New Product Information

iR2200/2800/3300

Date : January 25, 2001

File No. : C-17-01-001

Confidential

Released by : Canon Inc.

OIP QA Center

OIP TS Division

This document precedes the Service Manual for the product in question and

serves as a reference, thereby providing the Sales Companies with a good

understanding of the product in advance.

Most of the contents of this document are not official and, therefore, are subject to change before the product is brought into being, making it important to

bear in mind that the descriptions are true only as of the date indicated on the

cover.

Yoshiaki Takase, General Manager

OIP QA Division

(TS001102)

New Product Information

Introduction to New Product Information

The document “New Product Information” replaces the Trainer’s Manual (TR) most of

you are familiar with, and is the result of our efforts to provide information useful to all

departments concerned in each Sales Company.

Most of the contents of this document are not official and, therefore, are subject to

change before the product is brought into being, making it important to bear in mind that

the descriptions are true only as of the date indicated on the cover.

The Service Manual for the product will have descriptions updated to reflect the changes

that may have occurred. Kindly make arrangements so that this document is properly

disposed of as soon as the Service Manual is released.

January,25, 2001

Canon Inc.

OIP QA Center

OIP QA Division

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

1 Specifications

1.1 Main Body

1.1.1 Type

Item Description

Body Desktop

Copyboard Fixed

Light source Xenon lamp

Lens Lens array

Photosensitive medium OPC drum (30-mm dia.)

T01-101-01

1.1.2 Systems

Item Description

Reproduction Indirect electrostatic

Charging AC roller

Exposure Laser

Copy density adjustment Auto or manual

Development Single-component toner projection

Pickup Auto Front cassette (2 cassettes)

Retard method (about 500 sheets of 80 g/m2 paper, about 550

sheets of 64 g/m2 paper)

Manual Multifeeder

Dual process method (about 50 sheets of 80 g/m2 paper)

Transfer Roller

Separation Static eliminator (static separation) + curvature

Cleaning Blade

Fixing SURF method (plane heater and fixing film)

COPYRIGHT

©

T01-101-02

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-1

CHAPTER 1 GENERAL DESCRIPTION

1.1.3 Functions

Item Description

Resolution Reading 600dpi×600dpi

Copying 1200dpi×600dpi

Printer output 2400dpi×600dpi

Original type Sheet, book 3-D object (2 kg max.)

Maximum original size A3/279.4×431.8mm (11"×17")

Reproduction ratio Direct (1:1), Reduce I (1:0.250), Reduce II (1:0.500),

Reduce III (1:0.611), Reduce IV (1:0.707), Reduce III (1:1.414),

Enlarge IV (1:2.000), Enlarge V (1:4.000), Enlarge VI (1:8.000),

Zoom (1:0.250 to 8.000 in 1% increments)

Wait time 10 sec or less (at 20°C)

First copy time 5.4 sec (book mode, cassette 1, Direct, A4/LTR, text mode)

Continuous copying 999 copies max.

Copy size

Cassette A/B A3 max., A5 (vertical feed) min.

Inch 279.4×431.8 mm (11"×17") max., STMT (vertical feed) min.

Manual feed AB A3 max., postcard (vertical feed) min.

Inch 279.4×431.8 mm (11"×17") max., STMT (vertical feed) min.

Cassette 1/2 • Plain paper (64 to 80 g/m2):A3, B4, A4, B5, A5R, A4R, B5R,

279.4×431.8mm (11"×17"), LGL, LTR, LTRR, STMT, STMTR

• Tracing paper (SM-1):A3, B4, A4, B5, A4R, B5R

• Colored paper (Canon-recommended):B4, A4, A4R

Multifeeder • Plain paper (64 to 80 g/m2):A3, B4, A4, B5, A5R, A4R, B5R,

279.4×431.8mm (11"×17"), LGL, LTR, LTRR, STMT, STMTR

• Tracing paper (SM-1, GSN-75):A3, B4, A4, B5, A4R, B5R

• Transparency (Canon-recommended):A4, A4R, LTR, LTRR

• Colored paper (Canon-recommended):B4, A4, A4R

• Postcard: Jpn (vertical feed), double-card, 4-sheet card

• Label sheet (Canon-recommended):B4, A4, A4R, LTR, LTRR

• Thick paper (90 to 128 g/m2):A3, B4, A4, B5, A4R, B5R, LTR,

LTRR

• Envelope

T01-101-03

1-2

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

Item Description

Single-sided copying mode • Plain paper (64 to 80 g/m2):A3, B4, A4, B5, A5R, A4R, B5R,

279.4×431.5mm (11"×17"), LGL, LTR, LTRR, STMT, STMTR

• Tracing paper (SM-1, GSN-75):A3, B4, A4, B5, A4R, B5R

• Transparency (Canon-recommended)A4, A4R, LTR, LTRR

• Colored paper (Canon-recommended):B4, A4, A4R

• Postcard: Jpn postcard (vertical feed), double-card, 4-sheet card

• Label sheet (Canon-recommended):B4, A4, A4R, LTR, LTRR

• Thick paper (90 to 128 g/m2):A3, B4, A4, B5, A4R, B5R, LTR,

LTRR

• Envelope

Double-sided copying mode (automatic)

• Plain paper (64 to 80 g/m2):A3, B4, A4, B5, A5R, A4R, B5R,

279.4×431.8mm (11"×17"), LGL, LTR, LTRR, STMT, STMTR

• Colored paper (Canon-recommended):B4, A4, A4R

• Thick paper (90 to 128 g/m2):A3, B4, A4, B5, A4R, B5R, LTR,

LTRR

Double-sided copying mode (multifeeder)

• Plain paper (64 to 80 g/m2):A3, B4, A4, B5, A5R, A4R, B5R,

279.4×431.8mm (11"×17"), LGL, LTR, LTRR, STMT, STMTR

• Colored paper (Canon-recommended):B4, A4, A4R

• Postcard: Jpn (vertical feed), double-card, 4-sheet card

• Thick paper (90 to 128 g/m2):A3, B4, A4, B5, A4R, B5R, LTR,

LTRR

COPYRIGHT

©

T01-101-04

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-3

CHAPTER 1 GENERAL DESCRIPTION

Item Description

Cassette Claw None

Capacity 55 mm deep (approx.; about 500 sheets of 80 g/m2 paper)

Hard disk 6.4GB (*1)

Non-image width Leading edge Direct, Enlarge/Reduce:4.0±1.5/-1.0mm <4.5±1.8mm>*2

Trailing edge Direct, Enlarge/Reduce:2.0±1.5mm <2.0±1.8mm>*2

Left/right (1st side) Direct, Enlarge/Reduce:2.5±1.5mm <2.5±2.0mm>*2

Auto clear Yes (2 min standard; may be changed in 1-min increments

between 0 and 9 min)

Auto power-off Yes

Low-power mode Yes (15 min standard; may be changed in user mode to

10, 15, 20, 30, 40, 50, 60, 90 min, 2, 3, or 4 hr)

Sleep mode Yes (60 min standard; may be changed in user mode to

10, 15, 20, 30, 40, 50, 60, 90 min, 2, 3, or 4 hr)

Yes (-10% standard; may be changed in user mode to -

10%, -25%, -50%, or no return (0%))

Accessory • DADF-H1

• Copyboard Cover Type-E

• Copyboard-D1

• Copy Tray-F1

• Saddle Finisher-G1

• Puncher Unit-G1

• Finisher-J1

• Inner 2-Way Tray-A1

• Side Paper Deck-L1

• 2-cassette Pedestal-W1

• Options Power Supply-B1 (required for SF, PD)

• Cassette Heater Kit-16N

• Control Card-IV

• Network LIPS Printer Kit-A1 (100V model only)

• Network Multi-PDL Printer Kit-A1 (120/230V model

only)

*1:The HDD that comes with the machine and the HDD that is made available as a service part may

have different memory sizes; however, the area of the HDD used by the machine will be the same,

and either may be used without a problem.

*2:The values within parentheses indicate when the DADF is used.

T01-101-05

The above specifications are subject to change for product improvement.

1-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

1.1.4 Others

Item Description

Operating environment Temperature range 15° to 30°C

Humidity range 5 to 80%

Atmospheric pressure 810.6 to 1013.3 hpa (0.8 to 1.0 atm)

Power supply E201

LQHxxxxx

100V (50/60Hz) LQJxxxxx

NRFxxxxx

120V (50/60Hz) NRGxxxxx

PKMxxxxx

220V/60Hz PKKxxxxx

230V (50/60Hz) PKLxxxxx

QCWxxxxx

RBZxxxxx

SCKxxxxx

TBZxxxxx

UFMxxxxx

Power consumption Maximum E201: 1.5 kW or less

Standby E201: 282 W (approx.; reference only)

Continuous E201: 995 W (approx.; reference only)

Noise Sound power level (Impulse mode)

Copying E201: 66 dB or less, E202: 71 dB or less

Standby E201: 40 dB or less, E202: 50 dB or less

Ozone 0.01 ppm or less avg., 0.02 ppm or less max.

Dimensions (mm) (iP-Lite) 565 (W) × 678 (D) × 1020 (H)

(iP-Std) 565 (W) × 678 (D) × 1040 (H)

Weight 80 kg (approx.)

Consumables Copy paper Keep wrapped to protect against humidity.

Toner Keep away from direct sunshine, and keep at

40°C/85% or less.

T01-101-06

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-5

CHAPTER 1 GENERAL DESCRIPTION

Reproduction mode Side Paper size copies /min (1-to-N)

E201 E202

Direct A3 (297×420mm) A3 - 16

A4 (210×297mm) A5 - A5 (149×210mm) A4 22 33

B4 (257×364mm) B4 - 14

B5 (182×257mm) B5 - 28

A4R (297×210mm) A4R - B5R (257×182mm) B5R - A5R (210×149mm) A5R - -

Reduce II

(50.0%) A3 → A5R A5R - III

(61.1%) A3 → B5R B5R - IV

(70.7%) B4 → B5R B5R - V A3 → A4R A4R - (81.6%) B4 → A4R A4R - VI B5R → A5R A5R - (86.5%) A4 → B5 B5 - -

A3 → B4 B4 - -

Enlarge IV

(200.0%) A5R → A3 A3 - III

(141.4%) A4R → A3 A3 - II B5R → B4 B4 - (122.4%) A4R → B4 B4 - I A5 → B5 B5 - (115.4%) B4 → A3 A3 - -

B5 → A4 A4 - -

Delivery by copier, Auto paper select ON, Auto density, Non-sort, Deck/Cassette

T01-101-07 Copying Speeds (copier only)

1-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

Reproduction mode Size (1toN)

E201 E202

Direct 279.4×431.8mm 279.4×431.8mm - 16

(11"×17") (11"×17")

LTR LTR 22 33

LGL LGL - 14

LTRR LTRR - -

STMTR STMTR - -

Reduce II 279.4×431.8mm STMTR - -

(50.0%) (11"×17") → STMTR

III 279.4×431.8mm LTRR - (64.7%) (11"×17") → LTRR

IV 279.4×431.8mm LGL - (73.3%) (11"×17") → LGL

V LGL → LT RR L TRR - (78.6%)

Enlarge IV STMTR* → 279.4×431.8mm - -

(200.0%) 279.4×431.8mm (11"×17")

(11"×17")

III LTRR → 279.4×431.8mm - (129.4%) 279.4×431.8mm (11"×17")

(11"×17")

II LGL → 279.4×431.8mm - (121.4%) 279.4×431.8mm (11"×17")

(11"×17") copies/min

Paper size

*STMTR cannot be used as an original.

Delivery by copier, Auto paper select ON, Auto density, Non-sort, Deck/Cassette

T01-101-08 Copying Speeds (copier only)

The above specifications are subject to change for product improvement.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-7

CHAPTER 1 GENERAL DESCRIPTION

1.2 Side Paper Deck-L1

Item Description

Pickup method Retard

Paper accommodation Front loading

Paper type (horizontal feed only) Plain paper (65 to 80 g/m2): A4, B5, LT R

Colored paper (Canon-recommended): A4

Capacity 2,500 sheets (approx.; 80 g/m2 paper)

Serial number A4 type:XCQxxxxx LTR type: XCRxxxxx

Paper size switch By size guide plate/in service mode

Dimensions 324 (W) × 591 (D) × 432 (H) mm

Weight 30 kg (approx.)

Power supply None (DC power supplied by accessories power supply of

host machine)

Operating conditions Same as host machine

T01-200-01

The above specifications are subject to change for product improvement.

