Canon FC200, FC220, PC400, PC420, PC430 Service Manual

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

SERVICE MANUAL

REVISION 0

FY8-13F2-000

JAN.1998

IMPORTANT

Use of this manual should be strictly

supervised to avoid disclosure of

confidential information.

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A

SOURCE OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY

SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND

OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE

DIRECTED TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1998 CANON INC.

Printed in Japan

Imprimé au Japon

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302 Japan

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

This Service Manual provides information needed to service the plain paper copiers

FC200/PC400(120V model), FC220/PC420(120V model), and PC430(LGL model) in

the field.

The FC200/PC400 differs from the FC220/PC420/PC430 for the following:

INTRODUCTION

This Service Manual consists of the following chapters:

CHAPTER 1, “General Description,” introduces the copier’s features and specifications, shows how to operate the copier, and explains how copies are made.

CHAPTER 2, “Basic Operation,” provides outlines of the copier's various mechanical

workings.

CHAPTER 3, “Exposure System,” discusses the principles of operation used for the

copier's lens drive unit and scanner drive unit. It also explains the timing at which these

drive units are operated, and shows how they may be disassembled/assembled and

adjusted.

CHAPTER 4, “Image Formation System,” discusses the principles of how images

are formed. It also explains the timing at which the various units involved in image formation are operated, and shows how they may be disassembled/assembled and adjusted.

CHAPTER 5, “Pick-Up/Feeding System,” explains the principles used from when

copy paper is picked up to when a copy is delivered in view of the functions of electrical

and mechanical units and in relation to their timing of operation. It also shows how these

units may be disassembled/assembled and adjusted.

CHAPTER 6, “Fixing System,” explains the principles used to fuse toner images to

transfer media in view of the functions of electrical and mechanical units and in relation

to their timing of operation. It also shows how these units may be disassembled/assembled and adjusted.

CHAPTER 7, “Externals/Auxiliary Mechanisms,” shows the copier's external parts,

and explains the principles used for the copier's various control mechanisms in view of

the functions of electrical and mechanical units and in relation to their timing of operation. It also shows how these units may be disassembled/assembled and adjusted.

CHAPTER 8, “Installation,” introduces requirements for the site of installation, and

shows how the copier may be installed using step-by-step instructions.

CHAPTER 9, “Maintenance and Servicing,” provides tables of periodically replaced

parts and consumables/durables and scheduled servicing charts.

CHAPTER 10, “Troubleshooting,” provides tables of maintenance/inspection, standards/adjustments, and problem identification (image fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

Model Manual pick-up Multifeeder AE

FC220/PC420/PC430

Not available Available Available

FC200/PC400

Available Not available Not available

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and

the relationship between electrical and mechanical systems with reference to the

timing of operation.

In the diagrams, represents the path of mechanical drive where a signal name accompanies the symbol , the arrow indicates the direction of the

electric signal.

The expression "turn on the power" means flipping on the power switch, closing

the front door, and closing the delivery unit door, which results in supplying the

machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal

is "High," while '0' is used to indicate "Low." (The voltage value, however, differs

from circuit to circuit.)

In practically all cases, the internal mechanisms of a microprocessor cannot be

checked in the field. Therefore, the operations of the microprocessors used in the

machines are not discussed: they are explained in terms of from sensors to the

input of the DC controller PCB and from the output of the DC controller PCB to

the loads.

Note:

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated

in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of

this Service Manual and all relevant Service Information bulletins and be able to

identify and isolate faults in the machine.

ii

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES..................................1-1

II. SPECIFICATIONS.......................1-2

III. NAMES OF PARTS .....................1-4

A. External View..........................1-4

B. Cross Section .........................1-5

IV. OPERATION................................1-6

A. Control Panel..........................1-6

1. PC420/430/FC220.............1-6

2. PC400/FC200....................1-7

B. Making Copies........................1-8

C. Jam Indicator.........................1-11

D. Add Paper Indicator..............1-11

E. Replacing the Cartridge ........1-11

1. Time to Replace the Cartridge

.........................................1-11

2. Replacing the Cartridge...1-12

F. Changing the Density ...........1-14

G. Cleaning................................1-14

1. Copyboard Glass/Copyboard

Cover...............................1-14

2. Lens Array .......................1-15

3. Pick-Up Roller..................1-16

H. When Not Using the Copier for a

Long Time.............................1-16

V. IMAGE FORMATION.................1-17

A. Outline.....................................1-17

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATION ....................2-1

A. Outline ....................................2-1

B. Outline of Electrical Circuit......2-2

C. Basic Sequence of Operations

(A4, 2 copies)..........................2-3

D. Main Motor Control Circuit......2-5

1. Outline ...............................2-5

2. Operation...........................2-5

3. Overcurrent Sensor ...........2-5

E. Inputs to DC Controller...........2-6

1. Inputs to DC Controller (1/2)

...........................................2-6

2. Inputs to DC Controller (2/2)

...........................................2-7

F. Outputs from DC Controller....2-8

1. Outputs from DC Controller

(1/2) ...................................2-8

2. Outputs from DC Controller

(2/2) ...................................2-9

CHAPTER 3 EXPOSURE SYSTEM

I. EXPOSURE/COPYBOARD DRIVE

SYSTEM......................................3-1

A. Outline of Exposure System...3-1

B. Copyboard Drive System........3-1

1. Outline ...............................3-1

2. Controlling the Copyboard

Drive ..................................3-3

3. Mechanism of Copyboard

Drive Assembly..................3-4

II. Controlling the Scanning Lamp....3-7

A. Outline ....................................3-7

B. Operations..............................3-8

1. Turning the Scanning Lamp

ON and OFF......................3-8

2. Controlling the Intensity of the

Scanning Lamp..................3-8

C. Controlling the Intensity of the

Scanning Lamp (VR604) ........3-8

III. MECHANICAL SYSTEM..............3-9

A. Scanning System..................3-10

1. Detaching the Scanning Lamp

Unit ..................................3-10

B. Copyboard Drive Assembly...3-11

1. Detaching the Copyboard

Drive Assembly................3-11

CHAPTER 4 IMAGE FORMATION SYSTEM

I. PROCESS DESCRIPTION..........4-1

A. Outline ....................................4-1

B. Sequence of Image Formation

Operations (A4, 2 copies).......4-2

C. Primary Charging Control Circuit

................................................4-3

1. Outline ...............................4-3

2. Operations.........................4-4

D. Controlling Developing Bias....4-6

1. Outline ...............................4-6

2. Operations.........................4-8

E. Transfer Charging Control Circuit

..............................................4-10

1. Outline .............................4-10

2. Operations .......................4-11

F. Document Density Measurement

(AE; PC420/430/FC220).......4-14

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. OUTLINE .....................................5-1

II. CONTROLLING THE PICK-UP

ROLLER.......................................5-2

A. PC420/430/FC220..................5-2

B. PC400/FC200.........................5-3

III. CONTROLLING THE

REGISTRATION ROLLER...........5-4

A. Outline ....................................5-4

B. Pick-Up/Feeding Timing Chart

(A4, 2 copies)..........................5-5

IV. CHECKING FOR JAMS...............5-6

A. Delivery Delay Jam.................5-6

1. PC420/430/FC220.............5-6

2. PC400/FC200....................5-6

B. Delivery Stationary Jam..........5-7

1. PC420/430/FC220.............5-7

2. PC400/FC200....................5-7

C. Pick-Up Delay Jam

(PC420/430/FC220)................5-8

1. Outline .............................4-14

2. Operations.......................4-14

3. Adjusting the AE Mechanism

(VR602, VR603) ..............4-15

II. CHARGING, DEVELOPING, AND

CLEANING SYSTEMS ..............4-17

A. Cartridge...............................4-17

1. Outline .............................4-17

III. MECHANICAL SYSTEM............4-18

A. Photosensitive Drum.............4-19

1. Cleaning the Drum...........4-19

B. Transfer Charging Roller.......4-20

1. Cleaning the Transfer

Charging Roller................4-20

2. Detaching the Transfer

Charging Roller................4-20

D. Pick-Up Stationary Jam..........5-9

1. PC420/430/FC220.............5-9

2. PC400/FC200....................5-9

E. Paper is present at the pick-up or

delivery sensor at time of poweron or when the Copy Start key is

pressed...................................5-9

V. MECHANICAL SYSTEM............5-10

A. Pick-Up Roller Assembly.......5-11

1. Detaching the Pick-Up Roller

.........................................5-11

B. Registration Roller Assembly

..............................................5-14

1. Detaching the Registration

Roller Assembly...............5-14

C. Removing the Separation Pad

..............................................5-15

CHAPTER 6 FIXING SYSTEM

I. OUTLINE OF OPERATIONS.......6-1

A. Outline ....................................6-1

B. Controlling the Fixing Heater

Temperature............................6-3

iv

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

C. Controlling the Supply Power to

the Fixing Heater ....................6-3

D. Protection Mechanisms ..........6-5

II. MECHANICAL SYSTEM..............6-6

A. Fixing Assembly......................6-7

1. Construction.......................6-7

2. Detaching the Fixing

Assembly...........................6-7

3. Removing the Fixing Upper

Unit ....................................6-9

4. Detaching the Pressure Roller

.........................................6-11

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. POWER SUPPLY ........................7-1

