Canon iX7000 Series Service Manual

iX7000

Service Manual

Revision 0

QY8-13CJ-000

COPYRIGHTc2009 CANON INC. CANON iX7000 083109 XX 0.00-0

Scope

This manual has been issued by Canon Inc., to provide the service technicians of this product with the information necessary

for qualified persons to learn technical theory, installation, maintenance, and repair of products. The manual covers

information applicable in all regions where the product is sold. For this reason, it may contain information that is not

applicable to your region.

This manual does not provide sufficient information for disassembly and reassembly procedures.

Refer to the graphics in the separate Parts Catalog.

Revision

This manual could include technical inaccuracies or typographical errors due to improvements or changes made to the

product. When changes are made to the contents of the manual, Canon will release technical information when necessary.

When substantial changes are made to the contents of the manual, Canon will issue a revised edition.

The following do not apply if they do not conform to the laws and regulations of the region where the manual or product is

used:

Trademarks

Product and brand names appearing in this manual are registered trademarks or trademarks of the respective holders.

Copyright

All rights reserved. No parts of this manual may be reproduced in any form or by any means or translated into another

language without the written permission of Canon Inc., except in the case of internal business use.

Copyright © 2009 by Canon Inc.

CANON INC.

Inkjet Device Market Support Management Div.

451, Tsukagoshi 3-chome, Saiwai-ku, Kawasaki-shi, Kanagawa 212-8530, Japan

TABLE OF CONTENTS

1. MAINTENANCE

1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables

by Service Engineer

1-2. Customer Maintenance

1-3. Special Tools

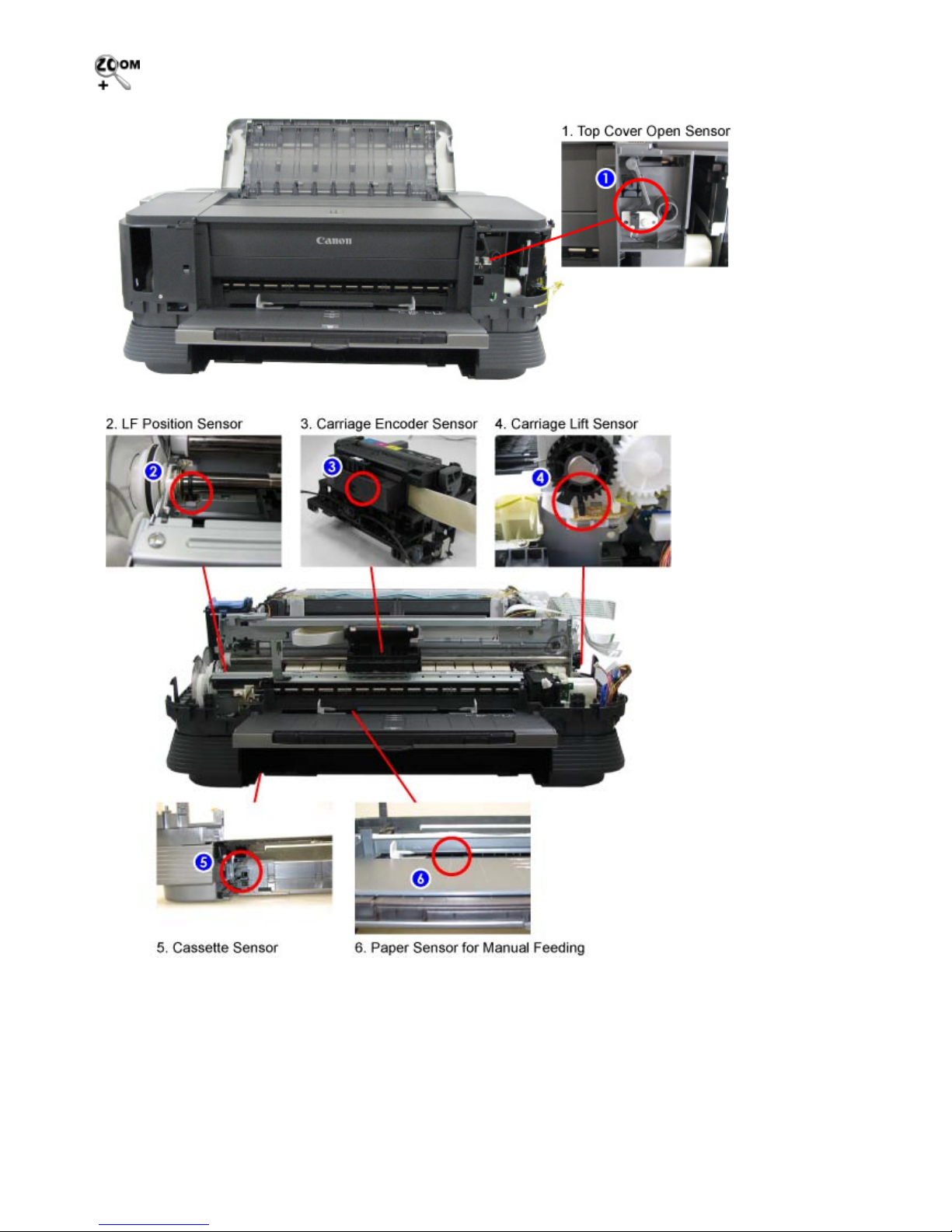

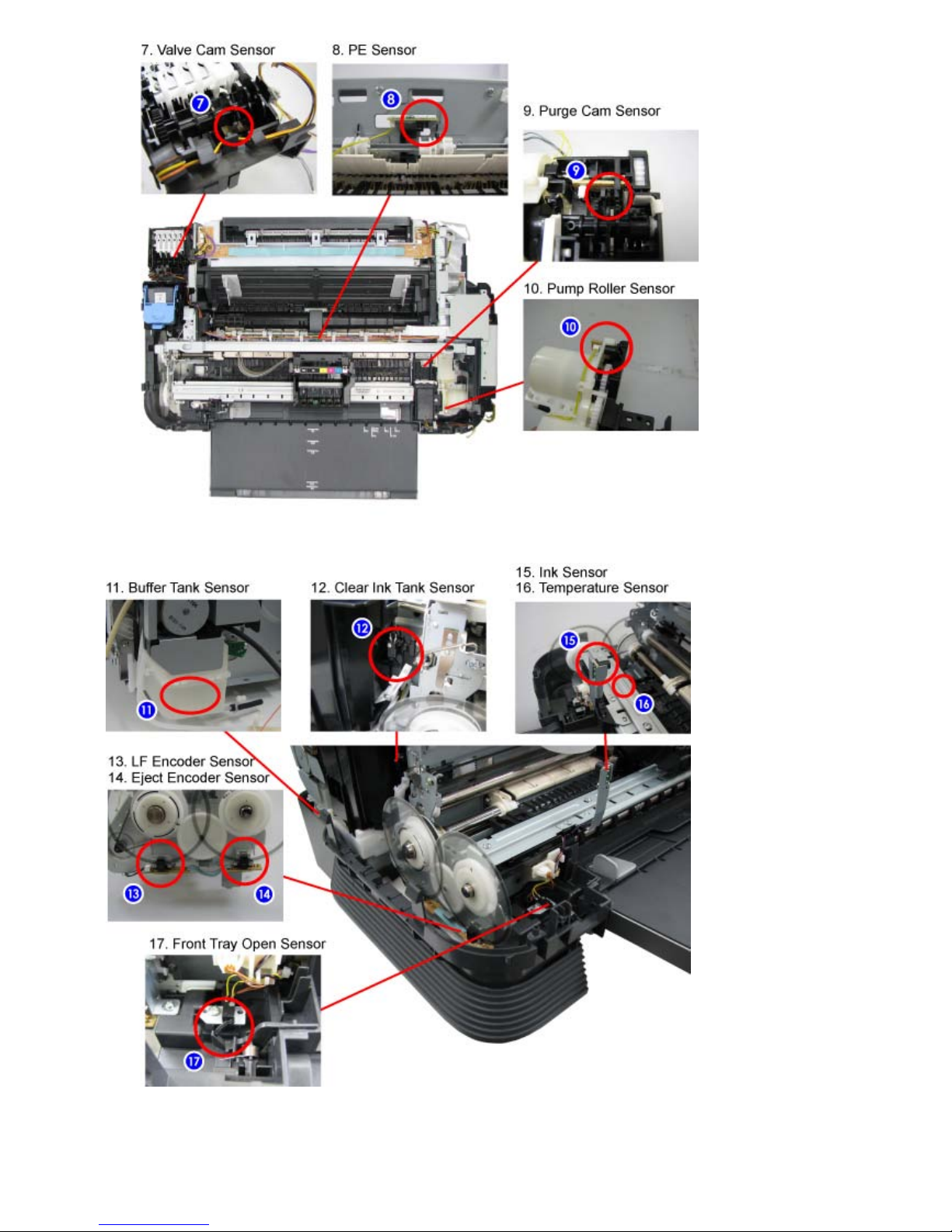

1-4. Sensors

1-5. Serial Number Location

2. LIST OF ERROR DISPLAY / TROUBLESHOOTING

2-1. Operator Call Errors

2-2. Service Call Errors

2-3. Troubleshooting by Symptom

3. REPAIR

3-1. Major Replacement Parts

3-2. Part Replacement Procedures

(1) External housing removal

(2) Carriage unlocking

(3) Printer unit removal

(4) Carriage unit removal

(5) ASF unit removal

(6) Purge unit removal

(7) Spur base unit and platen unit removal

4. ADJUSTMENT / SETTINGS

4-1. User Mode

4-2. Service Mode

(1) Service mode operation procedures

(2) Service Tool functions

(3) LF / Eject correction

(4) Ink absorber counter setting

(5) Wetting liquid counter setting

4-3. Grease Application

iX7000

4-4. Special Notes on Servicing

(1) Service test print

(2) For smeared printing, uneven printing, or non-ejection of ink

(3) Paper feed motor adjustment

(4) Ink absorber counter setting

4-5. Verification After Repair

(1) Standard inspection flow

(2) Service test print

