

2.5.1 Outline ............................... 2-24

2.5.2 Video interface signals....... 2-25

2.6 Interface Controller PCB ......... 2-26

2.6.1 Outline ............................... 2-26

2.6.2 Operation of the Blocks ..... 2-26

3 LASER/SCANNER SYSTEM ...... 2-29

3.1 Outline ..................................... 2-29

3.2 Laser Control ........................... 2-31

3.2.1 Outline ............................... 2-31

3.2.2 Laser emission control ....... 2-32

3.2.3 Automatic power control

(APC) ................................. 2-33

3.2.4 Horizontal synchronous

control ................................ 2-33

3.2.5 Image mask control ........... 2-34

3.2.6 Laser failure detection ....... 2-35

3.3 Scanner Motor Control ............ 2-35

3.3.1 Outline ............................... 2-35

3.3.2 Scanner motor speed

control ................................ 2-36

3.3.3 Scanner motor failure

detection ............................ 2-36

4 IMAGE FORMATION SYSTEM.. 2-37

4.1 Outline ..................................... 2-37

4.2 Image Formation Process......... 2-38

4.2.1 Electrostatic latent image

formation block ................. 2-38

4.2.2 Developing block ............... 2-38

4.2.3 Transfer block .................... 2-38

4.2.4 Fixing block ....................... 2-38

4.2.5 ITB cleaning block ............ 2-38

4.2.1 Electrostatic latent image

formation block ................. 2-40

4.2.2 Developing block ............... 2-42

4.2.3 Transfer block .................... 2-44

4.2.4 Fixing block ....................... 2-47

4.2.5 ITB cleaning block ............ 2-48

4.3 Developing rotary unit ............. 2-52

4.3.1 Outline ............................... 2-52

4.3.2 Developing rotary rotation

control ................................ 2-53

4.3.3 Developing rotary engaging

control ................................ 2-55

4.3.4 Developing rotary position

detection ............................ 2-57

4.4 Toner Cartridge ........................ 2-58

4.4.1 Outline ............................... 2-58

4.4.2 Memory tag ....................... 2-59

4.4.3 Memory tag contact engaging

control ................................ 2-60

4.4.4 Cartridge presence

detection ............................. 2-62

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

iii

CONTENTS

4.4.5 Toner cartridge life

detection ............................. 2-62

4.5 Drum cartridge ......................... 2-64

4.5.1 Outline ............................... 2-64

4.5.2 Cleaning roller engaging

control ................................ 2-65

4.5.3 Memory tag ....................... 2-67

4.5.4 Detecting the ITB Home

Position .............................. 2-68

4.5.5 Drum cartridge presence

detection ............................ 2-70

4.5.6 Checking the Life of the Drum

Cartridge ............................ 2-71

4.6 Transfer unit ............................. 2-73

4.6.1 Outline ............................... 2-73

4.6.2 Secondary transfer roller

engaging control ................ 2-74

4.6.3 Secondary roller position

detection ............................ 2-76

4.7 Image stabilization calibration

control ...................................... 2-78

4.7.1 Outline ............................... 2-78

4.7.2 Image density calibration

(D-max) control ................. 2-79

4.7.3 Image halftone calibration

(D-half) control .................. 2-79

5 PICK-UP/FEED SYSTEM ............ 2-80

5.1 Outline ...................................... 2-80

5.2 Pick-up/Feed Unit .................... 2-82

5.2.1 Outline ............................... 2-82

5.2.2 Multi-purpose tray

pick-up ............................... 2-83

5.2.3 Skew correction function ... 2-84

5.2.4 Feed speed control ............. 2-85

5.2.5 Internal temperature

detection ............................ 2-86

5.3 Fixing/Delivery Unit ................ 2-86

5.3.1 Outline ............................... 2-86

5.4 Jam Detection .......................... 2-87

5.4.1 Pick-up delay jam .............. 2-87

5.4.2 Pick-up stationary jam ....... 2-87

5.4.3 Fixing unit wrapping jam .. 2-87

5.4.4 Delivery delay jam ............. 2-87

5.4.5 Delivery stationary jam...... 2-87

5.4.6 Door open jam ................... 2-88

5.4.7 Residual paper jam ............ 2-88

6 PAPER FEEDER ............................ 2-89

6.1 Outline ..................................... 2-89

6.2 Pick-up and Feed Operations ... 2-90

6.2.1 250-sheet paper feeder ....... 2-90

6.3 Jam Detection .......................... 2-91

CHAPTER 3 THE MECHANICAL SYSTEM

1 PREFACE......................................... 3-1

1.1 Outline ....................................... 3-1

1.2 Cartridge Removal at Trouble

Eruption ..................................... 3-2

1.2.1 EP-87 toner cartridge

removal ................................ 3-2

1.2.2 EP-87 drum cartridge

removal ................................ 3-5

2 EXTERNALS .................................. 3-6

2.1 Locations .................................... 3-6

2.1.1 Left cover ............................. 3-7

2.1.2 Top cover unit ...................... 3-7

2.1.3 Right cover unit .................. 3-10

2.1.4 Front cover unit .................. 3-10

iv

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

2.1.5 Rear cover .......................... 3-11

2.1.6 Face-up cover ..................... 3-11

2.1.7 I/O cover ............................ 3-12

2.1.8 Control Panel ..................... 3-13

3 MAIN UNITS ................................ 3-14

3.1 Locations .................................. 3-14

3.2 Laser/Scanner Unit ................... 3-15

3.3 Main Drive Unit ....................... 3-16

3.4 Registration Shutter Unit .......... 3-20

3.5 Registration Roller Unit ............ 3-21

3.6 Rotary Drive Unit ..................... 3-22

3.7 Developing Rotary Unit ........... 3-24

3.8 Fixing Unit ............................... 3-28

4 MAIN PARTS ................................ 3-29

CONTENTS

4.1 Locations .................................. 3-29

4.2 Drum Cartridge Memory Tag

Contact ..................................... 3-30

4.3 Internal Temperature Detection

Thermistor ................................ 3-31

4.4 Multi-purpose Tray Pick-up

Roller ....................................... 3-31

4.5 Separation Pad ......................... 3-32

4.6 Registration Roller ................... 3-32

4.7 Toner Cartridge Memory Tag

Contact ..................................... 3-32

4.8 Secondary Transfer Roller ....... 3-33

4.9 Temperature Fuse/Main

Thermistor/Sub Thermistor...... 3-34

4.10 Fixing Film Unit ...................... 3-34

4.11 Pressure Roller ......................... 3-37

5 SENSORS/SWITCHES ................. 3-38

5.1 Locations .................................. 3-38

5.2 Multi-purpose Tray Paper

Sensor ...................................... 3-39

5.3 Fixing Delivery Paper Sensor .. 3-39

5.4 Developing Rotary Engaging

Sensor....................................... 3-39

5.5 Front fixing paper detection

sensor ....................................... 3-40

5.6 Roller Engaging Sensor ........... 3-41

5.7 Power Switch ........................... 3-41

5.8 Door Open Detection Switch ... 3-41

6 SOLENOIDS/CLUTCHES ............ 3-42