1-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

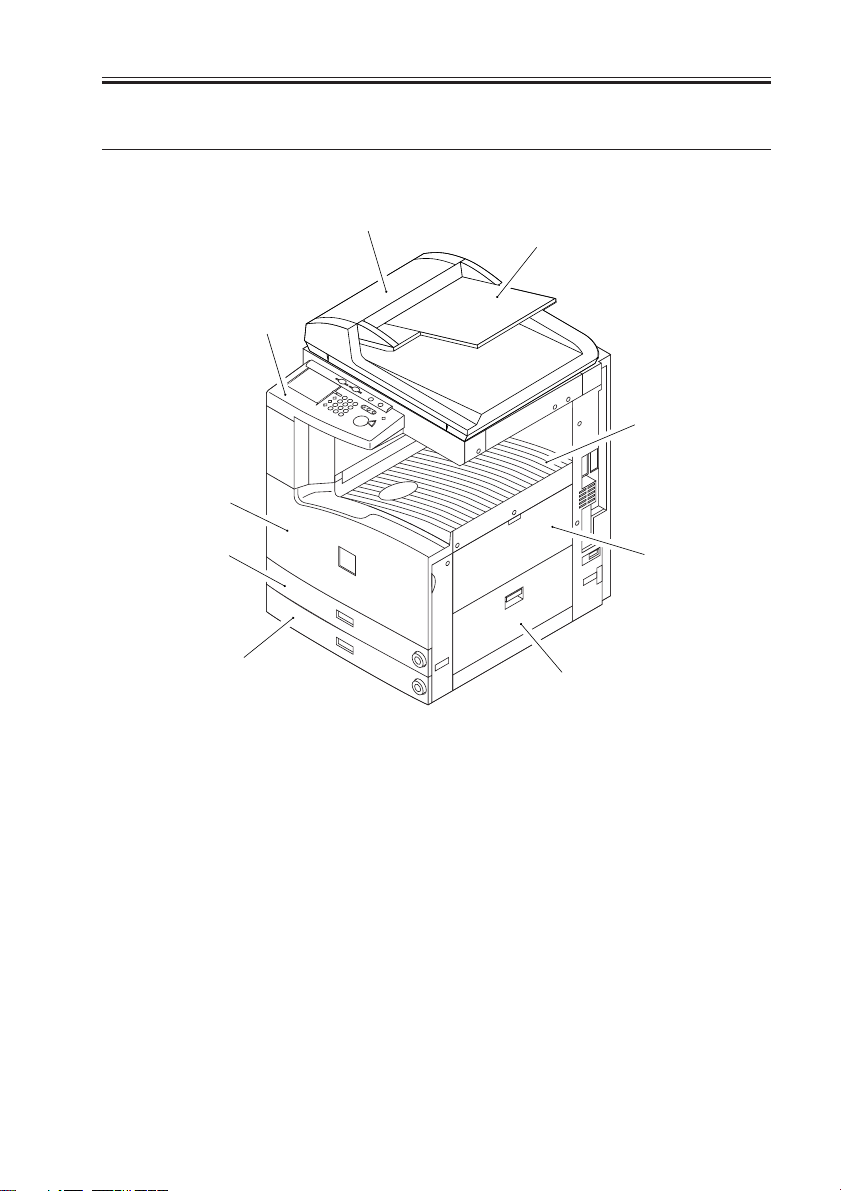

2 Names of Parts

2.1 External View

CHAPTER 1 GENERAL DESCRIPTION

[4]

[5]

[1] ADF

[2] Original tray

[3] Control panel

[4] Front cover

[5] Cassette 1

[6] Cassette 2

[7] Delivery tray

[8] Multifeeder

[6]

[3]

[1]

[2]

[7]

[8]

[9]

[9] Right lower cover

[10] DIMM ROM replacement cover

[11] Network card slot

[12] Parallel connector

[13] Extension board slot

[14] Main power switch

[15] Cassette heater switch

COPYRIGHT

©

F01-201-01 External View 1

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-9

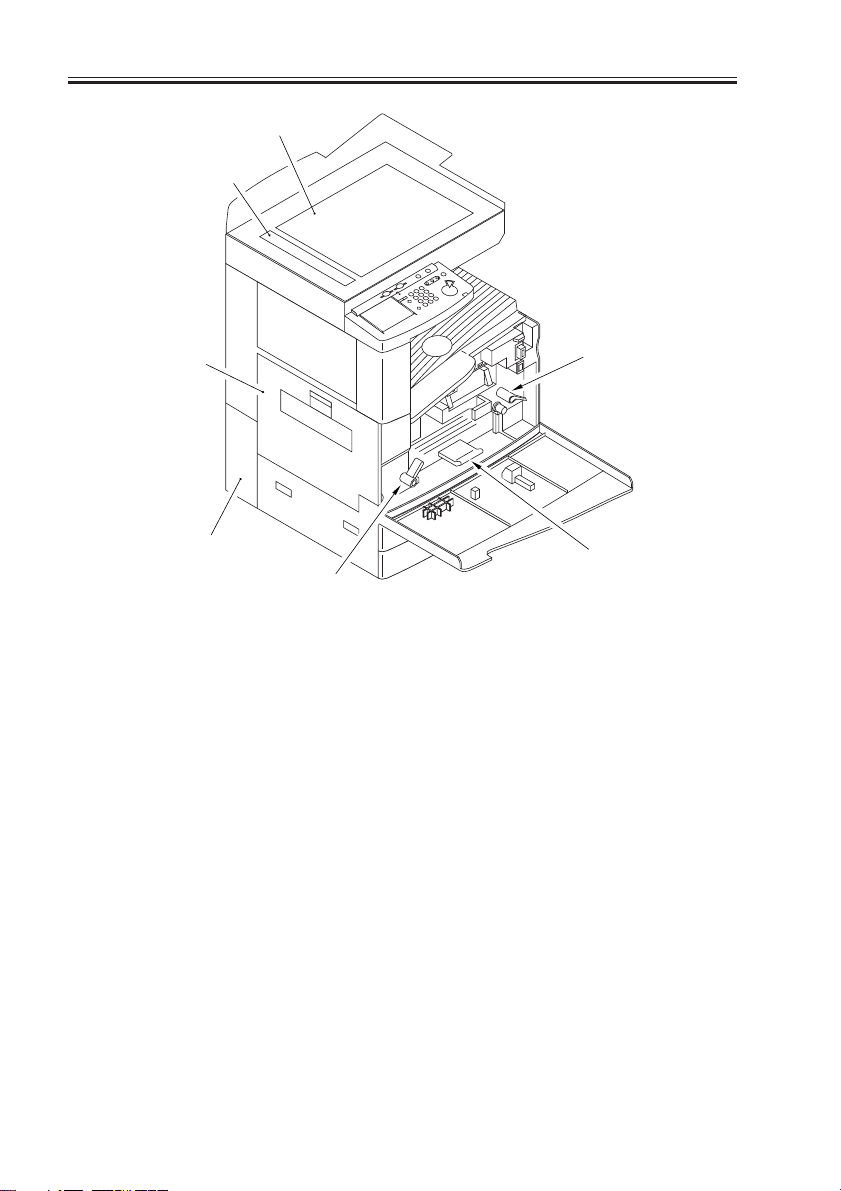

CHAPTER 1 GENERAL DESCRIPTION

[1]

[2]

[3]

[4]

[6]

[1] Copyboard glass

[2] DADF reading glass

[3] Left cover

[4] Left lower rear cover (waste toner

case cover)

F01-201-02 External View 2

[5]

[7]