A. Outline ....................................7-1

B. Power Supply PCB.................7-2

C. Protection Mechanism for Power

Supply Circuit..........................7-2

II.MECHANICAL SYSTEM .................7-3

A. External Covers......................7-4

1. Detaching the Control Panel

Cover.................................7-4

2. Detaching the Body Cover

...........................................7-5

3. Detaching the Top Cover

Assembly...........................7-7

4. Detaching the Delivery

Assembly Cover.................7-7

CHAPTER 8 INSTALLATION

I. SELECTING THE SITE ...............8-1

II. UNPACKING AND INSTALLATION

.....................................................8-2

5. Detaching the Bottom Cover

...........................................7-8

B. Copyboard Assembly..............7-9

1. Detaching the Copyboard

Cover.................................7-9

2. Detaching the Copyboard..7-9

C. DC Controller/DC Power Supply

PCB.......................................7-11

1. Detaching the DC

Controller/DC Power Supply

PCB..................................7-11

2. Points to Note When Installing

the Delivery Door Switch .7-13

D. Control Panel PCB................7-14

1. Detaching the Control Panel

PCB .................................7-14

III. RELOCATING THE MACHINE....8-5

CHAPTER 9 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED PARTS

.....................................................9-1

II. DURABLES..................................9-1

III. PERIODICAL SERVICING ..........9-1

IV. NOTES ABOUT CARTRIDGE.....9-2

A. Storing Sealed Cartridges.......9-2

B. Storing and Handling Unsealed

Cartridges ...............................9-3

1. Storing Unsealed Cartridges

...........................................9-3

2. Handling the Cartridge.......9-3

CHAPTER 10 TROUBLESHOOTING

I. MAINTENANCE AND INSPECTION

...................................................10-3

A. Image Adjustment Basic

Procedure.............................10-3

B. Points to Note.......................10-4

II. STANDARDS AND

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

ADJUSTMENTS ........................10-5

A. Mechanical............................10-5

1. Image Leading Edge Non-

Image Width (position of white

paint on back of glass).....10-5

2. Image Leading Edge Margin

v

(point of detection for

registration)......................10-5

B. Electrical ...............................10-6

1. Adjusting the Intensity

(VR604) ...........................10-6

2. Adjusting the AE Mechanism

(VR602, VR603) ..............10-8

III. IMAGE TROUBLESHOOTING 10-11

A. Making Initial Checks ..........10-11

1. Site Environment............10-11

2. Checking the Documents

.......................................10-11

3. Checking the Copyboard

Cover and Copyboard Glass

for Dirt and Scratches....10-12

4. Checking the Lens Array for

Dirt.................................10-12

5. Checking the Transfer

Charging Roller..............10-12

6. Checking the Feeding

Assembly.......................10-12

7. Checking the Copy Paper

.......................................10-12

8. Checking the Durables ..10-12

9. Others............................10-14

B. Samples of Image Faults....10-16

C. Troubleshooting by Image Fault

............................................10-17

1. The copy is too light (halftone

areas only).....................10-17

2. The copy is too light (dark

areas as well).................10-17

3. The copy is too light

(extremely light overall)..10-17

4. The copy has uneven density

(darker at front)..............10-18

5. The copy has uneven density

(lighter at front). .............10-18

6. The copy is foggy (overall).

.......................................10-18

7. The copy is foggy (paper feed

direction)........................10-19

8. The copy has dark lines

(paper feed direction,

relatively narrow). ..........10-19

9. The copy has dark lines

(paper feed direction, thin).

.......................................10-19

10. The copy has white spots

(paper feed direction).....10-19

11. The copy has white lines

(paper feed direction).....10-19

12. The copy has white spots

vi

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

(cross feed direction).....10-20

13. The back of the copy is soiled.

.......................................10-20

14. The copy has faulty fixing.

.......................................10-21

15. The copy has faulty leading

edge registration (blank area

much too wide). .............10-21

16. The copy has faulty leading

edge registration (blank area

too wide)........................10-21

17. The copy has faulty leading

edge registration (no blank

area). .............................10-21

18. The copy has a blurred image.

.......................................10-22

19. The copy is foggy (cross feed

direction)........................10-22

20. The copy has poor sharpness

(focus)............................10-22

21. The copy is blank...........10-23

22. The copy is solid black...10-23

IV. TROUBLESHOOTING

MALFUNCTIONS.....................10-24

A. Troubleshooting Malfunctions

............................................10-24

1. (self diagnosis;

PC400/FC200)...............10-24

2. E0 ..................................10-24

3. E2 ..................................10-25

4. E6 ..................................10-25

5. E9 ..................................10-26

6. AC power is absent........10-26

7. Pick-up fails. ..................10-27

8. The scanning lamp fails to go

ON. ................................10-27

9. The main motor fails to rotate.

.......................................10-28

10. The copyboard fails to move.

.......................................10-28

11. (paper feeding normally)

.......................................10-29

12. (at time of jam) ..........10-29

13. The fixing heater fails to

operate...........................10-29

V. TROUBLESHOOTING PAPER

FEED PROBLEMS ..................10-30

A. Copy Paper Jams...............10-30

1. Pick-Up Assembly..........10-31

2. Separation/Feeding Assembly

.......................................10-31

3. Fixing/Delivery Assembly

.......................................10-32

B. Feeding Faults....................10-33

1. Double Feeding .............10-33

2. Wrinkles.........................10-33

VI. FUNCTIONS AND ARRANGEMENT

OF ELECTRICAL PARTS........10-34

A. Sensors and Solenoids.......10-34

B. Switches .............................10-35

C. Lamp, Heater, Motor, and Others

APPENDIX

............................................10-36

D. Printed Circuit Board (PCB)10-37

E. Variable Resistors (VR) and

Check Pins by PCB ............10-38

1. DC Controller/DC Power

Supply PCB ...................10-38

2. Control Panel PCB.........10-39

VII. SELF DIAGNOSIS...................10-40

A. GENERAL TIMING CHART .........A-1

B. SIGNALS/ABBREVIATIONS LISTA-3

1. Signals....................................A-3

2. Abbreviations..........................A-4

C. GENERAL CIRCUIT DIAGRAM...A-5

D. SPECIAL TOOLS TABLE.............A-7

E. SOLVENTS/OILS TABLE.............A-8

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

vii

viii

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES..................................1-1

II. SPECIFICATIONS .......................1-2

III. NAMES OF PARTS .....................1-4

A. External View..........................1-4

B. Cross Section .........................1-5

IV. OPERATION................................1-6

A. Control Panel..........................1-6

B. Making Copies........................1-8

C. Jam Indicator.........................1-11

D. Add Paper Indicator ..............1-11

E. Replacing the Cartridge ........1-11

F. Changing the Density ...........1-14

G. Cleaning................................1-14

H. When Not Using the Copier for a

Long Time.............................1-16

V. IMAGE FORMATION.................1-17

A. Outline.....................................1-17

This chapter outlines the machine's specifications and how it may be operated.

CHAPTER 1 GENERAL DESCRIPTION

Blank Page

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Direct charging.

The charging roller directly charges paper, significantly reducing ozone emission.

2. Auto power-off.

The copier shuts off automatically when left alone for about 5 minutes after the last

copy operation.

3. Quick start.

The copier’s wait time is 0 second, always ready for quick copying work.

4. Cartridge type.

The core of the copier (photosensitive drum, toner case, charging roller, developing

assembly, and cleaning assembly) is integrated into a single cartridge. The user need

no more than replace the cartridge and perform simple cleaning to maintain the copier

in top condition.

5. Variety of copy effects.

In addition to black toner, the user has a choice of several colors. Taking advantage

of overlay copying, various copy effects may be obtained through mere replacement of

the cartridge.

6. Compact and light.

The copier is compact and light, providing good portability. It can easily substitute

as a personal copier.

7. Multifeeding (PC420/430/FC220).

A stack of copy paper may be placed on the pick-up tray. A press on the Copy Start

key is all it takes to generate multiple copies.

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

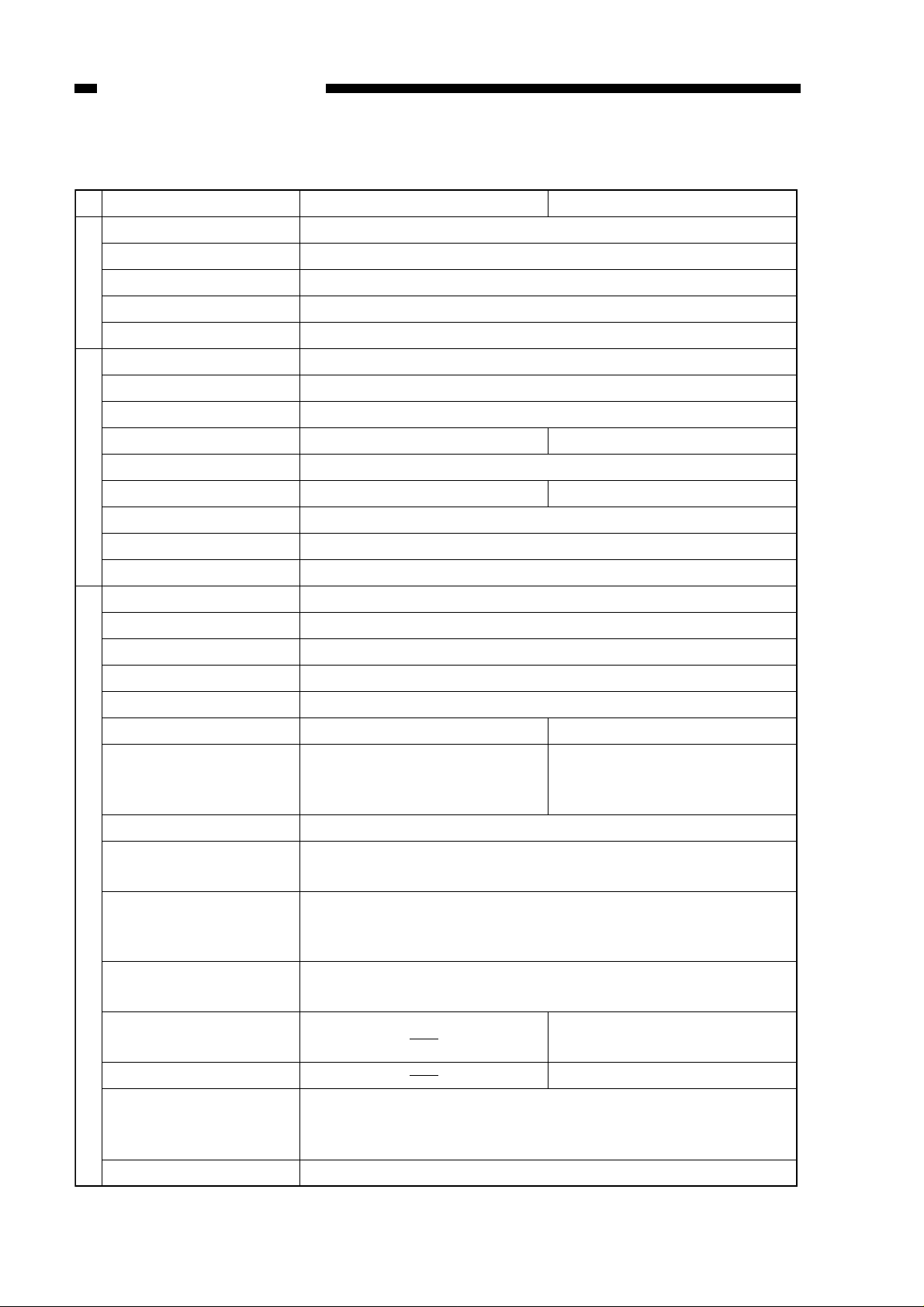

Item

Body Portable (w/ grips)

Copyboard Moving

Light source Tungsten lamp of fuse type

Lens Lens array

Photosensitive medium OPC (24 dia.)