6.1 Locations .................................. 3-42

6.2 Developing Rotary Stopper

Solenoid ................................... 3-43

6.3 Multi-purpose Tray Pick-up

Solenoid ................................... 3-43

6.4 Roller Engaging Clutch ........... 3-44

6.5 Registration Clutch ................... 3-44

7 MOTORS/FAN .............................. 3-45

7.1 Locations .................................. 3-45

7.2 Engaging Motor ....................... 3-46

7.3 Developing Rotary Motor ........ 3-46

7.4 Toner Cartridge Motor .............. 3-46

7.5 Fixing Motor ............................ 3-47

7.6 Main Motor .............................. 3-47

7.7 Cooling Fan .............................. 3-48

8 PCBs .............................................. 3-49

8.1 Locations .................................. 3-49

8.2 Waste Toner Detection PCB ..... 3-50

8.3 Registration Detection PCB ...... 3-50

8.4 Density Detection PCB ............ 3-51

8.5 ITB Home Position Detection

PCB .......................................... 3-52

8.6 Developing Rotary/Toner Level

Detection PCB ......................... 3-52

8.7 High-voltage Power Supply

PCB .......................................... 3-53

8.8 Sub High-voltage Power Supply

PCB .......................................... 3-53

8.9 Power Supply Unit ................... 3-54

8.10 DC Controller PCB .................. 3-57

8.11 Interface Controller PCB .......... 3-57

9 250-SHEET PAPER FEEDER ....... 3-59

9.1 Main parts ................................ 3-59

9.1.1 Locations ........................... 3-59

9.1.2 Pick-up roller ..................... 3-60

9.1.3 Separation pad ................... 3-60

9.2 Sensors/Solenoid/PCB ............. 3-61

9.2.1 Locations ........................... 3-61

9.2.2 Pick-up solenoid ................ 3-62

9.2.3 Pick-up sensor ................... 3-63

9.2.4 Feed sensor ........................ 3-63

9.2.5 Paper feeder driver PCB .... 3-64

CHAPTER 4 TROUBLESHOOTING

1 PREFACE......................................... 4-1

1.1 Malfunction Diagnosis

Flowchart .................................... 4-1

1.2 Initial Check ............................... 4-3

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1.2.1 Installation environment ....... 4-3

1.2.2 Paper checks ........................ 4-3

1.2.3 Paper sets ............................. 4-3

1.2.4 Cartridge sets ....................... 4-3

v

CONTENTS

1.2.5 Fixing unit sets ..................... 4-4

1.2.6 External cover sets ............... 4-4

1.2.7 Condensation ....................... 4-4

1.3 Test Print .................................... 4-5

2 IMAGE FORMATION

TROUBLESHOOTING ................... 4-6

3 PAPER JAM

TROUBLESHOOTING ................ 4-17

4 PAPER TRANSPORT

TROUBLESHOOTING ................. 4-22

5 MALFUNCTION

TROUBLESHOOTING ................. 4-24

6 MALFUNCTION STATUS

TROUBLESHOOTING ................. 4-25

7 MEASUREMENT AND

ADJUSTMENT ............................. 4-34

7.1 Mechanical Adjustment ........... 4-34

7.1.1 Checking the nip width of the

lower fixing roller .............. 4-34

7.2 Making Electrical

Adjustments ............................. 4-35

7.2.1 When Replacing the Laser/Scanner Assembly and

interface controller PCB .... 4-35

7.3 Variable Resistors (VR), Test Pins,

Jumpers, and Switches ............. 4-36

7.3.1 ITB home position detection

PCB.................................... 4-36

8 MAINTENANCE AND

SERVICING .................................. 4-37

8.1 Periodic Replacement Parts ...... 4-37

8.2 Expected Service Life of

Consumable Parts .................... 4-37

8.3 Periodic Service ....................... 4-37

8.4 Cleaning during a Service

Visit .......................................... 4-37

8.4.1 Pick-up roller ..................... 4-37

8.4.2 Separation pad .................... 4-37

8.4.3 Registration roller ............... 4-37

8.4.4 Registration shutter ............ 4-37

8.4.5 Secondary transfer roller .... 4-38

8.4.6 Feed belt ............................. 4-38

8.5 Standard Tools .......................... 4-39

8.6 Special Tools ............................ 4-40

8.7 Solvent/Oil List ........................ 4-40

9 SERVICE MODE .......................... 4-41

9.1 Outline ...................................... 4-41

9.2 Starting Service Mode .............. 4-42

10 LOCATION OF CONNECTORS . 4-43

10.1 Printer ....................................... 4-43

10.2 250 paper feeder ....................... 4-44

APPENDIX

1 GENERAL TIMING CHART ........ A-1

2 GENERAL CIRCUIT DIAGRAM .. A-7

3 LIST OF SIGNALS ........................ A-9

3.1 DC controller ............................ A-9

3.2 250-sheet Paper Feeder Drive

PCB ......................................... A-15

vi

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

4 STATUS AND ERROR

INDICATIONS ............................. A-16

4.1 Outline .................................... A-16

4.2 Service Messages .................... A-17

CHAPTER 1

PRODUCT INFORMATION

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

1 FEATURES

1.1.1 Compact color printer

The depth dimension of this printer is narrowed down by miniaturizing the image formation system units such as ITB unit, rotary, etc. The weight of it is reduced by adopting a

molded-plastic body frame, simplifying mechanical units, and making the multi-purpose

tray the only pick-up source in the printer.

1.1.2 Reduced wait time and low power consumption

This printer has realized wait time reduction and energy saving as compared to the models

using the roller fixing method by adopting the on-demand fixing method.

1.1.3 EP-87 DRUM CARTRIDGE

The drum cartridge, ITB unit, and ITB toner case are integrated into the EP-87 drum cartridge. This allows the burdensome replacement procedure of consumable parts to be minimized for users. It resulted in the enhancement of user maintenance.

1.1.4 Employment of Canon Advanced Printing Technology

With Canon Advanced Printing Technology, data can be processed within a host computer.

This frees the printer from the PDL conversion and image processing, increasing the

speed perforance and reducing the cost.

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-1

CHAPTER 1 PRODUCT INFORMATION

2 SPECIFICATIONS

2.1 Printer

2.1.1 Printer engine

1) Type Desktop page printer

2) Printing method Electrophotography

3) Print speed (Note 1) Approx. 4 pages/min. (A4/LTR in full-color)

Approx. 16 pages/min. (A4/LTR in mono-color)

4) First print time (Note 2) Approx. 27 seconds or less (A4/LTR in full-color)

Approx. 16 seconds or less (A4/LTR in mono-color)

5) Wait time Max. : 120 seconds or less (Note 3)

6) Resolution

Horizontal 600 DPI

Vertical 600 DPI

7) Image formation system

Laser Semiconductor laser (twin-beam laser) method

Scanning system Rotating four-sided prism mirror scanning method

Photosensitive drum OPC drum method

Charging Roller charging method

Exposure Laser scanning method

Toner (Note 4) Component: Non-magnetic single-component dry toner

Replenishment: Replaceable EP-87 toner cartridge

The Bk EP-87 toner cartridge can print about 5,000 pages on

A4 size paper.

The Y, M, and C EP-87 toner cartridges can print about 4,000

pages on A4 size paper.