(3) Ink absorber counter value print

5. PRINTER TRANSPORTATION

<TABLE OF CONTENTS>

1. MAINTENANCE

1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and

Replacement Consumables by Service Engineer

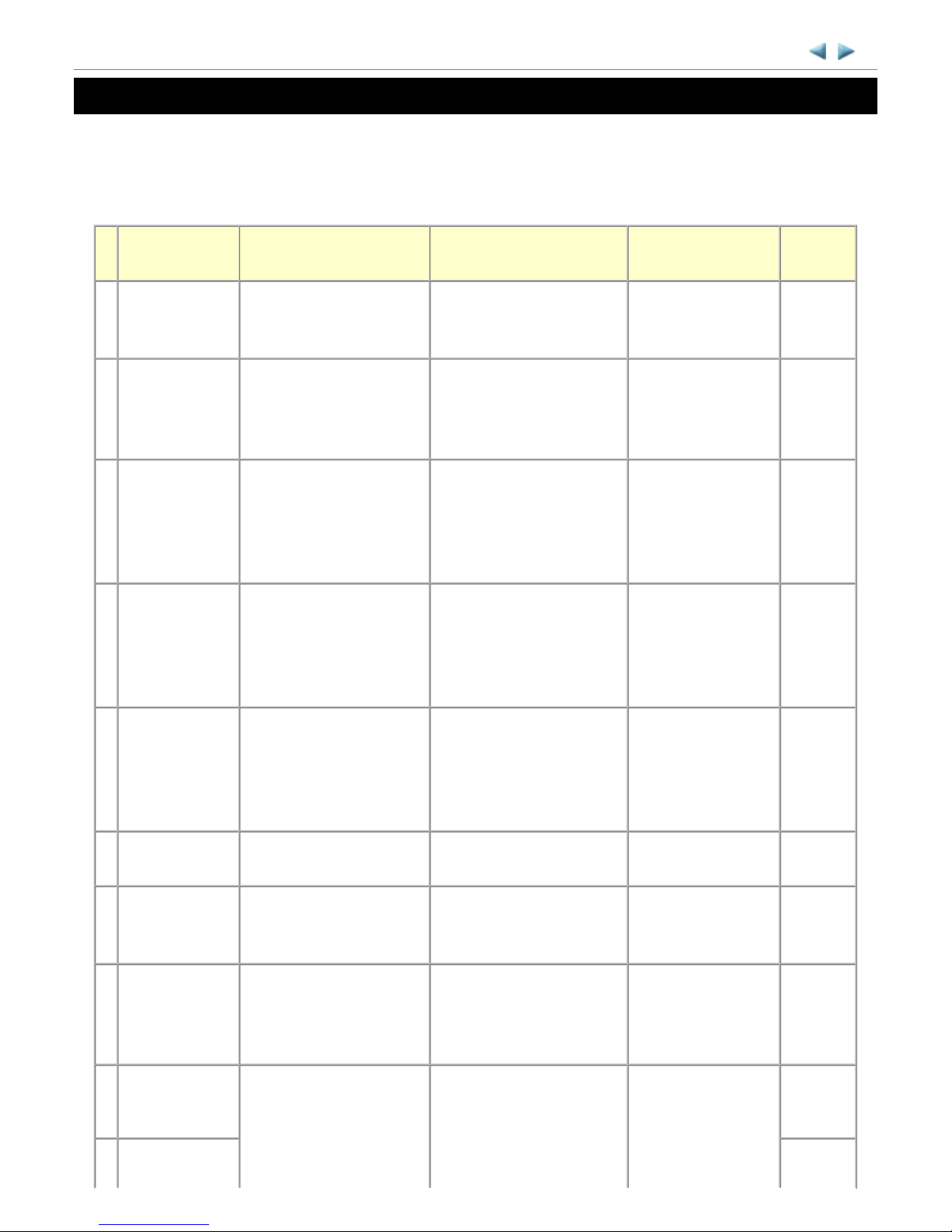

(1) Adjustment

iX7000 TABLE OF CONTENTS

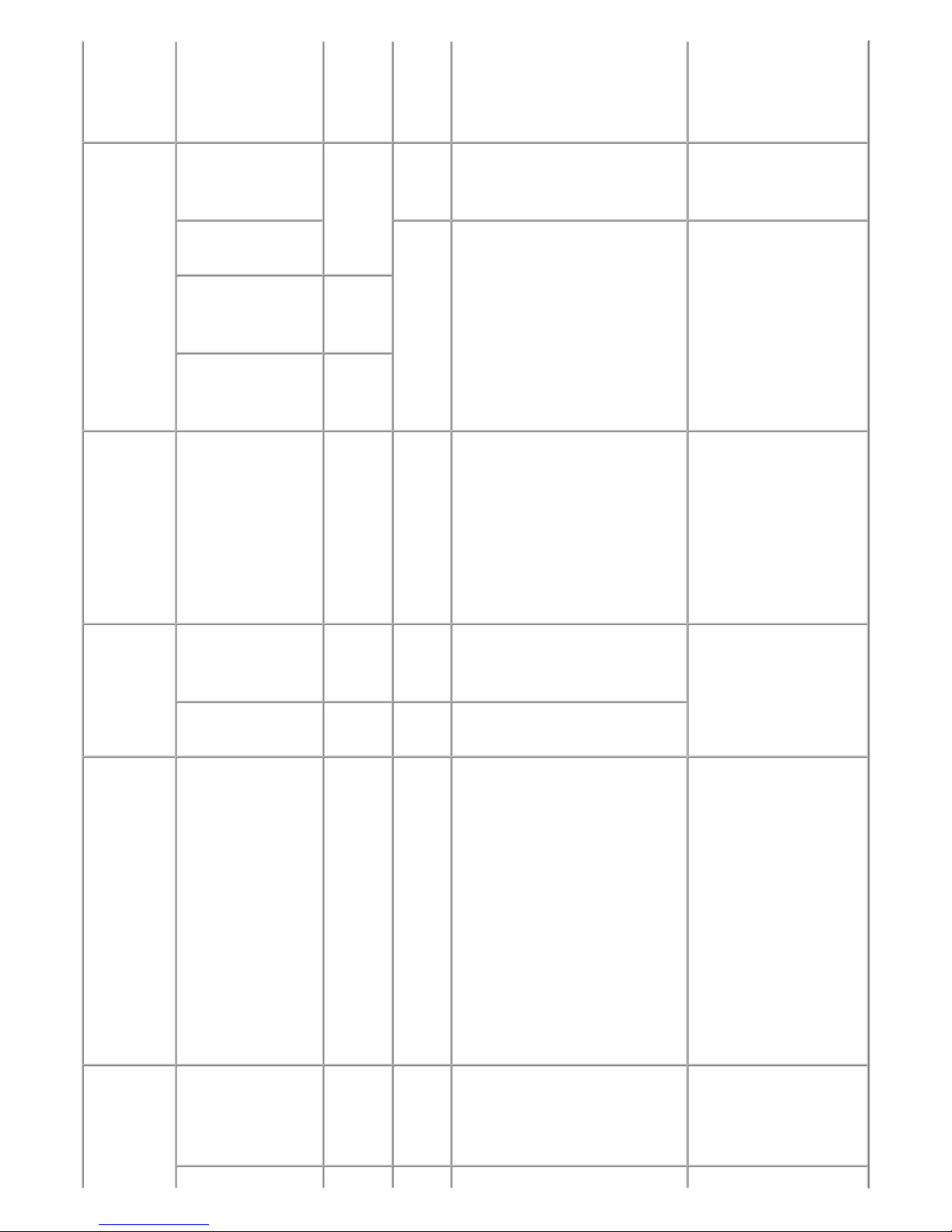

Adjustment Timing Purpose Tool

Approx.

time

EEPROM

initialization

- At logic board

replacement

To initialize settings

Service Tool

*1

Perform in the

service mode.

1 min.

Destination

settings

(EEPROM

settings)

- At logic board

replacement

To set destination.

Service Tool

*1

Perform in the

service mode.

1 min.

Ink absorber

counter

resetting

(EEPROM

settings)

- At logic board

replacement

- At ink absorber

replacement

To reset the ink absorber

counter.

Service Tool

*1

Perform in the

service mode.

1 min.

Ink absorber

counter value

setting

(EEPROM

settings)

- At logic board

replacement

To set the ink amount data

in the ink absorber to the

ink absorber counter.

Service Tool

*1

Perform in the

service mode.

1 min.

Wetting liquid

counter value

setting

(EEPROM

settings)

- At logic board

replacement

- At blade cleaner unit

replacement

To set the wetting liquid

counter value.

Service Tool

*1

Perform in the

service mode.

1 min.

Ink absorber

replacement

- When the ink absorber

becomes full

To replace the ink

absorber with a new one.

Screwdriver, a pair

of tweezers, etc.

15 min.

