Canon FC200, FC220, PC400, PC420, PC430 Service Handbook

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

SERVICE HANDBOOK

REVISION 0

FY8-23AV-000

JAN.1998

Use of this manual should be strictly

supervised to avoid disclosure of

confidential information.

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A

SOURCE OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY

SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND

OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE

DIRECTED TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1998 CANON INC.

Printed in Japan

Imprimé au Japon

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302 Japan

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Periodically Replaced Parts.........1-1

B. Durables.......................................1-1

C. Periodical Servicing.....................1-1

D. Notes on Cartridge.......................1-2

1. Storing Sealed Cartridges.......1-2

2. Storing and Handling Unsealed

Cartridges ...............................1-3

E. Image Adjustment Basic Procedure

.....................................................1-5

F. Points to Note ..............................1-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Mechanical...................................2-1

1. Image Leading Edge Non-Image

Width (position of white paint on

back of glass)..........................2-1

2. Image Leading Edge Margin

(point of detection for registration)

................................................2-1

B. Electrical ......................................2-2

1. Adjusting the Intensity (VR604)

................................................2-2

2. Adjusting the AE Mechanism

(VR602, VR603) .....................2-4

CHAPTER 3 IMAGE TROUBLESHOOTING

A. Making Initial Checks...................3-1

1. Site Environment ....................3-1

2. Checking the Documents........3-1

3. Checking the Copyboard Cover

and Copyboard Glass for Dirt

and Scratches.........................3-2

4. Checking the Lens Array for Dirt

................................................3-2

5. Checking the Transfer Charging

Roller ......................................3-2

6. Checking the Feeding Assembly

................................................3-2

7. Checking the Copy Paper.......3-2

8. Checking the Durables ...........3-2

9. Others.....................................3-4

B. Samples of Image Faults.............3-6

C. Troubleshooting by Image Fault

.....................................................3-7

1. The copy is too light (halftone

areas only)..............................3-7

2. The copy is too light (dark areas

as well)....................................3-7

3. The copy is too light (extremely

light overall). ...........................3-7

4. The copy has uneven density

(darker at front).......................3-8

5. The copy has uneven density

(lighter at front). ......................3-8

6. The copy is foggy (overall)......3-8

7. The copy is foggy (paper feed

direction).................................3-9

8. The copy has dark lines (paper

feed direction, relatively narrow).

................................................3-9

9. The copy has dark lines (paper

feed direction, thin).................3-9

10. The copy has white spots (paper

feed direction).........................3-9

11. The copy has white lines (paper

feed direction).........................3-9

12. The copy has white spots (cross

feed direction).......................3-10

13. The back of the copy is soiled.

..............................................3-10

1

2

3

4

5

6

7

14. The copy has faulty fixing......3-11

15. The copy has faulty leading

edge registration (blank area

much too wide)......................3-11

16. The copy has faulty leading

edge registration (blank area too

wide)......................................3-11

17. The copy has faulty leading

edge registration (no blank area)

..............................................3-11

18. The copy has a blurred image.

..............................................3-12

19. The copy is foggy (cross feed

direction)...............................3-12

20. The copy has poor sharpness

(focus)...................................3-12

21. The copy is blank..................3-13

22. The copy is solid black..........3-13

CHAPTER 4 TROUBLESHOOTING MALFUNCTIONS

A. Troubleshooting Malfunctions......4-1

1. (self diagnosis;PC400/FC200)

......................................4-1

2. E0 ...........................................4-1

3. E2 ...........................................4-2

4. E6 ...........................................4-2

5. E9 ...........................................4-3

6. AC power is absent.................4-3

7. Pick-up fails. ...........................4-4

8. The scanning lamp fails to go

ON. .........................................4-4

9. The main motor fails to rotate.

................................................4-5

10. The copyboard fails to move.

................................................4-5

11. (paper feeding normally) ....4-6

12. (at time of jam) ...................4-6

13. The fixing heater fails to operate

................................................4-6

CHAPTER 5 TROUBLESHOOTING PAPER FEED PROBLEMS

A. Copy Paper Jams ........................5-1

1. Pick-Up Assembly...................5-2

2. Separation/Feeding Assembly

................................................5-2

3. Fixing/Delivery Assembly

................................................5-3

B. Feeding Faults.............................5-4

1. Double Feeding ......................5-4

2. Wrinkles..................................5-4

CHAPTER 6 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

A. Sensors and Solenoids................6-1

B. Switches.......................................6-2

C. Lamp, Heater, Motor, and Others

.....................................................6-3

D. Printed Circuit Board (PCB).........6-4

ii

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

E. Variable Resistors (VR) and Check

Pins by PCB.................................6-5

1. DC Controller/DC Power Supply

PCB ........................................6-5

2. Control Panel PCB..................6-6

CHAPTER 7 SELF DIAGNOSIS

Self Diagnosis.....................................7-1

APPENDIX

A. General Timing Chart...................A-1

B. Signals/Abbreviations List............A-3

1. Signals....................................A-3

2. Abbreviations..........................A-4

C. General Circuit Diagram...............A-5

D. Special Tools Table.......................A-7

E. Solvents/Oils Table.......................A-8

F. Specifications...............................A-9

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

iv

CHAPTER 1 MAINTENANCE AND INSPECTION

1-1

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Periodically Replaced Parts

The machine does not have parts which must be replaced on a periodical basis.

B. Durables

The machine does not have parts which are classified as durables.

C. Periodical Servicing

The machine does not have parts that require periodical servicing.

1

CHAPTER 1 MAINTENANCE AND INSPECTION

Normal

(9/10 of period)

0° to 35°C/

32° to 95°F

35° to 40°C/

95° to 104°F

-20° to 0°C/

-4° to 32°F

High

Low

Severe (1/10

of period)

Temperature

Temperature fluctuations

(within about 3 min)

40° ➝ 15°C/

104° ➝ 59°F

-20°C ➝ 25°C/

-4°F ➝ 77°F

Normal

(9/10 of period)

35 to 85%RH

85 to 95%RH

HighSevere (1/10

of period)

Humidity

10 to 35%RHLow

Atmospheric pressure

460 to 760 mmHg

(0.1 to 1 atm)

Temperature

-20° to 40°C/-4° to 104°F

Humidity

90% or less

D. Notes on Cartridge

The cartridge is affected by the environment, regardless of whether it is sealed or

unsealed and installed in the machine or otherwise. Although the properties of the

cartridge change over time independent of how many copies have been made, the

degree of care taken for the cartridge affects how long it may remain stable.