[5] Developing assembly releasing

lever

[6] Feeding assembly releasing lever

[7] Duplex feeding assembly releas-

ing lever

1-10

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

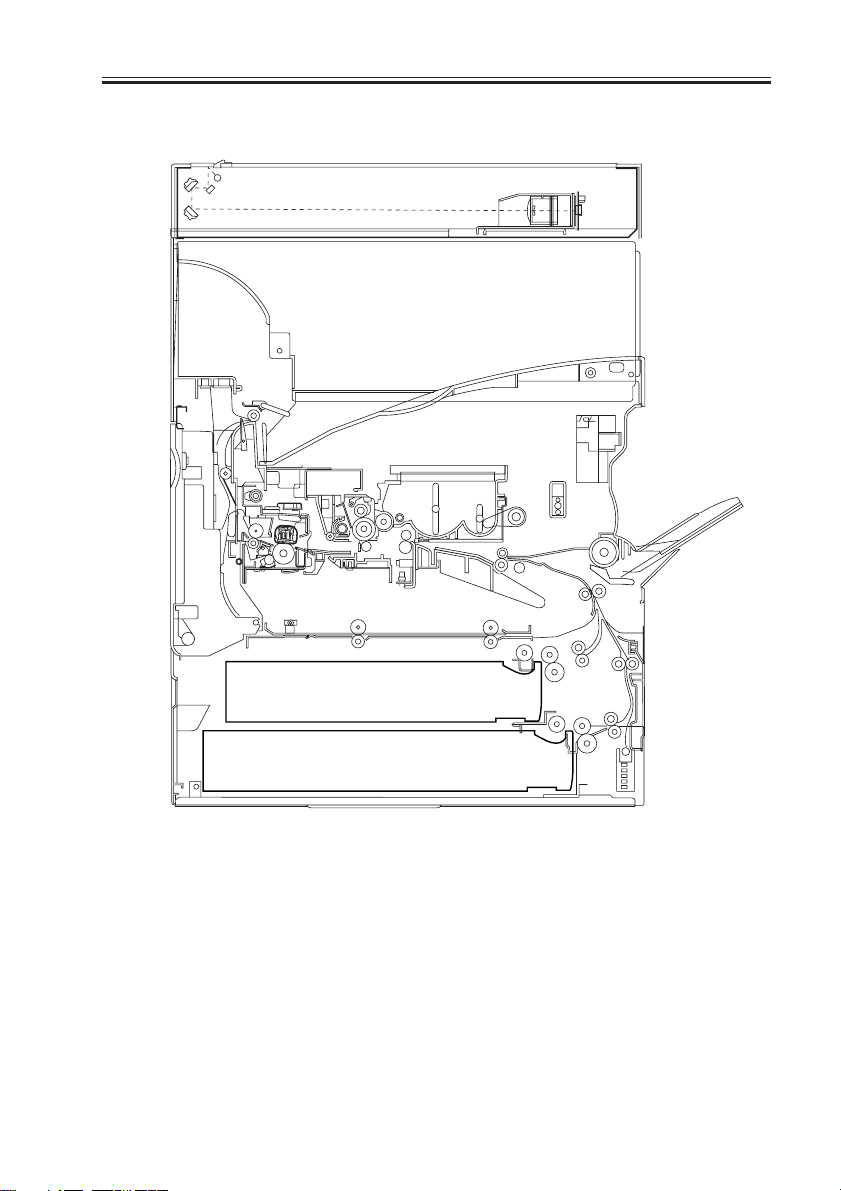

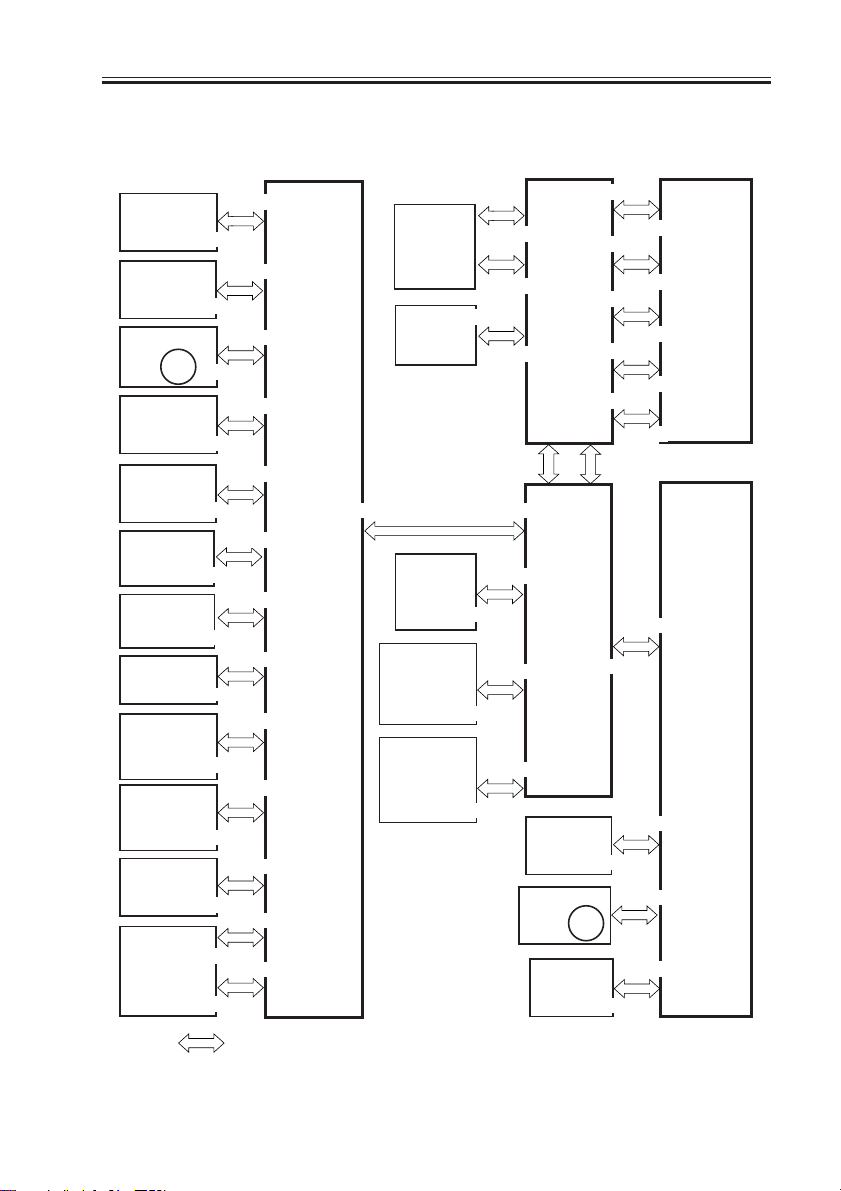

2.2 Cross Section

CHAPTER 1 GENERAL DESCRIPTION

COPYRIGHT

©

F01-202-01 Cross Section

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-11

CHAPTER 1 GENERAL DESCRIPTION

[1] DADF reading glass

[2] No. 1 mirror

[3] Scanning lamp

[4] Copyboard glass

[5] Fixing assembly

[6] Feeding assembly

[7] Laser mirror 3

[8] Laser mirror 2

[9] Laser mirror 1

[10] Drum cleaner assembly

[11] Primary charging assembly

[12] Photosensitive drum

[13] Laser mirror 4

[14] CCD unit

[15] Laser unit

[16] Dust-proofing glass

[17] Developing cylinder

[18] Pre-transfer charging assembly

[19] Multifeeder pickup roller

[20] Multifeeder separation roller

[21] Registration roller

[22] Transfer roller

[23] Static eliminator

[24] Cassette 1 pickup roller

[25] Cassette 1 feeding roller

[26] Cassette 1 separation roller

[27] Cassette 2 pickup roller

[28] Cassette 2 feeding roller

[29] Cassette 2 separation roller

[30] Cassette 1

[31] Cassette 2

[32] Lower fixing roller

[33] Inside delivery roller

[34] Outside delivery roller

[35] Upper fixing roller

[36] No. 3 mirror

[37] No. 2 mirror

T01-202-01

1-12

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

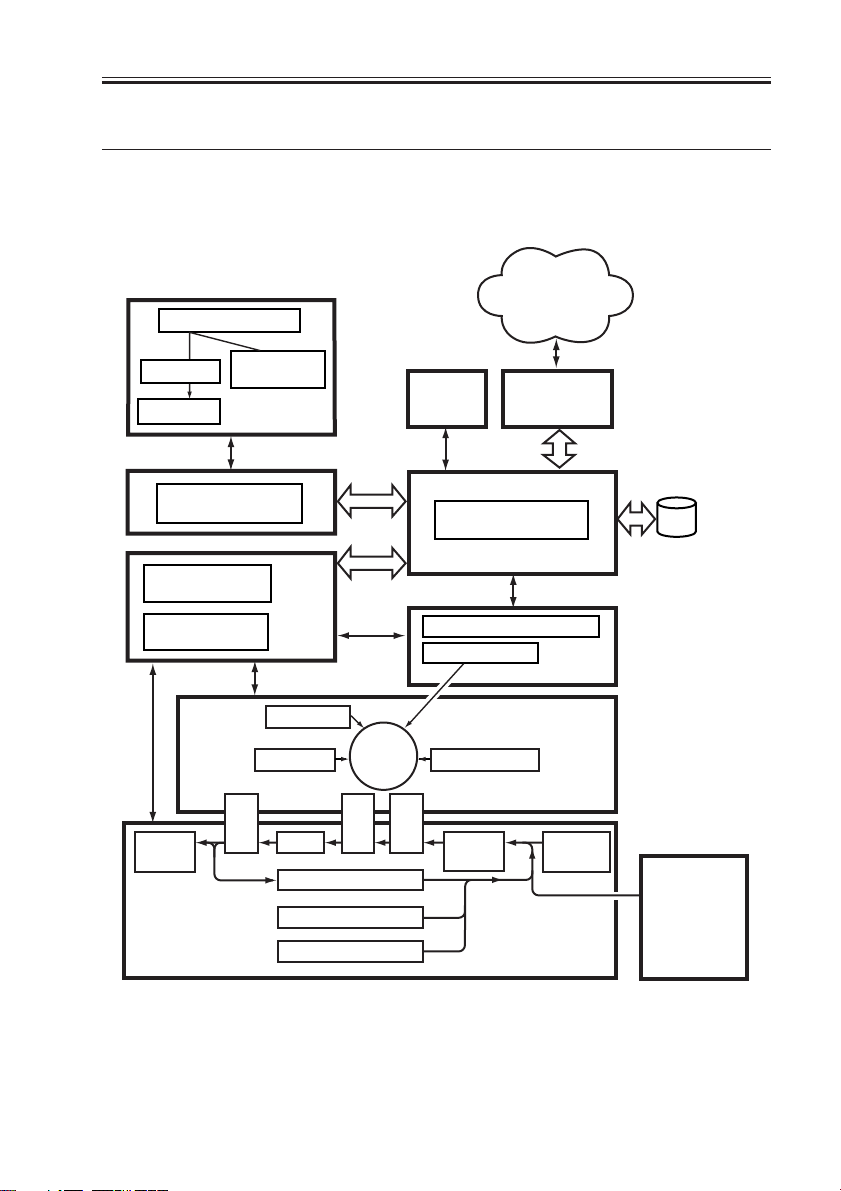

3. System Configuration

3.1 Functional Construction

The machine may be broadly divided into the following six functional blocks:

Various

networks or public

Original

telephone

network

Optical path

CCD PCB

Reader controller

DC controller

PCB

DC power

supply PCB

Delivery

tray

Original

illumination

Original

Exposure Block

PCB

Control

Block

Charging

Cleaning

Feeding

Fixing

Photo-

sensitive

drum

Separation

Lower feeding assembly

Cassette 1

Cassette 2

Control

panel

Main controller PCB

Image Processing Block

Laser driver PCB

Laser scanner

Development

Image Formation Block

Pickup

Transfer

control

Pickup/Feeding Block

Various

accessory

boards

Exposure Block

Laser

Multi-

feeder

HDD

Side paper

deck

(accessory)

COPYRIGHT

©

F01-301-01

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-13

CHAPTER 1 GENERAL DESCRIPTION

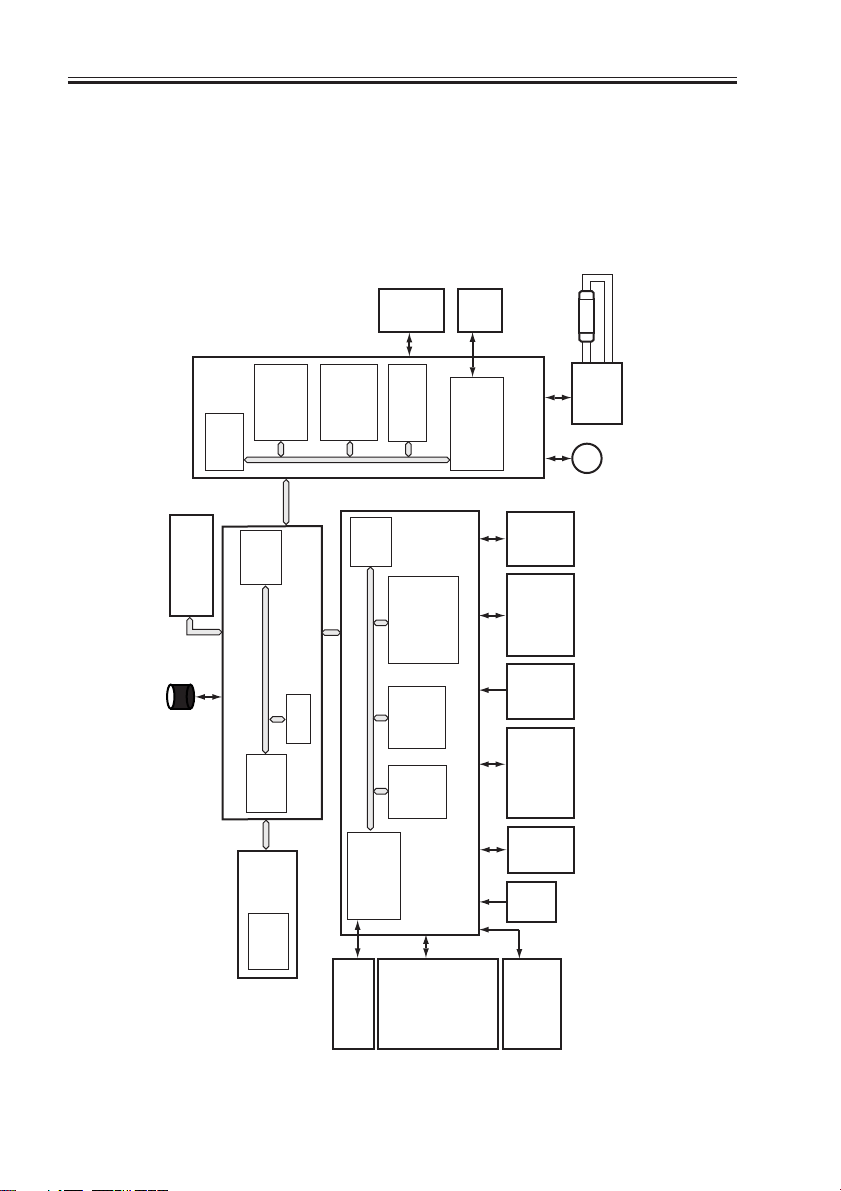

3.2 Outline of the Electrical Circuitry

3.2.1 Construction of the Electrical Circuit

The major electrical mechanisms of the machine are controlled by the following PCBs:

[1] Man controller PCB; controls the system as a whole, processes images

[2] DC controller PCB; controls the printer unit, controls the finisher communication

[3] Reader controller PCB; controls the reader unit, controls the DADF communication

IC5025

boards

Accessory

drive

(HDD)

Hard disk

(CPU)

IC1010

(DIMM-

Control

(ROM)

IC5008

IC5016

(CPU)

ROM)

panel

PCB

IC5009

Main controller PCB

(RAM)

CCD

(RAM)

IC5027

IC125

(CPU)

IC104,105

DIMM/

IC121

IC120

unication 2)

(IPC comm-

PCB

(EEPROM)

IC109,110

ROM

IC122

ADF

IC5021

(IPC comm-

IC127,130

(EEPROM)

(IC117)

(RAM)

DC controller PCB

unication 2)

Reader

controller PCB

Main

power

supply

power

supply

Composite

PCB

Drum

sensor

power

supply

Accessories

PCB

drive

Laser

BD

PCB

LA2

PCB

PCB

PCB

Inverter

M3

PCB

motor

Scanner

1-14

(CPU)

IC6501

COPYRIGHT

PCB

• Finisher

(accessory)

DC loads

• Clutch

• Solenoid

• Motor

• Sensor

• Fan

• Etc.

Pickup

F01-302-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

3.3 Inputs to and Outputs from the Major PCBs

3.3.1 Wiring Diagram of the Major PCBs

Potential

control

PCB

Duplex

driver

J2302

PCB

Laser scanner

motor

M15

J2511

Laser drive

PCB

J2501

BD PCB

DC power

supply PCB

J2701

J4003

HVT PCB

J4502

Environment

sensor PCB

Cassette 3

paper level

detection

Cassette 4

paper level

detection

AC driver

PCB

PCB

PCB

Motor

driver

PCB

J806

J810

J2052

J2101

J2108

J3

J8492

J103

J107

J116

J121

J120

J101

J102

J113

J113

J113

J102

J104

J105

DC

controller

PCB

LCD panel

(LCD)

Inverter

PCB

Hard disk

Control

Card-IV

(accessory)

Copy Data

Controller

(accessory)

J956

J1551

J1532

J1530

J6503

J6507

J6506

J6505

J1012

J1015J122

J1017

J1060

J1022

Control

panel

CPU PCB

Controller

assembly

CCD/AP

PCB

Scanner

motor

Inverter

PCB

M3

J6604

J6509

J6504

J6501

J6508

J6801

J1018

J1014

J6002

J5101

J6502

J6601

J6602

J6603

J6605

J5004

J5003

J5011

J5007

Keypad

PCB

Reader

controller

PCB

Note: The in the diagram indicates connection between PCBs, NOT the flow of signals.