Blade cleaner

unit

replacement

- When the wetting liquid

is used up

To replace the blade

cleaner unit with a new

one.

Screwdriver, etc. 10 min.

Paper feed

motor position

adjustment

- At paper feed motor

replacement

To adjust the belt tension.

(Position the paper feed

motor so that the belt is

stretched tight.)

None. 5 min.

Automatic print

head alignment

- At print head

replacement

- At logic board

replacement

To secure the dot

placement accuracy.

None. (Plain paper)

Perform in the user

mode.

6 min.

Manual print 10 min.

1 / 53

*1: Install the Service Tool to a pre-registered computer.

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this printer that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

head alignment - When print quality is

not satisfying

Grease

application

- At carriage unit

replacement

- At other part

replacement

To maintain sliding

properties of the carriage

shaft, other sliding parts,

and gears.

FLOIL KG-107A 1 min.

Ink system

function check

- At logic board

replacement

- At spur unit

replacement

- At carriage unit

replacement

To maintain detection

functionality for presence

of the ink tanks and each

ink tank position.

Service Tool

*1

Perform in the

service mode.

1 min.

LF / Eject

correction

- At logic board

replacement

- At paper feed roller

replacement

- At platen unit

replacement

To correct the paper

feeding amount according

to each LF and eject roller.

Service Tool

*1

Perform in the

service mode.

5 min.

The screws securing the paper feed motor may be loosened only at replacement of the

paper feed motor unit. DO NOT loosen them in other cases.

2 / 53

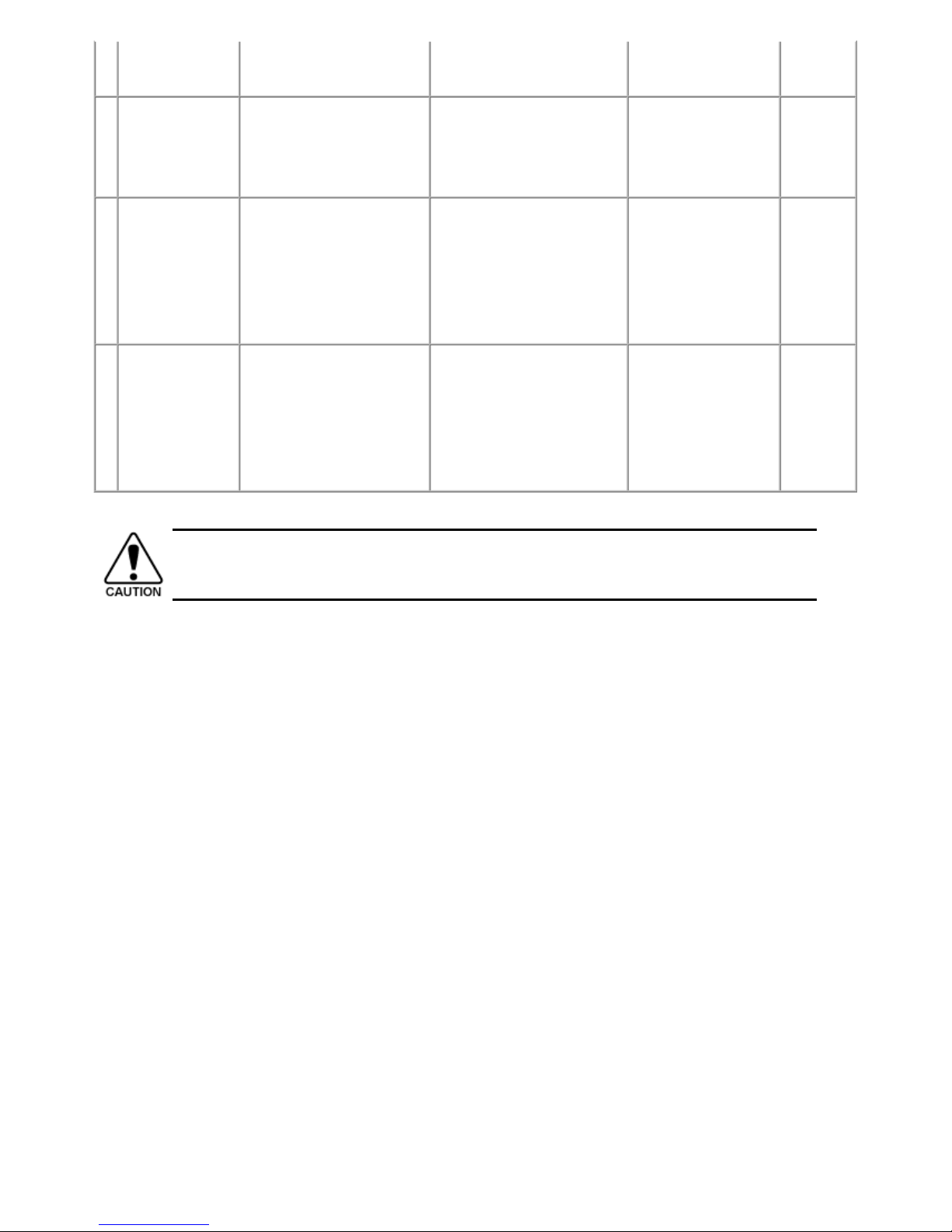

1-2. Customer Maintenance

Adjustment Timing Purpose Tool

Approx.

time

Automatic print

head alignment

- At print head replacement

- When print quality is not satisfying

(uneven printing, etc.)

To ensure accurate

dot placement.

- Printer

buttons

- Computer

(printer

driver)

6 min.

Manual print head

alignment

- Computer

(printer

driver)

10 min.

Print head

cleaning

When print quality is not satisfying. To improve nozzle

conditions.

- Printer

buttons

- Computer

(printer

driver)

1 min.

Print head deep

cleaning

When print quality is not satisfying, and

not improved by print head cleaning.

To improve nozzle

conditions.

- Computer

(printer

driver)

2 min.

Ink tank

replacement

When an ink tank becomes empty. ("No

ink error" displayed on the PC monitor,

or short flashing of an ink tank LED)

To replace the empty

ink tank.

--- 1 min.

Pick-up roller

cleaning

(Roller Cleaning)

- When paper does not feed properly.

- When the front side of the paper is

smeared.

To clean the pick-up

rollers of the rear

tray and the cassette.

- Computer

(printer

driver)

2 min.

Bottom plate

cleaning

When the back side of the paper is

smeared.