Development Contact development method

Transfer Primary transfer: Transfer belt method

Secondary transfer: Transfer roller method

Separation Curvature

Cleaning Photosensitive drum: Rubber blade method

ITB: Cleaning roller method

Fixing On-demand fixing method

8) Paper pick-up Multi-purpose tray

Paper types Plain paper, thick paper, recycled paper, colored paper, labels,

OHP sheets (Note 5), envelopes, (COM10, Monerch B5, C5)

and postcards (index cards)

Paper size Plain paper (64 g/m

paper (106 g/m

listed above from 76.2 (W)

(L) mm

Capacity Stack height 15 mm (equivalent to approx. 125 sheets of 75 g/

2

m

paper or 10 envelopes)

2

- 105 g/m2 recommended paper), thick

2

- 135 g/m2 recommended paper), and paper

127 (L) mm to 216 (W) 356

1-2

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

9) Paper delivery (Note 6) Facedown/faceup

2

Facedown tray capacity Approx. 125 sheets (75 g/m

paper)

10) Operating environment

Temperature 10 - 30 °C

Humidity 10 - 80 %RH

Air pressure 810 - 1013 hPa (608 - 760 mmHg)

11) Maximum power

consumption (Note 7) Approx. 1102 W or less (20 °C room temperature with rated

power voltage input)

12) Noise level (officially announced level based on ISO 9296)

Sound power level (1 B = 10 dB) 5.3 B or less (print)

13) Dimensions 482 (W)

451 (D) 325 (H) mm

14) Weight Approx. 15 kg (printer)

Approx. 2.5 kg (EP-87 drum cartridge)

Approx. 0.8 kg (EP-87 toner cartridge)

4

15) Power supply 110 - 127 V (± 10 %), 50/60 Hz (± 2 Hz)

220 - 240 V (± 10 %), 50/60 Hz (± 2 Hz)

16) Option Universal 250-sheet paper feeder

Note 1. Print speed when room temperature is 20 °C and the rated power

voltage is input. The printing speed may progressively decrease according to the settings of paper size, paper type, number of prints

to make, and the selected fixing mode.

Note 2. Time after the printer receives a print command from the interface

controller when it is in ready status until it finishes printing A4 or

LTR size paper and delivers it out on the facedown tray.

Note 3. When cartridge is exchanged and a power is turn on, a wait time

serves as the maximum.

Note 4. When the average print coverage is a 4 % dot ratio (equivalent to

about 5 % image print ratio) with the print density setting at mid

point.

Note 5. OHP sheets cannot be printed in colors.

Note 6. Paper smaller than 140 mm in length cannot be delivered out faced

down due to the shortage of a distance between the delivery rollers.

Note 7. It includes a peak that lasts for longer than one second.

2.1.2 Interface controller

1) Printing System Canon Advanced Printing Technology

2) RAM capacity 8MB

3) Interface USB interface (Standard)

Expansion interface (Option)

REF.

COPYRIGHT

©

Specifications are subject to change with product improvement.

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-3

CHAPTER 1 PRODUCT INFORMATION

2.2 Options

2.2.1 Universal 250-sheet paper feeder

1) Paper types Plain paper, thick paper, recycled paper, and colored paper

2) Paper size Plain paper (60 g/m

per listed above in letter, legal, A4, executive, A5, B5 size in

portrait orientation

3) Capacity Stack height 25 mm (equivalent to 250 sheets of 75 g/m

4) Dimensions 482 (W)

451 (D) 94 (H) mm

5) Weight Approx. 2.5 kg (including cassette)

6) Power supply DC 24 V (supplied through the printer)

Specifications are subject to change with product improvement.

REF.

2

- 105 g/m2 recommended paper) and pa-

2

paper)

1-4

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

3 SAFETY INFORMATION

3.1 Laser Safety

The laser/scanner unit emits invisible laser beam. DO NOT disassemble the unit as the

laser beam can possibly damage your eyes. The unit cannot be adjusted in the field. The

following label is attached to the cover of the unit:

F01-301-01

3.2 Toner Safety

Toner is a harmless substance composed of plastics and a small amount of pigment.

If you get toner on your skin or clothes, remove as much as possible with dry tissue and

then wash it with cold water. If you wash in hot water, the toner gels and becomes hard to

remove. As toner easily decomposes vinyl material, do not let it come into contact with the

material.

3.3 Ozone Safety

An infinitesimal amount of ozone gas (O3) is generated during corona discharge from the

cleaning charging roller used in this printer. The ozone gas is emitted only when the printer

is operating.

The printer meets the ozone emission standard decided by the Underwriters Laboratories

Inc. (UL) when it is shipped from the factory.

3.4 Power Supply Safety

Note that even if the power switch is turned off, the current still flows to the primary side

of the power supply unit.

Unplug the power cord before disassembling and reassembling the printer.