F01-303-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

1-15

CHAPTER 1 GENERAL DESCRIPTION

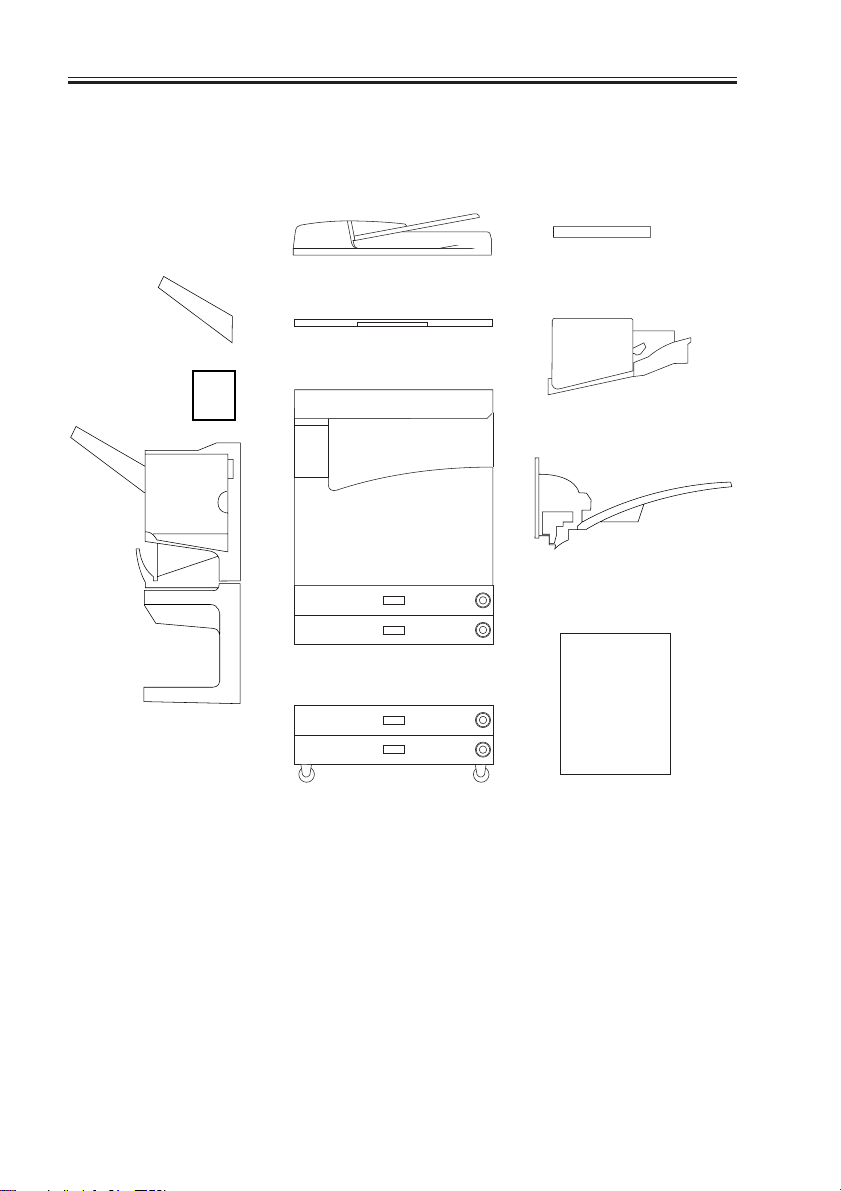

3.4 Configuration with Accessories

3.4.1 Accessories for Original/Paper Feeding

[5]

[4]

[6]

[1]

[2]

[10]

[3]

[7]

[8]

[9]

[1] DADF-H1

[2] Copyboard Cover Type-E

[3] Copyboard-D1

[4] Copy Tray-F1

[5] Saddle Finisher-G1

[6] Puncher Unit-E1

1-16

COPYRIGHT

[7] Finisher-J1

[8] Inner 2-Way Tray-A1

[9] Side Paper Deck-L1

[10] 2-Cassette Pedestal-W1

[11] Options Power supply-N1

(required when [5] or [9] is used)

F01-304-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

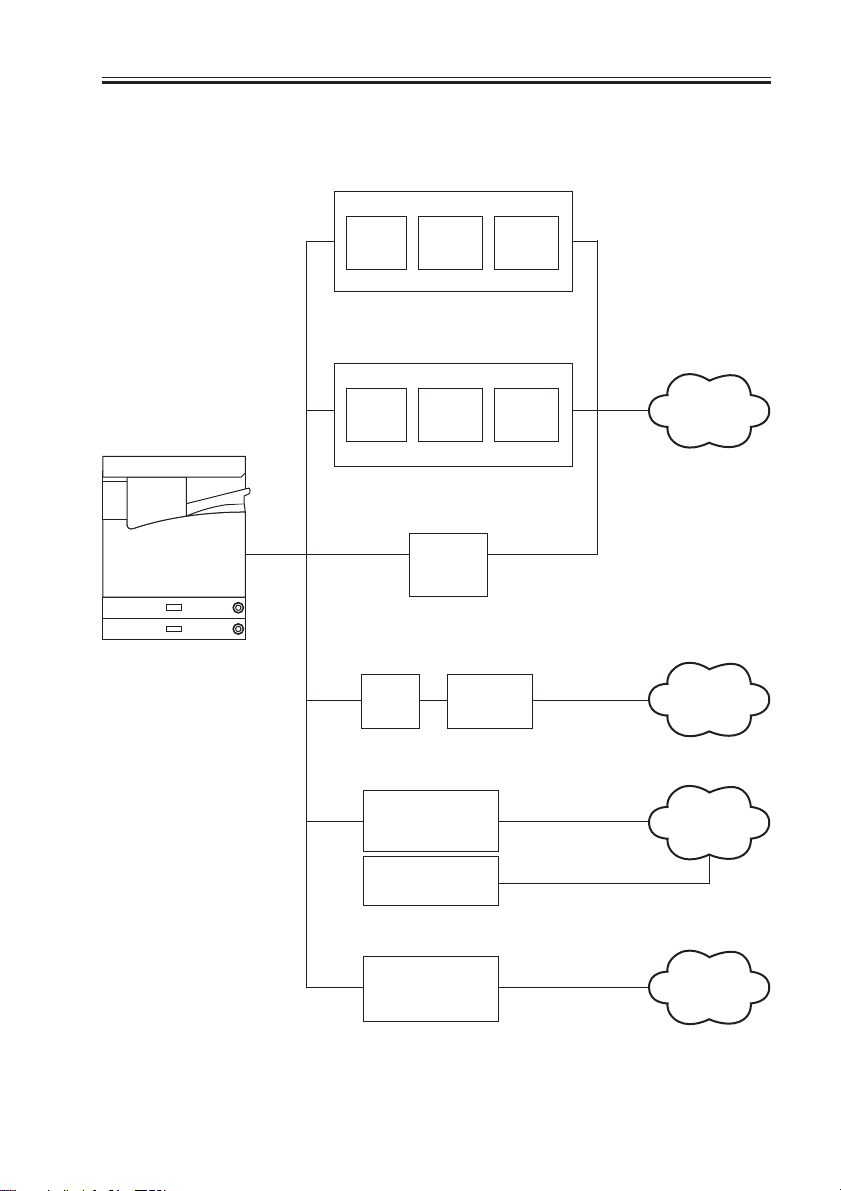

3.4.2 Accessory Boards

CHAPTER 1 GENERAL DESCRIPTION

LIPS Printer Kit-B1

LPS

PCB

Network Multi-PDL

Printer Kit-B1

RIP1

PCB

Relay PCB

Relay

PCB

Relay

PCB

Network

Network

PCB

Relay

PCB

Super G3 FAX

Board-J1

Token Ring

TokenRing

PCB

Network

PCB

Network

PCB

Ethernet

network

TokenRing

network

Public

telephone

network

COPYRIGHT

©

Multiport Kit-B1

G4 FAX Board-B1

F01-304-02

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

ISDN network

1-17

CHAPTER 2

ORIGINAL EXPOSURE SYSTEM

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 2 ORIGINAL EXPOSURE SYSTEM

1. Outline of Operations

1.1 Outline

The original exposure system has the following major functions:

Item Description

Original illumination Xenon tube

Original scanning In Book mode: by moving scanner

With ADF in use: by fixed No. 1 mirror base at stream reading po-

sition

scanner position detection Scanner HP sensor (PS400)

Reproduction ratio (zoom) [1] Copyboard Mode (25% to 800%)

Main scanning direction: image processing by controller assembly

Sub scanning direction: for a ratio of 50% or higher, changing

scanning speed of No. 1 mirror; for a

ratio of lower than 50% and 400% or

higher, chaining scanning speed and im-

age processing

[2] ADF Mode (25% to 400%)

Main scanning direction: image processing by controller assembly

Sub scanning direction: for a ratio of 50% or higher, changing

original feeding speed; for a ratio of

lower than 50% and 200% or higher,

Scanner drive control No. 1/No. 2 mirror base: control by stepping motor (M400)

Lens Lens array, fixed type

Scanning lamp control [1] Control of activation by inverter circuit

[2] Control for error detection

Original size detection [1] In Book Mode

Sub scanning direction: by reflection type sensor

Main scanning direction: by CCD

[2] With ADF in Use

By ADF

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

2-1

CHAPTER 2 ORIGINAL EXPOSURE SYSTEM

1.2 Changing the Reproduction Ratio (Zoom)

[1] In Copyboard Mode

If for a reproduction ratio of 25% to 800%, the speed of the scanner is changed.

[2] With ADF in Use

If for a reproduction ratio of 25% to 400%, the speed of the movement of the original is

changed.

1.2.1 Changing the Reproduction Ratio in Main Scanning Direction

For scanning direction, reading is always at 100% in both copyboard and ADF modes; the

ratio is changed in the course of data processing in the main controller assembly.

To reduce, data units are skipped.

To enlarge, data units are repeated.

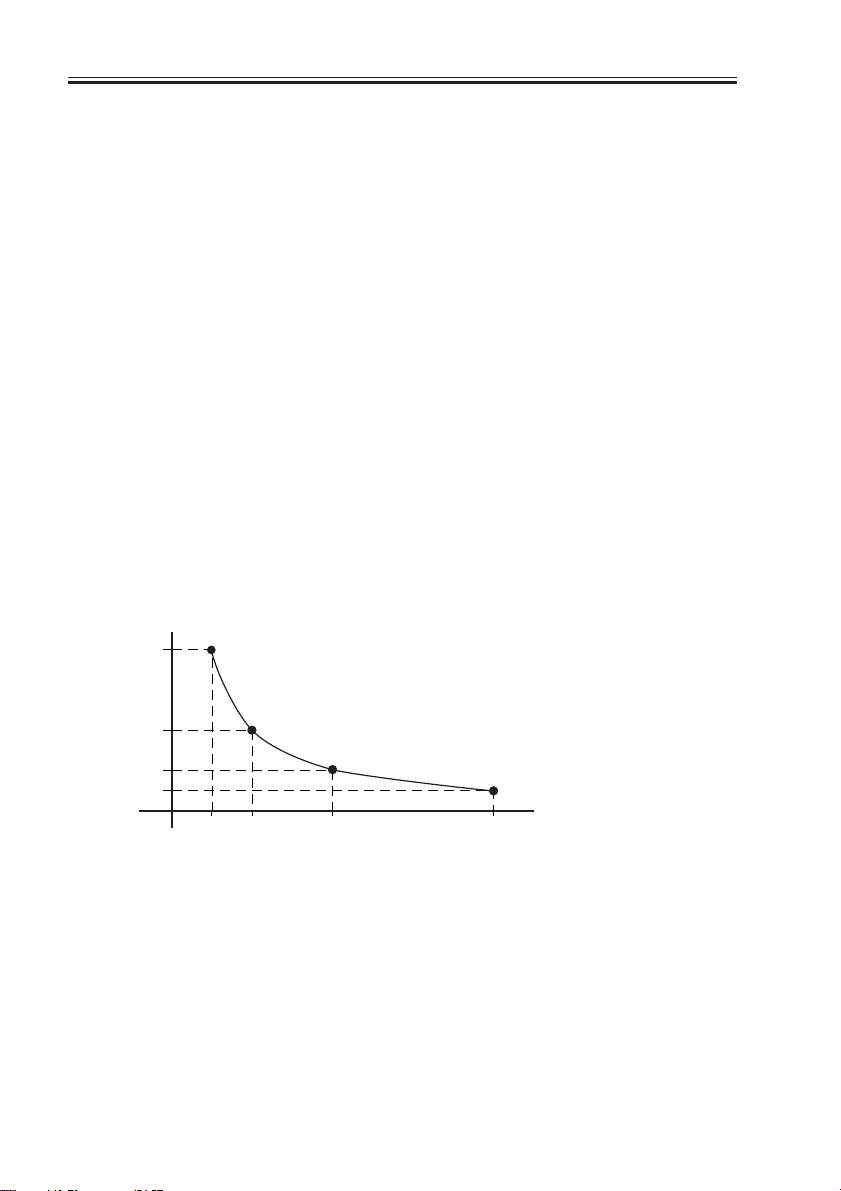

1.2.2 Changing the Reproduction Ratio in Sub Scanning Direction

For sub scanning direction, the speed of the scanner/movement of the original is changed.

However, for a reduction between 25% and 49% and enlargement between 401% and 800%,

data processing in the main controller assembly is also used in combination.

[1] For enlargement, the speed of the mirror/original is reduced from that used in Direct:

e.g., at 200%, the speed is 1/2 of the speed used in Direct.

[2] For reduction between 50% and 99%, the speed of the mirror/original is increased;

e.g., at 50%, the speed is twice as high as that used in Direct.

(speed ratio)

2

1

1/2

1/4

50%

(reproduction ratio)

400%200%100%

F02-102-01

[3] For a reduction between 25% and 49%, image data read at 50% to 98% is subjected to

skipping (1/2) in the main controller assembly.

[4] For an enlargement between 401% and 800%, image data read at 200% to 400% is sub-

jected to repeating (doubling) in the main controller assembly.

2-2

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 3

LASER EXPOSURE SYSTEM

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 3 LASER EXPOSURE SYSTEM

1 Outline of Operations

1.1 Outline

Part 2>Chapter 4>1.1 “Outline of Laser Exposure”

The reader controller PCB serves to read image signals from the CCD and send image

signals to the main controller assembly. The video signals from the main controller assembly are converted by the DC controller PCB into laser drive signals, and are turned into laser

intensity signals to suit signal levels by the laser driver PCB.

The laser intensity signals are used to cause the laser unit to generate a laser beam, which

is directed to the photosensitive drum for the formation of latent static images.

The laser beam is also used for blank exposure to create non-image areas.