Type

Copying Indirect electrostatic

Charging Roller (direct charging)

Exposure Slit (moving copyboard)

Copy density adjustment

Development Dry

Pick-up

Separation Curvature + Static eliminator

Cleaning Blade

Fixing Plane heater

System

Document type Sheet, Book, 3-D object (2 kg/4.4 lb max.)

Maximum document size LTR/A4; LGL*

Reproduction ratio 1:1 (±1.2%)

Wait time 0 sec (approx.; at 20°C/68°F)

First copy 22 sec (LTR)

Continuous copying Not available

Copying speed

Copy size A4/LTR; LGL* max.; postcard min.

52 to 128 g/m2, Tracing paper, Colored paper, OHP film, Postcard

(vertical), Labels, Wrapping paper (63 g/m2)

Copy paper type

Two-sided copying

Overlay copying

Copy tray

9 copies (approx.; A4/LTR, 80 g/m2)

Non-image width 2 mm (leading edge)

A4: 0 mm (left/right)

LTR/LGL: 2 mm (left/right)

Auto power-off Available (5 min, approx.)

Performance

*PC430 only.

PC400/FC200 PC420/430/FC220

Manual Automatic (AE) or Manual

Manual tray Multifeeder

4 copies/min (approx.; A4R/LTR-R

or smaller)

4 copies/min (A4R/LTR-R or

smaller)

3 copies/min (LGL)

• Same edge orientation.

• Copying on each side no more

than twice.

• Paper of 64 to 128 g/m

2

.

• Paper of 64 to 128 g/m2. • Copying on each side no more

than three times.

Multifeeder tray

5 mm deep (about 50 sheets of

A4, 80 g/m2)

1 to 9 copies or F

II. SPECIFICATIONS

1-2

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Item

7.5° to 32.5°C/45.5° to 90.5°F

Others

Temperature

Operating

environment

Humidity

Atmospheric pressure

5% to 85%

810.6 hPa to 1013.3 hPa (0.8 to 1 atm)

Serial numbers

ZTG ✕✕✕✕✕ (PC400:WHITE)

ZTH ✕✕✕✕✕ (PC400:GRAY)

120V, 60Hz

Power

supply

0.7 kW or less

Maximum

Power

consumption

Standby

Continuous

0.1 W (approx.; 5 min; reference only)

0.2 kWh (reference only)

Ozone 0.01 ppm or less (average over 8 hr)

71 dB

Copying

Standby

Noise

14.1 in./359 mm

Width

Dimensions

Depth

Height

15.7 in./402 mm

4.1 in./108 mm

Weight (including cartridge)

16.6 lb/7.4 kg (approx.)

Keep wrapped to protect against humidity.

Copy paper

Cartridge

See CHAPTER 9.

Consumables

Sound power level

by ISO

PC400/FC200 PC420/430/FC220

Serial numbers

NVD

✕✕✕✕✕

(FC220:WHITE)

ZTJ

✕✕✕✕✕

(PC420:WHITE)

RTL/PTQ

✕✕✕✕✕

(FC200:WHITE)

UTP/UTQ

230V, 50Hz

RTM/PTR

✕✕✕✕✕ (FC220:WHITE)

PTS ✕✕✕✕✕ (FC220:WHITE)

PTT ✕✕✕✕✕ (FC220:WHITE)

Specifications subject to change without notice.

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-4

CHAPTER 1 GENERAL DESCRIPTION

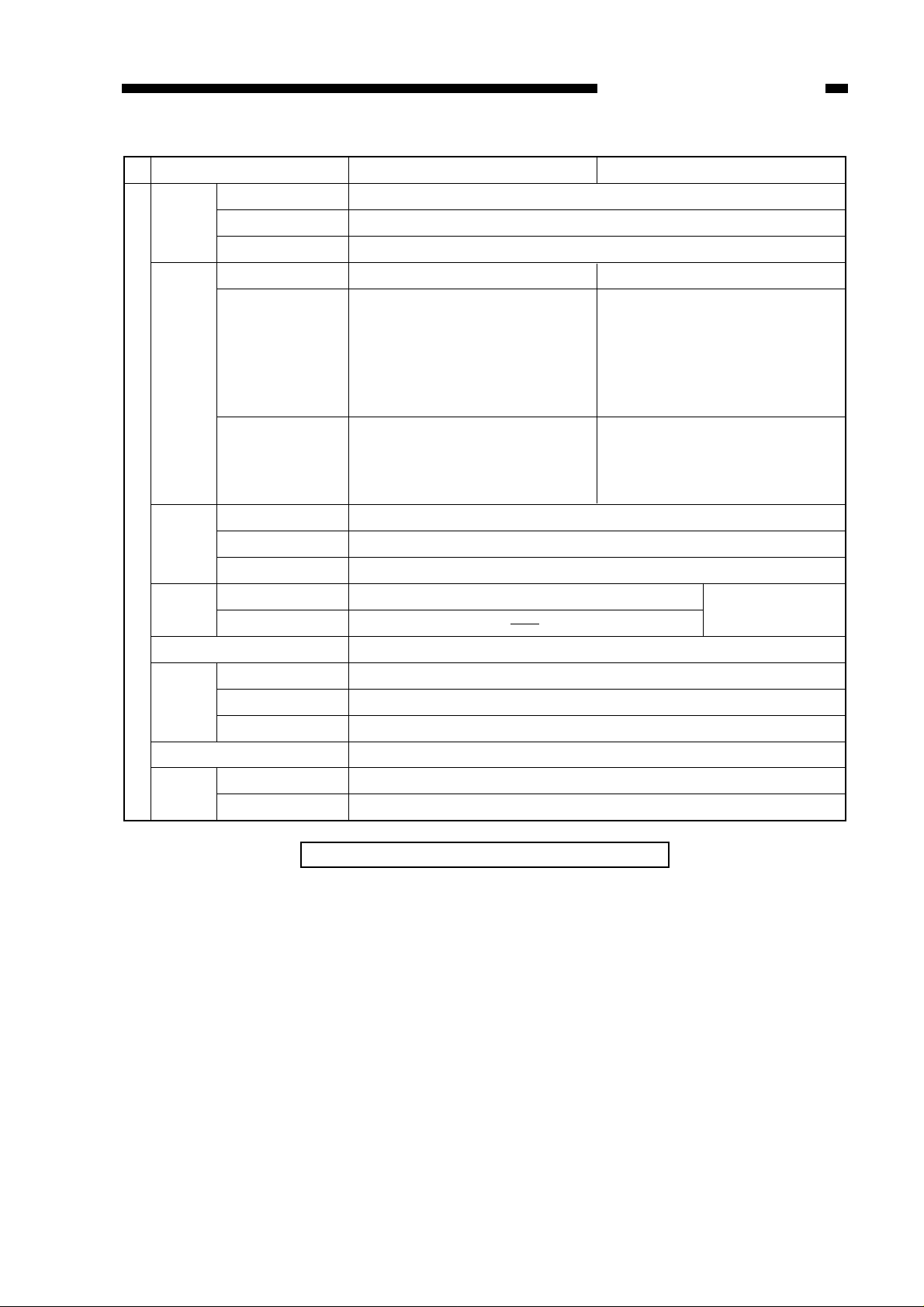

III. NAMES OF PARTS

A. External View

(PC420/430/FC220) (PC400/FC200)

q Copyboard cover

w Copyboard glass

e Pick-up tray

r Open/Close button

t Delivery assembly cover

open/close button

y Delivery assembly cover

u Copy tray

➀

➁

➂

➃

➄

➅

➆

➀

➁

➂

➃

➄

➀

➁

➂

➃

➄

➅

Figure 1-301A

q Upper cover

w Pick-up guide

e Density correction switch

r Power switch

t Cartridge

Figure 1-302A

B. Cross Section

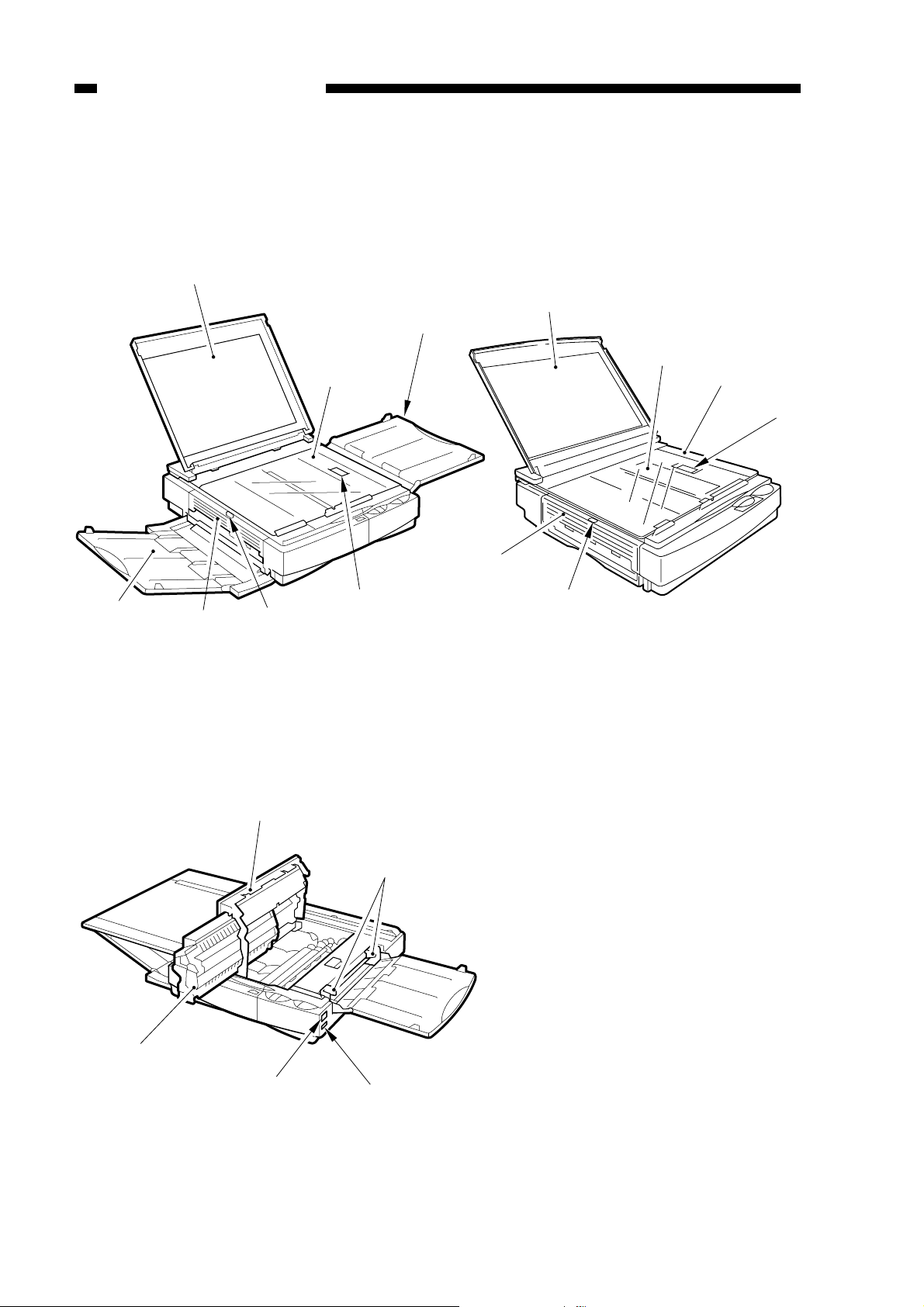

14 1317 16 15 1112

1031 2 4 5 6 7 8 9

12 11 98

CHAPTER 1 GENERAL DESCRIPTION

(PC420/430/FC220)