To clean the platen

ribs. (Feed the paper

from the rear tray.)

- Printer

buttons

- Computer

(printer

driver)

1 min.

Exterior cleaning When necessary. To clean the printer

exterior, or to wipe

off dusts.

Soft, dry, and

clean lint-free

cloth.

1 min.

Ink agitation When uneven printing occurs, or when

the automatic ink agitation ("Execute ink

quality maintenance automatically" in

the printer driver) is disabled for one or

more weeks.

To prevent

sedimentation of the

pigment.

- Computer

(printer

driver)

2 min.

Paper feed roller

cleaning

(Sheet Cleaning)

When "You need to execute sheet

cleaning because the predetermined print

count has been reached." is displayed on

the computer (at every 5,000 pages of

feeding from the cassette).

Use the Cleaning Sheet.

To clean the paper

feed rollers.

- Cleaning

sheet

- Computer

(printer

driver)

2 min.

3 / 53

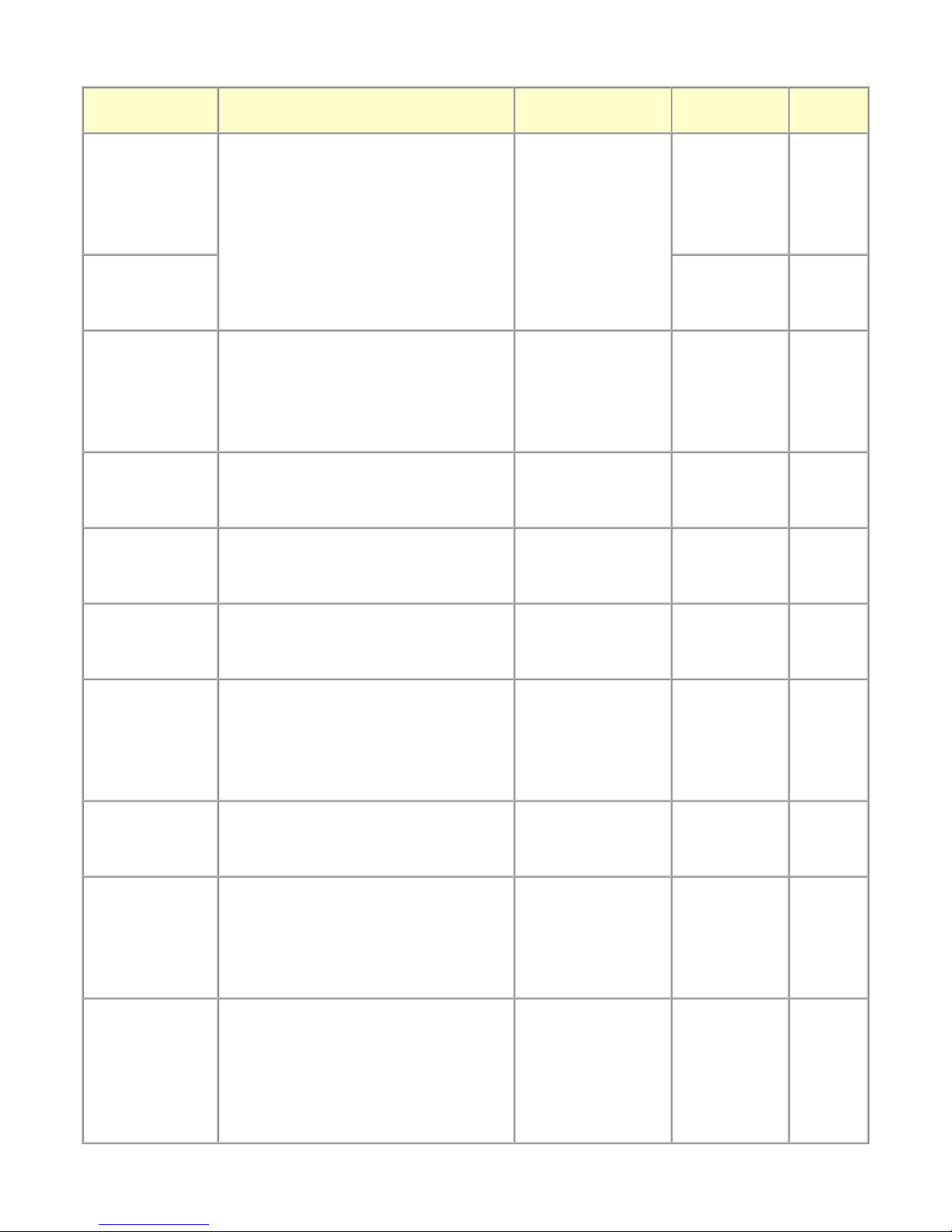

1-3. Special Tools

1-4. Sensors

Name Tool No. Application Remarks

FLOIL KG-107A QY9-0057-000 To the printer's sliding portions.

In common with other models

on the market.