Item Description

Laser intensity control Laser power auto control (APC control)

Laser scanning By semiconductor laser

Synchronization control Main scanning direction: control by BD signal

Sub scanning direction: control by image leading edge signal

Laser scanner motor control Constant speed rotation control

T03-101-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-1

CHAPTER 3 LASER EXPOSURE SYSTEM

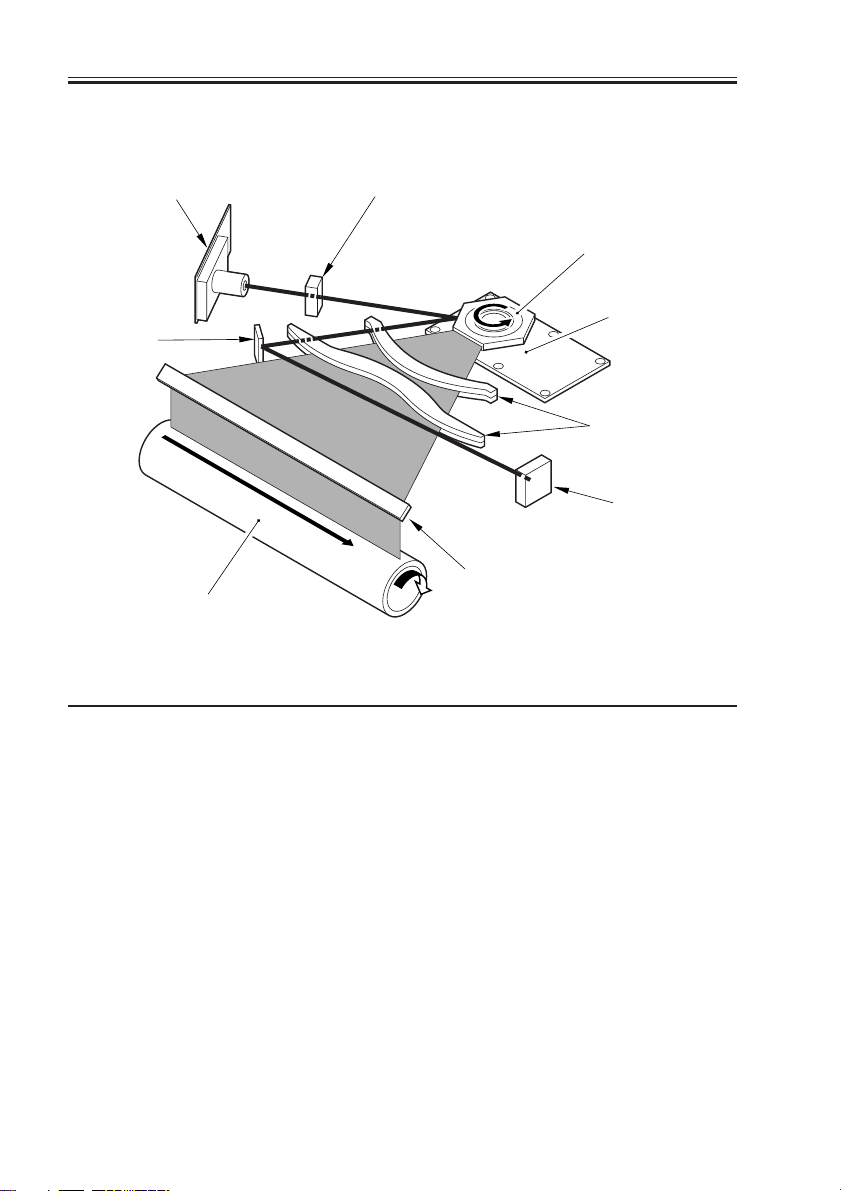

F03-101-01 shows the major components for the laser exposure system; the machine’s la-

ser scanning is performed by means of a 6-facet polygon mirror and a single-beam laser unit:

Laser unit

BD mirror

Photosensitive drum

Cylindrical lens

Polygon mirror

(6-faceted)

Laser scanner motor

Collimating lens

BD PCB

Laser mirror

F03-101-01 External View

Component Description

Laser semiconductor Visible laser light (about 6760 nm), single-beam

Laser scanner motor (M10) DC brush-less motor, constant speed control

Polygon mirror 6-faceted

BD mirror/BD PCB Laser beam detection

Laser driver PCB Laser activation control

DC controller PCB Laser scanner motor rotation control

3-2

T03-101-02 List of Components

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 3 LASER EXPOSURE SYSTEM

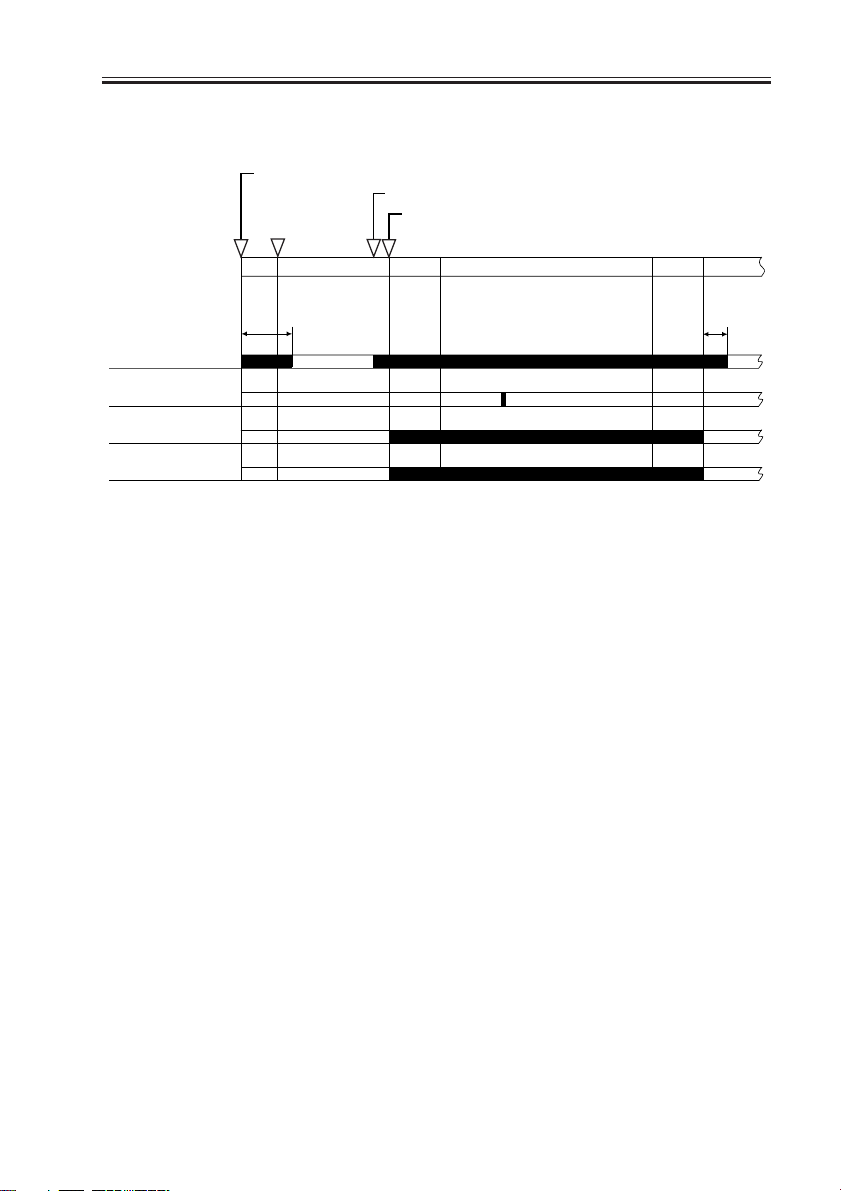

1.2 Sequence of Operations (laser exposure system)

Main power switch ON/sleep mode OFF

Original set/ADF opened

180˚C

Start key ON

Laser scanner

motor

Image leading

edge signal

Laser

BD signal

AINTR

8 sec

*: If silent mode (in user mode) is selected, the motor stops after a

specific period of time.

STBY

INTR

PRINT

LSTR

F03-102-01 Basic Sequence of Operations

STBY

*

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-3

CHAPTER 3 LASER EXPOSURE SYSTEM

2 Generating Sync Signals

2.1 Outline

Part 2>Chapter 4>2 “Generating BD Signals”

The BD signal used to synchronize the video signals in laser scanning direction is generated by the BD PCB with reference to the laser beam reflected by the BD mirror mounted in

the path of the laser beam.

The edge of paper re-picked in double-sided mode is detected by the horizontal registration sensor to measure the displacement to the rear/front. Based on the measurement, the

timing of laser activation is changed with reference to the BD signal so that the image will

be placed at a specific position on the paper without fail.

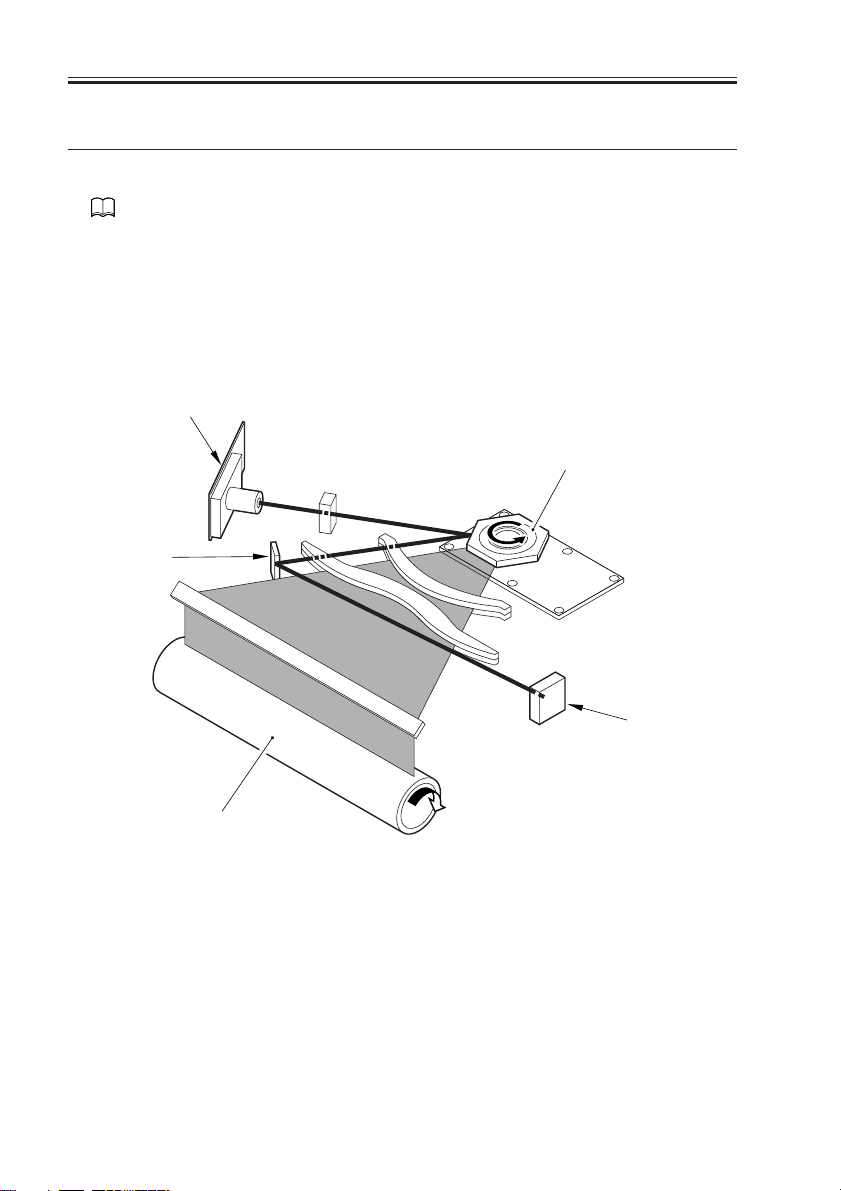

Laser unit

Polygon mirror (6-faceted)

BD mirror

3-4

Photosensitive drum

F03-201-01 Construction of the Control System

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

BD PCB

CHAPTER 3 LASER EXPOSURE SYSTEM

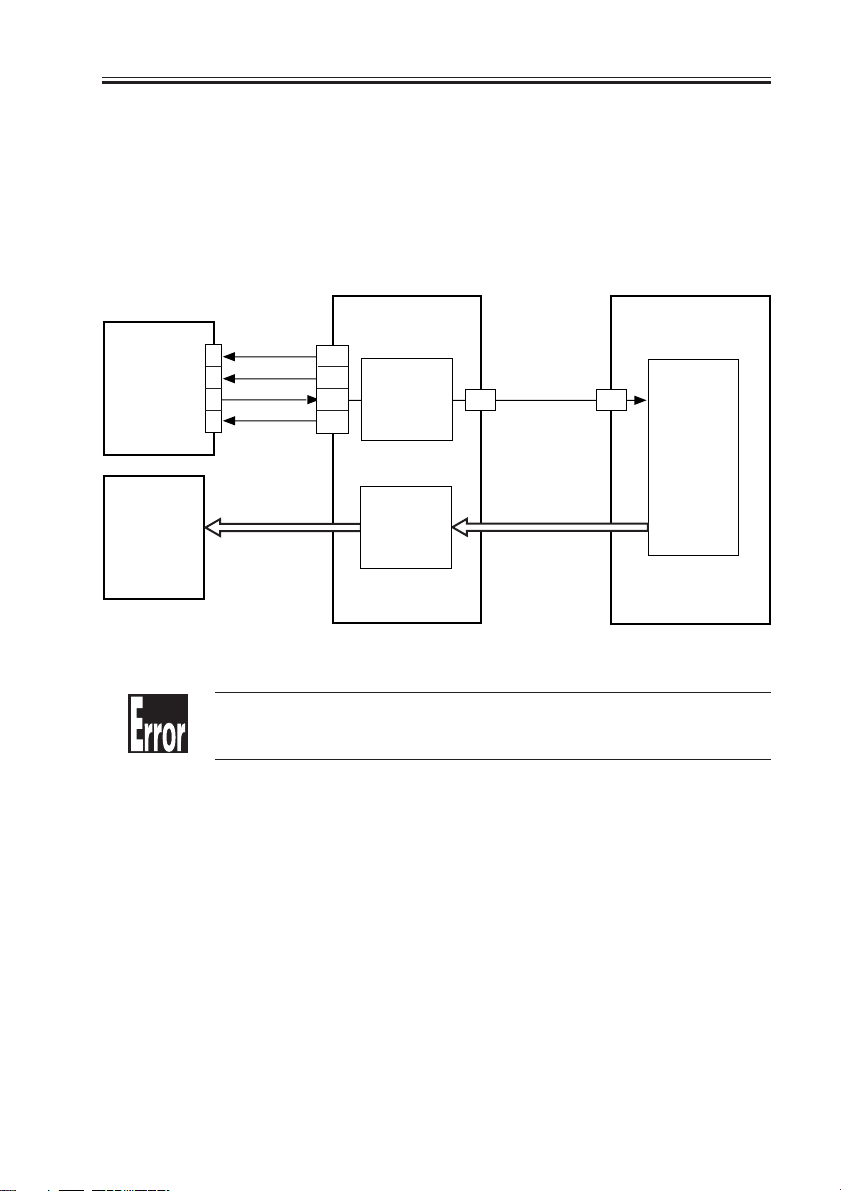

2.2 Flow of Sync signals

[1] The BD signal goes ‘0’ when laser light is detected.