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-5

CHAPTER 1 PRODUCT INFORMATION

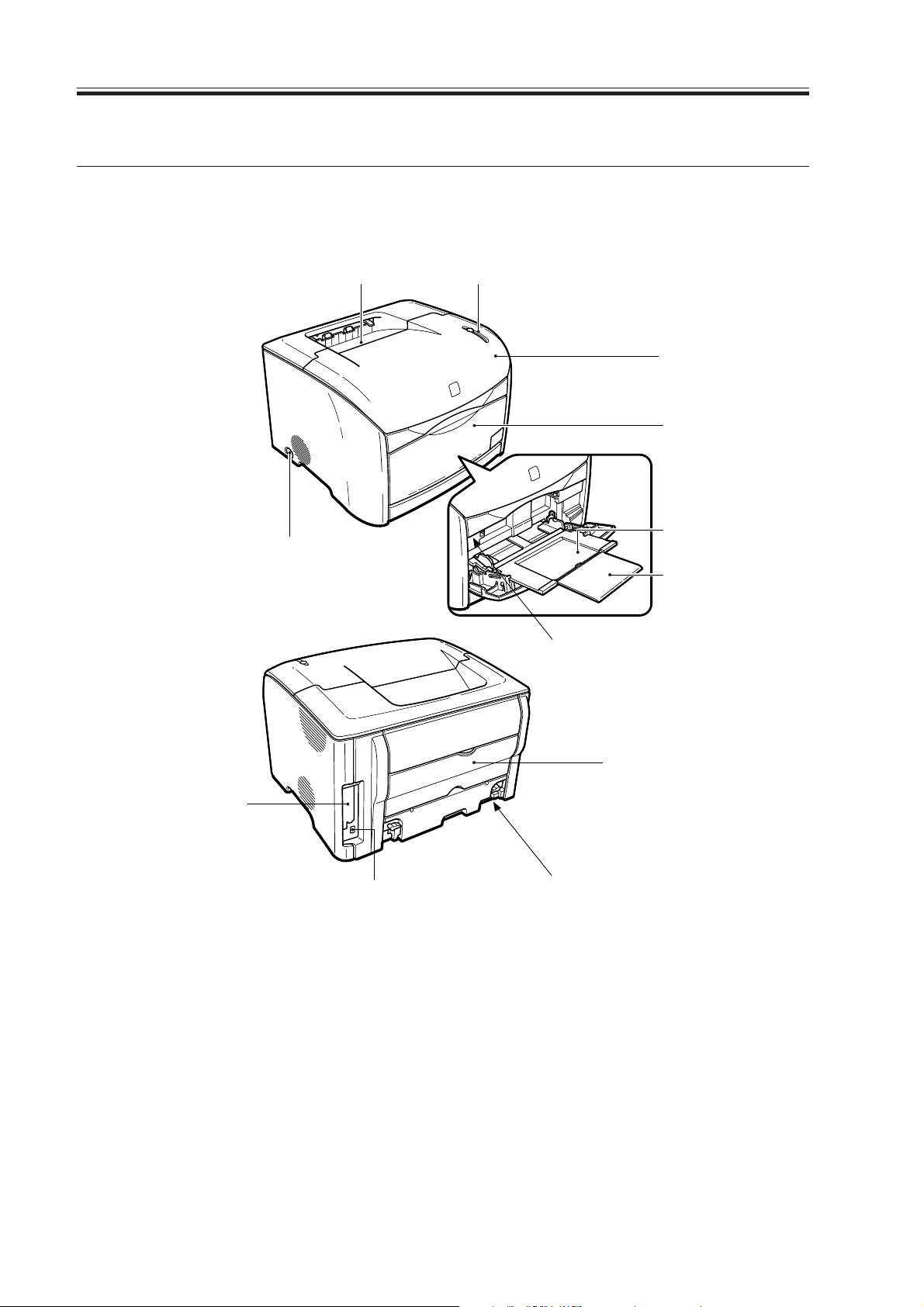

4 PARTS OF THE PRINTER

4.1 External View

4.1.1 Printer

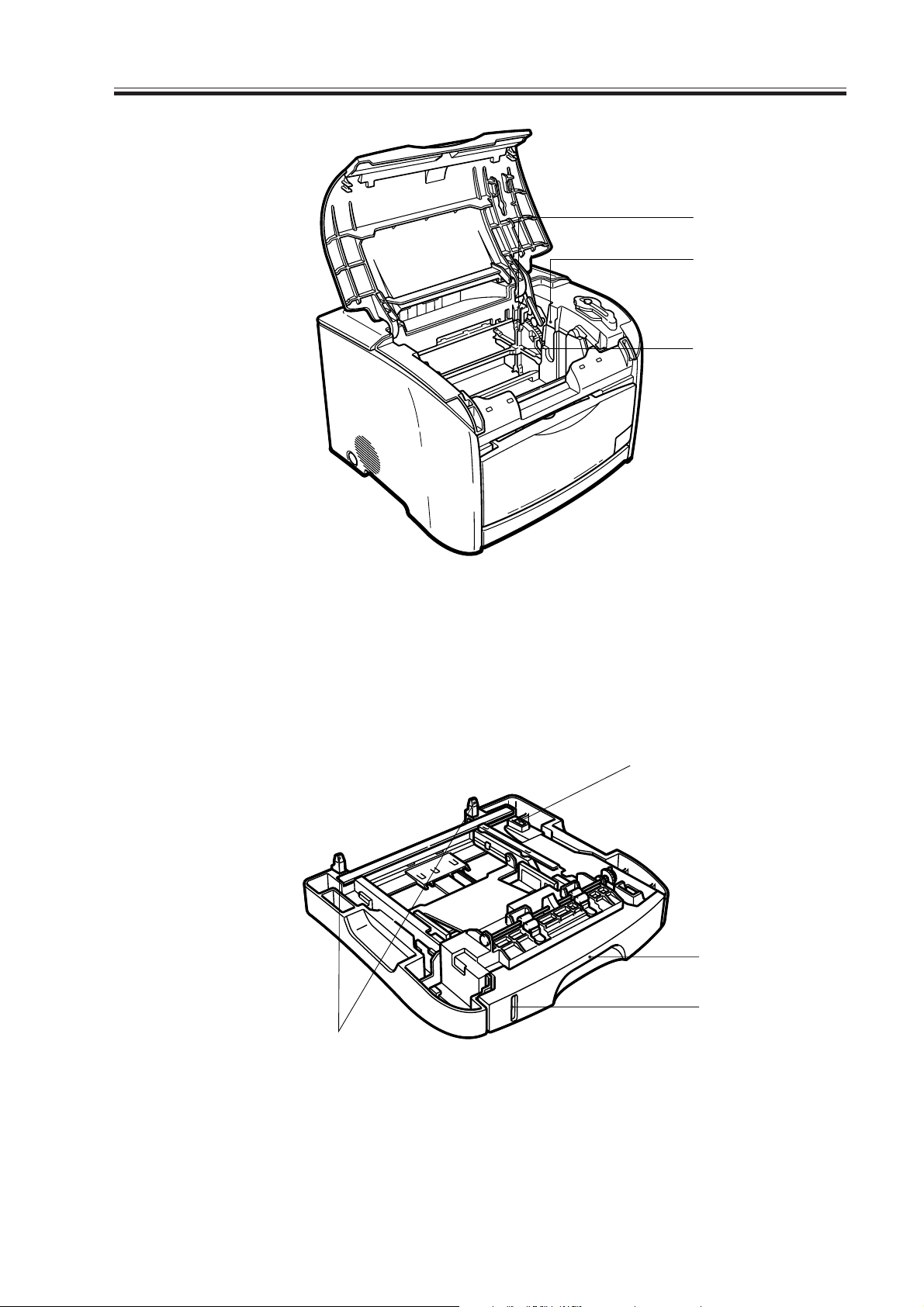

[1] [2]

[3]

[4]

[12]

[8]

[11]

F01-401-01

[5]

[6]

[7]

[9]

[10]

[1] Facedown tray

[2] Operation panel

[3] Top cover unit

[4] Front cover unit

[5] Multi-purpose tray

[6] Auxiliary tray

1-6

COPYRIGHT

©

[7] Test print switch

[8] Power switch

[9] Rear cover

[10]Power receptacle

[11]USB connector

[12]Expansion board slot

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

[13]

[14]

[15]

F01-401-02

[13]Toner cartridge slot

[14]Drum cartridge slot

4.1.2 Universal 250-sheet paper feeder

[4]

[15]Developing rotary

[1]

[2]

[3]