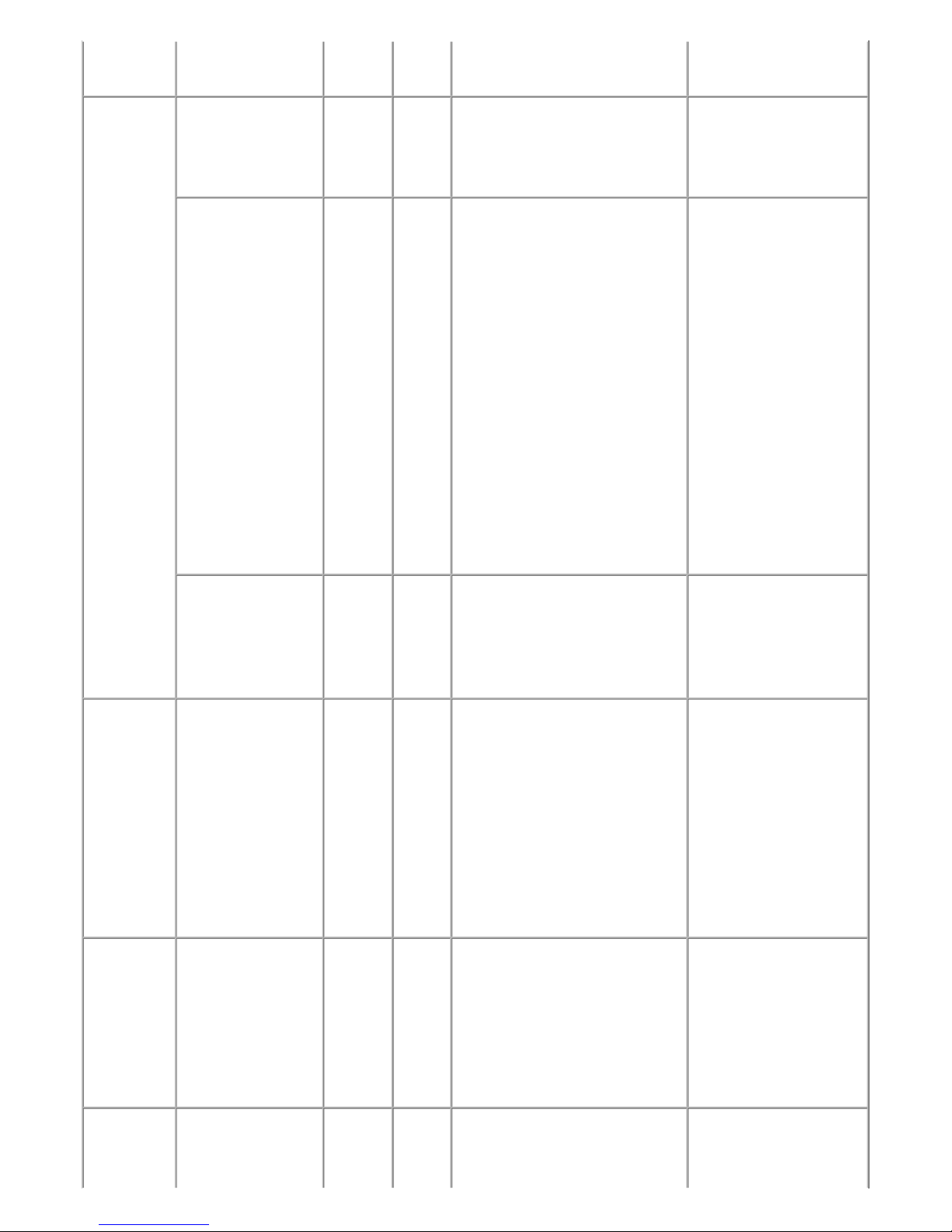

No. Sensor Function Possible problems

1 Top cover open

sensor

Detects opening and closing of the

top cover.

- The carriage does not move to the center.

2 LF position sensor Detects the standard rotation

position of the feed roller.

- LF position error

3 Carriage encoder

sensor

Detects the position of the timing

slit film, and controls printing.

- Printing shifts from the correct position.

- Carriage position error

4 Carriage lift

sensor

Detects the position of the carriage

lift cam.

- Carriage lift mechanism error

5 Cassette sensor Detects the cassette. - No cassette

6 Paper sensor for

manual feeding

Detects paper in the front tray and

manual feed slot

- No paper in the front tray

- Paper in the manual feed slot

- Paper not properly set in the manual feed

slot

7 Valve cam sensor Controls valve unit operation. - Reactor error

8 PE sensor Detects paper feeding and ejection. - No paper

- Paper jam

9 Purge cam sensor Controls purging operation. - PG cam sensor error

10 Pump roller

sensor

Detects the position of the pump

roller

- Pump roller sensor error

11 Buffer tank sensor Detects Clear ink in the buffer

tank

- No Clear ink

- Reactor error

12 Clear ink tank

sensor

Detects the Clear ink tank. - No Clear ink tank

13 LF encoder sensor Detects rotation of the LF encoder,

and controls its drive.

- Uneven printing

- LF position error

14 Eject encoder

sensor

Detects rotation of the eject

encoder, and controls its drive.

- Uneven printing at the trailing edge of paper

- Eject encoder error

15 Ink sensor Detects the position of an ink tank. - No recognition of an ink tank

- Wrong position of an ink tank

16 Temperature

sensor

Detects the temperature of the

inside of the printer.

- Internal temperature error

17 Front tray open

sensor

Detects opening and closing of the

front tray.

- Front tray closed

4 / 53

18 ASF cam sensor Detects the position of the ASF

cam (for paper feeding from the

rear tray).

- ASF cam sensor error

- Paper feeding problem

19 RR encoder

sensor

Detects rotation of the Clear ink

application roller encoder, and

controls its drive.

- RR position error

20 AP encoder

sensor

Controls paper feeding and

purging operation.

- AP position error

21 PF cam sensor Detects the position of the cassette

(and front tray) paper feeding cam

(for paper feeding from the

cassette).

- No paper feeding from the cassette (from the

front tray)

- PF cam sensor error

22 Rear cover PE

sensor

Detects paper feeding and ejection

at the rear cover.

- No paper

- Paper jam in the rear cover

23 Reactor roller

paper jam sensor

Detects if paper winds around the

reactor roller.

- Paper jam

24 PF encoder sensor Detects rotation of the encoder

during paper feeding from the

cassette, and controls its drive.

- PF position error

25 Liquid sensor Detects supply of the Clear ink to

the Clear ink application roller.

- Reactor error

26 PFPE sensor Detects paper feeding and ejection

from the cassette (or front tray).

- No paper in the cassette

- Paper jam in the cassette

- Paper not properly set in the manual feed

slot

5 / 53

Click on the image to enlarge it.

6 / 53

7 / 53

1-5. Serial Number Location

On the spur holder (visible when the top cover is opened).

When the printer power is OFF. When the printer power is ON.

<1. MAINTENANCE>

8 / 53

2. LIST OF ERROR DISPLAY / TROUBLESHOOTING

Errors and warnings are displayed by the following ways:

1. Operator call errors are indicated by the Alarm LED lit in orange, and the error messages are

displayed by the printer driver Status Monitor.