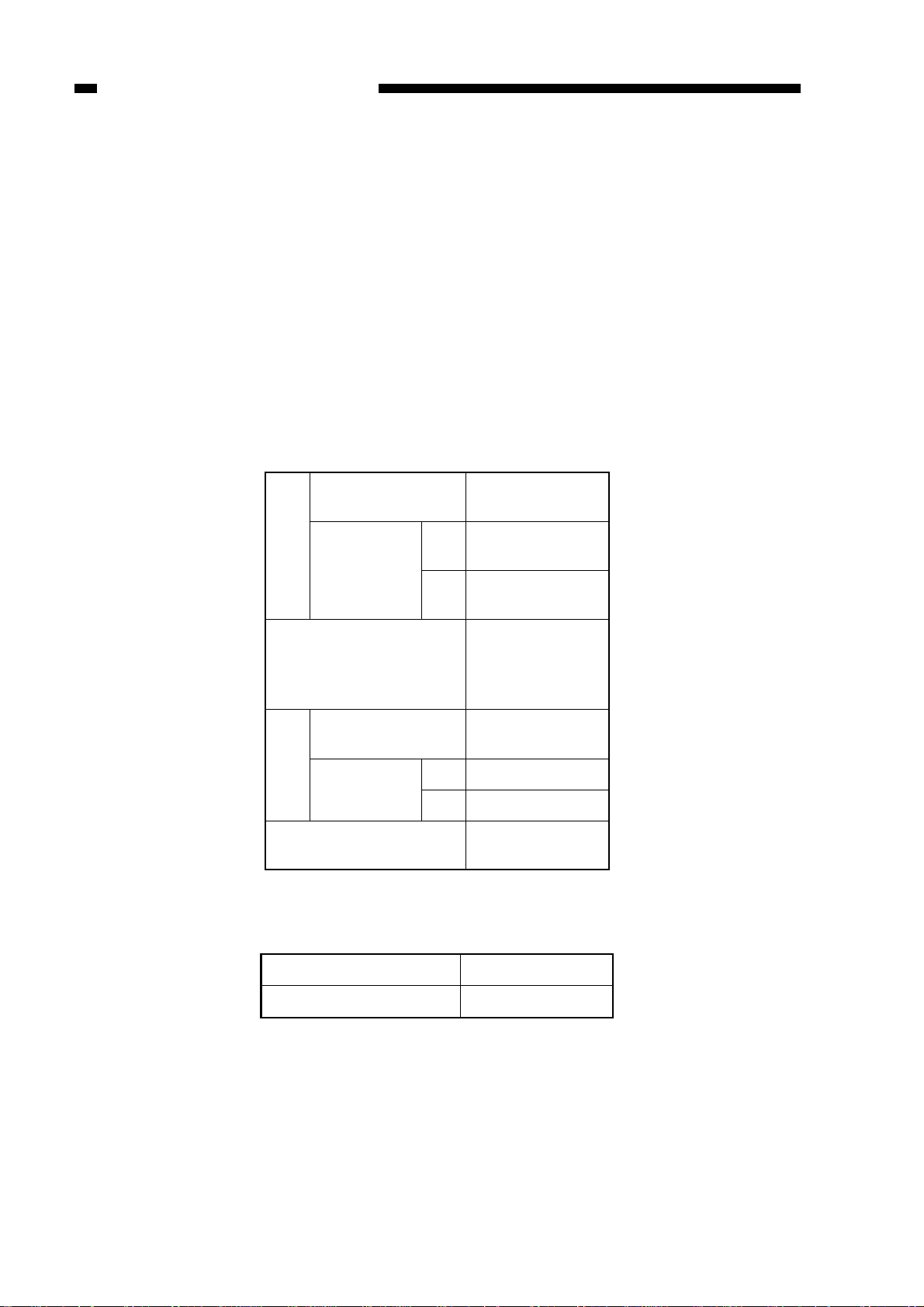

1. Storing Sealed Cartridges

When storing the cartridge in a warehouse or workshop, make sure the place is

controlled to the specifications shown in Table 1-1D.

a. Avoid direct rays of the sun.

b. Avoid areas subjected to appreciable vibration.

c. Do not drop or subject it to impact.

1-2

Table 1-1D Temperature/Humidity Specifications

Table 1-2D Transportation

CHAPTER 1 MAINTENANCE AND INSPECTION

2. Storing and Handling Unsealed Cartridges

The photosensitive medium is an organic photoconductor (OPC), which is extremely

susceptible to light. Since the cartridge also contains toner, you must be extra careful

when storing or handling the cartridge. Make sure the user is aware of this fact and will

handle the cartridge with care.

a. Storing Unsealed Cartridges

1) Avoid areas subjected to strong rays of the sun. Do not keep it in a car even in a

protective box; the inside may become extremely hot.

2) Avoid areas of high or low temperature/ humidity and areas where these elements

tend to change rapidly (for example, near air conditioners or heaters).

3) Avoid areas where dust, ammonium gas, or gases from organic solvents tend to

accumulate.

4) Keep the cartridge in a place 40°C or less.

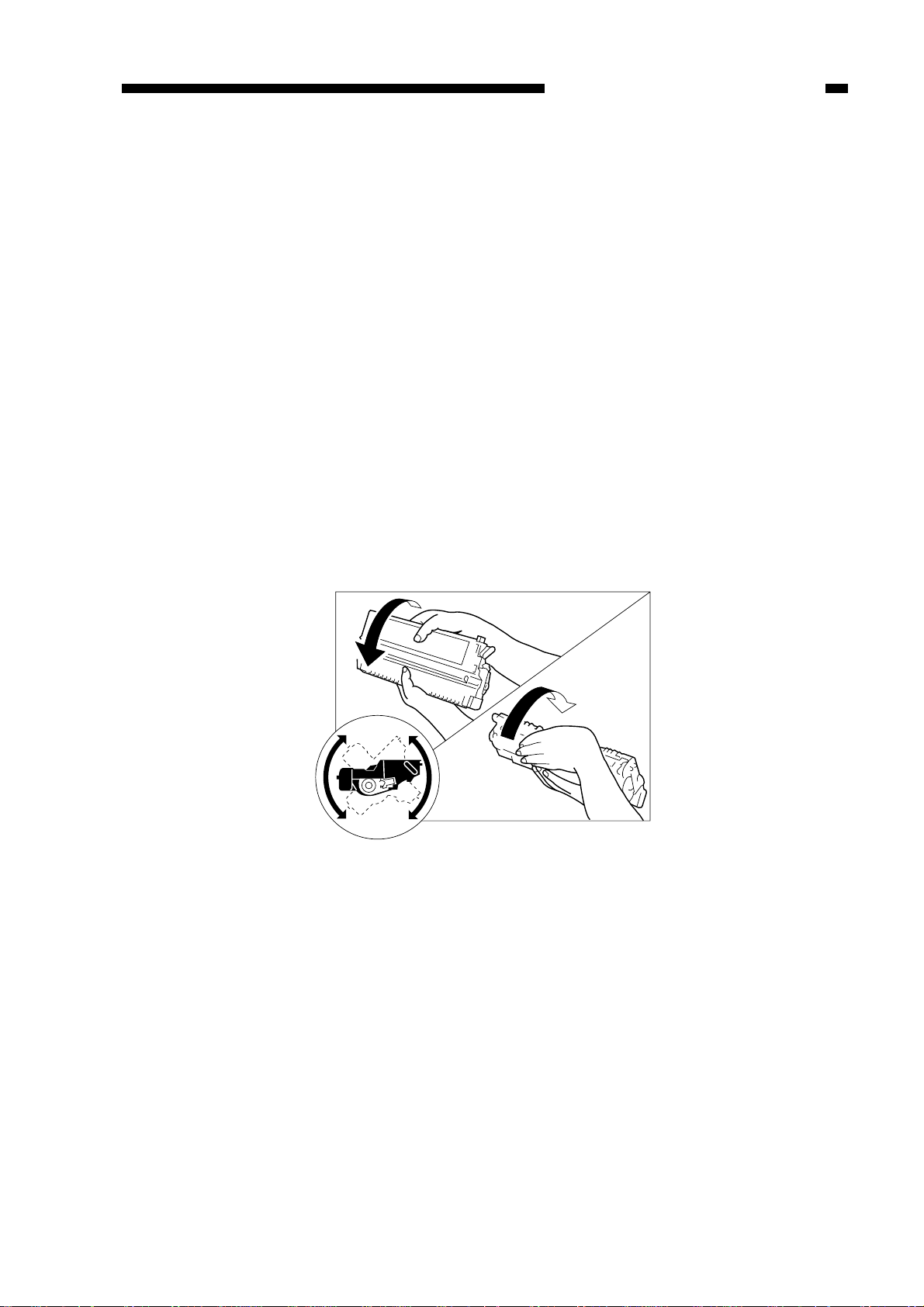

b. Handling the Cartridge

1) Before inserting the cartridge in the copier or if the toner starts to run short, hold the

cartridge horizontally as shown in Figure 1-1, and rotate it in both directions about

90° to even out the toner inside it. Do not shake the cartridge or hold it in a different

way; otherwise, toner may leak out the cartridge.