(PC400/FC200)

q Copyboard cover

w Copyboard glass

e Cleaning assembly

r Primary charging roller

t Scanning lamp

y Lens array

u Developing cylinder

i Registration roller

o Pick-up roller

!0 Pick-up tray

!1 Transfer charging roller

!2 Photosensitive drum

!3 Fixing assembly

!4 Delivery roller

!5 Delivery tray

!6 Heat exhaust fan

!7 Delivery assembly cover

open/close button

Figure 1-301B

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

6 4

5

C

A

AE

Error indications

:

Check jam/Supply paper

: Jam

and

: Check error

and

: Check error

and

: Check error

darker

lighter

ON OFF

lighter darker

10

3

1

2

4 5

6

7

8

9

IV. OPERATION

A. Control Panel

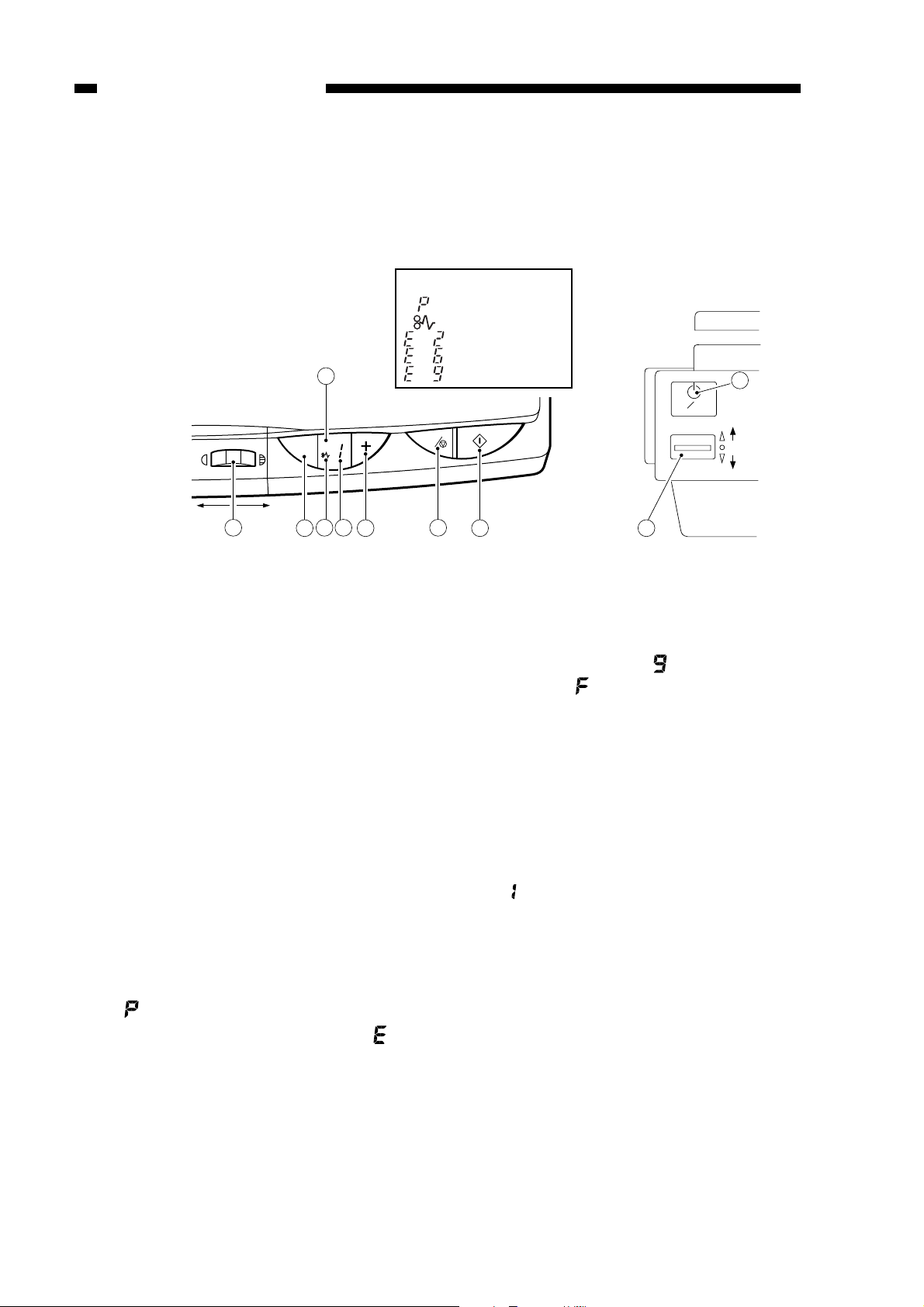

1. PC420/430/FC220

q Density Control Dial

w AE key

• Press it to select/deselect AE

(automatic exposure) mode.

e AE Indicator

• ‘A’ goes ON when AE mode is

selected.

• ‘A’ goes OFF when AE mode is

deselected.

r Jam Indicator

• Flashes when paper jams inside

the copier.

t Copy Count Indicator

• Displays the number of copies

entered by pressing the Copy

Count Set key.

• The count decreases for each copy

made; the initial number is

displayed after the last copy has

been made.

• ‘ ’ is displayed to indicate pick-up

failure or absence of paper; ‘ ’ is

displayed in response to an error

found by self diagnosis.

Figure 1-401A

y Copy Count Set Key

• Each press on the key increases

the copy count (up to 9).

• A press while ‘ ’ is displayed

causes ‘ ’ to appear, indicating all

sheets on the pick-up tray will be

used for continuous copying.

u Clear/Stop Key

• During continuous copying, the key

serves as a Copy Stop key; the

operation stops after finishing the

ongoing copy.

• During standby, the key serves as a

Clear key, setting the copy count to

‘’.

i Copy Start Key

o Power Switch

!0 Density Correction Switch

• Switches copy density among three

settings (top for darker, bottom for

lighter).

• The density is switched by varying

the developing bias.

1-6

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

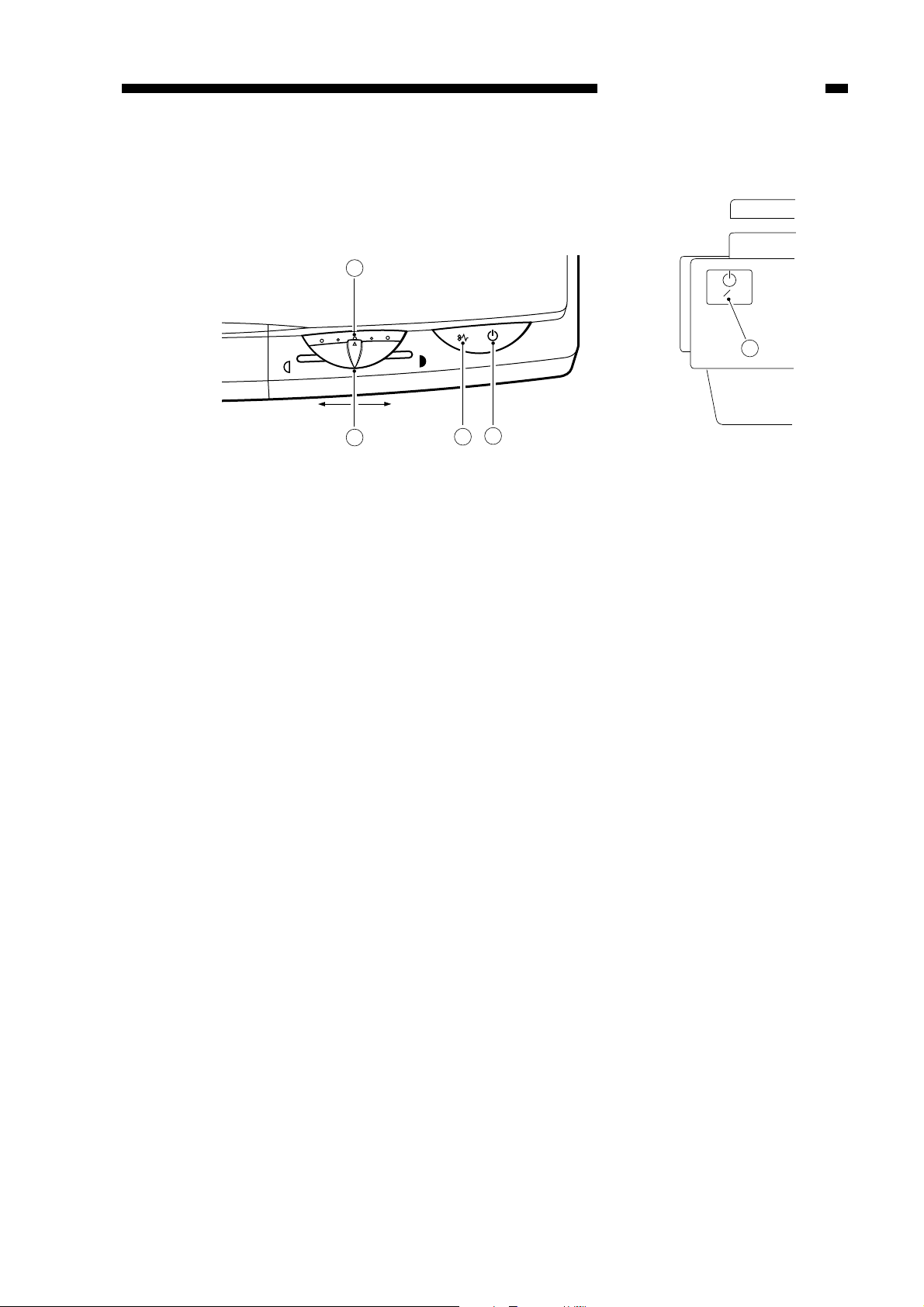

2. PC400/FC200

lighter darker

ON OFF

3

1

2

4

5

CHAPTER 1 GENERAL DESCRIPTION

q Density Control Lever

w Density Indicator

e Jam Indicator

• Flashes when paper jams inside

the copier.