[1] Intermediate connector

[2] 250-sheet cassette

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

F01-401-03

[3] Paper level mark

[4] Positioning pins

1-7

CHAPTER 1 PRODUCT INFORMATION

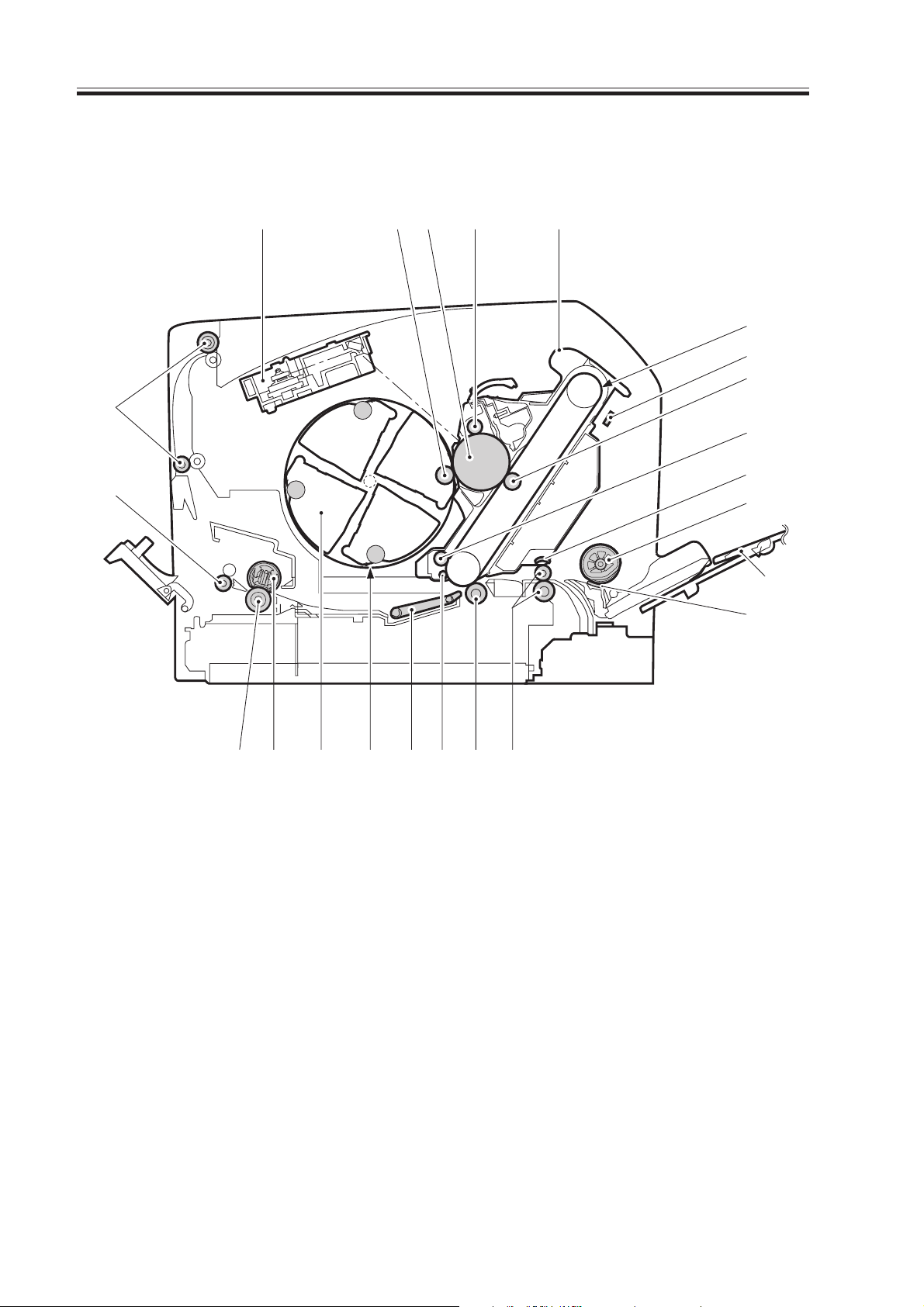

4.2 Cross Sectional View

4.2.1 Printer

[23]

[22]

[1]

[2] [3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[20]

[21]

[1] Laser/scanner unit

[2] Developing cylinder

[3] Photosensitive drum

[4] Primary charging roller

[5] EP-87 drum cartridge

[6] ITB

[7] Density sensor

[8] Primary transfer roller

[9] ITB cleaning roller

[10]Registration shutter

[11]Pick-up roller

[12]Multi-purpose tray

[19]

[18]

F01-402-01

[16][17]

[15]

[14]

[13]Separation pad

[14]Registration roller unit

[15]Secondary transfer roller

[16]Auxiliary ITB cleaning roller

[17]Feed belt

[18]Developing rotary

[19]EP-87 Toner cartridge

[20]Fixing film unit

[21]Pressure roller

[22]Fixing delivery roller

[23]Facedown delivery roller

1-8

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

4.2.2 Universal 250-sheet paper feeder

F01-402-02

[1] Pick-up roller

[2] Feed roller

[3] Separation pad

CHAPTER 1 PRODUCT INFORMATION

[1]

[2]

[3]

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-9

CHAPTER 1 PRODUCT INFORMATION

5 INSTALLATION

5.1 Outline

This printer is packaged and shipped from the factory after careful adjustments and strict

inspections.

To ensure that it performs as intended, it is very important to install the printer properly.

The service engineer should have a complete knowledge of the printer, choose an appropriate location, install the printer according to the proper procedure, and conduct sufficient

checks of the printer.

5.2 Selecting a location

Place the printer in a location where the following conditions are met. The service engineer should inspect the customer's premises before installing the printer.

5.2.1 Power supply

Use the power supplies that satisfies the following conditions:

• Line voltage (AC): Within ± 10 % of rated voltage

• Power frequency: 50/60 Hz ± 2 Hz

5.2.2 Operating environment

Place the printer in a location where the following conditions are met:

• Level, flat surface

• Temperature, humidity within the following ranges:

Surrounding temperature:10 - 30 °C

Surrounding humidity: 20 - 80 %RH

• Cool, well-ventilated space

Avoid placing the printer in the following locations:

• Places exposed to direct sunlight

If unavoidable, hang heavy curtains to shut out direct sunlight.