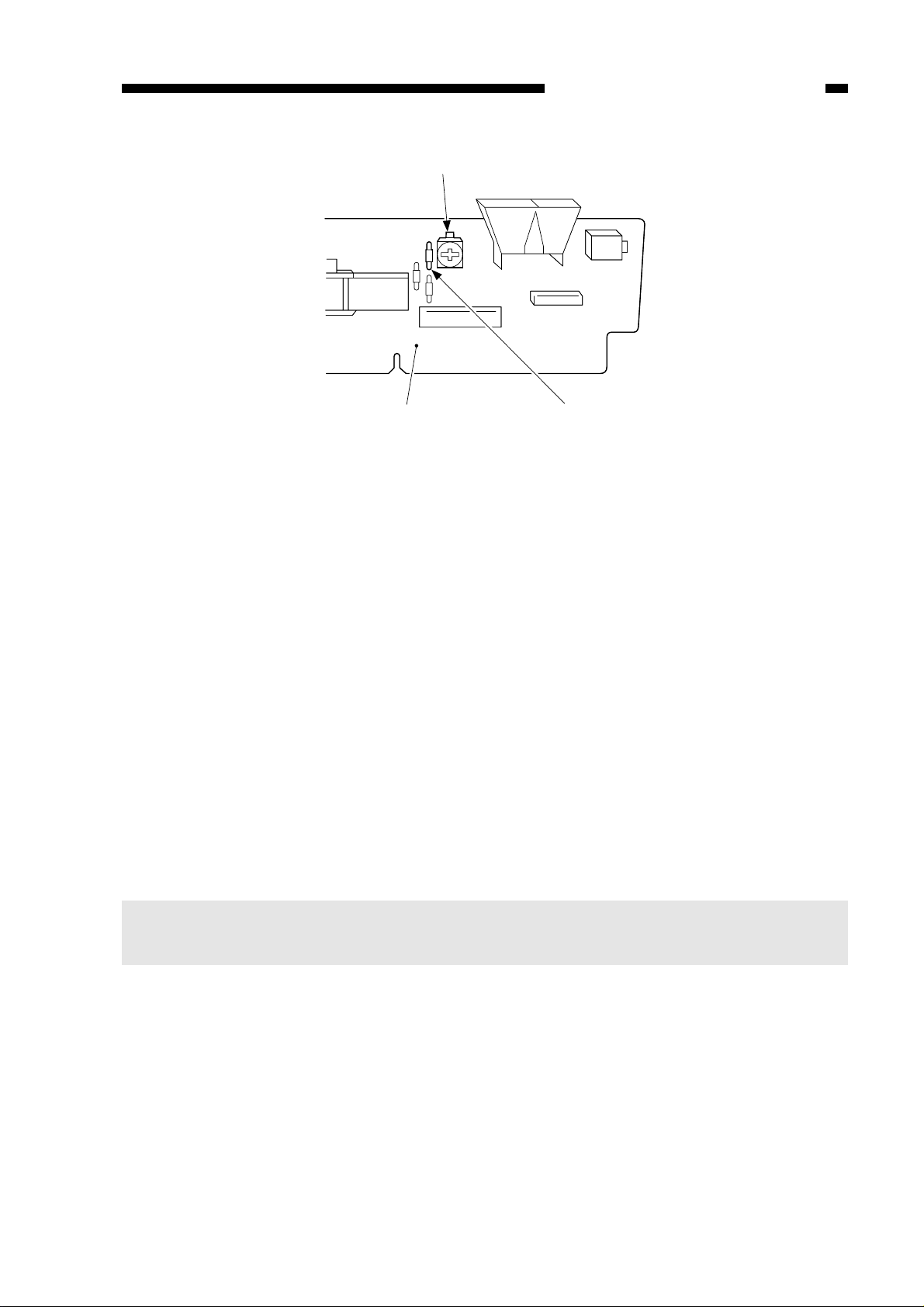

Figure 1-1D

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

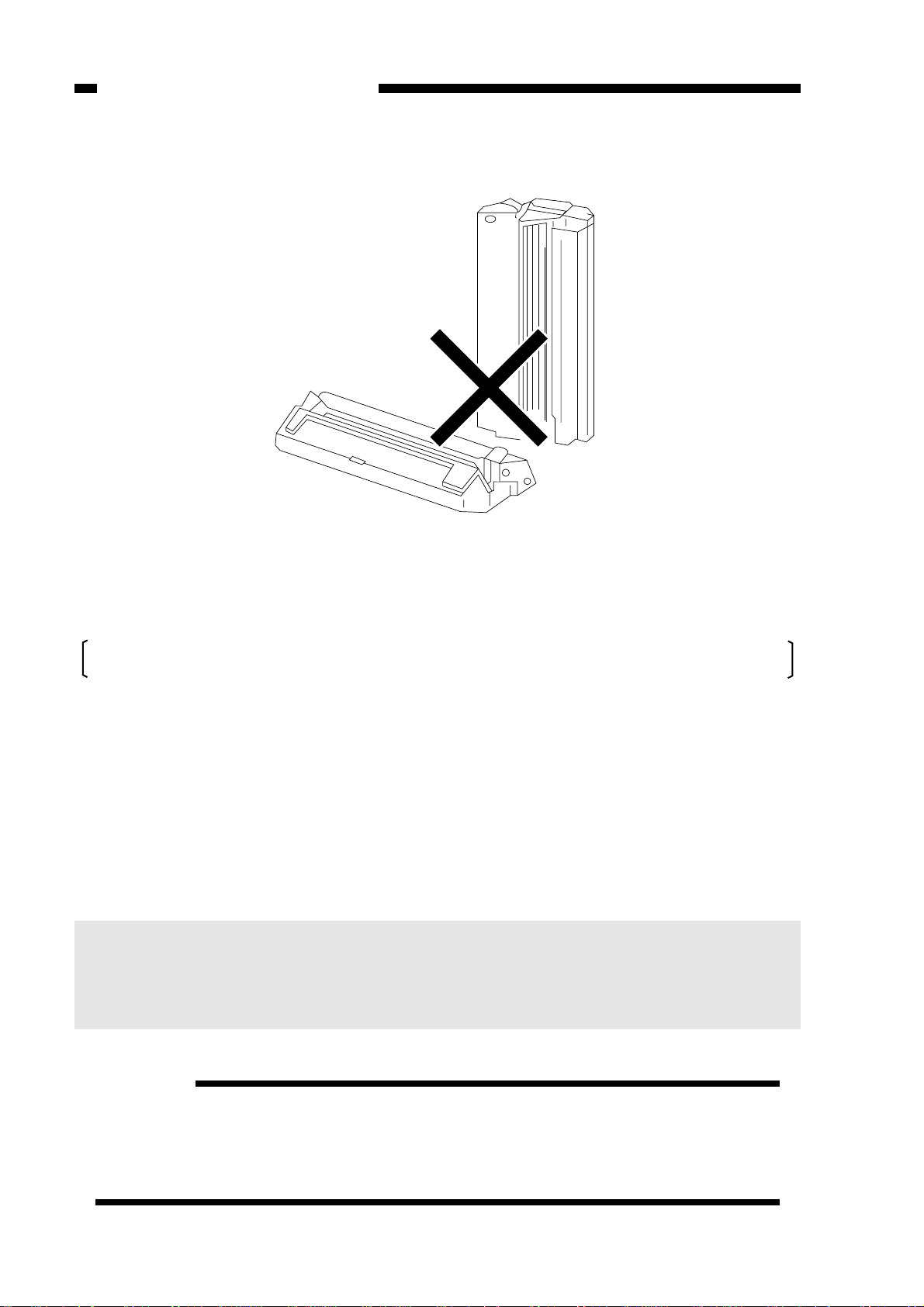

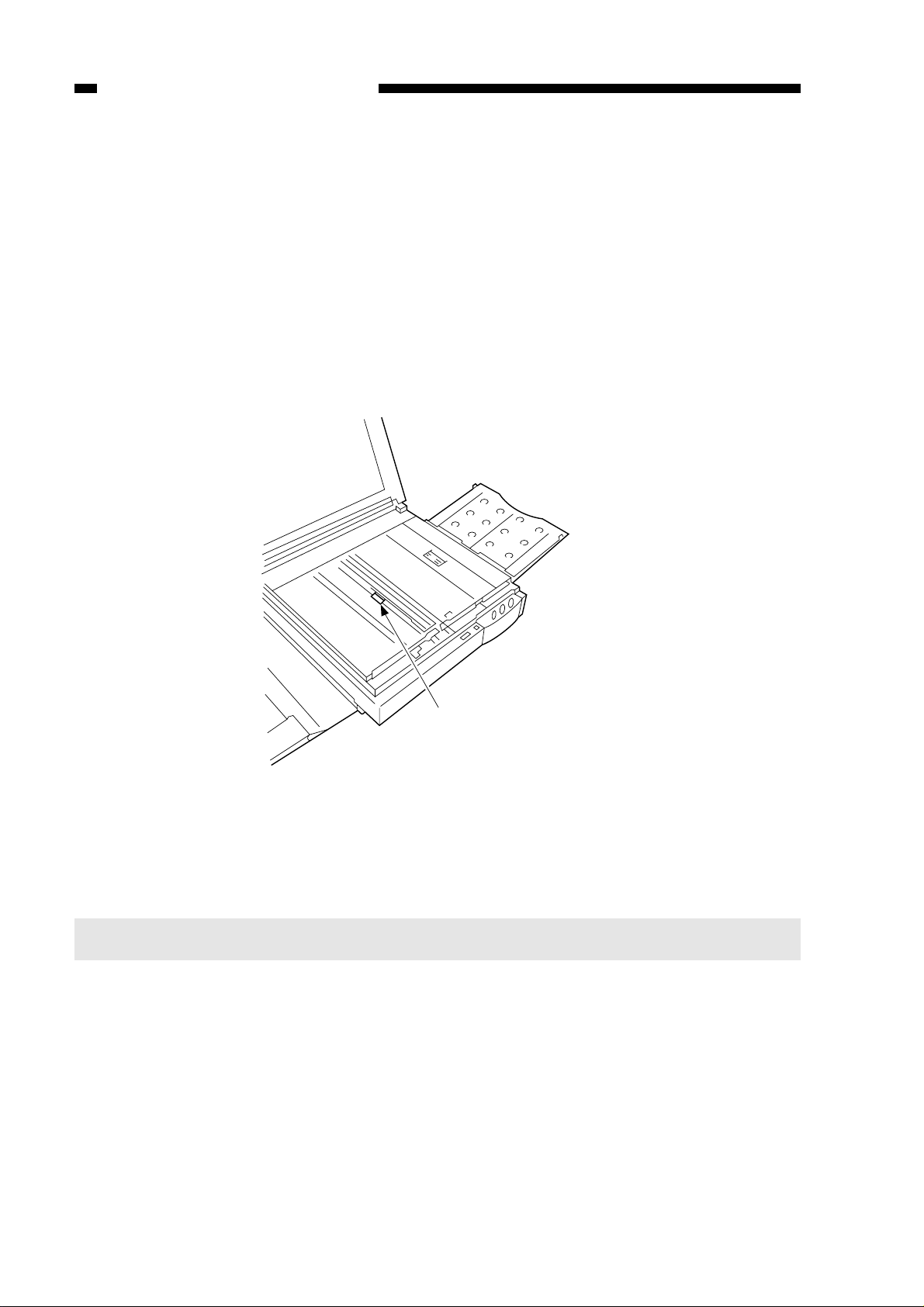

2) Do not place the cartridge upright or upside down; do not shake it.

Figure 1-2D

3) Do not force open the shutter for the photosensitive drum cover found at the bottom

of the cartridge; do not touch the surface of the photosensitive drum.

If the surface of the photosensitive drum has become soiled, wipe it using a flannel

cloth coated with toner. Do not dry wipe it or use solvent.

4) Do not disassemble the cartridge.

5) Do not subject the cartridge to vibration or impact; in particular, do not force down

the photosensitive drum from above the shutter for the drum cover.

6) Keep the cartridge out of reach of children.

7) The photosensitive drum is susceptible to light and, therefore, equipped with a lightblocking shutter; nevertheless, exposure to light for a long time can affect the drum,

resulting in copies with white spots or vertical lines. Leave the copier alone for

some time for possible recovery; to avoid residual memory, which results in white

spots or vertical lines, however, keep the following in mind.

Caution:

Work quickly when removing jams or replacing cartridges.

When the cartridge must be removed for work, be sure to put the cartridge in its

storage box or cover it; do not leave it without protective measures once it is

outside the copier.

Reference:

The drum would recover to more or less its normal condition if left alone for five

minutes in a dark place after exposure to an intensity of 1500 lux (about 5 minutes

under general lighting). However, you must try to avoid any exposure. (The rays

of the sun have intensities ranging between about 10000 and 30000 lux.)