• Goes and remains ON when an

error (self diagnosis) occurs in the

copier.

r Main Indicator

• Remains ON when copying is

ready.

t Power Switch

Figure 1-402A

(right view)

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

Document

Size index

B. Making Copies

1) Switch the copier ON.

• If necessary, wait until the intensity of the scanning lamp reaches the specified

value.

• The wait time is about 0 second.

• The copier will shut itself off in about 5 minutes if left alone without key operation.

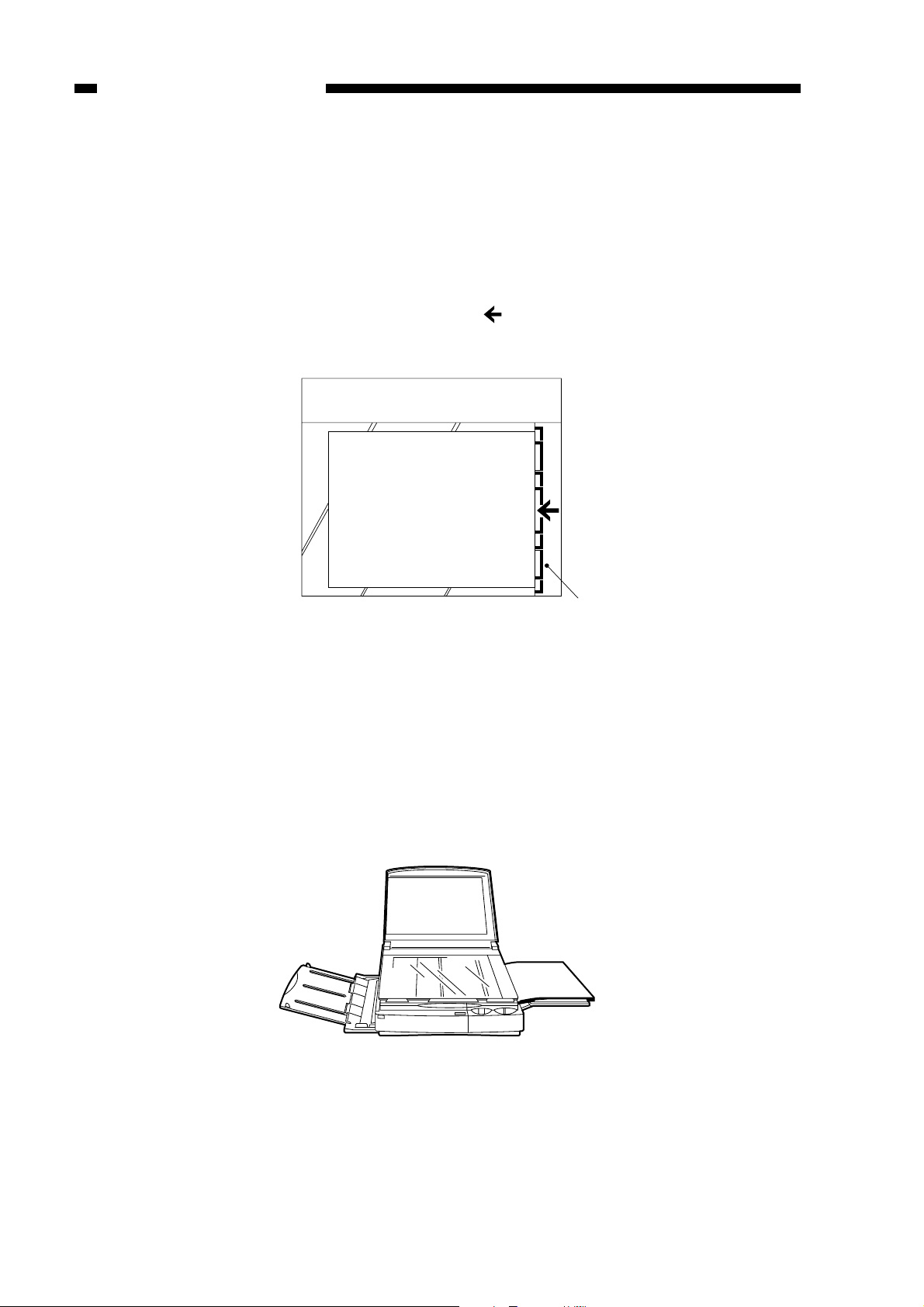

2) Lift the copyboard cover, and place a document face down, along the size index.

• Place the document so that its center is at on the size index (Figure 1-401B);

then, close the copyboard cover.

Figure 1-401B

3) Adjust the copy density to suit the document.

4) Slide the pick-up guide to suit the size of copy paper.

5) Set copy paper on the pick-up tray.

PC420/430/FC220

Place a stack of copy paper of a size suited to the document on the pick-up tray;

make sure the edges of the sheets are flush.

• The stack may be 5 mm (about 50 sheets of plain paper).

Figure 1-402B

6) Set the copy count.

PC420/430/FC220

Set the number of copies to make (1 to 9 or F) using the + key, and check the Copy

Count indicator.

1-8

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1cm1cm

7) Press the Copy Start key.

PC420/430/FC220

• To stop continuous copying, press the Clear/Stop key; the copier finishes the

ongoing copy and stops. The copy count displays the initial count.

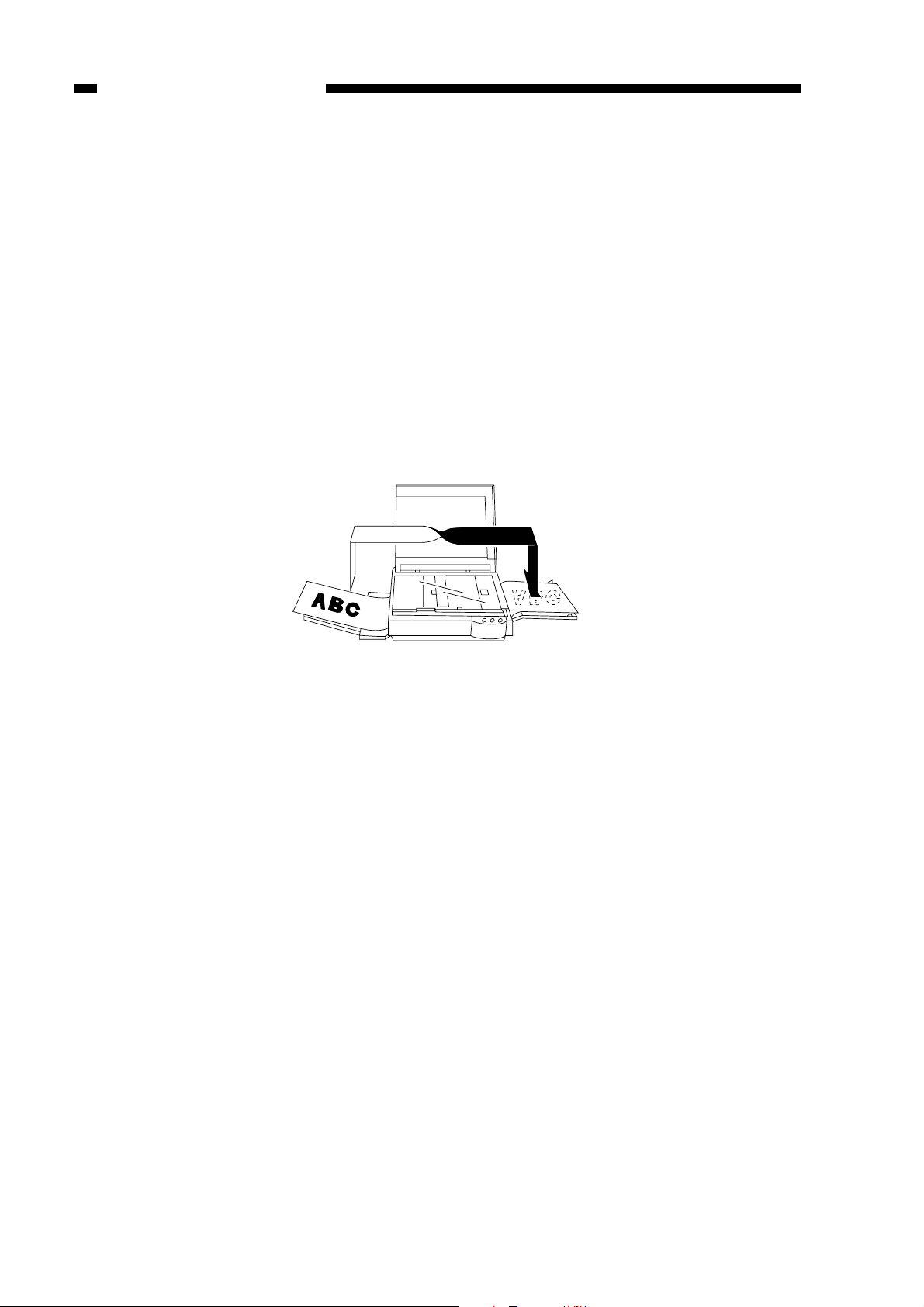

Copying on OHP Film

• Set one sheet of film on the pick-up tray for each copy.

• Depending on the environment of the site, a press on the Copy Start key may not

pull the film inside the copier; if this is the case, perform the following:

1) Place copy paper under the film; stagger the sheet and film so that the leading edge

of the film is about 1 cm behind that of the paper.

Figure 1-403B

2) Hold the trailing edge of the copy paper, and set the sheet and film on the pick-up

tray.

3) While holding the trailing edge of the copy paper, press the Copy Start key.

Remove the paper when the film begins to move into the copier; the paper will no

longer serve its purpose.

Figure 1-404B

Note:

Take away each OHP film delivered to the copy tray.

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

Manual Feeding

PC400/FC200

1) Set a document on the copyboard.

2) Adjust the Density Control lever to suit the document.

3) Slide the pick-up guide to suit the size of copy paper.

4) Insert copy paper along the pick-up guide.

• The copier starts copying operation automatically as soon as it detects paper.

• To continue copying, insert the next paper when the copyboard starts to return.

Making Two-Sided Copies

1) Turn over the copy while maintaining its feeding direction.

• Make sure that the paper is not moist or curled.

• Use paper of 64 to 128 g/m

2

when making two-sided copies.

• Do not process each side more than twice.

Figure 1-405B

Making Overlay Copies

You can make two- or three-colored copies by replacing the cartridge.

• Use paper of 64 to 128 g/m

2

when making overlay copies.

• Do not process each side more than three times.