• Near magnets or devices that emit magnetic field

• Subject to vibration

• Dusty places

• Near fire or water

1-10

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

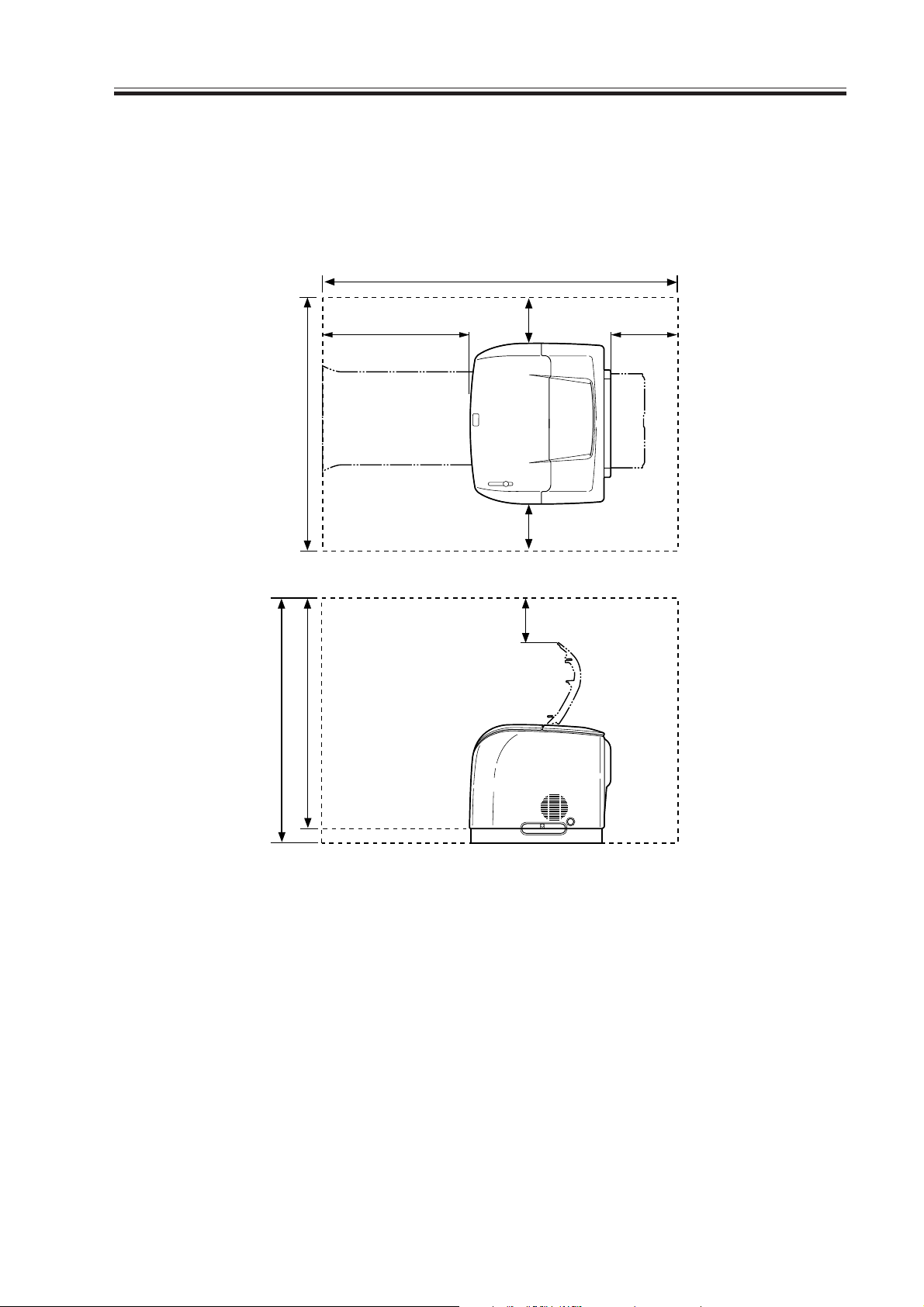

5.2.3 Space

Place the printer at a suitable distance from the walls, leaving enough room to operate it.

(See F01-502-01.) When placing the printer on a desk, be sure that it is large enough to accommodate the printer’s feet (rubber pads) and strong enough to stand printer's weight.

1175

758

682707

516

208

100100

100

COPYRIGHT

©

F01-502-01

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-11

CHAPTER 1 PRODUCT INFORMATION

5.3 Unpacking and Installation

Condensation will form on metal surfaces in the printer when brought from a cold area to

a warm area. This can cause various troubles including print defects. In such a case, leave

it in the carton at room temperature for at least an hour before unpacking so that it is acclimatized to room temperature.

When installing optional units, be sure that the printer is turned off.

5.3.1 Printer

1) Remove the printer from the packaging.

2) Take out the accessories. Confirm that the power cord, four EP-87 toner cartridges, and

EP-87 drum cartridge are included.

3) Remove the plastic bag from the printer and peel off the tape securing components.

Confirm that none of the covers were scratched or deformed during shipment.

4) Open the top cover, peel off the tape, and remove the packaging. Close the top cover.

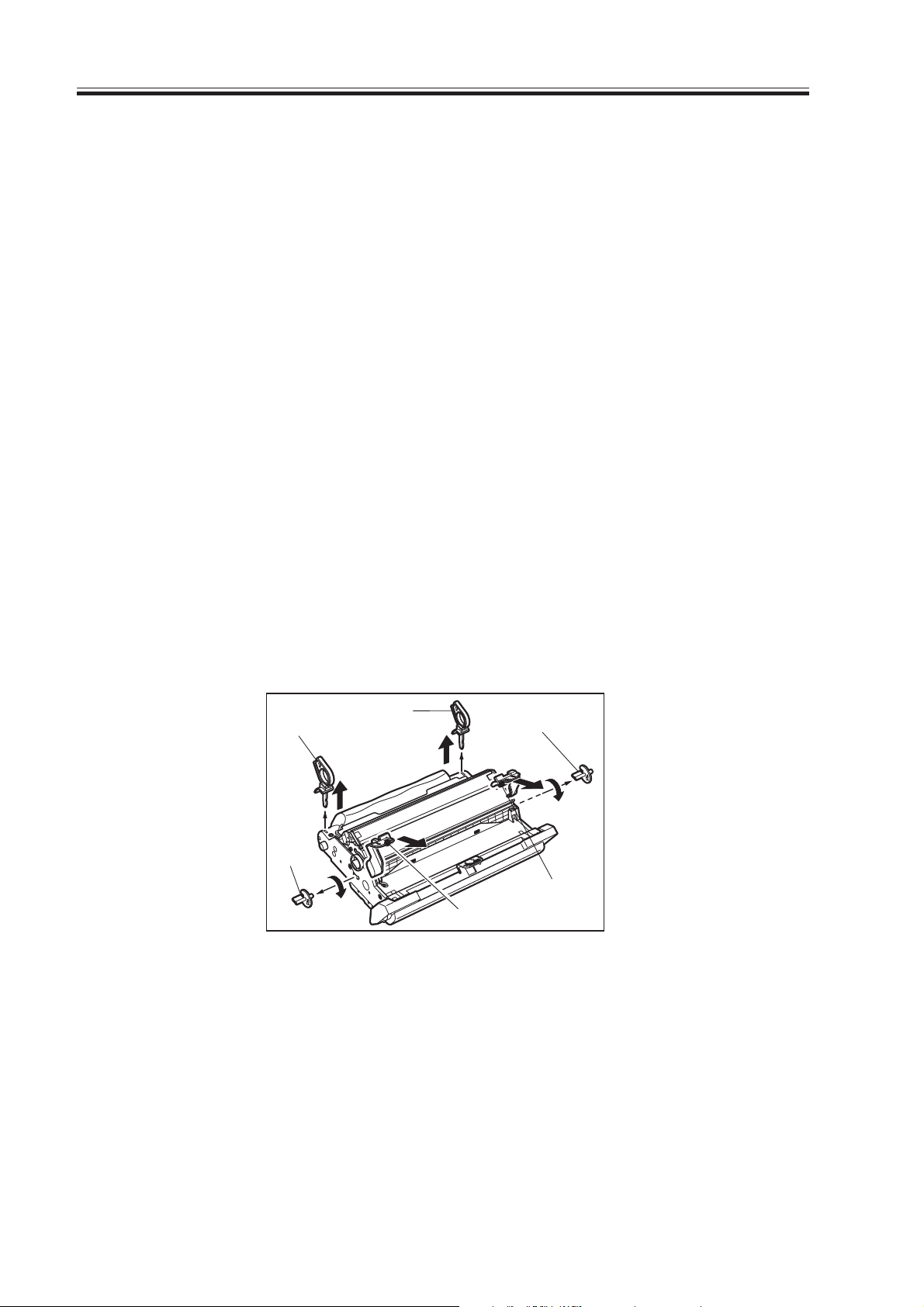

5.3.2 EP-87 Drum Cartridge

1) Lift up both ends of the top cover and open it.

2) Remove the EP-87 drum cartridge from the plastic bag.

3) Pull up the stoppers 1 and 2 (see the figure below).

4) Turn the stoppers 3 and 4 90 degrees in the direction of the arrow and then pull them out

to the sides (see the figure below).

5) Pull up the stoppers 5 and 6 (see the figure below).

[1] Stopper 1

[2] Stopper 2

[3] Stopper 3

[1]

[3]

[2]

[4]

[6]

[5]

F01-503-01

[4] Stopper 4

[5] Stopper 5

[6] Stopper 6

1-12

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

6) Remove the protective cover.