1-4

1-5

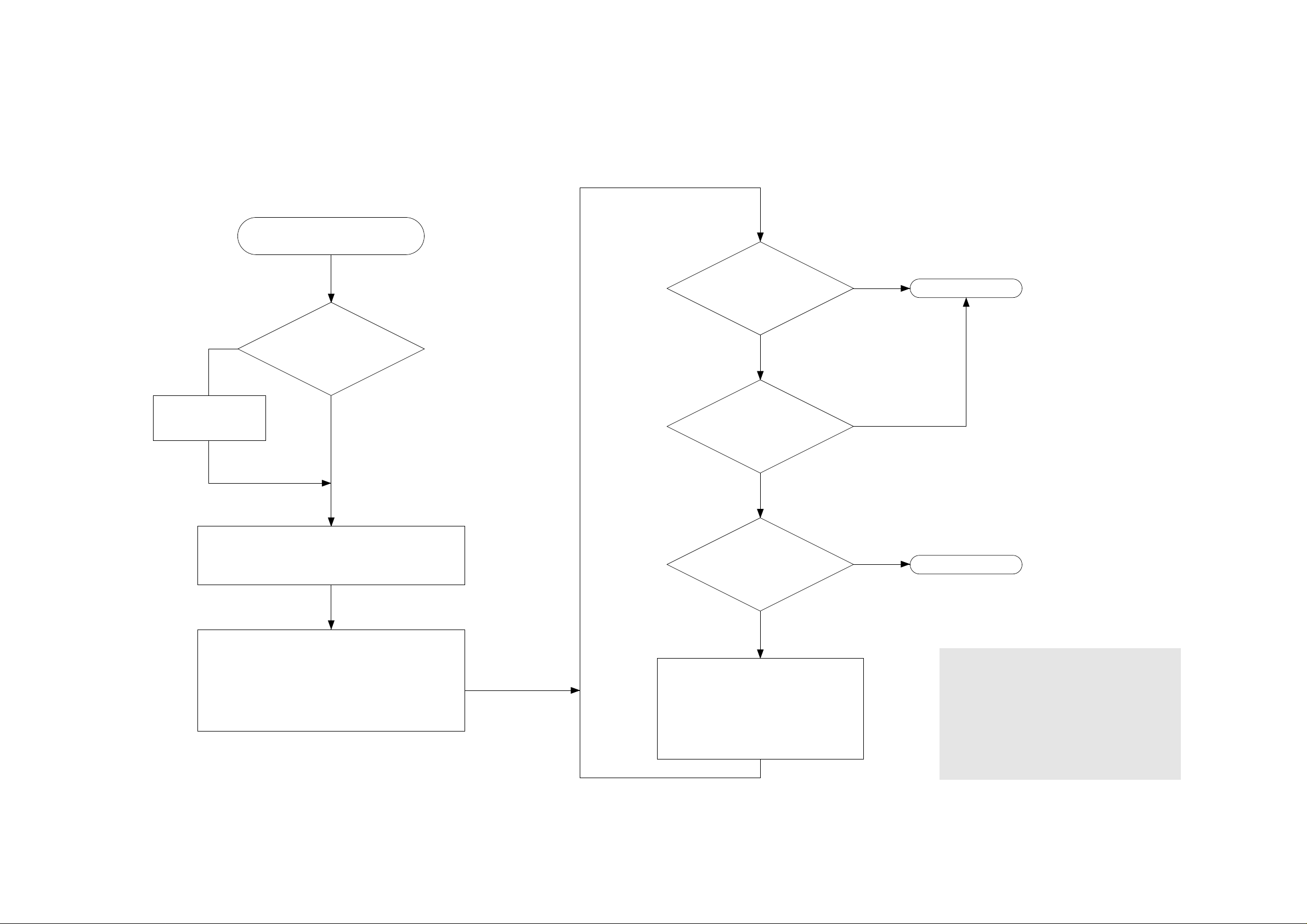

E. Image Adjustment Basic Procedure

Is the

setting of the density

correction switch at the

middle?

Scanning system, pick-up/feeding

system, and delivery assembly.

Select non-AE, and set the density control dial/lever

to 5.5; then, make two to three copies of the Test

Chart (NB-3, NA-2, NA-3); see Note 1.

Check the following:

1. Density of gray scale No. 9; see Note 2.

2. Difference in density between front and rear; see

Note 3.

3. Density of gray scale No. 1; see Note 3.

4. Fogging in white area; see Note 3.

Set the switch to the

middle.

Clean the parts.

Is the

problem corrected by

the density correction

switch?

Is

optimum

density obtained by

adjusting the intensity of

light?

(See

Is gray

scale No. 9 barely noted?

(See Note 2.)

Check the following:

1. Cartridge.

2. Scanning lamp unit.

3. DC controller/DC power supply PCB

(see “Troubleshooting by Image

Fault”).

End.

End.

NO

YES

YES

NO

YES

NO

YES

<Pre-Checks> <Optimum Density Adjustment>

1. If a mono color cartridge is used, set the

density control dial to 4.5.

2. If NB3 is used, refer to gray scale No. 10.

3. The machine is not equipped with an

adjustment function for each type of image

fault; see “Troubleshooting by Image Fault.”

4. For instructions on how to adjust the

intensity of light, see p. 2-2.

Notes:

NO

F. Points to Note

Remarks

Cleaning

Pick-up roller assembly

Parts

Pick-up roller Well-wrung

moist cloth;

or, alcohol

Parts Tools/Solve Remarks

Photosensitive

drum

Toner As a rule, do not

clean.

Do not use solvents.

Do not touch the

drum. Avoid light.

Drum cover

shutter

Well-wrung

moist cloth

Be sure to clean the

shutter; particles of

toner can cause

soiled copies.

Transfer

charging roller

Lint-free

paper

Cleaning

Do not use water or

solvent. Take care

not to touch the

roller or leave oil.

Cartridge, Transfer charging roller

Parts Tools/Solve Remarks

Inlet guide Solvent

Fixing assembly

Parts Tools/Solve Remarks

Lens array Cotton wad Do not use the wire

cleaner meant for

conventional

machines.

Optical assembly

Scanning lamp Blower

brush

Parts Tools/Solve Remarks

Intensity/AE

sensor

Blower

brush

Cleaning

Electrical

Parts Tools/Solve Remarks

Copyboard

cover

alcohol

Copyboard

Copyboard

glass

alcohol

White

reflecting strip

alcohol Dirt can soil the

leading edge

margin, causing

jams.