[2] The phase is matched with the phase of the printer, and a sync signal is generated.

[3] Based on the printer sync signal, image data is read from the image memory.

[4] Video signal

[5] The 2-pixel parallel signal is converted into a single-pixel serial signal.

[6] The laser drive signal is used to drive the laser unit to suit the video signal.

J3129 J312

GND

BD PCB

Laser driver

PCB

4

3

2

1

J500

GND

[6]

[1]

5V

J307

B11

B12

B13

B14

Sync signal

generation

[2]

Parallel/

serial

conversion

[5]

A18

J122

J122

[3]

[4]

J1015

A18

Memory

control

J1015

COPYRIGHT

©

DC controller

PCB

Controller assembly

F03-202-01 Flow of Signals

E100

Indicates that the BD signal cannot be detected within a specific period of

time after the laser has been turned on.

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-5

CHAPTER 3 LASER EXPOSURE SYSTEM

3 Laser Driver Circuit

3.1 Controlling the Laser Unit

The laser driver circuit is used to drive the semiconductor laser according to the laser

drive signal from the DC controller PCB.

The laser driver circuit performs the following:

1. Turning on/off the laser.

2. Controlling the light intensity of the laser (APC control).

The signals have the following meanings and functions:

[1] Laser drive signal; used to drive the semiconductor laser.

[2] Sample laser activation signal; used to turn on the laser for intensity sampling (the result

is used for activation for imaging).

[3] Laser enable signal; goes ‘0’ when the laser is ready after the Start key is pressed.

[4] Image leading edge signal; used to start laser writing when paper reaches the image

leading edge sensor (PSS12) mounted in front of the photosensitive drum.

[5] Used to monitor the laser intensity when the laser is turned on for sampling, and feeds

back the level appropriate to the intensity to the laser driver circuit.

[6] Used to control the output so that the feedback level and the reference level from the DC

controller will be identical.

[7] Laser intensity reference signal; used as the laser activation reference level determined

by the DC controller.

[8] Horizontal registration paper detection signal; used to adjust the image position by

changing the timing of laser activation with reference to the result of detection of the

edge of paper re-picked in double-sided mode by the horizontal registration sensor

(PS11).

3-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 3 LASER EXPOSURE SYSTEM

DC controller

PCB

REF.

J307

1

2

3

4

1

2

3

4

5

J310

GND

DATA(+) [1]

DATA(-) [1]

GND

GND

+5V

DAOUT [7]

S/H [2]

LDE [3]

J500

4

3

3

2

2

1

1

J501

5

4

3

2

1

Laser

drive

circuit

Laser assembly

[6]

Laser

Intensity

monitor [5]

Laser driver PCB

Laser unit

J312

INT_TOPO_PD [4]

A14

Image leading edge

(PS12)

J304

A8

Y_REG_PD [8]

sensor

Horizontal registration

paper sensor

(PS11)

F03-301-01

1. The laser power of the laser unit is adjusted when the unit is shipped out

of the factory.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-7

CHAPTER 3 LASER EXPOSURE SYSTEM

DISPLAY>DPOT>LLMT-P

Use it to indicate the laser power voltage control for printer (PDL) images.

DISPLAY>DPOT>LLMT

Use it to indicate the laser power voltage control for the copier.

DISPLAY>DPOT>LPOWER-P

Use it to indicate the result of potential control for the laser intensity during

output of printer (PDL) images.

DISPLAY>DPOT>LPOWER-C

Use it to indicate the result of potential control for laser intensity during

output of copier images.

ADJUST>LASER>PVE-OFST

Use it to adjust the position of laser illumination.

ADJUST>LASER>LA-OFF

Use it to adjust the timing of laser trailing edge de-activation for non-default size papers.

3-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 3 LASER EXPOSURE SYSTEM

4 Controlling the Laser Scanner Motor

4.1 Outline

Part 2> Chapter 4> 4.1 “Outline”

The following items are related to laser scanner motor control:

[1] Laser scanner motor drive signal; when ‘1’, the laser scanner motor goes ON (turning

on/off the motor).

[2] Laser scanner motor ready signal; when ‘0’, the laser scanner motor rotates at a specific

speed (constant speed rotation control).

DC controller

PCB

Main power

supply PCB

[1]

[2]

J3128

4

3

2

1

Speed

control

circuit

Reference

pulse

generation

circuit

Motor

driver

B10

J312

B9

GND

+24V

2

1

J204

F03-401-01 Functional Block Diagram

E110

Indicates the presence of an error in the laser scanner motor.

M10

Laser scanner

motor

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-9

CHAPTER 3 LASER EXPOSURE SYSTEM

5.1 Laser Scanner Assembly

5.1.1 Removing the Laser Unit

1) Remove the delivery tray. (See p. ?.)

2) Open the harness guide [1], and disconnect the two connectors [2].

3) Disconnect the connector [3] of the BD

PCB, and disconnect the two connectors

[4] of the laser PCB.

4) Remove the two springs [1] and the two

stepped screws [2] on the left side, and

remove the two screws [3] (w/washer)

on the right; then, detach the laser unit.

[3]

[2]

[1]

[1]

F03-501-01

[2]

F03-501-02

[1]

[4]

[3]

3-10

When mounting, be sure to do

so while butting it against the

two leaf springs [1] at the front.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

[1]

[1]

F03-501-03

CHAPTER 3 LASER EXPOSURE SYSTEM

When installing the Finisher-J1

(Chapter 10), be sure to attach

the protective sheet [2] along

the line marking [1] on the laser

unit.

[1]

[2]

F03-501-04

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3-11

CHAPTER 4

IMAGE FORMATION SYSTEM

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

1 Outline of Processes

1.1 Outline

T04-101-01 shows the functions of and the methods used in the image formation system:

Item Description

Photosensitive drum OPC (30-mm dia.)

drum cleaning cleaning blade

Developing assembly Developing cylinder (20-mm dia.)

Development method:dry, 1-component, toner projection

Toner:magnetic, negative

Pre-exposure (LAMP2) Fuse lamp (8 pc.)

ON/OFF control (activated in sync with main motor)

Drum sensor (U701) Primary charging roller DC bias corrected to temperature around

photosensitive drum

Environment sensor (S3) Primary charging roller AC bias corrected to suit humidity reading

Primary charging roller auto Pad push-on type

cleaning

Primary charging roller bias DC constant voltage control (-500 to -850 V)

control AC constant current control (2000 to 2300 µA; about 1800 Hz)

Developing bias control DC constant voltage control (0 to -650 V)

AC constant voltage control (810 Vp-p; about 1800 Hz)

Transfer charging roller bias Transfer bias:DC constant current control (switching

control among +15 µA, +10 µA, +7 µA) + DC constant voltage

control (up to 7 kVmax)

Cleaning bias: DC constant voltage control (-2.6 kV)

Transfer guide bias control DC constant voltage (-600 v)

Separation static eliminating DC constant voltage (switching between -2.3 KV and -3.0 KV)

bias control

COPYRIGHT

©

T04-101-01

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-1

CHAPTER 4 IMAGE FORMATION SYSTEM

F04-101-01 shows the major components of the image formation system:

Primary charging roller

Pre-exposure lamp

Developing assembly

Cleaner unit

Photosensitive

drum

Separation static eliminator

Transfer guide

Transfer charging roller

F04-101-01

4-2

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

1.2 Basic Sequence of Operations (image formation system)

• 1 Original, 2 Prints

Control panel

Main power

supply switch ON

AINRT

Main motor

Pre-exposure

lamp

Laser activation

Primary charging

bias

Primary charging

bias

Transfer charging

bias

Image leading

edge sensor

Developing bias

Developing bias

Transfer guide

bias

Separation static

eliminating bias

power switch

ON

STBY

SLEEP

[2]

Start key ON

INRT

[3][1] [3]

[2]

PRINT LSTR

[2]

STBY

COPYRIGHT

©

[1] transfer charging reference bias

[2] transfer charging cleaning bias

[3] transfer sheet-to-sheet interval bias

F04-102-01

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-3

CHAPTER 4 IMAGE FORMATION SYSTEM

2 Controlling the Primar y Charging Roller Bias

2.1 Outline

Part 2>Chapter 5>4.4 “Controlling the Primary Charging Roller Bias”

The machine’s primary charging is a direct charging method that uses a charging roller. In

addition to a DC bias, the charging roller is subjected to an AC bias to ensure stable charging.

The following items relate to the control of primary charging:

[1] Turning on/off the bias.

[2] Controlling the DC bias to a specific level of voltage.

[3] Controlling the AC bias to a specific level of current.

[4] Controlling the photosensitive drum resistance detection mechanism (APVC control).

[5] Controlling the AC bias based on the readings of the environment sensor (humidity) and

the soft counters.

[6] Controlling the DC bias based on the reading of the drum sensor (temperature).

Composite power supply PCB

+24V

signal

J135

J136

-B9

-A10

-A12

Transformer

drive signal

DC bias

output ON

signal

DC bias

output

control signal

Current level

(APVC measure ment)

PW-CPU

Voltage level

Transformer

drive signal

AC bias output

control signal

Primary DC

charging high-

voltage

transformer

(T502)

Output

control

Current

control

charging high-

voltage trans

Drive

control

Primary AC

former

Voltage

detection

Current

detection

DC bias

output

AC bias

output

Primary

charging roller

J130-4

Photosensitive

Drum sensor

(temperature)

drum

24 VDC input

Primary charging

J301

output enable

-B4

Serial communication

Print/standby mode signal

AC bias level signal

DC bias level signal

APVC measurement data

-A3

DC controller PCB

-A1

4-4

J311-A2

J302-B14

Memo

Environment

sensor

Measurement result

Measurement result

(humidity)

F04-201-01

The primary charging output enable signal is used as the AC pulse ON signal when the developing bias is being controlled.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

2.2 Turning On/Off the Bias

The primary charging roller bias is turned on/off as follows:

2.2.1 DC Bias

[1] When the primary charging output enable signal from the DC controller PCB goes ‘0’,

the DC bias output control signal (pulse signal) is generated.

[2] The DC bias is sent to the primary charging roller.

2.2.2 AC Bias

[1] When the primary charging output enable signal from the DC controller PCB goes ‘0’,

the AC bias output control signal is generated.

[2] The AC bias is generated to the primary charging roller.

2.3 Controlling the Current Voltage/Current to a Specific Level

The output level of the DC/AC bias applied to the primary charging roller is controlled by

the DC/AC bias output control signal from the PW-CPU.

2.3.1 Controlling the DC Bias to a Specific Level

[1] The output voltage level of the DC bias is fed back to the PW-CPU, and the DC bias

output control signal is varied as needed to suit the level when driving the transformer.

[2] The DC bias is made to assume a specific voltage level.

2.3.2 Controlling the AC Bias to a Specific Current Level

[1] The output current level of the AC bias is communicated to the drive control circuit and

is compared against the reference current level; the result is used to vary the AC bias

output control signal as needed to drive the transformer.

[2] The AC bias is made to assume a specific current level.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-5

CHAPTER 4 IMAGE FORMATION SYSTEM

2.4 Temperature Correction of the DC Bias

When the temperature inside the machine increases, the resistance of the photosensitive

drum will decrease, thereby lowering the charging characteristics. To ensure a stable potential level, the drum sensor (U701) mounted to the rear side plate is used to check the temperature inside the machine; when the temperature increases, the absolute value of the DC

bias level is increased.