2. Error codes (the latest 10 error codes at the maximum) are printed in the "operator call/service call

error record" area in EEPROM information print

Buttons valid when an operator call error occurs:

1. Power button: To turn the printer off and on again.

2. Resume/Cancel button: To cancel the job at error occurrence, and to clear the error.

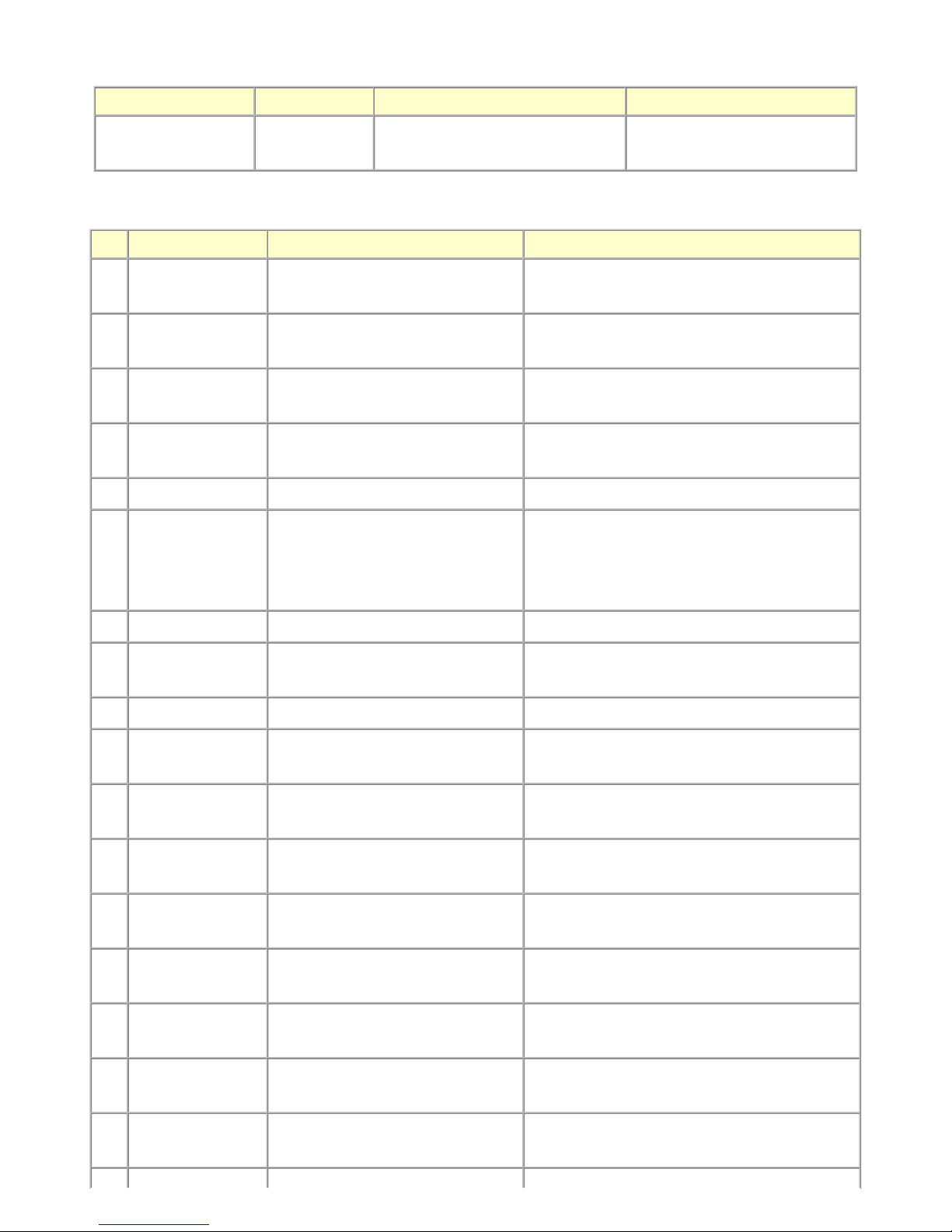

2-1. Operator Call Errors (by Alarm LED Lit in Orange)

iX7000 TABLE OF CONTENTS

Alarm

LED

blinking

in orange

Error

Error

code

U No.

Solution

Parts that are likely

to be faulty

2 times No paper in the

rear tray.

[1000] --- Confirm that the rear tray is

selected as the paper source.

(The rear tray is only for photo

papers and post cards.) Set the

paper in the rear tray, and press

the Resume/Cancel button.

- ASF unit

- Pressure roller unit

- PE sensor

- Paper feed motor

No paper in the

cassette.

[1003] --- Confirm that the cassette is

selected as the paper source.

(The cassette is only for plain

paper.) Set the paper in the

cassette, and press the

Resume/Cancel button.

- ASF unit

- Cassette

No paper in the

manual feed slot..

[1005] --- Confirm that the manual feed is

selected as the paper source.

(Manual feeding is available

only with plain paper.) Set the

paper in the manual feed slot,

and press the Resume/Cancel

button.

- Bottom case unit

3 times Front tray closed. [1250] --- Open the front tray. (The error

is indicated when the front tray

is not opened at start of

printing, or when the front tray

is closed during printing.)

- Bottom case unit

Paper jam in the

rear tray.

[1300] --- Remove the jammed paper or

foreign material causing a paper

- ASF unit

- Pressure roller unit

9 / 53

jam (paper remainings, clips,

pens, etc.), and press the

Resume/Cancel button.

- PE sensor

- Feed roller

- Platen unit

Paper jam in the

cassette.

[1303] --- Remove the jammed paper or

foreign material causing a paper

jam (paper remainings, clips,

pens, etc.), and press the

Resume/Cancel button.

- ASF unit

- Pressure roller unit

- PE sensor

- Feed roller

- Platen unit

- Cassette

Paper jam during

automatic duplex

printing.

[1304] --- Remove the jammed paper or

foreign material causing a paper

jam (paper remainings, clips,

pens, etc.), and press the

Resume/Cancel button.

- ASF unit

- Bottom case unit

- PE sensor

- Feed roller

- Platen unit

Paper in the

manual feed slot.

[1306] --- Remove the paper from the

manual feed slot, and press the

Resume/Cancel button. (The

error is indicated when paper is

left in the manual feed slot at

start of paper feeding from the

cassette.)

- Rear tray unit

- Rear tray holder R

unit

Paper jam in the

rear cover.

[1307] --- Open the rear cover, remove the

jammed paper or foreign

material causing a paper jam

(paper remainings, clips, pens,

etc.), then press the

Resume/Cancel button. (The

error is indicated at paper jam

in the rear cover during paper

feeding from the cassette or

during manual paper feeding

from the front tray.)

- ASF unit

4 times Ink may have run

out.

[1600] U044 Replace the applicable ink tank,

or press the Resume/Cancel

button to clear the error without

ink tank replacement. When the

error is cleared by pressing the

Resume/Cancel button, ink may

run out during printing.

- Ink tank

- Logic board

Ink tank not

installed.