Parts Tools/Solve Remarks

Registration

roller

Cleaning

Registration assembly

Tools/Solve

Well-wrung

moist cloth

1-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-1

CHAPTER 2 STANDARDS AND ADJUSTMENTS

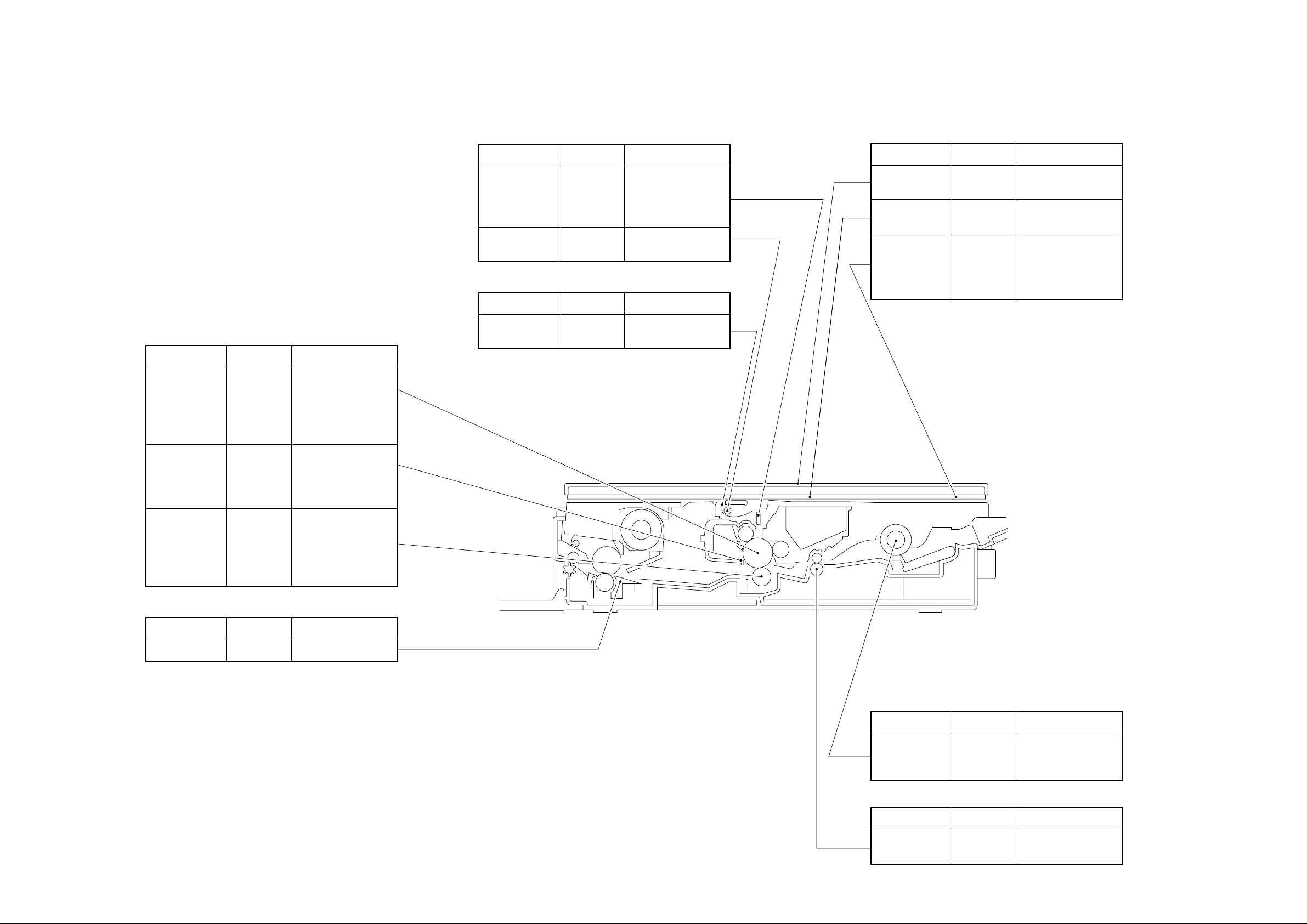

A. Mechanical

1. Image Leading Edge Non-Image Width (position of white paint on back of

glass)

The leading edge non-image width must be 2.0 ±1.0 mm when the Test Sheet is

copied.

Figure 2-1A

The leading edge non-image width is determined by the position of the white paint

found behind the copyboard glass.

Figure 2-2A

2. Image Leading Edge Margin (point of detection for registration)

The leading edge margin must be 0.2 to 5.0 mm when the Test Sheet is copied.

To adjust, move the position of the registration cam.

2.0 ± 1.0 [mm]

Copyboard glass

2mm

Size index

White paint

0.2 to 5.0 [mm]

Figure 2-3A

2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A (VR602)

B (VR603)

C (VR604) Control panel PCB

A (JP607)B (JP621)

C (R614)

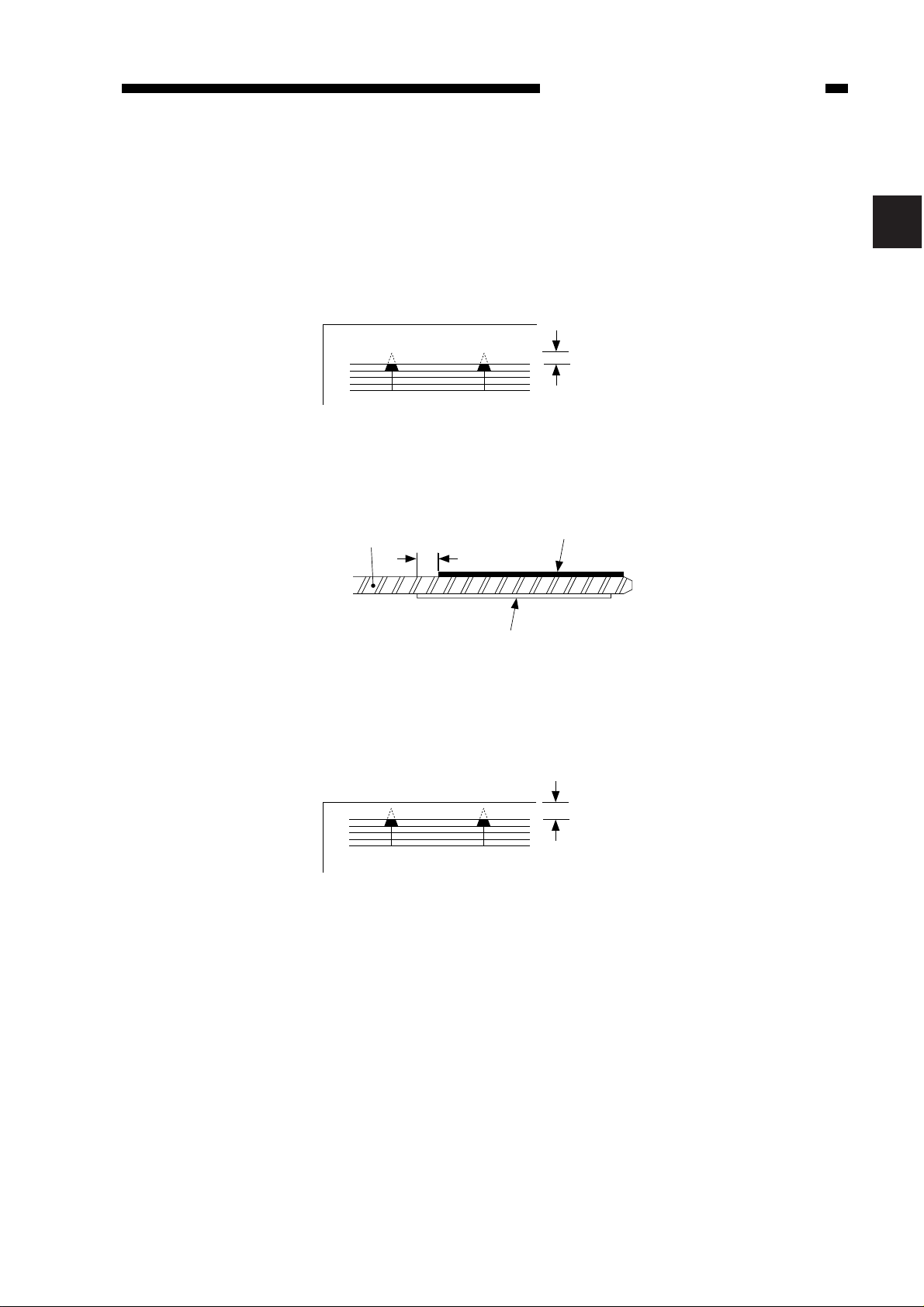

B. Electrical

Notes:

If you have replaced the scanning lamp unit, intensity sensor, AE sensor, or control

panel PCB, you must adjust the three variable resistors on the control panel PCB

(one, if PC400/FC200); you must, however, adjust them in the order of VR604,

VR602, and VR603 (from intensity to AE).

1. Adjusting the Intensity (VR604)

a. After Replacing the Control Panel PCB Only

1) Disconnect the power plug, and detach the faulty control panel PCB.

2) Set the meter to the ‘200 k ’ range, and measure C between the terminal of VR604

and the terminal of R614 on the detached control panel PCB; see Figure 2-1B.

3) Likewise, measure C between the terminal of VR604 and the terminal of R614 on

the new control PCB; then, turn VR604 so that the reading is the same as the

measurement taken in step 2).

4) In the case of the PC420/430/FC220, adjust VR602 (A between terminals of VR602

and JP607) and VR603 (Between terminals of VR603 and JP621); see Figure 2-1B.

5) Attach the new control panel PCB to the copier.

2-2

Figure 2-1B (PC420/430/FC220)

CHAPTER 2 STANDARDS AND ADJUSTMENTS

C (VR604)

Control panel PCB C (R614)

Figure 2-2B (PC400/FC200)

b. After Replacing the Scanning Lamp Unit, Intensity Sensor, or AE Sensor

(Before Adjustment)

• If the scanning lamp has blackened, replace it.

• Clean the scanning system (lens array, lamp reflector, lamp).

1) Set the cartridge to the copier.

2) De-select AE, and set the copy density control lever/dial to the center.

3) Set the density correction switch (SW606) to the center (PC420/430/FC220).

4) Set the Test Sheet (NA3/NB3/NA2), and make a copy.

5) Check if the copy is free of fogging, and gray scale No. 9 (No. 10, if NB3) is

somewhat visible.