-800V

-750V

Primary DC bias

(reference

value)

Low

23˚C 40˚C

Machine inside temperature

High

F04-204-01

2.5 Humidity Correction of the AC Bias

The current level of the AC bias needs to be kept on the higher side to prevent uneven

charging because of a lower changing efficiency occurring in a low-humidity environment.

The AC bias, therefore, is varied as shown in F04-205-01 to suit the readings of the environment sensor (humidity). When the resistance of the drum surface decreases because of advancing wear, the current level is decreased to facilitate the flow of current.

Counter reading: 0 to 10,000 sheets Counter reading: 10,001 or higher

2300µA

2150µA

2000µA

Primary AC bias

Low

35%

Humidity

High

F04-205-01

Low

35%

Humidity

High

4-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

2.6 Controlling the Detection of the Photosensitive Drum Resistance (APVC control)

The primary charging efficiency changes because of changes in the site environment (temperature, humidity), deterioration of the charging roller, and wear of the photosensitive

drum. The reference voltage is applied to the charging roller when the main power switch is

turned on, and the resulting output current level is measured for correction.

[1] When the main power switch is turned on, the reference voltage is applied to the charg-

ing roller, and the output is measured as the current level for use as feedback to the PWCPU.

[2] The photosensitive drum is charged (primary charging) using the voltage level deter-

mined by the PW-CPU.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-7

CHAPTER 4 IMAGE FORMATION SYSTEM

2.7 Controlling the Output Mode

In continuous print mode, the outputs of both AC bias and DC bias are varied between

image areas and non-image areas to prevent stray toner in the non-image areas.

E064

Indicates the presence of a high-voltage (primary charging, transfer charging, developing) output fault.

COPIER>DISPLAY>HV-STS>PRIMARY

Use it to indicate the current level of primary charging.

COPIER>ADJUST>HV-PRI>P-DC

Use it to enter the adjustment value of the primary charging DC component

for the image area.

COPIER>ADJUST>HV-PRI>P-AC

Use it to enter the adjustment value of the primary charging AC component

for the image area.

COPIER>ADJUST>HV-PRI>AGS-GAIN

Use it to enter the gain adjustment value of the application voltage level

correction for the primary charging bias.

CCOPIER>ADJUST>HV-PRI>AGS-OFST

Use it to enter the offset adjustment value of the application voltage level

correction for the primary charging bias.

CCOPIER>ADJUST>HV-PRI>OFST1-DC

Use it to enter the adjustment value of offset 1 for the primary charging DC

component.

CCOPIER>ADJUST>HV-PRI>OFST1-AC

Use it to enter the adjustment value of offset 1 for the primary charging AC

component.

CCOPIER>ADJUST>HV-PRI>P-AC2

Use it to enter the adjustment value of primary charging AC component 2 of

the image area.

CCOPIER>ADJUST>HV-PRI>P-AC3

Use it to enter the adjustment value of primary charging AC component for

the image area.

4-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

3 Controlling the Transfer Charging Roller Bias

3.1 Outline

Part 2>Chapter 5>7.8.3 “Controlling the Transfer Roller”

The machine’s transfer charging is a direct charging method that uses a transfer charging

roller. A DC bias is applied to the transfer charging roller.

The following relate to the transfer charging system:

[1] Turning on/off the bias.

[2] Controlling the DC bias to a specific voltage/current level.

[3] Controlling the detection of transfer charging roller resistance (ATVC control)

[4] Controlling the output by operation mode

[5] Controlling the output by the environment sensor (humidity)

Composite power supply PCB

+24V

24 VDC input

Transfer

charging

J301

output enable

-B9

Transfer output

mode signal 4

-B8

communication

Print/standby mode signal

Transfer bias output data

ATVC measurement data

-A3

-A1

Transfer output

DC controller PCB

mode signal 1

-B5

Transfer output

mode signal 2

-B6

Transfer output

mode signal 3

-B7

signal

Serial

J135

J136

-B4

-B5

-A10

-A12

-B8

-B7

Transfer bias output

current switching signal

-B6

Transformer drive

signal

Cleaning bias output

ON signal

Voltage level

(ATVC measurement result)

Voltage

detection

Transformer drive

signal

PW-CPU

Transfer bias output

ON signal

Transfer bias

output control

signal

Drive

control

Transfer cleaning

bias high-voltage

transformer

(T506)

Transfer bias

high-voltage

transformer

(T133)

Current

level

Cleaning

Transfer

output

Current

detection

bias out

bias

Photosensitive

T133

Transfer

charging roller

Environment

(humidity)

drum

sensor

COPYRIGHT

©

Measurement resultJ302-B14

F04-301-01

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-9

CHAPTER 4 IMAGE FORMATION SYSTEM

3.2 Turning On/Off the Bias

The transfer charging roller bias is turned on/off as follows:

[1] When the transfer charging output enable signal from the DC controller PCB goes ‘0’,

the transfer bias output signal (serial communication) is generated.

[2] The transfer bias output control signal (pulse) is generated, and the DC bias is sent to

the transfer charging roller.

3.3 Controlling the Detection of the Transfer Charging Roller

Resistance (ATVC control)

The transfer charging efficiency changes because of changes in humidity and deterioration in the transfer charging roller. The reference current is applied to the transfer charging

roller during initial multiple rotation after the main power switch is turned on, and the resulting output voltage is measured for correction.

[1] The reference current is applied to the transfer charging roller, and the output is checked

as a voltage level for use as feedback to the PW-CPU.

[2] The transfer charging mechanism operate using the voltage level determined by the PW-

CPU.

4-10

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

3.4 Controlling the Output by Operating Mode

3.4.1 Types of Modes

The transfer charging output may be any of the following output modes, and the output is

varied to suit each mode. The switch-over among these is based on the combination of transfer output mode signals from the DC controller PCB.

a. Image Transfer Bias

This bias is used to transfer toner from the photosensitive drum to paper, and is a positive

voltage.

b. Cleaning Bias

This bias is used to return toner sticking to the transfer charging roller to the photosensitive drum, and applies a negative voltage.

• During initial rotation after the Start key is pressed

• During last rotation

• During initial rotation after jam removal or error resetting

• During execution of roller cleaning in user mode (‘adjust/clean’; in this case, the pri-

mary charging roller is also cleaned)

• During multiple rotation after the main power switch is turned on

c. Reference Bias

This bias is used to control the detection of the photosensitive drum, and is applied during

multiple initial rotation after the main power switch is turned on.

d. Sheet-to-Sheet Interval Bias

This bias is used in a non-image area (between sheets) in continuous print mode; the bias

level is reduced to prevent adhesion of toner to the transfer charging roller.

E064

Indicates the presence of a high-voltage (primary charging, transfer charging, development) output fault.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-11

CHAPTER 4 IMAGE FORMATION SYSTEM

Control panel

Main power

switch ON

AINTR

Main motor (M1)

Cleaning bias

Reference bias

Sheet-to-sheet

bias

Image transfer

bias

power switch

ON

STBY

SLEEP

Start key ON

INTR

PRINT

LSTR STBY

F04-304-01

3.4.2 Turning On/Off the Cleaning Bias

When the cleaning bias output ON signal (composite power supply PCB) goes ‘1’, the

output of the transfer cleaning bias transformer is applied to the transfer charging roller.

4-12

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

3.5 Controlling the Output

The output of the DC bias applied to the transfer charging roller is controlled as follows:

The optimum transfer charging roller bias differs depending on paper size and site environment; as such, the DC controller is designed to automatically control the output level to suit

the paper size and the site environment in question.

COPIER>DIPLAY>HV-STS>TR

Use it to indicate the current level of transfer charging.

COPIER>DIPLAY>HV-STS>TR-V

Use it to indicate the voltage level of the transfer charging roller resistance

detection.

COPIER>ADJUST>HV-TR>TR-N1

Use it to enter the output adjustment value for transfer charging (plain paper; single-sided print or 1st side of double-sided print).

COPIER>ADJUST>HV-TR>TR-N2

Use it to enter the output adjustment value for transfer charging (plain paper; 2nd side of double-sided print)

COPIER>ADJUST>HV-TR>TR-OFST

Use it to enter the offset output adjustment value for transfer charging roller

resistance detection.

COPIER>ADJUST>HV-TR>TR-SPP

Use it to enter the output adjustment value for transfer charging (special paper; single-sided print and double-sided print)

COPIER>OPTION>BODY>TRANS-SW

Use it to set the transfer charging roller bias output control method for

large-size paper.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-13

CHAPTER 4 IMAGE FORMATION SYSTEM

4 Controlling the Separation Static Eliminator Bias

4.1 Outline

Part 2>Chapter 5>8.3 “Separation by the Static Eliminator”

The machine uses a static eliminator for separation. A DC bias is applied to the static

eliminator; the following are items of control:

[1] Turning on/off the bias

[2] Controlling the bias to a specific voltage level

[3] Controlling the output to suit paper type and reading by the environment sensor (humid-

ity)

Composite power supply PCB

+24V

Static

J135

J136

-B10

Transformer

drive signal

Static

eliminator bias

output ON signal

PW-CPU

Static eliminator bias

mode signal

High-voltage

main

transformer

(T504)

Output

control

Voltage

level

Voltage

detection

Static

eliminator

bias output

Photosensitive

drum

J132

Separation

static eliminator

24 VDC input

J301

eliminator bias

-B3

enable signal

Serial communication

Print/standby mode signal

Static eliminator bias

DC controller PCB

mode signal

4-14

-A3

-A1

-A10

-A12

COPYRIGHT

F04-401-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

4.2 Turning On/Off the Bias

The separation static eliminator bias is turned on/off as follows:

[1] When the static eliminator bias enable signal from the DC controller PCB goes ‘0’, the

static eliminator bias output ON signal is generated.

[2] A DC bias is sent to the separation static eliminator.

4.3 Controlling the Bias to a Specific Voltage Level

The bias output is fed back to the output control circuit, thereby ensuring a specific level

of voltage.

4.4 Controlling the Output by Paper Type and Environment

Sensor (humidity)

In a low-humidity environment, separation can fail when thin paper is used or when the

second side of a double-sided sheet is hadled. To ensure good separation, the voltage applied is increased between -2.3 and -3.0 KV with reference to the type of paper and the

reading of the environment sensor (humidity).

The selection of an application voltage is done in response to the static eliminator bias

mode signal (serial communication) from the DC controller PCB.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-15

CHAPTER 4 IMAGE FORMATION SYSTEM

5 Controlling the Transfer Guide Bias

5.1 Transfer Guide Bias

Part 2>Chapter 5>7.2 “Transfer Guide Method”

The transfer guide bias is used to prevent adhesion of toner to the transfer guide, and is a

negative component (-600 VDC), which is of the same polarity as the toner.

The transfer guide bias is continuously applied as long as printing is under way.

Composite power supply PCB

+24V

24 VDC input

J135

Serial communication

Print/standby mode signal

DC controller PCB

J301

-A3

-A1

J136

-A10

-A12

Transformer

drive signal

PW-CPU

High-voltage

main transformer

F04-501-01

(T504)

Transfer

guide output

Photosensitive

drum

J131-3

Transfer

guide

4-16

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

6 Primar y Charging Roller Cleaning Mechanism

6.1 Outline

Part 2>Chapter 5>10.1.5 “Primary Charging Roller Cleaning Mechanism”

The machine’s primary charging roller is cleaned by turning on the primary charging

roller cleaning solenoid (SL6) while the primary charging roller is rotating, thereby butting

the cleaning pad against the primary charging roller. At the same time, the cleaning pad is

moved back and forth in the axial direction of the primary charging roller.

Cleaning is executed under the following conditions:

• During last rotation after the cumulative count reaches 500 sheets

• During execution of roller cleaning in user mode (‘adjust/clean’; in this case, the clean-

ing bias is applied to the transfer charging roller pad for cleaning)

SL6 (ON)

Back-and-forth

movement

COPYRIGHT

©

Cleaning pad

Primary charging roller

Photosensitive drum

F04-601-01

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-17

CHAPTER 4 IMAGE FORMATION SYSTEM

7 Developing Assembly

7.1 Outline

The developing assembly consists of the developing cylinder, toner sensor (S1), and toner

stirring rod; its is locked manually together with the developing rail using the locking lever.

The developing cylinder and the toner stirring rod are rotated by the drive of the main mo-

tor (M1) transmitted by way of the developing clutch (CL3).

Developing bias

control signal

J301 J136

DC controller PCB

Main motor drive signal

J308

J302-5

Developing bias

J130-1

PW-CPU

supply PCB

Composite power

Photosensitive

Main

motor

M1

F04-701-01

Developing cylinder

drum

Toner sensor(S1)

Developing

clutch

CL3

Toner detention signal

Toner stirring rods

4-18

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

7.2 Controlling the Developing Bias

7.2.1 Outline

Both DC bias and AC bias are applied to the developing cylinder. The output is controlled

by the composite power supply PCB based on the control signal from the DC controller

PCB.

The following relate to the developing bias control system:

[1] Controlling the DC developing bias to a specific voltage level

[2] Controlling the AC developing bias to a specific voltage level

Composite power supply PCB

Photosensitive

drum

Developing

24 VDC input

DC bias

J301

ON signal

-B1

AC pulse

ON signal

-B4

communication

DC bias level signal

-A3

-A1

DC controller PCB

Serial

J135

J136

-B12

-A10

-A12

-B9

+24V

Transformer

drive signal

PW-CPU

Transformer

drive signal

High-voltage

main

transformer

(for DC)

DC bias control signal

Voltage level

Developing

high-voltage

transformer

(for AC)

Output

control

AC bias

Voltage

detection

J130-1

cylinder

-B2 -B11

Memo

COPYRIGHT

©

AC bias

ON signal

F04-702-01

The AC pulse ON signal is used as the primary charging output enable signal when controlling primary charging.