1-10

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

C. Jam Indicator

The Jam indicator starts to flash when paper jams inside the copier.

• Take care not to tear the paper when removing it; otherwise, be sure to remove all

pieces of paper.

1) Move the copyboard to the left until it stops.

2) Press the open/close button, and open the top cover.

3) Remove the jam.

• If the jam is in the pick-up or fixing assembly, hold the edge of the paper with both

hands, and pull it out slowly through the opening of the top cover.

• If the jam is in the delivery assembly, press the delivery assembly open/close

button to open the delivery cover; then, detach the paper from the delivery cover,

and pull it slowly in the direction of delivery.

4) Close the top cover and delivery cover; then, move the copyboard to the center.

• To resume copying, switch the copier ON, set the desired copy count, and set the

copy density.

D. Add Paper Indicator

PC420/430/FC220

’ flashes if you try to make a copy when the pick-up tray has run out of paper.

‘

1) Check the pick-up tray for copy paper.

2) If no paper is on the tray, place paper.

If a stack of paper is on the tray, remove it first, then place it back after putting its

edges flush.

3) Press the Copy Start key.

• ‘ ’ goes OFF, and the remaining number of copies are made.

E. Replacing the Cartridge

1. Time to Replace the Cartridge

When the cartridge is running out of toner, copies tend to show white lines or vertical

white spots (Figure 1-401E).

Figure 1-401E

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

CHAPTER 1 GENERAL DESCRIPTION

If white lines or spots appear on copies, replace the cartridge as follows:

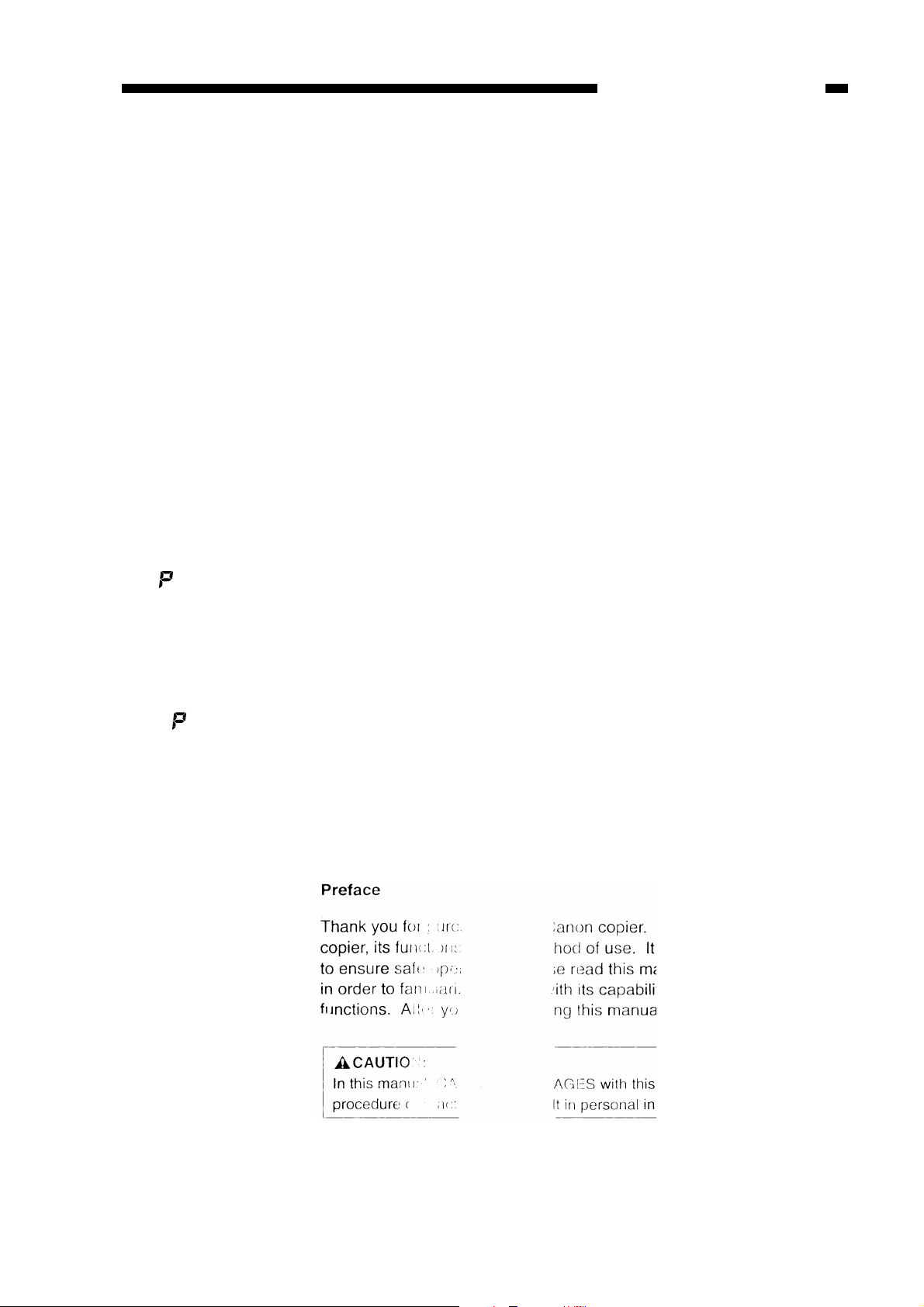

1) Remove the cartridge from the copier, and rotate it several times as shown in Figure

1-402E.

Figure 1-402E

2) Set the cartridge back in the copier, and make a copy.

a. If the output returns to normal,

• The cartridge may be used further; advise the user, however, to obtain a spare

cartridge.

b. If the output fails to return to normal,

• Replace the cartridge as described below.

2. Replacing the Cartridge

1) Move the copyboard to the left until it stops; then, press the open/close button to

open the top cover.

2) Slide the cartridge out of the copier.

3) Hold the cartridge with the Warning label facing up, and rotate it about 90 degrees in

both directions.

1-12

Figure 1-403E

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

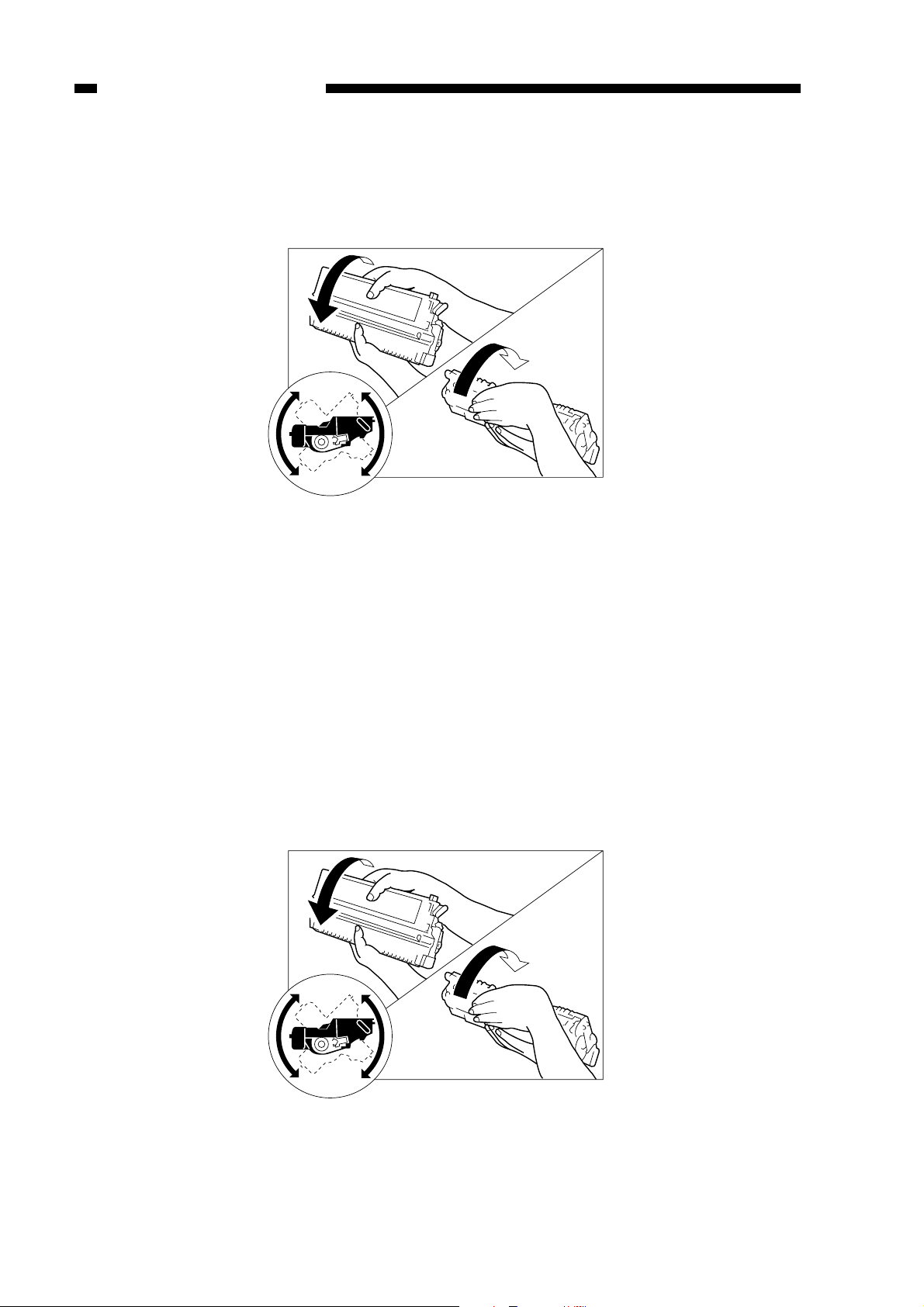

4) Detach the tip of the seal attached to the cartridge, and pull it straight out to the

front; about 50 cm.

Figure 1-404E

5) Hold the cartridge with its Warning label facing the left, and insert it in the copier with

care until it butts against the rear.

Figure 1-405E

6) Close the top cover, and return the copyboard to the center.

Note:

You can replace the black toner cartridge with any color cartridge the same way.

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

Density Correction Switch

Auto density

correction

F. Changing the Density

PC420/430/FC220

You have a choice of three settings for automatic density adjustment mode (AE);

switch the density if the copy is too dark or too light.

Figure 1-401F

Note:

You can also switch the density among three settings in manual density adjustment

mode.

G. Cleaning

Advise the user to clean the following if the copies are soiled.

1. Copyboard Glass/Copyboard Cover

Wipe the part with a moist cloth; then, dry wipe it.

If dirt cannot be removed, wipe the part using mild detergent; then, dry wipe it.