[1] Protective cover

CHAPTER 1 PRODUCT INFORMATION

[1]

F01-503-02

7) Hold the EP-87 drum cartridge with both hands as shown below and insert it into the

printer firmly.

F01-503-03

8) Close the top cover firmly.

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-13

CHAPTER 1 PRODUCT INFORMATION

5.3.3 EP-87 Toner cartridge

Toner replacement mode

This printer utilizes toner replacement mode to make EP-87 toner cartridge

replacement smooth.

This function detects toner cartridge presence when the power is turned on

or the top cover is closed. If not all of the cartridges are installed, the developing rotary automatically rotates that the compartment of a missing

toner cartridge comes to the installation slot. If two or more cartridges are

not installed, close the top cover after each installation so that the rotary

will rotate for the next missing cartridge. Detection and installation of the

toner cartridges are conducted in order of Y, M, C, and Bk.

A message will be indicated to prompt replacement when the toner cartridge reaches the end of its life. Hold down the Replace Toner key found in

the machine's upper left for 1 sec or more to move the cartridge to its position of replacement.

1) Insert the power cord and grounding cord to the printer and outlet. Be sure to use the

supplied power cord.

2) Turn on the printer.

3) Remove the toner cartridge out of its protective bag.

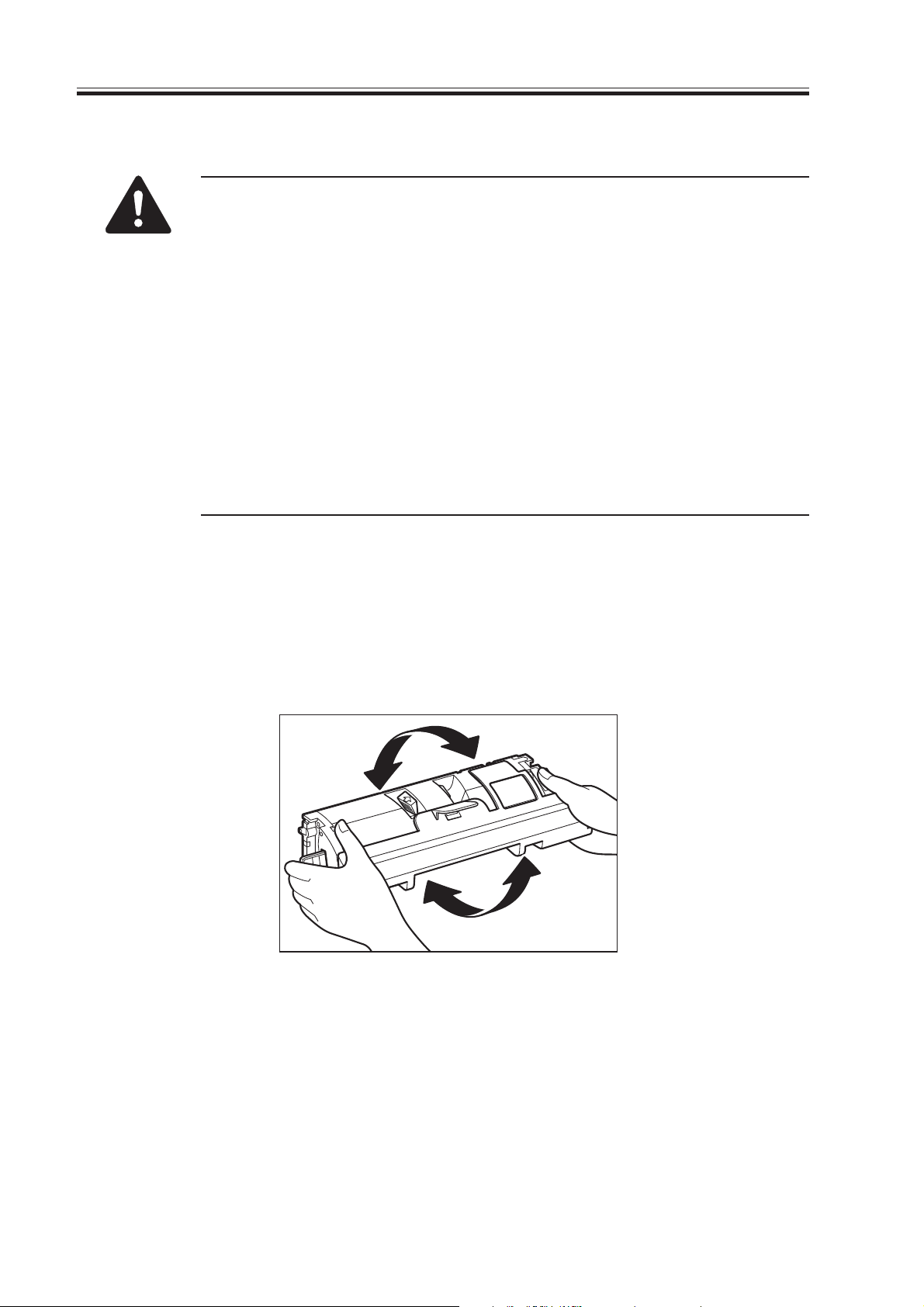

4) Hold the cartridge as shown below and slowly rock it up and down five or six times to

distribute toner evenly.