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-19

CHAPTER 4 IMAGE FORMATION SYSTEM

7.2.2 Controlling the DC Developing Bias

[1] When the DC bias ON signal from the DC controller PCB goes ‘0’, the bias control sig-

nals (pulse signals) are generated by the PW-CPU of the high-vole power supply PCB.

[2] The DC bias from the high-voltage main transformer is applied to the developing cylin-

der.

[3] The output voltage level of the DC bias is fed back to the HV-CPU.

[4] The pulse width of the DC control signal is varied to suit the return voltage, thereby

maintaining the DC bias to a specific level.

7.2.3 Controlling the AC Dev eloping Bias

[1] When the AC bias ON signal and the AC pulse ON signal from the DC controller PCB

goes ‘0’, the AC transformer is driven.

[2] An AC bias is added to the DC bias and applied to the developing cylinder.

7.2.4 Controlling the Level of the DC Developing Bias

the level of the DC developing bias is varied between image area and non-image area to

prevent stray toner inside the machine.

In memory copy mode, the laser is driven based on binary image data which lacks density

information, not enabling adjustment using a density correction curve for the density of the

image being generated. To make up for the lack, the DC developing bias is varied for density adjustment.

E064

Indicates the presence of a high-voltage (primary charging, transfer charging, development) output fault.

4-20

COPIER>ADJUST>DEVELOP>DE-DC

Use it to enter the adjustment value of the developing bias DC component

for the image area.

COPIER>ADJUST>DEVELOP>DE-OFST

Use it to enter the offset value for the developing bias DC component.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

7.3 Detecting the Level of Toner

Part 2>Chapter 5>6.2.2 “Piezoelectric Sensor”

A toner sensor (S1) of a piezoelectric oscillation type is mounted inside the developing

assembly for detection of the level of toner. The DC-CPU on the DC controller PCB reads

the output of the toner sensor as long as the developing clutch (CL3) remains on; it keeps

track of the ‘0’ state of the toner sensor (most recent two readings), and indicates the Add

Toner message as needed.

toner absent level 2

Toner absent level 1

The cumulative period of

absence of toner fro the

most recent two readings

is 7 sec or more,

Copying

FAX reception

FAX transmission

Printer output

enabled

enabled

enabled

enabled

The cumulative period of

absence of toner for the

most recent two readings

is 20 sec or more,

Copying

FAX reception

FAX output

Printer output

disabled

enabled

disabled

disabled

Check point

Developing clutch

(CL3)

Toner sensor(S1)

2 sec

OK

(6 sec in total)

4 sec

When the power switch is

turned off and then on,

recovery occurs after

stirring the toner for 6 sec.

NG

(8 sec in total)

4 sec

(5 sec in total)

F04-703-01

OK

22 sec

1 sec

When the power switch is turned

off and then on, the presence of

toner is detected; recovery occurs

after stirring the toner for 30 sec.

NG

(22 sec)

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-21

CHAPTER 4 IMAGE FORMATION SYSTEM

8 Drum Cleaner

8.1 Outline

The drum cleaner assembly is rotated by the drive of the main motor (M1) transmitted

through drive gears; the waste toner is colleted by the cleaning blade, and is sent to the

waste toner case using the waste toner feedscrew.

The amount of waste toner inside the waste toner case is monitored by the waste toner

case full sensor (S2); when the amount exceeds a specific level, the Waste Toner Full message will be indicated on the control panel.

Waste toner

feedscrew

Waste toner case full

sensor (S2)

S2

4-22

Waste toner box

COPYRIGHT

Main motor

M1

Waste toner case full signal

J311-B9

DC controller PCB

J308

F04-801-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

Main motor

M1

CHAPTER 4 IMAGE FORMATION SYSTEM

Waste toner case

full sensor

(S2; light-receiving)

Cleaning blade

Photosensitive drum

Waste toner case

full sensor

(S2; light-emitting)

Waste toner feedscrew

Waste toner case

F04-801-02

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-23

CHAPTER 4 IMAGE FORMATION SYSTEM

8.2 Monitoring the Waste Toner Case

The machine checks the waste toner case in reference to two levels.

The amount of waste toner inside the waste toner case is monitored by the waste toner

case full sensor (S2); the sensor is a pair of photosensors (light-emitting unit piece and

light-receiving piece). The machine will assume that the waste toner case has become full

when waste toner blocks the light between the two photosensors.

The DC controller PCB checks the waste toner case full sensor when the power is tuned

on and at time of delivery; it will assume a “waste toner full warning” after making a total of

100 prints (A4/LTR) after the waste toner case has become full, thereby indicating the Waste

Toner Case Full message on the control panel.

Thereafter, if the waste toner case is not replaced after making a total of about 2000 prints

(A4/LTR), the machine will indicate ‘E019’ on the control panel; the error code can be reset

by replacing the waste toner case and then turning off and then on the power switch.

If the waste toner case is not set, the light-blocking plate will block the light between the

photosensors, causing the Waste Toner Case Full message to appear.

The light between the photosensors is not visible to the eye.

Memo

DC controller PCB

Waste toner case

full sensor

(light-receiving)

4-24

Waste toner case

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

Waste toner case full signal

Waste toner case

full sensor

(light-emitting)

F04-802-01

+5V

J311-B7

-B9

a-B8

CHAPTER 4 IMAGE FORMATION SYSTEM

8.3 Locking of the Waste Toner Feedscrew

The waste toner feedscrew is rotated by the drive of the main motor transmitted by the

coupling built into the main motor drive assembly. The coupling is butted against the gear

used to rotate the screw by the work of a spring.

If the drum cleaning assembly is clogged with waste toner, the coupling will start to move

back and forth in the axial direction, causing a clicking sound.

The machine is not equipped with a sensor to detect the locking of the

Memo

Main motor

M1

waste toner feedscrew.

Photosensitive drum

Spring

Memo

COPYRIGHT

©

Coupling

Waste toner feedscrew

F04-803-01

E019

Indicates that the waste toner case is full.

The waste toner case can hold waste toner equivalent of about 200,000

prints.

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-25

CHAPTER 4 IMAGE FORMATION SYSTEM

9.1 Pre-Exposure Lamp Unit

9.1.1 Handling of the Pre-Exposure Lamp Unit

1) Remove the drum unit. (See p. $.)

2) Remove the inside cover. (See p. $.)

3) Disconnect the connector [1], and remove the screw [2].

4) Take out the pre-exposure lamp unit [3].

[1]

[3]

F04-901-01

[2]

4-26

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

9.2 Photosensitive Drum

9.2.1 Removing the Drum Unit

1) Open the front cover.

2) Release the feeding assembly.

3) Release the developing assembly.

4) Remove the fixing screw [1].

5) Slide out the drum unit [2] slowly to the

front.

Take care not to damage or soil

the photosensitive drum.

Further, be sure to protect the

photosensitive drum against

light once it is outside the machine; it is highly susceptible to

light.

As many as 19 stirrups [1] (4

types) are attached to the bottom of the drum unit. Take care

not to crush them.

Further, be sure to place the

drum unit on a flat surface once

it has been removed out of the

machine.

CHAPTER 4 IMAGE FORMATION SYSTEM

[2]

[1]

F04-902-01

[1]

COPYRIGHT

©

F04-902-02

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-27

CHAPTER 4 IMAGE FORMATION SYSTEM

9.2.2 Cleaning the Photosensitive Drum

If the surface of the photosensitive drum

has become soiled, wipe it with a flannel

cloth coated with toner. (Do not use paper,

lint-free or otherwise.)

Never dry-wipe the photosensitive drum or use solvent.

9.2.3 When Replacing the Drum Unit

Be sure to record the date of replacement

and the latest counter reading to the label

[1], and attach it to the front cover of the

drum unit; then, make adjustments according to the Image Adjustment Basic Procedure (p. $).

After replacing the drum unit,

be sure to perform the work under 7.7 “Removing Paper Lint.”

[1]

F04-902-03

4-28

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

CHAPTER 4 IMAGE FORMATION SYSTEM

9.3 Transfer Charging Roller

9.3.1 Removing the Transfer Charging Roller

Do not touch the surface of the

transfer charging roller when

removing it. Otherwise, image

faults can occur.

1) Remove the feeding assembly. (See p.

$.)

2) Pull off the static eliminator [1].

3) Remove the screw [2], and detach the

hinge bin [3].

[3]

[2]

[1]

F04-903-01

4) Remove the transfer arm [1] equipped

with a spring to the left together with

the transfer charging roller [2].

5) Pull it off to the front.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

[3]

[1]

F04-903-02

[2]

(1)

(2)

[4]

4-29

CHAPTER 4 IMAGE FORMATION SYSTEM

9.4 Charging Roller Solenoid

9.4.1 Removing the Charging

Roller Solenoid (SL6)

1) Remove the photosensitive drum. (See

p. $.)

2) Open the rear cover. (7 screws)

3) Remove the DC controller PCB. (see p.

$.)

4) Remove the four screws [1], and detach

the DC controller base [2].

[1]

[1]

[2]

5) Disconnect that two connectors [1] of

the harness.

6) Remove the three screws [2], and pull

out the duct unit [3] to the front.

7) Remove the claw, and detach the two

relay PCBs [1].

[1]

[2]

F04-904-01

[1]

[2]

F04-904-02

[1]

[1]

[3]

4-30

COPYRIGHT

F04-904-03

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

8) Remove the faston [1] of the harness,

and detach the duct unit [2].

CHAPTER 4 IMAGE FORMATION SYSTEM

[1]

[2]

F04-904-04

9) Remove the two screws [1], and disconnect the connector [2]; then, detach the

charging roller solenoid [3].

[1]

[2]

[3]

F04-904-05

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-31

CHAPTER 4 IMAGE FORMATION SYSTEM

9.5 Developing Assembly

Keep the following in mind

when disassembling/assembling

the developing assembly:

1. When holding the developing

assembly, avoid touching the

developing cylinder.

2. After mounting the developing assembly, be sure to

mount the developing assembly stopper.

3. The blade and the blade base

of the blade base unit are adjusted at the factory to a high

accuracy; do not separate

them.

9.5.1 Removing the Developing Assembly

1) Open the front cover.

2) Shift down the developing assembly releasing lever [1] to free the developing

assembly [2].

3) Remove the screw [3], and lift the bottom of the developing assembly stopper

[4] to the front to remove it to the bottom.

4) Holding the grip of the developing assembly with one hand and supporting it

on its bottom with the other, pull it to

the front.

[3]

[2]

4-32

COPYRIGHT

[4]

(1)

[4]

(2)

[1]

F04-905-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

9.5.2 Removing the Grip Assembly

1) Remove the developing assembly. (See

p. $.)

2) Remove the screw [1] and the three

claws [23], and detach the grip assembly [3].

CHAPTER 4 IMAGE FORMATION SYSTEM

[3]

[1]

F04-905-02

9.5.3 Removing the Tone Sensor

[3]

1) Remove the grip assembly. (See 7.6.2.)

2) Remove the two screws [1], and disconnect the connector [2].

3) Detach the toner sensor [3].

F04-905-03

9.5.4 Removing the Developing Assembly Upper Cover

1) Remove the grip assembly. (See 7.6.2.)

2) Remove the two screws [1] and the

three claws [2].

3) Remove the developing assembly upper

cover [3].

[2]

[2]

[1]

[2]

COPYRIGHT

©

[1]

F04-905-04

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

[3]

4-33

CHAPTER 4 IMAGE FORMATION SYSTEM

9.5.5 Removing the Developing Cylinder

1) Remove the developing assembly upper

cover. (See p. $.)

2) Remove the two screws [1], and detach

the blade base unit [2].

[2]

The blade [1] and the blade base

[2] of the blade base unit are assembled to a high accuracy at

the factory. Do not separate

them.

9.5.6 Developing Assembly Cylinder

1) Remove the developing assembly upper

cover. (See p. $.)

2) Remove the E-ring [1], bearing [2], and

gear [3].

[1]

F04-905-05

[2]

[1]

F04-905-06

4-34

COPYRIGHT

[1]

[2]

[3]

F04-905-07

©

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

3) Remove the two screws [1], and detach

the gear cover [2].

4) Remove the two gears [3].

CHAPTER 4 IMAGE FORMATION SYSTEM

[2]

[1]

[3]

F04-905-08

5) Put copy paper [3] between the developing cylinder [1] and the blade [2].

6) Remove the screw [1] and the grounding plate [2].

7) Remove the grip ring [3].

[1]

F04-905-09

[3]

[2]

[3]

[1]

[2]

COPYRIGHT

©

F04-905-10

2001 CANON INC. 2000 2000 2000 2000 CANON iR3300/2800/2200 REV.0 JAN. 2001

4-35

CHAPTER 4 IMAGE FORMATION SYSTEM

8) Remove the two screws [1], and detach

the member [2] and the front sleeve

holder [3].

9) Remove the two screws [1], and detach

the member [2] and the rear sleeve

holder [3].