• If too dark,

Turn VR604 on the control panel PCB clockwise slightly to increase the intensity.

• If too light,

Turn VR604 counterclockwise slightly to decrease the intensity.

6) Repeat steps 4) and 5) until the density is optimum.

Notes:

After adjusting the intensity, be sure to adjust the AE mechanism

(PC420/430/FC220).

2-3

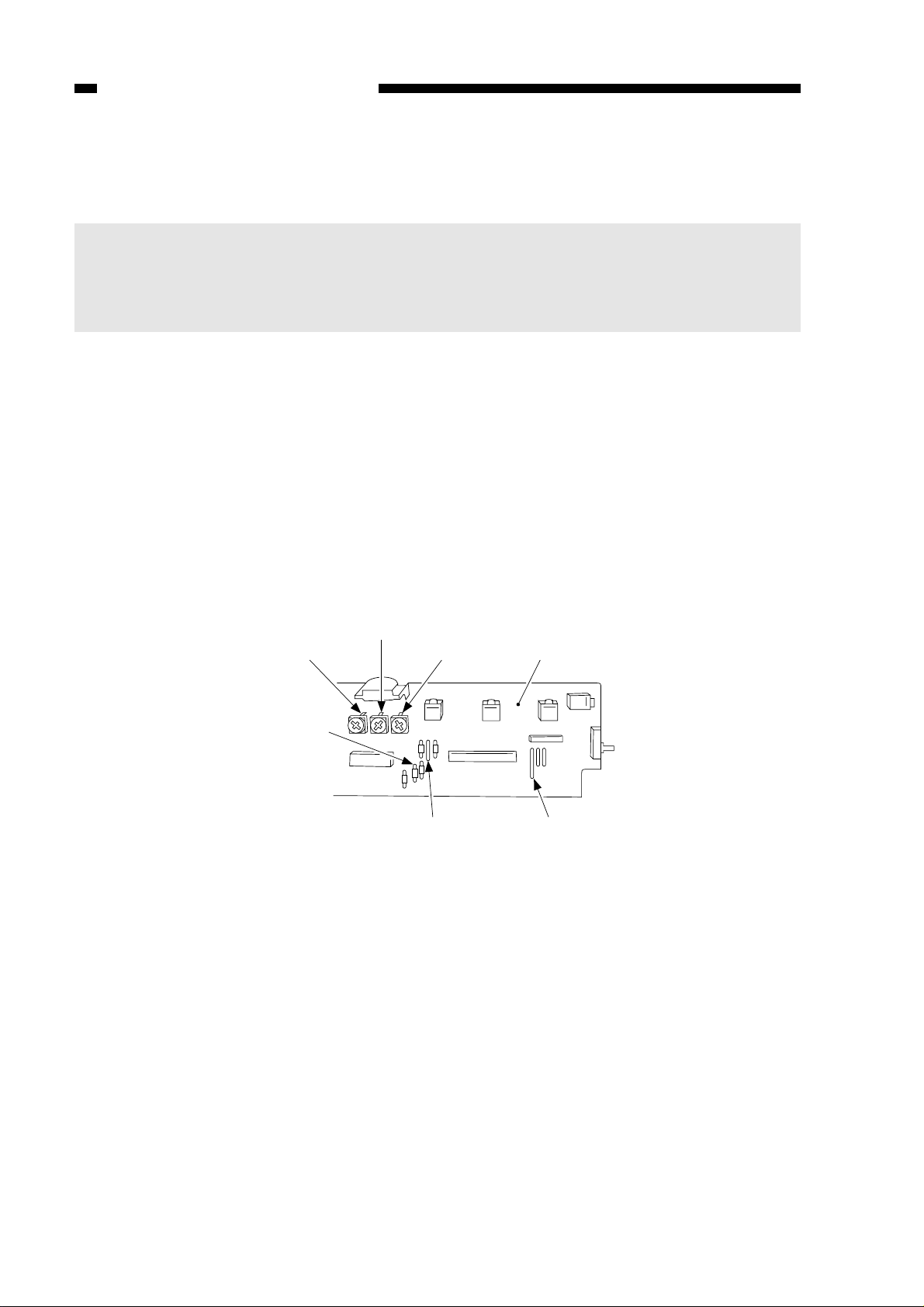

CHAPTER 2 STANDARDS AND ADJUSTMENTS

AE light-receiving section

2. Adjusting the AE Mechanism (VR602, VR603)

(Before Adjustment)

• Obtain a newspaper whose text consists of fine print; do not use a section with

photos or large characters.

• Make sure you have adjusted light intensity.

1) Switch the copier OFF.

2) Detach the control panel cover.

3) Turn VR602 and VR603 on the control panel PCB fully clockwise.

4) Place a newspaper over the AE light-receiving section of the copyboard, and close

the copyboard cover.

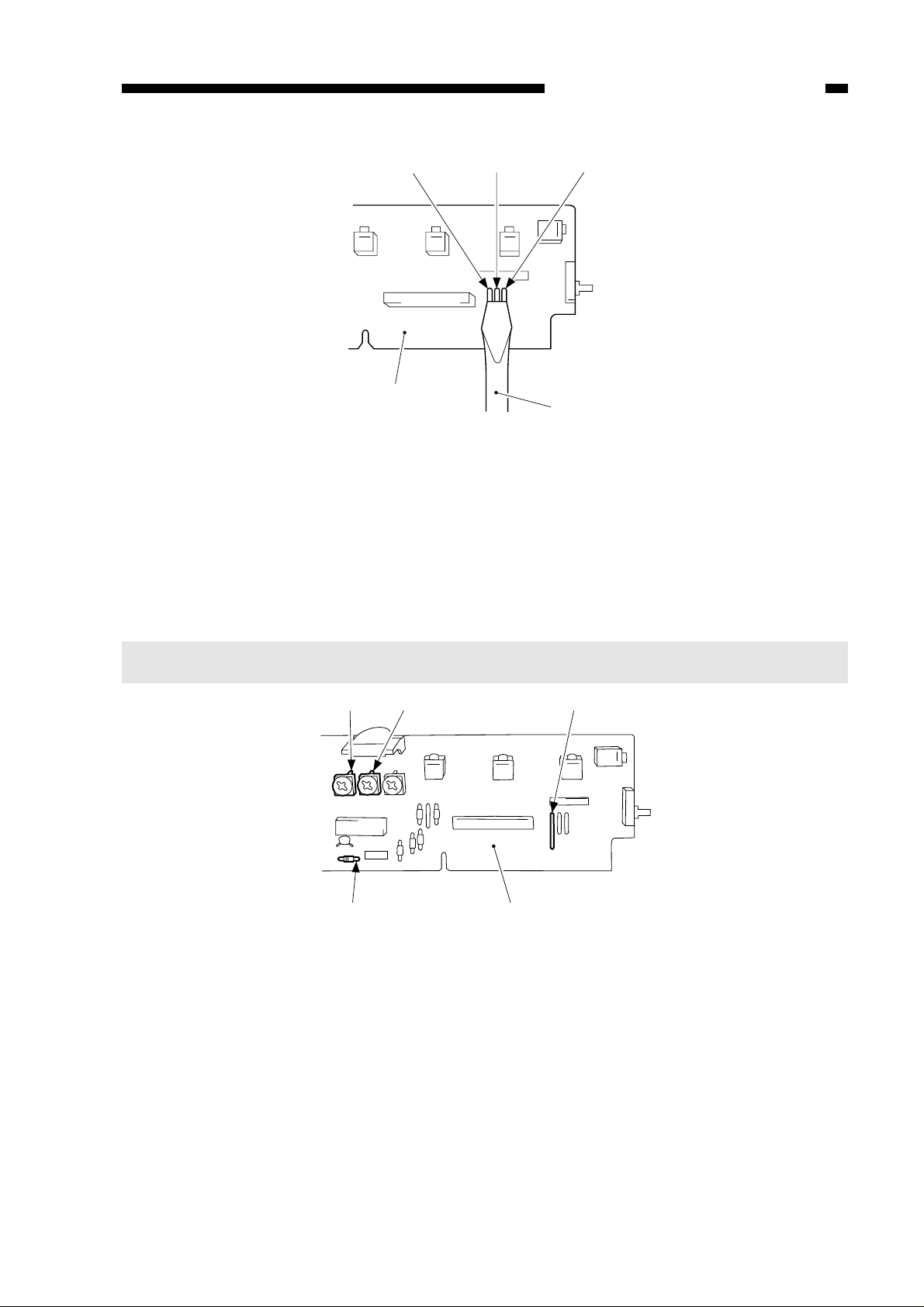

Figure 2-3B

5) Short the three jumper wires (JP604, JP605, JP607) on the control panel PCB at the

same time using a screwdriver.