F01-503-04

1-14

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

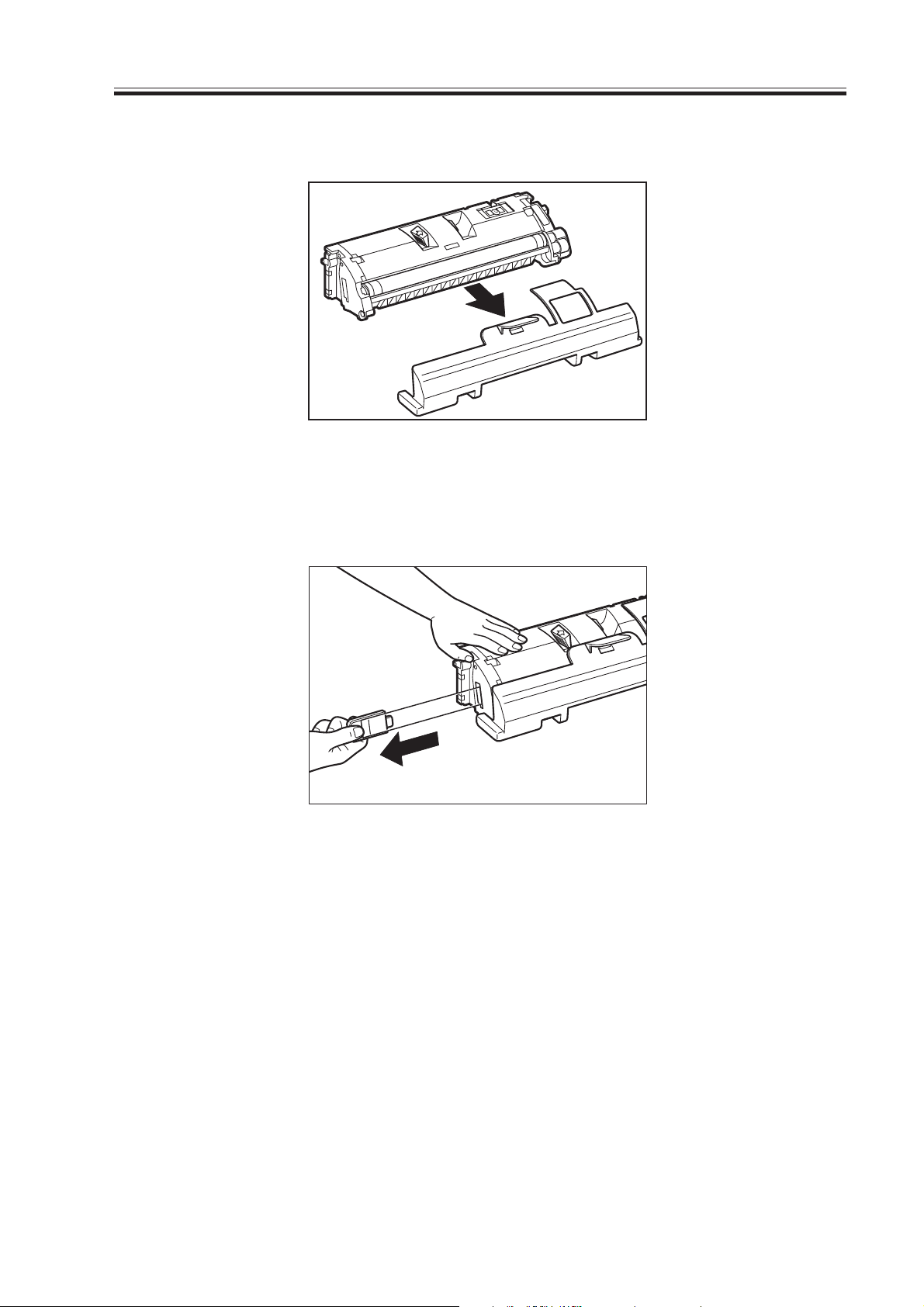

5) Remove the protective cover.

F01-503-05

6) Place the cartridge on a level surface and hold down the top of the cartridge with one

hand and pull out the tab gently with the other hand to remove the sealing tape.

F01-503-06

7) Open the top cover.

At this point, the toner cartridge Y compartment is at the installation slot as performed in

toner replacement mode (see note).

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-15

CHAPTER 1 PRODUCT INFORMATION

8) Check the seal and prepare the cartridge (Y) with the same color as the color seal.

Color seal

F01-503-07

9) Grasp the finger holding on the cartridge. Align the arrow mark on the toner cartridge

with the color mark on the printer and insert the cartridge into the printer.

F01-503-08

10) Close the top cover.

11) The printer will rotate the developing rotary so that the next compartment comes to the

replacement position for the next cartridge (M).

12) Repeat steps 3) to 12) in this procedure to install the remaining cartridges.

13) After inserting all the toner cartridges in the machine, close the upper cover and hold

down the Replace Toner key for 1 sec or more.

1-16

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

5.3.4 Paper feeder

1) Remove the paper feeder from the packaging.

2) Remove the plastic bag from the paper feeder and peel off the tapes securing the components. Confirm that none of the covers were scratched or deformed during shipment.

3) Take out the cassette from the paper feeder and remove the packaging and plastic materials (stoppers) holding the lifting plate.

4) Place the paper feeder on the level surface.

5) Lift up the printer. Align the positioning pins of the paper feeder and the positioning

holes of the printer. Install the printer on the top of the paper feeder.

When installing the paper feeder, be sure to turn off the printer and unplug

the power cord.

5.3.5 Confirming the performance

1) Open the multi-purpose tray.

2) Place paper on the tray.

3) Set the paper size guide at a specified position appropriate to the paper size.

4) Plug the “provided” power cord into the printer and outlet. Turn of the printer.

5) When the printer enters a standby status, press the test print switch (see F01-401-01.)

Check the output image for image defects.

6) Clean around the printer to allow the use of the printer at any time.

5.4 Notes for Storing and Handling the EP-87 Drum Cartridge

and EP-87 Toner Cartridge

The drum cartridge and toner cartridge scan be affected by the environment and change

over time whether they are still sealed in the box or installed in the printer, regardless of the

number of prints. Since the pace at which it changes depends on installation and storage environments, be very careful in storing and handling them.

5.4.1 Storing the sealed cartridges

When storing in a warehouse or workshop (service depot), store in a specified installation

environment. Note the following also:

1) Avoid areas exposed to sunlight.

2) Avoid areas that are subject to vibration.

3) Do not bump or drop it.

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-17

CHAPTER 1 PRODUCT INFORMATION

5.4.2 Storing the unsealed cartridges

A drum cartridge contains a photosensitive drum coated with an organic photoconductor

(OPC) that deteriorates when exposed to strong light. A toner cartridge contains toner. Advise the customer correct storing and handling of the cartridges.

a. Storage precautions

1) Store the cartridge always in its protection bag.

2) Avoid areas exposed to sunlight or near windows. Do not leave a cartridge in a car for a

long time, as the inside of the car can get extremely hot.

3) Avoid areas that get extremely hot and humid or extremely cold and dry. Also, avoid

areas where the temperature can change suddenly.

4) Avoid a salty air environment or areas exposed to corrosive gases, such as aerosols.

5) Store the cartridge in the temperature range 0 to 35 °C.

6) Keep cartridges away from computer CRT displays, disk drives, and floppy disks.

7) Keep the cartridge out of reach of children.

b. Handling precautions

1) Before installing a new toner cartridge in the printer, distribute the toner evenly as

shown in F01-503-04. Rocking it any other way may result in toner leaking from the

developing cylinder.

After installing a new cartridge, print three to five test patterns to check for toner leakage

to avoid image defects.

2) Before transporting the printer, remove all the cartridges.

Place the removed cartridges in their protection bag to avoid exposing them to light.

3) Do not expose all the cartridges to sunlight or strong light, since they are sensitive to

light. Otherwise, it may result in image defects.

4) Do not touch or scratch the surface of the photosensitive drum.

5) Do not stand all the cartridges on end or turn them upside down. Labeled side of the

cartridges should be facing up always.

6) Do not attempt to disassemble any cartridges.

7) Do not touch the waste toner detection window on the drum cartridge.

1-18

Waste toner

detection window

F01-504-01

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

CHAPTER 1 PRODUCT INFORMATION

8) Do not touch or open the protective shutter on the drum cartridge.

Protective shutter

Photosensitive drum

F01-504-02

9) Do not touch or scratch the surface of the ITB of the drum cartridge.

Imaging transfer belt

F01-504-03

10) Do not touch or scratch the surface of the electrical contact of the drum cartridge.

Electr ical

contacts

F01-504-04

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

1-19

CHAPTER 1 PRODUCT INFORMATION

The photosensitive drum is protected by the protective shutter as blank

spots or black lines may appear on the prints if the drum is exposed to

strong light. Therefore, avoid opening the shutter. (The protective shutter

opens automatically when the EP-87 drum cartridge is installed in the

printer.)

11) Do not touch the light guide and electrical contact of the toner cartridge.

Electrical contact

light guide

F01-504-05

1-20

COPYRIGHT

©

2003 CANON INC. 2000 2000 2000 2000 CANON LBP-2410 REV.0 FEB. 2003

Loading...

Loading...