1-14

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Fiber lens (face side)

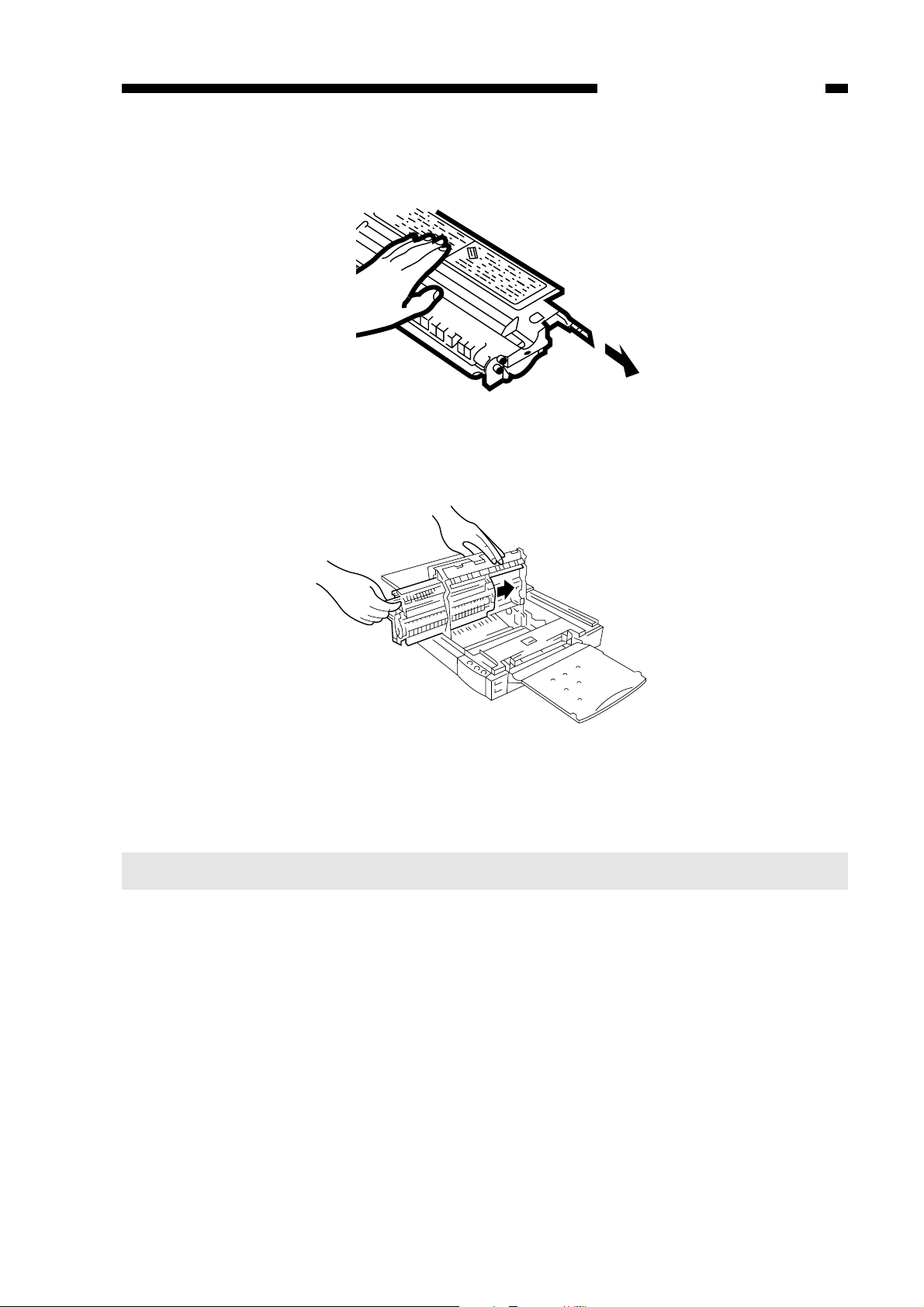

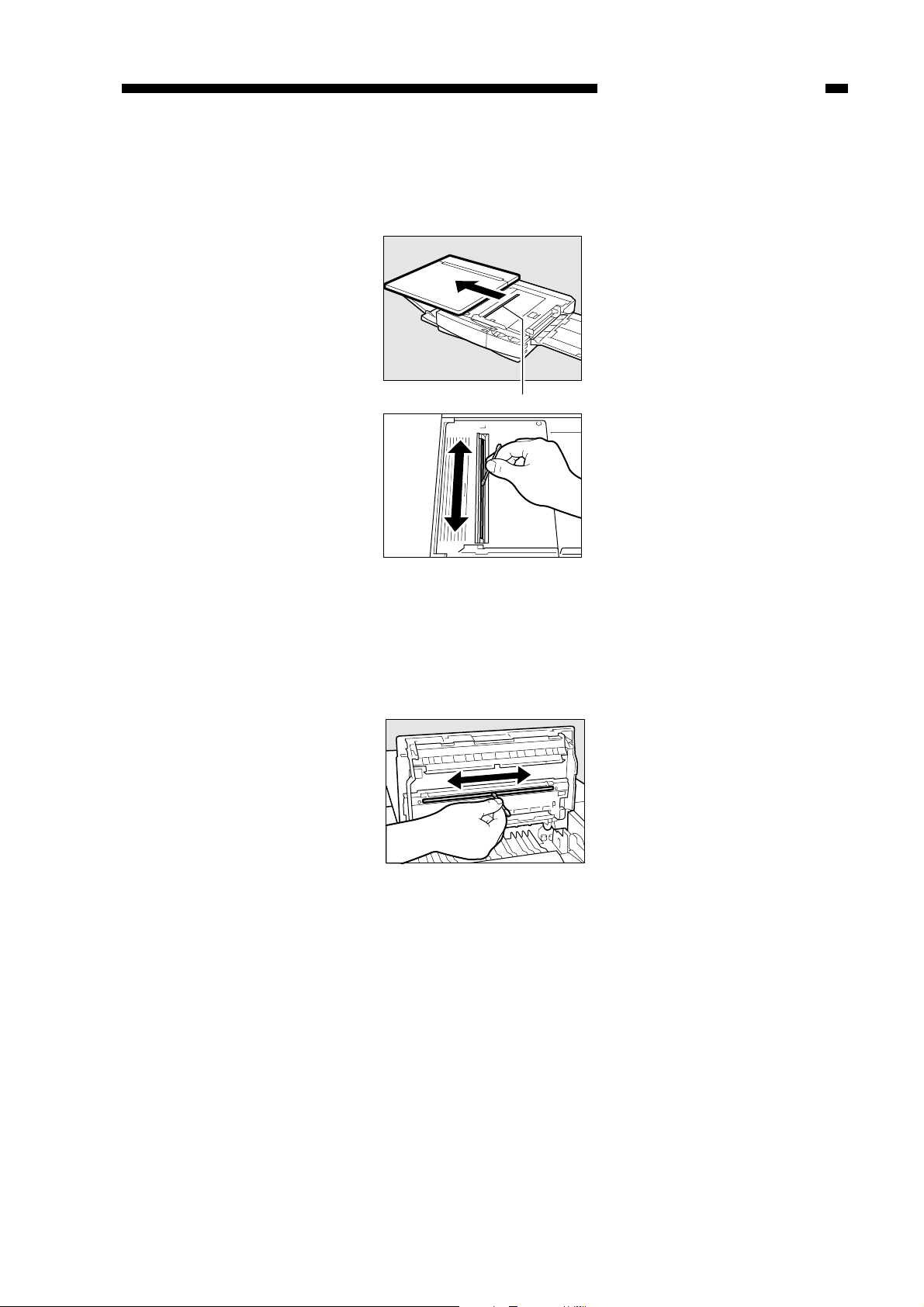

2. Lens Array

1) Move the copyboard to the left until it stops.

2) Put a cotton wad in the lens array groove, and move it back and forth lightly.

Figure 1-401G

3) Open the upper cover, and remove the cartridge.

4) Put a flat-tipped cotton wad in the lens array (rear) groove, and move it back and

forth.

Figure 1-402G

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-15

CHAPTER 1 GENERAL DESCRIPTION

Pick-up roller

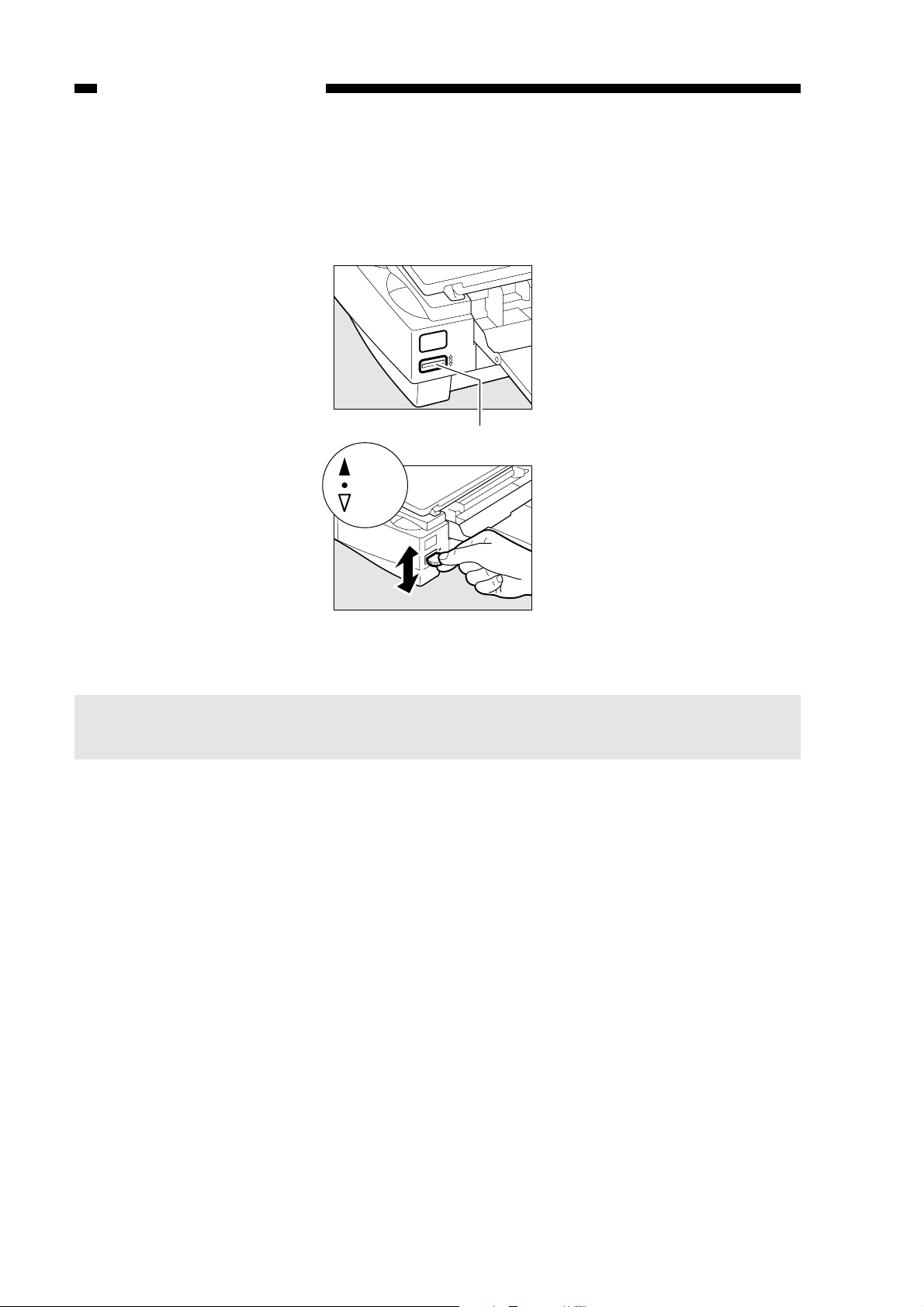

3. Pick-Up Roller

1) Open the top cover.