[1660] U043 Install the applicable ink tank(s)

properly, and confirm that the

LED's of all the ink tanks light

red.

- Ink tank

- Carriage unit

- Logic board

Clear ink is low. [1692] U045 Replace the Clear ink tank, or

press the Resume/Cancel button

to clear the error without ink

- Clear ink tank

- Valve unit

- ASF unit

10 / 53

tank replacement. When the

error is cleared by pressing the

Resume/Cancel button, Clear

ink may run out during printing.

5 times Print head not

installed, or not

properly installed.

[1401] U051 Install the print head properly. - Print head

- Carriage unit

- Logic board

Faulty print head

ID.

U052 Re-set the print head. If the

error is not cleared, the print

head may be defective. Replace

the print head.

- Print head

- Logic board

Print head

temperature sensor

error.

[1403]

Faulty EEPROM

data of the print

head.

[1405]

6 times Paper not set

properly in the

manual feed slot.

[1330] --- Set the paper in the manual feed

slot properly, and press the

Resume/Cancel button. (The

error is indicated when paper

does not feed from the front

tray though paper is supposed

to be set in the manual feed

slot.)

- ASF unit

- Bottom case unit

- Cassette

7 times Multiple ink tanks

of the same color

installed.

[1487] U071 Replace the wrong ink tank(s)

with the correct one(s).

- Ink tank

- Logic board

Ink tank in a wrong

position.

[1680] U072 Install the ink tank(s) in the

correct position.

8 times Warning: The ink

absorber becomes

almost full.

[1700] --- Replace the ink absorber, and

reset its counter. [See 4-4.

Special Notes on Servicing, (4)

Ink absorber counter setting.]

Pressing the Resume/Cancel

button will exit the error, and

enable printing without

replacing the ink absorber.

However, when the ink

absorber becomes full, no

further printing can be

performed unless the applicable

ink absorber is replaced.

- Absorber kit

10 times Paper size not

supported for

automatic duplex

printing.

[1310] --- Set a supported size of paper,

and press the Resume/Cancel

button.

- ASF unit

11 / 53

No cassette. [1282] --- Set the cassette, and press the

Resume/Cancel button.

- Bottom case unit

11 times Failed in automatic

print head

alignment

[2500] --- Press the Resume/Cancel button

to clear the error, then perform

the automatic print head

alignment again.

- Print head

- Ink tank

- Carriage unit

- Logic board

Paper size smaller

than specified

[1062] --- Press the Resume/Cancel

button. (The paper will be

ejected, and the print job will be

cancelled automatically.)

The error is indicated when the

size of paper actually set is

smaller than the one selected in

the printer driver, to prevent

printing on the platen.

(e.g. When A4 paper is set in

the printer though A3 is

selected in the printer driver,

the error occurs. If A3 paper is

set in the printer and A4 is

selected in the printer driver,

then the error does not occur.)

- Carriage unit

- Logic board

Smearing on the

paper feed rollers

[1870]

*1

--- Perform Sheet cleaning, using

the Cleaning Sheet. (The error

is indicated at every 5,000

pages of paper feeding from the

cassette.)

12 times Ink tank replaced

during printing

[1350]

*1

--- If ink runs out and the empty

ink tank is replaced during

printing, ink agitation is

performed after the ink tank

replacement, then printing stops

with the message displayed on

the screen. To resume printing,

press the Resume/Cancel

button. Printing resumes after

cleaning is performed.

14 times Ink tank not

recognized.

[1684] U140 A non-supported ink tank (an

ink tank that is sold in a

different region from where the

printer was purchased) is

installed (the ink tank LED is

turned off). Install the

supported ink tanks.

- Ink tank

- Logic board

- Carriage unit

15 times Ink tank not

recognized.

[1682] U150 A hardware error occurred in an

ink tank (the ink tank LED is

turned off). Replace the ink

- Ink tank

- Logic board

- Carriage unit

12 / 53

tank(s).

16 times No Clear ink

(during printing).

[1693] U165 Replace the Clear ink tank, or

press the Resume/Cancel button

to clear the error without ink

tank replacement. When the

error is cleared by pressing the

Resume/Cancel button, the print

job is cancelled.

Printing on plain paper cannot

be performed until the Clear ink

tank is replaced with a new one.

If the error persists even after

replacement of the Clear ink

tank, press and hold the

Resume/Cancel button in the

user mode until the Alarm lamp

blinks 9 times, release the

button, then remove and reinstall the Clear ink tank.

- Clear ink tank

- ASF unit

- Valve unit

- Logic board

No Clear ink

(printing is not

performed).

[1694] U166 Replace the Clear ink tank, and

press the Resume/Cancel

button.

Unless the Clear ink tank is

replaced with a new one, the

error will not be cleared only by

pressing the Resume/Cancel

button.

If the error persists even after

replacement of the Clear ink

tank, press and hold the

Resume/Cancel button in the

user mode until the Alarm lamp

blinks 9 times, release the

button, then remove and reinstall the Clear ink tank.

- Clear ink tank

- ASF unit

- Valve unit

- Logic board

Clear ink tank not

installed.

[1696,

1697]

--- Install the Clear ink tank. - Clear ink tank holder

- Logic board

17 times No ink (no raw

ink).

[1688,

1698]

U172 Replace the empty ink tank(s).

This error is indicated when the

applicable ink tank has never

been removed until ink is used

up. (Printing cannot be

continued even when the

Resume/Cancel button is

pressed for 5 sec. or longer.)

If the ink tank is removed and

re-set again (without being

- Ink tank

- Logic board

- Carriage unit

13 / 53

*1: In the EEPROM information print in the service mode, the error is indicated as "FFFF" (the two

types of errors are not distinguished since neither of them are a trouble).

replaced with a new one), the

error of 18 blinks is indicated.

18 times Remaining ink

amount unknown.

[1683,

1699]

U182 Replace the ink tank with a new

one.

This error is indicated when the

applicable ink tank has been

removed before the error

occurrence.

Printing with an empty ink tank

can damage the printer.

To continue printing without

replacing the ink tank(s), press

the Resume/Cancel button for 5

sec. or longer to disable the

function to detect the remaining

ink amount. After the operation,

it is recorded in the printer that

the function to detect the

remaining ink amount was

disabled.

- Ink tank

- Logic board

- Carriage unit

14 / 53

Loading...

Loading...