Caution:

Take adequate care not to short wires other than those specified.

2-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

JP607 JP605 JP604

Screwdriver

Control panel PCB

JP607

VR603VR602

Control panel PCB

D606 (anode side)

Figure 2-4B

6) While keeping the condition in step 5), switch the copier ON.

• ‘0’ is displayed, the scanning lamp goes ON, and the main motor starts to rotate.

7) Stop shorting the jumper wires.

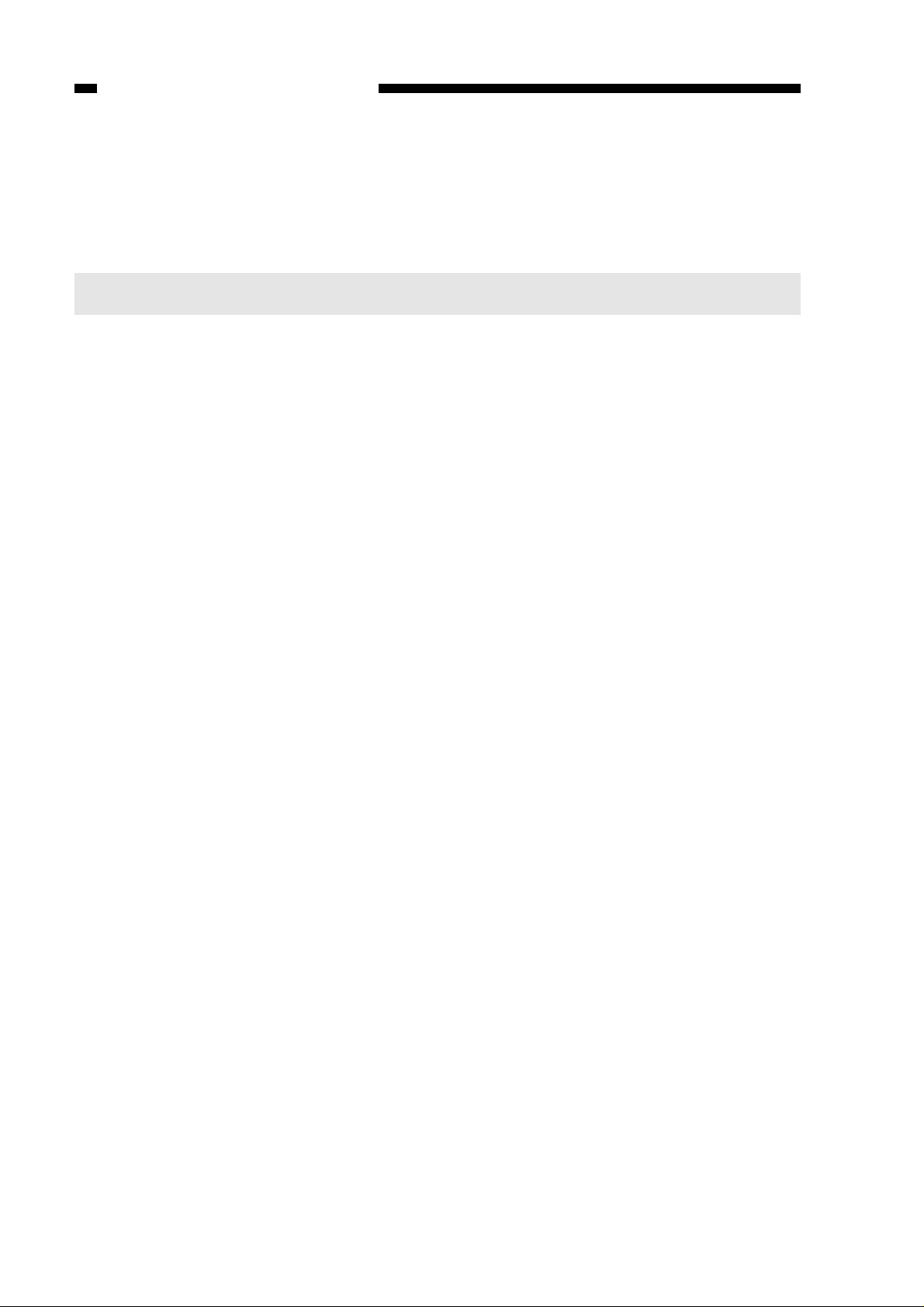

8) Set the digital multimeter to the 20V DC range, and turn VR602 (AE offset

adjustment) until the voltage between the anode side of the diode (D606; +) and

JP607 (GND) is 4.0 ±0.1 V.

Notes:

You must use a Digital Multimeter when making adjustments in steps 8) and 10).

Figure 2-5B

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENTS

9) Place about five sheets of blank copy paper.

10)Turn VR603 (AE gain adjustment) until the voltage between the anode side of the

diode (D606; it) and JP607 (GND) is 1.8 ±0.1 V; see Figure 2-5B.

11) Switch the copier OFF.

Notes:

Make sure that the jumping wires are no longer shorted.

12)Switch the copier ON once again.

13)Set the density correction switch (SW606) to the center (of the three settings).

14)Make sure that the AE indicator is ON.

15)Set the newspaper used in step 4) on the copyboard once again; this time, move the

newspaper to a different area.

16)Make a copy, and make sure that it is not foggy and has adequate text density.

• If foggy,

Turn VR602 clockwise slightly.

• If text density is low,

Turn VR602 counterclockwise slightly.

17)Repeat steps 15) and 16) until the density is optimum.

2-6

CHAPTER 3 IMAGE TROUBLESHOOTING

3-1

3

CHAPTER 3 IMAGE TROUBLESHOOTING

A. Making Initial Checks

1. Site Environment

a. The voltage of the power source must be within the specifications.

b. Avoid areas subjected to dust or high temperature/humidity (near water faucets,

water boilers, humidifiers) and areas near open fires.

c. Avoid areas subjected to ammonium gas.

d. Avoid direct rays of the sun; otherwise, provide curtains.

e. Make sure the site is well ventilated.

f. Make sure the floor is level.

Check the site to see if it meets the above requirements.

2. Checking the Documents

You must first check to see if a particular problem may not be due to the document

used.

a. The copy density reading should be 5.5 ±1.5 (black)/4.5 ±1.5 (color).

b. Some backgrounds, i.e., yellow shades, tend to produce copies with poor

contrast.

c. Diazo copies or translucent documents tend to produce copies that may be

mistaken for foggy copies.

d. Documents prepared in light pencil tend to produce copies that may be mistaken

for light copies.

Loading...

Loading...