2) Dry wipe the pick-up roller while rotating it in pick-up direction with a cloth.

Note:

Do not make copies until the pick-up roller has completely dried.

Figure 1-403G

H. When Not Using the Copier for a Long Time

Advise the user to perform the following if she/he does not have any plan to use the

copier for a long time.

1) Disconnect the power plug.

2) Place the copier in a dust-free, sunlight-free place.

1-16

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

Photo-

sensitive drum

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-17

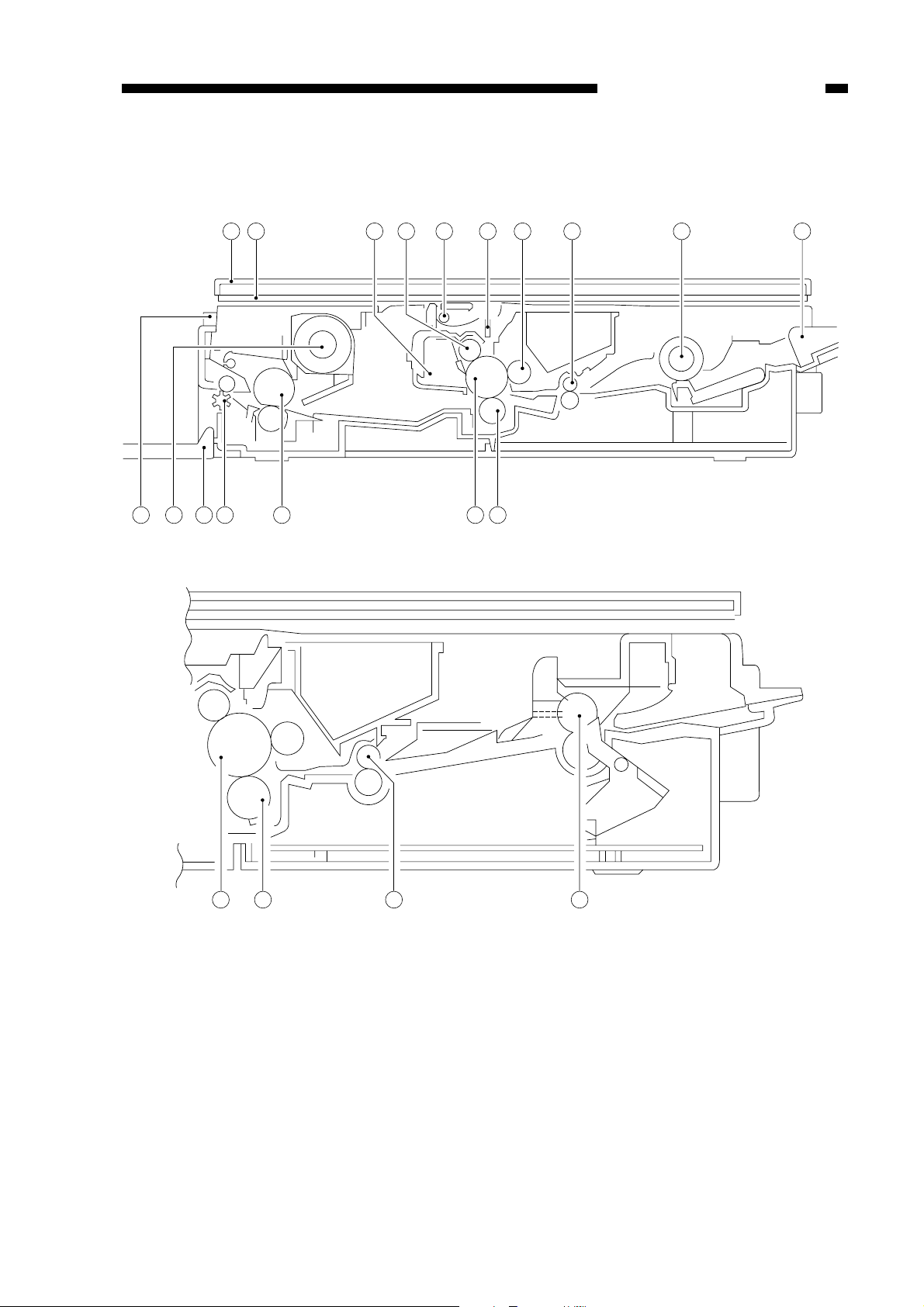

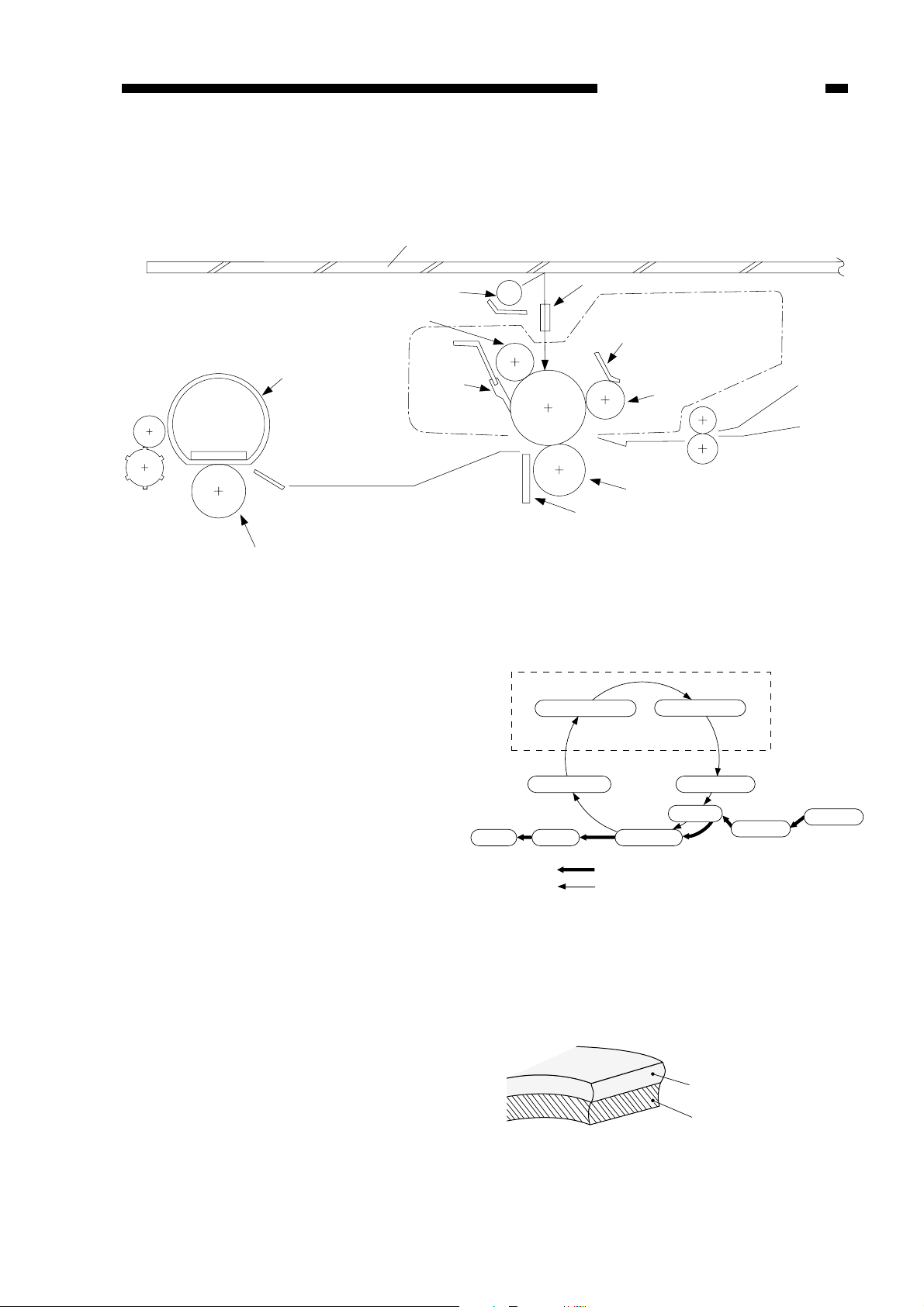

V. IMAGE FORMATION

A. Outline

Figure 1-501A

The copier is an indirect photorepro

graphic system constructed as shown in

Figure 1-501A.

The image formation process con

sists of seven steps as discussed below.

Step 1 : Primary charging (negative)

Step 2 : Image exposure

Step 3 : Development (AC and DC bias)

Step 4 : Transfer (negative)

Step 5 : Separation

Step 6 : Fixing

Step 7 : Drum cleaning

Figure 1-502A

The photosensitive drum has a layer

construction: the photoconductive layer

on the outside and the conductive alu

minum base, inside.

Figure 1-503A

Delivery

: Flow of copy paper

: Rotation of drum

4. Transfer

Latent static Image Formation

2. Image exposure

3. Development

7. Drum cleaning

Registration

Multifeeder

6. Fixing

5. Separation

1. Primary charging

Photoconductive layer

Aluminum base

Copyboard glass

Scanning lamp

Primary charging roller

Fixing film

Pressure roller

Cleaning

blade

Lens array

Developing blade

Developing

cylinder

Transfer charging roller

Static eliminator

CHAPTER 1 GENERAL DESCRIPTION

1-18

COPYRIGHT © 1998 CANON INC. CANON PC400/420/430,FC200/220 REV.0 JAN.1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...